Page 1

SLM Series Plug-in DC

Electronic Load

Module

Operating Manual

M540071-01 Rev C www.programmablepower.com

Page 2

Page 3

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse

industrial segments. From bench top supplies to rack-mounted industrial power subsystems,

AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen, California

Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromec hanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working

at more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc.

Other trademarks, registered trademarks, and product names are the property of their respective

owners and are used herein for identification purposes only.

Notice of Copyright

SLM Series Plug-in DC Electronic Load Module Operating Manual

Programmable Power, Inc. All rights reserved.

© August 2008 AMETEK

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL,

WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH

INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE

TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK CONTENT

IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION, WHICH IS POSTED AT

WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

August 2008 Revision C

Part Number

M540071-01

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

i

Page 4

This page intentionally left blank.

ii

Page 5

G

G

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

WARNIN

WARNIN

Only qualified personnel who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance

equipment must be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must

ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary

sales organizations can accept any responsibility for personnel, material or inconsequential injury,

loss or damage that results from improper use of the equipment and accessories.

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above

(below) chassis ground.

The equipment used contains ESD sensitive ports. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

SAFETY SYMBOLS

iii

Page 6

This page intentionally left blank.

iv

Page 7

Product Family: SLM Series Plug-in DC Electronic Load Module

Warranty Period: One Year

WARRANTY TERMS

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the

Product stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect in

material or workmanship within the applicable warranty period stated above, then AMETEK may,

at its option: repair or replace the Product; or issue a credit note for the defective Product; or

provide the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in

accordance with the return procedure specified below. AMETEK will, at its expense, deliver the

repaired or replaced Product or parts to the Buyer. Any warranty of AMETEK will not apply if the

Buyer is in default under the Purchase Order Agreement or where the Product or any part

thereof:

• is damaged by misuse, accident, negligence or failure to maintain the same as

specified or required by AMETEK;

• is damaged by modifications, alterations or attachments thereto which are not

authorized by AMETEK;

• is installed or operated contrary to the instructions of AMETEK;

• is opened, modified or disassembled in any way without AMETEK’s consent; or

• is used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty

until the Buyer has made all payments to AMETEK provided for in the Purchase Order Agreement.

PRODUCT RETURN PROCEDURE

1. Request a Return Material Authorization (RMA) number from the repair facility (must be

done in the country in which it was purchased):

• In the USA, contact the AMETEK Repair Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

• Outside the United States, contact the nearest Authorized Service Center

(ASC). A full listing can be found either through your local distributor or our

website, www.programmablepower.com, by clicking Support and going to the

Service Centers tab.

2. When requesting an RMA, have the following information ready:

• Model number

• Serial number

• Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject to

an evaluation fee and applicable freight charges.

v

Page 8

This page intentionally left blank.

vi

Page 9

Important Safety Instructions

This manual has been written expressly for the Sorensen brand SL series of electronic loads, which

have been designed and certified to meet the Low Voltage and Electromagnetic Compatibility Directive

Requirements of the European Community.

Since the goal of the Low Voltage Directive is to ensure the safety of the equipment operator, universal

graphic symbols have been used both on the unit itself and in this manual to warn the operator of

potentially hazardous situations (see Safety Symbols on page ii).

v

Page 10

CONTENTS

SECTION 1 Introduction, Features and Specifications ...........................................................1-1

1.1 GENERAL DESCRIPTION .....................................................................................................................1-1

1.1.1 POWER CONTOURS.............................................................................................................. 1-1

1.1.2 OPERATING MODES .............................................................................................................1-4

1.2 FEATURES...............................................................................................................................................1-7

1.2.1 ACCESSORIES........................................................................................................................1-7

1.3 MODULE SPECIFICATIONS .................................................................................................................1-8

1.4 REGULATORY COMPLIANCE.............................................................................................................1-9

1.5 BLOCK DIAGRAM..................................................................................................................................1-9

SECTION 2 Installation and Maintenance.................................................................................2-1

2.1 INSTALLATION AND REMOVAL OF SLM-SERIES DC PLUG IN MODULE..............................2-2

2.1.1 INSTALLATION ........................................................................................................................2-2

2.1.2 REMOVAL .................................................................................................................................2-3

2.2 CONNECTIONS.......................................................................................................................................2-3

2.2.1 INPUT BINDING POST AND WIRE CONSIDERATIONS .................................................2-3

2.2.2 TYPICAL CONNECTIONS .....................................................................................................2-4

2.2.3 THE CONNECTION FOR A MULTIPLE OUTPUT POWER SUPPLY ............................2-4

2.3 MAINTENANCE.......................................................................................................................................2-5

2.3.1 CLEANING AND STORAGE ..................................................................................................2-5

SECTION 3 Operation.................................................................................................................3-1

3.1 FRONT PANEL CONTROLS AND INDICATORS.............................................................................3-1

3.1.1 DESCRIPTION ......................................................................................................................... 3-1

3.1.2 SUMMARY CHART .................................................................................................................3-6

vi

Page 11

3.2 OPERATION – SETUP AND OCP/OPP TESTS................................................................................3-7

3.2.1 OVERVIEW OF FRONT PANEL OPERATION................................................................... 3-7

3.2.2 INITIAL SETUP (LIMIT KEY).................................................................................................. 3-7

3.2.3 NORMAL OPERATING MODES .........................................................................................3-11

3.2.4 INITIAL SETTING OF SLM-SERIES DC LOAD MODULES ...........................................3-16

3.2.5 ANALOG PROGRAMMING INPUT.....................................................................................3-16

3.2.6 LOAD COARSE/FINE INCREASE/DECREASE ADJUSTMENT KEY ..........................3-17

3.2.7 I-MONITOR .............................................................................................................................3-18

3.2.8 PROTECTION FEATURES ..................................................................................................3-19

SECTION 4 Applications.............................................................................................................4-1

4.1 LOCAL SENSE CONNECTIONS..........................................................................................................4-1

4.2 REMOTE SENSE CONNECTIONS ......................................................................................................4-2

4.3 CONSTANT CURRENT (CC) MODE APPLICATION.......................................................................4-3

4.3.1 STATIC MODE: ........................................................................................................................4-3

4.3.2 DYNAMIC MODE: ....................................................................................................................4-4

4.4 CONSTANT VOLTAGE (CV) MODE APPLICATION .......................................................................4-5

4.5 CONSTANT RESISTANCE (CR) MODE APPLICATION.................................................................4-6

4.6 CONSTANT POWER (CP) MODE APPLICATION............................................................................4-7

4.7 PARALLEL OPERATION ......................................................................................................................4-8

SECTION 5 Remote Programming.............................................................................................5-1

5.1 GPIB COMMANDS ..................................................................................................................................5-1

5.2 RS-232 INTERFACE AND COMMANDS ............................................................................................5-1

5.3 GPIB/RS-232C COMMAND LIST.........................................................................................................5-2

5.3.1 COMMAND SYNTAX ABBREVIATIONS ............................................................................. 5-2

5.4 GPIB/RS-232 COMMAND DESCRIPTION .........................................................................................5-7

5.4.1 SETTING COMMANDS ..........................................................................................................5-7

5.4.2 QUERY COMMANDS............................................................................................................5-20

