Page 1

OPERATION AND MAINTENANCE MANUAL

For the

MODEL 2400

DISTRIBUTION LINE AMPLIFIER

MANUAL NO. 385700-4006

REVISION 6

The information set forth in this document and all rights in and to inventions

disclosed herein, and patents which might be granted t her eon disclosing,

employing or covering the materials, methods, techniques or apparatus

described herein are the exclusive property of Andrew Corporation.

This document is an operation and maintenance manual. No disclosur e or

reproduction of the infor mation or drawings shall be made of any other

purpose without the prior written consent of Andrew. Use of the information

contained herein to fabricate or assem b le any item in whole or in part is

expressly prohibited

2601 Telecom Parkway, Richardson, Texas 75082-3521

.

TEL (972) 952 9700 FAX (972) 952-0000

Page 2

385700-4006-006 SAFETY SUMMARY

SAFETY SUMMARY

High voltage is used in the operation of

this equipment. Death on contact may

result, if personnel fail to observe t he

following safety precautions:

• Do not be misled by the term “Low Voltage.” Potent ials as low as 50 Volts may cause

death under adverse conditions.

• Do not crush, puncture, disassemble or other wise mutilate batteries. Leaking batteries

can cause serious damage to equipment and injur y to per sonnel.

• Do not remove covers or access plates on the equipment, unless you are author ized to do so.

• Do not work on electronic equipment unless ther e is anot her person nearby who is familiar

with the operation of the equipment and is t r ained in administering first aid.

• Whenever possible, disconnect t he equipment from the power source bef or e beginning

maintenance.

• To prevent electrical shock or damag e to the equipment, do not operate it until you

thoroughly understand the operation and f unction of all controls, indicators, and

connectors.

• Turn off all power to the equipment before replacing any f uses.

FIRST AID

In case of electrical shock:

• Do not try to pull or grab the individual.

• If possible, turn of f the electrical power.

• If you cannot turn off the electrical power, pull, push, or lift the person to safety using a dry

wooden pole, a dry rope, or some other insulating mater ial.

• Send for help as soon as possible.

• After the injured person is no longer in contact with the source of electrical shock , m ove

the person a short distance away and immediately administer firs t aid and ar tificial

resuscitation as required.

Document use is restricted to that described on cover A

Page 3

385700-4006-006 LIST OF ABBREVIATIONS AND ACRONYMS

WARNING

The Distribution Line Amplifier is an unlicensed device oper ating

under the conditions of FCC part 15 regulati ons. This equipment

is intended to be installed and operated by professional parties.

It is the responsibility of those parties to insure that the

equipment is operated in compliance with the applicable FCC

part 15 specifications.

LIST OF ABBREVIATIONS AND ACRONYMS

NOTE

All abbreviations/acronyms used in this

manual, other than those listed on this

page, are used per MIL-STD-12D.

BDR Base Data Radio

USER Communications-Based Train Control

DLA Distribution Line Amplifier

ESDS Elect r ostatic Discharge Sensitive

FWD Forward

LRU Line Replaceable Unit

MDR Mobile Data Radio

PC Personal Computer

RCS Radio Communication Subsystem

RF Radio Fr equency

RVS Reverse

SSR Spr ead Spect r um Radio

Document use is restricted to that described on cover B

Page 4

385700-4006-006 LIST OF REFERENCE DOCUMENTS

LIST OF REFERENCE DOCUMENTS

Andrew Catalog 37 (or latest version)

Drawings:

Assembly, Line Amplifier 385700-4000

Document use is restricted to that described on cover C

Page 5

385700-4006-006 TABLE OF CONTENTS

TABLE OF CONTENTS

CHAPTER 1............................................................................................................................................ 1-4

1.1 GENERAL MANUAL INFORMATION........................................................................................ 1-4

1.2 PREPARATION FOR STORAGE OR SHIPMENT.................................................................... 1-4

1.2.1Storage.............................................................................................................................. 1-4

1.2.2Shipment........................................................................................................................... 1-4

1.3 DESCRIPTION OF EQUIPMENT.............................................................................................. 1-5

1.3.1Type of Equipment............................................................................................................ 1-5

1.3.2Purpose of the Equipment................................................................................................. 1-5

1.4 LOCATIONS AND DESCRIPTIONS OF MAJOR COMPONENTS........................................... 1-6

1.4.1Distribution Line Amplifier Principles of Operation............................................................ 1-6

1.4.2Distribution Line Amplifier Major Components.................................................................. 1-9

1.5 EQUIPMENT CHARACTERISTICS......................................................................................... 1-10

1.5.1Power and Utility Requirements...................................................................................... 1-10

1.5.2Environmental Information .............................................................................................. 1-10

CHAPTER 2............................................................................................................................................ 2-1

2.1 INSTALLING THE DISTRIBUTION LINE AMPLIFIER EQUIPMENT........................................ 2-1

2.1.1Unpacking and Inspection................................................................................................. 2-1

2.1.2Proper Installation of Units ................................................................................................ 2-1

2.2 INTERCONNECTIONS.............................................................................................................. 2-1

2.2.1Forward Direction Configuration Interconnection.............................................................. 2-1

2.2.2Reverse Direction Configuration Interconnection.............................................................. 2-2

2.3 CABLE AND GROUND REQUIREMENTS................................................................................ 2-2

2.3.1Mating Connector Pin-outs................................................................................................ 2-5

2.4 DISTRIBUTION LINE AMPLIFIER COMPONENT JACK LOCATIONS.................................... 2-7

2.5 PREPARATION FOR USE ........................................................................................................ 2-8

2.5.1Distribution Line Amplifier Setup ....................................................................................... 2-8

2.5.2Distribution Line Amplifier Initial Operational Adjustments................................................ 2-9

2.5.2.1 Input AC Power............................................................................................................. 2-9

2.5.2.2 Power Amplifier (PA) Channel (Channel 1) ................................................................. 2-9

2.5.2.2.1 PA Equipment Setup............................................................................................ 2-9

2.5.2.2.2 PA Input Alarm Adjustment................................................................................ 2-10

2.5.2.2.3 PA Output Adjustment........................................................................................ 2-11

2.5.2.2.4 PA Output Alarm Adjustment ............................................................................. 2-11

2.5.2.3 Low Noise Amplifier (LNA) Channel (Channel 2)........................................................ 2-12

2.5.2.3.1 LNA Adjustment Equipment Setup..................................................................... 2-12

2.5.2.3.2 LNA Output Adjustment ..................................................................................... 2-13

2.5.2.3.3 LNA Output Alarm Adjustment........................................................................... 2-14

2.5.3Operational Check-Out ................................................................................................... 2-14

2.5.3.1 Forward PA Channel Verification................................................................................ 2-14

2.5.3.1.1 PA Output Level Verification .............................................................................. 2-14

2.5.3.1.2 PA Input Signal Alarm........................................................................................ 2-15

2.5.3.1.3 PA Output Signal Alarm ..................................................................................... 2-15

2.5.3.2 Forward LNA Channel Verification.............................................................................. 2-16

2.5.3.2.1 LNA Output Level Verification............................................................................ 2-16

2.5.3.2.2 LNA Output Signal Alarm................................................................................... 2-16

2.5.3.3 Reverse PA Channel Verification................................................................................ 2-16

2.5.3.3.1 PA Output Level Verification .............................................................................. 2-16

2.5.3.3.2 PA Input Signal Alarm........................................................................................ 2-17

2.5.3.3.3 PA Output Signal Alarm ..................................................................................... 2-17

2.5.3.4 Reverse LNA Channel Verification ............................................................................. 2-17

2.5.3.4.1 LNA Output Level Verification............................................................................ 2-17

2.5.3.4.2 LNA Output Signal Alarm................................................................................... 2-17

Document use is restricted to that described on cover i

Page 6

385700-4006-006 TABLE OF CONTENTS

CHAPTER 3............................................................................................................................................ 3-1

3.1 WIRING PROTECTION AND GROUNDING............................................................................. 3-1

3.2 STARTUP AND SHUTDOWN PRODECURES......................................................................... 3-2

3.2.1DLA Startup....................................................................................................................... 3-2

3.2.2Normal Operation.............................................................................................................. 3-2

3.2.3Shutdown .......................................................................................................................... 3-2

CHAPTER 4............................................................................................................................................ 4-1

4.1 TROUBLESHOOTING............................................................................................................... 4-1

4.2 CORRECTIVE MAINTENANCE ................................................................................................ 4-2

4.2.1Remove and Replace DLA................................................................................................ 4-2

4.3 TEST PROCEDURES ............................................................................................................... 4-4

4.3.1Inoperative Distribution Line Amplifier............................................................................... 4-4

4.3.1.1 Input Power Verification................................................................................................4-4

4.3.1.2 RADIAX

Alarm Asserted............................................................................................. 4-5

4.3.1.3 Amplifier Alarm Asserted.............................................................................................. 4-5

4.3.1.3.1 Loss of PA Input Signal........................................................................................ 4-5

4.3.1.3.2 PA Module Failure................................................................................................ 4-5

4.3.1.3.3 Loss of Pilot Tone Signal...................................................................................... 4-6

4.3.1.3.4 LNA Module Failure.............................................................................................. 4-6

CHAPTER 5............................................................................................................................................ 5-1

5.1 PARTS LIST .............................................................................................................................. 5-1

CHAPTER 6............................................................................................................................................ 6-1

CHAPTER 7............................................................................................................................................ 7-1

Document use is restricted to that described on cover ii

Page 7

385700-4006-006 TABLE OF CONTENTS

LIST OF FIGURES

Figure 1-1 Distribution Line Amplifier (4 port).......................................................................1-6

Figure 1-2 DLA Block Diagram ............................................................................................1-8

Figure 1-3 DLA Internal View................................................................................................1-9

Figure 2-1 DLA Forward Direction Interconnect Diagram.....................................................2-3

Figure 2-2 DLA Forward Direction Interconnect Diagram......................................................2-4

Figure 2-3 DLA Input VAC Pin-outs ......................................................................................2-5

Figure 2-4 DLA ALARM/CONTROL Port Pin-outs................................................................2-6

Figure 2-5 DLA Assembly Jack Locations............................................................................2-7

Figure 2-6 PA Output Level Test Setup ...............................................................................2-9

Figure 2-7 PA Module Outline............................................................................................2-10

Figure 2-8 LNA Module Outline..........................................................................................2-12

Figure 2-9 LNA Output Level Test Set Up..........................................................................2-13

Figure 3-1 DLA Connector Panel Layout..............................................................................3-1

Figure 4-1 Remove and Replace DLA..................................................................................4-3

Figure 6-1 DLA Mechanical Outline .....................................................................................6-1

LIST OF TABLES

Table 1-1 – DLA Part Numbers.............................................................................................1-5

Table 1-2 Distribution Line Amplifier Specifications............................................................1-11

Table 2-1 – Forward Direction RF Port Functions.................................................................2-3

Table 2-2 Reverse Direction RF Port Functions....................................................................2-4

Table 4-1 DLA Fault Isolation...............................................................................................4-1

Table 4-2 Test Equipment....................................................................................................4-4

Table 5-1 Vendors...............................................................................................................5-1

Table 5-2 Parts List..............................................................................................................5-2

Document use is restricted to that described on cover iii

Page 8

385700-4006-006 INTRODUCTION

CHAPTER 1

INTRODUCTION

1.1 GENERAL MANUAL INFORMATION

This manual contains instructions for the operation, maintenance, and support of the

Distribution Line Amplifier (DLA) assembly. T his manual describes the amplifier assembly in

detail. It provides the necessary inform ation for q ualified technical per sonnel to inst all, repair,

and maintain the Distribution Line Amplifier to the line replaceable unit (LRU).

