Page 1

LCR55A

Inductance, Capacitance,

Resistance Meter

User Manual

• Bedienungshandbuch

• Manualdeuso

• Moded’emploi

Page 2

200

2m

2m

FUSED

F

H

200mA MAX

HOLD

HmHH

h

FE

MAX

EBCE

nF FmF

k M

20 ADJ.

20m

200m

2

20

200

NPN

NPN

PNP

PNP

200p

2n

20n

200n

2

20

200

2000

20M

2M

200k

20k

2k

200

20

OFF

hFE

hFE

(Icec A)

(Icec A)

Cx

Lx

Hi(+)

Lo(-)

Rx

MAX 350V

FUSED

DISCHARGE CAPACITOR

BEFORE CONNECTING

Lx Cx

LCR55A

M.W.

LCR55A

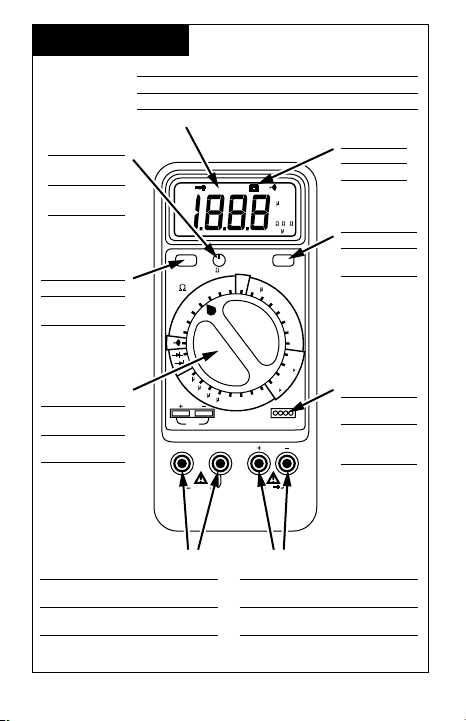

3-1/2 digit LCD; decimal point, function and unit indicators

3-1/2 Digit LCD ; Dezimalpunkt, Funktions- und Einheitsanzeigen

LCD de 3-1/2 dígitos, punto decimal, indicadores de función y unidades

LCD 3-1/2 digits ; point décimal, indicateurs de fonctions et d'unités

Low Battery

Batterie entladen

Pila baja

Pile déchargée

Zero adjustment for

20

Ω range

Nullabgleich für

20Ω Bereich

Ajuste de cero para

escala de 20 Ω

Mise-à-zéro pour

calibre 20Ω

Display Hold

Anzeigesperre

Retención de

lectura

Maintien de

lecture

Max Reading Hold

Max Anzeigesperre

Retención de

lectura maxima

Maintien de lecture

maximale

Positive and negative inputs for resistance

and diode test

Positive und negative Eingänge für

Widerstandsmessung und Diodentest

Entradas positiva y negativa para medidas

de resistencia y prueba de diodos

Entrées positives et négatives pour measures

de résistance et test de diodes

Function/Range/Off

Selector

Funktion-/Bereich-

/Aus Schalter

Selector de

Función/Escala/Off

Sélecteur fonctions/

calibres/marche-

arrêt

Input terminals

for transistor test

Eingänge für

Transistortest

Terminales de

entrada para prueba

de transistors

Entrées pour test

de transistors

High (+) and Low (-) inputs for capacitance

and inductance measurement

Hoch (+) und Niedrig (-) Eingänge für

Kapazitäts- und Induktanzmessung

Entradas alta (+) y baja (-) para medidas de

capacidad e inductancia

Entrées haute (+) et basse (-) pour measures

de capacité et d'inductance

Page 3

LCR55A

Inductance, Capacitance,

Resistance Meter

Operators Manual

• Bedienungsanleitung

• Manual de Instrucciones

• Manuel d’Utilisation

PN 1566247

©2007 Amprobe.

All rights reserved. Printed in Taiwan

English

Page 4

Limited Warranty and Limitation of Liability

Your Amprobe product will be free from defects in material and workmanship

for 1 year from the date of purchase. This warranty does not cover fuses,

disposable batteries or damage from accident, neglect, misuse, alteration,

contamination, or abnormal conditions of operation or handling. Resellers are

not authorized to extend any other warranty on Amprobe’s behalf. To obtain

service during the warranty period, return the product with proof of purchase

to an authorized Amprobe Test Tools Service Center or to a Amprobe dealer or

distributor. See Repair Section above for details. THIS WARRANTY IS YOUR ONLY

REMEDY. ALL OTHER WARRANTIES - WHETHER EXPRESS, IMPLIED OR STAUTORY

- INCLUDING IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE

OR MERCHANTABILITY, ARE HEREBY DISCLAIMED. MANUFACTURER SHALL

NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states

or countries do not allow the exclusion or limitation of an implied warranty or

of incidental or consequential damages, this limitation of liability may not apply

to you.

Page 5

Inductance, Capacitance, Resistance Meter

Contents

Symbols ..............................................................................................................1

Warnings and Precautions ................................................................................1

Overload Indication ..........................................................................................2

Preparation for Use – Unpacking .....................................................................2

Measuring Procedures ......................................................................................2

Specifications .....................................................................................................4

Troubleshooting/Maintenance .........................................................................6

Repair .................................................................................................................7

Symbols

Battery

Double insulated

Fuse

Conforms to relevant Australian standards

Warnings and Precautions

• Do not exceed the maximum overload limits per function (see specifications)

nor the limits marked on the instrument itself.

• Exercise extreme caution when: measuring voltage >20V .

• Inspect DMM, test leads and accessories before every use. Do not use any

damaged part.

• Never ground yourself when taking measurements. Do not touch exposed

circuit elements or probe tips.

• Do not operate instrument in an explosive atmosphere.

• Clean instrument with mild detergent only.

Refer to the manual

Audible tone

Complies with EU

directives

1

Page 6

OverloadIndication

Range overload is indicated by a “OL” in the display with all

other digits blanked. Overload indication is normal in the

OHMS range with open circuit or too high a resistance.

PreparationforUse–Unpacking

Your shipping carton should include the LCR55A, one test lead set (one black,

one red), one pair of alligator clips, one 9V battery (installed), one spare

0.1A/250V fuse (inside the case), one holster, a warranty card and this manual. If

any item is damaged or missing, return to the place of purchase for an exchange.

MeasuringProcedures

General Procedures

1. When connecting or disconnecting test leads to/from a circuit, always first

turn off power to device or circuit being tested and discharge all capacitors.

2. If the magnitude of a signal to be measured is not known, set selector switch

to highest range first and reduce until satisfactory reading is obtained.

3. Strictly observe the max input limits.

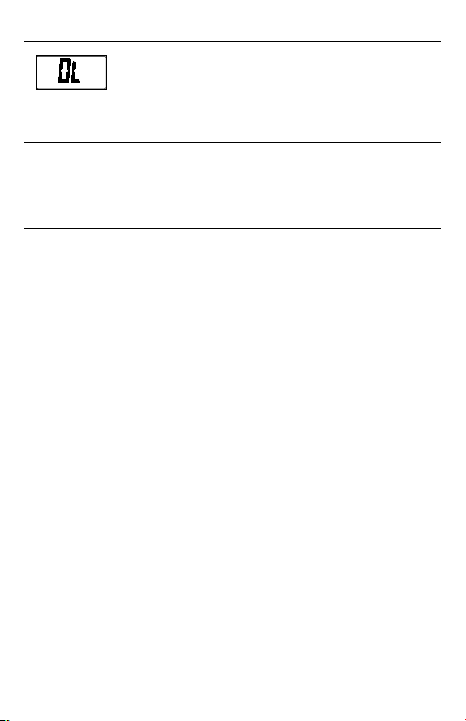

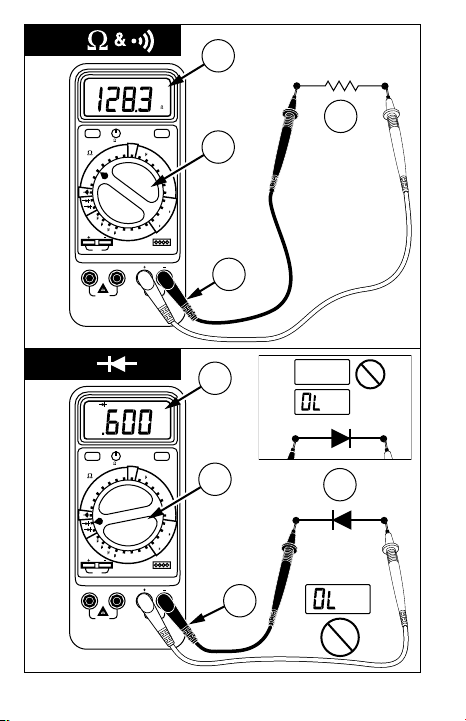

Resistance Measurement (Fig. -1-)

1. Turn off power to the resistance to be measured and discharge any

capacitors. Any voltage present during a resistance measurement will cause

inaccurate readings.

2. Connect red test lead to +Rx Input and black test lead to -Rx Input.

3. Set Function/Range Switch to the desired Ω position.

4. Connect test leads to resistance or circuit to be measured.

5. Read resistance value on Digital Display. Open circuits will be displayed as an

overload condition.

Note: On the 20Ω range, an adjustment potentiometer (ZERO ADJ.) allows you

to zero out the test lead resistance. Short test leads and adjust the knob until the

display reads zero.

Diode and Transister Test (Fig. -2-)

The diode test measures the voltage drop across the diode junction.

4. Connect the red test lead to the +Rx Input and the black test lead to the –Rx Input.

5. Set the Function/range switch to or to M.W. position (to test diodes

found in microwave ovens).

6. Apply probe tip of red lead to the anode and black lead to the cathode

of the diode. The meter’s display indicates the forward voltage drop

(approximately 0.7V for silicon diode or 0.4V for germanium diode). Meter

will display overload condition for an open diode.

7. Reverse test lead connections to the diode to perform a reverse bias test.

Overload indicates a good diode.

Note: Overload condition for both reverse and forward bias tests indicate an

open diode. A low voltage reading for both bias tests indicates a shorted diode.

If the diode is shunted by a resistor of 1000 ohms or less, it must be removed

from the circuit before taking the measurement. Bipolar transistor junctions may

2

Page 7

be tested in the same manner described above.

Note: The test procedure of microwave oven diodes is identical to regular diodes

except forward voltage drop will be higher (3 or more volts) than standard

silicon diodes. LEDs may also be tested with the LCR55A in the M.W. position.

