Page 1

Precision Micropower

∆∑ RMS-to-DC Converter

FeaTures DescripTion

n

Simple to Use, Requires One Capacitor

n

True RMS DC Conversion Using DS Technology

n

High Accuracy:

0.1% Gain Accuracy from 50Hz to 1kHz

0.25% Total Error from 50Hz to 1kHz

n

High Linearity:

0.02% Linearity Allows Simple System Calibration

n

Low Supply Current:

155µA Typ, 170µA Max

n

Ultralow Shutdown Current:

0.1µ A

n

Constant Bandwidth:

Independent of Input Voltage

800kHz –3dB, 6kHz ±1%

n

Flexible Supplies:

2.7V to 5.5V Single Supply

Up to ±5.5V Dual Supply

n

Flexible Inputs:

Differential or Single-Ended

Rail-to-Rail Common Mode Voltage Range

Up to 1V

n

Flexible Output:

Differential Voltage

PEAK

Rail-to-Rail Output

Separate Output Reference Pin Allows Level Shifting

n

Wide Temperature Range:

–55°C to 125°C

n

Small Size:

Space Saving 8-Pin MSOP Package

The LTC®1966 is a true RMS-to-DC converter that utilizes

an innovative patented DS computational technique. The

internal delta sigma circuitry of the LTC1966 makes it simpler to use, more accurate, lower power and dramatically

more flexible than conventional log antilog RMS-to-DC

converters.

The LTC1966 accepts single-ended or differential input

signals (for EMI/RFI rejection) and supports crest factors up

to 4. Common mode input range is rail-to-rail. Differential

input range is 1V

PEAK

Unlike previously available RMS-to-DC converters, the

superior linearity of the LTC1966 allows hassle free system

calibration at any input voltage.

The LTC1966 also has a rail-to-rail output with a separate

output reference pin providing flexible level shifting. The

LTC1966 operates on a single power supply from 2.7V to

5.5V or dual supplies up to ±5.5V. A low power shutdown

mode reduces supply current to 0.5µA.

The LTC1966 is insensitive to PC board soldering and

stresses, as well as operating temperature. The LTC1966

is packaged in the space saving MSOP package which is

ideal for portable applications.

applicaTions

n

True RMS Digital Multimeters and Panel Meters

n

True RMS AC + DC Measurements

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks and

No Latency DS is a trademark of Linear Technology Corporation. All other trademarks are the

property of their respective owners. Protected by U.S. Patents including 6359576, 6362677,

6516291 and 6651036.

LTC1966

, and offers unprecedented linearity.

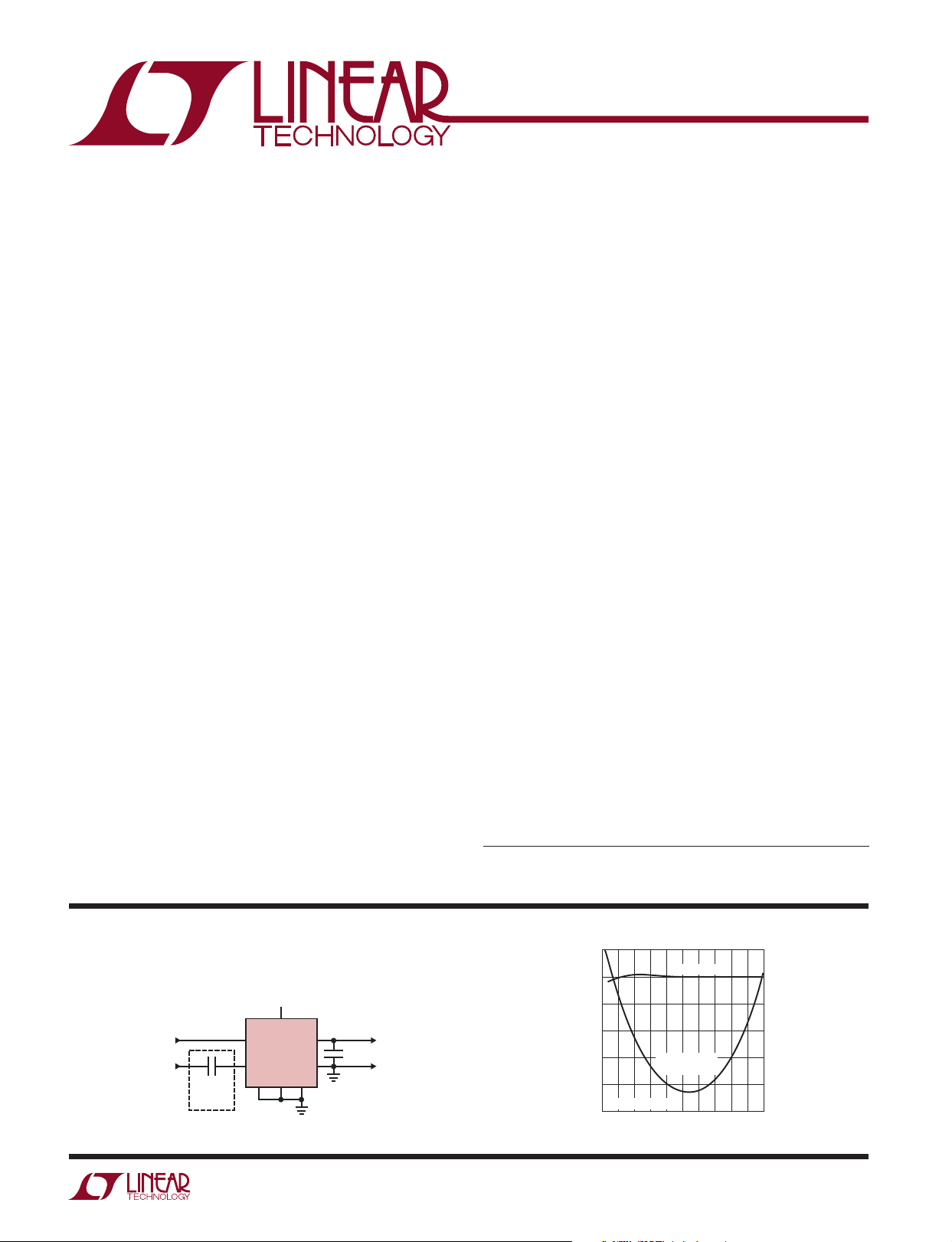

Typical applicaTion

Single Supply RMS-to-DC Converter

2.7V TO 5.5V

V

DD

OUTPUT

DIFFERENTIAL

INPUT

0.1µF

OPT. AC

COUPLING

IN1

LTC1966

OUT RTN

IN2

EN GND

V

SS

C

AVE

1µF

1966 TA01

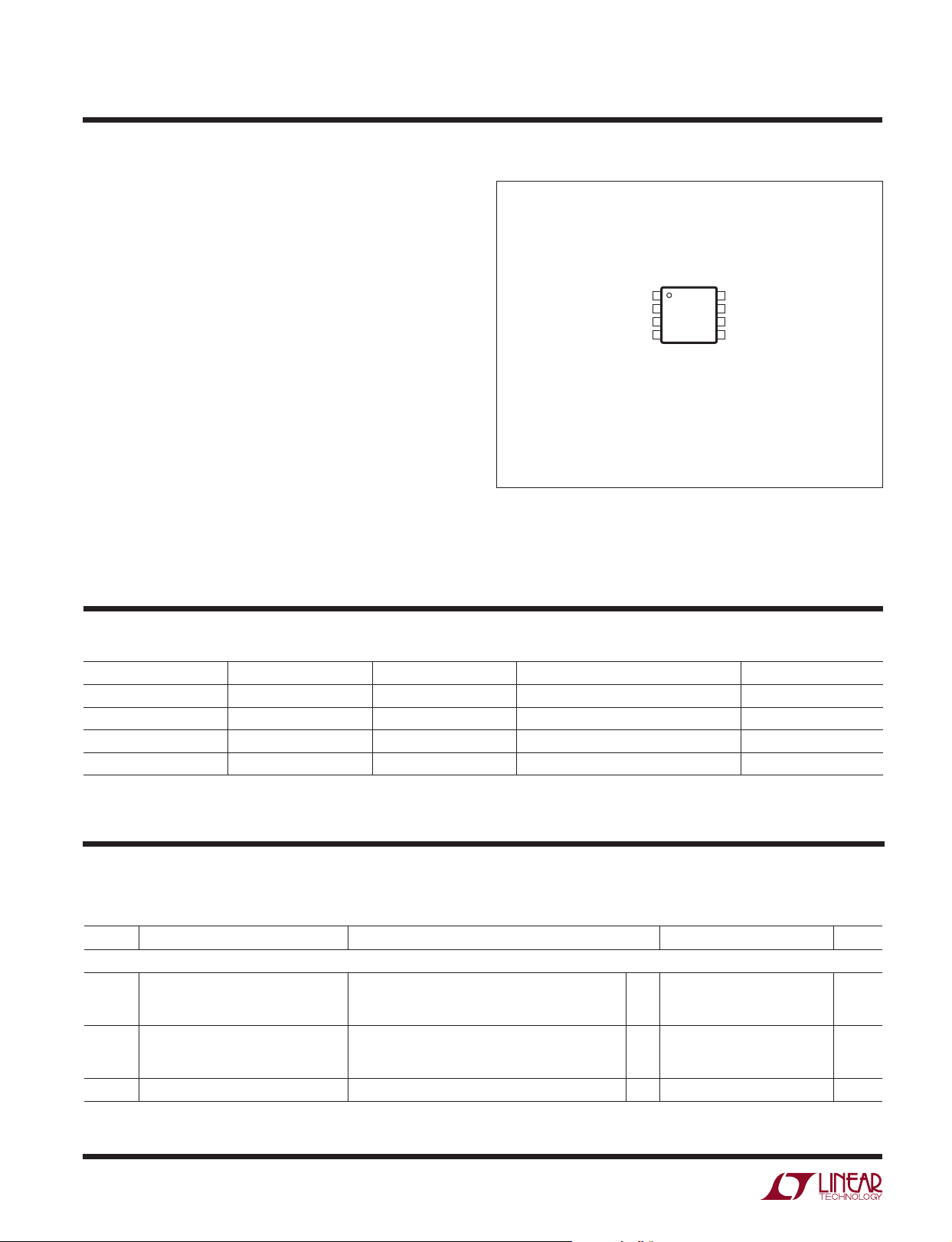

Quantum Leap in Linearity Performance

)

0.2

RMS

0

mV AC

IN

–0.2

mV DC – V

–0.4

+

V

OUT

–

OUT

–0.6

–0.8

60Hz SINEWAVES

–1.0

LINEARITY ERROR (V

100 200 300 400

LTC1966, ∆∑

CONVENTIONAL

LOG/ANTILOG

VIN (mV AC

RMS

1966 TA01b

500500 150 250 350 450

1966fb

)

1

Page 2

LTC1966

(Note 1)

Supply Voltage

to GND ............................................. – 0.3V to 7V

V

DD

to VSS ............................................ –0.3V to 12V

V

DD

to GND ............................................. –7V to 0.3V

V

SS

Input Currents (Note 2) ...................................... ± 10mA

Output Current (Note 3) ..................................... ± 10mA

ENABLE Voltage ....................... V

OUT RTN Voltage ............................... V

Operating Temperature Range (Note 4)

LTC1966C/LTC1966I ............................ –40°C to 85°C

LTC1966H .......................................... –40°C to 125°C

LTC1966MP ....................................... –55°C to 125°C

Specified Temperature Range (Note 5)

LTC1966C/LTC1966I ............................ –40°C to 85°C

LTC1966H .......................................... –40°C to 125°C

LTC1966MP ....................................... –55°C to 125°C

Maximum Junction Temperature ......................... 150°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec) .................. 300°C

