Page 1

Engineer To Engineer Note EE-151

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Copyright 2002, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer product d esign or the use or a pplication of custo me rs’ products o r for

any infringements of patents or rights of others which may result from Analog Devices assistance. All trademarks and logos are property of their respective holders. Information

furnished by Analog Devices Applications and Development Tools Engineers is believed to be accurate and reliable, however no responsibility is assumed by Analog Devices rega rding

the technical accuracy of the content provided in all Analog Devices’ Engineer-to-Engineer Notes.

only requiring one selected filter response at any

Implementing Software Data

Overlays for the ADSP-21161

Using the EZ-KIT Lite

Last Modified: 1/25/02

Contributed by: John Tomarakos

Overview

In many DSP applications, there may be system

memory requirements where the DSP

programmer wishes to assign a section of

internal “scratchpad” memory to use for

multiple temporary variables, then store the

variables back to external SDRAM or FLASH

memory for later usage. Often, variables arrays,

or lookup tables are only used during a small

fraction of time of the DSP’s processing, but

they often can take up a large portion of the

internal memory space of the DSP. Or, an audio

system developer may want to copy a block of

recorded audio samples to storage and then

retrieve the data for playback at a later time.

Once the audio data is stored, the internal

memory is free to use for other operations.

Another example could be an application which

requires using a temporary section of shared

memory for sine/cosine lookup tables or FFT

twiddle factors which are only required when

the FFT algorithm is executed, but then perhaps

during the FFT algorithm’s “down time” the

user wants to use the same memory for loading

one out of a number of stored sets of filter

coefficients for other post-filtering operations,

given time upon request from a user-controlled

interface. And finally, another DSP application

could be a music synthesizer, where the DSP is

performing a wavetable synthesis or sample

playback algorithm, and when the musician

selects a new “instrument” on command from a

set of control knobs, telling the system’s host

microcontroller to direct the DSP to download a

new block of wavetable data to the same section

of memory to generate the new sound. To

support such memory management tasks we can

set up what is called a “soft data overlay” to

automate the process of reusing a small section

of internal memory efficiently.

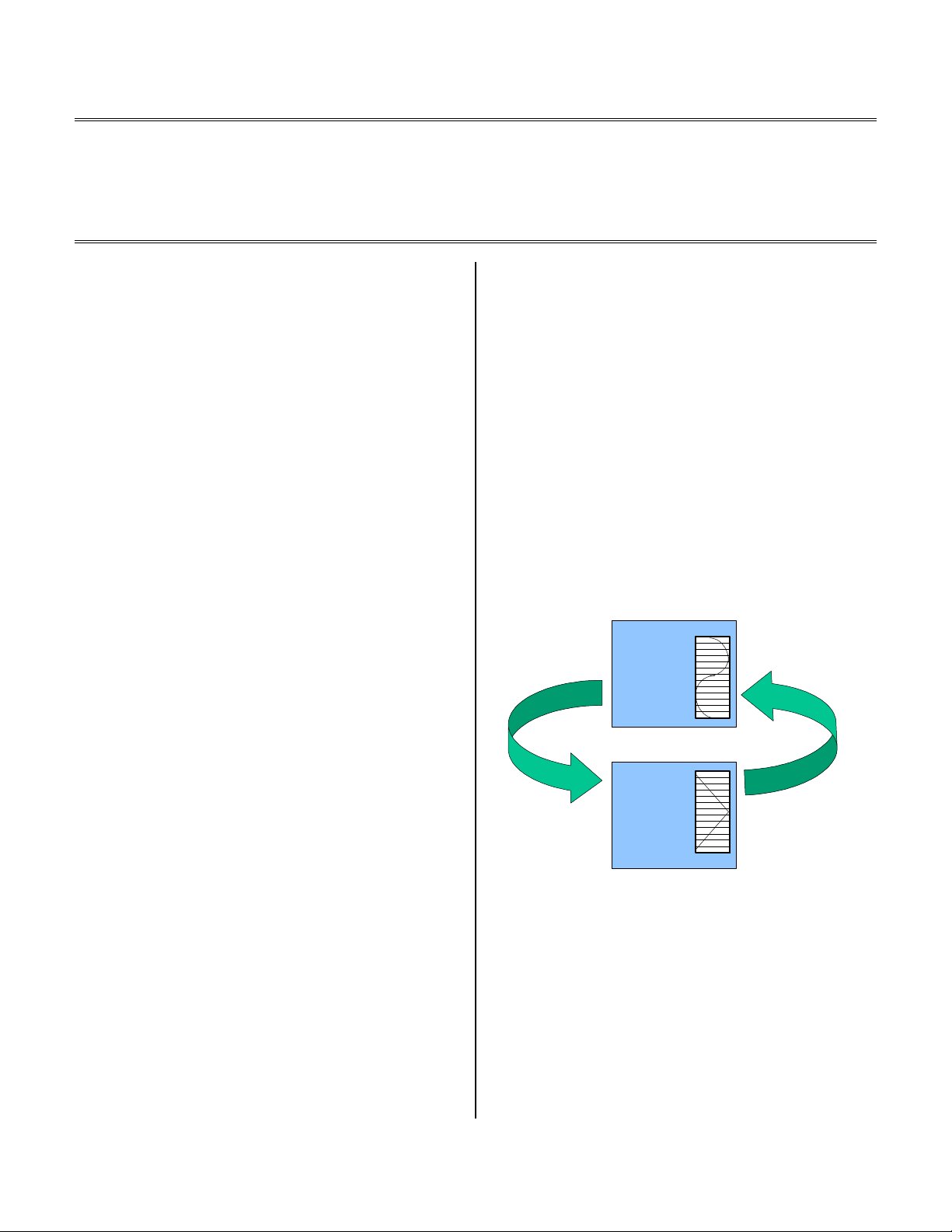

Store Data x[ ]

ADSP21161

Internal

Memory

Swap data buffers x[ ] & w[ ] to/from

same shared internal memory block

External

SDRAM

or FLASH

x[n]

w[n]

Load Data w[ ]

FIGURE 1: Basic Data Overlay Concept

Figure 1 demonstrates a basic concept of a soft

data overlay, where information is loaded from

external memory to a shared section if internal

memory, while the previous data is stored

simultaneously to external memory and recalled

at a later time. This data overlay technique may

provide support for applications where the total

amount of data memory required is greater than

a

Page 2

the available amount of internal data memory

provided by the processor, and the user is

seeking a way to “make the code and data fit

into the DSP’s internal memory space.”

The data overlay “save-and-restore” approach

may be desirable because by keeping all the data

buffers outside in the external memory and

operating on them there, it can result in a

significant reduction in available MIPS, due to

external waitstates or SDRAM latencies. MAC

operations can slow down significantly if the

delay line data or filter coefficients are accessed

from external memory, and the cycle overhead

can also increase significantly depending on

SDRAM latencies if we access non-consecutive

addresses. However, the SHARC processor

may often provide much available non-utilized

I/O processor bandwidth to take advantage of.

During these unused IOP bus cycles it would be

desirable to initiate data overlay transfers which

would execute with zero-overhead to internal

memory from SDRAM, or vice versa. Perhaps

the application is performing 5 active serial port

DMAs or link port DMAs, but this still provides

much IOP bus bandwidth available for quick

100 MHz external port SDRAM block transfers

on a dedicated EPBx DMA channel. 100 MHz

SDRAM DMA transfer throughput with 32-bit

fixed or floating point data can make the use of

data overlays attractive because the SDRAM

controller is able to sustain 100 MHz throughput

in consecutive reads/writes to the same page in

SDRAM (of course, as long as there is no other

core, host or EPBx DMA activity to slow down

access to the external bus). Therefore, the DSP

core can initiate a fast data overlay load, then go

and execute another task in internal instruction

space while the data is quickly loaded by the I/O

processor in the background with no core

intervention.