Continuity Test

The Continuity test checks electrical continuity between two contact points.

1. Set the Function/Range switch to .

2. Plug the black test lead into the –Rx jack and connect the test lead tip to one

of the contact points.

3. Plug the red test lead into the +Rx jack and connect its test lead point to the

other contact point. (See Figure 1 for connections).

4. The internal beeper emits a tone when resistance is less than approx. 30Ω.

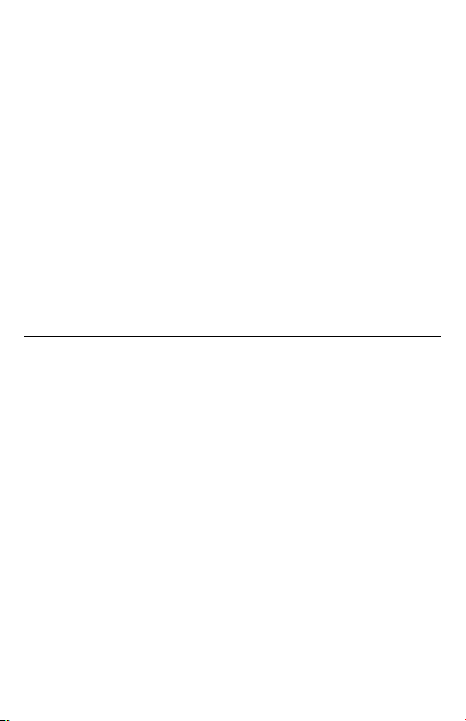

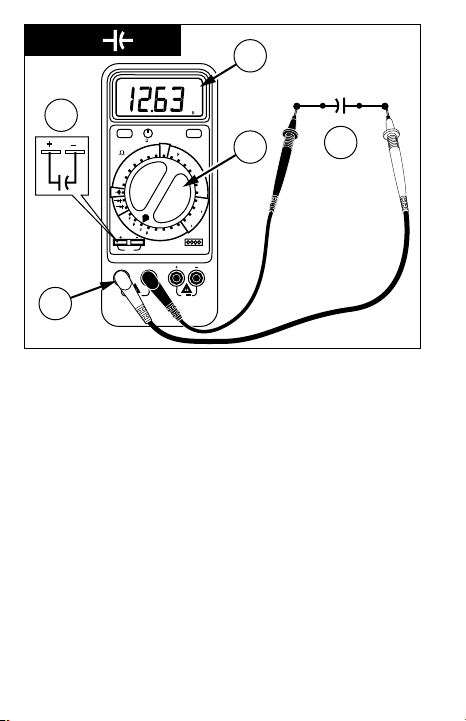

Capacitance Mesurements (Fig. -3-)

1. Discharge all voltage from the capacitor (via a 20kΩ resistor) before

measuring its value.

2. Connect the red test lead to the HI(+) input and the black test lead to the

Lo(–) input.

3. Set the function/range switch to the capacitance range that gives the best

resolution.

4. Apply probe tips to the capacitor leads

5. Read the capacitance value on the display (you may have to wait a few

seconds until the capacitor is fully charged). If “OL” appears in the highest

range, the capacitor is too large to be measured.

Note: Small value capacitors can also be measured by inserting their leads

directly into the Cx/Lx slots in the meter.

Note:The capacitance range is protected by a 0.1A/250V fast blow fuse. If fuse

blows, replace with same (see Battery and Fuse Replacement).

Note: The LCR55A has a residual capacitance of approximately 6pF in the 200nF

range. When using the 200nF range, note the residual capacitance and subtract

this value from the measured value.

Inductance Measurement

1. Connect the red test lead to the HI(+) input and the black test lead to the

Lo(–) input.

2. Set the function/range switch to the inductance range that gives the best

resolution.

3. Apply probe tips to the inductor leads.

4. Read the inductance value on the display. If “OL” appears in the highest

range, the inductor is too large to be measured.

Note: Small value inductors can also be measured by inserting their leads directly

into the Cx/Lx slots in the meter.

Note: The inductance range is protected by a 0.1A/250V fast blow ceramic fuse. If

fuse blows, replace with same (see Battery and Fuse Replacement).

Transistor Gain Measurement

The Transistor must be out of circuit.

3

Page 8

1. Set the Function/Range switch to the PNP(hFE) or NPN(hFE) position,

according to the type of transistor to be measured.

2. Plug the emitter, base and collector leads of the transistor into the correct

holes of test socket.

3. Read the hFE beta, (DC current gain) in the display.

Note: To measure the collector-emitter current, set the function/range switch to

the corresponding PNP(Icec µA) or NPN(Icec µA) position.

MAX Function

Push the MAX button to keep only the highest reading on the display. The

display is updated each time a higher value is encountered. Push MAX again to

release the display and to display current values.

Hold Function

Press the HOLD button to maintain a reading on the display. The reading is

maintained even when the probe tips are removed from the meter. Pushing the

HOLD button again releases the display.

Safety Test Leads

The test leads included with your meter have shrouded banana plugs to

eliminate the possibility of shock if the plugs accidentally pull out of the meter

while making a measurement. Always inspect the test leads for damage before

making any measurements.

Specications

General Specifications

Display: 3 1/2 digit LCD, 1999 counts, 0.7” (17.8mm) high numerals, unit

annunciators and function symbols

Polarity Indication: Automatic, positive implied, negative indicated

Zero Adjustment: Automatic

Overrange Indication: “OL”

Low Battery Indication: is displayed when the battery voltage drops below

accurate operating level. Change battery immediately.

Display Update Rate: 2.5 per second, nominal

Operating Temperature: 0°C to 50°C, 0 to 70% Relative Humidity

Storage Temperature: -20°C to 60°C, 0 to 80% RH with battery removed

Temperature coefficient: 0.1 x (spec. accur.) per °C (0-18°C, 28-50°C)

Power: Standard 9-volt transistor battery, NEDA 1604, JIS 006P, IEC 6F22

Auto Power Off: 60 minutes after no function or range change

Battery Life (Typical): 30 hours alkaline (changes with function and application)

Dimensions (H x W x D): 18.3 x 7.9 x 3.8 cm, (7.2 x 3.1 x 1.5 inches)

Weight (including battery): 311 grams (11 ounces)

Accessories: Test leads, 0.1A/250V spare fuse, battery, one pair of alligator clips

and Operator’s Manual.

4

Page 9

Agency Approvals: EMC

This product complies with requirements of the following European

Community Directives: 89/336/EEC (Electromagnetic Compatibility) and 73/23/

EEC (Low Voltage) as amended by 93/68/EEC (CE Marking).

However, electrical noise or intense electromagnetic fields in the vicinity of

the equipment may disturb the measurement circuit. Measuring instruments

will also respond to unwanted signals that may be present within the

measurement circuit. Users should exercise care and take appropriate

precautions to avoid misleading results when making measurements in the

presence of electronic interference

Electrical Specifications

Accuracies at 23°C ± 5°C, <75% RH.

Resistance

Ranges: 20, 200Ω, 2, 20, 200kΩ, 2, 20MΩ

Resolution, 20Ω range: 10mΩ

Accuracy: 20Ω range: ±1.2% rdg (zero adjust)

200Ω range: ±0.5% rdg +3dgt

2k to 2MΩ rgs: ±(0.5% rdg +1dgt)

20MΩ rg: ±(2.0% rdg +2dgt)

OL Protection, all ranges: 350VDC or AC RMS

Open Circuit Voltage; 20Ω range: 6.5VDC; 200Ω range: 3.0VDC; other ranges:

1.2VDC

Continuity

Audible Indication, 2kΩ rg: at R ≤30Ω

Response time: 800ms approx

OL Protection: 350VDC or AC RMS

Diode Test

Test Current: 1mA (approx.)

Test Voltage: 3.0VDC typical

Accuracy: ±(1.5%rdg +1dgt)

Display: Forward Junction Voltage

OL Protection: 350VDC or AC RMS

Micro Wave Diode Test

Test Current: 1.3mA (approx.)

Test Voltage: 8.0VDC typical

Accuracy: ±(3.0%rdg +1dgt)

Display: Forward Junction Voltage

OL Protection: 350VDC or AC RMS

Capacitance

Ranges: 200pF, 2, 20, 200nF, 2, 20, 200, 2000µF

Accuracy*:200pF to 200nF: ±(1.0% rdg +3dgt)

2µF to 200µF rgs: ±(2.0% rdg +3dgt)

2000µF range: ≤1000µF ±(3.0% rdg +3dgt)

>1000µF ±(5.0% rdg +5dgt)

Note: In lower ranges, substract 6 points residual offset reading from result

Test Frequency: 200p to 2µF: 1000Hz; 20, 200µF ranges: 100Hz; 2000µF range:

10Hz

5

Page 10

Temperature Coefficient: ≤0.5µF: 0.1%/°C; >0.5µF: 0.2%/°C

OL Protection: 0.1A/250V fast blow fuse.

Inductance

Ranges: 200µH, 2, 20, 200mH, 2, 20, 200H

Accuracy: 200µH rg: ±(5.0%rdg +30dgt)*

2 to 200mH: ±(3.0% +20dgt)*

2 to 200H: ±(5.0% +20dgt)*

*For values of Q ≤7

Test Frequency: 200µH to 2H rgs: 1000Hz; 20 and 200H ranges: 100Hz

Temperature Coefficient, ≤0.5H: 0.2%/°C; >0.5H: 0.5%/°C

OL Protection: 0.1A/250V fast blow fuse

Transistor Test

hFE Range: 0-1000

hFE Base Current: 5µA approx.

hFE Voltage C-E: 3.0VDC approx.

I

Range, Leakage Current: 10nA to 20µA

ceo

Optional Accessories

VC221B Vinyl Carrying Case (for meter and holster)

DL243D Standard Test Lead Set

DL248D Deluxe Test Lead Set

TL36A Replacement Test Leads with Alligator Clips

Troubleshooting/Maintenance

If there appears to be a malfunction during the operation of the meter, the

following steps should be performed in order to isolate the cause of the problem:

Check the battery.

Review the operating instructions for possible mistakes in operating procedure.

Inspect and test the Test Probes for a broken or intermittent connection.

Inspect and test the fuse. See Fuse Replacement.

Except for the replacement of the battery or fuse, repair of the multimeter

should be performed only by a Factory Authorized Service Center or by other

qualified instrument service personnel.

The front panel and case can be cleaned with a mild solution of detergent and

water. Apply sparingly with a soft cloth and allow to dry completely before using.

