Page 1

Evaluation Board User Guide

One Technology Way • P. O . Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel : 781.329.4700 • Fax : 781.461.3113 • www.analog.com

UG-001

Evaluating the AD9272/AD9273 for Ultrasound Systems

FEATURES

Full featured evaluation board for the AD9272/AD9273

SPI and alternate clock options

Internal and external reference options

VisualAnalog and SPI Controller software interfaces

EQUIPMENT NEEDED

Analog signal source and antialiasing filter

2 switching power supplies (6.0 V, 2.5 A) CUI EPS060250UH-

PHP-SZ, provided

Linear bench top dc voltage source (0 V to 1.6 V), not

required for CW Doppler mode

PC running Windows 98 (2nd ed.), Windows 2000, Windows ME,

or Windows XP

USB 2.0 port, recommended (USB 1.1 compatible)

AD9272/AD9273 evaluation board

HSC-ADC-EVALCZ FPGA-based data capture kit

For CW Doppler mode: spectrum analyzer

For CW Doppler mode: dc voltage source: +

5 V w/100 mA each

TYPICAL MEASUREMENT SETUP

DOCUMENTS NEEDED

AD9272 and AD9273 data sheets

HSC-ADC-EVALCZ data sheet, High Speed Converter

Evaluation Platform (FPGA-based data capture kit)

AN-905 Application Note, VisualAnalog Converter Evaluation

Tool Version 1.0 User Manual

AN-878 Application Note, High Speed ADC SPI Control Software

AN-877 Application Note, Interface to High Speed ADCs via SPI

SOFTWARE NEEDED

VisualAnalog

SPI Controller

GENERAL DESCRIPTION

This document describes the AD9272/AD9273 evaluation

board, which provides all of the support circuitry required to

operate the AD9272/AD9273 in their various modes and

configurations. The application software used to interface with

the devices is also described.

The AD9272/AD9273 data sheet, available at www.analog.com,

provides additional information and should be consulted when

using the evaluation board. All documents and software tools

are available at http://www.analog.com/fifo. For any questions,

send an email to highspeed.converters@analog.com.

Please see the last page for an important warning and disclaimers. Rev. 0 | Page 1 of 24

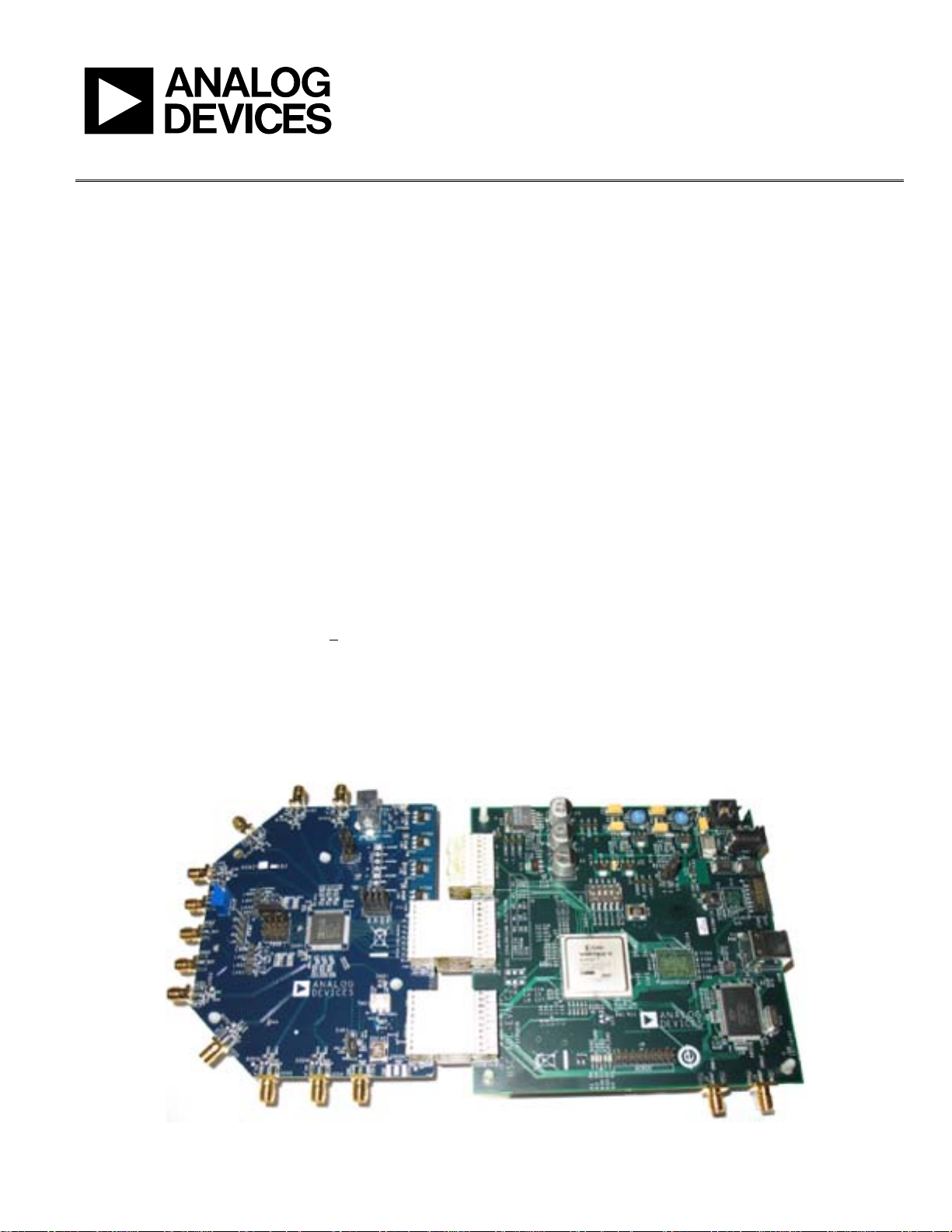

Figure 1. AD9272-65EBZ/AD9272-80KITZ/AD9273-50EBZ Evaluation Board and HSC-ADC-EVALCZ Data Capture Board

07782-001

Page 2

UG-001 Evaluation Board User Guide

TABLE OF CONTENTS

Features .............................................................................................. 1

Equipment Needed ........................................................................... 1

Documents Needed .......................................................................... 1

Software Needed ............................................................................... 1

General Description ......................................................................... 1

Typical Measurement Setup ............................................................ 1

Revision History ............................................................................... 2

Evaluation Board Hardware ............................................................ 3

Power Supplies .............................................................................. 3

Input Signals .................................................................................. 3

Output Signals ............................................................................... 3

REVISION HISTORY

2/09—Revision 0: Initial Version

Default Operation and Jumper Selection Settings ....................5

Evaluation Board Software Quick Start Procedures .....................7

Configuring the Board .................................................................7

Using the Software for Testing .....................................................7

Using the Integrated Crossp oint Switch

(CW Doppler Mode) ................................................................. 10

Evaluation Board Schematics and Artwork ................................ 12

Ordering Information .................................................................... 23

Bill of Materials ........................................................................... 23

ESD Caution .................................................................................... 24

Rev. 0 | Page 2 of 24

Page 3

Evaluation Board User Guide UG-001

EVALUATION BOARD HARDWARE

The AD9272/AD9273 evaluation board provides all of the support

circuitry required to operate the AD9272/AD9273 in its various

modes and configurations. Figure 2 shows the typical bench

characterization setup used to evaluate the ac performance of

the AD9272/AD9273. It is critical that the signal sources used for

the analog input and clock have very low phase noise (<1 ps rms

jitter) to realize the optimum performance of the signal chain.

