Analog Devices AD9888KS-205, AD9888KS-170, AD9888KS-140, AD9888KS-100, AD9888-PCB Datasheet

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

a

AD9888

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

100/140/170/205 MSPS Analog

Flat Panel Interface

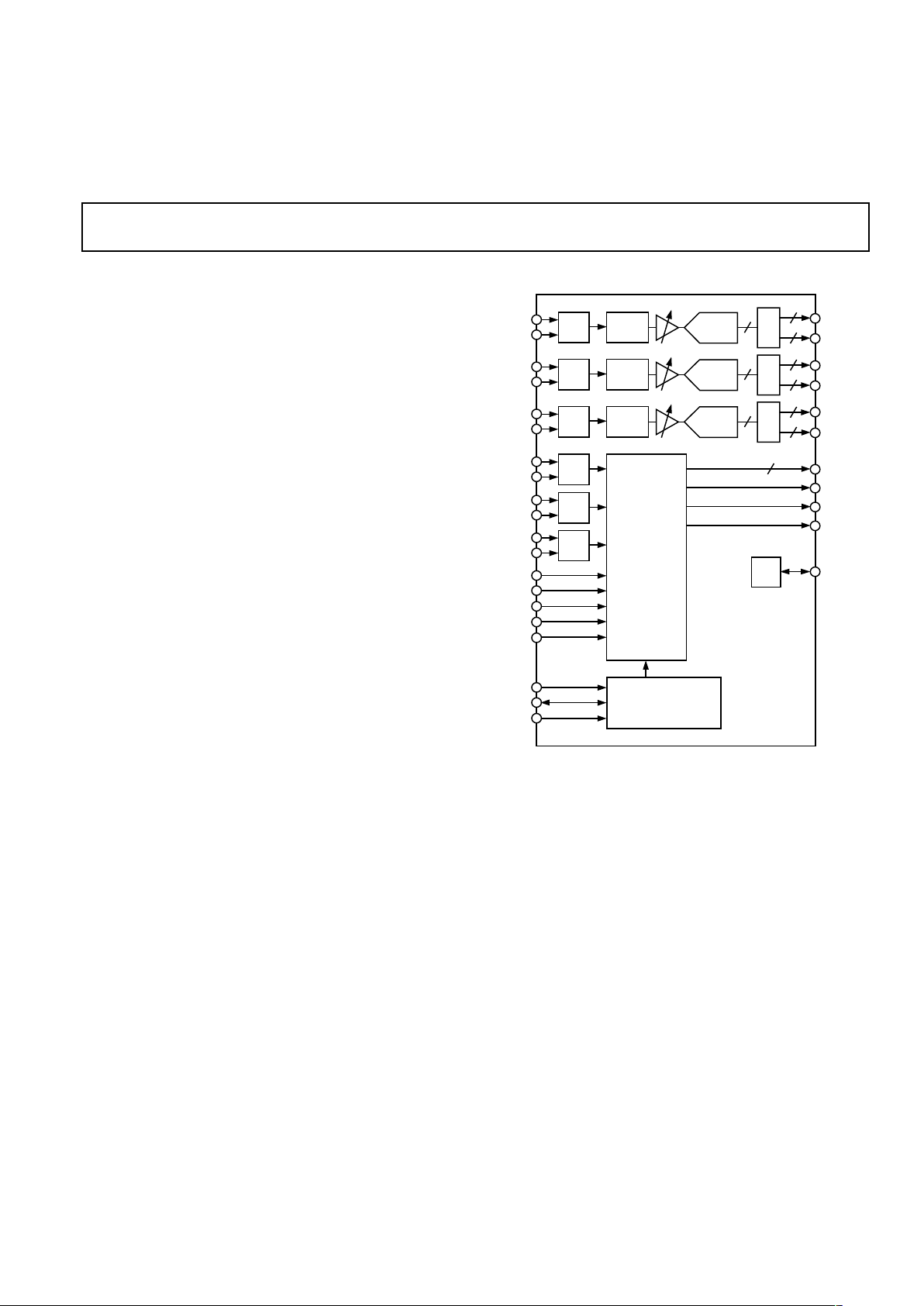

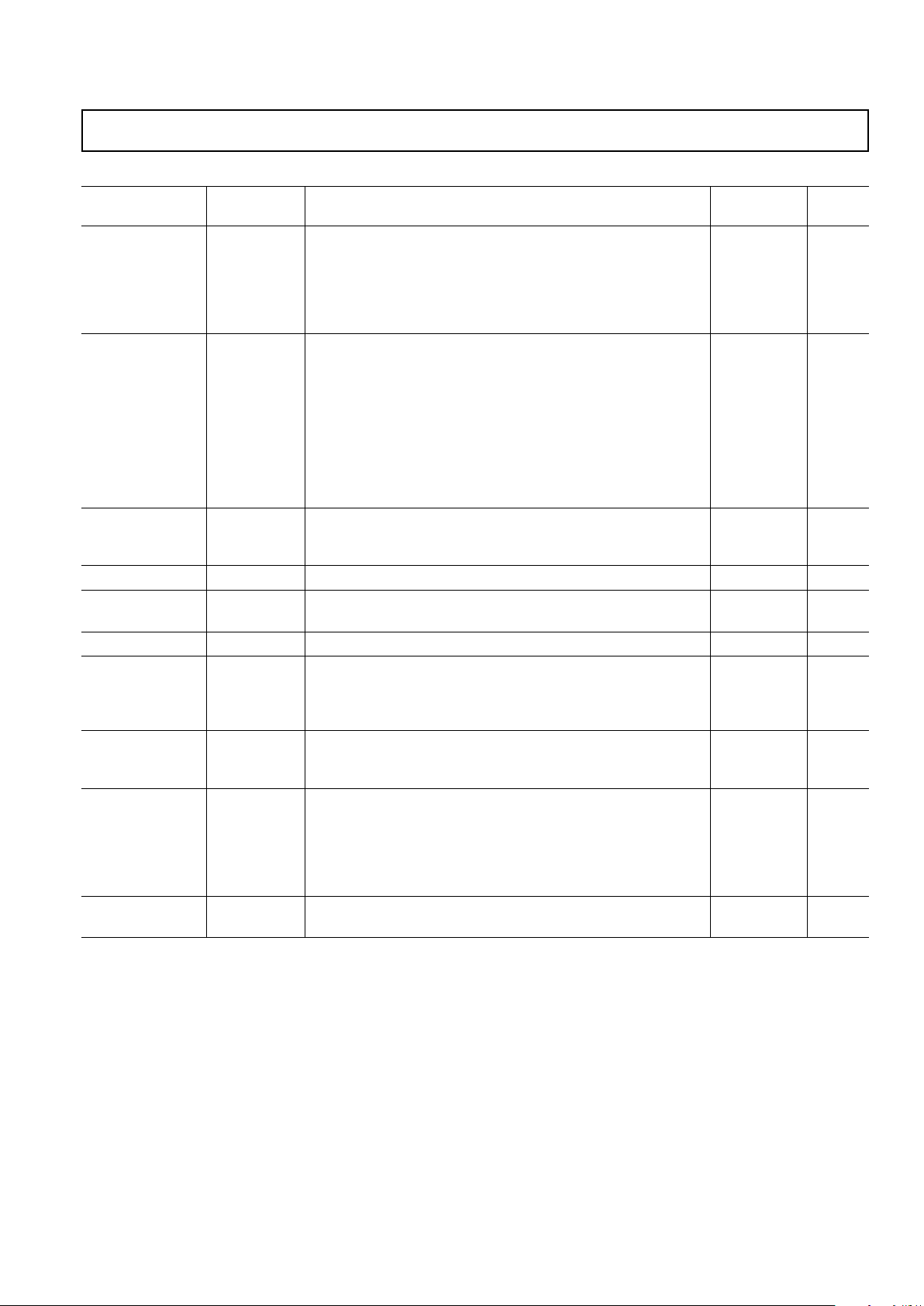

FUNCTIONAL BLOCK DIAGRAM

2:1

MUX

A/D

8

8

8

R

IN

R

OUTA

R

IN

R

OUTB

2:1

MUX

A/D

8

8

8

G

IN

G

OUTA

G

IN

G

OUTB

2:1

MUX

A/D

8

8

8

B

IN

B

OUTA

B

IN

B

OUTB

2:1

MUX

HSYNC

HSYNC

2:1

MUX

VSYNC

VSYNC

2:1

MUX

SOGIN

SOGIN

COAST

CLAMP

CKINV

CKEXT

FILT

SCL

SDA

A0

REF

BYPASS

DATACK

HSOUT

VSOUT

SOGOUT

SERIAL REGISTER

AND

POWER MANAGEMENT

REF

SYNC

PROCESSING

AND

CLOCK

GENERATION

CLAMP

CLAMP

CLAMP

AD9888

2

FEATURES

205 MSPS Maximum Conversion Rate

500 MHz Programmable Analog Bandwidth

0.5 V to 1.0 V Analog Input Range

Less than 450 ps p-p PLL Clock Jitter @ 205 MSPS

3.3 V Power Supply

Full Sync Processing

Sync Detect for “Hot Plugging”

2:1 Analog Input Mux

4:2:2 Output Format Mode

Midscale Clamping

Power-Down Mode

Low Power: <1 W Typical @ 205 MSPS

APPLICATIONS

RGB Graphics Processing

LCD Monitors and Projectors

Plasma Display Panels

Scan Converters

Microdisplays

Digital TV

GENERAL DESCRIPTION

The AD9888 is a complete 8-bit, 205 MSPS monolithic analog

interface optimized for capturing RGB graphics signals from

personal computers and workstations. Its 205 MSPS encode

rate capability and full-power analog bandwidth of 500 MHz

supports resolutions up to UXGA (1600 × 1200 at 75 Hz).