Battery/Fuse Replacement

To prevent electrical shock hazard, turn off the multimeter

and any device or circuit under test and disconnect the test

leads before removing the rear cover.

1. Remove the screws and lift off the rear case.

2. Fuse Replacement: Remove the blown fuse (5 x 20mm) from the fuse holder.

Replace with a 0.1A/250V quick acting glass fuse (one spare fuse is located on

the right side of the battery compartment). Amprobe replacement fuse part

number is FP 125.

3. Battery replacement: Remove battery and replace with NEDA type 1604 or

equivalent 9 volt alkaline battery.

4. Reassemble the instrument.

Warning

6

Page 11

Use of an incorrect fuse could result in serious injury or even

death. Failure to turn off the multimeter before installing

the battery could result in damage to instrument and battery.

Warning

Repair

All test tools returned for warranty or non-warranty repair or for calibration

should be accompanied by the following: your name, company’s name, address,

telephone number, and proof of purchase. Additionally, please include a brief

description of the problem or the service requested and include the test leads

with the meter. Non-warranty repair or replacement charges should be remitted

in the form of a check, a money order, credit card with expiration date, or a

purchase order made payable to Amprobe Test Tools.

In-Warranty Repairs and Replacement – All Countries

Please read the warranty statement and check your battery before requesting

repair. During the warranty period any defective test tool can be returned

to your Amprobe Test Tools distributor for an exchange for the same or like

product. Please check the “Where to Buy” section on www.amprobe.com for a

list of distributors near you. Additionally, in the United States and Canada InWarranty repair and replacement units can also be sent to a Amprobe Test Tools

Service Center (see below for address).

Non-Warranty Repairs and Replacement – US and Canada

Non-warranty repairs in the United States and Canada should be sent to a

Amprobe Test Tools Service Center. Call Amprobe Test Tools or inquire at your

point of purchase for current repair and replacement rates.

In USA In Canada

Amprobe Test Tools Amprobe Test Tools

1420 75th Street SW 400 Britannia Rd. E. Unit #1

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel: 888-993-5853 Tel: 905-890-7600

Fax: 425-446-6390 Fax: 905-890-6866

Non-Warranty Repairs and Replacement – Europe

European non-warranty units can be replaced by your Amprobe Test Tools

distributor for a nominal charge. Please check the “Where to Buy” section on

www.amprobe.com for a list of distributors near you.

European Correspondence Address*

Amprobe® Test Tools Europe

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

*(Correspondence only – no repair or replacement available from this address.

European customers please contact your distributor.)

7

Page 12

200

2m

2m

FUSED

F

H

200mA MAX

HOLD

MAX

EBCE

20 ADJ.

20m

200m

2

20

200

NPN

NPN

PNP

PNP

200p

2n

20n

200n

2

20

200

2000

20M

2M

200k

20k

2k

200

20

OFF

hFE

hFE

(Icec A)

(Icec A)

Cx

Lx

Hi(+)

Lo(-)

Rx

MAX 350V

FUSED

DISCHARGE CAPACITOR

BEFORE CONNECTING

Lx Cx

LCR55A

M.W.

2

1

Cathode Anode

Cathode

600 - 900 mV

<1 V

Anode

3

2

4

OK

OK

OK

OK

200

2m

2m

FUSED

F

H

200mA MAX

HOLD

MAX

EBCE

k

20 ADJ.

20m

200m

2

20

200

NPN

NPN

PNP

PNP

200p

2n

20n

200n

2

20

200

2000

20M

2M

200k

20k

2k

200

20

OFF

hFE

hFE

(Icec A)

(Icec A)

Cx

Lx

Hi(+)

Lo(-)

Rx

MAX 350V

FUSED

DISCHARGE CAPACITOR

BEFORE CONNECTING

Lx Cx

LCR55A

M.W.

4

3

2

5

1

8

Page 13

3

200

2m

2m

FUSED

F

H

200mA MAX

HOLD

MAX

EBCE

F

20 ADJ.

20m

200m

2

20

200

NPN

NPN

PNP

PNP

200p

2n

20n

200n

2

20

200

2000

20M

2M

200k

20k

2k

200

20

OFF

hFE

hFE

(Icec A)

(Icec A)

Cx

Lx

Hi(+)

Lo(-)

Rx

MAX 350V

FUSED

DISCHARGE CAPACITOR

BEFORE CONNECTING

Lx Cx

LCR55A

M.W.

3A

3B

1

2

4

9

Page 14

Page 15

LCR55A

Inductance, Capacitance,

Resistance Meter

Operators Manual

• Bedienungsanleitung

• Manual de Instrucciones

• Manuel d’Utilisation

German

Deutsch

1

Deutsch

Page 16

Beschränkte Gewährleistung und

Haftungsbeschränkung

Es wird gewährleistet, dass dieses Amprobe-Produkt für die Dauer von einem

Jahr ab dem Kaufdatum frei von Material- und Fertigungsdefekten ist. Diese

Gewährleistung erstreckt sich nicht auf Sicherungen, Einwegbatterien oder

Schäden durch Unfälle, Nachlässigkeit, Missbrauch, Änderungen oder abnormale

Betriebsbedingungen bzw. unsachgemäße Handhabung. Die Verkaufsstellen

sind nicht dazu berechtigt, diese Gewährleistung im Namen von Amprobe

zu erweitern. Um während der Gewährleistungsperiode Serviceleistungen zu

beanspruchen, das Produkt mit Kaufnachweis an ein autorisiertes Amprobe Test

Tools Service-Center oder an einen Amprobe-Fachhändler/-Distributor einsenden.

Einzelheiten siehe Abschnitt „Reparatur“ oben. DIESE GEWÄHRLEISTUNG STELLT

DEN EINZIGEN UND ALLEINIGEN RECHTSANSPRUCH AUF SCHADENERSATZ

DAR. ALLE ANDEREN GEWÄHRLEISTUNGEN - VERTRAGLICH GEREGELTE ODER

GESETZLICHE VORGESCHRIEBENE - EINSCHLIESSLICH DER GESETZLICHEN

GEWÄHRLEISTUNG DER MARKTFÄHIGKEIT UND DER EIGNUNG FÜR EINEN

BESTIMMTEN ZWECK, WERDEN ABGELEHNT DER HERSTELLER ÜBERNIMMT KEINE

HAFTUNG FÜR SPEZIELLE, INDIREKTE, NEBEN- ODER FOLGESCHÄDEN ODER

VERLUSTE, DIE AUF BELIEBIGER URSACHE ODER RECHTSTHEORIE BERUHEN.

Weil einige Staaten oder Länder den Ausschluss oder die Einschränkung einer

implizierten Gewährleistung sowie von Begleit- oder Folgeschäden nicht

zulassen, ist diese Gewährleistungsbeschränkung möglicherweise für Sie nicht

gültig.

2

Page 17

Inductance, Capacitance, Resistance Meter

Inhalt

Symbole .............................................................................................................1

Warnungen und Vorsichtsmaßnahmen ........................................................... 1

Überlastanzeige ................................................................................................2

Gebrauchsvorbereitung - Auspacken ............................................................... 2

Meßprozeduren ................................................................................................2

Spezifikatione .................................................................................................... 4

Fehlersuche/Unterhalt ....................................................................................... 6

Reparatur ........................................................................................................... 7

Symbole

Im Handbuch nachlesen.

Übereinstimmung mit

EU-Richtlinien

Akustischer Alarm

Batterie

Schutzisoliert

Sicherung

Übereinstimmung mit den relevanten australischen standards

WarnungenundVorsichtsmaßnahmen

• Überschreiten Sie nie die kontinuierlichen Überlastgrenzen per Funktion

(siehe Spezifikationen) oder andere Grenzen welche auf dem Gerät markiert

sind.

• Unsersuchen Sie Gerät, Meßkabel, Verbinder, usw. vor jeder Messung.

Beschädigte Teile nicht verwenden

• Meßspitzen und Stromkreis während der Messung nicht berühren. Sich selbst

isolieren !

• Sicherung immer mit gleichwertiger ersetzen.

• Gerät nicht in explosiver Umgebung verwenden.

3

Page 18

Überlastanzeige

Wenn ein Signal die Bereichsgrenze überschreitet erscheint das

Symbol “OL” in der Anzeige. Diese Anzeige ist normal bei

Widerstandsmessung wenn Mekabel/spitzen frei stehen oder

wenn der Meßwert den Bereich überschreitet.

Gebrauchsvorbereitung-Auspacken

Die Verpackung sollte enthalten: das LCR55A, ein Meßkabelsatz (ein schwarz,

ein rot), ein Paar Krokodilklemmen, eine 9V Batterie (im Gerät), eine 0.1A/250V

Ersatzsicherung (im Gerät), eine Garantiekarte und diese Anleitung. Wenn

ein Teil fehlt oder beschädigt ist, zur Verkaufstelle für einen Austausch

zurückbringen.

Meßprozeduren

Allgemein

1. Vor Verbinden und Trennen der Meßkabel mit dem Schaltkreis, diesen

abschalten und Kondensatoren entladen.

2. Bei unbekannter Signalgröße, bei höchstem Bereich beginnen und dann

niedriger schalten bis gute Auflösung erreicht wird.

3. Maximale Grenzen nicht überschreiten.

Widerstandsmessung (Fig. -1-)

4. Es darf keine Spannung am Widerstand anliegen. Kondensatoren entladen.

Eine Spannung würde die Messung verfälschen.

5. Rotes Meßkabel mit +Rx Eingang und schwarzes mit -Rx verbinden.

6. Funktionsschalter auf gewünschte Ω Position stellen.

7. Meßspitzen mit Schaltkreis verbinden. Meßwert ablesen. Eine offene

Schaltung wird mit Überlast angezeigt.

Anmerkun: Im 20Ω Bereich erlaubt ein Abgleichpotentiometer den Widerstand

der Meßkabel zu kompensieren. Meßspitzen kurzschließen und Knopf drehen bis

0 angezeigt wird.

Dioden- und Transistortest (Fig -2-)

Der Diodentest zeigt den Spannungsabfall über den Diodendurchgang

1. Rotes Meßkabel mit +Rx Eingang und schwarzes mit -Rx Eingang verbinden.

2. Funktions-schalter auf oder M.W. (zum Testen von Dioden aus

Microwellenöfen) stellen.

3. Meßkabel mit Diode verbinden – rotes mit Anode; schwarzes mit Kathode.

Spannungsabfall in Durchlaßrichtung ablesen (ung. 0.7V für eine SilikonDiode und 0.4V für eine Germaniumdiode. Eine offene Diode wird mit

Überlast angezeigt.

