AMS Asset Monitor

Online Prediction, Protection, and Process Monitor

Installation Guide

MHM-97923-PBF, Rev 2.5

June 2022

Copyright

©

2022 by Emerson. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language in any form by any means without the written permission of Emerson.

Disclaimer

This manual is provided for informational purposes. EMERSON MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. Emerson shall not be liable for errors, omissions, or inconsistencies that may be contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material. Information in this document is

subject to change without notice and does not represent a commitment on the part of Emerson. The information in this manual is

not all-inclusive and cannot cover all unique situations.

Patents

The product(s) described in this manual are covered under existing and pending patents.

Vermerk zur Installation der Messketten in explosionsgefährdeter Umgebung.

Soll die Messkette in explosionsgefährdeter Umgebung installiert werden, so ist auf die Einhaltung der in der

Gebrauchsanweisung enthaltenen Installationshinweise zu achten. Sollten dabei sprachliche Schwierigkeiten

auftreten, wenden Sie sich bitte an die Herstellerfirma, sie wird Ihnen eine Übersetzung der relevanten Artikel in der

Landessprache des Verwendungslandes zukommen lassen.

Nota fuq l−installazzjoni tal−ktajjen tal−kejl f’ambjent esplożiv

Jekk il−katina tal−kejl suppost li tigi installata f’ambjent esplożiv, hu importanti li ssegwi l−istruzzjonijiet pertinenti

tal−manwal.Jekk issib xi diffikultà bil−lingwa, jekk joghgbok ikkuntattja lill−manifattur biex tikseb traduzz-joni tal

−paragrafi rilevanti fil−lingwa mehtiega.

Anmärkning beträffande installation av mätkedjorna i explosionsfarlig miljö.

Ska mätkedjan installeras i explosionsfarlig miljö, måste de anvisningar följas som ges i instruktionsboken

beträffande installationen. Skulle därvid språkproblem uppstå, ber vi dig kontakta det tillverkande företaget som

då kommer att sända dig en översättning av de relevanta artiklarna på användningslandets språk.

Opomba za namestitev merilne verige v eksplozivno ogroženem okolju

Èe se merilna veriga namešèa v eksplozivno ogroženem okolju, je potrebno upoštevati namestitvena opozorila, ki

so v Navodilih za uporabo. Èe se pri tem pojavijo jezikovne težave, se posvetujte z izdelovalcem; poslali vam bodo

prevod ustreznih èlankov v jeziku države, kjer se naprava uporablja.

Záznam k inštalácii meracích reťazcov vo výbušnom prostredí

Ak má byť merací reťazec inštalovaný vo výbušnom prostredí, treba dbať na dodržiavanie pokynov k inštalácii,

uvedených v návode na použitie. V prípade, že by sa pritom vyskytli jazykové problémy, obráťte sa prosím na

výrobcu, ktorý Vám zašle preklad relevantných èlánkov v jazyku Vašej krajiny.

Nota referente à instalação de cadeias de agrimensor em ambientes potencialmente explosivos

Caso a cadeia de agrimensor deva ser instalada em um ambiente potencialmente explosivo, é imprescindível

observar e cumprir as indicações de instalação das instruções de serviço. Caso tenha dificuldades idiomáticas,

queira entrar em contato com a firma produtora, esta poderá enviar−lhe uma tradução dos capítulos mais

importantes no idioma do país onde o produto deverá ser empregado.

Wskazówka dotycząca instalacji łańcuchów mierniczych w otoczeniach zagrożonych eksplozją.

Jeżeli łańcuch mierniczy ma być zainstalowany w otoczeniu zagrożonym eksplozją, należy uwzględnić wskazówki

dotyczące instalacji, które są zawarte w instrukcji obsługi. Jeżeli w trakcie lektury wystąpią jakiekolwiek problemy

związane ze zrozumieniem tekstu, prosimy zwrócić się do producenta, który chętnie wykona tłumaczenie

wybranych części dokumentacji na język danego kraju.

2

Opmerking m.b.t. installatie van elektrische meet circuits in explosiegevaarlijke omgeving

Dient de installatie van elektrische meet circuits in een explosiegevaarlijke omgeving te geschieden, moet men

toezien dat de in de gebruikshandleiding opgenomen installatieinstructies worden nageleefd. Bij taalkundige

problemen gelieve contact op te nemen met de fabrikant, deze zal u vervolgens een vertaling in de taal van het

gebruiksland doen toekomen.

Pastaba dėl matavimo grandinės įrengimo sprogimo atžvilgiu pavojingoje aplinkoje

Jei matavimo grandinė turi būti įrengta sprogimo atžvilgiu pavojingoje aplinkoje, privaloma laikytis vartotojo

instrukcijoje pateiktų įrengimo nurodymų. Jei kiltų sunkumų dėl kalbos, prašome kreiptis į gamintojo įmonę, kuri

pateiks Jums reikiamo skyriaus vertimą į vartotojo valstybės kalbą.

Nota sull’installazione delle catene per misurazione in ambienti a rischio di esplosioni

Nel caso in cui si debbano installare le catene per misurazione in ambienti a rischio di esplosioni, è necessario

attenersi alle avvertenze per l’installazione contenute nelle istruzioni d’uso. Per difficoltà di carattere linguistico,

rivolgetevi alla ditta produttrice. Quest’ultima Vi farà pervenire una traduzione degli articoli rilevanti nella lingua

del paese d’impiego.

Megjegyzės a mėrőláncok robbanásveszėlyes környezetben törtėnő szerelėsėhez.

Ha a mėrőláncot robbanásveszėlyes környezetben kell felszerelni, akkor ügyeljen a Használati útmutatóban közölt

szerelėsi utasítások betartására. Amennyiben nyelvi nehėzsėgek merülnek fel, szíveskedjen a gyártó céghez

fordulni, amely elküldni Önnek a felhasználó ország nyelvėre lefordított, erre vonatkozó cikket.

Remarque concernant l’installation des chaînes de mesure dans un environnement présentant un risque

d’explosion

Si la chaîne de mesure doit être installée dans un environnement présentant un risque d’explosion, il est impératif

de veiller à respecter les consignes d’installation contenues dans les instructions de service. S’il devait ce faisant

surgir des problèmes linguistiques, veuillez vous adresser à la société fabricante: elle vous fera parvenir une

traduction des articles significatifs dans la langue du pays de mise en oeuvre.

Huomautus mittausketjun asentamisesta räjähdysalttiissa ympäristössä

Jos mittausketju tulee asentaa räjähdysalttiissa ympäristössä, on käyttöohjeessa annettuja asennusohjeita

noudatettava. Jos käyttöohjeessa käytetty kieli aiheuttaa ongelmia, kääntykää valmistajayrityksen puoleen. Se

toimittaa käyttöönne tarvittavat artikkelit käyttömaan vir alliselle kielelle käännettynä.

Juhend mõõdukettide ülespanemiseks plahvatusohtlikus piirkonnas.

Kui panna üles mõõdukettid plahvatusohtlikkus piirkonnas, nii tuleb jälgida kasutusjuhendis sisaldatud

instalationimärkmeid. Juhul kui tekkivad raskused keelega, siis pöörduge palun tootja poole. Tootja saadab

emakeelse tõlge vastavalt artiklile ning maale.

Notas sobre la instalación de cadenas de medición en un entorno potencialmente explosivo.

Si ha de instalar la cadena de medición en un entorno potencialmente explosivo, deberá respetar las indicaciones

sobre la instalación, contenidas en el manual de uso. Si surgieran dificultades lingüísticas, póngase en contacto con

la empresa fabricante, que le facilitará una traducción del artículo en la lengua del país donde se emplee.

Note on the installation of the measuring chains in an explosive environment

If the measuring chain is supposed to be installed in an explosive environment, it is important to follow the

pertinent installation instructions in the manual. Should you encounter difficulties with the language, please

contact the manufacturer to obtain a translation of the relevant paragraphs into the language required.

3

Σημεíωση για τηυ εγκατáσταση αλuσíδωυ μέτρησης σε περιβáλλου, στο oπoío uπàρΧει κíυδuυoς έκρηξης

Εáυ η αλuσυδα μέτρησης πρóκειται υα εγκατασταΘεí σε περιβáλλoυ, στo oπoío uπáρΧει κíυδuυoς έκρηξης, πρέπει

υα τηρηΘoúυ oπωσδńπoτε oι oδηγíες εγκατáστασης πoυ περιλαμβáυoυται στις oδηγíες Χρńσης. Εáυ υπáρξouυ

γλωσσικές δuσκoλíες καταυóησης, παρακαλoúμε υα απεuΘuυΘεíτε στηυ κατασκεuáστρια εταιρεíα, η oπoíα Θα

ϕρoυτíσει για τηυ απoστoλń μιας μετáϕρασης τωυ σΧετικωυ áρΘρωυ στη γλωσσα της Χωρας Χρńσης.

Info vedrørende installation af målekæderne i eksplosionstruede omgivelser

Hvis målekæden skal installeres i eksplosionstruede omgivelser, skal installationsanvisningerne i brugsanvisningen

følges. Hvis der i denne forbindelse opstår sproglige problemer, bedes De henvende Dem til produktionsfirmaet,

som så vil sørge for, at De modtager en oversætelse af den relevante artikel på Deres sprog.

Poznámka k instalaci mĕřicích řetězců v prostředí s nebezpečím výbuchu.

Když má být měřicí řetězec (sestávající z čidla a konvertoru) instalován v prostŕedí s nebezpečím výbuchu, tak je

třeba respektovat instalační pokyny, které jsou součástí návodu k upotřebení. Kdyby při tom došlo k jazykovým

potížím, tak prosíme kontaktujte výrobní firmu, která Vám relevantní článek zašle v jazyku krajiny použití.

Piezīme par mērīšanas ķēžu instalēšanu sprādziena bīstamās zonās.

Ja mērīšanas ķēde jāuzstāda sprādzienbīstamā zonâ, ir jāievēro lietošanas instrukcijā dotie instalēšanas norādījumi.

Ja rodas kādas valodas grūtības, lūdzu griezieties pie izgatavotāja firmas, kas Jums nosūtīs nozīmīgâko nodaļu

tulkojumus lietotāja valsts valodā.

Emerson

epro GmbH

Jöbkesweg 3

48599 Gronau

Germany

T +49 2562 709 0

F +49 2562 709 401

www.Emerson.com

4

Installation Guide Contents

MHM-97923-PBF June 2022

Contents

Chapter 1 General.......................................................................................................................... 9

1.1 About this manual............................................................................................................................ 9

1.2 Symbols......................................................................................................................................... 10

1.3 Liability and guarantee................................................................................................................... 11

1.4 Incoming goods inspection............................................................................................................ 11

1.5 Technical support...........................................................................................................................11

1.6 Storage and transport.....................................................................................................................12

1.7 Disposal of the device.....................................................................................................................12

1.8 China RoHS Compliance................................................................................................................. 12

1.9 CCC Certification – AMS Asset Monitor...........................................................................................13

1.10 Installation awareness.................................................................................................................. 13

Chapter 2 Safety instructions....................................................................................................... 15

2.1 Using the device............................................................................................................................. 15

2.2 Owner's responsibility.....................................................................................................................15

2.3 Radio interference.......................................................................................................................... 15

2.4 ESD safety...................................................................................................................................... 16

2.5 Important information about hazardous live voltages.................................................................... 16

Chapter 3 Planning the installation.............................................................................................. 17

3.1 Tools required to install the hardware.............................................................................................17

3.2 Torque limits for mounting screws................................................................................................. 17

3.3 Wiring guidelines............................................................................................................................18

3.3.1 Wiring overview.......................................................................................................................... 19

3.4 Select a mounting place................................................................................................................. 21

Chapter 4 Installing AMS Asset Monitor hardware........................................................................23

4.1 CSA – General safety.......................................................................................................................23

4.2 About the AMS Asset Monitor hardware......................................................................................... 23

4.3 Position of the mounting holes.......................................................................................................29

4.4 Open the AMS Asset Monitor..........................................................................................................31

4.5 Close the AMS Asset Monitor..........................................................................................................33

4.6 Recommended sequence for installing the AMS Asset Monitor...................................................... 33

4.7 Mount the AMS Asset Monitor........................................................................................................34

4.8 Mount the AMS Asset Monitor by using the universal mounting bracket.........................................34

4.9 Replace the cable inlet dust caps.................................................................................................... 38

4.10 Grounding....................................................................................................................................39

4.11 Network connection.....................................................................................................................41

Chapter 5 Installing CHARMs hardware........................................................................................45

5.1 Install the +24 V DC Power Module................................................................................................. 48

MHM-97923-PBF, Rev. 2.5 v

Contents Installation Guide

June 2022 MHM-97923-PBF

5.1.1 Connect the power supply...........................................................................................................49

5.2 Install a VI Piezo CHARM................................................................................................................. 49

5.2.1 Connect the sensor wiring........................................................................................................... 50

5.3 Install a VI Tach CHARM..................................................................................................................51

5.3.1 Connect the sensor wiring........................................................................................................... 52

5.4 Install a VI Voltage CHARM............................................................................................................. 55

5.4.1 Connect the voltage input wiring................................................................................................ 56

5.5 Install a DO 24 V DC High-Side CHARM...........................................................................................57

5.5.1 Connect the output signal wiring.................................................................................................58

5.5.2 Connect the relay output wiring.................................................................................................. 59

5.6 Install a DI 24 V DC Low-Side Sens CHARM......................................................................................60

5.6.1 Connect the input signal wiring................................................................................................... 61

5.7 Install a AI 4 to 20 mA CHARM........................................................................................................ 62

5.7.1 Connect the input signal wiring – self-powered........................................................................... 63

5.7.2 Connect the input signal wiring – loop-powered......................................................................... 64

5.8 Install a RTD CHARM.......................................................................................................................65

5.8.1 Connect the sensor wiring........................................................................................................... 66

5.9 Install a Thermocouple/mV input CHARM.......................................................................................67

5.9.1 Connect the sensor wiring........................................................................................................... 68

5.10 Install the Address Plug.................................................................................................................69

5.11 Label the installed CHARMs.......................................................................................................... 70

5.12 CHARM Protection Cover..............................................................................................................72

Chapter 6 Removing CHARMs hardware.......................................................................................73

6.1 Remove a CHARM...........................................................................................................................73

6.2 Remove a Terminal Block................................................................................................................74

6.3 Remove the Address Plug............................................................................................................... 75

6.4 Remove the CHARM Address Terminal Block.................................................................................. 75

6.5 Remove the +24 V DC Power Module............................................................................................. 75

Chapter 7 Hazardous location installation.................................................................................... 77

7.1 General installation requirements...................................................................................................77

7.2 Connection requirements...............................................................................................................77

7.3 Special conditions of safe use......................................................................................................... 77

7.4 Technical data, explosion protection.............................................................................................. 78

7.5 Revision history.............................................................................................................................. 79

Chapter 8 Maintenance, troubleshooting, replacement and repair .............................................. 81

8.1 Maintenance.................................................................................................................................. 81

8.2 Troubleshooting.............................................................................................................................81

8.3 Replacement and repair................................................................................................................. 82

8.3.1 Replace a defective +24 V DC Power Module............................................................................... 82

8.3.2 Replace a defective CHARM.........................................................................................................83

vi MHM-97923-PBF, Rev. 2.5

Installation Guide Contents

MHM-97923-PBF June 2022

8.3.3 Replace a defective AMS Asset Monitor....................................................................................... 83

Chapter 9 Technical data..............................................................................................................85

9.1 Connections and interfaces............................................................................................................ 85

9.2 Indications and buttons..................................................................................................................86

9.3 Slots............................................................................................................................................... 86

9.4 Dimensions and electrical data – AMS Asset Monitor......................................................................86

9.5 Dimensions and electrical data – +24 V DC Power Module..............................................................87

9.6 Environmental conditions – AMS Asset Monitor............................................................................. 88

9.7 Environmental conditions – +24 V DC Power Module..................................................................... 89

Chapter 10 Certificates.................................................................................................................. 91

MHM-97923-PBF, Rev. 2.5 vii

Contents Installation Guide

June 2022 MHM-97923-PBF

viii MHM-97923-PBF, Rev. 2.5

Installation Guide General

MHM-97923-PBF June 2022

1 General

1.1 About this manual

This manual contains specifications, wiring diagrams, dimensions, and step-by-step

instructions for installing the AMS Asset Monitor hardware.

Read this guide completely prior to starting installation of the device. Comply with all

safety instructions.

This installation guides applies for an AMS Asset Monitor with a hardware revision listed in

Table 1-1. See type plate for revision level.

