Page 1

AU92

Automotive

Multimeter

Users Manual

• Bedienungshandbuch

• Mode d’emploi

• Manuale d’Uso

• Manual de uso

• Användarhanbok

Page 2

AU92

Automotive Multimeter

AU92_Rev001

Users Manual

Page 3

Limited Warranty and Limitation of Liability

Your Amprobe product will be free from defects in material and workmanship for 1 year from

the date of purchase. This warranty does not cover fuses, disposable batteries or damage from

accident, neglect, misuse, alteration, contamination, or abnormal conditions of operation or

handling. Resellers are not authorized to extend any other warranty on Amprobe’s behalf.

To obtain service during the warranty period, return the product with proof of purchase to

an authorized Amprobe Test Tools Service Center or to an Amprobe dealer or distributor. See

Repair Section for details. THIS WARRANTY IS YOUR ONLY REMEDY. ALL OTHER WARRANTIES WHETHER EXPRESS, IMPLIED OR STAUTORY - INCLUDING IMPLIED WARRANTIES OF FITNESS FOR

A PARTICULAR PURPOSE OR MERCHANTABILITY, ARE HEREBY DISCLAIMED. MANUFACTURER

SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or countries do not allow

the exclusion or limitation of an implied warranty or of incidental or consequential damages,

this limitation of liability may not apply to you.

Repair

All test tools returned for warranty or non-warranty repair or for calibration should be accompanied by the following: your name, company’s name, address, telephone number, and proof of

purchase. Additionally, please include a brief description of the problem or the service requested and include the test leads with the meter. Non-warranty repair or replacement charges

should be remitted in the form of a check, a money order, credit card with expiration date, or a

purchase order made payable to Amprobe® Test Tools.

In-Warranty Repairs and Replacement – All Countries

Please read the warranty statement and check your battery before requesting repair. During the

warranty period any defective test tool can be returned to your Amprobe® Test Tools distributor for an exchange for the same or like product. Please check the “Where to Buy” section on

www.amprobe.com for a list of distributors near you. Additionally, in the United States and

Canada In-Warranty repair and replacement units can also be sent to a Amprobe® Test Tools

Service Center (see address below).

Non-Warranty Repairs and Replacement – US and Canada

Non-warranty repairs in the United States and Canada should be sent to a Amprobe® Test Tools

Service Center. Call Amprobe® Test Tools or inquire at your point of purchase for current repair

and replacement rates.

In USA In Canada

Amprobe Test Tools Amprobe Test Tools

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel: 877-AMPROBE (267-7623) Tel: 905-890-7600

Non-Warranty Repairs and Replacement – Europe

European non-warranty units can be replaced by your Amprobe® Test Tools distributor for a

nominal charge. Please check the “Where to Buy” section on www.amprobe.com for a list of

distributors near you.

European Correspondence Address*

Amprobe® Test Tools Europe

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

*(Correspondence only – no repair or replacement available from this address. European customers please contact your distributor.)

1

Page 4

RPM

DC/AC

Ω

/ /

COM

10A

μ

A mA

RANGE

HOLD

Hz

Mk

Ω

AC

DC

RANGE

APO

HOLD

mVA

μ

RPM

X10RPM

%

400

1000

1832

DUTY

10A

Hz

mA

6CYL

8CYL

400

A

5CYL

OFF

V

X10RPM

RPM

Ω

4CYL

μ

DWELL

%

CAT.III

MAX

600V

600V

MAX

FUSED

MAX

FUSED

400mA

10A/60sec

AUTOMOTIVE METER

AU92

℉

℉

℃

℃

℃

RPM

VΩ

℃ ℉

℉

➓

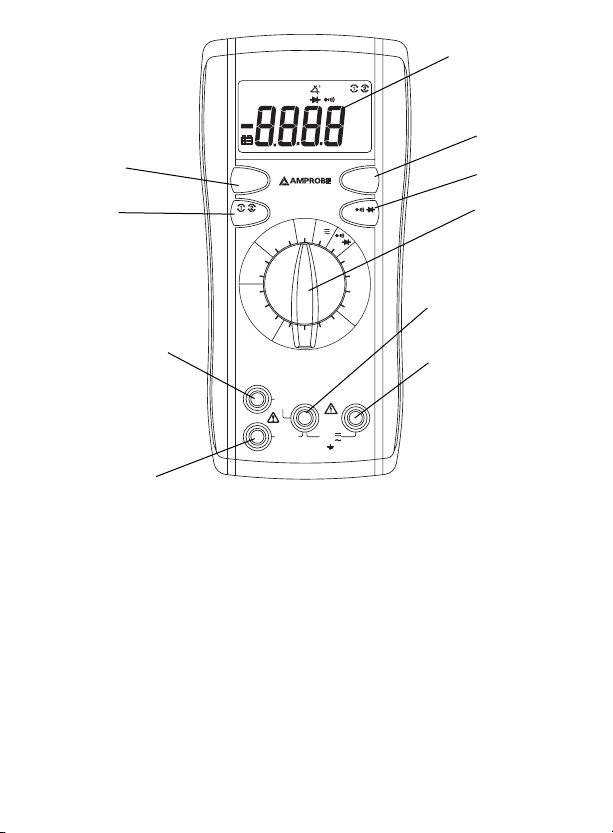

➊

➋

➌

➒

➑

➐

➊ 4 Digit LCD with Function Indicators

Data Hold Button

➋

Resistance / Continuity / Diode / AC/DC Button

➌

Function / Range / Selector Knob

➍

COM Input

➎

Temperature / Volts / Ohms / RPM / Dwell Input

➏

10 Amp Input

➐

uA, mA Input

➑

RPM Button

➒

Range Lock Button

➓

2

➍

➎

➏

Page 5

AU92 Automotive Multimeter

Contents

Symbols ............................................................................................................................................... 4

Introduction ....................................................................................................................................... 4

Warnings and Precautions ................................................................................................................ 5

Unpacking and Inspection ................................................................................................................ 6

Measuring Procedures ....................................................................................................................... 3

Maintenance ..................................................................................................................................... 10

Troubleshooting ................................................................................................................... 10

Battery Replacement ............................................................................................................ 10

General Specications ..................................................................................................................... 11

3

Page 6

SYMBOLS

Introduction

The AU92 is a digital meter for automotive applications that measure both AC and DC

voltage, AC and DC current, Resistance, Continuity, Diode Test Dwell, RPM, % Duty Cycle,

and Temperature.

Caution ! Refer to the explanation in this Manual

Caution ! Risk of electric shock

Earth (Ground)

Double Insulation or Reinforced insulation

AC--Alternating Current

DC--Direct Current

Conforms to relevant Australian standards

Underwriters Laboratories Inc. [Note: Canadian and US.]

Complies with European Directives

Do not dispose of this product as unsorted municipal waste

4

Page 7

WARNINGS AND PRECAUTIONS

Safety Information

• The AU92 Automotive Meter conforms to EN61010-1:2001; CAT III 600 V, class 2 and

pollution deg.2

• This instrument is EN61010-1 certified for Installation Category III ( 600V). It is recommended for use in distribution level and fixed installations, as well as lesser installations, and not for primary supply lines, overhead lines and cable systems.

• Do not exceed the maximum overload limits per function (see specifications) nor the

limits marked on the instrument itself. Never apply more than 600 Vdc/600 V ac rms

between the test lead and earth ground.

• The extension probe tip TP92 is intended for use only with TL36 test leads. The TP92

is CAT III-1000V / CAT IV-600V rated. Keep fingers behind the guard ring.

WARNING

• Before and after hazardous voltage measurements, test the voltage function on a

known source such as line voltage to determine proper meter functioning.

• Disconnect the test leads from the test points before changing meter functions.

• Inspect the Clampmeter, test leads and accessories before every use. Do not use any

damaged part.

• Never ground yourself when taking measurements. Do not touch exposed circuit elements or test probe tips.

• Do not operate the instrument in an explosive atmosphere.

• To reduce the risk of fire or electric shock, do not expose this product to rain or

moisture.

• The meter is intended only for indoor use. To avoid electrical shock hazard, observe

the proper safety precautions when working with voltages above 60 VDC or 30 VAC

rms. These voltage levels pose a potential shock hazard to the user.

• Before and after hazardous voltage measurements, test the voltage function on a

known source such as line voltage to determine proper meter functioning.

• Keep your hands/fingers behind the hand/finger barriers (of the meter and the test

leads) that indicate the limits of safe access of the hand-held part during measurement.

• Inspect test leads, connectors, and probes for damaged insulation or exposed metal

before using the instrument. If any defects are found, replace them immediately.

• Exercise extreme caution when: measuring voltage >20 V // current >10 mA // AC

power line with inductive loads // AC power line during electrical storms // current,

when the fuse blows in a circuit with open circuit voltage >600 V // servicing CRT

equipment.

• Remove test leads before opening the case to change the battery.

5

Page 8

• Disconnect circuit power and discharge all high-voltage capacitors before testing

resistance, continuity, diodes, or capacitance.

• To avoid false readings, which could lead to possible electric shock or personal

injury, replace the batteries as soon as the low battery indicator (

Unpacking and Inspection

Your shipping carton should include:

AU92 Digital meter

Inductive pick-up probe

Test lead set (one black, one red)

Test lead extender tip (threaded - one black, one red)

Alligator clips (threaded - one black, one red)

Temperature Adapter (TA-1A)

Temperature Sensor (TP-255A)

Spare fuse ( 500 mA) FP520

One 9V battery

Carrying case

Users Manual

If any of the items are damaged or missing, return the complete package to the place of

purchase for an exchange.

) appears.

6

Page 9

OPERATION

Before taking any measurements, read the Safety Information Section. Always examine

the instrument for damage, contamination (excessive dirt, grease, etc.) and defects.

Examine the test leads for cracked or frayed insulation. If any abnormal conditions exist

do not attempt to make any measurements.

Function

modes. Selects DC or AC current modes.

Auto Power Off

1. Auto power off: approx. 10 minutes.

2. After auto power off, press any button to restart the meter, and the reading of

measurement will be maintained in the display.

Disable Auto Power Off Feature:

Press and hold the (RANGE) button while rotating function switch from off to any

position to turn the meter on. The auto power off feature is disabled. Note “APO”

annunciator is turned off on the LCD.

Data Hold Button

Press [HOLD] button to lock the reading on display, and release it by pressing the button

again.

Range Button

The meter also has a manual range mode. In manual range, you select and lock the meter

in a range. To manually select a range: Press [RANGE] button to hold the selected range.

Subsequently pressing the [RANGE] button will select each range in sequence from the

lowest to highest range. Hold the button for 2 seconds to return to the Autorange Mode.

If magnitude is unknown, set meter to highest range and reduce range until a

satisfactory reading is obtained.

Functions that show RANGE when rst selecting indicate Range measurement is locked.

Anytime display shows RANGE, this is indication the meter is locked in that range.

Button: Selects ohm/continuity and diode modes. Selects DC or AC volts

7

Page 10

RPM ➊ ➋ Button: In the RPM function the meter defaults to RPM ➋ for conventional

4-Cycle engines. Press the RPM button to toggle to RPM ➊ for 2-Cycle engines or waste

spark (DIS) 4-Cycle engines.