4. Verbindung umdrehen um in Sperrrichtung zu messen. Überlast zeigt eine

gute Diode an.

Anmerkung: Überlast in beiden Richtungen zeigt eine offene Diode an; eine

niedrige Ablesung eine kurzgeschlossene Diode. Transistorübergänge können

wie Dioden getestet werden.

Anmerkung: Der Meßvorgang für Microwellendioden ist der gleiche als für

normale Dioden – nur der Spannungsabfall in Durchlaßrichtung is höher (3V

oder mehr). LEDs können auch in der M.W. Position getestet werden

4

Page 19

Durchgangstest

1. Funktionsschalter auf stellen.

2. Rotes Meßkabel mit +Rx Eingang und schwarzes mit -Rx Eingang verbinden.

3. Meßspizen mit Schaltkreis verbinden.

4. Bei R ≤100Ω wird ein akustische Signal abgegeben.

Kapazitätsmessung (Fig. -3-)

1. Kondensator entladen (über 20kΩ Widerstand).

2. Rotes Meßkabel mit HI(+) Eingang und schwarzes mit LO(-) Eingang

verbinden.

3. Wahlschalter auf den Kapazitätsbereich stellen der die beste Auflösung gibt.

4. Meßspitzen mit Kondensatorleitern verbinden.

5. Meßwert ablesen (Sie müssen vielleicht einige Sekunden warten bis der

Kondensator ganz aufgeladen ist). Wenn im höchsten Bereich “OL”

angezeigt wird, dann ist der Kondensator zu groß um gemessen zu werden.

Anmerkung: Die Anschlüsse kleinerer Kondensatoren können zum Messen auch

gleich in die Cx/Lx Schlitze am LCR55A eingesteckt werden.

Anmerkung: Die Kapazitätsbereiche sind mit einer 0.1A/250V flinken Sicherung

abgesichert. Wenn die Sicherung durchbrennt, mit gleichwertiger ersetzen (siehe

Batterie- und Sicherungswechsel).

Anmerkung: Im 200nF Bereich hat das LCR55A eine Restwertanzeige von

ungefähr 6pF. Notieren Sie diesen Wert und ziehen Sie ihn vom späteren

Meßwert ab.

Induktivitätsmessung

1. Rotes Meßkabel mit HI(+) Eingang und schwarzes mit LO(-) Eingang

verbinden.

2. Funktionsschalter auf den Induktivitätsbereich stellen der die beste

Auflösung gibt.

3. Meßspitzen mit den Spulenanschlüssen verbinden. Meßwert ablesen. Wenn

im höchsten Bereich “OL” angezeigt wird, dann ist die Spule zu groß um mit

dem LCR55A gemessen zu werden.

Anmerkung: Die Anschlüsse kleinerer Spulen können zum Messen auch gleich in

die Cx/Lx Schlitze am LCR55A eingesteckt werden.

Anmerkung: Die Induktivitätsbereiche sind mit einer 0.1A/250V flinken KeramikSicherung abgesichert. Wenn die Sicherung durchbrennt, mit gleichwertiger

ersetzen (siehe Batterie- und Sicherungswechsel).

Transistor hFE Messung

Der Transistor muß vom Schaltkreis entfernt sein.

1. Funktionsschalter gemäß Transistor auf PNP (hFE) oder NPN (hFE) stellen.

2. Emitter-, Basis- und Kollektorausgänge in entsprechende Eingänge des

Testsockels stecken.

3. Verstärkung h

Anmerkung: Um den Kollektor-Emitterstrom zu messen, Wahlschalter auf

entsprechende PNP(Icec µA) oder NPN(Icec µA) Position stellen.

MAX Funktion

MAX Taste drücken um den höchsten Meßwert auf der Anzeige festzuhalten. Bei

jedem höheren gemessenen Wert wird die Anzeige erneuert. MAX Taste erneut

drücken um die Anzeige freizugeben und den laufenden Wert anzuzeigen.

FE beta, ablesen.

5

Page 20

Anzeigesperre

HOLD Taste drücken um den Meßwert auf der Anzeige festzuhalten. Der

Meßwert bleibt erhalten, auch wenn die Meßspitzen vom Schaltkreis entfernt

sind. HOLD Taste erneut drücken um die Anzeige freizugeben.

Sicherheitsmeßkabel

Die Meßkabel haben versenkte Bananenstecker um elektrischen Schock zu

vermeiden. Die Meßspitzen sind zum Teil isoliert, um Kurzschlüsse in dichten

Schaltungen zu vermeiden. Diese Isolation kann entfernt werden.

Spezikatione

Allgemeine Spezifikationen

Anzeige: 3 1/2-stelliges LCD, 1999 Punkte, 0.7” (17.8mm) hohe Ziffern, Einheits-

und Funktionsanzeigen

Polaritätsanzeige: Automatisch, positiv unterstellt, negativ angegeben

Nullabgleich: AutomatischÜberlastanzeige: “OL” Entladene Batterieanzeige:

Batterie sofort wechseln.

Meßrate: 2.5 per Sekunde, nominal

Betriebstemperatur: 0°C bis 50°C, 0

bis 70% Relative Feuchte

Lagertemperatur: -20°C bis 60°C, 0 bis 80% R.F., Batterie entfernt.

Temperaturkoeffizient: 0.1 x (spez. Genauigk.) per °C (0-18°C, 28-50°C)

Stromversorgung: Standard 9-volt Transistorbatterie, NEDA 1604, JIS 006P, IEC

6F22

Automatische Abschaltung: nach 60 Minuten Inaktivität.

Batterielebensdauer (Typisch): 30 Stunden, Alkaline (ändert mit Funktion und

Anwendung)

Abmessung. (HxBxT): 18.3x7.9x3.8 cm

Gewicht (mit Batterie): 311 gr.

Zubehör: Meßkabel, 0.1A/250V Ersatzsicherung, Batterie, ein Paar

Krokodilklemmen, Anleitung.

Zulassungen:

Dieses Produkt beantwortet an die Bestimmungen der folgenden EWG

Elektrisches Rauschen und starke magnetische Felder in der direkten

Elektrische Spezifikationen

Genauigkeiten bei 23°C ± 5°C, <75% R.F.

Widerstand

Bereiche: 20, 200Ω, 2, 20, 200kΩ, 2, 20MΩ

Auflösung, 20Ω Bereich: 10mΩ

Genauigkeit, 20Ω Bereich: ±1.2% vMW (Nullabgleich)

EMC

Richtlinien: 89/336/EEC (Elektromagnetische Kompatibilität) und 73/23/EEC

(Niedrige Spannung) geändert durch 93/68/EEC (CE Marking).

Umgebung des Meßgerätes können jedoch den Meßkreis beeinflussen.

Das Gerät kann auch durch Störsignale im gemessenen Schaltkreis

beeinflußt werden. Der Anwender muß Vorsichtsmaßnahmen treffen um

irreführende Meßergebnisse bei Messungen in der Umgebung von starken

elektromagnetischen Feldern zu vermeiden.

6

Page 21

200Ω Bereich: ±0.5% vMW +3Dgt

2k to 2MΩ Ber.: ±(0.5% vMW +1Dgt)

20MΩ Ber.: ±(2.0% vMW +2Dgt)

Überlastschutz, alle Bereiche: 350VDC oder AC eff.

Leerlaufspannung, 20Ω Bereich: 6.5VDC, 200Ω Bereich: 3.0VDC, andere Bereiche:

1.2VDC

Durchgangstest

Akustisches Signal im 2kΩ Bereich bei R ≤30Ω

Ansprechzeit: ung. 800ms

Überlastschutz: 350VDC oder AC eff.

Diodentest

Teststrom: 1mA (approx.)

Testspannung: 3.0VDC typisch

Genauigkeit: ±(1.5%vMW +1Dgt)

Anzeige: Spannungsabfall

Überlastschutz: 350VDC oder AC eff.

Mikrowellendiodentest

Teststrom: 1.3mA (approx.)

Testspannung: 8.0VDC typisch

Genauigkeit: ±(3.0%vMW +1Dgt)

Anzeige: Spannungsabfall

Überlastschutz: 350VDC oder AC eff.

Kapazität

Bereiche: 200pF, 2, 20, 200nF, 2, 20, 200, 2000µF

Genauigkeit*, 200pF bis 200nF: ±(1.0% vMW +3Dgt)

2µF bis 200µF Ber.: ±(2.0% vMW +3Dgt)

2000µF Bereich: ≤1000µF ±(3.0% vMW+3Dgt)

>1000µF ±(5.0% vMW+5Dgt)

Anmerkung: In niedrigen Bereichen 6 Punkte Restanzeige vom Meßwert

abziehen.

Testfrequenz, Bereiche: 200p bis 2µF: 1000Hz; 20, 200µF: 100Hz; 2000µF: 10Hz

Temperaturkoeffizient, ≤0.5µF: 0.1%/°C; >0.5µF: 0.2%/°C

Überlastschutz: flinke 0.1A/250V Sicherung.

Induktivität Bereiche: 200µH, 2, 20, 200mH, 2, 20, 200H

Genauigkeit, 200µH Ber.: ±(5.0%vMW +5Dgt)

Überlastschutz: 350VDC oder AC eff. +30Dgt)*

2 bis 200mH: ±(3.0%vMW +20Dgt)*

2 bis 200H: ±(5.0%vMW +20Dgt)*

*Fur Induktore mit Q ≤7

Testfrequenz: 200µH bis 2H Ber: 1000Hz; 20 und 200H Bereiche: 100Hz

Temperaturkoeffizient, ≤0.5H: 0.2%/°C; >0.5H: 0.5%/°C

Überlastschutz: flinke 0.1A/250V

7

Page 22

Transistortest

hFE Bereich: 0-1000

hFE Basisstrom: 5µA approx.

hFE Spannung C-E: 3.0VDC approx.

Iceo Bereich: 10nA bis 20µA

Optionszubehör

VC221B Vinyltragetasche (Gerät und Holster)

DL243D Standard Meßkabelsatz

DL248D Deluxe Meßkabelsatz

TL36A Ein Meßkabelsatz, ein Paar Krokodilkemmen

Fehlersuche/Unterhalt

Prüfen Sie zuerst folgende Fehlerquellen: Meßkabel (Brüche), Anschluß, Zustand

von

Batterie und Sicherung, richtiger Meßvorgang, Eingangs- und Bereichsgrenzen,

usw. Mit Ausnahme des Batterie- und Sicherungswechsels soll jede Reparatur nur

durch eine durch Amprobe anerkannte Servicestelle durchgeführt werden.