The advantage of data overlays to SDRAM is

that SDRAM provides a low-cost, bulk-storage,

high-speed interface to move the blocks of data

at up to 100 MHz throughput. The disadvantage

is that a system requires external memory in

addition to a boot flash device, increasing

system cost. If the system does not necessarily

need fast access to swap data blocks, an external

boot flash used for data overlays can could meet

system cost constraints. It is possible to still use

the unused upper sectors of the flash device

which is not used for boot program storage to be

able to temporarily load and store samples, or

filter coefficients or data tables. In this case, we

can set up data overlays with the necessary 8-bit

DMA packing and flash memory commands.

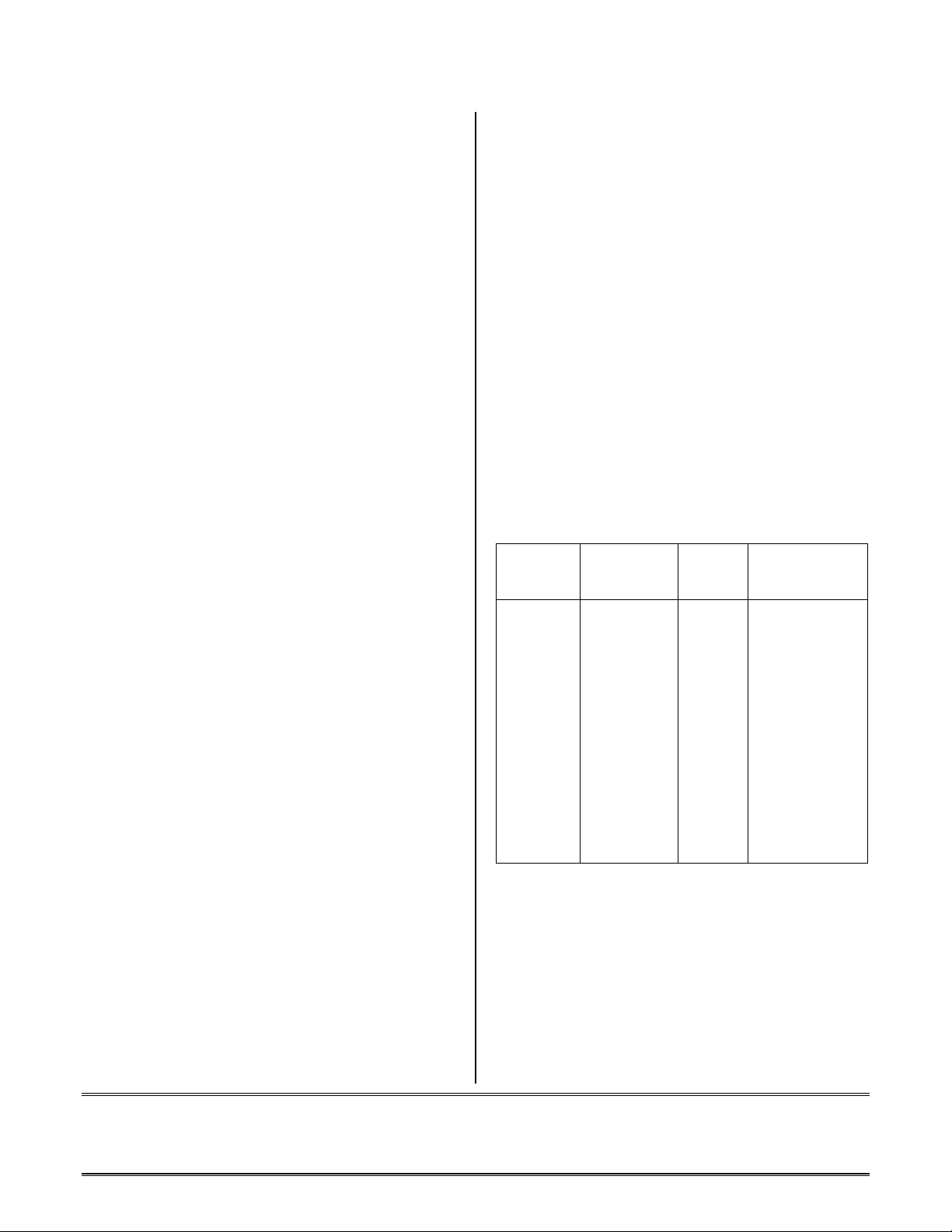

Table 1 below shows the tradeoffs for

implementing data overlays in flash or SDRAM.

TABLE 1. DATA OVERLAY SDRAM/Boot

FLASH comparisons:

MEMORY

Type

SDRAM

SBSRAM

FLASH

Data Overlay

Throughput

100 MHz

transfer

throughput

possible

50 MHz fixed

transfer

throughput

Could require

up to 7 CLKIN

waitstates,

slowest data

throughput

Bus

Width

32-bit

32-bit

8/16-bit

System Cost

May require both

SDRAM and boot

memory

May require both

SBSRAM and

boot memory

Only Boot Flash

Required, can be

mapped to both

/BMS and /MSx

space

So then the question becomes, how can we use

the current VisualDSP++ code generation tools

to provide the ability to load and store data

variables and buffers? As one suggested

solution, this Engineer-To-Engineer Note

discusses a simple technique using Analog

Devices’ Visual DSP++ 2.0 tools and it’s code

overlay support to implement “Data Software

Overlays.”

