Page 1

Engineer-to-Engineer Note EE-68

a

Technical notes on using Analog Devices DSPs, processors and development tools

Contact our technical support at dsp.support@analog.com and at dsptools.support@analog.com

Or vi sit our o n-li ne r esou rces htt p:/ /www.analog.com/ee-notes and http://www.analog.com/processors

Analog Devices JTAG Emulation Technical Reference

Contributed by David M. Doyle Rev 9 – October 18, 2004

Introduction

This document provides technical information to

properly design a JTAG emulator interface for

Analog Devices, Inc. (ADI) processor targets,

that in this document are all referred to as Digital

Signal Processors (DSPs).

ADI designs, manufactures, and sells several

different types of JTAG emulators for use with

ADI DSP targets supporting an embedded JTAG

emulator port. This document has been revised to

only support the current line of ADI emulators.

This product line includes the HPPCI, HPUSB

and USB emulators.

Table 4 explains in detail important

L

information referenced by a “Note n”

reference in figures and tables

throughout this document. You should

first review this table before continuing

with this document. Most questions

addressed by users regarding differences

with our JTAG emulator products and

previous versions of this document are

answered in this table.

Older versions of this document supported ADI

JTAG emulator legacy products. They included

the Mountain-ICE, Summit-ICE, Trek-ICE, Apex-

ICE, and EZ-ICE. If you require information for

any ADI JTAG emulators not supported in this

document, you should contact ADI’s DSP

development tools technical support for an older

revision of this document which contains legacy

JTAG emulator information.

Copyright 2004, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer product design or the use or application of

customers’ products or for any infringements of patents or rights of others, which may result from Analog Devices assistance. All trademarks and logos are property

of their respective holders. Information furnished by Analog Devices Applications and Development Tools Engineers is believed to be accurate and reliable;

however, no responsibility is assumed by Analog Devices regarding the technical accuracy and topicality of the content provided in all Analog Devices’ Engineer-toEngineer Notes.

L

JTAG Emulator Interface Design

All ADI JTAG emulators interface with the DSP

using a 14-pin JTAG emulator header. The

header provides a connection interface for the

JTAG emulator pod. The header can also be used

to route an optional local boundary scan

controller to the DSP when the JTAG emulator is

not attached.

All ADI JTAG emulators use a superset of the

IEEE 1149.1 standard to send and receive data

from the DSP JTAG emulation port. The JTAG

emulators use an additional signal called EMU~ as

a JTAG emulation status flag from the DSP. This

signal is a vendor specific signal, which is not

part of the IEEE 1149.1 specification.

The following pages will define in detail the

design requirements for supporting ADI JTAG

emulators. This information includes functional,

electrical, and mechanical requirements for

interfacing a target design with a JTAG

emulator.

Do not use older versions of EE-68 for

new target designs. Periodically check

ADI’s web site at

http://www.analog.com/ee-notes/

for newer revisions of this document.

Targets which were designed using an

older revision of EE-68 should only be

updated if there are problems

performing JTAG emulation.

Page 2

a

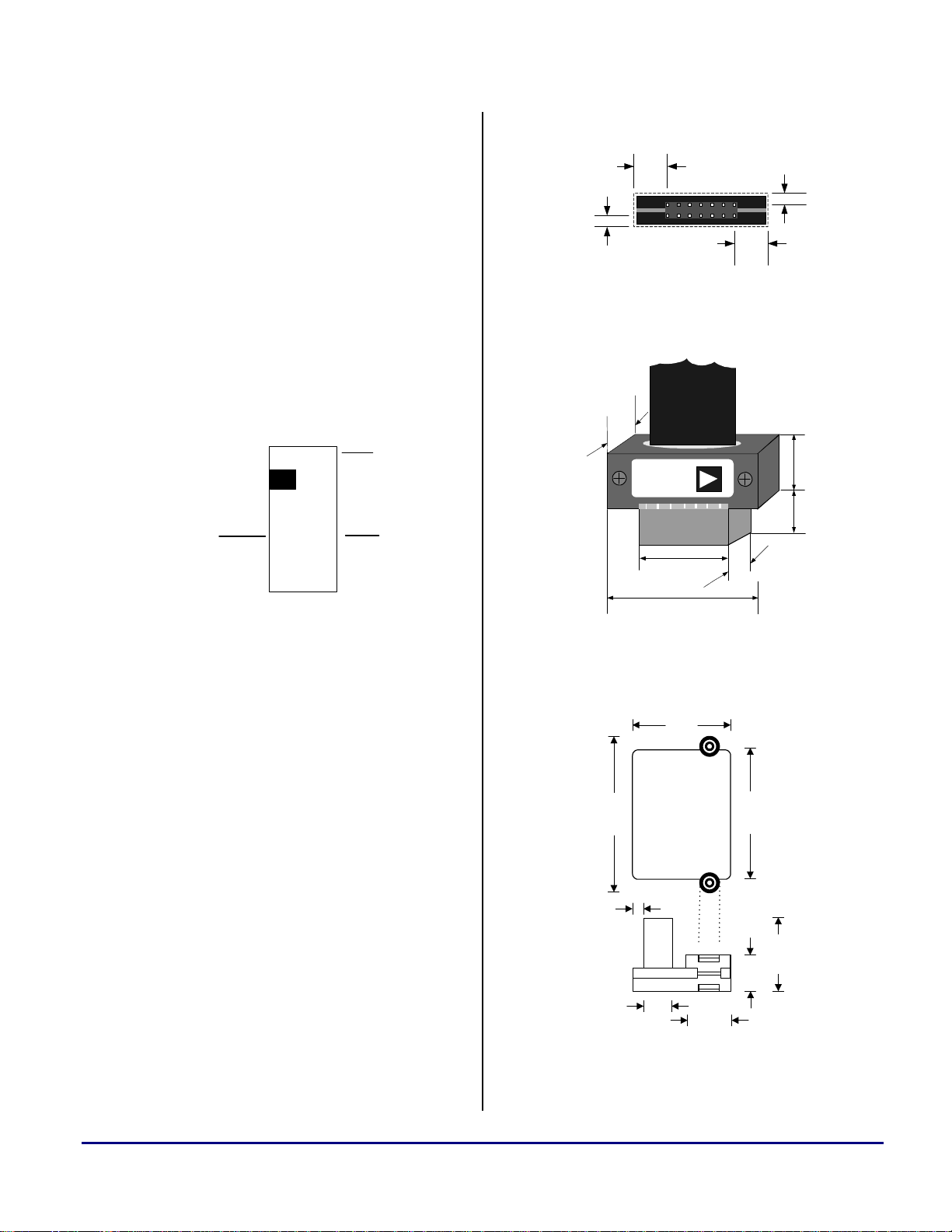

JTAG Emulator Target Header

Referring to Figure 1, the JTAG emulator header

has 14 pins. You must supply this header on your

target to communicate with the JTAG emulator.

