Single- and 4-Channel, 9 s, 10-Bit ADCs

with On-Chip Temperature Sensor

AD7816/AD7817/AD7818

FEATURES

10-Bit ADC with 9 s Conversion Time

One (AD7818) and Four (AD7817) Single-Ended Analog

Input Channels

The AD7816 Is a Temperature Measurement Only Device

On-Chip Temperature Sensor

Resolution of 0.25ⴗC

ⴞ2ⴗC Error from –40ⴗC to +85ⴗC

–55ⴗC to +125ⴗC Operating Range

Wide Operating Supply Range

2.7 V to 5.5 V

Inherent Track-and-Hold Functionality

On-Chip Reference (2.5 V ⴞ 1%)

Overtemperature Indicator

Automatic Power-Down at the End of a Conversion

Low Power Operation

4 W at a Throughput Rate of 10 SPS

40 W at a Throughput Rate of 1 kSPS

400 W at a Throughput Rate of 10 kSPS

Flexible Serial Interface

APPLICATIONS

Ambient Temperature Monitoring (AD7816)

Thermostat and Fan Control

High Speed Microprocessor

Temperature Measurement and Control

Data Acquisition Systems with Ambient Temperature

Monitoring (AD7817 and AD7818)

Industrial Process Control

Automotive

Battery Charging Applications

GENERAL DESCRIPTION

The AD7818 and AD7817 are 10-bit, single- and 4-channel

A/D converters with on-chip temperature sensor that can operate from a single 2.7 V to 5.5 V power supply. Each part contains a 9 µs successive-approximation converter based around

a capacitor DAC, an on-chip temperature sensor with an accuracy of ⫾2°C, an on-chip clock oscillator, inherent track-andhold functionality and an on-chip reference (2.5 V). The

AD7816 is a temperature monitoring only device in a SOIC/

MSOP package.

The on-chip temperature sensor of the AD7817 and AD7818

can be accessed via Channel 0. When Channel 0 is selected and

a conversion is initiated, the resulting ADC code at the end of

the conversion gives a measurement of the ambient temperature

with a resolution of ⫾0.25°C. See Temperature Measurement

section of this data sheet.

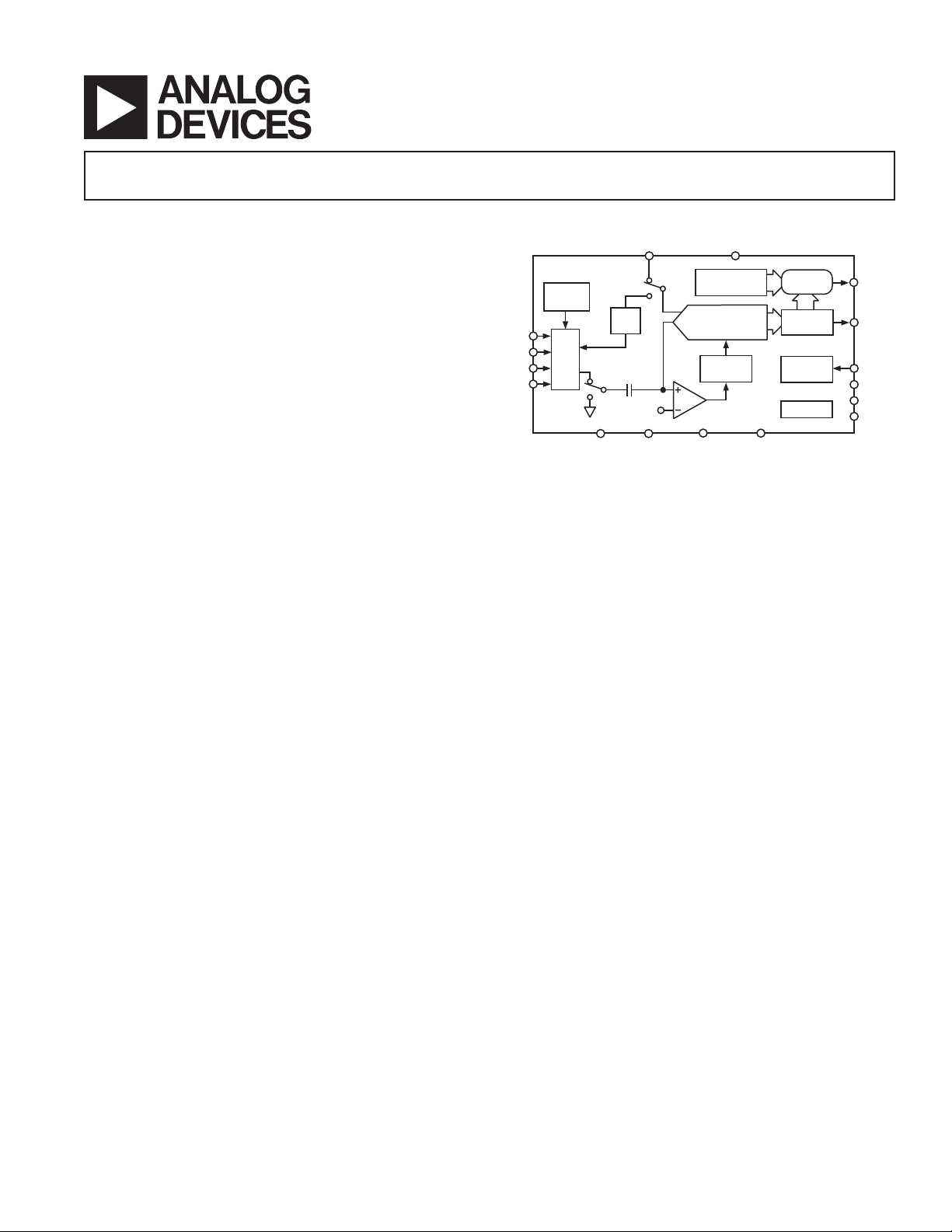

FUNCTIONAL BLOCK DIAGRAM

REF

IN

AD7817

TEMP

SENSOR

V

IN1

V

IN2

V

V

MUX

IN3

IN4

SAMPLING

CAPACITOR

V

AGND

REF

2.5V

BALANCE

DGND

V

DD

OVERTEMP

REG

CHARGE

REDISTRIBUTION

DAC

CONTROL

LOGIC

BUSY

CONVST

B

CONTROL

A > B

A

DATA

OUT

REG

CLOCK

OTI

D

OUT

D

IN

SCLK

RD/WR

CS

The AD7816, AD7817, and AD7818 have a flexible serial

interface that allows easy interfacing to most microcontrollers.

The interface is compatible with the Intel 8051, Motorola

®

and QSPI™ protocols and National Semiconductors

SPI

MICROWIRE™ protocol. For more information refer to the

Serial Interface section of this data sheet.

The AD7817 is available in a narrow body 0.15" 16-lead small

outline IC (SOIC), in a 16-lead, thin shrink small outline package (TSSOP), while the AD7816/AD7818 come in an 8-lead

small outline IC (SOIC) and an 8-lead microsmall outline IC

(MSOP).

PRODUCT HIGHLIGHTS

1. The devices have an on-chip temperature sensor that allows an

accurate measurement of the ambient temperature to be

made. The measurable temperature range is –55°C to +125°C.

2. An overtemperature indicator is implemented by carrying out a

digital comparison of the ADC code for Channel 0 (temperature sensor) with the contents of the on-chip overtemperature

register. The overtemperature indicator pin goes logic low when

a predetermined temperature is exceeded.

3. The automatic power-down feature enables the AD7816,

AD7817, and AD7818 to achieve superior power performance at slower throughput rates, e.g., 40 µW at 1 kSPS

throughput rate.

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2004 Analog Devices, Inc. All rights reserved.

AD7816/AD7817/AD7818

AD7817–SPECIFICATIONS

Parameter A Version *B Version *S Version Unit Test Conditions/Comments

DYNAMIC PERFORMANCE Sample Rate = 100 kSPS, Any

2

Signal to (Noise + Distortion) Ratio

Total Harmonic Distortion

Peak Harmonic or Spurious Noise2–65 –65 –65 dB max –75 dB typ

Intermodulation Distortion

2

2

Second Order Terms –67 –67 –67 dB typ

Third Order Terms –67 –67 –67 dB typ

Channel-to-Channel Isolation

2

DC ACCURACY Any Channel

Resolution 10 10 10 Bits

Minimum Resolution for Which

No Missing Codes are Guaranteed 10 10 10 Bits

Relative Accuracy

Differential Nonlinearity

Gain Error

Gain Error Match

Offset Error

2

2

2

2

2

Offset Error Match ⫾1/2 ⫾1/2 ⫾ 1/2 LSB max

TEMPERATURE SENSOR

1

Measurement Error External Reference V

Ambient Temperature 25°C ⫾2 ⫾1 ⫾2 °C max

to T

T

MIN

MAX

Measurement Error On-Chip Reference

Ambient Temperature 25°C ⫾2.25 ⫾2.25 ⫾2.25 °C max

to T

T

MIN

MAX

Temperature Resolution 1/4 1/4 1/4 °C/LSB

REFERENCE INPUT

REFIN Input Voltage Range

3, 4

3

Input Impedance 40 40 40 kΩ min

Input Capacitance 10 10 10 pF max

ON-CHIP REFERENCE

Temperature Coefficient

CONVERSION RATE

Track/Hold Acquisition Time

5

3

4

Conversion Time

Temperature Sensor 27 27 27 µs max

Channels 1 to 4 9 9 9 µs max

POWER REQUIREMENTS

V

DD

I

DD

Normal Operation 2 2 2 mA max 1.6 mA typ

Using External Reference 1.75 1.75 1.75 mA max 2.5 V External Reference Connected

