Analog Devices AD9887 Datasheet

Dual Interface for

a

FEATURES

Analog Interface

140 MSPS Maximum Conversion Rate

330 MHz Analog Bandwidth

0.5 V to 1.0 V Analog Input Range

500 ps p-p PLL Clock Jitter at 140 MSPS

3.3 V Power Supply

Full Sync Processing

Midscale Clamp

4:2:2 Output Format Mode

Digital (DVI 1.0 Compatible) Interface

112 MHz Operation (1 Pixel/Clock Mode)

High Skew Tolerance of One Full Input Clock

Sync Detect for “Hot Plugging”

APPLICATIONS

RGB Graphics Processing

LCD Monitors and Projectors

Plasma Display Panels

Scan Converters

Micro Displays

Digital TV

GENERAL DESCRIPTION

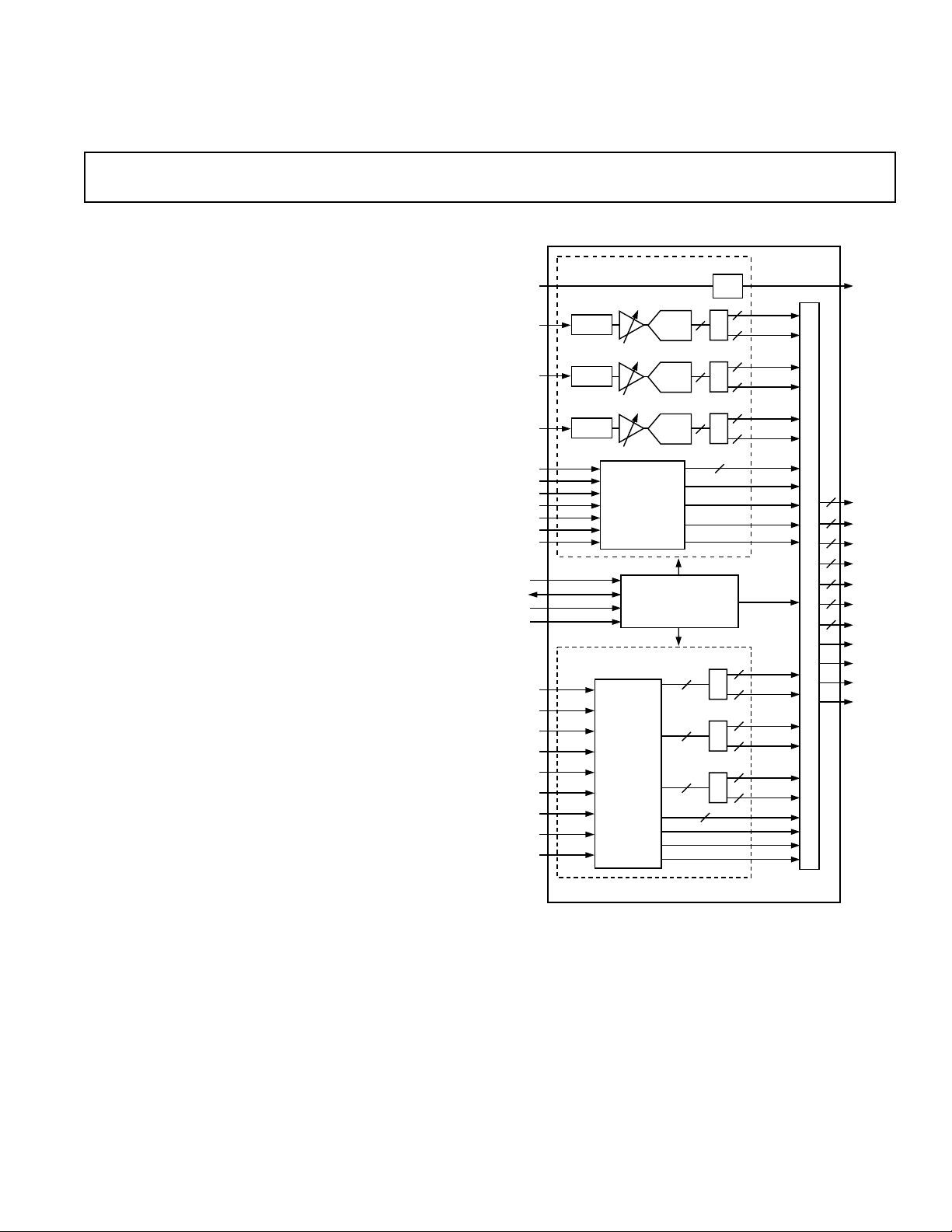

The AD9887 offers designers the flexibility of a dual analog and

digital interface for flat panel displays (FPDs) on a single chip.

Both interfaces are optimized for excellent image quality supporting

display resolutions up to SXGA (1280 × 1024 at 75 Hz). Either the

analog or the digital interface can be selected by the user.

Analog Interface

For ease of design and to minimize cost, the AD9887 is a fully

integrated interface solution for FPDs. The AD9887 includes an

analog interface with a 140 MHz triple ADC with internal 1.25 V

reference, PLL to generate a pixel clock from HSYNC, programmable gain, offset, and clamp control. The user provides only a

3.3 V power supply, analog input, and HSYNC. Three-state

CMOS outputs may be powered from 2.5 V to 3.3 V.

The AD9887’s on-chip PLL generates a pixel clock from HSYNC.

Pixel clock output frequencies range from 12 MHz to 140 MHz.

PLL clock jitter is 500 ps p-p typical at 140 MSPS. When a

COAST signal is presented, the PLL maintains its output frequency in the absence of HSYNC. A sampling phase adjustment is

provided. Data, HSYNC and Clock output phase relationships are

maintained. The PLL can be disabled and an external clock input

provided as the pixel clock. The AD9887 also offers full sync processing for composite sync and sync-on-green applications.

A clamp signal is generated internally or may be provided by

the user through the CLAMP input pin. The analog interface

is fully programmable via a 2-wire serial interface.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

Flat Panel Displays

AD9887

FUNCTIONAL BLOCK DIAGRAM

ANALOG

REFIN

R

G

B

HSYNC

VSYNC

COAST

CLAMP

CKINV

CKEXT

FILT

SCL

SDA

A

1

A

0

Rx0+

Rx0–

Rx1+

Rx1–

Rx2+

Rx2–

RxC+

RxC–

R

TERM

AIN

AIN

AIN

INTERFACE

CLAMP

CLAMP

CLAMP

DIGITAL

INTERFACE

A/D

A/D

A/D

SYNC

PROCESSING

AND CLOCK

GENERATION

SERIAL REGISTER

POWER MANAGEMENT

DVI

RECEIVER

AND

Digital Interface

The AD9887 contains a Digital Video Interface (DVI 1.0) compatible receiver. This receiver supports displays ranging from VGA

to SXGA (25 MHz to 112 MHz). The receiver operates with

true color (24-bit) panels in 1 or 2 pixel(s)/clock mode, and also

features an intrapair skew tolerance up to one full clock cycle.

Fabricated in an advanced CMOS process, the AD9887 is provided in a 160-lead MQFP surface mount plastic package and is

specified over the 0°C to 70°C temperature range.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