Proper filtering of the analog input signal to remove harmonics

and lower the integrated or broadband noise at the input is

necessary to achieve the specified noise performance (see the

AD9272 or AD9273 data sheet).

See the Evaluation Board Software Quick Start Procedures section

to get started and Figure 21 to Figure 31 for the complete schematics and layout diagrams that demonstrate the routing and

grounding techniques that should be applied at the system level.

POWER SUPPLIES

This evaluation board comes with a wall-mountable switching

power supply that provides a 6 V, 2 A maximum output. Connect

the supply to the rated 100 V ac to 240 V ac wall outlet at 47 Hz

to 63 Hz. The other end is a 2.1 mm inner diameter jack that

connects to the PCB at P701. Once on the PC board, the 6 V

supply is fused and conditioned before connecting to low dropout

linear regulators that supply the proper bias to each of the various

sections on the board.

When operating the evaluation board in a nondefault condition,

L705, L706, L707, and L709 can be removed to disconnect the

switching power supply. This enables the user to bias each section

of the board individually. Use P602 and P603 to connect a different

supply for each section. At least one 1.8 V supply is needed with

a 1 A current capability for AVDD_DUT and DRVDD_DUT;

however, it is recommended that separate supplies be used for

both analog and digital domains. An additional supply is also

required to supply 3.0 V to the device under test, AVDD2_DUT.

This should also have a 1A current capability. To operate the

evaluation board using the SPI and alternate clock options, a

separate 3.3 V analog supply is needed in addition to the other

supplies. The 3.3 V supply, or AVDD_3P3V, should have a 1 A

current capability.

To bias the crosspoint switch circuitry or CW section and

differential gain drive circuitry, separate +5 V and −5 V supplies

are required at P601. These should each have 1 A current capability.

This section cannot be biased from a 6 V, 2 A wall supply. Separate

supplies are required at P601.

INPUT SIGNALS

When connecting the clock and analog source, use clean signal

generators with low phase noise, such as Rohde & Schwarz SMA or

HP8644B signal generators or the equivalent. Use a 1 m, shielded,

RG-58, 50 Ω coaxial cable for making connections to the evaluation board. Enter the desired frequency and amplitude (refer to

the specifications in the AD9272 or AD9273 data sheet). The

evaluation board is set up to be clocked from the crystal oscillator, OSC401.

If a different or external clock source is desired, follow the

instructions Clock Circuitry section. Typically, most Analog

Devices evaluation boards can accept ~2.8 V p-p or 13 dBm sine

wave input for the clock. When connecting the analog input

source, it is recommended to use a multipole, narrow-band

band-pass filter with 50 Ω terminations. Analog Devices uses

TTE and K&L Microwave, Inc., band-pass filters. The filter

should be connected directly to the evaluation board.

OUTPUT SIGNALS

The default setup uses the FIFO5 high speed, dual-channel

FIFO data capture board (HSC-ADC-EVALCZ). Two of the

eight channels can then be evaluated at the same time. For more

information on channel settings on these boards and their optional

settings, visit www.analog.com/FIFO.

Rev. 0 | Page 3 of 24

Page 4

UG-001 Evaluation Board User Guide

T

WALL OUTLE

100V TO 240V AC

47Hz TO 63Hz

SIGNAL

SYNTHESIZER

SPECTRUM

ANALYZER

SWITCHING

POWER

SUPPLY

SWITCHING

POWER

SUPPLY

ANALOG INPUT

CW OUT PUT

AGILENT

POWER SUPPLY

GAIN CONTROL INPUT

6V DC

2A MAX

SIGNAL

SYNTHESIZER

OPTIO NAL CLOCK SOURCE

Figure 2. Evaluation Board Connection

6V DC

2A MAX

PC

RUNNING ADC

ANALYZER

OR VISUAL ANAL OG

USER SOFTWARE

07782-070

Rev. 0 | Page 4 of 24

Page 5

Evaluation Board User Guide UG-001

DEFAULT OPERATION AND JUMPER SELECTION SETTINGS

This section explains the default and optional settings or modes

allowed on the AD9272/AD9273 Rev. A evaluation board.

Power Circuitry

Connect the switching power supply that is supplied in the

evaluation kit between a rated 100 V ac to 240 V ac wall outlet

at 47 Hz to 63 Hz and P701.

Analog Input Front-End Circuit

The evaluation board is set up for a transformer-coupled analog

input with an optimum 50 Ω impedance match of 18 MHz of

bandwidth. For a different bandwidth response, use the

antialiasing filter settings.

VREF

VREF is set to 1.0 V. This causes the ADC to operate with the

internal reference in the 2.0 V p-p full-scale range. A separate

external reference option using the ADR130 is also included on

the evaluation board. Populate R311 with a 0 Ω resistor and remove

C426. Note that ADC full-scale ranges less than 2.0 V p-p are

not supported by the AD9272/AD9273.

RBIAS

RBIAS has a default setting of 10 kΩ (R301) to ground and is used

to set the ADC core bias current. However, note that using other

than a 10 kΩ, 1% resistor for RBIAS may degrade the performance

of the device, depending on the resistor chosen.

Clock Circuitry

The default clock input circuitry is derived from a simple transformer-coupled circuit using a high bandwidth

1:1 impedance ratio transformer (T401) that adds a very low

amount of jitter to the clock path. The clock input is 50 Ω

terminated and ac-coupled to handle single-ended sine wave

types of inputs. The transformer converts the single-ended

input to a differential signal that is clipped before entering the

ADC clock inputs.

The evaluation board is already set up to be clocked from the

crystal oscillator, OSC401. This oscillator is a low phase noise

oscillator from Valpey Fisher (VFAC3-BHL-50MHz/VFAC3BHL-65MHz/VFAC3-BHL-80MHz). If a different clock source

is desired, remove R403, set Jumper J401 to disable the oscillator

from running, and connect the external clock source to the

SMA connector, P401.

A differential LVPECL clock driver can also be used to clock the

ADC input using the AD9515 (U401). Populate R406 and R407

with 0 Ω resistors and remove R415 and R416 to disconnect the

default clock path inputs. In addition, populate C405 and C406

with a 0.1 μF capacitor and remove C409 and C410 to disconnect

the default clock path outputs. The AD9515 has many pinstrappable options that are set to a default mode of operation.

Consult the AD9515 data sheet for more information about

these and other options.

PDWN

To enable the power-down feature, short P303 to the on

position (AVDD) on the PDWN pin.

STBY

To enable the standby feature, short P302 to the on position

(AVDD) on the STBY pin.

