High Performance

T

FEATURES

10-bit analog-to-digital converter

95 MSPS maximum conversion rate

9% or less p-p PLL clock jitter at 95 MSPS

Automated offset adjustment

2:1 input mux

Power-down via dedicated pin or serial register

4:4:4, 4:2:2, and DDR output format modes

Variable output drive strength

Odd/even field detection

External clock input

Regenerated Hsync output

Programmable output high impedance control

Hsyncs per Vsyncs counter

Pb-free package

APPLICATIONS

Advanced TVs

Plasma display panels

LCDTV

HDTV

RGB graphics processing

LCD monitors and projectors

Scan converters

GENERAL DESCRIPTION

The AD9981 is a complete, 10-bit, 95 MSPS, monolithic analog

interface optimized for capturing YPbPr video and RGB

graphics signals. Its 95 MSPS encode rate capability and fullpower analog bandwidth of 200 MHz supports all HDTV

video modes and graphics resolutions up to XGA (1024 × 768

at 85 Hz).

The AD9981 includes a 95 MHz triple ADC with an internal

reference, a PLL, programmable gain, offset, and clamp controls.

The user provides only 3.3 V and 1.8 V power supplies and an

analog input. Three-state CMOS outputs may be powered from

1.8 V to 3.3 V.

The AD9981’s on-chip PLL generates a sample clock from

the three-level sync (for YPbPr video) or the horizontal sync

(for RGB graphics). Sample clock output frequencies range from

10 MHz to 95 MHz. PLL clock jitter is 9% or less p-p typical at

95 MSPS.

10-Bit Display Interface

AD9981

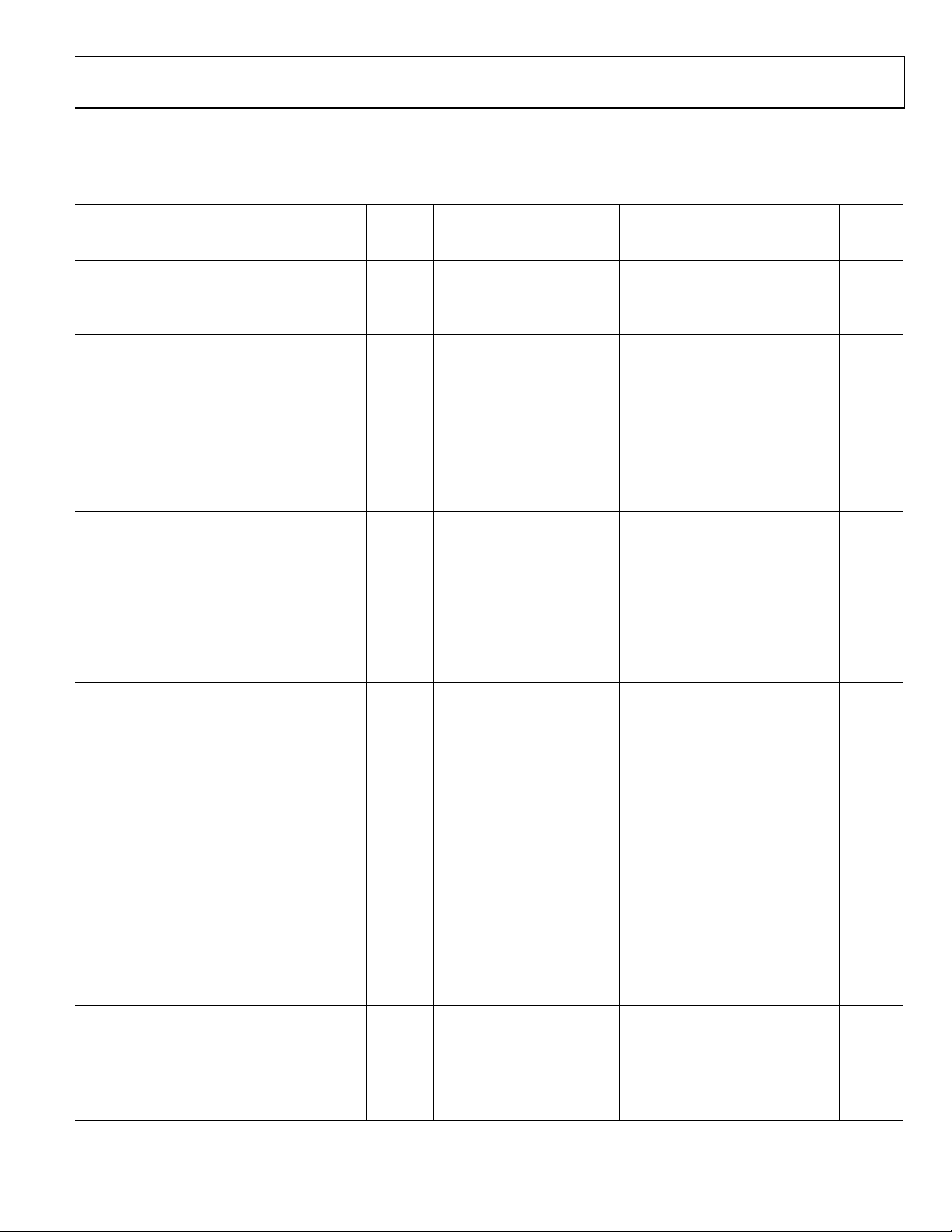

FUNCTIONAL BLOCK DIAGRAM

10

AUTO OFFSET

PR/REDIN1

PR/REDIN0

Y/GREENIN1

Y/GREENIN0

PB/BLUEIN1

PB/BLUEIN0

HSYNC1

HSYNC2

VSYNC1

VSYNC2

SOGIN1

SOGIN2

EXTCLK/COAS

CLAMP

FILT

SDA

SCL

2:1

CLAMP

MUX

2:1

CLAMP

MUX

2:1

CLAMP

MUX

2:1

MUX

2:1

MUX

2:1

MUX

SERIAL REGISTER

PGA

10

PGA

10

PGA

SYNC

PROCESSING

PLL

POWER

MANAGEMENT

10-BIT

ADC

AUTO OFFSET

10-BIT

ADC

AUTO OFFSET

10-BIT

ADC

Figure 1.

With internal Coast generation, the PLL maintains its output

frequency in the absence of sync input. A 32-step sampling

clock phase adjustment is provided. O utput dat a, sync, and

clock phase relationships are maintained.

The auto-offset feature can be enabled to automatically restore

the signal reference levels and to automatically calibrate out any

offset differences between the three channels. The AD9981 also

offers full sync processing for composite sync and sync-ongreen applications. A clamp signal is generated internally or

may be provided by the user through the CLAMP input pin.

Fabricated in an advanced CMOS process, the AD9981 is

provided in a space-saving, 80-pin, Pb-free, LQFP surface

mount plastic package. It is specified over the 0°C to +70°C

temperature range.

10

10

10

AD9981

OUPUT DATA FORMATTER

VOLTAGE

REFS

10

10

10

RED

OUT

GREEN

BLUE

OUT

DATACK

SOGOUT

O/E FIELD

HSOUT

VSOUT/A0

REFHI

REFCM

REFLO

OUT

04739-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2005 Analog Devices, Inc. All rights reserved.

www.analog.com

AD9981

TABLE OF CONTENTS

Analog Interface Specifications ...................................................... 3

Detailed 2-Wire Serial Control Register Descriptions .............. 29

Absolute Maximum Ratings............................................................ 5

Explanation of Test Levels........................................................... 5

ESD Caution.................................................................................. 5

Pin Configuration and Function Descriptions............................. 6

Design Guide................................................................................... 11

General Description................................................................... 11

Digital Inputs ..............................................................................11

Input Signal Handling................................................................ 11

Hsync and Vsync Inputs............................................................ 11

Serial Control Port ..................................................................... 11

Output Signal Handling............................................................. 11

Clamping .....................................................................................11

Gain and Offset Control............................................................ 12

Timing Diagrams........................................................................ 20

Hsync Timing ............................................................................. 21

Chip Identification..................................................................... 29

PLL Divider Control .................................................................. 29

Clock Generator Control .......................................................... 29

Phase Adjust................................................................................ 30

Input Gain ................................................................................... 30