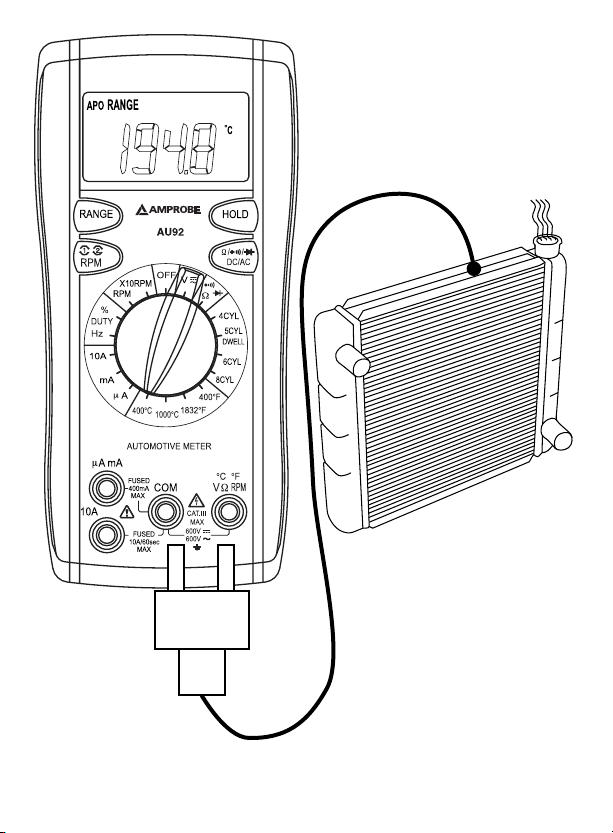

RPM Measurements (fig. 1)

1. Set the Function/Range switch to the desired RPM range.

2. Connect the red inductive pick-up to the “VΩ” jack and the black inductive pick-up

to the “COM” jack.

3. Connect the inductive pick-up to a spark plug wire. If no reading is received, unhook

the clamp, turn it over and connect again.

4. Press the RPM button to toggle between RPM ➊ for 2-Cycle engines or Distributorless

Ignition System (DIS) or RPM ➋ for 4-Cycle engines.

Dwell (fig. 2)

1. Set the Function/Range switch to the desired Dwell range.

2 Connect the red test lead to the “VΩ" jack and the black test lead to the "COM" jack.

3. Connect red lead to coil “-“ and black lead to ground

Voltage Measurements (see fig. 3)

1. Set the Function/Range knob to Voltage V

DC voltage

2. Connect the test leads to the device or circuit being measured.

3. For DC, a (-) sign is displayed for negative polarity; positive polarity is implied.

Current Measurements (see fig. 4)

1. Set the Function knob to uA, mA, 10A. Use the function button to select AC or DC

current.

2. Connect the red test lead to the (uA, mA or 10A) jack and the black test lead to the

“COM” jack.

3. Remove power from the circuit under test and open the normal circuit path where

the measurement is to be taken. Connect the meter in series with the circuit.

4. Apply power and read the value from the display.

. Use the Function button to select AC or

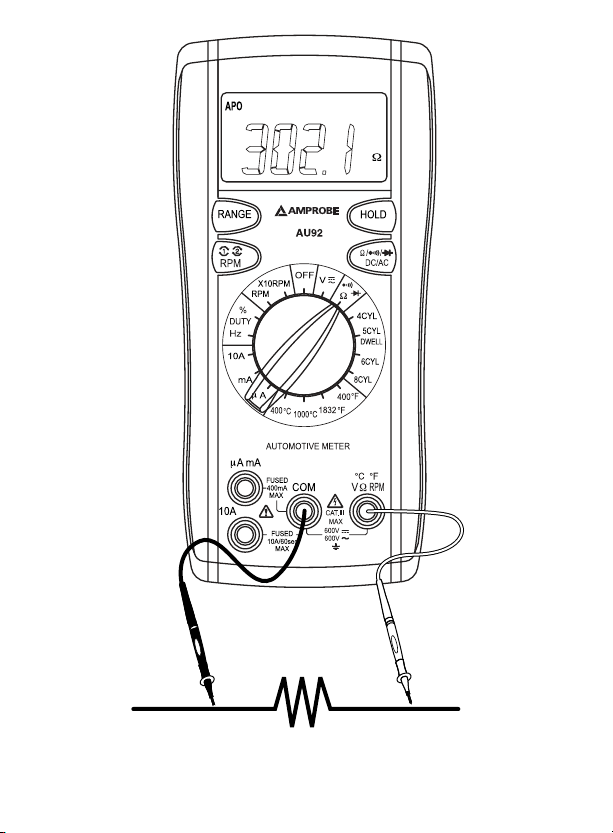

Resistance Measurements (see fig. 5)

1. Set the Function knob to the Ω

2. Connect the red test lead to the “VΩ" jack and the black test lead to the "COM" jack.

3. Remove power from the equipment under test.

4. Connect the test leads to the points of measurements and read the value from the

display.

. Use Function button to select ohms Ω.

8

Page 11

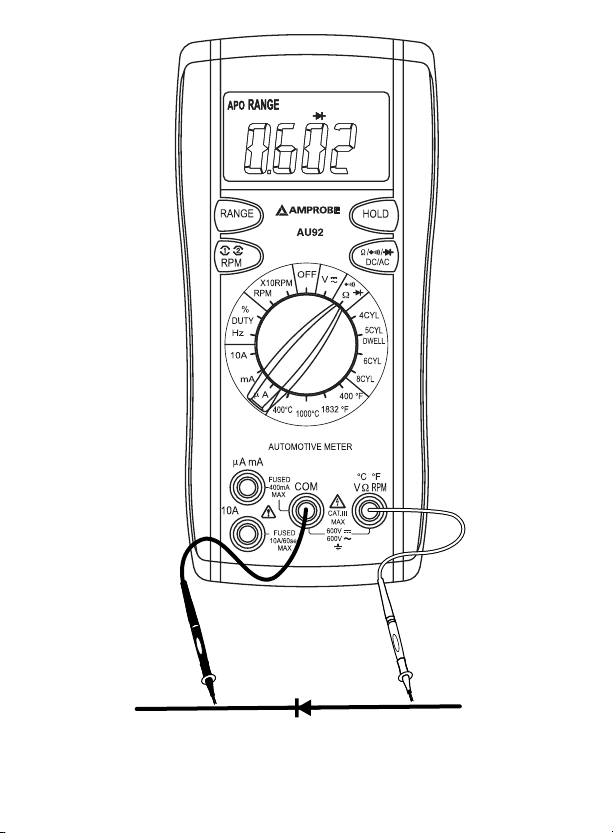

Diode Tests (see fig. 6)

1. Set the Function knob to the " Ω

2. Connect the red test lead to the “VΩ" jack and the black test lead to the "COM"

3. Turn off power to the circuit under test. External voltage across the components

4. Touch probes to the diode. A forward-voltage drop is about 0.6V (typical for a sili-

5. Reverse probes. If the diode is good, "OL" is displayed. If the diode is shorted,

6. If the diode is open, "OL" is displayed in both directions.

7. Audible Indication: Less than 0.25 Ω.

Continuity Measurements (see fig. 7)

1. Set the Function knob to the " Ω

2. Connect the red test lead to the “VΩ" jack and the black test lead to the “COM”

3. Turn off power to the circuit under test. External Voltage across the components

4. Connect the test leads to the two points at which continuity is to be tested. The

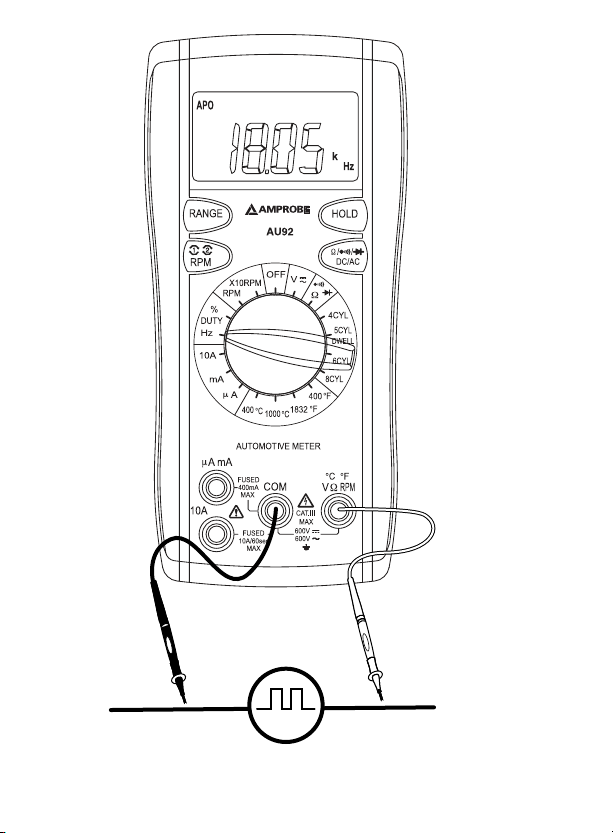

Frequency and Duty Cycle Measurements (see fig. 8)

1. Set the Function knob to the “Hz“ or “%” position.

2. Connect the red test lead to the “VΩ" jack and the black test lead to the “COM”

3. Connect the test leads to the point of measurement and read the frequency or duty

Temperature Measurements (see fig. 9)

1. Set the Function knob to the desired temperature range: °C, °F.

2. Connect the K-type thermocouple to the TEMP adapter and plug into VΩ and COM.

3. Match the polarity of the adapter to the polarity of the thermocouple.

4. Connect the TEMP adapter to the VΩ and COM jacks.

test.

diode

jack.

causes invalid readings.

con diode).

"0.00" or another number is displayed.

jack.

causes invalid reading.

buzzer will sound if the resistance is less than approximately 25Ω.

jack.

cycle from the display.

" position. Use the Function button to select

" position. Set Function button to “ “.

9

Page 12

MAINTENANCE

WARNING

Remove test leads before changing battery or fuse or performing any servicing.

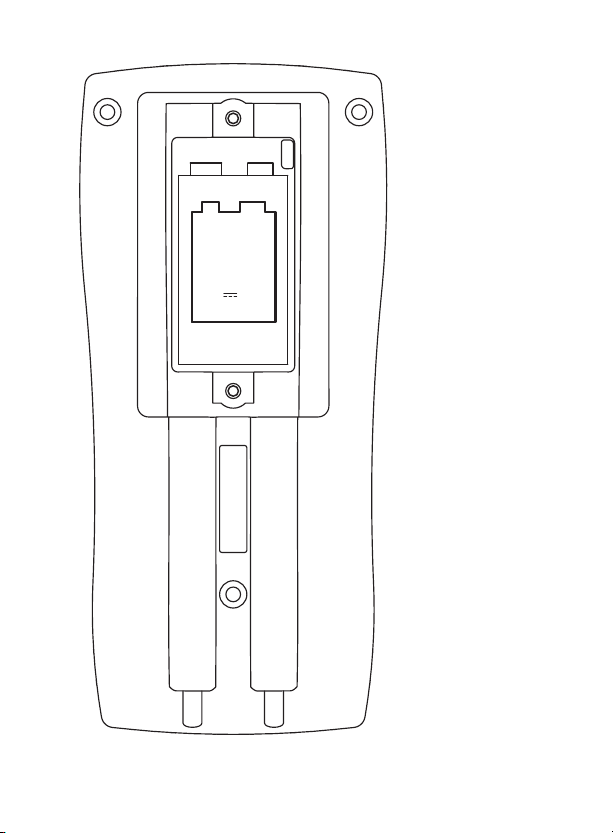

Battery Replacement (see fig. 10)

Power is supplied by a 9 volt battery. (NEDA 1604, IEC 6F22). The “

LCD display when replacement is needed. To replace the battery, remove the three screws

from the back of the meter and lift off the front case. Remove the battery from case

bottom.