GAIN+, GAIN−

To change the VGA attenuation, drive the GAIN+ pin from 0 V

to 1.6 V on J302 using a linear supply and use a single-ended

method to change the VGA gain from 0 dB to 42 dB. U403 is

available for users who wish to drive the gain pins (GAIN±)

differentially. Install R305, R347, and R349 and remove C308,

C309, and R303 to connect the amplifier correctly. Next, apply a

dc voltage source to P601, connecting the +5 V, −5 V, and ground

(0 V) appropriately to bias U403 (AD8138). These benchtop

linear supplies should each have 100 mA of current capability.

If an external source is not available, R337 can be installed to

use the on-board resistive divider for gain adjustment in either

the single-ended or differential case.

Non-SPI Mode

For users who wish to operate the DUT without using SPI,

remove the jumpers on J601. This disconnects the CSB, SCLK,

and SDIO pins from the control bus, allowing the DUT to

operate in its simplest mode. Each of these pins has internal

termination and will float to its respective level. Note that the

device will only work in its default condition.

CWDx+, CWDx−

To use the CWDx± outputs, first apply a dc voltage source to

P601, connecting the +5 V, −5 V, and ground (0 V) appropriately to

bias U402 (AD812). These benchtop linear supplies should each

have 100 mA of current capability.

To view the CWD2+/CWD2− through CWD5+/CWD5− outputs,

jumper together the appropriate outputs on P606 and P607. All

outputs are summed together on the IOP and ION buses, fed to

a 1:4 impedance ratio transformer, and buffered so that the user

can view the output on a spectrum analyzer. This can be configured

to be viewed in single-ended mode (default) or in differential mode

by using a spectrum analyzer. To set the voltage for the appropriate

number of channels to be summed, change the value of R447

and R448 on the primary transformer (T402).

Upon shipment, the CWD0+/CWD0−, CWD1+/CWD1−,

CWD6+/CWD6−, and CWD7+/CWD7− outputs are properly

biased and ready to use with the AD8339 quad I/Q demodulator

and phase shifter. The AD9272/AD9273 evaluation board simply

snaps into place on the AD8339 evaluation board (AD8339EVALZ). Remove the jumpers connected to P3A and P4A on

the AD8339 evaluation board, and snap the standoffs that are

provided with the AD9272/AD9273 into the AD8339 evaluation

board standoff holes in the center of the board. The standoffs

will automatically lock into place and create a direct connection

Rev. 0 | Page 5 of 24

Page 6

UG-001 Evaluation Board User Guide

between the AD9272/AD9273 CWDx± outputs and the

AD8339 inputs.

DOUTx+, DOUTx−

If an alternative data capture method to the setup described in

Figure 2 is used, optional receiver terminations, R701 to R710, can

be installed next to the high speed backplane connector.

Rev. 0 | Page 6 of 24

Page 7

Evaluation Board User Guide UG-001

EVALUATION BOARD SOFTWARE QUICK START PROCEDURES

This section provides quick start procedures for using the AD9272/

AD9273 either on the evaluation board or in a system level

design. Both the default and optional settings are described.

CONFIGURING THE BOARD

Before using the software for testing, configure the evaluation

board as follows:

1. Connect the evaluation board to the data capture board as

shown in Figure 1 and Figure 2.

2. Connect one 6 V, 2.5 A switching power supply (such as

the CUI Inc. EPS060250UH-PHP-SZ supplied) to the

AD9272/AD9273 board.

3. Connect one 6 V, 2.5 A switching power supply (such as

the CUI EPS060250UH-PHP-SZ supplied) to the HSCADC-EVALCZ board.

4. Connect the HSC-ADC-EVALCZ board (J6) to the PC

with a USB cable.

5. On the ADC evaluation board, place jumpers on all four

pin pairs of J601 to connect the SPI bus.

6. On the ADC evaluation board, ensure that J401 (OSC_EN)

is jumpered to the on setting to use the on-board 50 MHz/

65 MHz/80 MHz Valpey Fisher VFAC3 oscillator.

7. On the ADC evaluation board, use a clean signal generator

with low phase noise to provide an input signal to the

desired channel. Use a 1 m, shielded, RG-58, 50 Ω coaxial

cable to connect the signal generator. For best results, use a

narrow-band band-pass filter with 50 Ω terminations and

an appropriate center frequency. (Analog Devices uses

TTE, Allen Avionics, and K&L band-pass filters.)

USING THE SOFTWARE FOR TESTING

Setting Up the ADC Data Capture Block

After configuring the board, set up the ADC data capture block

using the following steps:

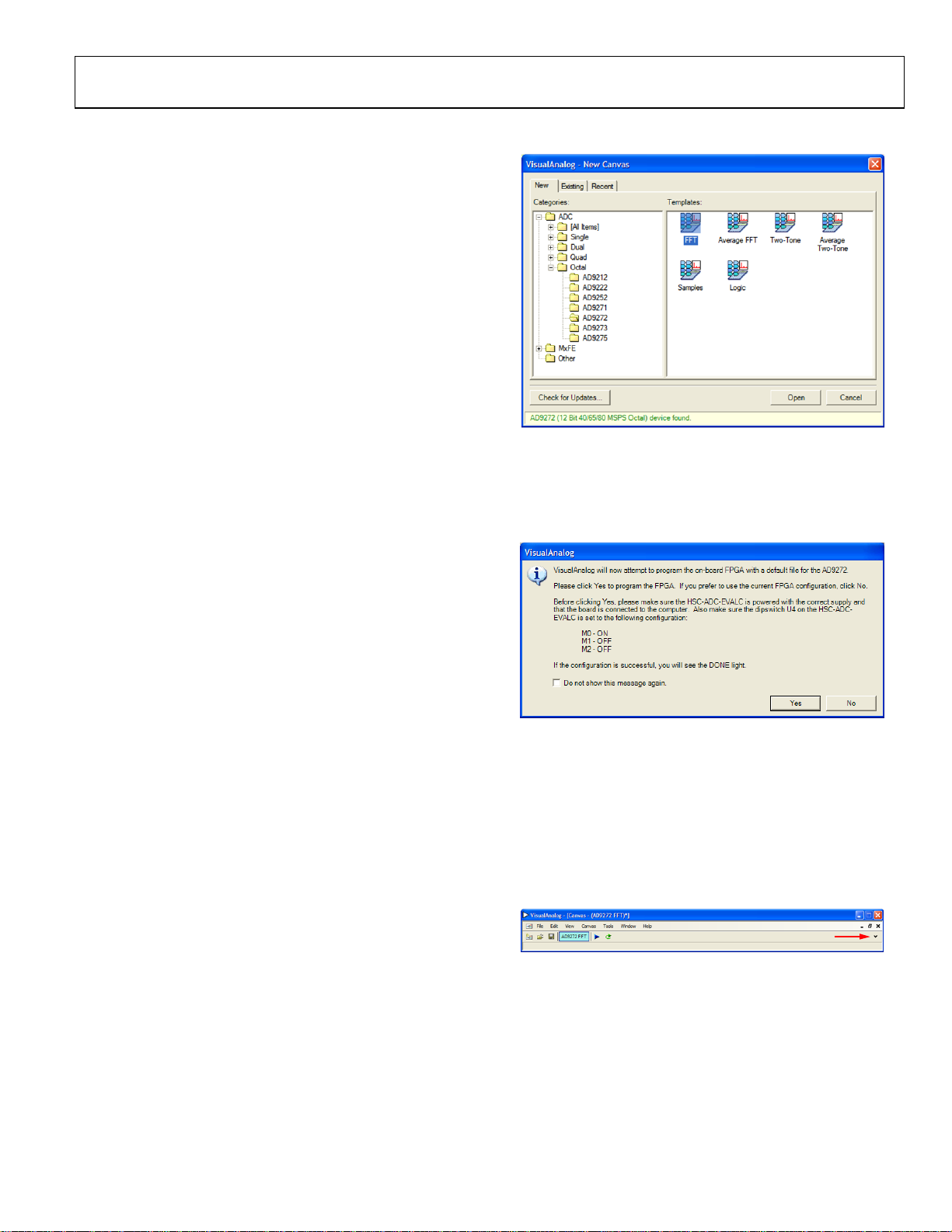

1. Open VisualAnalog™ on a PC. AD9272 or AD9273 should

be listed in the status bar of the New Canvas window.

Select the template that corresponds to the type of testing

to be performed (see Figure 3).

2. After the template is selected, a message appears, asking if

the default configuration can be used to program the FPGA

(see Figure 4). Click Yes , and the window closes.

If a different program is desired, follow Step 3.

3. To view different channels or change features to settings

other than the default settings, click the Expand Display

button. This is located on the bottom right corner of the

window, as shown in Figure 5.

This process is described in the AN-905 Application Note,

VisualAnalog Converter Evaluation Tool Version 1.0 User

Manual. After you are finished, click the Collapse Display

button (see Figure 6).

Figure 3. VisualAnalog, New Canvas Window

Figure 4. VisualAnalog, Default Configuration Message

07782-021

07782-028

Rev. 0 | Page 7 of 24

EXPAND DISPLAY BUTTO N

Figure 5. VisualAnalog Window Toolbar, Collapsed Display

07782-022

Page 8

UG-001 Evaluation Board User Guide

COLLAPSE DISPLAY BUTTON

SETTINGS

BUTTON

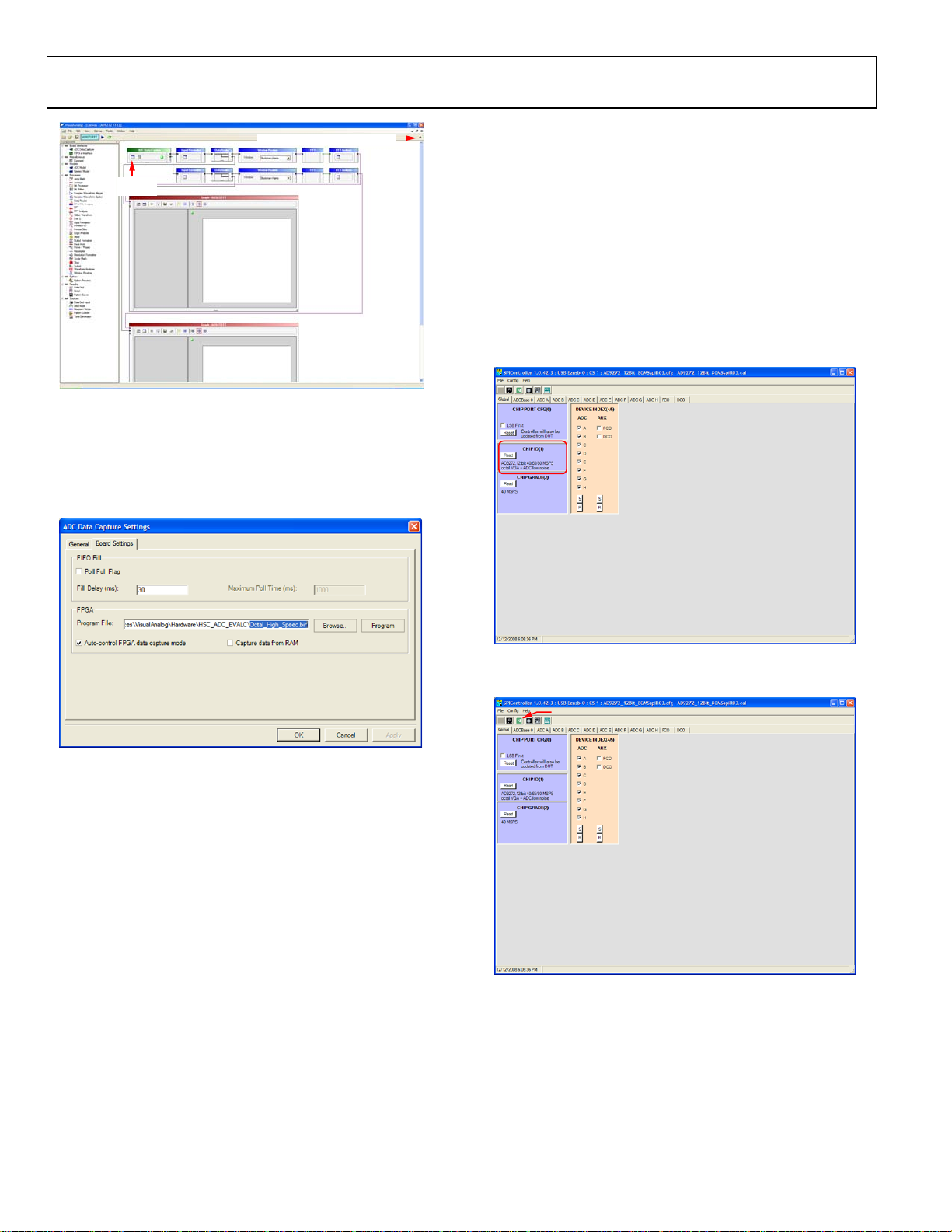

Figure 6. VisualAnalog, Main Window

4. Program the HSC-ADC-EVALCZ board’s FPGA to a setting

other than the default setting as described in Step 3. Then

expand the VisualAnalog display and click the Settings

button in the ADC Data Capture block (see Figure 6). The

ADC Data Capture Settings box opens (see Figure 7).

07782-023

Setting Up the SPI Controller

After the ADC data capture board setup is completed, set up the

SPI Controller using the following procedure:

1. Open the SPI Controller software by going to the Start

menu or double-clicking the SPI Controller software

desktop icon. If prompted for a configuration file, select

the appropriate one. If not, check the title bar of the

window to determine which configuration is loaded. If

necessary, choose Cfg Open from the File menu and select

the appropriate one. Note that the CHIP ID(1) field should

be filled to indicate whether the correct SPI Controller

configuration file is loaded or not (see Figure 8).