Input Offset ................................................................................. 30

Hsync Controls ........................................................................... 31

Vsync Controls........................................................................... 31

Coast and Clamp Controls........................................................ 32

SOG Control ............................................................................... 34

Input and Power Control........................................................... 34

Output Control........................................................................... 35

Two-Wire Serial Control Port....................................................... 40

Data Transfer via Serial Interface............................................. 40

PCB Layout Recommendations ............................................... 42

Coast Timing...............................................................................21

Output Formatter ....................................................................... 21

Two-Wire Serial Register Map...................................................... 23

REVISION HISTORY

1/05—Initial Version: Revision 0

PLL ............................................................................................... 42

Outline Dimensions....................................................................... 44

Ordering Guide .......................................................................... 44

Rev. 0 | Page 2 of 44

AD9981

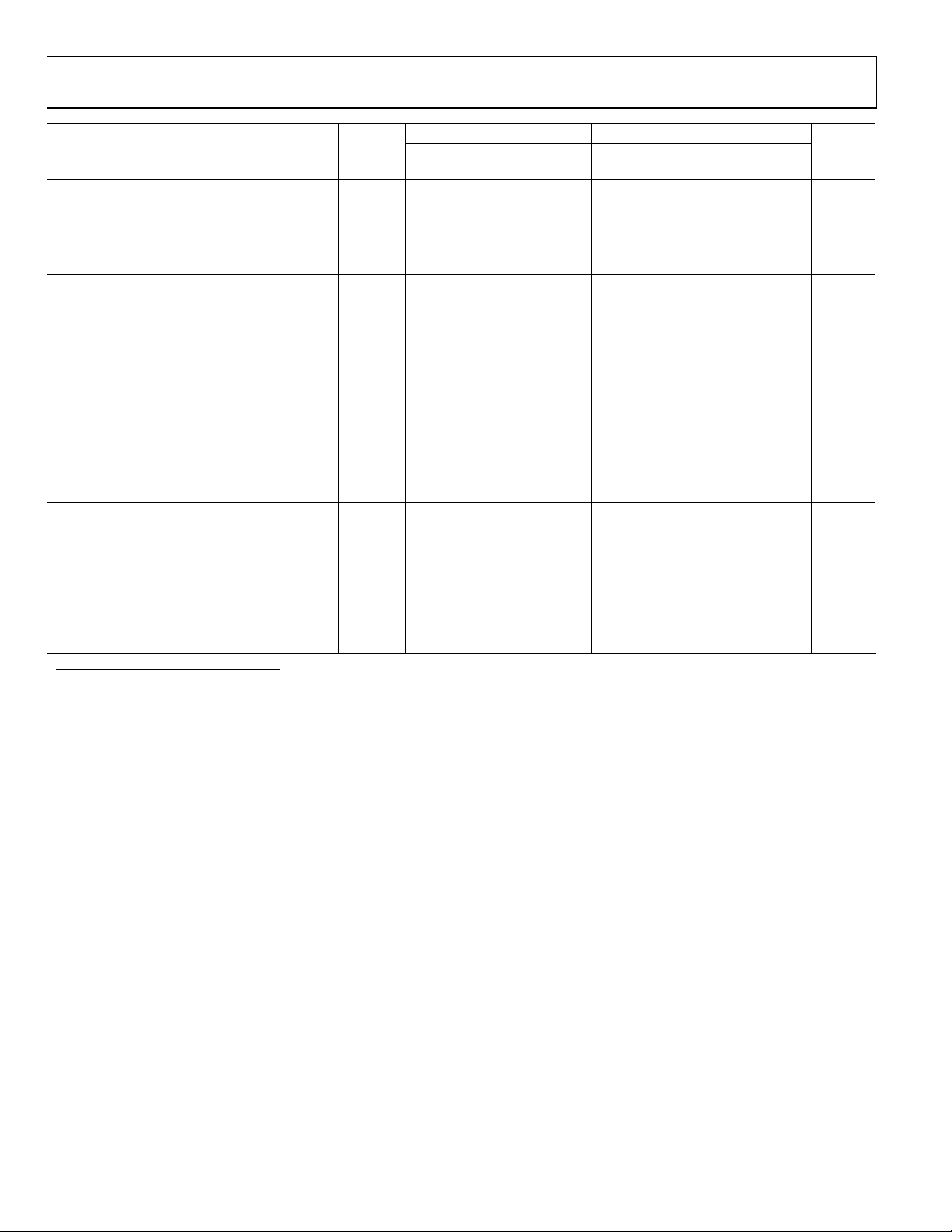

ANALOG INTERFACE SPECIFICATIONS

VD = 3.3 V, VDD = 3.3 V, PVD = 1.8 V, DAVDD = 1.8 V, ADC clock = maximum conversion rate , full temperature range = 0°C to 70°C.

Table 1. Electrical Characteristics

AD9981KSTZ-80

Test

Parameter Temp

Level

Min Typ Max Min Typ Max Unit

RESOLUTION

Number of Bits 10 10 Bits

LSB Size 0..098 0.098

DC ACCURACY LSB

Differential Nonlinearity

80 MSPS Conversion Rate

Differential Nonlinearity

95 MSPS Conversion Rate

Integral Nonlinearity

80 MSPS Conversion Rate

Integral Nonlinearity

95 MSPS Conversion Rate

25°C

Full

25°C

Full

25°C

Full

25°C

Full

I

VI

I

VI

I

VI

I

VI

0.3

0.4

±1.4

±1.4

No Missing Codes 25°C I Guaranteed Guaranteed

ANALOG INPUT

Input Voltage Range

Minimum Full VI 0.5 0.5 V p-p

Maximum Full VI 1.0 1.0 V p-p

Gain Tempco 25°C V 105 105 ppm/°C

Input Bias Current 25°C V 1 1 µA

Full V 1 1 µA

Input Full-Scale Matching Full VI 1 9 1 10 % FS

Offset Adjustment Range Full VI 44 44 % FS

SWITCHING PERFORMANCE

Maximum Conversion Rate Full VI 80 95 MSPS

Minimum Conversion Rate Full IV 10 10 MSPS

Clock to Data Skew t

t

BUFF

t

STAH

t

DHO

t

DAL

t

DAH

t

DSU

t

STASU

t

STOSU

SKEW

Full IV −0.5 +2 −0.5 +2 ns

Full VI 4.7 4.7 µS

Full VI 4.0 4.0 µS

Full VI 0 0 µS

Full VI 4.7 4.7 µS

Full VI 4.0 4.0 µS

Full VI 250 250 nS

Full VI 4.7 4.7 µS

Full VI 4.0 4.0 µS

Maximum PLL Clock Rate Full VI 80 95 MHz

Minimum PLL Clock Rate Full IV 10 10 MHz

PLL Jitter 25°C IV 750 980 ps p-p

Full IV ps p-p

Sampling Phase Tempco Full IV 15 15 ps/°C

DIGITAL INPUTS

3

Input Voltage, High (VIH) Full VI 2.5 2.5 V

Input Voltage, Low (VIL) Full VI 0.8 0.8 V

Input Current, High (IIH) Full V –82 –82 µA

Input Current, Low (IIL) Full V 82 82 µA

Input Capacitance 25°C V 2 2 pF

1

1.0

1.8

±3.75

±5.0

AD9981KSTZ-95

2

% of full

scale

0.3

0.4

1.3

1.75

±1.4

±1.4

±2.7

±3.7

1.0

1.8

2.75

5.4

±3.75

±5.0

±4.75

±8.6

LSB

LSB

LSB

LSB

Rev. 0 | Page 3 of 44

AD9981

AD9981KSTZ-80

1

AD9981KSTZ-95

2

Test

Parameter Temp

Level

Min Typ Max Min Typ Max Unit

DIGITAL OUTPUTS

Output Voltage, High (VOH) Full VI VDD − 0.2 V

− 0.2 V

DD

Output Voltage, Low (VOL) Full VI 0.2 0.1 V

Duty Cycle, DATACK Full IV 50 50 %

Output Coding Binary Binary

POWER SUPPLY

VD Supply Voltage Full IV 3.13 3.3 3.47 3.13 3.3 3.47 V

VDD Supply Voltage Full IV 1.7 3.3 3.47 1.7 3.3 3.47 V

PVD Supply Voltage Full IV 1.7 1.8 1.9 1.7 1.8 1.9 V

DAVD Supply Voltage Full IV 1.7 1.8 1.9 1.7 1.8 1.9 V

ID Supply Current (VD) 25°C V 233 205 mA

IDD Supply Current (VDD)

4

25°C V 42 49 mA

IPVD Supply Current (PVD) 25°C V 11 8 mA

IDAVD Supply Current (DAVD) 25°C V 10 12 mA

Total Power Dissipation Full VI 953 1070 993 1114 mW

Power-Down Supply Current Full VI 18 27 18 28 mA

Power-Down Dissipation Full VI 55 81 55 88 mW

DYNAMIC PERFORMANCE

Analog Bandwidth, Full Power 25°C V 200 200 MHz

Crosstalk Full V 60 60 dBc

THERMAL CHARACTERISTICS

θJC, Junction-to-Case

V 16 16 °C/W

Thermal Resistance

θJA, Junction-to-Ambient

V 35 35 °C/W

Thermal Resistance

1

Output drive strength = 0 was used for all 80 MHz parameters.