Das Gerät kann mit einer milden Seifenlösung gereinigt werden. Sparsam

auftragen und vor Gebrauch gut trocknen lassen.

Batterie/Sicherungsaustausch

Vor Öffnen des Gerätes, Gerät abschalten und Meßkabel

entfernen.

1. Schrauben entfernen und Geräterückwand abheben.

2. Sicherungsaustausch: Durchgebrannte Sicherung (5 x 20mm) entfernen und

durch neue flinke 0.1A/250V Glassicherung ersetzen (eine Ersatzsicherung ist

neben dem Batteriefach enthalten). Amprobe Teilnummer FP 125.

3. Batterieaustausch: Batterie entfernen und durch 9V NEDA type 1604 Batterie

oder gleichwertige ersetzen.

4. Gerät wieder zusammensetzen.

Verwendung einer verkehrten Batterie kann zu ernstiger

Verletzung leiten. Nicht-Abschalten des Gerätes bei

Batteriewechsel kann Gerät und Batterie zerstören.

Warnung

Warnung

Page 23

Reparatur

Zu allen Geräten, die zur Reparatur oder Kalibrierung im Rahmen der

Garantie oder außerhalb der Garantie eingesendet werden, muss folgendes

beigelegt werden: Name des Kunden, Firmenname, Adresse, Telefonnummer

und Kaufbeleg. Zusätzlich bitte eine kurze Beschreibung des Problems

oder der gewünschten Wartung sowie die Messleitungen dem Messgerät

beilegen. Die Gebühren für Reparaturen außerhalb der Garantie oder für

den Ersatz von Instrumenten müssen als Scheck, Geldanweisung, Kreditkarte

(Kreditkartennummer mit Ablaufdatum) beglichen werden oder es muss ein

Auftrag an Amprobe Test Tools formuliert werden.

Garantiereparaturen oder -austausch - alle Länder

Bitte die Garantieerklärung lesen und die Batterie prüfen, bevor Reparaturen

angefordert werden. Während der Garantieperiode können alle defekten Geräte

zum Umtausch gegen dasselbe oder ein ähnliches Produkt an den Amprobe

Test Tools-Distributor gesendet werden. Ein Verzeichnis der zuständigen

Distributoren ist im Abschnitt „Where to Buy“ (Verkaufsstellen) auf der Website

www.amprobe.com zu finden. Darüber hinaus können in den USA und in

Kanada Geräte an ein Amprobe Test Tools Service-Center (Adresse siehe weiter

unten) zur Reparatur oder zum Umtausch eingesendet werden.

Reparaturen und Austausch außerhalb der Garantie - USA und Kanada

Für Reparaturen außerhalb der Garantie in den Vereinigten Staaten und in

Kanada werden die Geräte an ein Amprobe Test Tools Service-Center gesendet.

Auskunft über die derzeit geltenden Reparatur- und Austauschgebühren

erhalten Sie von Amprobe Test Tools oder der Verkaufsstelle.

In den USA: In Kanada:

Amprobe Test Tools Amprobe Test Tools

1420 75th Street SW 400 Britannia Rd. E. Unit #1

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel.: 888-993-5853 Tel.: 905-890-7600

Fax: 425-446-6390 Fax: 905-890-6866

Reparaturen und Austausch außerhalb der Garantie - Europa

Geräte außerhalb der Garantie können durch den zuständigen Amprobe

Test Tools-Distributor gegen eine Gebühr ersetzt werden. Ein Verzeichnis der

zuständigen Distributoren ist im Abschnitt „Where to Buy“ (Verkaufsstellen) auf

der Website www.amprobe.com zu finden.

Korrespondenzanschrift für Europa*

Amprobe® Test Tools Europe

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

*(Nur Korrespondenz – keine Reparaturen, kein Umtausch unter dieser Anschrift.

Kunden in Europa wenden sich an den zuständigen Distributor.)

Page 24

Page 25

LCR55A

Inductance, Capacitance,

Resistance Meter

Operators Manual

• Bedienungsanleitung

• Manual de Instrucciones

• Manuel d’Utilisation

Spanish

Español

Español

Page 26

Garantía limitada y Limitación de responsabilidad

Su producto Amprobe estará libre de defectos de material y mano de obra

durante 1 año a partir de la fecha de adquisición. Esta garantía no cubre fusibles,

baterías descartables o daños que sean consecuencia de accidentes, negligencia,

uso indebido, alteración, contaminación o condiciones anormales de operación

o manipulación. Los revendedores no están autorizados a extender ninguna otra

garantía en nombre de Amprobe. Para obtener servicio durante el período de

garantía, regrese el producto con una prueba de compra a un centro de servicio

autorizado por Amprobe de equipos de comprobación o a un concesionario

o distribuidor de Amprobe. Consulte la sección Reparación que aparece

más arriba para obtener detalles. ESTA GARANTÍA CONSTITUYE SU ÚNICO

RESARCIMIENTO. TODAS LAS DEMÁS GARANTÍAS, TANTO EXPRESAS, IMPLÍCITAS

O ESTATUTARIAS, INCLUYENDO LAS GARANTÍAS IMPLÍCITAS DE ADECUACIÓN

PARA UN PROPÓSITO DETERMINADO O COMERCIABILIDAD, QUEDAN POR LA

PRESENTE DESCONOCIDAS. EL FABRICANTE NO DEBERÁ SER CONSIDERADO

RESPONSABLE DE NINGÚN DAÑO O PÉRDIDA TANTO ESPECIALES, INDIRECTOS,

CONTINGENTES O RESULTANTES QUE SURJAN DE CUALQUIER CAUSA O TEORÍA.

Debido a que ciertos estados o países no permiten la exclusión o limitación de

una garantía implícita o de los daños contingentes o resultantes, esta limitación

de responsabilidad puede no regir para usted.

Page 27

Inductance, Capacitance, Resistance Meter

Contenidos

Símbolos ............................................................................................................. 1

Advertencias y Precauciones ............................................................................. 1

Preparación del instrumento para su uso - Desembalaje ...............................2

Procedimientos de medida ............................................................................... 2

Especificaciones ................................................................................................. 4

Localización de Averías/Maintenimiento ......................................................... 6

Reparación ......................................................................................................... 7

Símbolos

Batería

Aislamiento doble

Fusible

Cumple con las normas australiansas relevantes

Consulte el manual

Cumple con las directivas

de la Unión Europea.

Señal acústica

AdvertenciasyPrecauciones

• No supere nunca los límites de entrada para las diferentes funciones (vea las

especificaciones), ni los límites marcados en el propio instrumento.

• Inspeccione el instrumento, las puntas de prueba y los accesorios antes de

cada uso. No utilice ningún componente que esté dañado.

• No se ponga Ud. a tierra cuando esté tomando medidas. No toque partes

expuestas de los circuitos ni los extremos de las puntas de prueba.

• Nunca sustituya un fusible con otro que no tenga las mismas especificaciones.

• No utilice el instrumento en ambientes potencialmente explosivos

1

Page 28

Indicación de sobrecarga

el circuito está abierto o la resistencia es demasiado alta.

La sobrecarga de escala se indica mediante el símbolo “OL” en

el visualizador, con los demás dígitos en blanco. La indicación

de sobrecarga es normal, durante la medida de OHMS, cuando

Preparacióndelinstrumentoparasuuso-Desembalaje

El embalaje debe contener: el LCR55A, un juego de puntas de prueba (una negra

y otra roja), un par de pinzas de cocodrilo, una pila de 9 V (instalada), un fusible

de repuesto de 0.1A/250V (dentro de la carcasa), una tarjeta de garantía y este

manual. Si falta algún componente u observa daños, devuelva el conjunto al

lugar donde lo adquirió para que se lo cambien.

Procedimientosdemedida

Procedimientos generales:

1. Antes de conectar o desconectar las puntas de prueba a/de un circuito,

apague siempre el dispositivo o circuito sometido a prueba y descargue todos

los condensadores.

2. Si no conoce la magnitud de la señal que va a medir, seleccione en primer

lugar la escala más alta y vaya reduciéndola hasta obtener una lectura

satisfactoria.

3. Observe estrictamente los límites máximos de entrada.

Medidas de resistencia (Fig. -1-)

Asegúrese de que no hay tensión aplicada a la resistencia y descargue los

condensadores. La presencia de tensión causará imprecisión en las medidas de

resistencia.

1. Conecte la punta de prueba roja a la entrada +Rx y la negra a la entrada -Rx.

2. Ponga el selector de función en la posición deseada de Ω.

3. Conecte las puntas de prueba a la resistencia o circuito que vaya a medir. Lea

el valor en el visualizador. Un circuito abierto se indicará como condición de

sobrecarga.

Nota: En la escala de 20 Ω, el potenciómetro de ajuste (ZERO ADJ) permite cancelar la

resistencia de las puntas de prueba. Una los extremos de ambas puntas de prueba y

ajuste el potenciómetro hasta obtener cero en el visualizador.

Comprobación de diodos y transistores (Fig. -2-)

En esta prueba se mide la caída de tensión en la unión del diodo.

1. Conecte la punta de prueba roja a la entrada +Rx y la negra a la entrada -Rx.

2. Ponga el selector de función en o en M.W. (para comprobar los

diodosutilizados en hornos de microondas).

3. Aplique la punta de prueba roja al ánodo del diodo y la negra al cátodo. El

visualizador indica la caída de tensión directa (aproximadamente 0.7 V para

diodos de silicio, o 0.4 V para diodos de germanio). Una unión abierta se

indica como condición de sobrecarga.

4. Invierta la conexión de las puntas de prueba para verificar la polarización inversa

del diodo. La condición de sobrecarga indica un diodo en buen estado.

Nota: La condición de sobrecarga en ambos sentidos indica un diodo abierto.

Un valor bajo de tensión en ambos sentidos indica un diodo cortocircuitado. Las

uniones de un transistor bipolar equivalen a diodos y se comprueban como tales.

2

Page 29

Nota: La prueba de diodos de hornos microondas es idéntica a la descrita, excepto en

que la caída de tensión directa será superior a la de un diodo normal de silicio (3 V o

más). También es posible comprobar diodos LED con el selector en la posición M.W.

Prueba de continuidad

1. Ponga el selector de función en la posición .

2. Conecte la punta de prueba negra a la entrada -Rx y toque uno de los puntos

de contacto con el extremo.