Trouble Shooting

If the instrument fails to operate correctly, check battery, fuses and test leads etc., and

replace as necessary.

Refer to the LIMITED WARRANTY section for obtaining warranty or repairing service.

Cleaning and Storage

Periodically wipe the case with a damp cloth and mild detergent; do not use abrasives

or solvents. If the meter is not to be used for periods of longer than 60 days, remove the

battery and store separately.

Fuse Replacement

If no current measurements are possible, check for a blown overload protection fuse. For

access to fuses, remove the three screws from the back of the meter and lift off the front

case. Replace F1 only with the original type 0.5A / 500V (FP520), fast acting ceramic fuse,

Replace F2 only with the original type 10A / 500V (FP540), fast acting ceramic fuse .

“ appears on the

10

Page 13

GENERAL SPECIFICATIONS

Display: 3¾ digit liquid crystal display (LCD) with a maximum reading of 3999.

Polarity: Automatic, positive implied, negative polarity indication.

Overrange: (OL) or (-OL) is displayed.

Zero: Automatic.

Low battery indication: The “

“ is displayed when the battery voltage drops below

the operating level.

Measurement rate: 2 times per second, nominal.

Auto power off: Approx. 10 minutes.

Operating environment: 0°C to 50°C at < 70% RH.

Storage temperature: -20°C to 60°C at < 80% RH.

Accuracy: Stated accuracy at 23°C ± 5°C, <75% RH.

Temperature Coefficient: 0.1 × (specied accuracy) per °C. (0°C to 18°C, 28°C to 50°C).

Altitude: 2000m, indoor operation

Power: Standard 9-volt battery, NEDA 1604, JIS 006P, IEC 6F22.

Battery life: 150 hours typical with carbon zinc.

Dimensions: 165 × 78 × 50 mm ( 6.5 x 3.1 x 1.9 in.)

Weight: Approx. 315g (11.1 oz). including holster.

Accessories: One pair test leads, temperature adapter, inductive pick-up probe,

type-K thermocouple, One spare fuse (0.5A/500V), 9V battery (installed) and users

manual.

Safety : Meets IEC61010-1 2

nd

Ed., UL61010-1 2nd Ed. CAT III-600 Volts AC & DC; Class II;

Pollution degree: 2; EN61010-2-032

EMC: Conforms to EN61326-1.

This product complies with requirements of the following European Community

Directives: 89/ 336/ EEC (Electromagnetic Compatibility) and 73/ 23/ EEC (Low Voltage)

as amended by 93/ 68/ EEC (CE Marking). However, electrical noise or intense

electromagnetic elds in the vicinity of the equipment may disturb the measurement

circuit. Measuring instruments will also respond to unwanted signals that may be

present within the measurement circuit. Users should exercise care and take appropriate

precautions to avoid misleading results when making measurements in the presence of

electronic interference.

11

Page 14

ELECTRICAL SPECIFICATION Accuracy at 23 °C ± 5 °C, < 75% R.H.

DC VOLTS

Ranges: 400 mV, 4 V, 40 V, 400 V, 600 V

Accuracy: ±(1.0% rdg + 2 dgts)

Resolution: 0.1 mV

Input impedance: 400 mV: >100 MΩ; 4 V:10 MΩ; 40 V ~ 600 V: 9.1 MΩ

Overload protection: 600VDC or AC rms

AC VOLTS

Ranges: 400 mV, 4 V, 40 V, 400 V, 600 V

Range: Accuracy:

400 mV (50 ~ 100 Hz) ±(2.0% rdg + 5 dgts)

4, 40, 400, 600 V (50 ~ 500 Hz) ±(2.0% rdg + 5 dgts)

Resolution: 0.1 mV

Input impedance: 400 mV: >100 MΩ; 4 V: 10 MΩ; 40 V ~ 600 V: 9.1 MΩ

Overload protection: 600 VDC or AC rms

DC CURRENT

Ranges: 400 µA, 4000 µA, 40 mA, 400 mA, 10 A

Range: Accuracy:

400 µA to 400 mA ranges ±(2.0% rdg + 2 dgts)

10 A range ±(3.0% rdg + 3 dgts)

10A input: 10 A for 60 seconds maximum followed by a 10 minutes cooling period

Resolution: 0.1 µA

Voltage burden: 0.2 V on 400uA, 40mA ranges ;

2V on 4000 uA, 400 mA ranges

Input protection: 0.5 A / 500V fast blow ceramic fuse (FP520)

10 A / 500 V fast blow ceramic fuse (FP540)

AC CURRENT

Ranges: 400 uA, 4000 uA, 40 mA, 400 mA, 10 A

Range: (50 ~ 500 Hz) Accuracy:

400 uA to 400 mA ranges ±(2.5% rdg + 5 dgts)

10 A range ±(3.5% rdg + 5 dgts)

10A input: 10 A for 60 seconds maximum followed by a 10 minutes cooling period

Voltage burden: see DC Current

Input protection: see DC Current

12

Page 15

RESISTANCE

Ranges: 400 Ω, 4 kΩ, 40 kΩ, 400 kΩ, 4 MΩ, 40 MΩ

Resolution: 0.1 Ω on 400 Ω range

Range: Accuracy:

400 Ω to 400 kΩ ranges ±(1.5% rdg + 4 dgts)

4 MΩ range ±(2.5% rdg + 4 dgts)

40 MΩ range ±(5.0% rdg + 5 dgts)

Open circuit volts: -0.45Vdc (-1.2Vdc on 400 Ω range)

Overload protection: 600 VDC or AC RMS

FREQUENCY (Hz) (Auto ranging)

Range: 4 kHz, 40 kHz, 400 kHz

Resolution: 1Hz

Accuracy: ±(0.1% rdg + 3 dgts)

Sensitivity: 10Hz ~ 400kHz: > 3.5Vrms

Minimum pulse width: > 2.5us

Duty cycle limits: >30% and < 70%

Overload protection: 600 VDC or AC RMS

TEMPERATURE

Ranges: -20°C ~ 1000°C, -4°F ~ 1832°F

Resolution: 0.1°C, 0.1°F

Accuracy: 10°C ~ 200°C ±(1.0% rdg + 3°C)

-20°C ~ 10°C ±(2.0% rdg + 4°C)

200°C ~ 1000°C ±(3.0% rdg + 2°C)

-4°F ~ 50°F ±(2.0% rdg + 8°F)

50°F ~ 400°F ±(1.0% rdg + 6°F)

400°F ~ 1832°F ±(3.0% rdg + 4°F)

Sensor type: K-type thermocouple

Overload protection: 600 VDC or AC RMS

RPM

Range: RPM 600 ~ 4000 RPM

X10 RPM 4000 ~ 12000 RPM

Resolution: 1 RPM

Accuracy: ±(2% rdg + 4 dgts)

Effect Reading: > 600 RPM

Overload protection: 600 VDC or AC RMS

13

Page 16

% DUTY CYCLE

Range: 1.0% ~ 90.0%

Resolution: 0.1%

Pulse width: > 100us, < 100ms

Accuracy: ±(2% rdg + 5 dgts)

Overload protection: 600 VDC or AC RMS

DWELL ANGLE

No. OF Cylinders: 4, 5, 6, 8

Range: 4 CYL 0 ~ 90.0°

5 CYL 0 ~ 72.0°

6 CYL 0 ~ 60.0°

8 CYL 0 ~ 45.0°

Resolution: 0.1°

Accuracy: ±(2% rdg + 5 dgts)

Overload protection: 600 VDC or AC RMS

CONTINUITY

Audible indication: Less than 25Ω

Response time: 500ms

Overload protection: 600VDC or AC RMS

DIODE TEST

Test current: 1.0mA (approximate)

Accuracy: ±(3.0% rdg + 3 dgts)

Resolution: 10mV

Audible indication: <0.25V

Open circuit volts: 3.0VDC typical

Overload protection: 600VDC or AC RMS

14

Page 17

RPM

Figure 1

15

Page 18

Dwell

Figure 2

16

Page 19

Black Red

Voltage

Figure 3

17

Page 20

Red Black

Current

X

Figure 4

18

Page 21

Black Red

Resistance

Figure 5

19

Page 22

Black Red

Diode

Figure 6

20

Page 23

Black Red

Continuity

Figure 7

21

Page 24

Black Red

Frequency

Duty Cycle

Figure 8

22

Page 25

- +

Temperature

+

-

Figure 9

23

Page 26

SIZE:

NEDA 1604

JIS 006P

IEC 6F22

9V

Battery

Replacement

Figure 10

24

Page 27

AU92

Multimètre automobile

Français

Page 28

Limites de garantie et de responsabilité

Amprobe garantit l’absence de vices de matériaux et de fabrication de ce produit dans des

conditions normales d’utilisation et d’entretien pendant une période d’un an prenant effet à la

date d’achat. Cette garantie ne s’applique pas aux fusibles, aux piles jetables ni à tout produit

mal utilisé, modifié, contaminé, négligé ou endommagé par accident ou soumis à des conditions

anormales d’utilisation et de manipulation. Les revendeurs n’ont pas l’autorisation de prolonger

toute autre garantie au nom d’Amprobe. Pour bénéficier de la garantie, renvoyez le produit

accompagné d’un justificatif d’achat auprès d’un centre de services agréé par Amprobe Test

Tools, d’un distributeur ou d’un revendeur Amprobe. Voir la section Réparation pour tous les

détails. LA PRESENTE GARANTIE EST LE SEUL ET EXCLUSIF RECOURS DE L’UTILISATEUR TOUTES

AUTRES GARANTIES, EXPLICITES, IMPLICITES OU STATUTAIRES, NOTAMMENT LES GARANTIES

DE QUALITE MARCHANDE OU D’ADAPTATION A UN OBJECTIF PARTICULIER SONT EXCLUES PAR

LES PRESENTES. LE FABRICANT NE SERA EN AUCUN CAS TENU RESPONSABLE DE DOMMAGES

PARTICULIERS, INDIRECTS, ACCIDENTELS OU CONSECUTIFS, NI D’AUCUNS DEGATS OU PERTES DE

DONNEES, SUR UNE BASE CONTRACTUELLE, EXTRA-CONTRACTUELLE OU AUTRE. Etant donné

que certaines juridictions n’admettent pas les limitations d’une condition de garantie implicite

ou l’exclusion ou la limitation de dégâts accidentels ou consécutifs, il se peut que les limitations

et les exclusions de cette garantie ne s’appliquent pas à votre cas.

Réparation

Tous les outils de test renvoyés pour un étalonnage ou une réparation couverte ou non par la

garantie doivent être accompagnés des éléments suivants : nom, raison sociale, adresse, numéro

de téléphone et justificatif d’achat. Ajoutez également une brève description du problème ou

du service demandé et incluez les cordons de test avec l’appareil. Les frais de remplacement

ou de réparation hors garantie doivent être acquittés par chèque, mandat, carte de crédit avec

date d’expiration, ou par bon de commande payable à l’ordre d’Amprobe® Test Tools.

Remplacements et réparations sous garantie – Tous pays

Veuillez lire la déclaration de garantie et vérifiez la pile avant de demander une réparation.