The JTAG emulator target header interface is a

standard dual-row 0.025” male square-post

header, set on 0.1” x 0.1” spacing, with a

minimum post length of 0.235”. Pin 3 on the

JTAG emulator cable header is keyed to prevent

accidental insertion of the pod to the target

backwards. Clip pin 3 on your target board

header allow insertion of the JTAG emulator

cable female header.

(See Table 4 for notes)

12

See Note 2

See Notes 3, 4, 14

BTMS/VDDIO

GND

no pin (key)

BTCK

BTRST

BTDI

GND

3

56

78

9

11 12

13 14

Figure 1. JTAG Emulator Target Header Interface

10

EMU

4

GND

TMS

TCK

TRST

TDI

TDO

JTAG Emulator Pod Mechanical Requirements

This section explains the mechanical

specifications for the JTAG emulator pod.

(See Table 4 for notes)

0.30”

0.30”

0.10”

0.10”

Figure 2. JTAG Emulator Header Keep Out Area

(See Table 4 for notes)

See Note 20

0.28"

0.20"

ANALOG

DEVICES

0.70"

1.19"

HPPCI

0.43"

0.29"

0.20"

Figure 3. HPPCI JTAG Emulator Pod Dimensions

(See Table 4 for notes)

See Note 21

0.668"

JTAG Emulator Header clearance requirements

HPUSB

Provide a clearance of at least 0.30” and 0.10”

around the length and width of the header. Refer

1.053"

or

USB

0.878"

to Figure 2 for information about the pod

connector keep out area.

0.065"

0.245"

L

Make sure you allow for height

clearance above the header for attaching

and detaching the JTAG emulator cable

0.300"

0.500"

from your target.

Refer to Figure 3 for any height clearance

restriction information regarding the HPPCI

JTAG emulator cable. Refer to Figure 4 for any

0.200"

Figure 4. HPUSB JTAG Emulator Pod Dimensions

height clearance restriction information for the

HPUSB and USB JTAG emulators.

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 2 of 15

Page 3

a

Local Boundary Scan Controller

Referring to Figure 1, the set of signals on the

odd-numbered side of the connector can be used

by targets which have an optional local boundary

Pin Signal Description Emulator Target

1 GND Digital Ground Passive Passive

2 EMU~ JTAG Emulation Flag Input

3 KEY Header Alignment position -- pin must be

clipped on target header

4 GND Digital Ground Passive Passive

5 VDDIO

or

BTMS

6 TMS JTAG TAP Test Mode Select Output Input

7 BTCK Target Local Boundary Scan Controller

8 TCK JTAG TAP Test Clock Output Input

9 BTRST~ Target Local Boundary Scan Controller

10 TRST~ JTAG TAP Test Reset Output Input {active low}

11 BTDI Target Local Boundary Scan Controller

12 TDI JTAG TAP Test Data In Output Input

13 GND Digital Ground Passive Passive

14 TDO JTAG TAP Test Data Out Input Output

Automatic Voltage Sense (VDDIO)

or

Target Local Boundary Scan Controller

JTAG TAP Test Mode Select

JTAG TAP Test Clock

JTAG TAP Test Reset

JTAG TAP Test Data In

See note 2

scan controller. These signals include the

boundary-scan controller JTAG signals

BTMS/VDDIO, BTCK, BTDI, and BTRST~. Each of these

signals is described in Table 1.

Output

See note 3

{active low}

No Connect No Connect

Input Passive

No Connect Output

No Connect Output

No Connect Output

{open drain} {active

low}

or

Output

{active low}

Table 1. JTAG Emulator Header Signal Descriptions

Only the HPPCI JTAG emulator

L

Pin 5 (

is used by the JTAG emulator to sense the DSP

IO voltage (

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 3 of 15

supports automatic voltage sensing with

pin 5. The USB and HPUSB JTAG

emulators pin 5 only supports the BTMS

functionality. See note 3 and note 4 in

Table 4 regarding special instructions

for pin 5.

BTMS/VDDIO) is a dual purpose pin. First, it

VDDIO). Second, it can be used to

route a local boundary scan controller BTMS

signal to the DSP

emulator is not connected.

The HPPCI JTAG emulator can automatically

sense a DSP IO voltage (VDDIO) up to 5 V. The

HPPCI JTAG emulator uses the VDDIO voltage it

senses from the

JTAG emulator interface input signal thresholds

and output signal drive levels to those shown in

Table 2. You must pull pin 5 (BTMS/VDDIO) up to

TMS pin when the JTAG

BTMS/VDDIO pin to adjust the

Page 4

a

the DSP IO voltage (VDDIO) with a 4.7 KΩ

resistor when using the HPPCI JTAG emulator.

See note 3 and note 4 in Table 4 regarding

special instructions for pin 5.