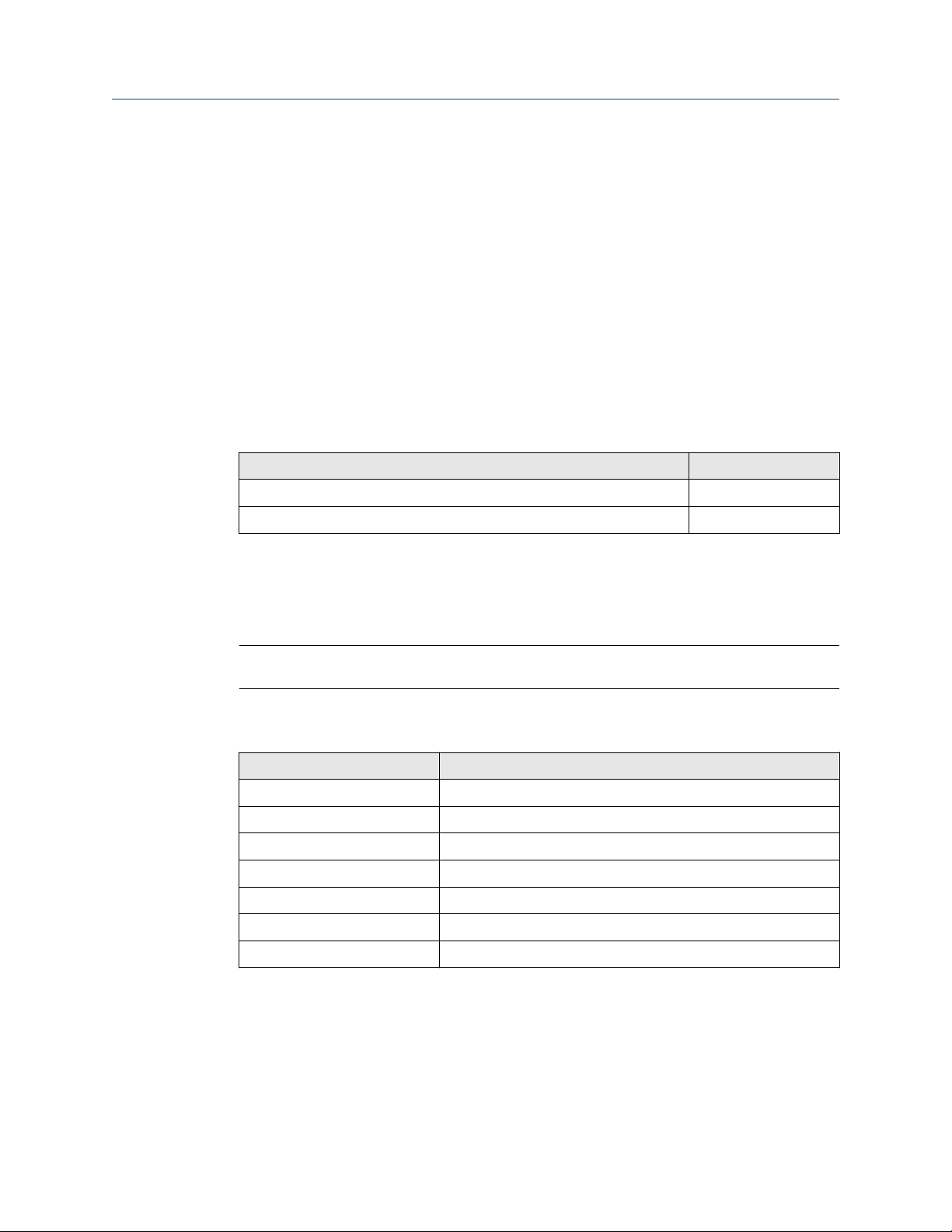

Table 1-1: Hardware revision

Component Revision

AMS Asset Monitor 13 and later

+24 V DC Power Module 08, 09

The hazardous location approvals described in Hazardous location installation and the EU

Declaration of Conformity (Certificates) do not apply to the blue AMS Asset Monitor –

Marine Paint variant AM 5820-IM BL.

Include the installation guide when transferring the device to third parties.

Note

When requesting technical support, indicate type and serial number from the type plate.

See Table 1-2 for a list of documents referred to in this installation guide.

Table 1-2: Referenced documents

Part number Document name

MHM-97924-PBF Operating Manual AMS Asset Monitor

MHM-97925-PBF Installation Guide VI Piezo CHARM

MHM-97930-PBF Installation Guide VI Tach CHARM

MHM-97929-PBF Installation Guide VI Voltage CHARM

D800040X072 DeltaV™ S-series and CHARMs Hardware Reference

12P5401 Div. 2 Installation Instruction

12P5403 Zone 2 Installation Instruction

See Table 1-3 for product type and ordering numbers of the hardware referred to in this

installation guide.

MHM-97923-PBF, Rev. 2.5 9

General Installation Guide

June 2022 MHM-97923-PBF

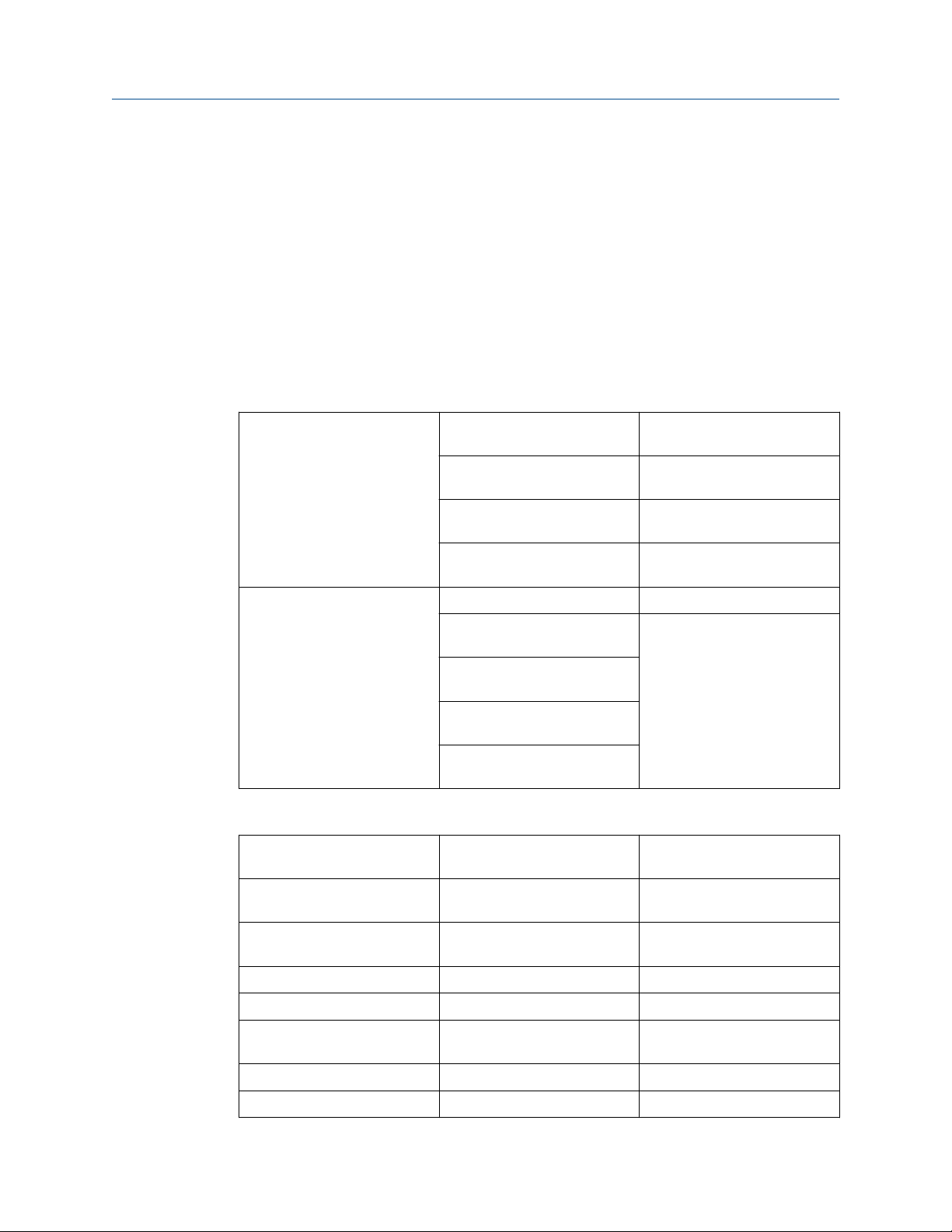

Table 1-3: Product type and ordering numbers of AMS Asset Monitor and compatible

DeltaV hardware

Hardware Product type number Ordering number

AMS Asset Monitor AM 5820-IM SE8701T01-IM

AMS Asset Monitor – Marine

Paint

+24 V DC Power Module AM 5730 SE8701T02-IP

VI Piezo CHARM AM 5125 SE8701V01-PZ

VI Voltage CHARM AM 5620 SE8701V02-VT

VI Tach CHARM AM 5312 SE8701V03-TH

RTD CHARM KL3031X1-BA1 SE4303T03

Thermocouple/mV input

CHARM

AI 4 to 20 mA CHARM KL3021X1-BA1 SE4303T01

DI 24 V DC Low-Side Sens (dry

contact) CHARM

DO 24 V DC High-Side CHARM KL3002X1-BA1 SE4302T01

Standard Terminal Block KL4502X1-BA1 SE4501

Thermocouple/mV Terminal

Block

Relay Output Terminal Block KL4502X1-MA1 SE4503

Address Terminal Screw Block KL4502X1-DA1 KL4502X1-DA1

Address Terminal Plug #1 KL4501X1-BA1 KL4501X1-BA1

AM 5820-IM BL SE8701T01-IM2

KL3032X1-BA1 SE4303T02

KL3003X1-BA1 SE4301T02

KL4502X1-NA1 SE4504

Channel Identifier Label\Wiring

Cover

--- SE4606T04

1.2 Symbols

Note

This symbol marks passages that contain important information.

CAUTION

This symbol marks operations that can lead to malfunctions or faulty measurements, but

will not damage the device.

DANGER

A danger indicates actions that can lead to property damage or personal injury.

According to IEC 61010, this symbol means that this device must be

operated with DC voltage.

10 MHM-97923-PBF, Rev. 2.5

Installation Guide General

MHM-97923-PBF June 2022

Warning, electric shock hazard.

According to IEC 61010, this symbol means that the documentation of

the device must completely be read and understood before installing and

commissioning of the device. Observe all safety related instructions in this

document.

1.3 Liability and guarantee

Emerson is not liable for damages that occur due to improper use. Proper use also includes

the knowledge of, and compliance with, this document.

Customer changes to the device that have not been expressly approved by Emerson will

result in the loss of guarantee.

Due to continuous research and further development, Emerson reserves the right to

change technical specifications without notice.

1.4 Incoming goods inspection

Check the content of the shipment to ensure that it is complete. Inspect the goods to

determine if the device has been damaged during transport. The following parts are at

least included in the scope of delivery and must be contained in the shipment:

• AMS Asset Monitor

• Quick Start Guide AMS Asset Monitor (MHM-97926-PBF)

If the contents are incomplete, or if you observe any defects, file a complaint with the

carrier immediately. Inform the responsible Emerson sales organization, so your device

can be replaced. In this case, attach a tag with customer name and the observed defect.

Additional parts are required to set up an operable system, see About the AMS Asset

Monitor hardware for details.

1.5 Technical support

You may need to ship this product for return, replacement, or repair to an Emerson

Product Service Center. Before shipping this product, contact Emerson Product Support to

obtain a Return Materials Authorization (RMA) number and receive additional instructions.

Product Support

Emerson provides a variety of ways to reach your Product Support team to get the answers

you need when you need them:

Phone

MHM-97923-PBF, Rev. 2.5 11

Toll free 800.833.8314 (U.S. and Canada)

+1.512.832.3774 (Latin America)

General Installation Guide

June 2022 MHM-97923-PBF

+63.2702.1111 (Asia Pacific, Europe, and Middle East)

Email

Web

To search for documentation, visit http://www.emerson.com.

To view toll free numbers for specific countries, visit http://www.emersonprocess.com/

technicalsupport.

Note

If the equipment has been exposed to a hazardous substance, a Material Safety Data Sheet

(MSDS) must be included with the returned materials. An MSDS is required by law to be

available to people exposed to specific hazardous substances.

Guardian.GSC@Emerson.com

http://www.emerson.com/en-us/contact-us

1.6 Storage and transport

Store and transport the device only in its original packaging. Technical data specifies the

environmental conditions for storage and support.

1.7 Disposal of the device

Provided that no repurchase or disposal agreement exists, recycle the following

components at appropriate facilities:

• Recyclable metal

• Plastic elements

Sort the remaining components for disposal, based on their condition. National laws or

provisions on waste disposal and protection of the environment apply.

Note

Environmental hazards! Electrical waste and electronic components are subject to

treatment as special waste and may only be disposed by approved specialized companies.

1.8 China RoHS Compliance

Our products manufactured later than June 30, 2016 and those which are sold in the

People's Republic of China are marked with one of the following two logos to indicate the

Environmental Friendly Use Period in which it can be used safely under normal operating

conditions.

Products without below mentioned marking are either manufactured before June 30 or

are non-electrical equipment products (EEP).

Circling arrow symbol with "e": The product contains no hazardous substances over

the Maximum Concentration Value and it has an indefinite Environmental Friendly

Use Period.

12 MHM-97923-PBF, Rev. 2.5

Installation Guide General

MHM-97923-PBF June 2022

Circling arrow symbol with a number: This product contains certain hazardous

substances over the Maximum Concentration Value and it can be used safely under

normal operating conditions for the number of years indicated in the symbol. The

names and contents of hazardous substances can be found in the folder "China

RoHS Compliance Certificates" on the documentation CD or DVD enclosed with the

product.

1.9 CCC Certification – AMS Asset Monitor

With the announcement of the Chinese market regulation authority SAMR (State

Administration for Market Regulation), a Compulsory Product Certification (CCC

certification) is mandatory for many explosion protection products. This explosion proof

(“Ex”) product complies to the CCC obligation and is certified (certification number:

2020322309002379).

This China Compulsory Certificate mark (CCC), is a compulsory safety mark for

many products imported, sold, or used in the Chinese market and indicates that the

product is certified in accordance to GB 3836.1-2010, GB 3836.4-2010, and GB

3836.8-2014. If the product label is to small to contain the CCC certification mark it

is sufficient to have the mark printed on the minimum package and in the attached

document.

1.10 Installation awareness

Note

When planning a measurement, observe the following items:

• Consider environmental conditions which might have an influence on the

measurement such as temperature, humidity, substances aggressive to the sensor,

and pollution.

• Always use a stiff and vibration-free sensor holder.

• Define a suitable measuring range, not larger than necessary, in consultation with the

operator of the plant.

• Define the trip limit in consultation with the operator of the plant.

• Take measurement deviations into account when defining the trip limit.

• Use a sensor that meets the requirements of the defined measuring range.

• Ensure an EMC-compatible installation including the use of proper cables.

• Ensure proper function of the measurement before activating the measurement for

regular operation.

MHM-97923-PBF, Rev. 2.5 13

General Installation Guide

June 2022 MHM-97923-PBF

14 MHM-97923-PBF, Rev. 2.5

Installation Guide Safety instructions

MHM-97923-PBF June 2022

2 Safety instructions

To ensure safe operation, carefully observe all instructions in this manual.

The correct and safe use of this device requires that operating and service personnel both

understand and comply with general safety guidelines and observe the special safety

comments listed in this manual. Where necessary, safety-sensitive points on the device

are marked.

DANGER

Because the device is electrical equipment, commissioning and service must be performed

only by trained and authorized personnel. Maintenance must be carried out only by

trained, specialized, and experienced personnel.

2.1 Using the device

Install and use the device as specified in this document.

If the device is used in a manner not specified by the manufacturer, the functions and

protection provided by the device may be impaired.

2.2 Owner's responsibility

If there is a reason to suspect that hazard-free operation, and thus, adequate machine

protection is no longer possible, take the device out of operation and safeguard it from

unintentional operation. This is the case:

• if the device shows visible damage.

• if the device no longer works.

• after any kind of overload that has exceeded the permissible limits (such as those

detailed in chapter "Technical data," section "Environmental conditions").

DANGER

If device tests have to be completed during operation or if the device has to be replaced or

decommissioned, it will impair the machine protection and may cause the machine to

shut down. Make sure to deactivate machine protection before starting such work, and

reactivate it after work has been completed.

2.3 Radio interference

The device is carefully shielded and tested to be technically immune to radio interference

and complies with current standards. However, if you operate this device together with

other peripheral devices that are not properly shielded against radio interference,

disturbances and radio interferences may occur.

MHM-97923-PBF, Rev. 2.5 15

Safety instructions Installation Guide

June 2022 MHM-97923-PBF

2.4 ESD safety

DANGER

Internal components can be damaged or destroyed due to electrostatic discharge (ESD)

during the handling of the device.

Take suitable precautions before handling the device to prevent electrostatic discharges

through the sensor electronics. Such measures might include, for example, wearing an

ESD bracelet. Transport and storage of electronic components may only be made in ESDsafe packaging.

Handle the device with particular care during dry meteorological conditions with relative

humidity below 30% as electrostatic discharges can appear more frequently.

2.5 Important information about hazardous live voltages

DANGER

The KL4502X1-MA1 CHARM Relay Output Terminal Block may have hazardous live

voltages on its output terminals. This terminal block is capable to switch field power of 250

V AC. Ensure that proper safety precautions, such as de-energizing field power, are

observed during installation, maintenance, or any time wiring changes are made to the

CHARM Relay Output Terminal Block.

For further information about hazardous live voltages see Wiring guidelines and CSA –

General safety.

16 MHM-97923-PBF, Rev. 2.5

Installation Guide Planning the installation

MHM-97923-PBF June 2022

3 Planning the installation

Emerson recommends two people to mount the AMS Asset Monitor.

3.1 Tools required to install the hardware

Standard tools are required to install the AMS Asset Monitor hardware:

Wire cutter

Wire stripper

Crimper

3.5 mm flat-tip

screwdriver

PH 2 cross-tip

screwdriver

PZ 3 cross-tip

screwdriver

Screwdriver

Voltmeter

For shortening the connection wires.

For removing the insulation from the wire.

For crimping ferrules.

For the CHARM Terminal Block, power supply terminals, and

baseplate grounding terminals.

For the internal grounding terminals of the AMS Asset

Monitor.

For the door screws and grounding terminal at the AMS Asset

Monitor bottom.

Suitable for the screws, selected for mounting the AMS Asset

Monitor on a wall, mounting plate, or mounting frame. Size

and type of the screwdriver depends on the selected fixing

method.

To check the supply voltage and the connected signals.

3.2 Torque limits for mounting screws

Table 3-1 lists the permissible maximum torque limits for the screws of the AMS Asset

Monitor hardware.

Table 3-1: Maximum torque limits

Hardware part Maximum torque limit

Power supply terminal screws 0.5 Nm

CHARM Terminal Block screws 0.45 Nm

Cable shield grounding terminals 0.45 Nm

Grounding terminal at the bottom 8.7 Nm

Additional grounding terminals for ground connection 5.1 Nm

The recommended tightening torque is the maximum torque limit minus 20%.

MHM-97923-PBF, Rev. 2.5 17

Planning the installation Installation Guide

June 2022 MHM-97923-PBF

3.3 Wiring guidelines

This section contains general information and wiring hints. As always, proper cable

installation depends on observation and judgment based on the situation on-site. Observe

the following points for a reliable cable installation:

• Install cables according to general standards for measuring and control cables.

• Separate AC voltage circuits from low voltage signals to comply with safety

recommendations and to mitigate induced noise in the signals. This good practice is

recommended by Emerson although any signal type can be installed in any CHARM slot

of the AMS Asset Monitor.

• If possible, install cables in metallic cable channels or tubes.

• Observe an orthogonal cable routing.

• Do not squeeze, bent, or twist cables. Always observe the permissible bending radius

of the used cable.