APPENDIX A SLM-SERIES DC LOAD GPIB/RS-232 OPERATING FLOW CHART......A

LIST of TABLES

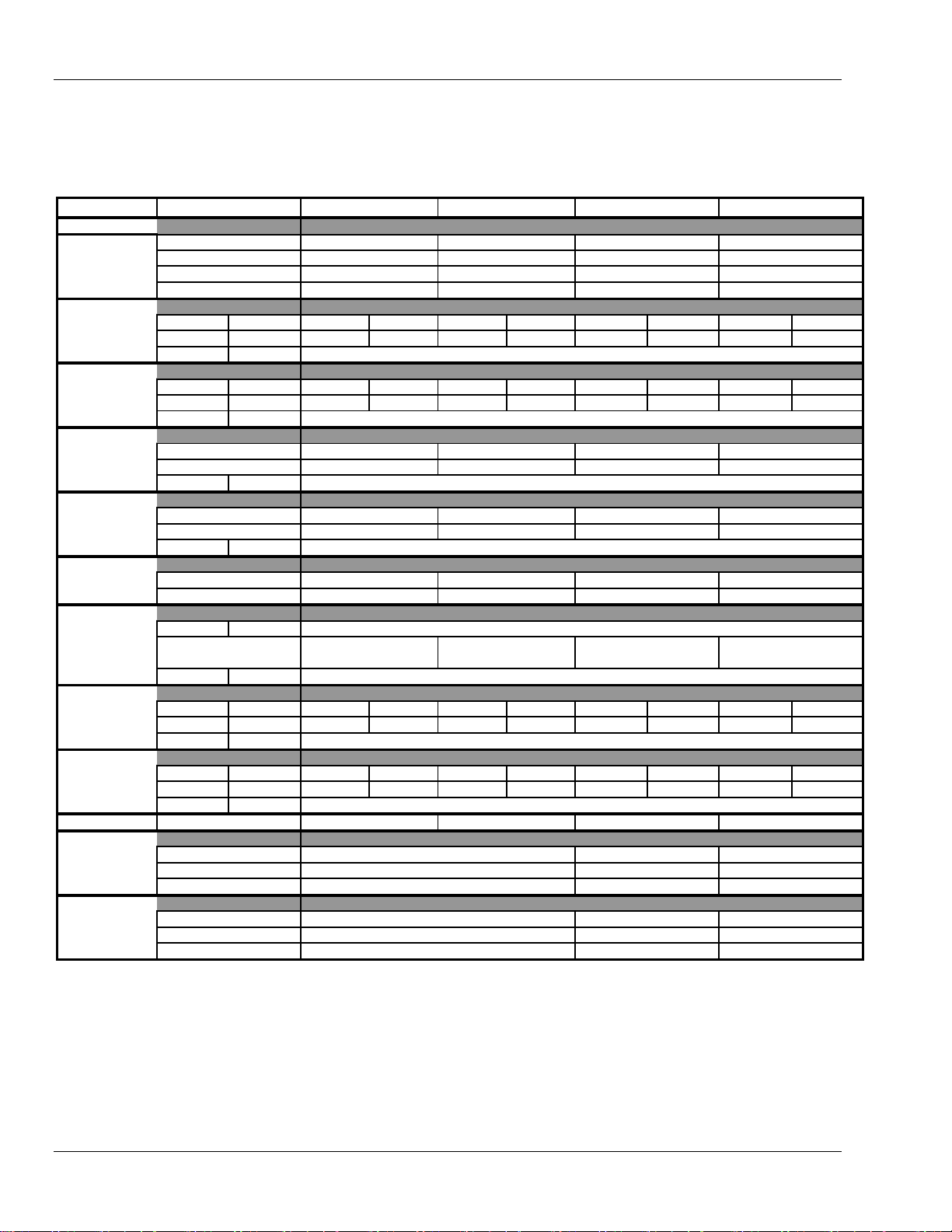

TABLE 1-1 SLM-SERIES DC LOAD MODULE SPECIFICATION ................................................................................. 1-8

TABLE 3-1 SLM-SERIES DC ELECTRONIC LOAD FACTORY SETTINGS FOR POWER ON ............................3-16

TABLE 3-2 RESOLUTION OF RANGE 1/2 VS COARSE/FINE LOAD CURRENT SETTING KEYS ....................3-18

vii

Page 12

TABLE 3-3 SUMMARY OF OVER PROTECTION VALUES.........................................................................................3-20

TABLE 5-1 GPIB COMMAND TERMINATOR.................................................................................................................. 5-3

TABLE 5-2 GPIB/RS-232 SETTING COMMAND SUMMARY....................................................................................... 5-4

TABLE 5-3 GPIB/RS-232 PRESET QUERY COMMAND SUMMARY WITH APPLICABLE MODULE TYPES .... 5-4

TABLE 5-4 STATE COMMAND SUMMARY..................................................................................................................... 5-5

TABLE 5-5 SYSTEM COMMANDS - ALL MODULES .................................................................................................... 5-6

TABLE 5-6 MEASURE AND LIMIT COMMANDS............................................................................................................ 5-6

TABLE 5-7 GLOBAL COMMANDS .................................................................................................................................... 5-6

TABLE 5-8 WAVEFORM INFORMATION .......................................................................................................................5-14

LIST of FIGURES

FIGURE 1-1 SLM-60-30-150 POWER CONTOUR ......................................................................................................... 1-1

FIGURE 1-2 SLM-60-60-300 POWER CONTOUR ......................................................................................................... 1-2

FIGURE 1-3 SLM-250-10-300 POWER CONTOUR ....................................................................................................... 1-2

FIGURE 1-4 SLM-500-10-300 POWER CONTOUR ....................................................................................................... 1-3

FIGURE 1-5 SLM-60-15-75 POWER CONTOUR............................................................................................................ 1-3

FIGURE 1-6 CONSTANT CURRENT (CC) MODE.......................................................................................................... 1-4

FIGURE 1-7 CONSTANT RESISTANCE (CR) MODE.................................................................................................... 1-4

FIGURE 1-8 CONSTANT VOLTAGE (CV) MODE .......................................................................................................... 1-5

FIGURE 1-9 CONSTANT POWER (CP) MODE .............................................................................................................. 1-5

FIGURE 1-10 DYNAMIC WAVEFORM ............................................................................................................................. 1-6

FIGURE 1-11 BLOCK DIAGRAM OF SLM-SERIES DC ELECTRONIC LOAD.......................................................... 1-9

FIGURE 2-1 BINDING POST AND SCREW ON SLM-SERIES DC PLUG-IN LOAD MODULE .............................. 2-1

FIGURE 2-2 PLUG-IN INSTALLATION AND REMOVAL............................................................................................... 2-2

FIGURE 2-3 TYPICAL CONNECTIONS FOR SLM-SERIES DC SERIES LOAD MODULE .................................... 2-4

FIGURE 2-4 SLM-SERIES DC PLUG-IN LOAD AND MULTIPLE OUTPUT POWER SUPPLY CONNECTION .. 2-4

FIGURE 3-1 SLM-SERIES DC PLUG-IN MODULE FRONT PANEL ........................................................................... 3-1

FIGURE 3-2 ORGANIZATION OF FRONT PANEL CONTROLS OF SLM-SERIES DC PLUG-IN MODULE........ 3-6

FIGURE 3-3 FLOWCHART FOR LOAD MODULE GENERAL SETUP PARAMETERS AND OCP AND OPP

TESTS ...........................................................................................................................................................3-10

FIGURE 3-4 DYNAMIC MODE WAVEFORM AND DEFINITION PARAMETERS....................................................3-13

FIGURE 3-5 NORMAL OPERATING MODE FLOWCHART.........................................................................................3-15

