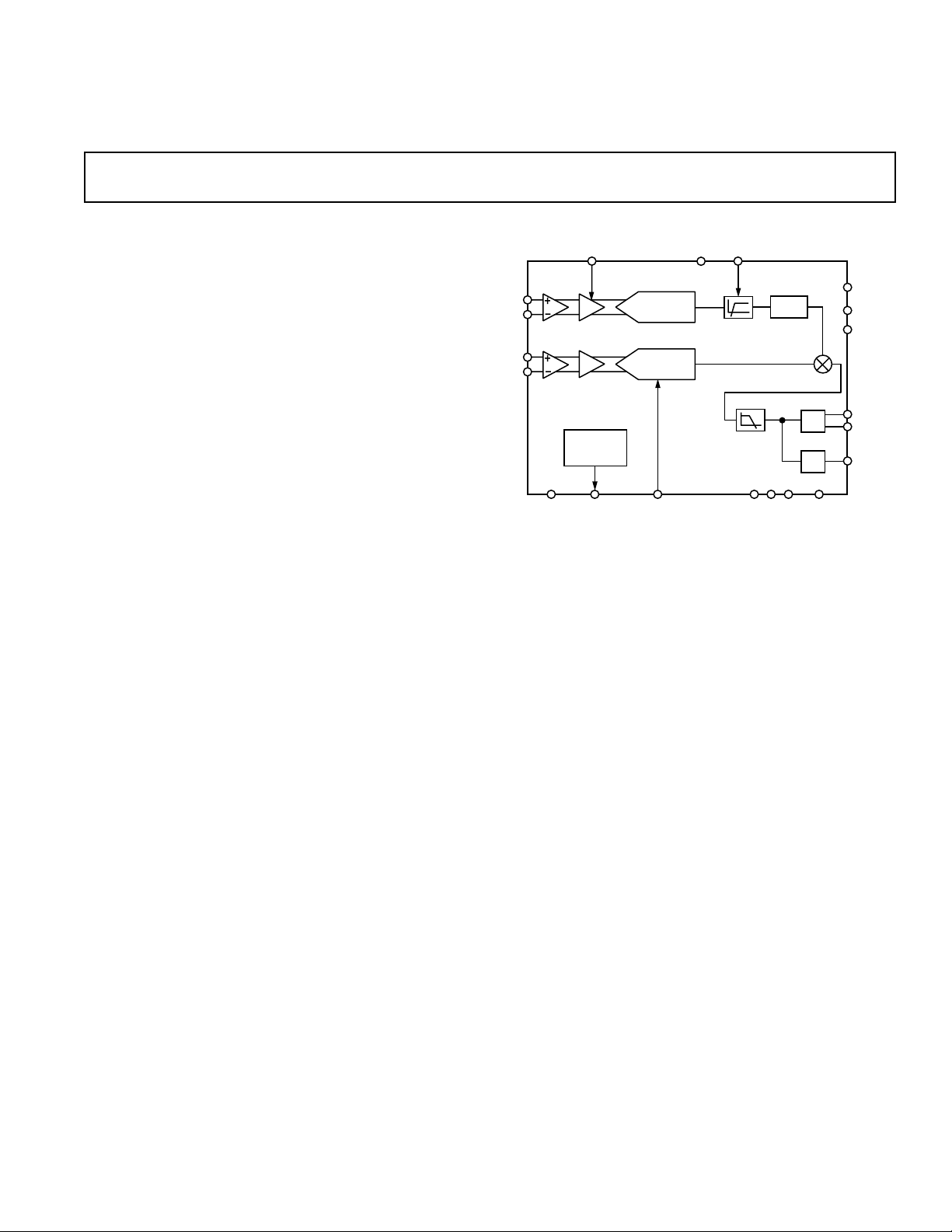

Product-to-Frequency

DELAY

2.5V

BAND GAP

REFERENCE

DTF

HPF

MULT

S1FS

VDD

DGND

DTF

LPF

2ND ORDER

MODULATOR

AGND REFOUT

G1

ADC1

ADC2

REFIN

V

1+

AD7750

2ND ORDER

MODULATOR

x2

x16

V

2+

S2

V

1–

V

2–

F2

CLKOUT

F1

F

OUT

REVP

CLKIN

ACDC

a

FEATURES

Two Differential Analog Input Channels

Product of Two Channels

Voltage-to-Frequency Conversion on a Single Channel

Real Power Measurement Capability

< 0.2% Error Over the Range 400% Ibasic to 2% Ibasic

Two or Four Quadrant Operation (Positive and

Negative Power)

Gain Select of 1 or 16 on the Current Channel (Channel 1)

Choice of On-Chip or External Reference

Choice of Output Pulse Frequencies Available

(Pins F1 and F2)

High Frequency Pulse Output for Calibration Purposes

(F

)

OUT

HPF on Current Channel for Offset Removal

Single 5 V Supply and Low Power

Converter

AD7750

FUNCTIONAL BLOCK DIAGRAM

GENERAL DESCRIPTION

The AD7750 is a Product-to-Frequency Converter (PFC)

that can be configured for power measurement or voltage-tofrequency conversion. The part contains the equivalent of two

channels of A/D conversion, a multiplier, a digital-to-frequency

converter, a reference and other conditioning circuitry. Channel 1

has a differential gain amplifier with selectable gains of 1 or 16.

Channel 2 has a differential gain amplifier with a gain of 2. A highpass filter can be switched into the signal path of Channel 1 to

remove any offsets.

The outputs F1 and F2 are fixed width (275 ms) logic low going

pulse streams for output frequencies less than 1.8 Hz. A range

of output frequencies is available and the frequency of F1 and

F2 is proportional to the product of V

and V2. These outputs

1

PRODUCT HIGHLIGHTS

1. The part can be configured for power measurement or

voltage-to-frequency conversion.

2. The output format and maximum frequency is selectable;

from low-frequency outputs, suitable for driving stepper

motors, to higher frequency outputs, suitable for calibration

and test.

3. There is a reverse polarity indicator output that becomes

active when negative power is detected in the Magnitude

Only Mode.

4. Error as a % of reading over a dynamic range of 1000:1 is

< 0.3%.

are suitable for directly driving an electromechanical pulse

counter or full stepping two phase stepper motors. The outputs

can be configured to represent the result of four-quadrant multiplication (i.e., Sign and Magnitude) or to represent the result of

a two quadrant multiplication (i.e., Magnitude Only). In this

configuration the outputs are always positive regardless of the

input polarities. In addition, there is a reverse polarity indicator

output that becomes active when negative power is detected in

the Magnitude Only Mode, see Reverse Polarity Indicator.

The error as a percent (%) of reading is less than 0.3% over a

dynamic range of 1000:1.

The AD7750 is fabricated on 0.6 µ CMOS technology; a pro-

cess that combines low power and low cost.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1997

(VDD = 5 V 6 5%, AGND = 0 V, DGND = 0 V, REFIN = +2.5 V, CLKIN = 3.58 MHz

T

to T

AD7750–SPECIFICA TIONS

MIN

A Version

–408C to

Parameter +858C Units Test Conditions/Comments

ACCURACY

Measurement Error

1

Gain = 1 0.2 % Reading max Measured Over a Dynamic Range on Channel 1 of 500:1

0.3 % Reading max Measured Over a Dynamic Range on Channel 1 of 1000:1

Gain = 16 0.2 % Reading max Measured Over a Dynamic Range on Channel 1 of 500:1

0.4 % Reading max Measured Over a Dynamic Range on Channel 1 of 1000:1

Phase Error Between Channels CLKIN = 3.58 MHz, Line Frequency = 50 Hz

Phase Lead 40° (PF = +0.8) ±0.2 Degrees (°) max HPF Filter On, ACDC = 1

Phase Lag 60° (PF = –0.5) ±0.2 Degrees (°) max HPF Filter On, ACDC = 1

Feedthrough Between Channels HPF Filter On, ACDC = 1, Mode 3, Channel 1 = 0 V

Output Frequency Variation (F

) 0.0005 % Full-Scale max Channel 2 = 500 mV rms at 50 Hz

OUT

Power Supply Rejection HPF Filter On, ACDC = 1, Mode 3, Channel 1 = 0 V

Output Frequency Variation (F

) 0.03 % Full-Scale max Channel 2 = 500 mV rms, Power Supply Ripple

OUT

ANALOG INPUTS

Maximum Signal Levels ±1 V max On Any Input, V1+, V1–, V2+ and V2–. See Analog Inputs.