– 0.3V to VSS + 12V

SS

– 0.3V to V

SS

DD

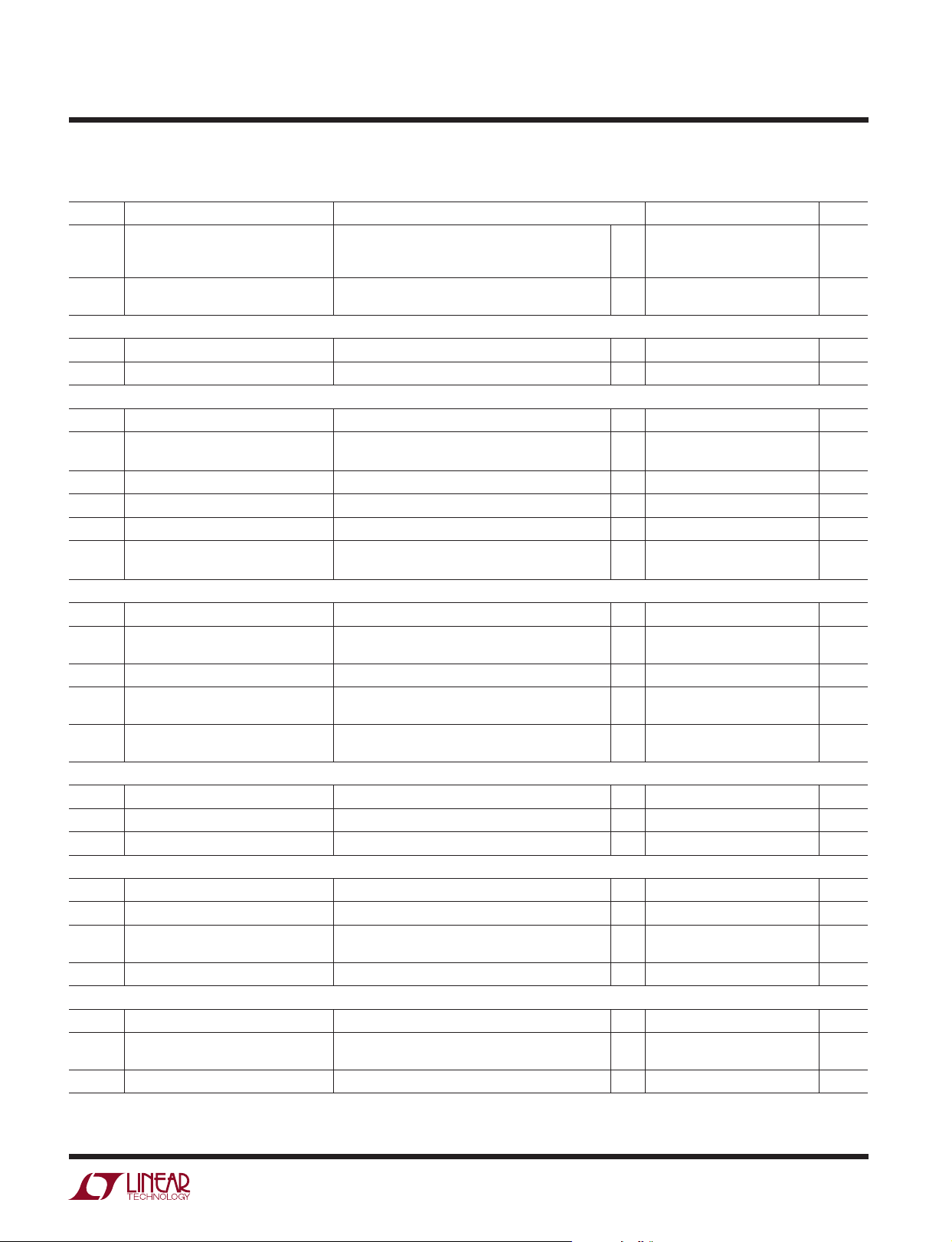

pin conFiguraTionabsoluTe MaxiMuM raTings

TOP VIEW

GND

1

IN1

2

IN2

3

V

4

SS

MS8 PACKAGE

8-LEAD PLASTIC MSOP

= 150°C, θJA = 220°C/W

T

JMAX

8

ENABLE

7

V

DD

6

OUT RTN

5

V

OUT

orDer inForMaTion

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC1966CMS8#PBF LTC1966CMS8#TRPBF LTT G 8-Lead Plastic MSOP 0°C to 70°C

LTC1966IMS8#PBF LTC1966IMS8#TRPBF LTT H 8-Lead Plastic MSOP –40°C to 85°C

LTC1966HMS8#PBF LTC1966HMS8#TRPBF LTT G 8-Lead Plastic MSOP –40°C to 125°C

LTC1966MPMS8#PBF LTC1966MPMS8#TRPBF LTT G 8-Lead Plastic MSOP –55°C to 125°C

Consult LTC Marketing for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifications, go to: http://www.linear.com/tapeandreel/

elecTrical characTerisTics

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VDD = 5V, VSS = –5V, V

V

= 0.5V unless otherwise noted.

ENABLE

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Conversion Accuracy

G

V

LIN

ERR

OOS

Conversion Gain Error 50Hz to 1kHz Input (Notes 6, 7)

Output Offset Voltage (Notes 6, 7)

Linearity Error 50mV to 350mV (Notes 7, 8)

ERR

LTC1966C, LTC1966I

LTC1966H, LTC1966MP

LTC1966C, LTC1966I

LTC1966H, LTC1966MP

OUTRTN

= 0V, C

l

l

l

l

l

= 10µF, VIN = 200mV

AVE

±0.1 ±0.3

0.1

0.02 0.15 %

±0.4

±0.7

0.2

0.4

0.6

RMS

,

mV

mV

mV

%

%

%

2

1966fb

Page 3

LTC1966

elecTrical characTerisTics

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VDD = 5V, VSS = –5V, V

V

= 0.5V unless otherwise noted.

ENABLE

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

PSRR Power Supply Rejection (Note 9)

V

IOS

Input Offset Voltage (Notes 6, 7, 10)

Accuracy vs Crest Factor (CF)

CF = 4 60Hz Fundamental, 200mV

CF = 5 60Hz Fundamental, 200mV

Input Characteristics

I

VR

Z

IN

Input Voltage Range (Note 14)

Input Impedance Average, Differential (Note 12)

CMRRI Input Common Mode Rejection (Note 13)

V

V

IMAX

IMIN

Maximum Input Swing Accuracy = 1% (Note 14)

Minimum RMS Input

PSRRI Power Supply Rejection V

Output Characteristics

OVR Output Voltage Range

Z

OUT

Output Impedance V

CMRRO Output Common Mode Rejection (Note 13)

V

OMAX

Maximum Differential Output Swing Accuracy = 2%, DC Input (Note 14)

PSRRO Power Supply Rejection V

Frequency Response

f

1P

f

10P

f

–3dB

1% Additional Error (Note 15) C

10% Additional Error (Note 15) C

±3dB Frequency (Note 15) 800 kHz

Power Supplies

V

DD

V

SS

I

DD

I

SS

Positive Supply Voltage

Negative Supply Voltage (Note 16)

Positive Supply Current IN1 = 20mV, IN2 = 0V

Negative Supply Current IN1 = 20mV, IN2 = 0V

Shutdown Characteristics

I

DDS

I

SSS

I

IH

Supply Currents V

Supply Currents V

ENABLE Pin Current High V

LTC1966C, LTC1966I

LTC1966H, LTC1966MP

(Note 11)

RMS

(Note 11)

RMS

Average, Common Mode (Note 12)

Supply (Note 9)

DD

V

Supply (Note 9)

SS

= 0.5V (Note 12)

ENABLE

V

= 4.5V

ENABLE

Supply (Note 9)

DD

V

Supply (Note 9)

SS

= 10µF 6 kHz

AVE

= 10µF 20 kHz

AVE

IN1 = 200mV, IN2 = 0V

= 4.5V

ENABLE

= 4.5V

ENABLE

LTC1966H, LTC1966MP

= 4.5V

ENABLE

OUTRTN

= 0V, C

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

= 10µF, VIN = 200mV

AVE

RMS

,

0.02 0.15

0.20

0.3

0.02 0.8

1.0

–1 2 mV

–20 30 mV

V

SS

8

100

V

DD

MΩ

MΩ

7 200 µV/V

1 1.05 V

5 mV

250

120

V

SS

75 85

600

300

V

DD

µV/V

µV/V

95 kΩ

30

16 200 µV/V

1.0

1.05 V

0.9

250 501000

500

µV/V

µV/V

2.7 5.5 V

–5.5 0 V

155

170 µA

158

12 20 µA

0.5 10 µA

–1

–0.1 µA

–2

–0.3 –0.05 µA

%V

%V

%V

mV

mV

kΩ

V

V

V

µA

µA

1966fb

3

Page 4

LTC1966

elecTrical characTerisTics

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VDD = 5V, VSS = –5V, V

V

= 0.5V unless otherwise noted.

ENABLE

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

IL

V

TH

V

HYS

ENABLE Pin Current Low V

ENABLE Threshold Voltage VDD = 5V, VSS = –5V

ENABLE Threshold Hysteresis 0.1 V

= 0.5V

ENABLE

LTC1966H, LTC1966MP

V

= 5V, VSS = GND

DD

V

= 2.7V, VSS = GND

DD

OUTRTN

= 0V, C

l

l

= 10µF, VIN = 200mV

AVE

–2

–1 –0.1 µA

–10

2.4

2.1

1.3

RMS

,

µA

V

V

V

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The inputs (IN1, IN2) are protected by shunt diodes to V

V

. If the inputs are driven beyond the rails, the current should be limited

DD

SS

and

to less than 10mA.

Note 3: The LTC1966 output (V

) is high impedance and can be

OUT

overdriven, either sinking or sourcing current, to the limits stated.

Note 4: The LTC1966C/LTC1966I are guaranteed functional over

the operating temperature range of –40°C to 85°C. The LTC1966H/

LTC1966MP are guaranteed functional over the operating temperature

range of –55°C to 125°C.

Note 5: The LTC1966C is guaranteed to meet specified performance from

0°C to 70°C. The LTC1966C is designed, characterized and expected to

meet specified performance from –40°C to 85°C but is not tested nor

QA sampled at these temperatures. The LTC1966I is guaranteed to meet

specified performance from –40°C to 85°C. The LTC1966H is guaranteed

to meet specified performance from –40°C to 125°C. The LTC1966MP is

guaranteed to meet specified performance from –55°C to 125°C.

Note 6: High speed automatic testing cannot be performed with

C

= 10µF. The LTC1966 is 100% tested with C

AVE

= 22nF. Correlation

AVE

tests have shown that the performance limits above can be guaranteed

with the additional testing being performed to guarantee proper operation

of all the internal circuitry.

Note 7: High speed automatic testing cannot be performed with 60Hz

inputs. The LTC1966 is 100% tested with DC and 10kHz input signals.

Measurements with DC inputs from 50mV to 350mV are used to calculate

the four parameters: G

ERR

, V

OOS

, V

and linearity error. Correlation tests

IOS

have shown that the performance limits above can be guaranteed with the

additional testing being performed to guarantee proper operation of all

internal circuitry.

Note 8: The LTC1966 is inherently very linear. Unlike older log/antilog

circuits, its behavior is the same with DC and AC inputs, and DC inputs are

used for high speed testing.

Note 9: The power supply rejections of the LTC1966 are measured with DC

inputs from 50mV to 350mV. The change in accuracy from V

V

= 5.5V with VSS = 0V is divided by 2.8V. The change in accuracy from

DD

V

= 0V to VSS = –5.5V with VDD = 5.5V is divided by 5.5V.

SS

= 2.7V to

DD

Note 10: Previous generation RMS-to-DC converters required nonlinear

input stages as well as a nonlinear core. Some parts specify a DC reversal

error, combining the effects of input nonlinearity and input offset voltage.

The LTC1966 behavior is simpler to characterize and the input offset

voltage is the only significant source of DC reversal error.

Note 11: High speed automatic testing cannot be performed with 60Hz

inputs. The LTC1966 is 100% tested with DC stimulus. Correlation tests

have shown that the performance limits above can be guaranteed with the

additional testing being performed to verify proper operation of all internal

circuitry.

Note 12: The LTC1966 is a switched capacitor device and the input/

output impedance is an average impedance over many clock cycles. The

input impedance will not necessarily lead to an attenuation of the input

signal measured. Refer to the Applications Information section titled Input

Impedance for more information.

Note 13: The common mode rejection ratios of the LTC1966 are measured

with DC inputs from 50mV to 350mV. The input CMRR is defined as the

change in V

input levels of V

output CMRR is defined as the change in V

V

and OUT RTN = VDD – 350mV divided by VDD – VSS – 350mV.

SS

measured between input levels of VSS to VSS + 350mV and

IOS

– 350mV to VDD divided by VDD – VSS – 350mV. The

DD

measured with OUT RTN =

OOS

Note 14: Each input of the LTC1966 can withstand any voltage within

the supply range. These inputs are protected with ESD diodes, so going

beyond the supply voltages can damage the part if the absolute maximum

current ratings are exceeded. Likewise for the output pins. The LTC1966

input and output voltage swings are limited by internal clipping. The

maximum differential input of the LTC1966 (referred to as maximum input

swing) is 1V. This applies to either input polarity, so it can be thought of as

±1V. Because the differential input voltage gets processed by the LTC1966

with gain, it is subject to internal clipping. Exceeding the 1V maximum

can, depending on the input crest factor, impact the accuracy of the output

voltage, but does not damage the part. Fortunately, the LTC1966’s ∆∑

topology is relatively tolerant of momentary internal clipping. The input

clipping is tested with a crest factor of 2, while the output clipping is

tested with a DC input.

Note 15: The LTC1966 exploits oversampling and noise shaping to reduce

the quantization noise of internal 1-bit analog-to-digital conversions. At

higher input frequencies, increasingly large portions of this noise are

aliased down to DC. Because the noise is shifted in frequency, it becomes

a low frequency rumble and is only filtered at the expense of increasingly

long settling times. The LTC1966 is inherently wideband, but the output

accuracy is degraded by this aliased noise. These specifications apply with

C

= 10µF and constitute a 3-sigma variation of the output rumble.