3. Conecte la punta de prueba roja a la entrada +Rx y toque el otro punto de

contacto con el extremo (vea las conexiones en la Fig. 1).

4. El zumbador interno emite un tono cuando la resistencia es menor de

aproximadamente 30Ω.

Medidas de Capacidad (Fig. -3-)

1. Descargue cualquier tensión presente en el condensador (a través de una

resistencia de 20 KΩ).

2. Conecte la punta de prueba roja a la entrada Hi(+) y la negra a la entrada Lo(-).

3. Ponga el selector de función en la escala de capacidad que proporcione la

mejor resolución.

4. Aplique las puntas de prueba a los terminales del condensador que desee medir.

5. Lea el valor de capacidad en el visualizador (es posible que tenga que

esperar unos segundos hasta que se cargue por completo el condensador). Si

aparece “OL” en la escala más alta, significa que el valor del condensador es

demasiado alto para el medidor.

Nota: Los condensadores de valor reducido también pueden medirse insertando

los terminales directamente en las ranuras Cx/Lx del medidor.

Nota: La entrada de capacidad está protegida mediante un fusible rápido

de 0.1A/250V. Si éste salta, cámbielo por otro de iguales características (vea

“Sustitución de la pila y el fusible”).

Nota: El LCR55A tiene una capacidad residual de unos 6 pF en la escala de 200 nF.

Si utiliza dicha escala de 200 nF, anote la capacidad residual y reste su valor del

valor medido.

Medidas de Inductancia

1. Conecte la punta de prueba roja a la entrada Hi(+) y la negra a la entrada

Lo(-).

2. Ponga el selector de función en la escala de inductancia que proporcione la

mejor resolución.

3. Aplique las puntas de prueba a los terminales de la bobina que desee medir

4. Lea el valor de la inductancia en el visualizador. Si aparece “OL” en la

escala más alta, significa que el valor de la bobina es demasiado alto para el

medidor.

Nota: Las bobinas de valor reducido también pueden medirse insertando los

terminales directamente en las ranuras Cx/Lx del medidor.

Nota: La entrada de inductancia está protegida mediante un fusible rápido

de 0.1A/250V. Si éste salta, cámbielo por otro de iguales características (vea

“Sustitución de la pila y el fusible”).

Medidas de ganancia en transistores

El transistor debe estar fuera de circuito.

1. Ponga el selector de función en la posición PNP(hFE) o NPN(hFE),

dependiendo del tipo de transistor que desee medir.

3

Page 30

2. Inserte los terminales del transistor (emisor, base, colector) en las entradas

correspondientes del conector de medida (E-B-C).

3. Lea el valor de hFE beta (ganancia de corriente CC) en el visualizador.

Nota: Para medir la corriente colector-emisor, ponga el selector de función en la

posición correspondiente, PNP(Icec µA) o NPN (Icec µA).

Retención de Máximos (MAX)

Pulse la tecla MAX para mantener en el visualizador solamente los valores

máximos de medida. La lectura se actualiza cada vez que se produce un valor

superior. Para liberar el visualizador y volver a medir en tiempo real, pulse de

nuevo MAX.

Retención de Lecturas (HOLD)

Pulse la tecla HOLD para mantener congelada la lectura del visualizador. Dicha

lectura se mantiene aunque se retiren las puntas de prueba del circuito. Para

liberar el visualizador, pulse de nuevo HOLD.

Puntas de Prueba de Seguridad

Las puntas de prueba suministradas con el multímetro incluyen unos conectores

de banana protegidos para eliminar la posibilidad de descargas eléctricas. Las

puntas están parcialmente aisladas para evitar cortocircuitos en áreas con alta

densidad de componentes. El usuario puede quitar dicho aislante si lo desea.

Especicaciones

Especificaciones generales

Visualizador: LCD de 3-1/2 dígitos, 1999 cuentas, dígitos de 17.8 mm de altura,

símbolos de función e indicación de unidades

Indicación de polaridad: Automática, positiva implícita, negativa indicada

Ajuste de cero: Automático

Indicación de sobrecarga: “OL” Indicación de “pila baja”: . Cambie la pila

inmediatamente

Frecuencia básica de refresco de lectura: 2.5 veces/segundo, nominal

Temp. de funcionamiento: 0 a 50 ºC, 0 a 70% H.R.

Temp. de almacenamiento: -20 a 60 ºC, 0 a 80% H.R., sin pila.

Coeficiente de temperatura: 0.1 x (especif. de precisión) por ºC (0-18ºC, 28-50ºC)

Alimentación: Pila normal de 9 V, NEDA 1604, JIS 006P, IEC 6F22

Apagado automático: Tras 60 minutos sin cambios de función o escala

Duración de la pila (típica): alcalina, 30 horas (varía según la función y la

aplicación)

Dimensiones (Al x An x Pr): 183 x 79 x 38 mm

Peso (pila incluida): 311 g

Accesorios: Puntas de prueba, fusible de repuesto 0.1A/250V, pila, un par de

pinzas de cocodrilo y Manual de Instrucciones

Aprobaciones de agencias:

Este producto cumple los requisitos de las siguientes Directivas de la

Comunidad Europea: 86/336/EEC (Compatibilidad Electromagnética) y 73/23/

EEC (Baja Tensión), con enmiendas según 93/68/EEC (Marcado CE).

No obstante, la presencia de ruido eléctrico o campos electromagnéticos

intensos en las proximidades del equipo pueden introducir perturbaciones en

EMC

4

Page 31

los circuitos de medida. Los instrumentos de medida también responden a las

señales no deseadas que puedan estar presentes en los circuitos de medida.

El usuario deberá tomar las precauciones necesarias para evitar obtener

resultados incorrectos cuando realiza medidas en presencia de interferencias

electromagnéticas.

Especificaciones eléctricas

Valores de precisión a 23 °C ±5 °C, H.R. <75%

Resistencia

Escalas: 20, 200 Ω; 2, 20, 200 KΩ; 2, 20 MΩ

Resolución, escala 20 Ω: 10 mΩ Precisión, escalas:

20Ω: ±1.2% (ajuste de cero)

200Ω: ±(0.5% lect + 3 dgt)

2 KΩ-2 MΩ: ±(0.5% lect + 1 dgt)

20 MΩ: ±(2.0% lect + 2 dgt)

Protección sobrecarga, todas las escalas: 350 V CC o CA ef.

Tensión de circuito abierto, escalas: 20Ω: 6.5VCC típ.; 200 Ω: 3.0 VCC típ. altras:

1.2 VCC

Continuidad

Indicación audible, escala 2 KΩ: R ≤30 Ω

Tiempo de respuesta: 800 ms aprox.

Protección sobrecarga: 350 V CC o CA ef.

Prueba de diodos

Corriente de medida: 1 mA aprox.

Tensión de medida: 3.0 VCC típ.

Precisión: ±(1.5% lect + 1 dgt)

Indicación: Tensión directa de la unión

Protección sobrecarga: 350 V CC o CA ef.

Prueba de diodos de microondas

Corriente de medida: 1.3 mA aprox.

Tensión de medida: 8.0 VCC típ.

Precisión: ±(3.0% lect + 1 dgt)

Indicación: Tensión directa de la unión

Protección sobrecarga: 350 V CC o CA ef.

Capacidad

Escalas: 200 pF; 2, 20, 200 nF; 2, 20, 200, 2000 mF

Precisión*, escalas: 200 pF a 200 nF: ±(1.0% lect +3 dgt)

2 µF a 200 µF: ±(2.0% lect +3 dgt)

2000 µF: ≤1000µF ±(3.0% lect +3 dgt)

>1000µF ±(5.0% lect +5 dgt)

Nota: En las escalas más bajas, reste 6 puntos del resultado como offset residual.

Frecuencia de medida, escalas: 200 pF a 2 µF: 1000 Hz; 20 y 200 µF: 100 Hz; 2000

µF: 10 Hz

Coeficiente de temperatura, ≤ 0.5 µF: 0.1%/ºC; >0.5 µF: 0.2%/ºC

Protección sobrecarga: Fusible de actuación rápida, 0.1A/250V

5

Page 32

Inductancia

Escalas: 200 µH; 2, 20, 200 mH; 2, 20, 200 H

Precisión, escalas:

200 µH: ±(5.0% lect +30 dgt)*

2 a 200 mH: ±(3.0% lect +20 dgt)*

2 a 200 H: ±(5.0% lect +20 dgt)*

*Para inductores con Q ≤7

Frecuencia de medida, escalas: 200 µH a 2 H: 1000 Hz; 20 y 200 H: 100 Hz

Coeficiente de temperatura, ≤ 0.5 H: 0.2%/ºC; >0.5 H: 0.5%/°C

Protección sobrecarga: Fusible de actuación rápida, 0.1A/250V

Prueba de transistores

Margen de hFE: 0-1000

Corriente de base hFE: 5µA aprox.

Tensión C-E hFE: 3.0 VCC aprox.

Margen de ICE0, corriente de fuga: 10 nA a 20 µA

Accessories opciohnales

VC221B Estuche de transporte de vinilo (para medidor y funda protectora)

DL243D Juego de puntas de prueba

DL248D Puntas de prueba (calidad especial)

TL36A Puntas de pruebba con dos d Cocodrilo

LocalizacióndeAverías/Maintenimiento

Para identificar la causa del problema: Compruebe la pila; revise las instrucciones

de uso; inspeccione las puntas de prueba por si hay una conexión rota o

intermitente; inspeccione la pila y el fusible.

Excepto la sustitución de la pila o el fusible, cualquier trabajo de reparación del

multímetro debe hacerse exclusivamente por personal técnico cualificado para

este tipo de reparaciones.

Para limpiar la carcasa puede utilizarse una solución suave de agua y detergente.

Aplique con un paño suave y deje secar antes de usar el medidor.

Sustitución de la pila y el fusible

Para evitar el peligro de descarga eléctrica, apague el

medidor y desconecte las puntas de prueba antes de abrir la

tapa posterior.

1. Quite los tornillos y separe la tapa posterior del medidor.

2. Sustitución del fusible: saque del portafusibles el fusible abierto, y cámbielo

por otro equivalente (5 x 20 mm, 0.1A/250V, cerámico, actuación rápida); hay

un fusible de repuesto en la parte derecha del compartimento de la pila. La

referencia de Wavetek es FP 125.

3. Sustitución de la pila: Retire la pila y cámbiela por otra equivalente (NEDA

1604, 9 V, alcalina).

4. Vuelva a montar el instrumento.

La utilización de un fusible incorrecto puede causar graves

daños personales. Si no apaga el instrumento antes de

cambiar la pila, puede dañar tanto el medidor como la pila.