For ease of design and to minimize cost, the AD9888 is a fully

integrated interface solution for flat panel displays. The AD9888

includes an analog interface with a 205 MHz triple ADC with

internal 1.25 V reference, PLL to generate a pixel clock from

HSYNC and COAST, midscale clamping, and programmable

gain, offset, and clamp control. The user provides only a 3.3 V

power supply, analog input, and HSYNC and COAST signals.

Three-state CMOS outputs may be powered from 2.5 V to 3.3 V.

The AD9888’s on-chip PLL generates a pixel clock from HSYNC

and COAST inputs. Pixel clock output frequencies range from

10 MHz to 205 MHz. PLL clock jitter is less than 450 ps p-p

typical at 205 MSPS. When the COAST signal is presented, the

PLL maintains its output frequency in the absence of HSYNC.

A sampling phase adjustment is provided. Data, HSYNC, and

Clock output phase relationships are maintained. The PLL can

be disabled and an external clock input provided as the pixel

clock. The AD9888 also offers full sync processing for composite sync and Sync-on-Green applications.

A clamp signal is generated internally or may be provided by the

user through the CLAMP input pin. This interface is fully programmable via a 2-wire serial interface.

Fabricated in an advanced CMOS process, the AD9888 is provided in a space-saving 128-lead MQFP surface mount plastic

package and is specified over the 0°C to 70°C temperature range.

REV. A

–2–

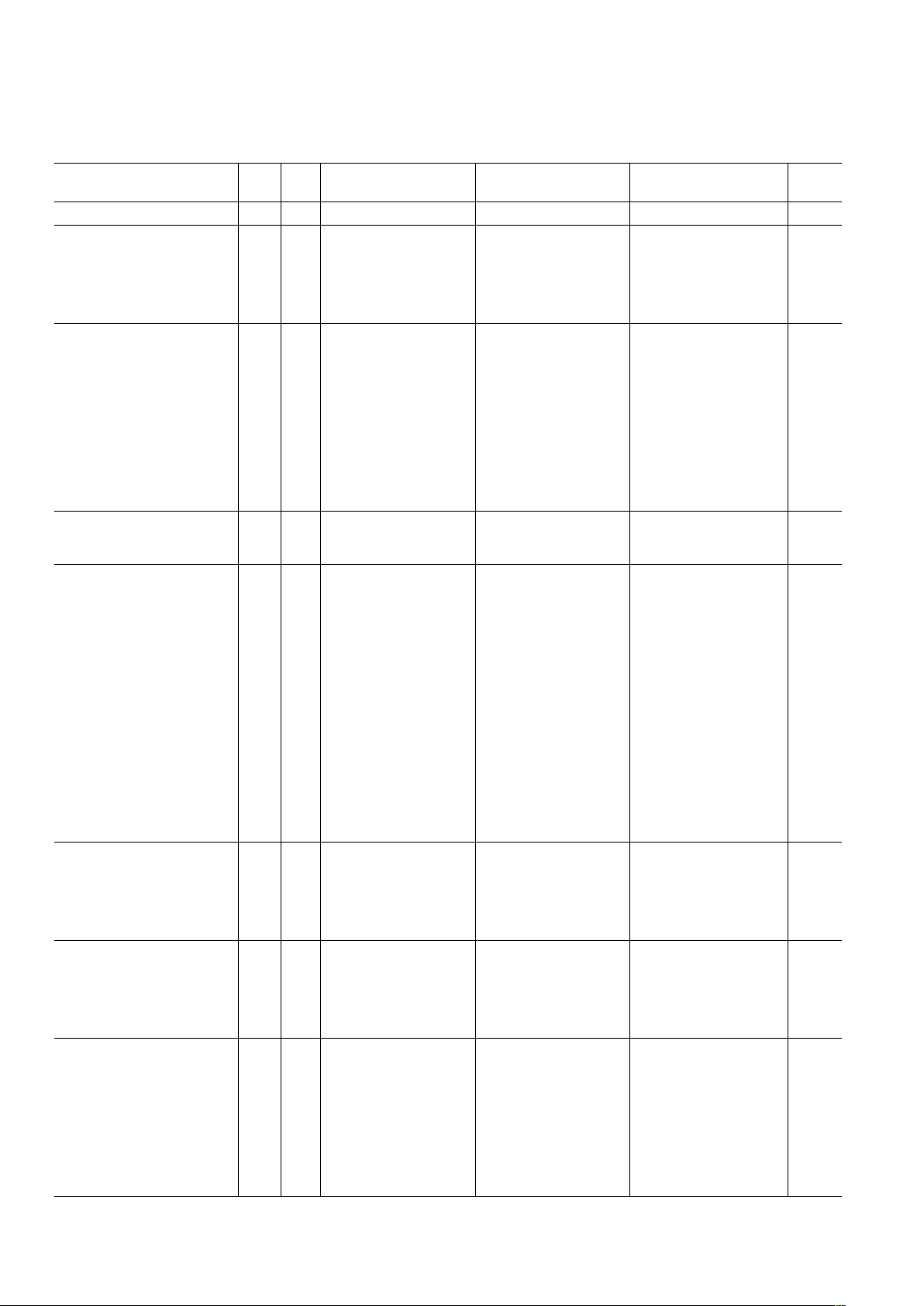

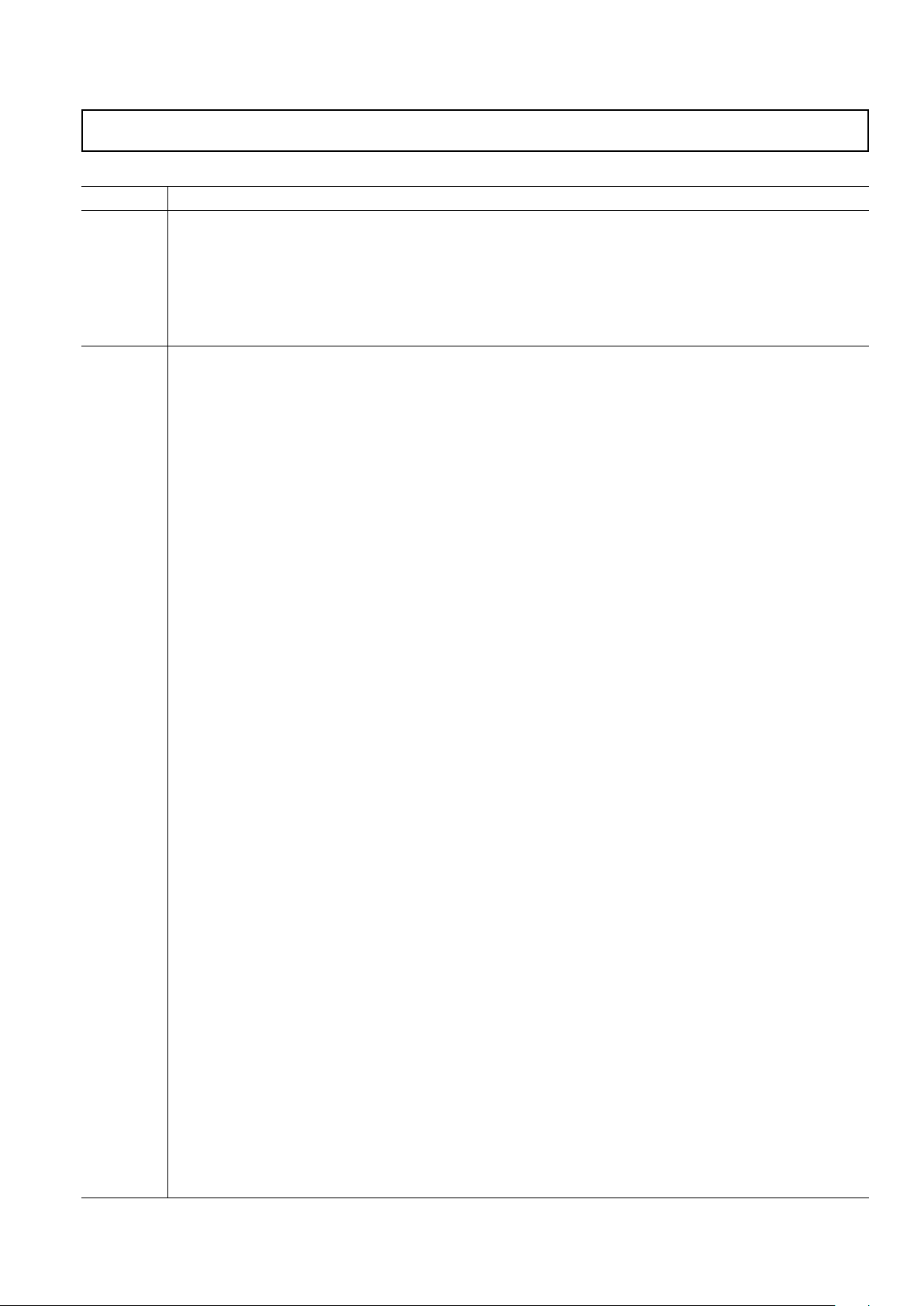

AD9888–SPECIFICATIONS

(VD = 3.3 V, VDD = 3.3 V, ADC Clock = Maximum Conversion Rate)