AVE

Note 16: The LTC1966 can operate down to 2.7V single supply but cannot

operate at ±2.7V. This additional constraint on V

mathematically as –3 • (V

– 2.7V) ≤ VSS ≤ Ground.

DD

can be expressed

SS

4

1966fb

Page 5

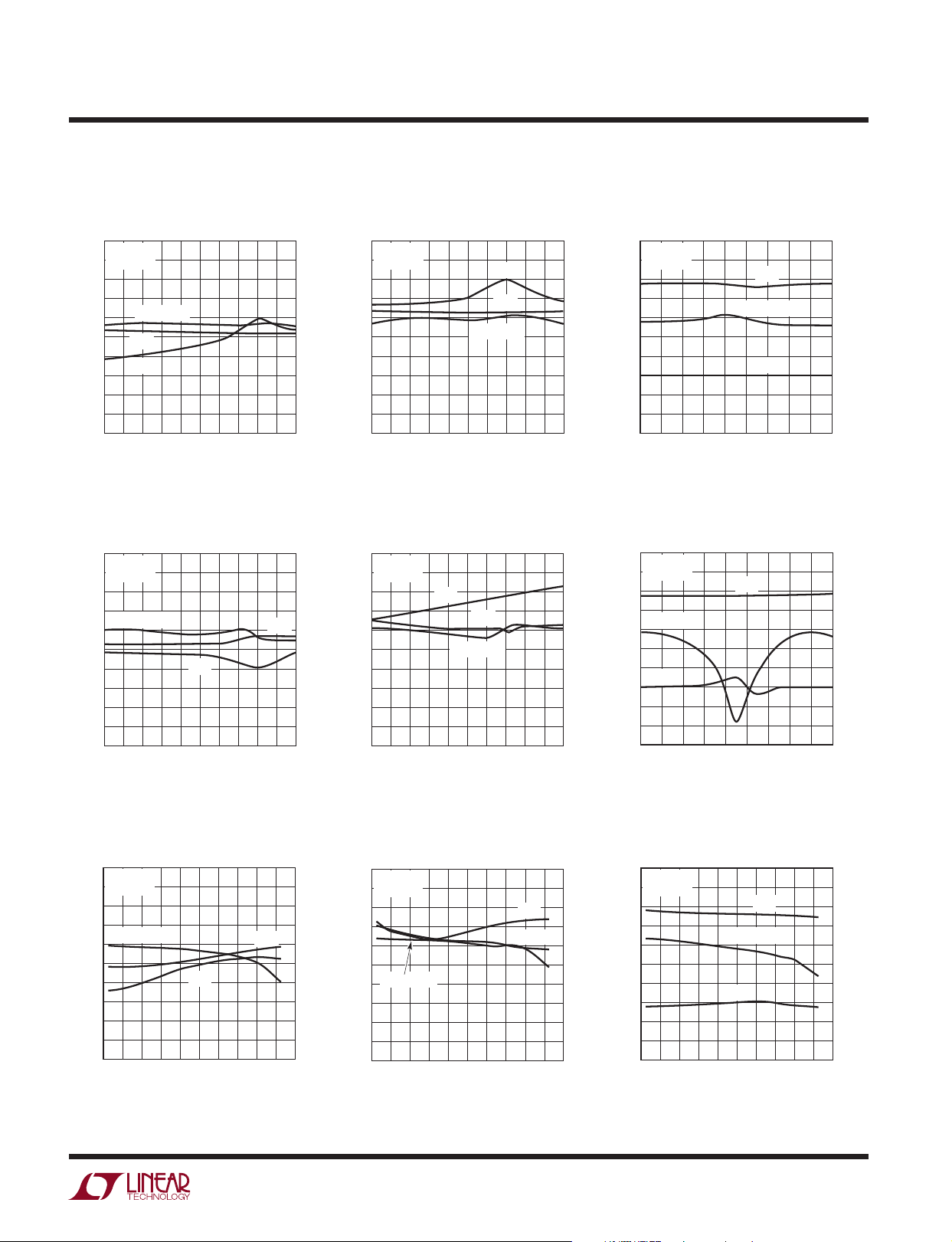

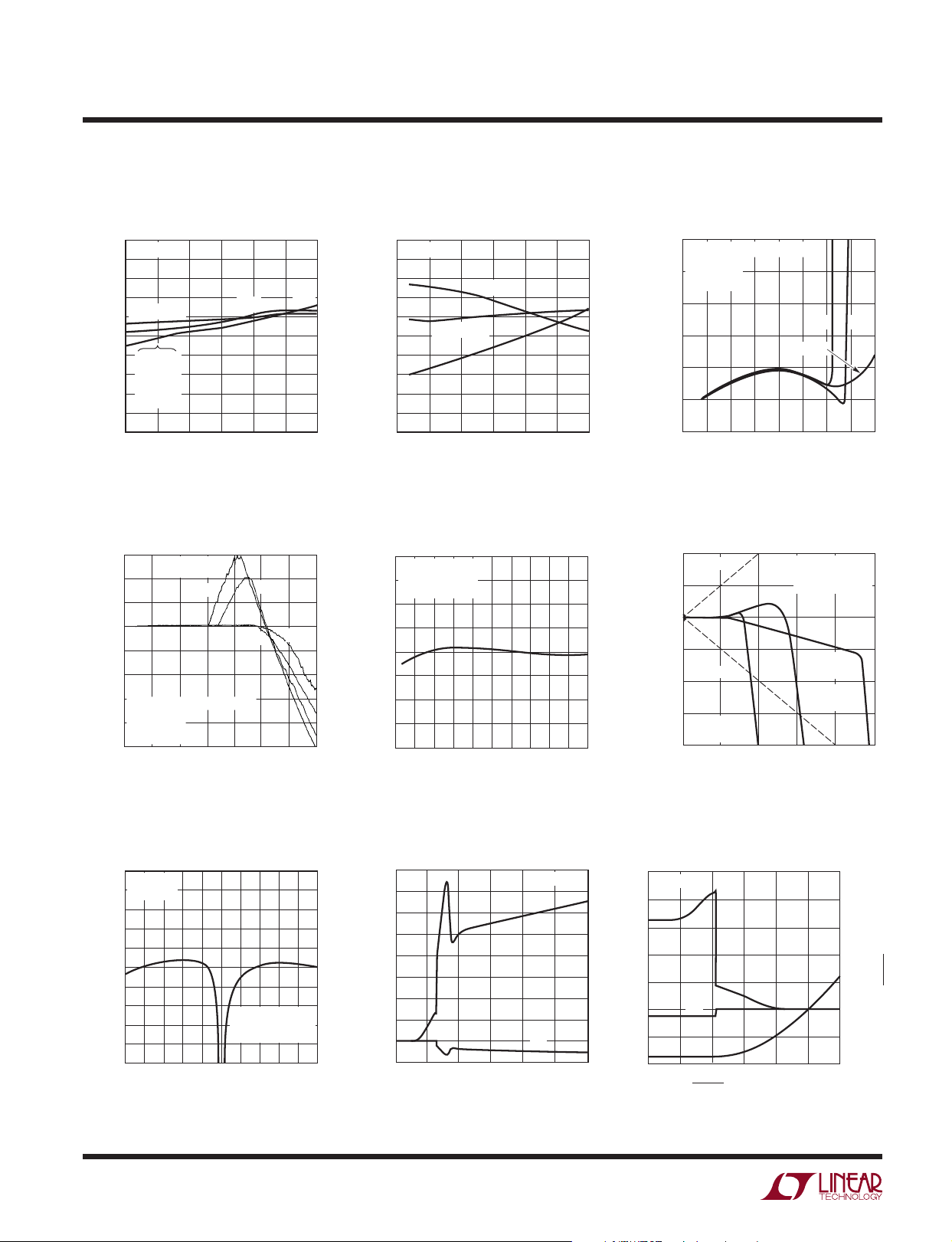

Typical perForMance characTerisTics

GAIN ERROR (%)

LTC1966

Gain and Offsets

vs Input Common Mode

0.5

VDD = 5V

0.4

= –5V

V

SS

0.3

0.2

0.1

–0.1

GAIN ERROR (%)

–0.2

–0.3

–0.4

–0.5

0

–5

GAIN ERROR

V

OOS

V

IOS

–4 –2

–3

–1

INPUT COMMON MODE (V)

Gain and Offsets

vs Output Common Mode

0.5

VDD = 5V

0.4

= –5V

V

SS

0.3

0.2

GAIN ERROR

0.1

0

–0.1

GAIN ERROR (%)

–0.2

–0.3

–0.4

–0.5

–4 –2

–5

–3

OUTPUT COMMON MODE (V)

V

–1

2

0 54

IOS

0 54

3

1

2

3

1

1966 G03

V

OOS

1966 G06

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

0.5

0.4

0.3

OFFSET VOLTAGE (mV)

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

0.5

0.4

0.3

OFFSET VOLTAGE (mV)

0.2

0.1

0

–0.1

GAIN ERROR (%)

–0.2

–0.3

–0.4

–0.5

Gain and Offsets

vs Input Common Mode

VDD = 5V

= GND

V

SS

0.5 1.5

1.0

0

INPUT COMMON MODE (V)

2.0

V

IOS

V

OOS

GAIN ERROR

3.5

2.5 5.04.5

3.0

Gain and Offsets

vs Output Common Mode

VDD = 5V

= GND

V

SS

V

IOS

V

OOS

GAIN ERROR

0.5 1.5

1.0

0

OUTPUT COMMON MODE (V)

2.0

3.5

2.5 5.04.5

3.0

4.0

4.0

1966 G02

1966 G05

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

0.5

0.4

0.3

OFFSET VOLTAGE (mV)

0.2

0.1

–0.1

GAIN ERROR (%)

–0.2

–0.3

–0.4

–0.5

0.5

0.4

0.3

OFFSET VOLTAGE (mV)

0.2

0.1

–0.1

GAIN ERROR (%)

–0.2

–0.3

–0.4

–0.5

Gain and Offsets

vs Input Common Mode

VDD = 2.7V

= GND

V

0

0

SS

0.3 0.9

0.6

INPUT COMMON MODE (V)

V

IOS

GAIN ERROR

V

OOS

1.5 2.7

1.8

1.2

Gain and Offsets

vs Output Common Mode

VDD = 2.7V

= GND

V

SS

GAIN ERROR

0

V

OOS

0.3 0.9

0.6

0

OUTPUT COMMON MODE (V)

V

IOS

1.5 2.7

1.8

1.2

2.1

2.1

2.4

1966 G01

2.4

1966 G04

1.0

0.8

0.6

OFFSET VOLTAGE (mV)

0.4

0.2

0

–0.2

–0.4

–0.6

–0.8

–1.0

1.0

0.8

0.6

OFFSET VOLTAGE (mV)

0.4

0.2

0

–0.2

–0.4

–0.6

–0.8

–1.0

Gain and Offsets vs Temperature

0.5

VDD = 5V

0.4

= –5V

V

SS

0.3

0.2

GAIN ERROR

0.1

0

–0.1

GAIN ERROR (%)

–0.2

–0.3

–0.4

–0.5

–40 –20

–60

V

IOS

40 602080

0

TEMPERATURE (°C)

V

OOS

100 120

1966 G09

0.5

0.4

0.3

OFFSET VOLTAGE (mV)

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

140

Gain and Offsets vs Temperature

0.5

VDD = 5V

0.4

= GND

V

SS

0.3

0.2

0.1

0

GAIN ERROR

–0.1

GAIN ERROR (%)

–0.2

–0.3

–0.4

–0.5

–60

–40

–20 0

TEMPERATURE (°C)

402060

80 100 120

Gain and Offsets vs Temperature

1966 G07

1.0

0.8

0.6

OFFSET VOLTAGE (mV)

0.4

0.2

0

–0.2

–0.4

–0.6

–0.8

–1.0

140

1966fb

0.5

0.4

IOS

0.3

0.2

V

OOS

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

140

1966 G08

V

0.5

VDD = 2.7V

0.4

= GND

V

SS

0.3

OFFSET VOLTAGE (mV)

0.2

0.1

0

–0.1

GAIN ERROR (%)

–0.2

–0.3

–0.4

–0.5

–60

–40

–20

V

IOS

GAIN ERROR

V

OOS

402060

0

TEMPERATURE (°C)