FIGURE 3-6 ANALOG PROGRAMMING LOAD CURRENT IN CC MODE OPERATION.......................................3-17

FIGURE 4-1 LOCAL VOLTAGE SENSE CONNECTIONS ............................................................................................ 4-1

FIGURE 4-2 REMOTE VOLTAGE SENSE CONNECTIONS......................................................................................... 4-2

FIGURE 4-3 CONSTANT CURRENT MODE APPLICATION........................................................................................ 4-3

FIGURE 4-4 DYNAMIC LOAD CURRENT WITH INDEPENDENT PROGRAMMED RISE/FALL SLEW RATE ... 4-4

FIGURE 4-5 CONSTANT VOLTAGE MODE APPLICATION ........................................................................................ 4-5

FIGURE 4-6 CONSTANT RESISTANCE ODE APPLICATION ..................................................................................... 4-6

FIGURE 4-7 CONSTANT POWER MODE APPLICATION............................................................................................ 4-7

FIGURE 4-8 SLM-SERIES DC PLUG-IN LOAD MODULE PARALLEL OPERATION (TOP) SERIES

CONNECTION NOT ALLOWED (BOTTOM)............................................................................................ 4-8

FIGURE 5-1 RS-232 INTERFACE DIAGRAM.................................................................................................................. 5-2

FIGURE 5-2 PROTECTION STATUS REGISTER .........................................................................................................5-23

FIGURE 5-3 ERROR STATUS BYTE REGISTER .........................................................................................................5-23

viii

Page 13

R

SECTION 1

INTRODUCTION, FEATURES

AND SPECIFICATIONS

1.1 General Description

The SLM-series DC electronic load module is designed for test, evaluation and burn-in of DC power

supplies and batteries. This module must be operated in the SLM Electronic Load chassis, the

mainframe whose front panel allows operation of its 150 store/recall setups and which has a remote

control feature. All load modules in the mainframe simultaneously return to the previously stored

memory when a recall operation is performed on the mainframe.

