1 2 3

D

OUT

V+

GND

VPTAT

V

REF

TEMPERATURE

SENSOR

DIGITAL

MODULATOR

TMP03/TMP04

a

Serial Digital Output Thermometers

TMP03/TMP04*

FEATURES

Low Cost 3-Pin Package

Modulated Serial Digital Output

Proportional to Temperature

1.5C Accuracy (typ) from –25C to +100C

Specified –40C to +100C, Operation to 150C

Power Consumption 6.5 mW Max at 5 V

Flexible Open-Collector Output on TMP03

CMOS/TTL-Compatible Output on TMP04

Low Voltage Operation (4.5 V to 7 V)

APPLICATIONS

Isolated Sensors

Environmental Control Systems

Computer Thermal Monitoring

Thermal Protection

Industrial Process Control

Power System Monitors

GENERAL DESCRIPTION

The TMP03/TMP04 are monolithic temperature detectors that

generate a modulated serial digital output that varies in direct

proportion to the temperature of the device. An onboard sensor

generates a voltage precisely proportional to absolute temperature which is compared to an internal voltage reference and

input to a precision digital modulator. The ratiometric encoding

format of the serial digital output is independent of the clock drift

errors common to most serial modulation techniques such as

voltage-to-frequency converters. Overall accuracy is ±1.5°C

(typical) from –25°C to +100°C, with excellent transducer linearity. The digital output of the TMP04 is CMOS/TTL

compatible, and is easily interfaced to the serial inputs of most

popular microprocessors. The open-collector output of the

TMP03 is capable of sinking 5 mA. The TMP03 is best suited

for systems requiring isolated circuits utilizing optocouplers or

isolation transformers.

The TMP03 and TMP04 are specified for operation at supply

voltages from 4.5 V to 7 V. Operating from 5 V, supply current

(unloaded) is less than 1.3 mA.

The TMP03/TMP04 are rated for operation over the –40°C to

+100°C temperature range in the low cost TO-92, SO-8, and

TSSOP-8 surface mount packages. Operation extends to 150°C

with reduced accuracy.

(continued on page 4)