Figure 7. ADC Data Capture Settings Window, Board Settings Tab

5. Select the Board Settings tab and browse to the appropriate

programming file. If you are using an encode rate <28 MSPS,

select Octal_Low_Speed.bin. If you are using an encode

rate >28 MSPS, select Octal_High_Speed.bin. Next, click

Program; the DONE LED in the HSC-ADC-EVALCZ board

should then turn on. If more than two channels are required

to be displayed, select Octal_High_8-Channel_synchronous

Capture.bin. This canvas allows the user to display all the

channels at once. The drawback is that each FFT display is

only 8k points.

Exit the ADC Data Capture Settings box by clicking OK.

07782-016

Figure 8. SPI Controller, CHIP ID(1) Box

2. Click the New DUT button in the SPI Controller.

NEW DUT BUTTON

07782-025

07782-116

Figure 9. SPI Controller, New DUT Button

3. In the Global tab of the SPI Controller, find the CHIP

GRADE(2) box. Use the drop-down box to select the

correct speed grade, if necessary. See the AD9272 or AD9273

data sheet, the AN-878 Application Note, and the AN-877

Application Note for reference.

Rev. 0 | Page 8 of 24

Page 9

Evaluation Board User Guide UG-001

5. In the ADC A tab of SPI Controller, find the OFFSET(10)

box. Use the drop-down box labeled Offset Adj to perform

an offset correction to the LNA if the LNA power setting

BIAS_CURR_A(12) has been set low. The default value is 32.

Select 33 if the low LNA power setting BIAS_CURR_A(12)

is used.

Figure 12. SPI Controller, OFFSET(10) Box

07782-017

Figure 10. SPI Controller, CHIP GRADE(2) Box

4. In the ADCBase 0 tab of the SPI Controller, find the

HIGHPASS(2B) box. Click Manual Tune to calibrate the

antialiasing filter. See the AD9272 or AD9273 data sheet,

the AN-878 Application Note, and the AN-877 Application

Note for reference.

07782-018

Figure 11. SPI Controller, HIGHPASS(2B) Box

07782-117

Rev. 0 | Page 9 of 24

Figure 13. SPI Controller, BIAS_CURR_A(12) Box

6. Click the Run button in the VisualAnalog toolbar.

RUN BUTTON

Figure 14. VisualAnalog Window Toolbar, Collapsed Display

07782-217

07782-122

Page 10

UG-001 Evaluation Board User Guide

Adjusting the Amplitude of the Input Signal

Next, adjust the amplitude of the input signal for each channel

as follows:

1. Adjust the amplitude of the input signal so that the

fundamental is at the desired level. (Examine the Fund

Power reading in the left panel of the VisualAnalog FFT

window.) If the gain pin voltage is too low, it is not possible

to reach full scale without distortion. Use a higher gain

setting or a lower input level to avoid distortion. This also

depends on the PGA gain setting, which can be 30 dB,

27 dB, 24 dB, or 21dB. See Figure 15 and Figure 16.

Figure 15. VisualAnalog, Graph Window

Figure 16. VisualAnalog, Formatted FFT Plot

2. Repeat this procedure for the other seven channels.

3. Click the disk icon within the Graph window to save the

performance plot. See Figure 17 for an example.

0

–10

–20

–30

–40

–50

–60

–70

–80

AMPLITUDE (dBFS)

–90

–100

–110

–120

–130

02

5101520

FREQUENCY (MHz )

Figure 17. Typical FFT, AD9272/AD9273

f

= 3.5MHz @ –1dBFS

IN

LNA = 6×

= 1V

V

GAIN

FILTER TUNED

HPF = 700kHz

07782-119

5

USING THE INTEGRATED CROSSPOINT SWITCH (CW DOPPLER MODE)

To examine the spectrum of the CW Doppler integrated

crosspoint switch output, use the following procedure:

1. Complete the steps in the Configuring the Board and

Using the Software for Testing sections to ensure that the

board is set up correctly.

2. Optionally, remove the voltage source from the gain pin. It

does not affect the CW Doppler output.

07782-026

7782-027

3. Connect the dc voltage source to P601, connecting the

−5 V pin, the 0 V ground pin, and the +5 V pin as shown

in Figure 1. These benchtop linear supplies should each have

100 mA of current capability.

4. Place jumpers on the top pin pairs of P606 or P607 to

connect CWD2+/CWD2− to CWD5+/CWD5− to the

IOP/ION buses. This directs each of these connections to

the output amplifier for display.

Note that the CWD0±/CWD1±/CWD6±/CWD7± outputs

are configured and biased to interface with the AD8339

evaluation board. The AD9272/AD9273 is specially designed

to snap onto the AD8339 evaluation board to allow the user to

evaluate a larger portion of this common signal chain. For

detailed instructions about enabling this function, send an

email to highspeed.converters@analog.com.

5. Use a 1 m, shielded, RG-58, 50 Ω coaxial cable to connect

the spectrum analyzer to J402 (labeled AOUT on the

evaluation board).

6. In the ADCBase 0 tab of the SPI Controller, find the

MODES(8) box. Select the CW Mode option (see Figure 18).

Rev. 0 | Page 10 of 24

Page 11

Evaluation Board User Guide UG-001

Figure 19. SPI Controller, CROSSPOINT SWITCH(2D) Box

8. Examine the spectrum analyzer for the CW Doppler output

(see Figure 20 for an example).

0

–10

FREQUENC Y = 2.3MHz

CWD1±, DIFFERENTIAL OUTPUT

FREQUENCY (MHz )

07782-004

Figure 18. SPI Controller, MODES(8) Box

7. In the ADC x tab of the SPI Controller, where x is the channel

to which an analog input is applied, find the CROSSPOINT

SWITCH(2D) box. From the Crosspoint Switch Modes

drop-down box, select the cwd2p/n option (see Figure 19).

–20

–30

–40

–50

–60

AMPLITUDE ( d Bm)

