Page 1

Engineer-to-Engineer Note EE-229

a

Technical notes on using Analog Devices DSPs, processors and development tools

Contact our technical support at dsp.support@analog.com and at dsptools.support@analog.com

Or vi sit our o n-li ne r esou rces htt p:/ /www.analog.com/ee-notes and http://www.analog.com/processors

Estimating Power for ADSP-BF533 Blackfin® Processors

Contributed by Joe B. Rev 1 – February 20, 2004

Introduction

This EE-Note discusses the methodology for

estimating total average power consumption on

the ADSP-BF533 Blackfin® family of

processors (including the ADSP-BF531 and

ADSP-BF532 derivatives). The following

documentation will detail how to interpret power

measurements published in the processor data

sheet and how to extrapolate data for individual

sets of operating conditions based on measured

data at specific operating conditions. A “worstcase” scenario is also made available as an

example for board designers to consider when

designing their power supplies.

Average Power Consumption

Total average power consumption (P

sum of the average power dissipated in each of

the three power domains in a Blackfin

application: internal supply (

supply (

supply (V

V

), and, optionally, Real-Time Clock

DDEXT

). There are different supply

DDRTC

V

DDINT

voltages because the core does not operate at the

same voltage as the I/O. The core operates within

the range of 0.8-1.32V with a nominal rating of

1.2V (

V

). The I/O circuitry supports a range

DDINT

of 2.25-3.6V with a nominal rating of 2.5V or

3.3V (

V

), depending on the system. The Real-

DDEXT

Time Clock can be powered by the I/O supply

but, if the user wanted to absolutely maximize

power savings, it could be the case that both

V

DDINT

and V

are powered off. The Hibernate

DDEXT

power mode on the ADSP-BF533 processor

) is the

DDTOT

), external

allows power to be removed from the core and,

optionally, removed from the I/O. To allow a

Real-Time Clock event to restore power to the

core after exiting Hibernate mode, the Real-Time

Clock must remain powered by a separate

supply, such as a battery. A third power domain

(

V

) satisfies this need.

DDRTC

Since power is defined as the product of the

supply voltage and the current drawn, the power

domains are described by the equations:

P = V * I

DDINT DDINT DDINT

P = V * I

DDEXT DDEXT DDEXT

P = V * I

DDRTC DDRTC DDRTC

For the purposes of this document, current and

power values are treated as average values and

voltages are assumed to be constant. The total

average power dissipated by the processor is the

sum of three components:

P = P + P + P

DDTOT DDINT DDEXT DDRTC

The following sections describe how to estimate

each of the three components.

Average Internal Power Consumption

There are a few things to consider when

estimating the average internal power dissipation

of a processor. The first consideration is the fact

that internal power is composed of two

components, one static and one dynamic.

The static component, as the name implies, is

independent of transistor switching frequency. It

Copyright 2004, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer product design or the use or application of

customers’ products or for any infringements of patents or rights of others which may result from Analog Devices assistance. All trademarks and logos are property

of their respective holders. Information furnished by Analog Devices applications and development tools engineers is believed to be accurate and reliable, however

no responsibility is assumed by Analog Devices regarding technical accuracy and topicality of the content provided in Analog Devices’ Engineer-to-Engineer Notes.

Page 2

a

is a reflection of “leakage” current, which is a

phenomenon that causes transistors to dissipate

power even when they are not switching.