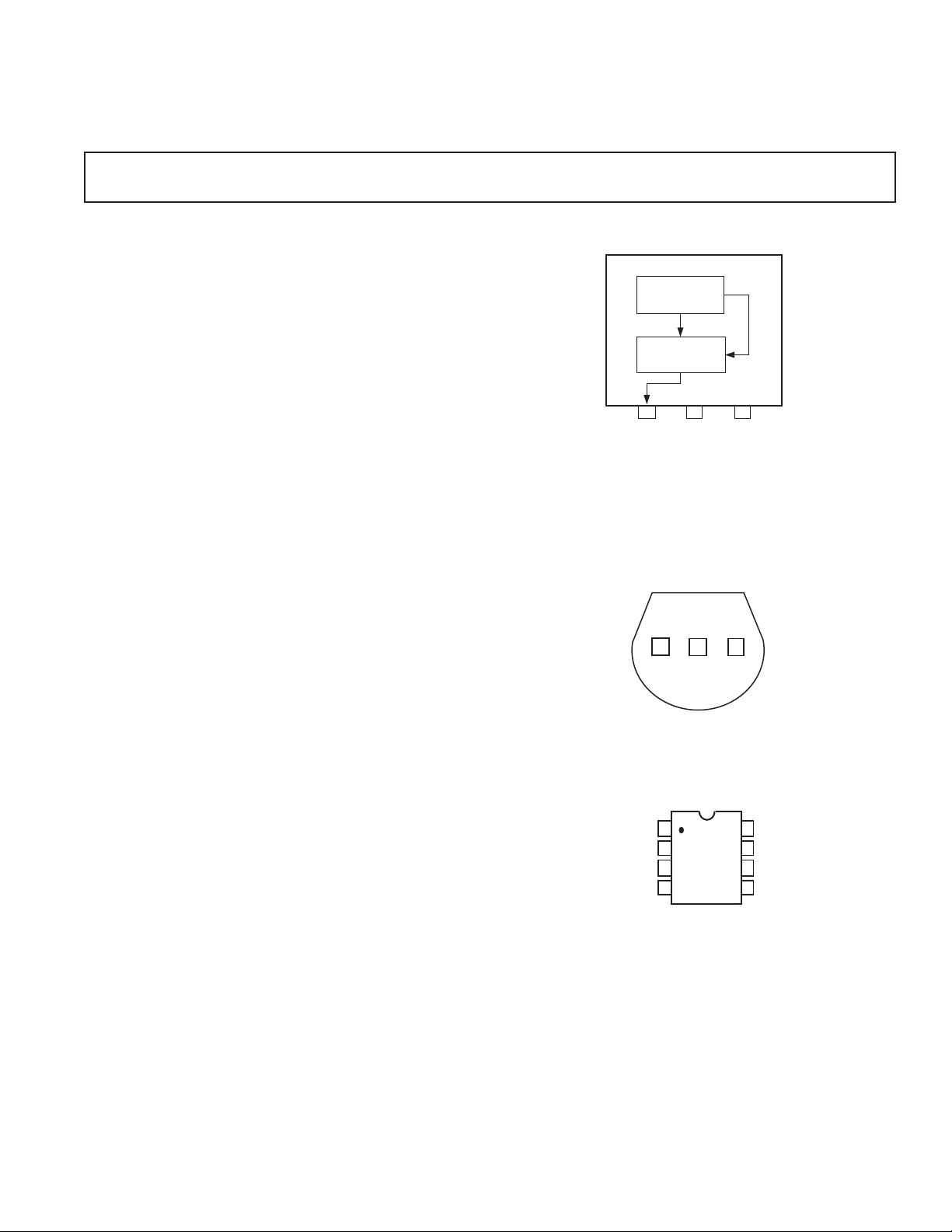

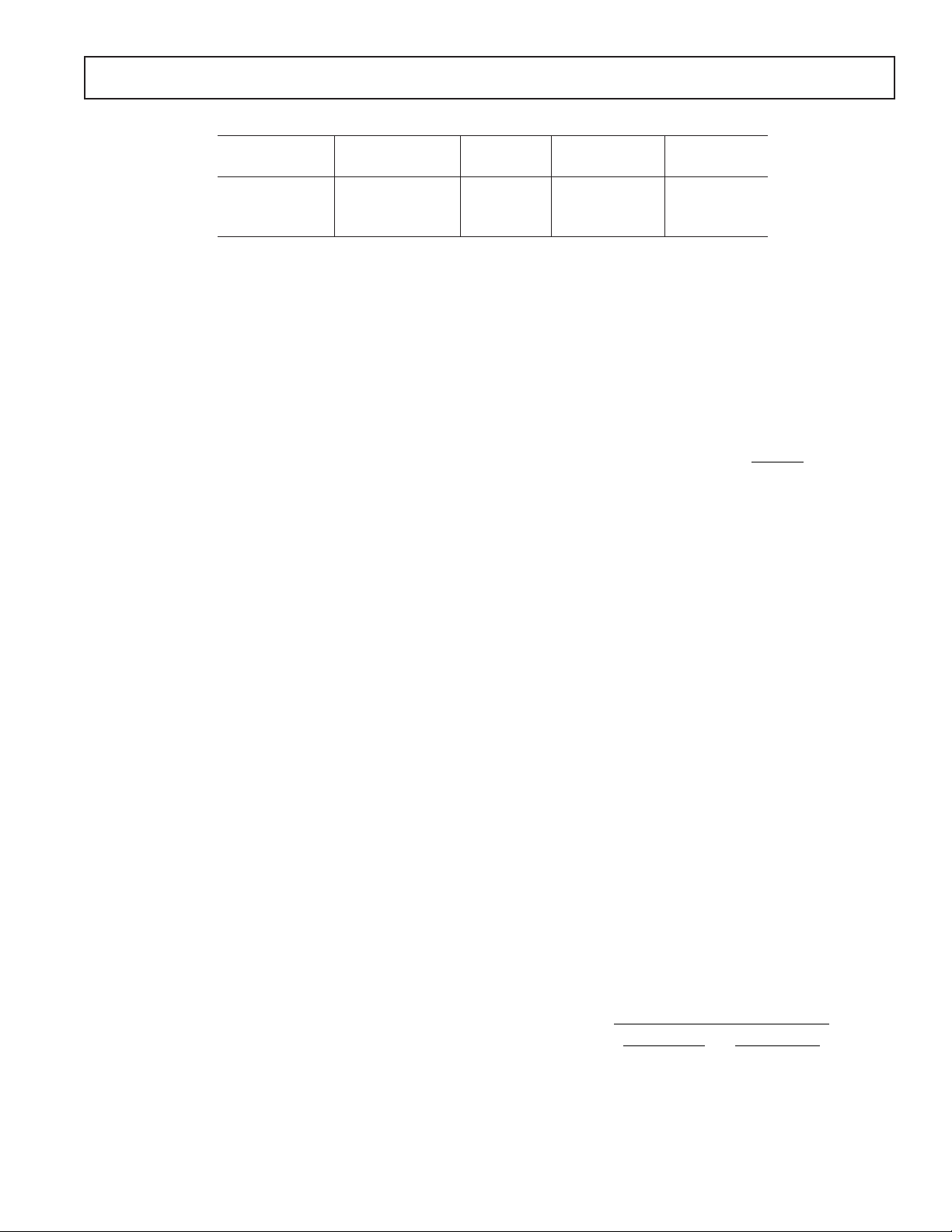

FUNCTIONAL BLOCK DIAGRAM

PACKAGE TYPES AVAILABLE

TO-92

TMP03/TMP04

1

2 3

V+

D

OUT

BOTTOM VIEW

(Not to Scale)

GND

SO-8 and RU-8 (TSSOP)

1

D

OUT

2

V+

3

GND

4

NC

NC = NO CONNECT

TMP03/

TMP04

TOP VIEW

(Not to Scale)

8

NC

NC

7

6

NC

5

NC

*Patent pending.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

TMP03/TMP04–SPECIFICATIONS

TMP03F

(V+ = 5 V, –40C ≤ TA ≤ 100C, unless otherwise noted.)

Parameter Symbol Conditions Min Typ Max Unit

ACCURACY

Temperature Error –25°C < T

–40°C < T

< +100°C

A

< –25°C

A

1

1

1.5 4.0 °C

2.0 5.0 °C

Temperature Linearity 0.5 °C

Long-Term Stability 1000 Hours at 125°C 0.5 °C

Nominal Mark-Space Ratio T1/T2 T

= 0°C 58.8 %

A

Nominal T1 Pulsewidth T1 10 ms

Power Supply Rejection Ratio PSRR Over Rated Supply 0.7 1.4 °C/V

TA = 25°C

OUTPUTS

Output Low Voltage V

Output Low Voltage V

Output Low Voltage V

Digital Output Capacitance C

Fall Time t

OL

OL

OL

OUT

HL

I

= 1.6 mA 0.2 V

SINK

I

= 5 mA 2 V

SINK

0°C < T

I

SINK

–40°C < T

< 100°C

A

= 4 mA 2 V

< 0°C

A

(Note 2) 15 pF

See Test Load 150 ns

Device Turn-On Time 20 ms

POWER SUPPLY

Supply Range V+ 4.5 7 V

Supply Current I

NOTES

1

Maximum deviation from output transfer function over specified temperature range.

2

Guaranteed but not tested.

Specifications subject to change without notice.

SY

Unloaded 0.9 1.3 mA

Test Load

10 kΩ to 5 V Supply, 100 pF to Ground

TMP04F

(V+ = 5 V, –40C ≤ TA ≤ 100C, unless otherwise noted.)

Parameter Symbol Conditions Min Typ Max Unit

ACCURACY

Temperature Error T

= 25°C 1.0 3.0 °C

A

–25°C < T

–40°C < T

< +100°C

A

< –25°C

A

1

1

1.5 4.0 °C

2.0 5.0 °C

Temperature Linearity 0.5 °C

Long-Term Stability 1000 Hours at 125°C 0.5 °C

Nominal Mark-Space Ratio T1/T2 T

= 0°C 58.8 %

A

Nominal T1 Pulsewidth T1 10 ms

Power Supply Rejection Ratio PSRR Over Rated Supply 0.7 1.2 °C/V

TA = 25°C

OUTPUTS

Output High Voltage V

Output Low Voltage V

Digital Output Capacitance C

Fall Time t

Rise Time t

OH

OL

OUT

HL

LH

IOH = 800 µA V+ –0.4 V

IOL = 800 µA 0.4 V

(Note 2) 15 pF

See Test Load 200 ns

See Test Load 160 ns

Device Turn-On Time 20 ms

POWER SUPPLY

Supply Range V+ 4.5 7 V

Supply Current I

NOTES

1

Maximum deviation from output transfer function over specified temperature range.

2

Guaranteed but not tested.

Specifications subject to change without notice.

SY

Unloaded 0.9 1.3 mA

Test Load

100 pF to Ground

–2–

REV. A

TMP03/TMP04

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Maximum Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . 9 V

Maximum Output Current (TMP03 D

Maximum Output Current (TMP04 D

) . . . . . . . . . 50 mA

OUT

) . . . . . . . . . 10 mA

OUT

Maximum Open-Collector Output Voltage (TMP03) . . . 18 V

Operating Temperature Range . . . . . . . . . . –55°C to +150°C

Dice Junction Temperature . . . . . . . . . . . . . . . . . . . . . . 175°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +160°C

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . . . 300°C

*CAUTION

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation at or

above this specification is not implied. Exposure to the above maximum rating

conditions for extended periods may affect device reliability.

2

Digital inputs and outputs are protected, however, permanent damage may occur

on unprotected units from high-energy electrostatic fields. Keep units in conductive foam or packaging at all times until ready to use. Use proper antistatic

handling procedures.

3

Remove power before inserting or removing units from their sockets.

Package Type

TO-92 (T9) 162

SO-8 (S) 158

TSSOP (RU) 240

NOTE

1

ΘJA is specified for device in socket (worst case conditions).

JA

1

1

1

JC

Units

120 °C/W

43 °C/W

43 °C/W

ORDERING GUIDE

Accuracy Temperature

Model at 25C Range Package

TMP03FT9 ± 3.0 XIND TO-92

TMP03FS ±3.0 XIND SO-8

TMP03FRU ±3.0 XIND TSSOP-8

TMP04FT9 ± 3.0 XIND TO-92

TMP04FS ±3.0 XIND SO-8

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the TMP03 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. A

–3–

TMP03/TMP04

(continued from page 1)

The TMP03 is a powerful, complete temperature measurement

system with digital output, on a single chip. The onboard temperature sensor follows in the footsteps of the TMP01 low

power programmable temperature controller, offering excellent

accuracy and linearity over the entire rated temperature range

without correction or calibration by the user.

