Page 1

Ceellll

IInnC

™ FFiibbeerr

™

Oppttiicc

O

Diissttrriibbuutteedd

D

Anntteennnnaa SSyyssttee

A

Installation and Users Guide

m

m

Copyright Andrew Corporation

Version 1.1

October 2000

Page 2

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

Proprietary Information

This document is the property of Andrew Corporation. The information contained herein is

proprietary to Andrew, and no part of this document may be reproduced or transmitted in

any form or by any means, electronic or mechanical, for any purpose, without the express

written permission of Andrew.

Disclaimer

Andrew reserves the right to make changes, without notice, to the specifications and

materials contained herein. While we have worked diligently to insure every element

presented is correct, we shall not be responsible for errors. For the latest product

information and technical specifications, please see the contact information below.

Copyright Andrew Corporation, October 2000, Printed in USA, All rights reserved.

FCC Notice

This equipment complies with Part 22 of the FCC rules. Any changes or modifications not

expressly approved by the manufacturer could void the user’s authority to operate the

equipment.

Warning

In order to comply with FCC rules for rf exposure, the following must be observed:

1. The antenna for this device must have a gain of no more than 12.7 dBi.

2. The antenna must be installed such that a minimum separation distance of 20 cm. is

maintained between the antenna and any persons.

Trademarks

InCell™ is a trademark of Andrew Corporation. All other trademarks belong to their

respective owner.

Contact Information

For more information about Andrew’s capabilities to extend RF signals coverage into

structures, including office buildings, shopping complexes, warehouses, tunnels, and mines,

please contact us using the information below:

Andrew Corporation

2601 Telecom Parkway

Richardson, Texas 75082

Attention: Mr. Matt Melester

E-mail:matt.melester@andrew.com

Fax: (972) 952-0018

Voice: (972) 952-9745

- ii -

Page 3

Table of Contents

Andrew Corporation.................................................................................................................1

Andrew In-Building Wireless Experience................................................................................1

InCell™ Fiber Optic Distributed Antenna System Description..............................................1

Central Distribution Unit (CDU)...........................................................................................1

CDU FRONT PANEL

.........................1

Remote Antenna Unit (RAU)................................................................................................2

CDU to RAU Interface Cables ..............................................................................................4

Composite Fiber Optic & Power Cables................................................................................4

Standard Duplex Fiber Optic Cables......................................................................................4

Indoor Antennas....................................................................................................................5

In-Building Implementations Using the Andrew InCell™ System.........................................7

Scalable System Architecture................................................................................................7

The Signal Distribution Unit............................................................................................8

The Interconnecting Cable...................................................................................................11

The Installation Parameters ...........................................................................................13

Sample Implementation.......................................................................................................16

InCell™ Specifications............................................................................................................17

Technical Performance........................................................................................................17

Interface Specifications.......................................................................................................18

Electrical Specifications......................................................................................................19

Environmental and Mechanical Specifications.....................................................................20

MTBF ...........................................................................................................................20

MTTR...........................................................................................................................20

Page 4

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

InCell™ Network Monitoring System ...................................................................................21

Pilot Tone Generation .........................................................................................................21

RAU Indicators...................................................................................................................21

