Page 1

a

a Engineer To Engineer Note EE-162

aa

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Interfacing the ADSP-21535 to HighSpeed Converters (like those on the

AD9860/2) over the External Memory

Bus

Last modified: 2/12/02

Contributed By: Jeff Sondermeyer, Jeritt Kent, Martin

Kessler, and Rick Gentile

Introduction

In the 1970’s and 80’s high speed mixed signal designs

were often constrained by digital circuitry limitations, not

analog. High-speed parallel converters (>10MSPS), for

example, have been available from industry leaders like

Analog Devices Inc. (NYSE: ADI), since the 1970’s.

More and more applications are demanding intensive realtime algorithms. In addition, higher sample rates (14 bits

at greater than 50MSPS) are available from both analogto-digital converters (ADCs) and digital-to-analog

converters (DACs). These factors mandate faster

programmable general-purpose (GP) digital signal

processors (DSPs) to handle the challenges presented by

these high-speed designs. Until recently, most designers

were forced to interface high-speed parallel converters to

Application Specific ICs (ASICs) or fast Field

Programmable Gate Arrays (FPGAs). Devices like these

are capable of resolving the many required simultaneous

parallel digital operations but are often inflexible and can

be prohibitively expensive. Now, with the recent launch

of the Blackfin™ DSP (ADSP-21535), ADI has a

programmable GP 16-bit fixed-point vector DSP that can

process the sustained input/output (I/O) and core

throughputs re quired to pro cess data from many of these

converters. In particular, the ADSP-21535’s core can be

clocked at 300MHz. Depending on the core clock

frequency, a maximum I/O or system clock (SCLK) of

133MHz can be achieved. This SCLK should not to be

confused with the serial clock for the Serial Peripheral

Interface (SPI).

Advantages of using a GP DSP

One of the biggest advantages of GP programmable DSPs

is that these solutions are typically much lower in cost

than their closest digital processing counterparts, FPGAs

and ASICs. Additionally, GP DSP design cycles are

much shorter which allows for a faster time to market.

Some companies must hire or consult professionals with

specialized skills to design FPGAs/ASICs. Companies

may even be forced to send their intellectual property (IP)

out-of-house involving certain risks in confidentiality

(hardware, firmware, and software). On the other hand,

GP DSP code can be converted to Read-Only-Memorybased (ROM) or be masked into a DSP, like the ADSP2153x, which further protects IP. Finally, GP DSPs are

fully programmable, unlike an ASIC implementation,

where every change requires a costly redesign (time and

money). These factors, alone, are driving many engineers

to reconsider GP DSP as the solution of choice, especially

as GP DSPs approach “Pentium class” core rates.

Generally speaking, the DSP needs to be clocked

minimally an order of magnitude (10X) faster than the

converter’s sample rate to guarantee sufficient data

processing bandwidth. Obviously, the amount of

processing bandwidth needed is dependent upon the

DSP’s interface capabilities which is, in turn, influenced

by several other factors including: block processing

versus sample processing, the existence of a Direct

Memory Access (DMA) controller, multi-ported memory,

and whether external FIFOs are used. Fortunately, the

first instantiation of ADI’s Blackfin DSP family, the

ADSP-21535, has a full DMA controller that operates

independent of the core with multi-ported Level 1 (L1)

and Level 2 (L2) memories. The combination of core

speed, an independent DMA controller, and a large multiported on-board memory (308K bytes) allows the ADSP21535 to perform efficient block processing at high data

rates. For example, if the Revision 2.2-compliant,

33MHz, 32-bit Peripheral Component Interconnect (PCI)

interface is used (not shown in this application), transfer

bandwidths can be achieved that approach 132MB/sec.

The ADSP-21532 has a dedicated Parallel Peripheral

Interface (PPI) to connect directly to high-speed

converters. Note that the ADSP-21535 does not this

interface. However, the External Bus Interface Unit

(EBIU) of the ADSP-21535 provides interfaces to

asynchronous (ASYNC) external memories. If the PCI

bus must be used for other system communications, the

EBIU is the only available parallel interface to connect to

a high-speed converter. Combining the DSP-mastered,

asynchronous control of this port with the synchronous,

continuous data stream of converters provides a challenge

for system designers.

Copyright 2002, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer product d esign or the use or ap plication of customers ’ products or

for any infringements of patents or rights of others w hich may result fro m Analog Devices assist ance. All trademarks and logos are property of their respective holders. Information

furnished by Analog Devices Applications and Development Tools Engineers is believed to be accurate and reliable, however no responsibility is assumed by Analog Devices

regarding the technical accuracy of the content provided in all Analog Devices’ Engineer-to-Engineer Notes.

Page 2

This application note will cover one particular hardware

implementation utilizing a low pin count, low cost

Programmable Array Logic (PAL), Complex

Programmable Logic Device (CPLD), or FPGA. This

logic will perform the control functions between the

AD9860/2 Mixed Signal Front-End (MxFE) and the

ASYNC external memory bus of the ADSP-21535.

Although the DSP code will not be disc ussed in this note,

the assembly code is included in the Appendix as a

reference. The application depicted in Figure 1 below is

for an Orthogonal Frequency Division Multiplexed

(OFDM) wireless portable terminal. Please note that the

ADC and DAC were time-shared (Time Division

Multiplexed or TDM) over the ASYNC interface of the

DSP. (The information given here applies equally to

other parallel high-speed ADCs and DACs.)

This engineering note assumes that the reader has prior

knowledge of the ADSP-21535 and the AD9860/2. If you

are unfamiliar with the ADSP-21535, please refer to the

“ADSP-2153x/21535 Blackfin DSP Hardware

Reference”. The datasheet for the AD9860/2 can be

found at www.analog.com

Design Goals

One of the early design goals for this project was to

minimize the amount of external control logic necessary to

interface the DSP and the converter(s). Driven by cost,

engineering wanted to eliminate any FIFOs or memory

within the external logic device. An additional constraint

was to avoid routing the data buses through the logic

thereby reducing the number of pins, package size, and

cost of the logic device. The initial design shown in

Figure 1 co mbines all functions (includi ng data latching)

into a single logic device. However, production models of

this design will utilize inexpensive tri-state-able latches

driven by a logic device. These latches or buffers will

multiplex (pack) the samples from the DSP memory

interface to the 12/14-bit DAC as well as buffer or demultiplex (unpack) the 10/12-bit ADC samples to the DSP

memory interface.

Design Challenges

One of the key factors in any mixed-signal/DSP design is

a solid understanding of the trade-offs between the

devices. The following discussion will illustrate the

various tradeoffs that must be considered when interfacing

ADCs/DACs to the ADSP-21535.