Power-Down (V

Power-Down (V

= 5 V) 10 10 12.5 µA max 5.5 µA typ

DD

= 3 V) 4 4 4.5 µA max 2 µA typ

DD

Auto Power-Down Mode V

10 SPS Throughput Rate 6.4 6.4 6.4 µW typ See Power vs. Throughput Section for

1 kSPS Throughput Rate 48.8 48.8 48.8 µW typ Description of Power Dissipation in

10 kSPS Throughput Rate 434 434 434 µW typ Auto Power-Down Mode

Power-Down 12 12 13.5 µW max Typically 6 µW

58 58 58 dB min

–65 –65 –65 dB max –75 dB typ

–80 –80 –80 dB typ fIN = 20 kHz

⫾1 ⫾1 ⫾1LSB max

⫾1 ⫾1 ⫾1LSB max

⫾2 ⫾2 ⫾2LSB max External Reference

⫾10 ⫾10 +20/–10 LSB max Internal Reference

⫾1/2 ⫾1/2 ⫾ 1/2 LSB max

⫾2 ⫾2 ⫾2LSB max

⫾3 ⫾2 ⫾3 °C max

⫾3 ⫾3 ⫾6 °C max

2.625 2.625 2.625 V max 2.5 V + 5%

2.375 2.375 2.375 V min 2.5 V – 5%

80 80 150 ppm/°C typ

400 400 400 ns max Source Impedance < 10 Ω

5.5 5.5 5.5 V max For Specified Performance

2.7 2.7 2.7 V min

(VDD = 2.7 V to 5.5 V, GND = 0 V, REFIN = 2.5 V unless otherwise noted)

Channel, fIN = 20 kHz

fa =19.9 kHz, fb = 20.1 kHz

Nominal 2.5 V

Logic Inputs = 0 V or V

= 3 V

DD

= 2.5 V

REF

DD

1

REV. C–2–

AD7816/AD7817/AD7818

1

AD7816/AD78186–SPECIFICATIONS

Parameter A Version Unit Test Conditions/Comments

DYNAMIC PERFORMANCE (AD7818 Only) Sample Rate = 100 kSPS, Any Channel,

Signal to (Noise + Distortion) Ratio

Total Harmonic Distortion

Peak Harmonic or Spurious Noise

Intermodulation Distortion

2

2

Second Order Terms –67 dB typ

Third Order Terms –67 dB typ

Channel-to-Channel Isolation

DC ACCURACY (AD7818 Only) Any Channel

Resolution 10 Bits

Minimum Resolution for Which

No Missing Codes are Guaranteed 10 Bits

Relative Accuracy

Differential Nonlinearity

Gain Error

Offset Error

TEMPERATURE SENSOR

2

2

2

2

1

Measurement Error External Reference V

Ambient Temperature 25°C ⫾2 °C max

to T

T

MIN

MAX

Measurement Error On-Chip Reference

Ambient Temperature 25°C ⫾2 °C max

to T

T

MIN

MAX

Temperature Resolution 1/4 °C/LSB

REFERENCE INPUT

Input Voltage Range

REF

IN

3, 4

(AD7816 Only)

3

Input Impedance 50 kΩ min

Input Capacitance 10 pF max

ON-CHIP REFERENCE

Temperature Coefficient

5

3

CONVERSION RATE

Track/Hold Acquisition Time

Conversion Time

Temperature Sensor 27 µs max

Channel 1 9 µs max (AD7818 Only)

POWER REQUIREMENTS

V

DD

I

DD

Normal Operation 2 mA max 1.3 mA typ

Using External Reference 1.75 mA max 2.5 V External Reference Connected

Power-Down (V

Power-Down (V

= 5 V) 10.75 µA max 6 µA typ

DD

= 3 V) 4.5 µA max 2 µA typ

DD

Auto Power-Down Mode V

10 SPS Throughput Rate 6.4 µW typ See Power vs. Throughput Section for

1 kSPS Throughput Rate 48.8 µW typ Description of Power Dissipation in

10 kSPS Throughput Rate 434 µW typ Auto Power-Down Mode

Power-Down 13.5 µW max Typically 6 µW

2

2

2

57 dB min

–65 dB max –75 dB typ

–67 dB typ –75 dB typ

–80 dB typ fIN = 20 kHz

⫾1 LSB max

⫾1 LSB max

⫾10 LSB max

⫾4 LSB max

⫾3 °C max

⫾3 °C max

2.625 V max 2.5 V + 5%

2.375 V min 2.5 V – 5%

30 ppm/°C typ

4

400 ns max Source Impedance < 10 Ω

5.5 V max For Specified Performance

2.7 V min

(VDD = 2.7 V to 5.5 V, GND = 0 V, REFIN = 2.5 V unless

otherwise noted)

fIN = 20 kHz

fa = 19.9 kHz, fb = 20.1 kHz

= 2.5 V

REF

Nominal 2.5 V

Logic Inputs = 0 V or V

= 3 V

DD

DD

REV. C

–3–

AD7816/AD7817/AD7818–SPECIFICATIONS

Parameter A Version *B Version *S Version Unit Test Conditions/Comments

ANALOG INPUTS

Input Voltage Range V

Input Leakage ⫾1 ⫾1 ⫾ 1 µA min

Input Capacitance 10 10 10 pF max

LOGIC INPUTS

Input High Voltage, V

Input Low Voltage, V

Input High Voltage, V

Input Low Voltage, V

Input Current, I

Input Capacitance, C

LOGIC OUTPUTS

Output High Voltage, V

Output Low Voltage, V

High Impedance Leakage Current ⫾1 ⫾1 ⫾ 1 µA max

High Impedance Capacitance 15 15 15 pF max

NOTES

*B and S Versions apply to AD7817 only. For operating temperature ranges, see Ordering Guide.

1

AD7816 and AD7817 temperature sensors specified with external 2.5 V reference, AD7818 specified with on-chip reference. All other specifications with external

and on-chip reference (2.5 V). For VDD = 2.7 V, TA = 85°C max and temperature sensor measurement error = ⫾3°C.

2

See Terminology.

3

The accuracy of the temperature sensor is affected by reference tolerance. The relationship between the two is explained in the section titled Temperature Measurement Error Due to Reference Error.

4

Sample tested during initial release and after any redesign or process change that may affect this parameter.

5

On-chip reference shuts down when external reference is applied.

6

All specifications are typical for AD7818 at temperatures above 85°C and with VDD greater than 3.6 V.

7

Refers to the input current when the part is not converting. Primarily due to reverse leakage current in the ESD protection diodes.

Specifications subject to change without notice.

7

REF

V

REF

V

REF

V max

(AD7817 and AD7818)