–70

–80

–90

–100

02

7782-029

Figure 20. Typical Spectrum Analyzer Display of CWD Output

5101520 5

07782-030

Rev. 0 | Page 11 of 24

Page 12

UG-001 Evaluation Board User Guide

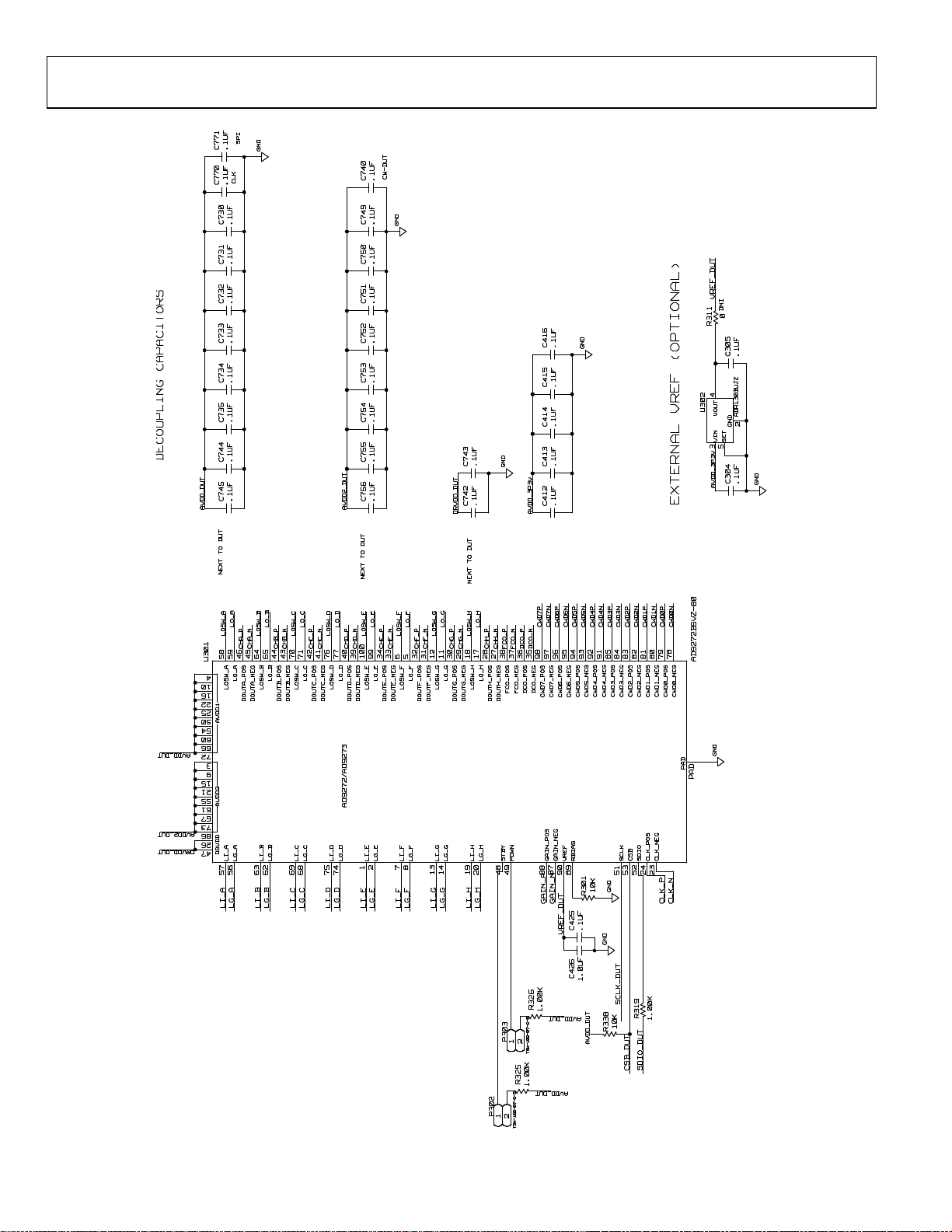

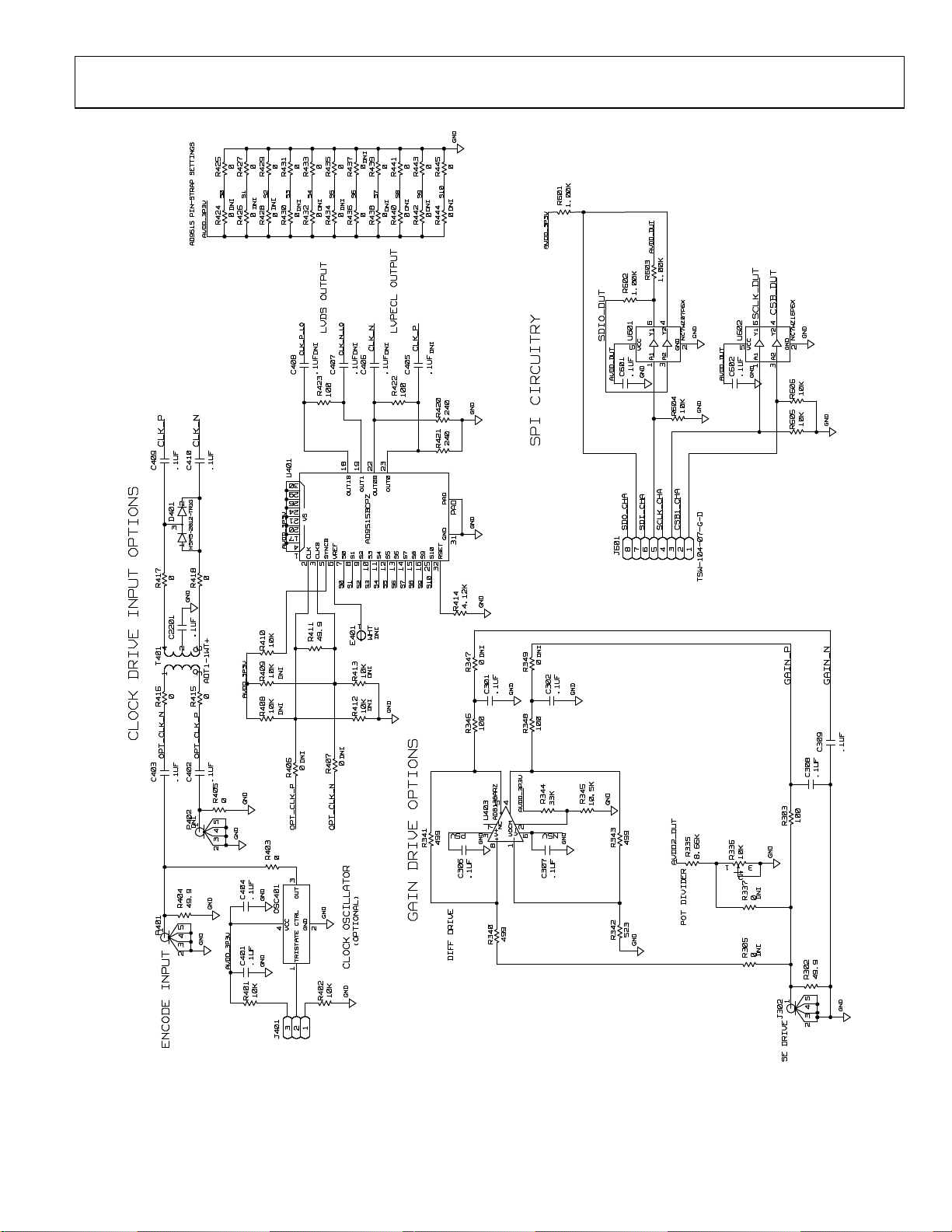

EVALUATION BOARD SCHEMATICS AND ARTWORK

07782-005

Figure 21. Evaluation Board Schematic, DUT Analog Input Circuits

Rev. 0 | Page 12 of 24

Page 13

Evaluation Board User Guide UG-001

07782-006

Figure 22. Evaluation Board Schematic, DUT Analog Input Circuits (Continued)

Rev. 0 | Page 13 of 24

Page 14

UG-001 Evaluation Board User Guide

07782-007

Figure 23. Evaluation Board Schematic, DUT, VREF, and Decoupling

Rev. 0 | Page 14 of 24

Page 15

Evaluation Board User Guide UG-001

07782-008

Figure 24. Evaluation Board Schematic, Clock, SPI, and Gain Circuits

Rev. 0 | Page 15 of 24

Page 16

UG-001 Evaluation Board User Guide

07782-009

Figure 25. Evaluation Board Schematic, Power Supply, CW Doppler, Digital Output Interface