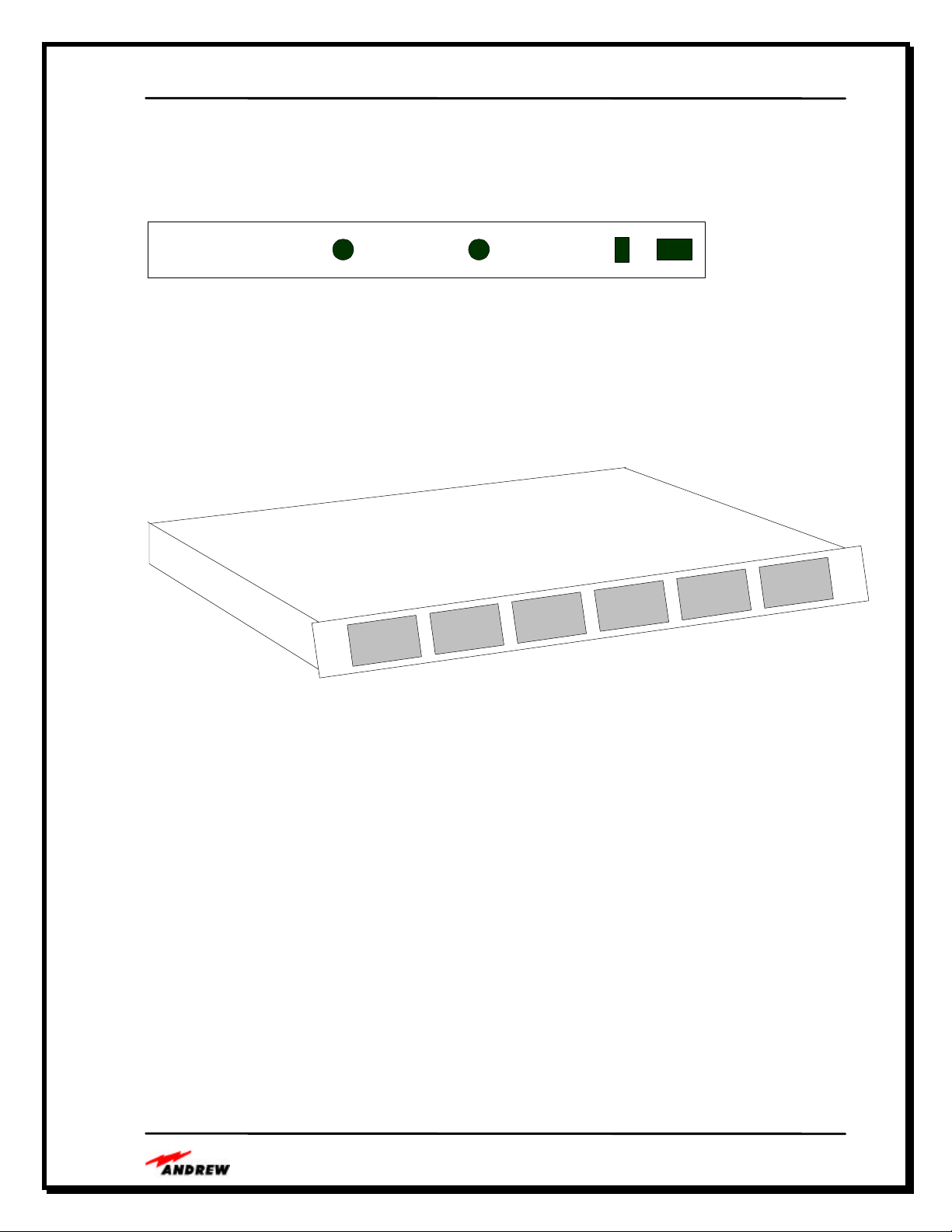

CDU Front Panel Indicators................................................................................................21

Alarm Functions..................................................................................................................22

Remote Monitoring Functions.............................................................................................22

InCell™ Operation, Maintenance and Support ....................................................................24

Operation............................................................................................................................24

Regular Maintenance...........................................................................................................24

Fault Repair ........................................................................................................................24

Support...............................................................................................................................24

Spare Policy........................................................................................................................24

- ii -

Page 5

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

List of Tables

Table 1. InCell™ Performance Specification............................................................................17

Table 2. BTS Interface Specifications ......................................................................................18

Table 3. Antenna Interface Specifications ................................................................................19

Table 4. Electrical Specifications .............................................................................................19

Table 5. InCell™ Environmental and Mechanical Specification...............................................20

List of Figures

Figure 1. InCell™......................................................................................................................1

Figure 2. InCell™ Form Factors ................................................................................................1

Figure 3. Andrew Dual Band Patch Antenna..............................................................................5

Figure 4. Andrew Dual Band Omni Antenna...............................................................................5

Figure 5. Simplified InCell™ Block Diagram ............................................................................7

Figure 6. InCell™ Central Distribution Unit ..............................................................................1

Figure 8. Remote Antenna Unit..................................................................................................8

Figure 9. System expandability to 48 RAUs...............................................................................9

Figure 10. System Expandability to more than 48 RAUs..........................................................10

Figure 11. Cross Section of Andrew Composite Fiber/Copper Cable........................................11

Figure 12. Remote and Local Power Connections on the RAU.................................................12

Figure 13. Typical System Configuration Using Off-Air Interface............................................16

Figure 15. Remote Alarm Capability........................................................................................23

Figure 16. Daisy Chaining CDU’s for Remote Monitoring.......................................................23

- iii -

Page 6

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

Andrew Corporation

Andrew Corporation is a global designer, manufacturer, and supplier of communications

equipment, services, and systems. Andrew products and expertise are found in

communications systems throughout the world, including wireless and distributed

communications, land mobile radio, cellular and personal communications, broadcast, radar,

and navigation. The Andrew "Flash" trademark seen on the cover can also be seen in every

corner of the world on broadcast towers and microwave antennas, HELIAX® and

RADIAX® cables, communications and computer networking equipment. The mark of

Andrew for more than 60 years, it is the benchmark of quality wherever it appears. It is a

symbol of commitment to customer satisfaction from the 4,500-plus employees of Andrew

Corporation. We are listed on the NASDAQ stock exchange under symbol “ANDW.” To

learn more about us, please visit our web site at www.andrew.com.

Andrew In-Building Wireless Experience

The Andrew Corporation Distributed Communications Systems (DCS) group has over 15

years experience designing, installing, and managing large complex RF distribution systems

for metropolitan railways, building owners, and public mobile radio and telephone operators

throughout the world. For clients who do not need turnkey solutions, we offer product sales

or product sales with engineering support services.

Andrew offers a range of products to meet requirements of the in-building market. In the

early 1980’s Andrew developed leaky cables as an adjunct to our coaxial cable business.

This product quickly led us to pursuing and executing wireless RF coverage in confined

spaces such as metros, road tunnels, and buildings. Through these projects, our Distributed

Communications Systems division acquired critical experience in project management and

RF engineering of these systems.