80 100 120

5

Page 6

LTC1966

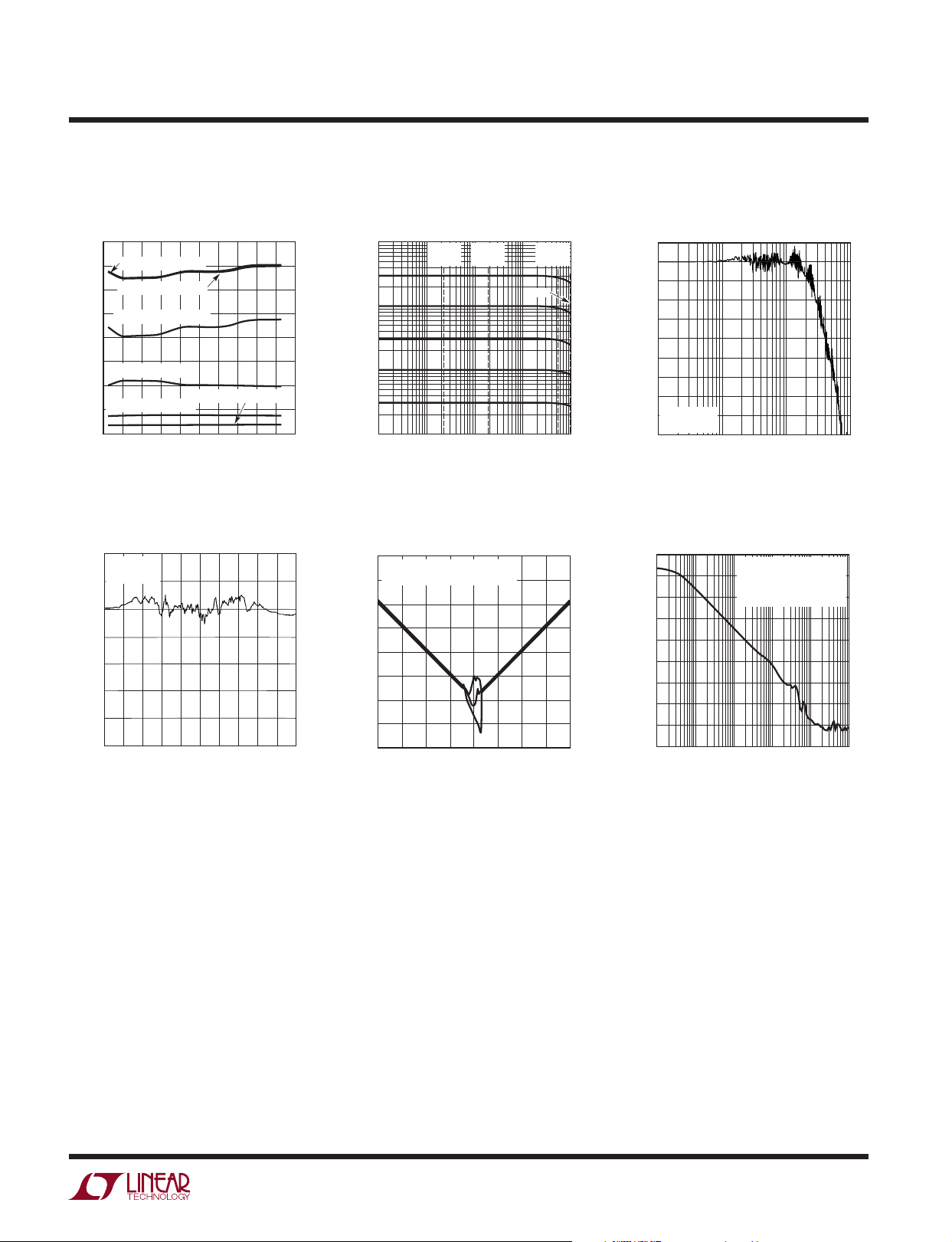

Typical perForMance characTerisTics

Gain and Offsets vs VSS Supply

0.5

VDD = 5V

0.4

0.3

0.2

GAIN ERROR

0.1

0

–0.1

GAIN ERROR (%)

–0.2

–0.3

–0.4

–0.5

–6

NOMINAL

–5

SPECIFIED

CONDITIONS

–4

VSS (V)

V

OOS

–2–3–1

Performance vs Large Crest Factors

230

220

210

200

190

180

170

OUTPUT VOLTAGE (mV DC)

160

150

FUNDAMENTAL

FREQUENCY

200mV

RMS

= 4.7µF

C

AVE

= 5V

V

DD

5%/DIV

2 3 5

1

20Hz

100Hz

SCR WAVEFORMS

4

CREST FACTOR

60Hz

6 7 8

V

1966 G11

250Hz

1966 G12

IOS

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

0

0.5

VSS = GND

0.4

0.3

OFFSET VOLTAGE (mV)

0.2

0.1

0

–0.1

GAIN ERROR (%)

–0.2

–0.3

–0.4

–0.5

2.5

3.0

AC Linearity

0.20

60Hz SINEWAVES

= 1µF

C

AVE

0.15

)

RMS

0.10

0.05

(mV AC

IN

–0.05

(mV DC) – V

–0.10

OUT

V

–0.15

–0.20

= GND

V

IN2

0

100 200 300 50035050 150 250 450

0

GAIN ERROR

V

3.5

V

(mV AC

IN1

V

IOS

OOS

4.0

VDD (V)

RMS

4.5

Performance vs Crest FactorGain and Offsets vs VDD Supply

5.0

1966 G10

5.5

1

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

–0.8

–1.0

201.0

200mV

C

AVE

200.8

V

DD

OFFSET VOLTAGE (mV)

O.1%/DIV

200.6

200.4

200.2

OUTPUT VOLTAGE (mV DC)

200.0

199.8

1.0

SCR WAVEFORMS

RMS

= 10µF

= 5V

1.5 2.5

2.0 3.0

CREST FACTOR

20Hz 60Hz

100Hz

3.5

4.0

4.5

5.0

1966 G15

Output Accuracy vs Signal

Amplitude

10

1% ERROR

5

)

RMS

0

(mV

IN

–5

–1% ERROR

–10

(mV DC) – V

OUT

V

–15

–20

400

)

1966 G13

AC INPUT

V

= 3V

DD

0

0.5 1 1.5 2

V

(V

IN1

AC INPUTS = 60Hz

SINEWAVES

V

= GND

IN2

AC INPUT

= 5V

V

DD

DC INPUT

VDD = 5V

)

RMS

2.5

1966 G24

| (mV)

INDC

– |V

OUTDC

V

6

0.10

0.08

0.06

0.04

0.02

–0.02

–0.04

–0.06

–0.08

–0.10

DC Linearity

C

= 1µF

AVE

= GND

V

IN2

0

–300

–500

–100

V

(mV)

IN1

EFFECT OF OFFSETS

MAY BE POSITIVE

OR NEGATIVE

100

300

1966 G14

500

Quiescent Supply Currents

vs Supply Voltage

200

175

150

125

100

75

50

SUPPLY CURRENT (µA)

25

0

–25

0

2 6

1 5

VDD SUPPLY VOLTAGE (V)

3

4

VSS = GND

I

DD

I

SS

1966 G16

Shutdown Currents

vs ENABLE Voltage

250

VDD = 5V

200

150

100

50

I

0

SUPPLY CURRENT (µA)

–50

–100

SS

0

1 2

ENABLE PIN VOLTAGE (V)

I

DD

3 5

I

EN

4 6

1966 G18

ENABLE PIN CURRENT (nA)

500

250

0

–250

–500

1966fb

Page 7

Typical perForMance characTerisTics

Quiescent Supply Currents

vs Temperature

170

VDD = 5V, VSS = –5V

160

VDD = 5V, VSS = GND

150

140

VDD = 2.7V, VSS = GND

(µA)

130

DD

I

120

VDD = 5V, VSS = –5V

110

VDD = 5V, VSS = GND

100

90

–40 –20 6040

–60

0 20

TEMPERATURE (°C)

Bandwidth to 100kHz

202

0.5%/DIV

= 47µF

C

AVE

201

200

199

198

197

OUTPUT DC VOLTAGE (mV)

196

195

0

30

40

20

10

INPUT FREQUENCY (kHz)

VDD = 2.7V, VSS = GND

80 100 120 140

1966 G17

70

60 80

50

90

1966 G21

100

40

35

30

25

I

SS

(µA)

20

15

10

5

0

Input Signal Bandwidth

1000

100

10

OUTPUT DC VOLTAGE (mV)

1

100 1K

0.1%

ERROR1%ERROR

INPUT SIGNAL FREQUENCY (Hz)

10K 100K 1M

DC Transfer Function Near Zero

30

V

= GND

IN2

THREE REPRESENTITIVE UNITS

25

20

15

10

(mV DC)

OUT

V

5

0

–5

–10

–20

–15

–10

–5

V

IN1

0

(mV DC)

5

–3dB

10

10%

ERROR

1966 G19

15

1966 G22

LTC1966

Input Signal Bandwidth

202

200

198

196

194

192

190

188

OUTPUT DC VOLTAGE (mV)

186

1%/DIV

184

= 2.2µF

C

AVE

182

1

Common Mode Rejection Ratio

vs Frequency

110

100

90

80

70

60

50

40

30

COMMON MODE REJECTION RATIO (dB)

20

20

10 1k 10k 1M

10 100 1000

INPUT FREQUENCY (kHz)

VDD = 5V

= –5V

V

SS

±5V INPUT CONVERSION

TO DC OUTPUT

100

FREQUENCY (Hz)

1966 G20

100k

1966 G23

1966fb

7

Page 8

LTC1966

––

()

pin FuncTions

GND (Pin 1): Ground. A power return pin.

IN1 (Pin 2): Differential Input. DC coupled (polarity is

irrelevant).

IN2 (Pin 3): Differential Input. DC coupled (polarity is

irrelevant).

(Pin 4): Negative Voltage Supply. GND to – 5.5V.

V

SS

(Pin 5): Output Voltage. This is high impedance.

V

OUT

The RMS averaging is accomplished with a single shunt

capacitor from this node to OUT RTN. The transfer function is given by:

V OUT RTN Average IN IN

()

OUT

=

21

2

OUT RTN (Pin 6): Output Return. The output voltage is

created relative to this pin. The V

are not balanced and this pin should be tied to a low

impedance, both AC and DC. Although it is typically tied

to GND, it can be tied to any arbitrary voltage, V

RTN < (V

OUT RTN = GND.

(Pin 7): Positive Voltage Supply. 2.7V to 5.5V.

V

DD

ENABLE (Pin 8): An Active Low Enable Input. LTC1966

is debiased if open circuited or driven to V

operation, pull to GND, a logic low or even V

– Max Output). Best results are obtained when

DD

and OUT RTN pins

OUT

SS

. For normal

DD

.

SS

< OUT

8

1966fb

Page 9

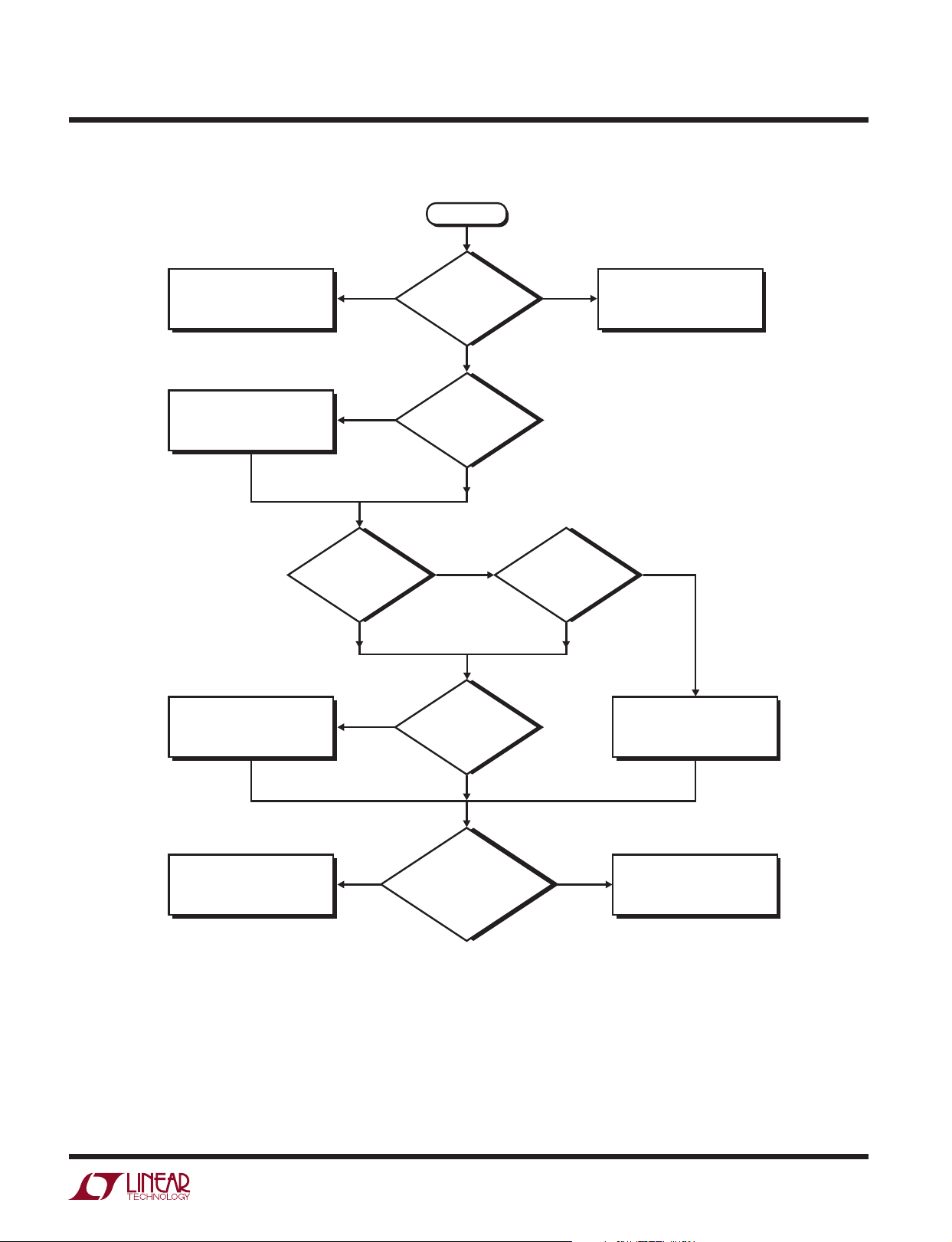

applicaTions inForMaTion

LTC1966

START

READ

RMS-TO-DC

CONVERSION

CONTACT LTC BY PHONE OR

AT www.linear.com AND

GET SOME NOW

YOU ALREADY TRY OUT

READ THE TROUBLESHOOTING

GUIDE. IF NECESSARY, CALL

LTC FOR APPLICATIONS SUPPORT

NOT

SURE

NO

DID

THE LTC1966?