Input Impedance (DC) 400 kΩ min CLKIN = 3.58 MHz

Bandwidth 3.5 kHz typ CLKIN = 3.58 MHz, CLKIN/1024

Offset Error ±10 mV typ

Gain Error ±4 % Full-Scale typ

Gain Error Match ±0.3 % Full-Scale typ

REFERENCE INPUT

REF

Input Voltage Range 2.7 V max 2.5 V + 8%

IN

2.3 V min 2.5 V – 8%

Input Impedance 50 kΩ min

ON-CHIP REFERENCE Nominal 2.5 V

Reference Error ±200 mV max

Temperature Coefficient 55 ppm/°C typ

CLKIN

Input Clock Frequency 4.5 MHz max

2 MHz min

LOGIC INPUTS

FS, S1, S2, ACDC and G1

Input High Voltage, V

Input Low Voltage, V

Input Current, I

Input Capacitance, C

INL

IN

IN

INH

2.4 V min VDD = 5 V ± 5%

0.8 V max VDD = 5 V ± 5%

±10 µA max Typically 10 nA, VIN = 0 V to V

10 pF max

CLKIN

Input High Voltage, V

Input Low Voltage, V

LOGIC OUTPUTS

INH

INL

2

4 V min

0.4 V max

F1 and F2

Output High Voltage, V

OH

4.3 V min V

Output Low Voltage, V

OL

0.5 V max V

F

and REVP

OUT

Output High Voltage, V

OH

4 V min V

Output Low Voltage, V

OL

0.4 V max V

High Impedance Leakage Current ±10 µA max

High Impedance Capacitance 15 pF max

= –408C to +858C, ACDC = Logic High)

MAX

Channel 2 with Full-Scale Signal

250 mV at 50 Hz. See Figures 1 and 3.

I

= 8 mA

SOURCE

= 5 V

DD

I

= 8 mA

SINK

= 5 V

DD

I

= 1 mA

SOURCE

= 5 V ± 5%

DD

I

= 200 µA

SINK

= 5 V ± 5%

DD

DD

–2– REV. 0

AD7750

WARNING!

ESD SENSITIVE DEVICE

A Version

–408C to

Parameter +858C Units Test Conditions/Comments

POWER SUPPLY For Specified Performance, Digital Input @ AGND

or V

V

DD

4.75 V min 5 V – 5%

5.25 V max 5 V + 5%

I

DD

NOTES

1

See plots in Typical Performance Graphs.

2

External current amplification/drive should be used if higher current source and sink capabilities are required, e.g., bipolar transistor.

All specifications subject to change without notice.

5.5 mA max Typically 3.5 mA

DD

(VDD = 5 V, AGND = 0 V, DVDD = 0 V, REFIN = REFOUT. All specifications T

TIMING CHARACTERISTICS

1, 2

unless otherwise noted.)

Parameter A Version Units Test Conditions/Comments

3

t

1

t

2

t

3

3

t

4

t

5

t

6

NOTES

1

Sample tested during initial release and after any redesign or process change that may affect this parameter.

2

See Figure 18.

3

The pulsewidths of F1, F2 and F

Specifications subject to change without notice.

ABSOLUTE MAXIMUM RATINGS*

(TA = +25°C unless otherwise noted)

VDD to AGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

to DGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

V

DD

Analog Input Voltage to AGND

, V1–, V2+ and V2– . . . . . . . . . . . . . . . . . . . . –6 V to +6 V

V

1+

Reference Input Voltage to AGND . . . . –0.3 V to V

Digital Input Voltage to DGND . . . . . . –0.3 V to V

Digital Output Voltage to DGND . . . . . –0.3 V to V

Operating Temperature Range

Commercial (A Version) . . . . . . . . . . . . . . .–40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . +150°C

275 ms F1 and F2 Pulsewidth (Logic Low)

See Table I s Output Pulse Period. See Table I to Determine the Output Frequency

t2/2 s Time Between F1 Falling Edge and F2 Falling Edge

90 ms F

See Table I s F

Pulsewidth (Logic High)

OUT

Pulse Period. See Table I to Determine the Output Frequency

OUT

CLKIN/4 s Minimum Time Between F1 and F2 Pulse

are not fixed for higher output frequencies. See the Digital-to-Frequency Converter (DTF) section for an explanation.

OUT

20-Lead SOIC Package, Power Dissipation . . . . . . . . 450 mW

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 74°C/W

θ

JA

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . +215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . +220°C

20-Lead Plastic DIP, Power Dissipation . . . . . . . . . . 450 mW

Thermal Impedance . . . . . . . . . . . . . . . . . . . . 102°C/W

θ

+ 0.3 V

DD

+ 0.3 V

DD

+ 0.3 V

DD

JA

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . +215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . +220°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

MIN

to T

MAX

ORDERING GUIDE

Temperature Package Package

Model Range Description Options

AD7750AN –40°C to +85°C 20-Lead Plastic DIP N-20

AD7750AR –40°C to +85°C 20-Lead Wide Body SOIC R-20

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD7750 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–3–REV. 0

AD7750

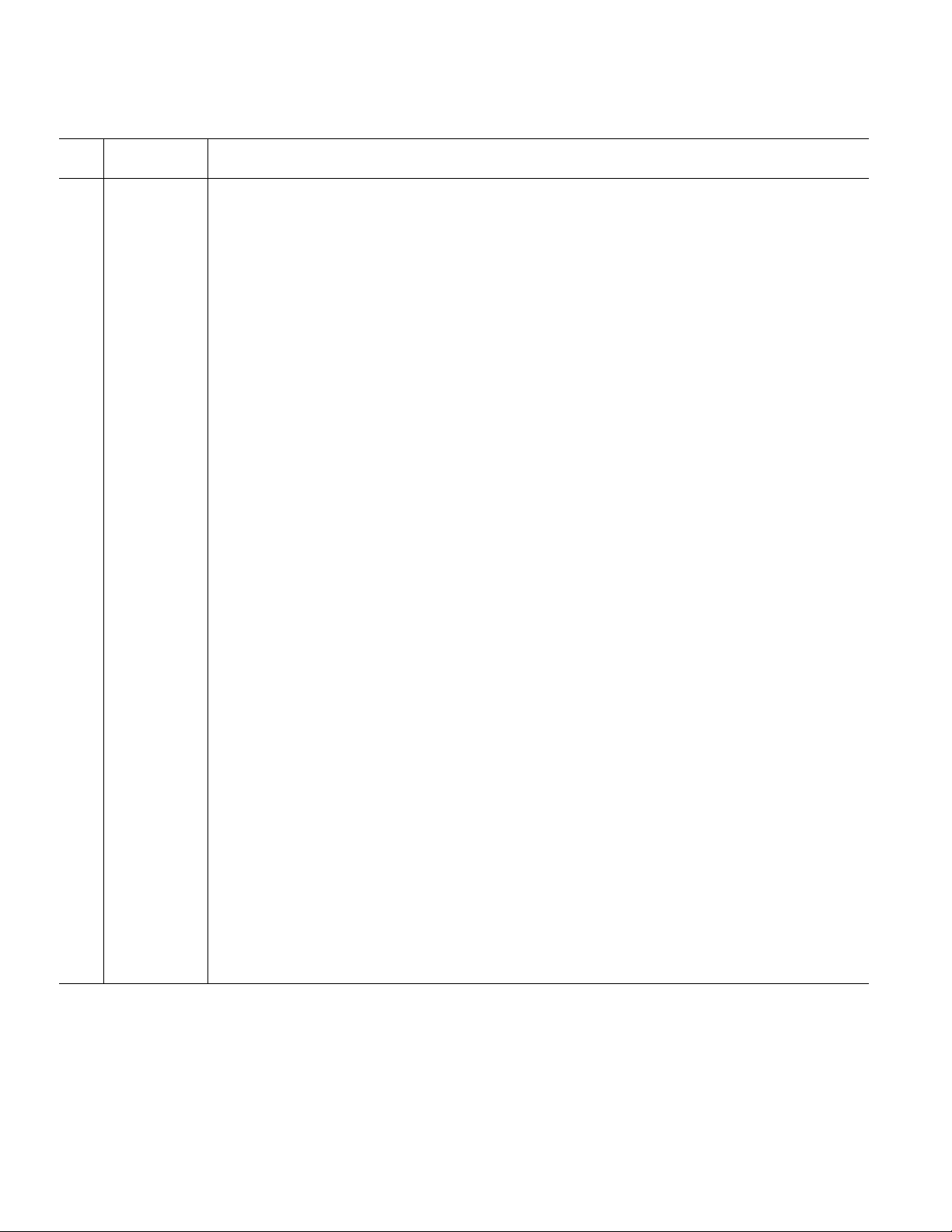

PIN FUNCTION DESCRIPTIONS

Pin

No. Mnemonic Descriptions

1V

DD

2 G1 Gain Select, Digital Input. This input selects the gain for the Channel 1 differential input. When G1 is

3, 4 V

1(+)

, V

1(–)

5 AGND The Analog Ground reference level for Channels 1 and 2 differential input voltages. Absolute voltage

6, 7 V

2(+)

, V

2(–)

8 REFOUT Internal Reference Output. The AD7750 can use either its own internal 2.5 V reference or an external

9 REFIN Reference Input. The AD7750 can use either its own internal 2.5 V reference or an external reference.

10 DGND The Ground and Substrate Supply Pin, 0 V. This is the reference ground for the digital inputs and out-

11 FS Frequency Select, Digital Input. This input, along with S1 and S2, selects the operating mode of the

13, 12 S1, S2 Mode Selection, Digital Inputs. These pins, along with FS, select the operating mode of the AD7750—

14 ACDC High-Pass Filter Control Digital Input. When this pin is high, the high-pass filter is switched into the

15 CLKIN An external clock can be provided at this pin. Alternatively, a crystal can be connected across CLKIN

16 CLKOUT When using a crystal, it must be connected across CLKIN and CLKOUT. The CLKOUT can drive

17 REVP Reverse Polarity, Digital Output. This output becomes active high when the polarity of the signal on

18 F

OUT

20, 19 F1, F2 Frequency Outputs. F1 and F2

Power Supply Pin, 5 V nominal ± 5% for specifications.

low, the gain is 1 and when G1 is high, the gain is 16. See Analog Inputs section.