- 1 -

Page 7

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

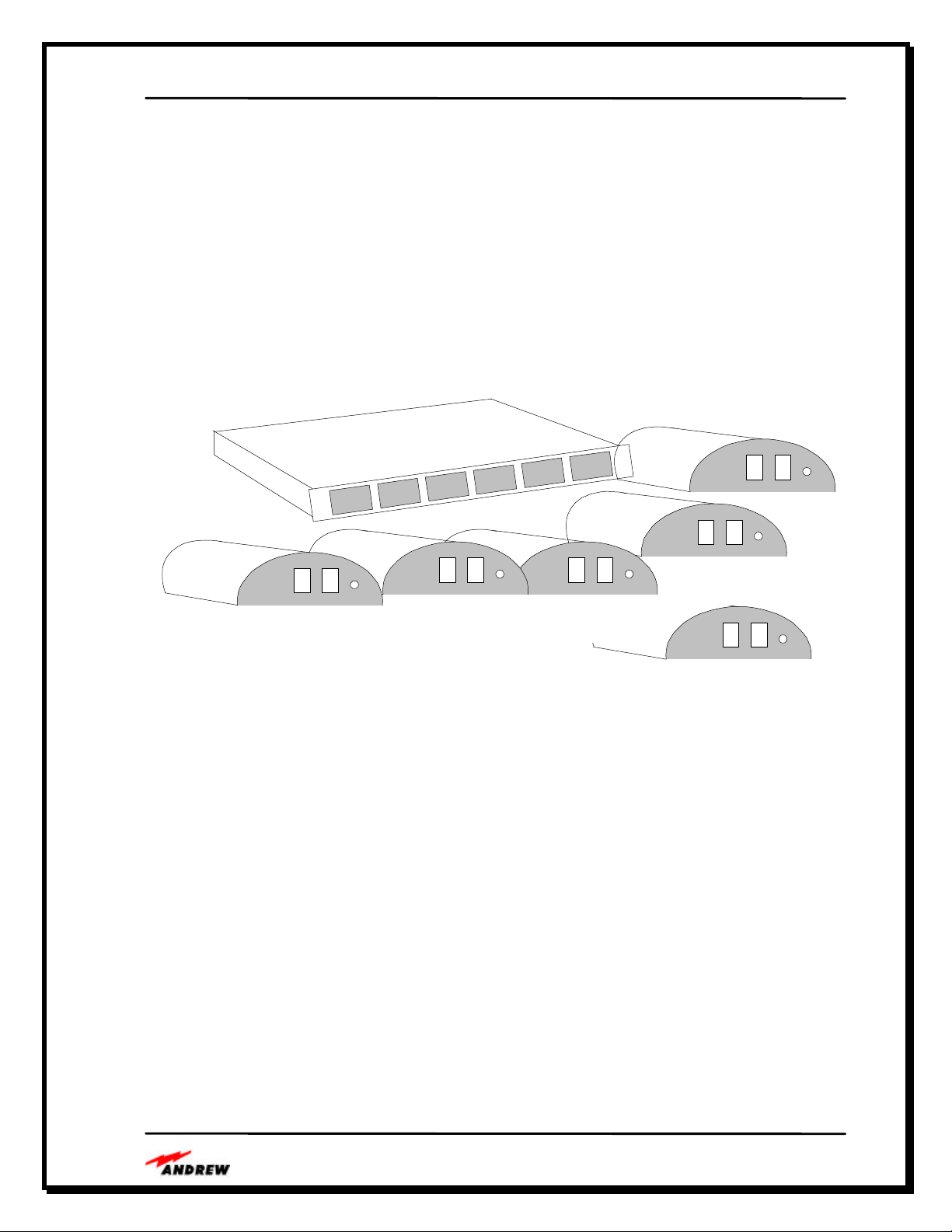

InCell™ Fiber Optic Distributed Antenna System Description

The subsystem consists of one or more Central Distribution Units (CDU) feeding multiple

Remote Antenna Units (RAU).

Figure 1. InCell™

This unit can drive up to 6 RAU’s. Additional CDU’s can be driven using one or more of

our Signal Distribution Units (SDU). The required signal distribution is built into the backplane of the chassis minimizing the need for interconnecting cables. Our design is

intrinsically optimized for new technologies operating at higher bandwidths.

Unlike other competing products, this product is designed for multi-operator, multi-service

capabilities with higher output levels and lower system sensitivities. This equates to greater

coverage range per antenna unit and hence lower implementation costs. When complete,

this product will be available in both single-band units, i.e., US Cellular, GSM 900, US

PCS-1900, and DCS-1800, and dual band units in which both low and high band services

are supported within the same unit using the same fiber pair.

Figure 2. InCell™ Form Factors

- 1 -

Page 8

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

CDU Side View

RAU Front

View

RAU Front

View

RAU Front

View

RAU Front

View

RAU Front

View

RAU Front

View

- 2 -

Page 9

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

Central Distribution Unit (CDU)

The Central Distribution Unit (CDU) is the core module that can drive up to six Remote

Antenna Units (RAU. The CDU separates the down and uplink RF signals and converts

these to optics for transmission over a 2-core single-mode fiber cable to one of six RAU’s.

The CDU (shown at Figure 3) is housed in a standard 1U, 19-inch rack mount unit and

provides 6 sets of duplex optical fiber links to the remote antenna units.

Figure 3. InCell™ Central Distribution Unit

The figure below provides a detailed view of the CDU front panel, showing the six remote

antenna interface ports. Each of the six ports is identical and provides DC power for the

remote antenna as well as a downlink interface and an uplink interface with the remote

antenna unit.

CDU FRONT PANEL

- 1 -

Page 10

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

The rear view of the CDU shows the RF input/output connector as well as the power

connection and the on/off switch. The RF connections are Type N.

CDU REAR PANEL

CDU Side View

Remote Antenna Unit (RAU)

The RAU converts the signal back to RF and provides a single duplex downlink and uplink

output port; and the dual band unit combines the two services to a single RF connector. The

third order intercept point is high (33dBm typical), and the output can go directly to a multiband antenna or be split to drive multiple antennas.