REF

R

OUTA

8

8

8

8

8

8

8

2

R

OUTB

8

G

OUTA

8

G

OUTB

8

B

8

OUTA

B

OUTB

8

DATAC K

2

HSOUT

VSOUT

SOGOUT

S

CDT

M

U

X

E

S

R

OUTA

8

R

8

OUTB

G

OUTA

8

G

8

OUTB

B

8

OUTA

B

8

OUTB

DATAC K

DE

HSYNC

VSYNC

REFOUT

8

R

OUTA

8

R

OUTB

8

G

OUTA

8

G

OUTB

8

B

OUTA

8

B

OUTB

2

DATAC K

HSOUT

VSOUT

SOGOUT

DE

AD9887

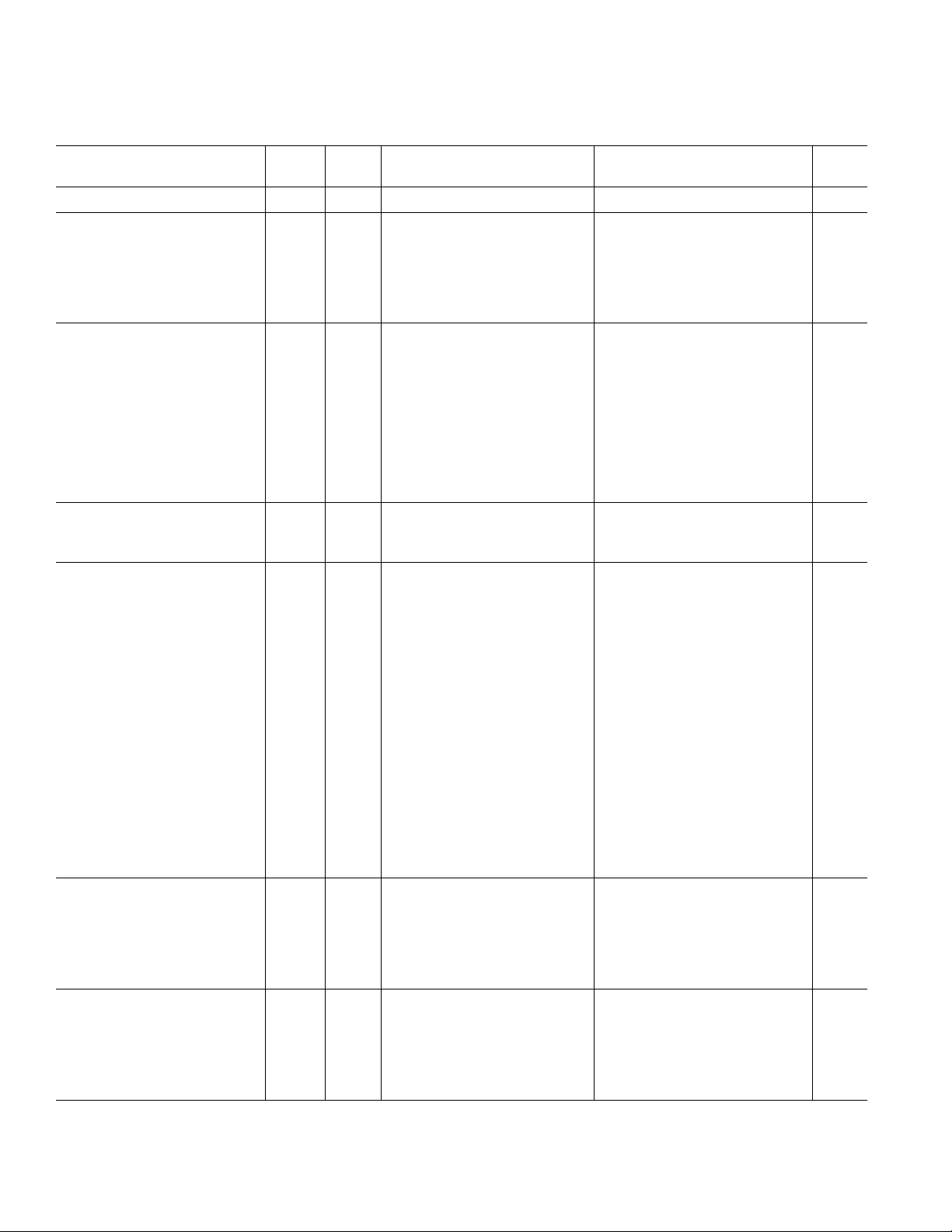

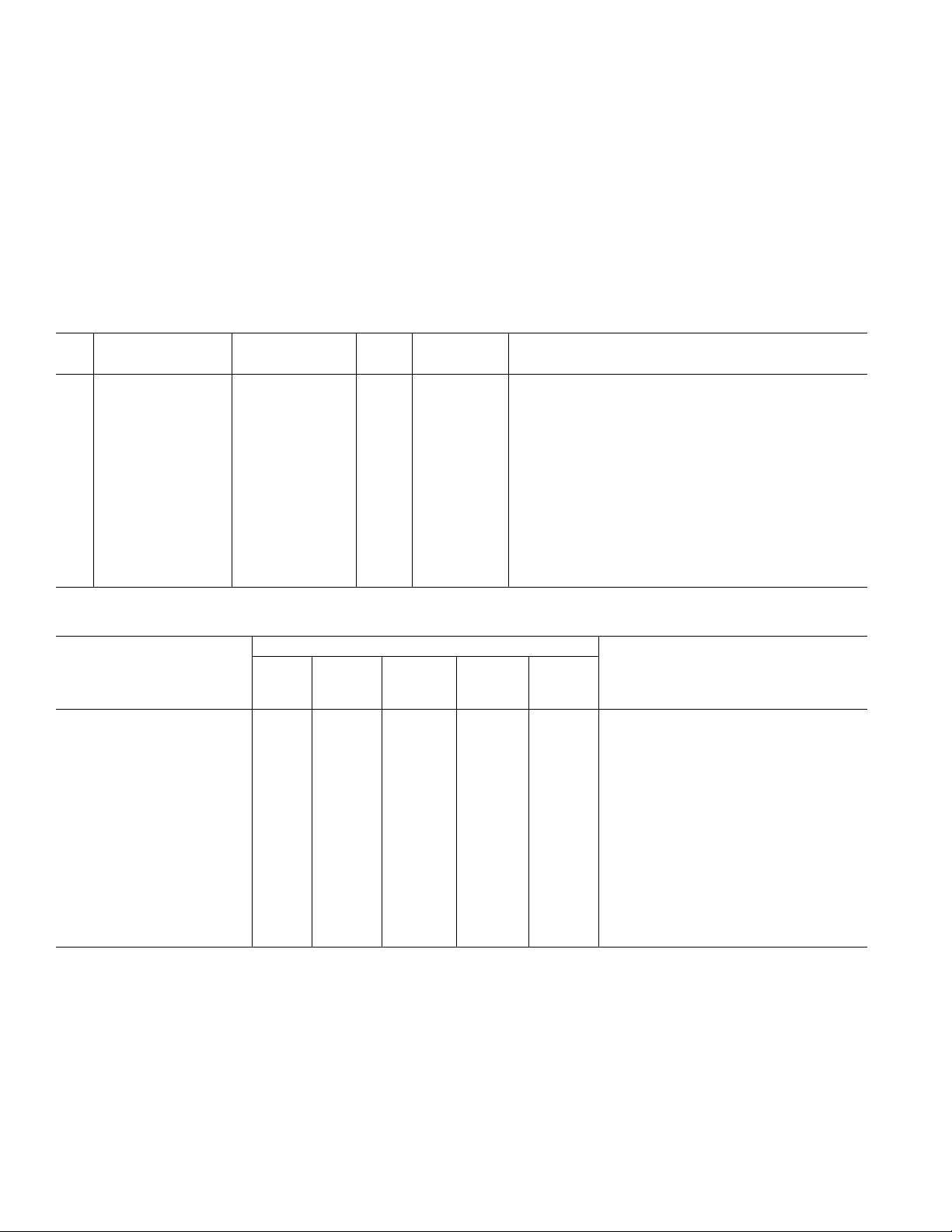

AD9887–SPECIFICATIONS

ANALOG INTERFACE

(VD = 3.3 V, VDD = 3.3 V, ADC Clock = Maximum Conversion Rate, unless otherwise noted.)

Test AD9887KS-100 AD9887KS-140

Parameter Temp Level Min Typ Max Min Typ Max Unit

RESOLUTION 8 8 Bits

DC ACCURACY

Differential Nonlinearity 25°CI ± 0.5 +1.15/–1.0 ±0.5 +1.25/–1.0 LSB

Full VI +1.15/–1.0 +1.25/–1.0 LSB

Integral Nonlinearity 25°CI ± 0.5 ± 1.40 ± 0.5 ± 1.4 LSB

Full VI ± 1.75 ± 2.5 LSB

No Missing Codes Full VI Guaranteed Guaranteed

ANALOG INPUT

Input Voltage Range

Minimum Full VI 0.5 0.5 V p-p

Maximum Full VI 1.0 1.0 V p-p

Gain Tempco 25°C V 135 150 ppm/°C

Input Bias Current 25°CIV 1 1 µA

Full IV 1 1 µA

Input Offset Voltage Full VI 7 50 7 50 mV

Input Full-Scale Matching Full VI 8.0 8.0 % FS

Offset Adjustment Range Full VI 44 50 56 44 50 56 % FS

REFERENCE OUTPUT

Output Voltage Full VI 1.20 1.25 1.30 1.20 1.25 1.30 V

Temperature Coefficient Full V ±50 ± 50 ppm/°C

SWITCHING PERFORMANCE

1

Maximum Conversion Rate Full VI 100 140 MSPS

Minimum Conversion Rate Full IV 10 10 MSPS

Clock to Data Skew, t

t

BUFF

t

STAH

t

DHO

t

DAL

t

DAH

t

DSU

t

STASU

t

STOSU

SKEW

Full IV –0.5 +2.0 –0.5 +2.0 ns

Full VI 4.7 4.7 µs

Full VI 4.0 4.0 µs

Full VI 0 0 µs

Full VI 4.7 4.7 µs

Full VI 4.0 4.0 µs

Full VI 250 250 ns

Full VI 4.7 4.7 µs

Full VI 4.0 4.0 µs

HSYNC Input Frequency Full IV 15 110 15 110 kHz

Maximum PLL Clock Rate Full VI 100 140 MHz

Minimum PLL Clock Rate Full IV 12 12 MHz

PLL Jitter 25°C IV 400 700

Full IV 1000

Sampling Phase Tempco Full IV

15 15 ps/°C

2

2

400 700

1000

3

3

ps p-p

ps p-p

DIGITAL INPUTS

Input Voltage, High (V

Input Voltage, Low (V

Input Current, High (V

Input Current, Low (V

) Full VI 2.6 2.6 V

IH

) Full VI 0.8 0.8 V

IL

) Full IV –1.0 –1.0 µA

IH

) Full IV 1.0 1.0 µA

IL

Input Capacitance 25°CV 3 3 pF

DIGITAL OUTPUTS

Output Voltage, High (VOH) Full VI 2.4 2.4 V

Output Voltage, Low (V

) Full VI 0.4 0.4 V

OL

Duty Cycle

DATACK, DATACK Full IV 45 50 55 45 50 55 %

Output Coding Binary Binary

–2–

REV. 0

AD9887

Test AD9887KS-100 AD9887KS-140

Parameter Temp Level Min Typ Max Min Typ Max Unit

POWER SUPPLY

VD Supply Voltage Full IV 3.0 3.3 3.6 3.0 3.3 3.6 V

Supply Voltage Full IV 2.2 3.3 3.6 2.2 3.3 3.6 V

V

DD

P

Supply Voltage Full IV 3.0 3.3 3.6 3.0 3.3 3.6 V

VD

Supply Current (VD)25°C V 140 155 mA

I

D

Supply Current (VDD)