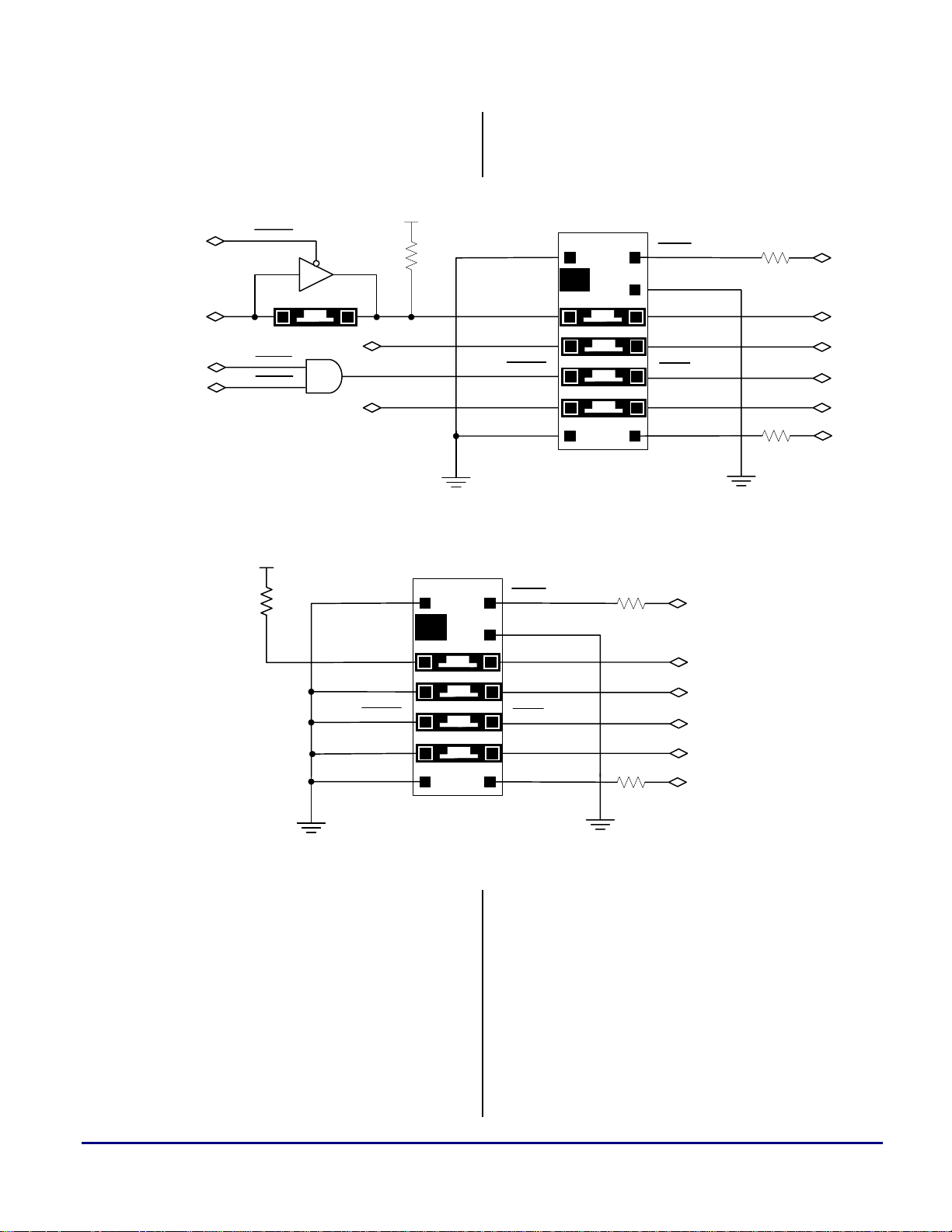

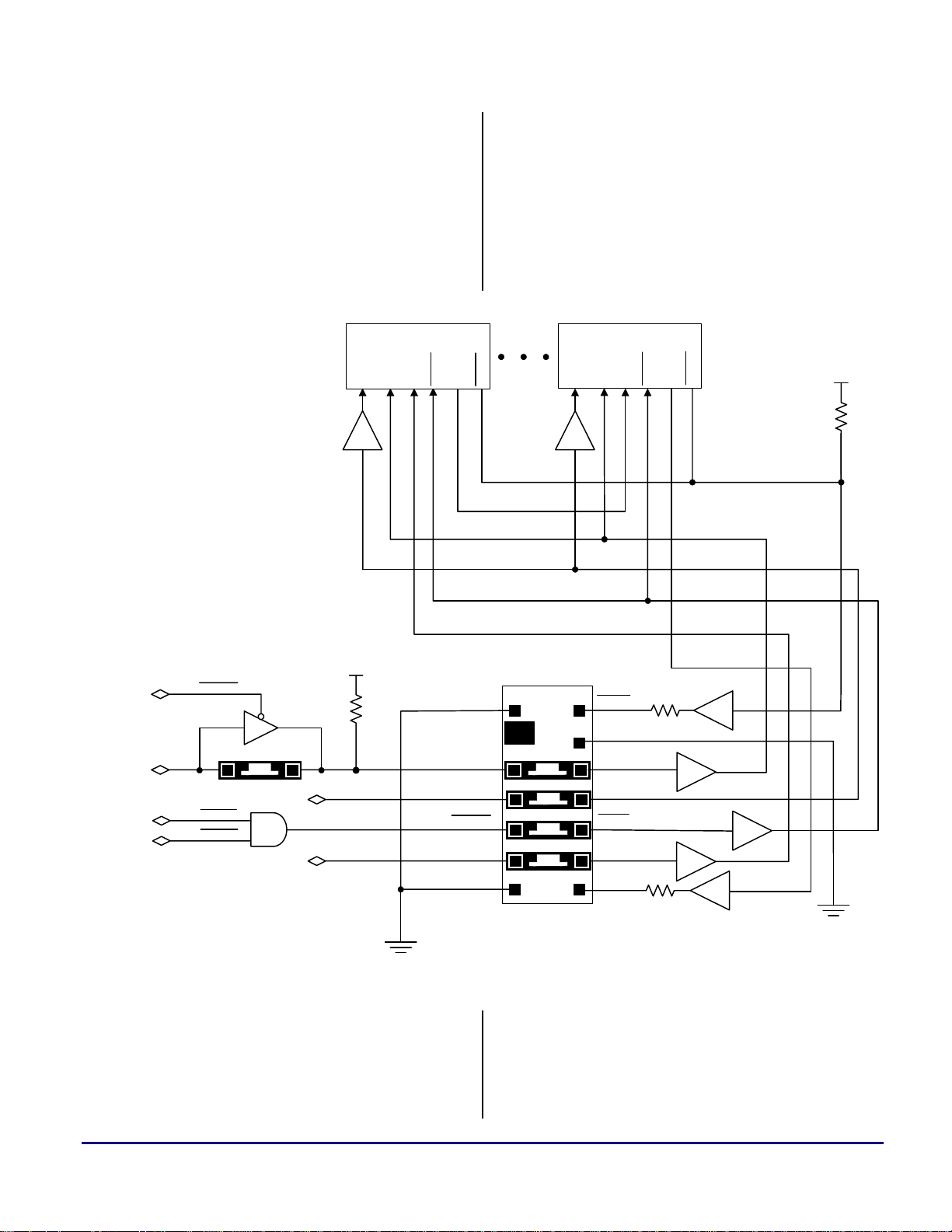

Targets with Local Boundary Scan Logic

Targets which use optional local boundary scan

controller logic should connect the local

boundary-scan signal pins to the JTAG emulator

header pins shown in Figure 5.