- 2 -

Page 11

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

RAU Front View

RAU Rear View

CDU Status Indicators

RAU Status Indicators

Alarm Output

Remote Monitoring Option

- 3 -

Page 12

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

CDU to RAU Interface Cables

Composite Fiber Optic & Power Cables

Standard Duplex Fiber Optic Cables

- 4 -

Page 13

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

Indoor Antennas

Andrew is developing several new low profile in-building antennas like the examples in

Figure 4 and Figure 5. These dual band antennas are based on a product originally designed

by our automotive accessory division. We anticipate releasing other antenna products in the

next calendar year.

Figure 4. Andrew Dual Band

Patch Antenna

Figure 5. Andrew Dual Band Omni Antenna

- 5 -

Page 14

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

Outdoor Donor Antennas

Lightning Arrestors

Bi-Directional Amplifiers

Coaxial Cables and Jumpers

Distributed Antenna System Planning

InCell Distributed Antenna System Bill of Material

- 6 -

Page 15

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

In-Building Implementations Using the Andrew InCell™ System

Scalable System Architecture

The InCell™ distributed antenna system is a scalable system that can be configured to support up

to 384 antenna locations using three building block modules.

6-Channel Central Distribution Unit

Remote Antenna Unit #1

Fiber Optic Receiver

O

E

Fiber Optic Transmitter

O

E

Power

D

U

P

L

E

X

E

R

RF, Test Signal & Power

Distribution

Fiber Optic Transmitter

E

O

Fiber Optic Receiver

E

O

Composite Fiber/Copper

Single Mode Fiber -- Downlink

18 AWG Copper Wire

Cable

Single Mode Fiber -- Uplink

Fiber Optic Transmitter

E

Fiber Optic Receiver

E

Single Mode Fiber -- Downlink

O

Single Mode Fiber -- Uplink

O

Local Power Supply

(Wall Transformer)

Figure 6. Simplified InCell™ Block Diagram

Remote Antenna Unit #6

Fiber Optic Receiver

O

E

Fiber Optic Transmitter

O

E

Power

D

U

P

L

E

X

E

R

- 7 -

Page 16

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

The RAU is (shown at Figure 7) weighs only 0.6 pounds and is 38 mm (length) x 127 mm

(width) x 165 mm (height). This compact size makes it suitable for close mounting to the

antenna.

Figure 7. Remote Antenna Unit

The Signal Distribution Unit

The third building block module is the Signal Distribution Unit (SDU). This is a 1U rack mount

unit housing a standard 8-way power divider that is placed in front of the CDU to drive eight

CDU’s from one service input. Using an architecture of one SDU and eight CDU’s, 48 antenna

locations can be served (see Figure 8). Using an architecture of nine SDU’s dividing the service

signal to 64 CDU’s, 384 antenna locations can be served (see Figure 9). These approaches are

best housed coherently in 19-inch equipment racks as depicted in Figures 25 and 26.

- 8 -

Page 17

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

RF IN

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF 100-240 VACRF POWER

RF RF RF RF RF RF RF RFRF

Figure 8. System expandability to 48 RAUs

- 9 -

D00-45

Page 18

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

RF IN

REMOTE ALARMREMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARMREMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARMREMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARMREMOTE ALARM

REMOTE ALARMREMOTE ALARM

RF

RF RF

RF RFRF RFRFRF RFRFRF

RF RF

RF

RFRFRF

RF

RFRFRF

RF

RFRFRF

RF RFRFRFRFRF RF

POWER 100-240 VAC

POWER

POWER

POWER

POWER

POWER

POWER

POWERRF100-240 VAC

100-240 VAC

100-240 VAC

100-240 VAC

100-240 VAC

100-240 VAC

100-240 VAC

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

RF RF RF RF RF RF RF RFRF

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF RF 100-240 VACPOWER

RF 100-240 VACRF POWER

D00-46

Figure 9. System Expandability to more than 48 RAUs

- 10 -

Page 19

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

The Interconnecting Cable

Any single mode 2-core fiber cable can be used to drive the RAU a distance of 20Km from the

CDU. In this configuration, power to the RAU is supplied from an external 12-28VDC source or

an Andrew supplied universal (110/240VAC, 50/60Hz) wall transformer (wall wart). An

Andrew manufactured composite cable is also available. This cable (shown at Figure 10)

combines 2-core fiber and 2-conductor copper elements in a single jacket. Using this cable,

power to the RAU is supplied by the CDU over the copper conductors eliminating the need for a

separate RAU power supply. Although the composite cable greatly simplifies the installation

process, the CDU-RAU separation is limited to 1.5Km. The limitation is the DC voltage drop

from the CDU to the RAU over the copper conductors.

0.210"

Microcable

Natural

Insulated

Copper

(Black)

Outer

Jacket

Figure 10. Cross Section of Andrew Composite Fiber/Copper Cable

TM

Rip Cord

Insulated

Copper

(Red)

Microcable

(Blue)

TM

D00-37

The Andrew composite cable is rugged, flexible and has an outside diameter of 0.21”, making it

easy to install. One optical fiber provides the downlink signal between the CDU and the RAU;

the second optical fiber provides the uplink signal between the RAU and the CDU. These cables

use industry standard SC type connectors to interface with the RAU and CDU. The two copper

lines are used to provide DC power and ground signals to the RAU so that no additional power

planning is required. System installers are not required to install AC power, conduit and

transformers at each remote antenna location. With the CDU in the center of a system, remote

antennas could be spaced as far as 3 km apart using the composite cable.