Leakage is a factor in high-performance CMOS

circuit design and is a function of both the supply

voltage and the ambient operating temperature at

some die to conduct faster than others, which

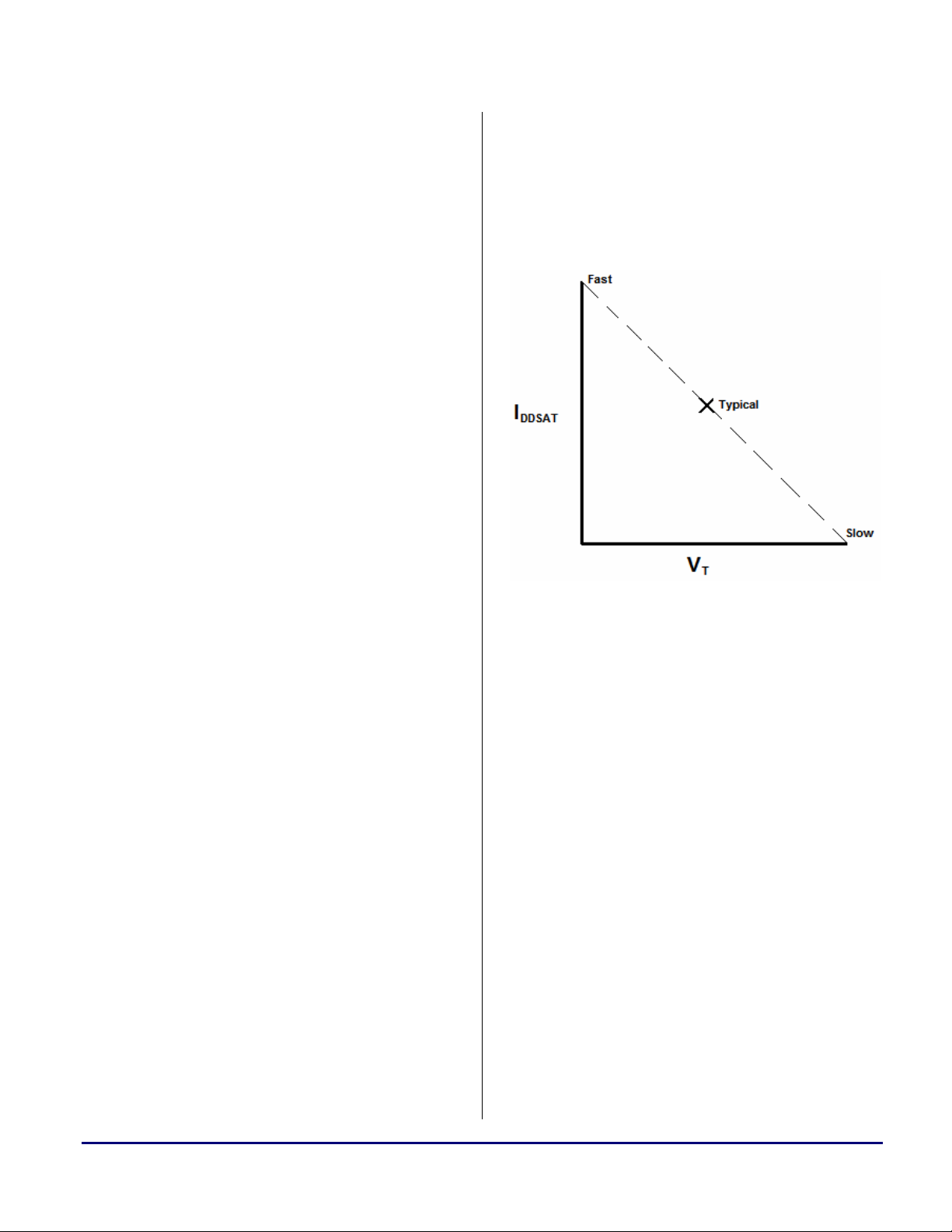

results in three process-related groupings. Figure

1 shows a process curve, which is a graphical

representation of this categorization based upon

transistor threshold voltage (

current (

I

DDSAT

).

V

) and saturation

T

which the part is expected to run. Leakage

current increases as temperature and/or voltage

increases.

The dynamic power component is largely

independent of temperature and is a function of

supply voltage and switching frequency. The

faster the transistors can switch, the more voltage

swings occur. The higher the supply voltage, the

larger the voltage swing between the on and off

transistor states. Thus, the dynamic component

will increase with voltage and/or frequency.

The second major consideration in estimating

average internal power is the type of application

code expected to run on the processor.

Specifications in the data sheet were obtained

while the processor ran a 75% Dual-MAC and

25% Dual-ALU algorithm, which was fetching

slowly changing data from L1 data memory. All

peripherals were disabled, but the core and L1

memory were running. To help the board

designer “size” the voltage regulators, power

numbers under full stress conditions are provided

in this document. These conditions include the

core running an algorithm consisting of 100%

Dual-MACs and more strenuous data-switching

Figure 1. Process Curve (I

DDSAT

vs VT)

The process contains three “corners”: fast,

typical, and slow. A “fast corner” part results

when the threshold voltage is minimized and the

saturation current is highest. Conversely, a “slow

corner” part has high threshold voltage and low

saturation current. Although “fast corner” parts

allow for higher operating frequencies, the tradeoff is higher leakage current and higher

dissipated power in general.

characteristics. This is discussed in more detail

in the “Estimating Average Static Power” section

of this document.

Finally, the actual power numbers can fluctuate

within a defined range based on the processor

fabrication process at the transistor geometries

required for such high speeds. This is largely due

to the semiconductor doping process (i.e., ion

implantation), which does not result in uniform

connectivity among the transistors, yielding

slight variations of the die in any given wafer of

silicon. Other physical phenomena related to the

fabrication process also contribute to this non-

Estimating Average Static Power

The static component for average internal power

is a result of the leakage current that occurs even

when the transistors are not changing state.

When the clocks (core and system) are off and

voltage is applied to the core and L1 memory,

Blackfin processors are in “Deep Sleep” mode.

The data sheet shows the

I

DDDEEPSLEEP

measurement

to indicate the static current component that

contributes to the internal static power

consumption (

P

P = V * I

DDINT_ST DDINT DDDEEPSLEEP

DDINT_ST

):