This manual is divided into seven chapters, which consist of sections to describe the

information or procedures in detail. The five chapters are as follows:

• Chapter 1 outlines the contents of this manual and provides a basic equipment

description of the Distribution Line Am plifier.

• Chapter 2 provides preparation for use and installation information.

• Chapter 3 provides operating procedures f or t he equipment.

• Chapter 4 provides preventive and corrective maintenance of the Dist ribution Line

Amplifier assembly.

• Chapter 5 contains a vendor list and parts list for procurement of replacement

parts.

• Chapter 6 provides mechanical outline informat ion

• Chapter 7 contains a schematic of a test fixture for the Alarm/Cont r ol int erface.

1.2 PREPARATION FOR STORAGE OR SHIPMENT

The following paragraphs describe guidelines for long term stor age and the shipment of the

equipment.

1.2.1 Storage

Before storage, wrap the equipment in static shielding bubble wrap. Bubble wrap protects

internal electrostatic discharge sensit ive (ESDS) assemblies, external panels, and connect ors.

Place wrapped equipment in the original shipping containers and seal. Store in a cool dry

place, away from the elements.

1.2.2 Shipment

Ship equipment in the original shipping containers or in a container that provides sufficient

protection for ESDS equipment. Pack the equipm ent in a manner that provides protection for

all external switches and mountings, because these items are most vulnerable to damage

during shipment.

Document use is restricted to that described on cover 1-4

Page 9

385700-4006-006 INTRODUCTION

1.3 DESCRIPTION OF EQUIPMENT

The Radio Communications Network consists of Base and Mobile Radio Communication

Systems (RCS) and a Wayside Antenna System. The Distribution Line Amplif ier (DLA) is par t

of the distributed Wayside Antenna System based on leaky-feeder cable RADI AX

®

. DLA’s are

used to compensate for attenuation losses in the cable by providing bi-dir ectional amplification

of signals. The DLA also includes a direction control signal and status signals to monitor

amplifier operation.

1.3.1 Type of Equipment

The DLA is a FCC approved bi-directional amplifier that is used with spread spectrum

transceivers that operate in the ISM 2400-2483.5 MHz frequency band. The 4 versions of the

DLA are shown in Table 1-1. The models differ in the number of RF ports and the type of

control interface.

Part Number Description

385700-4000-001 4 port amplifier with LONWorks™ Interface

385700-4000-002 4 port amplifier with dry contact Inter face

385700-4000-003 2 port amplifier with LONWorks™ Interface

385700-4000-004 2 port amplifier with dry contact Inter face

Table 1-1 – DLA Part Numbers

1.3.2 Purpose of the Equipment

The Distribution Line Amplifier provides selective frequency range amplification of both a

forward (downlink) and reverse (uplink) direction signals in RADIAX

defined as the direction of RF energy from the BDR at the wayside to the MDR. Reverse

direction is defined as the direction of RF energy fr om the MDR to the BDR. T he signals that

appear on the line amplifier RF ports are determined by the USER controlled direction signal.

®

cable. Forward is

Document use is restricted to that described on cover 1-5

Page 10

385700-4006-006 INTRODUCTION

1.4 LOCATIONS AND DESCRIPTIONS OF MAJOR COMPONENTS

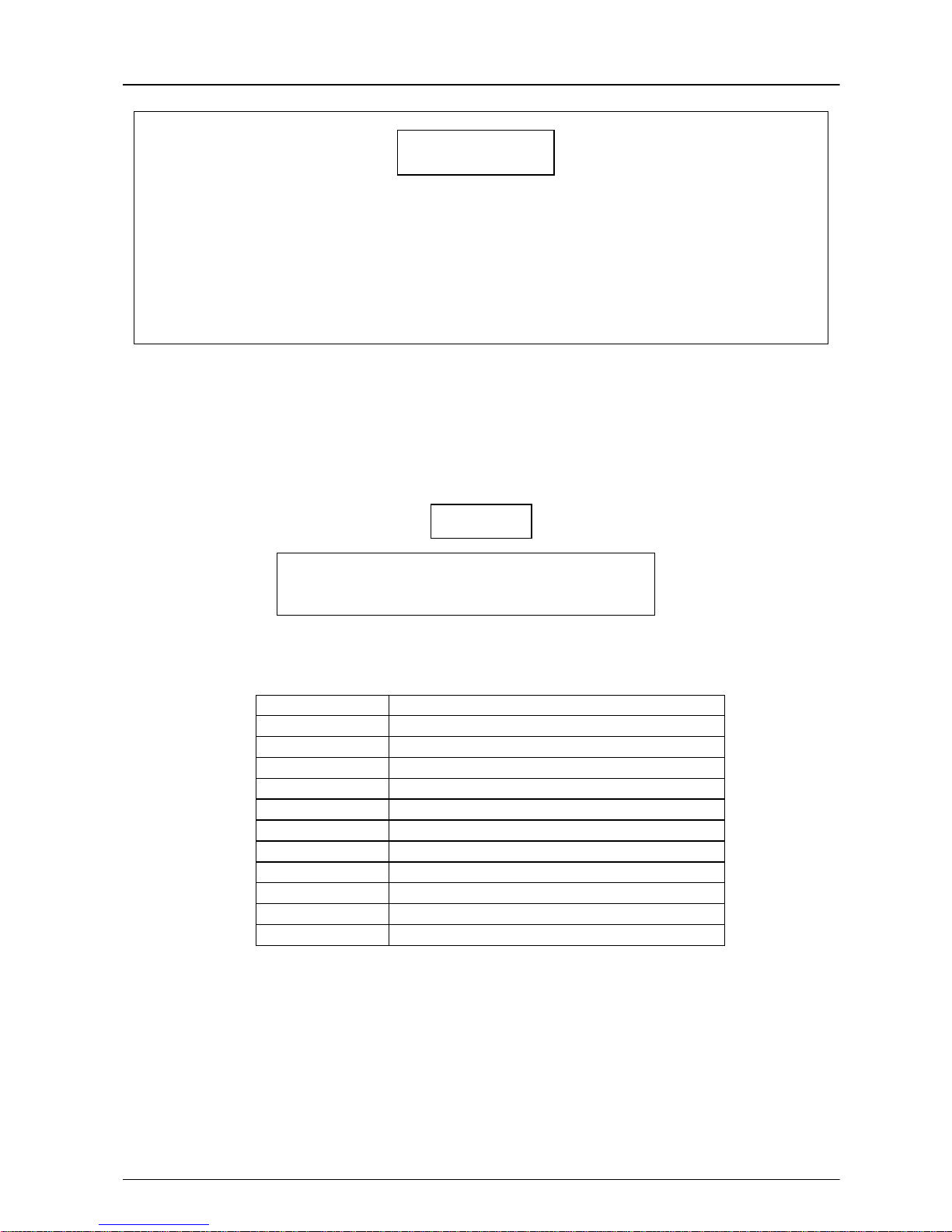

Refer to Figure 1-1 Dist ribution Line Amplifier (4 port) for a view of t he external connections

of the 4 port DLA. The 2 por t DLA does not include J5 or J6. The mechanical outline of t he

DLA is given in CHAPTER 6. The following paragraphs contain the description of the

Distribution Line Amplifier.

Figure 1-1 Distribution Line Amplifier (4 port)

1.4.1 Distribution Line Amplifier Principles of Operation

The bi-directional Distribution Line Amplifier operates within two sub-regions of the 2400 –

2483.5 MHz ISM band. It filters and amplifies at the BDR center f requency of 2416.64 MHz.

in one direction (FW D) and at the MDR center f requency of 2467.86 MHz in another direction

(RVS).

The RF signal at each amplifier is routed thr ough a diplexer (f ilter) to divide the signal int o two

paths: forward and reverse. The DLA has a direct ion control switch which changes the signal

path to the opposite direction upon the command from the user control equipment network

data interface via the alarm and control interface board. The internal status of the DLA is

monitored by the Amplifier Alarm Detectors. The status signals ar e sent to the USER control

equipment network data interface via the alarm and control interface.

The BDR path, also referr ed to as the PA channel or channel 1, contains a power amplifier.

The maximum PA output of the 4 port DLA is < +27 dBm per output port. T he PA output port

of the 2 port DLA is < +30 dBm. The PA channel maintains a constant output power over a

user adjustable range. See Table 1-2 Distribution Line Amplif ier Specifications for the input

range over which the output power is adjustable. The PA channel also contains an input

Document use is restricted to that described on cover 1-6

Page 11

385700-4006-006 INTRODUCTION

power level alarm as well as an output power alarm. The alarm levels are user adjustable.

The MDR path is also referred to as the LNA channel or channel 2. The LNA channel is

referenced to a pilot tone within the Distribution Line Amplifier. The pilot tone is used (1) to

set the gain of the LNA channel and (2) to provide a method of detecting a f ault y LNA module.

The LNA channel gain is user adjustable. The maximum LNA g ain is +27 dB for the 4 port

DLA per output port and +30 dB for the 2 port DLA. See Table 1-2 Distribution Line Amplifier

Specifications for the range over which the gain is adjustable. Under normal operation, the

input signal is expected to be lower (nominally 10 dB) than the pilot tone.

The PA channel input alarm is used to detect a loss of input signal due t o cable breakage, et c.

The PA channel output alarm and the LNA channel output alarm are combined to indicate an

amplifier failur e.