EE-151 Page 2

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 3

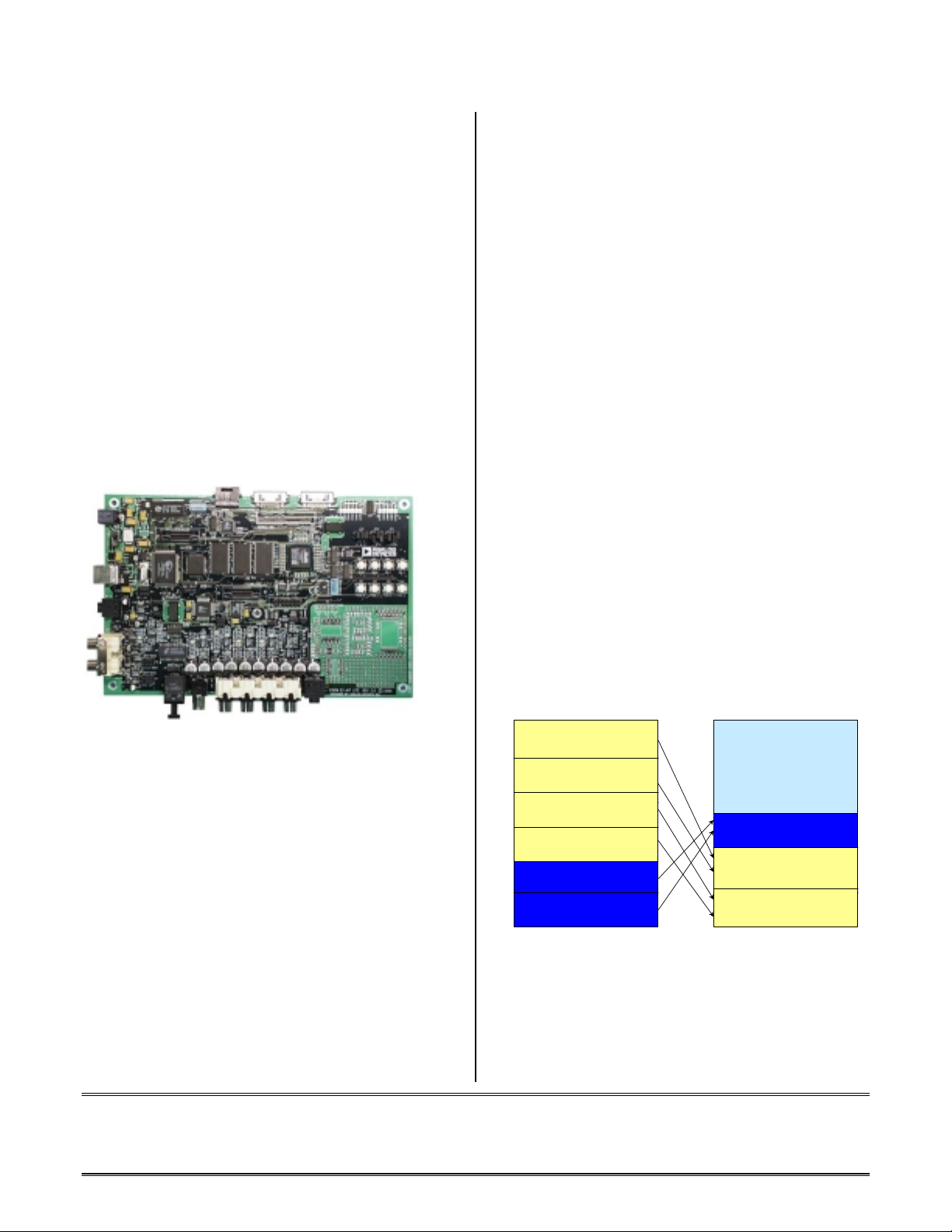

The source code listing in this EE-Note

demonstrates a way to accomplish swapping

data to and from SDRAM using the 21161 EZKIT Lite Evaluation Platform (Figure 2) as the

demonstration vehicle. For more information on

implementing software overlays, refer to EENote # 66: Using Memory Overlays. Keep in

mind the example demonstrated here is just a

sample of one process that may be required in

an actual application. Depending on the user’s

application, further customization of the overlay

process may be required to suit your needs

(through the modification of the overlay

manager discussed later in this document).

FIGURE 2: ADDX-21161-EZ-LITE

The current VisualDSP 2.0++ tools support

software code (instruction) overlays but no

direct data overlay support built into the linker.

By using some of the existing code overlay

support methods supplied with our tools, we can

alternatively develop a data overlay routine

which copy the data variables and buffers from

external memory to internal memory, and then

back to the external memory after the variables

have been modified. This is taken care by a

routine called the data overlay manager, but

when using data overlays (in the current

VisualDSP++ 2.0 toolset) the data movement

process is still required to be initiated by the

programmer in order to start the DMA transfer

(vs. code overlays, which are a more automatic

process with the linker generating the necessary

jump instructions via access to a jump table).

As mentioned earlier, it is also possible for the

ADSP-21161 programmer to perform data

overlays to flash memory. This can be done on

the flash memory used on the EZ-KIT Lite, by

simply modifying the overlay manager to

perform 8-bit DMA accesses to flash memory

while including all of the necessary

housekeeping flash instructions in with the data

overlay manager. For more information on

programming the EZ-KIT flash, refer to EE150: In-circuit programming a boot-image into

the FHASH on the ADDS-21161N-EZLITE.

Look for an additional update to this EE-NOTE

to include data overlays to/from flash memory

using the EZ-KIT Lite.

SDRAM Data Overlay System Design

Assembly and C Examples:

External

Memory

Data Overlay 1

Data Overlay 2

Data Overlay 3

Overlay

Data Overlay 4

Overlay 5

Overlay 6

X[1000]

Y[1000]

M[1000]

N[1000]

P[1024]

FUNC_

Q[1024]

FUNC_

U[512]

V[512]

FUNC_D

FUNC_E

FUNC_F

FUNC_G

Internal

Memory

(non-overlay code)

