Page 1

IR-750

IR-750-EUR

50:1 Infrared

Thermometer

Users Manual

Page 2

Page 3

IR-750

IR-750-EUR

50:1 Infrared Thermometer with memory

Users Manual

English

11/2013, 4279850 B

©2013 Amprobe Test Tools.

All rights reserved. Printed in China

Page 4

Limited Warranty and Limitation of Liability

Your Amprobe product will be free from defects in material and workmanship for one year from the date of

purchase, unless local laws require otherwise. This warranty does not cover fuses, disposable batteries or damage

from accident, neglect, misuse, alteration, contamination, or abnormal conditions of operation or handling.

Resellers are not authorized to extend any other warranty on Amprobe’s behalf. To obtain service during the

warranty period, return the product with proof of purchase to an authorized Amprobe Test Tools Service Center

or to an Amprobe dealer or distributor. See Repair Section for details. THIS WARRANTY IS YOUR ONLY REMEDY.

ALL OTHER WARRANTIES - WHETHER EXPRESS, IMPLIED OR STATUTORY - INCLUDING IMPLIED WARRANTIES OF

FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, ARE HEREBY DISCLAIMED. MANUFACTURER SHALL

NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING

FROM ANY CAUSE OR THEORY. Since some states or countries do not allow the exclusion or limitation of an

implied warranty or of incidental or consequential damages, this limitation of liability may not apply to you.

Repair

All test tools returned for warranty or non-warranty repair or for calibration should be accompanied by the

following: your name, company’s name, address, telephone number, and proof of purchase. Additionally, please

include a brief description of the problem or the service requested and include the test leads with the meter.

Non-warranty repair or replacement charges should be remitted in the form of a check, a money order, credit

card with expiration date, or a purchase order made payable to Amprobe.

In-Warranty Repairs and Replacement – All Countries

Please read the warranty statement and check your battery before requesting repair. During the warranty

period any defective test tool can be returned to your Amprobe distributor for an exchange for the same or

like product. Please check the “Where to Buy” section on www.amprobe.com for a list of distributors near you.

Additionally, in the United States and Canada In-Warranty repair and replacement units can also be sent to a

Amprobe® Test Tools Service Center.

Non-Warranty Repairs and Replacement – US and Canada

Non-warranty repairs in the United States and Canada should be sent to a Amprobe Service Center. Call

Amprobe or inquire at your point of purchase for current repair and replacement rates.

In USA In Canada

Amprobe Test Tools Amprobe Test Tools

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel: 877-AMPROBE (267-7623) Tel: 905-890-7600

Non-Warranty Repairs and Replacement – Europe

European non-warranty units can be replaced by your Amprobe distributor for a nominal charge. Please check

the “Where to Buy” section on www.amprobe.com for a list of distributors near you.

European Correspondence Address*

Amprobe® Test Tools Europe

Beha-Amprobe GmbH

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

www.amprobe.eu

*(Correspondence only – no repair or replacement available from this address. European customers please

contact your distributor.)

Page 5

IR-750 / IR-750-EUR 50:1 Infrared Thermometer with memory

CONTENTS

SYMBOLS ...................................................................................................................................................................... 3

SAFETY INFORMATION ................................................................................................................................................3

UNPACKING AND INSPECTION ....................................................................................................................................4

FEATURES ......................................................................................................................................................................4

HOW THE THERMOMETERS WORK ............................................................................................................................ 4

OPERATING THE THERMOMETER ................................................................................................................................4

Temperature Measurement ....................................................................................................................................4

Locating a Hot or Cold Spot ................................................................................................................................... 8

Distance and Spot Size ............................................................................................................................................ 8

Field of View.............................................................................................................................................................8

Emissivity .................................................................................................................................................................. 9

Reminders ................................................................................................................................................................ 9

TYPICAL MEASUREMENTS .......................................................................................................................................... 10

OPERATING IR-750 / IR-750-EUR SOFTWARE ............................................................................................................. 13

DETAILED SPECIFICATIONS .........................................................................................................................................17

MAINTENANCE ............................................................................................................................................................. 18

TROUBLE SHOOTING .................................................................................................................................................... 19

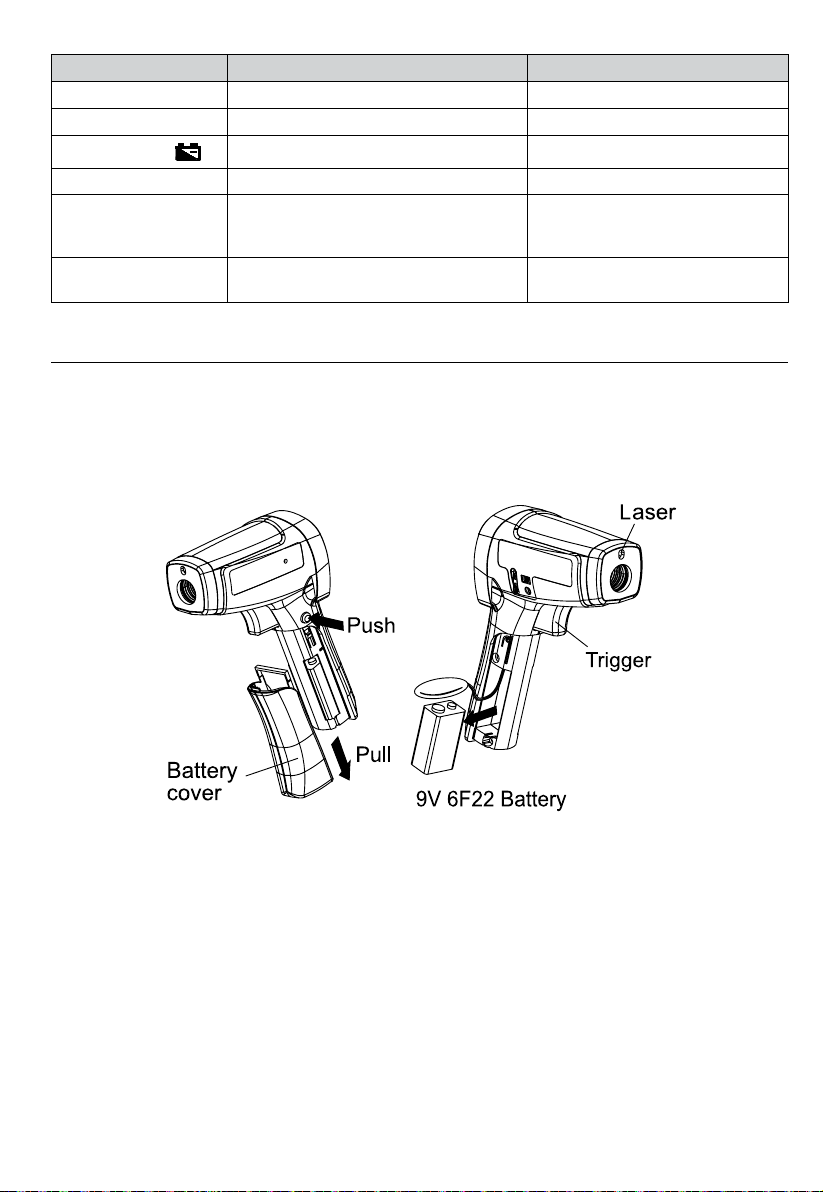

BATTERY REPLACEMENT ............................................................................................................................................. 19

1

Page 6

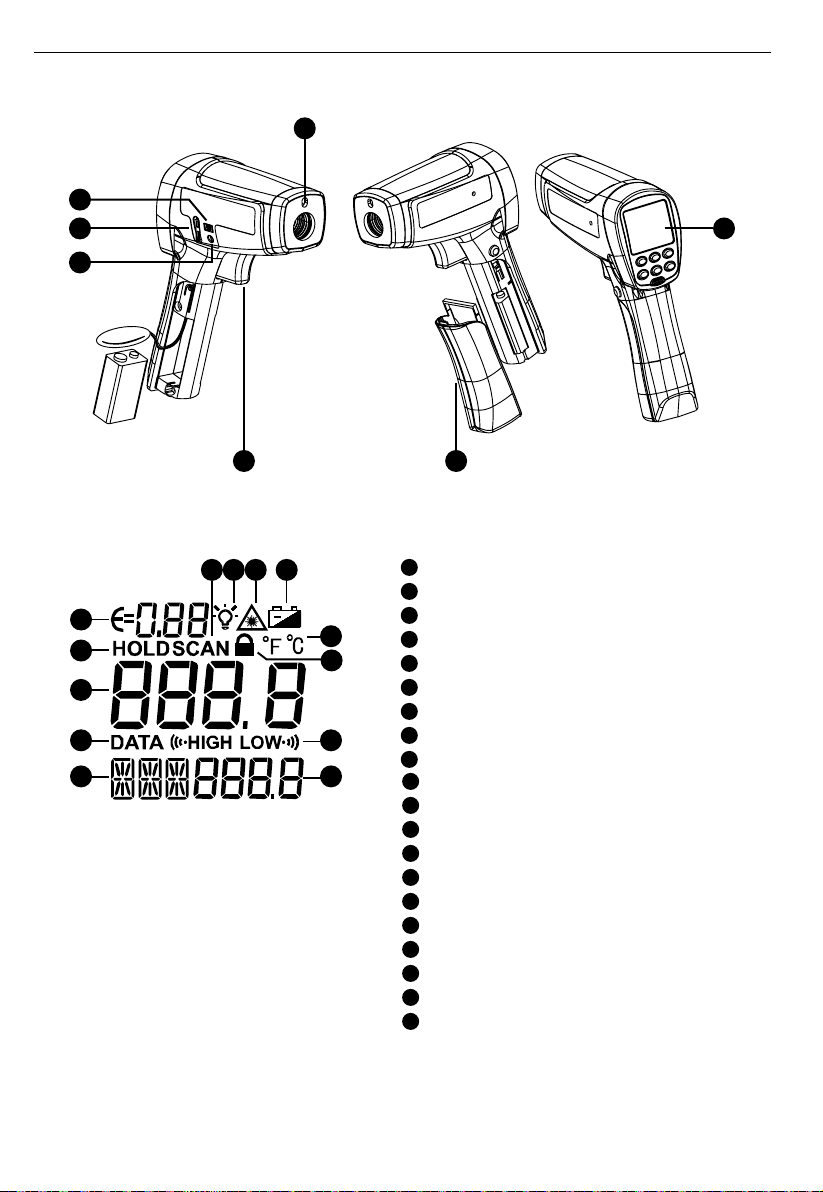

IR-750 / IR-750-EUR 50:1 Infrared Thermometer with memory

1

5

6

7

2 3

Laser aperture

1

Trigger

2

Battery cover

3

Display

4

USB connector

5

K-type thermocouple connector

6

Power adaptor connector (for optional accessory)

7

Laser “ON” symbol

8

Display backlight

9

10

Measurement lock (continuous measurement)

11

Temperature unit (Celsius / Fahrenheit)

12

8 seconds auto display hold

13

Making measurement (pulling the trigger)

14

Built in memory up to 99 points

15

Programmable high and low alarm

16

Low battery indicator

17

Primary display

18

Secondary display

19

Emissivity (adjustable from 0.10 to 1.00)

20

MAX, MIN, DIF, AVG temperature values

HAL, LAL temperature setting

DATA point selection

T-C K-type thermocouple measurement

19

12

17

14

20

1613

89

11

10

15

18

4

2

Page 7

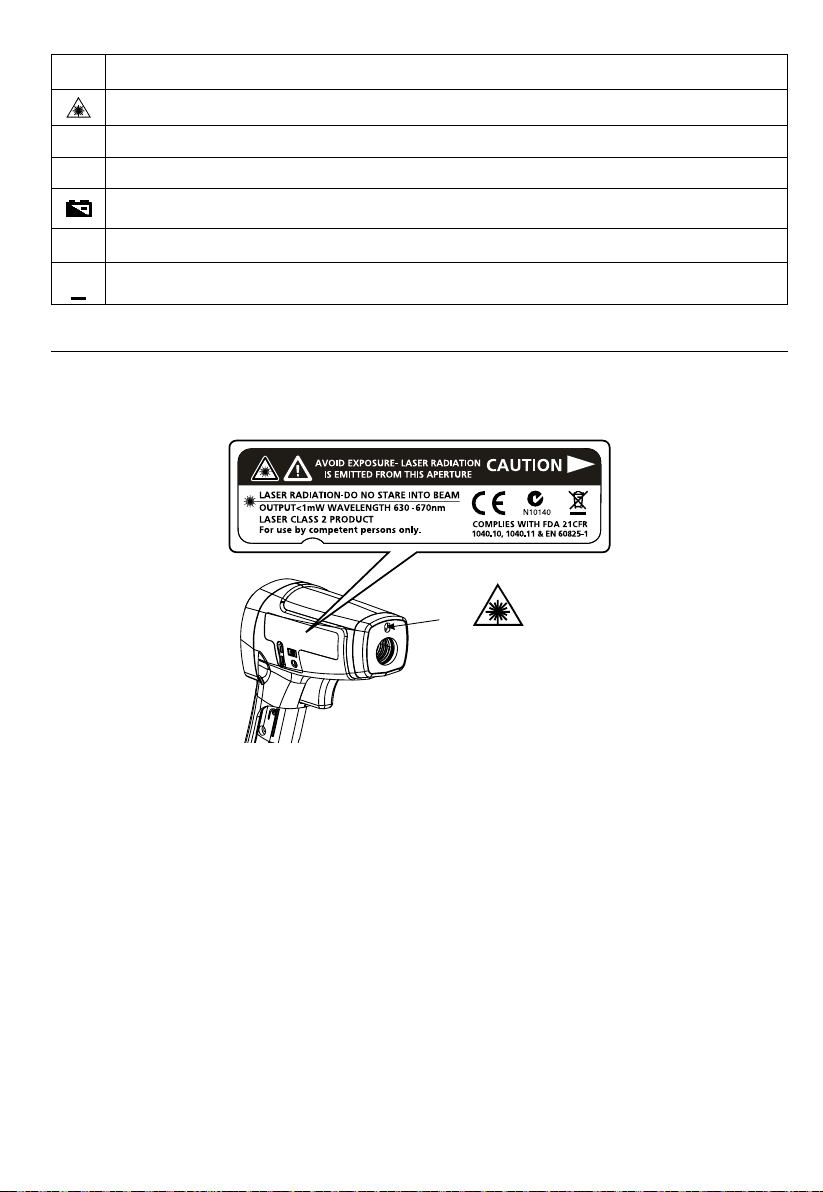

SYMBOLS

Caution! Refer to the explanation in this Manual.