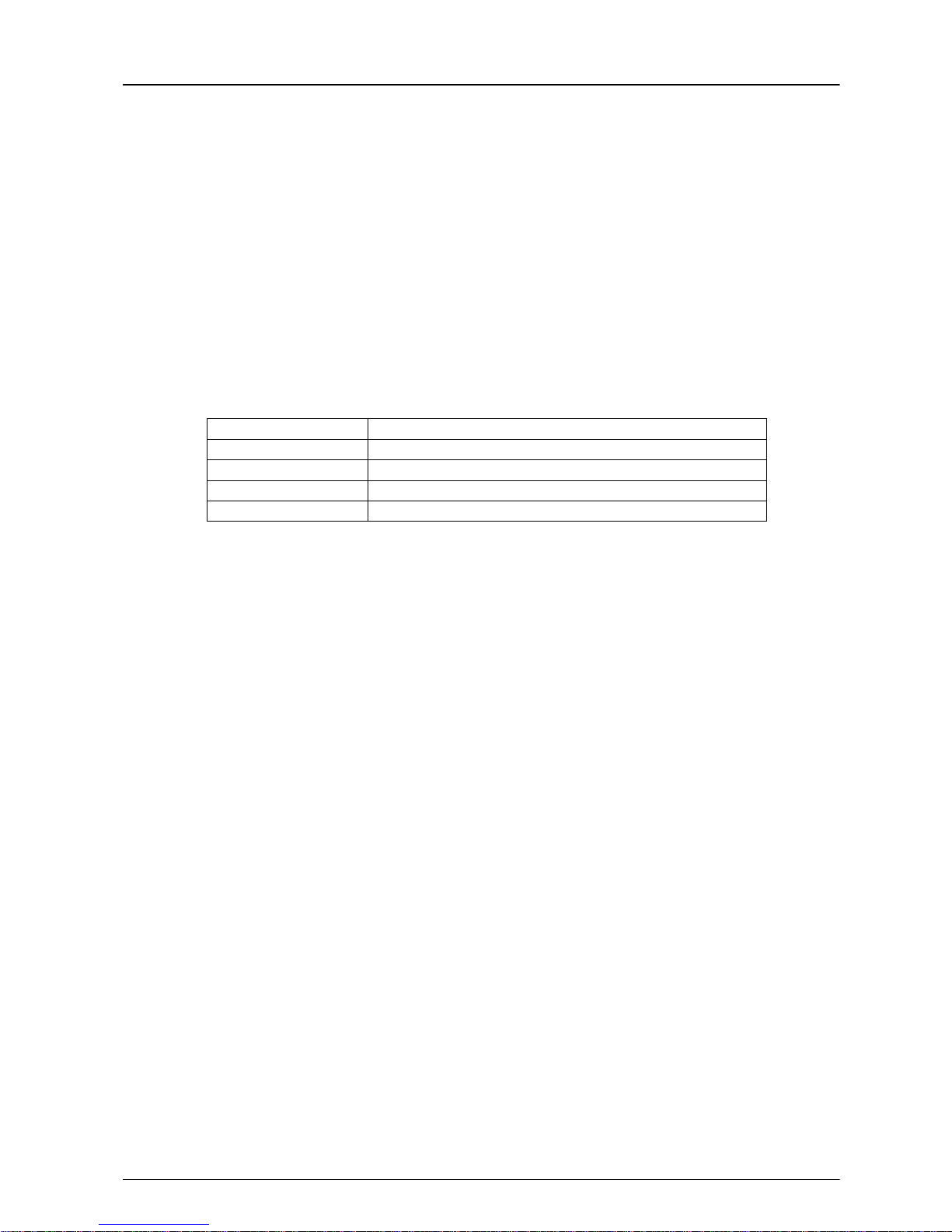

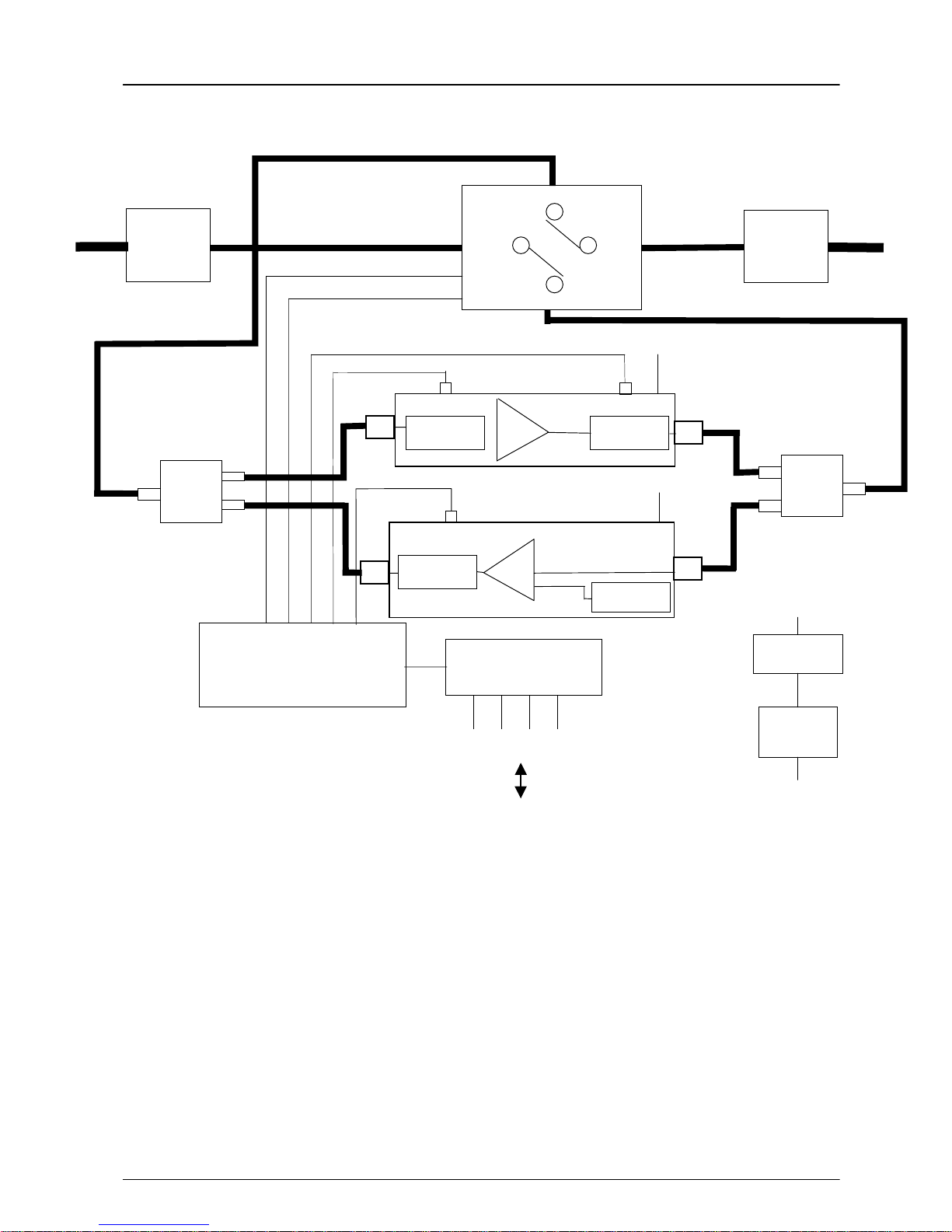

Refer to Figure 1-2 DLA Block Diagram, for bi-directional amplifier major component

identification.

Document use is restricted to that described on cover 1-7

Page 12

385700-4006-006 INTRODUCTION

A

Transfer

Relay

Radiax

RF Lightning

Protection

Direction Control

Direction Status

+12 VDC

RF Lightning

Protection

Radiax

Diplexer

Alarm & Control

Interface Board

Radiax Alarm

Detector

LNA Alarm

Detector

USER Control Equipment

PA

LNA

24V Lightning

Protectors

larm & Control

Connections

-10 dBm

PA Alarm

Detector

+12 VDC

Pilot Tone

Generator

Diplexer

+12 VDC

AC-DC

Power Supply

AC

Lightning

Protection

87-265 VAC

Document use is restricted to that described on cover 1-8

Figure 1-2 DLA Block Diagr am

Page 13

385700-4006-006 INTRODUCTION

1.4.2 Distribution Line Amplifier Major Components

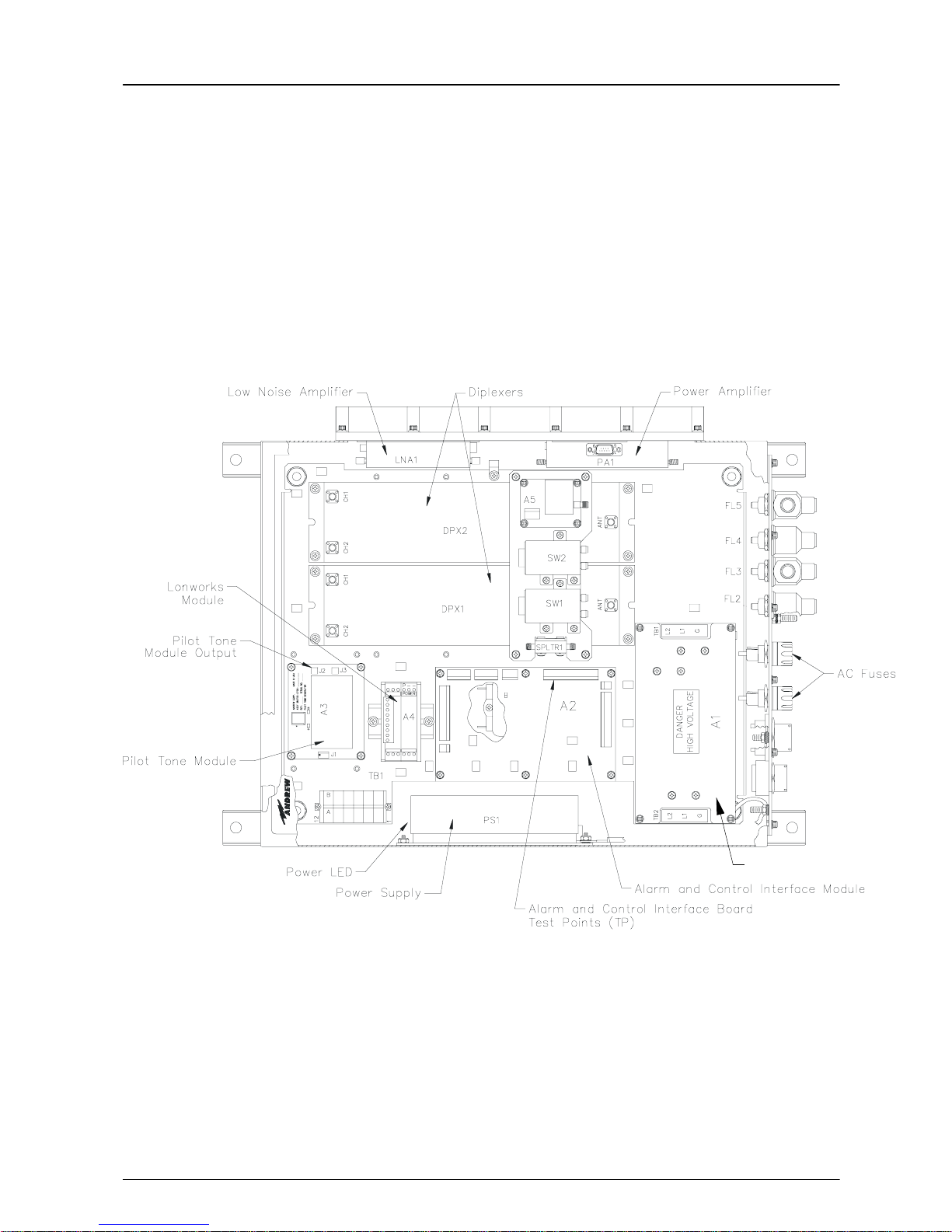

Refer to Figure 1-3 DLA I nternal View for locations of major DLA components. The t est point

locations, Pilot Tone Output J3 on the Pilot Tone Board and Alarm and Control Interface

Board Test Points J4, shown in

Figure 1-3 are used for init ial DLA adjustments and ref erenced later in this manual in section

2.5.