Pendant la période de garantie, tout outil de test défectueux peut être renvoyé auprès de

votre distributeur Amprobe® Test Tools pour être échangé contre un produit identique ou

similaire. Consultez la section « Where to Buy » sur le site www.amprobe.com pour obtenir la

liste des distributeurs dans votre région. Au Canada et aux Etats-Unis, les appareils devant être

remplacés ou réparés sous garantie peuvent également être envoyés dans un centre de services

Amprobe® Test Tools (voir les adresses ci-dessous).

Remplacements et réparations hors garantie – Canada et Etats-Unis

Les appareils à réparer hors garantie au Canada et aux Etats-Unis doivent être envoyés

dans un centre de services Amprobe

vous auprès de votre lieu d’achat pour connaître les tarifs en vigueur de remplacement ou

de réparation.

Aux Etats-Unis Au Canada

Amprobe Test Tools Amprobe Test Tools

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel: 877-AMPROBE (267-7623) Tel: 905-890-7600

Remplacements et réparations hors garantie – Europe

Les appareils européens non couverts par la garantie peuvent être remplacés par votre

distributeur Amprobe® Test Tools pour une somme nominale. Consultez la section « Where to

Buy » sur le site www.amprobe.com pour obtenir la liste des distributeurs dans votre région.

European Correspondence Address*

Amprobe

In den Engematten 14

79286 Glottertal, Germania

Tel.: +49 (0) 7684 8009 - 0

*(Réservée à la correspondance – Aucune réparation ou remplacement n’est possible à cette

adresse. Nos clients européens doivent contacter leur distributeur.)

®

Test Tools Europe

®

Test Tools. Appelez Amprobe® Test Tools ou renseignez-

1

Page 29

RPM

DC/AC

Ω

/ /

COM

10A

μ

A mA

RANGE

HOLD

Hz

Mk

Ω

AC

DC

RANGE

APO

HOLD

mVA

μ

RPM

X10RPM

%

400

1000

1832

DUTY

10A

Hz

mA

6CYL

8CYL

400

A

5CYL

OFF

V

X10RPM

RPM

Ω

4CYL

μ

DWELL

%

CAT.III

MAX

600V

600V

MAX

FUSED

MAX

FUSED

400mA

10A/60sec

AUTOMOTIVE METER

AU92

℉

℉

℃

℃

℃

RPM

VΩ

℃ ℉

℉

➓

➊

➋

➌

➒

➎

➑

➐

➊ Ecran LCD à 4 chiffres avec indicateurs de fonction

Bouton de maintien d’affichage

➋

Bouton de résistance / continuité / diode / c.a./c.c.

➌

Sélecteur de gamme / fonction

➍

Entrée COM

➎

Entrée de température / volts / ohms / RPM / Angle de came

➏

Entrée 10 A

➐

Entrée uA, mA

➑

Bouton RPM

➒

Verrouillage de gamme

➓

2

➏

➍

Page 30

AU92 Automotive Multimeter

Table des matières

Symboles ............................................................................................................................................. 4

Introduction ....................................................................................................................................... 4

Mises en garde et précautions .......................................................................................................... 5

Déballage et inspection ..................................................................................................................... 6

Techniques de mesure ........................................................................................................................ 3

Entretien ........................................................................................................................................... 10

Dépannage ............................................................................................................................ 10

Changement des piles ........................................................................................................... 10

Caractéristiques générales .............................................................................................................. 11

3

Page 31

SYMBOLES

Introduction

Destiné aux applications automobiles, l’AU92 est un multimètre numérique qui mesure

les tensions alternatives et continues, les courants alternatifs et continus, la résistance, la

continuité, l’angle de fermeture du test de diode, les RPM, le rapport cyclique en % et la

température.

Attention ! Se reporter aux explications de ce manuel

Attention ! Risque de décharge électrique

Prise de terre

Double isolation ou isolation renforcée

c.a. -- courant alternatif

c.c. -- courant continu

Conforme aux directives de l’association australienne de normalisation

Underwriters Laboratories, Inc. [Remarque : norme canadienne

et américaine.]

Conforme aux directives européennes

Ne pas mettre ce produit au rebut avec les déchets ménagers non triés

4

Page 32

AVERTISSEMENTS ET PRECAUTIONS

Consignes de sécurité

• Le multimètre automobile AU92 est conforme à EN61010-1:2001; CAT III 600 V,

classe 2 et degré de pollution 2.

• Cet appareil est certifié conforme à la norme EN61010-1 pour les installations de

catégorie III (600 V). Il est recommandé pour les installations fixes et les équipements

au niveau distribution, ainsi que pour les installations de catégories inférieures, mais

il n’est pas destiné aux lignes du réseau d’alimentation électrique principale, aux

lignes aériennes ou aux systèmes câblés.

• Ne pas dépasser les limites de surcharge maximum par fonction (voir les caractéristiques techniques) ou les limites indiquées sur l’appareil lui-même. Ne jamais

appliquer plus de 600 V c.c. / 600 V c.a. eff. entre le cordon de mesure et la prise

de terre.

• L’embout de rallonge de sonde TP92 est réservé aux cordons de mesure TL36.

L’embout TP92 est homologué CAT III-1000V / CAT IV-600V. Garder les doigts derrière la collerette de protection.

AVERTISSEMENT

• Avant et après les mesures de tensions dangereuses, tester la fonction de tension sur

une source connue, une tension secteur p. ex., pour déterminer le bon fonctionnement du multimètre.

• Débrancher les cordons de mesure des points de test avant de changer de fonction

sur le multimètre.

• Inspecter la pince ampèremétrique, les cordons de mesure et les accessoires avant

toute utilisation. Ne pas utiliser de pièce endommagée.

• Ne jamais se relier à la terre en prenant des mesures. Ne toucher ni aux éléments de

circuit exposés ni aux pointes des sondes de test.

• Ne pas utiliser l’appareil dans une atmosphère explosive.

• Pour réduire le risque d’incendie ou d’électrocution, ne pas exposer cet appareil à

l’humidité ou à la pluie.

• Le multimètre est destiné à être utilisé à l’intérieur uniquement. Pour éviter les chocs

électriques, observer les précautions de sécurité appropriées en intervenant sur des

tensions supérieures à 60 V c.c. ou à 30 V c.a. eff. Ces niveaux de tension présentent

un risque d’électrocution pour l’utilisateur.

• Avant et après les mesures de tensions dangereuses, tester la fonction de tension sur

une source connue, une tension secteur p. ex., pour déterminer le bon fonctionnement du multimètre.

• Garder les mains/doigts derrière les collerettes de protection qui indiquent les limites

de sécurité du multimètre et des cordons pendant la mesure.

• Inspecter les cordons de mesure, les connecteurs et les sondes pour détecter

l’endommagement de l’isolant ou les parties métalliques exposées avant d’utiliser

l’instrument. Remplacer immédiatement l’élément si des défauts sont détectés.

• Faire preuve d’extrême prudence en : mesurant une tension > 20 V // un courant

5

Page 33

> 10 mA // les lignes d’alimentation secteur avec charges inductives // les lignes

d’alimentation secteur pendant les orages électriques // un courant alors que le

fusible a sauté dans un circuit avec une tension en circuit ouvert > 600 V // lors d’une

intervention sur un appareil à écran cathodique.

• Retirer les cordons de mesure avant d’ouvrir le boîtier pour changer les piles.

• Débrancher l’alimentation du circuit et décharger tous les condensateurs à tension

élevée avant de contrôler la résistance, la continuité, les diodes ou la capacité.

• Pour éviter les mesures erronées qui posent des risques d’électrocution ou de blessure, remplacez les piles dès que l’indicateur d’état de piles faibles apparaît (

Déballage et inspection

Le carton d’emballage doit inclure les éléments suivants :

Multimètre numérique AU92

Sonde à prise de mesure inductive

Jeu de cordons de mesure (un noir, un rouge)

Pointe de rallonge de cordon de mesure (leté un noir, un rouge)

Pinces crocodiles (letées, une noire, une rouge)

Adaptateur de température (TA-1A)

Capteur de température (TP-255A)

Fusible de rechange (500 mA) FP520

Une pile 9 V

Sacoche de transport

Mode d’emploi

Si l’un de ces éléments est endommagé ou manquant, renvoyez le contenu complet de

l’emballage au lieu d’achat pour l’échanger.

).

6

Page 34

FONCTIONNEMENT

Lire la section Consignes de sécurité avant de relever des mesures. Toujours rechercher les

traces d’endommagement, de contamination (impuretés, graisse, etc.) et les défauts sur

l’appareil. Constater l’absence de ssures ou d’isolant efloché sur les cordons de mesure.

Ne tenter aucune mesure en présence de conditions anormales.

Bouton de fonction

de diode. Sélectionne les modes de mesure en volts c.c. ou c.a. Sélectionne les modes de

mesure en courant c.c. ou c.a.

Arrêt automatique

1. Arrêt automatique : environ 10 minutes.

2. Après l’arrêt automatique, appuyez sur un bouton pour redémarrer le multimètre :

le résultat de la mesure relevée est maintenu sur l’affichage.

Désactiver la fonction d’arrêt automatique :

Maintenez la touche [RANGE] enfoncée tout en déplaçant le sélecteur de fonction de la

position OFF pour activer le multimètre. La fonction d’arrêt automatique est désactivée.

L’indicateur « APO » est éteint sur l’écran LCD.

Bouton de maintien d’affichage

Appuyez sur la touche [HOLD] pour verrouiller le résultat afché et relâchez-le en

appuyant une deuxième fois.

Bouton de gamme

Le multimètre possède aussi un mode de gamme manuelle. En gamme manuelle,

sélectionnez et verrouillez le multimètre dans une gamme. Pour sélectionner

manuellement la gamme : Appuyez sur [RANGE] pour maintenir la gamme sélectionnée.

La pression consécutive du bouton [RANGE] sélectionne chaque gamme, de la plus basse

à la plus haute. Maintenez la touche enfoncée pendant 2 secondes pour revenir en mode

de gamme automatique.

Si l’amplitude est inconnue, réglez le multimètre sur la gamme la plus élevée, puis

réduisez-la an d’obtenir une valeur satisfaisante.

Les fonctions afchent RANGE à la première sélection pour indiquer le verrouillage de la

mesure dans une gamme. Quand l’afchage indique RANGE, le multimètre est verrouillé

dans cette gamme.

: Sélectionne les modes de mesure de résistance/continuité et

7

Page 35

Bouton RPM ➊ ➋ : Dans la fonction RPM, le multimètre sélectionne par défaut RPM ➋

pour les moteurs traditionnels à 4 temps. Appuyez sur RPM pour basculer RPM ➊

sur les moteurs à 2 temps ou sur les moteurs à 4 temps à système d’allumage (DIS) à

étincelle perdue.

Mesures RPM (voir fig. 1)

1. Réglez le sélecteur de fonction/gamme sur la gamme RPM souhaitée.

2. Reliez le fil de mesure inductive rouge à la prise « VΩ » et le fil de mesure inductive

noir à la prise « COM ».

3. Branchez la sonde inductive à un fil de bougie. Si aucun résultat n’est obtenu,

détachez la pince, inversez-la et rebranchez-la.

4. Appuyez sur la touche RPM pour basculer entre RPM ➊ sur les moteurs à 2 temps ou

sur les systèmes d’allumage sans distribution (DIS) et RPM ➋ sur les moteurs à 4 temps.