Interrupt Vector Table

Main code

PLIT

overlay manager

Run Space for

Overlays 5 an d 6

DM data “Run Space” for

Data Overlays 1 and 2

DM data “Ru n Space” for

Data Overlays 3 and 4

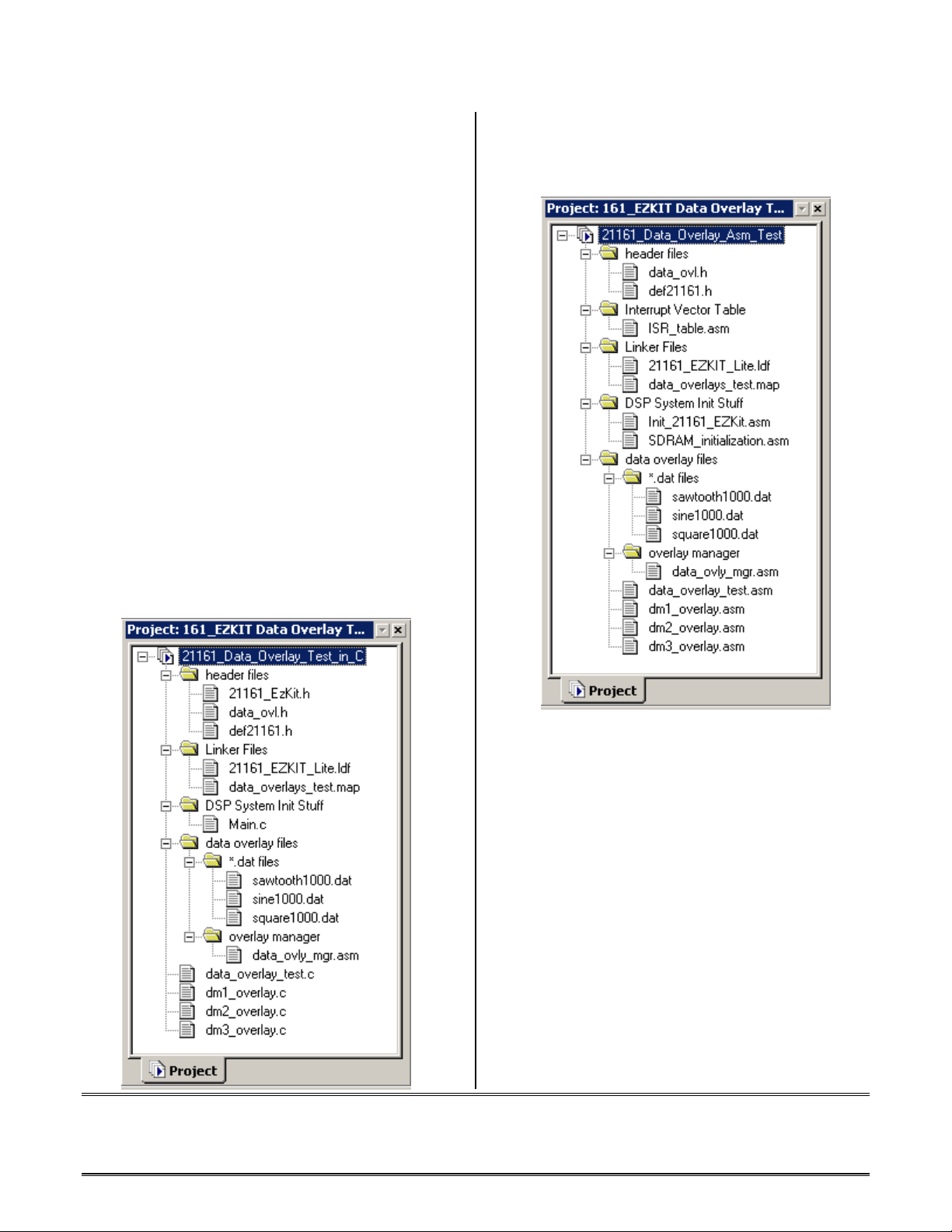

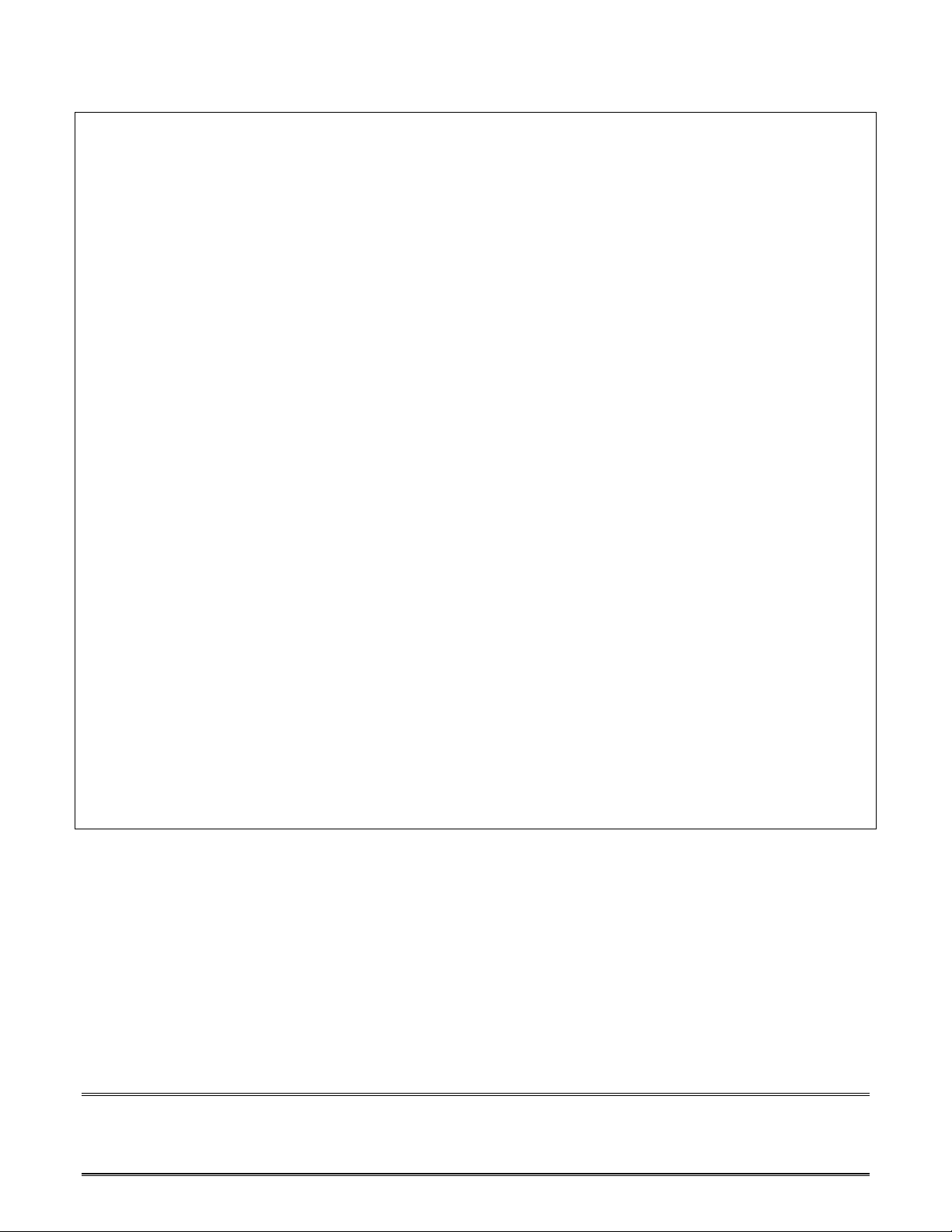

FIGURE 3: Data Overlay Live and Run

Segments

Like code overlays, data overlays are a “many to

one” memory mapping system. For example,

Figure 3 shows how several data overlays “live”

EE-151 Page 3

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 4

(or are stored) in unique external memory

locations, but then “run” (or are

executed/accessed) in a common shared location

in internal memory. This demonstrates an

application in which there are six “live”

segments in external SDRAM. Four segments

are data overlay segments, while the other two

are code overlay segments. There are also two

data overlay “run” segments and one code

overlay “run” segment which is shared between

the overlays in the internal memory of the DSP.

The data overlay concept is demonstrated in

both an assembly version and a C version.

Figures 3 and 4 show the project files for both

the assembly and C implementations. Both

projects consist of the linker description file,

DSP system initialization files, the main routine,

overlay, data files, macros/functions, three

overlay variable declaration files, the data

overlay manager and the data overlay test

routine.

FIGURE 5. Project Files for C Language

Data Overlay Example

FIGURE 4. Project Files for Assembly

Language Data Overlay Example

In these VisualDSP ++ project files, we

implement three data overlay segments which

share the same internal memory run space. The

example defines six 1K buffers x[], y[], m[],

n[], p[], q[] which will share a 2 k segment of

internal memory run space.

In the ADSP-21161’s 1 M-bit internal memory,

we would allocate at least 2K words of internal

memory in BLOCK1 as the “run” time memory

for the data by defining this memory segment in

the MEMORY{} section of the LDF file as

follows:

EE-151 Page 4

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 5

rundmda { TYPE(DM RAM) START(0x00051000)

END(0x00051fff) WIDTH(32) }

Next we want to define our “live” space in

SDRAM mapped to bank0, where our data

overlays will be stored. This is also defined in

the MEMORY {} section of the LDF file:

ovlydmda { TYPE(DM RAM) START(0x00200000)

END(0x0020FFFF) WIDTH(32) }

Each buffer within the two data overlay files are

defined with a length of 1000 words, and each

element contains 32 bit words. These are shown

in the two source listings below. Note that

Buffers x[] and m[] and q[] contain some

initialized values.

LISTING 1: Data Overlay Declarations for

ASM Example

dm1_overlay.asm

.SEGMENT/DM run_dmda;

.GLOBAL x, y;

.VAR x[1000]="sine1000.dat";

.VAR y[1000];

.ENDSEG;

dm2_overlay.asm

.SEGMENT/DM run_dmda;

.GLOBAL m, n;

.VAR m[1000]="sawtooth1000.dat";

.VAR n[1000];

.ENDSEG;

dm3_overlay.asm

.SEGMENT/DM run_dmda;

.GLOBAL p, q;

.VAR p[1000]="square1000.dat";

.VAR q[1000];

.ENDSEG;

LISTING 2: Data Overlay Declarations for

the C Example

dm1_overlay.c

/* Data Overlay 1 */

float sinetbl[1000] =

{

#include "sine1000.dat"

};

float y_out[1000];

dm2_overlay.c

/* Data Overlay 2 */

float sawtbl[1000] =

{

#include "sawtooth1000.dat"

};

float z_out[1000];

dm3_overlay.c

/* Data Overlay 3 */

float squartbl[1000] =

{

#include "square1000.dat"

};

float q_out[1000];

The objective in the ADSP-21161 data overlay

C and assembly tests shown here is to load in

the data buffers x[] and y[] inside to the internal

run space, copy the data from buffer x[] to

buffer y[], then store the current contents of

both buffers back to external SDRAM memory.