uniformity. These physical differences cause

Estimating Power for ADSP-BF533 Blackfin® Processors (EE-229) Page 2 of 10

Page 3

a

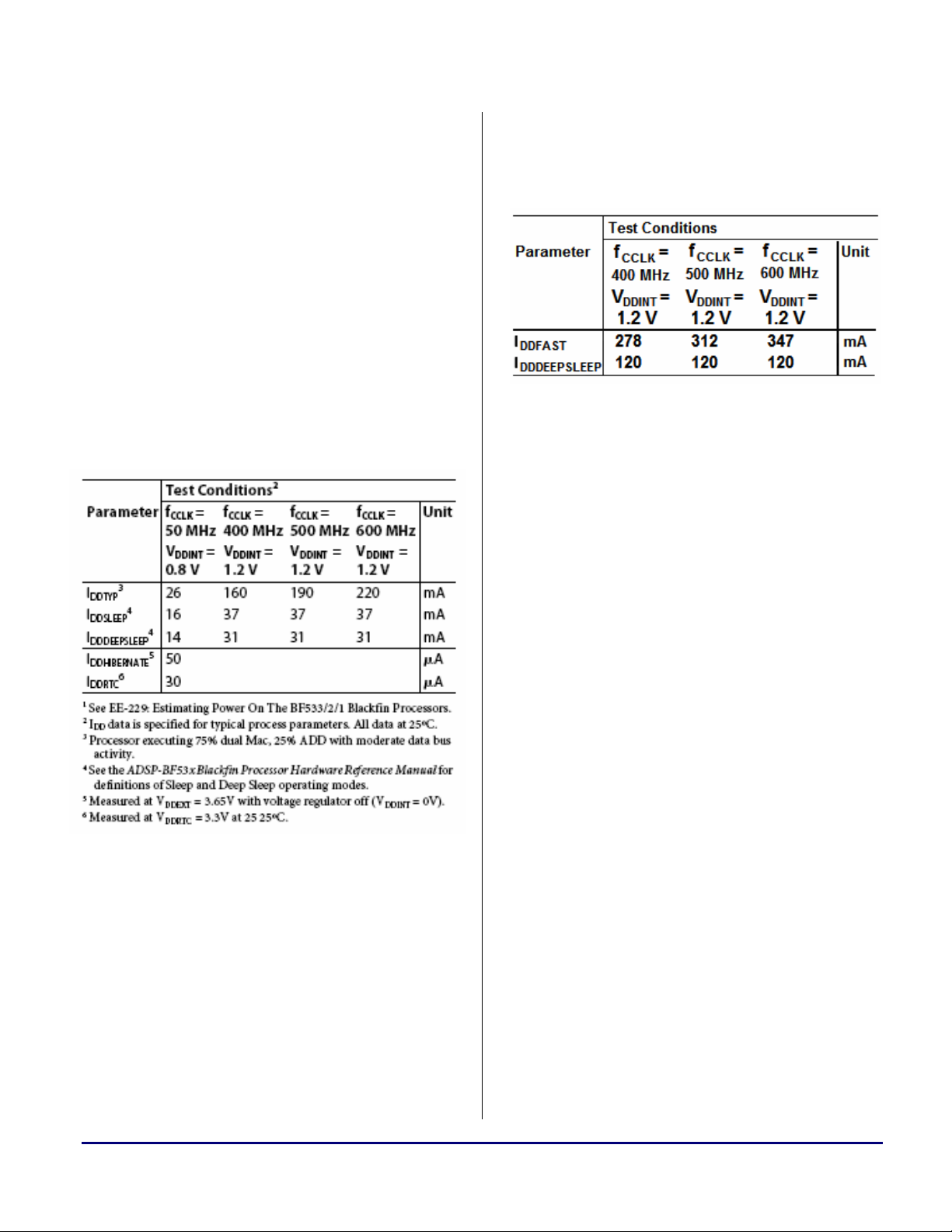

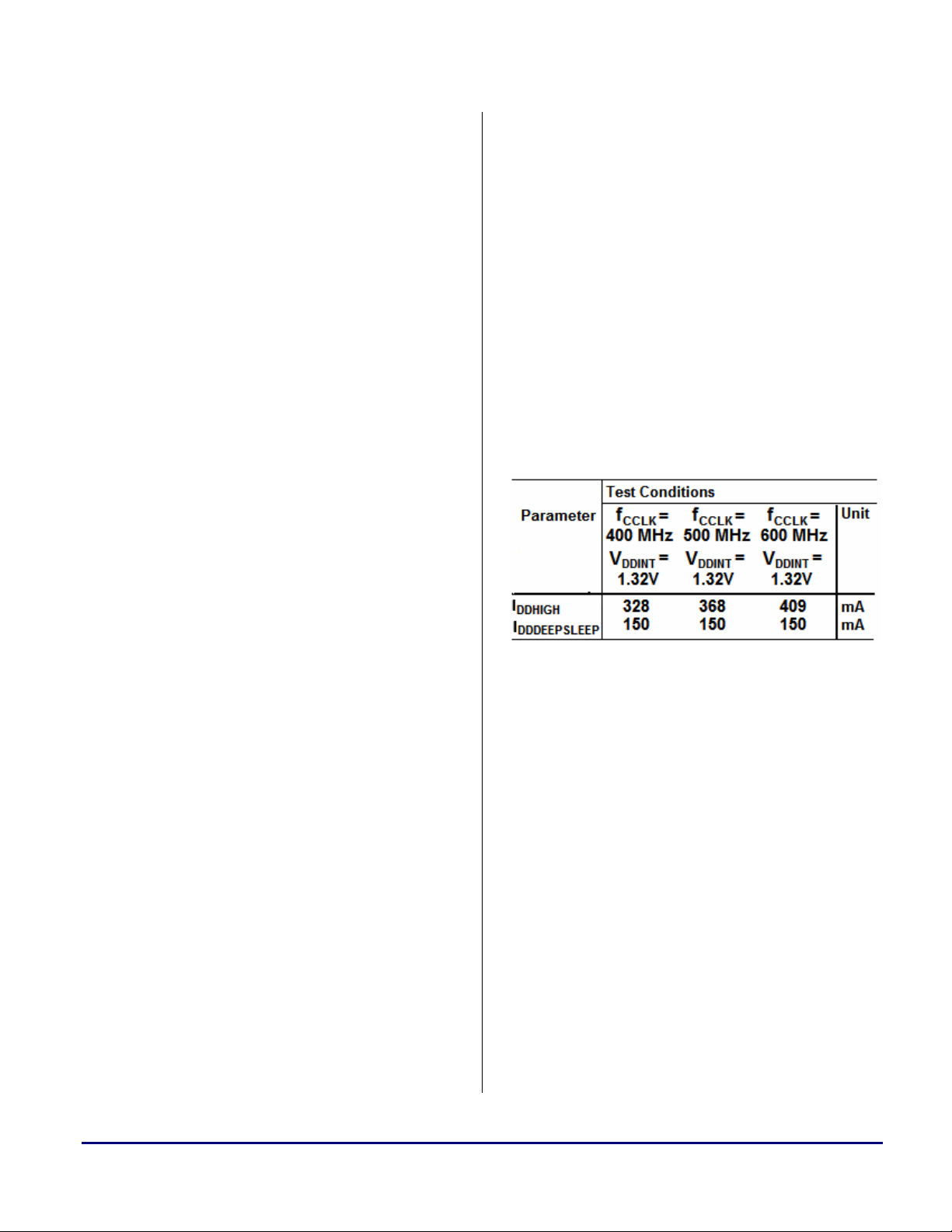

Table 1 shows the “Internal Power Dissipation”

table from the ADSP-BF531/BF532/BF533

Blackfin Embedded Processor Data Sheet [1].