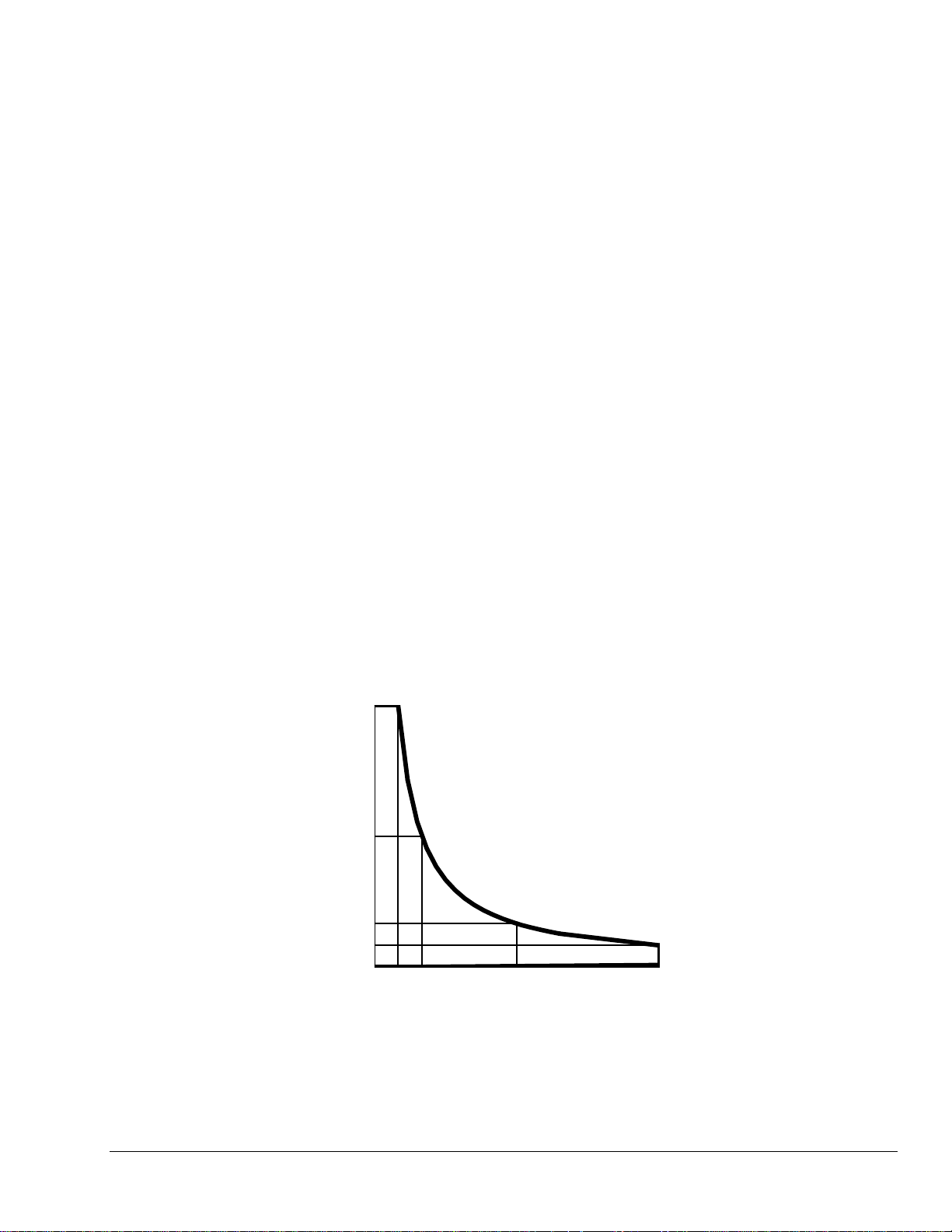

1.1.1 Power Contours

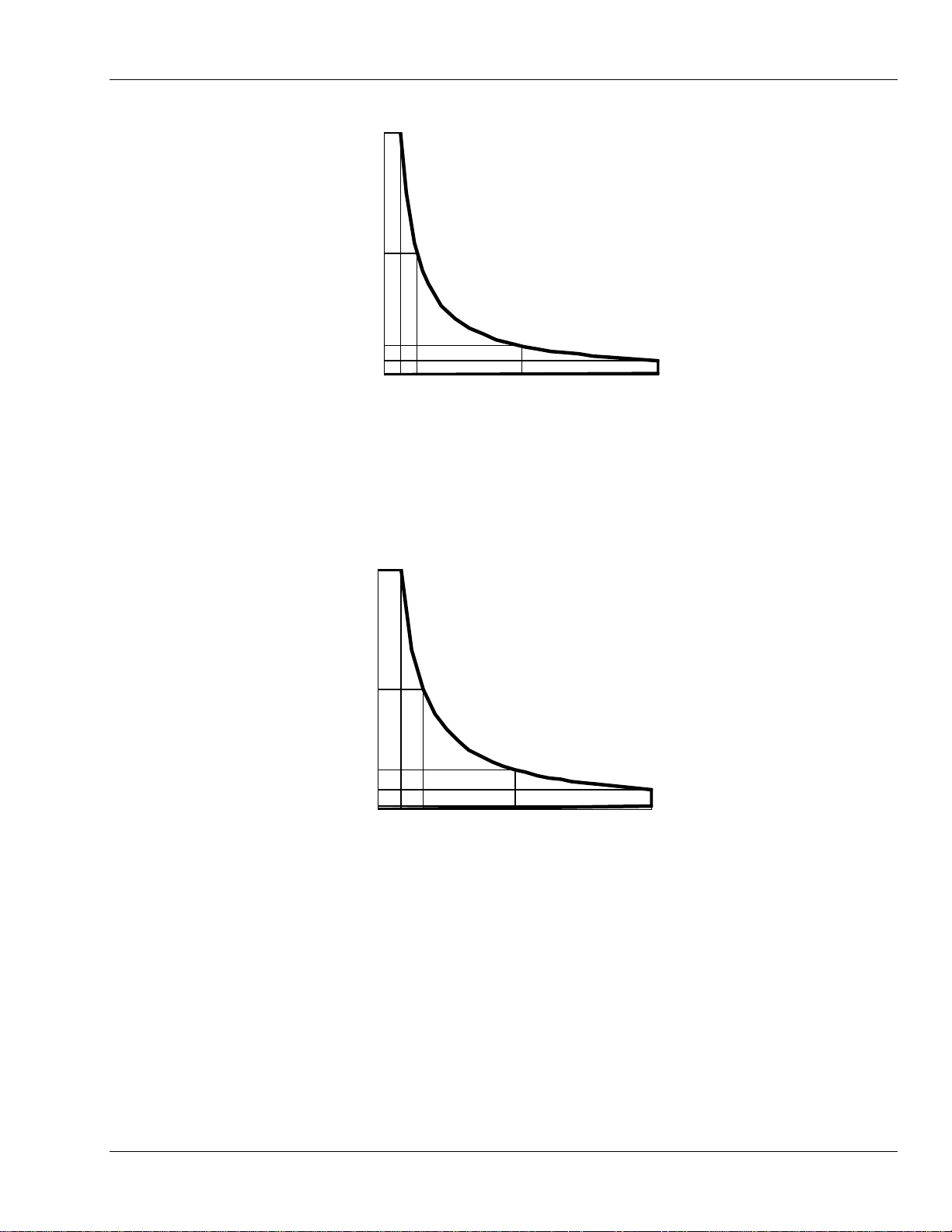

The power contours of SLM-series DC electronic loads are shown in Figure 1-1 through Figure 1-5.

60

30

Voltage (V)

10

5

0.5

0

01530

2.5 5

Figure 1-1 SLM-60-30-150 Power Contour

150W CONTOU

Current (A)

M540071-01 Rev C 1-1

Page 14

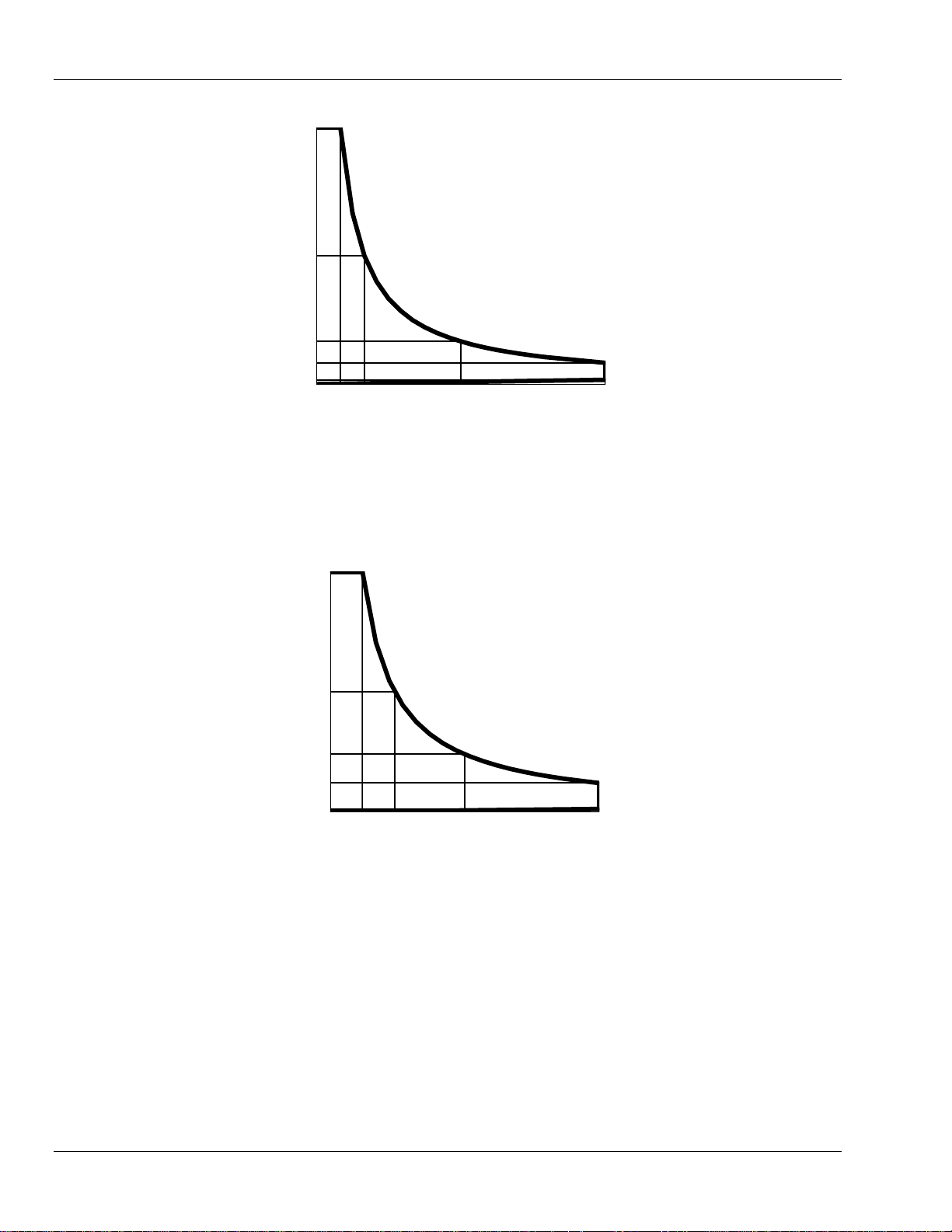

Introduction, Features, Specifications Sorensen SLM-Series DC Load

R

R

60

300W CONTOU

30

Voltage (V)

10

5

1

0

03060

510

Current (A)

Figure 1-2 SLM-60-60-300 Power Contour

250

300W CONTOU

125

Voltage (V)

60

30

3

0

1.2

2.

Current (A)

0510

Figure 1-3 SLM-250-10-300 Power Contour

1-2 M540071-01 Rev C

Page 15

Sorensen SLM-Series DC Load Introduction, Features, Specifications

R

R

500

250

Voltage (V)

60

30

3

0

0510

0.6 1.2

300W CONTOU

Current (A)

Figure 1-4 SLM-500-10-300 Power Contour

60

30

75W CONTOU

Voltage (V)

10

5

0.5

0

03060

510

Current (A)