• Install cables strain-free and spin-free to protect them against mechanical damages.

• Affix cables to a secure surface at regular, short distances.

• Ensure that no parts of the cable touch any rotating parts of the machine.

• Note that machine parts or other metallic parts can expand or shrink due to

temperature influences. Always install cables with a cable length reserve to

compensate the thermal behavior of such parts.

•

Always use ferrules for stranded wires. Ensure that all strands are covered by the

ferrule so that no strand can contact an adjacent terminal. When strands are

stripped 10 mm and ferrules are not used, consider that there is a risk of short

circuit – a possibility of accidental contact between HAZARDOUS LIVE parts of

different polarity.

• At environmental temperatures of 50°C and above use cables suitable for temperatures

above 60°C within the AMS Asset Monitor.

See Table 3-2 for the permissible wire-cross sections for the voltage supply terminals and

cable shield terminals. For the maximum tightening torque see Torque limits for mounting

screws.

Table 3-2: Permissible wire-cross sections

Wire description Wire cross-section

Minimum Maximum

Power supply terminals Conductor cross section

stranded

Conductor cross section

stranded AWG

Cable shield terminals Conductor cross section 0.32 mm

0.2 mm

24 12

2

2

2.5 mm

2.5 mm

2

2

Conductor cross section

AWG

18 MHM-97923-PBF, Rev. 2.5

22 14

Installation Guide Planning the installation

MHM-97923-PBF June 2022

Table 3-2: Permissible wire-cross sections

Wire description Wire cross-section

CHARM Terminal Blocks Conductor cross section

The recommended stripping length of the wires is 10 mm.

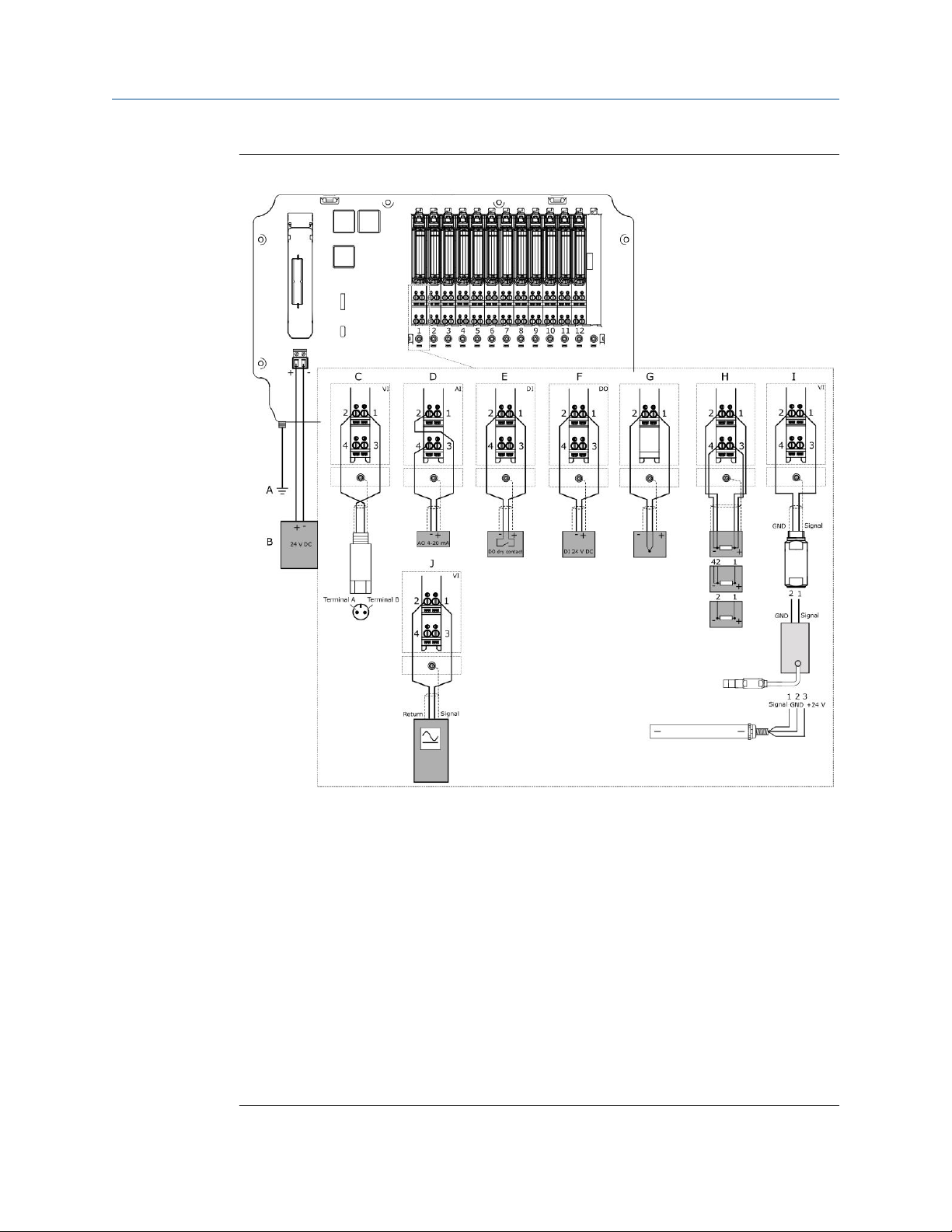

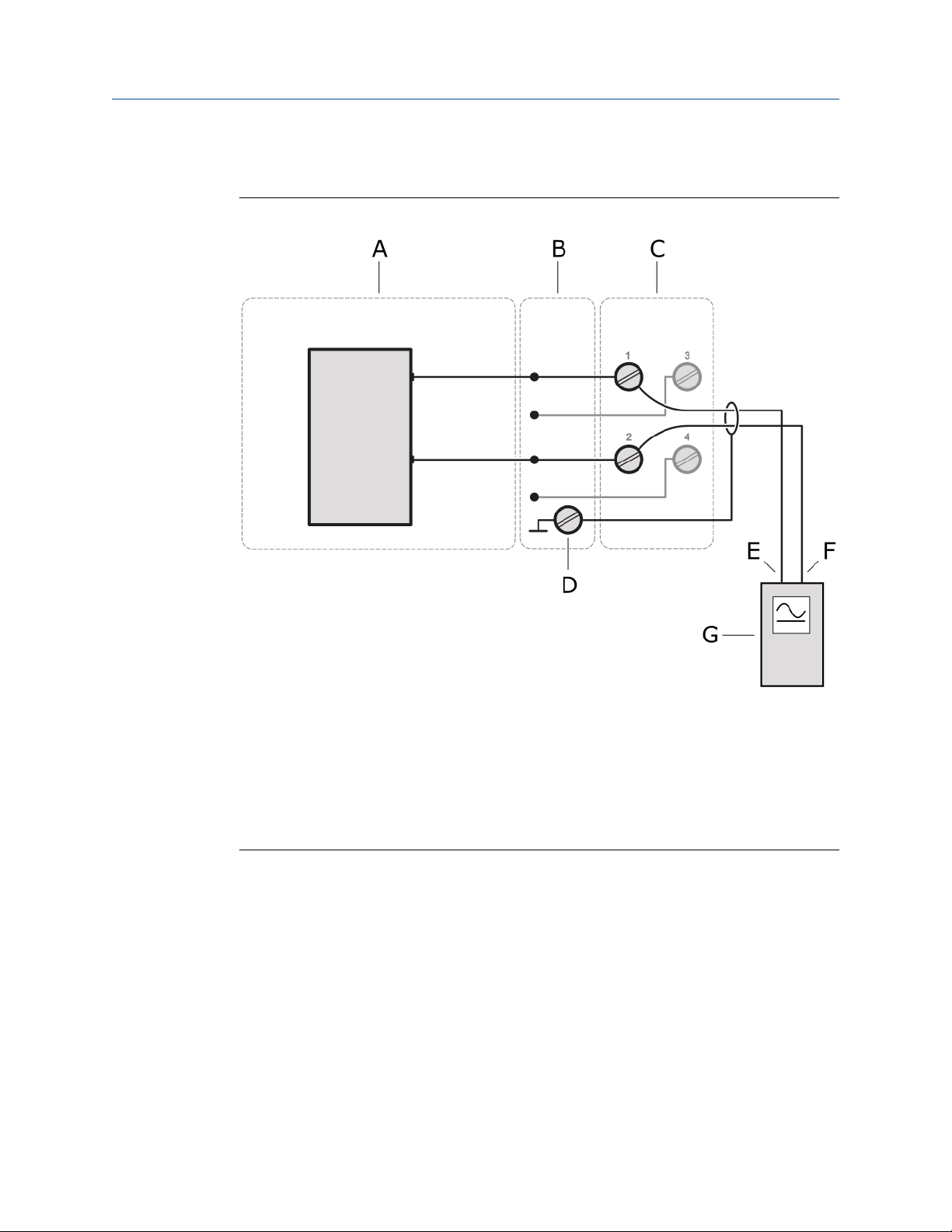

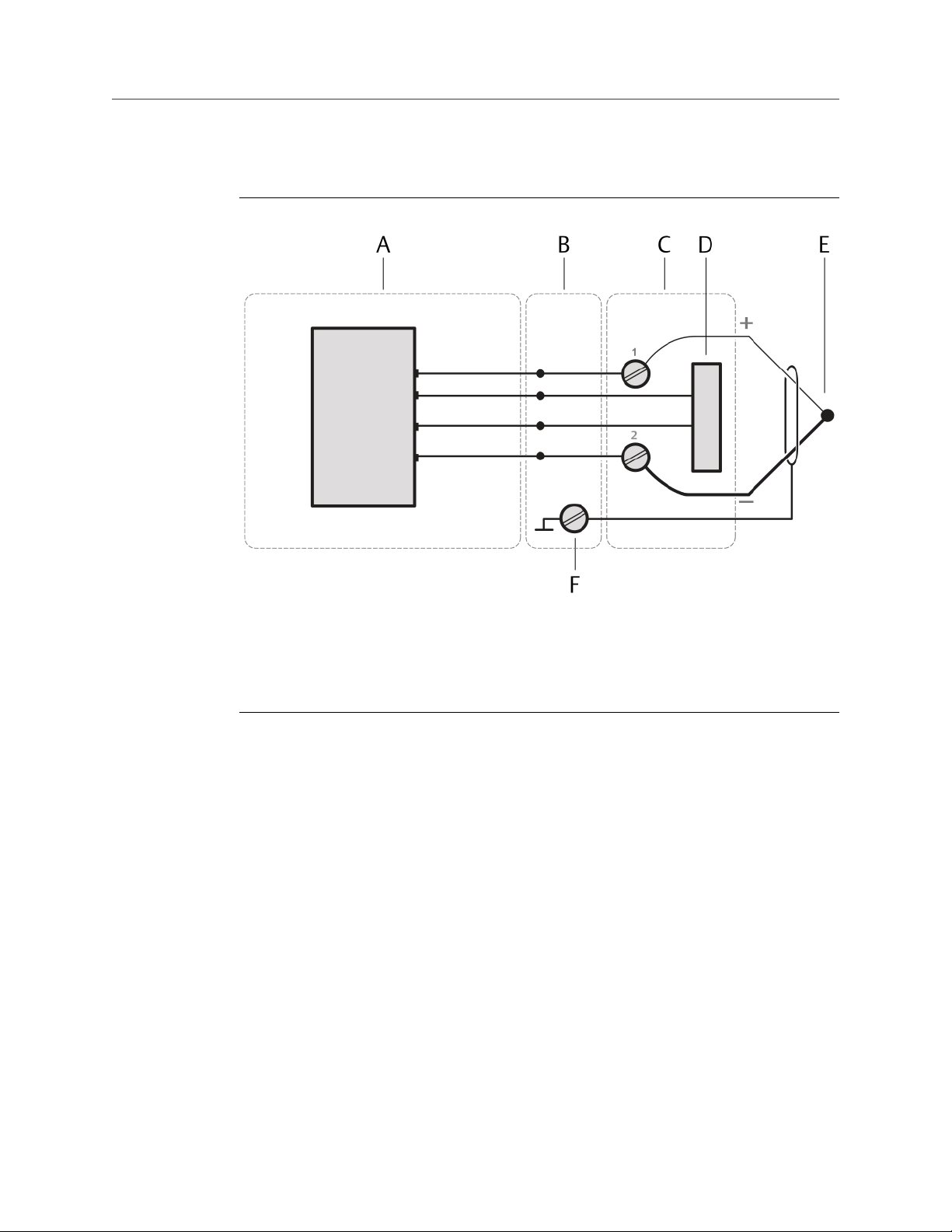

3.3.1 Wiring overview

See Figure 3-1 for an example overview of a standard wiring of an AMS Asset Monitor.

(continued)

Minimum Maximum

22 14

AWG (stranded or solid)

MHM-97923-PBF, Rev. 2.5 19

Planning the installation Installation Guide

June 2022 MHM-97923-PBF

Figure 3-1: Wiring overview

A. Connection to protective ground, see Grounding

B. 24 V DC power supply for the AMS Asset Monitor, see Connect the power supply

C. Connection VI Piezo CHARM, see Connect the sensor wiring

D. Connection analog input AI 4-20 mA CHARM, see Connect the input signal wiring – self-

powered and Connect the input signal wiring – loop-powered

E. Connection digital input DI 24 V DC low-side sense CHARM, see Connect the input signal

wiring

F. Connection digital output DO 24 V DC high-side CHARM, see Connect the output signal

wiring and Connect the relay output wiring

G. Connection Thermocouple Input CHARM, see Connect the sensor wiring

H. Connection RTD Input CHARM (4-wire RTD, 3-wire RTD, and 2-wire RTD), see Connect

the sensor wiring

I. Connection VI Tach CHARM (magnetic pickup, eddy current signal, and Hall-effect

sensor), see Connect the sensor wiring

J. Connection VI Voltage CHARM, see Connect the voltage input wiring

20 MHM-97923-PBF, Rev. 2.5

Installation Guide Planning the installation

MHM-97923-PBF June 2022

3.4 Select a mounting place

Select a suitable mounting place for the AMS Asset Monitor. Requirements for the

mounting place:

• A flat surface like a wall, mounting plate, or a framework. Ensure that the surface of the

selected mounting place does not impair the airflow at the rear side of the AMS Asset

Monitor.

• A location close to the machine to be monitored. The maximum distance between the

AMS Asset Monitor and the machine depends on the maximum permissible signal

cable length of the connected sensors.

• Place the AMS Asset Monitor on a higher level than sensors installed in the machine to

prevent oil from entering the AMS Asset Monitor through the cables.

• Place the AMS Asset Monitor so that all cables can be led through the cable glands at

the bottom of the AMS Asset Monitor.

• Avoid locations where the AMS Asset Monitor is commonly exposed to direct sunlight.

• A 24 V DC power supply for supplying the AMS Asset Monitor.

• An Ethernet network connection for connecting the AMS Asset Monitor to a network.

• Sufficient space in front of the AMS Asset Monitor to open the door (see Dimensions

and electrical data – AMS Asset Monitor for dimensions).

• Sufficient space around the AMS Asset Monitor to ensure proper cooling. Ensure that

there is no heated surface beneath the AMS Asset Monitor.

• Consider the environmental conditions stated in Environmental conditions – AMS

Asset Monitor.

MHM-97923-PBF, Rev. 2.5 21

Planning the installation Installation Guide

June 2022 MHM-97923-PBF

22 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

4 Installing AMS Asset Monitor

hardware

4.1 CSA – General safety

Conditions of acceptability

Observe the listed conditions to built-up a system in accordance with the CSA approval:

• A disconnecting device (required by clause 6.11 of IEC 61010-1:2010) has to be

provided, the power supply disconnecting device or interrupt facility may be used.

• The equipment is supplied by a certified power source which is approved in accordance

to IEC 60950-1 or IEC 61010-1. The DC output of this separately certified power source

shall be below the limits of clause 6.3.1 and 9.4 of IEC 61010-1:2010.

• In combination with a certified external fuse or circuit breaker that shall be used with

the device, all devices are considered to fulfill the requirements of a limited energy

source to clause 9.4 of IEC 61010-1:2010.

This condition does not apply to the Relay Output Terminal Block (KL4502X1MA1).

• Suitable external cords shall be used in the end application and shall be according to

local rules and standards.

• If at any time there is a conflict between the system safety provisions and any relevant

local (national or regional) requirements, the local requirements always take

precedence.

•

The voltage between adjacent terminal blocks must not exceed 300 V.

• The sum of the load current of the outputs of all Discrete Output CHARMs (KL3002X1-

BA1) installed in the AMS Asset Monitor must not exceed 1200 mA, each output must

not exceed 100 mA.

4.2 About the AMS Asset Monitor hardware

The AMS Asset Monitor BASE hardware consists of a rugged enclosure with internal

electronics designed to support up to 12 CHARMs1, an address module, and a +24 V DC

Power Module. The BASE unit provides the infrastructure that connects the CHARMs and

their field signal to the integrated analytics. For communication and configuration, the

AMS Asset Monitor is equipped with three Ethernet interfaces. Use two of the Ethernet

1

CHAR

acterizing Module

MHM-97923-PBF, Rev. 2.5 23

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

interfaces to daisy chain AMS Asset Monitors. Because of the possible network traffic,

Emerson recommends to daisy chain no more than eight AMS Asset Monitors.

The following parts are at least required to set up an operable system:

• AMS Asset Monitor

• +24 V DC Power Module

• CHARMs (CHARM types in accordance to the supervision tasks)

• CHARM Terminal Blocks suitable for the selected CHARMs

• Cable glands, suitable for the environmental conditions on-site

• Address plug with suitable terminal block

The AMS Asset Monitor supports the VI Piezo CHARM, the VI Voltage CHARM, the VI Tach

CHARM, and the DeltaV hardware listed in Table 4-1.