2

Output drive strength = 1 was used for all 95 MHz parameters.

3

Digital inputs are: HSYNC0, HSYNC1, VSYNC0, VSYNC1, SDA, SCL, EXTCLK, CLAMP, PWRDN, COAST

4

DATACK load = 10 pF, data load = 5 pF

Rev. 0 | Page 4 of 44

AD9981

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

V

D

V

DD

PV

D

DAV

DD

Analog Inputs VD to 0.0 V

REFHI VD to 0.0 V

REFCM VD to 0.0 V

REFLO VD to 0.0 V

Digital Inputs 5 V to 0.0 V

Digital Output Current 20 mA

Operating Temperature −25°C to +85°C

Storage Temperature −65°C to +150°C

Maximum Junction Temperature 150°C

3.6 V

3.6 V

1.98 V

1.98 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only and functional operation of the device at these or

any other conditions outside of those indicated in the operation

sections of this specification is not implied. Exposure to

absolute maximum ratings for extended periods may affect

device reliability.

EXPLANATION OF TEST LEVELS

Test Level

I. 100% production tested.

II. 100% production tested at 25°C and sample tested at

specified temperatures.

III. Sample tested only.

IV. Parameter is guaranteed by design and characterization

testing.

V. Parameter is a typical value only.

VI. 100% production tested at 25°C; guaranteed by design and

characterization testing.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. 0 | Page 5 of 44

AD9981

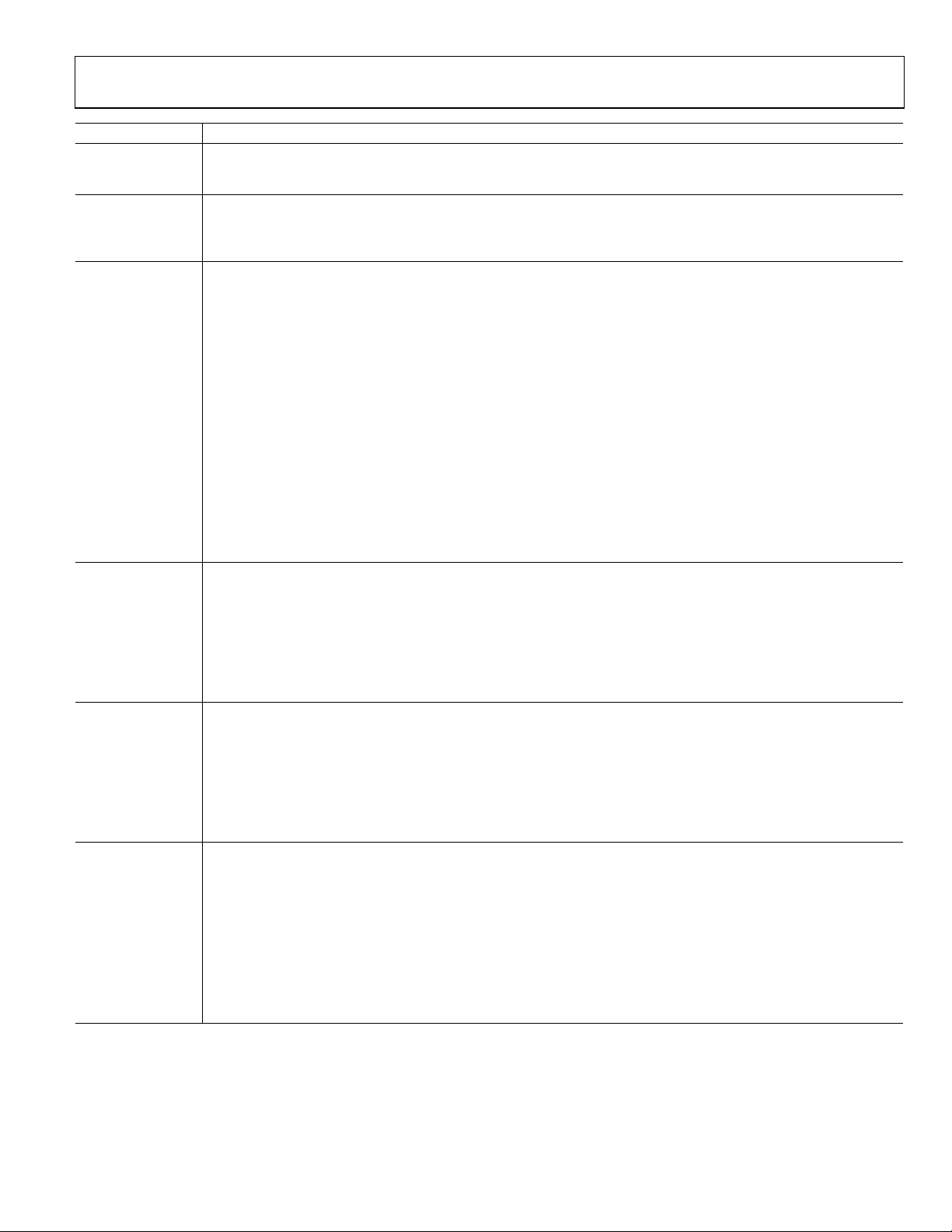

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

VD (3.3V)

B

AIN0

GND

B

AIN1

VD (3.3V)

G

AIN0

GND

SOGIN0

VD (3.3V)

G

AIN1

GND

SOGIN1

VD (3.3V)

R

AIN0

GND

R

AIN1

PWRDN

REFLO

REFCM

REFHI

(1.8V)

GND79P

80

1

PIN 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

O/E FIELD

VSOUT/A0

VD

78

23

FILT77GND76P

24

25

HSOUT

SOGOUT

(1.8V)

(1.8V)

VD

VD

GND74P

CCLAMP72EXTCLK/COAST71VSYNC070HSYNC069VSYNC168HSYNC167SCL66SDA65GND64VDD (3.3V)63BLUE <0>62BLUE <1>61BLUE <2>

75

73

AD9981

TOP VIEW

(Not to Scale)

26

27

28

GND

(3.3V)

RED <9>29RED <8>30RED <7>31RED <6>32RED <5>33RED <4>34RED <3>35RED <2>36RED <1>37RED <0>

DD

DATACK

V

60

BLUE <3>

59

BLUE <4>

58

BLUE <5>

57

BLUE <6>

56

BLUE <7>

55

BLUE <8>

54

BLUE <9>

53

GND

52

VDD (3.3V)

51

GREEN <0>

50

GREEN <1>

49

GREEN <2>

48

GREEN <3>

47

GREEN <4>

46

GREEN <5>

45

GREEN <6>

44

GREEN <7>

43

GREEN <8>

42

GREEN <9>

41

DAVDD (1.8)

38

39

(3.3V)

DD

V

GND40GND

04739-002

Figure 2. Top View (Pins Down)

Table 3. Complete Pinout List

Pin Type Mnemonic Function Value Pin No.