Once this process is over the run time memory

can be freed. Thus, this same process is then

repeated for buffers m[] and n[], where buffers

m[] and n[] are loaded to the same run space

previously used by the x[] and y[] buffers.

Buffer m[] is copied to buffer n[] and both

buffers are stored back to SDRAM for later use.

And again, the same process is repeated a third

time for buffers p[] and q[]. This process is

repeated over and over again, while the LED

EE-151 Page 5

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 6

blink status gives an indication which data

overlay load/store is executing.

Data Overlays Load/Store Functions:

As the VisualDSP++ tool only fully support

code overlays, we are still able take advantage

of this built in support to develop a scheme to

handle data overlays. This can be accomplished

by making a few modifications to the ADIsupplied instruction overlay manager which is

provided in EE-66. It does, however, require a

certain amount of house keeping on the

programmer’s part. Basically, this scheme

requires the programmer to initiate the loading

of an overlay containing the data buffers to be

brought into internal memory from external

SDRAM. This can be done by defining and

calling an assembly macro called

Load_Data_Overlay( ). For the C example, we

take a similar approach but instead of

implementing a macro, we can develop a small

C function to initiate the data overlay process.

The parameter the programmer must pass is the

ID of the overlay to be loaded. This can easily

be obtained from the map file.

To write the overlay back to external SDRAM

memory with the changes, the programmer then

calls a second macro or function called

Save_Data_Overlay( ). Again, this macro or

function requires the overlay ID as an input (this

also is obtained from symbol map file).

LISTING 3. data_ovl.h for ASM Data Overlay

Example

#define Load_Data_Overlay(SYMBOL_OVERLAYID)

r0 = 1;\

call _OverlayManager (DB);\

dm(DataTransfer) = r0;\

R0 = SYMBOL_OVERLAYID

#define Store_Data_Overlay(SYMBOL_OVERLAYID)

r0 = 1;\

dm(Internal2exttransfer)=r0;\

call _OverlayManager (DB);\

dm(DataTransfer) = r0;\

R0 = SYMBOL_OVERLAYID

LISTING 4. data_ovl.h for C Data Overlay

Example

extern int SYMBOL_OVERLAYID;

void load_data_overlay (int SYMBOL_OVERLAYID)

{

}

void store_data_overlay(int SYMBOL_OVERLAYID)

{

}

DataTransfer = 1;

asm volatile("R0 = R4;");

OverlayManager();

DataTransfer = 1;

Internal2exttransfer = 1;

asm volatile("R0 = R4;");

OverlayManager();

Thus, these two macros (assembly version) or

functions (C version) simply call the overlay

manager with the proper parameters set. This is

the only difference between data and code

overlays (aside from the overlay manager DMA

setup to initiate data vs. instruction transfers) as

far as the linker is concerned. The macros take

place of the PLIT table since a PLIT entry is not

created for data overlays.

The overlay support provided is built in to the

linker, and is partially designed by the user in

the linker description file (LDF). To set up a

data overlay, the user specifies which data

overlays share runt time memory and which

memory segments establish the live and run data

spaces. The following LDF file fragments shows

how we define three data overlays in the LDF.

The first example is the LDF file portion

contained in the assembly project. Listing 1

shows how to place the data overlay variables

defined in the three overlay asm files to reside in

the run space – run_dmda.

LISTING 3: Overlay Input/Output Sections

for assembly example

no_dmda

{

OVERLAY_INPUT

{

ALGORITHM(ALL_FIT)

OVERLAY_OUTPUT(dm1_ovly.ovl)

INPUT_SECTIONS(dm1_overlay.doj(run_dmda))

EE-151 Page 6

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 7

}>ovlydmda

OVERLAY_INPUT

{

ALGORITHM(ALL_FIT)

OVERLAY_OUTPUT(dm2_ovly.ovl)

INPUT_SECTIONS(dm2_overlay.doj(run_dmda))

}>ovlydmda

OVERLAY_INPUT

{

ALGORITHM(ALL_FIT)

OVERLAY_OUTPUT(dm3_ovly.ovl)

INPUT_SECTIONS(dm3_overlay.doj(run_dmda))

} >run_dmda

}>ovlydmda

The LDF file data overlay declaration shown

above demonstrates how to configure two data

overlays to share a common run time data

memory space. The first overlay, dm1_ovly,

contains buffers x[] and y[] and lives

somewhere in the external memory live segment

ovlydmda. The second data overlay,

dm2_ovly, contains buffers m[] and n[] and

also lives in the external memory segment

ovlydmda. The common run time data

locations shared by overlays dm1_ovly and

dm2_ovly is the segment run_dmda. The

third data overlay, dm3_ovly, contains buffers

p[] and q[] and also lives in the external

memory segment ovlydmda. The common

run time data locations shared by overlays

dm1_ovly, dm2_ovly, and dm3_ovly is the

segment run_dmda. The dummy output

section no_dmda is a placeholder to keep the

linker happy.

To set up our overlays in C for the floating point

variables defined in Listing 2, we set up a

similar redirection of the overlay input/output

files, except we tell the linker to scan all

seg_dmda sections in the 3 overlay object files

and create separate overlay output files with the

information pulled from each object file.

However, the variables will still be directed to

reside in the “run” space segment run_dmda.

LISTING 4: Overlay Input/Output Sections

for C example

no_dmda

{

OVERLAY_INPUT

{

ALGORITHM(ALL_FIT)

OVERLAY_OUTPUT(dm1_ovly.ovl)

INPUT_SECTIONS(dm1_overlay.doj(seg_dmda))

}>ovlydmda

OVERLAY_INPUT

{

ALGORITHM(ALL_FIT)

OVERLAY_OUTPUT(dm2_ovly.ovl)

INPUT_SECTIONS(dm2_overlay.doj(seg_dmda))

}>ovlydmda

OVERLAY_INPUT

{

ALGORITHM(ALL_FIT)

OVERLAY_OUTPUT(dm3_ovly.ovl)

INPUT_SECTIONS(dm3_overlay.doj(seg_dmda))

} >run_dmda

}>ovlydmda

The LDF provides the linker with direction on

how to configure overlays as well as the

information necessary for the data overlay

manager routine to load in the data overlays.

The data overlay information resolved by the

linker to initiate DMA transfers in our example

includes the following constants:

Data Overlay 1

_ov_word_run_size_1

_ov_word_live_size_1

_ov_startaddress_1

_ov_runtimestartaddress_1

Data Overlay 2

_ov_word_run_size_2

_ov_word_live_size_2

_ov_startaddress_2

_ov_runtimestartaddress_2

Data Overlay 3

_ov_word_run_size_3

_ov_word_live_size_3

_ov_startaddress_3

_ov_runtimestartaddress_3

These linker-generated constants are stored

specified locations in user-defined buffers for

the overlay manager to access and initiate DMA

EE-151 Page 7

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 8

transfers. In this overlay example the data is

stored as follows:

liveAddresses[3] = (EIEPx)

_ov_startaddress_1,

_ov_startaddress_2,

_ov_startaddress_3;

runAddresses[3] = (IIEPx)

_ov_runtimestartaddress_1,

_ov_runtimestartaddress_2,

_ov_runtimestartaddress_3;

runWordSize[3] = (CEPx)

_ov_word_size_run_1,

_ov_word_size_run_2,

_ov_word_size_run_3;

liveWordSize[3] = (ECEPx)

_ov_word_size_live_1,

_ov_word_size_live_2,

_ov_word_size_live_3;

The linker will replace these constants with

actual internal memory run space addresses and

sizes and external memory live space addresses

and sizes, which are used to program the IIEPx,

IMEPx, CEPx, EIEPx, EMEPx, ECEPx DMA

parameter registers to initiate the loading or

storing of a data overlay.