Warning! Laser light. Do not stare into laser beam.

Celsius.

°C

Fahrenheit.

°F

Battery indication.

Complies with European Directives.

Do not dispose of this product as unsorted municipal waste.

Contact a qualified recycler.

SAFETY INFORMATION

The instrument complies with:

EN 61010-1 General Safety

EN 60825-1 Laser Safety

EN 61326-1 Electromagnetic Emissions and Susceptibility

Warning

• Do not stare into laser beam.

• Do not point laser directly at eye or indirectly off reective surfaces.

• For use by competent persons only.

• Replace the batteries as soon as the low-battery indicator appears.

• Do not use the thermometer if it operates abnormally.

• Do not operate the thermometer around explosive gas, vapor, or dust.

• To avoid a burn hazard or re, know that reective objects may be much hotter than the indicated

temperature reading.

• Do not leave the thermometer on or near objects of high temperature.

• If the thermometer is used in a manner not specied by this manual, the protection provided by the

thermometer may be impaired or may result in hazardous laser radiation exposure.

Cautions

To avoid damaging the thermometer under measurement, protect them from the following:

• EMF (electro-magnetic elds) from arc welders, induction heaters

• Static electricity

• Thermal shock (caused by large or abrupt ambient temperature changes — allow 30 minutes for instrument to

stabilize before use)

• Do not leave the thermometer on or near objects of high temperature

3

Page 8

UNPACKING AND INSPECTION

Your shipping carton should include:

1 Thermometer (IR-750 / IR-750-EUR)

1 USB cable

1 K-type thermocouple probe

1 Carrying case

1 Hard carrying case

1 9V battery (installed)

1 Users manual

If any of the items are damaged or missing, return the complete package to the place of purchase for an

exchange.

FEATURES

The Amprobe IR-750 / IR-750-EUR, a precision performance 50:1 spot to distance ratio infrared thermometer,

offers unparalleled accuracy and response time with a temperature measurement range of -58°F to 2822°F

or -50°C to 1550°C. The IR-750 / IR-750-EUR is perfect for demanding quality and process control applications

with extremely high accuracy and distance to spot ratio. The IR-750 / IR-750-EUR also features 99 data points

recognition, thermocouple inputs, and USB download for advanced HVAC/R, electrical, industrial maintenance,

automotive as well as quality control and fire prevention applications.

• 50:1 Distance to Spot ratio

• Temperature range of 0°F to -58°F to 2822°F or -50°C to 1550°C

• Precision accuracy and rapid response time

• Laser pointer, backlit dual LCD Display

• Auto display hold and MAX/MIN memory

• Adjustable emissivity for measuring a variety of materials

• 99 Memory locations and PC download cable included

HOW THE THERMOMETERS WORK

Infrared thermometers measure the surface temperature of an object. The thermometer’s optics sense emitted,

reflected, and transmitted energy, which is collected and focused onto a detector. The unit’s electronics translate

the signal into a temperature reading which the unit displays .

OPERATING THE THERMOMETER

Temperature Measurement

The thermometer will turn on when you pull the trigger and also features an auto-off function that

automatically powers down the thermometer after 8 seconds of inactivity.

To measure temperature, point the thermometer at an object and pull the trigger. You can use the laser pointer

to help aim the thermometer. Pull and hold the trigger when measuring the target surface. When release the

trigger, the display will hold the reading for 8 seconds. Be sure to consider distance-to-spot size ratio and field of

view. The laser is used for aiming only and is not related to temperature measurement.

4

Page 9

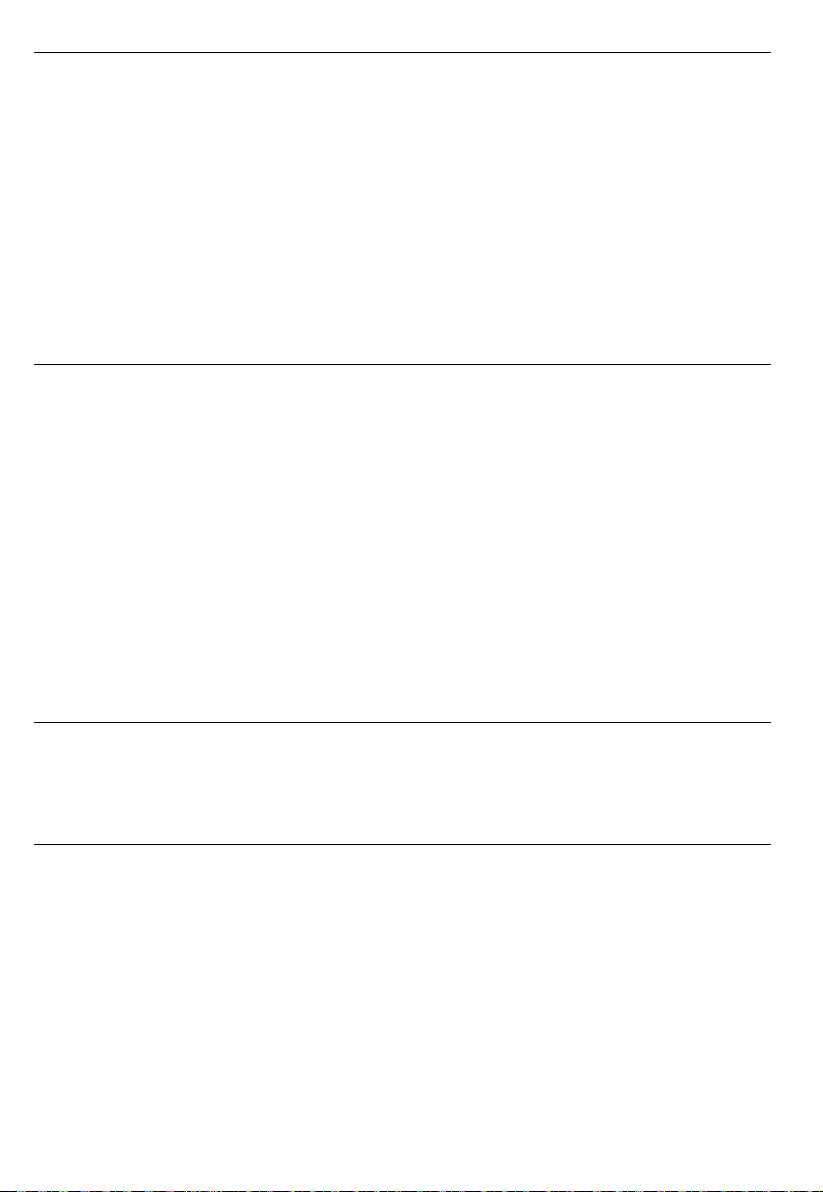

Rotary Switch Positions

Button Description

YELLOW

button

SET

/

Press YELLOW button to toggle between MAX, MIN, DIF, AVG, HAL, LAL, DATA and

T-C options. When the Thermometer goes into sleep mode, press MODE to turn the

thermometer ON again and it displays the last measurement result.

Press to enter set-up mode stepping through Emissivity, Trigger Lock and Switching °C/°F

set-up.

Details refer to the below Emissivity, Trigger Lock and °C / °F set-up.

to turn the display backlight ON or OFF.

Press

Selectable two level of display backlight to adapt different lighting conditions.

Press to turn the laser light ON or OFF.

symbol on the display Indicates laser light is ON.

When the thermometer enters the setup up mode (SET), press or to select a set-up

option (Emissivity, Trigger lock, Switching °C / °F).

When the thermometer enters HAL, LAL and DATA mode, press

option (Emissivity, Trigger lock, Switching °C / °F).

or to select a set-up

Laser

Caution

To avoid injury, do not point the laser directly at eye or indirectly off reflective surfaces.

The thermometer is equipped with a laser used for aiming purposes only. The laser turns off when the trigger

is released.

To enable or disable the laser:

1. Press

button to enable or disable the laser. Symbol appears on the display when laser is enabled.

Emissivity set-up

1. Press SET button to select Emissivity set-up, icon is blinking on the display

2. Press

3. Press

4. Press MODE button to complete the setting and exit Emissivity set-up, or press SET button to complete the setting

Note: Default emissivity is 0.95.

to increase the value by 0.01. Press and hold for quick setting. The maximum value is 1.00.

to decrease the value by 0.01. Press and hold for quick setting. The minimum value is 0.01.

and continue setting for Trigger Lock.

5

Page 10

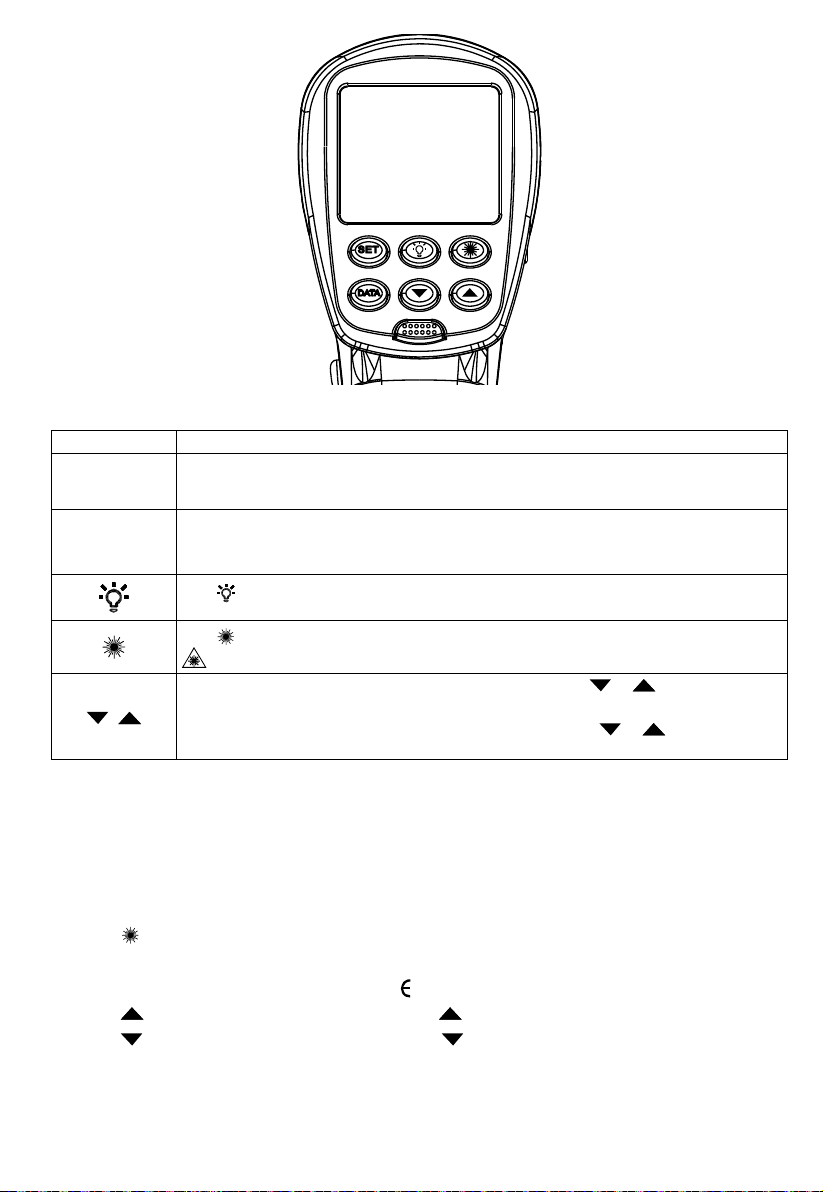

Table of Surface Emissivity

Measure Surface Switch Setting

METALS

Aluminum

Oxidized 0.2 – 0.4

Alloy A3003

Oxidized 0.3

Roughened 0.1 – 0.3

Brass

Burnished 0.3

Oxidized 0.5

Cooper

Oxidized 0.4 – 0.8

Electrical Terminal Blocks 0.6

Haynes

Alloy 0.3 – 0.8

Inconel

Oxidized 0.7 – 0.95

Sandblasted 0.3 – 0.6

Electoropolished 0.15

Iron

Oxidized 0.5 – 0.9

Rusted 0.5 – 0.7

Iron Cast

Oxidized 0.6 – 0.95

Unoxidized 0.2

Molten 0.2 – 0.3

Iron Wrought

Dull 0.9

Lead

Rough 0.4

Oxidized 0.2 – 0.6

Molydbenum

Oxidized 0.2 – 0.6

Nickel

Oxidized 0.2 – 0.5

Platinum

Black 0.9

Steel

Cold-Rolled 0.7 – 0.9

Ground Sheet 0.4 – 0.6

Polished Sheet 0.1

Zinc

Oxidized 0.1

Measure Surface Switch Setting

NON-METALS

Asbestos 0.95

Asphalt 0.95

Basalt 0.7

Carbon

Unoxidized 0.8 – 0.9

Graphite 0.7 – 0.8

Carborundum 0.9

Ceramic 0.95

Clay 0.95

Concrete 0.95

Cloth 0.95

Glass

Plate 0.85

Gravel 0.95

Gypsum 0.8 – 0.95

Ice 0.98

Limestone 0.98

Paper (any colour) 0.95

Plastic

Opaque 0.95

Soil 0.9 – 0.98

Water 0.93

Wood, (natural) 0.9 – 0.95

6

Page 11

Trigger Lock

The thermometer trigger can be locked on for continuous measurement.