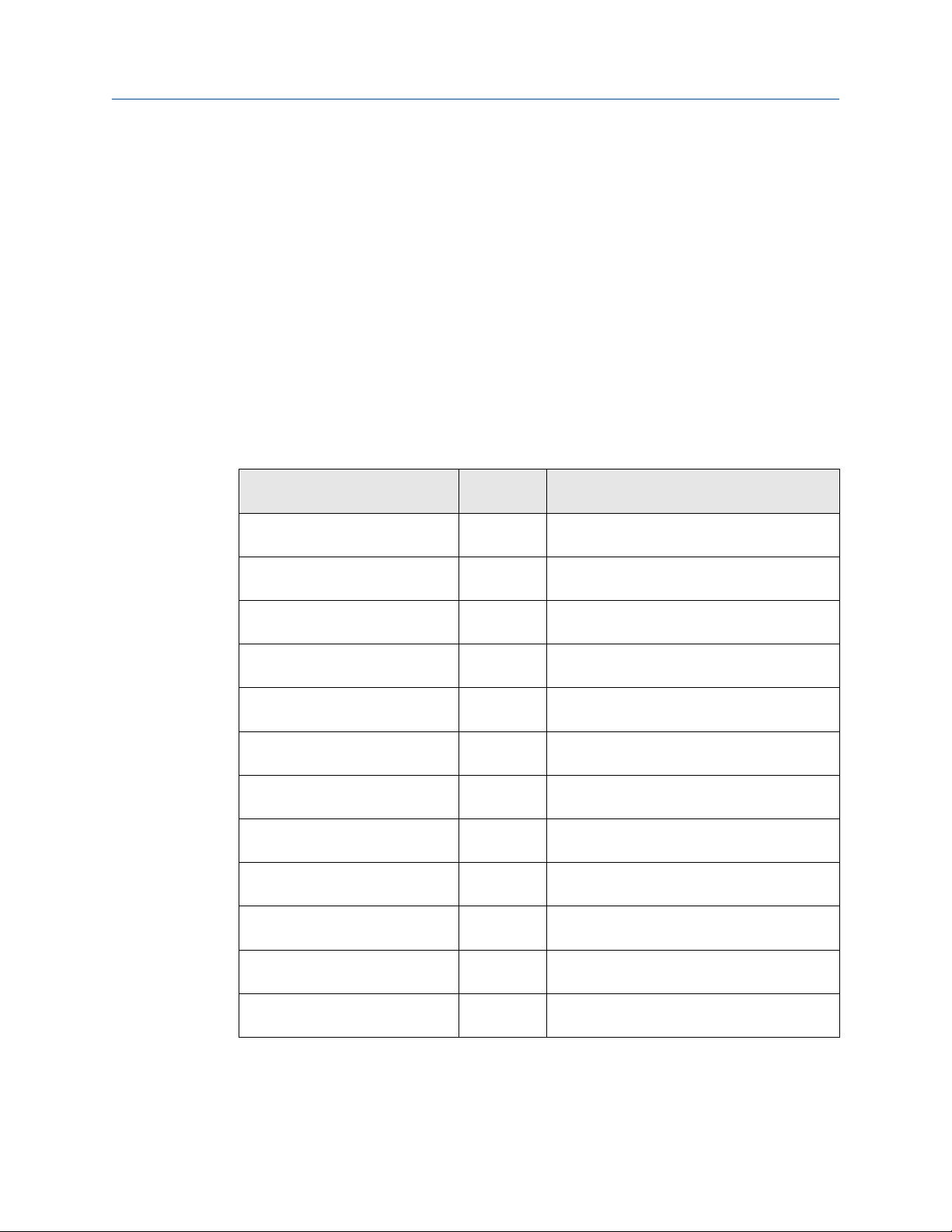

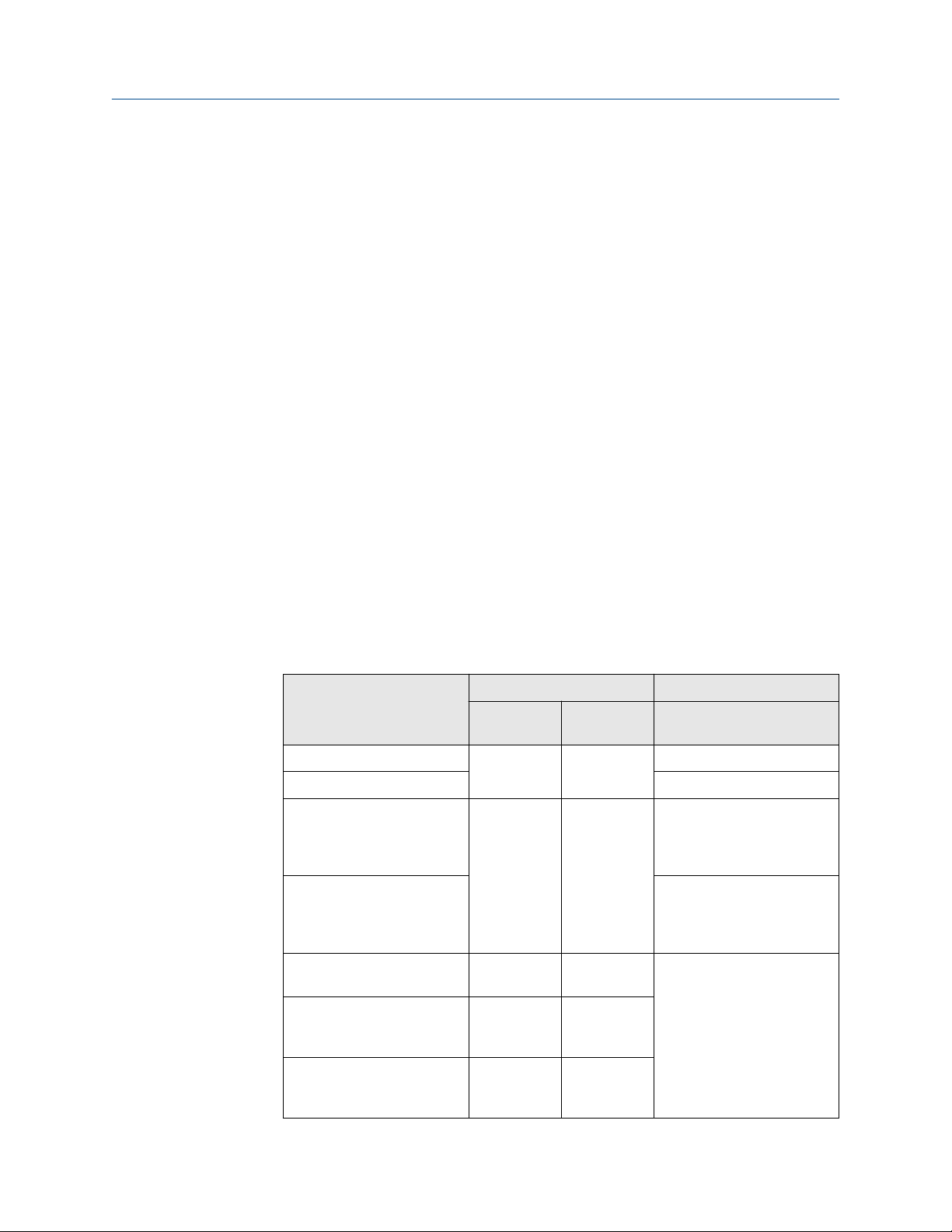

Table 4-1: Supported DeltaV devices

Hardware Type

number

RTD CHARM KL3031X1-

BA1

Thermocouple/mV input CHARM KL3032X1-

BA1

AI 4 to 20 mA CHARM

DI 24 V DC Low-Side Sens (dry

contact) CHARM

DO 24 V DC High-Side CHARM KL3002X1-

Standard Terminal Block KL4502X1-

Thermocouple/mV Terminal Block KL4502X1-

Relay Output Terminal Block KL4502X1-

Address Terminal Screw Block KL4502X1-

Address Terminal Plug #1 KL4501X1-

1

KL3021X1BA1

KL3003X1BA1

BA1

BA1

NA1

MA1

DA1

BA1

Description

CHARM for temperature measurement with

RTD sensors

CHARM for temperature measurement with

Thermocouples

Analog input CHARM for 4 to 20 mA signals

Discrete input CHARM for sensing relay/switch

contact closure

Discrete output CHARM for momentary output

signals or continuous pulse outputs

Terminal block for connection most of the

CHARMs

Terminal block for thermocouple sensors or

mV signals

Output terminal block with relay contacts

Screw terminal block for address plug

Address plug

CHARM Protection Cover KL4502X1-

QA1

Channel Identifier Label/Wiring

Cover

1

No HART (Highway Addressable Remote Transducer) support.

24 MHM-97923-PBF, Rev. 2.5

SE4606T04 Horizontal channel identifier label

Protection cover that fits all terminal blocks

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

The electrical rating of all devices listed in Table 4-1, except the Relay Output Terminal

Block (KL4502X1-MA1), is maximal 100 mA at 24 V DC. The electrical rating of the Relay

Output Terminal Block is maximal 5 A at 250 V, overvoltage category 2.

Ensure that an AMS Asset Monitor used in high voltage applications, high voltages on the

mainboard with rated values up to 250 V AC, 100 mA, and 25 VA, is fully equipped with

terminal blocks. Use a transformer to separate primary circuits (high voltage circuits) from

secondary circuits by double insulation, reinforced insulation or a separator, which is

connected to protection earth.

The maximum permissible input voltage of the VI Tach CHARM is 30.3 V AC. The

maximum input voltage of 30.3 V AC is also the maximum permissible input voltage when

using the VI Tach CHARM in explosion-hazardous areas.

The AMS Asset Monitor has cable entries with 1/2-NPT cable gland threading.

Note

The AMS Asset Monitor is shipped with dust protective caps in the cable inlets. These red

colored caps are only to protect the inner parts of the AMS Asset Monitor during transport.

Remove the dust caps and replace them with proper cable glands or screw plugs. See

Replace the cable inlet dust caps.

See Figure 4-1 to Figure 4-3 for hardware details.

MHM-97923-PBF, Rev. 2.5 25

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

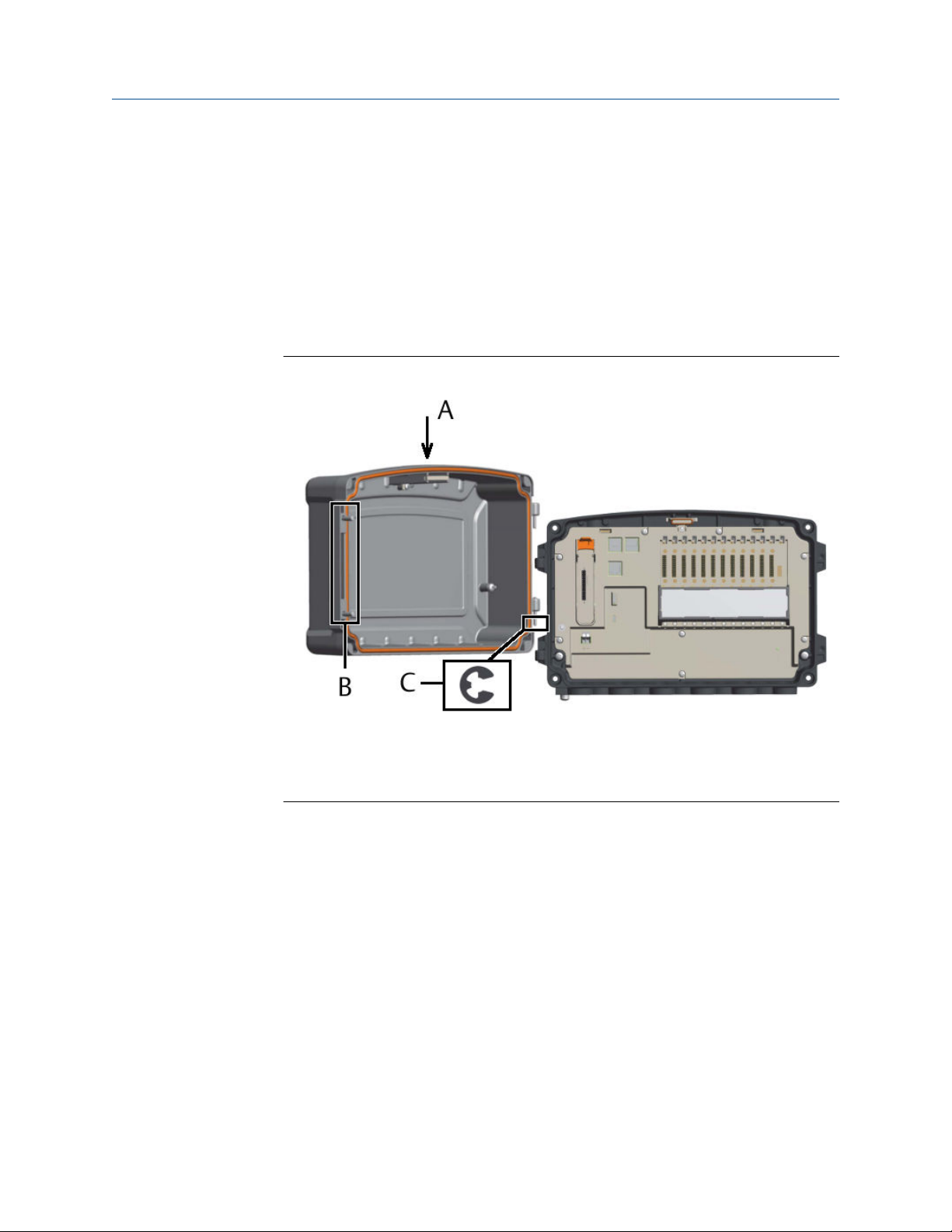

Figure 4-1: Overview – AMS Asset Monitor

A. Status light (if several notifications are present, always the worst is indicated)

B. Door

C. Screws for securing the door

D. Base

E. External grounding terminal

F. Cable entries (cable glands are an optional accessory)

26 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

Figure 4-2: Overview – rear side AMS Asset Monitor

A. Mounting holes

B. Pressure compensation vent

C. Blind mounting holes with standard M8x1.25 thread

MHM-97923-PBF, Rev. 2.5 27

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

Figure 4-3: Overview – open AMS Asset Monitor

A. Ethernet switch with two RJ-45 connectors (left connector: LAN2.1, right connector

LAN2.2) to daisy chain AMS Asset Monitors2, speed 100 Mbit/s

B. RJ-45 Ethernet connector LAN1 for configuration and connection to subsequent systems,

speed 1 Gbit/s

C. Status light

D. CHARM baseplate with 12 slots for up to 12 CHARM terminal blocks, 12 CHARMS, and a

CHARM labeling component

E. Mounting holes

F. Door hinge

G. Screws holes for securing the door

H. Power module slot

I. Address plug slot

J. External grounding terminal

K. Power supply terminals

L. Covered. Non-functional. For internal use only.

M. microSD Card slot (for future use)

N. Reset button with status LED

O. Internal grounding terminals

+24 V DC Power Module

The +24 V DC Power Module is used to supply the AMS Asset Monitor including all installed

CHARMs.

2

Because of the possible network traffic, Emerson recommends to daisy chain no more than eight AMS Asset Monitors.