The Data Overlay Manager:

The data overlay manager is a user-defined

routine that is responsible for loading a

referenced overlay data variable or buffer into

the internal memory “run” time space. The

central task of the data overlay manager is to

initiate an External Port DMA operation using

one of the external port buffer DMA channels

(DMA channels 10 to 13). This DMA operation

is managed with the aid of the linker generated

constants, in which the internal start address

(IIEPx), external start address (EIEPx), modify

(IMEPx/EMEPx) and DMA count

(CEPx/ECEPx) are programmed from the

linker-generated overlay constants. The main

objective of the data overlay manager is to set

up a DMA transfer to/from the “live” space

to/from the “run” space. Thus, the main

objective of the data overlay manager is to:

• Perform a context save/restore of all

registers used by the overlay manager via

a software stack.

• Identify the desired data overlay module

by getting the ID# of the overlay.

• Sets up an EPBx DMA transfer. Before

enabling the DMA transfer, the overlay

manager determines if the data overlay

module associated with the ID# will

require a load from external memory, or

a store to external memory. Thus, the

DMA transfer set up in the DMACx

register will either write the contents of

internal memory to external memory, or

read the contents from external memory

to internal memory.

• Assign the appropriate live/run addresses

and DMA count size to the I/O

processor, so that the data overlay is

properly loaded from or stored to

external memory.

The overlay manager shown here is written such

that the core processor sits at an “IDLE”

instruction while the transfer occurs. However,

there is additional instructional support which

allows the user to initiate an overlay load/store

while the DSP core executes another section of

unrelated code. The user is referred to EE-66

for more information on how to implement

more advanced predictive overlay managers.

EE-151 Page 8

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 9

Stored Live Space Overlay ID Identifiers for Visual DSP Debugger Symbol

Support

In order to support debugging of overlay variables and buffers, the latest VisualDSP ++ 2.0 linker

overlay support also includes the storage of the overlay ID in the live and run spaces to assist with

symbol support in the debugger. In our assembly data overlay example, since we define a data overlay

run memory section to beginning at address 0x51000 to be run space for overlays, that address will

always hold the Overlay ID, so then our data overlay actually begins at address 0x50001. And the image

in live space will always hold the overlay id. For example, the following memory window of 0x51000

shows the Overlay ID identifier for the data overlay run space, followed by the actual data buffers:

Overlay 1 ID @ 0x51000 Overlay 2 ID @ 0x51000 Overlay 3 ID @ 0x51000

Overlay 1 ID stored in live space at address 0x0x200000

Overlay 2 ID stored in live space at address 0x0x2009C6

Overlay 3 ID stored in live space at address 0x0x20138C

Since address 0x51000 contains the overlay ID, this allows the debugger to display the correct symbol

names for the data overlay variables. If you wanted for some reason to avoid having the overlay ID in

run memory you have to increment the live start address provided by the linker by 1… but doing do

would defeat the symbol support. Since we in most cases reference all the code or data symbolically,

this step of incrementing the live start address is not necessary.

In our assembly example, the following addresses show where all of the variables and overlay symbol

IDs reside in internal run space and external live space:

Address What resides here:

0x200000 Overlay 1 Symbol ID live space storage

0x2009C6 Overlay 2 Symbol ID live space storage

0x20138C Overlay 3 Symbol ID live space storage

0x51000 Symbol ID run space location for Data Overlays 1, 2 and 3

0x51001 Run space start address for data overlay variables x[ ], m[ ] and p[ ]

0x513E9 Run space start address for data overlay variables y[ ], n[ ] and q[ ]

0x200001 Live space start address for x[ ]

0x2003E9 Live space start address for y[ ]

0x2009c7 Live space start address for m[ ]

0x200DAF Live space start address for n[ ]

0x20138D Live space start address for p[ ]

0x20176E Live space start address for q[ ]

EE-151 Page 9

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 10

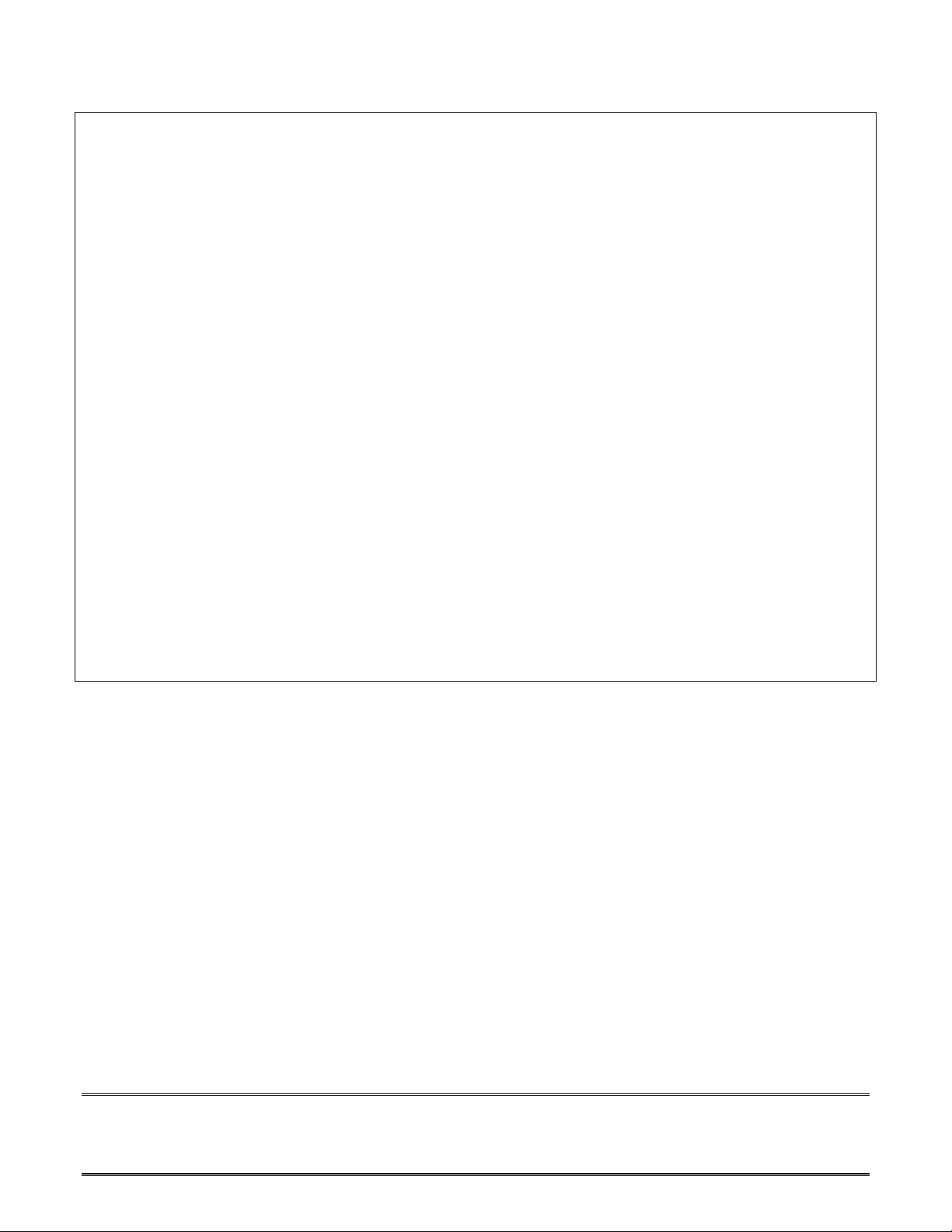

21161 EZ-KIT USB Debugger Session R esults of the 3 Data Overlay Buffer

Load/Copy operation in internal “RUN” space [Assembly Data Overlay Example]