I

DD

IP

Supply Current (PVD)25°C V 15 16 mA

VD

Total Supply Current

Power-Down Supply Current Full VI 18 25 18 25 mA

DYNAMIC PERFORMANCE

Analog Bandwidth, Full Power 25°C V 330 330 MHz

Transient Response 25°CV 2 2 ns

Overvoltage Recovery Time 25°C V 1.5 1.5 ns

Signal-to-Noise Ratio (SNR)

(Without Harmonics) Full V 45 45 dB

fIN = 40.7 MHz

Crosstalk Full V 60 60 dBc

THERMAL CHARACTERISTICS

θJA Junction-to-Ambient

Thermal Resistance

NOTES

1

Drive Strength = 11.

2

VCO Range = 01, Charge Pump Current = 001, PLL Divider = 1693.

3

VCO Range = 10, Charge Pump Current = 110, PLL Divider = 1600.

4

DEMUX = 1, DATACK and DATACK Load = 10 pF, Data Load = 5 pF.

5

Using external pixel clock.

6

Simulated typical performance with package mounted to a 4-layer board.

Specifications subject to change without notice.

4

4

6

25°C V 34 48 mA

Full VI 170 258 215 258 mA

5

25°C V 46 46 dB

V30 30 °C/W

REV. 0

–3–

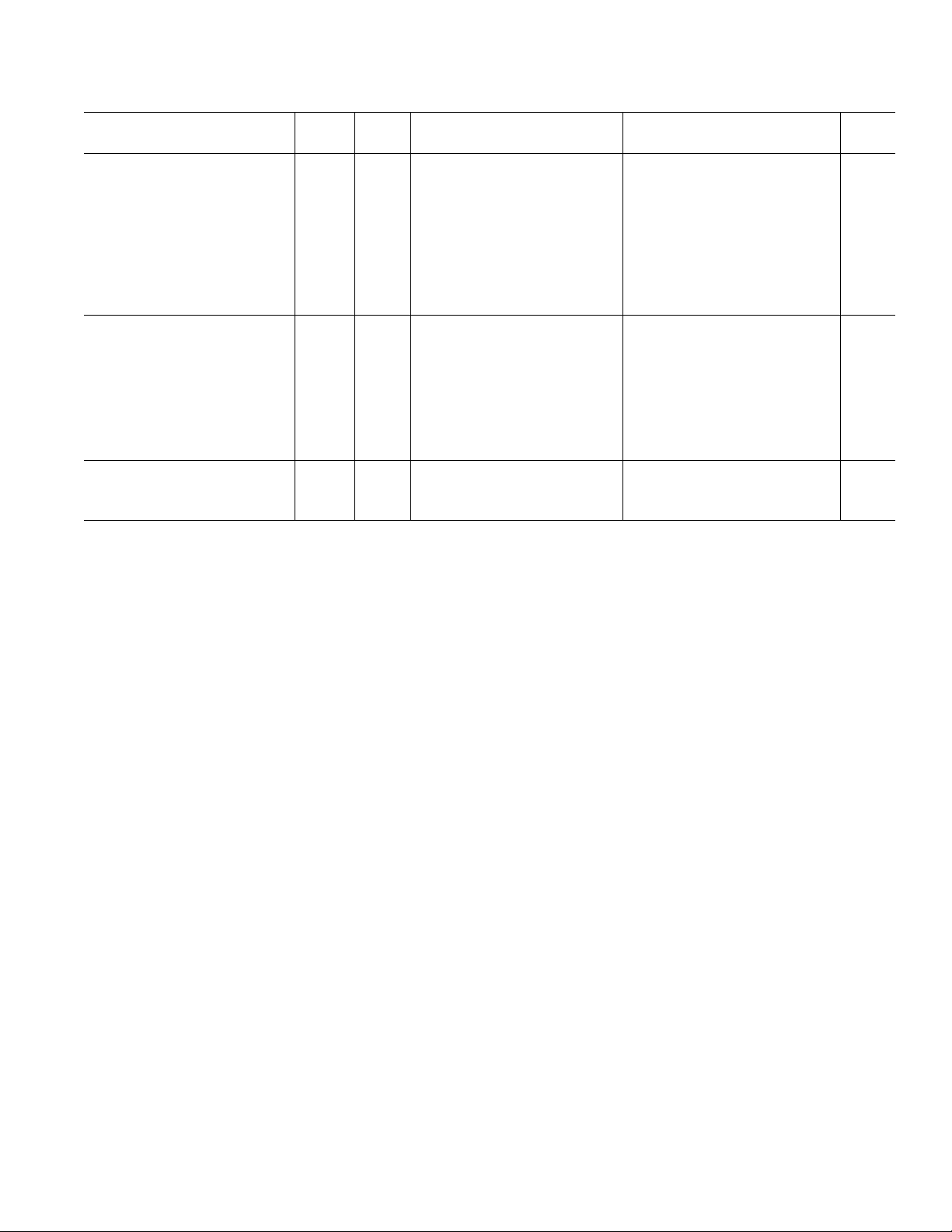

AD9887–SPECIFICATIONS

DIGITAL INTERFACE

(VD = 3.3 V, VDD = 3 V, Clock = Maximum)

Test AD9887KS

Parameter Conditions Level Min Typ Max Unit

RESOLUTION 8 Bits

DC DIGITAL I/O SPECIFICATIONS

High-Level Input Voltage, (V

Low-Level Input Voltage, (V

High-Level Output Voltage, (V

Low-Level Output Voltage, (V

Input Clamp Voltage, (V

Input Clamp Voltage, (V

Output Clamp Voltage, (V

Output Clamp Voltage, (V

) VI 2.6 V

IH

) VI 0.8 V

IL

) VI 2.4 V

OH

) VI 0.4 V

OL

)(I

CINL

)(I

CIPL

)(I

CONL

)(I

COPL

= –18 mA) IV GND – 0.8 V

CL

= +18 mA) IV VDD + 0.8 V

CL

= –18 mA) IV GND – 0.8 V

CL

= +18 mA) IV VDD + 0.8 V

CL

Output Leakage Current, (IOL) (High Impedance) IV –10 +10 µA

DC SPECIFICATIONS

Output High Drive Output Drive = High IV 13 mA

) (V

(I

OHD

= VOH) Output Drive = Med IV 8 mA

OUT

Output Drive = Low IV 5 mA

Output Drive = High IV –9 mA

(I

) (V

OLD

= VOL) Output Drive = Med IV –7 mA

OUT

Output Drive = Low IV –5 mA

Output Drive = High IV 25 mA

) (V

(V

OHC

= VOH) Output Drive = Med IV 12 mA

OUT

Output Drive = Low IV 8 mA

DATACK Low Drive Output Drive = High IV –25 mA

(V

) (V

OLC

= VOL) Output Drive = Med IV –19 mA

OUT

Output Drive = Low IV –8 mA

Differential Input Voltage Single-Ended Amplitude IV 75 800 mV

POWER SUPPLY

V

Supply Voltage IV 3.0 3.3 3.6 V

D

V

Supply Voltage Minimum Value for 2 Pixels per

DD

Clock Mode IV 2.2 3.3 3.6 V

P

Supply Voltage IV 3.0 3.3 3.6 V

VD

V

Supply Current (Typical Pattern)

D

VDD Supply Current (Typical Pattern)

P

Supply Current (Typical Pattern)

VD

Total Supply Current (Typical Pattern)

V

Supply Current (Worst-Case Pattern)

D

V

Supply Current (Worst-Case Pattern)

DD

P

Supply Current (Worst-Case Pattern)

VD

Total Supply Current (Worst-Case Pattern)

1

1, 4

1

1, 4

2

2, 4

2

2, 4

V 274 mA

V38 mA

V21 mA

VI 362 mA

V 280 mA

V75 mA

V21 mA

VI 400 mA

Power-Down Supply Current (IPD)VI1325mA

AC SPECIFICATIONS

Intrapair (+ to –) Differential Input Skew (T

Channel-to-Channel Differential Input Skew (T

) IV 360 ps

DPS

) IV 1.0 Clock

CCS

Period

Low-to-High Transition Time for Data and Output Drive = High; CL = 10 pF IV 2.0 ns

Controls (D

Low-to-High Transition Time for DATACK (D

High-to-Low Transition Time for Data and Output Drive = High; C

Controls (D

) Output Drive = Med; CL = 7 pF IV 3.0 ns

LHT

LHT

) Output Drive = Med; CL = 7 pF IV 3.0 ns

HLT

Output Drive = Low; C

= 5 pF IV 3.4 ns

L

) Output Drive = High; CL = 10 pF IV 1.3 ns

Output Drive = Med; C

Output Drive = Low; C

= 7 pF IV 1.9 ns

L

= 5 pF IV 2.5 ns

L

= 10 pF IV 2.7 ns

L

Output Drive = Low; CL = 5 pF IV 3.3 ns

–4–

REV. 0

AD9887

WARNING!