Rev. 0 | Page 16 of 24

Page 17

Evaluation Board User Guide UG-001

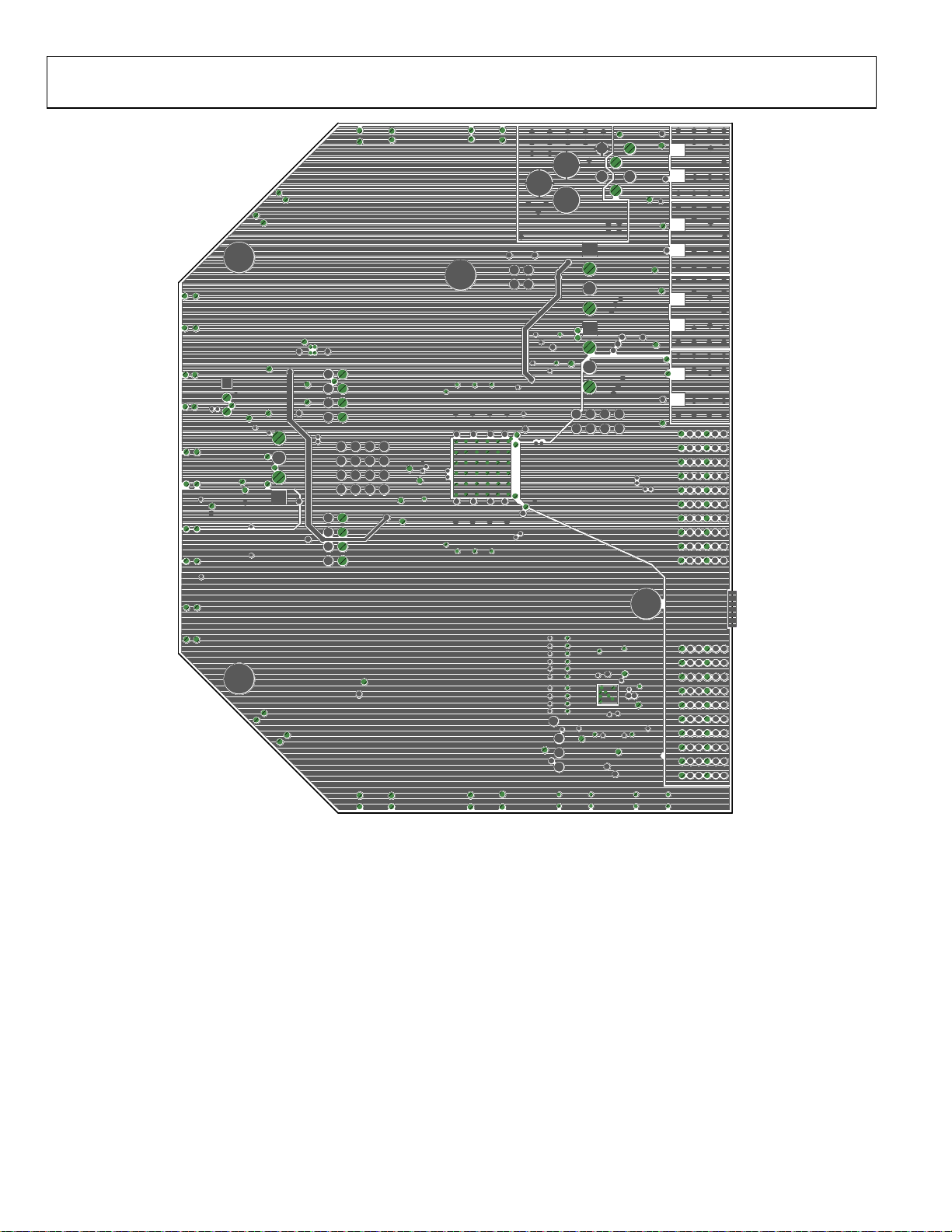

Figure 26. Evaluation Board Layout, Top Side

Rev. 0 | Page 17 of 24

07782-010

Page 18

UG-001 Evaluation Board User Guide

Figure 27. Evaluation Board Layout, Ground Plane (Layer 2)

Rev. 0 | Page 18 of 24

07782-011

Page 19

Evaluation Board User Guide UG-001

Figure 28. Evaluation Board Layout, Power Plane (Layer 3)

Rev. 0 | Page 19 of 24

07782-012

Page 20

UG-001 Evaluation Board User Guide

Figure 29. Evaluation Board Layout, Power Plane (Layer 4)

Rev. 0 | Page 20 of 24

07782-013

Page 21

Evaluation Board User Guide UG-001

Figure 30. Evaluation Board Layout, Ground Plane (Layer 5)

Rev. 0 | Page 21 of 24

07782-014

Page 22

UG-001 Evaluation Board User Guide

07782-015

Figure 31. Evaluation Board Layout, Bottom Side

Rev. 0 | Page 22 of 24

Page 23

Evaluation Board User Guide UG-001

ORDERING INFORMATION

BILL OF MATERIALS

Table 1.

Item Qty Reference Designator Description Manufacturer Part Number

1 79 C101, C102, C106, C110, C111, C115, C120,

C121, C125, C130, C131, C136, C201,

C202, C206, C210, C211, C215, C220,

C221, C225, C230, C231, C236, C301,

C302, C304, C305, C306, C307, C308,

C309, C401, C402, C403, C404, C409,

C410, C412, C413, C414, C415, C416,

C419, C420, C421, C422, C423, C425,

C502, C504, C601, C602, C706, C708,

C710, C712, C730, C731, C732, C733,

C734, C735, C740, C742, C743, C744,

C745, C749, C750, C751, C752, C753,

C754, C755, C756, C770, C771, C2201

2 9 C426, C714, C715, C716, C717, C719,

C720, C721, C722

3 6 C501, C503, C705, C707, C709, C711 Capacitor, 10 μF, 0603, ceramic, 6.3 V, 20%, X5R Panasonic ECJ-1VB0J106M

4 1 C704 Capacitor, 10 μF, 6032-28, tantalum, SMT, 16 V, 10% Kemet T491C106K016AT

5 2 C801, C802 Capacitor mono ceramic, 1 μF, 0402, X5R Murata GRM155B30J105KE18D

6 1 C803 Capacitor ceramic, 100 pF, 0402 Panasonic ECJ-0EC1H101J

7 1 CR702 LED, 0603, green Panasonic LNJ314G8TRA

8 1 D401 Diode Schottky GP LN 30 V, 20 mA SOT-23 Avago HSMS-2812-TR1G

9 8 D101, D102, D103, D104, D201, D202,

D203, D204

10 5 D701, D702, D703, D704, D705 Diode, silicon rectifier, SMBJ, 2 A, 50 V Microcommercial S2A-TP