Angle de came (voir fig. 2)

1. Réglez le sélecteur de fonction/gamme sur la gamme de fermeture souhaitée.

2 Reliez le cordon de mesure rouge à la prise « VΩ » et le cordon de mesure noir à la

prise « COM ».

3. Reliez le cordon rouge à la bobine « - » et le cordon noir à la terre.

Mesures de tension (voir fig. 3)

1. Réglez le sélecteur de gamme/fonction sur Voltage V

tion pour sélectionner une tension alternative ou continue AC ou DC.

2. Reliez les cordons de mesure à l’appareil ou au circuit mesuré.

3. Pour le courant continu, un signe (-) indique une polarité négative ; une polarité positive est impliquée.

Mesures de courant (voir fig. 4)

1. Réglez le sélecteur de fonction sur uA, mA, 10A. Utilisez la touche de fonction pour

sélectionner un courant c.a. ou c.c.

2. Reliez le cordon de mesure rouge à la prise (uA, mA ou 10A) et le cordon de mesure

noir à la prise « COM ».

3. Coupez l’alimentation du circuit testé et ouvrez le trajet normal du circuit à l’endroit

où la mesure doit être prise. Branchez le multimètre en série avec le circuit.

4. Mettez sous tension et relevez la valeur affichée.

. Utilisez le sélecteur de fonc-

Mesures de résistance (voir fig. 5)

1. Réglez le sélecteur de fonction sur Ω

sélectionner la résistance Ω.

2. Reliez le cordon de mesure rouge à la prise « VΩ » et le cordon de mesure noir à la

prise « COM ».

3. Coupez l’alimentation de l’équipement testé.

. Utilisez le sélecteur de fonction pour

8

Page 36

4. Reliez les cordons de mesure aux points de mesure et relevez la valeur affichée.

Contrôles de diode (voir fig. 6)

1. Réglez le sélecteur de fonction sur la position « Ω

ction pour sélectionner le contrôle de diode

2. Reliez le cordon de mesure rouge à la prise « VΩ » et le cordon de mesure noir à la

prise « COM ».

3. Mettez le circuit testé hors tension. La présence d’une tension externe aux bornes

des composants entraîne des mesures erronées.

4. Touchez la diode avec les sondes. Une baisse de tension directe est d’environ 0,6 V

(typique pour une diode au silicium).

5. Inversez les sondes. Si la diode est bonne, « OL » apparaît. Si la diode est en

court-circuit, « 0,00 » ou un autre chiffre est affiché.

6. Si la diode est ouverte, « OL » apparaît dans les deux sens.

7. Indication sonore : inférieur à 0,25 Ω.

Mesures de continuité (voir fig. 7)

1. Réglez le sélecteur de fonction sur la position « Ω

fonction sur «

2. Reliez le cordon de mesure rouge à la prise « VΩ » et le cordon de mesure noir à la

prise « COM ».

3. Mettez le circuit testé hors tension. La tension externe aux bornes des composants

entraîne une mesure erronée.

4. Connectez les cordons de mesure aux deux points auxquels la continuité est mesurée. L’avertisseur retentit si la résistance est inférieure à environ 25 Ω.

Mesures de fréquence et de rapport cyclique (voir fig. 8)

1. Réglez le sélecteur de fonction sur la position « Hz » ou « % ».

2. Reliez le cordon de mesure rouge à la prise « VΩ » et le cordon de mesure noir à la

prise « COM ».

3. Connectez les cordons de mesure au point de mesure et relevez la fréquence ou le

rapport cyclique affiché.

».

. » Utilisez la touche de fon-

.

. » Réglez le sélecteur de

Mesures de température (voir fig. 9)

1. Réglez le sélecteur de fonction sur la gamme de température souhaitée: °C, °F.

2. Reliez le thermocouple de type K à l’adaptateur TEMP et branchez-le dans VΩ et

dans COM.

3. Alignez la polarité de l’adaptateur sur celle du thermocouple.

4. Reliez l’adaptateur TEMP aux prises VΩ et COM.

9

Page 37

ENTRETIEN

AVERTISSEMENT

Retirez les cordons de mesure avant de changer la pile ou le fusible ou d’effectuer une

intervention.

Changement des piles (voir fig. 10)

L’alimentation est fournie par une pile de 9 volts. (NEDA 1604, CEI 6F22). Le symbole

» apparaît sur l’écran LCD quand la pile doit être remplacée. Pour remplacer la pile,

«

retirez les trois vis du boîtier dorsal et soulevez la face avant. Retirez la pile au fond

du boîtier.

Dépannage

Si l’appareil ne fonctionne pas correctement, vériez la pile, les fusibles et les cordons de

mesure, etc. et remplacez si nécessaire.

Consultez la section GARANTIE LIMITEE pour obtenir des renseignements sur la garantie

et le service après-vente.

Nettoyage et entreposage

Nettoyez régulièrement le boîtier avec un chiffon humide et du détergent doux.

N’utilisez ni abrasifs, ni solvants. Si le multimètre doit rester inutilisé pendant plus de

60 jours, retirez la pile et rangez-la séparément.

Changement de fusible

Si aucune mesure de courant n’est possible, vériez l’état des fusibles de protection

contre les surcharges. Pour accéder aux fusibles, retirez les trois vis du boîtier dorsal et

soulevez la face avant. Ne remplacez F1 qu’avec un fusible céramique rapide d’origine de

0,5 A / 500 V (FP520), ne remplacez F2 qu’avec un fusible céramique rapide d’origine de

10 A / 500 V (FP540).

10

Page 38

CARACTERISTIQUES GENERALES

Affichage : Afcheur à cristaux liquides (LCD), 3¾ chiffres de résolution et 3999 mesures

maximum.

Polarité : Indication de la polarité négative, à implication positive, automatique.

Dépassement de gamme : (OL) ou (-OL) s’afche.

Zéro : Automatique.

Témoin de pile faible : Le symbole «

» apparaît lorsque la tension de pile passe en

dessous du niveau d’exploitation.

Vitesse de mesure : 2 fois par seconde, nominal.

Arrêt automatique : environ 10 minutes.

Environnement de fonctionnement : de 0 °C à 50 °C à < 70 % HR.

Température d’entreposage : de -20 °C à 60 °C à < 80 % HR.

Précision : Précision déclarée à 23 °C ± 5 °C, < 75 % HR.

Coefficient thermique : 0,1 x (précision spéciée) par °C. (0 °C à 18 °C, 28 °C à 50 °C).

Altitude : 2000 m, à l’intérieur de locaux

Alimentation : Pile standard de 9 volts, NEDA 1604, JIS 006P, CEI 6F22.

Durée de vie de pile : 150 heures en moyenne pour la pile au carbone-zinc.

Dimensions : 165 x 78 x 50 mm (6,5 x 3,1 x 1,9 po)

Poids : environ 315 g (11,1 oz) étui inclus.

Accessoires : Une paire de cordons de mesure, un adaptateur de température, une sonde

à prise de mesure inductive, un thermocouple de type K, un fusible de rechange (0,5 A /

500 V), une pile 9 V (installée) et un mode d’emploi.

Sécurité : Conforme à CEI61010-1 2

e

édition UL61010-1 2e édition CAT III 600 volts c.a.

et c.c. ; classe II ; degré de pollution : 2 ; EN61010-2-032

EMC: Conforme à EN61326-1.

Ce produit est conforme aux exigences des directives suivantes de la Communauté

européenne : 89/ 336/ CEE (Compatibilité électromagnétique) et 73/ 23/ CEE (Basse

tension) modiée par 93/ 68/ CEE (Marquage CE). Toutefois, le bruit électrique ou les

champs électromagnétiques intenses à proximité de l’équipement sont susceptibles de

perturber le circuit de mesure. Les appareils de mesure réagissent également aux signaux

indésirables parfois présents dans le circuit de mesure. Les utilisateurs doivent faire

preuve de prudence et prendre les mesures nécessaires pour éviter les erreurs de mesure

en présence de parasites électromagnétiques.

11

Page 39

CARACTERISTIQUES ELECTRIQUES Précision à 23 °C ± 5 °C, < 75 % H.R.

VOLTS C.C.

Gammes : 400 mV, 4 V, 40 V, 400 V, 600 V

Précision : ± (1,0 % de lecture + 2 chiffres)

Résolution : 0,1 mV

Impédance d’entrée : 400 mV : > 100 MΩ ; 4 V : 10 MΩ ; 40 V à 600 V : 9,1 MΩ

Protection contre les surcharges : 600 Vc.c. ou c.a. eff.

Volts c.a.

Gammes : 400 mV, 4 V, 40 V, 400 V, 600 V

Gamme : Précision :

400 mV (50 à 100 Hz) ± (2,0 % de lecture + 5 chiffres)

4, 40, 400, 600 V (50 à 500 Hz) ± (2,0 % de lecture + 5 chiffres)

Résolution : 0,1 mV

Impédance d’entrée : 400 mV : > 100 MΩ ; 4 V : 10 MΩ ; 40 V à 600 V : 9,1 MΩ

Protection contre les surcharges : 600 V c.c. ou c.a. eff.

COURANT C.C.

Gammes : 400 µA, 4000 µA, 40 mA, 400 mA, 10 A

Gamme : Précision :

Gammes 400 µA à 400 mA : ± (2,0 % de lecture + 2 chiffres)

Gamme 10 A ± (3,0 % de lecture + 3 chiffres)

Entrée 10 A : 10 A pendant un délai de 60 secondes maximum suivi d’une période de

refroidissement de 10 minutes

Résolution : 0,1 µA

Tension de charge : 0,2 V sur les gammes 400 uA, 40 mA

2 V sur les gammes 4000 uA, 400 mA

Protection d’entrée : Fusible céramique rapide de 0,5 A / 500 V (FP520)

Fusible céramique rapide de 10 A / 500 V (FP540)

Courant alternatif

Gammes : 400 uA, 4000 uA, 40 mA, 400 mA, 10 A

Gamme : (50 à 500 Hz) Précision :

Gammes 400 uA à 400 mA ± (2,5 % de lecture + 5 chiffres)

Gamme 10 A ± (3,5 % de lecture + 5 chiffres)

Entrée 10 A : 10 A pendant un délai de 60 secondes maximum suivi d’une période de

refroidissement de 10 minutes

Tension de charge : voir Courant c.c.

Protection d’entrée : voir Courant c.c.

12

Page 40

RESISTANCE

Gammes : 400 Ω, 4 kΩ, 40 kΩ, 400 kΩ, 4 MΩ, 40 MΩ

Résolution : 0,1 Ω sur la gamme 400 Ω

Gamme : Précision :

Gammes 400 Ω à 400 kΩ ± (1,5 % de lecture + 4 chiffres)

Gamme 4 MΩ ± (2,5 % de lecture + 4 chiffres)

Gamme 40 M Ω ± (5,0 % de lecture + 5 chiffres)

Volts en circuit ouvert : -0,45 V c.c. (-1,2 V c.c. sur la gamme 400 Ω)

Protection contre les surcharges : 600 V c.c. ou c.a. eff.

FREQUENCE (Hz) (Gamme automatique)

Gamme : 4 kHz, 40 kHz, 400 kHz

Résolution : 1 Hz

Précision : ± (0,1 % de lecture + 3 chiffres)

Sensibilité : 10 Hz à 400 kHz : > 3,5 V eff.

Largeur d’impulsion minimum : > 2,5 us

Limites du rapport cyclique : > 30 % et < 70 %

Protection contre les surcharges : 600 V c.c. ou c.a. eff.