Inputs R

R

G

G

B

B

AIN0

AIN1

AIN0

AIN1

AIN0

AIN1

Channel 0 Analog Input for Converter R 0.0 V to 1.0 V 14

Channel 1 Analog Input for Converter R 0.0 V to 1.0 V 16

Channel 0 Analog Input for Converter G 0.0 V to 1.0 V 6

Channel 1 Analog Input for Converter G 0.0 V to 1.0 V 10

Channel 0 Analog Input for Converter B 0.0 V to 1.0 V 2

Channel 1 Analog Input for Converter B 0.0 V to 1.0 V 4

HSYNC0 Horizontal Sync Input for Channel 0 3.3 V CMOS 70

HSYNC1 Horizontal Sync Input for Channel 1 3.3 V CMOS 68

VSYNC0 Vertical Sync Input for Channel 0 3.3 V CMOS 71

VSYNC1 Vertical Sync Input for Channel 1 3.3 V CMOS 69

SOGIN0 Input for Sync-on-Green Channel 0 0.0 V to 1.0 V 8

SOGIN1 Input for Sync-on-Green Channel 1 0.0 V to 1.0 V 12

EXTCK External Clock Input 3.3 V CMOS 72

1

CLAMP External Clamp Input Signal 3.3 V CMOS 73

COAST External PLL Coast Signal Input 3.3 V CMOS 721

PWRDN Power-Down Control 3.3 V CMOS 17

Outputs RED [9:0] Outputs of Converter R, Bit 9 is the MSB 3.3 V CMOS 28 to 37

GREEN [9:0] Outputs of Converter G, Bit 9 is the MSB 3.3 V CMOS 42 to 51

BLUE [9:0] Outputs of Converter B, Bit 9 is the MSB 3.3 V CMOS 54 to 63

DATACK Data Output Clock 3.3 V CMOS 25

Rev. 0 | Page 6 of 44

AD9981

Pin Type Mnemonic Function Value Pin No.

HSOUT Hsync Output Clock (Phase-Aligned with DATACK) 3.3 V CMOS 23

VSOUT Vsync Output Clock 3.3 V CMOS 22

SOGOUT Sync-on-Green Slicer Output 3.3 V CMOS 24

O/E FIELD Odd/Even Field Output 3.3V CMOS 21

References FILT Connection for External Filter Components for Internal PLL 78

REFLO Connection for External Capacitor for Input Amplifier 18

REFCM Connection for External Capacitor for Input Amplifier 19

REFHI Connection for External Capacitor for Input Amplifier 20

Power Supply V

D

Analog Power Supply 3.3 V 1, 5, 9, 13

VDDOutput Power Supply 1.8 V or 3.3 V 26, 38, 52, 64

PV

DAV

D

DD

PLL Power Supply 1.8 V 74, 76, 79

Digital Logic Power Supply 1.8 V 41

GND Ground 0 V

Control SDA Serial Port Data I/O 3.3 V CMOS 66

SCL Serial Port Data Clock (100 kHz maximum) 3.3 V CMOS 67

A0 Serial Port Address Input 3.3 V CMOS 222

1

EXTCLK and COAST share the same pin.

2

VSOUT and A0 share the same pin.

2

3, 7, 11, 15, 27,

39, 40, 53, 65,

75, 77, 80

Rev. 0 | Page 7 of 44

AD9981

Table 4. Pin Function Descriptions

Pin Description

INPUTS

RAIN0 Analog Input for the Red Channel 0.

GAIN0 Analog Input for the Green Channel 0.

BAIN0 Analog Input for the Blue Channel 0.

RAIN1 Analog Input for the Red Channel 1.

GAIN1 Analog Input for the Green Channel 1.

BAIN1

HSYNC0 Horizontal Sync Input Channel 0.

HSYNC1

VSYNC0 Vertical Sync Input Channel 0.

VSYNC1

SOGIN0 Sync-on-Green Input Channel 0.

SOGIN1

CLAMP

EXTCLK/COAST

EXTCLK/COAST

PWRDN

Analog Input for the Blue Channel 1.

High impedance inputs that accept the red, green, and blue channel graphics signals, respectively. The three

channels are identical and can be used for any colors, but colors are assigned for convenient reference. They

accommodate input signals ranging from 0.5 V to 1.0 V full scale. Signals should be ac-coupled to these pins to

support clamp operation.

Horizontal Sync Input Channel 1.

These inputs receive a logic signal that establishes the horizontal timing reference and provides the frequency

reference for pixel clock generation. The logic sense of this pin can be automatically determined by the chip or

manually controlled by Serial Register 0x12, Bits [5:4] (Hsync polarity). Only the leading edge of Hsync is used by the

PLL; the trailing edge is used in clamp timing. When Hsync polarity = 0, the falling edge of Hsync is used. When Hsync

Polarity = 1, the rising edge is active. The input includes a Schmitt trigger for noise immunity.

Vertical Sync Input Channel 1.

These are the inputs for vertical sync and provide timing information for generation of the field (odd/even) and

internal Coast generation. The logic sense of this pin can be automatically determined by the chip or manually

controlled by Serial Register 0x14, Bits [5:4] (Vsync polarity).

Sync-on-Green Input Channel 1.

These inputs are provided to assist with processing signals with embedded sync, typically on the green channel. The

pin is connected to a high speed comparator with an internally generated threshold. The threshold level can be

programmed in 8 mV steps to any voltage between 8 mV and 256 mV above the negative peak of the input signal.

The default voltage threshold is 128 mV. When connected to an ac-coupled graphics signal with embedded sync, it

produces a noninverting digital output on SOGOUT. This is usually a composite sync signal, containing both vertical

and horizontal sync information that must be separated before passing the horizontal sync signal for Hsync

processing. When not used, this input should be left unconnected. For more details on this function and how it

should be configured, refer to the Sync-on-Green section.

External Clamp Input (Optional).

This logic input may be used to define the time during which the input signal is clamped to ground or midscale. It

should be exercised when the reference dc level is known to be present on the analog input channels, typically

during the back porch of the graphics signal. The CLAMP pin is enabled by setting the control bit clamp function to 1,

(Register 0x18, Bit 4; default is 0). When disabled, this pin is ignored and the clamp timing is determined internally by

counting a delay and duration from the trailing edge of the Hsync input. The logic sense of this pin can be automatically determined by the chip or controlled by clamp polarity Register 0x1B, Bits [7:6]. When not used, this pin may

be left unconnected (there is an internal pull-down resistor) and the clamp function programmed to 0.

Coast Input to Clock Generator (Optional).

This input may be used to cause the pixel clock generator to stop synchronizing with Hsync and continue producing a

clock at its current frequency and phase. This is useful when processing signals from sources that fail to produce

Hsync pulses during the vertical interval. The Coast signal is generally not required for PC-generated signals. The logic

sense of this pin can be determined automatically or controlled by Coast polarity (Register 0x18, Bits [7:6]). When not

used and EXTCLK is not used, this pin may be grounded and Coast polarity programmed to 1. Input Coast polarity

defaults to1 at power-up. This pin is shared with the EXTCLK function, which does not affect Coast functionality. For

more details on EXTCLK, see the description in this section.

External Clock.

This allows the insertion of an external clock source rather than the internally generated, PLL locked clock. EXTCLK is

enabled by programming Register 0x03, Bit 2 to 1. This pin is shared with the Coast function, which does not affect

EXTCLK functionality. For more details on Coast, see the above description in this section.

Power-Down Control

This pin can be used along with Register 0x1E, Bit 3 for manual power-down control. If manual power-down control is

selected (Register 0x1E, Bit 4) and this pin is not used, it is recommended to set the pin polarity (Register 0x1E, Bit 2) to

active high and hardwire this pin to ground with a 10 kΩ resistor.

Rev. 0 | Page 8 of 44

AD9981

Pin Description

REFLO

REFCM

REFHI

FILT

OUTPUTS

HSOUT

VSOUT/A0

SOGOUT

O/E FIELD

SERIAL PORT

SDA Serial Port Data I/O.

SCL Serial Port Data Clock.

VSOUT/A0

DATA OUTPUTS

RED [9:0] Data Output, Red Channel.

GREEN [9:0] Data Output, Green Channel.

BLUE [9:0]

DATA CLOCK

OUTPUT

DATACK

Input Amplifier Reference.