0 00V min

4

INH

INL

INH

INL

IN

IN

4

OH

OL

2.4 2.4 2.4 V min VDD = 5 V ⫾ 10%

0.8 0.8 0.8 V max VDD = 5 V ⫾ 10%

2 22V minV

= 3 V ⫾ 10%

DD

0.4 0.4 0.4 V max VDD = 3 V ⫾ 10%

⫾3 ⫾3 ⫾ 3 µA max Typically 10 nA, VIN = 0 V to V

10 10 10 pF max

I

= 200 µA

4 44V minV

2.4 2.4 2.4 V min V

0.4 0.4 0.4 V max V

0.2 0.2 0.2 V max V

SOURCE

= 5 V ⫾ 10%

DD

= 3 V ⫾ 10%

DD

I

= 200 µA

SINK

= 5 V ⫾ 10%

DD

= 3 V ⫾ 10%

DD

DD

V

DD

OVERTEMP

REG

CHARGE

REDISTRIBUTION

DAC

CONTROL

LOGIC

CONVST

B

CONTROL

A > B

A

DATA

OUT

REG

CLOCK

AD7816

TEMP

SENSOR

MUX

REF

REF

2.5V

SAMPLING

CAPACITOR

V

BALANCE

AGND

IN

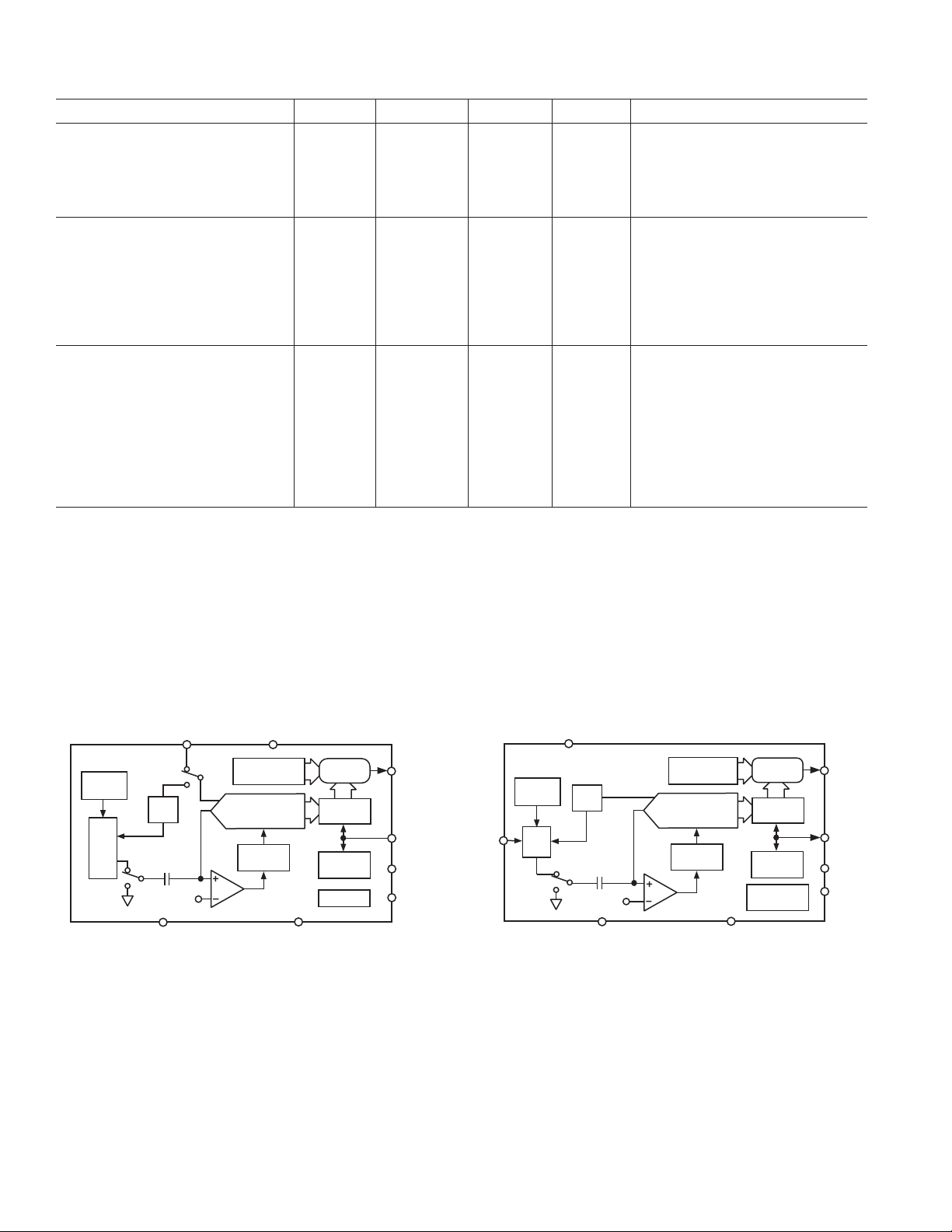

Figure 1. AD7816 Functional Block Diagram

OTI

D

OUT

IN/

SCLK

RD/WR

V

DD

AD7818

TEMP

SENSOR

V

MUX

IN1

REF

2.5V

SAMPLING

CAPACITOR

V

BALANCE

AGND

OVERTEMP

REG

CHARGE

REDISTRIBUTION

DAC

CONTROL

LOGIC

CONVST

Figure 2. AD7818 Functional Block Diagram

A > B

B

A

DATA

OUT

CONTROL

REG

CLOCK

GENERATOR

OTI

D

OUT

IN/

SCLK

RD/WR

REV. C–4–

AD7816/AD7817/AD7818

TIMING CHARACTERISTICS

(VDD = 2.7 V to 5.5 V, GND = 0 V, REFIN = 2.5 V. All specifications T

1, 2

otherwise noted)

MIN

to T

MAX

unless

Parameter A, B Versions Unit Test Conditions/Comments

t

POWER-UP

t

1a

t

1b

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

3

t

12

3

t

13

3, 4

t

14a

3, 4

t

14b

t

15

t

16

t

17

NOTES

1

Sample tested during initial release and after any redesign or process change that may affect this parameter. All input signals are measured with tr = tf = 1 ns (10% to

90% of 5 V) and timed from a voltage level of 1.6 V.

2

See Figures 16, 17, 20 and 21.

3

These figures are measured with the load circuit of Figure 3. They are defined as the time required for D

or 2 V for VDD = 3 V ⫾ 10%, as quoted on the specifications page of this data sheet.

4

These times are derived from the measured time taken by the data outputs to change 0.5 V when loaded with the circuit of Figure 3. The measured number is then

extrapolated back to remove the effects of charging or discharging the 50 pF capacitor. This means that the times quoted in the timing characteristics are the true bus

relinquish times of the part and as such are independent of external bus loading capacitances.

Specifications subject to change without notice.

2 µs max Power-Up Time from Rising Edge of CONVST

9 µs max Conversion Time Channels 1 to 4

27 µs max Conversion Time Temperature Sensor

20 ns min CONVST Pulse Width

50 ns max CONVST Falling Edge to BUSY Rising Edge

0 ns min CS Falling Edge to RD/WR Falling Edge Setup Time

0 ns min RD/WR Falling Edge to SCLK Falling Edge Setup

10 ns min DIN Setup Time before SCLK Rising Edge

10 ns min DIN Hold Time after SCLK Rising Edge

40 ns min SCLK Low Pulse Width

40 ns min SCLK High Pulse Width

0 ns min CS Falling Edge to RD/WR Rising Edge Setup Time

0 ns min RD/WR Rising Edge to SCLK Falling Edge Setup Time

20 ns max D

20 ns max D

30 ns max D

30 ns max D

Access Time after RD/WR Rising Edge

OUT

Access Time after SCLK Falling Edge

OUT

Bus Relinquish Time after Falling Edge of RD/WR

OUT

Bus Relinquish Time after Rising Edge of CS

OUT

150 ns max BUSY Falling Edge to OTI Falling Edge

40 ns min RD/WR Rising Edge to OTI Rising Edge

400 ns min SCLK Rising Edge to CONVST Falling Edge (Acquisition Time of T/H)

to cross 0.8 V or 2.4 V for VDD = 5 V ⫾ 10% and 0.4 V

OUT

I

OL

1.6V

I

OL

TO

OUTPUT

PIN

50pF

200A

C

L

200A

Figure 3. Load Circuit for Access Time and Bus Relinquish Time

REV. C

–5–

AD7816/AD7817/AD7818

ABSOLUTE MAXIMUM RATINGS

(

TA = 25°C unless otherwise noted)

1

VDD to AGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

to DGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

V

DD

Analog Input Voltage to AGND

to V

V

IN1

Reference Input Voltage to AGND

Digital Input Voltage to DGND . . . . . . –0.3 V to V

Digital Output Voltage to DGND . . . . . –0.3 V to V

. . . . . . . . . . . . . . . . . . . –0.3 V to VDD + 0.3 V

IN4

2

. . . –0.3 V to V

DD

DD

DD

+ 0.3 V

+ 0.3 V

+ 0.3 V

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 150°C

TSSOP, Power Dissipation . . . . . . . . . . . . . . . . . . . . 450 mW

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 120°C/W

θ

JA

Lead Temperature, Soldering . . . . . . . . . . . . . . . . . . 260°C

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

16-Lead SOIC Package, Power Dissipation . . . . . . . . 450 mW

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 100°C/W

θ

JA

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

8-Lead SOIC Package, Power Dissipation . . . . . . . . . . 450 mW

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 157°C/W

θ

JA

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

µSOIC Package, Power Dissipation . . . . . . . . . . . . . . 450 mW

θ

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 206°C/W

JA

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational sections

of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

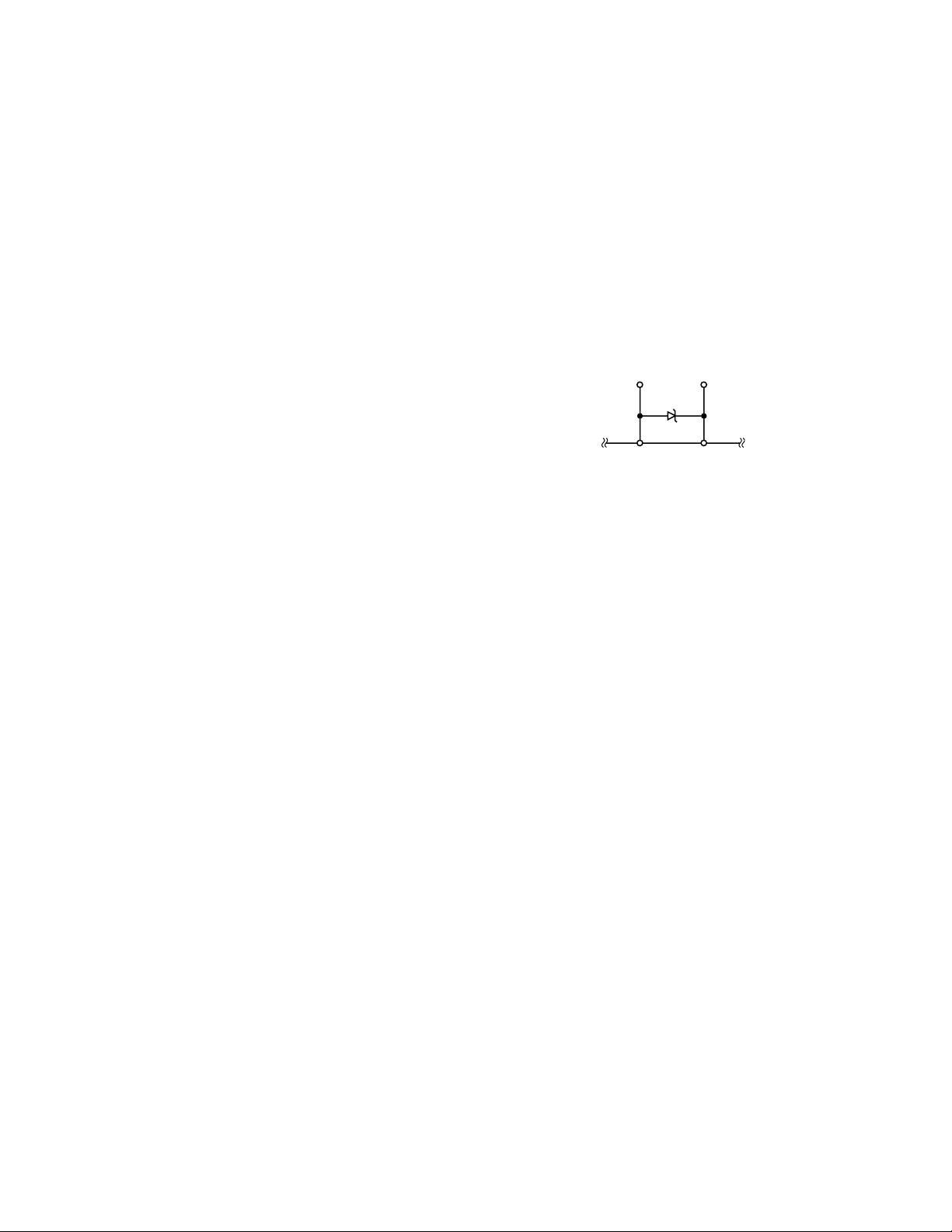

2

If the Reference Input Voltage is likely to exceed VDD by more than 0.3 V (e.g.,

during power-up) and the reference is capable of supplying 30 mA or more, it is

recommended to use a clamping diode between the REFIN pin and VDD pin. The

diagram below shows how the diode should be connected.