YES NO

NO

DO YOU

NEED TRUE RMS-TO-DC

CONVERSION?

YES

DO YOU

HAVE ANY LTC1966s

YET?

YES

NO

DID

YOUR CIRCUIT

WORK?

NO

DO YOU WANT TO

KNOW HOW TO USE THE

LTC1966 FIRST?

FIND SOMEONE WHO DOES

AND GIVE THEM THIS

DATA SHEET

YES

READ THE DESIGN COOKBOOK

CONTACT LTC

AND PLACE YOUR ORDER

YES

WELL ENOUGH THAT YOU

YES

NOW DOES YOUR

RMS CIRCUIT WORK

ARE READY TO BUY

THE LTC1966?

NO

READ THE TROUBLESHOOTING

GUIDE AGAIN OR CALL LTC

FOR APPLICATIONS SUPPORT

1966 TA02

1966fb

9

Page 10

LTC1966

VV

applicaTions inForMaTion

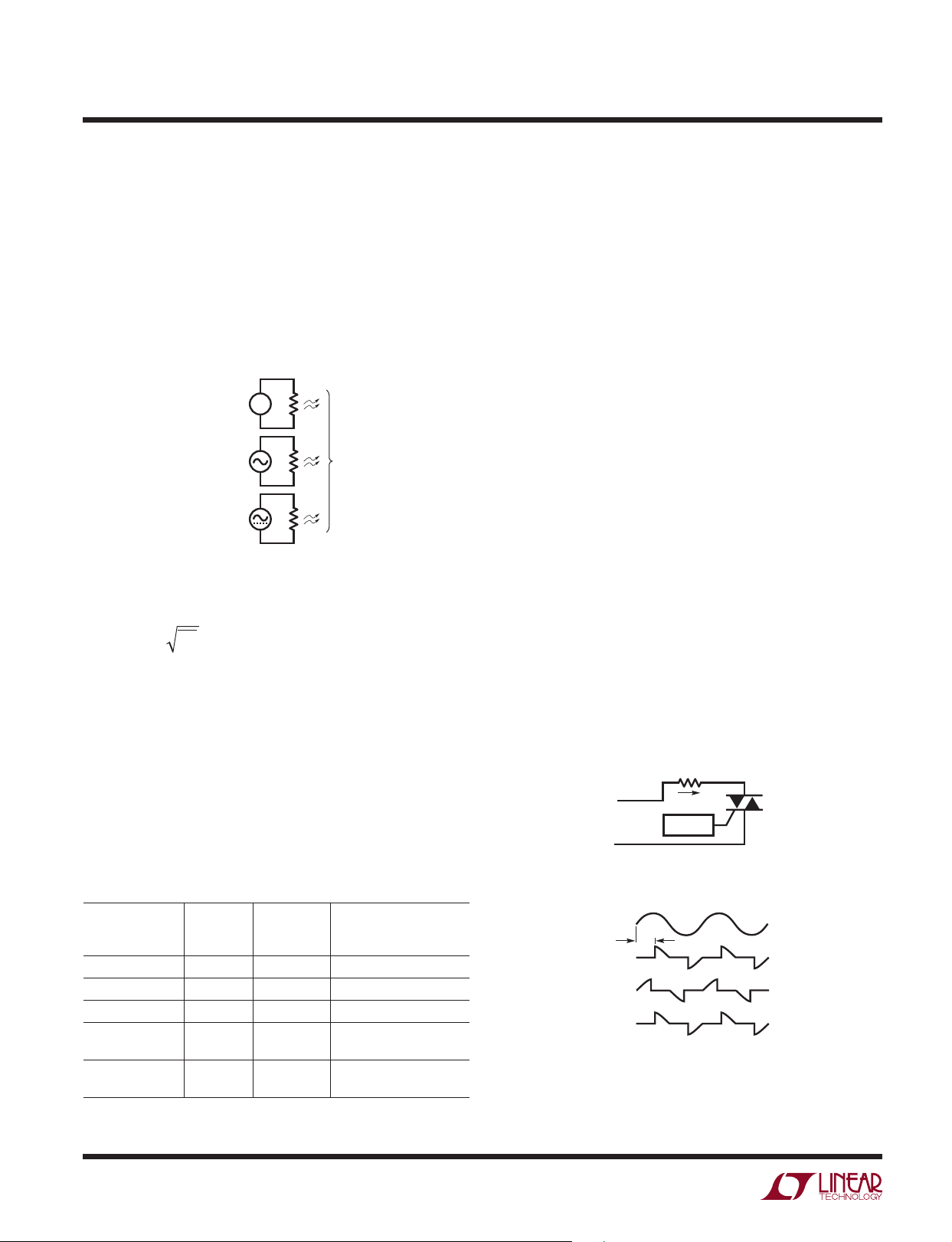

RMS-TO-DC CONVERSION

Definition of RMS

RMS amplitude is the consistent, fair and standard way to

measure and compare dynamic signals of all shapes and

sizes. Simply stated, the RMS amplitude is the heating

potential of a dynamic waveform. A 1V

AC waveform

RMS

will generate the same heat in a resistive load as will 1V DC.

+

R1V DC

–

1V AC

RMS

R

R1V (AC + DC) RMS

SAME

HEAT

1966 F01

Figure 1

Mathematically, RMS is the root of the mean of the square:

2

=

RMS

Alternatives to RMS

Other ways to quantify dynamic waveforms include peak

detection and average rectification. In both cases, an average (DC) value results, but the value is only accurate at

the one chosen waveform type for which it is calibrated,

typically sine waves. The errors with average rectification

are shown in Table 1. Peak detection is worse in all cases

and is rarely used.

Table 1. Errors with Average Rectification vs True RMS

AVERAGE

RECTIFIED

WAVEFORM V

Square Wave 1.000 1.000 11%

Sine Wave 1.000 0.900 *Calibrate for 0% Error

Triangle Wave 1.000 0.866 –3.8%

SCR at 1/2 Power,

Θ = 90°

SCR at 1/4 Power,

Θ = 114°

RMS

1.000 0.637 –29.3%

1.000 0.536 –40.4%

(V) ERROR*

The last two entries of Table 1 are chopped sine waves as

is commonly created with thyristors such as SCRs and

Triacs. Figure 2a shows a typical circuit and Figure 2b

shows the resulting load voltage, switch voltage and load

currents. The power delivered to the load depends on the

firing angle, as well as any parasitic losses such as switch

ON voltage drop. Real circuit waveforms will also typically

have significant ringing at the switching transition, dependent on exact circuit parasitics. For the purposes of this

data sheet, SCR waveforms refers to the ideal chopped

sine wave, though the LTC1966 will do faithful RMS-to-DC

conversion with real SCR waveforms as well.

The case shown is for Θ = 90°, which corresponds to 50%

of available power being delivered to the load. As noted in

Table 1, when Θ = 114°, only 25% of the available power

is being delivered to the load and the power drops quickly

as Θ approaches 180°.

With an average rectification scheme and the typical

calibration to compensate for errors with sine waves, the

RMS level of an input sine wave is properly reported; it

is only with a nonsinusoidal waveform that errors occur.

Because of this calibration, and the output reading in

, the term true RMS got coined to denote the use of

V

RMS

an actual RMS-to-DC converter as opposed to a calibrated

average rectifier.

V

LOAD

–

MAINS

AC

V

V

LOAD

V

I

LOAD

LINE

THY

+

V

LINE

–

Θ

+

I

LOAD

CONTROL

Figure 2a

Figure 2b

+

–

1966 F02a

1966 F02b

V

THY

10

1966fb

Page 11

applicaTions inForMaTion

()

LTC1966

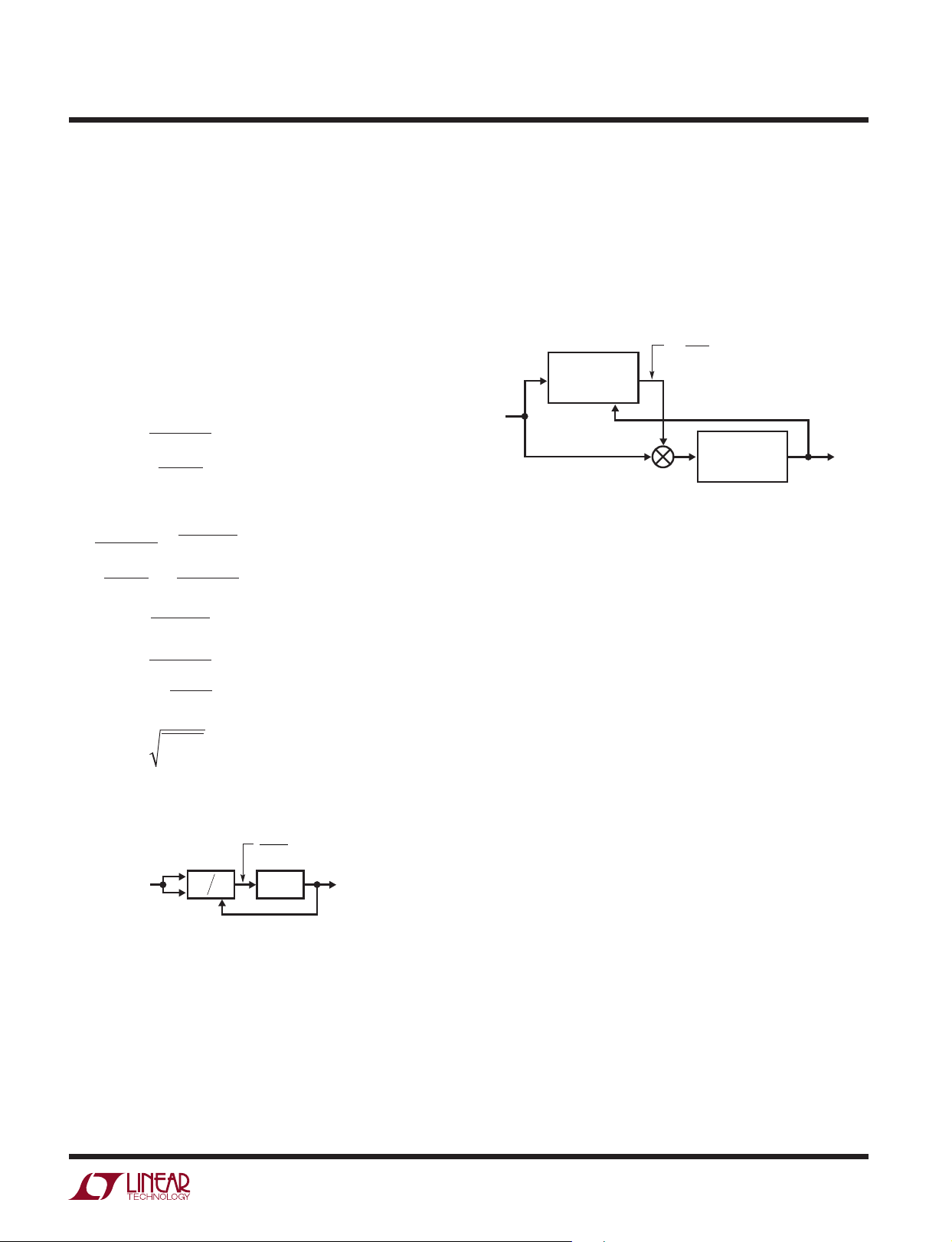

How an RMS-to-DC Converter Works

Monolithic RMS-to-DC converters use an implicit computation to calculate the RMS value of an input signal.

The fundamental building block is an analog multiply/

divide used as shown in Figure 3. Analysis of this topology is easy and starts by identifying the inputs and the

output of the lowpass filter. The input to the LPF is the

calculation from the multiplier/divider; (V

IN

)2/V

OUT

. The

lowpass filter will take the average of this to create the

output, mathematically:

2

V

OUT

()

=

Because V is DC,

2

V

VVor

()

VVRMS V

V

()

IN

V

OUT

()

=

OUT

22

OUT IN

OUT IN IN

=

=

V

IN

,

V

OUT

OUT

2

=

V

IN

V

OUT

()

()

V

()

IN

V

OUT

2

and

,

,

2

=

so

,

How the LTC1966 RMS-to-DC Converter Works

The LTC1966 uses a completely new topology for RMSto-DC conversion, in which a ∆S modulator acts as the

divider, and a simple polarity switch is used as the multiplier

as shown in Figure 4.