If your target has a optional local boundary scan

controller, and you attach the HPPCI JTAG

emulator, you will need to isolate BTMS signal

from the

BTMS/VDDIO voltage before starting the

emulator software. Referring to Figure 5 and

Figure 7, during JTAG emulation you can isolate

pin 5 on the HPPCI JTAG emulator header from

the local boundary scan controller logic using a

jumper or tri-state buffer. You must provide a

method to isolate the BTMS signal on your target

from the BTMS/VDDIO pin on the JTAG emulator

header when the HPPCI JTAG emulator is

connected. Isolation must be effective before the

HPPCI JTAG emulator software is invoked.

This isolation will prevent the local boundary

scan controller BTMS signal from confusing the

automatic voltage sensing logic in the HPPCI

JTAG emulator pod.

Connections are made between the local

boundary scan controller and the DSP by

installing or removing jumpers between the local

boundary scan controller JTAG signals and the

DSP JTAG emulation signals. The local

boundary scan signals include BTMS, BTCK, BTDI,

BTRST~. DSP JTAG emulation signals TMS,

and

TCK, TDI, and TRST~ connect to local boundary

scan signals using jumpers on the JTAG

emulator header shown in Figure 5.

TRST~ must be pulsed low at power up when

using a local boundary scan controller, and

should be kept low when the local boundary scan

controller and the JTAG emulator are not being

used. Figure 5 shows how

TRST~ should be

controlled when the target uses a local boundary

scan controller.

If your target has a local boundary scan

controller and your target does not control the

BTRST~ signal, you will need to control the BTRST~

signal with additional logic. This additional logic

needs to guarantee the BTRST~ signal is only

pulsed low during power on reset. It should be

driven high all other times during local boundary

scan. This will prevent holding the BTRST~ signal

low continuously during local boundary scans.

Keeping the DSP TAP constantly in reset with

the BTRST~ signal forced to ground with a jumper

or pull-down resistor will prevent the DSP from

executing a local boundary scan.

Jumpers can be substituted with zero ohm

resistors on production boards. If you plan to use

the same board revision for debugging and

production, you should design your target with a

dual footprint. The dual footprint should

accommodate the header described in Figure 1

for debug version boards, and surface mount

resistors for production version boards.

With the exception of pin 5 (BTMS/VDDIO) on the

HPPCI JTAG emulator, all target local boundary

scan controller pins (BTCK, BTRST~, BTDI) are not

connected inside the JTAG emulator pod. They

are used only to provide a method for inserting

or removing the DSP from the local boundaryscan controller logic using jumpers across the

JTAG emulation header.

Targets without Local Boundary Scan Logic

As shown in Figure 6 and Figure 8, targets which

do not use a local boundary scan controller, or do

not include the DSP in the local boundary scan

controller chain, should tie all boundary scan

pins to ground except for pin 5 on the HPPCI

JTAG emulator. Pin 5 the

BTMS/VDDIO signal, is

required by the HPPCI JTAG emulator pod to

automatically sense the DSP IO voltage (

VDDIO).

Jumpers can be substituted with zero ohm

resistors on production boards. If you plan to use

the same board revision for debugging and

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 4 of 15

Page 5

a

production, you should design your target with a

dual footprint. The dual footprint should

for debug boards, and surface mount resistors for

production boards.

accommodate the header described in Figure 1

Buffer Enable Logic

See Note 4

Boundary Scan Controller

Power Up Reset Logic

Boundary Scan Reset Logic

BTMSOE

Boundary Scan Controller

See Note 5

PONRST

See Note 5

BSCRST

Boundary Scan Controller

See Note 4

Figure 5. Single DSP Target with a Local Boundary Scan Controller

Target DSP VDDIO

See Notes 3, 4, 14

4.7K

Target DSP VDDIO

4.7K

See Note 5

GND

no pin (key)

BTMS/VDDIO

BTCK

BTRST

BTDI

GND

See Notes 3, 4, 14

GND

no pin (key)

BTMS/VDDIO

BTCK

BTRST

BTDI

GND

12

3

See Note 6

56

See Note 6

78

910

See Note 6

11 12

See Note 6

13 14

See Note 7

EMU~

4

GND

TMS

TCK

TRST

TDI

TDO

12

3

56

See Note 6

78

See Note 6

910

See Note 6

11 12

See Note 6

13 14

See Note 18

See Note 18

See Note 19

See Note 19

4

See Note 7

See Note 12

See Note 12

EMU~

GND

TMS

TCK

TRST

TDI

TDO

See Note 18

See Note 18

See Note 19

See Note 19

Target DSP

Target DSP

Target DSP

Target DSP

Target DSP

Target DSP

See Note 12

Target DSP

Target DSP

Target DSP

Target DSP

Target DSP

See Note 12

Target DSP

Figure 6. Single DSP Target without a Local Boundary Scan Controller

Single DSP Target Connections

Figure 6 shows the connections between the

JTAG emulator header and the DSP for a single

Single DSP targets with route distances between

the JTAG emulator header and DSP less than six

(6) inches do not require buffering. Your target

requires buffering if the worst case route distance

between the JTAG emulator header and the DSP

DSP target without a local boundary scan

controller. Figure 5 shows the connections

between the JTAG emulator header and the DSP

for a single DSP target with a local boundary

scan controller.

is greater than six (6) inches regardless of the

number of DSPs in the scan chain path.

Figure 5 and Figure 6 show series terminating

resistors for the

TDO and EMU~ signals going to the

JTAG emulator. These resistors are optional.

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 5 of 15

Page 6

a

You should design them into your target if you

have routes longer than 6 inches in length

between the TDO or EMU~ outputs from the DSP

back to the JTAG emulator header. The resistor

value is generally equal to the impedance of the

printed circuit (Z

) board minus the output

PCB

impedance of the TDO or EMU~ signal I/O driver

(Z

). Initially set these resistors to zero

Driver

TCK

See Note 10

DSP1

TMS

TRST

TDI

TDO

ohms. Change the value of the termination

resistance Z

Terminator,

to Z

PCB

– Z

if signal

Driver

integrity problems are observed when using the

JTAG emulator. Tuning the termination resistor

value to something slightly less than or greater

than (Z

Terminator

) may be required depending on

the condition of the signals. Place the termination

resistors as close as possible to the DSP.