To lock the trigger:

1. Press SET button to select Trigger Lock set-up, icon

2. Press

3. Press YELLOW button to complete the setting and exit Trigger Lock set-up, or press SET button to complete the

or to select ON or OFF.

setting and continue setting for °C / °F.

is blinking on the display

°C / °F Set-up

1. Press SET button to select °C / °F set-up, icon °C or °F is blinking on the display

2. Press

3. Press YELLOW button to complete the setting and exit °C / °F set-up.

or to select °C or °F.

MAX, MIN, DIF, AVG

The thermometer can measure maximum (MAX), minimum (MIN), differential (DIF) or average (AVG)

temperatures each time a reading is taken. These values are available for infrared measurements.

1. Press YELLOW button until MIN or MAX or AVG or DIF appears on the display

2. Pull and hold the trigger while aiming at the target surface.

3. The value will show on secondary display.

High Alarm (HAL) and Low Alarm (LAL)

The thermometer has a programmable high and low alarm to designate high or low readings depending on

the thresholds entered. When the alarm level is reached, an alarm will sound. This feature is not available when

measuring by thermocouple.

To set either the high or low alarm:

1. Press YELLOW button to select HAL or LAL option.

2. Press

3. Press SET button to complete the setting. Symbol

To turn off the high or low alarm:

1. Press YELLOW button to select HAL or LAL option.

2. Press SET button. Disappearance of Symbol

or to adjust the threshold value.

or

or

will appear on the display.

on the display indicates high or low alarm is off.

DATA Memory

The thermometer has 99 points data storage and the stored data can be downloaded via IR-750 /

IR-750-EUR software. To save the data:

1. Press YELLOW button to select DATA option.

2. Press

3. Pull and hold the trigger while aiming at the target surface, press DATA button to save the measurement value.

or to select data record number

You can also save the measurement value within 8 seconds of display hold after releasing the trigger.

K-Type Thermocouple Measurement

To avoid electrical shock or personal injury, do not connect the thermocouple contact probe to live

electrical circuits.

The thermometer comes with a bead K-type thermocouple probe.

K-type thermocouple is connected to the thermometer via TC-K input connector located on right side of

the thermometer. The probe can be used simultaneously while the thermometer is taking non-contact

measurements.

1. Press YELLOW button to enter T-C mode. The display shows OL before the measurement is made.

2. Connect the K-type thermocouple to the thermometer via TC-K input connector located on right side of

the thermometer. Press the trigger to start measuring. Secondary display shows the measurement reading.

3. Release the trigger, the reading is kept on display (display hold: 8 seconds)

7

Page 12

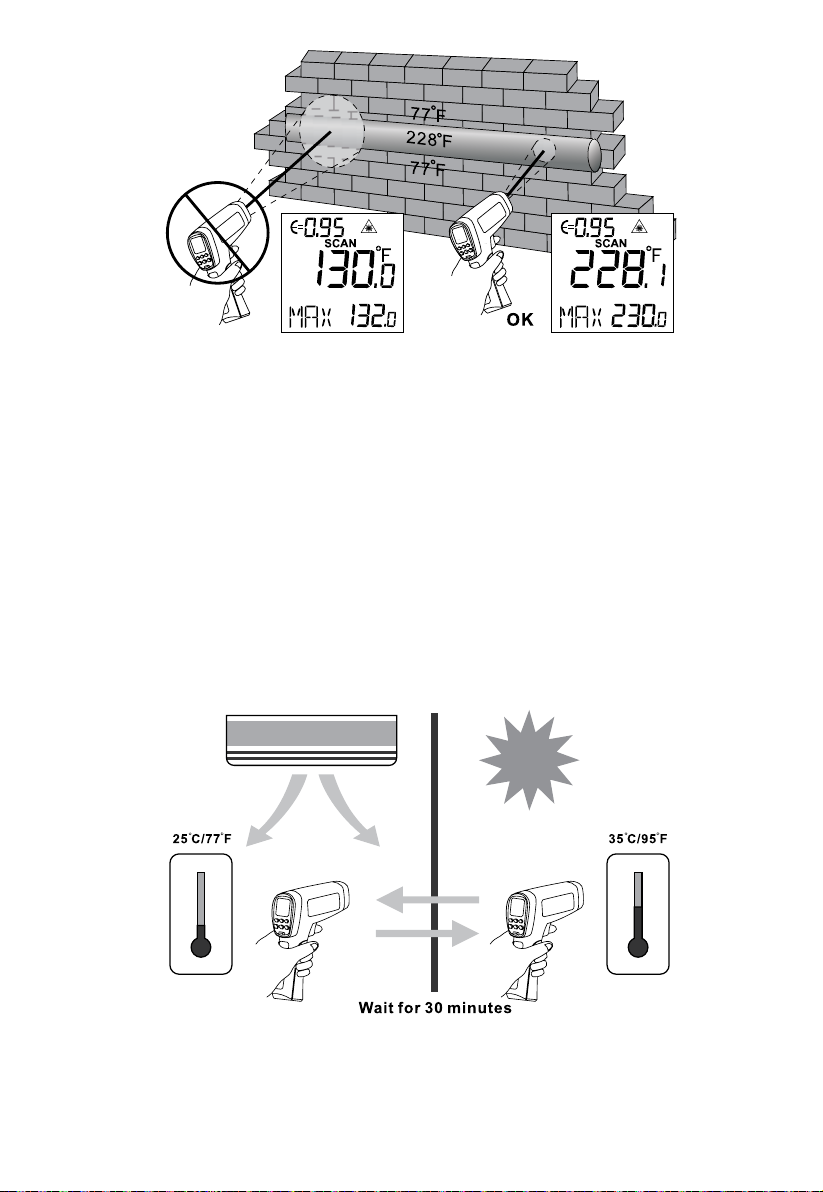

Locating a Hot or Cold Spot

To find a hot or cold spot, aim the thermometer outside the target area. Then, slowly scan across the area with

an up and down motion until you located the hot or cold spot.

Distance and Spot Size

As the distance (D) from the target being measured increases, the spot size (S) of the area measured by the

instrument becomes larger. The spot size indicates 90% encircled energy.

Field of View

Make sure that the target is larger than the spot size. The smaller the target, the closer you should be to it.

8

Page 13

Emissivity

Emissivity describes the energy-emitting characteristics of materials. Most organic materials and painted or oxidized

surfaces have an emissivity of about 0.95.

If possible, to compensate for inaccurate readings that may result from measuring shiny metal surfaces, cover

the surface to be measured with masking tape or flat black paint (<150°C / 302°F ) and use the high emissivity

setting. Allow time for the tape or paint to reach the same temperatures as the surface beneath it. Measure the

temperature of the tape or painted surface.

If you cannot use paint or use tape, then you could improve the accuracy of your measurements with the

emissivity selector. Even with emissivity selector, it can be difficult to get a completely accurate infrared

measurement of a target with a shiny or metallic surface.

The thermometer allows you to adjust the emissivity for the type of surface you’re trying to measure the

temperature of. Use a different setting for your application by referring to the Table of Surface Emissivity.

Reminders

1. Changes of surrounding ambient temperature can result in inaccurate reading, allow time for the

instrument to adopt the change of ambient temperature before use. Specified accuracy applies after 30

minutes when the instrument changes to a different temperature environment an inaccurate.

2. The instrument cannot measure through transparent surfaces such as glass. It will measure the surface

temperature of the glass instead.

9

Page 14

3. See Table of Surface Emissivity for use in measuring shiny or polished metal surfaces (stainless steel,

aluminum, etc.).

4. Steam, dust, smoke, etc., can prevent accurate measurement by obstructing the instrument’s optics.

TYPICAL MEASUREMENTS

This section describes a variety of measurements often performed by technicians.

Reminder:

• User could select to turn on or off the backlight and laser whenever you are making readings with the

thermometer.

• Relatively high emissivity normally means emissivity setting of about 0.95.

• Relatively low emissivity normally means emissivity setting of about 0.30.

• When user cannot identify the emissivity of the object to be measured, user could cover the surface to be

measured (temperature >150°C) with black electric tape (emissivity of about 0.95). Allow time for the tape

to reach the same temperature as the object to be measured. Measure and record the temperature of the

tape.

Aim the thermometer to the object to be measured, adjust the emissivity setting to make it as the same temperature

as the tape. At this time, the thermometer emissivity setting is close to the emissivity of the object to be measured,

measurement can be taken.

Testing Contactors (Starters)

1. Press SET to select emissivity. Press / to select relatively low emissivity for bright contacts, or 0.7 mid

level for darkened contacts.

2. Press YELLOW button to select MAX.

3. Measure line and load side of one pole without releasing trigger.

4. A temperature difference between the line and load sides of a pole indicate increased resistance of one

point and a contactor may be failing.

Testing Enclosed Relays

1. Press SET and then press / to set emissivity to relatively low for un-insulated connectors or relatively

high for plastic encased relays or for Bakelite enclosed relays or insulated connectors.

2. Press YELLOW button to select MAX.

3. Start to scan.

4. Measure the relay casing, looking for hot spots.

5. Measure electrical connections on relay terminals looking for hot spots.

10

Page 15

Testing Fuses and Buss Connections

1. Press SET and then press / to set emissivity to relatively high for paper covered fuse body or

insulated connections.

2. Press YELLOW button to select MAX.

3. Scan the paper covered length of fuse.

4. Without releasing the trigger, scan each fuse. Unequal temperatures between fuses may indicate voltage or

amperage imbalance.

5. Press SET and then press / to set emissivity to relatively low, for metal fuses and caps and insulated

buss connections.

6. Press MODE to select MAX.

7. Scan each end cap on each fuse.

Note: Unequal temperatures or a high temperature indicates loose or corroded connection through the fuse

buss spring clip

Testing Electrical Connections

1. Press SET and then press / to set emissivity to relatively low for

un-insulated connectors or buss connections or relatively high for insulated connections.

Note: Conductors are typically smaller than the thermometer’s spot size.

If the spot size is bigger than the connector, the temperature reading is the average within the spot.

2. Scan the conductor, moving toward direction of electrical connector (quick connector, wire nut, buss

connection, etc.).

Scanning Walls for Air Leaks or Insulation Deficiencies

1. Turn off heating, cooling, and blower.

2. Press SET to select emissivity. Press

window surfaces.

3. Press YELLOW button to select MIN when opposite side of wall is at lower temperature and or select MAX

when opposite side of wall is at higher temperature.

4. Measure an interior partition wall surface temperature.

5. Do not release the trigger. Record this temperature as your baseline (or benchmark) for a “perfectly”

insulated wall.

6. Face the wall to be scanned. Stand 1.5m away to scan a 4cm spot on the wall.

7. Scan horizontal rows of wall from top to bottom, or horizontal rows of ceiling from wall to wall. Look for

greatest deviations from baseline temperature to identify problems. This completes the insulation test scan.

Turn on the blower (no heat, no cooling) and retest. If test results with the blower on are different than results

with the blower off, this may indicate air leaks in conditioned envelope walls. The air leaks are caused by duct

leaks that create a pressure differential across the conditioned space envelope.

/ to select emissivity relatively high for painted surfaces or

Testing Bearings

Warning

To avoid injury when testing bearings:

1. Do not wear loose clothing, jewelry, or anything around neck when working around moving parts such as

motors, belts, blower, and fans.

2. Make sure an electrical disconnect is within reach and operating correctly and freely.

3. Do not work alone.

Note: It works best to compare two similar motors operating similar loads

11

Page 16

1. Press SET and then press

2. Press SELECT to select MAX.

3. Enable motor and allow it to reach steady state operating temperatures.

4. Disable the motor if possible.

5. Measure the two motor bearing temperatures.

6. Compare the two motor bearing temperatures. Unequal temperatures or a high temperature can indicate

a lubrication or other bearing problem that is resulting from excess friction.

7. Repeat the sequence for the blower bearings.

/ to select relatively high emissivity.