28 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

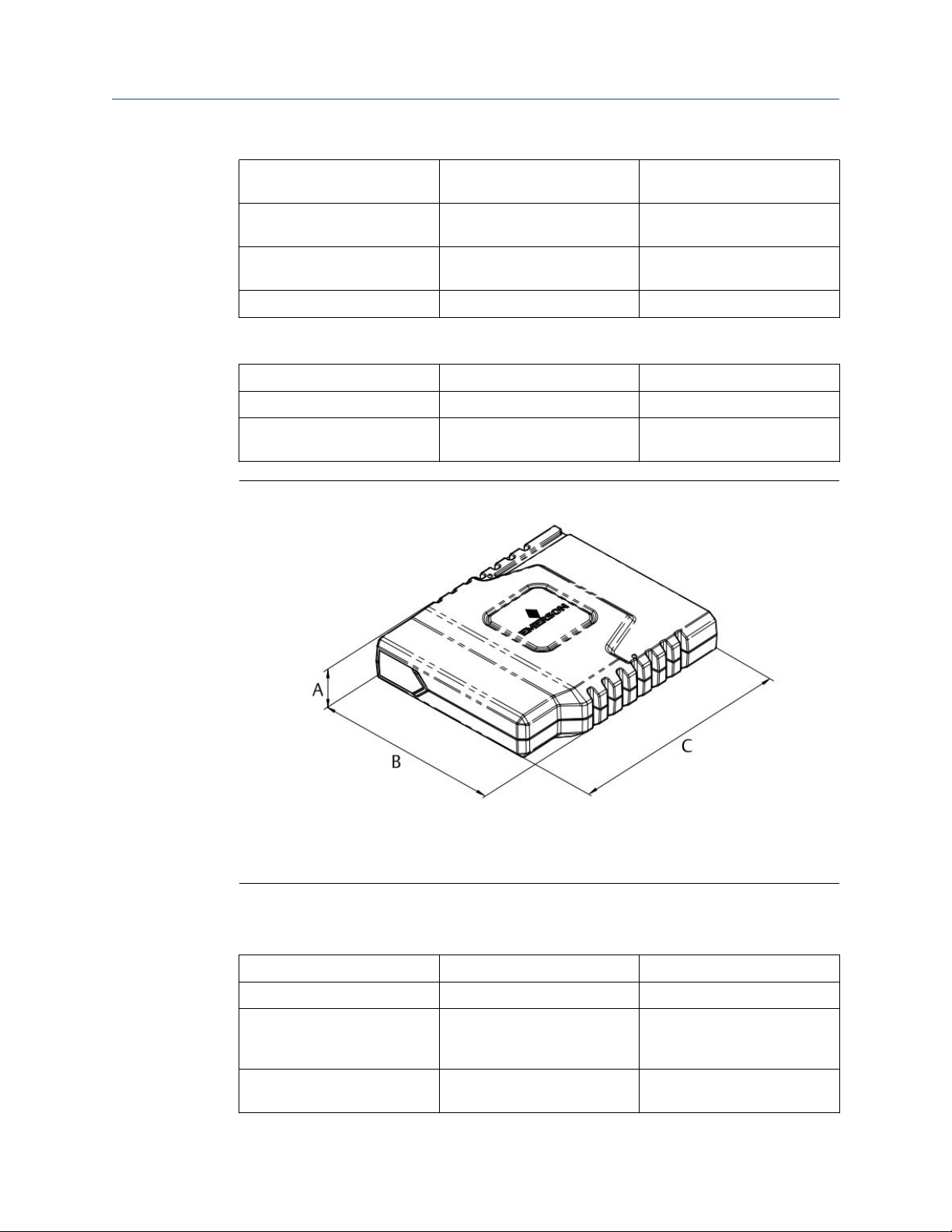

Figure 4-4: +24 V DC Power Module

A. Green and red LED for status indication, see Table 4-2

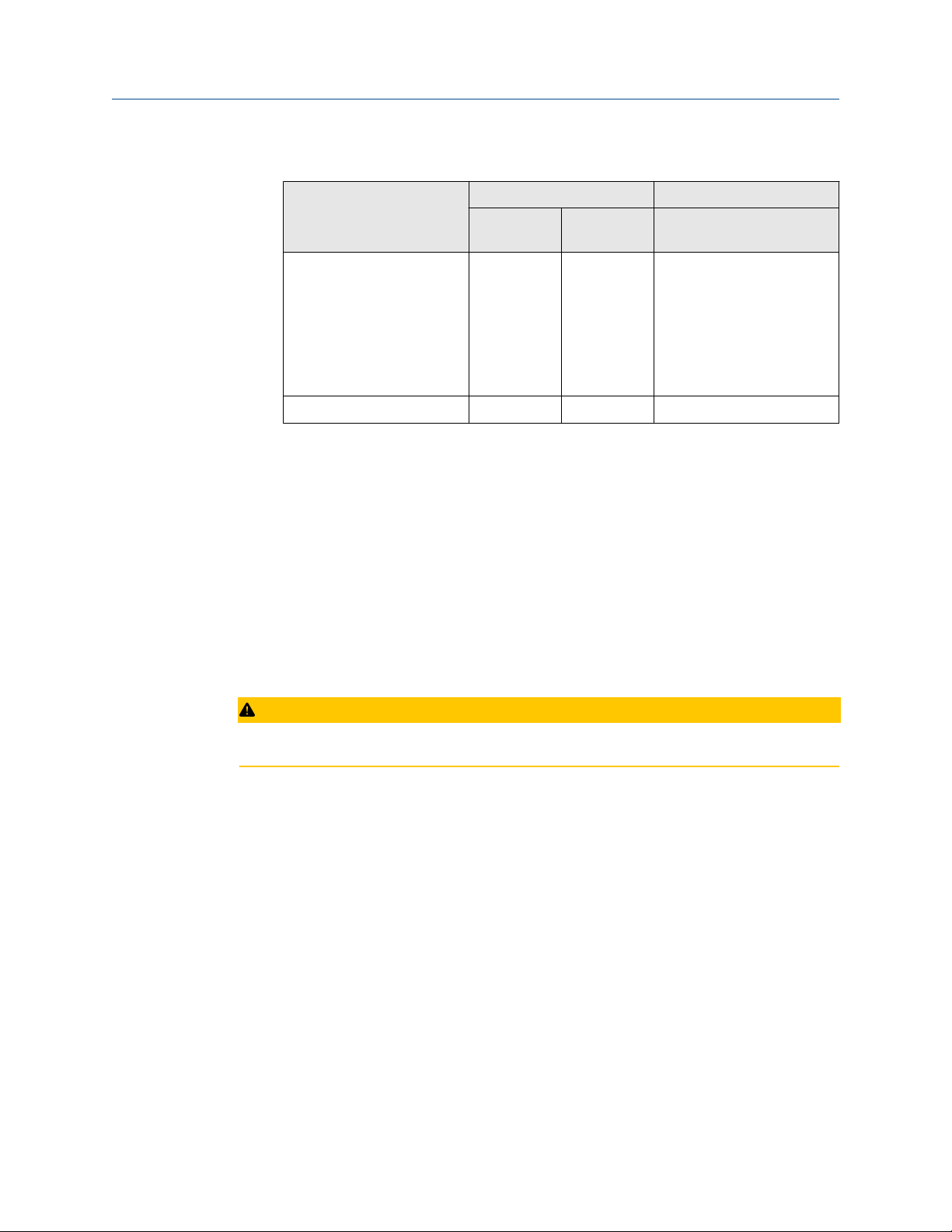

Table 4-2: Meaning of the LED indication

Event LED indication

LED Blinking pattern

Power Module active Green Solid

Power Module inactive Green Off

Input voltage is below 21.6 V DC Red Solid

Input voltage is above 26.4 V DC Red Solid

Input voltage is between 21.6 V DC and 26.4 V DC Red Off

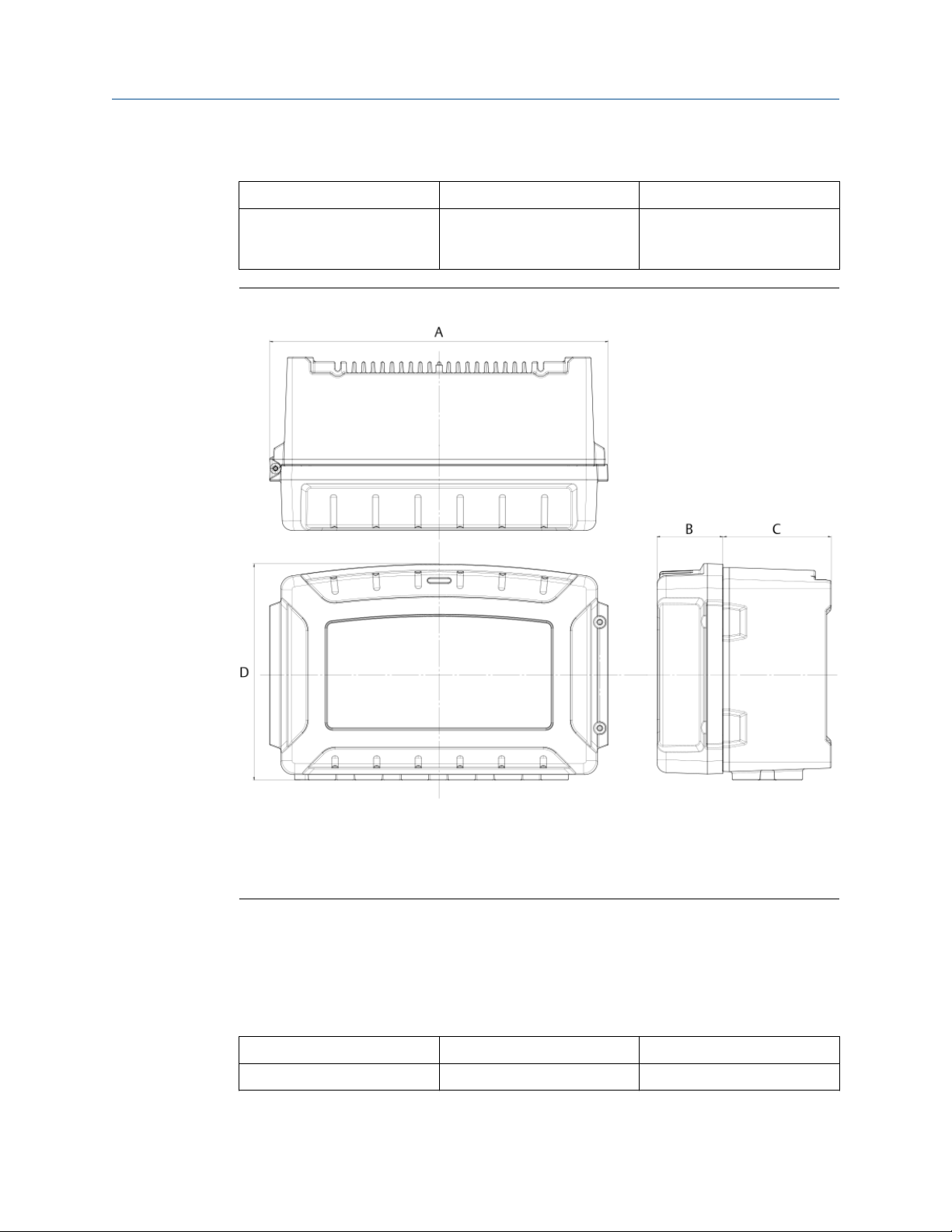

4.3 Position of the mounting holes

The AMS Asset Monitor has four through holes without thread and four blind holes with a

standard M8 thread to mount the AMS Asset Monitor on a flat surface like a wall or on a

framework.

MHM-97923-PBF, Rev. 2.5 29

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

Figure 4-5: Position of the four through holes for mounting

A. 196 mm

B. 6.5 mm

C. 330 mm

30 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

Figure 4-6: Position of the four blind holes for mounting

A. 298 mm

B. 164 mm

C. Blind hole with M8x1.25 thread; depth: 20 mm, threaded depth: 16 mm

4.4 Open the AMS Asset Monitor

All work at the AMS Asset Monitor requires an open door. If the door hinders you from

working at the AMS Asset Monitor, it can be completely removed.

Prerequisites

• A PZ 3 cross-tip screwdriver for the door screws.

• A pair of pliers or a flat-tip screwdriver to remove the circlip.

Procedure

1. Unfasten the screws which are securing the door.

MHM-97923-PBF, Rev. 2.5 31

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

Figure 4-7: Position of the screws

A. Screws for securing the door.

2. Swivel the door to the left to open the AMS Asset Monitor.

3. To remove the door completely, remove the circlip that secures the door from

unintentional removal.

4. Unhinge the door to remove it from the AMS Asset Monitor.

Figure 4-8: Remove the door

A. Lifting direction

B. Circlip

32 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

4.5 Close the AMS Asset Monitor

Prerequisites

• A PZ 3 cross-tip screwdriver for the door screws.

Procedure

1. If the door has been removed completely, hang the door on its hinges.

2. Secure the lower hinge with the circlip.

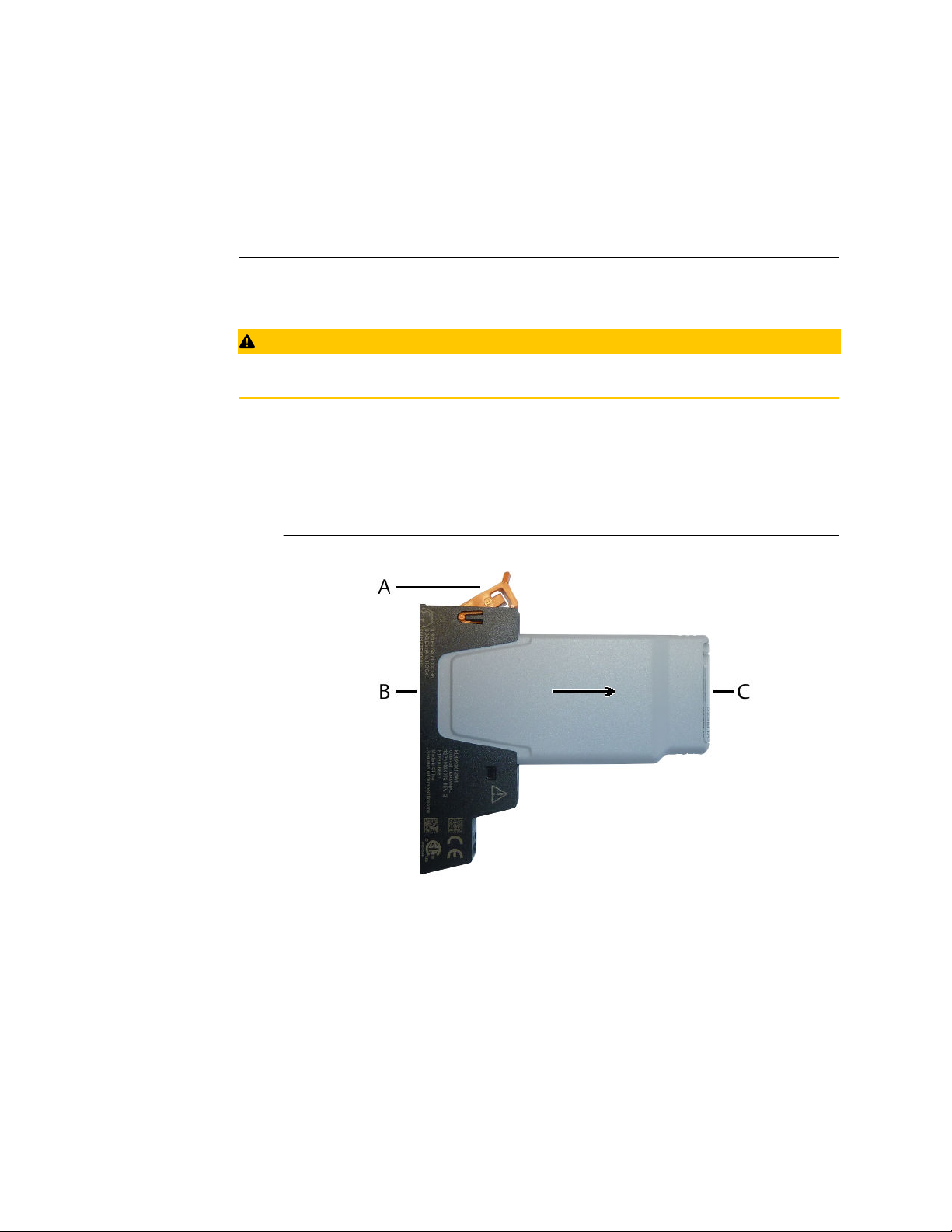

Figure 4-9: Reattach the door

A. Mounting direction

B. Screws for securing the door

C. Circlip

3. Close the door and secure it by fastening the screws.

Tighten the screws until the door touches the base, and is squeezed to ensure a

proper seal.

4.6 Recommended sequence for installing the AMS Asset Monitor

The described installation sequence is a recommendation and can be changed to the

needs of your project.

Procedure

1. Remove the door of the AMS Asset Monitor.

2. Mount the AMS Asset Monitor.

MHM-97923-PBF, Rev. 2.5 33

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

3. Mount cable glands or sealing blind plugs.

4. Install the +24 V DC Power Module.

5. Install the desired CHARMs with terminal blocks.

6. Install the address block.

7. Connect the field wiring.

8. Connect the Ethernet network.

If more than one AMS Asset Monitors are installed, Emerson recommends to daisy

chain them.

9. Connect the power supply and the grounding.

10. Check the installation by checking all cable connections, the power supply voltage,

the LEDs on the devices, and testing the field wiring.

11. Reattach the door.

4.7 Mount the AMS Asset Monitor

Prerequisites

You need two people to lift the AMS Asset Monitor and fix it on the mounting place.

Procedure

1. Remove the door of the AMS Asset Monitor. See Open the AMS Asset Monitor.

2. Prepare the mounting place. Check if available holes fit to the hole pattern of the

AMS Asset Monitor. If not, drill suitable holes according to the hole pattern. See

Position of the mounting holes.

The required diameter and depth of the holes depend on the selected fixing

method.

3. Lift the AMS Asset Monitor on the mounting place.

Ensure that the cable entries point downwards.

4. Fix the AMS Asset Monitor with screws.

The tightening torque depends on the selected screws.