TEMPERATURE

Gammes : -20 °C à 1000 °C, -4 °F à 1832 °F

Résolution : 0,1 ºC ; 0,1 ºF

Précision : 10 °C ~ 200 °C ± (1,0 % de lecture + 3 °C)

-20 °C ~ 10 °C ± (2.0 % de lecture + 4 °C)

-20 °C ~ 1000 °C ± (3,0 % de lecture + 2 °C)

-4 °F ~ 50 °F ± (2,0 % de lecture - 8 °F)

50 °F ~ 400 °F ± (1,0 % de lecture - 6 °F)

400 °F ~ 1832 °F ± (3,0 % de lecture - 4 °F)

Type de capteur : Thermocouple de type K

Protection contre les surcharges : 600 V c.c. ou c.a. eff.

RPM

Gamme : RPM 600 à 4000 RPM

X10 RPM 4000 ~ 12000 RPM

Résolution : 1 RPM

Précision : ± (2 % de lecture + 4 chiffres)

Mesure de l’effet : 600 RPM

Protection contre les surcharges : 600 V c.c. ou c.a. eff.

13

Page 41

% DE RAPPORT CYCLIQUE

Gamme : 1,0 % ~ 90,0 %

Résolution : 0,1 %

Largeur d’impulsion : > 100 us, < 100 ms

Précision : ± (2 % de lecture + 5 chiffres)

Protection contre les surcharges : 600 V c.c. ou c.a. eff.

ANGLE DE CAME

Nb de cylindres : 4, 5, 6, 8

Gamme : 4 CYL 0 ~ 90,0°

5 CYL 0 ~ 72,0°

6 CYL 0 ~ 60,0°

8 CYL 0 ~ 45,0°

Résolution : 0,1°

Précision : ± (2 % de lecture + 5 chiffres)

Protection contre les surcharges : 600 V c.c. ou c.a. eff.

CONTINUITE

Indication sonore : inférieur à 25 Ω

Temps de réponse : 500 ms

Protection contre les surcharges : 600 V c.c. ou c.a. eff.

TEST DE DIODE

Courant de test : 1,0 mA (approximatif)

Précision : ± (3,0 % de lecture + 3 chiffres)

Résolution : 10 mV

Indication sonore : < 0,25 V

Volts en circuit ouvert : 3,0 V c.c. typique

Protection contre les surcharges : 600 V c.c. ou c.a. eff.

14

Page 42

RPM

Figure 1

15

Page 43

ROUGE

CONTACTS DE RUPTEUR

NOIR

CONDENSATEUR

BOBINE

PILE

CIRCUIT ET CONTACT

D’ALLUMAGE

Angle de came

Figure 2

16

Page 44

Noir Rouge

Tension

Figure 3

17

Page 45

Rouge Noir

Courant

X

Figure 4

18

Page 46

Noir Rouge

Résistance

Figure 5

19

Page 47

Noir Rouge

Diode

Figure 6

20

Page 48

Noir Rouge

Continuité

Figure 7

21

Page 49

Noir Rouge

Fréquence

Rapport

cyclique

Figure 8

22

Page 50

- +

Température

+

-

Figure 9

23

Page 51

SIZE:

NEDA 1604

JIS 006P

IEC 6F22

9V

Changement

des piles

Figure 10

24

Page 52

AU92

Kfz-Multimeter

Deutsch

Page 53

Beschränkte Gewährleistung und Haftungsbeschränkung

Es wird gewährleistet, dass dieses Amprobe-Produkt für die Dauer von einem Jahr ab dem

Kaufdatum frei von Material- und Fertigungsdefekten ist. Diese Gewährleistung erstreckt sich

nicht auf Sicherungen, Einwegbatterien oder Schäden durch Unfälle, Nachlässigkeit, Missbrauch,

Änderungen oder abnormale Betriebsbedingungen bzw. unsachgemäße Handhabung. Die

Verkaufsstellen sind nicht dazu berechtigt, diese Gewährleistung im Namen von Amprobe zu

erweitern. Um während der Gewährleistungsperiode Serviceleistungen in Anspruch zu nehmen, das Produkt mit Kaufnachweis an ein autorisiertes Amprobe Test Tools Service-Center

oder an einen Amprobe-Fachhändler/-Distributor einsenden. Nähere Einzelheiten siehe

Abschnitt „Reparatur“. DIESE GEWÄHRLEISTUNG STELLT DEN EINZIGEN UND ALLEINIGEN

RECHTSANSPRUCH AUF SCHADENERSATZ DAR. ALLE ANDEREN (VERTRAGLICH GEREGELTEN ODER

GESETZLICH VORGESCHRIEBENEN) GEWÄHRLEISTUNGEN, EINSCHLIESSLICH DER GESETZLICHEN

GEWÄHRLEISTUNG DER MARKTFÄHIGKEIT UND DER EIGNUNG FÜR EINEN BESTIMMTEN

ZWECK, WERDEN ABGELEHNT. DER HERSTELLER ÜBERNIMMT KEINE HAFTUNG FÜR SPEZIELLE,

INDIREKTE, NEBEN- ODER FOLGESCHÄDEN ODER FÜR VERLUSTE, DIE AUF BELIEBIGER URSACHE

ODER RECHTSTHEORIE BERUHEN. Weil einige Staaten oder Länder den Ausschluss oder die

Einschränkung einer implizierten Gewährleistung sowie den Ausschluss von Begleit- oder Folgeschäden nicht zulassen, ist diese Gewährleistungsbeschränkung möglicherweise für Sie nicht gültig.

Reparatur

Allen Geräten, die innerhalb oder außerhalb des Garantiezeitraums zur Reparatur oder

Kalibrierung eingesendet werden, müssen mit folgenden Informationen und Dokumenten

versehen werden: Name des Kunden, Firmenname, Adresse, Telefonnummer und Kaufbeleg.

Zusätzlich bitte eine kurze Beschreibung des Problems oder der gewünschten Wartung sowie

die Messleitungen dem Messgerät beilegen. Die Gebühren für außerhalb des Garantiezeitraums

durchgeführteReparaturen oder für den Ersatz von Instrumenten müssen per Scheck,

Zahlunganweisung oder Kreditkarte (Kreditkartennummer mit Ablaufdatum) beglichen werden

oder es muss ein Auftrag auf Rechnung an Amprobe

Reparaturen und Ersatz während des Garantiezeitraums - alle Länder

Bitte die Garantieerklärung lesen und die Batterie prüfen, bevor Reparaturen angefordert

werden. Während der Garantieperiode können alle defekten Geräte zum Umtausch gegen

dasselbe oder ein ähnliches Produkt an den Amprobe

Ein Verzeichnis der zuständigen Distributoren ist im Abschnitt „Where to Buy“ (Verkaufsstellen)

auf der Website www.amprobe.com zu finden. Darüber hinaus können in den USA und in

Kanada Geräte an ein Amprobe® Test Tools Service-Center (siehe Adresse unten) zur Reparatur

oder zum Umtausch eingesendet werden.

Reparaturen und Ersatz außerhalb des Garantiezeitraums - USA und Kanada

Für Reparaturen außerhalb des Garantiezeitraums in den Vereinigten Staaten und in Kanada

werden die Geräte an ein Amprobe® Test Tools Service-Center gesendet. Auskunft über die

derzeit geltenden Reparatur- und Austauschgebühren erhalten Sie von Amprobe® Test Tools

oder der Verkaufsstelle.

In den USA In Kanada

Amprobe Test Tools Amprobe Test Tools

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel.: 877-AMPROBE (267-7623) Tel.: 905-890-7600

Reparaturen und Austausch außerhalb des Garantiezeitraums - Europa

Geräte mit abgelaufener Garantie können durch den zuständigen Amprobe® Test ToolsDistributor gegen eine Gebühr ersetzt werden. Ein Verzeichnis der zuständigen Distributoren ist

im Abschnitt „Where to Buy“ (Verkaufsstellen) auf der Website www.amprobe.com zu finden.

Korrespondenzanschrift für Europa*

Amprobe

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

*(Nur Korrespondenz – keine Reparaturen und kein Umtausch unter dieser Anschrift. Kunden in

Europa wenden sich an den zuständigen Distributor.)

®

Test Tools Europe

®

Test Tools formuliert werden.

®

Test Tools-Distributor gesendet werden.

1

Page 54

RPM

DC/AC

Ω

/ /

COM

10A

μ

A mA

RANGE

HOLD

Hz

Mk

Ω

AC

DC

RANGE

APO

HOLD

mVA

μ

RPM

X10RPM

%

400

1000

1832

DUTY

10A

Hz

mA

6CYL

8CYL

400

A

5CYL

OFF

V

X10RPM

RPM

Ω

4CYL

μ

DWELL

%

CAT.III

MAX

600V

600V

MAX

FUSED

MAX

FUSED

400mA

10A/60sec

AUTOMOTIVE METER

AU92

℉

℉

℃

℃

℃

RPM

VΩ

℃ ℉

℉

➓

➊

➋

➌

➒

➑

➊ 4 Stellen LCD mit Funktionsanzeige

➐

HOLD-Taste (Datenhaltemodus)

➋

Widerstand- / Kontinuität- / Dioden- und AC/DC-Taste

➌

Funktion- / Bereichsauswahl-Drehschalter

➍

COM-Eingang

➎

Temperatur- / Volt- / Ohm- / Drehzahl- / Schließwinkel-Eingang

➏

10-Ampere-Eingang

➐

uA-, mA-Eingang

➑

RPM-Taste (Drehzahl)

➒

➓

RANGE-Taste (Bereichsfixierung)

➍

➎

➏

2

Page 55

AU92 Automotive Multimeter

Inhalt

Symbole .............................................................................................................................................. 4

Einleitung ........................................................................................................................................... 4

Warn- und Vorsichtshinweise ............................................................................................................ 5

Auspacken und Überprüfen .............................................................................................................. 6

Messverfahren .................................................................................................................................... 3

Wartung ............................................................................................................................................ 10

Fehlerbehebung .................................................................................................................... 10

Ersetzen der Batterie ............................................................................................................. 10

Allgemeine Spezikationen ............................................................................................................ 11

3

Page 56

SYMBOLE

Einleitung

Das AU92 ist ein digitales Messgerät für Kfz-Anwendungen und misst Wechsel- und

Gleichspannung, Wechsel- und Gleichstromstärke, Widerstand, Kontinuität, Dioden,

Schließwinkel, RPM, %-Tastgrad und Temperatur.

Vorsicht! Siehe Erklärung in diesem Handbuch

Vorsicht! Stromschlaggefahr

Erde, Masse

Schutzisolierung oder verstärkte Isolierung

Wechselstrom (AC - Alternating Current)

Gleichstrom (DC - Direct Current)

Übereinstimmung mit den relevanten australischen Normen

Underwriters Laboratories Inc. [Hinweis: Kanada und USA]

Übereinstimmung mit EU-Vorschriften

Dieses Produkt nicht im unsortierten Kommunalabfall entsorgen.

4

Page 57

Warnungen und Sicherheitshinweise

Sicherheitsinformationen

• Das AU92 Kfz-Messgerät stimmt mit EN61010-1:2001, CAT III 600 V, Klasse 2 und

Verschmutzungsgrad 2 überein.

• Dieses Messgerät ist EN61010-1-zertifiziert für Installationskategorie III (600 V).