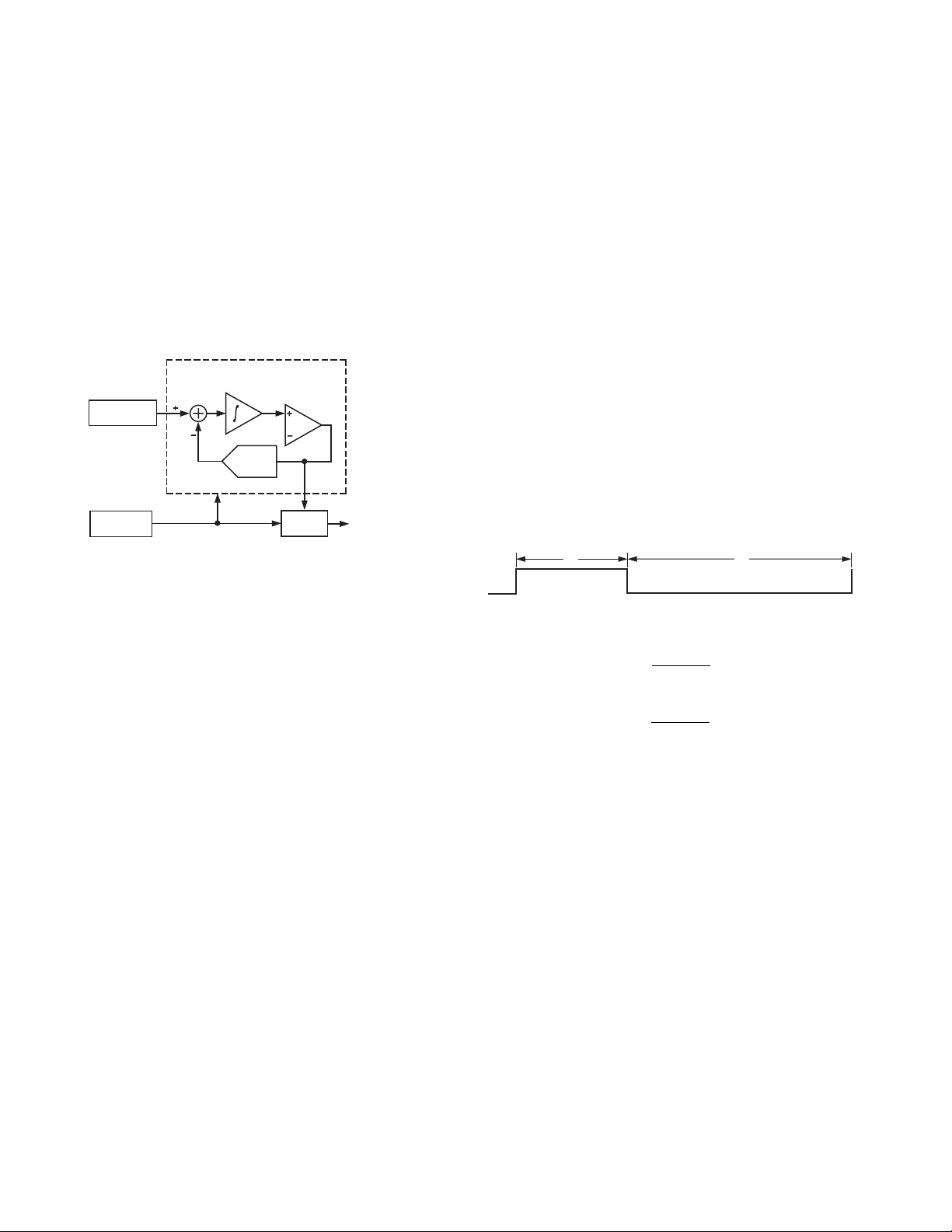

The sensor output is digitized by a first-order sigma-delta

modulator, also known as the “charge balance” type analog-todigital converter. (See Figure 1.) This type of converter utilizes

time-domain oversampling and a high accuracy comparator to

deliver 12 bits of effective accuracy in an extremely compact

circuit.

⌺⌬ MODULATOR

VOLTAGE REF

AND VPTAT

CLOCK

GENERATOR

INTEGRATOR

1-BIT

DAC

COMPARATOR

DIGITAL

FILTER

TMP03/04

OUT

(SINGLE-BIT)

Figure 1. TMP03 Block Diagram Showing First-Order

Sigma-Delta Modulator

Basically, the sigma-delta modulator consists of an input sampler, a

summing network, an integrator, a comparator, and a 1-bit

DAC. Similar to the voltage-to-frequency converter, this

architecture creates in effect a negative feedback loop whose

intent is to minimize the integrator output by changing the duty

cycle of the comparator output in response to input voltage

changes. The comparator samples the output of the integrator at

a much higher rate than the input sampling frequency, called

oversampling. This spreads the quantization noise over a much

wider band than that of the input signal, improving overall noise

performance and increasing accuracy.

The modulated output of the comparator is encoded using a

circuit technique (patent pending) which results in a serial digital signal with a mark-space ratio format that is easily decoded

by any microprocessor into either degrees centigrade or degrees

Fahrenheit values, and readily transmitted or modulated over a

single wire. Most importantly, this encoding method neatly

avoids major error sources common to other modulation techniques, as it is clock-independent.

Output Encoding

Accurate sampling of an analog signal requires precise spacing

of the sampling interval in order to maintain an accurate representation of the signal in the time domain. This dictates a

master clock between the digitizer and the signal processor. In

the case of compact, cost-effective data acquisition systems, the

addition of a buffered, high speed clock line can represent a

significant burden on the overall system design. Alternatively,

the addition of an onboard clock circuit with the appropriate

accuracy and drift performance to an integrated circuit can add

significant cost. The modulation and encoding techniques utilized in the TMP03 avoid this problem and allow the overall

circuit to fit into a compact, 3-pin package. To achieve this, a

simple, compact onboard clock and an oversampling digitizer

that is insensitive to sampling rate variations are used. Most

importantly, the digitized signal is encoded into a ratiometric

format in which the exact frequency of the TMP03’s clock is

irrelevant, and the effects of clock variations are effectively canceled upon decoding by the digital filter.

The output of the TMP03 is a square wave with a nominal

frequency of 35 Hz (±20%) at 25°C. The output format is

readily decoded by the user as follows:

T1

T2

Figure 2. TMP03 Output Format

Temperature (°C) =

Temperature (°F) =

235 −

455 −

400 ×T1

720 ×T1

T 2

T 2

The time periods T1 (high period) and T2 (low period) are

values easily read by a microprocessor timer/counter port, with

the above calculations performed in software. Since both periods are obtained consecutively, using the same clock,

performing the division indicated in the above formulas results

in a ratiometric value that is independent of the exact frequency

of, or drift in, either the originating clock of the TMP03 or the

user’s counting clock.

–4–

REV. A

TMP03/TMP04

Table I. Counter Size and Clock Frequency Effects on Quantization Error

Maximum Maximum Maximum Quantization Quantization

Count Available Temp Required Frequency Error (25C) Error (77F)

4096 125°C 94 kHz 0.284°C 0.512°F

8192 125°C 188 kHz 0.142°C 0.256°F

16384 125°C 376 kHz 0.071°C 0.128°F

Optimizing Counter Characteristics

Counter resolution, clock rate, and the resultant temperature

decode error that occurs using a counter scheme may be determined from the following calculations:

1. T1 is nominally 10 ms, and compared to T2 is relatively

insensitive to temperature changes. A useful worst-case

assumption is that T1 will never exceed 12 ms over the

specified temperature range.

T1 max = 12 ms

Substituting this value for T1 in the formula, temperature

(°C) = 235 – ([T1/T2] × 400), yields a maximum value of

T2 of 44 ms at 125°C. Rearranging the formula allows the

maximum value of T2 to be calculated at any maximum

operating temperature:

T2 (Temp) = (T1max × 400)/(235 – Temp) in seconds

2. We now need to calculate the maximum clock frequency we

can apply to the gated counter so it will not overflow during

T2 time measurement. The maximum frequency is calculated

using:

Frequency (max) = Counter Size/ (T2 at maximum

temperature)

Substituting in the equation using a 12-bit counter gives,

Fmax = 4096/44 ms ⯝ 94 kHz.

