ANALOG DEVICES ADXRS622 Service Manual

FEATURES

V

DD

AGND

PGND

AV

CC

ST2 ST1 TEMP V

RATIO

CP1 CP2 CP3 CP4 CP5 SUMJ RATEOUT

DEMOD

180kΩ ±1%

22nF

100nF

22n

F

100nF

100nF

100nF

DRIVE

AMP

MECHANICAL

SENSOR

CHARGE PUMP

AND VOLTAGE

REGULATOR

C

OUT

5V

5V

5V

(ADC REF)

AC

AMP

VGA

25kΩ

@ 25°C

ADXRS622

25kΩ

SELF-TEST

07754-001

http://www.BDTIC.com/ADI

Complete rate gyroscope on a single chip

Z-axis (yaw rate) response

High vibration rejection over wide frequency

2000 g powered shock survivability

Ratiometric to referenced supply

5 V single-supply operation

105°C operation

Self-test on digital command

Ultrasmall and light: <0.15 cc, <0.5 gram

Temperature sensor output

RoHS compliant

Qualified for automotive applications

APPLICATIONS

Vehicle chassis rollover sensing

Inertial measurement units

Platform stabilization

GENERAL DESCRIPTION

The ADXRS622 is a complete angular rate sensor (gyroscope)

that uses the Analog Devices, Inc., surface-micromachining

process to make a functionally complete and low cost angular

rate sensor, integrated with all of the required electronics on

one chip. The manufacturing technique for this device is the

same high volume BiMOS process used for high reliability

automotive airbag accelerometers.

The ADXRS622 is an automotive grade gyroscope that has

100% pin, package, temperature, and function compatible to the

available industrial grade ADXRS652 gyroscope. Automotive

grade gyroscopes have more extensive guaranteed minimum/

maximum specifications due to automotive testing.

The output signal, RATEOUT (1B, 2A), is a voltage proportional to

the angular rate about the axis that is normal to the top surface of

the package. The output is ratiometric with respect to a provided

reference supply. An external capacitor sets the bandwidth. Other

external capacitors are required for operation.

A temperature output is provided for compensation techniques.

Two digital self-test inputs electromechanically excite the sensor

to test proper operation of both the sensor and the signal conditioning circuits. The ADXRS622 is available in a 7 mm × 7 mm ×

3 mm BGA chip-scale package.

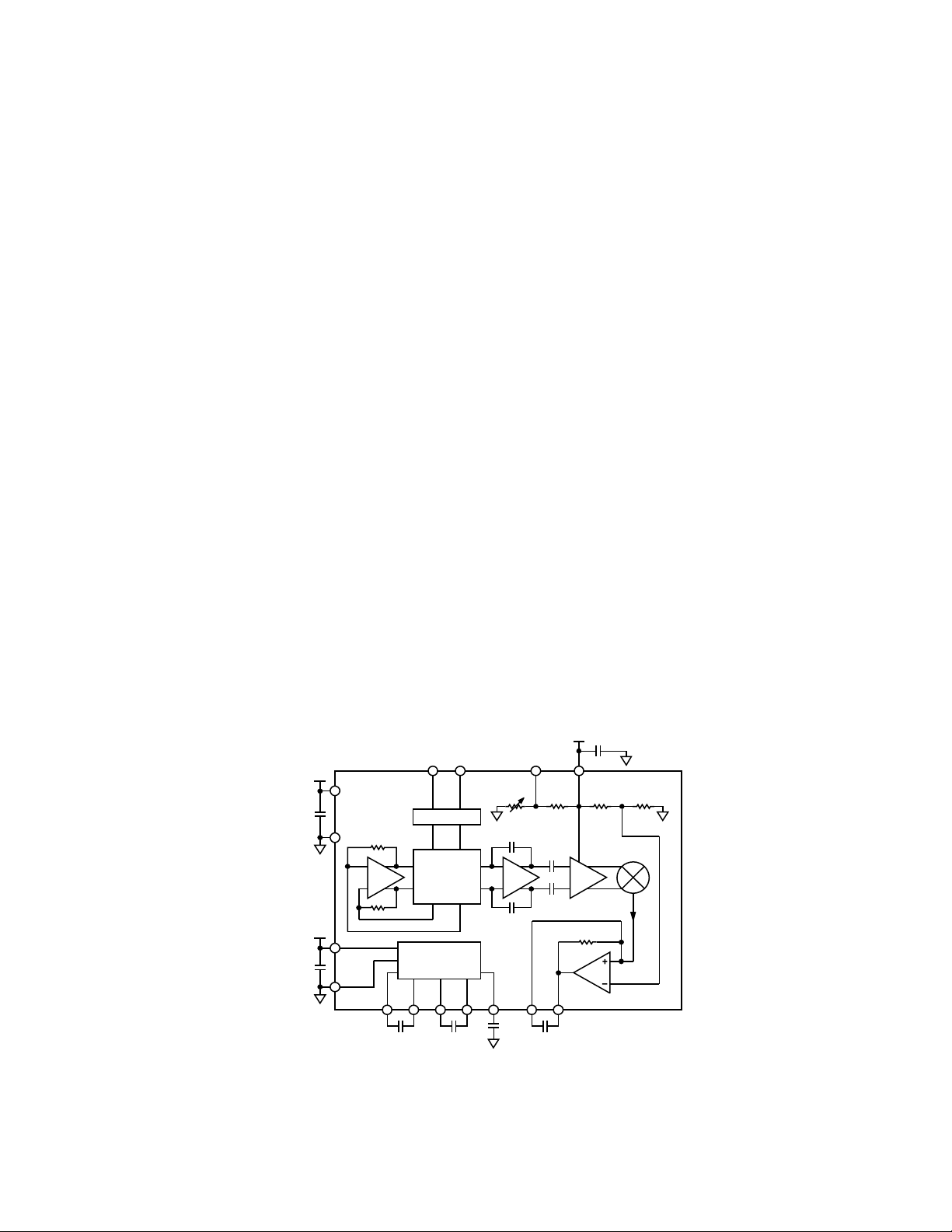

FUNCTIONAL BLOCK DIAGRAM

Figure 1.

Loading...

Loading...