Test AD9888KS-100/-140

1

AD9888KS-170 AD9888KS-205

Parameter Temp Level Min Typ Max Min Typ Max Min Typ Max Unit

RESOLUTION 8 8 8 Bits

DC ACCURACY

Differential Nonlinearity 25°CI ± 0.5 +1.25/–1.0 ± 0.6 +1.25/–1.0 ± 0.8 +1.50/–1.0 LSB

Full VI +1.35/–1.0 +1.50/–1.0 +1.80/–1.0 LSB

Integral Nonlinearity 25°CI ± 0.5 ± 2.0 ± 0.75 ±2.25 ± 1.0 ± 3.75 LSB

Full VI ± 2.5 ± 2.75 ± 4.25 LSB

No Missing Codes 25°C I Guaranteed Guaranteed Guaranteed

ANALOG INPUT

Input Voltage Range

Minimum 25°C I 0.5 0.5 0.5 V p-p

Maximum 25°C I 1.0 1.0 1.0 V p-p

Gain Tempco 25°C V 100 100 100 ppm/°C

Input Bias Current 25°CIV 1 1 1 µA

Full IV 2 2 2 µA

Input Capacitance Full V 3 3 3 pF

Input Resistance Full IV 1 1 1 MΩ

Input Offset Voltage Full VI 7 90 7 90 7 90 mV

Input Full-Scale Matching Full VI 2.5 9.0 2.5 9.0 2.5 9.0 % FS

Offset Adjustment Range Full VI 44 49 53 44 49 53 44 49 53 % FS

REFERENCE OUTPUT

Output Voltage Full VI 1.20 1.25 1.30 1.20 1.25 1.30 1.20 1.25 1.30 V

Temperature Coefficient Full V ± 50 ±50 ± 50 ppm/°C

SWITCHING PERFORMANCE

Maximum Conversion Rate Full VI 100/140 170 205 MSPS

Minimum Conversion Rate Full IV 10 10 10 MSPS

Data to Clock Skew Full IV –1.25 +1.25 –1.25 +1.25 –1.25 +1.25 ns

t

BUFF

2

Full VI 4.7 4.7 4.7 µs

t

STAH

2

Full VI 4.0 4.0 4.0 µs

t

DHO

2

Full VI 0 0 0 µs

t

DAL

2

Full VI 4.7 4.7 4.7 µs

t

DAH

2

Full VI 4.0 4.0 4.0 µs

t

DSU

2

Full VI 250 250 250 ns

t

STASU

2

Full VI 4.7 4.7 4.7 µs

t

STOSU

2

Full VI 4.0 4.0 4.0 µs

HSYNC Input Frequency Full IV 15 110 15 110 15 110 kHz

Maximum PLL Clock Rate Full VI 100/140 170 205 MHz

Minimum PLL Clock Rate Full IV 10 10 10 MHz

PLL Jitter 25°C IV 470 700

3

450 700

4

440 700

4

ps p-p

Full IV 1000

3

1000

4

1000

4

ps p-p

Sampling Phase Tempco Full IV 15 15 15 ps/°C

DIGITAL INPUTS

Input Voltage, High (V

IH

) Full VI 2.5 2.5 2.5 V

Input Voltage, Low (V

IL

) Full VI 0.8 0.8 0.8 V

Input Current, High (I

IH

) Full IV –1.0 –1.0 –1.0 µA

Input Current, Low (I

IL

) Full IV +1.0 +1.0 +1.0 µA

Input Capacitance 25°CV 3 3 3 pF

DIGITAL OUTPUTS

Output Voltage, High (V

OH

) Full VI VD – 0.1 VD – 0.1 VD – 0.1 V

Output Voltage, Low (V

OL

) Full VI 0.1 0 .1 0.1 V

Duty Cycle

DATACK, DATACK Full IV 44 49 55 44 49 55 44 49 55 %

Output Coding Binary Binary Binary

POWER SUPPLY

V

D

Supply Voltage Full IV 3.0 3.3 3.6 3.0 3.3 3.6 3.0 3.3 3.6 V

V

DD

Supply Voltage Full IV 2.2 3.3 3.6 2.2 3.3 3.6 2.2 3.3 3.6 V

P

VD

Supply Voltage Full IV 3.0 3.3 3.6 3.0 3.3 3.6 3.0 3.3 3.6 V

I

D

Supply Current (VD)25°C V 200 215 230 mA

I

DD

Supply Current (VDD)

5

25°C V 50 55 60 mA

IP

VD

Supply Current (PVD)25°CV 8 9 10 mA

Total Power Dissipation Full VI 850 1050 920 1150 990 1250 mW

Power-Down Supply Current Full VI 12 20 12 20 12 20 mA

Power-Down Dissipation Full VI 40 66 40 66 40 66 mW

REV. A

–3–

AD9888

Test AD9888KS-100/-140

1

AD9888KS-170 AD9888KS-205

Parameter Temp Level Min Typ Max Min Typ Max Min Typ Max Unit

DYNAMIC PERFORMANCE

Analog Bandwidth, Full Power

6

25°C V 500 500 500 MHz

Transient Response 25°CV 2 2 2 ns

Overvoltage Recovery Time 25°C V 1.5 1.5 1.5 ns

Signal-to-Noise Ratio (SNR)

7

25°CIV4245 4144 4042 dB

(Without Harmonics) Full V 44 43 41 dB

f

IN

= 40.7 MHz

Crosstalk Full V 50 50 50 dBc

THERMAL CHARACTERISTICS

θ

JC

–Junction-to-Case V 8.4 8.4 8.4 °C/W

Thermal Resistance

θ

JA

–Junction-to-Ambient V 35 35 35 °C/W

Thermal Resistance

NOTES

1

AD9888KS-100 specifications are tested at 100 MHz. AD9888KS-140 specifications are tested at 140 MHz.

2

See Figure 23.

3

VCO Range = 10, Charge Pump Current = 100, PLL Divider = 1693.

4

VCO Range = 11, Charge Pump Current = 100, PLL Divider = 2159.

5

DEMUX = 1, DATACK and DATACK Load = 15 pF, Data Load = 5 pF.

6

Maximum bandwidth setting. Bandwidth can also be programmed to 300 MHz, 150 MHz, and 75 MHz.

7

Using External Pixel Clock.

Specifications subject to change without notice.

EXPLANATION OF TEST LEVELS

Test Level

I. 100% production tested.

II. 100% production tested at 25°C and sample tested at

specified temperatures.

III. Sample tested only.

IV. Parameter is guaranteed by design and characterization

testing.

V. Parameter is a typical value only.

VI. 100% production tested at 25°C; guaranteed by design and

characterization testing.

ABSOLUTE MAXIMUM RATINGS*

VD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6 V

V

DD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6 V

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

D

to 0.0 V

VREF IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

D

to 0.0 V

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 V to 0.0 V

Digital Output Current . . . . . . . . . . . . . . . . . . . . . . . . . 20 mA

Operating Temperature . . . . . . . . . . . . . . . . . –25°C to +85°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Maximum Junction Temperature . . . . . . . . . . . . . . . . . 150°C

Maximum Case Temperature . . . . . . . . . . . . . . . . . . . . 150°C

*Stresses above those listed under Absolute Maximum Ratings may cause permanent

damage to the device. This is a stress rating only and functional operation of the

device at these or any other conditions outside of those indicated in the operation

sections of this specification is not implied. Exposure to absolute maximum ratings

for extended periods may affect device reliability.

WARNING!