ESD SENSITIVE DEVICE

Test AD9887KS

Parameter Conditions Level Min Typ Max Unit

AC SPECIFICATIONS (continued)

High-to-Low Transition Time for DATACK (D

Clock to Data Skew, t

Duty Cycle, t

DCYCLE

DATACK Frequency (F

DATACK Frequency (F

NOTES

1

The typical pattern contains a gray scale area, Output Drive = High.

2

The worst-case pattern contains a black and white checkerboard pattern, Output Drive = High.

3

The setup and hold times with respect to the DATACK rising edge are the same as the falling edge.

4

1 Pixel/clock mode, DATACK and DATACK Load = 10 pF, Data Load = 5 pF.

SKEW

) (1 Pixel/Clock) VI 20 112 MHz

CIP

) (2 Pixels/Clock) IV 10 56 MHz

CIP

) Output Drive = High; CL =10 pF IV 1.4 ns

HLT

Output Drive = Med; C

Output Drive = Low; C

= 7 pF IV 1.7 ns

L

= 5 pF IV 2.1 ns

L

IV –0.5 +2.0 ns

IV 45 55 % of

Period

High

ABSOLUTE MAXIMUM RATINGS

*

VD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6 V

V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6 V

DD

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . V

VREF IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

to 0.0 V

D

to 0.0 V

D

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 V to 0.0 V

Digital Output Current . . . . . . . . . . . . . . . . . . . . . . . . 20 mA

Operating Temperature . . . . . . . . . . . . . . . . . –25°C to +85°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Maximum Junction Temperature . . . . . . . . . . . . . . . . 150°C

Maximum Case Temperature . . . . . . . . . . . . . . . . . . . 150°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions outside of those indicated in the operation

sections of this specification is not implied. Exposure to absolute maximum ratings

for extended periods may affect device reliability.

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

AD9887KS-140 0°C to 70°C Plastic Quad Flatpack S-160

AD9887KS-100 0°C to 70°C Plastic Quad Flatpack S-160

AD9887/PCB 25°C Evaluation Board

EXPLANATION OF TEST LEVELS

Test Level Explanation

I 100% production tested.

II 100% production tested at 25°C and sample

tested at specified temperatures.

III Sample tested only.

IV Parameter is guaranteed by design and charac-

terization testing.

V Parameter is a typical value only.

VI 100% production tested at 25°C; guaranteed

by design and characterization testing.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD9887 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. 0

–5–

AD9887

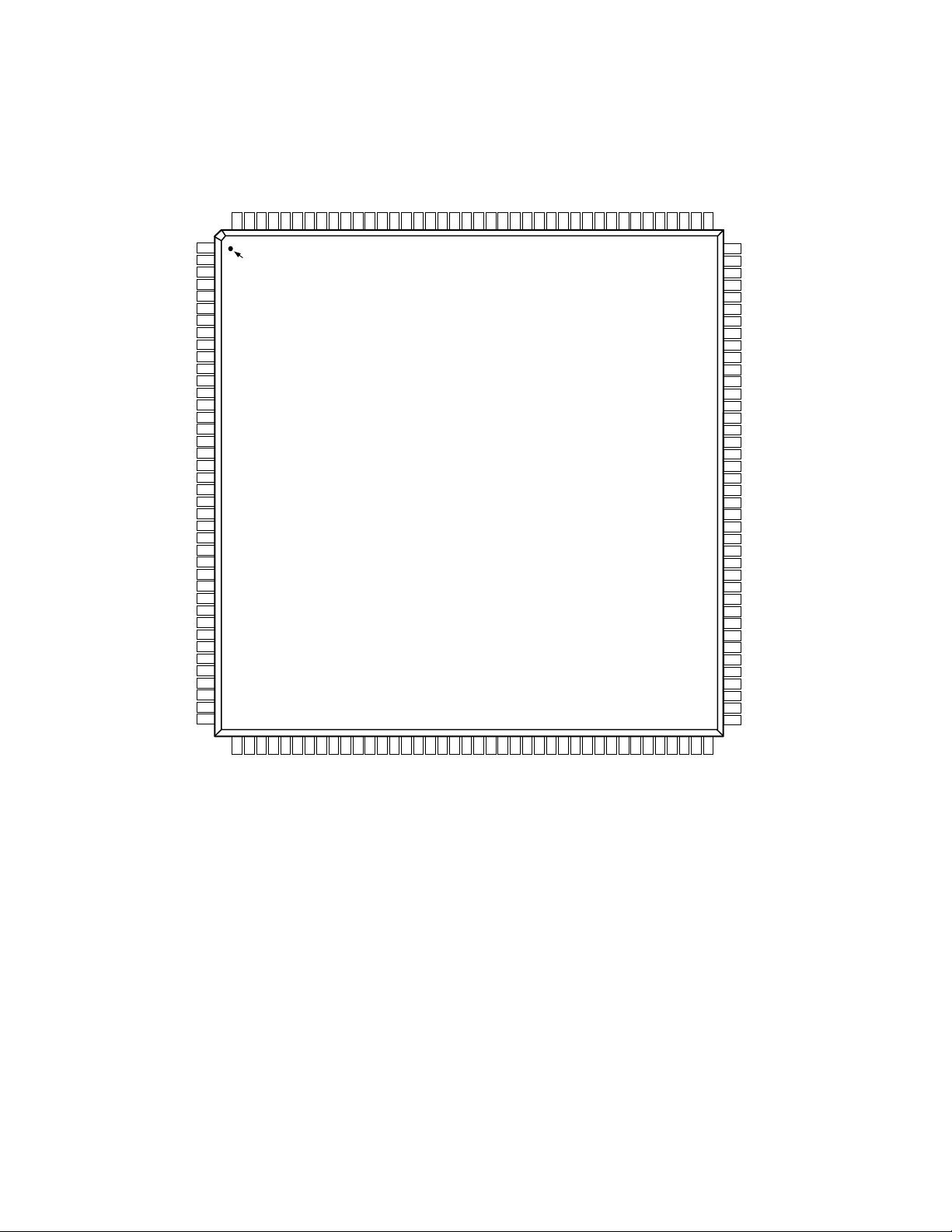

PIN CONFIGURATION

V

GND

GREEN A<7>

GREEN A<6>

GREEN A<5>

GREEN A<4>

GREEN A<3>

GREEN A<2>

GREEN A<1>

GREEN A<0>

V

GND

GREEN B<7>

GREEN B<6>

GREEN B<5>

GREEN B<4>

GREEN B<3>

GREEN B<2>

GREEN B<1>

GREEN B<0>

V

GND

BLUE A<7>

BLUE A<6>

BLUE A<5>

BLUE A<4>

BLUE A<3>

BLUE A<2>

BLUE A<1>

BLUE A<0>

V

GND

BLUE B<7>

BLUE B<6>

BLUE B<5>

BLUE B<4>

BLUE B<3>

BLUE B<2>

BLUE B<1>

BLUE B<0>

RED B<0>

RED B<1>

RED B<2>

RED B<3>

RED B<4>

RED B<5>

RED B<6>

RED B<7>

GND

VDDRED A<0>

RED A<1>

RED A<2>

RED A<3>

RED A<4>

RED A<5>

RED A<6>

RED A<7>

GND

VDDSOGOUT

160

159

158

157

156

155

154

153

152

151

150

149

146

145

144

143

142

141

148

147

1

DD

DD

DD

DD

PIN 1

2

IDENTIFIER

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

140

AD9887

TOP VIEW

(Not to Scale)