REFLO and REFHI are connected together through a 10 µF capacitor; REFCM is connected through a 10 µF capacitor to

ground. These are used for stability in the input PGA (programmable gain amplifier) circuitry. See Figure 4.

External Filter Connection.

For proper operation, the pixel clock generator PLL requires an external filter. Connect the filter shown in Figure 5to

this pin. For optimal performance, minimize noise and parasitics on this node. For more information, see the PCB

Layout Recommendations section.

Horizontal Sync Output.

A reconstructed and phase-aligned version of the Hsync input. Both the polarity and duration of this output can be

programmed via serial bus registers. By maintaining alignment with DATACK and Data Output, data timing with

respect to Hsync can always be determined.

Vertical Sync Output.

Pin shared with A0, serial port address. This can be either a separated Vsync from a composite signal or a direct pass

through of the Vsync signal. The polarity of this output can be controlled via a serial bus bit. The placement and

duration in all modes can be set by the graphics transmitter or the duration can be set by Register 0x14 and Register

0x15. This pin is shared with the A0 function, which does not affect Vsync Output functionality. For more details on

A0, see the description in the Serial Control Port section.

Sync-On-Green Slicer Output.

This pin outputs one of four possible signals (controlled by Register 0x1D, Bits [1:0]): raw SOG, raw Hsync, regenerated

Hsync from the filter, or the filtered Hsync. See the sync processing block diagram (see Figure 8) to view how this pin

is connected. Other than slicing off SOG, the output from this pin gets no other additional processing on the AD9981.

Vsync separation is performed via the sync separator.

Odd/Even Field Bit for Interlaced Video. This output will identify whether the current field (in an interlaced signal) is

odd or even.

Serial Port Address Input 0.

Pin shared with VSOUT. This pin selects the LSB of the serial port device address, allowing two Analog Devices parts to

be on the same serial bus. A high impedance external pull-up resistor enables this pin to be read at power-up as 1, or

a high impedance, external pull-down resistor enables this pin to be read at power-up as a 0 and not interfere with

the VSOUT functionality. For more details on VSOUT, see the Data Outputs section in this table.

Data Output, Blue Channel.

The main data outputs.

Bit 9 is the MSB. The delay from pixel sampling time to output is fixed. When the sampling time is changed by

adjusting the phase register, the output timing is shifted as well. The DATACK and HSOUT outputs are also moved, so

the timing relationship among the signals is maintained.

Data Clock Output.

This is the main clock output signal used to strobe the output data and HSOUT into external logic. Four possible

output clocks can be selected with Register 0x20, Bits [7:6]. Three of these are related to the pixel clock (pixel clock,

90° phase-shifted pixel clock and 2× frequency pixel clock). They are produced either by the internal PLL clock

generator or EXTCLK and are synchronous with the pixel sampling clock. The fourth option for the data clock output is

an internally generated 40 MHz clock.

The sampling time of the internal pixel clock can be changed by adjusting the phase register (Register 0x04). When

this is changed, the pixel related DATACK timing is also shifted. The Data, DATACK, and HSOUT outputs are all moved

so that the timing relationship among the signals is maintained.

Rev. 0 | Page 9 of 44

AD9981

Pin Description

POWER SUPPLY

VD (3.3 V)

VDD (1.8 V–3.3 V)

PVD (1.8 V)

DAVDD (1.8 V) Digital Input Power Supply. This supplies power to the digital logic.

GND

Main Power Supply.

These pins supply power to the main elements of the circuit. They should be as quiet and filtered as possible.

Digital Output Power Supply.

A large number of output pins (up to 35) switching at high speed (up to 95 MHz) generate a lot of power supply

transients (noise). These supply pins are identified separately from the V

minimize output noise transferred into the sensitive analog circuitry. If the AD9981 is interfacing with lower voltage

logic, V

may be connected to a lower supply voltage (as low as 1.8 V) for compatibility.

DD

Clock Generator Power Supply.

The most sensitive portion of the AD9981 is the clock generation circuitry. These pins provide power to the clock PLL

and help the user design for optimal performance. The designer should provide quiet, noise-free power to these pins.

Ground.

The ground return for all circuitry on-chip. It is recommended that the AD9981 be assembled on a single solid ground

plane, with careful attention to ground current paths.

pins, so special care can be taken to

D

Rev. 0 | Page 10 of 44

AD9981

DESIGN GUIDE

GENERAL DESCRIPTION

The AD9981 is a fully integrated solution for capturing analog

RGB or YPbPr signals and digitizing them for display on

advanced TVs, flat panel monitors, projectors, and other types

of digital displays. Implemented in a high-performance CMOS

process, the interface can capture signals with pixel rates of up

to 95 MHz.

The AD9981 includes all necessary input buffering, signal DC

restoration (clamping), offset and gain (brightness and contrast)

adjustment, pixel clock generation, sampling phase control, and

output data formatting. All controls are programmable via a

2

two-wire serial interface (I

sensitive analog functions makes system design straightforward

and less sensitive to the physical and electrical environment.

C®). Full integration of these

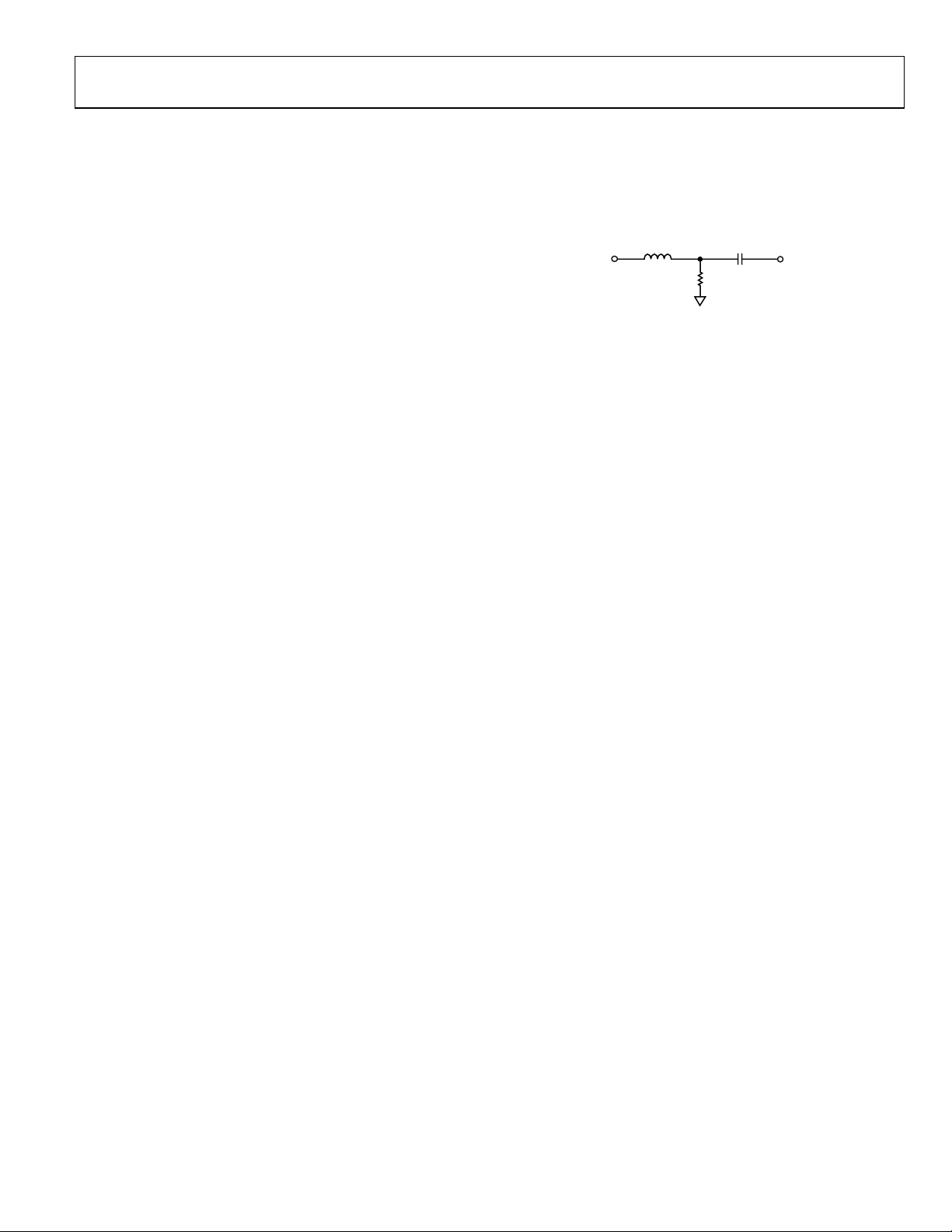

slightly and providing a high quality signal over a wider range

of conditions. Using a Fair-Rite #2508051217Z0-High Speed,

Signal Chip Bead Inductor in the circuit shown in Figure 3 gives

good results in most applications.

