AN-1149

APPLICATION NOTE

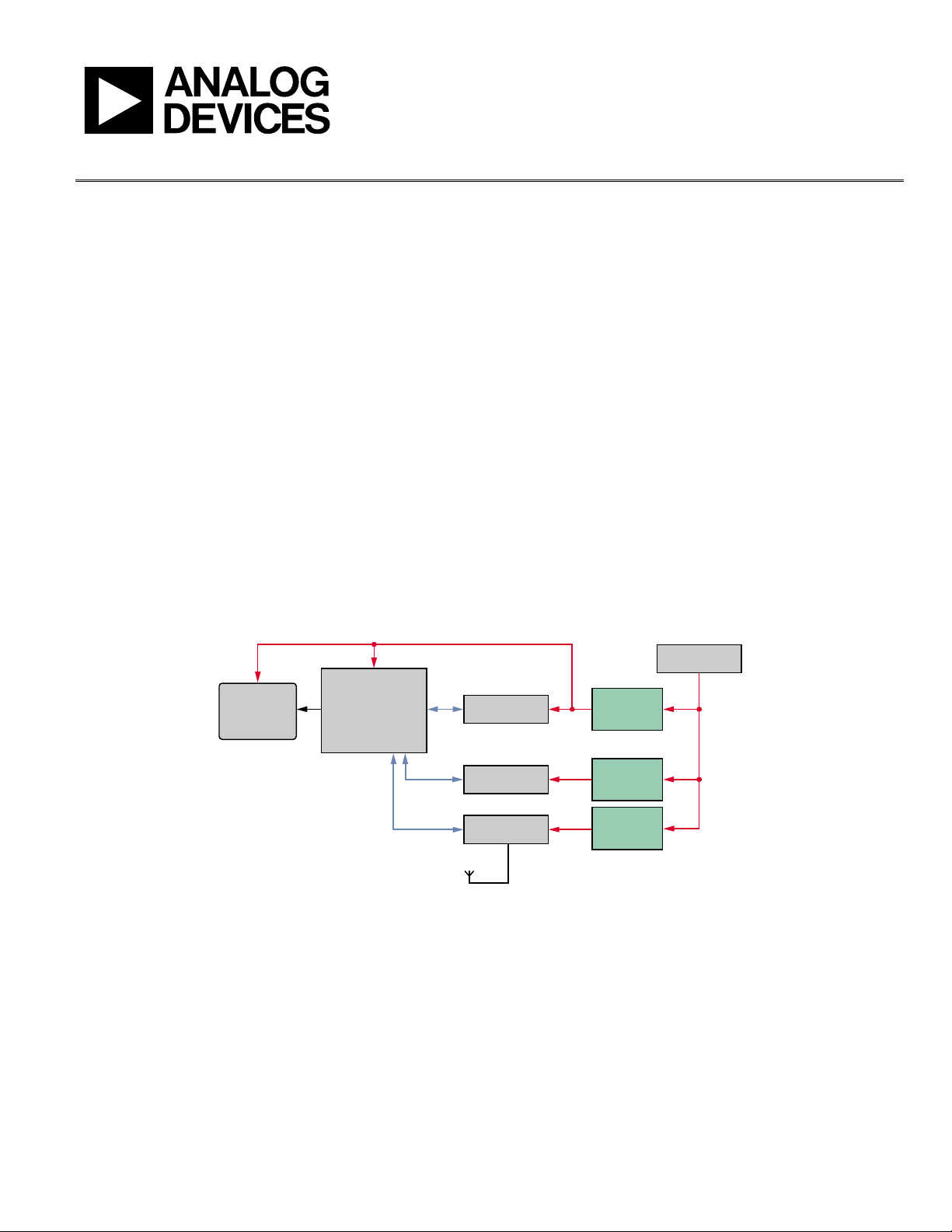

MEMORY

V

DD

MICROPROCESSOR

LCD DISPLAY

BUCK

REGULATOR

ADP2139

SENSOR

BATTERY

Li-Ion

1.8V

3.6V

3.3V

RF PA

BUCK-BOOST

REGULATOR

ADP2503

BUCK-BOOST

REGULATOR

ADP2504

3.0V TO 4.2V

10542-001

One Technology Way • P. O. Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel: 781.329.4700 • Fax: 781.461.3113 • www.analog.com

How to Apply DC-to-DC Step-Down/Step-Up (Buck/Boost) Regulators

by Ken Marasco

INTRODUCTION

DC-to-DC switching converters are used to change one dc

voltage to another efficiently. High efficiency dc-to-dc

converters come in three basic topologies: step-down (buck),

step-up (boost), and step-down/step-up (buck/boost).