Testing Belts and Sheaves

1. Press SET and then press / to select relatively high emissivity.

2. Press SELECT to select MAX.

3. Enable the motor and allow it to reach a steady state operating temperatures.

4. Aim the thermometer at the surface to be measured.

5. Start recording temperature.

6. Slowly move the thermometer up the belt toward second sheave.

• If belt is slipping, sheave temperature will be high from friction.

• If belt is slipping, belt temperature will remain high between sheaves.

• If belt is not slipping, belt temperature will reduce between sheaves.

• If inner surfaces of sheaves are not a true “V” shape, this indicates belt slippage and will continue to

operate at elevated temperatures until sheave is replaced.

• Sheaves must be properly aligned (include “pitch & yaw”) for belt and sheaves to operate at

appropriate temperatures. A straight edge or taut string, can be used to check alignments.

• Motor sheave should operate at a temperature consistent with blower sheaves.

• If motor sheave is at a higher temperature at motor shaft than at outer circumference, belt is probably

not slipping.

• If outer circumference of sheave is at higher temperature than sheave at motor shaft, then belt is probably

slipping and sheaves may be misaligned.

Checking Hydronic Radiant Heat Applications

1. Press SET and then press / to select relatively high emissivity.

2. Press YELLOW button to select MAX.

3. To locate radiant heat tubes in floor, temporarily elevate the loop temperature to create hotter spots for

identifying tubing runs.

4. Before releasing trigger, press YELLOW button to toggle between MIN, MAX, DIF floor temperatures and

record the temperature for future comparison and trending under similar conditions.

Measuring Grill, Register, or Diffuser Discharge Temperature

1. Press SET and then press / to select relatively high emissivity.

2. Aim the thermometer at the discharge air grille, register, or diffuser.

3. Measure discharge temperature.

4. Release trigger to freeze the temperature reading for 8 seconds and record this temperature.

5. Grille, register, or diffuser temperature should be equivalent to discharge temperature at the air handler.

12

Page 17

Checking for Blockage in Air-To-Air Evaporator or Condensers

1. Remove panels to gain access to coil return bends or hairpins.

2. Press SET and then press

3. Start the refrigeration system.

4. Aim the thermometer at coil turn bends/hairpins.

5. Start recording temperature.

6. Take temperature of each return bend/hairpin.

• All evaporator return bends/hairpins should be at or slightly above evaporator saturation temperature from the

pressure/temperature chart.

• All condenser return bend/hairpins should be at or slightly less than condenser saturation temperature.

• If a group of return bends/hairpins do not conform to expected temperatures, that indicates a blocked

or restricted distributor or distributor tube.

/ to select relatively high emissivity for copper tube.

OPERATING IR-750 / IR-750-EUR SOFTWARE

System Prerequisites

Recommended configuration

Processor Pentium® 4 or higher with support of all customary operating systems

Operating system Microsoft Windows® 2000 / XP / Vista / Win7

Memory 512 MB RAM or higher

Monitor VGA (1024 x 768)

Drive CD-ROM

Input device Mouse or compatible

Interface USB for data transmission

Install IR-750 / IR-750-EUR Software

• Insert the provided CD disk into CD-ROM drive.

• Double-click “IR-750_VX.XX.exe” (X can be 0 to 9 or blank,

indicating the software version)

• The pop-up windows will guide you through the program setup process.

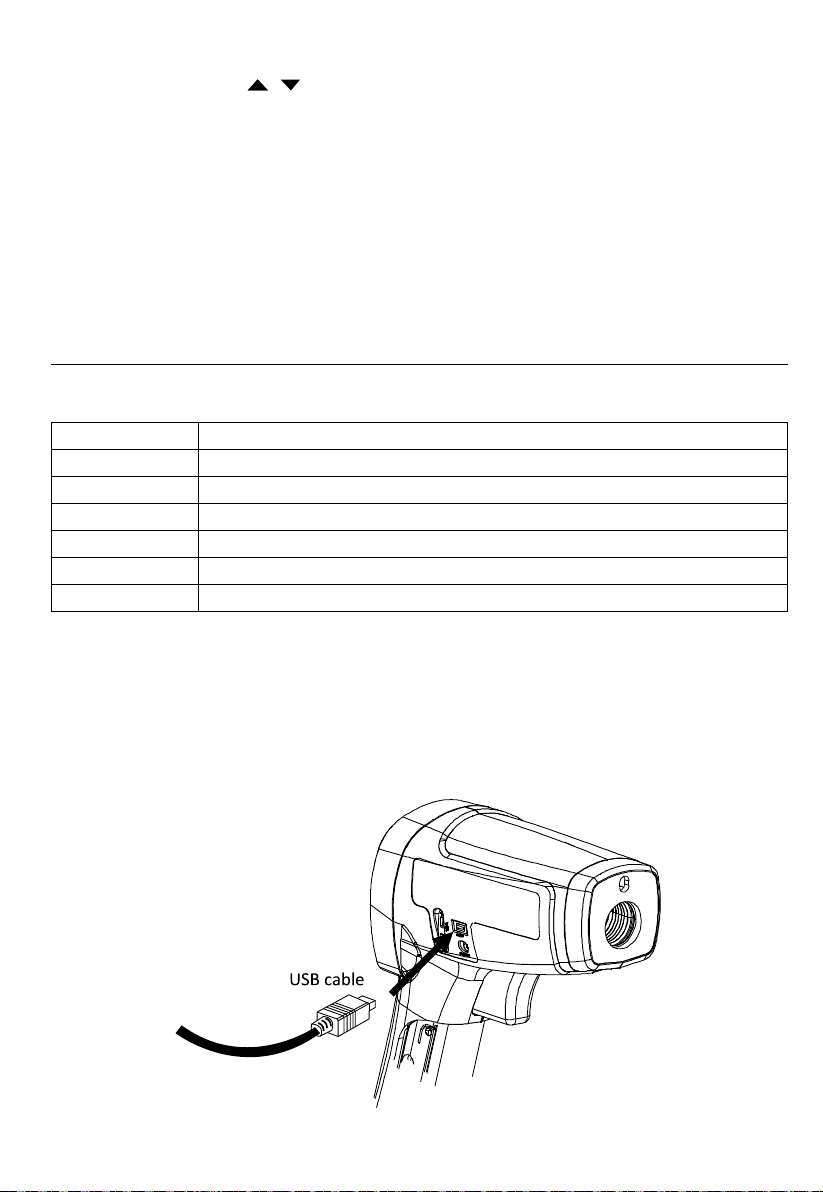

Connecting USB cable to IR-750 / IR-750-EUR Thermometer

13

Page 18

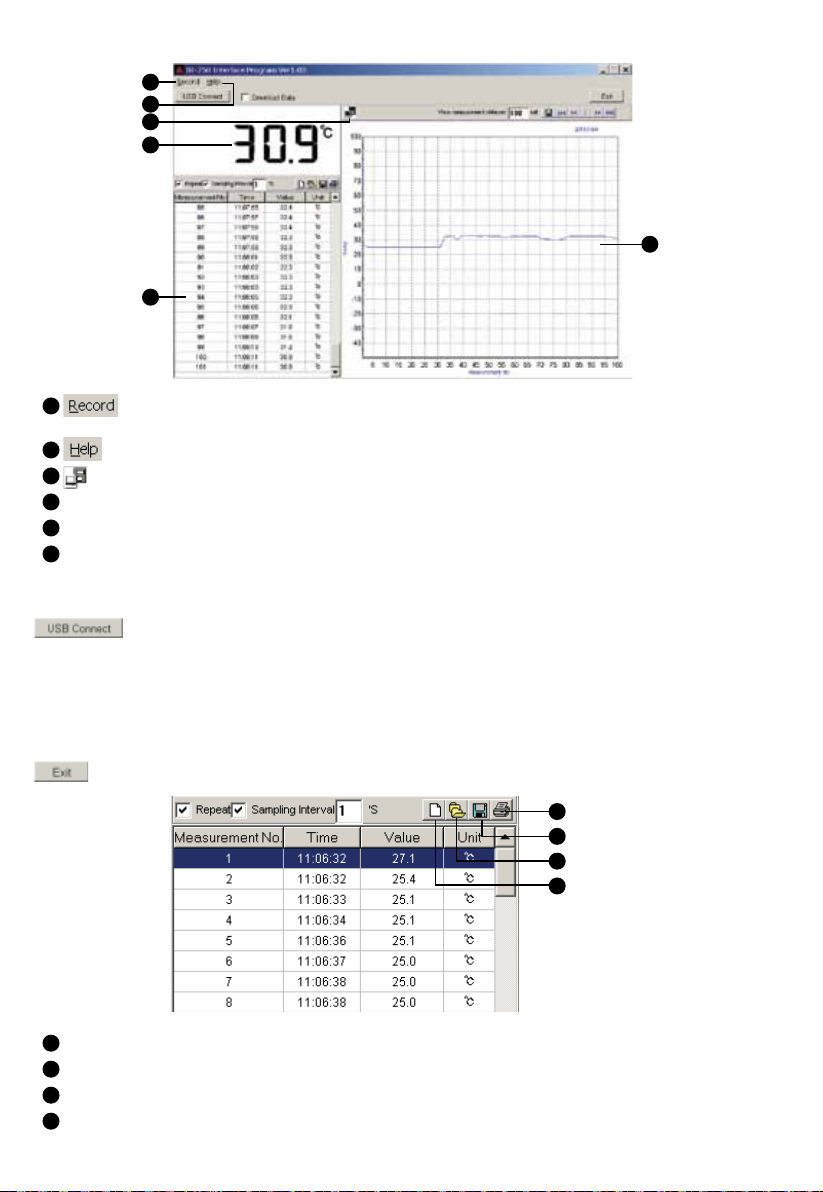

Main Screen

1

2

3

4

6

5

command enables you to create New, Save file and set the numbers of measurement (1000, 5000,

1

10000, 50000, 100000 or limitless).

command enables you to view the software operation instructions.

2

Blinking indicates IR-750 / IR-750-EUR is connected to the software

3

Main display screen of measurement

4

Secondary display screen for measurement data

5

Measurement data in graph

6

Using Program

Connect” blinking indicates that the IR-750 / IR-750-EUR Thermometer is successfully connected to the

PC and that the thermometer will automatically start taking measurements. The primary display screen shows

current measurement temperatures and the secondary display screen shows all measurement data.

Download Data enables you to download temperature measurements saved in IR-750 / IR-750-EUR Thermometer.

Tick “Download Data” and then click “USB Connect”; the saved data will automatically upload to your PC and

display on secondary display.

button enables you to connect to IR-750 / IR-750-EUR thermometer and start measurement. “USB

Exit and close the program

1

Print data

2

Save data (*.txt, *.xls, *.xml)

3

Open files (*.txt, *.xls, *.xml)

Deleting current data and create a new data.

4

1

2

3

4

14

Page 19

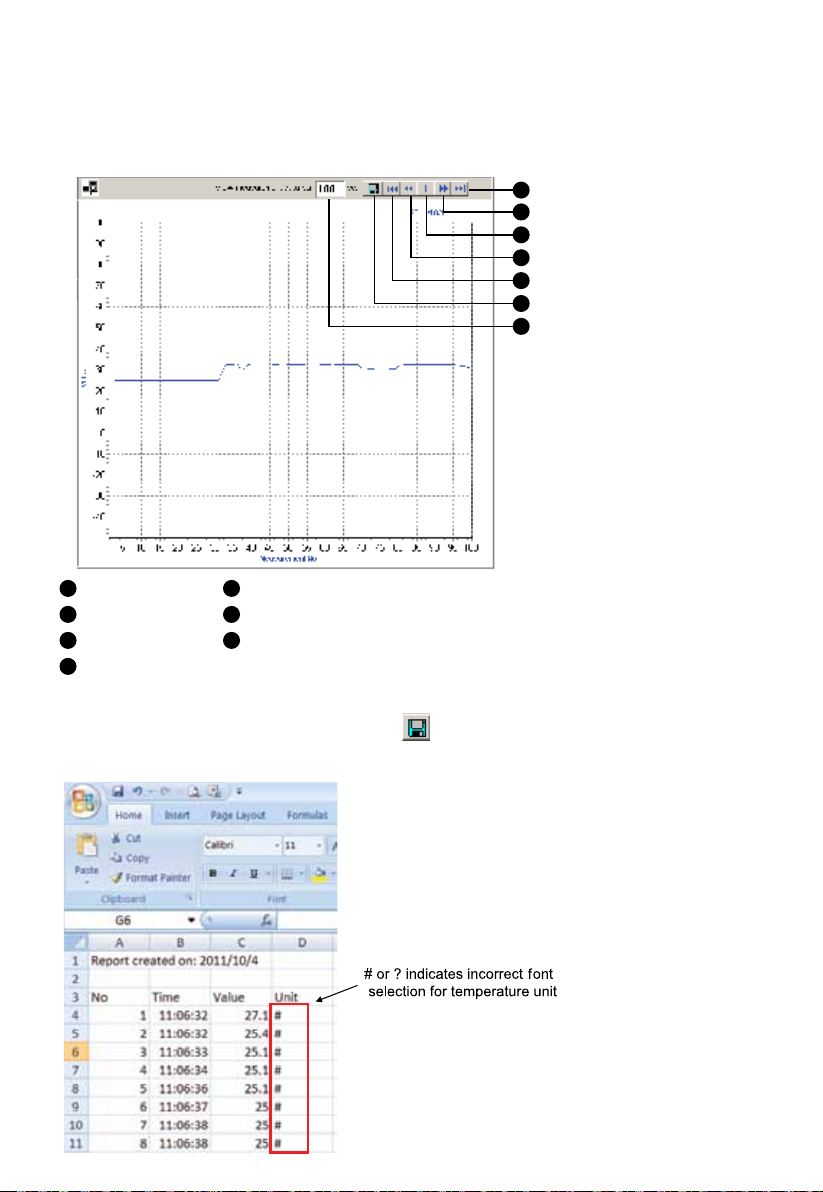

Repeat: Tick to display every measurement with the interval you set. Un-tick “Repeat”, the secondary display will

only show measurement results that are different from the last measured temperature. The graph display will

show complete measurement results in the graphics despite whether “Repeat” is ticked or un-ticked.