Andrew provides plenum rated and riser rated composite cables for in-building installation as

fully tested cable assemblies and as bulk cable. The cables meet demanding building codes for

safety. Tested cable assemblies are available in lengths of 50, 100, 150 and 200 meters, with

optical and power connectors installed. Bulk composite cable is also available on spools and

- 11 -

Page 20

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

requires system installers to add crimp-on connectors for the copper lines and add SC type

connectors to the fiber cables. Refer to Andrew Catalog 38, pages 642-645, for full

specifications of the plenum and riser rated cables. Andrew cable assemblies also come with a

pulling hook and harness to make the cables easier to install.

If the in-building location for each of the remote antenna units is pre-planned and the distances

are all known, then composite cables with connectorized ends and installation-ready wraps can

be ordered to specific lengths. The other option is to buy reels of composite cable and then

connectorize them in field. The connectors for the copper wires are fairly easy to crimp on, but

the SC-connectors take a few minutes and require the use of a non-fusion based splicing device

and well trained technicians to insure that reliable, low loss splices are made.

Single mode fiber optic cable is used in the InCell™ products because of its wide bandwidth and

loss attenuation characteristics. Single mode fiber optic cable has the lowest attenuation of all

fiber optic cable types and is typically lower in cost than multimode fiber cable. Single mode

fiber is used in communications systems where high data rates and wide bandwidths are

required. Wideband fiber optic line provides for unlimited future growth. Typical single mode

cable loss is 0.4 dB per km. The loss of two SC connectors is typically 0.5 dB.

The SC type connector is the most popular connector type for the fiber-optic cables. The SC

connector is the recommended connector in the EIA/TIA-568A building wiring standard. It

provides a very reliable, low loss connection at a reasonable cost. The SC type connector is easy

to install and provides positive feedback when correctly seated. SC connectors have good lock,

pull and wiggle characteristics, ensuring that they will stay in place when installed and that they

are immune to tension or lateral pressure on the fiber cable.

Figure 11 shows the RAU fiber and power connections.

U/L D/L

POWER

Figure 11. Remote and Local Power Connections on the RAU

PWR

Rem Loc

D00-44

- 12 -

Page 21

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

The Installation Parameters

Installation times will depend on the size of each installation; however, Andrew can provide

rough guidelines for installing the CDU and RAU that may be used to determine the total system

installation time once the number of equipment parts is determined.

The CDU may be mounted in a standard 19” equipment rack or on a wall. Allow 30 minutes for

unpacking the CDU, installing the unit into the rack or wall and connecting the RF, fiber and

power cables. Upon application of system power, front panel indicators will give the installer a

visual indication of power and link status. Mounting hardware is provided for rack or wall

mounting.

RAUs are typically mounted on walls or ceilings throughout the building. The units are small

and lightweight and installers may carry multiple RAUs at one time to speed installation.

Mounting the RAU to a wall or ceiling and connecting the fiber and power cables and the

antenna takes only minutes. Upon application of system power, indicators on the RAU give the

installer a visual indication of RAU power and link status. Mounting hardware is provided for

the RAU.

To minimize system wiring times, Andrew composite cable is recommended to allow the fiber

optic links and the power to be routed to each RAU in one small, easy to pull cable. The

composite cables eliminate the need for conduit to each remote antenna location, improving

wiring installation time.

Disruption to business is minimal as the CDU is typically installed in a electronic equipment

room and the remote antennas and wiring may be installed after work hours. The cables are

small and lightweight making them easy to pull through risers, above roofs and through tubes.

Site survey testing before and after installation may be done during business hours using small,

portable RF measurement tools.

- 13 -

Page 22

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

CDU REAR PANEL

CDU FRONT PANEL

CDU Side View

CDU Side View

- 14 -

Page 23

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

RAU Front View

RAU Front View

RAU Rear View

- 15 -

Page 24

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

Sample Implementation

Figure 12 illustrates a small off-air implementation using an Andrew GridPACK donor antenna,

an Andrew Cellular Extender (ACE), and a single InCell™ Central Distribution Unit driving up

to six Remote Antenna Units. The donor antenna and extender can be replaced with other RF

inputs, such as another off-air interface, a base station, or distribution unit depending on the

application.

Andrew

Andrew

Andrew

GRIDPACK

GRIDPACK

GRIDPACK

High Gain Donor Antenna

High Gain Donor Antenna

High Gain Donor Antenna

Andrew

Andrew

Andrew

Surge Arrester

Surge Arrester

Surge Arrester

Andrew

Andrew

Andrew

Cable

Cable

Cable

Heliax

Heliax

Heliax

Andrew

Andrew

Andrew

Composite

Composite

Composite

Optical Fiber Cable

Optical Fiber Cable

Optical Fiber Cable

(up to 1.5 Km)

(up to 1.5 Km)

(up to 1.5 Km)

Andrew

Andrew

Andrew

Air

Air

Air

-

-

-

Off

Off

Off

Repeater Family

Repeater Family

Repeater Family

Central Distribution Unit

Central Distribution Unit

Central Distribution Unit

Andrew

Andrew

Andrew

InCell

InCell

InCell

I

I

I

Remote Antenna Unit

Remote Antenna Unit

Remote Antenna Unit

Indoor

Indoor

Indoor

Patch Antenna

Patch Antenna

Patch Antenna

Figure 12. Typical System Configuration Using Off-Air Interface

Andrew

Andrew

Andrew

InCell

InCell

InCell

- 16 -

Page 25

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

InCell™ Specifications

Technical Performance

The technical specifications are summarized in Table 1.