Figure 1-5 SLM-60-15-75 Power Contour

M540071-01 Rev C 1-3

Page 16

Introduction, Features, Specifications Sorensen SLM-Series DC Load

CC

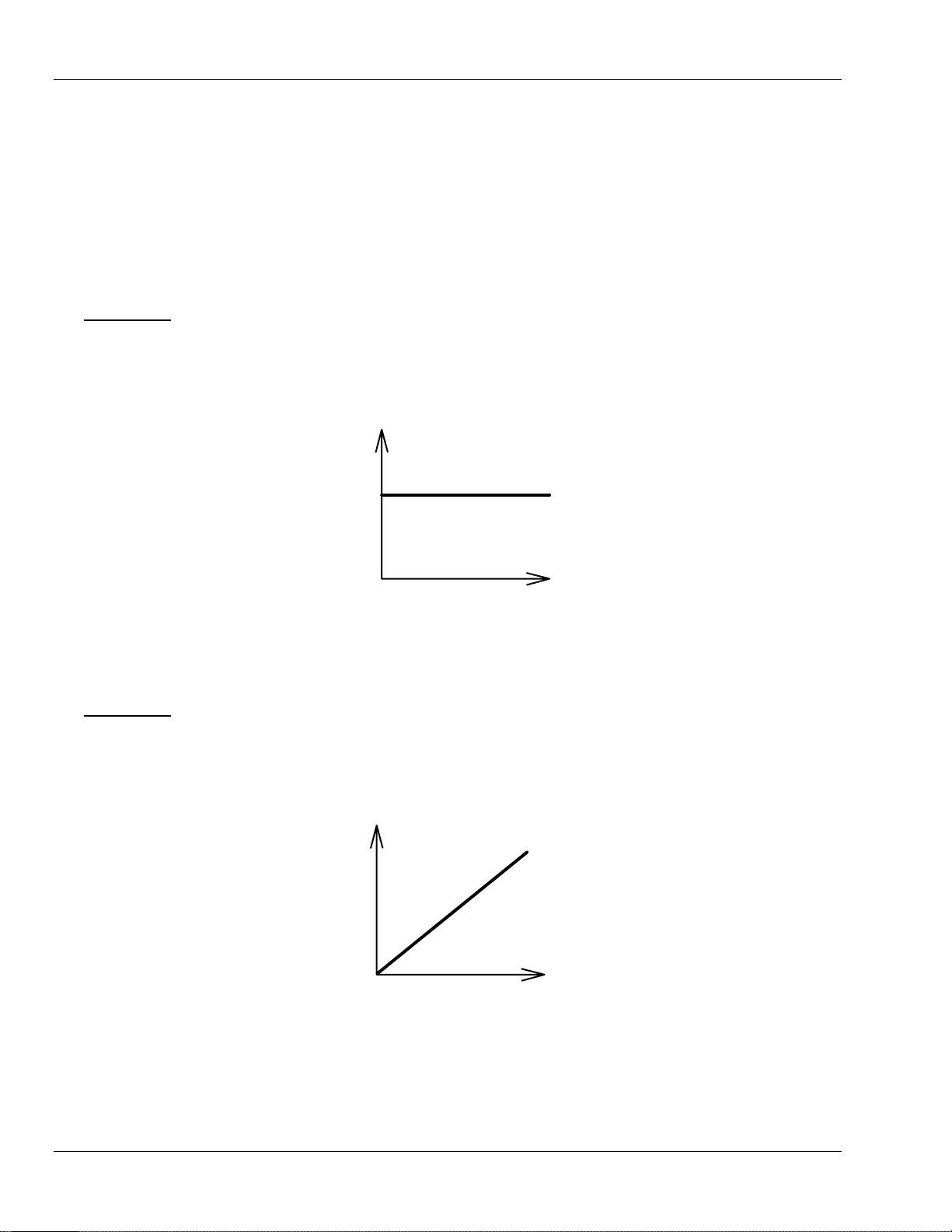

1.1.2 Operating Modes

The four operating modes of SLM-series DC electronic load include: Constant Current (CC) mode,

Constant Resistance (CR) mode, Constant Voltage (CV) mode, and Constant Power (CP) mode. The

wide-range dynamic load with independent rise/fall current slew rate and analog programming input

with arbitrary waveform input, is available in Constant Current and Constant Power modes. This

dynamic feature enables SLM-series DC electronic loads to simulate real world loads.

CC Mode:

In Constant Current mode, the load will sink a current in accordance with the programmed

current setting regardless of the input voltage (see Figure 1-6).

I

CURRENT SETTING

LOAD

CURRENT

CR Mode:

In Constant Resistance mode, the load will sink a current linearly proportional to the load input

voltage in accordance with the programmed resistance setting (see Figure 1-7).

V

INPUT VOLTAGE

Figure 1-6 Constant Current (CC) Mode

I

LOAD

CURRENT

RESISTANCE

SETTING

V

INPUT VOLTAGE

Figure 1-7 Constant Resistance (CR) Mode

1-4 M540071-01 Rev C

Page 17

Sorensen SLM-Series DC Load Introduction, Features, Specifications

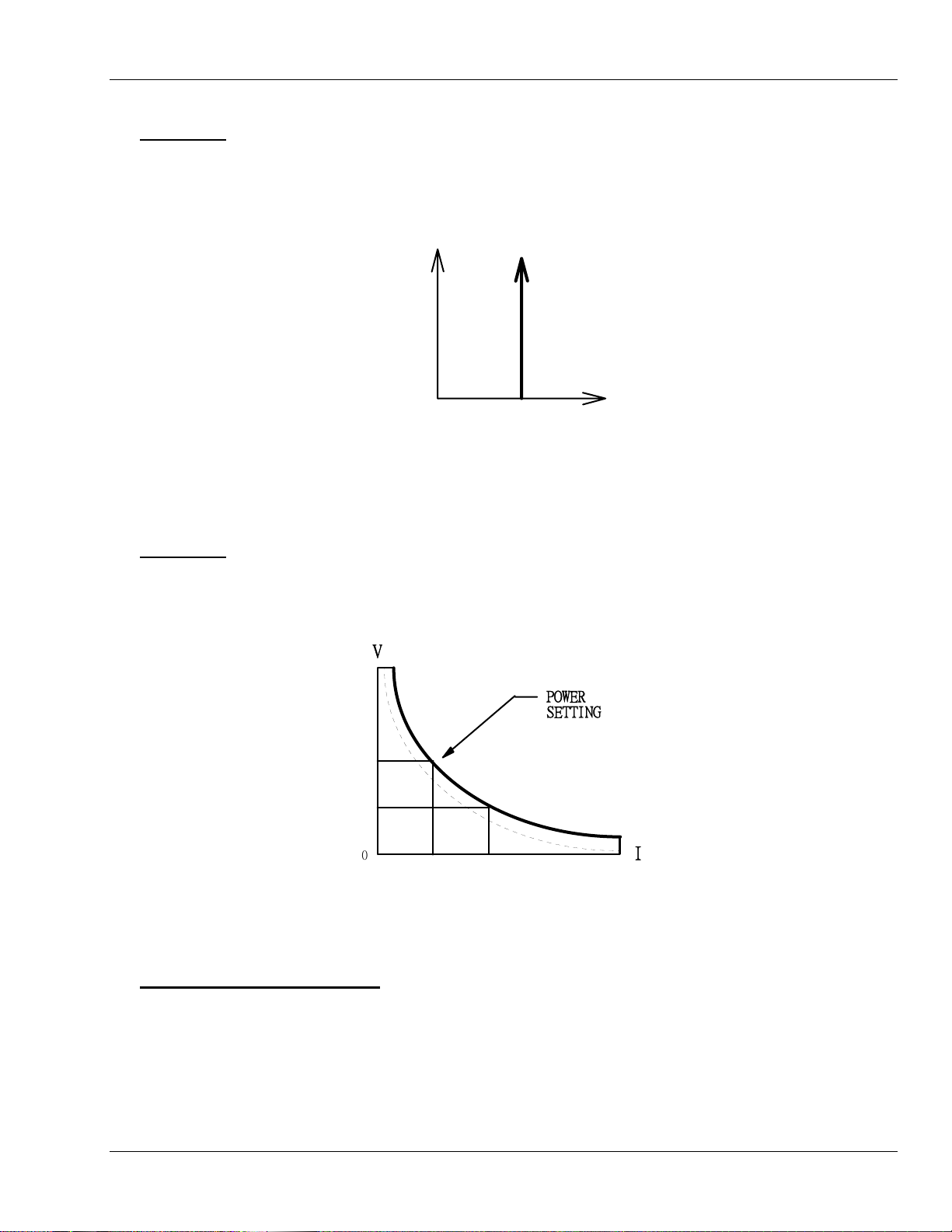

CV Mode:

In Constant Voltage mode, the load will attempt to sink enough current to maintain the

programmed voltage setting (see Figure 1-8).