ESD SENSITIVE DEVICE

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD9888 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

ORDERING GUIDE

Temperature Package

Model Range Option

AD9888KS-100 0°C to 70°C S-128A

AD9888KS-140 0°C to 70°C S-128A

AD9888KS-170 0°C to 70°C S-128A

AD9888KS-205 0°C to 70°C S-128A

AD9888/PCB 25°C Evaluation Board

REV. A

AD9888

–4–

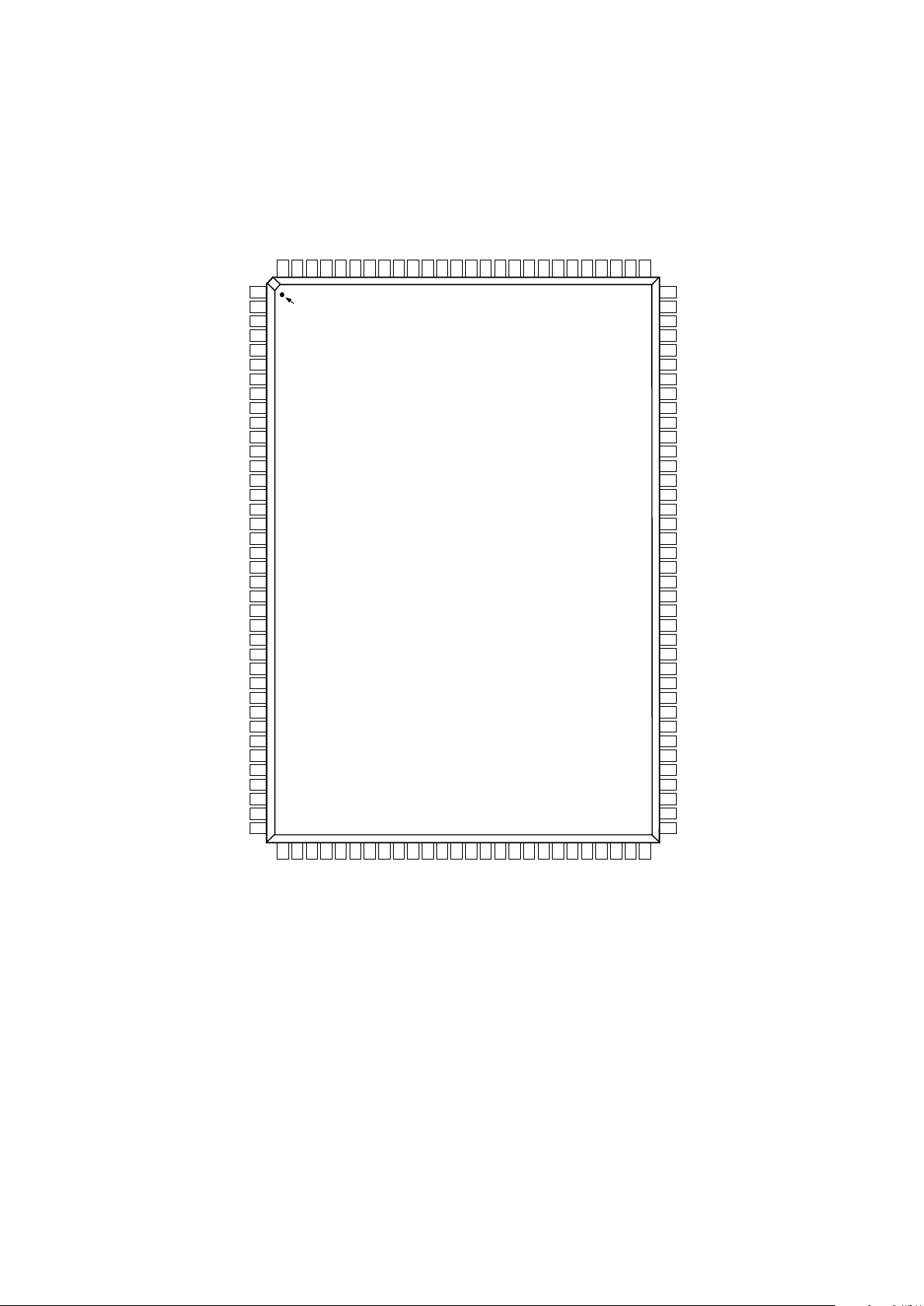

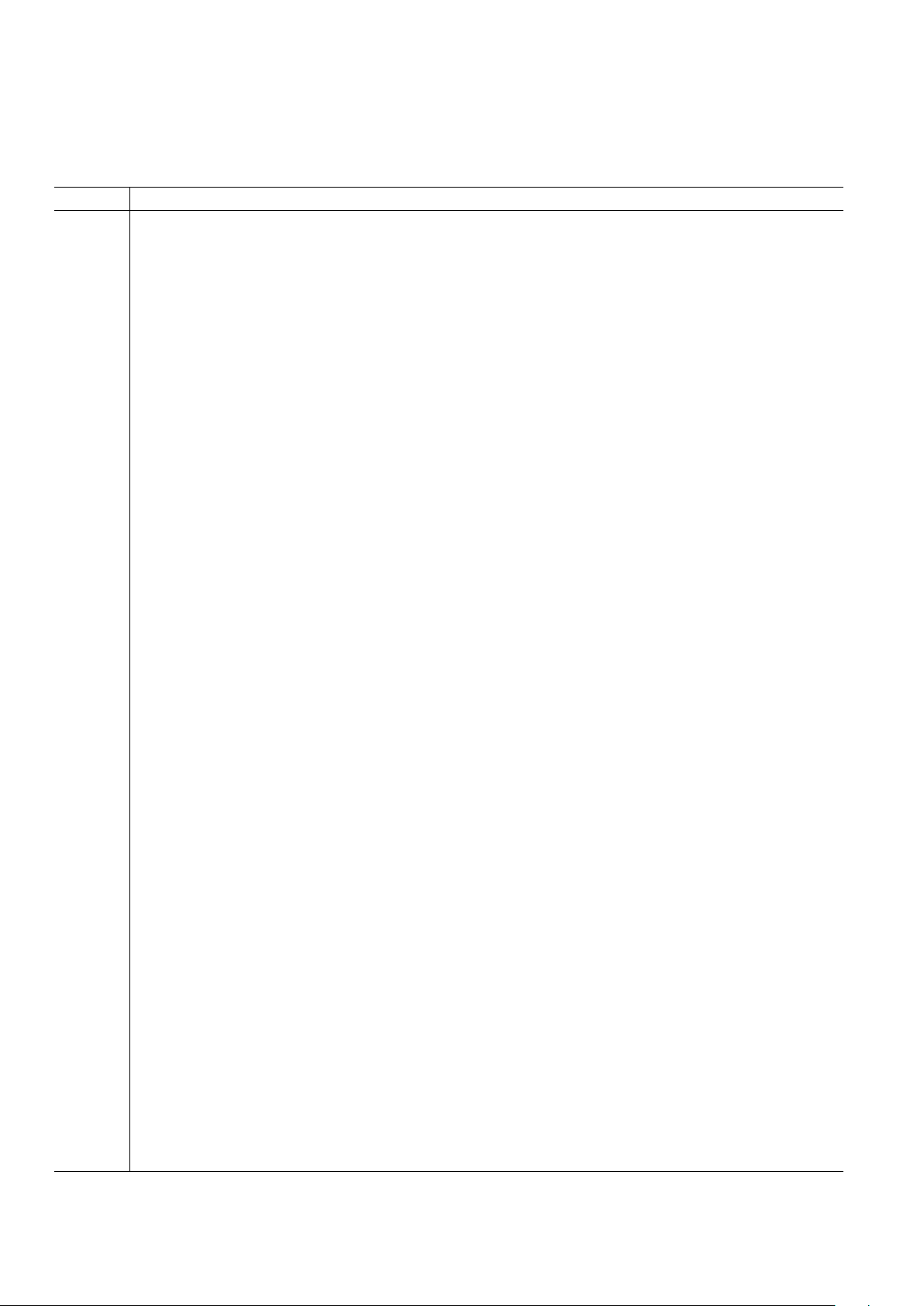

PIN CONFIGURATION

92

93

95

90

91

88

89

87

96

86

94

81

82

83

84

79

80

78

76

77

85

75

73

74

71

72

69

70

67

68

66

65

98

99

101

97

102

100

41

42

43

44

46

47

48

49

39

45

40

62

61

60

64

63

59

55

50

51

52

53

54

56

57

58

11

10

16

15

14

13

18

17

20

19

22

21

12

24

23

26

25

28

27

30

29

32

31

5

4

3

2

7

6

9

8

1

34

33

36

35

38

37

120

121

122

123

124

125

126

127

128

119

111

118

117

116

115

114

113

112

110

109

108

107

106

105

104

103

PIN 1

IDENTIFIER

TOP VIEW

(Not to Scale)