Table 1. InCell™ Performance Specification

Wireless Service Standard InCell Part Number

US Cellular

(AMPS/TDMA/CDMA)

GSM-900

DCS-1800

PCS-1900

2.4 GHz ISM WLAN

US Cellular/PCS-1900

GSM-900/GSM-1800

Uplink Frequency Range

2000-1000-000 (US Cellular)

2000-2000-000 (GSM-900)

2000-3000-000 (DCS-1800)

2000-4000-000 (PCS)

2000-5000-000 (WLAN)

2000-6000-000 (Dual Band)

2000-7000-000 (Dual Band)

End-to-End RF Gain (dB) 15 dB

Gain Flatness Over Frequency +/- 2.5 dB

Maximum Input Power Limiter threshold at -40 dBm

Noise Figure* 11 dB

Downlink Freqnency Range

2000-1000-000 (US Cellular)

2000-2000-000 (GSM 900)

2000-3000-000 (DCS-1800)

2000-4000-00 (PCS)

2000-5000-000 (WLAN)

2000-6000-000 (Dual Band)

2000-7000-000 (Dual Band)

End-to-End RF Gain (dB) 15 dB

Gain Flatness Over Frequency +/-2.5 dB

Maximum Input Power 20 dBm

Return Loss >17 dB

Spurious/Intermodulation

1 dB Compression Point 20 dBm

Output Intercept Point 20 dBm

Wideband Noise -121.5 dBm/Hz

CDMA Spectral Regrowth -45 dBc

Output

Power

Analog

15 dBm, 2 carriers

12 dBm, 4 carriers

9 dBm, 8 carriers

2000-1000-000

2000-2000-000

2000-3000-000

2000-4000-000

2000-5000-000

2000-6000-000

2000-7000-000

InCell™ Uplink Performance

824-849 MHz

890-915 MHz

1710-1785 MHz

1850-1910 MHz

2400-2500 MHz

824-849/1850-1910 MHz

890-915/1710-1785 MHz

InCell™ Downlink Performance

869-894 MHz

935-960 MHz

1805-1880 MHz

1930-1990 MHz

2400-2500 MHz

869-894/1930-1990 MHz

935-960/1805-1880 MHz

-13 dBm for non-European Systems

-36 dBm from 9 kHz to 1 GHz

-30 dBm from 1 GHz to 12.75 GHz

TDMA

15 dBm, 2 carriers

12 dBm, 4 carriers

9 dBm, 8 carriers

10 dBm, 1 carrier

4 dBm, 2 carriers

Downlink Passband

(MHz)

869-894

935-960

1805-1880

1930-1990

2400-2500

869-894/1930-1990

935-960/1805-1880

CDMA

GSM-900

10 dBm, 2 carriers

7 dBm, 4 carriers

4 dBm, 8 carriers

Uplink Passband

(MHz)

824-849

890-915

1710-1785

1850-1910

2400-2500

824-849/1850-1910

890-915/1710-1785

DCS-1800

12 dBm, 2 carriers

9 dBm, 4 carriers

6 dBm, 8 carriers

- 17 -

Page 26

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

Interface Specifications

The BTS interface specifications are shown in Table 2 and the antenna interface specifications

are in Table 3.

Table 2. BTS Interface Specifications

Requirement Performance Specification

Operational Bandwidth

GSM-900

DCS-1800

Dual Band 900/1800

Connector Types- CDU

RF

Type N

Optical Fiber

AC Power (CDU only)

DC Power

Connector Locations RF and AC connectors on rear of CDU

Interface Type

RF

Optical Fiber

RF Impedance/VSWR 50 ohms, typical 10 dB return loss

1 dB Compression Point

Downlink 20 dBm

Third Order Output Intercept Point

Downlink

Uplink

Spurious Response -36 dBm from 9 kHz to 1 GHz

Gain/Gain Linearity

Downlink

Uplink

Group Delay <1.0 usec (CDU, fiber and RAU)

Type SC Single Mode Fiber

Standard 3-pin “D” type

Molex 2-pin

Uplink

890-915 MHz

1710-1785 MHz

890-915 MHz

1710-1785 MHz

Fiber and DC power on front of CDU

Duplex (bi-directional port)

Single mode fiber: 1 uplink, 1 downlink

N/A

-30 dBm from 1 GHz to 12.75 GHz

15 db ± 2.5

15 db ± 2.5

Downlink

935-960 MHz

1805-1880 MHz

935-960 MHz

1805-1880 MHz

- 18 -

Page 27

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

Table 3. Antenna Interface Specifications

Requirement Performance Specification

Operational Bandwidth

GSM-900

DCS-1800

Dual Band 900/1800

Connector Types- RAU

RF

Optical Fiber

AC Power (CDU only)

DC Power

Connector Locations RF connector on rear of RAU

Interface Type

RF

Optical Fiber

RF Impedance/VSWR 50 ohms, typical 10 dB return loss

1 dB Compression Point

Downlink

Uplink

Third Order Output Intercept Point

Downlink

Uplink

Spurious Response -36 dBm from 9 kHz to 1 GHz

Gain/Gain Linearity

Downlink

Uplink

Group Delay <1.0 usec (CDU, fiber and RAU)

Uplink

890-915 MHz

1710-1785 MHz

890-915 MHz

1710-1785 MHz

SMA

Type SC Single Mode Fiber

N/A

Molex 2-pin

Fiber and DC power on front of RAU

Duplex (bi-directional port)

Single mode fiber: 1 uplink, 1 downlink

20 dBm

N/A

36 dBm

-6 dBm

-30 dBm from 1 GHz to 12.75 GHz

15 db ± 2.5

15 db ± 2.5

Downlink

935-960 MHz

1805-1880 MHz

935-960 MHz

1805-1880 MHz

Electrical Specifications

The power requirements for the first and second generation Central Distribution Units (CDU) are

summarized in Table 4. The RAU is generally remotely powered from the CDU.