I

VOLTAGE

LOAD

CURRENT

SETTING

V

INPUT VOLTAGE

Figure 1-8 Constant Voltage (CV) Mode

CP Mode:

In Constant Power mode, the load will attempt to sink load power (load voltage x load current) in

accordance with the programmed power setting. (see Figure 1-9).

0

Figure 1-9 Constant Power (CP) Mode

Wide-Range Dynamic Load

V

POWER

SETTING

I

The Dynamic load can simulate real-world load conditions, thereby providing relevant testing

and evaluation for the power source products. Dynamic loading is available for CC (Constant

Current) and CP (Constant Power) modes.

M540071-01 Rev C 1-5

Page 18

Introduction, Features, Specifications Sorensen SLM-Series DC Load

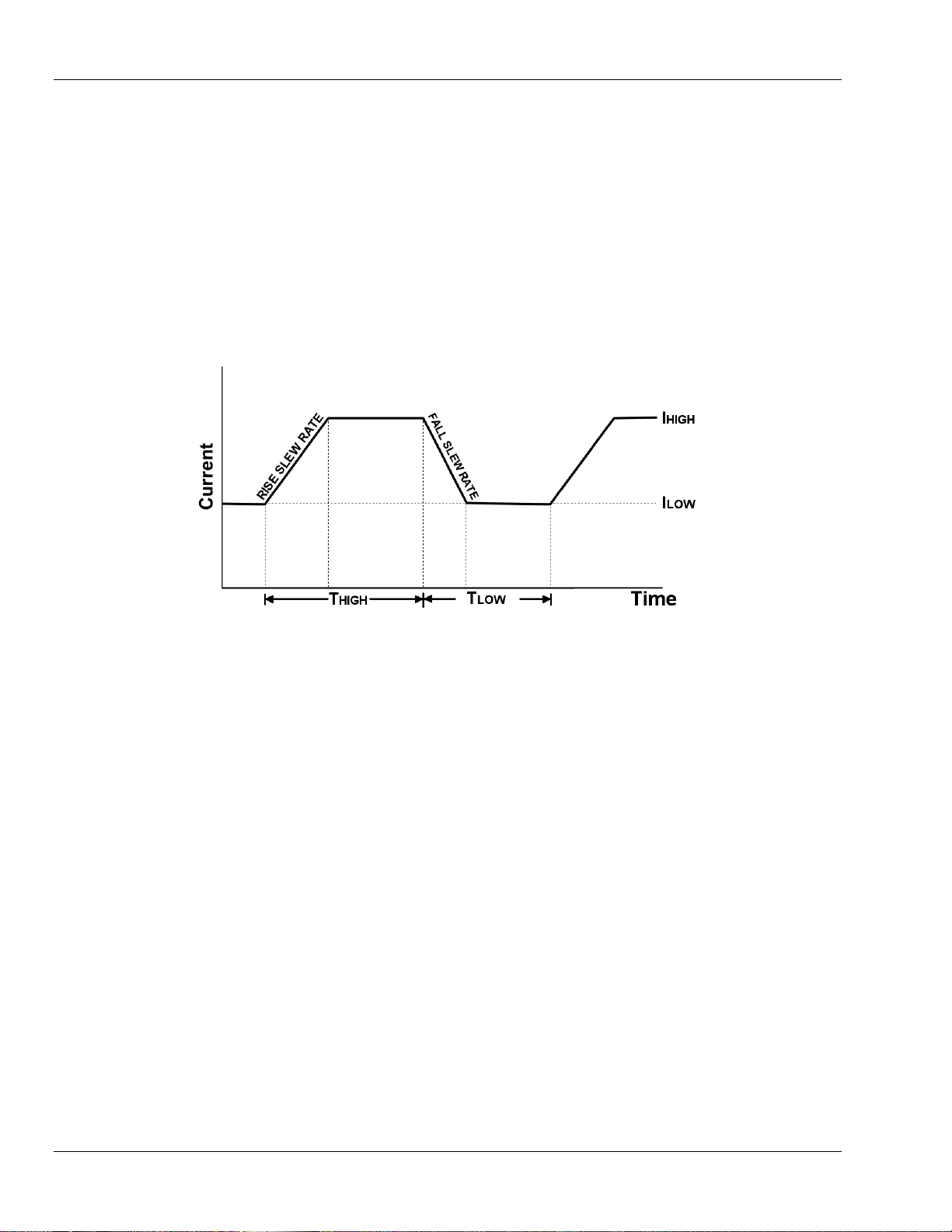

Dynamic Waveform Definition:

There are six parameters to generate a dynamic waveform or pulse waveform: High/Low load

levels, Rise/Fall slew rates, and T

HIGH/TLOW durations. The SLM-series DC electronic load will

sink current from the power source, proportional to the dynamic waveform. The dynamic

waveform definition is shown in Figure 1-10.

The formula to define the period of dynamic waveform is:

Dynamic frequency = 1 /(T

Duty cycle = T

HIGH / (THIGH + TLOW)

HIGH + TLOW)

Figure 1-10 Dynamic Waveform

The load current level and load status can be set by any of three ways:

• on the front panel of each load module,

• through the mainframe store/recall memory, or

• with GPIB/RS-232 commands

The load input voltage and load current can be read back to the computer through GPIB or RS-232 bus.

(See the SLM Mainframe Operation Manual for a description of the mainframe store/recall and

GPIB/RS-232 remote operation).

1-6 M540071-01 Rev C

Page 19

Sorensen SLM-Series DC Load Introduction, Features, Specifications

1.2 Features

• Flexible configuration of plug-in electronic load module and mainframe

• CC, CR, CV, CP, Dynamic, and Short Operating Mode

• Remote control of load condition setting and meter read back

• Dual high accuracy & resolution 16-bit voltage and current meter

• Built-in pulse generator includes wide T

current slew rate control, and High/Low Load level

• Controllable load current slew rate of load level change, load ON/OFF switch change, and power

supply turn-on

• Short circuit test and current measure capability

• Programmable voltage sense capability

• Full protection from over power, over temperature, over voltage, and reverse polarity

• Analog programming input capability at each load module

• Isolated I-monitor BNC output, 10V full scale (except models with maximum voltage >100V)

• Digital calibration

• Variable fan speed control

HIGH/TLOW dynamic load range, independent Rise/Fall load

• Up to 150 Sets Store/Recall EEPROM memory

1.2.1 Accessories

• V-sense cable: BNC-CLIP (1M) 1 ea.

• Binding Post Plug (Black) 1 ea.

• Binding Post Plug (Red) 1 ea.

• Hook terminal 2 ea.

• SLM-series operation manual 1 ea.

• High Voltage V-sense Cable: BNC-CLIP 1M (250 and 500V models) 1 ea.