The OFDM modulation scheme for this design drove the

converter sample rate for this application to be

15.36MSPS. The AD9860/2 has a dual 10/12-bit,

64MSPS ADC as well as a dual 12/14-bit, 128MSPS

DAC. Unlike ADI’s SHARC® processors that have a

DMA-Request and DMA-Grant (i.e. DMA can be

mastered from external device), the ADSP-21535 only has

one set of internal memory DMA channels (memDMA),

which must be mastered from the DSP. In addition, when

the ADSP-21535 ASYNC interface is connected to

devices that do contain FIFOs or memory, all latencies

must be understood. Every time the memDMA

relinquishes the bus after a burst of eight (8) transfers, it

requires ten (10) SCLK cycles to begin the next transfer.

Future Blackfin derivatives will have programmable

priority levels for the DMA controller as well as a

dedicated high-speed parallel interface with DMARequest and DMA-Grant signaling. With a dedicated PPI

on future Blackfin products, the ASYNC memory

interface will not be required to connect to parallel

converters.

This approach assumes that the memory interface is

dedicated to the converters. Multiplexing external

SRAM/SDRAM memory with the converter(s) would be

difficult and is not recommended, especially considering

that there is only one memDMA, and it would need to be

shared. The existence of a large on-board L2 memory

(256K bytes) minimizes the need for any external

memory. However, multiplexing the parallel converter(s)

with a Flash or EPROM for boot purposes is permissible.

This design uses a TDM time-slice approach for sharing

the external bus between the ADCs and the DACs.

Simultaneous access is not possible with the ADSP-21535

because, as mentioned previously, there is only one

memory interface that either does a read or a write, and

there is only one set of memDMA channels (source and

destination).

The ADSP-21535 will support a maximum SCLK of

133MHz (peak DMA bandwidth). At this rate, and with

no external FIFO, the memDMA could sustain a transfer

(32 bit word) rate of 133M/10 (nine cycles are required

for bus acquisition plus one to make the next transfer) or

13.3M words/second. Note, however, that the SCLK of

the ADSP-21535 is derived from the core clock (CCLK).

Here, there are four available divide ratios: 2, 2.5, 3, and

4. As a result, one possible combination of CCLK and

divisor that will allow a 133MHz SCLK is CCLK =

266MHz and CCLK/SCLK = 2. If the core must run at

300MHz, the highest SCLK that can be obtained is

EE-162 Page 2

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 3

120MHz (divisor=2.5) to stay under the maximum

133MHz. Now, since the ASYNC memory interface is 32

bits wide, one can pack up to two 16-bit samples (in this

case I and Q) into each word. This effectively halves the

word rate that the DSP must process (with a 15.36MSPS

converter sample rate, the DSP will “see” 7.68MSPS).

The highest external converter sample rate, though, that

the memDMA will support under these conditions is 2 *

120/10 = 24MSPS. Furthermore, the SCLK must be an

integer multiple of the converter sample rate to ensure

proper phase alignment between converter timing and

DSP timing and eliminate the need for any external

FIFOs. So, if the 120MHz SCLK must be evenly

divisible by the sample rate, the highest even divisor of

120 is 12. Therefore, the highest converter sample rate

that the ADSP-21535 will support is 2 * 12M = 24MSPS.

Again, the DSP will only process half of this rate,

12MSPS, and this is, in fact, equal to the maximum rate

that the memDMA can sustain, 12M words/second. Note

that higher sample rates can be processed by the ADSP21535 by including small external FIFOs between the

converter(s) and the EBIU.

It is again noted that this application dictated a

15.36MSPS converter sample rate driven by OFDM

requirements. To obtain a SCLK that is an integer

multiple of this converter sample rate, then, one must

choose a Phase Locked Loop (PLL) Multiplier that is an

integer multiple, in turn, of one of the four available

divisor ratios (2, 2.5, 3, or 4). The maximum CCLK

allowed is 276.48MHz (using a PLL multiplier of 18).

This, in turn, limits the SCLK to the integer multiple

276.48/3 = 92.16MHz (a divide ratio of 2 would give an

SCLK over the 133MHz maximum). Under these

constraints, the maximum sustained rate that the

memDMA can support is 92.16/10 = 9.21 words/second.

DMA Considerations

Careful consideration must be given to the combined,

required, “sustained” DMA performance. Since the

memDMA is a shared resource over the DMA bus (DAB),

other DMA activity is arbitrated on this bus. This

application required a 10Mbit/second serial channel on a

SPORT that also must arbitrate for the DAB. This will

consume an additional 625K words/second at 16 bits/word

of DMA bandwidth. The ADSP-21535 supports a total of

133M words/second peak DMA bandwidth, and the

SPORT has higher arbitration priority over the memDMA

(see Table 1). Given this, the SPORT DMA should

effectively utilize the ten-cycle (10) delay previously

discussed and allow most, if not all, of the 9.21M

words/seconds to be used by the memDMA. There are

9.21M – 7.68M (15.36/2) = 1.53M words/second of

additional bandwidth which should provide enough

margin for a sustained 7.68MSPS.