J2

J1

J9J7J6J3 J4

J2

J1

J8

J5

Lightning Protection Module

Figure 1-3 DLA Internal View

Refer to section 2.5.1, Distribution Line Amplifier Setup, for PA and LNA outline views and

controls.

Document use is restricted to that described on cover 1-9

Page 14

385700-4006-006 INTRODUCTION

1.5 EQUIPMENT CHARACTERISTICS

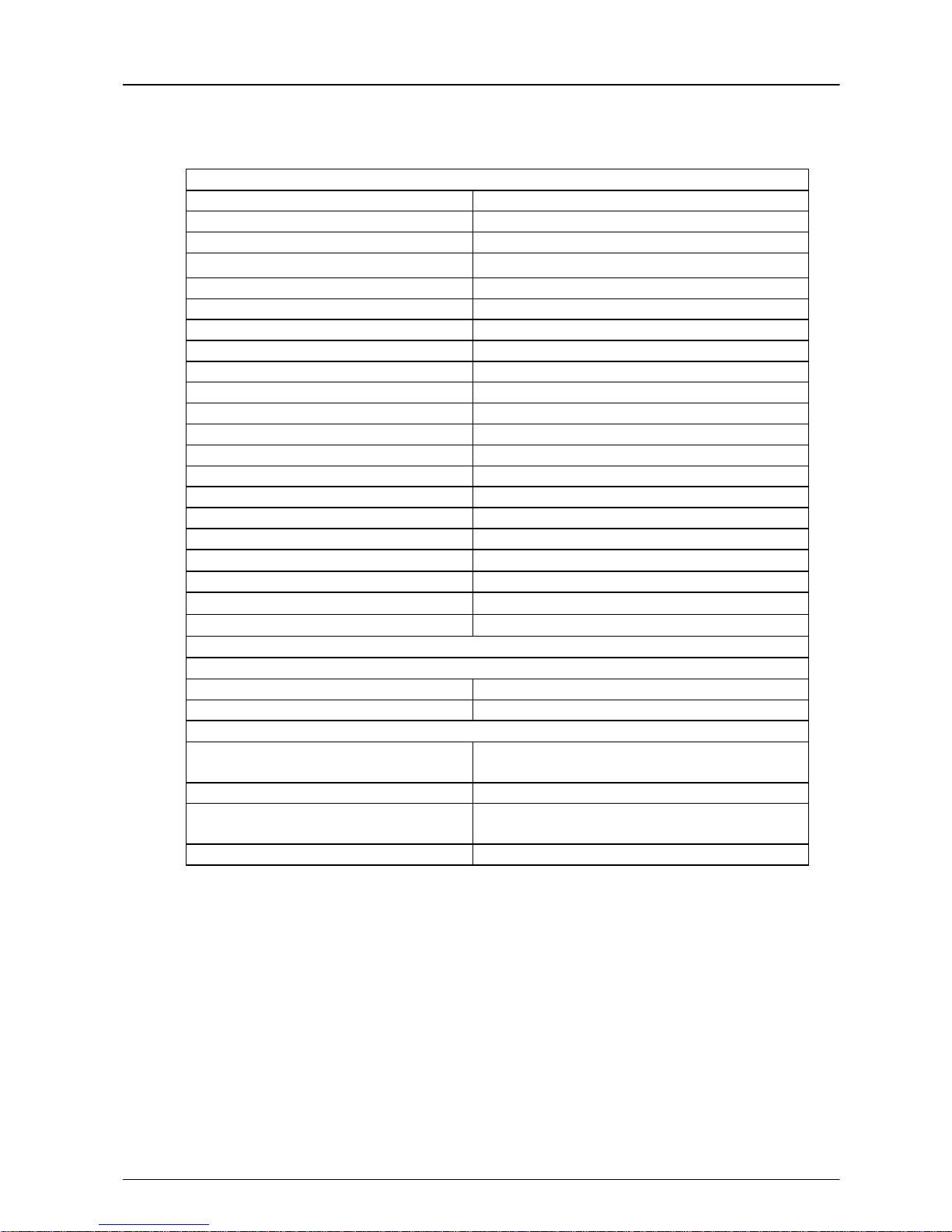

Refer to Table 1-2 Distribution Line Amplifier Specifications. The table contains the

specifications for the DLA. The table includes characteristics and specifications in three

categories: technical, environmental, and physical.

1.5.1 Power and Utility Requirements

The DLA operates across an AC input range of 87 to 265 VAC. No user adjustment is

required.

1.5.2 Environmental Information

The DLA assembly is designed for above and below ground environments. Refer to Table 1-2

Distribution Line Amplifier Specifications, for more det ailed information.

The DLA is housed in a NEMA4X enclosure. It is intended for indoor or outdoor use to

provide a degree of protection against corrosion, windblown dust and rain, splashing water,

and hose-direct water; undamaged by the format ion of ice on the enclosure. The NEMA4X

enclosure is manufactured fr om 16 gauge Type 304 stainless steel.

Document use is restricted to that described on cover 1-10

Page 15

385700-4006-006 INTRODUCTION

Electrical Specifications

Channels 2

Channel 1, MHz 2416.64 ± 13.5 MHz

Channel 2, MHz 2467.86 ± 13.5 MHz

Input and Output Impedance, ohms 50

Channel 1 (PA channel)

input power -15 dBm to +5 dBm

output power, adjustable +15 to +30 dBm (2 port amplif ier )

+12 to +27 dBm (4 port amplifier )

input signal alarm, adjustable -10 dBm nominal

output signal alarm, adjustable +20 dBm nominal

Channel 2 (LNA channel)

input power -25 dBm maximum

output power +0 dBm maximum (2 port amplifier )

-3 dBm maximum (4 port amplifier)

output gain, adjustable 15 to 30 dB

output signal alarm 10 dB below the pilot tone level

Gain, dB

≥ 30 (at maximum gain)

Noise Figure, dB

Channel 1

Channel 2

≤ 8

≤ 6

Environment Specifications

Operating Temperature, °C -40 to +70

Storage Temperature, °C -55 to +85

Physical Specifications

Power Requirements 87-265 VAC

47-63 Hz

Power Consumption, watts 50

Dimensions, in (mm) 20 (508) x 16 (406) x 7 (178)

excluding mounting feet

Weight, lbs. (kg) 43 (19.5)

Table 1-2 Distribution Line Amplif ier Specifications

Document use is restricted to that described on cover 1-11

Page 16

385700-4006-006 INSTALLATION

CHAPTER 2

INSTALLATION

2.1 INSTALLING THE DISTRIBUTION LINE AMPLIFIER EQUIPMENT

This chapter provides informat ion t o inst all the Distribution Line Amplifier (DLA) and to prepare

the equipment for use.

2.1.1 Unpacking and Inspection

Unpacking the Distribution Line Amplifier does not require special procedures. Use normal

shop procedures to unpack the equipment.

Carefully inspect the shipping containers and equipment. If the containers show damage,

inspect the equipment in those containers with extra care. Do not open containers with

extreme damage.

Check equipment for bent frames, protrusions, and dents. Pay close attention to external

brackets, controls and connectors, because they are especially susceptible to damage during

shipment.

If you find damage to t he equipment, notify Andrew Corporation’s Customer Ser vice Center at :

• 1-800-255-1479 (Inside the USA)

• 708-873-2307 (Outside the USA)

2.1.2 Proper Installation of Units

The amplifier has a weatherproof NEMA4X enclosure. The layout is optimized for vertical

mounting of the amplifier with the cables connected at the bottom of the amplifier. The

enclosure is accompanied with hanger brackets that are used to mount the amplifier. The

type of fasteners will depend on the construction of the mounting surface. Typical

construction in a concrete tunnel would be to use concrete anchors embedded in concrete.

Once DLA is mounted, the power connections and RF connections can be made next.

2.2 INTERCONNECTIONS

Refer to Figure 2-1 DLA Forward Direction Interconnect Diagram, for a block diagram of

wiring runs and connector designations. The following paragraphs describe the

interconnections directly related to the Distribution Line Amplifier.

WARNING

Before applying power, verify that the

input/output cables are securely

connected to the DLA Input/Output J3 and

J4 ports. Failure to observe these

warnings will damage the equipment.

2.2.1 Forward Direction Configuration Interconnection

Document use is restricted to that described on cover 2-1

Page 17

385700-4006-006 INSTALLATION

In normal usage, the RF connections to the Distribution Line Amplifier are made with nonradiating coaxial cable that is attached to t he m ain radiating coaxial cable RADIAX

radiating RF cable is type HELIAX

In the forward configurat ion, connect the HELIAX

®

LDF4-50A (or equivalent) with N male type connectors.

®

coaxial cable coming from the direction of

®

. The non-

BDR or the preceding DLA in a cascaded configuration to the Distribution Line Amplifier at

NORM PA IN/LNA OUT (J4) port on the connector panel of the unit. Connect the HELIAX

coaxial cable coming from the direction of the succeeding DLA in a cascaded conf iguration at

the DLA NORM PA OUT1/LNA IN (J3) port. See Figure 2-1 DLA Forward Direction

Interconnect Diagram for a typical 4 port conf iguration. For 2 port configur ations, J5 and J6

are not connected. Refer to Andrew Catalog, -- HELIAX® Coaxial Cable – for cable and

connector information.

Connect a nominal 120 VAC power source to the DLA connector panel POWER I N (J1) port.

Refer to Figure 2-3 DLA Input VAC Pin-outs.

The ALARM/CONTROL (J2) connector is connected via cable to the USER control equipm ent

network data interface. T he data interface may be represented by eit her LONW ORKS

®

type

connection or by twisted pair cable connection. For the dry contacts ref er to Figur e 2-4 DLA

ALARM/CONTROL Port Pin-outs. The ALARM/CONTROL interface includes a signal that

controls the direction of the line amplifier. In normal usage the direction control is set to

FORWARD.

2.2.2 Reverse Direction Configuration Interconnection

In normal usage, the direction of t he amplifier is reversed by controlling the amplifier from the

ALA RM/CONTROL interface. The signals are connected to t he line amplifier as described in

the previous section. Selecting the reverse direction reverses the direction of the signals

within the line amplifier as well as the signals that appear on J3 and J4 of the line amplifier.

2.3 CABLE AND GROUND REQUIREMENTS

The following paragraphs contain the r equirements for constructing the interconnect cabling

between the DLA vendor supplied equipment.

The chassis of the DLA must be bonded to earth with 6-guage solid conductor. See Figure

1-1. Connection to the DLA is made at ground lug provided at the connector panel of the

DLA.

The RF coaxial cables that are connected to the main radiat ing cable under normal conditions

must support potential bends in the path from the main radiating cable to the DLA plat e. Loss

through this cable must be less than 2 dB.

For the ALARM/CONTROL interface (direction and am plifier status signals), construct signal

cabling using 16 gauge shielded cabling.

All signal cables shall be shielded for EMI reduction.