Sampling Interval allows you to set the sampling intervals of measurement ( 1 to 9999 seconds).

Note: When measurement data reaching to 10000 sets (measurement number), a warning message will pop up

and stop measurements. Save or clear the measurement data before continuing next measurements.

1

2

3

4

5

6

7

1

Last page

2

Next page

3

Current page

4

Previous page

5

First page

6

Save graph in current page as *.bmp

7

Set numbers of measurement data on graph display

Test Report

Test data can be saved as *.txt, *.xls, *.xml by clicking button. When opening data report, make sure

selecting font format as Amprobe-A1 or Amprobe-A2 in “Unit” column in order to display correct temperature

unit °C or °F.

15

Page 20

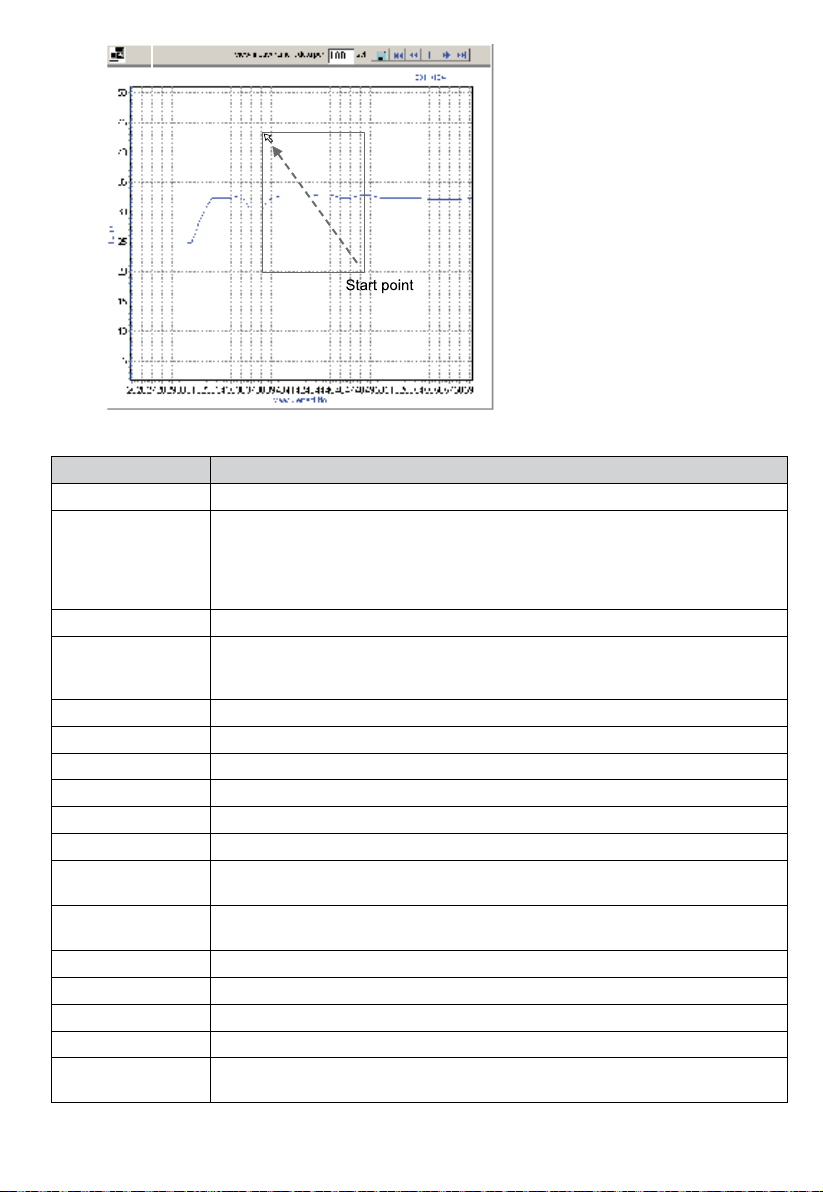

Zoom In Selected Graph

To enlarge the particular part of the graph, use the mouse pointer to select area from upper-left point to lower-right

point.

You can use button to save the selected enlarged graph.

To resume to its original full view, use the mouse pointer to select any area on the graph from lower-right point

to upper-left point.

16

Page 21

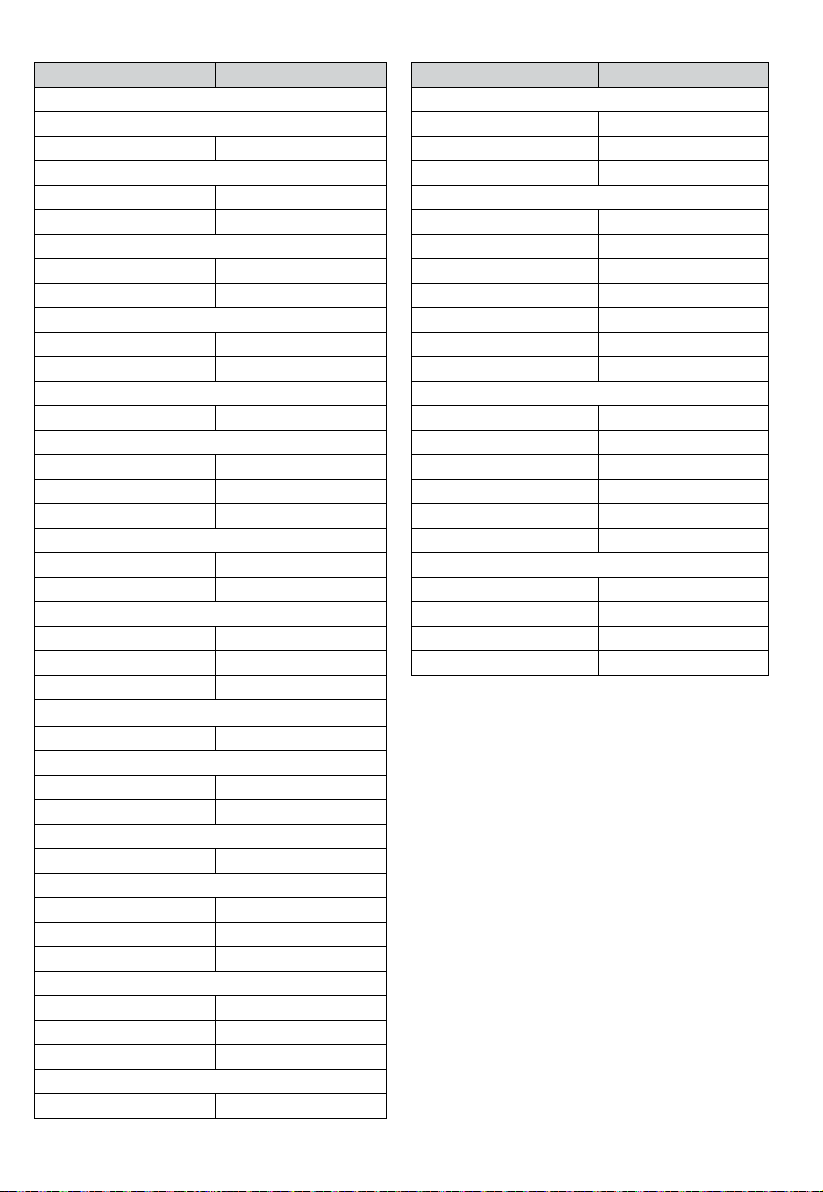

DETAILED SPECIFICATIONS

Feature IR-750 / IR-750-EUR

Temperature Range -50°C to 1550°C (-58°F to 2822°F)

Accuracy (assumes

ambient operating

temperature of 21°C

to 25°C (70°F to 77°F))

Repeatability ±0.5% of reading or ±0.5°C (±1°F), whichever is greater (Typical)

Display Resolution 0.1°C / 0.1°F of reading < 999.9

Spectral Response 8µm to14µm

Laser Sighting Single point laser

Laser Power Output > 1mW Class 2, wavelength 630 to 670nm

Response Time (95%) 250ms

Distance to Spot (D:S) 50:1

Minimum Spot Size 19mm

Emissivity Digitally adjustable from 0.10 to 1.00 by 0.01.

Ambient Operating

Temperature

Relative Humidity 0% to 75% non-condensing

Storage Temperature -20°C to 65°C / -4°F to 150°F (Battery not installed)

Temperature Display °C or °F selectable

Display Hold 8 sec

MAX/MIN

Temperature Display

>0°C to 1550°C (>32°F to 2822°F): ±1.8% or ±1.8°C (±4°F),

whichever is greater (Typical)

>-35°C to 0°C (-31°F to 32°F): ±1.8%+1°C (2°F) or ±2.8°C (±6°F),

whichever is greater (Typical)

-50°C to -35°C (-58°F to -31°F): not specified (for reference only)

0.2°C / 0.2°F of reading below 10°C (50°F)

1°C / 1°F of reading > 999.9

Pre-set emissivity is 0.95

0°C to 50°C

32°F to 120°F

√

17

Page 22

DIF/AVG Temperature

Display

USB Interface √

Data Storage 99

Programmable High

and Low Alarm

K-Type Thermocouple

Measurement

Dual LCD Display √

LCD Backlit √

Low Battery Indication

Tripod Mount √

Power 9V 6F22 alkaline battery or by Amprobe EPS-700-US (US plug) or EPS-700-EUR (European

Battery Life

Dimension (H x L x W) Approx.183 x 147 x 57 mm (7.2 x 5.8 x 2.3 in)

Weight Approx.345 g (0.76 lb) with battery installed

Optional Accessory Power adaptor EPS-700-US (US plug), EPS-700-EUR (European plug)

√

√

√

√

plug) power adaptor

10 hours with laser and backlight on

30 hours with laser and backlight off

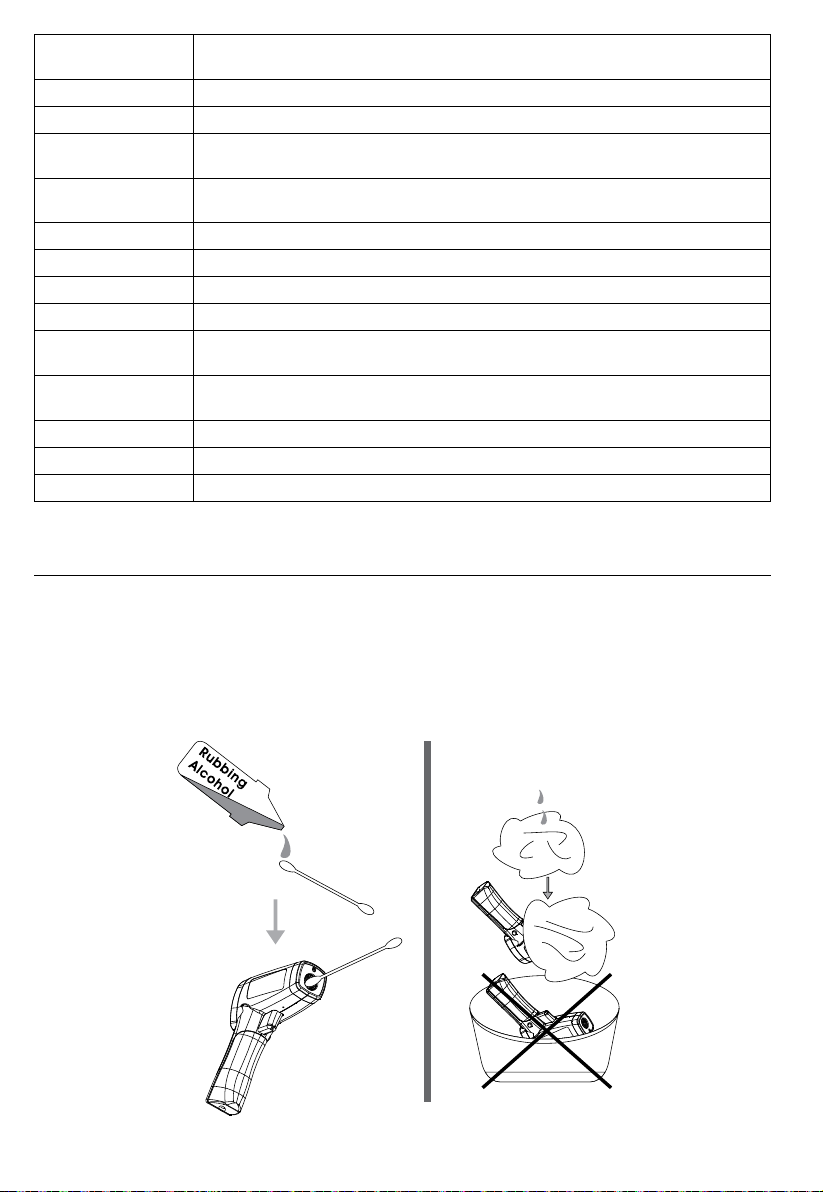

MAINTENANCE

Lens Cleaning: Blow off loose particles using clean compressed air. Gently brush remaining debris away with a

camel hair brush. Carefully wipe the surface with a moist cotton swab. The swab may be moistened with water

or rubbing alcohol.