VSOUT

SOGOUT

HSOUT

DATAC KB

DATAC K

V

DD

GND

GND

GND

V

DD

GND

GND

GND

GND

V

DD

GND

DGA

0

FILT

DGA

1

DGA

2

DGA

3

COAST

DGA

4

CKEXT

DGA

5

GND

DGA

6

V

DD

DGA

7

DGB

7

V

DD

GND

D

BA0

DBA

1

DBA

2

DBA

3

DBA

4

V

D

REF BYPASS

GND

GND

R

AIN

0

V

D

V

D

R

AIN

1

RMIDSCV

V

D

GND

SOGIN0

G

AIN

0

V

D

GND

SOGIN1

G

AIN

1

V

D

GND

B

AIN

0

V

D

GND

B

AIN

1

BMIDSCV

V

D

V

D

GND

GND

CKINV

CLAMP

SDA

SCL

D

BA5

DBA

6

V

DD

GND

D

GB0

DGB

1

DGB

2

DGB

3

DGB

4

DGB

5

DGB

6

AD9888

A0

V

D

GND

GND

V

PV

D

D

D

DBA

7

V

DD

PV

DPVD

PV

D

PV

GND

GND

GND

GND

D

R

A

0

D

R

A

1

D

R

A

2

D

R

A

3

D

R

A

4

D

R

A

5

D

R

A

6

D

R

A

7

V

DD

D

R

B

0

D

R

B

1

GND

VSYNC1

HSYNC1

VSYNC0

HSYNC0

GND

D

B

B

7

D

B

B

6

D

B

B

5

D

B

B

4

D

B

B

3

D

B

B

2

D

B

B

1

D

B

B

0

D

R

B

2

D

R

B

3

D

R

B

4

D

R

B

5

D

R

B

6

D

R

B

7

GND

REV. A

AD9888

–5–

Table I. Complete Pinout List

Pin

Pin Type Mnemonic Function Value Number

Analog Video Inputs R

AIN

0 Channel 0 Analog Input for Converter R 0.0 V to 1.0 V 5

G

AIN

0 Channel 0 Analog Input for Converter G 0.0 V to 1.0 V 13

B

AIN

0 Channel 0 Analog Input for Converter B 0.0 V to 1.0 V 20

R

AIN

1 Channel 1 Analog Input for Converter R 0.0 V to 1.0 V 8

G

AIN

1 Channel 1 Analog Input for Converter G 0.0 V to 1.0 V 17

B

AIN

1 Channel 1 Analog Input for Converter B 0.0 V to 1.0 V 23

Sync/Clock Inputs HSYNC0 Channel 0 Horizontal SYNC Input 3.3 V CMOS 45

VSYNC0 Channel 0 Vertical SYNC Input 3.3 V CMOS 44

SOGIN0 Channel 0 Input for Sync-on-Green 0.0 V to 1.0 V 12

HSYNC1 Channel 1 Horizontal SYNC Input 3.3 V CMOS 43

VSYNC1 Channel 1 Vertical SYNC Input 3.3 V CMOS 42

SOGIN1 Channel 1 Input for Sync-on-Green 0.0 V to 1.0 V 16

CLAMP Clamp Input (External CLAMP signal) 3.3 V CMOS 30

COAST PLL Coast Signal Input 3.3 V CMOS 53

CKEXT External Pixel Clock Input (to Bypass the PLL) or 10 kΩ to Ground 3.3 V CMOS 54

CKINV ADC Sampling Clock Invert 3.3 V CMOS 29

Sync Outputs HSOUT HSYNC Output Clock (Phase-Aligned with DATACK) 3.3 V CMOS 125

VSOUT VSYNC Output Clock (Phase-Aligned with DATACK) 3.3 V CMOS 127

SOGOUT Sync-on-Green Slicer Output 3.3 V CMOS 126

Voltage REF BYPASS Internal Reference Bypass (Bypass with 0.1 µF to Ground) 1.25 V ± 10% 2

Clamp Voltages R

MIDSC

V Red Channel Midscale Clamp Voltage Bypass 9

B

MIDSC

V Blue Channel Midscale Clamp Voltage Bypass 24

PLL Filter FILT Connection for External Filter Components for Internal PLL 50

Power Supply V

D

Analog Power Supply 3.3 V ± 10%

V

DD

Output Power Supply 3.3 V ± 10%

PV

D

PLL Power Supply 3.3 V ± 10%

GND Ground 0 V

Serial Port SDA Serial Port Data I/O 3.3 V CMOS 31

(2-Wire SCL Serial Port Data Clock 3.3 V CMOS 32

Serial Interface) A0 Serial Port Address Input 1 3.3 V CMOS 33

Data Outputs Red A[7:0] Port A Outputs of Converter “Red,” Bit 7 is the MSB. 3.3 V CMOS 113–120

Red B[7:0] Port B Outputs of Converter “Red,” Bit 7 is the MSB. 3.3 V CMOS 103–110

Green A[7:0] Port A Outputs of Converter “Green,” Bit 7 is the MSB. 3.3 V CMOS 90–97

Green B[7:0] Port B Outputs of Converter “Green,” Bit 7 is the MSB. 3.3 V CMOS 80–87

Blue A[7:0] Port A Outputs of Converter “Blue,” Bit 7 is the MSB. 3.3 V CMOS 70–77

Blue B[7:0] Port B Outputs of Converter “Blue,” Bit 7 is the MSB. 3.3 V CMOS 57–64

Data Clock DATACK Data Output Clock 3.3 V CMOS 123

Output DATACK Data Output Clock Complement 3.3 V CMOS 124

REV. A

AD9888

–6–

PIN FUNCTION DESCRIPTIONS

Pin Description

Inputs

R

AIN

0 Channel 0 Analog Input for RED

G

AIN

0 Channel 0 Analog Input for GREEN

B

AIN

0 Channel 0 Analog Input for BLUE

R

AIN

1 Channel 1 Analog Input for RED

G

AIN

1 Channel 1 Analog Input for GREEN

B

AIN

1 Channel 1 Analog Input for BLUE

High-impedance inputs that accept the RED, GREEN, and BLUE channel graphics signals, respectively. (The six

channels are identical and can be used for any colors; colors are assigned for convenient reference.)

They accommodate input signals ranging from 0.5 V to 1.0 V full scale. Signals should be ac-coupled to these pins to

support clamp operation.

HSYNC0 Channel 0 Horizontal Sync Input

HSYNC1 Channel 1 Horizontal Sync Input

These inputs receive a logic signal that establishes the horizontal timing reference and provides the frequency reference

for pixel clock generation.

The logic sense of this pin is controlled by serial register 0Eh Bit 6 (Hsync Polarity). Only the leading edge of Hsync is

used by the PLL. The trailing edge is used for clamp timing only. When HSPOL = 0, the falling edge of Hsync is used.

When HSPOL = 1, the rising edge is active.

The input includes a Schmitt trigger for noise immunity, with a nominal input threshold of 1.5 V.

VSYNC0 Channel 0 Vertical Sync Input

VSYNC1 Channel 1 Vertical Sync Input

These are the inputs for vertical sync.

SOGIN0 Channel 0 Sync-on-Green Input

SOGIN1 Channel 1 Sync-on-Green Input

This input is provided to assist with processing signals with embedded sync, typically on the GREEN channel. The pin is

connected to a high-speed comparator with an internally generated, variable threshold level, which is nominally set to

0.15 V above the negative peak of the input signal.

When connected to an ac-coupled graphics signal with embedded sync, it will produce a noninverting digital output on

SOGOUT. (This is usually a composite sync signal, con taining both vertical and horizontal sync information.)

When not used, this input should be left unconnected. For more details on this function and how it should be configured, refer to the Sync-on-Green section.

CLAMP External Clamp Input

This logic input may be used to define the time during which the input signal is clamped to the reference dc level

(ground for RGB or midscale for YUV). It should be exercised when the reference dc level is known to be present

on

the analog input channels, typically during the back porch of the graphics signal. The CLAMP pin is enabled by setting

the external clamp control (register 0Fh, Bit 7) to 1 (default is 0). When disabled, this pin is ignored and the clamp

timing is determined internally by counting a delay and duration from the trailing edge of the HSYNC input. The logic

sense of this pin is controlled by the clamp polarity control (register 0Fh, Bit 6). When not used, this pin must be grounded

and external clamp programmed to 0.

COAST Clock Generator Coast Input (Optional)

This input may be used to cause the pixel clock generator to stop synchronizing with HSYNC and continue producing

a clock at its current frequency and phase. This is useful when processing signals from sources that fail to produce horizontal

sync pulses when in the vertical interval or that include equalization pulses. The Coast signal is usually not required for

PC-generated signals.

The logic sense of this pin is controlled by 0FH Bit 3 (Coast Polarity).

When not used, this pin may be grounded and Coast Polarity programmed to 1, or tied HIGH (to V

D

through a 10 kΩ resistor)

and Coast Polarity programmed to 0. The Coast Polarity register bit defaults to 1 at power-up.

CKEXT External Clock Input (Optional)

This pin may be used to provide an external clock to the AD9888, in place of the clock internally generated from

HSYNC. It is enabled by programming the External clock register to 1 (15H, Bit 0). When an external clock is used, all

other internal functions operate normally. When unused, this pin should be tied through a 10 kΩ resistor to GROUND,

and the External Clock register programmed to 0. The clock phase adjustment still operates when an external clock

source is used.

REV. A

AD9888

–7–

PIN FUNCTION DESCRIPTIONS (continued)

Pin Description

CKINV Sampling Clock Inversion (Optional)

This pin may be used to invert the pixel sampling clock, which has the effect of shifting the sampling phase 180°. This is

in support of Alternate Pixel Sampling mode, wherein higher-frequency input signals (up to 410 Mpps) may be captured by

first sampling the odd pixels, then capturing the even pixels on the subsequent frame.

This pin should be exercised only during blanking intervals (typically vertical blanking) as it may produce several

samples of corrupted data during the phase shift.

CKINV should be grounded when not used.

Outputs

D

RA7-0

Data Output, Red Channel, Port A

D

RB7-0

Data Output, Red Channel, Port B

D

GA7-0

Data Output, Green Channel, Port A

D

GB7-0

Data Output, Green Channel, Port B

D

BA7-0

Data Output, Blue Channel, Port A

D

BB7-0

Data Output, Blue Channel, Port B

These are the main data outputs. Bit 7 is the MSB.

Each channel has two ports. When the part is operated in single-channel mode (Channel Mode bit (15H, Bit 7) = 0), all

data are presented to Port A, and Port B is placed in a high-impedance state.

Programming the Channel Mode bit to 1 establishes dual-channel mode, wherein alternate pixels are presented to Port A

and

Port B of each channel. These will appear simultaneously; two pixels are presented at the time of every second input

pixel, when the Output Mode bit (15H, Bit 6) is set to 1 (parallel mode). When the Output Mode bit is set

to 0, pixel

data appear alternately on the two ports, one new sample with each incoming pixel (interleaved mode).