Channel 1 Differential Inputs. See the Analog Inputs section for an explanation of the maximum input

signal ranges. Channel 1 has selectable gains of 1 and 16. The absolute maximum rating is ±6 V for each

pin. The recommended clamp voltage for external protection circuitry is ± 5 V.

range relative to DGND pin is –20 mV to +20 mV. The Analog Ground of the PCB should be connected

to digital ground by connecting the AGND pin and DGND pin together at the DGND pin.

Channel 2 Differential Inputs. See the Analog Inputs section for an explanation of the maximum input

signal ranges. Channel 2 has a fixed gain of 2. The absolute maximum rating is ±6 V for each pin. The

recommended clamp voltage for external protection circuitry is ± 5 V.

reference. For operation with the internal reference this pin should be connected to the REFIN pin.

For operation with an external reference, a 2.5 V ± 8%, reference should be applied at this pin. For operation with an internal reference, the REFOUT pin should be connected to this input. For both internal

or external reference connections, an input filtering capacitor should be connected between the REFIN

pin and Analog Ground.

puts. These pins should have their own ground return on the PCB, which is joined to the Analog Ground

reference at one point, i.e., the DGND pin.

AD7750—see Table I.

see Table I.

signal path of Channel 1. When this pin is low, the high-pass filter is removed. Note when the filter is off

there is a fixed time delay between channels; this is explained in the Functional Description section.

and CLKOUT for the clock source. The clock frequency is 3.58 MHz for specified operation.

only one CMOS load when CLKIN is driven externally.

Channel 1 is reversed. This output is reset to zero at power-up. This output becomes active only when

there is a pulse output on F1 or F2. See Reverse Polarity Indicator section.

High-Speed Frequency Output. This is also a fixed-width pulse stream that is synchronized to the

AD7750 CLKIN. The frequency is proportional to the product of Channel 1 and Channel 2 or the signal

on either channel, depending on the operating mode—see Table I. The output format is an active high

pulse approximately 90 ms wide—see Digital-to-Frequency Conversion section.

provide fixed-width pulse streams that are synchronized to the AD7750

CLKIN. The frequency is proportional to the product of Channel 1 and Channel 2—see Table I. The

output format is an active low pulse approximately 275 ms wide—see Digital-to-Frequency Conversion section.

–4– REV. 0

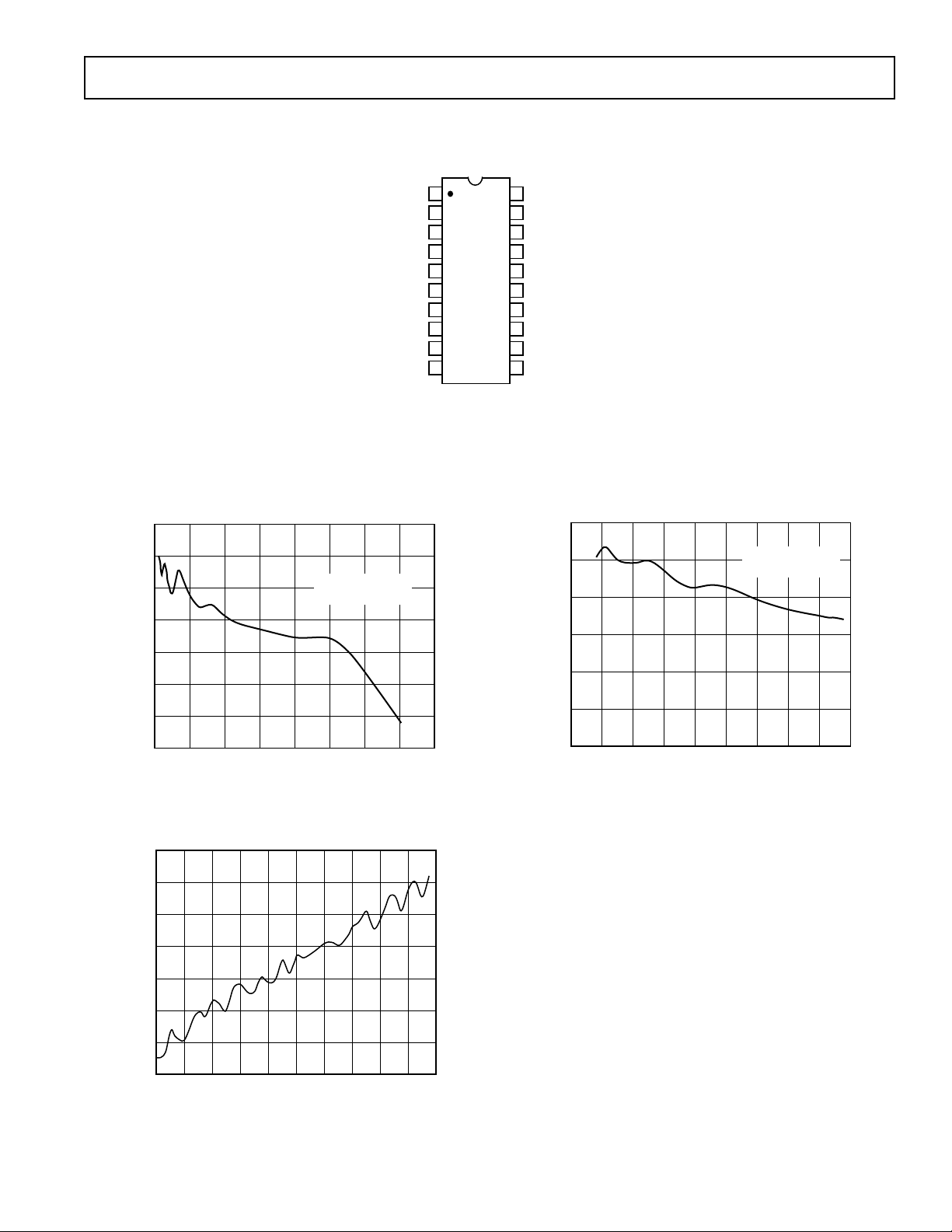

PIN CONFIGURATION

50Hz RIPPLE – V rms

120

0 0.080.01 0.02 0.03 0.04 0.05 0.06 0.07

100

60

40

20

0

80

AS PER DATA SHEET

CONDITIONS WITH

GAIN = 16

0.09

dBs

SOIC and DIP

AD7750

1

V

DD

2

G1

3

V

1+

V

4

1–

5

V

6

2+

V

7

2–

8

REFOUT

9

REFIN

10

DGND

Typical Performance Characteristics

140

120

AS PER DATA SHEET

CONDITIONS WITH

GAIN = 1

dBs

100

80

60

AD7750

TOP VIEW

(Not to Scale)

20

F1

19

F2

18

F

OUT

REVP

17

CLKOUTAGND

16

CLKIN

15

ACDC

14

S1

13

S2

12

FS

11

40

20

0

0 0.80.1 0.2 0.3 0.4 0.5 0.6 0.7

Figure 1. PSR as a Function of VDD 50 Hz Ripple

0.6

0.4

0.2

0

–0.2

Degrees

–0.4

–0.6

–0.8

45 5346 47 48 49 50 51 52

Figure 2. Phase Error as a Function of Line Frequency

50Hz RIPPLE – V rms

LINE FREQUENCY – Hz

Figure 3. PSR as a Function of VDD 50 Hz Ripple

54 55

–5–REV. 0

AD7750

V1 AMPLITUDE – mV rms

0.2

10

–2

–0.4

–0.6

0

10

–1

10

0

10

2

0.4

0.6

ERROR – % of Reading

V

DD

= 5.25V

V

DD

= 5.00V

V

DD

= 4.75V

–0.2

0.8

10

1

0.1

0.05

0

–0.05

–0.1

–0.15

ERROR – % of Reading

–0.2

–0.25

–0.3

0.001

0.01 0.1 1.0 10

V1 AMPLITUDE – mV rms

VDD = 5V

V2 = FULL SCALE

Figure 4. Error as a Percentage (%) of Reading Over a

Dynamic Range of 1000, Gain = 1

0

–0.05

–0.1

–0.15

–0.2

–0.25

–0.3

ERROR – % of Reading

–0.35

–0.4

–0.45

–0.5

0.0001

0.001

V1 AMPLITUDE – mV rms

VDD = 5V

V2 = FULL SCALE

0.01 0.1

0.6

0.4

V

= 5.25V

DD

0.2

0

V

= 5.00V

–0.2

ERROR – % of Reading

–0.4

–0.6

0

10

DD

V

= 4.75V

DD

1

10

V1 AMPLITUDE – mV rms

2

10

3

10

Figure 6. Measurement Error vs. Input Signal Level and

Varying V

with Channel 1, Gain = 1

DD

Figure 5. Error as a Percentage (%) of Reading Over a

Dynamic Range of 1000, Gain = 16

Figure 7. Measurement Error vs. Input Signal Level and

Varying V

–6– REV. 0

with Channel 1, Gain = 16

DD

AD7750

A CURRENT TRANSFORMER

PROVIDES COMPLEMENTARY

DIFFERENTIAL INPUTS TO THE

AD7750

A CURRENT SENSE RESISTOR

PROVIDES A SINGLE-ENDED

INPUT TO THE AD7750

V+

V–

V–

V+

SHUNT

RESISTOR

ANALOG INPUTS

The analog inputs of the AD7750 are high impedance bipolar

voltage inputs. The four voltage inputs make up two truly

differential voltage input channels called V

and V2. As with

1

any ADC, an antialiasing filter or low-pass filter is required on

the analog input. The AD7750 is designed with a unique

switched capacitor architecture that allows a bipolar analog

input with a single 5 V power supply. The four analog inputs

, V1–, V2+, V2–) each have a voltage range from –1.0 V to

(V

1+

+1.0 V. This is an absolute voltage range and is relative to the

ground (AGND) pin. This ground is nominally at a potential of

0 V relative to the board level ground. Figure 8 shows a very

simplified diagram of the analog input structure. When the analog input voltage is sampled, the switch is closed and a very

small sampling capacitor is charged up to the input voltage. The

resistor in the diagram can be thought of as a lumped component made up of the on resistance of various switches.