Document use is restricted to that described on cover 2-2

Page 18

BDR 1

®

®

®

A

®

®

®

®

®

®

385700-4006-006 INSTALLATION

FORWARD CONFIGURATION : DIRECTION CONTROL = NORMAL

USER Control

Equipment

HELIAX

RADIAX

DLA

ALARM/CONTROL

J2

NORM PA IN

LNA OUT

J4

NORM PA

OUT2

J5

NORM PA OUT1

LNA IN

J3

RADIAX

HELIAX

RADIAX

DL

ALARM/CONTROL

J2

NORM PA IN

LNA OUT

J4

NORM PA

NORM PA OUT1

LNA IN

J3

OUT2

J5

RADIAX

HELIAX

BDR 2

VAC Power

J3 – LNA In 2467.84 MHz ± 13.5 MHz I Y

J3 – Norm PA Out1 2416.64 MHz ± 13.5 MHz O Y

J4 – Norm PA In 2416.64 MHz ± 13.5 MHz I Y

J4 – LNA Out 2467.84 MHz ± 13.5 MHz O Y

J5 – Norm PA Out2 2416.64 MHz ± 13.5 MHz 0 4 Port only

J6 – Norm Det In 2416.64 MHz ± 13.5 MHz I 4 Port only

POWER IN

J1

NORM DET IN

J6

RADIAX

POWER IN

J1

NORM DET IN

J6

BDR 1

ZONE

Figure 2-1 DLA Forward Direction Interc onnect Diagram

RF Port Frequency Input/Output 4 Port/2 Port

RADIAX

BDR 2

ZONE

Table 2-1 – Forward Direction RF Port Functions

Document use is restricted to that described on cover 2-3

Page 19

BDR 1

®

®

®

A

®

®

®

®

®

®

385700-4006-006 INSTALLATION

USER Control

Equipment

HELIAX

RADIAX

DLA

ALARM/CONTROL

J2

NORM PA IN

LNA OUT

J4

NORM PA

OUT2

J5

NORM PA OUT1

LNA IN

J3

RADIAX

HELIAX

RADIAX

DL

ALARM/CONTROL

J2

NORM PA IN

LNA OUT

J4

NORM PA

OUT2

J5

NORM PA OUT1

LNA IN

J3

RADIAX

HELIAX

BDR 2

POWER IN

J1

NORM DET IN

J6

RADIAX

POWER IN

J1

VAC Power

BDR 2

BDR 1

ZONE

ZONE

Figure 2-2 DLA Forward Direction Interc onnect Diagram

RF Port Frequency Input/Output 4 Port/2 Port

J3 – LNA In 2467.84 MHz ± 13.5 MHz O Y

J3 – Norm PA Out1 2416.64 MHz ± 13.5 MHz I Y

J4 – Norm PA In 2416.64 MHz ± 13.5 MHz O Y

J4 – LNA Out 2467.84 MHz ± 13.5 MHz I Y

J5 – Norm PA Out2 2416.64 MHz ± 13.5 MHz I 4 Port only

J6 – Norm Det In 2416.64 MHz ± 13.5 MHz O 4 Port only

NORM DET IN

J6

RADIAX

Table 2-2 Reverse Direction RF Port Functions

Document use is restricted to that described on cover 2-4

Page 20

385700-4006-006 INSTALLATION

2.3.1 Connector Pin-outs

Refer to Figures Figure 2-3 and Figure 2-4 for the connector pin-out information for the

Distribution Line Amplifier por t s .

Figure 2-3 DLA Input VAC Pin-outs shows the pin assignments for the Distribution Line

Amplifier POWE R IN connector.

The DLA Power Connector is a MIL-C-26482, Series 2 connector. The connector is

MS3474W14-4P or equivalent. Mating connectors are MS3475W 14-4S, PV75W14-4S,

or equivalent.

Figure 2-3 DLA Input VAC Pin-outs

Document use is restricted to that described on cover 2-5

Page 21

385700-4006-006 INSTALLATION

Figure 2-4 DLA ALARM/CONTROL Port Pin-outs, shows the pin assignments for the

Distribution Line Amplifier ALARM/CONTROL connector.

Figure 2-4 DLA ALARM/CONTROL Port Pin-outs

The Alarm/Control connector is a MIL-C-26482, Series 1 connector. T he part is MS3124E2016P, KPSE07E20-16P, or equivalent. The mating connectors are MS3126F20-16S,

KPSE06F20-16S, or equivalent. These are crimp connecto rs with a grommet seal and strain

relief. Other options are available including a right angle plug assembly(KPSE08F20-16S)

and solder connections.

Document use is restricted to that described on cover 2-6

Page 22

385700-4006-006 INSTALLATION

2.4 DISTRIBUTION LINE AMPLIFIER COMPONENT JACK LOCATIONS

The following paragraphs describe the pur pose and location of the jacks for the Distribution

Line Amplifier. Refer to Figure 2-5 DLA Assembly Jack Locations. The amplifier connector

panel contains one data jack, ALARM/CONTROL (J2). The DLA exchanges status and

control signals with USER control equipment over ALARM/CONTROL (J2) port.

The NORM PA OUT1/LNA IN (J3) port and NORM PA IN/LNA OUT (J4) are connected to

RADIAX

®

cable via HELIAX® coaxial cable. The signal (downlink) coming from the BDR is

routed through the section of RADIAX cable to the NORM PA IN/LNA OUT (J4) port of the

DLA. The signal (uplink) com ing from the succeeding DLA NORM PA OUT1/LNA IN RF FWD

OUT/RVS IN (J3) port is routed through the section of RADIAX cable to the next DLA in

cascade.

Port POWER IN (J1) connects the DLA to the AC power source.

In the normal direction, NORM PA OUT2 ((J5), if installed, is used with a non cascaded

section of RADIAX

In the normal direction, NORM DET IN (J6), if installed, is used to terminate a section of

RADIAX

®

cable.

®

cable.

Document use is restricted to that described on cover 2-7

Figure 2-5 DLA Assembly Jack Locations

Page 23

385700-4006-006 INSTALLATION

2.5 PREPARATION FOR USE

CAUTION

Before applying power to the Distribution

Line Amplifier, securely connect the RF

ports to 50-ohm terminations. Failure to

observe these cautions can damage the

equipment.

2.5.1 Distribution Line Amplifier Setup

A Distribution Line Amplifier is part of a wayside antenna system; a RADIAX based signal

distribution system. The amplif ier provides signal gain to of fset the signal loss of the system.

The signal loss is based on the length and type of cable used. The Dist ribution Line Amplif ier

includes gain adjustments for both channels as well as adjustable thresholds for the status

signals.

Channel 1, whose center frequency is 2416.64 MHz, is referred t o as the Power Amplifier ( PA)

or downlink channel. Refer Figure 1-3 DLA Internal View for the location of the PA module

(part number 385700-2012). The output of this channel is a nominal +30 dBm f or a two port

DLA. The output of a 4 port DLA is a nominal +27 dBm per PA output port. For the downlink

channel, the signal input level as well as the output level are monitored. R

, R2, and R3 are

1

adjustment points on the PA module. See Figure 2-7 PA Module Outline for more details.

Channel 2, whose center frequency is 2467.84 MHz, is referred t o as the Low Noise Amplifier

(LNA) or uplink channel. Refer to Figure 1-3 DLA Internal View, f or f or t he location of t he LNA

module (part number 385700-2011). A pilot tone module within the Distribut ion Line Amplif ier

serves as a constant input signal for the LNA channel. The output level of the pilot tone is

monitored within the LNA module. No user adjustment of this sig nal is required. Because of

the diplexers within the DLA the pilot tone may not be observable at the exter nal DLA coaxial

connectors. The input signal range of the LNA channel is approximately -30 dBm to < -100

dBm. R

and R2 are adjustment points on the LNA module. See Figure 2-8 LNA Module

1

Outline for more det ails.

A configuration sheet is included with the DLA that specifies the adjustable settings at the time

of shipping the equipment.

The direction of the DLA must be set by the user for proper operation. The am plifier direction

status is indeterminate after powering up the unit . T his manual assum es t hat either the user’s

system control interface is available or a test box similar t o an example given at the end of this

manual is used.

Document use is restricted to that described on cover 2-8

Page 24

385700-4006-006 INSTALLATION

2.5.2 Distribution Line Amplifier Initial Operational Adjustments

2.5.2.1 Input AC Power

The Distribution Line Amplifier AC power supply automatically senses the input AC voltag e.

The DLA input voltage range is 87-265 VAC. Refer to Table 1-2 Distribution Line Amplifier

Specifications.

2.5.2.2 Power Amplifier (PA) Channel (Channel 1)

The nominal output level of the PA channel, as set at the time of manufacturing, is set to +27

dBm (4 port) or +30 dBm (2 port). T he output alarm level is set f or a thr eshold of 10 dB below

the expected output level. The expected input is 0 dBm. The input signal level threshold is

set for 10 dB below the input level. If other levels are desired, the cust omer should contact

Andrew with additional information when ordering the equipment. Refer to Figure 2-7 PA

Module Outline, for PA adjustment point s locations.

2.5.2.2.1 PA Equipment Setup

The equipment requir ed t o adjust the PA output level is:

• Signal Generator

• Power Meter or Spectrum Analyzer

• Digital Volt Meter

• small Blade Screwdriver

• ≥ 10 dB power attenuator

• direction control signal

Refer to Table 4-2 Test Equipment for a listing of sug gested equipment . Refer to Fig ure 2-6

PA Output Level Test Setup, f or t est equipment setup.

Direction Control = Forward

Signal

Generator

J4

J2

Distribution Line

Amplifier Assembly

J3

≥ 10 dB

power

attenuator

Power Meter

or

Spectrum

Analyzer

Figure 2-6 PA Output Level Test Set up

The signal generator should be set for an output frequency of 2416.64 MHz with an output

level of 0 dBm.

The power meter, if used, should be conf igured to measure signals f rom 0 dBm t o +40 dBm.

This can be done by either using the appropriate power sensor head(s) or by using power

attenuators.

Document use is restricted to that described on cover 2-9

Page 25

385700-4006-006 INSTALLATION

The spectrum analyzer, if used, should be configured as follows:

Center Frequency 2416.64 MHz

Span 2 MHz

RBW 30 KHz

VBW 3 Hz

Ref. Level as required

Attach a ≥ 10 dB, 2 watt or greater, power attenuator to t he spectrum analyzer RF input.

The direction control signal characteristics required will depend on the interface option

installed. The direction must be set t o t he NORMAL state.

R1 = Input Threshold Set

R2 = Output Level Set

R3 = Output Threshold Set

Figure 2-7 PA Module Outline

2.5.2.2.2 PA Input Alarm Adjustment

Set the signal generator out put to RF ON. Adjust the output level of the generator to 10 dB

less than the expected input level. If this level exceeds the range of the input detector, the

detector should be set to its minimum det ectable level.

Document use is restricted to that described on cover 2-10

Page 26

385700-4006-006 INSTALLATION

Attach a voltmeter to J4-3 on the Alarm I/O board. (PA input alarm test point). TP1 or TP2

can be used as the ground connection. Refer t o Figure 1- 3 DLA Internal View for the locat ion

of the Alarm and Control Int erface Board test points. Standard 0.080 test probes should be

used for test points.