Advertencia

Advertencia

6

Page 33

Reparación

Todas las herramientas de comprobación devueltas para su calibración o

reparación, cubiertas o no por la garantía, deberán estar acompañadas por

lo siguiente: su nombre, el nombre de la empresa, la dirección, el número de

teléfono y una prueba de compra. Además, incluya una breve descripción del

problema o del servicio solicitado y las puntas de prueba del medidor. Los pagos

correspondientes a reparaciones o reemplazos no cubiertos por la garantía se

deben remitir a la orden de Amprobe Test Tools en forma de cheque, giro postal,

pago mediante tarjeta de crédito (incluir el número y la fecha de vencimiento) u

orden de compra.

Reparaciones y reemplazos cubiertos por la garantía – Todos los países

Antes de solicitar una reparación sirvase leer la declaración de garantía

y compruebe el estado de la pila. Durante el periodo de garantía, toda

herramienta de comprobación en mal estado de funcionamiento puede ser

devuelta al distribuidor de Amprobe Test Tools para cambiarla por otra igual o

un producto semejante. Consulte la sección “Dónde comprar” del sitio www.

amprobe.com en Internet para obtener una lista de los distribuidores de su

zona. Además, en los Estados Unidos y Canadá las unidades para reparación y

reemplazo cubiertas por la garantía también se pueden enviar a un Centro de

Servicio de Amprobe Test Tools (las direcciones se incluyen más adelante).

Reparaciones y reemplazos no cubiertos por la garantía – Estados Unidos y

Canadá

Las unidades para reparaciones no cubiertas por la garantía en Estados Unidos y

Canadá se deben enviar a un Centro de Servicio de Amprobe Test Tools. Póngase

en contacto con Amprobe Test Tools o con el vendedor de su producto para

solicitar información acerca de los precios vigentes para reparación y reemplazo.

En Estados Unidos En Canadá

Amprobe Test Tools Amprobe Test Tools

1420 75th Street SW 400 Britannia Rd. E. Unit #1

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel: 888-993-5853 Tel: 905-890-7600

Fax: 425-446-6390 Fax: 905-890-6866

Reparaciones y reemplazos no cubiertos por la garantía – Europa

El distribuidor de Amprobe Test Tools puede reemplazar aplicando un cargo

nominal las unidades vendidas en Europa no cubiertas por la garantía. Consulte

la sección “Dónde comprar” del sitio www.amprobe.com en Internet para

obtener una lista de los distribuidores de su zona.

Dirección para envío de correspondencia en Europa*

Amprobe® Test Tools Europe

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

*(Correspondencia solamente. En esta dirección no se suministran reparaciones

ni reemplazos. Los clientes europeos deben ponerse en contacto con el

distribuidor).

Page 34

Page 35

LCR55A

Inductance, Capacitance,

Resistance Meter

Operators Manual

• Bedienungsanleitung

• Manual de Instrucciones

• Manuel d’Utilisation

French

Francais

Francais

Page 36

Limites de garantie et de responsabilité

Amprobe garantit l’absence de vices de matériaux et de fabrication de ce produit

dans des conditions normales d’utilisation et d’entretien pendant une période

d’un an prenant effet à la date d’achat. Cette garantie ne s’applique pas aux

fusibles, aux piles jetables ni à tout produit mal utilisé, modifié, contaminé,

négligé ou endommagé par accident ou soumis à des conditions anormales

d’utilisation et de manipulation. Les distributeurs agréés par Amprobe ne sont

pas autorisés à appliquer une garantie plus étendue au nom de Amprobe. Pour

bénéficier de la garantie, renvoyez le produit accompagné d’un justificatif

d’achat auprès d’un centre de services agréé par Amprobe Test ou du distributeur

ou du revendeur Amprobe. Voir la section Réparation ci-dessus pour tous les

détails. LA PRESENTE GARANTIE EST LE SEUL ET EXCLUSIF RECOURS TOUTES

AUTRES GARANTIES, EXPLICITES, IMPLICITES OU STATUTAIRES, NOTAMMENT LE

CAS ECHEANT LES GARANTIES DE QUALITE MARCHANDE OU D’ADAPTATION A

UN OBJECTIF PARTICULIER SONT EXCLUES PAR LES PRESENTES. LE FABRICANT

NE SERA EN AUCUN CAS TENU RESPONSABLE DE DOMMAGES PARTICULIERS,

INDIRECTS, ACCIDENTELS OU CONSECUTIFS, NI D’AUCUNS DEGATS OU PERTES

DE DONNEES, SUR UNE BASE CONTRACTUELLE, EXTRA-CONTRACTUELLE OU

AUTRE. Etant donné que certains pays ou états n’admettent pas les limitations

d’une condition de garantie implicite, ou l’exclusion ou la limitation de dégâts

accidentels ou consécutifs, les limitations et les exclusions de cette garantie ne

s’appliquent pas obligatoirement à chaque acheteur.

Page 37

Inductance, Capacitance, Resistance Meter

Contenu

Explication des Symboles .................................................................................. 1

Avertissements et Précautions .......................................................................... 1

Indication de Surcharge .................................................................................... 2

Préparation pour l’Emploi - Déballage ............................................................ 2

Procédures de Mesure ....................................................................................... 2

Specifications ..................................................................................................... 4

Dépannage/Maintenance .................................................................................6

Réparation ......................................................................................................... 7

ExplicationdesSymboles

Pile

Double isolation

Fusible

Conforme aux normes australiennes pertinentes

Se reporter au mode

d’emploi.

Signal sonore

Conforme aux directives

de l’UE

Avertissements et Précautions

• N’excédez jamais les limites de surcharge continue par fonction (voir

spécifications) ou d’autres limites marquées sur l’appareil.

• Inspectezappareil,câbles,connecteursavantchaquemesure.N’utilisezpas

des pièces endommagées.

• Netouchezpaslespointesdetoucheoulecircuitpendantlesmesures.Isolez-

vous !

• Neremplacezlesfusiblesquepardesfusibleséquivalents.

• N’utilisezpasl’appareildansuneatmosphèreexplosive.

1

Page 38

IndicationdeSurcharge

Quand un signal dépasse la limite d’un calibre choisi, le sybole

“OL” apparait sur l’afficheur. Ceci est normal dans les calibres

de résistance, quand les pointes de touche ne sont pas

connectées, ou si la résistance mesurée dépasse le calibre.

Préparationpourl’Emploi-Déballage

Votre emballage doit contenir: le LCR55A, un jeu de câbles de mesure (un rouge,

un noir), une paire de pinces crocodile, une pile 9V (installée), un fusible de réserve

0.1A/250V (dans l’appareil), une carte de garantie et ce manuel. Si une pièce manque

ou est endommagée, ramenez l’ensemble au point de vente pour un échange.

ProcéduresdeMesure

Général

1. Avant de connecter ou de déconnecter les cordons de test, coupez

l’alimentation du circuit mesuré et déchargez les condensateurs.

2. Si la magnitude du signal n’est pas connue, commencez par la gamme la plus

élevée, et diminuez ensuite jusqu’à obtenir une bonne lecture.

3. Ne dépassez pas les limites d’entrée.

Mesure de Résistance (Fig -1-)

4. Coupez l’alimentation du circuit et déchargez les condensateurs. La présence

d’une tension fausserait le résultat.

5. Connectez le cordon rouge à l’entrée +Rx et le noir à lentrée -Rx.

6. Placez le sélecteur sur la position Ω souhaitée.

7. Connectez les cordons au circuit à mesurer.

8. Lisez la valeur affichée. Un circuit ouvert est indiqué comme surcharge.

Note: Pour le calibre 20Ω, un potentiomètre (ZERO ADJ.) permet de neutraliser

la résistance des cordons de test. Court-circuitez les pointes de touche et tournez

le bouton pour amener la lecture à zéro.

Test de Diodes et de Transistors (Fig. -2-)

Le test de diodes affiche la chute de tension à travers le transistor.

1. Connectez les cordon rouge à l’entrée +Rx et le noir à l’entrée -Rx.

2. Placez le sélecteur sur ou sur M.W. (pour tester les diodes d’un four à

micro-ondes).

3. Connectez les pointes de touche à la diode – le rouge à l’anode, le noir à la

cathode. Lisez la chute de tension en direction passante (environ 0.7V pour une

diode au Si; 0.4V pour une diode au Ge. Une diode ouverte est affichée par “OL”.

4. Inversez la connection pour mesurer en direction de bloquage. Une bonne

diode est affichée par “OL”.

Note : “OL” dans les deux directions indique une diode ouverte; une lecture

basse indique une diode court-circuitée. Les jonctions de transistors peuvent être

testées comme des diodes.

Note : Les diodes pour micro-ondes sondes testées de la même manière que les

diodes normales – seulement la chute de tension en direction passante est plus

élevée (3V et plus). Les LEDs peuvent également être testées dans la position

M.W.

2

Page 39

Test de Continuité

1. Placez le sélecteur sur .

2. Connectez le cordon rouge à l’entrée +Rx et le cordon noir à l’entrée -Rx.

3. Connectez les pointes de touche au circuit.

4. Un signal sonore retentit pour R ≤30Ω.

Mesure de Capacité (Fig. -3-)

1. Déchargez le condensateur (à travers une résistance de 20kΩ).

2. Connectez le cordon rouge à l’entrée HI(+) et le cordon noir à l’entrée LO(-).

3. Placez le sélecteur sur le calibre de capacité qui donne la meilleure résolution.

4. Connectez les pointes de touche aux conducteurs du condensateur.

5. Lisez la valeur sur l’afficheur (vous devez peut-être attendre quelques

secondes, le temps de chargement du condensateur). Si “OL” est affiché dans

le calibre le plus élevé, le condensateur est trop grand pour être mesuré par

le LCR55A.

Note : Les conducteurs de petits condensateurs peuvent être insérés directement

dans les fentes Cx/Lx du LCR55A.

Note : Les calibres de capacité sont protégés par un fusible rapide 0.1A/250V. Si

le fusible saute, remplacez-le par un fusible identique. (voir remplacement de la

pile et du fusible)

Note : Dans le calibre 200nF, le LCR55A a un affichage résiduel d’approx. 6pF.

Notez cette valeur et déduisez la de la mesure ultérieure.