R

V

IN

1.4kV

2pF

C

SAMPLING

CAPACITOR

Figure 8. Equivalent Analog Input Circuit

Analog Inputs Protection Circuitry

The analog input section also has protection circuitry. Since the

power supply rails are 0 V to 5 V, the analog inputs can no

longer be clamped to the supply rails by diodes. Thus, the internal protection circuitry monitors the current paths during a fault

condition and protects the device from continuous overvoltage,

continuous undervoltage and ESD events. The maximum overvoltage the AD7750 analog inputs can withstand without causing irreversible damage is ±6 V relative to AGND pin.

In the case of continuous overvoltage and undervoltage the

series resistance of the antialiasing filter can be used to limit

input current. The total input current in the case of a fault

should be limited to 10 mA.

For normal operation of the AD7750 there are two further restrictions on the signal levels presented to the analog inputs.

1. The voltage on any input relative to the AGND pin must not

exceed ±1 V.

2. The differential voltage presented to the ADC (Analog

Modulator) must not exceed ±2 V.

In Figure 12, Channel 1 has a peak voltage on V

and V1– of

1+

±1 V. These signals are not gained (G1 = 0) and so the

differential signal presented to the modulator is ± 2 V.

However, Channel 2 has an associated gain of two and so

care must be taken to ensure the modulator input does not

exceed ±2 V. Therefore, the maximum signal voltage that

can appear on V

and V2– is ±0.5 V.

2+

The difference between single-ended and complementary

differential input schemes is shown in the diagram below,

Figure 9. For a single-ended input scheme the V– input is

held at the same potential as the AGND Pin. The maximum voltages can then be applied to the V+ input are

shown in Figures 10 and 11. An example of this input

scheme uses a shunt resistor to convert the line current to a

voltage that is then applied to the V

input of the AD7750.

1+

An example of the complementary differential input scheme

uses a current transformer to convert the line current to a

voltage that is then applied to V

and V1–. With this

1+

scheme the voltage on the V+ input is always equal to, but

of opposite polarity to the voltage on V–. The maximum

voltage that can be applied to the inputs of the AD7750

using this scheme is shown in Figures 12 and 13.

Note that the common mode of the analog inputs must

be driven. The output terminals of the CT are, therefore,

referenced to ground.

Figure 9. Examples of Complementary and SingleEnded Input Schemes

–7–REV. 0

AD7750

Figure 10. Maximum Input Signals with Respect to AGND for a Single-Ended Input Scheme, G1 = 0

V1+ = 61V MAX

= AGND

V

1–

V

= 61V MAX

2+

V2– = AGND

V1+ = 6125mV MAX

V

= AGND

1–

V

= 61V MAX

2+

V

= AGND

2–

61V MAX

ADC

ADC

ADC

ADC

DTF

DTF

F

OUT

F1

F2

F

OUT

F1

F2

X16

X2

61V

62V MAX

62V

62V MAX

62V

62V MAX

62V

X1

X2

Figure 11. Maximum Input Signals with Respect to AGND for a Single-Ended Input Scheme, G1 = 1

61V MAX

V+ = 61V MAX

ADC

ADC

DTF

F

OUT

F1

F2

V– = 61V MAX

V+ = 60.5V MAX

V– = 60.5V MAX

62V

X1

61V MAX

61V MAX

X2

62V

61V MAX

Figure 12. Maximum Input Signals for a Complementary Input Scheme, G1 = 0

61V MAX

V+ = 662.5V MAX

ADC

ADC

DTF

F

OUT

F1

F2

V– = 662.5V MAX

V+ = 60.5V MAX

V– = 60.5V MAX

X16

X2

62V

61V MAX

61V MAX

62V

61V MAX

Figure 13. Maximum Input Signals for a Complementary Input Scheme, G1 = 1

–8– REV. 0

AD7750

DETERMINING THE OUTPUT FREQUENCIES OF THE AD7750

F

, F1 and F2 are the frequency outputs of the AD7750. The

OUT

output frequencies of the AD7750 are a multiple of a binary

fraction of the master clock frequency CLKIN. This binary

fraction of the master clock is referred to as F

in this data

MAX

sheet. F

depending on which mode of operation the AD7750 is in. The

operating modes of the AD7750 are selected by the logic inputs

FS, S2 and S1. The table below outlines the F

and the transfer functions for the various operating modes of the

AD7750.

can have one of two values, F

MAX

Table I. Operating Mode

edoMSF2S1SnoitpircseDedoM2F,1F

0000 .edoMtnemerusaeMrewoP

1

)zH(F

F

1XAM

F.k±

1XAM

noitacilpitluMtnardnauQruoF

.)tuptuOedutingaMdnangiS(

1001 .edoMtnemerusaeMrewoP

F.kot0

1XAM

noitacilpitluMtnardnauQowT

.)ylnOedutingaM(

2010 .edoMtnemerusaeMrewoP

F.kot0

1XAM

noitacilpitluMtnardnauQowT

.)ylnOedutingaM(

2

3

011V

1

FnoedoMrotinoMlennahC

edoMtnemerusaeMrewoPFno1

,

.TUO

F

F.k±

1XAM

1XAM

.)tuptuOedutingaMdnangiS(2F

4100 .edoMtnemerusaeMrewoP

F

2XAM

F.k±

2XAM

noitacilpitluMtnardnauQruoF

.)tuptuOedutingaMdnangiS(

5101 .edoMtnemerusaeMrewoP

F.kot0

2XAM

noitacilpitluMtnardnauQowT

.)ylnOedutingaM(

6110 .edoMtnemerusaeMrewoP

F.kot0

2XAM

noitacilpitluMtnardnauQowT

.)ylnOedutingaM(

2

7

111V

2

FnoedoMrotinoMlennahC

F

.TUO

2XAM

F.k±

2XAM

,1FnoedoMtnemerusaeMrewoP

.)tuptuOedutingaMdnangiS(2F

NOTES

1

The variable k is proportional to the product of the rms differential input voltages on Channel 1 and Channel 2 (V

k = (1.32 × V1 × V2 × Gain)/V

2

Applies to F

ential voltage on Channel 2 (FS = 1, S1 = 1, S0 = 1), i.e., Channel Monitor Mode.

k = (0.81 × V)/V

V = V1 × Gain or

V = V2 × 2

NOTE: V1 and V2 here refer to the instantaneous differential voltage on Channel 1 or Channel 2, not the rms value.

only. The variable k is proportional to the instantaneous differential input voltage on Channel 1 (FS = 0, S1 = 1, S0 = 1) or the instantaneous differ-

OUT

REF

REF

2

1

TUO

F[.61

F[.23

F[.61

F[.61

and V2).

1

and F

MAX1

frequencies

MAX

)zH(F

F.k±

1XAM

F.kot0[.8

F.kot0[.61

1XAM

2XAM

F.kot0[.61

F.kot0[.23

2XAM

]F

1XAM

]F

1XAM

]F

1XAM

k±2F.

1XAM

F.k±

]F

2XAM

]F

2XAM

]F

2XAM

2

k±

F.