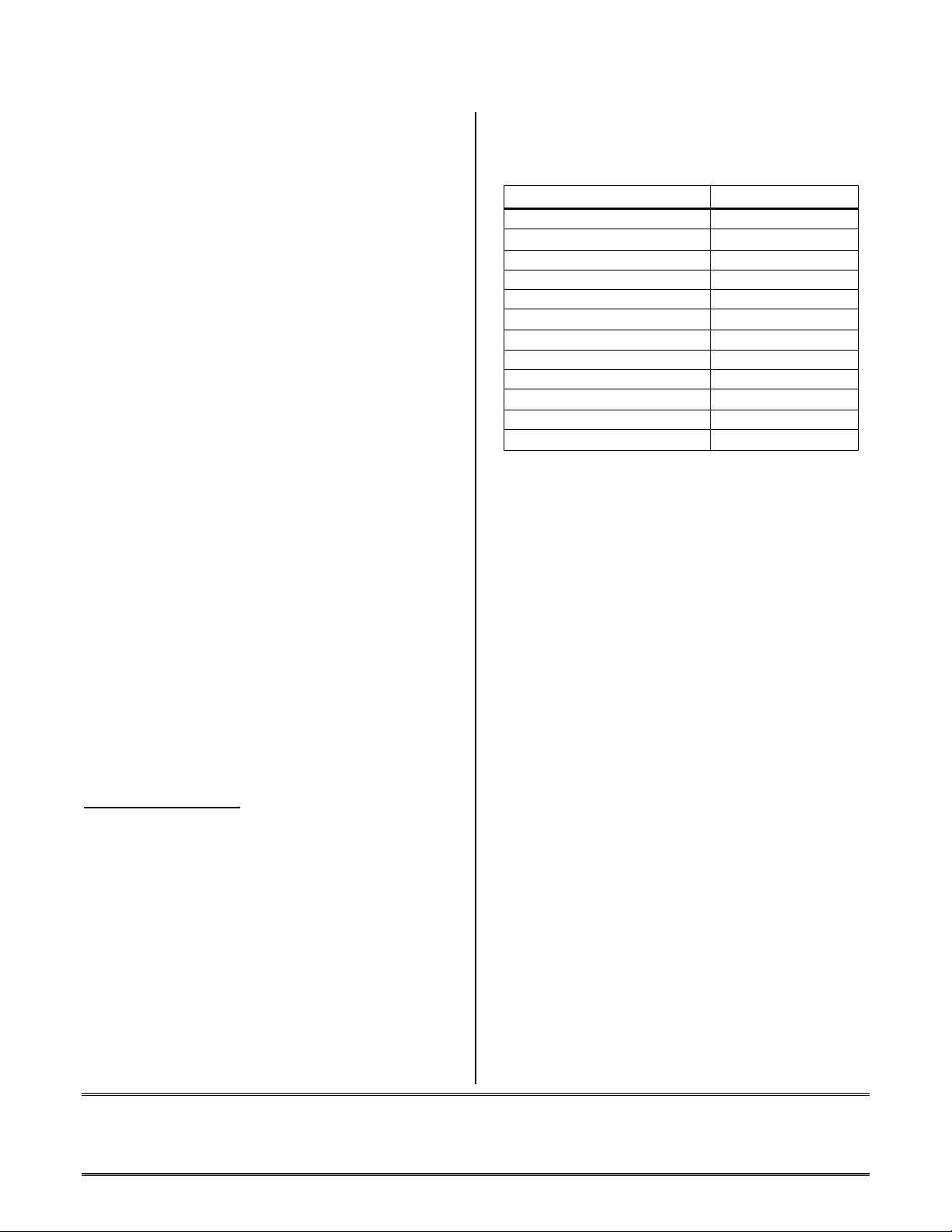

DAB Master Arbitration Priority

SPORT0 RCV DMA Controller 0 - highest

SPORT1 RCV DMA Controller 1

SPORT0 XMT DMA Controller 2

SPORT1 XMT DMA Controller 3

USB DMA Controller 4

SPI0 DMA Controller 5

SPI1 DMA Controller 6

UART0 RCV Controller 7

UART1 RCV Controller 8

UART0 XMT Controller 9

UART1 XMT Controller 10

Memory DMA Controller 11 - lowest

Table 1: Arbitration Priority

Analysis of the DMA engine within the ADSP-21535

reveals a few other considerations. While the DMA

engine supports two types of DMA transfers: descriptorbased and autobuffer-based, the ADSP-21535 memDMA

controller does not support autobuffer-based DMA.

Therefore, descriptor-based transfers must be used. The

descriptor fetch from L1/L2 memory involves two (2)

five-word block moves, one for the source descriptor and

another for the destination descriptor. Additionally, the

memDMA has a 16-entry 32-bit FIFO that is filled from

the source and emptied from the destination. If both

descriptors are loaded simultaneously, this requires 39

SCLK cycles (worst case) from L2. The destination

descriptor load has priority over the source load to avoid

overrunning the FIFO. Thus, in this example, the amount

of time required to load both descriptors simultaneously is

1/92.16M * 39 = 423 nanoseconds. The DMA engine

descriptor load performance is best when the descriptors

are loaded from L2 memory. If the descriptors are located

in L1 memory, there are additional delays. The source

plus destination descriptors’ load time from L1 is 65

SCLK cycles worst case. To effectively process data at

these sample rates, ping-pong buffers are normally used

(this design utilizes two (2) 1024-word buffers). This

technique allows data to be filled into one buffer while the

core processes the other buffer. See the Appendix for the

Blackfin™ assembly code that utilizes the memDMA to

pull data in from an ADC and “ping-pongs” between two

internal buffers. As a reference, the complete

VisualDSP++ 2.0 project is available from ADI.

EE-162 Page 3

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 4

There are two phases of operation that must be analyzed.

First, samples must be received from the ADC into the

DSP (receiver TDM phase) and secondly, samples must

be transmitted from the DSP to the DAC (transmitter

TDM phase).

Receiver TDM Phase

During the receive phase (i.e. data from the ADC), the

data movement is in this direction: ADC → EBIU

(source) → memDMA → FIFO → L1/L2 (destination).

At the 15.36MHz converter sample rate, a new 32-bit

sample arrives at the DSP every 1/7.68M = 130.2

nanoseconds. As seen from the descriptor load time

latency, 423 nanoseconds, something must be done to

avoid overrunning the DSP and losing samples.

Fortunately, the converters are attached to an external bus,

and the address bus is not being used. Thus, when

moving samples into the DSP, one can setup the source

descriptor with the maximum transfer count, 65536 words,

and destination descriptor with intended ping-pong buffer

transfer size, 1024 words. In this way, upon interrupt

from the core every 1024 words, only the destination

descriptor is reloaded, and the load time is reduced to 20

SCLKs * 1/92.16M = 217 nanoseconds. As previously

mentioned, this design utilizes a TDM scheme in which

the ADC and DAC occupy time slices. The multiplex rate

is a variable 5-8 milliseconds. Since the ADC and DAC

data is interleaved, at a worst case, the interface changes

from receiver to transmitter and vice versa every 8

milliseconds. Therefore, 65536 words * 130.2

nanoseconds or 8.5 milliseconds is adequate time, and the

source descriptor only needs to be setup once at the

beginning of each receiver TDM phase. Finally, the 16entry memDMA FIFO “hides” the destination descriptor

load time because the source is still filling the FIFO while

the destination descriptor is being loaded from memory.

In a worst-case scenario, the memDMA FIFO will only

accumulate a few samples of data before the descriptor is

reloaded. Then, these samples are burst into memory.

So, the need for an external FIFO on the receiver side is

eliminated and no samples are lost.

Transmitter TDM Phase

During the transmit phase (i.e. DAC), data movement is in

the opposite direction: L2/L1 (source) → memDMA →

FIFO → EBIU (destination) → DAC. Unlike the

previous mode, the source descriptor must be updated

every 1024 words. This will require 20 SCLK cycles or

217 nanoseconds. However, since the memDMA (9.21M

words/second) is running slightly faster than the sample

rate (7.68M words/second), this should maintain 16

samples in the memDMA FIFO, which will feed the DAC

while the descriptor loads. The destination descriptor

transfer count can be fixed at 65536 words. Again, no

external FIFO is required and no samples are lost.