Mesure d’Inductance

1. Connectez le cordon rouge à l’entrée HI(+) et le cordon noir à l’entrée LO(-)

2. Placez le sélecteur sur le calibre d’inductance qui donne la meilleure

résolution

3. Connectez les pointes de touche aux conducteurs de la bobine.

4. Lisez la valeur sur l’afficheur. Si “OL” est affiché, la bobine est trop grande

pour être mesurée avec le LCR55A.

Note : Les conducteurs de petites bobines peuvent être insérés directement dans

les fentes Cx/Lx du LCR55A.

Note : Les calibres d’inductance sont protégés par un fusible céramique rapide

de 0.1A/250V. Si le fusible saute, remplacez-le par un fusible identique. (voir

remplacement de la pile et du fusible)

Mesure du Gain de Transistors

Le transistor doit être enlevé du circuit.

1. Placez le sélecteur sur la position PNP ou NPN, selon le type de transistor à

tester.

2. Insérez les conducteurs d’émetteur, de base et de collecteur dans les trous

appropriés du socket de test.

3. Lisez le gain tu transistor h

Note : Pour mesurer le courant collecteur-émetteur, placez le sélecteur sur la

position PNP(Icec µA) ou NPN(Icec) appropriée.

Fonction MAX

Pressez la touche MAX pour maintenir la valeur maximale sur l’afficheur. A

chaque mesure d’une valeur plus élevée, l’affichage est remis à jour. Pressez à

nouveau la touche MAX pour libérer l’afficheur et afficher la valeur courante.

FE beta, sur l’afficheur

3

Page 40

Maintien de Lecture

Pressez la touche HOLD pour maintenir l’affichage. L’affichage est maintenu

même quand les pointes de touche sont déconnectées du circuit. Pressez à

nouveau HOLD pour libérer l’affichage.

Cordons de Sécurité

Les fiches banane des cordons sont munis de protecteurs fixes afin de supprimer

les risques de chocs électriques. Les pointes métalliques sont partiellement isolées

pour éviter des court-circuits dans des circuits denses. Cette isolation peut être

enlevée.

Specications

Spécifications Générales

Affichage: LCD 3 1/2 digits, 1999 points, chiffres de 17.8mm), indicateurs d’unités

et de fonctions.

Indication de polarité: Automatique, positive sous-entendue, négative indiquée

Ajustement du zéro: Automatique

Indication de surcharge: “OL”

Indication de pile déchargée: Changez pile immédiatement.

Taux de mesure: 2,5/sec, nominal

Temp. de fonctionnement: 0°C à 50°C, 0 à 70% Humidité Relative

Température de stockage: -20°C à 60°C, 0 à 80% HR, pile enlevée.

Coefficient de température: 0.1 x (préc. spéc.) par °C (0-18°C, 28-50°C)

Alimentation: pile standard 9-volt, NEDA 1604, JIS 006P, IEC 6F22

Coupure automatique: après 60 minutes d’inactivité.

Autonomie (typiq.): 30 hrs alcalin (change avec la fonction et l’application)

Dimensions (HxWxD): 18.3x7.9x3.8 cm

Poids (avec pile): 311 gr

Accessoires: câbles de mesure, une paire de pinces crocodile, un fusible de

réserve 0.1A/ 250V, pile, manuel.

Homologations d’organismes: EMC

Ce produit est conforme aux exigences des directives suivantes de la

Communauté Européenne: 89/336/EEC (Compatibilité Electromagnétique) et

73/23/EEC (Basse Tension), modifiée par 93/68/EEC (CE Marking).

Cependant, du bruit électrique ou des champs électromagnétiques intenses

dans la proximité de l’instrument peuvent influencer le circuit de mesure.

L’instrument peut également être perturbé par des signaux parasytes dans

le circuit mesuré. L’utilisateur doit être vigilant et prendre des précautions

appropriées pour éviter des résultats erronés quand les mesures sont prises en

présence d’interférences électromagnétiques.

Spécifications Electriques

Précision à 23°C ± 5°C, <75% H.R.

Résistance:

Cilbres: 20, 200Ω, 2, 20, 200kΩ, 2, 20MΩ

4

Page 41

Résolution, cal. 20Ω: 10mΩ

Précision, cal. 20Ω: ±1.2% lect (ajustement du zéro)

cal. 200Ω: ±0.5% lect +3dgt

cal. 2k à 2MΩ: ±(0.5% lect +1dgt)

cal. 20MΩ: ±(2.0% lect +2dgt)

Protection de surcharge, tous calibres: 350Vcc ou ca eff.

Tension en circuit ouvert; calibre 20Ω: 6.5Vcc; calibre 200Ω: 3.0Vcc, autres;

calibres: 1.2Vcc

Continuité

Indication sonore, cal. 2kΩ à R ≤30Ω

Temps de réponse: 800ms approx

Prot. de surcharge: 350Vcc ou AC eff.

Test de Diodes

Courant de test: 1mA (approx.)

Tension de test: 3.0Vcc typiq.

Précision: ±(1.5%lect +1dgt)

Affichage: chute de tension, direction passante

Prot. de surcharge: 350Vcc ou AC eff.

Test de Diodes à Micro-ondes

Courant de test: 1.3mA (approx.)

Tension de test: 8.0VDC typiq.

Précision: ±(3.0%lect +1dgt)

Affichage: chute de tension, direction passante

Prot. de surcharge: 350Vcc ou AC eff.

Capacité

Calibres: 200pF, 2, 20, 200nF, 2, 20, 200, 2000µF

Précision*, calibres: 200pF à 200nF: ±(1.0% lect +3dgt)

2µF à 200µF: ±(2.0% lect +3dgt)

2000µF: ≤1000µF ±(3.0% lect +3dgt) ≥

>1000µF ±(5.0% lect +5dgt)

Note: Dans les calibres inférieurs, déduisez 6 points d’affichage résiduel du

résultat de mesure .

Fréquence de test, calibres: 200p à 2µF: 1000Hz; 20, 200µF: 100Hz; 2000µF: 10Hz

Coefficient de température, ≤0.5µF: 0.1%/°C; >0.5µF: 0.2%/°C

Prot. de surcharge: fusible rapide 0.1A/250V.

Inductance

Calibres: 200µH, 2, 20, 200mH, 2, 20, 200H

Précision, calibres:

200µH: ±(5.0%lect +30dgt)*

2 à 200mH: ±(3.0%lect +20dgt)*

2 à 200H: ±(5.0%lect +20dgt)*

*Pour inductors avec Q ≤ 7

Fréquence de test, calibres: 200µH à 2H: 1000Hz; 20 et 200H: 100Hz

Coefficient de température, ≤0.5H: 0.2%/°C; >0.5H: 0.5%/°C

Prot. de surcharge: fusible rapide 0.1A/250V

5

Page 42

Test de Transistors

Gamme hFE: 0-1000

Courant base hFE: 5µA approx.

Tension hFE C-E: 3.0VDC approx.

Courant I

: 10nA à 20µA

ceo

Accessories en Option

VC221B Sacoche en vynil (LCR55A et holster)

DL243D Cordons de mesure standards

DL248D Cordons de mesure Deluxe

TL36A Cordons de mesure avec pjnces crocodile

Dépannage/Maintenance

Avant d’expédier votre multimètre pour réparation, vérifiez les cordons de

mesure

(rupture), pile et fusible, connections, procédure de mesure, limites d’entrée et

decalibres, etc.

Excepté pour le remplacement de la pile et du fusible, toute réparation doit être

effectuée uniquement par un Centre de Services agrée par Amprobe.

Vous pouvez nettoyer le boîtier avec un détergent doux. Appliquez

parcimonieusement et laissez sécher complètement avant utilisation.

Remplacement Pile et Batterie

Avant d’ouvrir l’appareil, coupez l’alimentation et retirez les

cordons de test.

1. Enlevez les vis et soulevez le boîtier arrière.

2. Remplacement du fusible: Enlevez le fusible brulé et remplacez-le par un

fusible rapide équivalent 0.1A/250V (5 x 20mm) (un fusible de réserve est

contenu dans le compartiment de la pile. Référence Amprobe: FP 125.

3. Remplacement de la pile: Enlevez la pile et remplacez la par une pile alcalin

9V, NEDA type 1604 ou équivalente.

4. Reassemblez l’instrument.

L’utilisation d’un mauvais fusible peut entraîner des blessures

graves. Ne pas éteindre l’appareil pour installer une nouvelle

pile peut endommager la pile et l’appareil.

Avertissement

Avertissement

6

Page 43

Réparation

Tous les outils de test renvoyés pour un étalonnage ou une réparation couverte

ou non par la garantie doivent être accompagnés des éléments suivants : nom,

raison sociale, adresse, numéro de téléphone et justificatif d’achat. Ajoutez

également une brève description du problème ou du service demandé et

incluez les cordons de test avec le multimètre. Les frais de remplacement ou

de réparation hors garantie doivent être acquittés par chèque, mandat, carte

de crédit avec date d’expiration ou par bon de commande payable à l’ordre de

Amprobe Test Tools.

Remplacements et réparations sous garantie – Tous pays

Veuillez lire la déclaration de garantie et vérifier la pile avant de demander une

réparation. Pendant la période de garantie, tout outil de test défectueux peut

être renvoyé auprès de votre distributeur Amprobe Test Tools pour être échangé

contre un produit identique ou similaire. Consultez la section « Where to Buy »

sur le site www.amprobe.com pour obtenir la liste des distributeurs dans votre

région. Au Canada et aux Etats-Unis, les appareils devant être remplacé ou

réparé sous garantie peuvent également être envoyés dans un centre de services

Amprobe Test Tools (voir les adresses ci-dessous).

Remplacements et réparations hors garantie – Canada et Etats-Unis

Les appareils à réparer hors garantie au Canada et aux Etats-Unis doivent être

envoyés dans un centre de services Amprobe Test Tools. Appelez Amprobe Test

Tools ou renseignez-vous auprès de votre lieu d’achat pour connaître les tarifs en

vigueur pour le remplacement ou les réparations.

Aux Etats-Unis Au Canada

Amprobe Test Tools Amprobe Test Tools

1420 75

Everett, WA 98203 Mississauga, Ontario L4Z 1X9

Tél. : 888-993-5853 Tél. : 905-890-7600

Fax : 425-446-6390 Fax : 905-890-6866

Remplacements et réparations hors garantie – Europe

Les appareils européens non couverts par la garantie peuvent être remplacés par

votre distributeur Amprobe Test Tools pour une somme nominale. Consultez la

section « Where to Buy » sur le site www.amprobe.com pour obtenir la liste des

distributeurs dans votre région.

Adresse postale européenne*

Amprobe® Test Tools Europe

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0