See Note 8

TRST

TMS

TDO

TDI

EMU~

Target DSP VDDIO

See Note 11

4.7K

EMU~

DSP2 … 8

TCK

See Note 10

Buffer Enable

Logic

Boundary Scan

Controller

Power Up

Reset Logic

Boundary Scan

Reset Logic

See Note 4

See Note 5

See Note 5

BTMSOE

PONRST

BSCRST

See Note 4

Boundary Scan

Controller

Boundary Scan

Controller

Target DSP VDDIO

4.7K

See Note 5

See Notes 3, 4, 14

BTMS/VDDIO

GND

no pin (key)

BTCK

BTRST

BTDI

GND

12

3

56

See Note 6

78

See Note 6

910

See Note 6

11 12

See Note 9

13 14

See Note 7

4

EMU~

GND

TMS

TCK

TRST

TDI

TDO

See Note 12

See Note 18

See Note 18

See Note 19

See Note 19

See Note 12

See Note 9

See Note 9

See Note 9

See Note 9

See Note 9

Figure 7. Multiple DSP Target with a Local Boundary Scan Controller

Printed circuit board traces between the JTAG

emulator header and the DSP on a single DSP

target without JTAG signal buffers must be

as a group, using equal lengths (if possible).

Provide good crosstalk isolation from other

signal nets especially clocks.

shorter than six (6) inches. Route all traces

between the JTAG emulator header and the DSP

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 6 of 15

Page 7

a

Multiple DSP Target Connections

have routes longer than 6 inches in length

between the TDO or EMU~ buffers and the JTAG

Targets with more than one DSP in the scan path

require buffering as shown in Figure 7 and

Figure 8. Figure 7 shows the connections

between the JTAG emulator header and the

buffers for a multiple DSP target with a local

boundary scan controller. Figure 8 shows the

connections between the JTAG emulator header

and the buffers for a multiple DSP target without

a local boundary scan controller.

Figure 7 and Figure 8 show series terminating

resistors for the TDO and EMU~ signals going to the

JTAG emulator. These resistors are optional.

You should design them into your target if you

See Note 11

Target DSP VDDIO

See Notes 3, 4, 14

4.7K

no pin (key)

BTMS/VDDIO

GND

BTCK

BTRST

BTDI

GND

12

3

56

78

910

11 12

13 14

4

See Note 6

See Note 6

See Note 6

See Note 6

See Note 7

Figure 8. Multiple DSP Target without a Local Boundary Scan Controller

EMU~

GND

TMS

TCK

TRST

TDI

TDO

See Note 12

See Note 9

See Note 18

See Note 18

See Note 19

See Note 18

See Note 12

See Note 9

emulator header. The resistor value is generally

equal to the impedance of the printed circuit

(Z

) board minus the output impedance of the

PCB

TDO or EMU~ signal I/O driver (Z

set these resistors to zero ohms. Change the

value of the termination resistance Z

Z

– Z

PCB

observed when using the JTAG emulator. Tuning

the termination resistor value to something

slightly less than or greater than (Z

be required depending on the condition of the

signals. Place the termination resistors as close to

the DSP as possible.

Target DSP VDDIO

4.7K

See Note 9

See Note 9

TCK

See Note 10 See Note 10

See Note 9

). Initially

Driver

if signal integrity problems are

Driver

Terminator

DSP1

TMS

TDI

DSP2 … 8

TRST

EMU~

TDO

TCK

See Note 8

TRST

TMS

TDO

TDI

Terminator,

) may

EMU~

to

Route all traces between the JTAG emulator

header and the DSP as a group, using equal

lengths when possible. Provide good crosstalk

isolation from other signal nets especially clocks.

To minimize signal skew, ensure buffers for the

TMS, TDI, TRST~ TDO, and EMU~ signals come from a

single package. For

TCK signals, use a driver with

a high fan out. The drivers should come from a

single dedicated package that is not used by other

TMS, TDI, TRST~, TDO, and EMU~ signals.

Limit the number of loads (DSPs) for the

TRST~, and EMU~ buffered signals to eight (8).

Limit the number of loads for the

TCK buffered

TMS,

signals to one (1). Additional loads (DSPs)

should use another buffer to support up to eight

(8) more devices.

Using more than sixteen (16) physical devices in

one scan chain is not recommended. The best

approach for large numbers (>16) of physical

devices is to break the chain into smaller

independent chains, each with its own JTAG

header and buffers. If this is not possible, try

adding jumpers to reduce the number of devices

in one chain at a time for debug purposes. Pay

special attention to PCB routing to minimize

transmission line effects.

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 7 of 15

Page 8

a

JTAG Emulator Interface PCB Layout

Treat all JTAG emulator signals (TCK, TMS, TDI,

TDO, EMU~, and TRST~) as critical route signals.

Pay special attention when routing these signals

on your target. Specify a controlled impedance

requirement between 50 Ω and 75 Ω. Minimize

cross-talk and inductance on these signal lines by

using a solid ground plane and routing the JTAG

emulator signals away from high frequency nets,

especially clock lines. Keep these routes as short

as possible, and equal in length when possible.

These lines must be clean. You may need to

provide series terminations for very long TDO and

EMU~ routes. See note 12 in Table 4 regarding

series terminations.

JTAG Emulator Power Sequence

Your JTAG emulator should be powered on, and

connected to a host PC, prior to attaching it to a

target JTAG emulator header. All ADI High

Performance JTAG emulator products can be

attached or removed from a powered “hot” target

without any power restrictions.

Avoid emulation errors by making sure

[

the emulation software is not started or

executing when power is not applied to

the target, or when attaching the JTAG

emulator to a target with or without

power.

jumper the TMS, TCK, and TDI signals at the JTAG

emulation header.

JTAG Emulator Pod Electrical Requirements

This section explains the electrical specifications

for the JTAG emulator pod.

HPPCI JTAG Emulator Automatic Voltage Sense Pod Logic

The HPPCI JTAG emulator pod uses pin 5

(

BTMS/VDDIO) of the JTAG emulator header to

automatically sense the target I/O voltage. The

voltage sensing logic controls which voltage

threshold values the JTAG emulator uses for

JTAG signals received from the target. The

voltage sensing logic also sets the drive levels for

JTAG signals sent to the target.

Your target DSP IO voltage (VDDIO) may or may

not be the same voltage used by the DSP core.

Make sure you are using correct DSP supply

voltage for VDDIO when configuring your target

for the HPPCI JTAG emulator automatic voltage

sense. You must pull the signal up to the correct

voltage plane with a 4.7 KΩ resistor. Do not

connect the BTMS/VDDIO pin directly to the VDDIO

voltage plane. See note 3 and note 4 in Table 4

for more information regarding the BTMS/VDDIO

pin.