Logic Overview and Timing

In avoiding the need for FIFOs in the external logic, it is

still important to synchronize the converter clocks to the

DSP SCLK. Depending on the sample rate, this limits the

available ADSP-21535 clocking options. Minimally,

SCLK must be evenly divisible by the converter sample

rate, and CCLK may need to be evenly divisible by the

converter sample rate as well (there is only one noninteger divisor, 2.5, and this may not be useable in some

cases). External latches or buffers must be used to align

the data from the converters with the timing of the DSP

(See Figures 2 and 3 for sample skew and delay). The

four-wire DSP SPI port is directly connected to the

AD9860/2 SPI port. To ensure proper power sequencing

and initialization, the DSP should reset the converter(s).

In an effort to further reduce the pin count of the external

logic, another option available on the AD9860/2 (not

shown here) allows two (2) 10/12-bit ADC values to be

time-multiplexed onto a single 10/12-bit RXDATA bus.

This would eliminate one of the two (2) 10/12-bit buses,

but it requires the external logic to de-multiplex the data

before it is transmitted to the DSP.

All data movement is controlled or mastered by the

memDMA within the DSP. When the ADC data is read

(see Figure 2), the external logic must drive the data and

the ARDY signal. The external logic must sample the

/AOE pin to check when data can be driven to the ADSP-

21535. The /AOE signal indicates to the external logic

that the DMA controller is ready to take data. The

receiver three-state machine is shown at the bottom of

Figure 2.

When data is being sent out (see Figure 3) to the DAC, the

external logic has to sample the /AWE signal and then

drive ARDY. /AWE indicates to the external logic when

the DMA controller is ready with new data. The

transmitter four-state machine is shown at the bottom of

Figure 3.

Conclusions

Even though the ADSP-21535 was not specifically

designed to interface to high-speed parallel converters,

this engineering note provides a low-cost “FIFO-free”

solution for interfacing to both ADCs and DACs with

sample rates up to 24MSPS if the core is constrained to

EE-162 Page 4

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 5

run at 300MHz. If the ADSP-21535 core can be clocked

specifically at 264MHz, then the highest converter sample

rate is limited only by the maximum SCLK that the

ADSP-21535 can support (133MHz) and the inter-burst

10-cycle memDMA latency: 2 * 133M/10 = 26.6MHz.

In summary, the following table is included as a set of

rules specific to the ADSP-21535:

The Ten Commandments of Interfacing to the ADSP-21535

1) The ADSP-21535’s maximum allowed core

frequency is 300MHz.

2) ADSP-21535's maximum allowed system clock

(SCLK) is 133MHz.

3) ADSP-21535's memDMA has a worst-case tencycle (10) reacquisition latency every time the DMA

bus is relinquished.

4) ADSP-21535's SCLK shalt be derived from CCLK,

and there are four available divide ratios between

CCLK and SCLK (2, 2.5, 3, and 4).

5) If the ADSP-21535's core shalt run at the maximum

(300MHz), then the maximum SCLK is 120MHz. See

Commandments 1, 2, and 4.

6) The maximum ADSP-21535 memDMA rate is

133M/10 = 13.3Mwords/sec. See Commandments 2

and 3.

7) In order to obtain the fastest ADSP-21535 SCLK

(133MHz) and memDMA transfer rate

(13.3Mwords/sec), the core shalt not run at maximum,

but at 266MHz with a CCLK /SCLK divide ratio of 2.

"Only" 34 MIPs are not utilized!

8) When not using external FIFOs, the ADSP-21535's

core shalt operate minimally at an order of magnitude

(10X) greater than the greatest external interfacing

converter sample r ate to provi de suffi cient pro cessing

bandwidth.

9) To eliminate the need for external FIFOs, the ADSP21535's SCLK shalt be an integer multiple of the

external interfacing converter sample rates to ensure

proper phase alignment between converter timing

and DSP timing.

10) To halve the sample rate that the DSP must

process, th e externa l log ic shal t pack up to two 16-b it

samples into each 32-bit word.

EE-162 Page 5

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 6

PF[X1] RESET

21535

TXBLANK

RXSYNC

0 MHz

TXSYNC

3.84 MHz

TXDATA[13:0]

7.68 MSPS

AMS[X]

AWE

ARDY

7.68 MHz

GPIOPF[X2]

CS

+/-0

FPGA / PAL AD9860/2ADSP-

MUX

MUX

DATA[31:20, 15:2]

7.68 MSPS

AOE

ARE

Buffer

RXDATA[23:0]

7.68 MSPS

CLKOUT2

7.68 MHz

ABE[3]

CLKOUT1

3.3V

30.72 MHz

CLKSEL

VCXOp

30.72 MHz

CLKOUT

92.16 MHz

XTALI

15.36 MHz

XTAL OSC

SPISEL[X] SEN

SCKx

MISOx

MOSIx

SCLK

SDO

SDIO

15.36 MSPS

4x

3.84 MSPS

4x

15.36 MSPS

1/2

7.68 MSPS

1/2

30.72 MHz

SSEL1

SSEL0

TXSYNC

TXDATA

RXDATA

RXSYNC

CLKOUT1

CLKOUT2

TX-A TX-B TX-A TX-B

RX-AB

RX-AB RX-AB RX-AB

CCLK=276.48 MHz

SysCLK=92.16 MHz

Martin Kessler 01/18/02, Analog Devices

3.84 MHz

30.72 MHz

7.68 MHz

Figure 1: External Logic

EE-162 Page 6

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 7

CCLK

SCLK

AMS[x]

AWE

ARDY

DATA

AOE

ARE

ABE[3]

CLKOUT2

Set-up

Hold

4

Read

Access

1

25

123456789

Hold4Set-up Read

10 11 12

Data0 AB [31:20, 15:4]

Use ASYNC

Clear

Access

1

2

123456789

12345

5

Data1 AB [31:20, 15:4]

Hold

4

276.48 MHz

1011 1 2

92.16 MHz

7.68 MHz

7.68 MSPS

7.68 MHz

RXDATA

CLKOUT1

Consecutive Read Access from FPGA, RX-path AD9860/2

1) ARDY low; if /AMS==low & /AOE==low: Output DATA-AB; CLKOUT2==high ?

true

true

Martin Kessler 01/18/02, Analog Devices

2a) ARDY high; 2b) ARDY low

3) ARDY low (use asynchronous clear); Sample RX Data AB

4) ARDY low; Temp=1; CLKOUT2==low ?