This table contains average internal current draw

measurements, which were taken from a

representative sample of typical parts. In terms of

the static current component,

I

DDDEEPSLEEP

, the

ambient temperature that yielded these numbers

was 25

°C, denoted by footnote 2. The table

shows that the drawn current increases when the

voltage rises from 0.8V to 1.2V. Although no

direct correlation between voltage increases and

leakage can be made, the table sufficiently

details the leakage that can be expected within

the acceptable voltage range at 25

°C for “typical

corner” parts.

internal power dissipated when the core is

running a 100% Dual-MAC algorithm, which

maximizes the workload on the core but is not

typical application code.

Table 2. Average I

on Faster Part (1.2V)

DDINT

The average internal power

!

consumption data is an average

measurement of the representative

sample of faster, higher leakage parts.

Therefore, some parts from within this

sample yielded power measurements

that slightly exceed the estimations

presented in this document as “worstcase”.

As can be extrapolated in the comparison

between Table 1 and Table 2, leakage current

can increase in magnitude by a factor of four due

to normal semiconductor processing variations.

Note that the current draw in Table 2 is labeled

I

to differentiate between the current draw

DDFAST

from typical parts (I

) and the current draw

DDTYP

obtained on faster, higher leakage parts.

Another important factor relative to leakage

Table 1. Internal Power Dissipation (Typical)

To help size the power supply, a set of faster,

higher leakage parts were measured. Table 2 is

similar to Table 1, except that it focuses on parts

that have higher leakage current, which are very

close to a worst-case average internal power

dissipation scenario in terms of silicon type with

no DMA and no peripherals enabled.

The ambient temperature is still 25

maximum 85

°C example is addressed in the

°C, as the

“Worst-Case Model” section of this note.

current is ambient temperature. Static power

consumption increases exponentially with

ambient temperature, as detailed by the equation:

P = P * e

DDINT_ST@T DDINT_ST@T0

where P

DDINT_ST@T0

is the power dissipated due to

leakage current at the known temperature (

P

and

DDINT_ST@T

temperature (

is the unknown number at the target

T). Using Table 2, the static

component of 120mA, given at

(0.015 * (T – T0))

T0)

T0 = 25°C, can be

multiplied by the supply voltage (1.2V) to obtain

the

P

DDINT_ST@T0

value of 144mW. Since the goal is

Additionally, these numbers reflect average

Estimating Power for ADSP-BF533 Blackfin® Processors (EE-229) Page 3 of 10

Page 4

a

to estimate the worst-case scenario in terms of

temperature, the target temperature

T is 85°C.

Given these known values, the estimate for

P

DDINT_ST@T

P

can now be calculated:

DDINT_ST@85°C

= 144mW * e

= 144mW * 2.4596

= 354.183mW

(0.015 * (85 – 25))

To compare to the values detailed in Table 2,

extract the current component:

I

DDDEEPSLEEP@85°C

= 354.183mW / 1.2V

= 295mA

= P

DDINT_ST@85°C

/ V

DDINT

The actual average measurement on a set of

faster parts under these conditions yielded:

I

DDDEEPSLEEP@85°C

= 302mA

As shown, the exponential estimate is within 3%

of the measured value. For those who do not

care for exponents, it is observed that the leakage

current roughly doubles for every 50

°C increase

in ambient temperature. In other words:

I

DDDEEPSLEEP@75°C

= 2 * I

= 2 * 120mA

= 240mA

DDDEEPSLEEP@25°C

Since the temperature increase from 25°C to

85

°C is greater than 50°C, the baseline for the

doubling leakage current changes from the

known value at 25°C to the estimated value at

75

°C. The same “doubles over 50°C” theory is

applied again, knowing that the increase is now

10°C instead of 50°C, which is 20% of the 50°C

used in the doubling estimation. Therefore, the

estimated leakage at 85

increase over the estimated leakage at 75

I

DDDEEPSLEEP@85°C

= 1.2 * I

= 1.2 * 240mA

= 288mA

°C is roughly a 20%

°C:

DDDEEPSLEEP@75°C

This method, while not as accurate as the

exponential estimate, is still within an error of

5% and is a fairly accurate mathematical model.

The “doubling” estimate is not linear, so the

error increases once the 20% assumption is

made.

In summary, these methods can be applied for

the acceptable ambient temperature range once a

baseline “Deep Sleep” mode current

measurement is obtained from the part in

question at the operating voltage of choice. Also,

please recall that these measurements and

estimations are averages across a representative

sample of parts.

Estimating Average Dynamic Power

The dynamic component of average internal

power is a function of the operating frequency

and the supplied voltage. Remember that the

values in Table 2 are from a set of faster, higherleakage parts and represent the maximum current

drawn at 1.2V and 25

°C on a fully-loaded core.

The process of extrapolating measurements by

virtue of frequency and voltage scaling will now

be discussed.