Table 4. Electrical Specifications

Slim Line Smart Rack 3U

Line Voltage 100 – 240 VAC, 47 – 63 Hz 100 – 240 VAC, 47 – 63 Hz

Power Consumption 40 Watts (CDU w/6 RAU’s) 140 Watts (CDU w/20 RAU’s)

Power Supply Redundancy None Hot Standby

Backup Power Supply External External

- 19 -

Page 28

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

Environmental and Mechanical Specifications

The environmental and mechanical specifications are summarized in Table 5. We have not

completed shock and vibration testing at this time.

Table 5. InCell™ Environmental and Mechanical Specification

Parameters CDU RAU

Enclosure Dimensions

Enclosure Weight 4 pounds 0.6 pounds

RF Connector N-female, bi-directional SMA-female, bi-directional

Fiber Connector 6 pairs (12), SC Type 1 pair (2), SC Type

Remote Alarm from CDU

Local Alarm

AC Power 100-240 VAC, 47-63 Hz N/A

DC Power 24 VDC output to each RAU +28 to +12 VDC input

Maximum DC Power Draw

MTBF > 27,000 hours > 180,000 hours

Storage Temperature -10 to +70o C

Operating Temperature 0 to +50o C

1.75”H x 16.75”W x 12”D

1U, 19” rack-mountable

9-pin D-Sub with summary power and

system link status

One power and one link status LED per

antenna port

CDU: 10 Watts

System: 40 Watts with 6 RAUs

1.5”H x 5”W x 6.5”D

N/A

One power and one link status LED

5 Watts

Humidity 0 to 95 % RH, non-condensing

MTBF

A system MTBF using one CDU and six RAU’s is calculated to be 26,954 hours for the slim line

unit and 9,851 hours for a fully populated 3U 20 unit chassis. Each RAU has a MTBF of

181,265 hours. These MTBF values were calculated using the Bellcore part count method.

MTTR

Low MTTR values are achieved due to the extensive internally monitoring capability. The

MTTR of the Slim Line unit is estimated at 15 minutes using a board replacement maintenance

concept. The MTTR for the 3U chassis is less than 5 minutes as modules can be easily replaced

while the unit is operating. The RAU MTTR is 5 to 30 minutes depending upon the complexity

and ease of access to the installed device. The proposed maintenance concept for the RAU is a

direct replacement of the unit.

- 20 -

Page 29

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

InCell™ Network Monitoring System

The InCell™ family is designed to minimize maintenance and monitoring costs. Provisions are

made for both local and remote monitoring of small and large systems. The InCell™ system

continuously monitors and reports status of the system hardware, by a combination of indicators

available at the central hub and at each remote antenna and alarms for remote monitoring that aid

in system fault detection and fault isolation down to a circuit board or cable.

The wideband, single mode fiber cable allows a low frequency RF test signal to be continuously

passed over the downlink and uplink signal paths with multiple RF wireless signals. In a dual

band system, the 67 MHz pilot test signal, the 800 MHz service, and the 1900 MHz service

signals simultaneously pass through the downlink and uplink paths.

Pilot Tone Generation

The CDU generates a continuous pilot tone for system level fault detection and isolation and

distributes the signal to each RAU port. This low frequency RF tone is combined with the

downlink RF signal and transmitted over the fiber optic cable to the RAU where it is received

and filtered from the downlink RF signal. In the RAU, the pilot tone is filtered, amplified and

combined with the RF uplink signal to be sent over the optical uplink path back to the CDU.

Within the RAU, the pilot tone is detected by a threshold detector to indicate the presence of the

pilot tone at a minimum signal level. The pilot threshold detector drives an LED on the RAU

that indicates that the downlink optical signal path to the RAU is connected.

The return path pilot tone from the RAU is also filtered, amplified and detected. The detected

pilot signal is passed to a threshold detector to indicate the tone presence at a minimum signal

level. The pilot threshold detector in turn drives an LED at each port of the CDU indicating that

both the downlink to the RAU and the uplink back to the CDU are connected and that power is

properly functioning at the RAU.

RAU Indicators

The Power indicator on the RAU shows that DC power from the composite cable is present at

the RAU. If the indicator is green, DC power is present in the RAU.

The LINK indicator on the RAU shows that the pilot tone from the CDU is present over the

downlink. When the LINK indicator is off on the RAU, the downlink optical path between the

CDU and the RAU is installed correctly and DC power is present in the RAU. If the LINK

indicator is red, there may be a problem with the downlink optical path between the CDU and

RAU or a problem with the RAU power. The RAU indicators allow system installers and

maintainers to easily determine the RAU functional status, the power supply status, and the

downlink optical path status.

CDU Front Panel Indicators

The Power indicator for each port of the CDU indicates that the DC power is present at that port.

If the CDU Power indicator is green, power is good at that CDU port, also indicating that the

internal AC power supply is good. If the Power indicator for one CDU port is off, there is

- 21 -

Page 30

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

problem with that CDU port interface. If the Power indicators for all CDU ports are off, the AC

power supply may be bad, AC power may be switched off or there may be another problem with

the AC power.

The LINK indicator at each CDU port shows that the CDU generated pilot tone was sent over

the downlink from the CDU to the RAU then received and transmitted over the uplink path from

the RAU back to the CDU. When the CDU LINK indicator is off, the downlink and uplink

optical paths are installed correctly and DC power is present in the RAU. If the LINK indicator

is red, there may be a problem with the fiber optic signals between the CDU and RAU; a

problem with the RAU power; or a problem with the RAU itself. The CDU indicators allow

system installers and maintainers to easily determine each RAU functional status, power

distribution to each RAU, and the correct connection of the fiber optic cables.