NOTE: DO NOT use solvents to clean the plastic lens.

Case Cleaning: Use soap and water on a damp sponge or soft cloth.

Caution!

Do not submerge the unit in water.

18

Page 23

TROUBLE SHOOTING

Code Problem Action

OL Target temperature is over range Select target within specifications

-OL Target temperature is under range Select target within specifications

Low battery

Battery indication

Blank display Possible dead battery Check and/or replace battery

Laser does not work

Beeper beeps

continuously

1. Low or dead battery

2. Ambient temperature above 40°C (104°F)

Check if high/low alarm has been set and if

the measurement value is over the limit

Check and/or replace battery

1. Replace battery

2. Use in area with lower ambient

temperature

Reset high/low alarm setting or

cancel the limit setting

BATTERY REPLACEMENT

To install or change one 9V battery (see below):

1. Push the button and pull the handle downward to open battery cover.

2. Install the battery noting its correct polarity.

3. Re-install the battery cover.

Battery: 9V 6F22 alkaline battery or equivalent

19

Page 24

Page 25

IR-750

IR-750-EUR

Thermomètre IR 50:1 avec mémoire

Mode d’emploi

Français

11/2013, 4279850 B

©2013 Amprobe Test Tools.

Tous droits réservés. Imprimé en Chine.

Page 26

Limites de garantie et de responsabilité

Amprobe garantit l’absence de vices de matériaux et de fabrication de ce produit pendant une période d’un

an prenant effet à la date d’achat, sauf disposition contraire prévue par la loi. Cette garantie ne s’applique

pas aux fusibles, aux piles jetables ni à tout produit mal utilisé, modié, contaminé, négligé ou endommagé

par accident ou soumis à des conditions anormales d’utilisation et de manipulation. Les revendeurs n’ont pas

l’autorisation de prolonger toute autre garantie au nom d’Amprobe. Pour bénéficier de la garantie, renvoyez

le produit accompagné d’un justicatif d’achat auprès d’un centre de services agréé par Amprobe Test Tools ou

d’un distributeur ou d’un revendeur Amprobe. Voir la section Réparation pour tous les détails. LA PRÉSENTE

GARANTIE EST LE SEUL ET EXCLUSIF RECOURS DE L’UTILISATEUR TOUTES AUTRES GARANTIES, EXPLICITES,

IMPLICITES OU STATUTAIRES, NOTAMMENT LE CAS ÉCHÉANT LES GARANTIES DE QUALITÉ MARCHANDE OU

D’ADAPTATION À UN OBJECTIF PARTICULIER SONT EXCLUES PAR LES PRÉSENTES. LE FABRICANT NE SERA EN

AUCUN CAS TENU RESPONSABLE DE DOMMAGES PARTICULIERS, INDIRECTS, ACCIDENTELS OU CONSÉCUTIFS,

NI D’AUCUNS DÉGATS OU PERTES DE DONNÉES, SUR UNE BASE CONTRACTUELLE, EXTRA-CONTRACTUELLE

OU AUTRE. Étant donné que certaines juridictions n’admettent pas les limitations d’une condition de garantie

implicite ou l’exclusion ou la limitation de dégâts accidentels ou consécutifs, il se peut que les limitations et les

exclusions de cette garantie ne s’appliquent pas à votre cas.

Réparation

Tous les outils de test renvoyés pour être réparés au titre de la garantie ou pour étalonnage doivent être

accompagnés des éléments suivants : nom, raison sociale, adresse, numéro de téléphone et justicatif d’achat.

Ajoutez également une brève description du problème ou du service demandé et incluez les cordons de test avec

l’appareil. Les frais de remplacement ou de réparation hors garantie doivent être acquittés par chèque, mandat,

carte de crédit avec date d’expiration, ou par bon de commande payable à l’ordre de Amprobe® Test Tools.

Remplacements et réparations sous garantie – Tous pays

Veuillez lire la déclaration de garantie et vérifier les piles avant de demander une réparation. Pendant la période

de garantie, tout outil de test défectueux peut être renvoyé auprès de votre distributeur Amprobe® Test Tools

pour être échangé contre un produit identique ou similaire. Consultez la section « Where to Buy » sur le site

www.amprobe.com pour obtenir la liste des distributeurs dans votre région. Les appareils sous garantie devant

être remplacés ou réparés au Canada et aux États-Unis peuvent également être envoyés dans un centre de

services Amprobe® Test Tools (voir les adresses ci-dessous).

Remplacements et réparations hors garantie – Canada et États-Unis

Les appareils à réparer hors garantie au Canada et aux États-Unis doivent être envoyés dans un centre de

services Amprobe® Test Tools. Appelez Amprobe® Test Tools ou renseignez-vous auprès de votre lieu d’achat

pour connaître les tarifs en vigueur de remplacement ou de réparation.

Aux États-Unis Au Canada

Amprobe Test Tools Amprobe Test Tools

Everett, WA 98203 Mississauga, Ontario L4Z 1X9

Tél. : 877-AMPROBE (267-7623) Tél. : 905-890-7600

Remplacements et réparations hors garantie – Europe

Les appareils européens non couverts par la garantie peuvent être remplacés par votre distributeur Amprobe®

Test Tools pour une somme nominale. Consultez la section « Where to Buy » sur le site www.amprobe.com pour

obtenir la liste des distributeurs dans votre région.

Adresse postale européenne*

Amprobe® Test Tools Europe

Beha-Amprobe GmbH

In den Engematten 14

79286 Glottertal, Allemagne

Tél. : +49 (0) 7684 8009 - 0

www.amprobe.eu

*(Réservée à la correspondance – Aucune réparation ou remplacement n’est possible à cette adresse. Nos clients

européens doivent contacter leur distributeur.)

Page 27

IR-750 / IR-750-EUR Thermomètre IR 50:1 avec mémoire

TABLE DES MATIÈRES

SYMBOLES .................................................................................................................................................................... 3

CONSIGNES DE SÉCURITÉ ............................................................................................................................................ 3

DÉBALLAGE ET INSPECTION ........................................................................................................................................ 4

FONCTIONNALITÉS ....................................................................................................................................................... 4

FONCTIONNEMENT DES THERMOMÈTRES ................................................................................................................. 4

UTILISATION DU THERMOMÈTRE ................................................................................................................................4

Mesures de température ......................................................................................................................................... 4

Localisation d'un point chaud ou froid .................................................................................................................. 8

Distance et taille du point focal (spot) ................................................................................................................... 8

Champ de visée ........................................................................................................................................................ 8

Émissivité .................................................................................................................................................................. 9

Rappels ..................................................................................................................................................................... 9

MESURES TYPIQUES ..................................................................................................................................................... 10

FONCTIONNEMENT DU LOGICIEL IR-750 / IR-750-EUR ............................................................................................... 13

CARACTÉRISTIQUES ..................................................................................................................................................... 17

ENTRETIEN .................................................................................................................................................................... 18

DÉPANNAGE .................................................................................................................................................................19

CHANGEMENT DES PILES ............................................................................................................................................. 19

1

Page 28

IR-750 / IR-750-EUR Thermomètre IR 50:1 avec mémoire

1

5

6

7

2 3

Ouverture laser

1

Gâchette

2

Couvercle de pile

3

Affichage

4

Connecteur USB

5

Connecteur de thermocouple de type K

6

Connecteur d'adaptateur secteur (pour un accessoire

7

optionnel)

Symbole laser « actif »

8

Rétroéclairage

9

10

Verrouillage de mesure (mesure continue)

11

Unité de température (Celsius / Fahrenheit)

12

Maintien d'affichage automatique de 8 secondes

13

Établissement des mesures (en actionnant la gâchette)

14

Mémoire intégrée de 99 points

15

Alarme haute et basse programmable

16

Témoin de pile faible

17

Fenêtre principale

18

Fenêtre secondaire

19

Émissivité (réglable de 0,10 à 1,00)

20

Valeurs de température MAX, MIN, DIF, AVG

Réglage de température HAL, LAL Sélection des

points de données DATA

Mesure de thermocouple de type T-C K

19

12

17

14

20

1613

89

11

10

15

18

4

2

Page 29

SYMBOLES

Attention ! Se reporter aux explications de ce manuel.

Avertissement ! Lumière laser. Ne pas regarder dans le faisceau laser.

Celsius.

°C

Fahrenheit.

°F

Témoin de pile.

Conforme aux directives européennes.

Ne pas mettre ce produit au rebut parmi les déchets ménagers. Consulter un centre de recyclage

homologué.

CONSIGNES DE SÉCURITÉ

L'instrument est conforme aux normes suivantes :

Sécurité générale EN 61010-1

Sécurité laser EN 60825-1

Émissions et sensibilité électromagnétique EN 61326-1

Ouverture laser

Avertissement

• Ne pas regarder dans le faisceau laser.

• Ne pas pointer directement le laser en direction des yeux, ou indirectement vers des surfaces

rééchissantes.

• Utilisation réservée aux personnes compétentes.

• Remplacer les piles dès que l’indicateur des piles déchargées apparaît.

• Vérier le fonctionnement du thermomètre en mesurant une source de tension connue. Ne pas utiliser le

thermomètre s’il ne fonctionne pas normalement.

• Ne pas utiliser le thermomètre à proximité de gaz explosifs, de vapeurs ou de poussière.

• Pour éviter les risques d’incendie ou de brûlures, ne pas oublier que les objets rééchissants sont souvent

plus chauds que la température indiquée sur le thermomètre.

• Ne pas laisser le thermomètre sur ou à proximité d'objets à température élevée.

• Utiliser le thermomètre en respectant les indications de ce mode d’emploi an de ne pas entraver la

protection intégrée au thermomètre et de pas provoquer d'exposition dangereuse au rayonnement

laser.

Attention

Pour ne pas endommager le thermomètre pendant la mesure, le protéger des éléments suivants :

• CEM (champs électromagnétiques) des soudeurs à l'arc, chauffages à induction

• Électricité statique

• Chocs thermiques (provoqués par des changements de température ambiante importants ou abrupts : laisser

l'appareil se stabiliser 30 minutes avant l'emploi)

• Ne pas laisser le thermomètre sur ou à proximité d'objets à température élevée

3

Page 30

DÉBALLAGE ET INSPECTION

Le carton d’emballage doit inclure les éléments suivants :

1 thermomètre (IR-750 / IR-750-EUR)

1 câble USB

1 sonde thermocouple de type K

1 sacoche de transport

1 étui de transport

1 pile de 9 V (installée)

1 Mode d’emploi

Si l’un de ces éléments est endommagé ou manquant, renvoyez le contenu complet de l’emballage au lieu

d’achat pour l’échanger.

FONCTIONNALITÉS

Le thermomètre Amprobe IR-750 / IR-750-EUR, un thermomètre infrarouge avec un rapport de distance à taille

de point focal de 50:1, offre la meilleure précision de sa classe et un temps de réponse avec une plage de mesure

de températures de -50 °C à 1550 °C (-58 °F à 2822 °F). L'IR-750 / IR-750-EUR est spécialement conçu pour les

applications de contrôle de procédés avec une précision extrêmement élevée de la distance au point focal. Le

thermomètre Amprobe IR-750 / IR-750-EUR propose également la reconnaissance de 99 points de données, des

entrées de thermocouple et le téléchargement par connexion USB pour les applications avancées de CVC/R,

électricité, maintenance industrielle, automobile et le contrôle de la qualité et la prévention des incendies.

• Rapport de distance à taille de point focal 50:1

• Plage de températures de -50 °C à 1550 °C (-58 °F à 2822 °F)

• Précision des mesures et temps de réponse rapide

• Pointeur laser, double afchage LCD rétroéclairé

• Maintien automatique de l'afchage et mémoire MAX/MIN

• Émissivité réglable pour la mesure de divers matériaux

• 99 emplacements mémoire et câble de téléchargement vers PC inclus

FONCTIONNEMENT DES THERMOMÈTRES

Les thermomètres infrarouges mesurent la température de surface d'un objet. L'optique du thermomètre

détecte l'énergie émise, réfléchie et transmise qui est collectée et focalisée sur un détecteur. L'électronique de

l'appareil convertit le signal dans la lecture de température qui apparaît sur l'afficheur.

UTILISATION DU THERMOMÈTRE

Mesures de température

Le thermomètre se met sous tension lorsque vous appuyez sur la gâchette.

Le thermomètre se met hors tension lorsqu'aucune activité n'est détectée pendant 8 secondes.

Pour mesurer la température, pointez le thermomètre sur un objet et actionnez la gâchette. Vous pouvez utiliser

le pointeur laser pour mieux viser avec le thermomètre. Actionnez et maintenez la gâchette pour mesurer la

surface ciblée. Quand vous relâchez la gâchette, l'écran maintient l'affichage de la mesure pendant 8 secondes.