RXData1 AB [23:0]

12

3412

/ARE==low ?

true false

Figure 2: Receive Timing and State Machine

RXData2 AB [23:0]

7.68 MSPS

30.76 MHz

false

false

EE-162 Page 7

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 8

CCLK

SysCLK

AMS[x]

AWE

ARDY

DATA

AOE

ARE

ABE[3]

CLKOUT2

Set-up

Hold

1

6

123456789

Write Access

12

Data1 A [15:2] Data1 B [15:2]

Hold

7

10 11 12

Set-up

4

1

123456789

Write Access

7

Hold

4

276.48 MHz

1011 1 2

92.16 MHz

7.68 MHz

7.68 MSPS

7.68 MHz

TXDATA

CLKOUT1

TXSYNC

Consecutive Write Access to FPGA, TX-path AD9860/2

If /AMS==low and /AOE==high:

1) /AWE==low ?

true

Martin Kessler 01/18/02, Analog Devices

2) /AWE==low ? yes: Sample DATA and ABE[3]

3) Output new TX DATA and TXSYNC one cycle after CLKOUT2 high detected

TXData0 B [13:0]

TXData1 A [13:0]

false

7.68 MSPS

30.72 MHz

3.84 MHz

Figure 3: Transmit Timing and State Machine

EE-162 Page 8

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 9

Appendix

#include <def21535.h>

#define RX_DMA_LENGTH_SOURCE 65535

#define RX_DMA_LENGTH_DESTINATION 1023

#define TX_DMA_LENGTH_SOURCE 1023

#define TX_DMA_LENGTH_DESTINATION 65535

#define RX_MODE 1

#define TX_MODE 2

#define PR_MODE 4

#define PT_MODE 8

#define IO_PORT_ADDR 0x28000000

//Bank2 od asych mem, AMS2 effective

/*SSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSS*/

/*Program Section*/

.section program;

/* Init operating mode, stay in supervisor */

SetupOpMode:

/* int 15 point to user program */

p0.l = EVT15 & 0xffff;

p0.h = (EVT15 >> 16) & 0xffff;

r0 = MainProc(Z);

r0.h = MainProc;

[p0] = r0;

/* Enable int 15 */

p0.l = IMASK & 0xffff;

p0.h = (IMASK >>16) & 0xffff;

r0.l = W[p0];

r1.l = EVT_IVG15;

r0 = r0 | r1;

W[p0] = r0.l;

/* Create int 15 */

raise 15;

p0.l = DeadLoop;

p0.h = DeadLoop;

reti = p0;

rti;

nop;

nop;

DeadLoop:

nop;

jump DeadLoop;

MainProc:

call InitRegs;

/* Initialize Stack */

SP =UserStack (Z);

SP.h =UserStack;

/* Enable interrupt,still in superviser mode */

[--sp] =reti;

call SetupEvtHandler;

call SetupCoreTimer;

/* Setup EBIU */

call SetupEBIUAsynchMem;

/* Init Mode as TX, 0-RX, 1-TX, 2-PR, 3-PT */

p0.l = SysMode;

p0.h = SysMode;

r0.l = RX_MODE;

W[p0] = r0.l;

/* Setup DMA */

call InitCommonDMA;

call SetupRXDMA;

/* Setup PF pin, PF0,1,2,3 output */

r0.l=0x000f;

p0.l = FIO_DIR & 0xffff;

p0.h = FIO_DIR >> 16;

p1.l = FIO_FLAG_S & 0xffff;

p1.h = FIO_FLAG_S >> 16;

p2.l = FIO_FLAG_C & 0xffff;

p2.h = FIO_FLAG_C >> 16;

W[p0] = r0;

/* Enable MemDMA sys int . Manual has something

wrong, it is clear to enable interrupt*/

i1.L = SIC_IMASK & 0xffff;

i1.H = SIC_IMASK >> 16;

r3 = [i1];

bitclr(r3, 19);

[i1] = r3;

csync;

/* Enable core timer interrupt & MemDMA write int

*/

i1.L = IMASK & 0xffff;

i1.H = IMASK >> 16;

r3 = 0x2040 (Z);

[i1]=r3;

csync;

/* Start RX DMA operation */

call StartRXDMA;

/* Start core timer */

i0.l = TCNTL & 0xffff;

i0.h = TCNTL >> 16;

r4 = 0x0007 (Z);

r5=0x1;

/* Testing DMA */

LoopA:

p1.l = RXReadDMADp1;

p1.h = RXReadDMADp1;

DMA_WAIT1:

R6 = W[P1];

cc = bittst(R6,15);

IF cc JUMP DMA_WAIT1;

nop;

bitset(r6,15);

W[p1] = R6;

nop;

p1.l = RXWriteDMADp1;

p1.h = RXWriteDMADp1;

R6 = W[P1];

bitset(r6,15);

W[p1] = R6;

nop;

EE-162 Page 9

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 10

p1.l = RXReadDMADp2;

p1.h = RXReadDMADp2;

r5 = [sp ++];

p2 = [sp ++];

p1 = [sp ++];

DMA_WAIT2:

R6 = W[P1];

cc = bittst(R6,15);

IF cc JUMP DMA_WAIT2;

nop;

bitset(r6,15);

W[p1] = R6;

nop;

nop;

p1.l = RXWriteDMADp2;

p1.h = RXWriteDMADp2;

R6 = W[P1];

bitset(r6,15);

W[p1] = R6;

nop;

jump LoopA;

_EHANDLER: // Emulation Handler 0

RTE;

_RHANDLER: // Reset Handler 1

RTI;

_NHANDLER: // NMI Handler 2

RTN;

_XHANDLER: // Exception Handler 3

off1:

nop;

nop;

Jump off1;

RTX;

_HWHANDLER: // HW Error Handler 5

off2:

nop;

nop;

Jump off2;

RTI;

_THANDLER: // Timer Handler 6

RTI;

_RTCHANDLER: // IVG 7 Handler (RTC)

RTI;

_I8HANDLER: // IVG 8 Handler

RTI;

_I9HANDLER: // IVG 9 Handler

RTI;

_I10HANDLER: // IVG 10 Handler

RTI;

_I11HANDLER: // IVG 11 Handler

RTI;

_I12HANDLER: // IVG 12 Handler

RTI;

_I13HANDLER: // IVG 13 Handler

[--sp] = p0;

[--sp] = r0;

[--sp] = r1;