HSOUT

VSOUTDES

139

138

137

CDT

DATACK

136

135

DATACK

GND

VDDGND

133

132

134

131

GND

130

SCANINGND

129

128

OUT

VDREF

127

126

REFINVDVDGND

125

123

122

124

GND

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

R

MIDSC

R

AIN

R

CLAMP

V

D

GND

V

D

V

D

GND

GND

G

MIDSC

G

AIN

G

CLAMP

SOGIN

V

D

GND

V

D

V

D

GND

GND

B

MIDSC

B

AIN

B

CLAMP

V

D

GND

V

D

GND

CKINV

CLAMP

SDA

SCL

A0

A1

PV

D

PV

D

GND

GND

COAST

CKEXT

HSYNC

VSYNC

V

V

V

V

V

V

4142434445464748495051

GND

NC = NO CONNECT

GND

535455565758596061

52

DD

OUT

V

GND

CTL0

CTL1

SCAN

CTL2

CTL3

SCAN

CLK

D

V

GND

TERM

R

VDV

D

Rx2+

GND

Rx2–

Rx1+

–6–

62

6364656668697071726773747576787980

GND

Rx1–

Rx0–

Rx0+

GND

RxC+

DVD

D

V

V

RxC–

GND

NCNCNC

GND

PV

77

D

D

D

PV

PV

FILT

GND

GND

REV. 0

AD9887

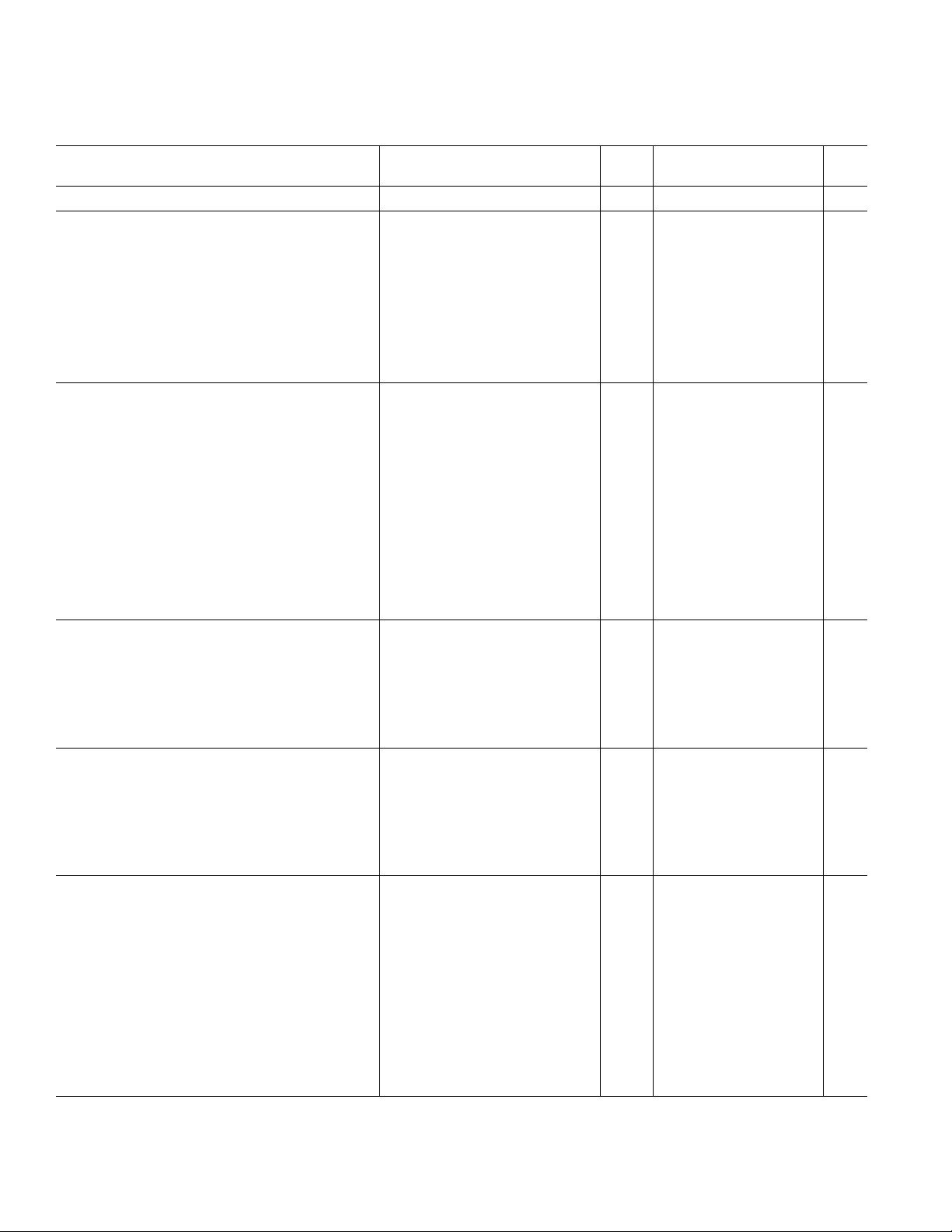

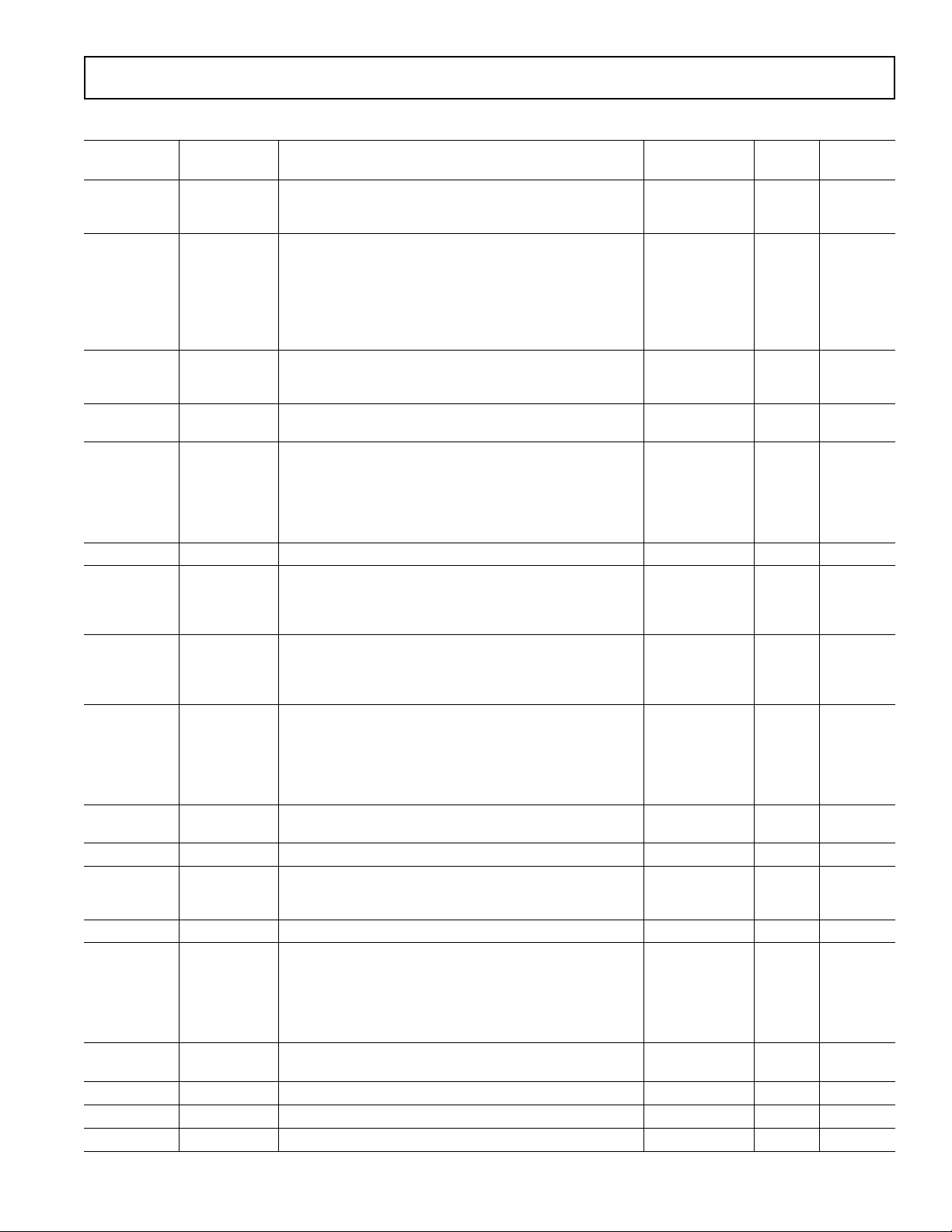

Table I. Complete Pinout List

P

in Pin Pin

Type Name Function Value Number Interface

Analog Video R

Inputs G

AIN

AIN

B

AIN

External HSYNC Horizontal SYNC Input 3.3 V CMOS 82 Analog

Sync/Clock VSYNC Vertical SYNC Input 3.3 V CMOS 81 Analog

Inputs SOGIN Input for Sync-on-Green 0.0 V to 1.0 V 108 Analog

CLAMP Clamp Input (External CLAMP Signal) 3.3 V CMOS 93 Analog

COAST PLL COAST Signal Input 3.3 V CMOS 84 Analog

CKEXT External Pixel Clock Input (to Bypass the PLL) to V

CKINV ADC Sampling Clock Invert 3.3 V CMOS 94 Analog

Sync Outputs HSOUT HSYNC Output Clock (Phase-Aligned with DATACK) 3.3 V CMOS 139 Both