BAT81

V

DD

REF

IN

AD7816/AD7817

REV. C–6–

AD7816/AD7817/AD7818

ORDERING GUIDE

Temperature Temperature Package Package

Model Range Error @ +25°C Description Options Branding

AD7816AR –40°C to +85°C ± 2°C 8-Lead Narrow Body (SOIC) R-8

AD7816AR-REEL –40°C to +85°C ± 2°C 8-Lead Narrow Body (SOIC) R-8

AD7816AR-REEL7 –40°C to +85°C ±2°C 8-Lead Narrow Body (SOIC) R-8

AD7816ARM –40°C to +85°C ±2°C 8-Lead MSOP RM-8 C4A

AD7816ARM-REEL –40°C to +85°C ±2°C 8-Lead MSOP RM-8 C4A

AD7816ARM-REEL7 –40°C to +85°C ± 2°C 8-Lead MSOP RM-8 C4A

AD7816ACHIPS Die

AD7817AR –40°C to +85°C ± 2°C 16-Lead Narrow Body (SOIC) R-16

AD7817AR-REEL –40°C to +85°C ± 2°C 16-Lead Narrow Body (SOIC) R-16

AD7817AR-REEL7 –40°C to +85°C ± 2°C 16-Lead Narrow Body (SOIC) R-16

AD7817ARZ* –40°C to +85°C ±2°C 16-Lead Narrow Body (SOIC) R-16

AD7817ARU –40°C to +85°C ± 2°C 16-Lead (TSSOP) RU-16

AD7817ARU-REEL –40°C to +85°C ± 2°C 16-Lead (TSSOP) RU-16

AD7817ARU-REEL7 –40°C to +85°C ± 2°C 16-Lead (TSSOP) RU-16

AD7817BR –40°C to +85°C ± 1°C 16-Lead Narrow Body (SOIC) R-16

AD7817BR-REEL –40°C to +85°C ± 1°C 16-Lead Narrow Body (SOIC) R-16

AD7817BR-REEL7 –40°C to +85°C ± 1°C 16-Lead Narrow Body (SOIC) R-16

AD7817BRZ* –40°C to +85°C ± 1°C 16-Lead Narrow Body (SOIC) R-16

AD7817BRZ-REEL* –40°C to +85°C ± 1°C 16-Lead Narrow Body (SOIC) R-16

AD7817BRZ-REEL7* –40°C to +85°C ± 1°C 16-Lead Narrow Body (SOIC) R-16

AD7817BRU –40°C to +85°C ± 1°C 16-Lead (TSSOP) RU-16

AD7817BRU-REEL –40°C to +85°C ±1°C 16-Lead (TSSOP) RU-16

AD7817BRU-REEL7 –40°C to +85°C ± 1°C 16-Lead (TSSOP) RU-16

AD7817SR –40°C to +85°C ± 2°C 16-Lead Narrow Body (SOIC) R-16

AD7817SR-REEL –40°C to +85°C ± 2°C 16-Lead Narrow Body (SOIC) R-16

AD7817SR-REEL7 –40°C to +85°C ±2°C 16-Lead Narrow Body (SOIC) R-16

AD7818AR –40°C to +85°C ± 2°C 16-Lead Narrow Body (SOIC) R-16

AD7818AR-REEL –40°C to +85°C ± 2°C 8-Lead Narrow Body (SOIC) R-8

AD7818AR-REEL7 –40°C to +85°C ± 2°C 8-Lead Narrow Body (SOIC) R-8

AD7818ARM –40°C to +85°C ± 2°C 8-Lead MSOP RM-8 C3A

AD7818ARM-REEL –40°C to +85°C ± 2°C 8-Lead MSOP RM-8 C3A

AD7818ARM-REEL7 –40°C to +85°C ± 2°C 8-Lead MSOP RM-8 C3A

EVAL-AD7816/ Evaluation Board

AD7817/AD7818EB

*Z = Pb free part

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

AD7816/AD7817/AD7818 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions

are recommended to avoid performance degradation or loss of functionality.

REV. C

–7–

WARNING!

ESD SENSITIVE DEVICE

AD7816/AD7817/AD7818

AD7817 PIN FUNCTION DESCRIPTIONS

Pin Mnemonic Description

1 CONVST Logic Input Signal. The convert start signal. A 10-bit analog-to-digital conversion is initiated on the

falling edge of this signal. The falling edge of this signal places the track/hold in hold mode. The track/

hold goes into track mode again at the end of the conversion. The state of the CONVST signal is checked

at the end of a conversion. If it is logic low, the AD7817 will power-down—see Operating Mode section

of the data sheet.

2 BUSY Logic Output. The busy signal is logic high during a temperature or voltage A/D conversion. The signal

can be used to interrupt a microcontroller when a conversion has finished.

3 OTI Logic Output. The Overtemperature Indicator (OTI) is set logic low if the result of a conversion on

Channel 0 (Temperature Sensor) is greater that an 8-bit word in the Overtemperature Register (OTR).

The signal is reset at the end of a serial read operation, i.e., a rising RD/WR edge when CS is low.

4 CS Logic Input Signal. The chip select signal is used to enable the serial port of the AD7817. This is neces-

sary if the AD7817 is sharing the serial bus with more than one device.

5 AGND Analog Ground. Ground reference for track/hold, comparator and capacitor DAC.

6 REF

7–10 V

11 V

IN1

DD

IN

to V

IN4

12 DGND Digital Ground. Ground reference for digital circuitry.

13 D

14 D

OUT

IN

15 SCLK Clock Input for the Serial Port. The serial clock is used to clock data into and out of the AD7817. Data is

16 RD/WR Logic Input Signal. The read/write signal is used to indicate to the AD7817 whether the data transfer

Analog Input. An external 2.5 V reference can be connected to the AD7817 at this pin. To enable the on-

chip reference the REF

pin should be tied to AGND. If an external reference is connected to the

IN

AD7817, the internal reference will shut down.

Analog Input Channels. The AD7817 has four analog input channels. The input channels are single-

ended with respect to AGND (analog ground). The input channels can convert voltage signals in the

range 0 V to V

. A channel is selected by writing to the Address Register of the AD7817—see Control

REF

Byte section.

Positive Supply Voltage, 2.7 V to 5.5 V.

Logic Output With a High Impedance State. Data is clocked out of the AD7817 serial port at this pin.

This output goes into a high impedance state on the falling edge of RD/WR or on the rising edge of the

CS signal, whichever occurs first.

Logic Input. Data is clocked into the AD7817 at this pin.

clocked out on the falling edge and clocked in on the rising edge.

operation is a read or a write. The RD/WR should be set logic high for a read operation and logic low for

a write operation.

PIN CONFIGURATION

SOIC/TSSOP

CONVST

BUSY

O T I

CS

AGND

REF

V

IN1

V

IN2

1

2

3

4

5

6

IN

7

8

AD7817

TOP VIEW

(Not to Scale)

16

15

14

13

12

11

10

9

RD/WR

SCLK

D

D

DGND

V

V

V

IN

OUT

DD

IN4

IN3

REV. C–8–

AD7816/AD7817/AD7818

AD7816 AND AD7818 PIN FUNCTION DESCRIPTIONS

Pin Mnemonic Description

1 CONVST Logic Input Signal. The convert start signal initiates a 10-bit analog-to-digital conversion on the

falling edge of the this signal. The falling edge of this signal places the track/hold in hold mode.

The track/hold goes into track mode again at the end of the conversion. The state of the

CONVST signal is checked at the end of a conversion. If it is logic low, the AD7816 and

AD7818 will power down—see Operating Mode section of the data sheet.

2 OTI Logic Output. The Overtemperature Indicator (OTI) is set logic low if the result of a conversion

on Channel 0 (Temperature Sensor) is greater that an 8-bit word in the Overtemperature Register

(OTR). The signal is reset at the end of a serial read operation, i.e., a rising RD/WR edge.

3 GND Analog and Digital Ground.

4 (AD7818) V

4 (AD7816) REF

5V

6D

IN

IN

DD

IN/OUT

7 SCLK Clock Input for the Serial Port. The serial clock is used to clock data into and out of the

8 RD/WR Logic Input. The read/write signal is used to indicate to the AD7816 and AD7818 whether

Analog Input Channel. The input channel is single-ended with respect to GND. The input

channel can convert voltage signals in the range 0 V to 2.5 V. The input channel is selected by

writing to the Address Register of the AD7818—see Control Byte section.

Reference Input. An external 2.5 V reference can be connected to the AD7816 at this pin. To

enable the on-chip reference the REF

pin should be tied to AGND. If an external reference is

IN

connected to the AD7816, the internal reference will shut down.

Positive supply voltage, 2.7 V to 5.5 V.

Logic Input and Output. Serial data is clocked in and out of the AD7816/AD7818 at this pin.

AD7816/AD7818. Data is clocked out on the falling edge and clocked in on the rising edge.

the next data transfer operation is a read or a write. The RD/WR should be set logic high for a

read operation and logic low for a write.