Alarm Functions

The CDU has two alarm outputs on the rear panel to indicate the overall health of the power

supply and the uplink and downlink to each remote antenna units. The link alarm output is a

summary alarm of all of system uplinks and downlinks and remote antenna power. The alarm

outputs are through a DB-9 connector located on the CDU chassis rear panel.

Remote Monitoring Functions

As an option that will be available in February 2001, InCell™ Systems will support remote

system health monitoring using standard protocols that will allow customers to monitor full

system status. This feature uses an embedded processor (see Error! Reference source not

found.) to monitor and report system health for the CDU and all RAUs, including power

supplies, uplink and downlink paths and cables.

With this option, the InCell™ System hardware can be remotely monitored in three ways:

v Locally using a RS-232 connection to a terminal or PC (see Figure 13)

v Remotely using an SNMP Agent chassis connected to a telephone, LAN/WAN or other

communications medium

v Remotely using dry-contact terminals connected to a third party SCADA

In the first method, the RS-232C interface option does not require a separate chassis. An RS-485

bus daisy chains the system status and alarms together as illustrated in Figure 13 and Figure 14.

Communications between CDU’s is accomplished over an RS-485 link, and the user can connect

to the master bus using a standard computer or RS-232C terminal.

In the second method, a separate 1U chassis is required to act as the SNMP agent. The SNMP

agent allows a network management system to monitor InCell™ device(s) by telephone or

network connection using industry standard interfaces. The SNMP agent performs network

management operations such as setting configuration parameters, alarm notification and current

operation statistics. A database of the InCell™ network management information, called the

management information base (MIB), is maintained by the Agent.

- 22 -

Page 31

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

In the third method, dry contact alarm terminals can be connected to a third party SCADA

system over copper wires.

Management

Management

System

System

RS-485

RS-485

(network)

(network)

InCell Agent

InCell Agent

InCell

InCell

InCell

InCell

InCell

InCell

SNMP

SNMP

RS-232

RS-232

(Local)

(Local)

Laptop computer

Laptop computer

RS485

SERIAL

INTERFACE

RF IN

Figure 13. Remote Alarm Capability

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

REMOTE ALARM

RF RF 100-240 VACPOWER

REMOTE ALARM

RF RF 100-240 VACPOWER

REMOTE ALARM

RF RF 100-240 VACPOWER

REMOTE ALARM

RF RF 100-240 VACPOWER

REMOTE ALARM

RF RF 100-240 VACPOWER

REMOTE ALARM

RF RF 100-240 VACPOWER

REMOTE ALARM

RF RF 100-240 VACPOWER

REMOTE ALARM

RF 100-240 VACRF POWER

REMOTE ALARM

RF RF RF RF RF RF RF RFRF

NETWORK

D00-48

Figure 14. Daisy Chaining CDU’s for Remote Monitoring

- 23 -

Page 32

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

InCell™ Operation, Maintenance and Support

Operation

InCell™ system operation is continuous. Andrew recommends using an uninterruptible power

supply (UPS) to provide power to the CDU. If the system uses composite cable to provide

power to the remote antenna units located throughout the building, the UPS can keep the CDU

and all RAUs powered and operational during brownouts and power outages.

Unlike some hybrid fiber distributed antenna systems that use frequency translation in the

wireless distribution process, the InCell™ uses no frequency synthesizers or synchronizing

circuitry that may be affected by power failures. The InCell™ operates immediately after power

is applied and is not susceptible to power failures.

Regular Maintenance

Minimal maintenance is required to support installed InCell™ systems. System maintainers

should ensure that all RF, power and fiber connectors are tight and that the CDU is mounted with

adequate room to allow air to flow into the chassis. Indicator LEDs show system status while

relay and optional remote alarm interfaces allow small or large system status to be monitored.

Andrew does recommend using a commercially available fiber optic cleaning kit to maintain

clean fiber optic connections. Typically, after system installation, no removal or cleaning of the

fiber connectors will be required.

Fault Repair

If a fault is detected in the system, maintainers can determine the problem cause problem by

reviewing reports from remote monitoring systems or by observing the front panel LED

indicators on the CDU chassis. Because the different CDU ports correspond to different remote

antenna locations, maintainers can determine where the problem exists in the building.

Maintainers can replace RAUs in the building without having to power down the system. If a

CDU fails, spare CDU boards can be installed.

Support

Andrew engineers and technicians familiar with the operation of the InCell™ system are

available Monday through Friday, 8am to 5pm CST. These personnel are familiar with

distributed in-building antenna systems, with fiber optic cable installation and with

troubleshooting and in-building coverage solutions.

In special cases, Andrew has provided local support of indoor wireless distributed antenna

systems. Please contact Andrew DCS if this type of maintenance support is required.

Spare Policy

For the Slim Line CDU assembly, we recommend sparing at the board level. This unit is

comprised of 2 unique board types and a power supply module. There is a single printed circuit

board that provides the necessary RF power, DC and alarm distribution and 6 identical printed

- 24 -

Page 33

Andrew InCell™ Fiber Optic Distributed Antenna System Users Guide

circuit boards that perform the gain and optical conversion (see Error! Reference source not

found.). If the remote monitoring option is selected, there is a third 2-teir printed circuit board.

- 25 -

Loading...

Loading...