Table 2 shows the

frequencies with

I

measurements at three

DDFAST

V

= 1.2V. Using two

DDINT

measurements in the table, one can calculate the

ratio of current draw increase to frequency

increase. For example, the 400MHz

measurement for

I

DDFAST

is 278mA and the

500MHz measurement is 312mA. The ratio is

34mA per 100MHz, which can be seen between

500 and 600MHz as well. Once this ratio is

known, the expected current draw can be

calculated at any frequency:

I = I + [(F – F0) * Ratio]

DDINT@F DDINT@F0

where F is the target frequency, F0 is the known

frequency, and

Ratio is the change in current

draw per change in frequency. Given this model,

to estimate the total current drawn at 600MHz:

I = I + [(600 – 400) * (34/100)]

DDFAST600 DDFAST400

= 278 + 68

= 346mA

Comparing this estimated value with the

measured value at 600MHz (347mA), the

Estimating Power for ADSP-BF533 Blackfin® Processors (EE-229) Page 4 of 10

Page 5

a

estimate is within 1% of the actual data. In this

model,

Ratio is applied only as a dynamic

current adjustment to the total measured current

draw at a different frequency. Since the static

current component is independent of frequency

and is already included in the

I

DDFAST400

measurement, it is not impacted by this

adjustment.

A second extrapolation from the data in Table 2

is known as “frequency scaling”. A common

question regarding frequency scaling is “Why is

the current draw at 600MHz not equal to 1.5

times the value obtained at 400MHz?”. The basis

for this question is understandable because the

ratio from 400MHz to 600MHz is 1.5. However,

the answer is based on the fundamental

understanding that the static power component is

not affected by a change in frequency. In Table

2, the measured value

I

contains both the

DDFAST

static and dynamic components:

I

DDFAST600

= I

DDDEEPSLEEP

= 120 + 237

= 357mA

+ I

DD_DYN600

This estimate falls within an error of 3% of the

measured data of 347mA.

Aside from the frequency factor, the dynamic

component is also affected by changes in supply

voltage. Another extrapolation method called

“voltage scaling” can be applied to estimate

power when

V

is changing. Table 3 depicts

DDINT

the same data as Table 2, only now the supply

voltage has been increased 10% to the nominal

V

of 1.32V. The other parameters are the

DDINT

same (i.e., application is 100% Dual-MACs, and

ambient temperature is 25

°C):

I

where I

DDFAST

DDDEEPSLEEP

= I

DDDEEPSLEEP

is the leakage, which remains

+ I

DDFAST_DYN

constant across the frequency domain, and

I

DDFAST_DYN

is the dynamic component, which is

affected by changes in frequency. Since the

intent is to apply the dynamic power ratio to the

current draw measurement, the static component

must be removed prior to performing this

operation:

I

DDFAST_DYN400

= I

DDFAST400

= 278 – 120

= 158mA

- I

DDDEEPSLEEP

Because the frequency is being increased by a

factor of 50%, the dynamic ratio can be applied:

I

DD_DYN600

= 1.5 * I

= 1.5 * 158

= 237mA

DD_DYN400

At this point, the static component can be added

back in, yielding a total estimated current drawn:

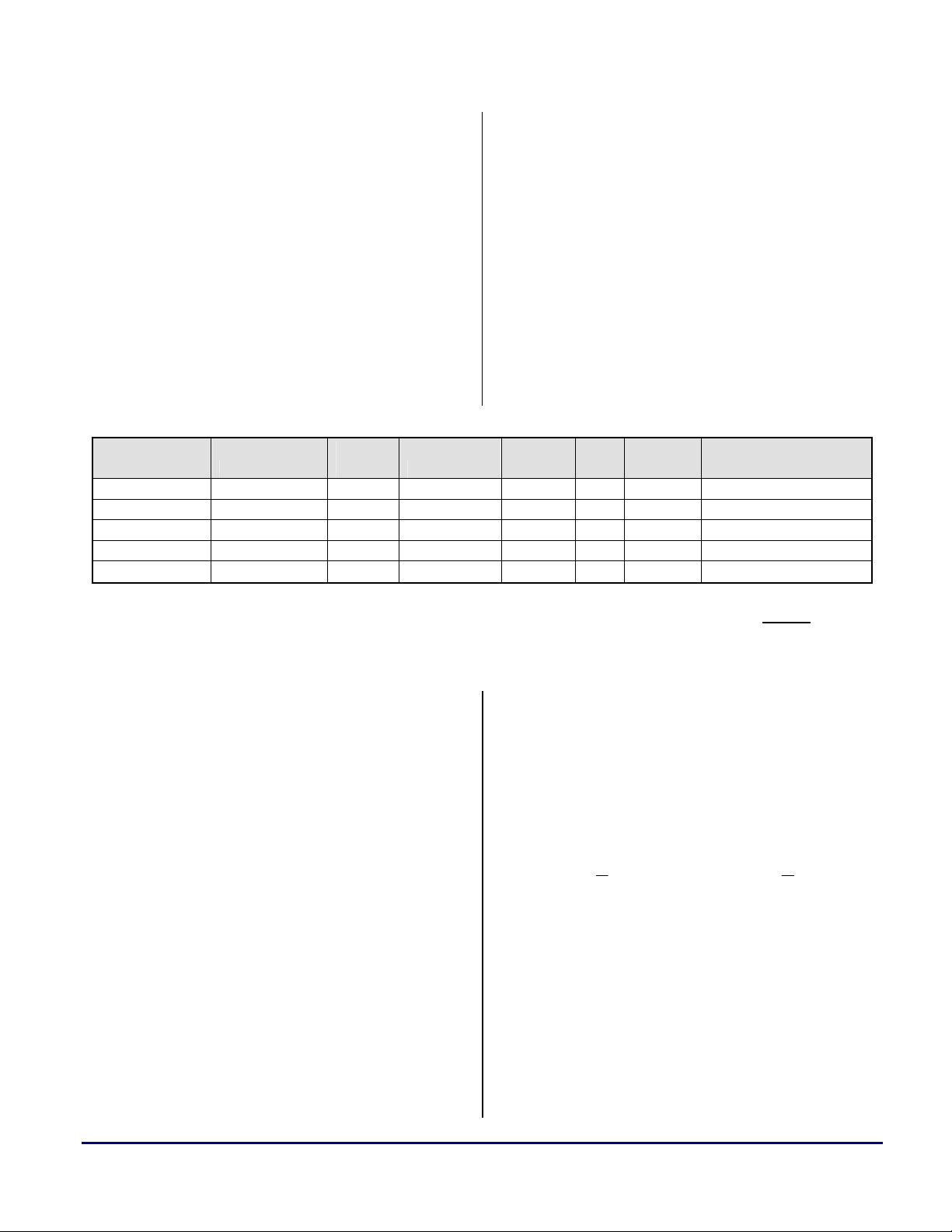

Table 3. Average I

on Faster Part (1.32V)

DDINT

Note that the nomenclature for the current draw

has changed to

I

to indicate that these

DDHIGH

numbers were obtained under the same

conditions as

of the highest allowed

I

, except now they are a result

DDFAST

V

. Using Tables 2 and

DDINT

3, one can obtain the two measurements taken at

400MHz for the typical current draw value:

I = 278mA

DDFAST400

I

DDHIGH400

= 328mA

Again, these numbers are a combination of the

static and dynamic components, so the static

component must be removed first:

I = 278 – 120 = 158mA

DDFAST400_DYN

I

DDHIGH400_DYN

= 328 – 150 = 178mA

The ratio of dynamic power consumption from

one applied voltage to another is directly

Estimating Power for ADSP-BF533 Blackfin® Processors (EE-229) Page 5 of 10

Page 6

a

proportional to the square of the voltage ratio

itself, or:

P

= (1.2V * 158mA) * (1.21)

DDHIGH_DYN

= P

DDFAST_DYN

= 229.416mW

* (1.32V/1.20V)

2

The current component is easily extracted by

dividing this value by the supply voltage:

I

= 229.416mW / 1.32V

= 173.8mA

DDHIGH_DYN

= P

DDHIGH_DYN

/ 1.32V

Now the static component at 1.32V can be

added:

I

= I

DDHIGH

= 173.8 + 150

= 323.8mA

DDHIGH_DYN

+ I

DDHIGH_DEEPSLEEP

The estimated value is within 2% of the actual

value of 328mA. The total current draw can then

be used to calculate the average internal power

consumption:

P

= I

DDHIGH

DDHIGH

= 323.8mA * 1.32V

= 427.4mW

* V

DDINT

These extrapolation methods can be taken a step

further by applying both the frequency and

voltage scales with one equation. Since the

frequency ratio is linear, it can be factored into

the equation used for voltage scaling:

P

DDDYN@V

= P

* (V/V0)2 * (F/F0)

DDDYN@V0

Second, the known values are substituted into the

equation:

P

P

= P

DDDYN@V

DDHIGH_DYN

* (V/V0)2 * (F/F0)

DDDYN@V0

= P

DDFAST_DYN

= (1.2V * 158mA) * 1.815

= 344.124mW

* (1.32/1.2)2 * (600/400)

The current component is easily extracted by

dividing this value by the supply voltage:

I

= 344.124mW / 1.32V

= 260.7mA

DDHIGH_DYN

= P

DDHIGH_DYN

/ 1.32V

Now the static component at 1.32V can be

added:

I

= I

DDHIGH

= 260.7 + 150

= 410.7mA

DDHIGH_DYN

+ I

DDHIGH_DEEPSLEEP

The estimated value is within 0.5% of the actual

measured value of 409mA. The value can then be

used to calculate the average internal power

consumption:

P

= I

DDHIGH

DDHIGH

= 410.7mA * 1.32V

= 542.1mW

* V

DDINT

In summary, there are many methods available to

estimate internal power consumption based on

the values presented in the data sheet or on

values obtained under nominal conditions when

considering worst-case operating conditions.

where V0 is the reference voltage, V is the target

voltage,

F0 is the reference frequency, and F is

the target frequency. For example, the current

values in Table 2 at

F0=400MHz and V0=1.2V are

known and the wish is to obtain the estimated

measurements at

F=600MHz and V=1.32V. Again,

the first step is to remove the static component:

I

DDFAST400_DYN

= 278 – 120 = 158mA

Average External Power Consumption

Average external power dissipation is the

average power dissipated in the

V

DDEXT

power

domain. The number of components that

contribute to the overall external power value is

the number of enabled peripherals in a given

system. Each unique group of peripheral pins

contributes to a piece of the overall external

power based upon several parameters:

Estimating Power for ADSP-BF533 Blackfin® Processors (EE-229) Page 6 of 10

Page 7

a

• Number of output pins (O)

• Number of pins toggling each clock cycle (TR)

• Frequency at which the peripheral runs (

• Utilization factor - percentage of time that the

V

U)

DDEXT

)

peripheral is on (

• Load capacitance (C)

• Voltage swing (

f)

The equation used to derive each component’s

contribution to the total external power is:

P

DDEXT

= (V

)2 * C * f/2 * (O*TR) * U

DDEXT

The worst external pin power scenario is when

the load capacitor continuously charges and

discharges, requiring the pin to toggle

continuously. Since the state of the pin can

change only once per cycle, the maximum

toggling frequency is

power, the worst-case

f/2. In terms of supply

V

value is 3.65V. Table

DDEXT

4 contains data for a realistic example of a PPI

application, which runs several peripherals

simultaneously. Actual results may vary, but

again, the intent is to help designers size the

power supplies.