V

IN

D

α

V

OUT

∆–∑

REF

V

IN

±1

LPF

Figure 4. Topology of LTC1966

V

OUT

The ∆S modulator has a single-bit output whose average

duty cycle (D) will be proportional to the ratio of the input

signal divided by the output. The ∆S is a 2nd order modulator with excellent linearity. The single bit output is used to

selectively buffer or invert the input signal. Again, this is a

circuit with excellent linearity, because it operates at only

two points: ±1 gain; the average effective multiplication

over time will be on the straight line between these two

points. The combination of these two elements again creates

a lowpass filter input signal proportional to (VIN)2/V

OUT

,

which, as shown above, results in RMS-to-DC conversion.

2

V

()

IN

V

OUT

V

IN

Figure 3. RMS-to-DC Converter with Implicit Computation

× ÷

LPF

1966 F03

V

OUT

Unlike the prior generation RMS-to-DC converters, the

LTC1966 computation does NOT use log/antilog circuits,

which have all the same problems, and more, of log/antilog

multipliers/dividers, i.e., linearity is poor, the bandwidth

changes with the signal amplitude and the gain drifts with

temperature.

The lowpass filter performs the averaging of the RMS

function and must be a lower corner frequency than the

lowest frequency of interest. For line frequency measurements, this filter is simply too large to implement on-chip,

but the LTC1966 needs only one capacitor on the output

to implement the lowpass filter. The user can select this

capacitor depending on frequency range and settling time

requirements, as will be covered in the Design Cookbook

section to follow.

This topology is inherently more stable and linear than

log/antilog implementations primarily because all of the

signal processing occurs in circuits with high gain op amps

operating closed loop.

1966fb

11

Page 12

LTC1966

applicaTions inForMaTion

More detail of the LTC1966 inner workings is shown in

the Simplified Schematic towards the end of this data

sheet. Note that the internal scalings are such that the ∆S

output duty cycle is limited to 0% or 100% only when VIN

exceeds ± 4 • V

OUT

.

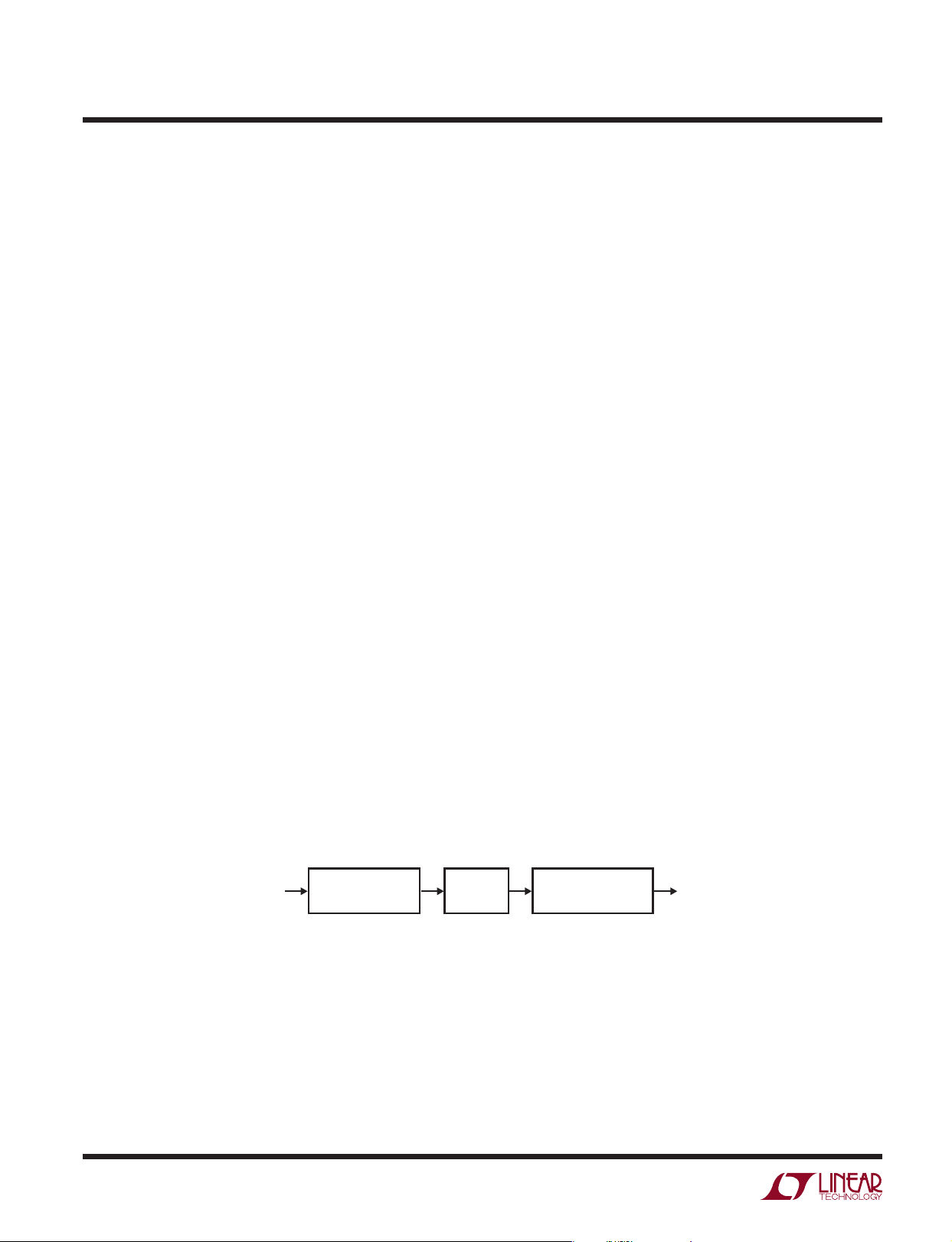

Linearity of an RMS-to-DC Converter

Linearity may seem like an odd property for a device that

implements a function that includes two very nonlinear

processes: squaring and square rooting.

However, an RMS-to-DC converter has a transfer function,

RMS volts in to DC volts out, that should ideally have a

1:1 transfer function. To the extent that the input to output

transfer function does not lie on a straight line, the part

is nonlinear.

A more complete look at linearity uses the simple model

shown in Figure 5. Here an ideal RMS core is corrupted by

both input circuitry and output circuitry that have imperfect

transfer functions. As noted, input offset is introduced in

the input circuitry, while output offset is introduced in the

output circuitry.

Any nonlinearity that occurs in the output circuity will corrupt the RMS in to DC out transfer function. A nonlinearity

in the input circuitry will typically corrupt that transfer

function far less, simply because with an AC input, the

RMS-to-DC conversion will average the nonlinearity from

a whole range of input values together.

But the input nonlinearity will still cause problems in an

RMS-to-DC converter because it will corrupt the accuracy

as the input signal shape changes. Although an RMS-to-DC

converter will convert any input waveform to a DC output,

the accuracy is not necessarily as good for all waveforms

as it is with sine waves. A common way to describe dynamic signal wave shapes is crest factor. The crest factor

is the ratio of the peak value relative to the RMS value of

a waveform. A signal with a crest factor of 4, for instance,

has a peak that is four times its RMS value. Because this

peak has energy (proportional to voltage squared) that is

16 times (4

2

) the energy of the RMS value, the peak is

necessarily present for at most 6.25% (1/16) of the time.

The LTC1966 performs very well with crest factors of 4

or less and will respond with reduced accuracy to signals

with higher crest factors. The high performance with crest

factors less than 4 is directly attributable to the high linearity throughout the LTC1966.

The LTC1966 does not require an input rectifier, as is common with traditional log/antilog RMS-to-DC converters.

Thus, the LTC1966 has none of the nonlinearities that are

introduced by rectification.

The excellent linearity of the LTC1966 allows calibration to

be highly effective at reducing system errors. See System

Calibration section following the Design Cookbook.

12

INPUT CIRCUITRY

INPUT OUTPUT

• V

IOS

• INPUT NONLINEARITY

Figure 5. Linearity Model of an RMS-to-DC Converter

IDEAL

RMS-TO-DC

CONVERTER

OUTPUT CIRCUITRY

• V

OOS

• OUTPUT NONLINEARITY

1966 F05

1966fb

Page 13

applicaTions inForMaTion

LTC1966

DESIGN COOKBOOK

The LTC1966 RMS-to-DC converter makes it easy to

implement a rather quirky function. For many applications

all that will be needed is a single capacitor for averaging,

appropriate selection of the I/O connections and power

supply bypassing. Of course, the LTC1966 also requires

power. A wide variety of power supply configurations are

shown in the Typical Applications section towards the end

of this data sheet.

Capacitor Value Selection

The RMS or root-mean-squared value of a signal, the root

of the mean of the square, cannot be computed without

some averaging to obtain the mean function. The LTC1966

true RMS-to-DC converter utilizes a single capacitor on

the output to do the low frequency averaging required for

RMS-to-DC conversion. To give an accurate measure of a

dynamic waveform, the averaging must take place over a

sufficiently long interval to average, rather than track, the

lowest frequency signals of interest. For a single averaging capacitor, the accuracy at low frequencies is depicted

in Figure 6.

However, if the output is examined on an oscilloscope

with a very low frequency input, the incomplete averaging will be seen, and this ripple will be larger than the

error depicted in Figure 6. Such an output is depicted in

Figure7. The ripple is at twice the frequency of the input

because of the computation of the square of the input.

The typical values shown, 5% peak ripple with 0.05% DC

error, occur with C

= 1µF and f

AVE

INPUT

= 10Hz.

If the application calls for the output of the LTC1966 to feed

a sampling or Nyquist A/D converter (or other circuitry that

will not average out this double frequency ripple) a larger

averaging capacitor can be used. This trade-off is depicted

in Figure 8. The peak ripple error can also be reduced by

additional lowpass filtering after the LTC1966, but the

simplest solution is to use a larger averaging capacitor.

1

This frequency dependent error is in addition to the static errors that affect all readings and are

therefore easy to trim or calibrate out. The Error Analyses section to follow discusses the effect

of static error terms.

ACTUAL OUTPUT

WITH RIPPLE

f = 2 × f

INPUT

PEAK

RIPPLE

(5%)

IDEAL

OUTPUT

DC

ERROR

(0.05%)

Figure 6 depicts the so-called DC error that results at a

given combination of input frequency and filter capacitor

1

values

. It is appropriate for most applications, in which

the output is fed to a circuit with an inherently band limited frequency response, such as a dual slope/integrating

A/D converter, a ∆S A/D converter or even a mechanical

analog meter.

0

–0.2

C = 4.7µF

–0.4

–0.6

–0.8

–1.0

–1.2

DC ERROR (%)

–1.4

–1.6

–1.8

–2.0

1

C = 10µF

C = 2.2µF

C = 1.0µF

C = 0.47µF

INPUT FREQUENCY (Hz)

Figure 6. DC Error vs Input Frequency

OUTPUT

PEAK

ERROR =

DC ERROR +

PEAK RIPPLE

(5.05%)

TIME

DC

AVERAGE

OF ACTUAL

OUTPUT

1966 F07

Figure 7. Output Ripple Exceeds DC Error

C = 0.22µF

10 20 50 60 100

C = 0.1µF

1966 F06

1966fb

13

Page 14

LTC1966

applicaTions inForMaTion

0

–0.2

–0.4

C = 100µF

–0.6

–0.8

–1.0

–1.2

PEAK ERROR (%)

–1.4

–1.6

–1.8

–2.0

C = 47µF

1

C = 22µF C = 10µF

Figure 8. Peak Error vs Input Frequency with One Cap Averaging

C = 4.7µF

10 20 50 60 100

INPUT FREQUENCY (Hz)

C = 2.2µF C = 1µF

1966 F08

A 1µF capacitor is a good choice for many applications.

The peak error at 50Hz/60Hz will be <1% and the DC error

will be <0.1% with frequencies of 10Hz or more.

Note that both Figure 6 and Figure 8 assume AC-coupled

waveforms with a crest factor less than 2, such as sine

waves or triangle waves. For higher crest factors and/or

AC + DC waveforms, a larger C

will generally be required.

AVE

See Crest Factor and AC + DC Waveforms.

Capacitor Type Selection

The LTC1966 can operate with many types of capacitors.

The various types offer a wide array of sizes, tolerances,

parasitics, package styles and costs.

Ceramic chip capacitors offer low cost and small size,

but are not recommended for critical applications. The

value stability over voltage and temperature is poor with

many types of ceramic dielectrics. This will not cause an

RMS-to-DC accuracy problem except at low frequencies,

where it can aggravate the effects discussed in the previous section. If a ceramic capacitor is used, it may be

necessary to use a much higher nominal value in order

to assure the low frequency accuracy desired.