11 1 F701 Polyswitch 1.1 A reset fuse SMD Tyco/Raychem NANOSMDC110F-2

12 1 OSC401 CLK oscillator, 3.3 V, 50 MHz/65 MHz/80 MHz Valpey Fisher VFAC3-BHL-50MHz,

13 12 J101, J102, J103, J104, J201, J202, J203,

J204, J302, J402, J403 ,P401

14 2 P302, P303 Header, 2-pin, single row, male, 100 mil, straight Samtec TSW-102-07-G-S

15 3 J601, P606, P607 Conn-PCB header 8-pin double row Samtec TSW-104-07-G-D

16 2 P604, P605 Conn-PCB header, 8-pin, double row Samtec SSW-104-06-G-D

17 1 J401 Header, 3-pin, single row, male, 100 mil, straight Samtec TSW-103-07-G-S

18 1 P601 Terminal block, 4-pin, straight Weiland Z5.531.3425.0

19 1 P701 Power supply connector Switchcraft RAPC722X

20 2 P702, P703 Header Tyco 6469169-1

21 8 L401, L402, L403, L404, L405, L406,

L407, L408

22 10 L501, L502, L702, L703, L704, L705,

L706, L707, L708, L709

23 1 L701 EMI filter LC block choke coil Murata BNX016-01

24 11 R425, R427, R429, R431, R433, R435,

R436, R439, R441, R443, R445

25 8 R107, R121, R136, R151, R207, R221,

R236, R251

26 16 R102, R116, R131, R146, R202, R216,

R231, R246, R403, R405, R415, R416,

R417, R418, R451, R452

27 5 R303, R346, R348, R422, R423 Resistor, thick film, SMT 0402, 100 Ω, 1/16 W, 1% Panasonic ERJ-2RKF1000X

28 6 R319, R325, R326, R601, R602, R603 Resistor, thick film, SMT 0402, 1.00 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF1001X

29 8 R301, R338, R401, R402, R410, R604,

R605, R606

30 13 R101, R115, R130, R145, R201, R215, R230,

R245, R302, R404, R411, R455, R458

31 1 R335 Resistor, thick film, SMT 0402, 8.66 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF8661X

32 3 R340, R341, R343 Resistor, thick film, SMT 0402, 499 Ω, 1/16 W, 1% Panasonic ERJ-2RKF4 990X

33 1 R342 Resistor, thick film, SMT 0402, 523 Ω, 1/16 W, 1% Panasonic ERJ-2RKF5230X

Capacitor, 0.1 μF, 0402, ceramic, X5R, 10 V Panasonic ECJ-0EB1A104K

Capacitor, 1.0 μF, 0603, ceramic, 16 V, X5R Panasonic ECJ-BVB1C105M

Diode Schottky GP LN 20 V SOT-23 Fairchild MMBD4148SE

VFAC3-BHL-65MHz,

VFAC3-BHL-80MHz

SMA, end launch, coaxial Samtec SMA-J-P-H-ST-EM1

Inductor chip coil, 560 μH, 1210 Murata LQH32MN561J23L

Ferrite chip 50 Ω, 3 A 1206 Murata BLM31PG500SN1L

Resistor, thick film, SMT 0201, 0 Ω Panasonic ERJ-1GE0R00C

Resistor, thick film, SMT 0402, 348 Ω, 1/16 W, 1% Panasonic ERJ-2RKF3480X

Resistor, thick film, SMT 0402, 0 Ω Panasonic ERJ-2GE0R00X

Resistor, thick film, SMT 0402, 10 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF1002X

Resistor, thick film, SMT 0402, 49.9 Ω, 1/16 W, 1% Panasonic ERJ-2RKF49R9X

Rev. 0 | Page 23 of 24

Page 24

UG-001 Evaluation Board User Guide

Item Qty Reference Designator Description Manufacturer Part Number

34 1 R344 Resistor, thick film, SMT 0402, 33 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF3302X

35 1 R345 Resistor, thick film, SMT 0402, 10.5 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF1052X

36 1 R414 Resistor, thick film, SMT 0402, 4.12 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF4121X

37 3 R420, R421, R716 Resistor, thick film, SMT 0402, 240 Ω, 1/16 W, 5% Panas onic ERJ-2GEJ241X

38 2 R447, R448 Resistor, thick film, SMT 0402, 124 Ω, 1/16 W, 1% Panasonic ERJ-2RKF1240X

39 6 R453, R454, R801, R802, R803, R804 Resistor, thick film, SMT 0402, 750 Ω, 1/16 W, 1% Panasonic ERJ-2RKF7500X

40 1 R446 Resistor, thick film, SMT 0402, 113 Ω, 1/16 W, 1% Panasonic ERJ-2RKF1130X

41 1 R336 potentiometer, 10 kΩ square cermet top Copal CT94EW103

42 1 T401 Transformer, RF, 1:1 Minicircuits ADT1-1WT+

43 1 T402 Transformer, ADTT4-1, CD542 Minicircuits ADTT4-1+

44 1 U601 IC, buffer, UHS dual, OD out, SC70-6 Fairchild NC7WZ07P6X

45 1 U602 IC, buffer, UHS dual, SC70-6 Fairchild NC7WZ16P6X

46 1 U302 IC, VREF, precision sub–band gap, 3-lead TSOT Analog Devices ADR130BUJZ-R2

47 1 U401 IC, clock distribution, 32-lead LFCSP Analog Devices AD9515BCPZ

48 1 U402 IC, op amp, current feedback, dual, 8-lead SOIC Analog Devices AD812ARZ

49 1 U701 IC high ACC. 500 mA anyCAP® low drop 2.5 V

regulator

50 2 U704, U707 IC, regulator, high accuracy, 1.8 V, SOT-223 Analog Devices ADP3339AKCZ-1.8-R7

51 1 U705 IC, regulator, high accuracy, 3.3 V, SOT-223 Analog Devices ADP3339AKCZ-3.3-R7

52 1 U706 IC, regulator, high accuracy, 3.0 V, SOT-223 Analog Devices ADP3339AKCZ-3-RL7

53 1 U403 IC, low distortion diff ADC driver, 8-lead SOIC Analog Devices AD8138ARZ

54 1 U301 IC, octal LNA/VGA/AAF/ADC and crosspoint switch

TQFP-100 (SV-100-3)

Analog Devices ADP3335ACPZ-2.5R7

Analog Devices AD9273BSVZ-50,

AD9272BSVZ-65,

AD9272BSVZ-80

ESD CAUTION

Evaluation boards are only intended for device evaluation and not for production purposes. Evaluation boards are supplied “as is” and without warranties of any kind, express,

implied, or statutory including, but not limited to, any implied warranty of merchantability or fitness for a particular purpose. No license is granted by implication or otherwise under

any patents or other intellectual property by application or use of evaluation boards. Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other rights of third parties that may result from its use. Analog Devices reserves the

right to change devices or specifications at any time without notice. Trademarks and registered trademarks are the property of their respective owners. Evaluation boards are not

authorized to be used in life support devices or systems.

©2009 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

UG07782-0-2/09(0)

Rev. 0 | Page 24 of 24

Loading...

Loading...