The buck converter is used to generate a lower dc output

voltage, the boost converter is used to generate a higher dc

output voltage, and the buck/boost converter is used to generate

an output voltage less than, greater than, or equal to the input

voltage.

This application note focuses on how to successfully apply

buck/boost dc-to-dc converters. Buck and boost converters are

described individually in the AN-1125 Application Note, How

to Apply DC-to-DC Step-Down (Buck) Regulators, and the

AN-1132 Application Note, How to Apply DC-to-DC Step-Up

(Boost) Regulators.

Figure 1 shows a typical low power system powered from a

single-cell lithium ion (Li-Ion) battery. The battery’s usable

output varies from about 3.0 V when discharged to 4.2 V when

fully charged. The system ICs require 1.8 V, 3.3 V, and 3.6 V for

optimum operation. Whereas the lithium ion battery starts at

4.2 V and ends at 3.0 V, a buck/boost regulator can supply a

constant 3.3 V, and a buck regulator or low dropout (LDO)

regulator can supply 1.8 V, as the battery discharges. A buck

regulator or LDO can conceivably be used for the 3.3 V while

the battery voltage is above 3.5 V, but the system would cease to

operate when the battery voltage drops below 3.5 V. Allowing

the system to be turned off prematurely reduces the system’s

operating time before the battery must be recharged.

Figure 1. Typical Low Power Portable System

Rev. 0 | Page 1 of 8

AN-1149 Application Note

TABLE OF CONTENTS

Introduction ...................................................................................... 1

Revision History ............................................................................... 2

Buck/Boost Regulators ..................................................................... 3

Buck/Boost Regulators Improve System Efficiency ..................... 5

Buck/Boost Regulator Key Specifications and Definitions ......... 6

Output Voltage Range Options ................................................... 6

Ground or Quiescent Current .................................................... 6

Shutdown Current ........................................................................ 6

REVISION HISTORY

4/12—Revision 0: Initial Version

Soft Start .........................................................................................6

Switching Frequency .....................................................................6

Thermal Shutdown (TSD) ...........................................................6

Buck/Boost DC-to-DC Switching Converters Operate at

MHz ................................................................................................7

Conclusion..........................................................................................8

References .......................................................................................8