Peripheral Freq (Hz)

PPI 2.70E+07 9 3.00E-11 1 1.00 3.65 48.56

SPORT0 4.00E+06 2 3.00E-11 1 1.00 3.65 1.60

SPORT1 4.00E+06 2 3.00E-11 1 1.00 3.65 1.60

UART 1.15E+05 2 3.00E-11 1 0.25 3.65 0.01

SDRAM 1.33E+08 36 3.00E-11 0.25 0.50 3.65 119.60

Total External Power Dissipation @ 3.65V (est mW)

# of

pins C/pin (F)

Toggle

Ratio Util

Vddext

(V) Pout @ 3.65V (mW)

171.37

Table 4. Sample Calculation For Total Average External Power

In the above example, the total average external

power consumption is estimated to be ~170mW.

This number was obtained with the parameters

listed in Table 4 by applying the

P

DDEXT

equation

given above. Notice that the recommended load

capacitance of 30pF when the

V

is 3.65V was

DDEXT

used in this calculation. The chosen operating

frequencies are reasonable for each of the

their application, adding or deleting rows as

necessary. Since the equation provides results in

Watts (W), an additional scale factor of 1000 in

the spreadsheet converts results into mW.

This second equation is a more theoretically

accurate version of the one used in the

spreadsheet:

peripherals, including the maximum allowed

SDRAM frequency of 133MHz. This model

assumes that each output pin changes state every

clock cycle, which is a worst-case model, except

in the case of the SDRAM (because the number

of output pins transitioning each clock cycle will

be less than the maximum number of output

pins). Table 4 was taken from External Power

Spreadsheet [2], which is associated with this

EE-Note. It contains calculations for four sample

systems. The reader can tailor this spreadsheet to

Rather than estimating average external power

dissipated in each peripheral, the estimate

applies to each individual output pin, based on

the pin’s load capacitance and average toggling

frequency. The voltage swing is uniform across

all output pins within the

it is multiplied by the summation of the dynamic

charge changes on each output.

ext

2

V

DDEXT

⋅⋅=

∑

fCVP

LDDext

−−

PinsOutputAll

supply domain, so

Estimating Power for ADSP-BF533 Blackfin® Processors (EE-229) Page 7 of 10

Page 8

a

Using the PPI data in Table 4, nine output pins

change every cycle at an average frequency of

27MHz. Since toggling between on-to-off and

off-to-on requires two cycles,

F

is half the PPI

AVG

clock (13.5MHz). Since each pin changes at the

same rate and the pin capacitance is, presumably,

the same, the summation is simply nine times the

value of any one PPI pin:

P

= V

EXT_AVG

= (3.65)

= 13.3225 * 0.003645

= 0.048561W

= 48.561mW

2

* 9 pins * (F

DDEXT

2

* 9 * 13.5e6 * 30e-12

* CL)

AVG

As can be seen, the value derived using this

equation is the same as the value estimated in

Table 4. This model obtains the same estimate on

a per-pin basis rather than a per-peripheral basis.

Finally, a board designer must also be mindful of

power supply efficiency when sizing the

V

DDEXT

supply. Refer to Switching Regulator Design

Considerations for ADSP-BF533 Blackfin

Processors (EE-228) [3] for more details

regarding the Internal Voltage Regulator.

modes. Having a battery supply the

allows the removal of the

V

V

and V

DDINT

DDRTC

domain

DDEXT

supplies, thus significantly reducing total average

power consumption.

Worst-Case Model

To help size voltage regulators, let’s consider the

worst-case conditions under which an ADSPBF533 processor might operate (maximum

supply voltage, maximum ambient temperature,

and maximum operating frequency). To further

stress the part, a full load of 100% Dual-MAC

operations would be performed by the core and

the part under scrutiny would be the faster,

higher leakage type. Table 3 shows the current

drawn with all of the parameters maximized

except the ambient temperature. Table 5 contains

the same measurements taken at the maximum

ambient temperature, 85

°C.

Real-Time Clock (RTC) Power Consumption

The final source of total power consumption

comes from the optional third power domain, the

Real-Time Clock power domain (

V

DDRTC

), which is

a specified value. The RTC can be powered

between 2.25V and 3.6V. For a worst-case

analysis, a supply voltage of 3.65V yields a

current draw of 30-50µA for a range of ambient

temperature from 25

°C to 85°C. For the sake of

including this number in the final “Worst-Case

Model”, the power consumption is:

Table 5. Maximum I

The current draw is now represented as

(Extreme Conditions)

DDINT

I

DDMAX

to

differentiate between the current measurements

under these extreme conditions versus those

obtained in previous data sets. These numbers do

not include DMA or peripheral activity, but it is

estimated that the internal power dissipation will

increase by a maximum of 10% with these

additional parameters. Characterization tests are

being conducted to identify what sort of power

P

DDRTCMAX

= V

= 3.65V * 50µA

= 182.5µW

DDRTCMAX

* I

DDRTCMAX

draw increase might be expected in the internal

power domain when peripherals are enabled, but

two stipulations exist that may deem these

increases negligible.

Knowing this value also helps in selecting a

battery as a potential power source for the RTC.

The RTC can be used to take the ADSP-BF533

First, the application being run to generate these

I

numbers is not realistic because it keeps a

DDMAX

processor out of any of the low-power operating

Estimating Power for ADSP-BF533 Blackfin® Processors (EE-229) Page 8 of 10

Page 9

a

full load on the core 100% of the time, which is

not indicative of a real application.