RGB

INPUT

Figure 3. Analog Input Interface Circuit

47nF

75Ω

R

AIN

G

AIN

B

AIN

04739-003

HSYNC AND VSYNC INPUTS

The interface also accepts Hsync and Vsync signals, which are

used to generate the pixel clock, clamp timing, Coast and field

information. These can be either a sync signal directly from the

graphics source, or a preprocessed TTL or CMOS level signal.

With a typical power dissipation of less than 900 mW and an

operating temperature range of 0°C to 70°C, the device requires

no special environmental considerations.

DIGITAL INPUTS

All digital inputs on the AD9981 operate to 3.3 V CMOS levels.

The following digital inputs are 5 V tolerant (Applying 5 V to

them will not cause any damage.): HSYNC0, HSYNC1,

VSYNC0, VSYNC1, SOGIN0, SOGIN1, SDA, SCL and CLAMP.

INPUT SIGNAL HANDLING

The AD9981 has six high-impedance analog input pins for the

red, green, and blue channels. They accommodate signals

ranging from 0.5 V to 1.0 V p-p.

Signals are typically brought onto the interface board with a

DVI-I connector, a 15-pin D connector, or RCA connectors.

The AD9981 should be located as close as possible to the input

connector. Signals should be routed using matched-impedance

traces (normally 75 Ω) to the IC input pins.

At the input pins the signal should be resistively terminated

(75 Ω to the signal ground return) and capacitively coupled to

the AD9981 inputs through 47 nF capacitors. These capacitors

form part of the DC restoration circuit.

In an ideal world of perfectly matched impedances, the best

performance can be obtained with the widest possible signal

bandwidth. The wide bandwidth inputs of the AD9981

(200 MHz) can continuously track the input signal as it moves

from one pixel level to the next and can digitize the pixel during

a long, flat pixel time. In many systems, however, there are

mismatches, reflections, and noise, which can result in excessive

ringing and distortion of the input waveform. This makes it

more difficult to establish a sampling phase that provides good

image quality. It has been shown that a small inductor in series

with the input is effective in rolling off the input bandwidth

The Hsync input includes a Schmitt trigger buffer for immunity

to noise and signals with long rise times. In typical PC-based

graphic systems, the sync signals are simply TTL-level drivers

feeding unshielded wires in the monitor cable. As such, no

termination is required.

SERIAL CONTROL PORT

The serial control port is designed for 3.3 V logic; however, it is

tolerant of 5 V logic signals.

OUTPUT SIGNAL HANDLING

The digital outputs are designed to operate from 1.8 V to

3.3 V (V

DD

).

CLAMPING

RGB Clamping

To properly digitize the incoming signal, the dc offset of the

input must be adjusted to fit the range of the on-board ADCs.

Most graphics systems produce RGB signals with black at

ground and white at approximately 0.75 V. However, if sync

signals are embedded in the graphics, the sync tip is often at

ground and black is at 300 mV; then white is at approximately

1.0 V. Some common RGB line amplifier boxes use emitterfollower buffers to split signals and increase drive capability.

This introduces a 700 mV dc offset to the signal, which must be

removed for proper capture by the AD9981.

The key to clamping is to identify a portion (time) of the signal

when the graphic system is known to be producing black. An

offset is then introduced that results in the ADC producing a

black output (Code 0x00) when the known black input is

present. The offset then remains in place when other signal

levels are processed, and the entire signal is shifted to eliminate

offset errors.

Rev. 0 | Page 11 of 44

AD9981

In most PC graphics systems, black is transmitted between

active video lines. With CRT displays, when the electron beam

has completed writing a horizontal line on the screen (at the

right side), the beam is deflected quickly to the left side of the

screen (called horizontal retrace) and a black signal is provided

to prevent the beam from disturbing the image.

Clamping to midscale rather than ground can be accomplished

by setting the clamp select bits in the serial bus register. Each of

the three converters has its own selection bit so that they can be

independently clamped to either midscale or ground. These bits

are located in Register 0x18, Bits [3:1]. The midscale reference

voltage is internally generated for each converter.

In systems with embedded sync, a blacker-than-black signal

(Hsync) is produced briefly to signal the CRT that it is time to

begin a retrace. Because the input is not at black level at this

time, it is important to avoid clamping during Hsync. Fortunately, there is virtually always a period following Hsync, called

the ‘back porch’, where a good black reference is provided. This

is the time when clamping should be done.

The clamp timing can be established by simply exercising the

CLAMP pin at the appropriate time with clamp source

(Register 0x18, Bit 4) = 1. The polarity of this signal is set by

the clamp polarity bit (Register 0x1B, Bits [7:6]).

A simpler method of clamp timing employs the AD9981

internal clamp timing generator. The clamp placement register

(Register 0x19) is programmed with the number of pixel

periods that should pass after the trailing edge of Hsync

before clamping star ts. A second reg ister, clamp duration,

(Register 0x1A) sets the duration of the clamp. These are both

8-bit values, providing considerable flexibility in clamp

generation. The clamp timing is referenced to the trailing edge

of Hsync because, though Hsync duration can vary widely, the

back porch (black reference) always follows Hsync. A good

starting point for establishing clamping is to set the clamp

placement to 0x04 (providing 4 pixel periods for the graphics

signal to stabilize after sync) and set the clamp duration to

0x28 (giving the clamp 40 pixel periods to reestablish the

black reference).

Clamping is accomplished by placing an appropriate charge on

the external input coupling capacitor. The value of this capacitor

affects the performance of the clamp. If it is too small, there will

be a significant amplitude change during a horizontal line time

(between clamping intervals). If the capacitor is too large, then

it will take excessively long for the clamp to recover from a large

change in incoming signal offset. The recommended value

(47 nF) results in recovering from a step error of 100 mV to

within 1 LSB in 30 lines with a clamp duration of 20 pixel

periods on a 85 Hz XGA signal.

YPbPr Clamping

YPbPr graphic signals are slightly different from RGB signals in

that the dc reference level (black level in RGB signals) of color

difference signals is at the midpoint of the video signal rather

than at the bottom. The three inputs are composed of

luminance (Y) and color difference (Pb and Pr) signals. For

color difference signals it is necessary to clamp to the midscale

range of the ADC range (512) rather than to the bottom of the

ADC range (0), while the Y channel is clamped to ground.

GAIN AND OFFSET CONTROL

The AD9981 contains three programmable gain amplifiers

(PGAs), one for each of the three analog inputs. The range of

the PGA is sufficient to accommodate input signals with inputs

ranging from 0.5 V to 1.0 V full scale. The gain is set in three

9-bit registers (red gain [0x05, 0x06], green gain [0x07, 0x08],

blue gain [0x09, 0x0A]). For each of these registers, a gain

setting of 0 corresponds to the highest gain, while a gain setting

of 511 corresponds to the lowest gain. Note that increasing the

gain setting results in an image with less contrast.

The offset control shifts the analog input, resulting in a change

in brightness. Three 11-bit registers (red offset [0x0B, 0x0C],

green offset [0x0D, 0x0E], blue offset [0x0F, 0x10]) provide

independent settings for each channel. Note that the function of

the offset register depends on whether auto-offset is enabled

(Register 0x1B, Bit 5).

If manual offset is used, nine bits of the offset registers (for

the red channel Register 0x0B, Bits [6:0] plus Register 0x0C,

Bits [7:6]) control the absolute offset added to the channel. The

offset control provides ±255 LSBs of adjustment range, with one

LSB of offset corresponding to one LSB of output code.