PIN CONFIGURATIONS

SOIC/MSOP (AD7816)

CONVST

OTI

GND

REF

1

2

3

4

IN

AD7816

TOP VIEW

(Not to Scale)

8

7

6

5

RD/WR

SCLK

D

IN/OUT

V

DD

SOIC/MSOP (AD7818)

CONVST

OTI

GND

V

IN

1

AD7818

2

TOP VIEW

(Not to Scale)

3

4

8

7

6

5

RD/WR

SCLK

D

IN/OUT

V

DD

TERMINOLOGY

Signal-to-(Noise + Distortion) Ratio

This is the measured ratio of signal-to-(noise + distortion) at the

output of the A/D converter. The signal is the rms amplitude of

the fundamental. Noise is the rms sum of all nonfundamental

signals up to half the sampling frequency (f

/2), excluding dc.

S

The ratio is dependent upon the number of quantization levels in

the digitization process; the more levels, the smaller the quantization noise. The theoretical signal-to-(noise + distortion) ratio for

an ideal N-bit converter with a sine wave input is given by:

Signal-to-(Noise + Distortion) = (6.02 N + 1.76) dB

Thus for a 10-bit converter, this is 62 dB.

Total Harmonic Distortion

Total harmonic distortion (THD) is the ratio of the rms sum of

harmonics to the fundamental. For the AD7891 it is defined as:

2

2

2

2

2

+V

5

6

THD (dB) = 20 log

V

+V

+V

2

+V

3

4

V

1

where V1 is the rms amplitude of the fundamental and V2, V3,

V

, V5, and V6 are the rms amplitudes of the second through the

4

sixth harmonics.

Peak Harmonic or Spurious Noise

Peak harmonic or spurious noise is defined as the ratio of the

rms value of the next largest component in the ADC output

spectrum (up to f

/2 and excluding dc) to the rms value of the

S

fundamental. Normally, the value of this specification is determined by the largest harmonic in the spectrum, but for parts

where the harmonics are buried in the noise floor, it will be a

noise peak.

Intermodulation Distortion

With inputs consisting of sine waves at two frequencies, fa and

fb, any active device with nonlinearities will create distortion

products at sum and difference frequencies of mfa ⫾ nfb where

m, n = 0, 1, 2, 3, etc. Intermodulation terms are those for which

neither m nor n are equal to zero. For example, the second

order terms include (fa + fb) and (fa – fb), while the third order

terms include (2fa + fb), (2fa – fb), (fa + 2fb) and (fa – 2fb).

REV. C

–9–

AD7816/AD7817/AD7818

DB0DB1DB2DB3

DB4

DB5DB6DB7

MSB

LSB

CONTROL BYTE

DB0

DB1

DB2 ADDRESS REGISTER

OVERTEMPERATURE

REGISTER (OTR)

IF ANY BIT DB7 TO DB3 IS SET TO

A LOGIC 1 THEN THE FULL 8 BITS

OF THE CONTROL WORD ARE WRITTEN

TO THE OVERTEMPERATURE REGISTER

IF DB7 TO DB3 ARE LOGIC 0

THEN DB2 TO DB0 ARE WRITTEN

TO THE ADDRESS REGISTER

DB0DB1DB2DB3

DB4

DB5DB6DB7

The AD7816, AD7817, and AD7818 are tested using the CCIF

standard where two input frequencies near the top end of the

input bandwidth are used. In this case, the second and third

order terms are of different significance. The second order terms

are usually distanced in frequency from the original sine waves

while the third order terms are usually at a frequency close to

the input frequencies. As a result, the second and third order

terms are specified separately. The calculation of the intermodulation distortion is as per the THD specification where it is the

ratio of the rms sum of the individual distortion products to the

rms amplitude of the fundamental expressed in dBs.

Channel-to-Channel Isolation

Channel-to-channel isolation is a measure of the level of

crosstalk between channels. It is measured by applying a fullscale 20 kHz sine wave signal to one input channel and determining how much that signal is attenuated in each of the other

channels. The figure given is the worst case across all four

channels.

Relative Accuracy

Relative accuracy or endpoint nonlinearity is the maximum

deviation from a straight line passing through the endpoints of

the ADC transfer function.

Differential Nonlinearity

This is the difference between the measured and the ideal

1LSB change between any two adjacent codes in the ADC.

Offset Error

This is the deviation of the first code transition (0000 . . . 000)

to (0000 . . . 001) from the ideal, i.e., AGND + 1 LSB.

Offset Error Match

This is the difference in Offset Error between any two channels.

Gain Error

This is the deviation of the last code transition (1111 ...110) to

(1111 ...111) from the ideal, i.e., VREF – 1 LSB, after the

offset error has been adjusted out.

Gain Error Match

This is the difference in Gain Error between any two channels.

Track/Hold Acquisition Time

Track/hold acquisition time is the time required for the output

of the track/hold amplifier to reach its final value, within

⫾1/2 LSB, after the end of conversion (the point at which the

track/hold returns to track mode). It also applies to situations

where a change in the selected input channel takes place or

where there is a step input change on the input voltage applied

to the selected V

input of the AD7817 or AD7818. It means

IN

that the user must wait for the duration of the track/hold acquisition time after the end of conversion or after a channel change/

step input change to V

before starting another conversion, to

IN

ensure that the part operates to specification.

Address Register

If the five MSBs of the control byte are logic zero, the three

LSBs of the control byte are transferred to the Address Register—see Figure 4. The Address Register is a 3-bit-wide register

used to select the analog input channel on which to carry out a

conversion. It is also used to select the temperature sensor,

which has the address 000. Table I shows the selection. The

Internal Reference selection connects the input of the ADC to a

band gap reference. When this selection is made and a conversion is initiated, the ADC output should be approximately midscale. After power-up the default channel selection is DB2 = DB1

= DB0 = 0 (Temperature Sensor).

Table I. Channel Selection

DB2 DB1 DB0 Channel Selection Device

000Temperature Sensor All

001Channel 1 AD7817/AD7818

010Channel 2 AD7817

011Channel 3 AD7817

100Channel 4 AD7817

111Internal Ref (1.23 V) All

Overtemperature Register

If any of the five MSBs of the control byte are logic one, then

the entire eight bits of the control byte are transferred to the

Overtemperature Register—see Figure 4. At the end of a temperature conversion a digital comparison is carried out between

the 8 MSBs of the temperature conversion result (10 bits) and

the contents of the Overtemperature Register (8 bits). If the result

of the temperature conversion is greater that the contents of the

Overtemperature Register (OTR), then the Overtemperature

Indicator (OTI) goes logic low. The resolution of the OTR is

1°C. The lowest temperature that can be written to the OTR is –

95°C and the highest is +152°C—see Figure 5. However, the

usable temperature range of the temperature sensor is –55°C to

+125°C. Figure 5 shows the OTR and how to set T

ALARM

(the

temperature at which the OTI goes low).

OTR (Dec) = T

For example, to set T

ALARM

(°C) + 103°C

ALARM

to 50°C, OTR = 50 + 103 = 153

Dec or 10011001 Bin. If the result of a temperature conversion

exceeds 50°C then OTI will go logic low. The OTI logic output

is reset high at the end of a serial read operation or if a new

temperature measurement is lower than T

power on T

ALARM

is 50°C.

ALARM

. The default

CONTROL BYTE

The AD7816, AD7817, and AD7818 contain two on-chip registers, the Address Register and the Overtemperature Register.

These registers can be accessed by carrying out an 8-bit serial

write operation to the devices. The 8-bit word or control byte

written to the AD7816, AD7817, and AD7818 is transferred to

one of the two on-chip registers as follows.

Figure 4. Address and Overtemperature Register Selection

REV. C–10–

AD7816/AD7817/AD7818

V

DD

AIN1

CONVST

AGND

DGND

REF

IN

SUPPLY

2.7V TO

5.5V

0.1F10F

10F

EXTERNAL

REFERENCE

OPTIONAL

EXTERNAL

REFERENCE

AD780/

REF-192

0V TO 2.5V

INPUT

D

OUT

RD/WR

AIN2

AIN3

AIN4

D

IN

BUSY

OTI

C/P

SCLK

3-WIRE

SERIAL

INTERFACE

CS

AD7817

MSB

0000 0001

11111111

OVERTEMPERATURE REGISTER (DEC) = T

T

RESOLUTION = 1ⴗ/ LSB

ALARM

OVERTEMPERATURE REGISTER

DB5DB6DB7

DB4

ALARM

+ 103ⴗC

Figure 5. The Overtemperature Register (OTR)

CIRCUIT INFORMATION

The AD7817 and AD7818 are single- and four-channel, 9 µs

conversion time, 10-bit A/D converters with on-chip temperature sensor, reference, and serial interface logic functions on a

single chip. The AD7816 has no analog input channel and is

intended for temperature measurement only. The A/D converter

section consists of a conventional successive-approximation

converter based around a capacitor DAC. The AD7816,

AD7817, and AD7818 are capable of running on a 2.7 V to

5.5 V power supply and the AD7817 and AD7818 accept an

analog input range of 0 V to +V

. The on-chip temperature

REF

sensor allows an accurate measurement of the ambient device

temperature to be made. The working measurement range of

the temperature sensor is –55°C to +125°C. The part requires a

2.5 V reference, which can be provided from the part’s own

internal reference or from an external reference source. The

on-chip reference is selected by connecting the REF

pin to

IN

analog ground.

LSB

DB2DB3

DB1

DB0

MINIMUM TEMPERATURE = –95 C

MAXIMUM TEMPERATURE = +152 C

TYPICAL CONNECTION DIAGRAM

Figure 6 shows a typical connection diagram for the AD7817.

The AGND and DGND are connected together at the device

for good noise suppression. The BUSY line is used to interrupt

the microcontroller at the end of the conversion process and the

serial interface is implemented using three wires—see Serial

Interface section for more details. An external 2.5 V reference

can be connected at the REF

pin. If an external reference is

IN

used, a 10 µF capacitor should be connected between REF

and AGND. For applications where power consumption is of

concern, the automatic power-down at the end of a conversion

should be used to improve power performance. See Power vs.