2XAM

F

F

F

]F

F

F

F

F

]F

F

XAM

1XAM

1XAM

1XAM

1XAM

1XAM

1XAM

1XAM

1XAM

2XAM

2XAM

2XAM

2XAM

2XAM

2XAM

2XAM

2XAM

MAX2

2/NIKLC=

zH8.6=

2/NIKLC=

zH8.6=

2/NIKLC=

zH8.6=

2/NIKLC=

zH8.6=

2/NIKLC=

zH6.31=

2/NIKLC=

zH6.31=

2/NIKLC=

zH6.31=

2/NIKLC=

zH6.31=

,

91

91

91

91

81

81

81

81

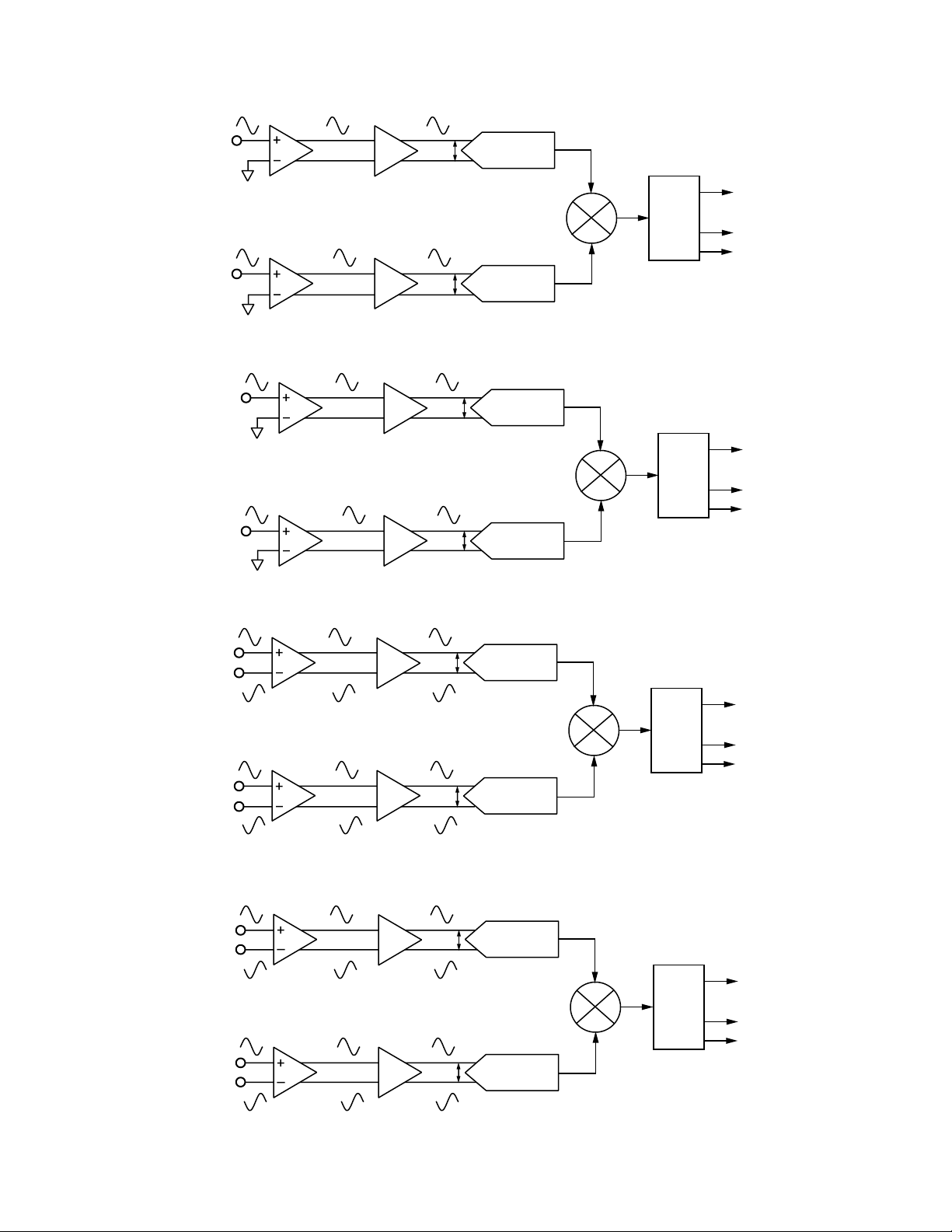

Mode Description (Table I)

The section of Table I labeled Mode Description summarizes

the functional modes of the AD7750. The AD7750 has two

basic modes of operation, i.e., four and two quadrant multiplication. The diagram in Figure 14 is a graphical representation of

the transfer functions for two and four quadrant multiplication.

Four Quadrant Multiplication (Modes 0, 3, 4 and 7)

When the AD7750 is operating in its four quadrant multiplication mode the output pulse frequency on F1, F2 and F

OUT

contains both sign and magnitude information. The magnitude information is indicated by the output frequency variation

(k.F

) from a center frequency (F

MAX

). The sign informa-

MAX

tion is indicated by the sign of the frequency variation around

. For example if the output frequency is equal to F

F

MAX

then the magnitude of the product is given by k.F

k.F

MAX

MAX

MAX

–

and it has a negative sign.

Two Quadrant Multiplication (Modes 1, 2, 5 and 6)

When operating in this mode the output pulse frequency only

contains magnitude information. Again as in the case of four

–9–REV. 0

quadrant multiplication the magnitude information is included

in the output frequency variation (k.F

). However, in this

MAX

mode the zero power frequency is 0 Hz, so the output frequency

variation is from 0 Hz to (k.F

) Hz. Also note that a no-load

MAX

threshold and the reverse polarity indicator are implemented in

these modes see No Load Threshold and Reverse Polarity

Indicator sections. These modes are the most suitable for a

Class 1 meter implementation.

Channel Monitor Modes (Modes 3 and 7)

In this mode of operation the F

give product information. When FS = 0, the F

pulse frequency does not

OUT

output fre-

OUT

quency gives sign and magnitude information about the voltage on Channel 1. When FS = 1 the F

output frequency

OUT

gives sign and magnitude information about the voltage on

Channel 2.

Note the F1, F2 pulse outputs still continue to give power

information.

AD7750

FOUR QUADRANT MULTIPLICATION

(SIGN AND MAGNITUDE)

V2(+)

V2(–)

F

+ k 3 F

MAX

0

F

MAX

(+)

_ k 3 F

(–)

MAX

MAX

(1.32 3 V1 3 V2 3 GAIN)

K =

V

F

– k 3 F

MAX

V1(–) V1(+) V1(–) V1(+)

F

MAX

(–)

+ k 3 F

(+)

MAX

MAX

Figure 14. Transfer Functions (Four and Two Quadrant Multiplication)

Maximum Output Frequencies

Table II shows the maximum output frequencies of F

OUT

and

F1, F2 for the various operating modes of the AD7750. The

table shows the maximum output frequencies for dc and ac

input signals on V

applied to V

and V2. When an ac signal (sinusoidal) is

1

and V2 the AD7750 produces an output frequency

1

which is proportional to the product of the rms value of these

inputs. If two ac signals with peak differential values of V

and V

the output frequency is proportional to V

sqrt(2) = (V

are applied to Channels 1 and 2, respectively, then

2MAX

1MAX

× V

2MAX

)/2. If V

1MAX

1MAX

and V

/sqrt(2) × V

2MAX

1MAX

2MAX

are also the

/

maximum dc input voltages then the maximum output frequencies for ac signals will always be half that of dc input signals.

Example calculation of F1, F2 max for Mode 2 and Gain = 1.

The maximum input voltage (dc) on Channel 1 is 2 V (V

+1 V, V

= –1 V)—see Analog Inputs section. The maximum

1–

=

1+

input voltage on Channel 2 is 1 V. Using the transfer function:

k = (1.32 × V

× V2 × Gain)/V

1

REF

2

k = 0.4224

F1, F2 = k.6.8 Hz = 2.9 Hz

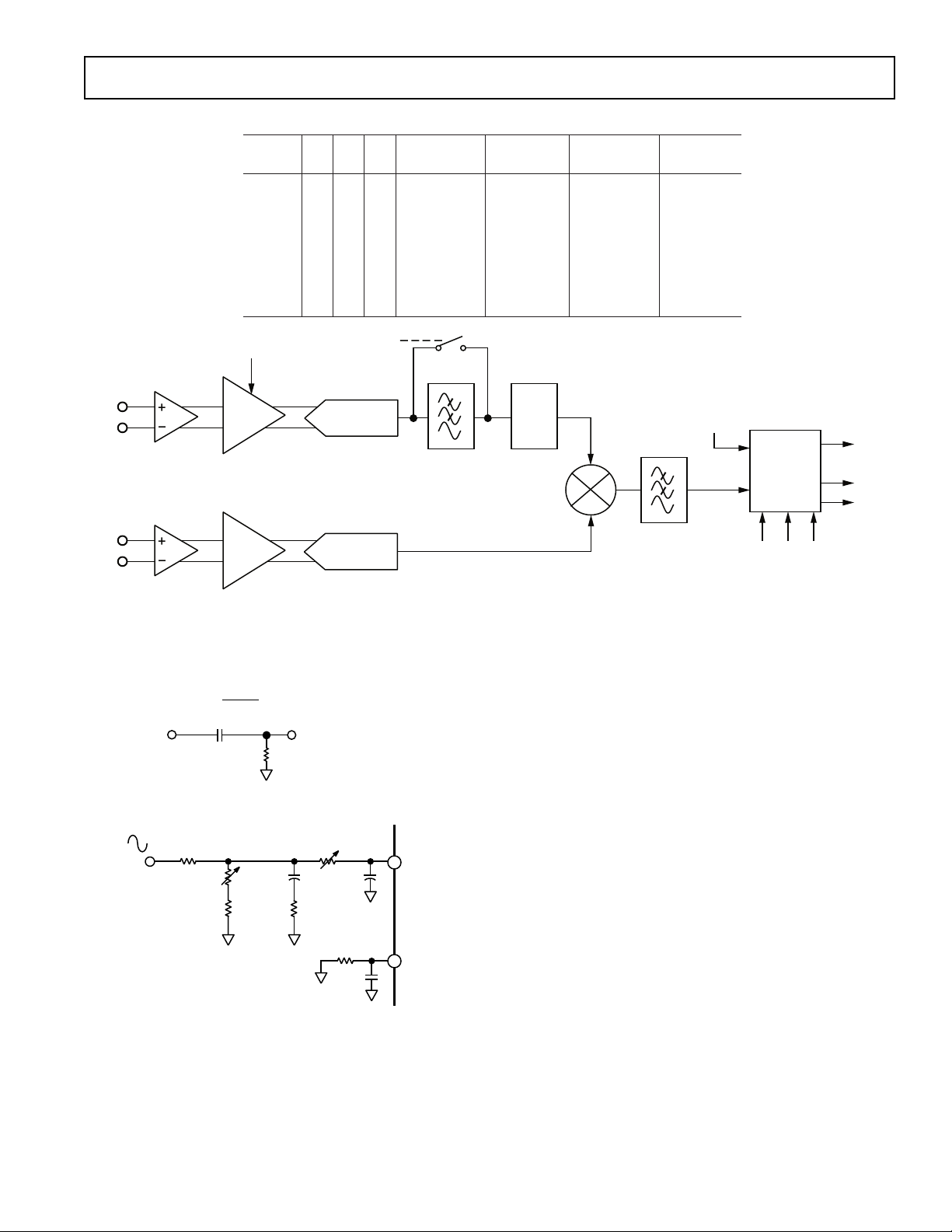

FUNCTIONAL DESCRIPTION

The AD7750 combines two analog-to-digital converters, a digital multiplier, digital filters and a digital-to-frequency (DTF)

converter onto one low cost integrated circuit. The AD7750 is

fabricated on a double poly CMOS process (0.6 µ) and retains

its high accuracy by performing all multiplications and manipulations in the digital domain. The schematic in Figure 15 shows

an equivalent circuit for the AD7750 signal processing chain.

The first thing to notice is that the analog signals are first converted to digital signals by the two second-order sigma-delta

modulators. All subsequent signal processing is carried out in

the digital domain. The main source of errors in an application

is therefore in the analog-to-digital conversion process. For this

TWO QUADRANT MULTIPLICATION

( MAGNITUDE ONLY)

V2(+)

V2(–)

k

3 F

MAX

(+)

k

3 F

MAX

(+)

REF

k 3 F

MAX

(+)

3 F

k

MAX

(+)

2

reason great care must be taken when interfacing the analog

inputs of the AD7750 to the transducer. This is discussed in the

Applications section.

HPF in Channel 1

To remove any dc offset that may be present at the output

modulator 1, a user selectable high-pass IIR filter (Pin ACDC)

can be introduced into the signal path. This HPF is necessary

when carrying out power measurements. However, this HPF

has an associated phase lead given by 90°–tan

–1

(f/2.25). Figure

16 shows the transfer function of the HPF in Channel 1. The

Phase lead is 2.58° at 50 Hz. In order to equalize the phase

difference between the two channels a fixed time delay is introduced. The time delay is set at 143 µs, which is equivalent to a

phase lag of –2.58° at 50 Hz. Thus the cumulative phase shift

through Channel 1 is 0°.

Because the time delay is fixed, external phase compensation

circuitry will be required if the line frequency differs from

50 Hz. For example with a line frequency of 60 Hz the phase

lead due to the HPF is 2.148° and the phase lag due to the fixed

time delay is 3.1°. This means there is a net phase lag in Channel 1 of 0.952°. This phase lag in Channel 1 can be compensated for by using a phase lag compensation circuit like the

one shown in Figure 17. The phase lag compensation is placed

on Channel 2 (voltage channel) to equalize the channels. The

antialiasing filter associated with Channel 1 (see Applications

section) produces a phase lag of 0.6° at 50 Hz; therefore, to

equalize the channels, a net phase lag of (0.6° + 0.952°) 1.552°

should be in place on Channel 2. The gain trim resistor VR1

(100 Ω) produces a phase lag variation of 1.4° to 1.5° with VR2

= 0 Ω. VR2 can add an additional 0.1° phase lag (VR2 = 200 Ω).

–10– REV. 0

AD7750

Table II. Maximum Output Frequencies

)zH(2F,1F

F

edoMSF2S1S

)CD(

0000 9.2±8.664±90154.1±8.632±901

1001 9.2ot032ot054.1ot05.11ot0

2010 9.2ot064ot054.1ot032ot0

3011 9.2±8.6241±81254.1±8.6241±812

4100 8.5±6.3129±8129.2±6.3164±812

5101 8.5ot029ot09.2ot064ot0

6110 8.5ot0481ot09.2ot029ot0

7111 8.5±6.31241±8129.2±6.31241±812

TUO

)zH(

)CD(

)zH(2F,1F

F

)CA(

TUO

)zH(

)CA(

ADC 1

ADC 2

ACDC

HPF

PHASE LEAD OF

2.588C AT 50Hz

G1

V

1+

V

1–

V

2+

V

2–

PGA

X2

Figure 15. Equivalent AD7750 Signal Processing Chain

sRC

H(s) =

1 + sRC

C

R

R = 1MV

C = 0.0707mF

Figure 16. HPF in Channel 1

R1

1MV

VR1

100V

R3

860:1 ATTENUTATION

1.1kV

47nF

33kV

VR2

200V

C1

R2

33nF

R4

1.1kV

33mF

C2

C3

PIN 7

PIN 6

Figure 17. Phase Lag Compensation on Channel 1 for

60 Hz Line Frequency

TIME DELAY 143ms

(CLKIN = 3.5795MHz)

2.588C AT 50Hz

DIGITAL-TO-FREQUENCY BLOCK

COUNTER/ACCUMULATOR

τ

DIGITAL

MULTIPLIER

LPF

CLKIN

F

OUT

DTF

FS

S2 S1

F1

F2

Digital-to-Frequency Converter (DTF)

After they have been filtered, the outputs of the two sigma-delta

modulators are fed into a digital multiplier. The output of the

multiplier is then low-pass filtered to obtain the real power

information. The output of the LPF enters a digital-to-frequency

converter whose output frequency is now proportional to the

real power. The DTF offers a range of output frequencies to

suit most power measurement applications. There is also a high

frequency output called F

, which can be used for calibra-

OUT

tion purposes. The output frequencies are determined by the

logic inputs FS, S2 and S1. This is explained in the section of

this data sheet called Determining the Output Frequencies of

the AD7750.

Figure 18 shows the waveforms of the various frequency outputs. The outputs F1 and F2 are the low frequency outputs

that can be used to directly drive a stepper motor or electromechanical pulse counter. The F1 and F2 outputs provide two

alternating low going pulses. The pulsewidth is set at 275 ms

and the time between the falling edges of F1 and F2 is approximately half the period of F1. If, however, the period of

F1 and F2 falls below 550 ms (1.81 Hz) the pulsewidth of F1

and F2 is set to half the period. For example in Mode 3,

where F1 and F2 vary around 6.8 Hz, the pulsewidth would vary

from 1/2.(6.8+1.45) seconds to 1/2.(6.8–1.45) seconds—see

Table II.

–11–REV. 0

AD7750

The high frequency F

communications (via IR LED) and calibration purposes. F

output is intended to be used for

OUT

OUT

produces a 90 ms wide pulse at a frequency that is proportional

to the product of Channel 1 and Channel 2 or the instantaneous voltage on Channel 1 or Channel 2. The output frequencies are given in Table I in the Determining the Output

Frequencies of the AD7750 section of this data sheet. As in

the case o f F1 and F2, if the period of F

the F

F

F

pulsewidth is set to half the period. For example, if the

OUT

frequency is 20 Hz, the F

OUT

F1

F2

OUT

t

1

t

6

t

3

t

4

t

5

OUT

t

2

falls below 180 ms,

OUT

pulsewidth is 25 ms.

V

DD

0V

V

DD

0V

V

DD

0V

Figure 18. Timing Diagram for Frequency Outputs

VOLTAGE REFERENCE

The AD7750 has an on-chip temperature compensated bandgap voltage reference of 2.5 V with a tolerance of ±250 mV.

The temperature drift for the reference is specified at 50 ppm/°C.

It should be noted that this reference variation will cause a

frequency output variation from device to device for a given set

of input signals. This should not be a problem in most applications since it is a straight gain error that can easily be removed

at the calibration stage.

meter accuracy with small load currents. Hence an error of less

than 1% from 4% Ib to 400% Ib will be easier to achieve.

We will assume the design of a Class 1 meter. The specification

(IEC1036) requires that the meter have an error of no greater

than 1% over the range 4% Ib to 400% Ib (I

the basic current

1

. In addition, we will design a meter that ac-

), where Ib is

MAX

commodates signals with a crest factor of 2. The crest factor is

the ratio of V

/V rms. A pure sinusoidal waveform has a crest

PEAK

of sqrt(2) = 1.414 and an undistorted triangular waveform has a

crest factor of sqrt(3) = 1.73. Using a gain of 1 on Channel 1

the maximum differential signal which can be applied to Channel 1 is ±2 V—See Analog Input Ranges section. With a crest

factor of 2 the maximum rms signal on Channel 1 is, therefore,

1 V rms (equivalent to I

). The smallest signal (4% Ib) ap-

MAX

pearing on Channel 1 is therefore 10 mV rms.