Sine Wavetable Data Overlay Loaded and Processed

Sawtooth Wavetable Data Overlay Loaded and Processed

EE-151 Page 10

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 11

Square Wavetable Data Overlay Loaded and Processed

Linker-Generated Data Overlay “Live” and “Run” Address and Size Buffer Constants for the EZ-KIT Data

Overlay Example

Assembly Example C Example

EE-151 Page 11

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 12

Listing 5. Assembly Data Overlay Test: data_overlay_test.asm

///////////////////////////////////////////////////////////////////////////

// //

// In this example data overlay code there are four buffers x,y,m,n. //

// Each are of length 1000.(32 bit words) //

// //

// Buffers x and m contain some initialised values. //

// //

// Our objective is to copy x to y, m to n and p to q. //

// //

// To save internal memory, we allocate the same 2k internal memory as //

// the run time data memory. //

// //

// First we bring in x and y inside copy x to y and copy back //

// the current values to the external SDRAM memory. //

// Once this process is over the run time memory can be freed. //

// //

// The same process same block copy process is also repeated for //

// buffers m and n, and then again for p and q. //

// //

///////////////////////////////////////////////////////////////////////////

#include "data_ovl.h"

#define xy_ovl 1

#define mn_ovl 2

#define pq_ovl 3

.GLOBAL data_overlay_test;

.EXTERN x, y, m, n, p, q;

.EXTERN Blink_LEDs_Twice, Blink_LEDs_Thrice, Blink_LEDs_4times;

.EXTERN prefetch;

.EXTERN DataTransfer;

.EXTERN Internal2exttransfer;

.SEGMENT/PM pm_code;

data_overlay_test:

copy_x2y: dm(i1,1) = r0;

Load_Data_Overlay(xy_ovl); /* load x & y data buffers from overlay live space

in SDRAM */

l0 =0;

i0 =x;

l1 =0;

i1 =y;

lcntr=1000, do copy_m2n until lce;

r0 = dm(i0,1);

Store_Data_Overlay(xy_ovl); /* storex&ydata buffers to overlay live space in

SDRAM */

call Blink_LEDs_Twice; /* Data Overlayx&yload/store LED confirm */

Load_Data_Overlay(mn_ovl); /* load m & n data buffers from overlay live space

in SDRAM */

l0 =0;

i0 =m;

l1 =0;

i1 =n;

lcntr =1000, do copy_m2n until lce;

r0 = dm(i0,1);

EE-151 Page 12

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 13

copy_m2n: dm(i1,1) = r0;

Store_Data_Overlay(mn_ovl); /* storem&ndata buffers to overlay live space in

call Blink_LEDs_Thrice; /* Data Overlaym&nload/store LED confirm */

Load_Data_Overlay(pq_ovl); /* load p & q data buffers from overlay live space

l0 =0;

i0 =p;

l1 =0;

i1 =q;

lcntr =1000, do copy_p2q until lce;

r0 = dm(i0,1);

copy_p2q: dm(i1,1) = r0;

Store_Data_Overlay(pq_ovl); /* storep&qdata buffers to overlay live space in

call Blink_LEDs_4times; /* Data Overlayp&qload/store LED confirm */

RTS;

.ENDSEG;

SDRAM */

in SDRAM */

SDRAM */

Listing 6. C Data Overlay Code Test: data_overlay_test.c

///////////////////////////////////////////////////////////////////////////

// //

// In this example data overlay code there are six buffers, which //

// consist of 3 input wavetables: sine, triangle and square, and 3 //

// output buffers used as output sources for each input wavetable. //

// Each buffer is of length 1000.(32 bit words) //

// //

// Buffers sinetbl[], sawtbl[] and squartbl[] contain initialized //

// floating point data //

// //

// Our objective is to copy sinetbl[] to y_out[], //

// sawtbl[] to z_out[] and squartbl[] to q_out[], //

// //

// To save internal memory, we allocate the same 2k internal memory as //

// the run time data memory. //

// //

// First we bring in sinetbl[] and y_out[] inside copy sinetbl[] //

// to y_out[] and copy back the current values to the external //

// SDRAM memory. Once this process is over the run time memory //

// can be freed. //

// //

// The same process same block copy process is also repeated for //

// buffers sawtbl[], squartbl[], z_out[] and q_out[]. //

// //

// Analog Devices, DSP Applications //

// Last Modified: 01/22/02 //

// //

///////////////////////////////////////////////////////////////////////////

#include "21161_EZKit.h"

#include "data_ovl.h.h "

#define sine_ovl 1

#define triang_ovl 2

EE-151 Page 13

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 14

#define square_ovl 3

int num_times;

int OverlayID;

void data_overlay_test()

{

int i, j, k;

OverlayID = sine_ovl;

load_data_overlay(OverlayID); /* load sine wave data buffers from overlay live

for (i=0;i<1000; ++i)

{

y_out[i] = sinetbl[i];

}

store_data_overlay(OverlayID); /* store sine wave data buffers to overlay live space

num_times = 4; in SDRAM */

Blink_LEDs_Slow(num_times); /* sine wave data overlay load/store LED

OverlayID = triang_ovl;

load_data_overlay(OverlayID); /* load m & n data buffers from overlay live

for (j=1;j<=1000; ++j)

{

z_out[j] = sawtbl[j];

}

store_data_overlay(OverlayID); /* store triangle wave data buffers to overlay live

num_times = 6; space in SDRAM */

Blink_LEDs_Medium(num_times); /* sawtooth wave data overlay load/store LED

space in SDRAM */

confirm */

space in SDRAM */

confirm */

OverlayID = square_ovl;

load_data_overlay(OverlayID); /* load m & n data buffers from overlay live space

for (k=1;k<=1000; ++k)

{

q_out[k] = squartbl[k];

}

store_data_overlay(OverlayID); /* store square wave data buffers to overlay live

num_times = 8; space in SDRAM */

Blink_LEDs_Fast(num_times); /* Square Wave Data Overlay load/store LED confirm */

}

in SDRAM */

EE-151 Page 14

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 15

Listing 7. Overlay Manager Source File: data_ovly_mgr.asm

///////////////////////////////////////////////////////////////////////////////////

// //

// This code/data overlay manager sets up data overlays to/from SDRAM //

// mapped to Bank 0 on the 21161 EZ-KIT Lite. Since the SDRAM data accesses //

// are 32-bits, a generic 32-to-32 non-packed is used to transfer of data //

// to/from interal/external memory. Therefore, no PACKING{} command is //

// required in the overlay declaration section of the linker. //

// //

// This example could be modified to set up data overlays to/from Bank 1 Flash //

// memory, using 8to32 or 8to48 DMA packing modes and the appropriate flash //

// write commands. The Overlay Declaration in the LDF file would require //

// the necessary PACKING{} command to prestore data to 8-bit space. //

// Refer to EE-150 for information on how to write to the EZ-KIT Flash Memory. //

// //

///////////////////////////////////////////////////////////////////////////////////

#include "def21161.h"

.SEGMENT/DM dm_data;

.EXTERN _ov_word_run_size_1;

.EXTERN _ov_word_run_size_2;

.EXTERN _ov_word_run_size_3;

.EXTERN _ov_word_live_size_1;

.EXTERN _ov_word_live_size_2;

.EXTERN _ov_word_live_size_3;

.EXTERN _ov_startaddress_1;

.EXTERN _ov_startaddress_2;