Adjust R1 (Input Alarm Set) on the PA module for TP3 to go to the high condition (≥ 3 VDC),

low (≤1 VDC), and then high again. Reduce the signal generator level by 2 dB and verify that

the alarm is asserted. Increase the signal gener ator level by 4 dB and verify that the alarm is

negated. If needed, readjust R1 and repeat this process as necessary.

2.5.2.2.3 PA Output Adjustment

Set the signal generator output to RF ON at the nominal input level (i.e. 0 dBm). The

maximum input level is +5 dBm. Adjust R2 (Out put Power Set) on the PA module to obtain

the desired amplifier output level. Note that the actual level measured will depend on the

attenuation used on the spectrum analyzer or power meter.

2.5.2.2.4 PA Output Alarm Adjustment

Attach a voltmeter to J4-1 on the Alarm I/O relay board. (P.A. output Alarm test point). TP1 or

TP2 can be used as the ground connection.

Adjust the signal generator level as necessary to obtain 10 dB below the desired output power

as observed at J3 (FWD OUT/RVS IN) port. If this level exceeds the range of the output

detector, the detector should be set t o it s minimum detectable level.

Adjust R3 (output Alarm Set) on PA for high condition (> 3 VDC), low (< 1.0 VDC), and t hen

high again. Reduce the signal gener ator level until the alar m is assert ed. Ver if y that the out put

level is ± 2 dB of the desired level. If needed, readjust R3 and repeat this process as

necessary.

Document use is restricted to that described on cover 2-11

Page 27

385700-4006-006 INSTALLATION

2.5.2.3 Low Noise Amplifier (LNA) Channel (Channel 2)

The nominal gain of the LNA channel, as set at the time of manuf acturing, is set to 30 dB.

The output alarm level is set for a threshold nominally 10 dB below the expected output pilot

level. The expected signal input range is -40 to -90 dBm. If other settings are desired, the

customer should contact Andrew with additional information when ordering the equipment.

Refer to Figure 2-8 LNA Module Outline, for LNA adjustment points locations.

Figure 2-8 LNA Module Outline

2.5.2.3.1 LNA Adjustment Equipment Setup

The equipment requir ed t o adjust the LNA output level is:

• signal generator

• power meter or spectrum analyzer

• digital volt meter

• small Blade screwdriver

• ≥ 10 dB power attenuator

• 50 ohm SMA termination

• direction control interface

See Table 4-2 Test Equipment, for a listing of suggested equipment. Refer to Figure 2-9

Output Level Test Set Up, f or t est equipment setup.

LNA

The signal generator should be set for an output frequency of 2467.86 MHz with an output

level of -40 dBm.

The power meter, if used, should be configured to measure sig nals from -70 dBm to 0 dBm.

This can be done by either using the appropriate power sensor head(s) or by using

attenuators.

The spectrum analyzer, if used, should be configured as follows:

Document use is restricted to that described on cover 2-12

Page 28

385700-4006-006 INSTALLATION

Center Frequency 2467 MHz

Span 2 MHz

RBW 30 KHz

VBW 3 Hz

Ref. Level as required

Attach a 10 dB, 2 watt or greater, power att enuator to the spectrum analyzer RF input.

The direction control signal characteristics required will depend on the interface option

installed. The direction must be set t o t he NORMAL state.

Direction Control = Forward

Power Meter

Signal

Generator

J3

Distribution Line

Amplifier Assembly

J4

or

Spectrum

Analyzer

≥ 10 dB

power

attenuator

Figure 2-9 LNA

Output Level Test Set Up

2.5.2.3.2 LNA Output Adjustment

Disconnect the pilot tone signal fr om the LNA module J5 Aux RF IN port. Terminate the pilot

tone input port with a 50 ohm termination.

Connect the signal generator t o J3 of the DLA as shown in Fig ure 2-9 LNA

Set Up.

Adjust R1 so that the signal at J3 at 2467 MHz is the desired level ±0. 5 dB. The maximum

output value for the LNA channel is +5 dBm.

With the LNA out put set, go to the next step to set the LNA output alarm adjustment.

Output Level Test

Document use is restricted to that described on cover 2-13

Page 29

385700-4006-006 INSTALLATION

2.5.2.3.3 LNA Output Alarm Adjustment

NOTE

The previous step must be completed

before adjusting the output alarm.

Attach a voltmeter to J4-2 (LNA output Alarm test point) on the Alarm I/O board. TP1 or TP2

can be used as the ground connection.

Adjust R2 on the LNA until the voltage on J4-2 goes high (≥ 3 VDC), low (≤ 1.0 VDC), and

then high again.

Decrease the signal generator output as required to obtain a 10 dB drop in out put level, from

the level set in the previous section, of the LNA channel.

Adjust R2 on the LNA until the voltage on TP2 g oes low (≤ 1.0 VDC), high (≥ 3 VDC), and

then low (≤ 1.0 VDC) again. Increase the sig nal generator input by 10 dB and verify that the

output alarm signal at TP2 is high (≥ 3 VDC) . Decrease the signal generator level by 10 dB

and verify that the output alarm sig nal at TP2 is low (≤ 1.0 VDC). Readjust R2 and repeat as

necessary.

Remove the SMA termination from the LNA m odule J5 Aux RF IN port and reattach the pilot

tone signal cable to the LNA module J5 Aux RF IN port.

2.5.3 Operational Check-Out

Attach a 2 watt or greater 10 dB power attenuat or t o the J3 and J4 ports of the DLA. From the

configuration documentation sent with the amplifier or using on site documentation that

reflects any changes from the factory setting s, determine the output level settings of the PA

and LNA channels, the PA input alarm level, and the PA and LNA output alar m levels.

2.5.3.1 Forward PA Channel Verification

Set the DLA direction to the forward direct ion.

2.5.3.1.1 PA Output Level Verification

Attach either a signal generator (freq uency = 2417 MHz) or a BDR to J4 (FWD IN/RVS O UT)

port of the Distribution Line Amplifier Assembly. Adjust the signal generator or BDR signal

level at J4 to 0 dBm ± 0.1 dB. Using a power meter verif y that the sig nal level at the J3 ( FWD

OUT/RVS IN) port of the Distribut ion Line Amplifier Assem bly equals G

is equal to the expected gain of t he PA channel. If the g ain is not equal to Gpa dBm ± 1

G

pa

dB, perform the steps out lined in section 2.5 f or the PA output adjustment . If af ter complet ing

the amplifier setup procedure t he output level of the PA channel is not G

dBm ± 1 dB where

pa

dBm ± 1 dB and all

pa

Document use is restricted to that described on cover 2-14

Page 30

385700-4006-006 INSTALLATION

external test measurement cable losses are accounted for, the am plifier should be replaced.

Contact Andrew for additional infor m at ion.

2.5.3.1.2 PA Input Signal Alarm

Attach a voltmeter to J4-3 on the Alarm I/O relay board (PA output alarm test point). TP1 or

TP2 can be used as the ground connection. After removing the signal from the J4 (FWD

IN/RVS OUT) port of the Distribut ion Line Amplif ier Assembly verify t hat J4- 3 is < 0.7 VDC. If

J4-3 is > 1.0 VDC, perform the steps outlined in section 2.5 for the PA input alarm adjust ment .

If after completing the amplif ier setup procedure the input alar m is not < 0. 7 VDC with no input

to J4, the amplifier should be replaced. Contact Andrew for additional inform at ion.

2.5.3.1.3 PA Output Signal Alarm

Attach a voltmeter to J4-1 on the Alarm I/O relay board (PA output alarm test point). TP1 or

TP2 can be used as the ground connection. After removing the signal from the J4 (FWD

IN/RVS OUT) port of the Distribut ion Line Amplif ier Assembly verify t hat J4- 1 is < 0.7 VDC. If

J4-1 is > 1.0 VDC perform the steps outlined in section 2.5 for the PA output alarm

adjustment. If after completing the amplif ier set up procedur e the input alar m is not < 0. 7 VDC

with the expected input to J4, the amplifier should be replaced. Contact Andrew for addit ional

information.

Document use is restricted to that described on cover 2-15

Page 31

385700-4006-006 INSTALLATION

2.5.3.2 Forward LNA Channel Verification

Set the DLA direction to the forward direct ion.

2.5.3.2.1 LNA Output Level Verification

Attach either a signal generator (f requency = 2467 MHz) or a MDR to J3 (FW D OUT/RVS IN)

port of the Distribution Line Amplifier Assembly. Adjust the signal generator or BDR signal

level at J3 to -50 dBm ± 1 dB. Using a power meter verif y that the sig nal level at the J4 (FWD

IN/RVS OUT) port of the Distribution Line Amplif ier Assembly equals G

is equal to the expected gain of t he LNA channel. If the gain is not equal t o G

G

lna

dBm ± 1 dB where

lna

dBm ± 1

lna

dB perform the steps outlined in sect ion 2. 5 for the LNA output adjustment. If after completing

the amplifier setup procedure the out put level of the LNA channel is not G

dBm ± 1 dB and

lna

all external test measurement cable losses are accounted for, the amplifier should be

replaced. Contact Andrew for additional information.

2.5.3.2.2 LNA Output Signal Alarm

This step assumes that the LNA output level has been set as explained in section 2.5.3.2.1

Attach a voltmeter to J4-2 on the Alarm I/O relay board (LNA output alarm test point). TP1 or

TP2 can be used as the ground connection. Remove the pilot tone cable from the LNA

module J5 Aux RF IN port port. Verify that J4-2 on the Alarm I/O relay board is < 0.7 VDC. If

J4-2 is > 0.7 VDC, perform the steps outlined in section 2.5 for the LNA output alarm

adjustment. If after completing the amplifier setup procedure the output alarm is not < 0.7

VDC with the previously set input level to J3, the amplifier should be replaced. Contact

Andrew for additional informat ion.

2.5.3.3 Reverse PA Channel Verification

Set the DLA direction to the reverse direction.

2.5.3.3.1 PA Output Level Verification

Attach either a signal generator (freq uency = 2417 MHz) or a BDR to J3 (FWD OUT /RVS IN)

port of the Distribution Line Amplifier Assembly. Adjust the signal generator or BDR signal

level at J3 to 0 dBm ± 1 dB. Using a power meter verify that the signal level at the J4 (FW D

IN/RVS OUT) port of the Distribution Line Am plifier Assembly eq uals G

is equal to the expected gain of t he PA channel. If the g ain is not equal to Gpa dBm ± 1

G

pa

dB and the Distribution Line Amplifier has not been tested for the forward direction, perf orm

the steps outlined in section 2.5 for the PA output adjustment. If after completing the

amplifier setup procedure the out put level of the PA channel is not G

external test measurement cable losses are accounted for, the am plifier should be replaced.