VSOUT VSYNC Output Clock (Phase-Aligned with DATACK) 3.3 V CMOS 138 Both

SOGOUT Sync on Green Slicer Output 3.3 V CMOS 140 Analog

Voltage REFOUT Internal Reference Output (Bypass with 0.1 µF to Ground) 1.25 V 126 Analog

Reference REFIN Reference Input (1.25 V ± 10%) 1.25 V ± 10% 125 Analog

Clamp Voltages R

V Red Channel Midscale Clamp Voltage Output 120 Analog

MIDSC

V Red Channel Midscale Clamp Voltage Input 0.0 V to 0.75 V 118 Analog

R

CLAMP

V Green Channel Midscale Clamp Voltage Output 111 Analog

G

MIDSC

V Green Channel Midscale Clamp Voltage Input 0.0 V to 0.75 V 109 Analog

G

CLAMP

V Blue Channel Midscale Clamp Voltage Output 101 Analog

B

MIDSC

B

V Blue Channel Midscale Clamp Voltage Input 0.0 V to 0.75 V 99 Analog

CLAMP

PLL Filter FILT Connection for External Filter Components for Internal PLL 78 Analog

Power Supply V

V

PV

D

DD

D

GND Ground 0 V Both

Serial Port SDA Serial Port Data I/O 3.3 V CMOS 92 Both

(2-Wire SCL Serial Port Data Clock (100 kHz Max) 3.3 V CMOS 91 Both

Serial Interface) A0 Serial Port Address Input 1 3.3 V CMOS 90 Both

A1 Serial Port Address Input 2 3.3 V CMOS 89 Both

Data Outputs Red B[7:0] Port B/Odd Outputs of Converter “Red,” Bit 7 Is the MSB 3.3 V CMOS 153–160 Both

Green B[7:0] Port B/Odd Outputs of Converter “Green,” Bit 7 Is the MSB 3.3 V CMOS 13–20 Both

Blue B[7:0] Port B/Odd Outputs of Converter “Blue,” Bit 7 Is the MSB 3.3 V CMOS 33–40 Both

Red A[7:0] Port A/Even Outputs of Converter “Red,” Bit 7 Is the MSB 3.3 V CMOS 143–150 Both

Green A[7:0] Port A/Even Outputs of Converter “Green,” Bit 7 Is the MSB 3.3 V CMOS 3–10 Both

Blue A[7:0] Port A/Even Outputs of Converter “Blue,” Bit 7 Is the MSB 3.3 V CMOS 23–30 Both

Data Clock DATACK Data Output Clock for the Analog and Digital Interface 3.3 V CMOS 134 Both

Outputs DATACK Data Output Clock Complement for the Analog Interface Only 3.3 V CMOS 135 Both

Sync Detect S

Scan Function SCAN

CDT

SCAN

SCAN

IN

OUT

CLK

No Connect NC These Pins Should be Left Unconnected 71–73 Both

Digital Video R

Data Inputs R

+ Digital Input Channel 0 True 62 Digital

x0

– Digital Input Channel 0 Complement 63 Digital

x0

+ Digital Input Channel 1 True 59 Digital

R

x1

– Digital Input Channel 1 Complement 60 Digital

R

x1

+ Digital Input Channel 2 True 56 Digital

R

x2

Rx2– Digital Input Channel 2 Complement 57 Digital

Digital Video R

+ Digital Data Clock True 65 Digital

xc

Clock Inputs Rxc– Digital Data Clock Complement 66 Digital

Data Enable DE Data Enable 3.3 V CMOS 137 Digital

Control Bits CTL[0:3] Decoded Control Bits 3.3 V CMOS 46–49 Digital

R

TERM

R

TERM

Analog Input for Converter R 0.0 V to 1.0 V 119 Analog

Analog Input for Converter G 0.0 V to 1.0 V 110 Analog

Analog Input for Converter B 0.0 V to 1.0 V 100 Analog

or Ground 3.3 V CMOS 83 Analog

DD

Analog Power Supply 3.3 V ± 10% Both

Output Power Supply 3.3 V ± 10% Both

PLL Power Supply 3.3 V ± 10% Both

Sync Detect Output 3.3 V CMOS 136 Both

Input for SCAN Function 3.3 V CMOS 129 Both

Output for SCAN Function 3.3 V CMOS 45 Both

Clock for SCAN Function 3.3 V CMOS 50 Both

Sets Internal Termination Resistance 53 Digital

REV. 0

–7–

AD9887

DESCRIPTIONS OF PINS SHARED BETWEEN ANALOG

AND DIGITAL INTERFACES

HSOUT Horizontal Sync Output

A reconstructed and phase-aligned version of

the video HSYNC. The polarity of this output

can be controlled via a serial bus bit. In analog

interface mode the placement and duration

are variable. In digital interface mode the

placement and duration are set by the graphics

transmitter.

VSOUT Vertical Sync Output

The separated VSYNC from a composite

signal or a direct pass through of the VSYNC

input. The polarity of this output can be controlled via a serial bus bit. The placement and

duration in all modes is set by the graphics

transmitter.

Serial Port (2-Wire)

SDA Serial Port Data I/O

SCL Serial Port Data Clock

A0 Serial Port Address Input 1

A1 Serial Port Address Input 2

For a full description of the 2-wire serial register and how it works, refer to the Control

Register section.

Data Outputs

RED A Data Output, Red Channel, Port A/Even

RED B Data Output, Red Channel, Port B/Odd

GREEN A Data Output, Green Channel, Port A/Even

GREEN B Data Output, Green Channel, Port B/Odd

BLUE A Data Output, Blue Channel, Port A/Even

BLUE B Data Output, Blue Channel, Port B/Odd

The main data outputs. Bit 7 is the MSB.

These outputs are shared between the two

interfaces and behave according to which

interface is active. Refer to the sections on the

two interfaces for more information on how

these outputs behave.

Data Clock Outputs

DATACK Data Output Clock

DATACK Data Output Clock Complement

Just like the data outputs, the data clock outputs are shared between the two interfaces.

They also behave differently depending on

which interface is active. Refer to the sections

on the two interfaces to determine how these

pins behave.

Various

S

CDT

Chip Active/Inactive Detect Output

The logic for the S

pin is [analog interface

CDT

HSYNC detection] OR [digital interface DE

detection]. So, the S

pin will switch to

CDT

logic LOW under two conditions, when neither interface is active or when the chip is in

full chip power-down mode. The data outputs

are automatically three-stated when S

LOW. This pin can be read by a controller in

order to determine periods of inactivity.

SCAN Function

SCAN

IN

Data Input for SCAN Function

Data can be loaded serially into the 48-bit

SCAN register through this pin, clocking it in

with the SCAN

pin. It then comes out of

CLK

the 48 data outputs in parallel. This function

is useful for loading known data into a graphics controller chip for testing purposes.

SCAN

OUT

Data Output for SCAN Function

The data in the 48-bit SCAN register can be

read through this pin. Data is read on a FIFO

basis and is clocked via the SCAN

SCAN

CLK

Data Clock for SCAN Function

This pin clocks the data through the SCAN

register. It controls both data input and data

output.

CLK

CDT

pin.