M540071-01 Rev C 1-7

Page 20

Introduction, Features, Specifications Sorensen SLM-Series DC Load

μ

μ

μ

V

1.3 Module Specifications

NOTE: The following specifications apply 25°±5°

MODEL SLM-60-15-75 SLM-60-30-150 SLM-60-60-300 SLM-250-10-300 SLM-500-10-300

INPUT RATING

VOLTAGE

Current

POWER

MIN. VOLTAGE

CC MODE

Range 1 | Range 2 0-1.5A 0-15A 0 - 3A 0 - 30A 0 - 6A 0 - 60A 0 - 1A 0 - 10A 0-1A 0-10A

Resolution 0.4mA 4.0mA 0.8mA 8.0mA 1.6mA 16mA 0.268mA 2.68mA 0.134mA 1.34mA

Accuracy

CR MODE

Range 1 | Range 2 4-15KΩ 0.213-4Ω 2-7.5KΩ 0.1067-2Ω 1-3.75KΩ 0.0533-1Ω 25-18.75KΩ 1.333-25Ω 0.1-18.75KΩ 5.33-100Ω

Resolution 66.66uS 1.066mΩ 0.133mS 0.533mΩ 0.266mS 0.266mΩ 0.053mS 6.666mΩ 13.333uS 26.66mΩ

Accuracy

CV MODE

Range

Resolution

Accuracy

CP MODE

Range

Resolution

Accuracy

SHORT MODE

Resistance

Current

DYNAMIC

THIGH & TLOW

Rise/Fall (Range

1)

Accuracy

4 1/2 DVM

Range 15.0V 60.0V 15.0V 60.0V 15.0V 60.0V 30.0V 250.0V 60.0V 500.0V

Resolution 0.001V 0.002V 0.001V 0.002V 0.001V 0.002V 0.001V 0.01V 0.002V 0.02V

Accuracy

4 1/2 DAM

Range 1.5A 15.0A 3.0A 30.0A 6.0A 60.0A 1.2A 12.0A 1A 10.0A

Resolution 0.0001A 0.001A 0.001A 0.01A 0.001A 0.01A 0.0001A 0.001A 0.0001A 0.001A

Accuracy

Imonitor

Load ON Volt.

Range

Resolution

Accuracy

Load OFF Volt.

Range

Resolution

Accuracy

0.05% of Setting + 0.0125

60V 60V 60V 250V 500V

15A 30A 60A 10A 10A

75W 150W 300W 300W 200W

1V @ 15A 1V @30A 1V @ 60A 3V @ 10A 5V @ 10A

± 0.2﹪,OF(SETTING +RANGE)

± 0.2﹪OF (SETTING +RANGE)

0 - 60V 0 - 60V 0 - 60V 0 - 250V N/A

0.015V 0.016V 0.016V 0.0667V N/A

0 - 75W 0 - 150W 0 – 300W 0 – 300 W 0 - 300W

0.02W 0.04W 0.08W 0.08W 0.08W

0.017Ω 0.034Ω 0.0167Ω 0.08Ω 0.43Ω

15A 30A 60A 10A 10A

1.0-62.5 mA/μs

10-625 mA/μs

1.5 A/V 3.0 A/V 6.0 A/V N/A N/A

0.1 - 25V 0.1 - 25V 0.2 - 50V 0.4 - 100V

0.1V 0.1V 0.2V 0.4V

1% of Setting + 0.25V 1% of Setting + 0.25V 1% + 0.5V 1% of Setting + 1V

0 - 25V 0 - 25V 0 - 50V 0 - 100V

0.002V 0.002V 0.01V 0.02V

2.0-125 mA/

0.2-1.2 A/μs

s

0.05% of Setting + 0.0125V 0.05% of Setting + 0.025V 0.05% of Setting + 0.05V

± 0.1﹪OF (SETTING +RANGE)

± 0.5﹪OF (SETTING +RANGE)

50

4-250 mA/μs

0.04-2.5 A/μs

± 0.05﹪OF (READING +RANGE)

± 0.2﹪OF (READING +RANGE)

sec to 9.999 sec

± (5﹪+10

0.8-50 mA/μs

8.0-500 mA/μs

s)

0.8-50 mA/μs

8.0-500 mA/μs

Table 1-1 SLM-series DC Load Module Specification

1-8 M540071-01 Rev C

Page 21

Sorensen SLM-Series DC Load Introduction, Features, Specifications

1.4 Regulatory Compliance

• Certified to UL 61010-1, CSA C22.2 No. 61010.1 and IEC/EN 61010-1

• CE Compliant:

o Low Voltage Directive (73/23/EEC) using EN 61010-1, and

o EMC Directive (89/336/EEC) using EN 61326

• FCC Compliant to 21 CFR, Subpart J.

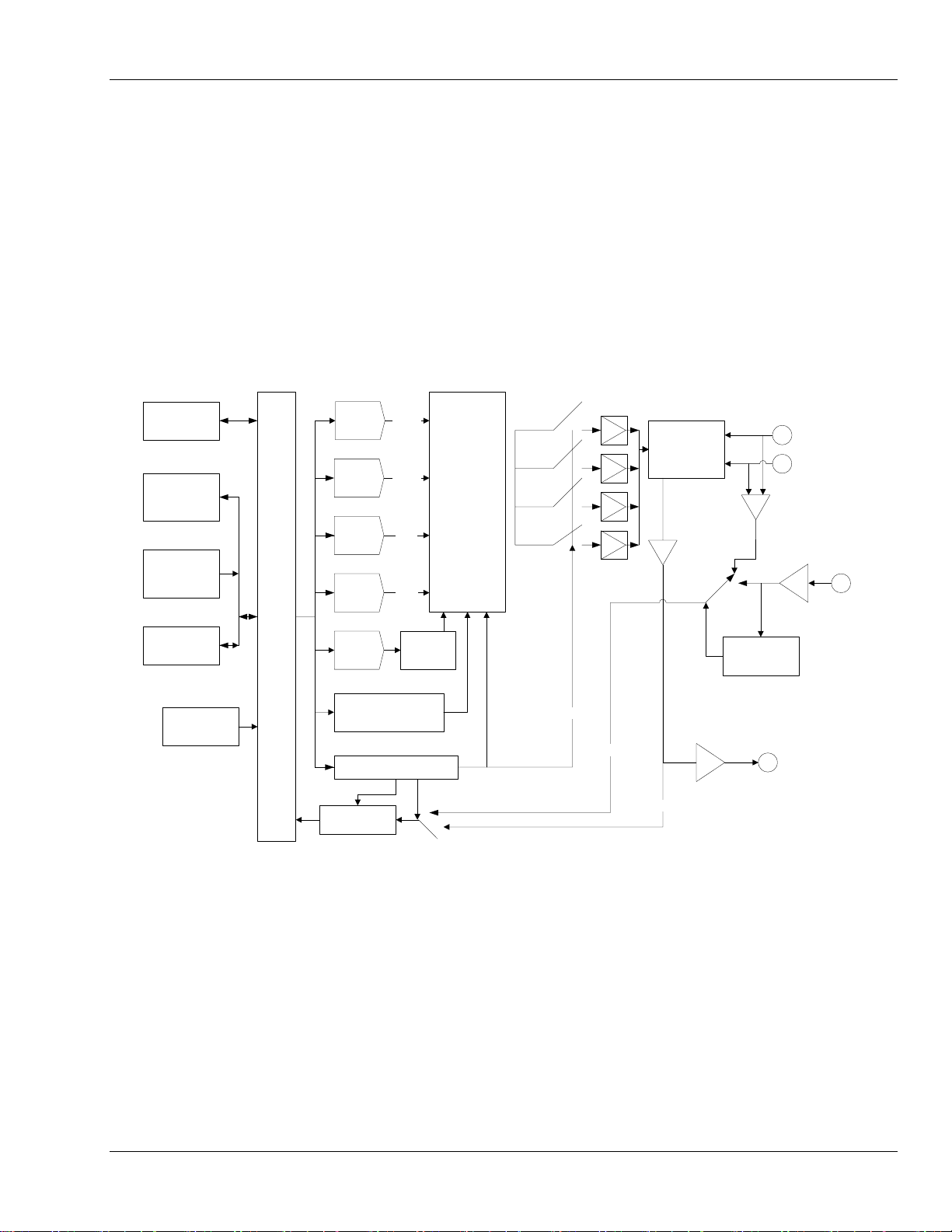

1.5 Block Diagram

A functional block diagram of the SLM-series DC electronic load module is illustrated in Figure 1-11.