Throughput section of this data sheet.

IN

CONVERTER DETAILS

Conversion is initiated by pulsing the CONVST input. The

conversion clock for the part is internally generated so no external clock is required except when reading from and writing to

the serial port. The on-chip track/hold goes from track-to-hold

mode and the conversion sequence is started on the falling edge

of the CONVST signal. At this point the BUSY signal goes high

and low again 9 µs or 27 µs later (depending on whether an

analog input or the temperature sensor is selected) to indicate

the end of the conversion process. This signal can be used by a

microcontroller to determine when the result of the conversion

should be read. The track/hold acquisition time of the AD7817

and AD7818 is 400 ns.

A temperature measurement is made by selecting the Channel 0

of the on-chip MUX and carrying out a conversion on this

channel. A conversion on Channel 0 takes 27 µs to complete.

Temperature measurement is explained in the Temperature

Measurement section of this data sheet.

The on-chip reference is not available to the user, but REF

can be overdriven by an external reference source (2.5 V only).

The effect of reference tolerances on temperature measurements

is discussed in the section titled Temperature Measurement

Error Due to Reference Error.

All unused analog inputs should be tied to a voltage within the

nominal analog input range to avoid noise pickup. For minimum power consumption, the unused analog inputs should be

tied to AGND.

REV. C

Figure 6. Typical Connection Diagram

ANALOG INPUTS

Analog Input

Figure 7 shows an equivalent circuit of the analog input structure of the AD7817 and AD7818. The two diodes D1 and D2

provide ESD protection for the analog inputs. Care must be

taken to ensure that the analog input signal never exceeds the

supply rails by more than 200 mV. This will cause these diodes

to become forward biased and start conducting current into the

IN

substrate. The maximum current these diodes can conduct

without causing irreversible damage to the part is 20 mA. The

capacitor C2 in Figure 7 is typically about 4 pF and can mostly

be attributed to pin capacitance. The resistor R1 is a lumped

component made up of the on resistance of a multiplexer and a

switch. This resistor is typically about 1 kΩ. The capacitor C1 is

the ADC sampling capacitor and has a capacitance of 3 pF.

–11–

AD7816/AD7817/AD7818

V

DD

D1

A

IN

4pF

C2

D2

R1

1k⍀

CONVERT PHASE - SWITCH OPEN

TRACK PHASE - SWITCH CLOSED

C1

3pF

V

BALANCE

Figure 7. Equivalent Analog Input Circuit

DC Acquisition Time

The ADC starts a new acquisition phase at the end of a conversion and ends on the falling edge of the CONVST signal. At the

end of a conversion a settling time is associated with the sampling circuit. This settling time lasts approximately 100 ns. The

analog signal on V

is also being acquired during this settling

IN +

time. Therefore, the minimum acquisition time needed is

approximately 100 ns.

Figure 8 shows the equivalent charging circuit for the sampling

capacitor when the ADC is in its acquisition phase. R2 represents the source impedance of a buffer amplifier or resistive

network, R1 is an internal multiplexer resistance and C1 is the

sampling capacitor.

V

R2

IN

R1

1k⍀

C1

3pF

2.5V

EXTERNAL

REFERENCE

DETECT

BUFFER

1.2V

SW1

REF

IN

1.2V

26k⍀

24k⍀

Figure 9. On-Chip Reference

ADC TRANSFER FUNCTION

The output coding of the AD7816, AD7817, and AD7818 is

straight binary. The designed code transitions occur at successive integer LSB values (i.e., 1 LSB, 2 LSBs, etc.). The LSB

size is = 2.5 V/1024 = 2.44 mV. The ideal transfer characteristic

is shown in Figure 10 below.

111...111

111...110

111...000

011...111

ADC CODE

1LSB=2.5/1024

2.44mV

Figure 8. Equivalent Sampling Circuit

During the acquisition phase the sampling capacitor must be

charged to within a 1/2 LSB of its final value. The time it takes

to charge the sampling capacitor (T

) is given by the

CHARGE

following formula:

T

= 7.6 × (R2 + 1 kΩ) × 3 pF

CHARGE

For small values of source impedance, the settling time associated with the sampling circuit (100 ns) is, in effect, the acquisition time of the ADC. For example, with a source impedance (R2)

of 10 Ω the charge time for the sampling capacitor is approximately 23 ns. The charge time becomes significant for source

impedances of 1 kΩ and greater.

AC Acquisition Time

In ac applications it is recommended to always buffer analog

input signals. The source impedance of the drive circuitry must

be kept as low as possible to minimize the acquisition time of

the ADC. Large values of source impedance will cause the THD

to degrade at high throughput rates.

ON-CHIP REFERENCE

The AD7816, AD7817, and AD7818 have an on-chip 1.2 V

band gap reference that is gained up to give an output of 2.5 V.

The on-chip reference is selected by connecting the REF

IN

pin

to analog ground. This causes SW1 (see Figure 9) to open and

the reference amplifier to power up during a conversion. Therefore, the on-chip reference is not available externally. An external

2.5 V reference can be connected to the REF

pin. This has the

IN

effect of shutting down the on-chip reference circuitry and reduc-

by about 0.25 mA.

ing I

DD

000...010

000...001

000...000

1LSB

0V

ANALOG INPUT

+2.5V•1LSB

Figure 10. ADC Transfer Function

TEMPERATURE MEASUREMENT

The on-chip temperature sensor can be accessed via multiplexer

Channel 0, i.e., by writing 0 0 0 to the channel address register.

The temperature is also the power on default selection. The

transfer characteristic of the temperature sensor is shown in

Figure 11 below. The result of the 10-bit conversion on Channel 0 can be converted to degrees centigrade by using the following equation.

T

= –103°C + (ADC Code/4)

AMB

125°C

TEMPERATURE

–55°C

192Dec 912Dec

ADC CODE

Figure 11. Temperature Sensor Transfer Characteristic

REV. C–12–

AD7816/AD7817/AD7818

TIME – secs

TEMPERATURE – ⴗC

0.50

–0.05

06010 20 30 40 50

0.45

0.30

0.15

0.10

0.05

0.40

0.35

0.25

0.20

0.00

4-LAYER PCB

2-LAYER PCB

TIME – secs

TEMPERATURE – ⴗC

0.25

–0.05

051234

0.15

0.05

0.20

0.10

0.00

4-LAYER PCB

2-LAYER PCB

For example, if the result of a conversion on Channel 0 was

1000000000 (512 Dec), the ambient temperature is equal to

–103°C + (512/4) = +25°C.

Table II below shows some ADC codes for various temperatures.

Table II. Temperature Sensor Output

ADC Code Temperature

00 1100 0000 –55°C

01 0011 1000 –25°C

01 1001 1100 0°C

10 0000 0000 +25°C

10 0111 1000 +55°C

11 1001 0000 +125°C

TEMPERATURE MEASUREMENT ERROR DUE TO REFERENCE ERROR

The AD7816, AD7817, and AD7818 are trimmed using a precision 2.5 V reference to give the transfer function described

previously. To show the effect of the reference tolerance on a

temperature reading, the temperature sensor transfer function

can be rewritten as a function of the reference voltage and the

temperature.

CODE (Dec) = ([113.3285 × K × T]/[q × V

] – 0.6646) × 1024

REF

where:

K = Boltzmann’s Constant, 1.38 × 10

q = Charge on an electron, 1.6 × 10

–23

–19

T =Temperature (K)

So, for example, to calculate the ADC code at 25°C

CODE = ([113.3285

– 0.6646)

×

×

298 × 1.38 × 10

1024

–23

]/[1.6 × 10

–19

× 2.5]

= 511.5 (200 Hex)

As can be seen from the expression, a reference error will produce a gain error. This means that the temperature measurement error due to reference error will be greater at higher

temperatures. For example, with a reference error of –1%, the

measurement error at –55°C would be 2.2 LSBs (0.5°C) and

16 LSBs (4°C) at 125°C.

and temperature sensor (diode) in the package being evaluated.

In Figure 12, the heater (6 mW) is turned off after 30 sec. The

PCB has little influence on the self-heating over the first few

seconds after the heater is turned on. This can be more clearly

seen in Figure 13 where the heater is switched off after 2 seconds. Figure 14 shows the relative effects of self-heating in air,

fluid and in thermal contact with a large heat sink.

These diagrams represent the worst-case effects of self-heating.

The heater delivered 6 mW to the interior of the package in all

cases. This power level is equivalent to the ADC continuously

converting at 100 kSPS. The effects of the self-heating can be

reduced at lower ADC throughput rates by operating on Mode

2 (see Operating Modes section). When operating in this mode,

the on-chip power dissipation reduces dramatically and, as a

consequence, the self-heating effects.