/* Clear MemWDMA interrupt reg */

p0.l = MDR_DI & 0xffff;

p0.h = (MDR_DI >> 16) & 0xffff;

r0.l = W[p0];

W[p0] = r0.l;

/*=======*/

p0.l = SysMode;

p0.h = SysMode;

r0.l = W[p0];

cc= bittst(r0, 1);

if cc Jump TXProcessing;

RXProcessing:

p0.l = RXDMACount;

p0.h = RXDMACount;

r0 = [p0];

r0 += 1;

[p0] = r0;

[--sp] = p1;

[--sp] = p2;

[--sp] = r5;

p1.l = FIO_FLAG_S & 0xffff;

p1.h = FIO_FLAG_S >> 16;

p2.l = TimerToggle ;

p2.h = TimerToggle ;

r5 = W[p2](Z);

bittgl(r5,0);

W[p2] =r5.l;

CC = r5 == 0x1;

IF CC JUMP on;

p1.l = FIO_FLAG_C & 0xffff;

p1.h = FIO_FLAG_C >> 16;

on:

r5 = 0x0001;

W[p1]=r5;

p0.l = FIO_FLAG_C & 0xffff;

p0.h = FIO_FLAG_C >> 16;

cc = bittst(r0,22);

if cc jump RXLedOff;

p0.l = FIO_FLAG_S & 0xffff;

p0.h = FIO_FLAG_S >> 16;

RXLedOff:

r1 = 0x0002;

W[p0] = r1;

cc = bittst(r0,0);

if cc jump RXOddFrame;

p0.l = RXReadDMADp2;

p0.h = RXReadDMADp2;

r0 = W[p0];

bitset(r0,15);

W[p0] = r0;

p0.l = RXWriteDMADp2;

EE-162 Page 10

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 11

p0.h = RXWriteDMADp2;

r0 = W[p0];

bitset(r0,15);

W[p0] = r0;

jump MemDMAISREnd;

RXOddFrame:

p0.l = RXReadDMADp1;

p0.h = RXReadDMADp1;

r0 = W[p0];

bitset(r0,15);

W[p0] = r0;

p0.l = RXWriteDMADp1;

p0.h = RXWriteDMADp1;

r0 = W[p0];

bitset(r0,15);

W[p0] = r0;

MemDMAISREnd:

r1 = [sp++];

r0 = [sp++];

p0 = [sp++];

rti;

TXProcessing:

p0.l = TXDMACount;

p0.h = TXDMACount;

r0 = [p0];

r0 += 1;

[p0] = r0;

p0.l = FIO_FLAG_C & 0xffff;

p0.h = FIO_FLAG_C >> 16;

cc = bittst(r0,22);

if cc jump TXLedOff;

p0.l = FIO_FLAG_S & 0xffff;

p0.h = FIO_FLAG_S >> 16;

bitset(r0,15);

W[p0] = r0;

Jump MemDMAISREnd;

_I14HANDLER:

RTI;

_I15HANDLER:

RTI;

/////////////////////

/* Subroutine area */

/////////////////////

/*-----------------------------------------/

Init all register

Because the reset might not reset

the register into a legal value

/----------------------------------------*/

InitRegs:

/* Initialize all register file */

R0=0;R1=0;R2=0;R3=0;

R4=0;R5=0;R6=0;R7=0;

P0=0;P1=0;P2=0;P3=0;P4=0;P5=0;

I0 = 0 (X); I1 = 0 (X); I2 = 0 (X); I3 = 0 (X);

M0 = 0 (X); M1 = 0 (X); M2 = 0 (X); M3 = 0 (X);

L0 = 0 (X); L1 = 0 (X); L2 = 0 (X); L3 = 0 (X);

B0 = 0 (X); B1 = 0 (X); B2 = 0 (X); B3 = 0 (X);

rts;

/*-----------------------------------------/

Setup all the interrupt handler

/----------------------------------------*/

SetupEvtHandler:

/*===================================*/

/* Setup Event Vectors and Handlers */

R0=0;

p0.l = EVT0 & 0xffff;

p0.h = EVT0 >> 16;

TXLedOff:

r1 = 0x0004;

W[p0] = r1;

cc = bittst(r0,0);

if cc jump TXOddFrame;

p0.l = TXReadDMADp2;

p0.h = TXReadDMADp2;

r0 = W[p0];

bitset(r0,15);

W[p0] = r0;

p0.l = TXWriteDMADp2;

p0.h = TXWriteDMADp2;

r0 = W[p0];

bitset(r0,15);

W[p0] = r0;

jump MemDMAISREnd;

TXOddFrame:

p0.l = TXReadDMADp1;

p0.h = TXReadDMADp1;

r0 = W[p0];

bitset(r0,15);

W[p0] = r0;

p0.l = TXWriteDMADp1;

p0.h = TXWriteDMADp1;

r0 = W[p0];

p0 +=4;

// Reset Handler (Int1)

R0 = _RHANDLER (Z);

R0.H = _RHANDLER;

[P0++]=R0;

// NMI Handler (Int2)

R0 = _NHANDLER (Z);

R0.H = _NHANDLER;

[P0++]=R0;

// Exception Handler (Int3)

R0.L = _XHANDLER;

R0.H = _XHANDLER;

[P0++]=R0;

// IVT4 isn't used, Reserved

[P0++]=R0;

// HW Error Handler (Int5)

R0 = _HWHANDLER (Z);

R0.H = _HWHANDLER;

[P0++]=R0;

// Core Timer Handler (Int6)

R0 = _THANDLER (Z);

R0.H = _THANDLER;

[P0++]=R0;

EE-162 Page 11

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 12

// IVG7 Handler, (RTC, USB, PCI)

R0 = _RTCHANDLER (Z);

R0.H = _RTCHANDLER;

[P0++]=R0;

// IVG8 Handler (SPORT0,1-RX/TX )

R0 = _I8HANDLER (Z);

R0.H = _I8HANDLER;

[P0++]=R0;

// IVG9 Handler (SPI0,1)

R0 = _I9HANDLER (Z);

R0.H = _I9HANDLER;

[P0++]=R0;

// IVG10 Handler (UART0,1 --RX/TX )

R0 = _I10HANDLER (Z);

R0.H = _I10HANDLER;

[P0++]=R0;

// IVG11 Handler (Timer 0,1,2)

R0 = _I11HANDLER (Z);

R0.H = _I11HANDLER;

[P0++]=R0;

// IVG12 Handler (Programmable flag A/B)

R0 = _I12HANDLER (Z);

R0.H = _I12HANDLER;

[P0++]=R0;

// IVG13 Handler (Memory DMA )