In dual-channel mode, the first pixel after HSYNC is routed to Port A. The second pixel goes to Port B, the third to A,

etc. This can be reversed by setting the A/B Invert bit to 1 (15H, Bit 5).

The delay from pixel sampling time to output is fixed. When the sampling time is changed by adjusting the PHASE

regis-

ter, the output timing is shifted as well. The DATACK, DATACK and HSOUT outputs are also moved, so the

timing relationship among the signals is maintained.

DATACK Data Output Clock

DATACK Data Output Clock Complement

Differential data clock output signals to be used to strobe the output data and HSOUT into external logic.

They are produced by the internal clock generator and are synchronous with the internal pixel sampling clock.

When the AD9888 is operated in single-channel mode, the output frequency is equal to the pixel sampling frequency.

When operating in dual-channel mode, the clock frequency is one-half the pixel frequency, as is the output data frequency.

When the sampling time is changed by adjusting the PHASE register, the output timing is shifted as well. The Data,

DATACK, DATACK and HSOUT outputs are all moved, so the timing relationship among the signals is maintained.

Either or both signals may be used, depending on the timing mode and interface design employed.

HSOUT Horizontal Sync Output

A reconstructed and phase-aligned version of the Hsync input. Both the polarity and duration of this output can be

programmed via serial bus registers.

By maintaining alignment with DATACK, DATACK, and Data, data timing with respect to horizontal sync can always

be determined.

SOGOUT Sync-On-Green Slicer Output

This pin can be programmed to output either the output from the Sync-On-Green slicer comparator or an unprocessed but delayed version of the Hsync input. See the Sync Processing Block Diagram (Figure 25) to view how this pin is

connected. (Note: Besides slicing off SOG, the output from this pin gets no other additional processing on the AD9888.

Vsync separation is performed via the sync separator.)

REF BYPASS Internal Reference BYPASS

Bypass for the internal 1.25 V band gap reference. It should be connected to ground through a 0.1 µF capacitor. The absolute accuracy of this reference is ± 4%, and the temperature coefficient is ±50 ppm, which is adequate for most AD9888

applications. If higher accuracy is required, an external reference may be employed instead.

RMIDSCV RED Channel Midscale Voltage BYPASS

BMIDSCV BLUE Channel Midscale Voltage BYPASS

Bypasses for the internal midscale voltage references. They should each be connected to ground through 0.1 µF

capacitors. The exact voltage varies with the gain setting of the BLUE channel.

REV. A

AD9888

–8–

PIN FUNCTION DESCRIPTIONS (continued)

Pin Description

FILT External Filter Connection

For proper operation, the pixel clock generator PLL requires an external filter. Connect the filter shown in Figure 6 to this

pin. For optimal performance, minimize noise and parasitics on this node.

Power Supply

V

D

Main Power Supply

These pins supply power to the main elements of the circuit. It should be as quiet and filtered as possible.

V

DD

Digital Output Power Supply

A large number of output pins (up to 52) switching at high speed (up to 110 MHz) generates a lot of power supply

transients (noise). These supply pins are identified separately from the V

D

pins, so special care can be taken to minimize output noise transferred into the sensitive analog circuitry. If the AD9888 is interfacing with lower voltage logic,

V

DD

may be connected to a lower supply voltage (as low as 2.5 V) for compatibility.

PV

D

Clock Generator Power Supply

The most sensitive portion of the AD9888 is the clock generation circuitry. These pins provide power to the clock PLL

and help the user design for optimal performance. The designer should provide “quiet,” noise-free power to these pins.

GND Ground

The ground return for all circuitry on chip. It is recommended that the AD9888 be assembled on a single solid ground plane,

with careful attention to ground current paths.

Serial Port (2-Wire)

SDA Serial Port Data I/O

SCL ISerial Port Data Clock

A0 Serial Port Address Input 1

For a full description of the 2-wire serial register and how it works, refer to the Control Register section.

DESIGN GUIDE

General Description

The AD9888 is a fully integrated solution for capturing analog

RGB signals and digitizing them for display on flat panel monitors

or projectors. The circuit is ideal for providing a computer interface for HDTV monitors or as the front-end to high-performance

video scan converters.

Implemented in a high-performance CMOS process, the interface can capture signals with pixel rates of up to 205 MHz, and

with an Alternate Pixel Sampling mode, up to 340 MHz.

The AD9888 includes all necessary input buffering, signal dc

restoration (clamping), offset and gain (brightness and contrast)

adjustment, pixel clock generation, sampling phase control, and

output data formatting. All controls are programmable via a

2-wire serial interface. Full integration of these sensitive analog

functions makes system design straightforward and less sensitive

to the physical and electrical environment.

With a typical power dissipation of only 650 mW and an operating temperature range of 0°C to 70°C, the device requires no

special environmental considerations.

Input Signal Handling

The AD9888 has six high-impedance analog input pins for the

red, green, and blue channels. They will accommodate signals

ranging from 0.5 V to 1.0 V p-p.

Signals are typically brought onto the interface board via a DVI-I

connector, a 15-pin D connector, or via BNC connectors. The

AD9888 should be located as close as practical to the input

connector. Signals should be routed via matched-impedance

traces (normally 75 Ω) to the IC input pins.

At that point, the signal should be resistively terminated (to the

signal ground return) and capacitively coupled to the AD9888

inputs through 47 nF capacitors. These capacitors form part of

the dc restoration circuit.

In an ideal world of perfectly matched impedances, the best

performance can be obtained with the widest possible signal

bandwidth. The ultrawide bandwidth inputs of the AD9888

(500 MHz) can track the input signal continuously as it moves

from one pixel level to the next, and digitize the pixel during

a long, flat pixel time. In many systems, however, there are

mismatches, reflections, and noise, which can result in excessive

ringing and distortion of the input waveform. This makes it

more difficult to establish a sampling phase that provides good

image quality. The AD9888 can digitize graphics signals over a

very wide range of frequencies (10 MHz to 205 MHz). Often

characteristics that are beneficial at one frequency can be detrimental at another. Analog bandwidth is one such characteristic.

For UXGA resolutions (up to 205 MHz), a very high analog

bandwidth is desirable because of the fast input signal slew

rates. For VGA and lower resolutions (down to 12.5 MHz), a

very high bandwidth is not desirable, because it allows excess

noise to pass through. To accommodate these varying needs,

the AD9888 includes variable analog bandwidth control.

Four settings are available (75 MHz, 150 MHz, 300 MHz,

and 500 MHz), allowing the analog bandwidth to be matched

with the resolution of the incoming graphics signal.

R

AIN

G

AIN

B

AIN

75⍀

RGB

INPUT

47nF

Figure 1. Analog Input Interface Circuit

REV. A

AD9888

–9–

Sync Processing

The AD9888 contains circuitry that enables it to accept composite sync inputs, such as Sync-on-Green or the trilevel syncs

found in digital TV signals. A complete description of the sync

processing functionality is found in the Sync Slicer and Sync

Separator sections.

Hsync, Vsync Inputs

The interface also takes a horizontal sync signal, which is used

to generate the pixel clock and clamp timing. It is possible to

operate the AD9888 without applying Hsync (using an external

clock, external clamp, and single port output mode) but a number

of features of the chip will be unavailable, so it is recommended

that Hsync be provided. This can be either a sync signal directly

from the graphics source, or a preprocessed TTL or CMOS

level signal.

The Hsync input includes a Schmitt trigger buffer for immunity

to noise and signals with long rise times. In typical PC-based

graphic systems, the sync signals are simply TTL-level drivers

feeding unshielded wires in the monitor cable. As such, no termination is required or desired.

Serial Control Port

The serial control port is designed for 3.3 V logic. If there are

5 V drivers on the bus, these pins should be protected with

150 Ω series resistors placed between the pull-up resistors and

the input pins.

Output Signal Handling

The digital outputs are designed and specified to operate from a

3.3 V power supply (V

DD

). They can also work with a VDD as

low as 2.5 V for compatibility with other 2.5 V logic.

Clamping

RGB Clamping

To digitize the incoming signal properly, the dc offset of the input

must be adjusted to fit the range of the on-board A/D converters.

Most graphics systems produce RGB signals with black at ground

and white at approximately 0.75 V. However, if sync signals are

embedded in the graphics, the sync tip is often at ground and

black is at 300 mV. Then white is at approximately 1.0 V. Some

common RGB line amplifier boxes use emitter-follower buffers

to split signals and increase drive capability. This introduces a

700 mV dc offset to the signal, which must be removed for

proper capture by the AD9888.

The key to clamping is to identify a portion (time) of the signal

when the graphic system is known to be producing black. An

offset is then introduced which results in the A/D converters

producing a black output (code 00h) when the known black

input is present. The offset then remains in place when other

signal levels are processed, and the entire signal is shifted to

eliminate offset errors.

In most graphics systems, black is transmitted between active

video lines. Going back to CRT displays, when the electron

beam has completed writing a horizontal line on the screen

(at the right side), the beam is deflected quickly to the left side

of the screen (called horizontal retrace) and a black signal is

provided to prevent the beam from disturbing the image.