5. Reattach the door. See Close the AMS Asset Monitor.

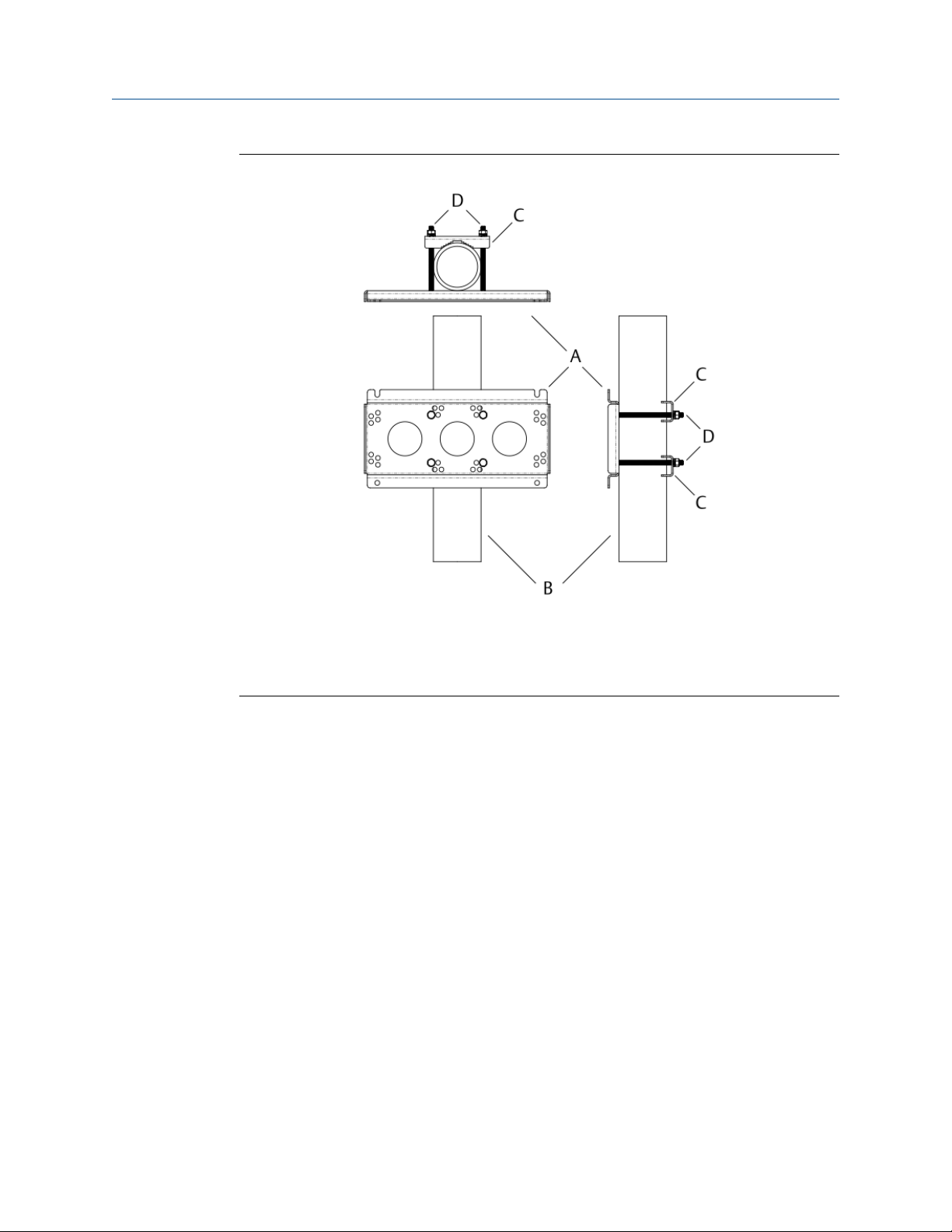

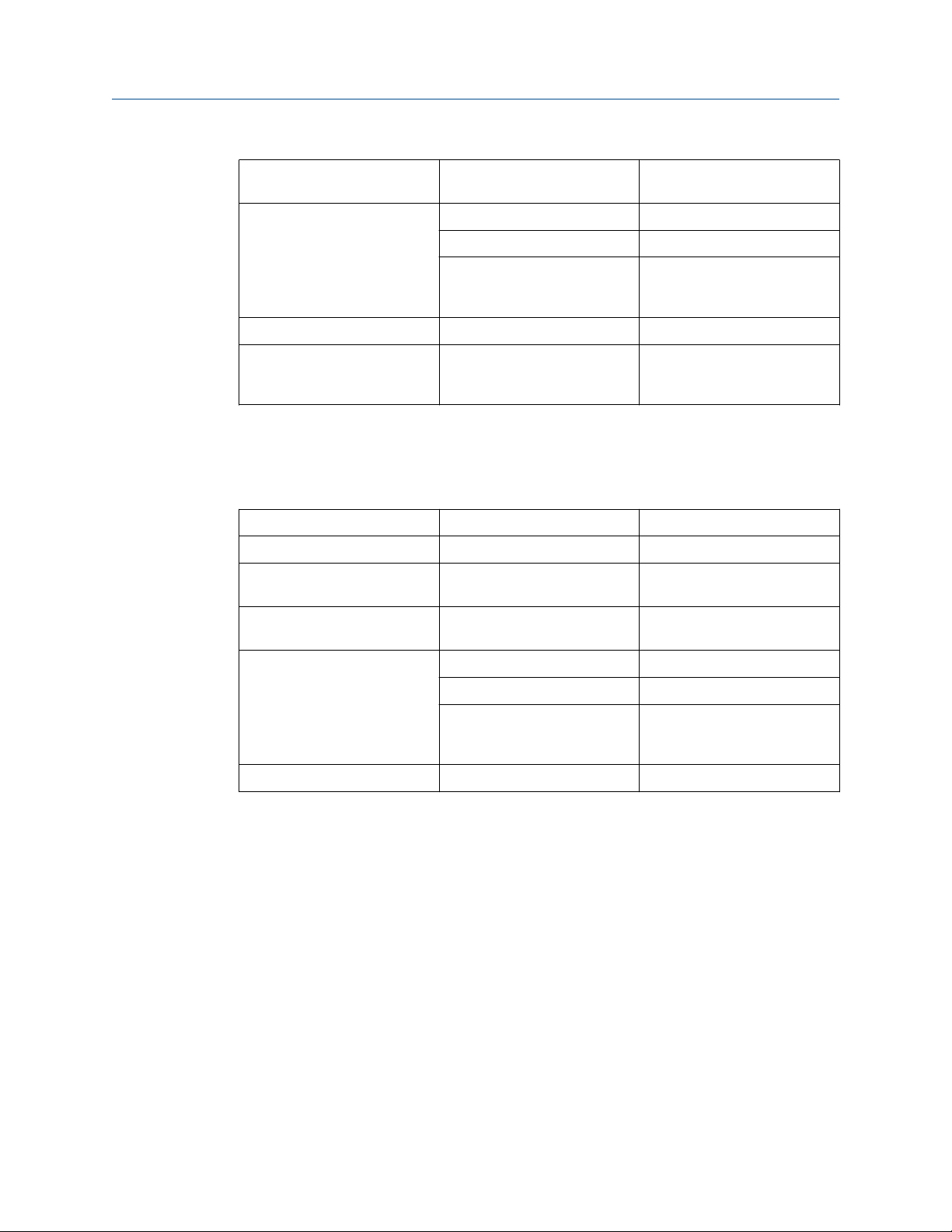

4.8 Mount the AMS Asset Monitor by using the universal mounting bracket

Use the universal mounting bracket SE8701UMB if the AMS Asset Monitor must be

mounted at a post. The bracket is compatible with square profile posts or round profile

posts with the following dimensions:

• Round profile: outside diameter from 50 mm (2.0 in) to 88 mm (3.5 in).

• Square profile: maximum side length 88 mm (3.5 in). Reverse the clamping jaws.

• When installing a new post, Emerson recommends a post with a wall thickness of 3.2

mm (1/8 in).

34 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

Figure 4-10: Universal mounting bracket

A. Plate

B. Post

C. Clamping jaws

D. Bolts with nuts

MHM-97923-PBF, Rev. 2.5 35

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

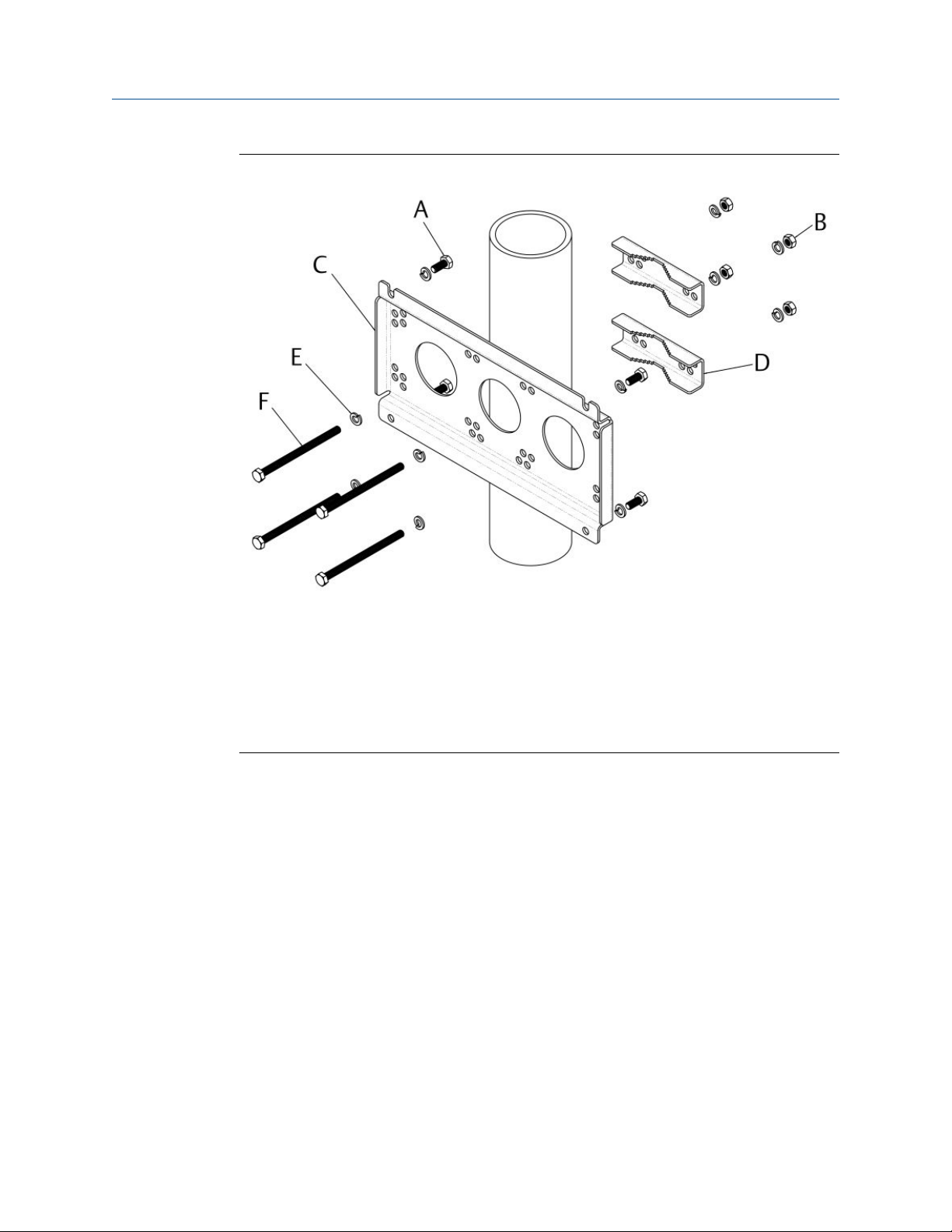

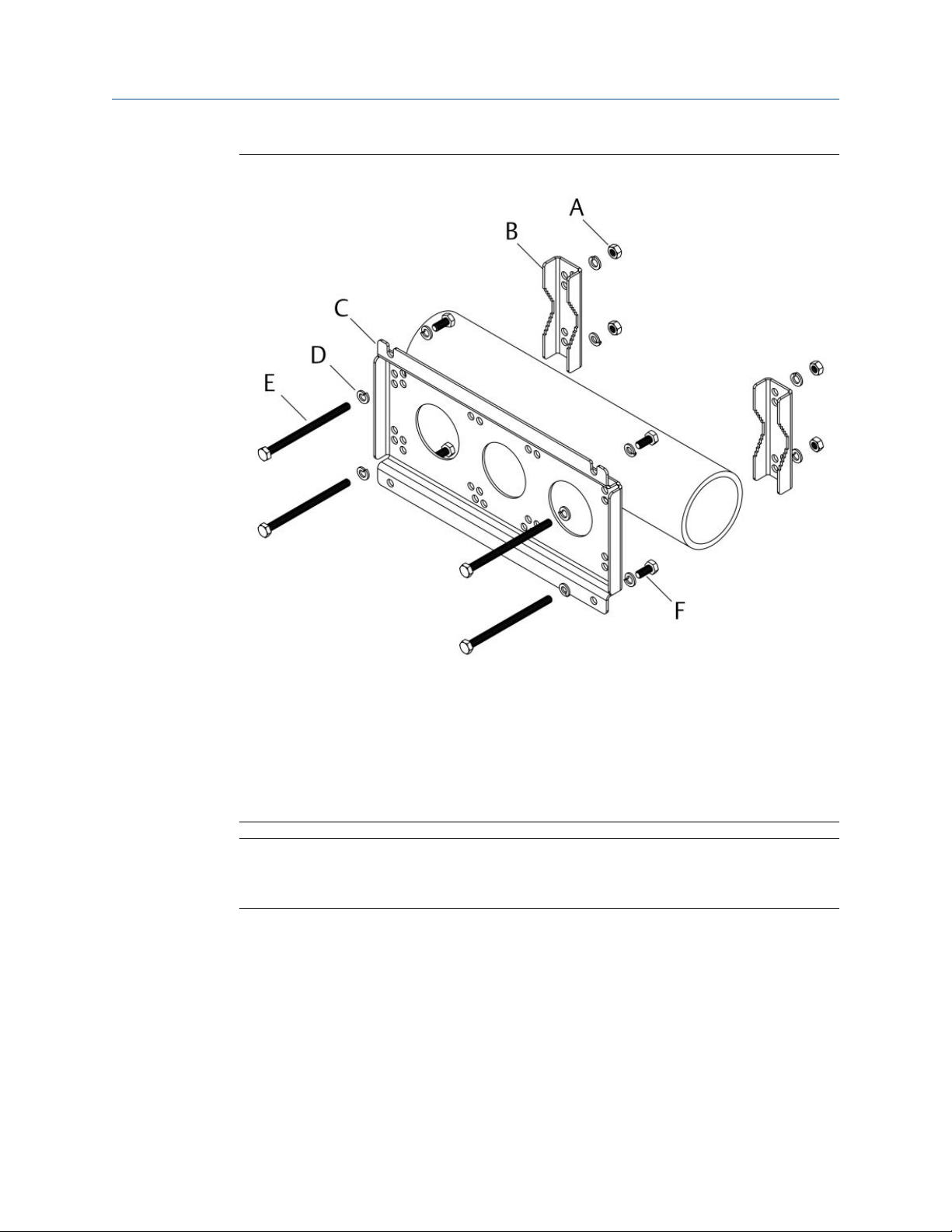

Figure 4-11: Universal mounting bracket – vertical mounting

A. M8 x 1.25 x 18 mm hex head bolt (4x) for mounting the plate on the back of the AMS

Asset Monitor

B. M8 x 1.25 hex nut (4x) for fastening the clamping jaws

C. Mounting plate

D. Clamping jaw (2x)

E. M8 split lock washer (12x)

F. M8 x 1.25 x 120 mm hex head bolt for fastening the clamping jaws

36 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

Figure 4-12: Universal mounting bracket – horizontal mounting

A. M8 x 1.25 hex nut (4x) for fastening the clamping jaws

B. Clamping jaw (2x)

C. Mounting plate

D. M8 split lock washer (12x)

E. M8 x 1.25 x 120 mm hex head bolt for fastening the clamping jaws

F. M8 x 1.25 x 18 mm hex head bolt (4x) for mounting the plate on the back of the AMS

Asset Monitor

Note

Ensure that the post can permanently bear the weight of the AMS Asset Monitor.

Do not mount the AMS Asset Monitor on piping in use.

Prerequisites

You need two suitable spanners/wrenches with 13 mm opening. The tightening torque

may vary depending on the on-site situation.

Procedure

1. Insert the M8 x 1.25 x 120 mm hex head bolts including the split lock washers in the

mounting plate.

• For mounting on a vertical post, use the holes in the middle of the bracket (see

Figure 4-11).

MHM-97923-PBF, Rev. 2.5 37

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

• For mounting on a horizontal post, use the outer holes of the bracket (see Figure

4-12).

2. Place the bracket according to the selected mounting orientation (vertical or

horizontal) on the post. The recesses for the M8 x 1.25 x 18 mm hex head bolts for

mounting the plate on the back of the AMS Asset Monitor must point upwards.

3. Put the clamping jaws on the 120 mm bolts. Align them with the profile of the pole

and fasten the jaws with the included M8 nuts.

4. Check for a tight fit of the mounting bracket.

After proper fastening of the nuts, the mounting bracket cannot be turned at the

post or slipped down.

5. Screw two of the four M8 x 1.25 x 18 mm hex head bolts into both upper blind

mounting holes of the AMS Asset Monitor (see About the AMS Asset Monitor

hardware for location of the blind holes) so that the bolts protrude approximately 8

mm from the Monitor's surface.

6. Hang the AMS Asset Monitor with the bolts mounted beforehand in the recesses of

the bracket.

Ensure that the cable entries point downwards.

7. Screw in the remaining M8 x 1.25 x 18 mm hex head bolts into the lower blind

mounting holes.

8. Tighten the bolts to fix the AMS Asset Monitor on the mounting bracket.

4.9 Replace the cable inlet dust caps

The AMS Asset Monitor is shipped with dust protective caps in the cable inlets. These red

colored caps are only to protect the inner parts of the AMS Asset Monitor during transport.

Remove the dust caps and replace them by proper cable glands or screw plugs to achieve

the specified protection class of the AMS Asset Monitor.

Figure 4-13: Dust protective caps – bottom view

Prerequisites

Select cable glands and screw plugs suitable for the application. Observe the following

points when selecting cable glands and screw plugs:

• Ensure that the cable glands are suitable for the diameter of the used cables.

• All not used cable inlets must be closed by using screw plugs.

38 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

• The AMS Asset Monitor is available with cable inlets with NPT thread.

• For hazardous location installation, use cable glands and screw plugs with an

appropriate approval.

Procedure

1. Remove all red dust caps.

Press the caps out from the inside or use a pair of pliers to pull them out.

2. Screw the required cable glands into the cable inlets.

Ensure proper sealing of the cable glands to keep the IP protection of the AMS Asset

Monitor. See documentation of the used cable glands for details.

3. Close the remaining cable inlets with screw plugs.

Ensure proper sealing of the cable inlets to keep the IP protection of the AMS Asset

Monitor. See documentation of the used screw plugs for details.

4. Continue with wiring and cable installation.

4.10 Grounding

Note

The grounding connections, described in this section, are examples. Adapt these examples

to the installation situation on-site. Observe local regulations regarding grounding and

installation of electrical equipment. The transition resistance between housing and

protective ground must be <100 mΩ measured at 40 A. The connection cable must be

colored green or green/yellow.

The AMS Asset Monitor has a grounding terminal at the bottom. The grounding terminals

for the shields of the field wiring cables and the two additional internal grounding

terminals in the lower left and right corner are internally connected to this grounding

terminal.

A ground connection between the housing of the AMS Asset Monitor and protective

ground is at least required if field signals with up to 250 V AC are connected. The

KL4502X1-MA1 CHARM Relay Output Terminal Block may have hazardous live voltages on

its output terminals. This terminal block is capable to switch field power of up to 250 V AC.

The minimum required grounding connection is a connection between the labeled

internal grounding terminal and protective ground.

MHM-97923-PBF, Rev. 2.5 39

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

Figure 4-14: Ground connection

A. Grounding terminals for connecting the shields of the sensor or signal field cables

B. Shield of the field cable

C. Labeled internal grounding terminal

D. Internal grounding terminal

E. Minimum required grounding connection

F. External grounding terminal

G. Field cables

H. Equipotential busbar

I. Protective ground

Prerequisites

• A cross-tip screwdriver size PZ 3 for the external grounding terminal at the device

bottom

• A flat-tip screwdriver size 3.5 mm for the shield grounding terminals

• A cross-tip screwdriver size PH 2 (if using the internal grounding terminal)

Procedure

1. Connect the grounding terminal (external or internal) with the equipotential

busbar.

40 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

• External grounding terminal (recommended): Use a grounding cable with a

wire cross section in accordance to the local rules and standards. Emerson

recommends a grounding cable with a wire cross section of 6 mm2 and a cable

lug at the end suitable for the diameter of the grounding screw.

• Internal grounding terminal (minimum requirement): Use a grounding cable

with a wire cross section equal to the wire cross section of the cable with the

hazardous live voltages and a cable lug at the end suitable for the diameter of

the grounding screw.

Ensure that the equipotential busbar is connected to protective ground.

2. Connect the shields of the field wiring cables to ground.

• Field-side grounding (recommended): Connect the shields of the field wiring

through the asset housing to ground. The grounding ensures the electrical

interferences are not conducted through the AMS Asset Monitor.

• AMS Asset Monitor-side grounding: Select this option if it is not possible to

connect the shield of the field wiring as described above. Connect the cable

shields to the internal grounding terminals (see Figure 4-14, A).

Note

Ensure that the cable shield is not double-sided connected to ground to avoid

ground loops. There may be exceptions to this recommendation.