Figure 12. Self-Heating Effect Two-Layer and

Four-Layer PCB

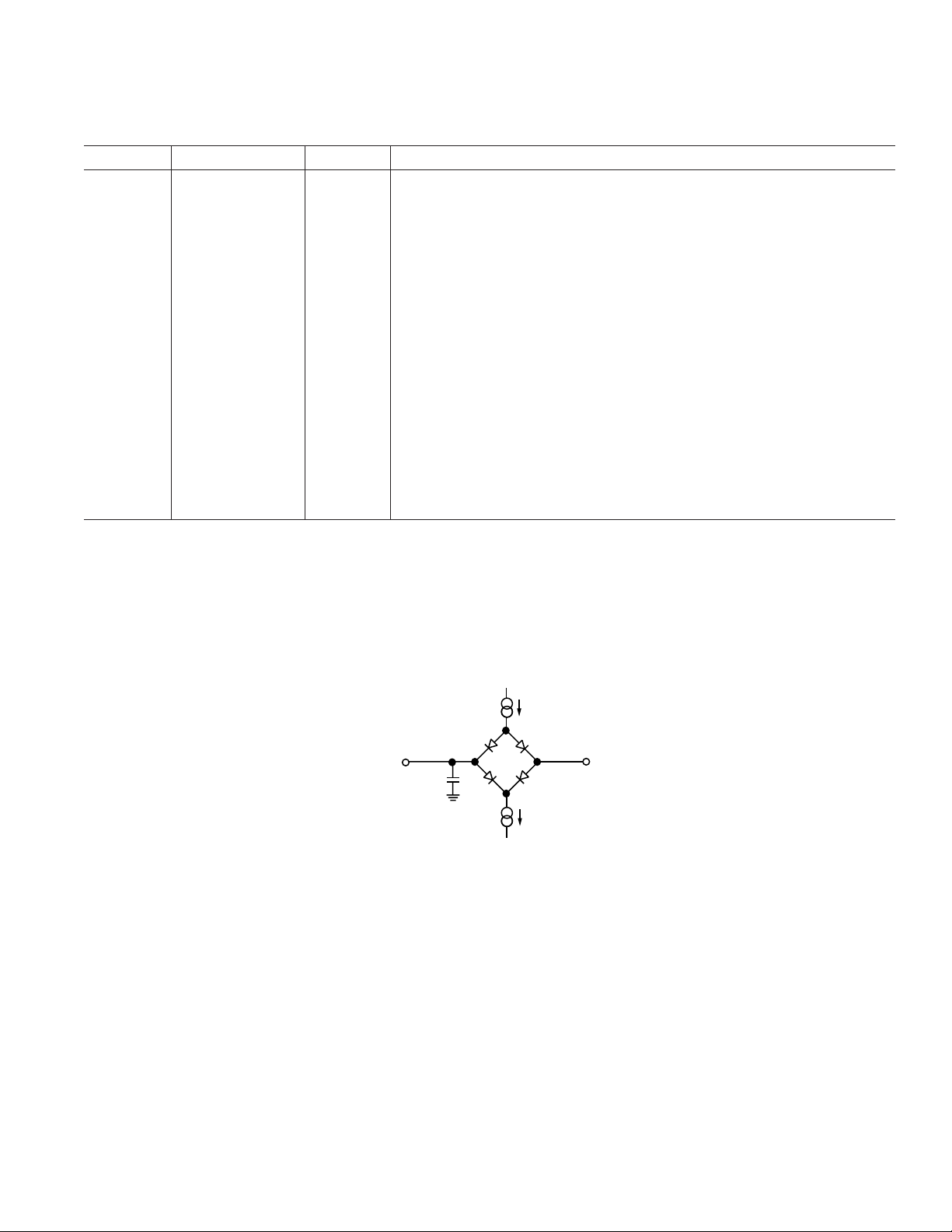

SELF-HEATING CONSIDERATIONS

The AD7817 and AD7818 have an analog-to-digital conversion

function capable of a throughput rate of 100 kSPS. At this

throughput rate the AD7817 and AD7818 will consume between

4 mW and 6.5 mW of power. Because a thermal impedance is

associated with the IC package, the temperature of the die will

rise as a result of this power dissipation. The graphs below show

the self-heating effect in a 16-lead SOIC package. Figures 12

and 13 show the self-heating effect on a two-layer and four-layer

PCB. The plots were generated by assembling a heater (resistor)

REV. C

Figure 13. Self-Heating Effect Two-Layer and

Four-Layer PCB

–13–

AD7816/AD7817/AD7818

0.8

0.7

0.6

0.5

0.4

0.3

0.2

TEMPERATURE – ⴗC

0.1

0.0

–0.01

28

01646 1012

AIR

FLUID

HEAT SINK

14

TIME – secs

Figure 14. Self-Heating Effect in Air, Fluid, and in Thermal

Contact with a Heat Sink

0.25

0.20

0.15

0.10

AIR

FLUID

HEATSINK

OPERATING MODES

The AD7816, AD7817, and AD7818 have two possible modes

of operation depending on the state of the CONVST pulse at

the end of a conversion.

Mode 1

In this mode of operation the CONVST pulse is brought high

before the end of a conversion, i.e., before the BUSY goes low

(see Figure 16). When operating in this mode a new conversion

should not be initiated until 100 ns after the end of a serial read

operation. This quiet time is to allow the track/hold to accurately acquire the input signal after a serial read.

Mode 2

When the AD7816, AD7817, and AD7818 are operated in Mode

2 (see Figure 17), they automatically power down at the end of

a conversion. The CONVST is brought low to initiate a conversion and is left logic low until after the end of the conversion. At

this point, i.e., when BUSY goes low, the devices will powerdown. The devices are powered up again on the rising edge of

the CONVST signal. Superior power performance can be

achieved in this mode of operation by powering up the AD7816,

AD7817, and AD7818 only to carry out a conversion (see Power

vs. Throughput section). In Figure 17 the CS line is applicable

to the AD7817 only.

0.05

TEMPERATURE – ⴗC

0.00

–0.05

0.0 2.00.5 1.5

1.0

TIME – secs

Figure 15. Self-Heating Effect in Air, Fluid, and in Thermal

Contact with a Heat Sink

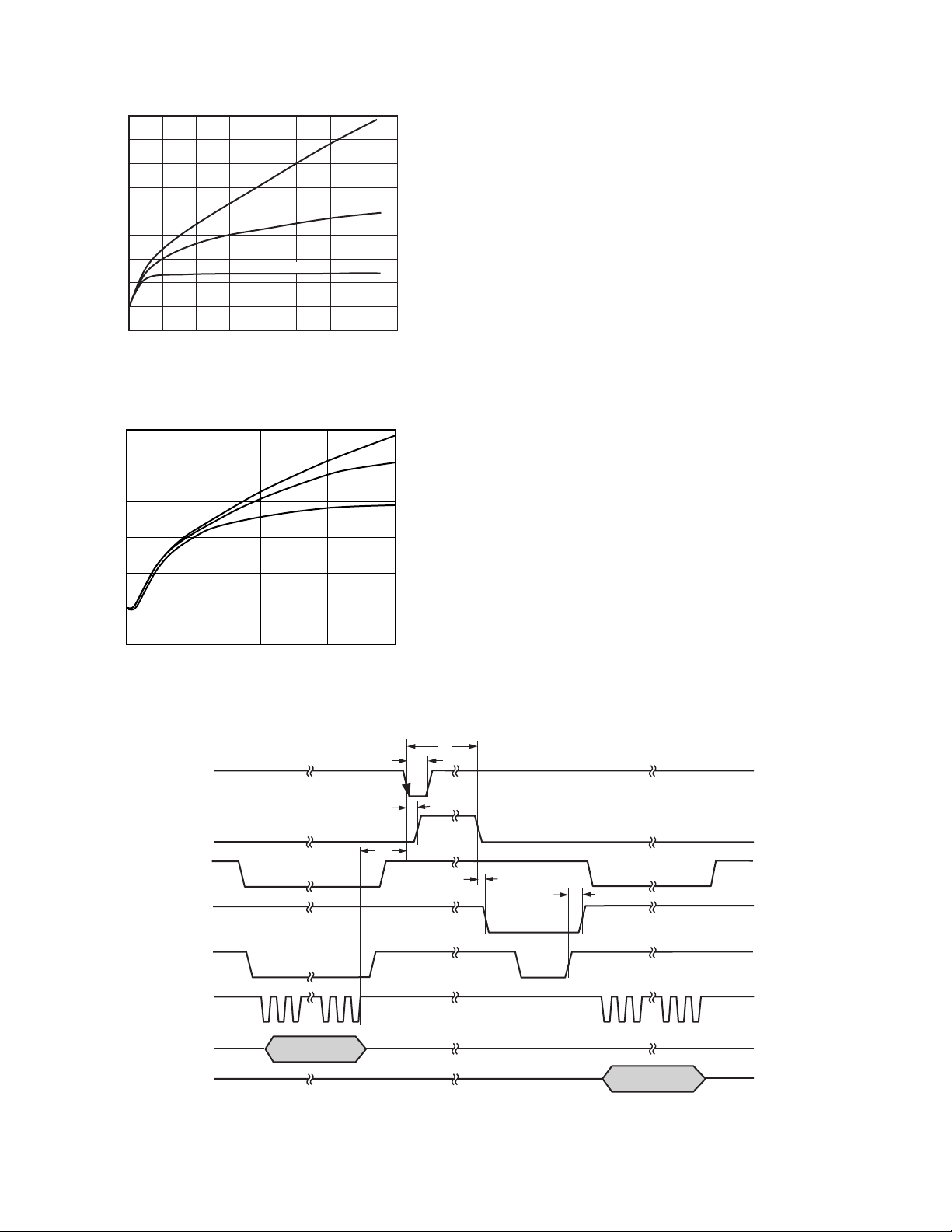

t

t

2

CONVST

t

3

BUSY

t

17

CS

OTI

RD/ WR

SCLK

1

t

15

t

16

D

IN

D

OUT

DB7 – DB0

DB7(DB9) – DB0

Figure 16. Mode 1 Operation

REV. C–14–

THROUGHPUT – kHz

10

1

0.01

08010

POWER – mW

0.1

20 30 40 50 60 70

CONVST

BUSY

t

POWER-UP

AD7816/AD7817/AD7818

t

1

t

3

CS

OTI

RD/ WR

SCLK

D

IN

D

OUT

DB7 – DB0

Figure 17. Mode 2 Operation

POWER VS. THROUGHPUT

Superior power performance can be achieved by using the Automatic Power-Down (Mode 2) at the end of a conversion (see

Operating Modes section of this data sheet).

CONVST

t

POWER-UP

t

CONVERT

2s 8s

t

15

t

16

DB7(DB9) – DB0

BUSY

t

CYCLE

100s @ 10kSPS

Figure 18. Automatic Power-Down

Figure 18 shows how the Automatic Power-Down is implemented to achieve the optimum power performance from the

AD7816, AD7817, and AD7818. The devices are operated in

Mode 2 and the duration of CONVST pulse is set to be equal to

the power-up time (2 µs). As the throughput rate of the device is

reduced the device remains in its power-down state longer, and

the average power consumption over time drops accordingly.