Rev. 0 | Page 2 of 8

Application Note AN-1149

V

V

V

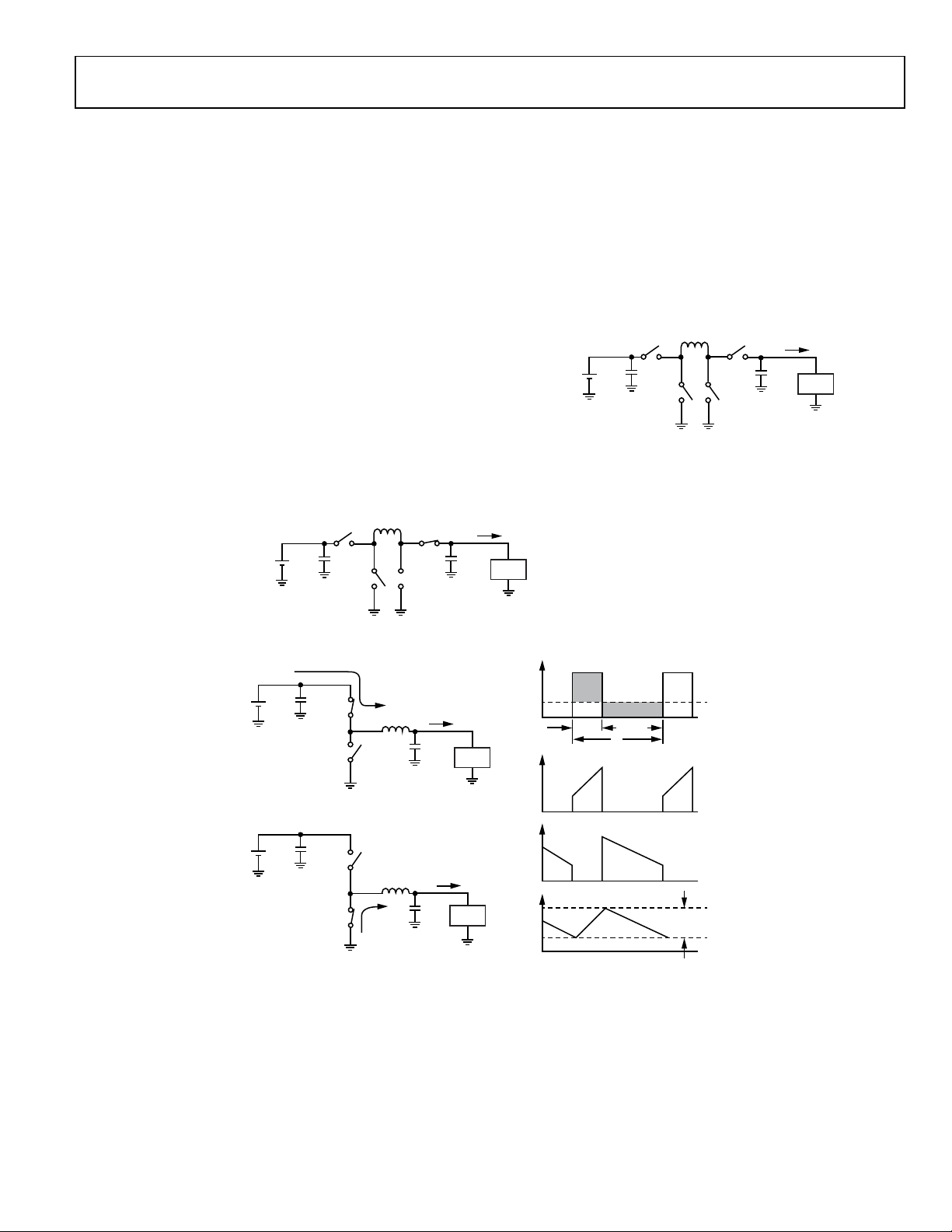

BUCK/BOOST REGULATORS

Buck/boost regulators contain four switches, two capacitors,

and an inductor, as shown in Figure 2. Current low power, high

efficiency buck/boost regulators reduce losses and improve

efficiency by actively operating only two of the four switches

when operating in buck or boost mode.

When V

is greater than V

IN

, Switch C is open and Switch D

OUT

is closed. Switch A and Switch B operate as in a standard buck

regulator, as shown in Figure 3.

When V

is less than V

IN

, Switch B is open and Switch A is

OUT

closed. Switch C and Switch D operate as in a boost regulator,

as shown in Figure 4. The most difficult operating mode is

when V

is in the range of V

IN

± 10% and the regulator enters

OUT

the buck/boost mode. In buck/boost mode, the two operations,

buck and boost, take place during a switching cycle. Care must

be taken to reduce losses, optimize efficiency, and eliminate

instability due to mode switching. The objective is to maintain

voltage regulation with minimal current ripple in the inductor

to guarantee good transient performance.

L

+

V

IN

–

A

C

IN

BC

D

I

C

OUT

At high load currents, the buck/boost uses voltage or currentmode, fixed frequency pulse-width modulation (PWM) control

for optimal stability and transient response. To ensure the

longest battery life in portable applications, a power save mode

reduces the switching frequency under light load conditions.

For wireless and other low noise applications where variablefrequency power save mode may cause interference, the

addition of a logic control input to force fixed frequency PWM

operation under all load conditions is included.

L

+

IN

–

A

C

IN

BC

Figure 2. Buck/Boost Converter Topology

I

LOAD

D

C

OUT

LOAD

V

OUT

LOAD

LOAD

V

OUT

10542-002

IN BUCK MODE SWITCH C IS O PEN AND SWIT CH D IS CLOSED.

I

+

IN

–

TYPICAL BUCK

OPERATION

+

IN

–

C

IN

PWM ON

C

IN

PWM OFF

A

A

V

SW

B

A

V

SW

B

I

B

I

LOAD

L

C

I

L

C

OUT

LOAD

OUT

LOAD

LOAD

V

OUT

V

OUT

Figure 3. Buck Mode When V

V

I

LOAD

PWM

OUT

MODULATIO N

t

OFF

T

∆I

LOAD

V

OUT

10542-003

SW

t

ON

I

A

I

B

> V

IN

Rev. 0 | Page 3 of 8

Loading...

Loading...