4.11 Network connection

The AMS Asset Monitor is equipped with an 100 MBit/s Ethernet switch with two RJ-45

sockets to daisy chain AMS Asset Monitors. Because of the possible network traffic,

Emerson recommends to daisy chain no more than eight AMS Asset Monitors. Both RJ-45

sockets (right connector: LAN2.1 and left connector: LAN2.2) of the switch are equal. See

the following diagram for an example of a network architecture with a group of AMS Asset

Monitors.

MHM-97923-PBF, Rev. 2.5 41

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

Figure 4-15: Example network architecture

A. Ethernet switch

B. Firewall

C. Plantweb Optics

D. Ethernet switch

E. AMS Asset Monitors

DMZ: De-Militarized Zone

The third RJ-45 Ethernet socket with a speed of 1 Gbit/s is for configuration and

connection to subsequent systems in Level 3 (see Figure 4-15) such as Plantweb Optics.

See Figure 4-3 for the location of the RJ-45 sockets.

Note

There is no connection between the 100 MBit/s Ethernet switch with the two RJ-45 sockets

and the 1 Gbit/s RJ-45 Ethernet socket.

42 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing AMS Asset Monitor hardware

MHM-97923-PBF June 2022

To keep the IP protection class of the AMS Asset Monitor, Emerson recommends not to

use prefabricated Ethernet cables with RJ-45 plugs. Instead, use Ethernet cables without

plugs and RJ-45 plugs that can be crimped onto an Ethernet cable.

Prerequisites

• RJ 45 plugs that can be crimped onto an Ethernet cable.

• Crimping tool for RJ 45 plugs, if required for the selected plugs.

• Cable tester

• CAT 5(e) or higher Ethernet cable

• Maximum Ethernet cable length between devices is 100 meters.

• Installation in accordance to Ethernet standards.

All Ethernet cables used to connect the AMS Asset Monitor must be made, installed, and

tested by an experienced LAN installer.

Follow the steps to connect an Ethernet cable:

Procedure

1. Lead the Ethernet cable through a suitable cable gland at the bottom of the AMS

Asset Monitor.

2. Strip the Ethernet cable in accordance to the needs of the RJ 45 plug.

3. Crimp the RJ 45 plug on the Ethernet cable.

4. Plug the RJ 45 plug into the needed Ethernet connector.

MHM-97923-PBF, Rev. 2.5 43

Installing AMS Asset Monitor hardware Installation Guide

June 2022 MHM-97923-PBF

44 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing CHARMs hardware

MHM-97923-PBF June 2022

5 Installing CHARMs hardware

This section describes the general CHARM installation. The CHARMs together with their

required CHARM Terminal Blocks can be installed in any arbitrary slot of the AMS Asset

Monitor. You can mix and match the CHARMs and their Terminal Blocks in any order on

the baseplate.

Note

The CHARM is hot-swappable. It is not necessary to switch off the power supply of the

system before installing or removing the CHARM.

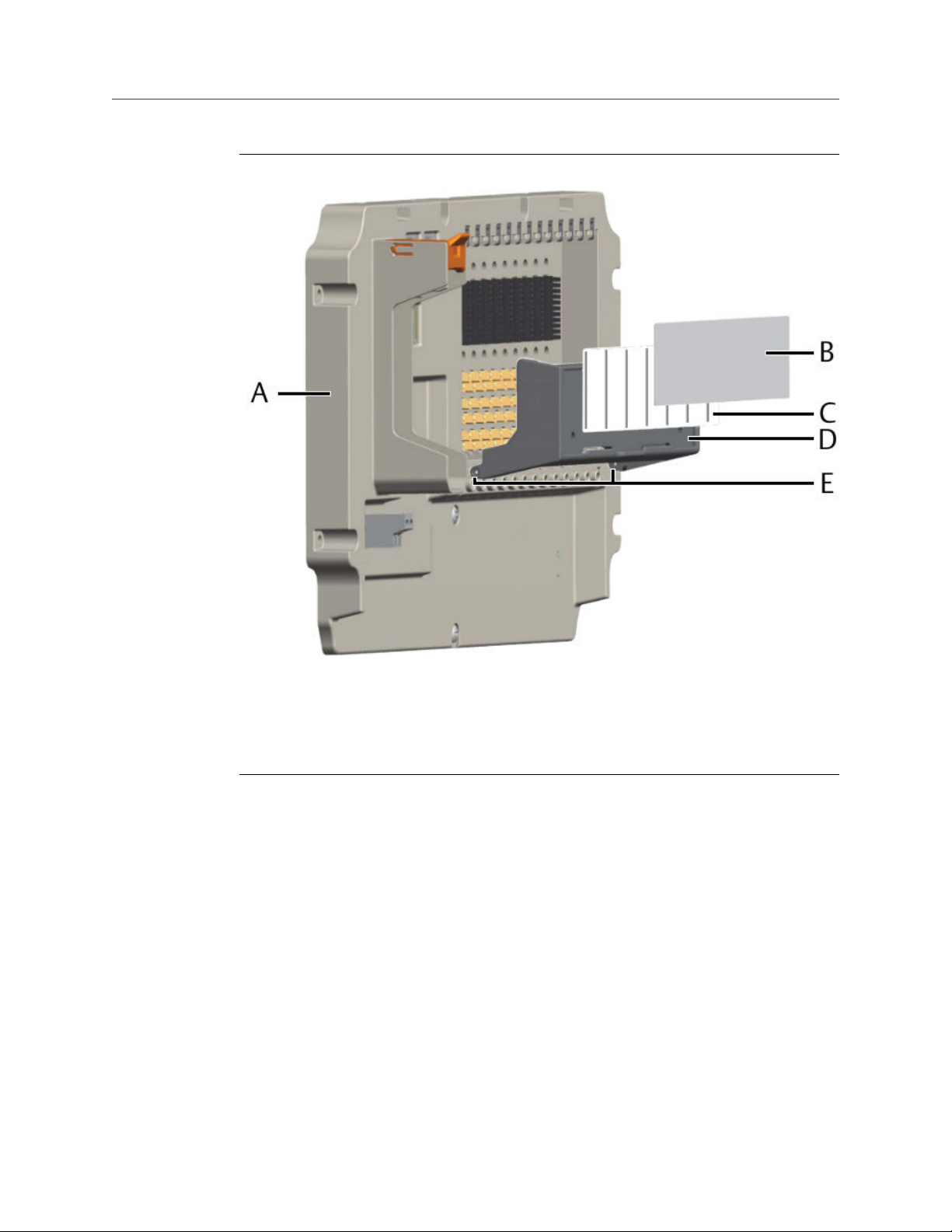

Figure 5-1: Baseplate overview

A. CHARM Terminal Block release

B. 12 slots for CHARM installation

C. Slot for address plug

D. Terminals for cable shield connection

Procedure

1. Open the AMS Asset Monitor (see Open the AMS Asset Monitor), if not already

done.

2. Flip-down the CHARM labeling component (see Figure 4-3 for location), if there is

one.

3. Locate the slot where the CHARM must be installed. CHARMs can be installed in

slots 1 to 12.

4. Hook the CHARM Terminal Block into the lower part of the needed slot and push it

in.

MHM-97923-PBF, Rev. 2.5 45

Installing CHARMs hardware Installation Guide

June 2022 MHM-97923-PBF

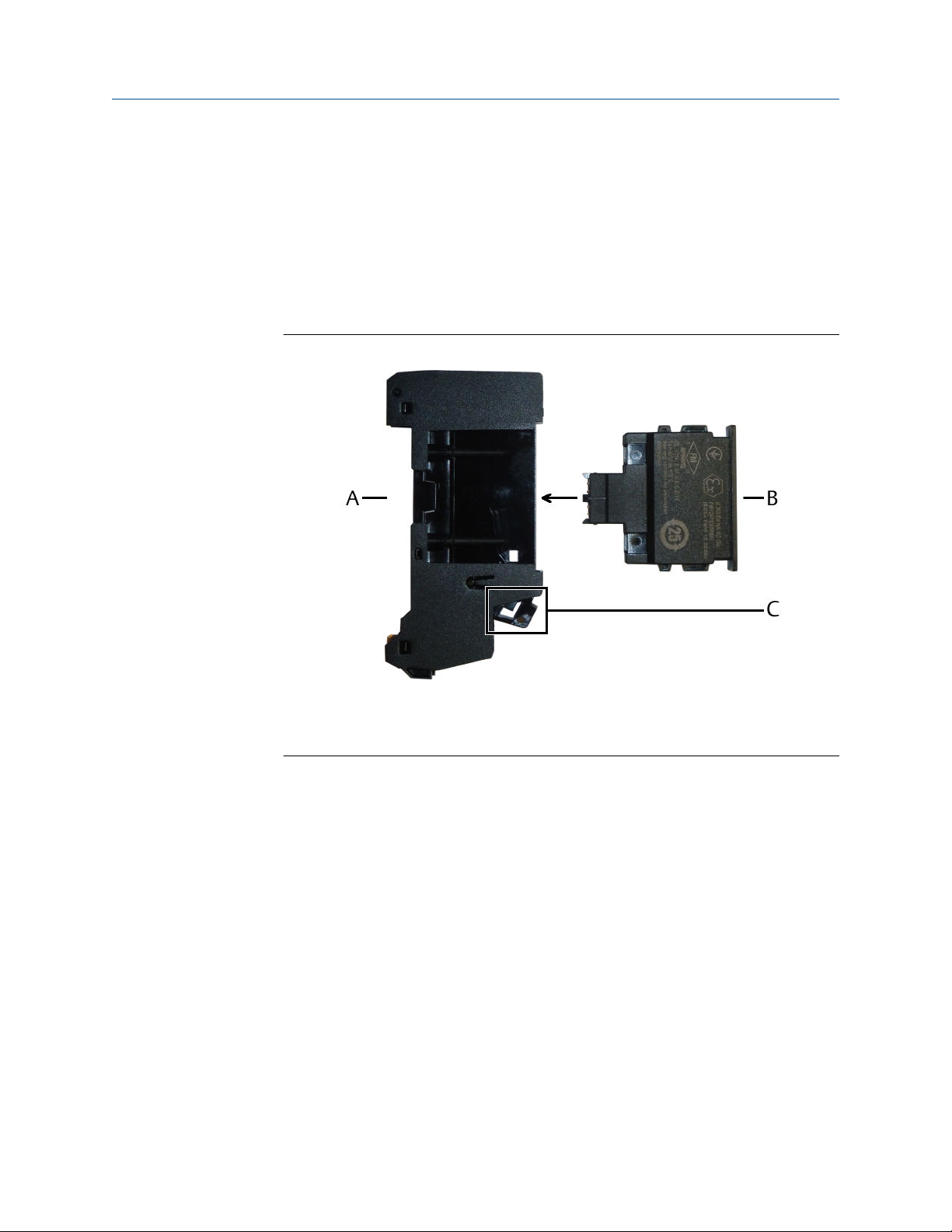

Figure 5-2: CHARM Terminal Block installation

The CHARM Terminal Block locks with an audible click.

5. Ensure that the latch of the CHARM Terminal Block is in the open position. If the

latch is in the closed position, move it outwards to open it.

Figure 5-3: Latch positions

A. Latch open

B. Latch close

6. Gently push the CHARM straight into the CHARM Terminal Block installed before.

The CHARM latch locks with an audible click in the closed position.

46 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing CHARMs hardware

MHM-97923-PBF June 2022

Figure 5-4: CHARM Installation

A. CHARM Terminal Block

B. CHARM

CHARMs fit only in one direction. The CHARM Terminal Blocks contain keying posts

that are automatically set and locked to the unique position of the installed CHARM.

The keys prevent the insertion of an incorrect CHARM during maintenance

activities.

To reset the keying mechanism, remove the CHARM Terminal Block from the

CHARM Baseplate (see Remove a Terminal Block), flip the terminal block 180°, and

use your fingers to push the two keying posts completely in so they are sub flush to

the bottom face of the terminal block. Sub flush is the neutral position. You will

hear a click when the posts are in the neutral position. When the posts are in the

neutral position, the terminal block can receive a different CHARM type.

DANGER

Do not try to install a CHARM into a CHARM Terminal Block with keying posts set for

another CHARM type. This might damage the terminal block and CHARM. Always

reset the keying post settings before installing another CHARM.

7. Wire the CHARM Terminal Block according to the requirements of the installed

CHARM.

8. Label the installed CHARM. See Label the installed CHARMs.

9. Continue with the installation work or close the door (see Close the AMS Asset

Monitor).

MHM-97923-PBF, Rev. 2.5 47

Installing CHARMs hardware Installation Guide

June 2022 MHM-97923-PBF

5.1 Install the +24 V DC Power Module

CAUTION

Any work on the system may impair asset health monitoring and machine protection.

Procedure

1. Open the AMS Asset Monitor (see Open the AMS Asset Monitor), if not already

done.

2. Ensure that the latch is in open position as shown in Figure 5-5. If the latch is in the

close position, move it upwards to open it.

3. Gently push the +24 V DC Power Module without tilting into the slot.

The +24 V DC Power Module fits only in one direction.

Note

The +24 V DC Power Module is hot-swappable. It is not necessary to switch off the

power supply of the system before installing or removing the +24 V DC Power

Module.

Figure 5-5: +24 V DC Power Module installation

A. Latch

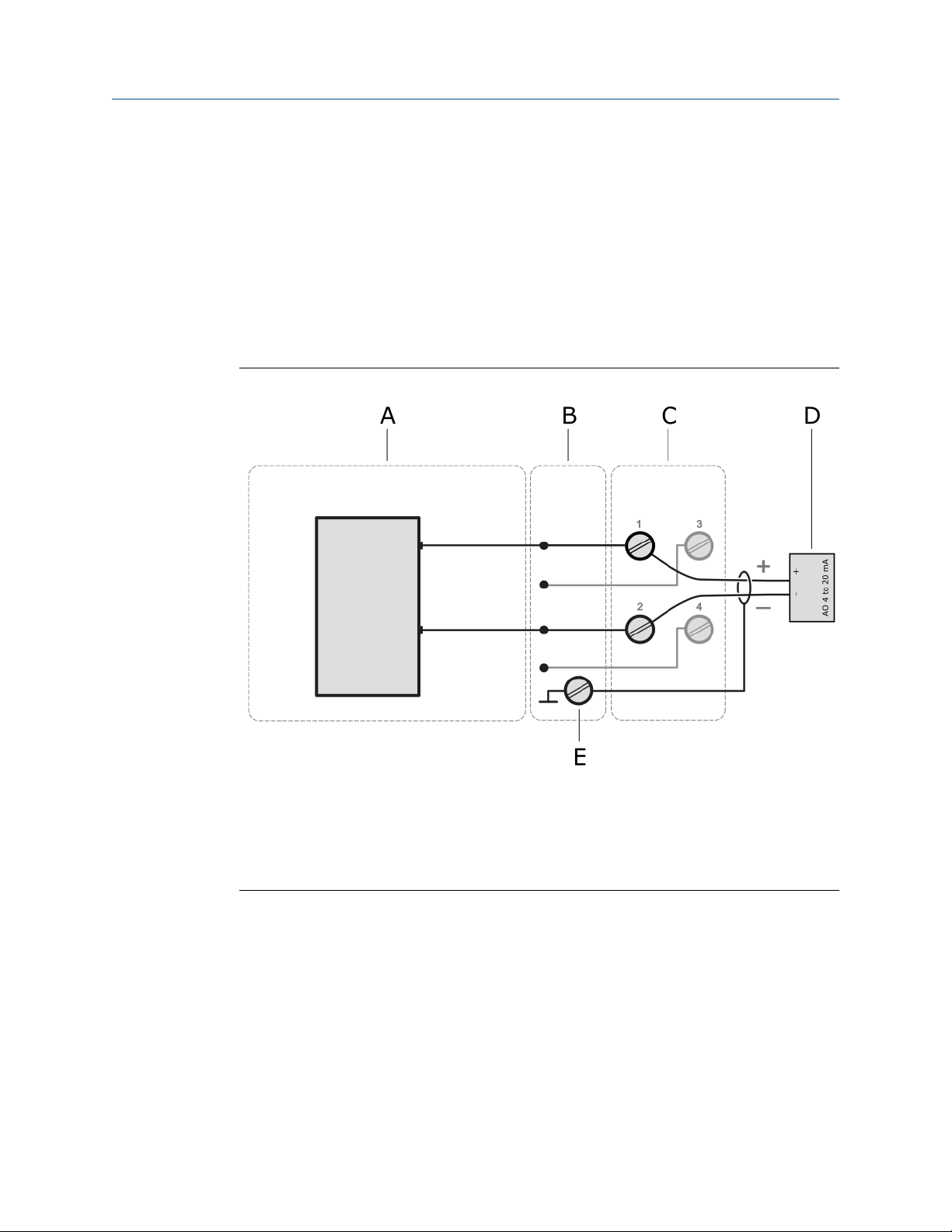

B. +24 V DC Power Module

C. Slot for the +24 V DC Power Module

The +24 V DC Power Module locks with an audible click – the latch of the slot flips

down.

4. Continue with the installation or close the door (see Close the AMS Asset Monitor).

48 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing CHARMs hardware

MHM-97923-PBF June 2022

5.1.1 Connect the power supply

Procedure

Connect a +24 V DC power supply to the power supply terminals of the AMS Asset

Monitor.

Connect the +24 V DC of the power supply to the + terminal of the AMS Asset Monitor and

GND of the power supply to the - terminal.

Figure 5-6: Power supply connection

A. Slot for the +24 V DC Power Module

B. Power supply terminals

5.2 Install a VI Piezo CHARM

The VI Piezo CHARM is designed for the connection of 2-wire piezoelectric sensors. The VI

Piezo CHARM is supplied by the AMS Asset Monitor. A CHARM Terminal Block is required

for the installation. See installation guide of the VI Piezo CHARM for further details. See

Installing CHARMs hardware for the general CHARM installation procedure.