is

–8–

REV. 0

AD9887

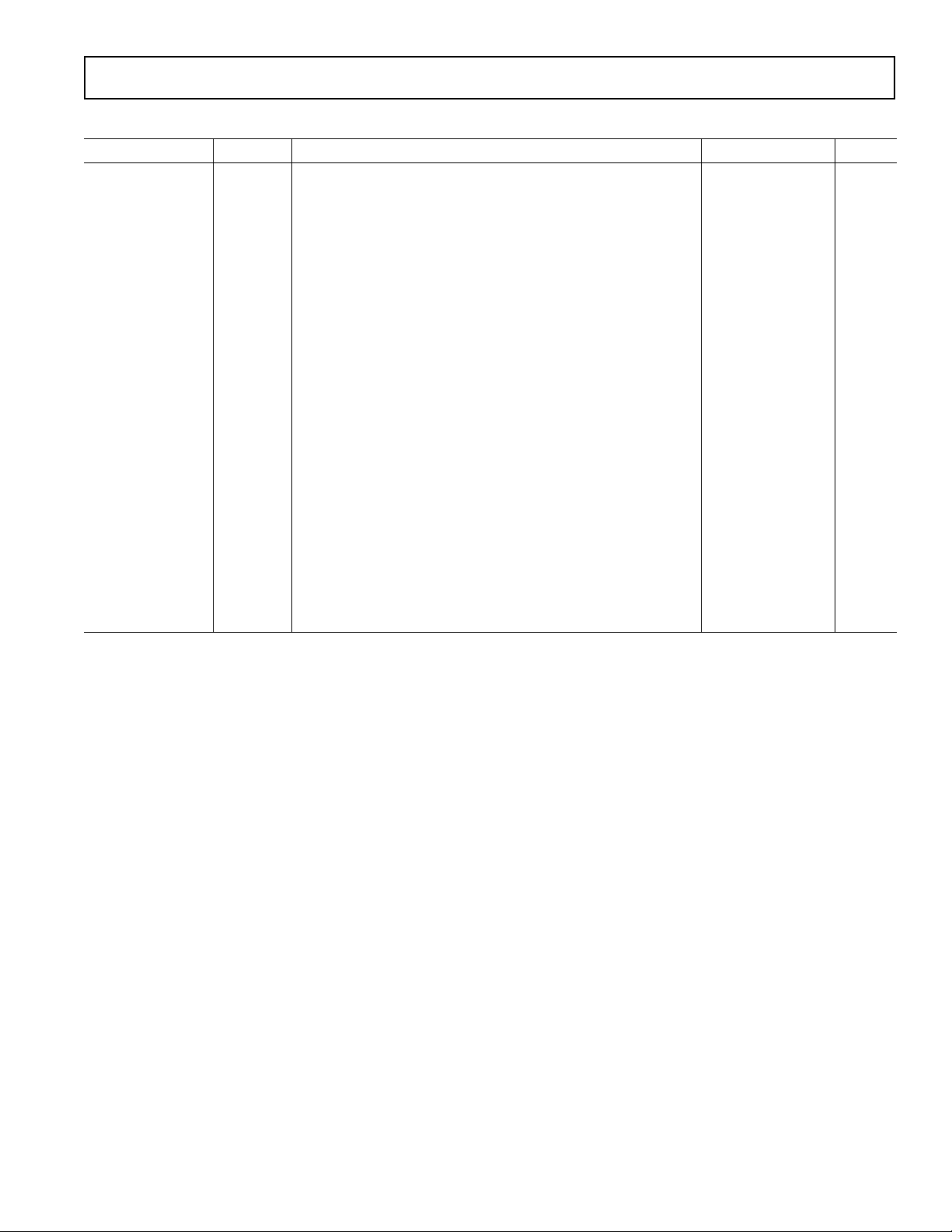

Table II. Analog Interface Pin List

Pin Type Pin Name Function Value Pin No.

Analog Video Inputs R

AIN

G

AIN

B

AIN

External HSYNC Horizontal SYNC Input 3.3 V CMOS 82

VSYNC Vertical SYNC Input 3.3 V CMOS 81

Sync/Clock SOGIN Sync-on-Green Input 0.0 V to 1.0 V 108

Inputs CLAMP Clamp Input (External CLAMP Signal) 3.3 V CMOS 93

COAST PLL COAST Signal Input 3.3 V CMOS 84

CKEXT External Pixel Clock Input (to Bypass Internal PLL) 3.3 V CMOS 83

CKINV ADC Sampling Clock Invert 3.3 V CMOS 94

Sync Outputs HSOUT HSYNC Output (Phase-Aligned with DATACK and DATACK) 3.3 V CMOS 139

VSOUT VSYNC Output (Asynchronous) 3.3 V CMOS 138

SOGOUT Sync-on-Green Slicer Output or Raw HSYNC Output 3.3 V CMOS 140

Voltage Reference REFOUT Internal Reference Output (bypass with 0.1 µF to ground) 1.25 V 126

REFIN Reference Input (1.25 V ± 10%) 1.25 V ± 10% 125

Clamp Voltages R

MIDSC

R

CLAMP

G

MIDSC

G

CLAMP

B

MIDSC

B

CLAMP

PLL Filter FILT Connection for External Filter Components for Internal PLL 78

Power Supply V

PV

V

D

D

DD

GND Ground 0 V

Analog Input for Converter R 0.0 V to 1.0 V 119

Analog Input for Converter G 0.0 V to 1.0 V 110

Analog Input for Converter B 0.0 V to 1.0 V 100

or 10 kΩ to V

DD

V Voltage output equal to the RED converter midscale voltage. 0.5 V ± 50% 120

V During midscale clamping, the RED Input is clamped to this pin. 0.0 V to 0.75 V 118

V Voltage output equal to the GREEN converter midscale voltage. 0.5 V ± 50% 111

V During midscale clamping, the GREEN Input is clamped to this pin. 0.0 V to 0.75 V 109

V Voltage output equal to the BLUE converter midscale voltage. 0.5 V ± 50% 101

V During midscale clamping, the BLUE Input is clamped to this pin. 0.0 V to 0.75 V 99

Main Power Supply 3.3 V ± 5%

PLL Power Supply (Nominally 3.3 V) 3.3 V ± 5%

Output Power Supply 3.3 V or 2.5 V ± 5%

PIN FUNCTION DETAILS (ANALOG INTERFACE)

Inputs

R

AIN

G

AIN

B

AIN

Analog Input for RED Channel

Analog Input for GREEN Channel

Analog Input for BLUE Channel

High-impedance inputs that accept the RED,

GREEN, and BLUE channel graphics signals,

respectively. For RGB, the three channels

identical and can be used for any colors, but

colors are assigned for convenient reference.

For proper 4:2:2 formatting in a YUV

application, the Y channel must be connected

the G

B

R

input, U must be connected to the

AIN

input, and V must be connected to the

AIN

input.

AIN

They accommodate input signals ranging

from 0.5 V to 1.0 V full scale. Signals should

be ac-coupled to these pins to support clamp

operation.

HSYNC Horizontal Sync Input

This input receives a logic signal that establishes the horizontal timing reference and

provides the frequency reference for pixel

clock generation.

The logic sense of this pin is controlled by

serial register 0Fh Bit 7 (HSYNC Polarity).

Only the leading edge of HSYNC is active,

the trailing edge is ignored. When HSYNC

to

are

Polarity = 0, the falling edge of HSYNC is

used. When HSYNC Polarity = 1, the rising

edge is active.

The input includes a Schmitt trigger for noise

immunity, with a nominal input threshold

of 1.5 V.

Electrostatic Discharge (ESD) protection

diodes will conduct heavily if this pin is driven

more than 0.5 V above the maximum tolerance voltage (3.3 V), or more than 0.5 V

below ground.

VSYNC Vertical Sync Input

This is the input for vertical sync.

SOGIN Sync-on-Green Input

This input is provided to assist with processing

signals with embedded sync, typically on the

GREEN channel. The pin is connected to a

high-speed comparator with an internally

generated threshold, which is set to 0.15 V

above the negative peak of the input signal.

When connected to an ac-coupled graphics

signal with embedded sync, it will produce a

noninverting digital output on SOGOUT.

When not used, this input should be left

unconnected. For more details on this function and how it should be configured, refer to

the Sync-on-Green section.

REV. 0

–9–

AD9887

CLAMP External Clamp Input (Optional)

This logic input may be used to define the

time during which the input signal is clamped

to the reference dc level, (ground for RGB or

midscale for YUV). It should be exercised

when the reference dc level is known to be

present on the analog input channels, typically

during the back porch of the graphics signal.

The CLAMP pin is enabled by setting control

bit EXTCLMP to 1, (the default power-up is 0).

When disabled, this pin is ignored and the

clamp timing is determined internally by

counting a delay and duration from the trailing

edge of the HSYNC input. The logic sense of

this pin is controlled by CLAMPOL. When

not used, this pin must be grounded and

EXTCLMP programmed to 0.

COAST Clock Generator Coast Input (Optional)

This input may be used to cause the pixel clock

generator to stop synchronizing with HSYNC

and continue producing a clock at its current

frequency and phase. This is useful when

processing signals from sources that fail to

produce horizontal sync pulses when in the

vertical interval. The COAST signal is generally

not required for PC-generated signals. Applications requiring COAST can do so through

the internal COAST found in the SYNC

processing engine.

The logic sense of this pin is controlled by

COAST Polarity.

When not used, this pin may be grounded and

COAST Polarity programmed to 1, or tied

HIGH and COAST Polarity programmed to 0.

COAST Polarity defaults to 1 at power-up.

CKEXT External Clock Input (Optional)

This pin may be used to provide an external

clock to the AD9887, in place of the clock

internally generated from HSYNC.

It is enabled by programming EXTCLK to 1.

When an external clock is used, all other internal

functions operate normally. When unused, this

pin should be tied to V

EXTCLK programmed to 0. The clock

adjustment still operates when an external

or to GROUND, and

DD

phase

clock

source is used.

CKINV Sampling Clock Inversion (Optional)

This pin may be used to invert the pixel

sampling clock, which has the effect of

shifting the sampling phase 180°. This is in

support of Alternate Pixel Sampling mode,

wherein higher-frequency input signals (up

to 280 Mpps) may be captured by first sampling the odd pixels, then capturing the even

pixels on the subsequent frame.