Veillez à respecter la distance par rapport à la taille du point focal et le champ de visée. Le laser n'est utilisé que

pour viser et n'a pas d'incidence sur la mesure de température.

Le thermomètre possède une fonction d'arrêt automatique qui met le thermomètre automatiquement hors

tension après 8 secondes d'inactivité. Actionnez la gâchette pour mettre le thermomètre sous tension.

4

Page 31

Positions du sélecteur rotatif

Bouton Description

Bouton

JAUNE

SET

Appuyer sur le bouton JAUNE pour basculer entre les options MAX, MIN, DIF, AVG, HAL, LAL,

DATA et T-C. Lorsque le thermomètre passe en mode de veille, appuyer sur MODE pour remettre

le thermomètre de nouveau sous tension pour qu'il afche la dernière mesure obtenue.

Appuyer sur cette touche pour passer en mode de configuration, soit alternativement pour

définir l'émissivité, verrouiller le déclenchement des mesures et sélectionner °C / °F. Les détails

ci-dessous renvoient à la configuration de l'émissivité, au verrouillage du déclenchement des

mesures et à la sélection °C / °F.

Appuyer sur

sélectionnables pour s'adapter aux différentes conditions d'éclairage.

Appuyer sur pour allumer ou éteindre la lumière laser. Le symbole sur l'affichage indique

que la lumière laser est allumée.

Quand le thermomètre passe en mode de conguration (SET), appuyer sur ou sur

pour sélectionner une option de configuration (émissivité, verrouillage du déclenchement des

mesures et sélection °C / °F).

/

Quand le thermomètre passe en mode HAL, LAL et DATA, appuyer sur

sélectionner une option de configuration (émissivité, verrouillage du déclenchement des

mesures et sélection °C / °F).

pour activer ou désactiver le rétroéclairage. Deux niveaux de rétroéclairage

ou sur pour

Laser

Attention

Pour éviter les blessures, ne pas pointer directement le laser en direction des yeux, ou indirectement vers des

surfaces réfléchissantes.

Le thermomètre est équipé d'un laser, celui-ci ne doit être utilisé que pour viser. Le laser s'éteint quand la

gâchette est relâchée.

Pour activer ou désactiver le laser :

1. Appuyez

laser est activé.

le bouton pour activer ou désactiver le laser. Un symbole apparaît sur l'afchage lorsque le

Configuration de l'émissivité

1. Appuyez sur le bouton SET pour sélectionner la configuration de l'émissivité, l'icône clignote sur

l'affichage.

2. Appuyez sur la touche

un réglage rapide. La valeur maximale est 1,00.

3. Appuyez sur la touche

rapide. La valeur par défaut est 0,01.

4. Appuyez sur le bouton MODE pour compléter le réglage et quitter la configuration de l'émissivité, ou sur le bouton

SET pour compléter le réglage et procéder au verrouillage du déclenchement des mesures.

Remarque : L'émissivité par défaut est 0,95.

pour augmenter la valeur affichée par pas de 0,01. Maintenez enfoncé pour

pour diminuer la valeur par pas de 0,01. Maintenez enfoncé pour un réglage

5

Page 32

Tableau d’émissivité des surfaces

Surface de mesure

MÉTAUX

Aluminium

Oxydé 0,2 à 0,4

Alliage A3003

Oxydé 0,3

Rugosifié 0,1 à 0,3

Laiton

Lustré 0,3

Oxydé 0,5

Cuivre

Oxydé 0,4 à 0,8

Bornier électrique 0,6

Haynes

Alliage 0,3 à 0,8

Inconel

Oxydé 0,7 à 0,95

Sablé 0,3 à 0,6

Électropoli 0,15

Fer

Oxydé 0,5 à 0,9

Rouillé 0,5 à 0,7

Fonte

Oxydé 0,6 à 0,95

Inoxydé 0,2

Fondu 0,2 à 0,3

Fer forgé

Terne 0,9

Plomb

Rugueux 0,4

Oxydé 0,2 à 0,6

Molybdène

Oxydé 0,2 à 0,6

Nickel

Oxydé 0,2 à 0,5

Platine

Noir 0,9

Acier

Laminé à froid 0,7 à 0,9

Meulé 0,4 à 0,6

Poli 0,1

Zinc

Oxydé 0,1

Réglage du

commutateur

Surface de mesure

NON-MÉTAUX

Amiante 0,95

Asphalte 0,95

Basalte 0,7

Carbone

Inoxydé 0,8 à 0,9

Graphite 0,7 à 0,8

Carborundum 0,9

Céramique 0,95

Argile 0,95

Béton 0,95

Tissu 0,95

Verre

Tôle 0,85

Gravier 0,95

Gypse 0,8 à 0,95

Glace 0,98

Calcaire 0,98

Papier (toutes couleurs) 0,95

Plastique

Opaque 0,95

Sols 0,9 à 0,98

Eau 0,93

Bois, (naturel) 0,9 à 0,95

6

Réglage du

commutateur

Page 33

Verrouillage du déclenchement des mesures

Le déclenchement du thermomètre peut être verrouillé pour obtenir une mesure continue.

Pour verrouiller le déclenchement :

1. Appuyez sur le bouton SET pour verrouiller le déclenchement des mesures, l'icône

2. Appuyez sur

3. Appuyez sur le bouton JAUNE pour compléter le réglage et quitter le verrouillage du déclenchement des

mesures, ou sur le bouton SET pour compléter le réglage et passer à la sélection des degrés °C / °F.

ou sur pour activer ou désactiver l'option.

clignote sur l'affichage.

Configuration °C / °F

1. Appuyez sur le bouton SET pour sélectionner la configuration des degrés °C ou °F, l'icône °C ou °F clignote sur

l'affichage.

2. Appuyez sur

3. Appuyez sur le bouton JAUNE pour compléter le réglage et quitter la configuration des degrés °C ou °F.

ou sur pour sélectionner °C ou °F.

MAX, MIN, DIF et AVG

Le thermomètre peut mesurer les températures maximale (MAX), minimale (MIN), différentielle (DIF) ou

moyenne (AVG) à chaque lecture de l'appareil. Ces valeurs sont disponibles pour les mesures infrarouges.

1. Appuyez sur le bouton JAUNE jusqu'à l'apparition de MIN , MAX, AVG ou DIF sur l'afficheur.

2. Actionnez et maintenez la gâchette tout en visant la surface ciblée.

3. La valeur s'affiche sur la fenêtre secondaire.

Alarme haute (HAL) et alarme basse (LAL)

Le thermomètre possède une alarme programmable haute et basse pour désigner les seuils hauts ou bas de

la gamme définie. Lorsque le niveau d'alarme est atteint, une alarme retentit. Cette fonctionnalité n'est pas

disponible lors des mesures par thermocouple.

Pour configurer l'alarme haute ou basse :

1. Appuyez sur le bouton JAUNE pour sélectionner l'option HAL ou LAL.

2. Appuyez sur ou sur pour ajuster la valeur du seuil.

3. Appuyez sur le bouton SET pour compléter le réglage. Le symbole

Pour éteindre l'alarme haute ou basse :

1. Appuyez sur le bouton JAUNE pour sélectionner l'option HAL ou LAL.

2. Appuyez sur le bouton SET. La disparition du symbole

ou basse est éteinte.

ou

ou

de l'afficheur indique que l'alarme haute

apparaît sur l'affichage.

Mémoire de stockage DATA

Le thermomètre possède une capacité de stockage de 99 points de données et les données

mémorisées peuvent être téléchargées avec le logiciel IR-750 / IR-750-EUR. Pour enregistrer les

données :

1. Appuyez sur le bouton JAUNE pour sélectionner l'option DATA.

2. Appuyez sur

3. Actionnez et maintenez la gâchette pour mesurer la surface ciblée, appuyez sur le bouton DATA pour

enregistrer la valeur mesurée. Vous pouvez également enregistrer la mesure pendant les 8 secondes du

maintien d'afchage après avoir relâché la gâchette.

ou sur pour sélectionner le numéro d'enregistrement des données.

Mesure du thermocouple de type K

Pour éviter les chocs électriques ou les blessures corporelles, ne brancher pas la sonde

thermocouple de contact à des circuits électriques sous tension.

Le thermomètre est fourni avec une sonde thermocouple de type K à boule. Le thermocouple de type K est

branché au thermomètre par le biais du connecteur d'entrée TC-K situé à droite du thermomètre. La sonde peut

être utilisée simultanément pendant que le thermomètre relève des mesures sans contact.

1. Appuyez sur le bouton JAUNE pour passer en mode T-C. L'affichage affiche OL avant l'établissement de la

mesure.

2. Branchez le thermocouple de type K au thermomètre par le biais du connecteur d'entrée TC-K situé à

droite du thermomètre. Appuyez sur la gâchette pour lancer une mesure. La fenêtre secondaire afche la

mesure relevée.

3. Quand vous relâchez la gâchette, l'écran maintient l'affichage de la mesure pendant 8 secondes.

7

Page 34

Localisation d'un point chaud ou froid

Pour identier un point chaud ou froid, pointez le thermomètre en dehors de la zone ciblée. Balayez ensuite

lentement la zone d'un mouvement de bas en haut jusqu'à ce que le point chaud ou froid soit localisé.

Distance et taille du point focal (spot)

À mesure que la distance (D) de la cible mesurée augmente, la taille du point focal (S) de la zone mesurée par

l'instrument grandit. La taille du point focal indique 90 % d'énergie circonscrite.

Spot à distance

0,7 à 36

0,8 à 12

1,7 à 60

Pouce

19 à 300

Champ de visée

Vérifiez que la cible est plus grande que la taille du point focal. Plus la cible est petite, plus il faut s'en

rapprocher.

18 à 900

42 à 1500

NON

OUI

8

Page 35

Émissivité

L'émissivité décrit les caractéristiques d'émission d'énergie des matériaux. La plupart des matériaux organiques

et des surfaces peintes ou oxydées ont une émissivité de 0,95. Le cas échéant, pour compenser les lectures

inexactes susceptibles de résulter des mesures de surfaces métalliques brillantes, couvrez la surface à mesurer de

ruban opaque ou de peinture matte noire (< 150 °C / 302 °F) et utiliser le paramètre de haute émissivité. Laissez

au ruban ou à la peinture le temps d'atteindre les mêmes températures que la surface sous-jacente. Mesurez la

température du ruban ou de la surface peinte.

Si vous ne pouvez pas utiliser de peinture ou de ruban, vous pouvez améliorer la précision de vos mesures avec le

sélecteur d'émissivité. Même avec le sélecteur d'émissivité, il est parfois difficile d'obtenir une lecture infrarouge

absolument précise si la cible présente une surface brillante ou métallique.

Le thermomètre permet d'ajuster l'émissivité selon le type de surface mesuré.

Reportez-vous au tableau d'émissivité des surfaces Mais il ne s'agit que d'un cas typique. Vous pouvez utiliser vos

propres données et utiliser d'autres définitions pour vos matériaux.

Rappels

1. Les changements de la température ambiante environnante peuvent entraîner des mesures inexactes,

laissez l'instrument s'adapter au changement de température ambiant avant de l'utiliser. La précision

spéciée s'applique après 30 minutes lorsque l'instrument passe dans un milieu ambiant différent.

25 °C/77 °F

35 °C/95 °F

Attendre 30 minutes

9

Page 36

2. L'instrument ne peut pas établir de mesures à travers des surfaces transparentes telles que le verre. Dans ce

cas, il mesure en fait la température de surface du verre.

3. Reportez-vous au tableau d'émissivité des surfaces pour mesurer les surfaces métalliques brillantes ou polies

(acier inoxydable, aluminium, etc.).

4. La vapeur, la poussière, la fumée, etc., peuvent perturber la précision des mesures en obstruant l'optique

de l'instrument.

MESURES TYPIQUES

Cette section décrit une variété de mesures souvent effectuées par les techniciens.

Rappel :

• L'utilisateur peut décider de mettre sous tension ou hors tension le rétroéclairage et le laser en effectuant

des mesures avec le thermomètre.

• Une émissivité relativement élevée renvoie normalement à une émissivité d'environ 0,95.

• Une émissivité relativement faible renvoie normalement à une émissivité d'environ 0,30.

• Lorsque l'utilisateur ne peut pas identier l'émissivité de l'objet à mesurer, il peut couvrir la surface à

mesurer (température > 150 °C) avec du ruban d'électricien noir (émissivité d'environ 0,95). Laissez le temps

au ruban d'atteindre la même température que l'objet à mesurer. Mesurez et enregistrez la température

du ruban.

Pointez le thermomètre vers l'objet à mesurer, ajustez le paramètre d'émissivité pour l'aligner sur la même

température que le ruban. À ce stade, le paramètre d'émissivité du thermomètre est proche de l'émissivité de l'objet

à mesurer; la mesure peut démarrer.

Tests des contacteurs (démarreurs)

1. Appuyez sur SET pour sélectionner l'émissivité. Appuyez sur / pour sélectionner une émissivité

relativement faible pour les contacts brillants, ou un niveau intermédiaire de 0,7 pour les contacts sombres.

2. Appuyez sur le bouton JAUNE pour sélectionner MAX.

3. Mesurez la ligne et le côté charge d'un pôle sans relâcher la gâchette.

4. Une différence de température entre la ligne et le côté charge d'un pôle indique une résistance accrue d'un

point et la défaillance probable d'un contacteur.