Automatic Offset

In addition to the manual offset adjustment mode, the AD9981

also includes circuitry to automatically calibrate the offset for

each channel. By monitoring the output of each ADC during

the back porch of the input signals, the AD9981 can self-adjust

to eliminate any offset errors in its own ADC channels and any

offset errors present on the incoming graphics or video signals.

To activate the auto-offset mode, set Register 0x1B, Bit 5 to 1.

Next, the target code registers (0x0B through 0x10) must be

programmed. The values programmed into the target code

registers should be the output code desired from the AD9981

during the back porch reference time. For example, for RGB

signals, all three registers would normally be programmed to

Code 1, while for YPbPr signals the green (Y) channel is normally set to Code 1 and the blue and red channels (Pb and Pr)

are set to 512. The target code registers have 11 bits per channel

and are in twos complement format. This allows any value

between –1024 and +1023 to be programmed. Although any

value in this range can be programmed, the AD9981’s offset

range may not be able to reach every value. Intended target code

values range from (but are not limited to) –160 to –1 and +1 to

+160 when ground clamping, and +350 to +670 when midscale

clamping. Note that a target code of 0 is not valid.

Rev. 0 | Page 12 of 44

AD9981

Negative target codes are included in order to duplicate a feature that is present with manual offset adjustment. The benefit

that is being mimicked is the ability to easily adjust brightness

on a display. By setting the target code to a value that does not

correspond to the ideal ADC range, the end result is an image

that is either brighter or darker. A target code higher than ideal

results in a brighter image, while a target code lower than ideal

results in a darker image.

The ability to program a target code gives a large degree of

freedom and flexibility. While in most cases all channels are set

to either 1 or 512, the flexibility to select other values allows the

possibility of inserting intentional skews between channels. It

also allows the ADC range to be skewed so that voltages outside

of the normal range can be digitized. For example, setting the

target code to 40 allows the sync tip, which is normally below

black level, to be digitized and evaluated.

The internal logic for the auto-offset circuit requires 16 data

clock cycles to perform its function. This operation is executed

immediately after the clamping pulse. Therefore, it is important

to end the clamping pulse signal at least 16 data clock cycles

before active video. This is true whether using the AD9981’s

internal clamp circuit or an external clamp signal. The autooffset function can be programmed to run continuously or on a

one-time basis (see auto-offset hold, Register 0x2C, Bit 4). In

continuous mode, the update frequency can be programmed

(Register 0x1B, Bits [4:3]). Continuous operation with updates

every 64 Hsyncs is recommended.

A guideline for basic auto-offset operation is shown in Table 5

and Table 6.

Table 5. RGB Auto-Offset Register Settings

Register Value Comments

0x0B 0x00 Sets red target to 4

0x0C 0x80 Must be written

0x0D 0x00 Sets green target to 4

0x0E 0x80 Must be written

0x0F 0x00 Sets blue target to 4

0x10 0x80 Must be written

0x18, Bits [3:1] 000 Sets red, green, and blue

channels to ground clamp

0x1B, Bit [5:3] 110 Selects update rate and

enables auto-offset.

Table 6. PbPr Auto-Offset Register Settings

Register Value Comments

0x0B 0x40 Sets Pr (red) target to 512

0x0C 0x00 Must be written

0x0D 0x00 Sets Y (green) target to 4

0x0E 0x80 Must be written

0x0F 0x40 Sets Pb (blue) target to 512

0x10 0x00 Must be written

0x18 Bits [3:1] 101 Sets Pb, Pr to midscale clamp

and Y to ground clamp

0x1B, Bit [5:3] 110 Selects update rate and

enables auto-offset.

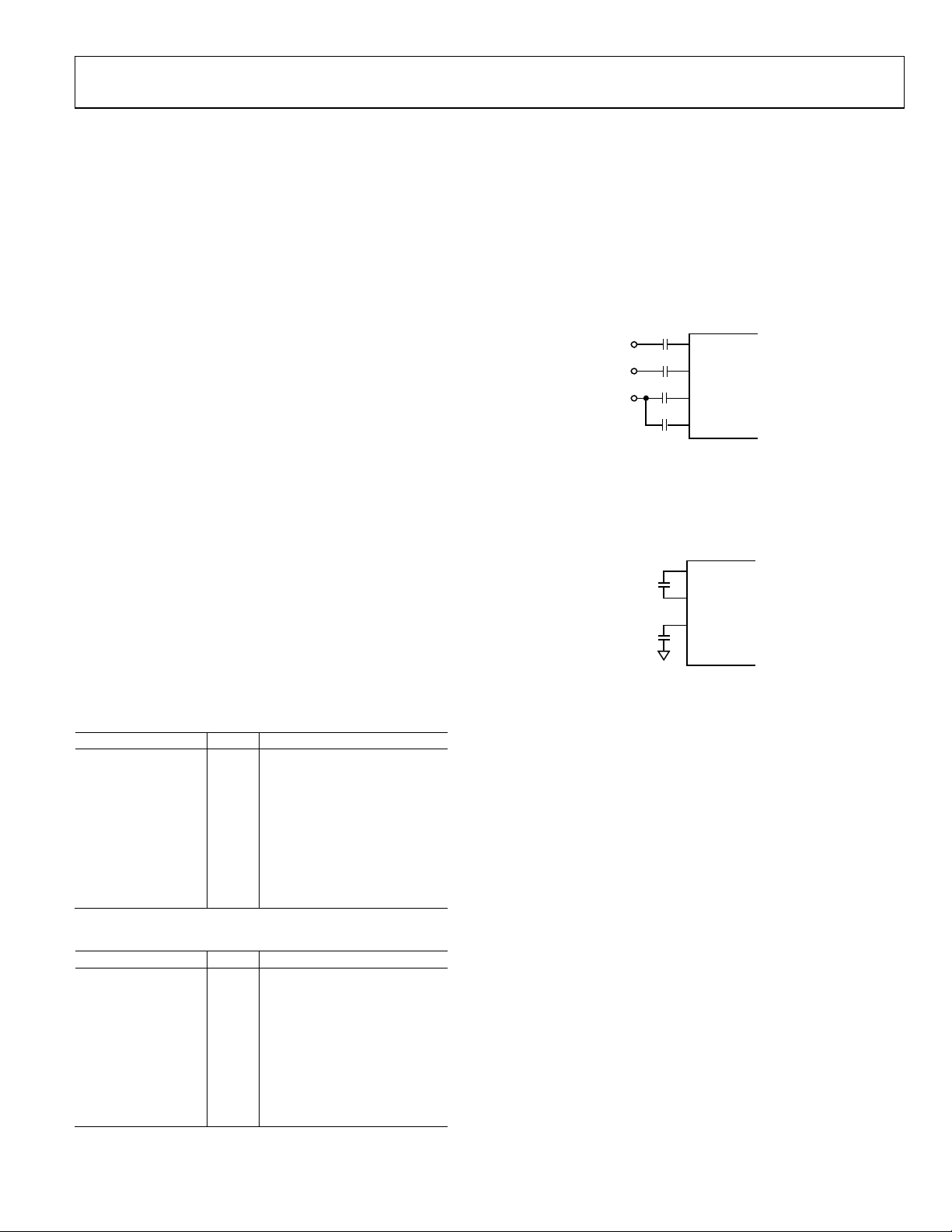

Sync-on-Green

The sync-on-green input operates in two steps. First, it sets a

baseline clamp level off of the incoming video signal with a

negative peak detector. Second, it sets the sync trigger level to

a programmable (Register 0x1D, Bits [7:3]) level (typically

128 mV) above the negative peak. The sync-on-green input

must be ac-coupled to the green analog input through its own

capacitor. The value of the capacitor must be 1 nF ±20%. If

sync-on-green is not used, this connection is not required. The

sync-on-green signal always has negative polarity.

47nF

R

AIN

47nF

B

AIN

47nF

G

AIN

1nF

SOG

Figure 4. Typical Input Configuration

04739-004

Reference Bypassing

REFLO and REFHI are connected to each other by a 10 µF

capacitor. REFCM is connected to ground by a 10 µF capacitor.

These references are used by the input PGA circuitry.