This pin should be exercised only during blanking

intervals (typically vertical blanking) as it may

produce several samples of corrupted data during

the phase shift.

CKINV should be grounded when not used.

Outputs

DRA

D

RB7-0

D

GA7-0

D

GB7-0

D

BA7-0

D

BB7-0

7-0

Data Output, Red Channel, Port A

Data Output, Red Channel, Port B

Data Output, Green Channel, Port A

Data Output, Green Channel, Port B

Data Output, Blue Channel, Port A

Data Output, Blue Channel, Port B

These are the main data outputs. Bit 7 is the MSB.

Each channel has two ports. When the part is

operated in single-channel mode (DEMUX = 0),

all data are presented to Port A, and Port B is

placed in a high-impedance state.

Programming DEMUX to 1 established dualchannel mode, wherein alternate pixels are

presented to Port A and Port B of each channel. These will appear simultaneously, two

pixels presented at the time of every second

input pixel, when PAR is set to 1 (parallel

mode). When PAR = 0, pixel data appear

alternately on the two ports, one new sample

with each incoming pixel (interleaved mode).

In dual channel mode, the first pixel after

HSYNC is routed to Port A. The second pixel

goes to Port B, the third to A, etc.

The delay from pixel sampling time to output is

fixed. When the sampling time is changed by

adjusting the PHASE register, the output timing is

shifted as well. The DATACK, DATACK, and

HSOUT outputs are also moved, so the timing

relationship among the signals is maintained.

DATACK Data Output Clock

DATACK Data Output Clock Complement

Differential data clock output signals to be

used to strobe the output data and HSOUT

into external logic.

They are produced by the internal clock generator and are synchronous with the internal

pixel sampling clock.

When the AD9887 is operated in single-channel mode, the output frequency is equal to the

pixel sampling frequency. When operating in

dual channel mode, the clock frequency is onehalf the pixel frequency.

When the sampling time is changed by adjusting

the PHASE register, the output timing is

as well. The Data, DATACK,

DATACK, and

HSOUT outputs are all moved, so the timing

relationship among the signals is maintained.

shifted

–10–

REV. 0

AD9887

Either or both signals may be used, depending on the timing mode and interface design

employed.

HSOUT Horizontal Sync Output

A reconstructed and phase-aligned version of

the Hsync input. Both the polarity and duration of this output can be programmed via

serial bus registers.

By maintaining alignment with DATACK,

DATACK, and Data, data timing with

respect to horizontal sync can always be

determined.

SOGOUT Sync-On-Green Slicer Output

This pin can be programmed to output

either the output from the Sync-On-Green

slicer comparator or an unprocessed but

delayed version of the HSYNC input. See

the Sync Block Diagram to view how this

pin is connected.

(Note: The output from this pin is the sliced

SOG, without additional processing from the

AD9887.)

Analog Interface

REFOUT Internal Reference Output

Output from the internal 1.25 V bandgap reference. This output is intended to drive relatively

light loads. It can drive the AD9887 Reference

Input directly, but should be externally buffered if it is used to drive other loads as well.

The absolute accuracy of this output is ±4%,

and the temperature coefficient is ±50 ppm,

which is adequate for most AD9887 applications. If higher accuracy is required, an

external reference may be employed instead.

If an external reference is used, connect this

pin to ground through a 0.1 µF capacitor.

REFIN Reference Input

The reference input accepts the master reference voltage for all AD9887 internal circuitry

(1.25 V ± 10%). It may be driven directly by

the REFOUT pin. Its high impedance presents a very light load to the reference source.

This pin should always be bypassed to Ground

with a 0.1 µF capacitor.

FILT External Filter Connection

For proper operation, the pixel clock generator PLL requires an external filter. Connect

the filter shown Figure 7 to this pin. For

optimal performance, minimize noise and

parasitics on this node.

Power Supply

V

D

Main Power Supply

These pins supply power to the main elements

of the circuit. It should be filtered

as possible.

quiet

V

DD

Digital Output Power Supply

to be

as

These supply pins are identified separately

from the V

pins so special care can be taken

D

to minimize output noise transferred into the

sensitive analog circuitry.

If the AD9887 is interfacing with lowervoltage logic, V

may be connected to a

DD

lower supply voltage (as low as 2.2 V) for

compatibility.

PV

D

Clock Generator Power Supply

The most sensitive portion of the AD9887 is

the clock generation circuitry. These pins

provide power to the clock PLL and help the

user design for optimal performance. The

designer should provide noise-free power to

these pins.

GND Ground

The ground return for all circuitry on chip.

It is recommended that the application circuit

board have a single, solid ground plane.

THEORY OF OPERATION (INTERFACE DETECTION)

Active Interface Detection and Selection

The AD9887 includes circuitry to detect whether or not an

interface is active.

For detecting the analog interface, the circuitry monitors the

presence of HSYNC, VSYNC, and Sync-on-Green. The result of

the detection circuitry can be read from the 2-wire serial interface bus at address 11H Bits 7, 6, and 5 respectively. If one of

these sync signals disappears, the maximum time it takes for the

circuitry to detect it is 100 ms.

There are two stages for detecting the digital interface. The first

stage searches for the presence of the digital interface clock.

The circuitry for detecting the digital interface clock is active

even when the digital interface is powered down. The result of

this detection stage can be read from the 2-wire serial interface

bus at address 11H Bit 4. If the clock disappears, the maximum

time it takes for the circuitry to detect it is 100 ms. The second

stage attempts to detect DE on the digital interface. Detection is

accomplished when 32 DEs have been counted. DE can only be

detected when the digital interface is powered up, so it is not

always active. The DE detection circuitry is one of the logic

inputs used to set the SyncDT output pin (Pin 136). The logic

for the SyncDT pin is [DE detect] OR [HSYNC detect].

There is an override for the automatic interface selection. It is

the AIO bit (Active Interface Override). When the AIO bit is set

to Logic 0, the automatic circuitry will be used. When the AIO

bit is set to Logic 1, the AIS bit will be used to determine the

active interface rather than the automatic circuitry.

REV. 0

–11–

AD9887

Power Management

The AD9887 is a dual interface device with shared outputs.

Only one interface can be used at a time. For this reason, the

chip automatically powers down the unused interface. When

the analog interface is being used, most of the digital interface

circuitry is powered down and vice-versa. This helps to minimize

the AD9887 total power dissipation. In addition, if neither interface has activity on it, the chip powers down both interfaces.

The AD9887 uses the activity detect circuits, the active interface bits in the serial registers, the active interface override bits,

Table III. Interface Selection Controls

and the power-down bit to determine the correct power state.

In a given power mode not all circuitry in the inactive interface

is powered down completely. When the digital interface is

active, the bandgap reference and HSYNC detect circuitry is not

powered down. When the analog interface is active, the digital

interface clock detect circuit is not powered down. Table IV

summarizes how the AD9887 determines which power mode to

be in and what circuitry is powered on/off in each of these

modes. The power-down command has priority, followed by the

active interface override, and then the automatic circuitry.

Analog Digital Active

AIO Interface Detect Interface Detect AIS Interface Description

1 X X 0 Analog Force the analog interface active.

1 Digital Force the digital interface active.

0 0 0 X None Neither interface was detected. Both interfaces are

powered down and the SyncDT pin gets set to Logic 0.

0 1 X Digital The digital interface was detected. Power down the

analog interface.

1 0 X Analog The analog interface was detected. Power down the

digital interface.

1 0 X Analog Both interfaces were detected. The analog interface has

priority.

1 Digital Both interfaces were detected. The digital interface has

priority.

Table IV. Power-Down Mode Descriptions

Inputs

Analog Digital Active Active

Power- Interface Interface Interface Interface

Mode Down1Detect2Detect3Override Select Powered On or Comments

Soft Power-Down (Seek Mode) 1 0 0 0 X Serial Bus, Digital Interface Clock Detect,

Analog Interface Activity Detect, SOG,

Bandgap Reference

Digital Interface On 1 0 1 0 X Serial Bus, Digital Interface, Analog Interface

Activity Detect, SOG, Outputs, Bandgap

Reference

Analog Interface On 1 1 0 0 X Serial Bus, Analog Interface, Digital Interface

Clock Detect, SOG, Outputs, Bandgap

Reference

Serial Bus Arbitrated Interface 1 1 1 0 0 Same as Analog Interface On Mode

Serial Bus Arbitrated Interface 1 1 1 0 1 Same as Digital Interface On Mode

Override to Analog Interface 1 X X 1 0 Same as Analog Interface On Mode

Override to Digital Interface 1 X X 1 1 Same as Digital Interface On Mode

Absolute Power-Down 0 X X X X Serial Bus

NOTES

1

Power-down is controlled via bit 0 in serial bus Register 12h.

2

Analog Interface Detect is determined by OR-ing Bits 7, 6, and 5 in serial bus Register 11h.

3

Digital Interface Detect is determined by Bit 4 in serial bus Register 11h.

–12–

REV. 0

Loading...

Loading...