R0 = _I13HANDLER (Z);

R0.H = _I13HANDLER;

[P0++]=R0;

[i0]=r1; //Ctimer count

csync;

rts;

/*----------------------------------------------*

* Name : SetupEBIUAsynchMem

* Function : Setup EBIU 's Aych

memory for

ADC/DAC

data

* Register :

* In: None

* Out: None

* Used:

* Author : Jeff Sondermeyer

* Create Date : 01/11/2002

* Modified :

*----------------------------------------------*/

SetupEBIUAsynchMem:

p0.l = EBIU_AMBCTL0 & 0xffff;

p0.h = (EBIU_AMBCTL0 >> 16) & 0xffff;

// Bank 0: Ardy =0, ArdyPol =0, BTT =01(1), BST

=01(1), BHT =10 (2), BRAT =0001 (1), BWAT =

0100(4).

r0.l = 0xffc7; //0x4194;

//Keep Default value for bank 1

// IVG14 Handler (Software Interrrupt 0)

R0 = _I14HANDLER (Z);

R0.H = _I14HANDLER;

[P0++]=R0;

// IVG15 Handler (Software Interrupt 1)

R0 = _I15HANDLER (Z);

R0.H = _I15HANDLER;

[P0++]=R0;

// ???????????

P0 = EVT_OVERRIDE & 0xffff;

P0.H = EVT_OVERRIDE >> 16;

R0=0;

[P0]=R0;

/*===================================*/

rts;

/*-----------------------------------------/

Setup all the interrupt handler

/----------------------------------------*/

SetupCoreTimer:

/* Setup core timer */

i0.l = TCNTL & 0xffff;

i0.h = TCNTL >> 16;

m0=4;

r0=0x5 (Z);

[i0++m0] = r0; //Ctimer Control reg

csync;

r1.l=0x0000;

r1.h=0x0004;

[i0++m0]=r1; //Ctimer period

csync;

r2 = 0x0080 (Z);

[i0++m0]=r2; //Ctimer scale

csync;

r0.h = 0xffc2;

[p0] = r0;

SSYNC;

p0.l = EBIU_AMBCTL1 & 0xffff;

p0.h = (EBIU_AMBCTL1 >> 16) & 0xffff;

// Bank 2: Ardy =1, ArdyPol =1, BTT =01(1), BST

=00(3), BHT =11 (3), BRAT =1111 (15), BWAT =

1111(15).

r0.l = 0xffc7;

//Keep Default value for bank 3

r0.h = 0xffc2;

[p0] = r0;

SSYNC;

p0.l = EBIU_AMGCTL & 0xffff;

p0.h = (EBIU_AMGCTL >> 16) & 0xffff;

//Clockout: Enabled, Bank0,1,2,3: enabled; 32

bits data path enabled

r0 = 0x0007 (z);

W[p0] = r0;

SSYNC;

RTS;

/*----------------------------------------------*

* Name : InitCommonDMA

* Function : Initialize some

common stuff for DMA.

For ex: DP

BASE address, End DMA DP etc.

* Register :

EE-162 Page 12

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 13

* In: None

* Out: None

* Used:

* Author : Jeff Sondermeyer

* Create Date : 01/11/2002

* Modified :

*----------------------------------------------*/

InitCommonDMA:

//Initialize RXDMA count and TX DMA count

p0.l = RXDMACount;

p0.h = RXDMACount;

r0 = 0;

[p0++] = r0; //RX

[p0] = r0; //TX

//Init ending dp, all DMA DP point to this after

transaction;

p0.l = DMAEndDp;

p0.h = DMAEndDp;

r0.l = 0;

W[p0] = r0.l;

//Init Descriptor base pointer register */

r0.l = RXReadDMADp1;

r0.h = RXReadDMADp1;

P0.L = DB_NDBP & 0xFFFF;

P0.H = (DB_NDBP >> 16) & 0xFFFF;

W[p0] = r0.h;

RTS;

/*----------------------------------------------*

* Name : SetupRXDMA

* Function : Setup RX MemDMA for

get data

From ADC

* Register :

* In: None

* Out: None

* Used:

* Author : Jeff Sondermeyer

* Create Date : 01/11/2002

* Modified :

*----------------------------------------------*/

SetupRXDMA:

p0.l = RXReadDMADp2;

p0.h = RXReadDMADp2;

//Configuration, 32bit, int disable

r0.l = 0x8009;

W[p0] = r0.l;

r0.l = RX_DMA_LENGTH_SOURCE;

W[p0+0x2] = r0;

r0.l = IO_PORT_ADDR & 0xffff;

r0.h = (IO_PORT_ADDR >> 16) & 0xffff;

[p0+0x4] = r0;

r0.l = RXReadDMADp1;

W[p0+0x8] = r0;

/* Destination DMA */

// Write descriptor1 Setup

p0.l = RXWriteDMADp1;

p0.h = RXWriteDMADp1;

//Configuration, 32bit, int enabled on completion

r0.l = 0x800b;

W[p0] = r0.l;

r0.l = RX_DMA_LENGTH_DESTINATION;

W[p0+0x2] = r0;

r0.l = RXDMABufferA;

r0.h = RXDMABufferA;

[p0+0x4] = r0;

r0.l = RXWriteDMADp2;

W[p0+0x8] = r0;

//Setup Next DP pointer

r0 = p0;

P0.L = MDW_DND & 0xFFFF;

P0.H = (MDW_DND >> 16) & 0xFFFF;

W[p0] = r0.l;

// Write descriptor2 Setup

p0.l = RXWriteDMADp2;

p0.h = RXWriteDMADp2;

//Configuration, 32bit, int enabled on completion

r0.l = 0x800b;

W[p0] = r0.l;

r0.l = RX_DMA_LENGTH_DESTINATION;

W[p0+0x2] = r0;

r0.l = RXDMABufferB;

r0.h = RXDMABufferB;

[p0+0x4] = r0;

r0.l = RXWriteDMADp1;

W[p0+0x8] = r0;

/* Source DMA */

//Read Descripter1 Setup

p0.l = RXReadDMADp1;

p0.h = RXReadDMADp1;

//Configuration, 32bit, int disable

r0.l = 0x8009;

W[p0] = r0.l;

r0.l = RX_DMA_LENGTH_SOURCE;

W[p0+0x2] = r0;

r0.l = IO_PORT_ADDR & 0xffff;

r0.h = (IO_PORT_ADDR >> 16) & 0xffff;

[p0+0x4] = r0;

r0.l = RXReadDMADp2;

W[p0+0x8] = r0;