3. Now we can calculate the temperature resolution, or quantization error, provided by the counter at the chosen clock

frequency and temperature of interest. Again, using a 12-bit

counter being clocked at 90 kHz (to allow for ~5% temperature over-range), the temperature resolution at 25°C is

calculated from:

Quantization Error (

°

C) = 400 × ([Count1/Count2] –

[Count1 – 1]/[Count2 + 1])

Quantization Error (

°

F) = 720 × ([Count1/Count2] –

[Count1 – 1]/[Count2 + 1])

where, Count1 = T1max × Frequency, and Count2 =

T2 (Temp) × Frequency. At 25°C this gives a resolution of

better than 0.3°C. Note that the temperature resolution

calculated from these equations improves as temperature

increases. Higher temperature resolution will be obtained by

employing larger counters as shown in Table I. The internal

quantization error of the TMP03 sets a theoretical minimum

resolution of approximately 0.1°C at 25°C.

Self-Heating Effects

The temperature measurement accuracy of the TMP03 may be

degraded in some applications due to self-heating. Errors introduced are from the quiescent dissipation, and power dissipated

by the digital output. The magnitude of these temperature errors is dependent on the thermal conductivity of the TMP03

package, the mounting technique, and effects of airflow. Static

dissipation in the TMP03 is typically 4.5 mW operating at 5 V

with no load. In the TO-92 package mounted in free air, this

accounts for a temperature increase due to self-heating of

∆T = P

× θJA = 4.5 mW × 162°C/W = 0.73°C (1.3°F)

DISS

For a free-standing surface-mount TSSOP package, the temperature increase due to self-heating would be

∆T = P

× θJA = 4.5 mW × 240°C/W = 1.08°C (1.9°F)

DISS

In addition, power is dissipated by the digital output which is

capable of sinking 800 µA continuous (TMP04). Under full

load, the output may dissipate

P

= 0. 6 V

()

DISS

0.8 mA

()

T1 +T 2

T 2

For example, with T2 = 20 ms and T1 = 10 ms, the power

dissipation due to the digital output is approximately 0.32 mW

with a 0.8 mA load. In a free-standing TSSOP package, this

accounts for a temperature increase due to output self-heating

of

∆T = P

× ΘJA = 0.32 mW × 240°C/W = 0.08°C (0.14°F)

DISS

This temperature increase adds directly to that from the quiescent dissipation and affects the accuracy of the TMP03 relative

to the true ambient temperature. Alternatively, when the same

package has been bonded to a large plate or other thermal mass

(effectively a large heatsink) to measure its temperature, the

total self-heating error would be reduced to approximately

∆T = P

Calibration

× ΘJC = (4.5 mW + 0.32 mW) × 43°C/W = 0.21°C (0.37°F)

DISS

The TMP03 and TMP04 are laser-trimmed for accuracy and

linearity during manufacture and, in most cases, no further

adjustments are required. However, some improvement in performance can be gained by additional system calibration. To

perform a single-point calibration at room temperature, measure

the TMP03 output, record the actual measurement temperature, and modify the offset constant (normally 235; see the

Output Encoding section) as follows:

Offset Constant = 235 + (T

OBSERVED

– T

TMP03OUTPUT

)

A more complicated 2-point calibration is also possible. This

involves measuring the TMP03 output at two temperatures,

Temp1 and Temp2, and modifying the slope constant (normally

400) as follows:

Slope Constant =

T1@ Temp1

T 2@Temp1

Temp 2 −Temp1

T1@ Temp 2

−

T 2@Temp 2

where T1 and T2 are the output high and output low times,

respectively.

REV. A

–5–

TMP03/TMP04–Typical Performance Characteristics

70

60

V+ = 5V

R

LOAD

= 10k

50

40

30

20

OUTPUT FREQUENCY – Hz

10

0

–75

–25 25 75 125 175

TEMPERATURE – C

TPC 1. Output Frequency vs. Temperature

45

VS = 5V

40

R

= 10k

LOAD

TIME – ms

35

30

25

20

15

10

5

0

–75

–25 25 75 125 175

TEMPERATURE – C

T2

T1

1.05

TA = 25C

1.04

R

= 10k

LOAD

1.03

1.02

1.01

1.00

0.99

NORMALIZED OUTPUT FREQUENCY

0.98

0.97

4.5

5

5.5 6 6.5 7 7.5

SUPPLY VOLTAGE – Volts

TPC 4. Normalized Output Frequency vs. Supply Voltage

RUNNING:

50.0MS/s

TA = 25 C

V

DD

VOLTAGE SCALE = 2V/DIV

SAMPLE

( T )

= 5V

TIME SCALE = 1s/DIV

C

R

LOAD

LOAD

= 100pF

= 1k

CH 1 +WIDTH

s

Wfm DOES NOT

CROSS REF

CH 1 –WIDTH

s

Wfm DOES NOT

CROSS REF

CH 1 RISE

500ns

CH 1 FALL

s

NO VALID EDGE

TPC 2. T1 and T2 Times vs. Temperature

RUNNING:

200MS/s ET

VOLTAGE SCALE = 2V/DIV

SAMPLE

( T )

TA = 25 C

V

DD

C

LOAD

R

LOAD

TIME SCALE = 250ns/DIV

= 5V

= 100pF

= 1k

CH 1 +WIDTH

Wfm DOES NOT

CROSS REF

CH 1 –WIDTH

Wfm DOES NOT

CROSS REF

CH 1 RISE

NO VALID EDGE

CH 1 FALL

209.6ns

TPC 3. TMP03 Output Fall Time at 25°C

TPC 5. TMP03 Output Rise Time at 25°C

RUNNING:

50.0MS/s

s

s

s

TA = 125 C

V

DD

VOLTAGE SCALE = 2V/DIV

SAMPLE

( T )

= 5V

TIME SCALE = 1s/DIV

C

R

LOAD

LOAD

= 100pF

= 1k

CH 1 +WIDTH

s

Wfm DOES NOT

CROSS REF

CH 1 –WIDTH

s

Wfm DOES NOT

CROSS REF

CH 1 RISE

5380ns

CH 1 FALL

s

NO VALID EDGE

TPC 6. TMP03 Output Rise Time at 125°C

–6–

REV. A

TMP03/TMP04

= 1k

SAMPLE

( T )

CH 1 +WIDTH

s

Wfm DOES NOT

CROSS REF

CH 1 –WIDTH

s

Wfm DOES NOT

CROSS REF

CH 1 RISE

s

NO VALID EDGE

CH 1 FALL

139.5ns

EDGE SLOPE

RUNNING:

200MS/s ET

TA = 125 C

= 5V

V

DD

C

R

LOAD

LOAD

= 100pF

VOLTAGE SCALE = 2V/DIV

TIME SCALE = 250ns/DIV

TPC 7. TMP03 Output Fall Time at 125°C

= 100pF

= 0

SAMPLE

( T )

TA = 25 C

V

= 5V

DD

CH 1 +WIDTH

Wfm DOES NOT

CROSS REF

CH 1 –WIDTH

Wfm DOES NOT

CROSS REF

CH 1 RISE

NO VALID EDGE

CH 1 FALL

RUNNING:

200MS/s ET

C

LOAD

VOLTAGE SCALE = 2V/DIV

R

LOAD

s

s

s

127.6ns

= 5V

SAMPLE

( T )