JTAG Emulator Pod I/O Characteristics

A jumper should be installed for the

across the JTAG emulator header TRST~ and

BTRST~ pins before applying power to the target.

You should also have this jumper installed

whenever the JTAG emulator is not attached to

the JTAG emulator header after power has been

applied to the target. This jumper will prevent

the JTAG TAP in the DSP from getting “lost” in

an un-recoverable state. All though not required,

as an extra added precaution you should also

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 8 of 15

TRST~, signal

The JTAG emulator pod is tolerant up to 5VDC.

It will work with all Analog Devices JTAG

family DSPs with JTAG I/O voltages of 5 V,

3.3 V, 2.5 V, and 1.8 V. The pod will drive 5 V

targets with 3.3 V logic levels, which are well

within the 5 V logic threshold requirements.

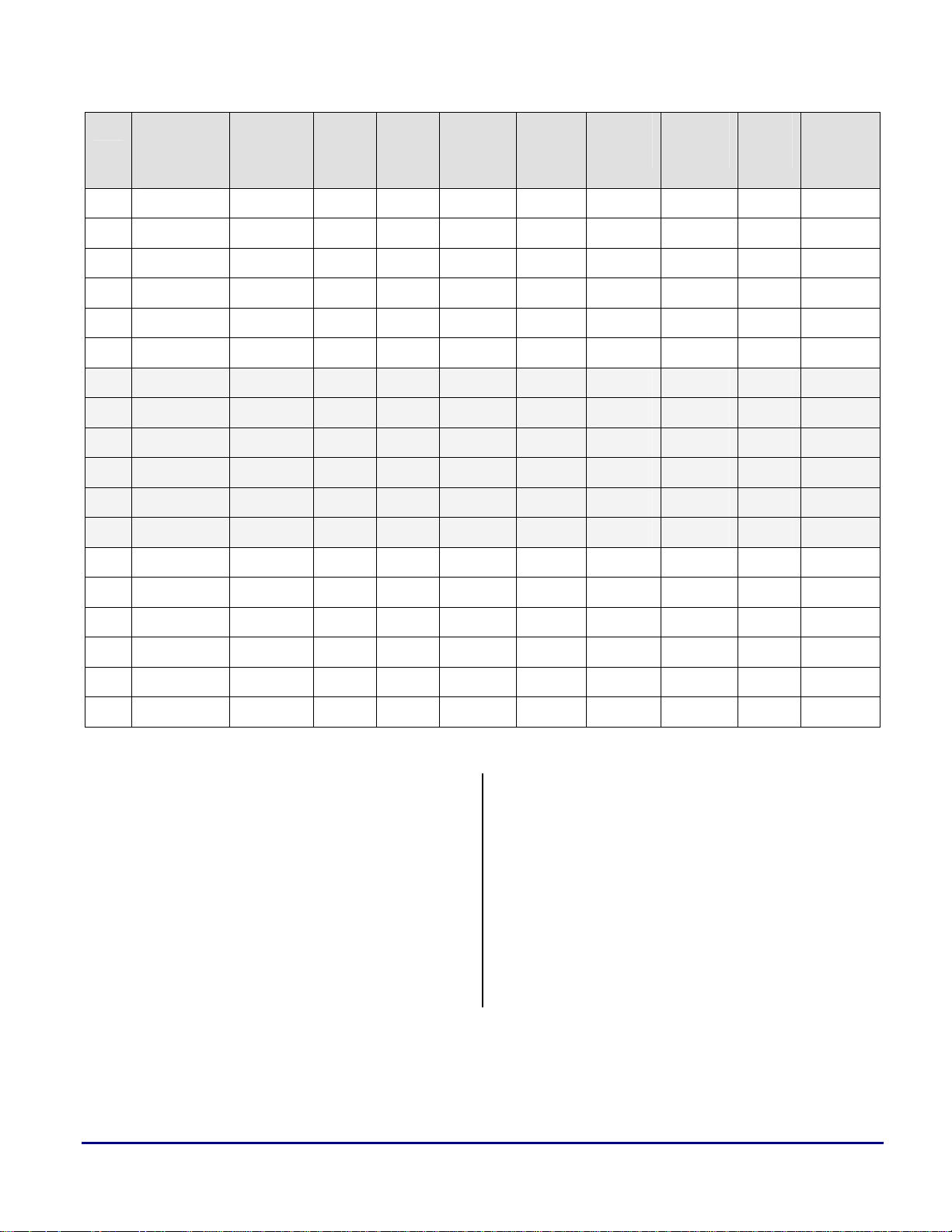

Table 2 includes all the I/O characteristics for the

JTAG emulator pod.

Page 9

a

Pin JTAG

Emulator

Signal

VDDIO

(VDC)

Cin

(pF)

Cout

(pF)

VIH

(VDC)

VIL

(VDC)

VOH

(VDC)

VOL

(VDC)

IOL

(mA)

IOH

(mA)

2 EMU~ 5 / 3.3 6 2.0 0.8 - - - 6 TMS 5 / 3.3 6.5 - - 2.3 0.7 12 12

8 TCK 5 / 3.3 6.5 - - 2.3 0.7 12 12

10 TRST~ 5 / 3.3 6.5 - - 2.3 0.7 12 12

12 TDI 5 / 3.3 6.5 - - 2.3 0.7 12 12

14 TDO 5 / 3.3 6 2.0 0.8 - - - -

2 EMU~ 2.5 6 1.7 0.7 - - - -

6 TMS 2.5 6.5 - - 1.8 0.6 8 8

8 TCK 2.5 6.5 - - 1.8 0.6 8 8

10 TRST~ 2.5 6.5 - - 1.8 0.6 8 8

12 TDI 2.5 6.5 - - 1.8 0.6 8 8

14 TDO 2.5 6 1.7 0.7 - - - -

2 EMU~ 1.8 6 1.2 0.6 - - - -

6 TMS 1.8 6.5 - - 1.3 0.5 4 4

8 TCK 1.8 6.5 - - 1.3 0.5 4 4

10 TRST~ 1.8 6.5 - - 1.3 0.5 4 4

12 TDI 1.8 6.5 - - 1.3 0.5 4 4

14 TDO 1.8 6 1.2 0.6 - - - -

Table 2. JTAG Emulator Pod I/O Characteristics

JTAG Emulator Pod Timing

This section details important timing information

regarding JTAG signals at the target JTAG

emulator header. Figure 9 diagrams switching

and timing relationships for JTAG signals at the

target JTAG emulator header.