Test de relais sous coffret

1. Appuyez sur SET puis sur / pour définir une émissivité relativement faible pour les connecteurs non

isolés, ou relativement haute pour les relais sous coffret en plastique ou en bakélite ou les connecteurs

isolés.

2. Appuyez sur le bouton JAUNE pour sélectionner MAX.

3. Lancez l'analyse.

4. Mesurez le boîtier du relais en recherchant les points chauds.

5. Mesurez les connexions électriques aux bornes du relais en recherchant les points chauds.

10

Page 37

Test des raccordements à fusibles et à barres omnibus

1. Appuyez sur SET puis sur / pour définir une émissivité relativement élevée pour un corps de fusible à

revêtement papier ou des connexions isolées.

2. Appuyez sur le bouton JAUNE pour sélectionner MAX.

3. Balayez la partie recouverte de papier du fusible.

4. Balayez chaque fusible sans relâcher la gâchette. Des températures inégales entre les fusibles sont

susceptibles d'indiquer un déséquilibre d'intensité ou de tension.

5. Appuyez sur SET puis sur

fusibles métalliques et les connexions de barres omnibus non isolées.

6. Appuyez sur MODE pour sélectionner MAX.

7. Balayez chaque capuchon d'extrémité de chaque fusible.

Remarque : Des températures inégales ou une température élevée indiquent une connexion desserrée ou

corrodée dans la pince à ressort de la barre omnibus à fusibles.

/ pour définir une émissivité relativement faible pour les capuchons et les

Test des branchements électriques

1. Appuyez sur SET puis sur / pour définir une émissivité relativement faible pour les connexions de

barres omnibus ou les connecteurs non isolés, ou relativement haute pour les connexions isolées.

Remarque : Les conducteurs sont généralement plus petits que la taille du spot du thermomètre. Si la taille

du spot est plus grande que celle du connecteur, la température mesurée est la moyenne à l'intérieur du

spot.

2. Scrutez le conducteur, en déplaçant l'appareil en direction du connecteur électrique (connecteur rapide,

serre-fil, connexion de barre omnibus, etc.).

Inspection des murs pour détecter les fuites d'air ou les défauts d'isolation

1. Mettez le chauffage, le refroidissement et la ventilation hors tension.

2. Appuyez sur SET pour sélectionner l'émissivité. Appuyez sur

relativement élevée pour des surfaces peintes ou les surfaces de fenêtres.

3. Appuyez sur JAUNE pour sélectionner MIN quand la paroi opposée du mur est de température inférieure

et/ou sélectionner MAX quand la paroi opposée du mur est de température supérieure.

4. Mesurez une température de surface murale de partition intérieure.

5. Ne relâchez pas la gâchette. Enregistrez cette température de référence (point zéro) pour un mur

« parfaitement » isolé.

6. Faites face au mur à examiner. Tenez-vous à 1,5 m pour balayer un spot de 4 cm sur le mur.

7. Balayez des bandes horizontales de mur de haut en bas, ou des rangées horizontales de plafond d'un mur

à l'autre. Recherchez les plus grands écarts par rapport à la température de référence pour identifier les

problèmes. Cela complète l'examen du test d'isolation.

Mettez le ventilateur en route (sans chaleur ni refroidissement) et répétez le test. Si les résultats du test avec le

ventilateur activé sont différents des résultats avec le ventilateur éteint, cela signale probablement des fuites

d'air dans l'enveloppe d'isolation des murs. Les fuites d'air sont liées à des fuites dans les conduits créant un

différentiel de pression sur l'ensemble de l'enveloppe de l'espace climatisé.

/ pour sélectionner une émissivité

Test de paliers de roulement

Avertissement

Pour éviter les blessures en testant les paliers :

1. L’utilisateur ne doit pas porter de vêtements lâches, de bijoux ou tout autre élément autour du cou en

travaillant à proximité de pièces mobiles telles que les moteurs, courroies et ventilateurs.

2. Vérifier qu'un interrupteur électrique est à portée de la main et qu'il fonctionne correctement et

librement.

3. Ne pas travailler sans assistance.

Remarque : Il vaut mieux comparer deux moteurs similaires utilisant des charges similaires.

1. Appuyez sur SET, puis sur

2. Appuyez sur SELECT pour sélectionner MAX.

3. Actionnez le moteur et laissez-le atteindre les températures de régime permanent.

4. Coupez le moteur si possible.

5. Mesurez les deux températures des paliers moteur.

/ pour sélectionner une émissivité relativement élevée.

11

Page 38

6. Comparez les deux températures des paliers moteur. Des températures inégales ou une température élevée

peuvent indiquer une anomalie de lubrification ou autre du palier résultant d'une friction excessive.

7. Répétez la séquence pour les paliers du ventilateur.

Test des courroies et des poulies

1. Appuyez sur SET, puis sur / pour sélectionner une émissivité relativement élevée.

2. Appuyez sur SELECT pour sélectionner MAX.

3. Actionnez le moteur et laissez-le atteindre les températures de régime permanent.

4. Pointez le thermomètre vers la surface à mesurer.

5. Lancez l'enregistrement de la température.

6. Déplacez lentement le thermomètre vers le haut de la courroie et la deuxième poulie.

• Si la courroie est en train de glisser, la température de courroie sera élevée à cause de la friction.

• Si la courroie glisse, la température de courroie restera élevée entre les poulies.

• Si la courroie ne glisse pas, la température de courroie diminuera entre les poulies.

• Si les surfaces intérieures des poulies ne sont pas véritablement en forme en « V », la courroie risque de

glisser et le moteur continuera de fonctionner à des températures élevées tant que la poulie n'est pas

remplacée.

• Les poulies doivent être correctement alignées (y compris le « tangage et le roulis ») pour que la

courroie et les poulies fonctionnent aux températures appropriées. Un règle rectiée ou une ligne

droite peut être utilisée pour vérifier les alignements.

• La poulie du moteur doit fonctionner à une température cohérente avec les poulies de ventilateur.

• Si la poulie du moteur est à une température plus élevée au niveau de l'arbre moteur que de la

circonférence extérieure, la courroie n'est probablement pas en train de glisser.

• Si la circonférence extérieure de la poulie a une température supérieure à celle de la poulie au niveau de l'arbre

moteur, alors la courroie est probablement en train de glisser et les poulies sont sans doute incorrectement

alignées.

Contrôle des applications de chauffage hydronique

1. Appuyez sur SET, puis sur / pour sélectionner une émissivité relativement élevée.

2. Appuyez sur le bouton JAUNE pour sélectionner MAX.

3. Pour localiser les tuyaux de chauffage radiant dans les planchers, élevez temporairement la température de

la boucle pour créer des points plus chauds afin de repérer les longueurs de tuyaux.

4. Avant de relâcher la gâchette, appuyez sur JAUNE pour basculer entre les températures de plancher MIN,

MAX, DIF et enregistrer la température pour de futures comparaisons et les tendances en conditions

similaires.

Mesure des températures de sortie d'air de grille, de registre ou de diffuseur

1. Appuyez sur SET, puis sur / pour sélectionner une émissivité relativement élevée.

2. Pointez le thermomètre sur le diffuseur, le registre ou la grille de sortie d'air.

3. Mesurez la température de sortie.

4. Relâchez la gâchette pour figer la température pendant 8 secondes et enregistrez cette température.

5. La température de diffuseur, le registre ou la grille de sortie d'air doit être équivalente à la température de

sortie du système de traitement d'air.

Contrôle des blocages dans les condensateurs ou l'évaporateur à circulation d'air

1. Retirez les panneaux pour accéder aux coudes ou bobines en U.

2. Appuyez sur SET puis sur

cuivre.

3. Lancez le système de réfrigération.

4. Pointez le thermomètre au niveau des coudes/bobines en U.

5. Lancez l'enregistrement de la température.

6. Prenez la température de chaque coudes/bobines en U.

/ pour sélectionner une émissivité relativement élevée pour le tuyau en

12

Page 39

• Tous les coudes/bobines en U de l'évaporateur doivent être à un niveau égal ou légèrement supérieur à la

température de saturation de l'évaporateur sur le tableau de pressions/températures.

• Tous les coudes ou bobines en U de l'évaporateur doivent être à un niveau égal ou légèrement

supérieur à la température de saturation de l'évaporateur du tableau de pression/température.

• Si un groupe de coudes/bobines en U n'est pas conforme aux températures attendues, cela signale la

présence d'un tube de distribution ou d'un distributeur bloqué ou limité.

FONCTIONNEMENT DU LOGICIEL IR-750 / IR-750-EUR

Configuration nécessaire du système

Configuration recommandée

Processeur

Système d’exploitation Microsoft Windows® 2000 / XP / Vista / Win7

Mémoire 512 Mo RAM ou supérieur

Moniteur VGA (1024 x 768)

Lecteur CD-ROM

Périphérique d'entrée Souris ou compatible

Interface USB pour la transmission des données

Pentium® 4 ou supérieur avec prise en charge de tous les systèmes d'exploitation

traditionnels

Installer le logiciel IR-750 / IR-750-EUR

• Introduisez le CD fourni dans le lecteur de CD-ROM.

• Cliquez deux fois sur « IR-750_VX.XX.exe » (pour indiquer la version du logiciel, X est compris entre 0 et 9 ou

laissé vierge)

• Les fenêtres déroulantes vous guideront au l des étapes de conguration du programme.

Connexion du câble USB au thermomètre IR-750 / IR-750-EUR

Câble USB

13

Page 40

Écran principal

1

2

3

4

5

6

La commande

1

nombre de mesures (1000, 5000, 10000, 50000, 100000 ou infini).

La commande

2

clignotant indique que l'IR-750 / IR-750-EUR est connecté au logiciel

Un

3

Écran principal des mesures

4

Fenêtre secondaire des résultats de mesure

5

Résultats de mesure dans le graphe

6

permet de créer de nouvelles mesures, d'enregistrer des fichiers et de définir le

permet d'afficher les instructions d'utilisation du logiciel.

Utilisation du programme

Le bouton permet de connecter le thermomètre IR-750 / IR-750-EUR et de lancer la mesure. Cliquez

sur « USB Connect » (Connexion USB),

correctement connecté au PC et qu'il commence à relever automatiquement les mesures. La fenêtre principale

affiche les températures de mesure actives, la fenêtre secondaire affiche tous les résultats de mesure.

Le téléchargement des données vous permet de télécharger les données enregistrées dans le thermomètre

IR-750 / IR-750-EUR. Cochez « Download Data » (Télécharger les données) et cliquez sur « USB Connect », les

données enregistrées seront automatiquement transférées vers le PC et s'afficheront dans la fenêtre secondaire.

Pour quitter et fermer le programme

clignote pour indiquer que le thermomètre IR-750 / IR-750-EUR est

1

2

3

4

1

Impression des données

2

Enregistrement des données (*.txt, *.xls, *.xml)

3

Ouverture des fichiers (*.txt, *.xls, *.xml)

Suppression des données actuelles et création de nouvelles données.

4

14

Page 41

Repeat : Cochez cette case pour afficher chaque mesure à l'intervalle que vous avez défini. Supprimez la coche

devant « Répéter », la fenêtre secondaire n'afchera que les résultats de mesure qui diffèrent de la dernière

température mesurée. L'affichage graphique indiquera les résultats de mesure complets en format graphique

malgré la présence ou l'absence d'une coche devant « Repeat » (Répéter).

Sampling Interval vous permet de définir les intervalles d'échantillonnage des mesures (1 à 9999 secondes).

Remarque : Un message d'avertissement avertit l'utilisateur et arrête les mesures quand les résultats de mesure

atteignent 10000 ensembles sous Measurement No. (Nº de mesure). Enregistrez ou effacez les résultats des

mesures avant d'effectuer d'autres mesures.

1

2

3

4

5

6

7

1

Dernière page

2

Page suivante

3

Page active

4

Page précédente

5

Première page

6

Enregistre le graphique dans la page active sous la forme *.bmp

7

Définit les nombres de mesures sur l’affichage graphique

Rapport de test

Les données de test peuvent être enregistrées au format *.txt, *.xls, *.xml en

cliquant sur le bouton . En ouvrant le rapport des données, veillez à sélectionner le format de polices sous la

forme Amprobe-A1 ou Amprobe-A2 dans la colonne « Unité » pour afficher l'unité de température correcte °C ou °F.

# ou ? indique une sélection

de polices incorrecte pour

l'unité de température

15

Page 42

Sélectionner Amprobe-A1 ou

Amprobe-A2 pour afficher

l'unité de température correcte

Affichage correct de

l'unité de température

Zoom avant sur le graphique sélectionné

Pour agrandir une partie du graphique, utilisez le pointeur de la souris pour sélectionner la zone entre le point

supérieur gauche et le point inférieur droit.

Point de départ

Vous pouvez utiliser le bouton pour enregistrer le graphique agrandi sélectionné.

Pour revenir à l'écran complet initial, utilisez le pointeur de la souris pour sélectionner une zone du graphique

du point inférieur droit au point supérieur gauche.

16

Page 43

Point de départ

CARACTÉRISTIQUES

Fonctionnalité IR-750 / IR-750-EUR

Plage de températures -50 °C à 1550 °C (-58 °F à 2822 °F)

Précision (avec une

température ambiante

supposée de 21 °C à