C

R

LOAD

LOAD

= 100pF

= 0

CH 1 +WIDTH

Wfm DOES NOT

CROSS REF

CH 1 –WIDTH

Wfm DOES NOT

CROSS REF

CH 1 RISE

110.6ns

CH 1 FALL

NO VALID EDGE

RUNNING:

200MS/s ET

TA = 25 C

V

DD

VOLTAGE SCALE = 2V/DIV

TIME SCALE = 250ns/DIV

TPC 10. TMP04 Output Rise Time at 25°C

= 5V

SAMPLE

( T )

C

R

LOAD

LOAD

= 100pF

= 0

CH 1 +WIDTH

Wfm DOES NOT

CROSS REF

CH 1 –WIDTH

Wfm DOES NOT

CROSS REF

CH 1 RISE

149.6ns

CH 1 FALL

NO VALID EDGE

RUNNING:

200MS/s ET

TA = 125 C

V

DD

VOLTAGE SCALE = 2V/DIV

s

s

s

s

s

s

TIME SCALE = 250ns/DIV

TPC 8. TMP04 Output Fall Time at 25°C

RUNNING:

200MS/s ET

C

LOAD

VOLTAGE SCALE = 2V/DIV

R

LOAD

SAMPLE

( T )

= 100pF

= 0

TIME SCALE = 250ns/DIV

TA = 125 C

= 5V

V

DD

CH 1 +WIDTH

Wfm DOES NOT

CROSS REF

CH 1 –WIDTH

Wfm DOES NOT

CROSS REF

CH 1 RISE

NO VALID EDGE

CH 1 FALL

TPC 9. TMP04 Output Fall Time at 125°C

s

s

s

188.0ns

TIME SCALE = 250ns/DIV

TPC 11. TMP04 Output Rise Time at 125°C

2500

TA = 25C

= 5V

V

S

=

R

2000

LOAD

FAL L TIME

1500

TIME – ns

1000

RISE TIME

500

0

500

0

1000

1500

2000

2500

3000

3500 4000

4500

LOAD CAPACITANCE – pF

TPC 12. TMP04 Output Rise and Fall Times

vs. Capacitive Load

5000

REV. A

–7–

TMP03/TMP04

5

4

3

V+ = 5V

R

= 10k

2

LOAD

1

0

–1

–2

OUTPUT ACCURACY – C

–3

–4

–5

–50

–25 0

MAXIMUM LIMIT

TMP03

TMP04

MINIMUM LIMIT

25

TEMPERATURE – C

MEASUREMENTS IN

STIRRED OIL BATH

50 75 100

TPC 13. Output Accuracy vs. Temperature

OUTPUT

STARTS

LOW

OUTPUT

STARTS

HIGH

V+ = 5V

R

LOAD

= 10k

0, T2

T1

0, T1

T2

T1T2

TYPICAL VALUES

TEMP T2 T1

C ms ms

–55 15 10

25 20 10

125 35 10

125

5

START-UP VOLTAGE DEFINED AS OUTPUT READING

BEING WITHIN 5C OF OUTPUT AT 4.5V SUPPLY

4.5

R

= 10k

4

3.5

START-UP SUPPLY VOLTAGE – Volts

3

–75

LOAD

–25 25 75 125 175

TEMPERATURE – C

TPC 16. Start-Up Voltage vs. Temperature

1600

1400

1200

1000

SUPPLY CURRENT – A

800

600

400

TA = 25C

NO LOAD

V+

10 20 30 40 50

0

TIME – ms

60 70 80 90 100

TPC 14. Start-Up Response

1100

V+ = 5V

1050

NO LOAD

1000

950

900

850

SUPPLY CURRENT – A

800

750

–75

–25 25 75 125 175

TMP04

TEMPERATURE – C

TMP03

TPC 15. Supply Current vs. Temperature

200

0

1

0

3

2

SUPPLY VOLTAGE – Volts

4

5

678

TPC 17. Supply Current vs. Supply Voltage

4

V+ = 4.5V TO 7V

POWER SUPPLY REJECTION – C/V

3.5

2.5

1.5

0.5

3

2

1

0

–75

= 10k

R

LOAD

–25 25 75 125 175

TEMPERATURE – C

TPC 18. Power Supply Rejection vs. Temperature

–8–

REV. A

1

TEMPERATURE – C

2

–75

SINK CURRENT – mA

–25

25

75

125 150

8

10

12

14

V

OL

= 1V

V+ = 5V

16

20

18

6

4

TIME – sec

25

0

OUTPUT TEMPERATURE – C

10 20 30

40

50

V+ = 5V

R

LOAD =

10k

100

TRANSITION FROM STILL 25C AIR

TO STIRRED 100C OIL BATH

60

SOIC

TO –92

1.25 SEC (SOIC IN SOCKET)

2 SEC (TO –92 IN SOCKET)

V+ = 5V DC 50mV AC

R

LOAD =

0.5

TMP03/TMP04

10k

NORMAL PSSR

1k 100k 1M

FREQUENCY – Hz

10M10k

DEVIATION IN TEMPERATURE – C

–0.5

0

–1

1

100

10

TPC 19. Power Supply Rejection vs. Frequency

400

V+ = 5V

350

300

250

200

150

100

OPEN-COLLECTOR OUTPUT VOLTAGE – mV

I

LOAD

50

0

–75

–25 25 75 125 175

I

= 5mA

LOAD

= 1mA

I

= 0.5mA

LOAD

TEMPERATURE – C

TPC 22. TMP03 Open-Collector Sink Current

vs. Temperature

105

100

95

90

85

80

75

70

65

60

55

50

45

OUTPUT TEMPERATURE – C

40

35

SOIC

30

25

0

TRANSITION FROM 100C STIRRED

OIL BATH TO STILL 25C AIR

~ 23 SEC (SOIC, NO SOCKET)

~ 40 SEC (TO –92, NO SOCKET)

TO –92

25 50 75 100 125

TIME – sec

150 175

V

= 5V

S

R

10k

LOAD =

200 225 250 275 300

TPC 20. TMP03 Open-Collector Output Voltage

TPC 23. Thermal Response Time in Still Air

vs. Temperature

140

TRANSITION FROM 100C OIL BATH

120

100

80

60

40

TIME CONSTANT – sec

REV. A

20

0

0

TPC 21. Thermal Time Constant in Forced Air

TO FORCED 25C AIR

TO –92 - WITH SOCKET

TO –92 - NO SOCKET

100

200 300

AIR VELOCITY – FPM

SOIC - NO SOCKET

400

500

V+ = 5V

R

LOAD

= 10k

600 700

TPC 24. Thermal Response Time in Stirred Oil Bath

–9–

TMP03/TMP04

APPLICATIONS INFORMATION

Supply Bypassing

Precision analog products, such as the TMP03, require a wellfiltered power source. Since the TMP03 operate from a single 5

V supply, it seems convenient to simply tap into the digital logic

power supply. Unfortunately, the logic supply is often a switchmode design, which generates noise in the 20 kHz to 1 MHz

range. In addition, fast logic gates can generate glitches hundred

of millivolts in amplitude due to wiring resistance and inductance.

If possible, the TMP03 should be powered directly from the

system power supply. This arrangement, shown in Figure 3, will

isolate the analog section from the logic switching transients. Even

if a separate power supply trace is not available, however, generous supply bypassing will reduce supply-line induced errors.

Local supply bypassing consisting of a 10 µF tantalum electro-

lytic in parallel with a 0.1 µF ceramic capacitor is recommended

(Figure 4a).