//Setup Next DP pointer

r0 = p0;

P0.L = MDR_DND & 0xFFFF;

P0.H = (MDR_DND >> 16) & 0xFFFF;

W[p0] = r0.l;

//Read Descripter2 Setup

RTS;

/*----------------------------------------------*

* Name : StartRXDMA

* Function : Start RX MemDMA for

get data

From ADC

* Register :

* In: None

* Out: None

* Used:

* Author : Jeff Sondermeyer

* Create Date : 01/11/2002

* Modified :

*----------------------------------------------*/

StartRXDMA:

// Enable Destination

P0.L = MDW_DCFG & 0xFFFF;

P0.H = (MDW_DCFG >> 16) & 0xFFFF;

R0 = W[P0];

EE-162 Page 13

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 14

BITSET(R0,0);

W[p0] = R0.l;

// Enable source

P0.L = MDR_DCFG & 0xFFFF;

P0.H = (MDR_DCFG >> 16) & 0xFFFF;

R0 = W[P0];

BITSET(R0,0);

W[p0] = r0.l;

RTS;

/*----------------------------------------------*

* Name : SetupTXDMA

* Function : Setup TX MemDMA to

send data

to DAC

* Register :

* In: None

* Out: None

* Used:

* Author : Jeff Sondermeyer

* Create Date : 01/17/2002

* Modified :

*----------------------------------------------*/

SetupTXDMA:

/* Source DMA */

//Read Descripter1 Setup

p0.l = TXReadDMADp1;

p0.h = TXReadDMADp1;

//Configuration, 32bit, int disable

r0.l = 0x8009;

W[p0] = r0.l;

r0.l = TX_DMA_LENGTH_SOURCE;

W[p0+0x2] = r0;

r0.l = TXDMABufferA;

r0.h = TXDMABufferA;

[p0+0x4] = r0;

r0.l = TXReadDMADp2;

W[p0+0x8] = r0;

//Setup Next DP pointer

r0 = p0;

P0.L = MDR_DND & 0xFFFF;

P0.H = (MDR_DND >> 16) & 0xFFFF;

W[p0] = r0.l;

//Read Descripter2 Setup

p0.l = TXReadDMADp2;

p0.h = TXReadDMADp2;

//Configuration, 32bit, int disable

r0.l = 0x8009;

W[p0] = r0.l;

r0.l = TX_DMA_LENGTH_SOURCE;

W[p0+0x2] = r0;

r0.l = TXDMABufferB;

r0.h = TXDMABufferB;

[p0+0x4] = r0;

r0.l = TXReadDMADp1;

W[p0+0x8] = r0;

/* Destination DMA */

// Write descriptor1 Setup

p0.l = TXWriteDMADp1;

p0.h = TXWriteDMADp1;

//Configuration, 32bit, int enabled on completion

r0.l = 0x800f;

W[p0] = r0.l;

r0.l = TX_DMA_LENGTH_DESTINATION;

W[p0+0x2] = r0;

r0.l = IO_PORT_ADDR & 0xffff;

r0.h = (IO_PORT_ADDR >> 16) & 0xffff;

[p0+0x4] = r0;

r0.l = TXWriteDMADp2;

W[p0+0x8] = r0;

//Setup Next DP pointer

r0 = p0;

P0.L = MDW_DND & 0xFFFF;

P0.H = (MDW_DND >> 16) & 0xFFFF;

W[p0] = r0.l;

// Write descriptor2 Setup

p0.l = TXWriteDMADp2;

p0.h = TXWriteDMADp2;

//Configuration, 32bit, int enabled on completion

r0.l = 0x800f;

W[p0] = r0.l;

r0.l = TX_DMA_LENGTH_DESTINATION;

W[p0+0x2] = r0;

r0.l = IO_PORT_ADDR & 0xffff;

r0.h = (IO_PORT_ADDR >> 16) & 0xffff;

[p0+0x4] = r0;

r0.l = TXWriteDMADp1;

W[p0+0x8] = r0;

RTS;

/*----------------------------------------------*

* Name : StartTXDMA

* Function : Start TX MemDMA to

send data to DA

* Register :

* In: None

* Out: None

* Used:

* Author : Jeff Sondermeyer

* Create Date : 01/11/2002

* Modified :

*----------------------------------------------*/

StartTXDMA:

// Enable Dest

P0.L = MDW_DCFG & 0xFFFF;

P0.H = (MDW_DCFG >> 16) & 0xFFFF;

R0 = W[P0];

BITSET(R0,0);

W[p0] = R0.l;

// Enable source

P0.L = MDR_DCFG & 0xFFFF;

P0.H = (MDR_DCFG >> 16) & 0xFFFF;

R0 = W[P0];

BITSET(R0,0);

W[p0] = r0.l;

RTS;

/*SSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSS*/

/*Start code Section*/

.section start_from_here;

r0 = SetupOpMode(Z);

r0.h = SetupOpMode;

p0 = r0;

csync;

jump (p0);

nop;

nop;

EE-162 Page 14

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 15

/*SSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSS*/

/*Stack Section*/

.section ustack;

.align 4;

.var UserStackSpace0[1000];

UserStack:

.var UserStackSpace1[4];

/*SSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSS*/

/*Data Section*/

// L2 bank 2 */

.section L2_B2_data;

/* MemDMA descriptor buffer */

//First RX

.align 4;

.BYTE2 RXReadDMADp1[5];

.align 4;

.BYTE2 RXWriteDMADp1[5];

//First TX

.align 4;

.BYTE2 TXReadDMADp1[5];

.align 4;

.BYTE2 TXWriteDMADp1[5];

//END

.align 4;

.BYTE2 DMAEndDp[1];

.BYTE2 TimerToggle[1];

.align 4;

.BYTE4 RXDMACount[1];

.BYTE4 TXDMACount[1];

.align 4;

.BYTE2 SysMode[1];

// L2 Bank 3 */

.section L2_B3_data;

/* MemDMA descriptor buffer */

//Second RX

.align 4;

.BYTE2 RXReadDMADp2[5];

.align 4;

.BYTE2 RXWriteDMADp2[5];

//Second TX

.align 4;

.BYTE2 TXReadDMADp2[5];

.align 4;

.BYTE2 TXWriteDMADp2[5];

// L1 B bank, sub bank 0 */

.section L1_B0_data;

.align 4;

TXDMABufferA:

.BYTE4 RXDMABufferA[1024];

// L1 B bank, sub bank 1 */

.section L1_B1_data;

.align 4;

TXDMABufferB:

.BYTE4 RXDMABufferB

EE-162 Page 15

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Loading...

Loading...