For example, if the AD7817 is operated in a continuous sampling mode with a throughput rate of 10 kSPS, the power consumption is calculated as follows. The power dissipation during

normal operation is 4.8 mW, VDD = 3 V. If the power up time is

2 µs and the conversion time is 9 µs, the AD7817 can be said to

dissipate 4.8 mW typically for 11 µs (worst case) during each

conversion cycle. If the throughput rate is 10 kSPS, the cycle

time is 100 µs and the power dissipated while powered up dur-

ing each cycle is (11/100) × (4.8 mW) = 528 µW typ. Power

dissipated while powered down during each cycle is (89/100) ×

(3 V × 2 µA) = 5.34 µW typ. Overall power dissipated is 528 µW

+ 5.34 µW = 533 µW.

Figure 19. Power vs. Throughput Rate

AD7817 SERIAL INTERFACE

The serial interface on the AD7817 is a 5-wire interface with

read and write capabilities, with data being read from the output

register via the D

register via the D

line and data being written to the control

OUT

line. The part operates in a slave mode and

IN

requires an externally applied serial clock to the SCLK input to

access data from the data register or write to the control byte.

The RD/WR line is used to determine whether data is being

written to or read from the AD7817. When data is being written

to the AD7817, the RD/WR line is set logic low and when data

is being read from the part the line is set logic high (see Figure

20). The serial interface on the AD7817 is designed to allow the

part to be interfaced to systems that provide a serial clock that is

synchronized to the serial data, such as the 80C51, 87C51,

68HC11, 68HC05, and PIC16Cxx microcontrollers.

REV. C

–15–

AD7816/AD7817/AD7818

CS

t

4

RD/WR

t

5

SCLK

D

D

OUT

IN

132

t

6

DB7 DB6

t

7

DB5

CONTROL BYTE

t

10

t

8

87

t

9

DB1

DB0

t

11

123

t

12

DB9 DB8 DB7

t

13

Figure 20. AD7817 Serial Interface Timing Diagram

910

DB1

DB0

t

14b

t

14a

Read Operation

Figure 20 shows the timing diagram for a serial read from the

AD7817. CS is brought low to enable the serial interface and RD/

WR is set logic high to indicate that the data transfer is a serial read

from the AD7817. The rising edge of RD/WR clocks out the first

data bit (DB9), subsequent bits are clocked out on the falling edge

of SCLK (except for the first falling SCLK edge) and are valid on

the rising edge. 10 bits of data are transferred during a read operation. However, the user has the choice of clocking only eight bits if

the full 10 bits of the conversion result are not required. The serial

data can be accessed in a number of bytes if 10 bits of data are

being read. However, RD/WR must remain high for the duration of

the data transfer operation. Before starting a new data read operation the RD/WR signal must be brought low and high again. At the

end of the read operation, the D

line enters a high impedance

OUT

state on the rising edge of the CS or the falling edge of RD/WR,

whichever occurs first. The readback process is a destructive

process in that once the data is read back it is erased. A conversion

must be done again; otherwise no data will be read back.

Write Operation

Figure 20 also shows a control byte write operation to the AD7817.

The RD/WR input goes low to indicate to the part that a serial

write is about to occur. The AD7817 control byte is loaded on

the rising edge of the first eight clock cycles of the serial clock

with data on all subsequent clock cycles being ignored. To carry

out a second successive write operation, the RD/WR signal must

be brought high and low again.

Simplifying the Serial Interface

To minimize the number of interconnect lines to the AD7817,

the user can connect the CS line to DGND. This is possible if

the AD7817 is not sharing the serial bus with another device. It

is also possible to tie the D

and D

IN

lines together. This

OUT

arrangement is compatible with the 8051 microcontroller. The

68HC11, 68HC05, and PIC16Cxx can be configured to operate

with a single serial data line. In this way the number of lines

required to operate the serial interface can be reduced to three,

i.e., RD/WR, SCLK, and D

(see Figure 6).

IN/OUT

AD7816 AND AD7818 SERIAL INTERFACE MODE

The serial interface on the AD7816 and AD7818 is a 3-wire

interface with read and write capabilities. Data is read from the

output register and the control byte is written to the AD7816

and AD7818 via the D

line. The part operates in a slave

IN/OUT

mode and requires an externally applied serial clock to the SCLK

input to access data from the data register or write the control

byte. The RD/WR line is used to determine whether data is

being written to or read from the AD7816 and AD7818. When

data is being written to the devices the RD/WR line is set logic

low and when data is being read from the part the line is set

logic high (see Figure 21). The serial interface on the AD7816

and AD7818 are designed to allow the part to be interfaced to

systems that provide a serial clock that is synchronized to the

serial data, such as the 80C51, 87C51, 68HC11, 68HC05, and

PIC16Cxx microcontrollers.

Read Operation

Figure 21 shows the timing diagram for a serial read from the

AD7816 and AD7818. The RD/WR is set logic high to indicate

that the data transfer is a serial read from the devices. When

RD/WR is logic high the D

pin becomes a logic output

IN/OUT

and the first data bit (DB9) appears on the pin. Subsequent bits

are clocked out on the falling edge of SCLK, starting with the

second SCLK falling edge after RD/WR goes high and are valid

on the rising edge of SCLK. Ten bits of data are transferred

during a read operation. However the user has the choice of

clocking only eight bits if the full 10 bits of the conversion result

are not required. The serial data can be accessed in a number of

bytes if 10 bits of data are being read; however, RD/WR must

remain high for the duration of the data transfer operation. To

carry out a successive read operation the RD/WR pin must be

brought logic low and high again. At the end of the read operation, the D

pin becomes a logic input on the falling edge

IN/OUT

of RD/WR.

Write Operation

A control byte write operation to the AD7816 and AD7818 is

also shown in Figure 21. The RD/WR input goes low to indicate

to the part that a serial write is about to occur. The AD7816

and AD7818 control bytes are loaded on the rising edge of the

first eight clock cycles of the serial clock with data on all subsequent clock cycles being ignored. To carry out a successive write

to the AD7816 or AD7818 the RD/WR pin must be brought

logic high and low again.

REV. C–16–

RD/WR

16

9

81

PIN 1

SEATING

PLANE

8ⴗ

0ⴗ

4.50

4.40

4.30

6.40

BSC

5.10

5.00

4.90

0.65

BSC

0.15

0.05

1.20

MAX

0.20

0.09

0.75

0.60

0.45

0.30

0.19

COPLANARITY

0.10

COMPLIANT TO JEDEC STANDARDS MO-153AB

SCLK

DIN/D

OUT

t

5

132

t

6

DB7 DB6

AD7816/AD7817/AD7818

t

8

87

t

t

7

DB5

CONTROL BYTE

9

DB0DB1

Figure 21. AD7816/AD7818 Serial Interface Timing Diagram

OUTLINE DIMENSIONS

t

11

123

t

12

DB9 DB8 DB7

t

13

910

DB0DB1

t

14a

8-Lead Standard Small Outline Package [SOIC]

Narrow Body

(R-8)

Dimensions shown in millimeters and (inches)

5.00 (0.1968)

4.80 (0.1890)

4.00 (0.1574)

3.80 (0.1497)

0.25 (0.0098)

0.10 (0.0040)

COPLANARITY

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

85

1.27 (0.0500)

SEATING

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012AA

BSC

6.20 (0.2440)

5.80 (0.2284)

41

1.75 (0.0688)

1.35 (0.0532)

0.51 (0.0201)

0.31 (0.0122)

0.25 (0.0098)

0.17 (0.0067)

0.50 (0.0196)

0.25 (0.0099)

8ⴗ

0ⴗ

1.27 (0.0500)

0.40 (0.0157)

16-Lead Standard Small Outline Package [SOIC]

Narrow Body

(R-16)

Dimensions shown in millimeters and (inches)

ⴛ 45ⴗ

8-Lead Mini Small Outline Package [MSOP]

(RM-8)

Dimensions shown in millimeters

3.00

BSC

85

3.00

BSC

1

PIN 1

0.65 BSC

0.15

0.00

0.38

0.22

COPLANARITY

0.10

COMPLIANT TO JEDEC STANDARDS MO-187AA

4

SEATING

PLANE

4.90

BSC

1.10 MAX

0.23

0.08

8ⴗ

0ⴗ

0.80

0.60

0.40

16-Lead Thin Shrink Small Outline Package [TSSOP]

(RU-16)

Dimensions shown in millimeters

10.00 (0.3937)

9.80 (0.3858)

4.00 (0.1575)

3.80 (0.1496)

0.25 (0.0098)

0.10 (0.0039)

COPLANARITY

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

REV. C

16

1

1.27 (0.0500)

BSC

0.10

COMPLIANT TO JEDEC STANDARDS MS-012AC

1.75 (0.0689)

1.35 (0.0531)

0.51 (0.0201)

0.31 (0.0122)

9

6.20 (0.2441)

5.80 (0.2283)

8

SEATING

PLANE

0.25 (0.0098)

0.17 (0.0067)

0.50 (0.0197)

0.25 (0.0098)

8ⴗ

0ⴗ

1.27 (0.0500)

0.40 (0.0157)

ⴛ 45ⴗ

–17–

AD7816/AD7817/AD7818

Revision History

Location Page

9/04—Data Sheet changed from REV. B to REV. C.

Updated ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Changes to Operating Modes section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Changes to Figure 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Changes to Figure 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Changes to AD7817 Serial Interface, Read Operation section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Changes to Figure 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Changes to Figure 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

REV. C–18–

–19–

C01316–0–9/04(C)

–20–

Loading...

Loading...