Another parasitic of ceramic capacitors is leakage, which is

again dependent on voltage and particularly temperature.

If the leakage is a constant current leak, the I • R drop of

the leak multiplied by the output impedance of the LTC1966

will create a constant offset of the output voltage. If the

leak is Ohmic, the resistor divider formed with the LTC1966

output impedance will cause a gain error. For < 0.1%

gain accuracy degradation, the parallel impedance of the

capacitor leakage will need to be > 1000 times the LTC1966

output impedance. Accuracy at this level can be hard to

achieve with a ceramic capacitor, particularly with a large

value of capacitance and at high temperature.

For critical applications, a film capacitor, such as metalized

polyester, will be a much better choice. Although more

expensive, and larger for a given value, the value stability and low leakage make metal film capacitors a trouble

free choice.

With any type of capacitor, the self resonance of the capacitor can be an issue with the switched capacitor LTC1966.

If the self resonant frequency of the averaging capacitor

is 1MHz or less, a second smaller capacitor should be

added in parallel to reduce the impedance seen by the

LTC1966 output stage at high frequencies. A capacitor 100

times smaller than the averaging capacitor will typically be

small enough to be a low cost ceramic with a high quality

dielectric such as X7R or NPO/COG.

Input Connections

The LTC1966 input is differential and DC coupled. The

LTC1966 responds to the RMS value of the differential

voltage between Pin 2 and Pin 3, including the DC portion of that difference. However, there is no DC-coupled

path from the inputs to ground. Therefore, at least one of

the two inputs must be connected with a DC return path

to ground.

Both inputs must be connected to something. If either

input is left floating, a zero volt output will result.

1966fb

14

Page 15

applicaTions inForMaTion

LTC1966

For single-ended DC-coupled applications, simply connect one of the two inputs (they are interchangeable) to

the signal, and the other to ground. This will work well

for dual supply configurations, but for single supply

configurations it will only work well for unipolar input

signals. The LTC1966 input voltage range is from railto-rail, and when the input is driven above V

(ground for single supply operation) the gain and

V

SS

or below

DD

offset errors will increase substantially after just a few

hundred millivolts of overdrive. Fortunately, most single

supply circuits measuring a DC-coupled RMS value will

include some reference voltage other than ground, and

the second LTC1966 input can be connected to that point.

For single-ended AC-coupled applications, Figure 9 shows

three alternate topologies. The first one, shown in Figure 9a

uses a coupling capacitor to one input while the other is

grounded. This will remove the DC voltage difference from

the input to the LTC1966, and it will therefore not be part

of the resulting output voltage. Again, this connection will

work well with dual supply configurations, but in single

supply configurations it will be necessary to raise the voltage on the grounded input to assure that the signal at the

active input stays within the range of V

to VDD. If there

SS

is already a suitable voltage reference available, connect

the second input to that point. If not, a midsupply voltage

can be created with two resistors as shown in Figure 9b.

Finally, if the input voltage is known to be between V

and V

, it can be AC-coupled by using the configuration

DD

SS

shown in Figure 9c. Whereas the DC return path was

provided through Pin 3 in Figures 9a and 9b, in this case,

the return path is provided on Pin 2, through the input

signal voltages. The switched capacitor action between

the two input pins of the LTC1966 will cause the voltage

on the coupling capacitor connected to the second input

to follow the DC average of the input voltage.

For differential input applications, connect the two inputs

to the differential signal. If AC coupling is desired, one of

the two inputs can be connected through a series capacitor.

In all of these connections, to choose the input coupling

capacitor, C

, calculate the low frequency coupling time

C

constant desired, and divide by the LTC1966 differential

input impedance. Because the LTC1966 input impedance

is about 100 times its output impedance, this capacitor is

typically much smaller than the output averaging capacitor. Its requirements are also much less stringent, and a

ceramic chip capacitor will usually suffice.

Output Connections

The LTC1966 output is differentially, but not symmetrically,

generated. That is to say, the RMS value that the LTC1966

computes will be generated on the output (Pin 5) relative

to the output return (Pin 6), but these two pins are not

interchangeable. For most applications, Pin 6 will be tied

to ground (Pin 1), and this will result in the best accuracy.

However, Pin 6 can be tied to any voltage between V

(Pin 4) and V

swing desired. This last restriction keeps V

within the range of V

(Pin 7) less the maximum output voltage

DD

itself (Pin 5)

OUT

to VDD. If a reference level other

SS

SS

than ground is used, it should be a low impedance, both

AC and DC, for proper operation of the LTC1966.

Use of a voltage in the range of V

– 1V to VDD – 1.3V can

DD

lead to errors due to the switch dynamics as the NMOS

transistor is cut off. For this reason, it is recommended

that OUT RTN = 0V if V

is ≤3V.

DD

V

DD

C

C

LTC1966

2

IN1

3

V

IN

IN2

V

SS

(9a)

Figure 9. Single-Ended AC-Coupled Input Connection Alternatives

V

V

DD

C

C

IN

R1

100k

2

3

R2

100k

IN1

IN2

(9b)

V

DD

LTC1966

V

DD

LTC1966

2

IN1

3

C

C

(9c)

IN2

V

SS

1966 F09

OR GND

1966fb

V

IN

+

V

DC

–

15

Page 16

LTC1966

applicaTions inForMaTion

In any configuration, the averaging capacitor should be

connected between Pins 5 and 6. The LTC1966 RMS DC

output will be a positive voltage created at V

with respect to OUT RTN (Pin 6).

Power Supply Bypassing

The LTC1966 is a switched capacitor device, and large

transient power supply currents will be drawn as the

switching occurs. For reliable operation, standard power

supply bypassing must be included. For single supply

operation, a 0.01µF capacitor from V

(Pin 7) to GND

DD

(Pin1) located close to the device will suffice. For dual

supplies, add a second 0.01µF capacitor from V

to GND (Pin 1), located close to the device. If there is a

good quality ground plane available, the capacitors can go

directly to that instead. Power supply bypass capacitors

can, of course, be inexpensive ceramic types.

The sampling clock of the LTC1966 operates at approximately 200kHz, and most operations repeat at a rate of

100kHz. If this internal clock becomes synchronized to a

multiple or submultiple of the input frequency, significant

conversion error could occur. This is particularly important

when frequencies exceeding 10kHz can be injected into

the LTC1966 via supply or ground bounce. To minimize

this possibility, capacitive bypassing is recommended on

both supplies with capacitors placed immediately adjacent

to the LTC1966. For best results, the bypass capacitors

should be separately routed from Pin 7 to Pin 1, and from

Pin 4 to Pin 1.

OUT

SS

(Pin 5)

(Pin 4)

0

–1

–2

(V)

–3

SS

V

–4

–5

–6

2.5

Figure 10. VSS Limits vs V

3.5 4 4.5

3

LTC1966

OPERATES IN THIS RANGE

5 5.5

VDD (V)

1966 F10

DD

Up and Running!

If you have followed along this far, you should have the

LTC1966 up and running by now! Don’t forget to enable

the device by grounding Pin 8, or driving it with a logic low.

Keep in mind that the LTC1966 output impedance is fairly

high, and that even the standard 10MΩ input impedance of

a digital multimeter (DMM) or a 10× scope probe will load

down the output enough to degrade its typical gain error

of 0.1%. In the end application circuit, either a buffer or

another component with an extremely high input impedance

(such as a dual slope integrating ADC) should be used.

For laboratory evaluation, it may suffice to use a bench

top DMM with the ability to disconnect the 10MΩ shunt.

If you are still having trouble, it may be helpful to skip

ahead a few pages and review the Troubleshooting Guide.

The LTC1966 needs at least 2.7V for its power supply,

more for dual supply configurations. The range of allowable negative supply voltages (V

voltages (V

constraint is:

V

SS

–3 • (V

) is shown in Figure 10. Mathematically, the

DD

– 2.7V) ≤ VSS ≤ GND

DD

) vs positive supply

SS

The LTC1966 has internal ESD absorption devices, which

are referenced to the V

and V

DD

in-circuit ESD immunity, the V

supplies. For effective

SS

and VSS pins must be

DD

connected to a low external impedance. This can be accomplished with low impedance power planes or simply

with the recommended 0.01µF decoupling to ground on

each supply.

16

What About Response Time?

With a large value averaging capacitor, the LTC1966 can

easily perform RMS-to-DC conversion on low frequency

signals. It compares quite favorably in this regard to

prior generation products because nothing about the ∆S

circuitry is temperature sensitive. So the RMS result doesn’t

get distorted by signal driven thermal fluctuations like a

log/antilog circuit output does.

However, using large value capacitors results in a slow

response time. Figure 11 shows the rising and falling

step responses with a 1µF averaging capacitor. Although

they both appear at first glance to be standard exponential

1966fb

Page 17

applicaTions inForMaTion

120

C

= 1µF

AVE

100

120

100

LTC1966

C

= 1µF

AVE

80

60

40

LTC1966 OUTPUT (mV)

20

0

0

0.1 0.2 0.3 0.4

TIME (SEC)

Figure 11a. LTC1966 Rising Edge with C

10

1

SETTLING ACCURACY (%)

0.1

0.01

80

60

40

LTC1966 OUTPUT (mV)

20

0

0

0.5

1966 F11a

= 1µF Figure 11b. LTC1966 Falling Edge with C

AVE

1 100.1 100

SETTLING TIME (SEC)

0.2 0.4 0.6 0.8

Figure 12. LTC1966 Settling Time with One Cap Averaging

TIME (SEC)

1966 F11b

AVE

1

= 1µF

C = 100µFC = 47µFC = 22µFC = 10µFC = 4.7µFC = 2.2µFC = 0.47µFC = 0.22µFC = 0.1µF C = 1µF

1966 F12

decay type settling, they are not. This is due to the nonlinear

nature of an RMS-to-DC calculation. Also note the change

in the time scale between the two; the rising edge is more

than twice as fast to settle to a given accuracy. Again this

is a necessary consequence of RMS-to-DC calculation.

2

Although shown with a step change between 0mV and

100mV, the same response shapes will occur with the

LTC1966 for ANY step size. This is in marked contrast

to prior generation log/antilog RMS-to-DC converters,

whose averaging time constants are dependent on the

signal level, resulting in excruciatingly long waits for the

output to go to zero.

The shape of the rising and falling edges will be dependent

on the total percent change in the step, but for less than

the 100% changes shown in Figure 11, the responses will

be less distorted and more like a standard exponential

decay. For example, when the input amplitude is changed

from 100mV to 110mV (+10%) and back (–10%), the step

responses are essentially the same as a standard exponential rise and decay between those two levels. In such

cases, the time constant of the decay will be in between

that of the rising edge and falling edge cases of Figure 11.

Therefore, the worst case is the falling edge response as

it goes to zero, and it can be used as a design guide.

Figure12 shows the settling accuracy vs settling time for

a variety of averaging capacitor values. If the capacitor

value previously selected (based on error requirements)

gives an acceptable settling time, your design is done.

2

To convince oneself of this necessity, consider a pulse train of 50% duty cycle between 0mV

and 100mV. At very low frequencies, the LTC1966 will essentially track the input. But as the input

frequency is increased, the average result will converge to the RMS value of the input. If the rise

and fall characteristics were symmetrical, the output would converge to 50mV. In fact though, the

RMS value of a 100mV DC-coupled 50% duty cycle pulse train is 70.71mV, which the asymmetrical

rise and fall characteristics will converge to as the input frequency is increased.

1966fb

17

Page 18

LTC1966

applicaTions inForMaTion

But with 100µF, the settling time to even 10% is a full 38

seconds, which is a long time to wait. What can be done

about such a design? If the reason for choosing 100µF is

to keep the DC error with a 75mHz input less than 0.1%,

the answer is: not much. The settling time to 1% of 76

seconds is just 5.7 cycles of this extremely low frequency.

Averaging very low frequency signals takes a long time.

However, if the reason for choosing 100µF is to keep the

peak error with a 10Hz input less than 0.05%, there is

another way to achieve that result with a much improved

settling time.

Reducing Ripple with a Post Filter

The output ripple is always much larger than the DC error, so filtering out the ripple can reduce the peak error

substantially, without the large settling time penalty of

simply increasing the averaging capacitor.

Figure 13 shows a basic 2nd order post filter, for a net 3rd

order filtering of the LTC1966 RMS calculation. It uses the

85kΩ output impedance of the LTC1966 as the first resistor

of a 3rd order Sallen-Key active RC filter. This topology

features a buffered output, which can be desirable depending on the application. However, there are disadvantages

to this topology, the first of which is that the op amp input

voltage and current errors directly degrade the effective

LTC1966 V

. The table inset in Figure 13 shows these

OOS

errors for four of Linear Technology’s op amps.