Contact Andrew for additional infor m at ion.

dBm ± 1 dB where

pa

dBm ± 1 dB and all

pa

Document use is restricted to that described on cover 2-16

Page 32

385700-4006-006 INSTALLATION

2.5.3.3.2 PA Input Signal Alarm

Attach a voltmeter to J4-3 on the Alarm I/O relay board (PA output alarm test point). TP1 or

TP2 can be used as the ground connection. After removing the signal from the J3 (FWD

OUT/RVS IN) port of the Distr ibution Line Amplif ier Assembly verify that J4-3 is < 0.7 VDC. If

J4-3 is > 0.7 VDC and the Distribution Line Amplifier has not been tested for the forward

direction, perform t he steps outlined in section 2.5 for the PA input alarm adjustment. If af ter

completing the amplifier setup procedure t he input alarm is not < 0.7 VDC with no input t o J4,

the amplifier should be replaced. Contact Andrew for additional information.

2.5.3.3.3 PA Output Signal Alarm

Attach a voltmeter to TP1 on the Alarm I/O relay board (PA output alarm test point). TP1 or

TP2 can be used as the ground connection. After removing the signal from J3 (FWD

OUT/RVS IN) port of t he Distr ibution Line Amplifier Assembly, verify that J4-1 is < 0.7 VDC. If

J4-1 is > 0.7 VDC and the Distribution Line Amplifier has not been tested for the forward

direction, perform the steps outlined in section 2.5 f or t he PA output alar m adj ustment . I f af te r

completing the amplifier setup procedure the input alar m is not < 0.7 VDC with the expected

input to J4, the amplifier should be replaced. Contact Andrew for additional infor m ation.

2.5.3.4 Reverse LNA Channel Verification

Set the DLA direction to the reverse direction.

2.5.3.4.1 LNA Output Level Verification

Attach either a signal generator (f requency = 2467 MHz) or a MDR to J4 (FW D IN/RVS OUT)

port of the Distribution Line Amplifier Assembly. Adjust the signal generator or BDR signal

level at J4 to -50 dBm ± 1 dB. Using a power meter verif y that the sig nal level at the J3 (FWD

OUT/RVS IN) port of the Distr ibution Line Amplif ier Assembly eq uals G

is equal to the expected gain of t he LNA channel. If the gain is not equal t o G

G

lna

dBm ± 1 dB where

lna

dBm ± 1

lna

dB and the Distribution Line Amplifier has not been tested for the forward direction, perf orm

the steps outlined in section 2.5 for the LNA output adjustment. If after completing the

amplifier setup procedure the output level of t he LNA channel is not G

dBm ± 1 dB and all

lna

external test measurement cable losses are accounted for, the am plifier should be replaced.

Contact Andrew for additional infor m at ion.

2.5.3.4.2 LNA Output Signal Alarm

This step assumes that the LNA output level has been set as explained in section 2.5.3.2.1

Attach a voltmeter to J4-2 on the Alarm I/O relay board (PA output alarm test point). TP1 or

TP2 can be used as the ground connection. Remove the pilot tone cable from the LNA

module J5 Aux RF IN port. Verify that J4- on the Alarm I/O relay board is < 0.7 VDC. If J4-2

is > 0.7 VDC, perform the st eps outlined in section 2.5 for the LNA output alarm adj ustment.

If after com pleting the amplifier setup procedure the output alar m is not < 0.7 VDC with the

previously set input level to J3, the amplifier should be replaced. Cont act Andrew for additional

information.

Document use is restricted to that described on cover 2-17

Page 33

385700-4006-006 OPERATIONS

CHAPTER 3

OPERATIONS

3.1 WIRING PROTECTION AND GROUNDING

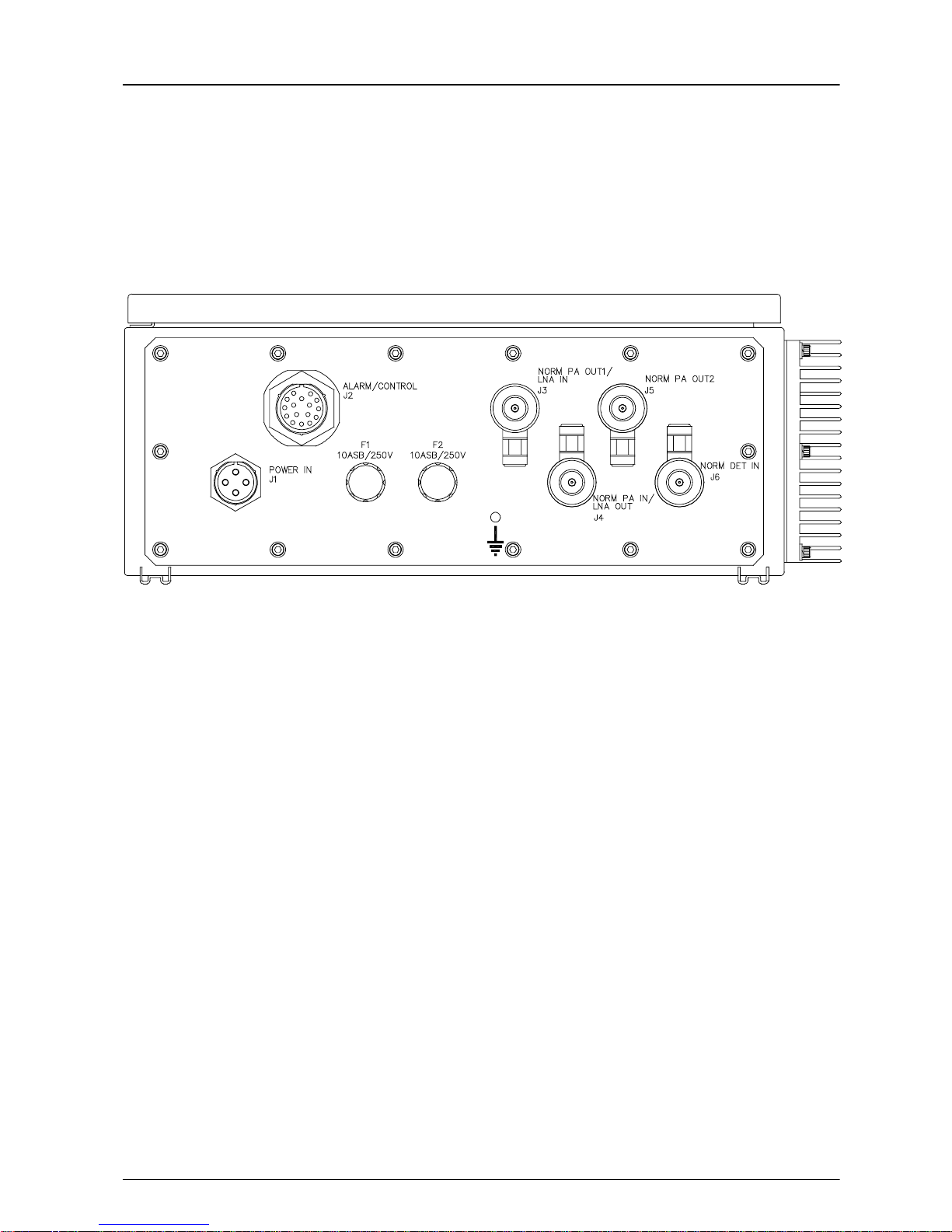

The Distribution Line Amplifier does not have controls and indicators accessible from the

outside of the unit. The DLA has two 10 Ampere fuses F1 and F2 for wiring protection on the

connector panel. Refer to Fig ure 3-1 DLA Connector Panel Layout.

There is a ground stud on the DLA connector panel f or a ground wire connection. Refer to

Figure 3-1 DLA Connector Panel Layout.

Document use is restricted to that described on cover 3-1

Figure 3-1 DLA Connector Panel Layout

Page 34

385700-4006-006 OPERATIONS

3.2 STARTUP AND SHUTDOWN PRODECURES

The following procedures ensure that installation does not damage the equipment.

3.2.1 DLA Startup

Refer to section 4.2.1, for procedures to properly install the DLA. Mount the DLA in the

equipment room or in the tunnel with no connections made. To start the DLA perform t he

following:

®

1. Securely connect HELIAX

cables to DLA J3 and J4 ports.

2. Connect the USER control equipment to the DLA connector panel J2 port.

3. Connect the VAC power supply to the DLA J1 port.

3.2.2 Normal Operation

Refer to section 1.4.1, Dist ribution Line Amplifier Principles of O peration.

3.2.3 Shutdown

Disconnect the DLA from the VAC power source.

WARNING

IN CASE OF EMERGENCY; Immediately

turn off power to the unit.

Document use is restricted to that described on cover 3-2

Page 35

385700-4006-006 MAINTENANCE AND TROUBLESHOOTING

CHAPTER 4

MAINTENANCE AND TROUBLESHOOTING

4.1 TROUBLESHOOTING

Before beginning any in-depth tr oubleshooting, ensure that power is available to the unit. Ensure

that all cable connections are secure.

Table 4-1 DLA Fault Isolation, describes the troubleshooting procedures for t he DLA. Locate

the unit’s symptom in the Fault Indication column. The Fault Description column lists

components or functions that can cause faults. The last column, Corrective Action, specifies the

action necessary to correct the fault. After taking corrective action, per form the appropriate

diagnostic procedure to verify that the correct ion was successful.

For malfunctions that the fault isolation table does not list, contact Andr ew’s technical support

personnel.

NOTE

The following table onl y isolates f aul ts to

the LRU level. The test procedures in

Section III of this chapter provide

assistance for further fault isolati on. I f an

LRU fails, return it to the equipment

manufacturer for maintenance or repair.

Step Fault Indication Fault Description Corrective Action

1 No output signal No input power Verify power input cable

2 No output signal No power in amplifier Replace fuses

3 No output signals Poor connections Verify connections

4

RADIAX

Alarm

No BDR input signal Verify cables connections to J4 (forward

direction) or J3 (reverse direction)

5

RADIAX

Alarm

No BDR input signal Verify preceding cascaded amplifier is

operational

6

RADIAX

7 Amplifier Alarm No BDR and/or MDR

Alarm

No BDR input signal If valid inputs, replace amplifier

If valid inputs, replace amplif ier

output RF signals

8 Direction Control

invalid status

Direction control status

is opposite of direction

If valid inputs, replace amplif ier

control input control

Document use is restricted to that described on cover 4-1

Table 4-1 DLA Fault Isolation

Page 36

385700-4006-006 MAINTENANCE AND TROUBLESHOOTING

4.2 CORRECTIVE MAINTENANCE

This section describes the removal and replacement of the DLA. See Table 4-1 DLA Fault

Isolation, to determine when to remove and replace a line r eplaceable unit ( LRU).

4.2.1 Remove and Replace DLA

Referring to Figure 4-1 Remove and Replace DLA, perf orm the following actions to r emove the

DLA (shown as Item 2)

1. Disconnect VAC power cable from DLA (2) POWER IN (3) port.

2. Disconnect the USER control equipment data cable that attaches to the DLA’s

ALARM/CONTROL port (6).

®

3. Disconnect the HELIAX

4. Disconnect grounding wire from the grounding stud (7) on the connector panel of

the DLA.

5. Remove four bolts (1) f r om the DLA (2) mounting brackets.

6. Remove DLA (2).

Referring to Figur e 4-1 Remove and Replace DLA, perform t he following actions to replace t he

DLA:

1. Place DLA (2) in position.

2. Secure DLA (2) with four bolts (1) .

3. Reconnect the HELIAX cables to RADIAX input / output ports (4) and (5).

4. Reconnect the USER control equipment data cable that attaches to the DLA’s

ALARM/CONTROL port (6).