TTL/CMOS

LOGIC

CIRCUITS

5V

POWER SUPPLY

+

10F

TANT

0.1F

TMP03/

TMP04

Figure 3. Use Separate Traces to Reduce Power Supply

Noise

5V

10F 0.1F

TMP03/

TMP04

5V

V+

GND

D

OUT

10F 0.1F

TMP03/

TMP04

GND

50

V+

D

OUT

a. b.

Figure 4. Recommended Supply Bypassing for the

TMP03

The quiescent power supply current requirement of the TMP03

is typically only 900 µA. The supply current will not change

appreciably when driving a light load (such as a CMOS gate), so

a simple RC filter can be added to further reduce power supply

noise (Figure 4b).

TMP03 Output Configurations

The TMP03 (Figure 5a) has an open-collector NPN output

which is suitable for driving a high current load, such as an

opto-isolator. Since the output source current is set by the pullup resistor, output capacitance should be minimized in TMP03

applications. Otherwise, unequal rise and fall times will skew the

pulsewidth and introduce measurement errors. The NPN transistor has a breakdown voltage of 18 V.

TMP03

D

OUT

TMP04

V+

D

OUT

a. b.

Figure 5. TMP03 Digital Output Structure

The TMP04 has a “totem-pole” CMOS output (Figure 5b) and

provides rail-to-rail output drive for logic interfaces. The rise

and fall times of the TMP04 output are closely matched, so that

errors caused by capacitive loading are minimized. If load capacitance is large, for example when driving a long cable, an

external buffer may improve accuracy. See the “Remote Temperature Measurement” section of this data sheet for

suggestions.

Interfacing the TMP03 to Low Voltage Logic

The TMP03’s open-collector output is ideal for driving logic

gates that operate from low supply voltages, such as 3.3 V. As

shown in Figure 6, a pull-up resistor is connected from the low

voltage logic supply (2.9 V, 3 V, etc.) to the TMP03 output.

Current through the pull-up resistor should be limited to about

1 mA, which will maintain an output LOW logic level of

<200 mV.

TMP03

5V

V+

D

GND

OUT

3.3V

3.3k

TO LOW VOLTAGE

LOGIC GATE INPUT

Figure 6. Interfacing to Low Voltage Logic

Remote Temperature Measurement

When measuring a temperature in situations where high common-mode voltages exist, an opto-isolator can be used to isolate

the output (Figure 7a). The TMP03 is recommended in this

application because its open-collector NPN transistor has a

higher current sink capability than the CMOS output of the

TMP04. To maintain the integrity of the measurement, the

opto-isolator must have relatively equal turn-on and turn-off

times. Some Darlington opto-isolators, such as the 4N32, have

a turn-off time that is much longer than their turn-on time. In

this case, the T1 time will be longer than T2, and an erroneous

reading will result. A PNP transistor can be used to provide

greater current drive to the opto-isolator (Figure 7b). An optoisolator with an integral logic gate output, such as the H11L1

from Quality Technology, can also be used (Figure 8).

–10–

REV. A

TMP03/TMP04

5V

V+

TMP03

GND

620

OPTO-COUPLER

D

OUT

V

LOGIC

4.7k

a.

5V

10k

V

LOGIC

430

V+

TMP03

GND

2N2907

OPTO-COUPLER

270

4.3k

D

OUT

b.

Figure 7. Optically Isolating the Digital Output

5V

5V

V+

TMP03

GND

680

4.7k

D

OUT

H11L1

Figure 8. An Opto-Isolator with Schmitt Trigger Logic

Gate Improves Output Rise and Fall Times

The TMP03 and TMP04 are superior to analog-output transducers for measuring temperature at remote locations, because

the digital output provides better noise immunity than an analog

signal. When measuring temperature at a remote location, the

ratio of the output pulses must be maintained. To maintain the

integrity of the pulsewidth, an external buffer can be added. For

example, adding a differential line driver such as the ADM485

permits precise temperature measurements at distances up to

4000 ft. (Figure 9). The ADM485 driver and receiver skew is

only 5 ns maximum, so the TMP04 duty cycle is not degraded.

Up to 32 ADM485s can be multiplexed onto one line by providing additional decoding.

As previously mentioned, the digital output of the TMP03

provides excellent noise immunity in remote measurement applications. The user should be aware, however, that heat from an

external cable can be conducted back to the TMP03. This heat

conduction through the connecting wires can influence the

temperature of the TMP03. If large temperature differences

exist within the sensor environment, an opto-isolator, level

shifter or other thermal barrier can be used to minimize measurement errors.

5V

V+

D

TMP04

GND

OUT

NC

5V

DE

V

CC

DI

B

A

ADM485

Figure 9. A Differential Line Driver for Remote Temperature Measurement

Microcomputer Interfaces

The TMP03 output is easily decoded with a microcomputer.

The microcomputer simply measures the T1 and T2 periods in

software or hardware, and then calculates the temperature using

the equation in the Output Encoding section of this data sheet.

Since the TMP03’s output is ratiometric, precise control of the

counting frequency is not required. The only timing requirements are that the clock frequency be high enough to provide

the required measurement resolution (see the Output Encoding

section for details) and that the clock source be stable. The

ratiometric output of the TMP03 is an advantage because the

microcomputer’s crystal clock frequency is often dictated by the

serial baud rate or other timing considerations.

Pulsewidth timing is usually done with the microcomputer’s

on-chip timer. A typical example, using the 80C51, is shown in

Figure 10. This circuit requires only one input pin on the microcomputer, which highlights the efficiency of the TMP04’s

pulsewidth output format. Traditional serial input protocols,

with data line, clock and chip select, usually require three or

more I/O pins.

5V

V+

D

TMP04

GND

OUT

INPUT

PORT 1.0

MICROCOMPUTER

TIMER 0

(16-BITS)

80C51

TIMER 1

(16-BITS)

OSC

12

TMOD REGISTER

TIMER 0 TIMER 1

TCON REGISTER

TIMER 0 TIMER 1

Figure 10. A TMP04 Interface to the 80C51 Microcomputer

The 80C51 has two 16-bit timers. The clock source for the timers

is the crystal oscillator frequency divided by 12. Thus, a crystal

frequency of 12 MHz or greater will provide resolution of 1 µs

or less.

The 80C51 timers are controlled by two dedicated registers. The

TMOD register controls the timer mode of operation, while

TCON controls the start and stop times. Both the TMOD and

TCON registers must be set to start the timer.

REV. A

–11–

TMP03/TMP04

Software for the interface is shown in Listing 1. The program

monitors the TMP04 output, and turns the counters on and off

to measure the duty cycle. The time that the output is high is mea-

Listing 1. An 80C51 Software Routine for the TMP04

;

; Test of a TMP04 interface to the 8051,

; using timer 0 and timer 1 to measure the duty cycle

;

; This program has three steps:

; 1. Clear the timer registers, then wait for a low-to; high transition on input P1.0 (which is connected

; to the output of the TMP04).

; 2. When P1.0 goes high, timer 0 starts. The program

; then loops, testing P1.0.

; 3. When P1.0 goes low, timer 0 stops & timer 1 starts. The

; program loops until P1.0 goes low, when timer 1 stops

; and the TMP04’s T1 and T2 values are stored in Special

; Function registers 8AH through 8DH (TL0 through TH1).