5

LTC1966 C

6

OP AMP

LTC1966 V

OOS

V

IOS

I

• R

B/OS

TOTAL OFFSET

VALUE

R

B

I

SQ

R1

38.3k

AVE

1µF

LT1494

±375µV

±73µV

±648µV

294k

1µA

R2

169k

C1

1µF

LT1880

±150µV

±329µV

±679µV

SHORT

1.2mA

–

+

C2

0.1µF

LT1077

±200µV

±60µV

±329µV

±589µV

294k

48µA

LT1880

LT 2050

±27µV

±230µV

SHORT

750µA

±3µV

R

B

1966 F13

A second disadvantage is that the op amp output has

to operate over the same range as the LTC1966 output,

including ground, which in single supply applications is

the negative supply. Although the LTC1966 output will

function fine just millivolts from the rail, most op amp

output stages (and even some input stages) will not.

There are at least two ways to address this. First of all,

the op amp can be operated split supply if a negative

supply is available. Just the op amp would need to do so;

the LTC1966 can remain single supply. A second way to

address this issue is to create a signal reference voltage a

half volt or so above ground. This is most attractive when

the circuitry that follows has a differential input, so that

the tolerance of the signal reference is not a concern. To

do this, tie all three ground symbols shown in Figure 13

to the signal reference, as well as to the differential return

for the circuitry that follows.

Figure 14 shows an alternative 2nd order post filter, for

a net 3rd order filtering of the LTC1966 RMS calculation.

It also uses the 85kΩ output impedance of the LTC1966

as the first resistor of a 3rd order active RC filter, but this

topology filters without buffering so that the op amp DC

error characteristics do not affect the output. Although the

output impedance of the LTC1966 is increased from 85kΩ

to 285kΩ, this is not an issue with an extremely high input

impedance load, such as a dual slope integrating ADC like

the ICL7106. And it allows a generic op amp to be used,

such as the SOT-23 one shown. Furthermore, it easily

works on a single supply rail by tying the noninverting

input of the op amp to a low noise reference as optionally

shown. This reference will not change the DC voltage at

the circuit output, although it does become the AC ground

for the filter, thus the (relatively) low noise requirement.

R1

5

LTC1966 C

6

200k

AVE

1µF

OTHER

REF VOLTAGE,

SEE TEXT

C1

0.22µF

–

+

LT1782

R2

681k

C2

0.22µF

1066 F14

18

Figure 13. Buffered Post Filter

Figure 14. DC Accurate Post Filter

1966fb

Page 19

applicaTions inForMaTion

LTC1966

Step Responses with a Post Filter

oth of the post filters, shown in Figures 13 and 14,

B

are optimized for additional filtering with clean step

responses. The 85kΩ output impedance of the LTC1966

working into a 1µF capacitor forms a 1st order LPF with

a –3dB frequency of ~1.8Hz. The two filters have 1µF at

the LTC1966 output for easy comparison with a 1µF only

case, and both have the same relative (Bessel-like) shape.

However, because of the topological differences of pole

placements between the various components within the

two filters, the net effective bandwidth for Figure 13 is

slightly higher (≈1.2 • 1.8 ≈ 2.1Hz) than with 1µF alone,

while the bandwidth for Figure 14 is somewhat lower

(≈0.7 • 1.8 ≈ 1.3Hz) than with 1µF alone. To adjust the

bandwidth of either of them, simply scale all the capacitors

by a common multiple, and leave the resistors unchanged.

The step responses of the LTC1966 with 1µF only and with

the two post filters are shown in Figure 15. This is the rising edge RMS output response to a 10Hz input starting

at t = 0. Although the falling edge response is the worst

case for settling, the rising edge illustrates the ripple that

these post filters are designed to address, so the rising

edge makes for a better intuitive comparison.

an issue with input frequency bursts at 50Hz or less, and

even with the overshoot, the settling to a given level of

accuracy improves due to the initial speedup.

As predicted by Figure 6, the DC error with 1µF is well

under 1mV and is not noticeable at this scale. However, as

predicted by Figure 8, the peak error with the ripple from a

10Hz input is much larger, in this case about 5mV. As can

be clearly seen, the post filters reduce this ripple. Even

the wider bandwidth of Figure 13’s filter is seen to cut the

ripple down substantially (to <1mV) while the settling to

1% happens faster. With the narrower bandwidth of Figure

14’s filter, the step response is somewhat slower, but the

double frequency output ripple is just 180µV.

Figure 16 shows the step response of the same three cases

with a burst of 60Hz rather than 10Hz. With 60Hz, the initial portion of the step response is free of the boost seen

in Figure 15 and the two post filter responses have less

than 1% overshoot. The 1µF only case still has noticeable

120Hz ripple, but both filters have removed all detectable

ripple on this scale. This is to be expected; the first order

filter will reduce the ripple about 6:1 for a 6:1 change in

frequency, while the third order filters will reduce the

3

ripple about 6

:1 or 216:1 for a 6:1 change in frequency.

The initial rise of the LTC1966 will have enhanced slew rates

with DC and very low frequency inputs due to saturation

effects in the ∆S modulator. This is seen in Figure 15 in

two ways. First, the 1µF only output is seen to rise very

quickly in the first 40ms. The second way this effect shows

up is that the post filter outputs have a modest overshoot,

on the order of 3mV to 4mV, or 3% to 4%. This is only

1966 F15

200mV/

0

DIV

20mV/

DIV

0

INPUT

BURST

1µF ONLY

FIGURE 13

FIGURE 14

STEP

RESPONSE

100ms/DIV

Figure 15. Step Responses with 10Hz Burst

Again, the two filter topologies have the same relative

shape, so the step response and ripple filtering trade-offs of

the two are the same, with the same performance of each

possible with the other by scaling it accordingly. Figures

17 and 18 show the peak error vs. frequency for a selection of capacitors for the two different filter topologies.

To keep the clean step response, scale all three capacitors

1966 F16

200mV/

0

DIV

20mV/

DIV

0

1966fb

INPUT

BURST

1µF ONLY

FIGURE 13

FIGURE 14

STEP

RESPONSE

100ms/DIV

Figure 16. Step Responses with 60Hz Burst

19

Page 20

LTC1966

applicaTions inForMaTion

0

–0.2

–0.4

–0.6

–0.8

–1.0

–1.2

PEAK ERROR (%)

–1.4

–1.6

–1.8

–2.0

–0.2

–0.4

–0.6

–0.8

–1.0

–1.2

PEAK ERROR (%)

–1.4

–1.6

–1.8

–2.0

C = 10µF

C = 4.7µF C = 2.2µF C = 1.0µF C = 0.47µF C = 0.22µF

1

Figure 17. Peak Error vs Input Frequency with Buffered Post Filter

0

C = 10µF

C = 4.7µF

1

C = 2.2µF C = 1.0µF C = 0.47µF C = 0.22µF C = 0.1µF

Figure 18. Peak Error vs Input Frequency with DC Accurate Post Filter

C = 0.1µF

10 100

INPUT FREQUENCY (Hz)

1966 F17

10 100

INPUT FREQUENCY (Hz)

1966 F18

within the filter. Scaling the buffered topology of Figure 13

is simple because the capacitors are in a 10:1:10 ratio.

Scaling the DC accurate topology of Figure 14 can be done

with standard value capacitors; one decade of scaling is

shown in Table 2.

Table 2. One Decade of Capacitor Scaling for Figure 14 with EIA

Standard Values

C

AVE

1µF 0.22µF

1.5µF 0.33µF

2.2µF 0.47µF

3.3µF 0.68µF

4.7µF 1µF

6.8µF 1.5µF

C1 = C2 =

20

Figures 19 and 20 show the settling time versus settling

accuracy for the buffered and DC accurate post filters,

respectively. The different curves represent different scalings of the filters, as indicated by the C

value. These are

AVE

comparable to the curves in Figure 12 (single capacitor

case), with somewhat less settling time for the buffered

post filter, and somewhat more settling time for the DC

accurate post filter. These differences are due to the change

in overall bandwidth as mentioned earlier.

The other difference is the settling behavior of the filters

below the 1% level. Unlike the case of a 1st order filter,

any 3rd order filter can have overshoot and ringing. The

filter designs presented here have minimal overshoot

and ringing, but are somewhat sensitive to component

mismatches. Even the ±12% tolerance of the LTC1966

output impedance can be enough to cause some ringing.

The dashed lines indicate what can happen when ±5%

capacitors and ±1% resistors are used.

1966fb

Page 21

applicaTions inForMaTion

()

32

10

1

SETTLING ACCURACY (%)

LTC1966

C = 100µFC = 47µFC = 22µFC = 10µFC = 4.7µFC = 2.2µFC = 1.0µFC = 0.47µFC = 0.22µFC = 0.1µF

0.1

0.01

10

1

SETTLING ACCURACY (%)

0.1

0.01

Figure 19. Settling Time with Buffered Post Filter

Figure 20. Settling Time with DC Accurate Post Filter

SETTLING TIME (SEC)

SETTLING TIME (SEC)

Although the settling times for the post filtered configurations shown on Figures 19 and 20 are not that much

different from those with a single capacitor, the point of

using a post filter is that the settling times are far better

for a given level peak error. The filters dramatically reduce

the low frequency averaging ripple with far less impact

on settling time.

Crest Factor and AC + DC Waveforms

In the preceding discussion, the waveform was assumed

to be AC-coupled, with a modest crest factor. Both assumptions ease the requirements for the averaging

capacitor. With an AC-coupled sine wave, the calculation

engine squares the input, so the averaging filter that

follows is required to filter twice the input frequency,

making its job easier. But with a sinewave that includes

DC offset, the square of the input has frequency content

10.1 10 100

1066 F14

C = 100µFC = 47µFC = 22µFC = 10µFC = 4.7µFC = 2.2µFC = 1.0µFC = 0.47µFC = 0.22µFC = 0.1µF

10.1 10 100

1066 F20

at the input frequency and the filter must average out

that lower frequency. So with AC + DC waveforms, the

required value for C

should be based on half of the

AVE

lowest input frequency, using the same design curves

presented in Figures 6, 8, 17 and 18.

Crest factor, which is the peak to RMS ratio of a dynamic

signal, also effects the required C

value. With a higher

AVE

crest factor, more of the energy in the signal is concentrated into a smaller portion of the waveform, and the

averaging has to ride out the long lull in signal activity.

For busy waveforms, such as a sum of sine waves, ECG

traces or SCR chopped sine waves, the required value for

should be based on the lowest fundamental input

C

AVE

frequency divided as such:

f

INPUT MIN

=

•–

CF

1966fb

f

DESIGN

21

Page 22

LTC1966

()

62

fH

==

applicaTions inForMaTion

using the same design curves presented in Figures 6, 8,

17 and 18. For the worst-case of square top pulse trains,

that are always either zero volts or the peak voltage, base

the selection on the lowest fundamental input frequency

divided by twice as much:

f

INPUT MIN

=

•–

CF

f

DESIGN

The effects of crest factor and DC offsets are cumulative.

So for example, a 10% duty cycle pulse train from 0V

to 1V

(CF = √10 = 3.16) repeating at 16.67ms (60Hz)

PEAK

PEAK

input is effectively only 30Hz due to the DC asymmetry

and is effectively only:

DESIGN

30

6316 2

•.–

378

.

z

for the purposes of Figures 6, 8, 17 and 18.

Obviously, the effect of crest factor is somewhat simplified

above given the factor of 2 difference based on a subjective description of the waveform type. The results will vary

somewhat based on actual crest factor and waveform

dynamics and the type of filtering used. The above method

is conservative for some cases and about right for others.

The LTC1966 works well with signals whose crest factor is

4 or less. At higher crest factors, the internal ∆∑ modulator

will saturate, and results will vary depending on the exact

frequency, shape and (to a lesser extent) amplitude of the

input waveform. The output voltage could be higher or

lower than the actual RMS of the input signal.

The ∆∑ modulator may also saturate when signals with crest

factors less than 4 are used with insufficient averaging.

This will only occur when the output droops to less than

1/4 of the input voltage peak. For instance, a DC-coupled

pulse train with a crest factor of 4 has a duty cycle of

6.25% and a 1V

input is 250mV

PEAK

50Hz, repeating every 20ms, and C

. If this input is

RMS

= 1µF, the output

AVE

will droop during the inactive 93.75% of the waveform.

This droop is calculated as:

INACTIVE TIME

1–

−

2 • Z• C

e

OUT AVE

V

V

MIN

RMS

=

2

For the LTC1966, whose output impedance (Z

) is 85kΩ,

OUT

this droop works out to –5.22%, so the output would be

reduced to 237mV at the end of the inactive portion of the

input. When the input signal again climbs to 1V

PEAK

, the

peak/output ratio is 4.22.

With C

= 10µF, the droop is only –0.548% to 248.6mV

AVE

and the peak/output ratio is just 4.022, which the LTC1966

has enough margin to handle without error.

For crest factors less than 3.5, the selection of C

AVE

as

previously described should be sufficient to avoid this

droop and modulator saturation effect. But with crest

factors above 3.5, the droop should also be checked for

each design.

Error Analyses

Once the RMS-to-DC conversion circuit is working, it is

time to take a step back and do an analysis of the accuracy

of that conversion. The LTC1966 specifications include

, V

three basic static error terms, V

OOS

and GAIN. The

IOS