MHM-97923-PBF, Rev. 2.5 49

Installing CHARMs hardware Installation Guide

June 2022 MHM-97923-PBF

5.2.1 Connect the sensor wiring

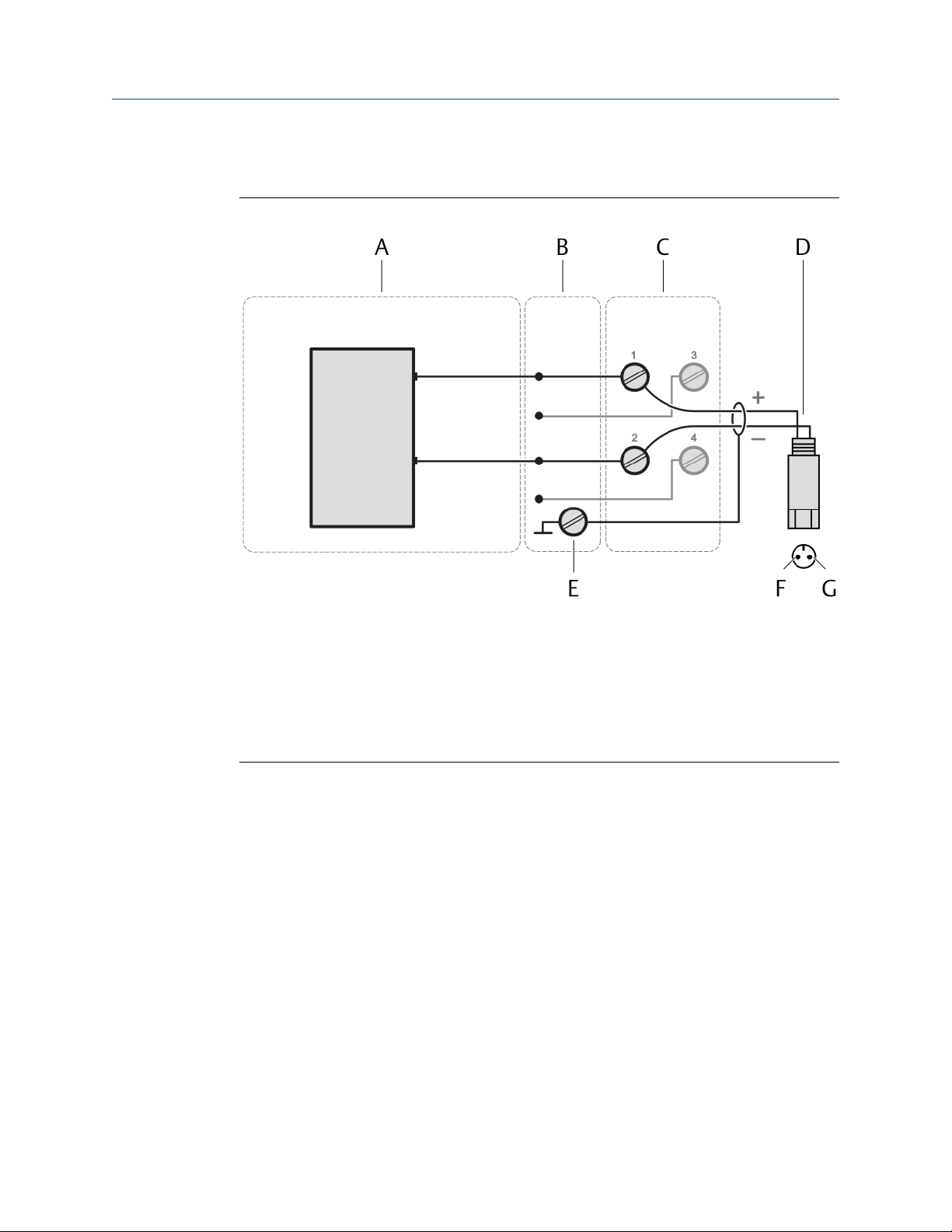

Figure 5-7: Sensor connection

A. VI Piezo CHARM

B. CHARM Baseplate

C. CHARM Terminal Block

D. 2-wire piezoelectric sensor

E. Cable shield connection

F. Top view of the sensor connector – terminal A

G. Top view of the sensor connector – terminal B

Prerequisites

• Wire cutter

• Tool for removing the cable sheath

• Wire stripper

• Suitable screw driver for the CHARM Terminal Block screws

• Shielded sensor cable

• Observe the hints in Wiring guidelines.

Procedure

1. At opened door, lead the sensor cable through a cable gland close to the slot where

the CHARM to be connected is installed.

2. Strip the cable sheath at a length of approximately 200 mm.

3. Strip each wire at a length of approximately 10 mm.

4. Connect the wires to the CHARM Terminal Block.

50 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing CHARMs hardware

MHM-97923-PBF June 2022

• Connect terminal A of the 2-wire piezoelectric sensor to terminal 1 of the

CHARM Terminal Block.

• Connect terminal B of the 2-wire piezoelectric sensor to terminal 2 of the

CHARM Terminal Block.

• Connect the cable shield to a grounding terminal (see Grounding).

5. Ensure that the cable gland, where the sensor cable is led through, is closed to keep

the IP protection class of the AMS Asset Monitor.

6. Continue with the installation or close the door (see Close the AMS Asset Monitor).

5.3 Install a VI Tach CHARM

The VI Tach CHARM is designed for the connection of magnetic pickups, output signals of

eddy current measurement chains, and Hall-effect sensors. The VI Tach CHARM is supplied

by the AMS Asset Monitor. A CHARM Terminal Block is required for the installation. See

installation guide of the VI Tach CHARM for further details. See Installing CHARMs

hardware for the general CHARM installation procedure.

MHM-97923-PBF, Rev. 2.5 51

Installing CHARMs hardware Installation Guide

June 2022 MHM-97923-PBF

5.3.1 Connect the sensor wiring

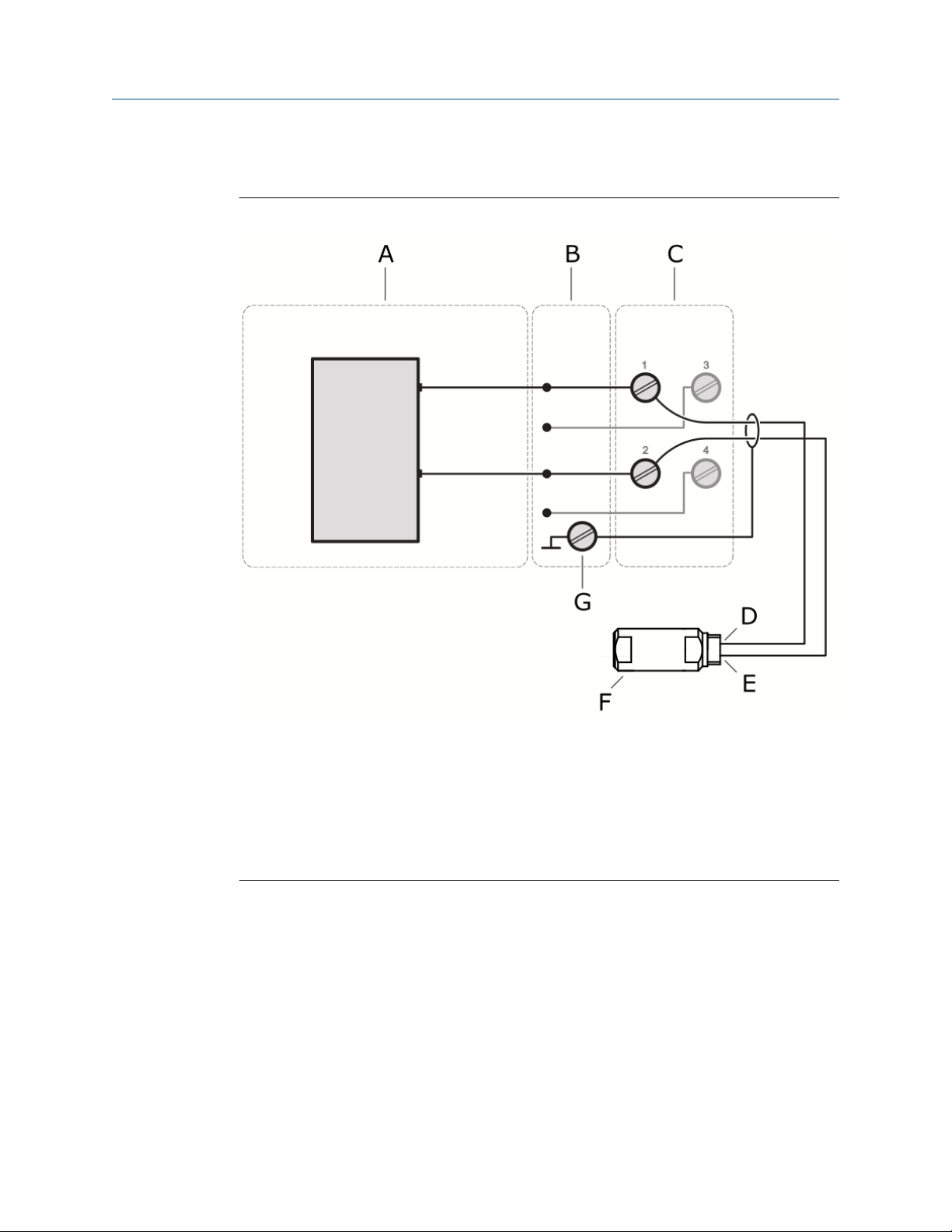

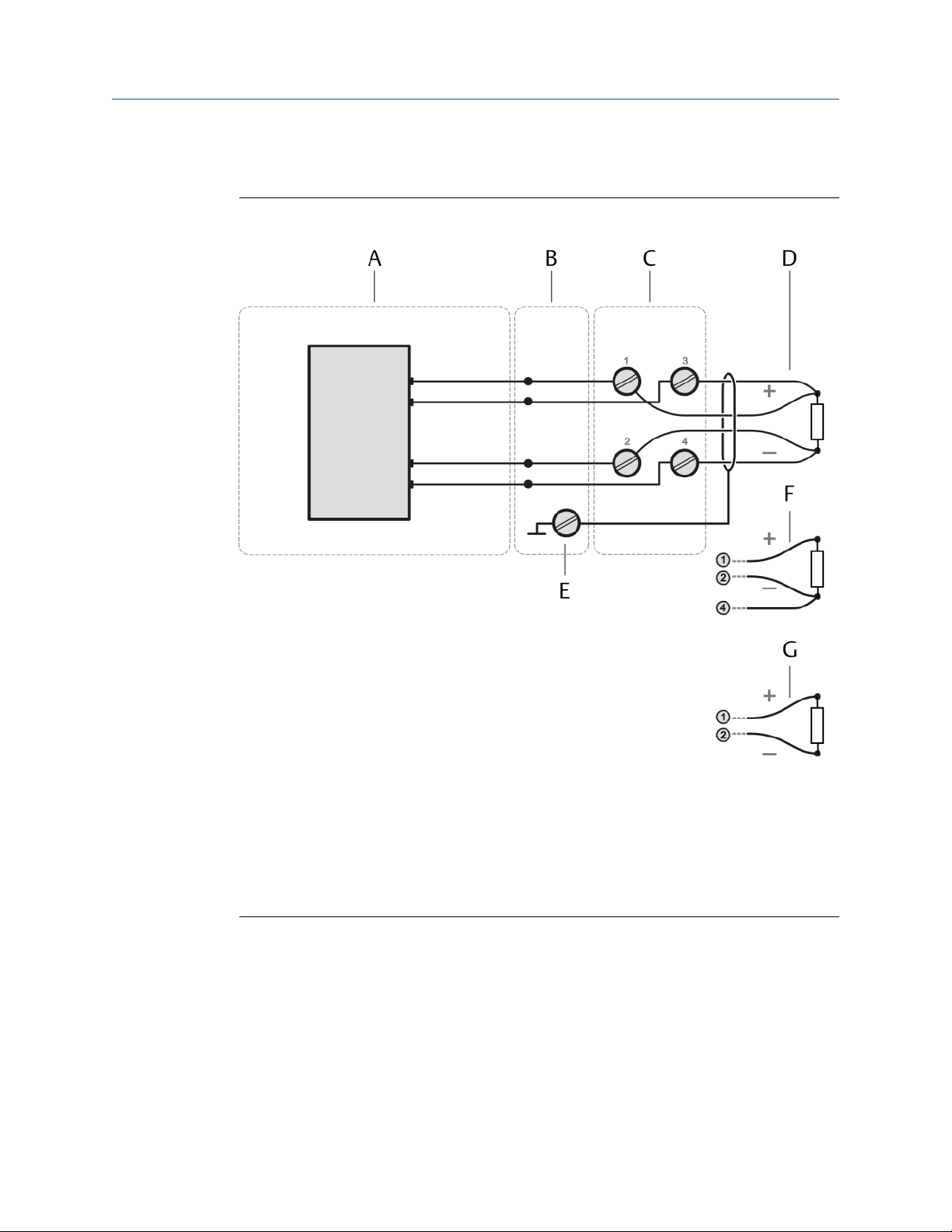

Figure 5-8: Sensor connection – magnetic pickup

A. VI Tach CHARM

B. CHARM Baseplate

C. Standard CHARM Terminal Block

D. Signal Out

E. Signal GND

F. Magnetic pickup

G. Cable shield connection

52 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing CHARMs hardware

MHM-97923-PBF June 2022

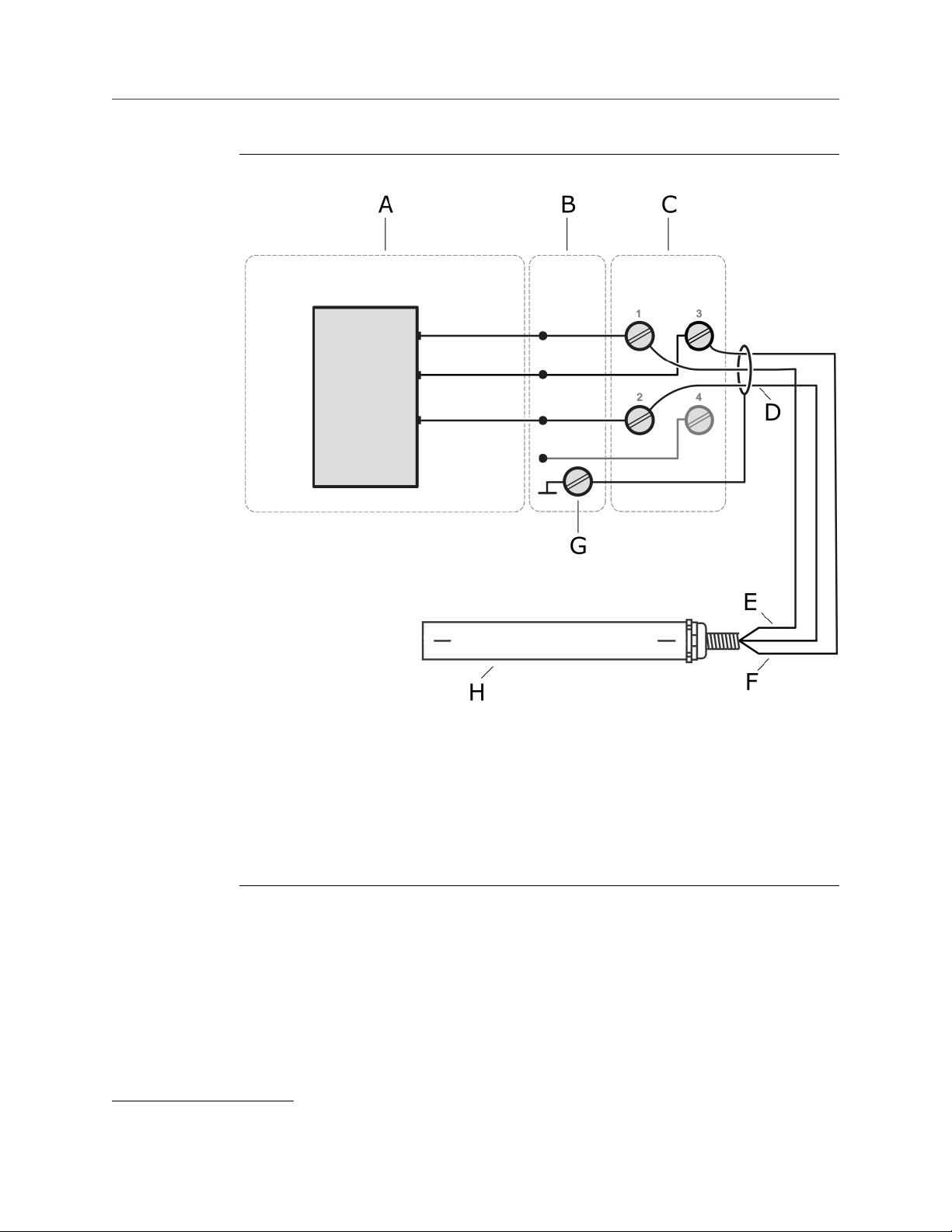

Figure 5-9: Sensor connection – output signal of an eddy current measuring chain

A. VI Tach CHARM

B. CHARM Baseplate

C. Standard CHARM Terminal Block

D. Signal GND

E. Signal OUT

F. External power supply for the eddy current measuring chain

G. Eddy current converter

H. Cable shield connection

I. Eddy current sensor

MHM-97923-PBF, Rev. 2.5 53

Installing CHARMs hardware Installation Guide

June 2022 MHM-97923-PBF

Figure 5-10: Sensor connection – Hall-effect sensor

A. VI Tach CHARM

B. CHARM Baseplate

C. Standard CHARM Terminal Block

D. GND

E. Signal output

F. +24 V power supply

G. Cable shield connection

3

H. Hall-effect sensor

Prerequisites

• Wire cutter

• Tool for removing the cable sheath

• Wire stripper

• Suitable screw driver for the CHARM Terminal Block screws

• Observe the hints in Wiring guidelines

3

Only if the cable shield is not used for signal GND and supply GND.

54 MHM-97923-PBF, Rev. 2.5

Installation Guide Installing CHARMs hardware

MHM-97923-PBF June 2022

Procedure

1. At opened door, lead the sensor cable through a cable gland close to the slot where

the CHARM to be connected is installed.

2. Strip the cable sheath at a length of approximately 200 mm.

3. Strip each wire at a length of approximately 10 mm.

4. Connect the wires to the CHARM Terminal Block.

Table 5-1:

Sensor Sensor terminals CHARM terminals

Magnetic pickup Signal Out

Signal GND

Output signal of an eddy

current measuring chain

Hall-effect sensor Signal Out

Connect the cable shield to a grounding terminal (see Grounding). With Hall-effect sensors,

only if the cable shield is not used for signal GND and supply GND.

Out

GND

GND

+24 V Power Supply

5. Ensure that the cable gland, where the signal cable is led through, is closed to keep