;

;

; Primary controls

$MOD51

$TITLE(TMP04 Interface, Using T0 and T1)

$PAGEWIDTH(80)

$DEBUG

$OBJECT

;

; Variable declarations

;

PORT1 DATA 90H ;SFR register for port 1

;TCON DATA 88H ;timer control

;TMOD DATA 89H ;timer mode

;TH0 DATA 8CH ;timer 0 hi byte

;TH1 DATA 8DH ;timer 1 hi byte

;TL0 DATA 8AH ;timer 0 lo byte

;TL1 DATA 8BH ;timer 1 low byte

;

;

ORG 100H ;arbitrary start

;

READ_TMP04: MOV A,#00 ;clear the

MOV TH0,A ; counters

MOV TH1,A ; first

MOV TL0,A ;

MOV TL1,A ;

WAIT_LO: JB PORT1.0,WAIT_LO ;wait for TMP04 output to go low

MOV A,#11H ;get ready to start timer0

MOV TMOD,A

WAIT_HI: JNB PORT1.0,WAIT_HI ;wait for output to go high

;

;Timer 0 runs while TMP04 output is high

;

SETB TCON.4 ;start timer 0

WAITTIMER0: JB PORT1.0,WAITTIMER0

CLR TCON.4 ;shut off timer 0

;

;Timer 1 runs while TMP04 output is low

;

SETB TCON.6 ;start timer 1

WAITTIMER1: JNB PORT1.0,WAITTIMER1

CLR TCON.6 ;stop timer 1

MOV A,#0H ;get ready to disable timers

MOV TMOD,A

RET

END

sured by Timer 0, and the time that the output is low is measured

by Timer 1. When the routine finishes, the results are available

in Special Function Registers (SFRs) 08AH through 08DH.

–12–

REV. A

TMP03/TMP04

When the READ_TMP04 routine is called, the counter registers

are cleared. The program sets the counters to their 16-bit mode,

and then waits for the TMP04 output to go high. When the

input port returns a logic high level, Timer 0 starts. The timer

continues to run while the program monitors the input port.

When the TMP04 output goes low, Timer 0 stops and Timer 1

starts. Timer 1 runs until the TMP04 output goes high, at which

time the TMP04 interface is complete. When the subroutine

ends, the timer values are stored in their respective SFRs and

the TMP04’s temperature can be calculated in software.

Since the 80C51 operates asynchronously to the TMP04, there

is a delay between the TMP04 output transition and the start

of the timer. This delay can vary between 0 µs and the execution

time of the instruction that recognized the transition. The

80C51’s “jump on port.bit” instructions (JB and JNB) require

24 clock cycles for execution. With a 12 MHz clock, this produces an uncertainty of 2 µs (24 clock cycles/12 MHz) at each

transition of the TMP04 output. The worst case condition occurs

when T1 is 4 µs shorter than the actual value and T2 is 4 µs

longer. For a 25°C reading (“room temperature”), the nominal

error caused by the 2 µs delay is only about ±0.15°C.

The TMP04 is also easily interfaced to digital signal processors

(DSPs), such as the ADSP210x series. Again, only a single I/O

pin is required for the interface (Figure 11).

5V

V+

D

TMP04

GND

OUT

FI (FLAG IN)

16-BIT DOWN

COUNTER

ADSP-210x

TIMER

ENABLE

10MHz

CLOCK

OSCILLATOR

n

Figure 11. Interfacing the TMP04 to the ADSP-210x Digital

Signal Processor

The ADSP2101 only has one counter, so the interface software

differs somewhat from the 80C51 example. The lack of two

counters is not a limitation, however, because the DSP architecture provides very high execution speed. The ADSP-2101

executes one instruction for each clock cycle, versus one instruction for twelve clock cycles in the 80C51, so the ADSP-2101

actually produces a more accurate conversion while using a

lower oscillator frequency.

The timer of the ADSP2101 is implemented as a down counter.

When enabled by means of a software instruction, the counter is

decremented at the clock rate divided by a programmable prescaler. Loading the value n – 1 into the prescaler register will

divide the crystal oscillator frequency by n. For the circuit of

Figure 11, therefore, loading 4 into the prescaler will divide the

10 MHz crystal oscillator by 5 and thereby decrement the counter

at a 2 MHz rate. The TMP04 output is ratiometric, of course,

so the exact clock frequency is not important.

A typical software routine for interfacing the TMP04 to the

ADSP2101 is shown in Listing 2. The program begins by initializing the prescaler and loading the counter with 0FFFF

. The

H

ADSP2101 monitors the FI flag input to establish the falling

edge of the TMP04 output, and starts the counter. When the

TMP04 output goes high, the counter is stopped. The

counter value is then subtracted from 0FFFFH to obtain the

actual number of counts, and the count is saved. Then the

counter is reloaded and runs until the TMP04 output goes low.

Finally, the TMP04 pulsewidths are converted to temperature

using the scale factor of Equation 1.

Some applications may require a hardware interface for the

TMP04. One such application could be to monitor the temperature of a high power microprocessor. The TMP04 interface

would be included as part of the system ASIC, so that the microprocessor would not be burdened with the overhead of timing

the output pulsewidths.

A typical hardware interface for the TMP04 is shown in Figure

12. The circuit measures the output pulsewidths with a resolution of ±1 µs. The TMP04 T1 and T2 periods are measured

with two cascaded 74HC4520 8-bit counters. The counters,

accumulating clock pulses from the 1 MHz external oscillator,

have a maximum period of 65 ms.

The logic interface is straightforward. On both the rising and

falling edges of the TMP04 output, an exclusive-or gate generates a pulse. This pulse triggers one half of a 74HC4538 dual

one-shot. The pulse from the one-shot is ANDed with the

TMP04 output polarity to store the counter contents in the

appropriate output registers. The falling edge of this pulse also

triggers the second one-shot, which generates a reset pulse for

the counters. After the reset pulse, the counters will begin to

count the next TMP04 output phase.

As previously mentioned, the counters have a maximum period

of 65 ms with a 1 MHz clock input. However, the TMP04’s T1

and T2 times will never exceed 32 ms. Therefore, the most

significant bit (MSB) of counter #2 will not go high in normal operation, and can be used to warn the system that an

error condition (such as a broken connection to the TMP04)

exists.

The circuit of Figure 12 will latch and save both the T1 and T2

times simultaneously. This makes the circuit suitable for debugging or test purposes as well as for a general purpose hardware

interface. In a typical ASIC application, of course, one set of

latches could be eliminated if the latch contents, and the output

polarity, were read before the next phase reversal of the TMP04.

REV. A

–13–

TMP03/TMP04

Listing 2. Software Routine for the TMP04-to-ADSP-210x Interface

;

{ ADSP-21XX Temperature Measurement Routine TEMPERAT.DSP

Altered Registers: ax0, ay0, af, ar,

si, sr0,

my0, mr0, mr1, mr2.

Return value: ar —> temperature result in 14.2 format

Computation time: 2 * TMP04 output period

}

.MODULE/RAM/BOOT=0 TEMPERAT; { Beginning TEMPERAT Program }

.ENTRY TEMPMEAS; { Entry point of this subroutine }

.CONST PRESCALER=4;

.CONST TIMFULSCALE=0Xffff;

TEMPMEAS: si=PRESCALER; { For timer prescaler }

sr0=TIMFULSCALE; { Timer counter full scale }

dm(0x3FFB)=si; { Timer Prescaler set up to 5 }

si=TIMFULSCALE; { CLKin=10MHz,Timer Period=32.768ms }

dm(0x3FFC)=si; { Timer Counter Register to 65535 }

dm(0x3FFD)=si; { Timer Period Register to 65535 }

imask=0x01; { Unmask Interrupt timer }

TEST1: if not fi jump TEST1; { Check for FI=1 }

TEST0: if fi jump TEST0; { Check for FI=0 to locate transition }

ena timer; { Enable timer, count at a 500ns rate }

COUNT2: if not fi jump COUNT2; { Check for FI=1 to stop count }

dis timer;

ay0=dm(0x3FFC); { Save counter=T2 in ALU register }

ar=sr0-ay0;

ax0=ar;

dm(0x3FFC)=si; { Reload counter at full scale }

ena timer;