.EXTERN _ov_startaddress_3;

.EXTERN _ov_runtimestartaddress_1;

.EXTERN _ov_runtimestartaddress_2;

.EXTERN _ov_runtimestartaddress_3;

.VAR liveAddresses[2] = _ov_startaddress_1,

.VAR runAddresses[2] = _ov_runtimestartaddress_1,

.VAR runWordSize[4] = _ov_word_size_run_1,

.VAR liveWordSize[4] = _ov_word_size_live_1,

.VAR prefetch=0;

.GLOBAL prefetch;

.VAR ov_stack[10];

.VAR DataTransfer;

.VAR Internal2exttransfer;

_ov_startaddress_2,

_ov_startaddress_3;

_ov_runtimestartaddress_2,

_ov_runtimestartaddress_3;

_ov_word_size_run_2,

_ov_word_size_run_3;

_ov_word_size_live_2,

_ov_word_size_live_3;

.GLOBAL DataTransfer;

.GLOBAL Internal2exttransfer;

.ENDSEG;

EE-151 Page 15

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 16

/* ------------------------------------------------------------------------------ */

.SEGMENT/PM pm_code;

.GLOBAL _OverlayManager;

_OverlayManager:

/* R0 register is the overlay ID 1,2,... */

/* R1 register is the SYMBOL REFERENCE Address */

dm(ov_stack) = i8; /* save user registers temporarily to overlay stack */

dm(ov_stack+1) = m8;

dm(ov_stack+2) = l8;

dm(ov_stack+3) = r2;

m8 = R0; /* get user-selected overlay ID from table */

skip_if_overlay_loaded:

i8 = runAddresses - 1; /* pointer to previous address before runAddresses

r0 = dm(Internal2exttransfer); /* check if we are loading or storing data ovelay

r0 = pass r0; /* if = 1, we store to ext mem, otherwise, = 0 loads

if NE jump continue_ovly_load_process;

i8 = runAddresses - 1; /* pointer to previous address before runAddresses buffer */

i8 = pm (m8,i8); /* Can we skip overlay transfer if data already resident? */

px = pm(0,i8);

r2 = px1; /* Now check if already loaded */

r0 = r0 – r2; /* If equal to zero, data still there */

if EQ jump TransferOver; /* we can skip DMA setup for load to run space */

continue_ovly_load_process:

i8 = runAddresses - 1; /* pointer to previous address before runAddresses buffer */

buffer */

data */

from ext mem */

dm(ov_stack+4) = i0; /* save more user registers temporarily to overlay stack */

dm(ov_stack+5) = m0;

dm(ov_stack+6) = l0;

dm(ov_stack+7) = ustat1;

l8 =0; /* disable DAGs modulus logic, no circular buffering */

l0 =0;

m0 = m8; /* premodify values are equal to the overlay symbol ID # */

i0 = liveAddresses - 1; /* pointer to previous address before live Addresses

r0 =0;

dm(DMAC10) = r0; /* initially disable and clear out DMA channel 10 */

r0 = dm(m0,i0); /* External Live Address from liveAddresses buffer */

dm(EIEP0) = r0; /* write Live Address to EPB0 external index address register */

r0 = pm(m8,i8); /* Internal Run Address from runAddresses buffer */

dm(IIEP0) = r0; /* write Run Address to EPB0 internal index address register */

r0 =1; /* DMA int/ext modifys=1*/

dm(EMEP0) = r0; /* setup EPB0 external and internal index modify registers */

dm(IMEP0) = r0;

i8 = liveWordSize - 1; /* pointer to buffer for DMA external count size */

buffer */

EE-151 Page 16

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 17

i0 = runWordSize - 1; /* pointer to buffer get DMA internal count size */

r0 = dm(m0,i0);

dm(CEP0) = r0; /* set number of "Run" internal words to transfer */

r0 = pm(m8,i8);

pm(ECEP0) = r0; /* set number of "Live" external words to transfer */

Program_or_Data_Transfer:

r0 = dm(DataTransfer); /* check for data overlay task */

r0 = pass r0; /* if DataTransfer = 1, we do a data overlay DMA */

if eq jump LoadOpcodes;

r1 = pcstk; /* Jump back to location where call was made */

pop pcstk; /* This will help us get back using the indirect delayed

LoadData:

r0 = dm(Internal2exttransfer); /* check if we are loading or storing data

r0 = pass r0; /* if = 1, we store to ext mem, otherwise, = 0

if ne jump StoreData;

/* master mode DMA, 32-32 no packing, data xfer, ext-to-int, DMA enable */

r0 = MASTER | PMODE4;

dm(DMAC10) = r0;

jump Start_DMA_Sequence;

StoreData:

/* master mode DMA, 32-32 no packing, data xfer, int-to-ext, DMA enable */

jump Start_DMA_Sequence (db);

r0 = MASTER | PMODE4 | TRAN;

dm(DMAC10) = r0;

LoadOpcodes:

/* NOTE: This data overlay example never calls the instruction overlay support. This

code is not executed in this example, but is included in case the programmer wants to

do both code and data overlays */

/* master mode DMA, 32-to-48 packing, instructions xfer, ext-to-int, DMA enable */

r0 = MASTER | PMODE3 | DTYPE | TRAN;

dm(DMAC10) = r0;

jump instruction */

overlay data */

loads from ext mem */

Start_DMA_Sequence:

IRPTL = 0x00000000;

bit set mode1 IRPTEN;

bit set imask EP0I;

/* now turn on DMA channel 10 for code/data overlay loading or storing */

ustat1 = dm(DMAC10);

bit set ustat1 DEN; /* DMA enable bit on */

dm(DMAC10) = ustat1;

r0 =0; /* Used to reset key variables */

dm(DataTransfer) = r0; /* Reset to 0 */

dm(Internal2exttransfer) = r0; /* Reset to 0 */

ustat1 = dm(ov_stack+7); /* restore overlay modified registers */

l0 = dm(ov_stack+6);

m0 = dm(ov_stack+5);

i0 = dm(ov_stack+4);

i8 = prefetch; /* determines if we wish to sit at IDLE or return */

r2 = pm(0,i8); /* to do some other core accesses while load

completes */

EE-151 Page 17

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Page 18

r2 = pass r2;

if NE jump dont_wait_for_DMA_IRQ;

wait_for_EPB0_DMA_end:

idle; /* Overlay Load/Store complete */

bit clr imask EP0I; /* temporarily disable EPB0 interrupts */

jump TransferOver;

dont_wait_for_DMA_IRQ:

r2 =0;

dm(prefetch) = r2;

r2 = dm(ov_stack+3); /* restore the rest of overlay-modified variables */

l8 = dm(ov_stack+2);

r0 = dm(ov_stack);

i8 = r0;

m8 = r1;

rts; /* return if we don't need to wait for EPB0 DMA

TransferOver:

r2 = dm(ov_stack+3); /* restore the rest of overlay-modified variables */

l8 = dm(ov_stack+2);

i8 = r1;

m8 =0;

r1 = dm(ov_stack+1);

r0 = dm(ov_stack);

flush cache; /* this instruction not required for data overlay

jump (m8,i8) (db); /* indirect jump and return from overlay manager */

i8 = r0; /* remember we already popped the PC Stack earlier */

m8 = r1;

Interrupt */

transfers */

.ENDSEG;

EE-151 Page 18

Technical Notes on using Analog Devices’ DSP components and development tools

Phone: (800) ANALOG-D, FAX: (781)461-3010, EMAIL: dsp.support@analog.com, FTP: ftp.analog.com, WEB: www.analog.com/dsp

Loading...

Loading...