Es wird zum Gebrauch auf Verteilungsebene und in Festinstallationen sowie

auch in untergeordneten Installationen empfohlen, nicht jedoch für primäre

Stromverteilung, Hochspannungsleitungen und Kabelsysteme.

• Die maximalen Überlastungsgrenzen der einzelnen Funktionen (siehe technische

Daten) und die auf dem Instrument markierten Grenzwerte nicht überschreiten.

Zwischen Messleitung und Masse niemals mehr als 600 V Gleichspannung oder 600 V

Wechselspannung eff. anlegen.

• Die Verlängerungs-Sondenspitze TP92 ist nur zur Verwendung mit TL36 Prüfkabeln

vorgesehen. Die TP92-Spitze stimmt mit CAT III-1000V / CAT IV-600V überein. Finger

hinter dem Schutzring halten.

ACHTUNG

• Vor und nach gefährlichen Spannungsmessungen die Spannungsfunktion an einer

bekannten Quelle, z. B. Netzspannung, testen, um die Funktionstüchtigkeit des

Messgeräts zu prüfen.

• Die Messleitungen vor dem Wechseln von Messgerätfunktionen von den

Prüfpunkten trennen.

• Vor jedem Gebrauch das Zangenmessgerät, die Messleitungen und das Zubehör prüfen. Keine beschädigten Teile verwenden.

• Sich selbst isolieren, wenn Messungen durchgeführt werden. Keine freiliegenden

Schaltungselemente oder Prüfspitzen/Messleitungen berühren.

• Das Messgerät nicht in Umgebungen mit explosiven Gasen betreiben.

• Um das Risiko von Feuer und Stromschlag zu verringern, dieses Produkt nicht Regen

oder Feuchtigkeit aussetzen.

• Das Messgerät ist ausschließlich für Gebrauch in Gebäuden konzipiert. Zur

Vermeidung von Stromschlaggefahr bei Arbeiten mit Spannungen oberhalb 60 V

Gleichspannung bzw. 30 V Wechselspannung eff. die ordnungsgemäßen Sicherheitsvorkehrungen einhalten. Diese Spannungen stellen eine Stromschlaggefahr für den

Bediener dar.

• Vor und nach gefährlichen Spannungsmessungen die Spannungsfunktion an einer

bekannten Quelle, z. B. Netzspannung, testen, um die Funktionsfähigkeit des

Messgeräts zu prüfen.

• Die Hände/Finger stets hinter dem Hand-/Fingerschutz (des Messgeräts und der

Messleitungen) halten, der die Grenzen sicherer Berührung des handgehaltenen

Teils während Messungen angibt.

• Vor jedem Gebrauch die Messleitungen, Anschlüsse und Sonden bezüglich beschädigter Isolierung und exponiertem Metall untersuchen. Falls ein Defekt festgestellt

wird, das entsprechende Teil unverzüglich ersetzen.

5

Page 58

• In den folgenden Situationen besonders vorsichtig vorgehen: Messung von

Spannung > 20 V // Stromstärke > 10 mA // Wechselspannungsleitungen mit

Induktivlasten // Wechselspannungsleitungen während Gewittern // Strom mit einer

durchgebrannten Sicherung in einem Schaltkreis mit Leerlaufspannung > 600 V // bei

der Wartung von Kathodenröhrengeräten.

• Vor dem Öffnen des Gehäuses zum Auswechseln der Batterie die Messleitungen

entfernen.

• Vor dem Prüfen von Widerstand, Kontinuität, Dioden oder Kapazität den Strom des

Stromkreises ausschalten und alle Hochspannungskondensatoren entladen.

• Zur Vermeidung falscher Ablesungen, die zu Stromschlag oder Verletzungen führen

können, die Batterie ersetzen, sobald das Symbol für schwache Batterie (

geblendet wird.

Auspacken und Überprüfen

Der Verpackungskarton sollte Folgendes enthalten:

AU92 Digitales Messgerät

Induktive Messsonde

Messleitungssatz (1 schwarz, 1 rot)

Messleitungsverlängerungsspitze (mit Gewinde - 1 schwarz, 1 rot)

Krokodilklemmen (mit Gewinde - 1 schwarz, 1 rot)

Temperaturadapter (TA-1A)

Temperatursensor (TP-255A)

Ersatzsicherung (500 mA) FP520

Eine (1) 9-V-Batterie

Tragbehälter

Bedienungshandbuch

Wenn einer dieser Artikel beschädigt ist oder fehlt, die gesamte Lieferung zwecks Ersatz

an die Verkaufsstelle zurücksenden.

) ein-

6

Page 59

BEDIENUNG

Vor der Durchführung von Messungen den Abschnitt „Sicherheitsinformationen“

durchlesen. Das Messgerät stets auf Beschädigung, Verunreinigung (übermäßiger

Schmutz, Fett usw.) und Defekte untersuchen. Die Messleitungen auf rissige oder

anderweitig beschädigte Isolierung untersuchen. Falls abnormale Umstände herrschen,

nicht versuchen, Messungen durchzuführen.

Funktionstaste

bzw. Wechselspannungsmodus aus. Wählt Gleich- bzw. Wechselstrommodus aus.

Automatische Abschaltung

1. Auto Power Off: ungefähr 10 Minuten.

2. Nach automatischer Ausschaltung eine beliebige Taste drücken, um das Messgerät

neu zu starten. Der Messwert bleibt auf der Anzeige erhalten.

Automatische Ausschaltfunktion (APO):

Die RANGE-Taste drücken und gedrückt halten und gleichzeitig den Funktionsschalter

von OFF in eine beliebige Position schalten Die automatische Ausschaltfunktion (APO) ist

deaktiviert. Das APO-Symbol auf der LCD wird ausgeblendet.

HOLD-Taste (Datenhaltemodus)

Die HOLD-Taste drücken, um den Messwert auf der Anzeige festzuhalten, und die Taste

erneut drücken, um den Wert wieder freizugeben.

RANGE-Taste

Das Messgerät verfügt auch über manuelle Bereichswahl. Bei manueller Bereichswahl

wird ein Bereich ausgewählt und das Messgerät wird in diesem Bereich xiert. Manuelles

Auswählen eines Bereichs: Die RANGE-Taste drücken, um den ausgewählten Bereich zu

halten. Wiederholtes Drücken der RANGE-Taste wählt jeden verfügbaren Bereich der

Reihe nach vom niedrigsten bis zum höchsten Bereich aus. Die Taste 2 Sekunden gedrückt

halten, um zur automatischen Bereichswahl zurückzukehren.

Falls die Größe unbekannt ist, das Messgerät auf den höchsten Bereich einstellen und

dann den Bereich reduzieren, bis ein zufriedenstellender Messwert erzielt wird.

Funktionen, die RANGE einblenden, wenn sie ausgewählt werden, geben an, dass die

RANGE-Messung xiert ist. Wenn immer RANGE angezeigt wird, gibt dies an, dass das

Messgerät in diesem Bereich xiert ist.

: Wählt Ohm/Kontinuitäts- und Dioden-Modus aus. Wählt Gleich-

7

Page 60

Taste RPM ➊ ➋ : In der RPM-Funktion schaltet das Messgerät standardmäßig auf RPM ➋

für herkömmliche 4-Takt-Motoren. Die RPM-Taste drücken, um auf RPM ➊ für 2-TaktMotoren oder Zündsystem-4-Takt-Motoren (DIS) zu schalten

RPM-Messung (siehe Abb. 1)

1. Den Funktions-/Bereichsschalter auf den gewünschten Drehzahlbereich einstellen.

2. Die rote induktive Messsonde an die Buchse VΩ und die schwarze induktive Messsonde

an die Buchse COM anschließen.

3. Die induktive Messsonde an ein Zündkerzenkabel anschließen. Wenn kein Messwert

erzielt wird, die Zange abnehmen, umkehren und wieder anlegen.

4. Die RPM-Taste drücken, um zwischen RPM ➊ für 2-Takt-Motoren und verteilerlose

Zündsysteme (DIS) und RPM ➋ für 4-Takt-Motoren umzuschalten.

Schließwinkel (siehe Abb. 2)

1. Den Funktions-/Bereichsschalter auf den gewünschten Schließwinkelbereich einstellen.

2 Die rote Messleitung an die Buchse VΩ und die schwarze Messleitung an die Buchse

COM anschließen.

3. Die rote Messleitung an Spule „-“ und die schwarze Messleitung an Erde anschließen.

Spannungsmessung (siehe Abb. 3)

1. Den Funktions-/Bereichsdrehschalter auf V

den, um Wechselspannung (AC) oder Gleichspannung (DC) auszuwählen.

2. Die Messleitungen an das zu messende Gerät bzw. den zu messenden Stromkreis

anschließen.

3. Für Gleichspannung (DC) wird ein Minuszeichen (-) für negative Polarität angezeigt.

Positive Polarität wird impliziert.

Stromstärkemessung (siehe Abb. 4)

1. Den Funktionsdrehschalter auf uA, mA oder 10A einstellen. Die Funktionstaste verwenden, um Wechselstrom (AC) oder Gleichstrom (DC) auszuwählen.

2. Die rote Messleitung an die Buchse uA, mA oder 10A und die schwarze Messleitung an

die Buchse COM anschließen.

3. Den Strom vom zu prüfenden Stromkreis entfernen und den normalen Strompfad an

der Stelle öffnen, an der die Messung erfolgen soll. Das Messgerät mit dem Stromkreis

in Reihe schalten.

4. Strom anlegen und den Wert von der Anzeige ablesen.

einstellen. Die Funktionstaste verwen-

Widerstandsmessung (siehe Abb. 5)

1. Den Funktionsdrehschalter auf Ω

Ohm Ω auszuwählen.

2. Die rote Messleitung an die Buchse VΩ und die schwarze Messleitung an die Buchse

COM anschließen.

3. Den Strom vom zu prüfenden Gerät trennen.

einstellen. Die Funktionstaste verwenden, um

8

Page 61

4. Die Messleitungen an die Messpunkte anschließen und den Wert von der Anzeige

ablesen.

Diodenprüfung (siehe Abb. 6)

1. Den Funktionsdrehschalter auf die Position Ω einstellen. Die Funktionstaste

verwenden, um Diodenprüfung auszuwählen

2. Die rote Messleitung an die Buchse VΩ und die schwarze Messleitung an die Buchse

COM anschließen.

3. Die Stromversorgung des zu prüfenden Stromkreises ausschalten. Externe Spannung

über den Komponenten verursacht ungültige Messwerte.

4. Mit den Sonden die Diode berühren. Ein Vorwärtsspannungsabfall beträgt ungefähr

0,6 V (typisch für eine Silikondiode).

5. Sonden umkehren. Wenn die Diode in Ordnung ist, wird OL angezeigt. Wenn die

Diode kurzgeschlossen ist, wird 0,00 oder eine andere Zahl angezeigt.

6. Wenn die Diode offen ist, wird OL in beiden Richtungen angezeigt.

7. Akustische Anzeige: Weniger als 0,25 Ω.

Kontinuitätsmessung (siehe Abb. 7)

1. Den Funktionsdrehschalter in die Position Ω

stellen.

2. Die rote Messleitung an die Buchse VΩ und die schwarze Messleitung an die Buchse

COM anschließen.

3. Die Stromversorgung des zu prüfenden Stromkreises ausschalten. Externe Spannung

über den Komponenten verursacht ungültige Messwerte.