Second, peripheral hardware activity and DMA

will cause stalls in the code being executed by

the “fully-loaded” core, which will save power in

the core dissipation when small increases in

dissipation are being introduced elsewhere onchip. Given these facts, the measurements in

Table 5 should be considered as the worst-case

scenario.

From this data, the extreme worst case for total

power dissipation can be estimated, assuming all

the conditions in Table 5 are met, for the

P

DDMAX

component. The external power component,

P

, is the example used in the “Average

DDEXT

External Power Consumption” section of this

document and the Real-Time Clock component

implies a maximum

temperature of 85

°C.

V

of 3.65V and ambient

DDRTC

The ADSP-BF533 is available in two

!

speed grades, 500MHz and 600MHz.

Although the 500MHz part can be run

up to 85

specified up to 70

°C, the 600MHz part is

°C. Therefore, the

“worst-case” conditions vary between

the two.

Using the data in Table 5 and given all of these

assumptions, the total power dissipation,

P

DDTOT

,

can be estimated for the 500MHz part:

P

= P

DDTOT500

= (579mA*1.32V) + 171.37mW + 182.5µW

= (764.28 + 171.37 + 0.1825)mW

= ~936mW

DDMAX500

+ P

DDEXT

+ P

DDRTC

For the 600MHz part, the measured current

drawn at 85

°C includes a leakage component of

362mA. Since the dynamic power component

remains the same across the temperature domain,

it can be separated out:

I = I - I

DDMAX_DYN600 DDMAX600 DDDEEPSLEEP

= 623 – 362

= 261mA

The static power component can then be used

with the exponential temperature model from the

“Estimating Average Static Power” section to

estimate the leakage at 70

P = P * e

DDMAX_ST@70°C DDMAX_ST@85°C

= (362mA * 1.32V) * e

= 477.84mW * 0.7985

= 381.563mW

°C:

(0.015 * (T – T0))

(–0.225)

The current component is easily extracted by

dividing this value by the supply voltage:

I = P / V

DDDEEPSLEEP@70°C DDMAX_ST@70°C DDINT

= 381.563mW / 1.32V

= 289.063mA

Now that both the static and dynamic current

components are known, a total current draw can

be calculated and used to estimate total average

power:

P = (I + I ) * V

DDMAX600 DDDEEPSLEEP@70°C DDMAX_DYN600 DDINT

= (289.063 + 261)mA * 1.32V

The total power dissipation, P

= 550.063mA * 1.32V

= 726.083mW

, can now be

DDTOT

estimated for the 600MHz part:

P = P + P + P

= 726.1mW + 171.4mW + 182.5µW

= (726.1 + 171.4 + 0.2)mW

= ~898mW

DDTOT600 DDMAX600 DDEXT DDRTC

These numbers are certainly not typical power

consumption numbers. Rather, they may occur if

all the critical parameters are maximized, the

application code fully stresses the core, and the

part is the faster, higher-leakage variety. These

numbers are being supplied to aid in specifying

the maximum power requirements for a

particular system’s voltage regulator.

Estimating Power for ADSP-BF533 Blackfin® Processors (EE-229) Page 9 of 10

Page 10

a

Conclusions

Several variables affect the power requirements

of an embedded system. Measurements

published in the ADSP-BF533 data sheet are

indicative of typical parts running under typical

conditions. However, these numbers do not

necessarily reflect the actual numbers that may

occur for a given processor under non-typical

conditions. The fabrication process plays a large

role in the total estimated power calculations that

are feasible for the ADSP-BF533. In addition to

the type of silicon that the customer could have,

the ambient temperature, core and system

frequencies, supply voltages, pin capacitances,

power modes used, application code, and

peripheral utilization all contribute to the average

total power that may be dissipated.

Even with all the estimates discussed in this

document, the result is an estimated average

power consumption number at any given time.

Assuming that a system can be in several

possible states, calculating a true average power

dissipation, the user would be required to run a

statistical analysis to determine what percentage

of the time the processor spends in each of the

defined states, apply those percentages to the

estimated power consumption calculated for that

state, and then add each of the state averages. For

example:

STATE1 = 20% of application

STATE2 = 10% of application

STATE3 = 70% of application

For example, if statistical analysis yields the

numbers above for percentage of time spent in a

particular system state, the total average power

(

P

) is summarized as follows:

TOT

P

= (0.2*P

TOT

STATE1)

+ (0.1*P

STATE2

)+ (0.7*P

STATE3

)

The average power number that results from this

equation shows how much the Blackfin

processor is loading a power source over time.

Do not use this calculation to size the power

supply! The power supply must support peak

requirements.

Average power estimates are useful in terms of

expected power dissipation within a system, but

designs must support the worst conditions under

which the application can be run.

References

[1] ADSP-BF531/ADSP-BF532/ADSP-BF533 Blackfin Embedded Processor Preliminary Data Sheet. Rev. PrC,

January 2004. Analog Devices, Inc

[2] External Power Spreadsheet. Associated file with Estimating Power for ADSP-BF533 Blackfin Processors (EE-229)

February 2004. Analog Devices, Inc.

[3] Switching Regulator Design Considerations for ADSP-BF533 Blackfin Processors (EE-228). Rev 1,

Available March 2004. Analog Devices, Inc.

Document History

Revision Description

Rev 1 – February 20, 2004

by Joe B.

Estimating Power for ADSP-BF533 Blackfin® Processors (EE-229) Page 10 of 10

Initial Release

Loading...

Loading...