Table 3 defines switching parameters for the

JTAG emulator output signals (

TRST~), and setup and hold requirements for

TCK, TMS, TDI, and

Table 3 also defines the frequency of operation

range for high performance JTAG emulator

products. The table parameter reference numbers

maps to the timing diagram reference numbers

shown in Figure 9.

You should use this information to determine

your target’s maximum routing lengths, net

loading, and load capacitance which can be

tolerated for JTAG emulation signal routes.

JTAG emulator input signals (TDO, and EMU~).

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 9 of 15

Page 10

a

# Parameter Product Frequency Description Min Max Unit

1 t

1 t

1 t

2 t

2 t

2 t

3 t

3 t

3 t

4 t

4 t

4 t

5 t

5 t

5 t

5 t

5 t

5 t

6 t

6 t

6 t

cTCK

cTCK

cTCK

wTCKH

wTCKH

wTCKH

wTCKL

wTCKL

wTCKL

dTMS

dTMS

dTMS

suTDO

suTDO

suTDO

suTDO

suTDO

suTDO

hTDO

hTDO

hTDO

HPPCI 10↔50 MHz TCK period

HPUSB 5↔50 MHz TCK period

USB 10 MHz TCK period

HPPCI 10↔50 MHz TCK high pulse width

HPUSB 5↔50 MHz TCK high pulse width

USB 10 MHz TCK high pulse width

HPPCI 10↔50 MHz TCK low pulse width

HPUSB 5↔50 MHz TCK low pulse width

USB 10 MHz TCK low pulse width

HPPCI 10↔50 MHz Delay TMS/TDI/TRST~

from TCK ↓

HPUSB 5↔50 MHz Delay TMS/TDI/TRST~

from TCK ↓

USB 10 MHz Delay TMS/TDI/TRST~

from TCK ↓

HPPCI 10 MHz Setup time TDO/EMU~

to TCK ↑

HPPCI 25 MHz Setup time TDO/EMU~

to TCK ↑

HPPCI 33 MHz Setup time TDO/EMU~

to TCK ↑

HPPCI 50 MHz Setup time TDO/EMU~

to TCK ↑

HPUSB 5-50 MHz Setup time TDO/EMU~

to TCK ↑

USB 10 MHz Setup time TDO/EMU~

to TCK ↑

HPPCI 10-50 MHz Hold time TDO/EMU~

from TCK ↑

HPUSB 5-50 MHz Hold time TDO/EMU~

from TCK ↑

USB 10 MHz Hold time TDO/EMU~

from TCK ↑

19.9 100.1

19.9 200.1

99.1 100.1

9.95 50.05

9.95 100.05

49.95 50.05

9.95 50.05

9.95 100.05

49.95 50.05

3 ns

3 ns

3 ns

14.1 ns

1 ns

8.4 ns

9.9 ns

2 ns

2 ns

0 ns

0 ns

0 ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Table 3. JTAG Emulator Pod Timing Information

The maximum frequency numbers shown in

Table 3 are only guaranteed when your target

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 10 of 15

meets the setup and hold requirements defined in

Table 3. When calculating your setup and hold

Page 11

a

margins, remember to include the TDO and EMU~

delay parameters from the target DSP datasheet.

If your target does not meet the setup and hold

requirements defined in Table 3, you will have to

operate the JTAG emulator at a lower frequency

for reliable performance.

If you can not operate the JTAG

L

The setup and hold time requirements are based

on the worst case maximum delay of the JTAG

emulator hardware. Typically, the setup and hold

time requirements will be considerably smaller

than the values in the table. If you have a

complex JTAG emulation path with long

propagation delays, you should perform a timing

analysis on your targets JTAG paths. This

emulator using the lowest available

frequency, you should check your target

for a miss wiring or redesign your target

to reduce delays. You should look at

reducing trace lengths, reducing

electrical loads, and using faster buffers.

analysis should determine if your target JTAG

emulation paths have sufficient timing margin to

operate at the desired JTAG TCK frequency.

When performing a timing analysis, the timing

margin must be a positive number. As a general

rule, the margin desired should be at least 10 %

of a full TCK clock period. However, be aware

when you are doing your analysis, the delay

numbers given are based on worst case delay.

Typically, logic will tend to run somewhere in

the middle between minimum and maximum

delay, although this cannot be guaranteed. If

your margin is negative, but very close (< 1 ns),

you may want to try using typical numbers in

your analysis to see you still have a negative

margin.

If you still calculate a negative margin using

typical values, you must try selecting a slower

TCK frequency if available, or make changes to

your target to reduce the JTAG emulator path

delays.

Figure 9. JTAG Emulator Pod Timing Waveform

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 11 of 15

Page 12

a

Conclusion

Using the recommendations described in this

document, should make designing the JTAG

emulation interface for your target straight

forward. Having a well designed JTAG emulator

interface on your target will allow you to rapidly

begin development and testing your application,

instead of spending valuable time debugging the

JTAG emulation port.

You should check the ADI DSP Tools Web site

Reference

The IEEE 1149.1 JTAG standard is sponsored by

the Test Technology Standards Committee of the

IEEE Computer Society, and published by the

IEEE.

To order a copy, call IEEE at 1-800-678-4333 in

the US and Canada, 1-908-981-1393 outside of

the US and Canada. You can also visit the IEEE

standards web site at

http://standards.ieee.org/

periodically for updates to this document

Appendix

# Note Description

1 Deleted –

2 The JTAG emulator 14-pin female header has position 3 plugged to prevent improper connection,

and is used as a orientation key. The JTAG emulator 14-pin female header position 3 does connect

to a wire in the JTAG cable which is connected to ground at the JTAG emulator.

Pin 5 BTMS/VDDIO is a dual purpose pin on the HPPCI JTAG emulator. First, it allows you to route

3

an optional local boundary scan controller TMS signal to the target DSP TMS signal when the JTAG

ICE is not attached to the JTAG header and a jumper is installed between pins 5 and 6 of the

JTAG header. Second, this pin is used by the JTAG ICE to auto detect the targets DSP I/O voltage

(VDDIO) up to 5 V. The JTAG ICE uses the sensed voltage to establish input and output voltage

levels for the DSP JTAG signals. You should pull this pin up to the VDDIO level using a 4.7 KΩ

resistor. Do not connect it directly to the VDDIO plane.