Load Current Channel 1

4% Ib 10 mV rms

Ib 250 mV rms

400 Ib 1 V rms

2

400% Ib

0. 2

0. 02

4% Ib

CHANNEL 1 INPUT SIGNAL – Vrms

1

0.01

REVERSE POLARITY INDICATOR

When the AD7750 is operated in a Magnitude Only mode of

operation (i.e., Modes 1, 2, 5 and 6), and the polarity of the

power changes, the logic output REVP will go high. However,

the REVP pin is only activated when the there is pulse output

on F1 or F2. Therefore, if the power being measured is low, it may

be some time before the REVP pin goes logic high even though the

polarity of the power is reversed. Once activated the REVP output

will remain high until the AD7750 is powered down.

APPLICATIONS INFORMATION

Designing a Single Phase Class 1 Energy Meter (IEC 1036)

The AD7750 Product-to-Frequency Converter is designed for

use in a wide range of power metering applications. In a typical

power meter two parameters are measured (i.e., line voltage and

current) and their product obtained. The real power is then

obtained by low-pass filtering this product result. The line

voltage can b e measured through a resistor divider or voltage

transformer, and the current can be sensed and converted to

a voltage through a shunt resistor, current transformer or hall

effect device.

The design methodology used in the following example is to use

the upper end of the current channel dynamic range, i.e., Channel 1 of the AD7750. The assumption here is that the signal on

the voltage channel will remain relatively constant while the

signal on the current channel will vary with load. Using the

upper end of the dynamic range of Channel 1 will improve the

1

See IEC 1036 2nd Edition 1996-09 Section 3.5.1.1.

–12– REV. 0

0. 002

Figure 19. Use the Upper End of the Dynamic Range of

Channel 1 (Current)

Calculations for a 100 PPKWHR Meter

The AD7750 offers a range of maximum output frequencies—

see Table I and Table II. In the Magnitude Only modes of

operation the two maximum output frequencies are 1.45 Hz

and 2.9 Hz. The signal on the voltage channel (Channel 2) is

scaled to achieve the correct output pulse frequency for a given

load (e.g., 100 PPKWHR). The relationship between the input

signals and the output frequency is given by the equation:

Freq = k × F

where k = (1.32 × V1 × V2 × Gain)/V

F

= 6.8 Hz or 13.6 Hz depending on the mode—see Table

MAX

I, Gain is the gain of Channel 1, V

voltages on Channels 1 and 2 and V

MAX

and V2 are the differential

1

is the reference voltage

REF

REF

2

(2.5 V ± 8%).

To design a 100 PPKWHR meter with Ib = 15 A rms and a line

voltage of 220 V rms the output pulse frequency with a load

current of Ib is 0.0916 Hz (See Calculation 1 below).

Therefore, 0.0916 Hz = k × 6.8 Hz (Mode 2) or k = 0.01347.

With a load current of Ib the signal on Channel 1 (V

) is equal

1

to 0.25 V rms (remember 400% Ib = 1 V rms) and, therefore,

the signal on Channel 2 (V

) is equal to 0.255 V rms (See Calcula-

2

tion 2). This means that the nominal line voltage (220 V rms)

needs to be attenuated by approximately 860, i.e., 220/0.255.

AD7750

TIME 2 ms

5.065

5.060

5.050

600 620

VOLTS

5.055

640 660 680 700 720 740 760 780 800

For 100 PPKWHR V2 is equal to 0.255 V rms or the line voltage attenuated by a factor of 860.

Calculation 1

100 PPKWHR = 0.02777 Hz/kW.

Ib of 15 A rms and line voltage of 220 V = 3.3 kΩ. Hence, the

output frequency is given by 3.3 × 0.02777 Hz = 0.0916 Hz.

Calculation 2

k = (1.32 × V

0.01347 = (1.32 × 0.25 × V

= 0.255.

V

2

× V2 × Gain)/V

1

2

.

REF

× 1)/6.25.

2

Figure 21 below shows how the design equations from the previous page are implemented.

Measuring the Load Current

The load current is converted to a voltage signal for Channel 1

using a CT (Current Transformer). A 15 A rms load should

produce a 250 mV rms signal on Channel 1. A CT with a turns

ratio of 120 and a shunt resistor of 2 Ω. will carry out the necessary current to voltage conversion. The CT and its shunt resistance should be placed as close as possible to the AD7750. This

will improve the accuracy of the meter at very small load currents. At small load currents the voltage levels on Channel 1 are

in the order of 10 mV and the meter is more prone to error due

to stray signal “pick up.” When measuring power the HPF in

the current channel must be switched on. This is done by connecting the ACDC pin to V

NOTE: The voltage signals on V

.

DD

and V1– must be referenced

1+

to ground. This can be achieved as shown in Figure 21 below,

i.e., by referencing 1/2 R

to ground or by connecting a

CT

centertap on the CT secondary to ground.

Measuring the Line Voltage

When the AD7750 is biased around the live wire as shown in

Figure 21, the task of measuring the line voltage is greatly

simplified. A resistor divider attenuates the line voltage and

provides a single-ended input for Channel 2. The component

values of the divider are chosen to give the correct rating (e.g.,

100 PPKWHR) for the meter. See the design equations on the

previous page. For this design an attenuation ratio of 860:1 is

required.

V

DD

C5

C7

C11

Z1

C8

R7

C10

C12

V

DD

LOAD

PHASE

NEUTRAL

SOURCE

*BIASING AROUND THE LIVE WIRE PATENTED BY SCHLUMBERGER.

CT

120:1

MOV

1/2 R

1/2 R

R5

*

C1

R1

CT

1V

CT

1V

VR1

R6

R4

C6

R3

C9

D1

D2

R2

C2

Antialiasing Components Channels 1 and 2

The AD7750 is basically two ADCs and a digital multiplier. As

with any ADC, a LPF (Low-Pass Filter) should be used on the

analog inputs to avoid out of band signal being aliased into the

band of interest. In the case of a Class 1 meter the band of

interest lies in the range 48 Hz to 1 kHz approximately. The

components R3, R4, R6, R7, C5, C6, C9 and C10 make up the

LPFs on each of the four analog inputs. Note that although

Channel 2 is used single ended a LPF is still required on V

.

2–

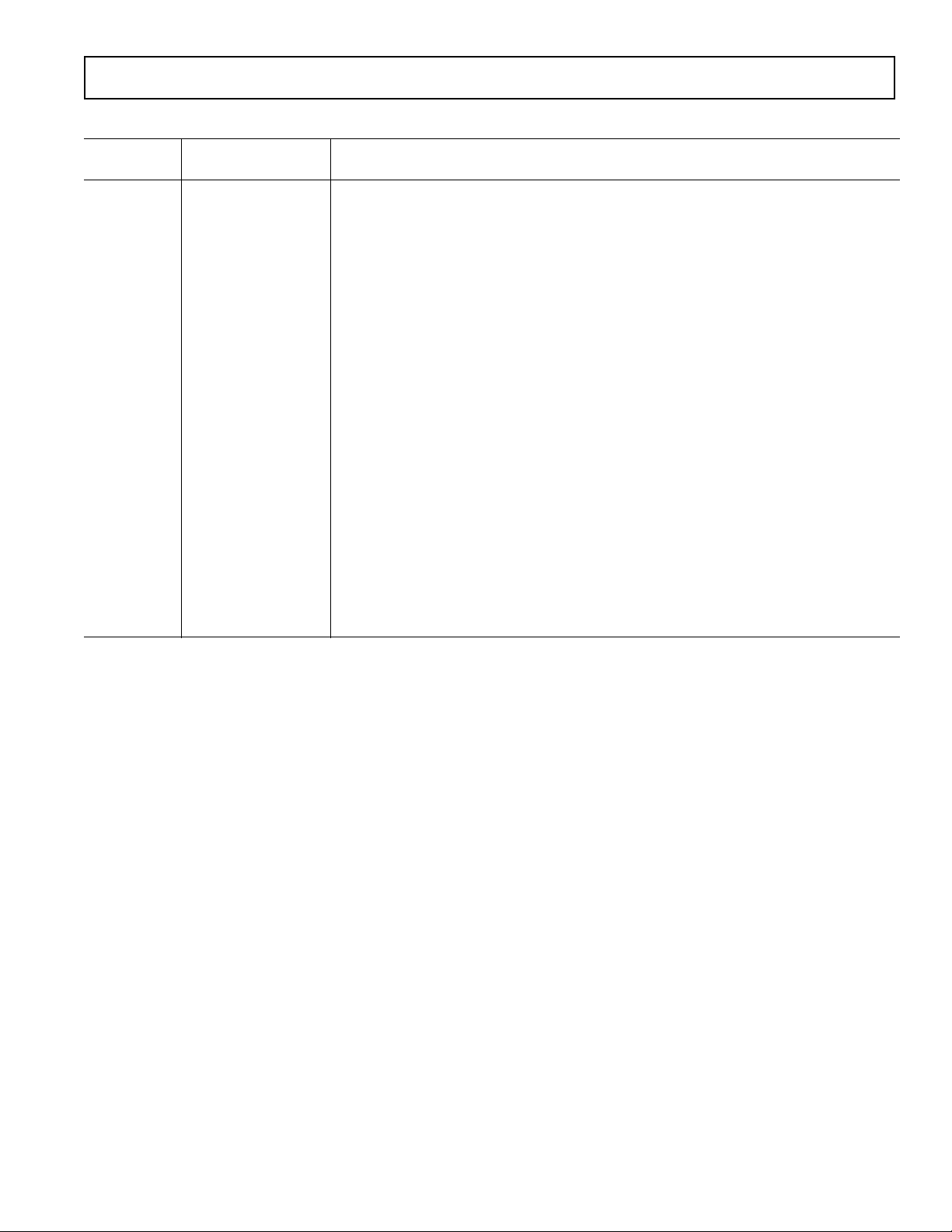

Power Supply Circuit

The AD7750 operates from a single power supply of 5 V ± 5%

but still accommodates input signals in the range ±1 V. Because

the AD7750 doesn’t require dual supplies the number of external components for the power supply is reduced. One of the

most important design goals for the power supply is to ensure

that the ripple on the output is as low as possible. Every analog

or mixed signal IC is to a greater or lesser extent susceptible to

power supply variations. Power supply variations or ripple, if

large enough, may affect the accuracy of the device when measuring small signals. The plot in Figure 20 shows the ripple

associated with the circuit in Figure 21. The ripple is in the

region of 10 mV peak to peak.