4. Die Messleitungen an die zwei Punkte anschließen, an denen Kontinuität gemessen

werden soll. Der Summer ertönt, wenn der Widerstand kleiner als ungefähr 25 Ω ist.

Frequenz- und Tastgradmessung (siehe Abb. 8)

1. Den Funktionsdrehschalter auf die Position Hz oder % einstellen.

2. Die rote Messleitung an die Buchse VΩ und die schwarze Messleitung an die Buchse

COM anschließen.

3. Die Messleitungen an die Messpunkte anschließen und die Frequenz bzw. den

Tastgrad von der Anzeige ablesen.

.

stellen. Die Funktionstaste auf

Temperaturmessung (siehe Abb. 9)

1. Den Funktionsdrehschalter auf den gewünschten Temperaturbereich einstellen: °C, °F.

2. Das Thermoelement-Typ-K an den TEMP-Adapter und dann an VΩ und COM

anschließen.

3. Die Polarität des Adapters an die Polarität des Thermoelements anpassen.

4. Den TEMP-Adapter an die Buchsen VΩ und COM anschließen.

9

Page 62

WARTUNG

WARNUNG

Vor dem Ersetzen der Batterie oder Sicherung bzw. vor dem Durchführen von

Servicearbeiten die Messleitungen entfernen.

Batterie ersetzen (siehe Abb. 10)

Strom wird durch eine 9-Volt-Batterie geliefert. (NEDA 1604, IEC 6F22). „

auf der LCD-Anzeige, wenn die Batterien ausgewechselt werden müssen. Um die Batterie

zu ersetzen, die drei Schrauben von der Rückseite des Messgeräts entfernen und die

Rückseite von der Gehäusevorderseite abheben. Die Batterie aus dem Gehäuseunterteil

entfernen.

Fehlerbehebung

Wenn das Gerät nicht korrekt funktioniert, die Batterie, die Sicherungen und die

Messleitungen prüfen und ggf. ersetzen.

Für Garantieansprüche oder Reparaturservice siehe Abschnitt BESCHRÄNKTE

GEWÄHRLEISTUNG.

Reinigung und Aufbewahrung

Das Gehäuse von Zeit zu Zeit mit einem feuchten Tuch und mildem Reinigungsmittel

abwischen. Keine Scheuer- oder Lösungsmittel verwenden. Wenn das Messgerät

für 60 Tage oder länger nicht verwendet wird, die Batterie entfernen und getrennt

aufbewahren.

Sicherung ersetzen

Wenn keine Strommessungen möglich sind, prüfen, ob eine Überlastschutzsicherung

durchgebrannt ist. Um die Sicherungen zu ersetzen, die drei Schrauben von der

Rückseite des Messgeräts entfernen und die Rückseite von der Gehäusevorderseite

abheben. F1 ausschließlich mit dem ursprünglichen Typ 0,5 A / 500 V (FP520), inke

Keramiksicherung ersetzen. F2 ausschließlich mit dem ursprünglichen Typ 10 A / 500 V

(FP540), inke Keramiksicherung ersetzen.

“ erscheint

10

Page 63

ALLGEMEINE TECHNISCHE DATEN

Anzeige: Flüssigkristallanzeige (LCD) mit 3¾ Stellen, mit Maximalanzeige von 3999.

Polarität: Automatisch, positiv = Standard, negativ = Anzeiger.

Überlast: (OL) oder (-OL) wird angezeigt.

Null: Automatisch.

Anzeige für schwache Batterie: „

den Betriebswert abfällt.

Messintervall: 2 mal pro Sekunde, Nennwert.

Auto Power Off: Ungefähr 10 Minuten.

Betriebsbereich: 0 °C bis 50 °C bei < 70 % RH.

Lagertemperatur: -20 °C bis 60 °C bei < 80 % RH.

Genauigkeit: Nenngenauigkeit bei 23 °C ± 5 °C, < 75 % RH.

Temperaturkoeffizient: 0,1 x (spezizierte Genauigkeit) / °C. (0 °C bis 18 °C, 28 °C bis 50 °C).

Höhenlage: 2000 m, Innenverwendung

Speisung: Standard-9-V-Batterie, NEDA 1604, JIS 006P, IEC 6F22.

Battery life: 150 Stunden, typisch, mit Zink-Kohle.

Abmessungen: 165 x 78 x 50 mm

Gewicht: Ungefähr 315 g, einschließlich Holster.

Zubehör: 1 Paar Messleitungen, Temperaturadapter, induktive Messsonde,

Thermoelement-Typ-K, 1 Ersatzsicherung (0,5 A / 500 V), 9-V-Batterie (eingelegt),

Bedienungshandbuch.

“ wird angezeigt, wenn die Batteriespannung unter

Sicherheit : Erfüllt IEC61010-1 2. Ausgabe, UL61010-1 2. Ausgabe. CAT III-600 Volt AC

und DC; Klasse II; Verschmutzungsgrad: 2; EN61010-2-032

EMC (elektromagnetische Verträglichkeit): Stimmt überein mit EN61326-1.

Dieses Produkt erfüllt die Anforderungen der folgenden EU-Richtlinien:

89/ 336/ EEC (Elektromagnetische Verträglichkeit) und 73/ 23/ EEC (Niederspannung)

mit dem Zusatz 93/ 68/ EEC (CE-Kennzeichnung). Elektrisches Rauschen oder intensive

elektromagnetische Felder in der Nähe des Geräts können jedoch den Messschaltkreis

stören. Messinstrumente reagieren auch auf unerwünschte Impulse/Signale, die unter

Umständen im Messschaltkreis vorkommen. Die Benutzer müssen die nötige Sorgfalt

walten lassen und geeignete Vorkehrungen treffen, um irreführende Ergebnisse bei

Messungen bei Vorhandensein elektrischer Störeinüsse zu vermeiden.

11

Page 64

ELEKTRISCHE SPEZIFIKATION Genauigkeit bei 23 °C ± 5 °C, < 75 % RH

DC VOLT

Bereiche: 400 mV, 4 V, 40 V, 400 V, 600 V

Genauigkeit: ± (1,0 % Anzeige + 2 Stellen)

Auflösung: 0,1 mV

Eingangsimpedanz: 400 mV: >100 MΩ; 4 V: 10 MΩ; 40 V ~ 600 V: 9,1 MΩ

Überlastschutz: 600 V DC oder AC eff.

AC VOLT

Bereiche: 400 mV, 4 V, 40 V, 400 V, 600 V

Bereich: Genauigkeit:

400 mV (50 ~ 100 Hz) ± (2,0 % Anzeige + 5 Stellen)

4, 40, 400, 600 V (50 ~ 500 Hz) ± (2,0 % Anzeige + 5 Stellen)

Auflösung: 0,1 mV

Eingangsimpedanz: 400 mV: > 100 MΩ; 4 V: 10 MΩ; 40 V ~ 600 V: 9,1 MΩ

Überlastschutz: 600 V DC oder AC eff.

GLEICHSTROM (DC - DIRECT CURRENT)

Bereiche: 400 µA, 4000 µA, 40 mA, 400 mA, 10 A

Bereich: Genauigkeit:

400 µA bis 400 mA Bereiche ± (2,0 % Anzeige + 2 Stellen)

10 A Bereich ± (3,0 % Anzeige + 3 Stellen)

10A Eingang: 10 A für 60 Sekunden maximal, gefolgt von einer 10 Minuten

Abkühlperiode

Auflösung: 0,1 µA

Spannungsbürde: 0,2 V auf 400 uA, 40 mA Bereichen;

2 V auf 4000 uA, 400 mA Bereichen

Eingangsschutz: 0,5 A / 500 V, flinke Keramiksicherung (FP520)

10 A / 500 V, flinke Keramiksicherung (FP540)

WECHSELSTROM

Bereiche: 400 µA, 4000 µA, 40 mA, 400 mA, 10 A

Bereich: (50 ~ 500 Hz) Genauigkeit:

400 uA bis 400 mA Bereiche ± (2,5 % Anzeige + 5 Stellen)

10 A Bereich ± (3,5 % Anzeige + 5 Stellen)

10A Eingang: 10 A für 60 Sekunden maximal, gefolgt von einer 10 Minuten

Abkühlperiode

Spannungsbürde: siehe DC Strom

Eingangsschutz: siehe DC Strom

12

Page 65

WIDERSTAND

Bereiche: 400 Ω, 4 kΩ, 40 kΩ, 400 kΩ, 4 MΩ, 40 MΩ

Auflösung: 0,1 Ω auf 400 Ω Bereich

Bereich: Genauigkeit:

400 Ω bis 400 kΩ Bereiche ± (1,5 % Anzeige + 4 Stellen)

4 MΩ Bereich ± (2,5 % Anzeige + 4 Stellen)

40 MΩ Bereich ± (5,0 % Anzeige + 5 Stellen)

Spannung in unterbrochenen

Schaltkreisen: -0,45 V DC (-1,2 V DC auf 400 Ω Bereich)

Überlastschutz: 600 V DC oder AC eff.

FREQUENZ (Hz) (automatische Bereichswahl)

Bereich: 4 kHz, 40 kHz, 400 kHz

Auflösung: 1 Hz

Genauigkeit: ± (0,1 % Anzeige + 3 Stellen)

Frequenzempfindlichkeit: 10 Hz ~ 400 kHz: > 3,5 V eff.

Mindest-Impulsbreite: > 2,5 us

Arbeitszykluslimits: > 30 % und < 70 %

Überlastschutz: 600 V DC oder AC eff.

TEMPERATUR

Bereiche: -20 °C ~ 1000 °C, -4 °F ~ 1832 °F

Auflösung: 0,1 °C, 0,1 °F

Genauigkeit: 10 °C ~ 200 °C ± (1,0 % Anzeige + 3 °C)

-20 °C ~ 10 °C ± (2,0 % Anzeige + 4 °C)

200 °C ~ 1000 °C ± (3,0 % Anzeige + 2 °C)

-4 °F ~ 50 °F ± (2,0 % Anzeige + 8 °F)

50 °F ~ 400 °F ± (1,0 % Anzeige + 6 °F)

400 °F ~ 1832 °F ± (3,0 % Anzeige + 4 °F)

Sensortyp: K-Thermoelement

Überlastschutz: 600 V DC oder AC eff.

RPM

Bereich: RPM 600 ~ 4000 RPM

X10 RPM 4000 ~ 12000 RPM

Auflösung: 1 RPM

Genauigkeit: ± (2 % Anzeige + 4 Stellen)

Wirkung: > 600 RPM

Überlastschutz: 600 V DC oder AC eff.

13

Page 66

% TASTGRAD

Bereich: 1,0 % ~ 90,0 %

Auflösung: 0,1 %

Impulsbreite: > 100 us, < 100 ms

Genauigkeit: ± (2 % Anzeige + 5 Stellen)

Überlastschutz: 600 V DC oder AC eff.

SCHLIESSWINKEL

Anzahl Zylinder 4, 5, 6, 8

Bereich: 4 ZYL 0 ~ 90,0°

5 ZYL 0 ~ 72,0°

6 ZYL 0 ~ 60,0°

8 ZYL 0 ~ 45,0°

Auflösung: 0,1°

Genauigkeit: ± (2 % Anzeige + 5 Stellen)

Überlastschutz: 600 V DC oder AC eff.

KONTINUITÄT

Akustische Anzeige: Weniger als 25 Ω

Ansprechzeit: 500 ms

Überlastschutz: 600 V DC oder AC eff.

DIODENPRÜFUNG