10µF

10µF

Figure 5. Input Amplifier Reference Capacitors

REFHI

REFLO

REFCM

04739-014

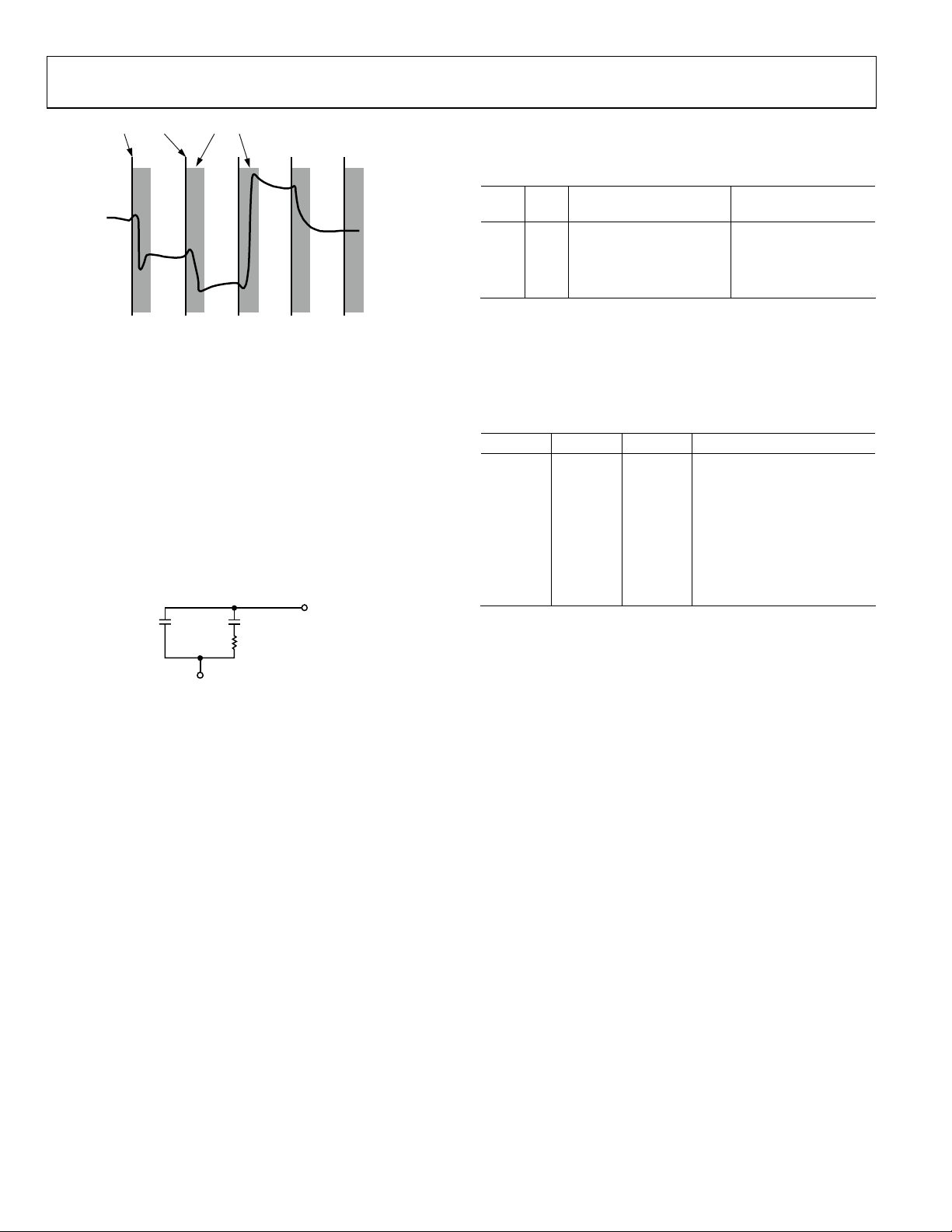

Clock Generation

A PLL is used to generate the pixel clock. The Hsync input

provides a reference frequency to the PLL. A voltagecontrolled oscillator (VCO) generates a much higher pixel clock

frequency. The pixel clock is divided by the PLL divide value

(Register 0x01 and Register 0x02) and phase-compared with the

Hsync input. Any error is used to shift the VCO frequency and

maintain lock between the two signals.

The stability of this clock is a very important element in

providing the clearest and most stable image. During each pixel

time, there is a period when the signal is slewing from the old

pixel amplitude and settling at its new value. Then there is a

time when the input voltage is stable, before the signal must

slew to a new value (see Figure 6). The ratio of the slewing time

to the stable time is a function of the bandwidth of the graphics

DAC and the bandwidth of the transmission system (cable and

termination). It is also a function of the overall pixel rate.

Clearly, if the dynamic characteristics of the system remain

fixed, then the slewing and settling time is likewise fixed. This

time must be subtracted from the total pixel period, leaving the

stable period. At higher pixel frequencies, the total cycle time is

shorter and the stable pixel time also becomes shorter.

Rev. 0 | Page 13 of 44

AD9981

PIXEL CLOCK INVALID SAMPLE TIMES

Figure 6. Pixel Sampling Times

04739-005

Any jitter in the clock reduces the precision with which the

sampling time can be determined and must also be subtracted

from the stable pixel time. Considerable care has been taken in

the design of the AD9981’s clock generation circuit to minimize

jitter. The clock jitter of the AD9981 is 9% or less of the total

pixel time in all operating modes, making the reduction in the

valid sampling time due to jitter negligible.

The PLL characteristics are determined by the loop filter design,

the PLL charge pump current, and the VCO range setting. The

loop filter design is illustrated in Figure 7. Recommended

settings of the VCO range and charge pump current for VESA

standard display modes are listed in Table 9.

PV

D

04739-006

1.5kΩ

C

80nF

R

Z

C

P

8nF

FILT

Figure 7. PLL Loop Filter Detail

Z

Four programmable registers are provided to optimize the

performance of the PLL. These registers are

1. The 12-Bit Divisor Register. The input Hsync frequencies

can accommodate any Hsync as long as the product of the

Hsync and the PLL divisor falls within the operating range

of the VCO. The PLL multiplies the frequency of the Hsync

signal, producing pixel clock frequencies in the range of

10 MHz to 95 MHz. The divisor register controls the exact

multiplication factor. This register may be set to any value

between 2 and 4095 as long as the output frequency is

within range.

2. The 2-Bit VCO Range Register. To improve the noise

performance of the AD9981, the VCO operating frequency

range is divided into four overlapping regions. The VCO

range register sets this operating range. The frequency

ranges for the four regions are shown in Table 7.

Table 7. VCO Frequency Ranges

PV1 PV0

Pixel Clock

Range (MHz)

KVCO

Gain (MHz/V)

0 0 10–21 150

0 1 21–42 150

1 0 42–84 150

1 1 84-95 150

3. The 3-Bit Charge Pump Current Register. This register

varies the current that drives the low-pass loop filter. The

possible current values are listed in Table 8.

Table 8. Charge Pump Current/Control Bits

Ip2 Ip1 Ip0 Current (µA)

0 0 0 50

0 0 1 100

0 1 0 150

0 1 1 250

1 0 0 350

1 0 1 500

1 1 0 750

1 1 1 1500

4. The 5-Bit Phase Adjust Register. The phase of the gen-

erated sampling clock may be shifted to locate an optimum

sampling point within a clock cycle. The phase adjust

register provides 32 phase-shift steps of 11.25° each. The

Hsync signal with an identical phase shift is available

through the HSOUT pin. Phase adjust is still available if an

external pixel clock is used. The COAST pin or the internal

Coast is used to allow the PLL to continue to run at the

same frequency in the absence of the incoming Hsync

signal or during disturbances in Hsync (such as from

equalization pulses). This may be used during the vertical

sync period or at any other time that the Hsync signal is

unavailable. The polarity of the Coast signal may be set

through the Coast polarity register (Register 0x18,

Bits [6:5]). Also, the polarity of the Hsync signal may

be set through the Hsync polarity register (Register 0x12,

Bits [5:4]). For both Hsync and Coast, a value of 1 is active

high. The internal Coast function is driven off the Vsync

signal, which is typically a time when Hsync signals may be

disrupted with extra equalization pulses.

Rev. 0 | Page 14 of 44

Loading...

Loading...