5. Reconnect the grounding wire to grounding stud (7).

6. Reconnect the VAC power cable to the POWER IN (3) port.

7. Configure Channel 1 and Channel 2 output level and status alarm

adjustments per section 2.5.2 if not already performed.

cables from the RADIAX® input/out ports (4) and (5).

Document use is restricted to that described on cover 4-2

Page 37

385700-4006-006 MAINTENANCE AND TROUBLESHOOTING

1

2

7

3

6

4

5

Figure 4-1 Remove and Replace DLA

Document use is restricted to that described on cover 4-3

Page 38

385700-4006-006 MAINTENANCE AND TROUBLESHOOTING

4.3 TEST PROCEDURES

Refer to Table 4-2 Test Equipment, for a list of test equipment to perform the following test

procedures. If necessary, substitut e an equivalent to the equipment listed.

The following test procedures help the user verif y that a DLA is f ault y. Ret urn f aulty am plif iers t o

Andrew Corporation for maintenance and repair . Refer to paragr aph 2.1.1 for equipment return

information.

Equipment

Qty

Spectrum Analyzer 1 HP8561B

Power Meter 1 HP437B

Power Sensor 1 HP8481A

Power Sensor 1 HP8481D

Digital Volt Meter 1 Fluke Model 77

RF Signal Generator 1 HP 8664A

10 dB Power Attenuator As required Inmet 6N10W-10

Variable Attenuator As required HP 8495B

Coaxial Cables As required

Table 4-2 Test Equipment

4.3.1 Inoperative Distribution Line Amplifier

WARNING

Part Number

4.3.1.1 Input Power Verification

Disconnect the power connector to the DLA. Using a DVM verify the levels of the AC input

voltage. See Figure 2-3 DLA Input VAC Pin-outs for additional infor mation. If the input power

level is present, reconnect the power connector to the DLA.

If the input power is available to the DLA, open the amplifier and verify that the LED on the power

supply is illuminated. See Figure 1-3 DLA Internal View. If the LED is illuminated, then verify the

coaxial and Alarm/control signal connections.

If the power supply LED is not illuminated, unscrew the two fuses at t he DLA connector plate.

Document use is restricted to that described on cover 4-4

DANGER! High voltage shock hazard.

Page 39

385700-4006-006 MAINTENANCE AND TROUBLESHOOTING

Remove the fuses from the holder. Measure the resistance across the fuses. If the r esistance is

> 1.0 ohms, replace the fuse. Reinst all the fuses in the DLA. If the fuses are oper ational and

the power supply remains off, replace t he Dist ribution Line Amplifier.

4.3.1.2 RADIAX

Alarm Asserted

Assertion of the RADIAX input alarm indicates a loss of signal (Signal Center Frequency is

2416.64 MHz) from the preceding Distribution Line Amplifier and or base station radio. The

following trouble shooting procedure assumes that the amplifiers are cascaded in the forward

configuration normal direction mode and that the amplifier has been correctly configured as

indicated in 2.5.

Visually inspect the cable assemblies from the preceding amplifier or radio f or loose connections

and or cable breakage. Tighten all cable connections. Replace br oken or damaged cables as

necessary.

If all cable assemblies are secure and intact, disconnect the cable at J4 of the DLA. Using a

power meter or spectrum analyzer attached to the cable, verif y the presence and expected level

of the RF signal (F

= 2416.64 MHz, 0 dBm nominal). If the signal is present and the alarm is

c

configured correctly (ref er t o section 2.5.2. 2.2) the am plifier should be replaced. If the RF signal

is not present continue to determine the or igin of the signal loss.

4.3.1.3 Amplifier Alarm Asserted

Assertion of the Amplif ier Alar m can be caused by:

• Loss of an input signal on the PA Channel (RADIAX Alar m Asser ted)

• Failure of the PA module

• Loss of the Pilot Tone Signal t o the LNA module

• Failure of the LNA module.

4.3.1.3.1 Loss of PA Input Signal

When the RADIAX Alarm is asserted, t he loss of input signal can also cause the PA module to

also assert its output alarm. With a loss of input signal, the PA module gain is insufficient to

generate a signal level above the level represented by the output thr eshold detector in the PA

module. If both the RADIAX alarm signal and t he Amplifier Alarm sig nals are asser ted, the user

should determine the cause for the loss of input signal.

4.3.1.3.2 PA Module Failure

If the input signal to t he PA channel is at the expected level and the PA channel out put alarm is

asserted, either the PA module has failed or it is incorrectly configured. T he PA module output

alarm can be monitored with a DVM at J4-1 of the Relay/IO board. A voltage level < 1 VDC

indicates a fault condition for the PA channel.

The output signal can be measured with a power meter or spectrum analyzer. If no signal is

detected at the Distribution Line Amplifier output port (J3 f or the forward direction) the unit should

be returned to Andrew Corporation. If a signal is present, the user should confirm that the

amplifier output is below the levels indicated on the configuration sheet attached to the

Distribution Line Amplifier. I f t he input and output signal levels are at t he levels specif ied on the

Document use is restricted to that described on cover 4-5

Page 40

385700-4006-006 MAINTENANCE AND TROUBLESHOOTING

configuration sheet, t he PA module alarm may be indicating a faulty setting on the output level

monitor. Refer to sect ion 2.5.2.2.4 for details on setting the output alarm. If the output level

monitor is correctly configured, the Distribution Line Amplifier should be returned to Andrew

Corporation.

4.3.1.3.3 Loss of Pilot Tone Signal

In a correctly configured DLA, the pilot tone is monitored by the LNA output detector circuit.

Without the pilot tone there may not be sufficient signal at the LNA module output. As a result,

the LNA module will signal an amplifier failure. T he pilot t one sig nal can be monit ored with either

a power meter or a spectrum analyzer.

Figure 1-3 DLA Internal View shows the location of the pilot tone module and its output port J3.

The expected output at the pilot tone module J3 port is a nominal - 10 dBm signal at 2401 ± 2

MHz. If this signal is not present, the Distribution Line Am plifier should be returned to Andrew

Corporation. If the signal is present, reattach the cable fr om J3 of the pilot tone module to the

LNA module AUX RF input port. Tigh t en t he connections as necessary.

4.3.1.3.4 LNA Module Failure

If the pilot tone signal t o the LNA channel is at the expected level and the LNA channel output

alarm is asserted, either the LNA module has failed or it is incorrectly configured. The LNA

module output alarm can be monitored with a DVM at J4-2 on the Relay/IO board. A voltage

level < 1 VDC indicates a fault condition for the LNA channel.

In order to measure the output of the LNA channel, it is necessary to inject an external signal into

the LNA channel. The external signal can be either a CW signal at a frequency in the passband

of the LNA channel (see Table 1-2 Distribution Line Amplifier Specifications in section 1.5. 2) or it

can be the output signal of an MDR. In either case, the signal input level to J3 of the DLA

(normal forward config uration) should be -50 dBm.

Based on the gain setting specified on t he configuration sheet attached to t he DLA, the external

signal can be verified with a power meter or spectrum analyzer. If no signal is detected at the

Distribution Line Amplifier output port (J4 for t he f orward direct ion) t he DLA should be ret urned t o

Andrew Corporation. If a signal is pr esent, the user should confirm that the amplif ier output is

below the levels indicated on the configuration sheet att ached to the Distribution Line Amplifier .

If the measured level is below the expected value the Distribution Line Amplifier should be

returned to Andrew Corporation. If the input and output signal levels are at the levels specif ied

on the configuration sheet, the PA module alarm may be indicat ing a f aulty sett ing on t he output

level monitor. Refer to section 2.5 for details on sett ing the output alarm. If the output level

monitor is correctly configured, the Distribution Line Amplifier should be returned to Andrew

Corporation

Document use is restricted to that described on cover 4-6

Page 41

385700-4006-006 ORDERING INFORMATION

CHAPTER 5

ORDERING INFORMATION

5.1 PARTS LIST

This chapter provides a list of replacement parts and mating connectors for the Distribution

Line Amplifier assembly. It also provides vendor names and addresses. Table 1-1 – DLA

Part Numbers lists the various versions of the DLA and t heir respective part num bers. Figure

1-1 Distribution Line Amplifier ( 4 por t) shows all of the items on the list . To procure any of the

parts, contact Andrew Corporation or the appr opr iate vendor for the part.

The parts list includes three columns: Description, Part Number, and Quantity (Qty). The

Description column identifies the specif ic part , beg inning with the assembly or line-r eplaceable

unit (LRU) that contains it. The information in the Description column includes an (AP) symbol

to denote attaching hardware for the LRUs. The Part Number column provides the vendor’s

number for that drawing or par t. T he Quantity column def ines how many of the part icular part

the next higher assembly (NHA) contains.

Table 5-1 provides a list of applicable vendors and their addresses.

Vendor

Andrew Corporation 2601 Telecom Parkway

ITT Corporation

ITT Canon Division

Bussman P.O. Box 14460

Table 5-1 Vendors

Address (Phone Number)

Richardson, Texas 75082-3521

(972) 235-7300

666 East Dyer Road

Santa Ana, CA 92702

St Louis, MO 63178

314-394-2877

Document use is restricted to that described on cover 5-1

Page 42

385700-4006-006 ORDERING INFORMATION

Table 5-2 provides a list of replaceable parts and mating connectors for the am plifier

assemblies.

Description Part Number Qty

Distribution Line Amplifier 385700-4000 1

Mating Power Connector Assembly (J1) MS3475W14-4S 1

Mating Alarm/Control Connector (J2) MS3126F20-16S or

1

KPSE08F20-16S

AC Fuses (F1, F2) Bussman MDA-10 2

Table 5-2 Parts List

Document use is restricted to that described on cover 5-2

Page 43

385700-4006-006 MECHANICAL INFORMATION

CHAPTER 6

MECHANICAL INFORMATION

Document use is restricted to that described on cover 6-1

Figure 6-1 DLA Mechanical Outline

Page 44

385700-4006-006 ALARM/CONTROL TEST

CIRCUIT

Document use is restricted to that described on cover 7-1

CHAPTER 7

ALARM/CONTROL TEST CIRCUIT

The following schematic can be used to construct a test fixture to control the direction of the DLA and to monit or t he status of the various

Figure 7-1

Page 45

385700-4006-006 ALARM/CONTROL TEST

CIRCUIT

Document use is restricted to that described on cover 7-2

Page 46

385700-4006-006 ALARM/CONTROL TEST

CIRCUIT

Document use is restricted to that described on cover 7-3

Page 47

385700-4006-006 ALARM/CONTROL TEST

CIRCUIT

Document use is restricted to that described on cover 7-4

Page 48

385700-4006-006 ALARM/CONTROL TEST

CIRCUIT

Document use is restricted to that described on cover 7-5

alarms. The test fixture connects to J2 Alarm/Control of the DLA. This t est f ixture r equ ires an external 24 VDC supply. T he circuit should be

mounted within a metal enclosure so that the required cable shielding integrity is maintained.

Loading...

Loading...