COUNT1: if fi jump COUNT1; { Check for FI=0 to stop count }

dis timer;

ay0=dm(0x3FFC); { Save counter=T1 in ALU register }

ar=sr0-ay0;

my0=400;

mr=ar*my0(uu); { mr=400*T1 }

ay0=mr0; { af=MSW of dividend, ay0=LSW }

ar=mr1; af=pass ar; { ax0=16-bit divisor }

COMPUTE: astat=0; { To clear AQ flag }

divq ax0; divq ax0; { Division 400*T1/T2 }

divq ax0; divq ax0; { with 0.3 < T1/T2 < 0.7 }

divq ax0; divq ax0;

divq ax0; divq ax0;

divq ax0; divq ax0;

divq ax0; divq ax0;

divq ax0; divq ax0;

divq ax0; divq ax0;

divq ax0; divq ax0; { Result in ay0 }

ax0=0x03AC; { ax0=235*4 }

ar=ax0-ay0; { ar=235-400*T1/T2, result in øC }

rts; { format 14.2 }

.ENDMOD; { End of the subprogram }

–14–

REV. A

TMP03/TMP04

T1 DATA (MICROSECONDS) T2 DATA (MICROSECONDS)

1

OUT

10

GND

D8

15

20pF

15 14

T1 T2

GND

5V

2 5 6 9 12 15 16 19

Q1 Q2 Q3 Q4 Q5 Q6 Q7 Q8

20

V

CC

11

LE

D1 D2 D3D4D5D6D7

3 4 7 8 13 14 17 18

3.9k

5V

10

Q

9

Q

NC

8

74HC373

5V

2 5 6 9 12 15 16 19

Q1 Q2 Q3 Q4 Q5 Q6 Q7 Q8

20

V

CC

11

1

5V

2

3

1

3

2

74HC08

4

6

5

5V

16

1MHZ

CLOCK

5V

0.1F

10F

74HC373

LE

D1 D2 D3D4D5D6D7

3 4 7 8 13 14 17 18

3 4 5 6 11 12 13 14

Q0 Q1 Q2 Q3 Q0 Q1 Q2 Q3

V

CC

2

74HC4520 #1

EN

1

CLK

CLK GND RESET RESET

815

9

74HC86

4

5

10k

10

EN

10pF

OUT

GND

7

6

5V

5V

2 5 6 9 12 15 16 19

Q1 Q2 Q3 Q4 Q5 Q6 Q7 Q8

20

1

10

D8

4

5

3

V

CC

11

LE

D1 D2 D3D4D5D6D7

3 4 7 8 13 14 17 18

3456 11121314

5V

Q0 Q1 Q2 Q3 Q0 Q1 Q2 Q3

16

V

CC

2

EN

CLK

17

20pF

1k

T1 T2

V

A

CC

GND

Q

Q

8

B

CLR

74HC373

10

EN

74HC4520 #2

CLK GND RESET RESET

8

9

5V

NC

12

A

11

B

13

CLR

16

6

7

74HC4538

OUT

GND

5V

2 5 6 9 12 15 16 19

Q1 Q2 Q3 Q4 Q5 Q6 Q7 Q8

20

1

10

D8

V

CC

11

74HC373

LE

D1 D2 D3D4D5D6D7

3 4 7 8 13 14 17 18

OUT

GND

1

10

D8

V+

D

OUT

TMP04

GND

Figure 12. A Hardware Interface for the TMP04

Monitoring Electronic Equipment

The TMP03 are ideal for monitoring the thermal environment

within electronic equipment. For example, the surface-mounted

package will accurately reflect the exact thermal conditions which

affect nearby integrated circuits. The TO-92 package, on the

other hand, can be mounted above the surface of the board, to

measure the temperature of the air flowing over the board.

The TMP03 and TMP04 measure and convert the temperature

at the surface of their own semiconductor chip. When the TMP03

are used to measure the temperature of a nearby heat source,

the thermal impedance between the heat source and the TMP03

must be considered. Often, a thermocouple or other temperature sensor is used to measure the temperature of the source

while the TMP03 temperature is monitored by measuring T1

and T2. Once the thermal impedance is determined, the temperature of the heat source can be inferred from the TMP03

output.

One example of using the TMP04 to monitor a high power

dissipation microprocessor or other IC is shown in Figure 13.

The TMP04, in a surface mount package, is mounted directly

beneath the microprocessor’s pin grid array (PGA) package. In

a typical application, the TMP04’s output would be connected

to an ASIC where the pulsewidth would be measured (see the

Hardware Interface section of this data sheet for a typical interface schematic). The TMP04 pulse output provides a significant

REV. A

–15–

TMP03/TMP04

advantage in this application because it produces a linear temperature output while needing only one I/O pin and without

requiring an A/D converter.

FAST MICROPROCESSOR, DSP, ETC., IN PGA PACKAGE

PGA SOCKET

TMP04 IN SURFACE MOUNT PACKAGE

PC BOARD

Figure 13. Monitoring the Temperature of a High Power

Microprocessor Improves System Reliability

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

Thermal Response Time

The time required for a temperature sensor to settle to a specified accuracy is a function of the thermal mass of, and the

thermal conductivity between, the sensor and the object being

sensed. Thermal mass is often considered equivalent to capacitance. Thermal conductivity is commonly specified using the

symbol Θ, and can be thought of as thermal resistance. It is

commonly specified in units of degrees per watt of power transferred across the thermal joint. Thus, the time required for the

TMP03 to settle to the desired accuracy is dependent on the

package selected, the thermal contact established in that particular application, and the equivalent power of the heat source.

In most applications, the settling time is probably best determined empirically. The TMP03 output operates at a nominal

frequency of 35 Hz at 25°C, so the minimum settling time resolution is 27 ms.

C00334–0–1/02(A)

SEATING

PLANE

0.105 (2.66)

0.095 (2.42)

0.105 (2.66)

0.080 (2.42)

0.105 (2.66)

0.080 (2.42)

3-Pin TO-92

0.135

(3.43)

MIN

0.500

(12.70)

MIN

BOTTOM

VIEW

12 3

0.205 (5.20)

0.175 (4.96)

0.210 (5.33)

0.170 (4.38)

0.050

(1.27)

MAX

0.019 (0.482)

0.016 (0.407)

SQUARE

0.055 (1.39)

0.045 (1.15)

0.165 (4.19)

0.125 (3.94)

0.1574 (4.00)

0.1497 (3.80)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

SEATING

0.006 (0.15)

0.002 (0.05)

SEATING

PLANE

0.1968 (5.00)

0.1890 (4.80)

85

0.0500 (1.27)

PLANE

0.122 (3.10)

0.114 (2.90)

8

PIN 1

0.0256 (0.65)

0.0118 (0.30)

0.0075 (0.19)

8-Pin SOIC (SO-8)

0.2440 (6.20)

0.2284 (5.80)

41

BSC

0.0192 (0.49)

0.0138 (0.35)

0.0688 (1.75)

0.0532 (1.35)

0.0098 (0.25)

0.0075 (0.19)

8-Pin TSSOP (RU-8)

5

0.177 (4.50)

0.169 (4.30)

0.256 (6.50)

41

BSC

0.246 (6.25)

0.0433

(1.10)

MAX

0.0079 (0.20)

0.0035 (0.090)

0.0196 (0.50)

0.0099 (0.25)

8ⴗ

0.0500 (1.27)

0ⴗ

0.0160 (0.41)

ⴛ 45ⴗ

PRINTED IN U.S.A.

8ⴗ

0ⴗ

0.028 (0.70)

0.020 (0.50)

–16–

REV. A

Loading...

Loading...