In systems with embedded sync, a blacker-than-black signal

(Hsync) is produced briefly to signal the CRT that it is time to

begin a retrace. For obvious reasons, it is important to avoid

clamping on the tip of Hsync. Fortunately, there is almost always

a period following Hsync called the back porch where a good

black reference is provided. This is the time when clamping

should be done.

The clamp timing can be established by simply exercising the

CLAMP pin at the appropriate time (with External Clamp = 1).

The polarity of this signal is set by the Clamp Polarity (Register

0Fh, Bit 6).

A simpler method of clamp timing employs the AD9888 internal clamp timing generator. The Clamp Placement register is

programmed with the number of pixel times that should pass

after the trailing edge of HSYNC before clamping starts. A

second register (Clamp Duration, Register 06h) sets the duration

of the clamp. These are both 8-bit values, providing considerable

flexibility in clamp generation. The clamp timing is referenced

to the trailing edge of Hsync because, though Hsync duration

can vary widely, the back porch (black reference) always follows

Hsync. A good starting point for establishing clamping is to set

the clamp placement to 08h (providing 8 pixel periods for the

graphics signal to stabilize after sync) and set the clamp duration to 14h (giving the clamp 20 pixel periods to reestablish the

black reference).

Clamping is accomplished by placing an appropriate charge on

the external input coupling capacitor. The value of this capacitor

affects the performance of the clamp. If it is too small, there will

be a significant amplitude change during a horizontal line time

(between clamping intervals). If the capacitor is too large, then

it will take excessively long for the clamp to recover from a large

change in incoming signal offset. The recommended value (47 nF)

results in recovering from a step error of 100 mV to within

1/2 LSB in 10 lines with a clamp duration of 20 pixel periods

on a 60 Hz SXGA signal.

YUV Clamping

YUV graphic signals are slightly different from RGB signals in

that the dc reference level (black level in RGB signals) can be at

the midpoint of the video signal rather than the bottom. For

these signals it can be necessary to clamp to the midscale range

of the A/D converter range (80h) rather than bottom of the

A/D converter range (00h).

Clamping to midscale rather than ground can be accomplished

by setting the clamp select bits in the series bus register. The red

and blue channels each have their own selection bit so that they

can be clamped to either midscale or ground independently. The

clamp controls are located in register 10h and are Bits 1 and 2.

The midscale reference voltage that each A/D converter clamps

to is provided independently on the RMIDSCV and BMIDSCV

pins. These two pins should be bypassed to ground with a

0.1 µF capacitor (even if midscale clamping is not required).

Gain and Offset Control

The AD9888 can accommodate input signals with inputs ranging

from 0.5 V to 1.0 V full scale. The full-scale range is set in three

8-bit registers (Red Gain, Green Gain, and Blue Gain; Registers

08h, 09h, and 10h respectively).

Note that increasing the gain setting results in an image with

less contrast.

The offset control shifts the entire input range, resulting in a

change in image brightness. Three 7-bit registers (Red Offset,

Green Offset, Blue Offset; Registers 0Bh, 0Ch, and 0Dh respectively) provide independent settings for each channel.

REV. A

AD9888

–10–

The offset controls provide a ±63 LSB adjustment range. This

range is connected with the full-scale range, so if the input range

is doubled (from 0.5 V to 1.0 V), the offset step size is also

doubled (from 2 mV per step to 4 mV per step).

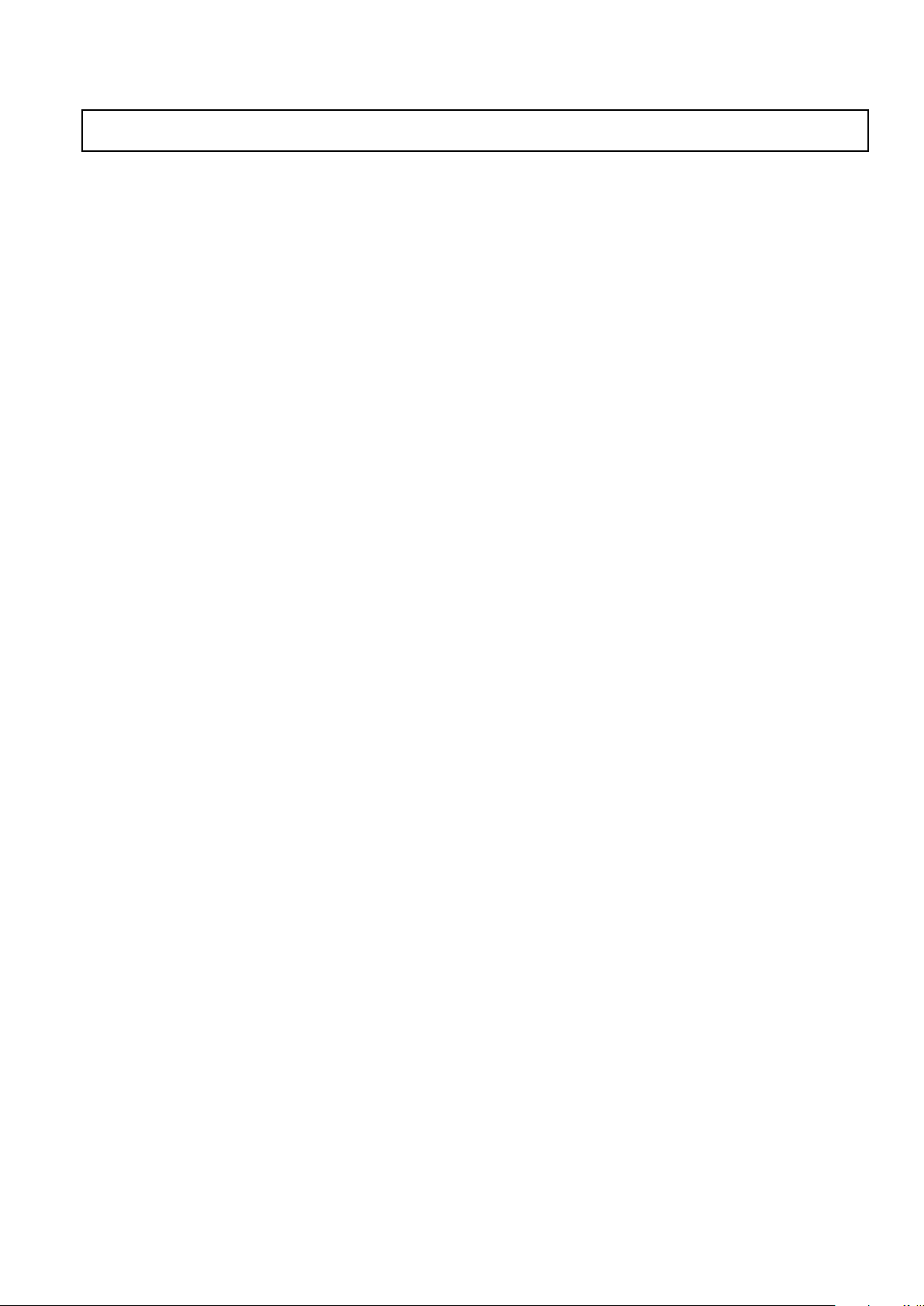

Figure 2 illustrates the interaction of gain and offset controls.

The magnitude of an LSB in offset adjustment is proportional

to the full-scale range, so changing the full-scale range also

changes the offset. The change is minimal if the offset setting is

near midscale. When changing the offset, the full-scale range is

not affected, but the full-scale level is shifted by the same amount

as the zero-scale level.

GAIN

1.0

0.0

00h FFh

INPUT RANGE – V

0.5

OFFSET = 00h

OFFSET = 3Fh

OFFSET = 7Fh

OFFSET = 00h

OFFSET = 7Fh

OFFSET = 3Fh

Figure 2. Gain and Offset Control

Sync-on-Green

The Sync-on-Green input operates in two steps. First, it sets a

baseline clamp level off of the incoming video signal with a

negative peak detector. Second, it sets the sync trigger level

(nominally 150 mV above the negative peak). The exact trigger

level is variable and can be programmed via register 11H. The

Sync-on-Green input must be ac-coupled to the green analog

input through its own capacitor as shown in Figure 3. The value

of the capacitor must be 1 nF ± 20%. If Sync-on-Green is not

used, this connection is not required and the SOGIN pin should be

left unconnected. (Note: the Sync-on-Green signal is always

negative polarity.) For more details, see the Sync Processing section.

R

AIN

B

AIN

G

AIN

SOG

47nF

47nF

47nF

1nF

Figure 3. Typical Clamp Configuration for RGB/YUV

Applications

Clock Generation

A Phase Locked Loop (PLL) is employed to generate the pixel

clock. The Hsync input provides a reference frequency to the PLL.

A Voltage Controlled Oscillator (VCO) generates a much higher

pixel clock frequency. This pixel clock is divided by the PLL

divide value (registers 01H and 02H) and phase compared with

the Hsync input. Any error is used to shift the VCO frequency

and maintain lock between the two signals.