Figure 20. Power Supply Ripple

1

2

3

4

5

AD7750

TOP VIEW

6

(Not to Scale)

7

8

9

10

20

M

19

18

17

16

15

14

13

12

11

PULSE COUNTER

R8

R9

C4

C3

V

DD

V

DD

D5

D4

D3

REVERSE POLARITY

INDICATOR

XTAL 3.57954MHz

MODE2

IR DIODE FOR

CALIBRATION

Figure 21. Suggested Class 1 Meter Implementation

–13–REV. 0

AD7750

Registering the Power Output

The low frequency pulse outputs (F1 and F2) of the AD7750

provide the frequency output from the product-to-frequency

conversion. These outputs can be used to drive a stepper motor

or impulse counter.

A high frequency output is available at the pin F

. This high

OUT

frequency output is used for calibration purposes. In Mode 2

the output frequency is 16 × F1(2). With a load current of Ib

the frequency at F

will be 1.4656 Hz (0.0916 Hz × 16 from

OUT

calculations). If a higher frequency output is required, the FS

pin can be set to V

5 V for calibration. In this case the output

DD

frequency is equal to 64 × F1 or 5.8624 Hz at Ib—see Table I.

NO LOAD THRESHOLD OF THE AD7750

The AD7750 will detect when the power drops below a certain

level. When the power (current) drops below a predefined

threshold the AD7750 will cease to generate an output drive for

the stepper motor (F1, F2). This feature of the AD7750 is

intended to reproduce the behavior of Ferraris meters. A

Ferraris meter will have friction associated with the wheel rotation, therefore the wheel will not rotate below a certain power

level. The no load threshold is only implemented in the Magnitude Only modes (Modes 1, 2, 5 and 6—see Table I). The

IEC1036 specification includes a test for this effect by requiring

no output pulses during some predetermined time period. This

time period is calculated as:

time period = 60,000/pulses-per-minute

If a meter is calibrated to 100 PPKWHR with a F

OUT

running

16 times faster than F1 and F2, this time period is 37.5 minutes

(60,000/1,600). The IEC1036 specifications state that the no

load threshold must be less than the start up current level. This

is specified as 0.4% of Ib.

The threshold level for a given design can be easily calculated

given that the minimum output frequency of the AD7750 is

0.00048% of the maximum output frequency for a full-scale

differential dc input. For example if FS = 0, the maximum

output frequency for a full-scale dc input is 2.9 Hz (see Table II)

and the minimum output frequency is, therefore, 1.39 × 10

Calculating the Threshold Power (Current)

–5

Hz.

The meter used in this example is calibrated to 100 PPKWHR,

has an Ib (basic current) of 15 A rms, the line voltage is 220 V

rms and the turns ratio of the CT on Channel 1 is 120:1 with an

2 Ω shunt resistor.

The nominal voltage on Channel 2 of the AD7750 is 255 mV

rms. An F

of 6.8 Hz is selected by setting FS = 0. A Magni-

MAX

tude Only Mode (Mode 2) is selected to enable the no load threshold. The gain on Channel 1 is set to 1. The threshold power or

current can be found by using the transfer function in Table I.

F1, F2 = (1.32

×

V1 × V2 × Gain × F

MAX

)/V

REF

2

From the transfer function V1 is calculated as 37.95 µV rms—

see Calculation 3.

This is equivalent to a line current of:

(37.95 µV/2 Ω ) × 120 = 2.27 mA rms or 0.5 W

or

×

(2.27 mA/15 A)

100% = 0.015% of Ib.

NOTE: The no load threshold as a percentage of Ib will be

different for each value of Ib since the no load in watts is fixed:

FS = 0, the no load threshold is (F

= 6.8 Hz)

MAX

0.5 Watts for a 100 PPKWHR meter

5 Watts for a 10 PPKWHR meter

FS = 1, the no load threshold is (F

= 13.6 Hz)

MAX

1 Watt for a 100 PPKWHR meter

10 Watts for a 10 PPKWHR meter

Calculation 3

F

= 1.32 × V1 × V2 × Gain × 6.8 Hz) V

MIN

REF

2

1.39 × 10–5 Hz = V1 × 0.2555 × 1 × 6.8)/6.25

= 37.95 µV

V

1

EXTERNAL LEAD/LAG COMPENSATION

External phase compensation is often required in a power meter

design to eliminate the phase errors introduced by transducers

and external components. The design restriction on any external

compensating network is that the network must have an overall

low-pass response with a 3 dB point located somewhere between

5 kHz and 6 kHz. The corner frequency of this LPF(s) is much

higher than the band of interest. The reason for this is to minimize its effect on phase variation at 50 Hz due to component

tolerances.

With the antialiasing filters on all channels having the same

corner (–3 dB) frequency, the main contribution to phase error

will be due to the CT. A phase lead in a channel is compensated

by lowering the corner frequency of the antialiasing filter to

increase its associated lag and therefore cancel the lead. A phase

lag in a channel should be compensated by introducing extra lag

in the other channel. This can be done as previously described,

i.e., moving the corner frequency of the antialiasing filters. The

result in this case is that the signal on both channels has the

same amount of phase lag and is therefore in phase at the analog

inputs to the AD7750. The recommended RC values for the

antialiasing filters on the voltage and current channels (see

Antialiasing Components Channels 1 and 2) are R = 1 kΩ,

C = 33 nF and R = 100 Ω, C = 330 nF respectively. These

values produce a phase lag of 0.6° through the filters. Varying R

in the antialiasing network from 80 Ω to 100 Ω or 800 Ω to 1 kΩ

produces a phase variation from 0.475° to 0.6° at 50 Hz. This

allows the user to vary the lag by 0.125°.

–14– REV. 0

AD7750

Table III. Components for Suggested Class 1 Meter Implementation in Figure 21

Schematic

Designator Description Comments

R1 470 Ω, 5%, 1 W

R2 1 kΩ , 5%, 1/2 W

R3, R4, 100 Ω, 10%, 1/2W These registers are required to form part of the antialiasing filtering on the analog inputs;

R7 1 kΩ, 10%, 1/2 W they do not perform a voltage-to-current conversion.

R5 1 MΩ , 5%, 2 W The choice of R5 determines the attenuation on the voltage channels and hence the meter

rating, e.g., 100 PPKWHR.

R6 1.1 kΩ, 5%, 1/2 W Forms part of the Gain Calibration network with R5 and VR1.

R8, R9 500 Ω, 10%, 1/2 W

VR1 100 Ω, 10/15 Turn This potentiometer is used to perform the Gain Calibration of the meter. Attenuation of

830 to 900—see Applications section.

C1 470 nF, 250 V ac

C2 100 µF, 24 V dc

C3, C4 33 pF

C5, C6, 330 nF Forms part of the antialiasing filters on the analog inputs.

C9, C10 33 nF

C7, C11 10 µF, 10 V

C8, C12 10 nF

Z1 1N750

D1, D2 1N4007

D3 LED

D4, D5 IR LEDS

XTAL 3.579545 MHz

MOV V250PA40A Metal Oxide Varistor–Harris Semiconductor.

–15–REV. 0

AD7750

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

20-Lead Plastic DIP

(N-20)

1.060 (26.90)

0.925 (23.50)

20

110

PIN 1

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

11

0.070 (1.77)

0.045 (1.15)

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

20-Lead Wide Body SOIC

(R-20)

0.5118 (13.00)

0.4961 (12.60)

0.195 (4.95)

0.115 (2.93)

0.015 (0.381)

0.008 (0.204)

C3156–8–10/97

20 11

PIN 1

0.0118 (0.30)

0.0040 (0.10)

0.0500

(1.27)

BSC

0.1043 (2.65)

0.0926 (2.35)

0.0192 (0.49)

0.0138 (0.35)

101

SEATING

PLANE

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

0.3937 (10.00)

0.0125 (0.32)

0.0091 (0.23)

0.0291 (0.74)

0.0098 (0.25)

0.0500 (1.27)

8°

0°

0.0157 (0.40)

x 45°

–16–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...