The HPUSB and USB emulators do not support VDDIO auto sensing on pin 5. Pin 5 is a single

function pin used to route an optional local boundary scan controller

TMS signal when the JTAG ICE is not attached to the JTAG header and a jumper is installed

TMS signal to the target DSP

between pins 5 and 6 of the JTAG header.

You may connect a HPUSB or USB JTAG emulator to a target designed for the HPPCI JTAG

emulator, with the VDDIO auto sensing logic. The HPUSB or USB JTAG emulator does not connect

pin 5 back at the emulator, so no harm will be done to the target or the emulator. The voltage

thresholds for your target when using the HPUSB or USB JTAG emulators are set manually by

the user in the VisualDSP Debugger session configurator.

When using the HPPCI JTAG emulator, you need to control the

4

BTMS signal at pin 5 so that it is

not being driven by the local boundary scan controller when the JTAG ICE is attached to the

header. Failure to isolate the

BTMS signal when the JTAG ICE is connected could result in

unpredictable behavior by the JTAG ICE due to possible incorrect voltage sensing on pin 5. As

shown above, you can isolate the BTMS signal using a jumper, or a buffer. When using a buffer, its

output must be disabled when the JTAG ICE is connected.

When using the HPUSB and USB JTAG emulators which do not support

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 12 of 15

VDDIO auto sensing, you

Page 13

a

# Note Description

can connect pin 5 directly to the target local boundary scan controller BTMS signal without any

pull-up resistor required.

5 When using local boundary scan, you must control the TRST~ signal on the DSP so that it is pulsed

low when power is first applied to the target. Failure to properly reset the DSP JTAG TAP can

result in unpredictable DSP behavior during boundary scans. The circuit shown above (AND gate)

is one possible way to control the

If your target has a local boundary scan controller but your target does not control the BTRST~

signal, you will need to control the BTRST~ signal with additional logic. The additional logic needs

to guarantee the BTRST~ signal is only pulsed low during power on reset, and is then driven high all

other times during local boundary scan. This will prevent holding the BTRST~ signal low

continuously during local boundary scans. Keeping the DSP TAP constantly in reset with the

BTRST~ signal will prevent the DSP from executing a local boundary scan.

6 You may substitute jumpers with zero ohm resistors on production boards.

7 See figure 1 for description of the JTAG emulator header pins.

Each buffer should support a maximum of 8 DSPs, except for TCK buffers, which should support

8

only one DSP per buffer.

TRST~ signal correctly.

For 5 V targets, buffer the TMS, TDI, TRST~, TDO, and EMU~ signals with a type 74AC11244 buffer (or

9

equivalent).

For 3.3 V / 2.5 V / 1.8 V low-voltage targets, buffer the TMS, TDI, TRST~, TDO, and EMU~ signals with

a type 74AVC16244 buffer (or equivalent).

For 5 V targets, buffer the TCK signal with a low skew, high fan out, minimal input-to-output delay

10

dual 1-to-5 clock driver type IDT49FCT3805E (or equivalent).

For 3.3 V low voltage targets, buffer the TCK signal with a low skew, high fan out, minimal input-

to-output delay dual 1-to-5 clock driver type IDT49FCT805 (or equivalent).

For 2.5 V / 1.8 V very low voltage targets, buffer the

TCK signal with a low skew, high fan out,

minimal input-to-output delay single 1-to-5 clock driver type IDT5T9050 (or equivalent).

11

The DSP

EMU~ signal is an open drain signal which must be pulled up with a 4.7 KΩ resistor on

multiprocessor targets at the buffer input. On single processor targets without a buffer, the JTAG

ICE internal logic will pull up the open drain signal with a internal 4.7 KΩ resistor.

These resistors are optional. We recommended you design them into your target if you have TDO or

12

EMU~ routes between the DSP and JTAG emulation header greater than 6 inches in length. The

resistor value (Z

Termination

minus the output impedance of the TDO or EMU~ signal I/O driver (Z

) is generally equal to the impedance of the printed circuit (Z

).

Driver

13 BSC -- Local Boundary Scan Controller if implemented on target.

VDDIO is the Target DSP I/O voltage supply not the DSP core voltage supply, make sure you

14

connect

VDDIO to the correct voltage plane when using the HPPCI VDDIO auto sense function.

) board

PCB

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 13 of 15

Page 14

a

# Note Description

15 Currently, the High Performance product line includes ADI’s HPPCI ICE, HPUSB ICE, and the

USB ICE.

JTAG emulator signals

16

JTAG emulator signals TCK, TMS, TDI, and TRST~ are type output.

17

Previous versions of EE-68 have called for 4.7 KΩ pull-up resistors for TMS, TCK, and TDI to

18

increase the noise immunity for these signals. High speed rail to rail CMOS buffers with strong

output drive current now used in our High Performance JTAG emulator product line makes this

requirement unnecessary .

19

Previous versions of EE-68 have called out for a 4.7 KΩ pull-down resistor for

resistor has been removed. This is to prevent the DSP JTAG TAP from being constantly in reset

on targets which use a local boundary scan controller but do not drive

20 This figure shows dimensions for the HPPCI JTAG emulator pod only.

21 This figure shows dimensions for the HPUSB and USB JTAG emulator pods only.

Table 4. Document Notations

EMU~ and TDO are type input.

TRST~. This

TRST~.

Document History

Revision Description

Rev 9 – October 18, 2004

by David M. Doyle

Rev 2.6 – July 9, 2003

by David M. Doyle

Rev 2.5 – March 20, 2003

by David M. Doyle

Rev 2.4 – December 3, 2002

by David M. Doyle

Rev 2.3 – August 2001

by David M. Doyle

Major update.

• Incremented revision code to Rev 9 due to revision system change

• Removed all obsolete Legacy information.

• Simplified and combined drawings and tables when possible

• Re-wrote most sections in more concise format

Updated all document discussions for the TRST~ signal and JTAG Emulation header

jumper requirements. Most sections of the document were affected. Change keep out

clearance requirements for larger HPPCI pod.

Divided document into discussion of Legacy ICE products and our new HPPCI ICE

product.

Added HPPCI information.

Updated all sections and added timing information

Update to power up sections

Rev 2.2 – March 2001

by David M. Doyle

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 14 of 15

Update to target connections

Page 15

a

Rev 2.1 – August 2000

by David M. Doyle

Rev 2.0 – February 2000

by David M. Doyle

Rev 1.0 – December 1999

by David M. Doyle

Update to 2.5 logic

General update

Initial Release

Analog Devices JTAG Emulation Technical Reference (EE-68) Page 15 of 15

Loading...

Loading...