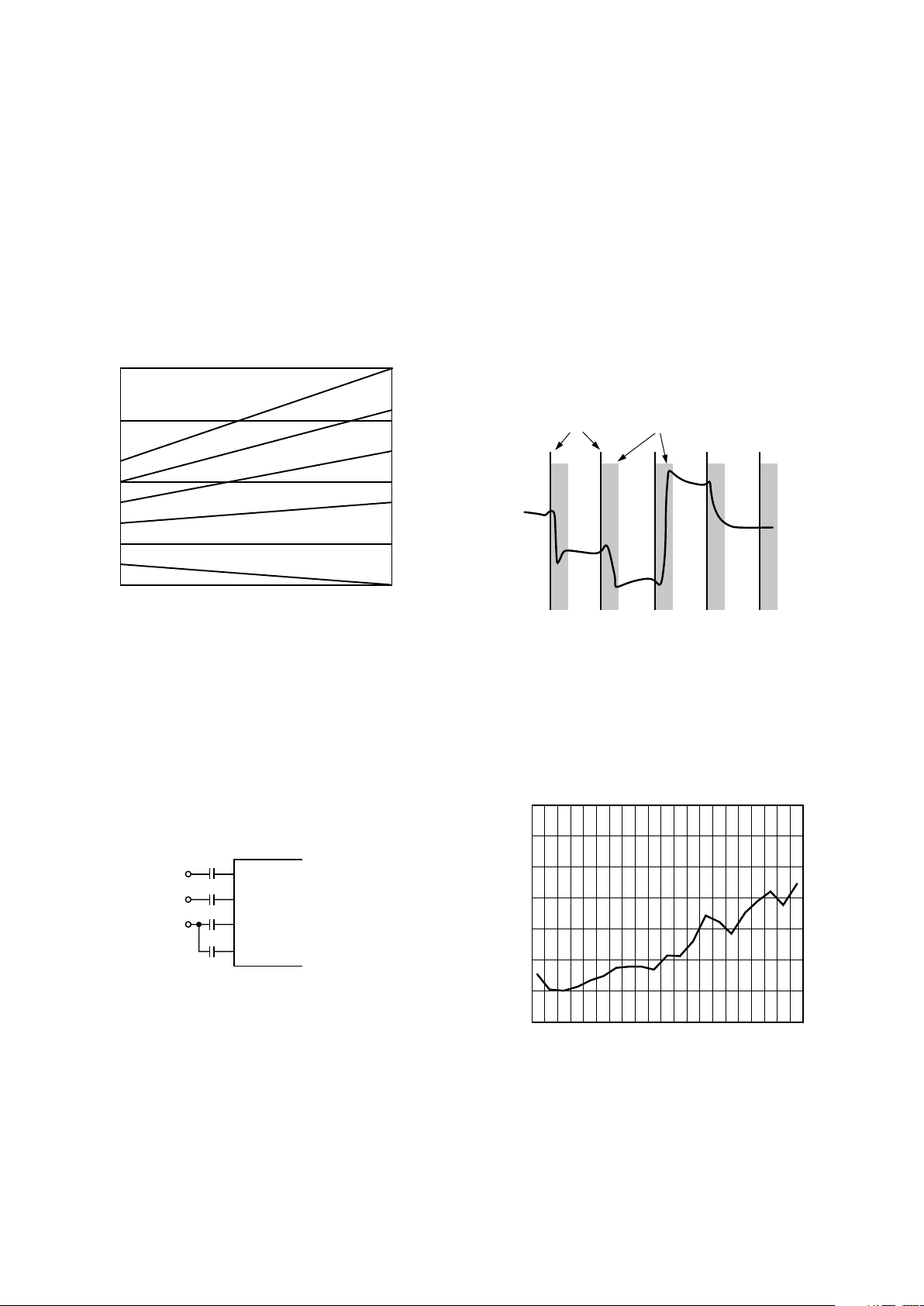

The stability of this clock is a very important element in providing the clearest and most stable image. During each pixel time,

there is a period during which the signal is slewing from the old

pixel amplitude and settling at its new value. Then there is a time

when the input voltage is stable, before the signal must slew to a

new value (Figure 4). The ratio of the slewing time to the stable

time is a function of the bandwidth of the graphics DAC and the

bandwidth of the transmission system (cable and termination). It

is also a function of the overall pixel rate. Clearly, if the dynamic

characteristics of the system remain fixed, then the slewing and

settling time is likewise fixed. This time must be subtracted from

the total pixel period, leaving the stable period. At higher pixel

frequencies, the total cycle time is shorter, and the stable pixel

time becomes shorter as well.

PIXEL CLOCK

INVALID SAMPLE

TIMES

Figure 4. Pixel Sampling Times

Any jitter in the clock reduces the precision with which the

sampling time can be determined, and must also be subtracted

from the stable pixel time.

Considerable care has been taken in the design of the AD9888’s

clock generation circuit to minimize jitter. As indicated in Figure 5, the clock jitter of the AD9888 is less than 9% of the total

pixel time in all operating modes, making the reduction in the valid

sampling time due to jitter negligible.

PIXEL CLOCK – MHz

0

25.2

31.5

31.5

36.0

36.0

40.0

50.0

49.5

56.3

65.0

75.0

78.8

85.5

94.5

108.0

135.0

160.0

162.0

175.5

189.0

202.5

JITTER (p-p) – %

2

4

6

8

10

12

14

Figure 5. Pixel Clock Jitter vs. Frequency

The PLL characteristics are determined by the loop filter design,

by the PLL Charge Pump Current and by the VCO range setting.

The loop filter design is illustrated in Figure 6. Recommended

settings of VCO range and charge pump current for VESA standard

display modes are listed in Table IV.

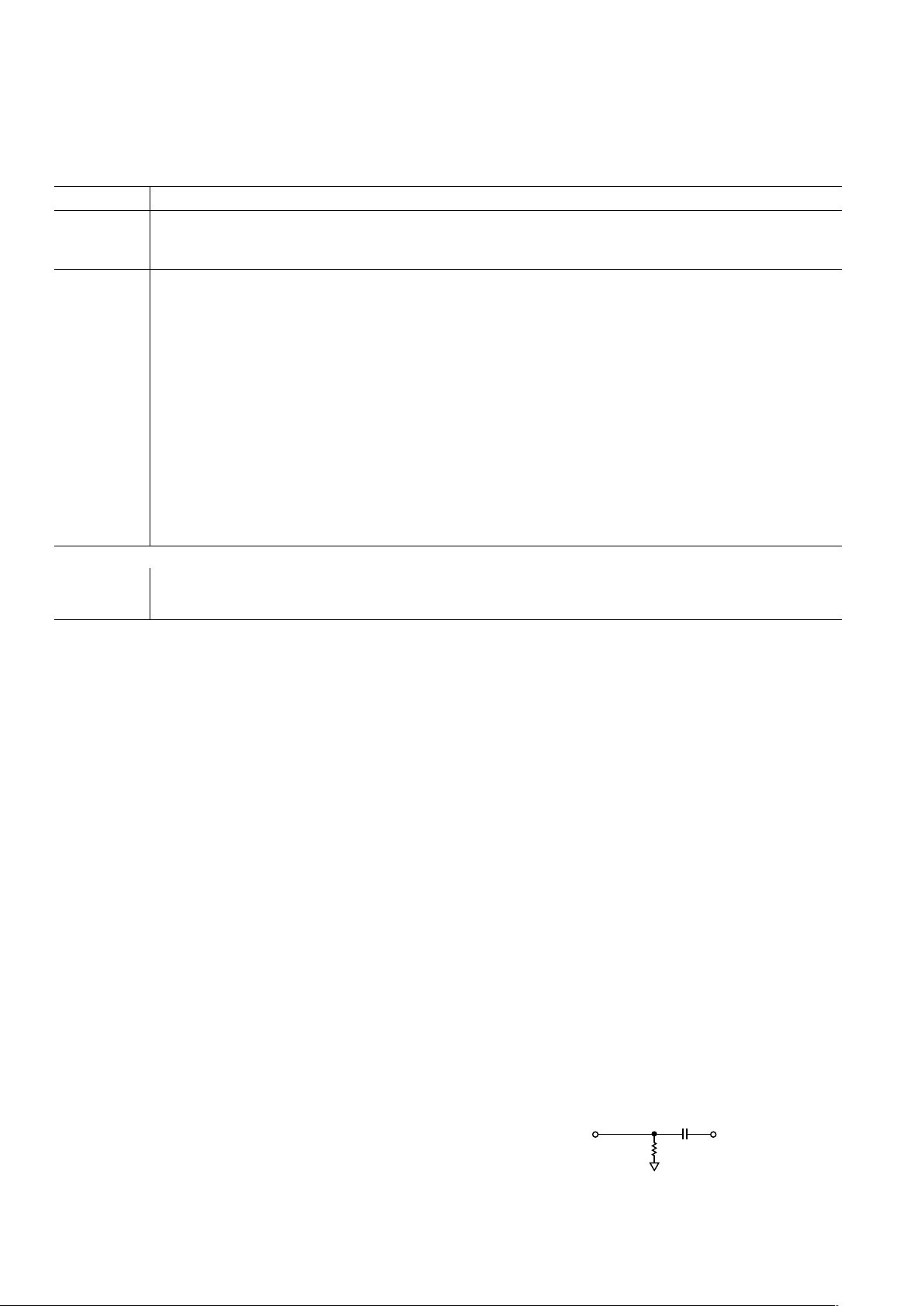

Loading...

Loading...