(Please refer to the SLM Mainframe Operation Manual for the functional block diagram of the

mainframe).

Memory

Front Panel

Display and

Keyboard

OTP Protection

Circuitry

Serial Port

Osciallator Circuit

12-bit

12-bit

CPU

Programmable Pulse

16-bit A/D

D/A

D/A

8-bit

D/A

8-bit

D/A

8-bit

D/A

Generator

Control Circuit

LOW

LEVEL

HIGH

LEVEL

RISE

FALL

Dynamic Funct ion

Load ON

Control

DVM/DAM

Select

Control

MODE Select

LEVEL

Digital Voltmeter

CC

CR

CV

CP

Power MOSFET

Stage

Current

Sense

Digital Ammeter

Buffer

Figure 1-11 Block Diagram of SLM-Series DC Electronic Load

Voltage Amp

Voltage

Vsense Control

Circuit

Amp

LOAD

INPUT

Imonitor

Output

Vsense

Input

The isolated serial port of the SLM mainframe receives the remote programming load level status.

Six parameters (Hi/Low levels, Rise/Fall slew rates, T

HIGH/TLOW durations) constitute the wide range

pulse generator, and can be used to test the power supply - Device Under Test (DUT).

The two 12-bit Digital/Analog (D/A) converters convert the programmed High/Low load level data to an

analog signal, and then feed the signal to the input of static/dynamic function control circuit.

The two 8-bit D/A converters control the load current slew rate for Rise and for Fall slew rates.

The two 16-bit timers set T

HIGH and TLOW durations.

M540071-01 Rev C 1-9

Page 22

Introduction, Features, Specifications Sorensen SLM-Series DC Load

The Constant Current (CC), Constant Resistance (CR), Constant Voltage (CV) and Constant Power

(CP) control and the Range circuitry are selected depending upon which operating mode and range are

programmed. The drive circuit controls the load current flow through power MOSFET, which is

proportional to the analog control signal. The load power energy is converted to heat and is dissipated

on the heat sink.

The voltage sensing circuit selects the load input terminal or V-sense BNC input, depending on the

V-sense setting.

The current sense amplifier feeds the load current signal to16-bit DAM, which feeds the 5-digit LED

display and isolated amplifier (I-Monitor BNC output).

The Auto-ranged 16-bit high accuracy digit voltage meter feeds the input voltage to the 5-digit LED

display. The 16-bit voltage and current meter digital bus is connected to CPU circuitry. Each load

module can transfer the meter readings to SLM mainframe through isolated serial circuitry.

1-10 M540071-01 Rev C

Page 23

SECTION 2

INSTALLATION AND MAINTENANCE

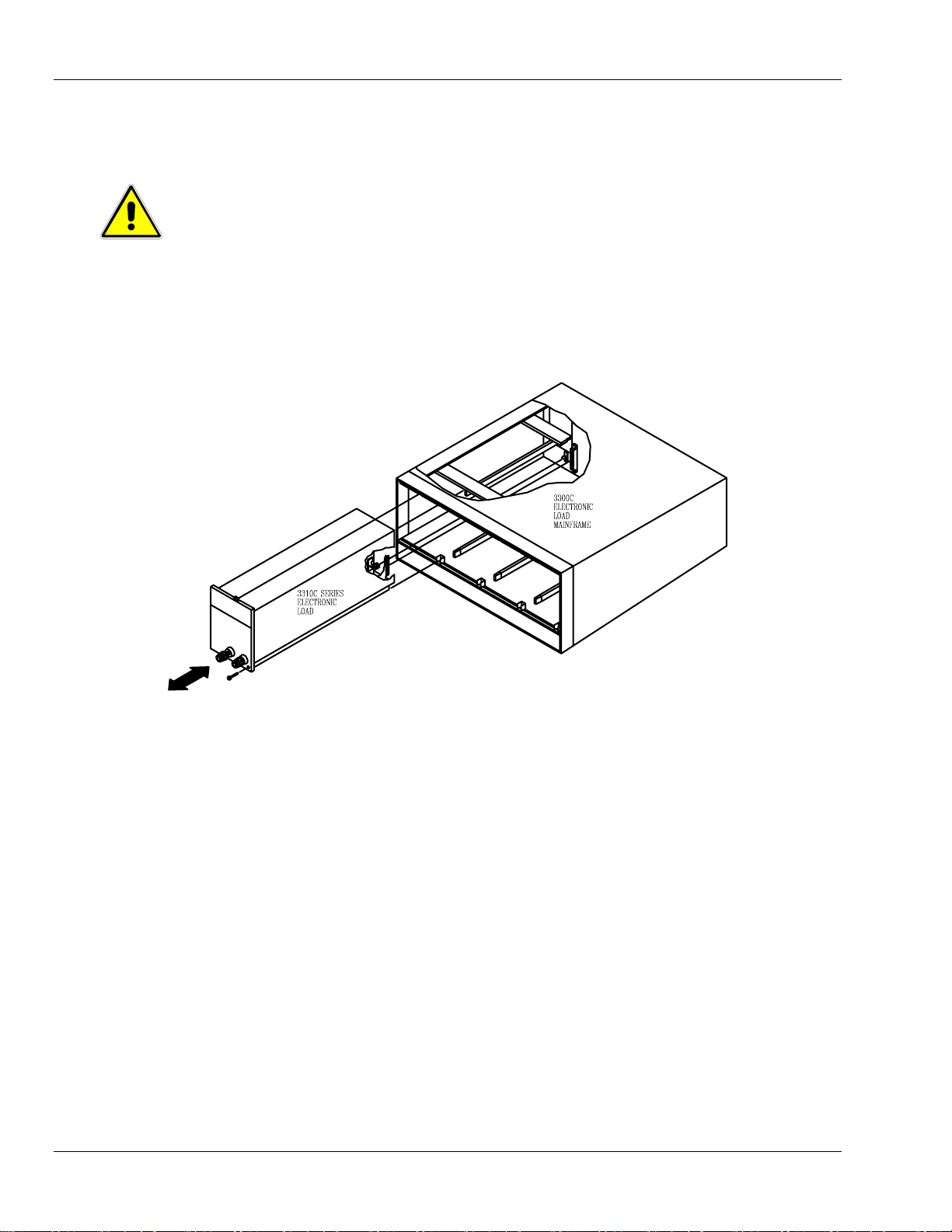

This section discusses the installation and removal procedures for the SLM-series DC load module and

the SLM quad module mainframe. The SLM-series DC load module does not need any adjustment

after plugging into the SLM mainframe.

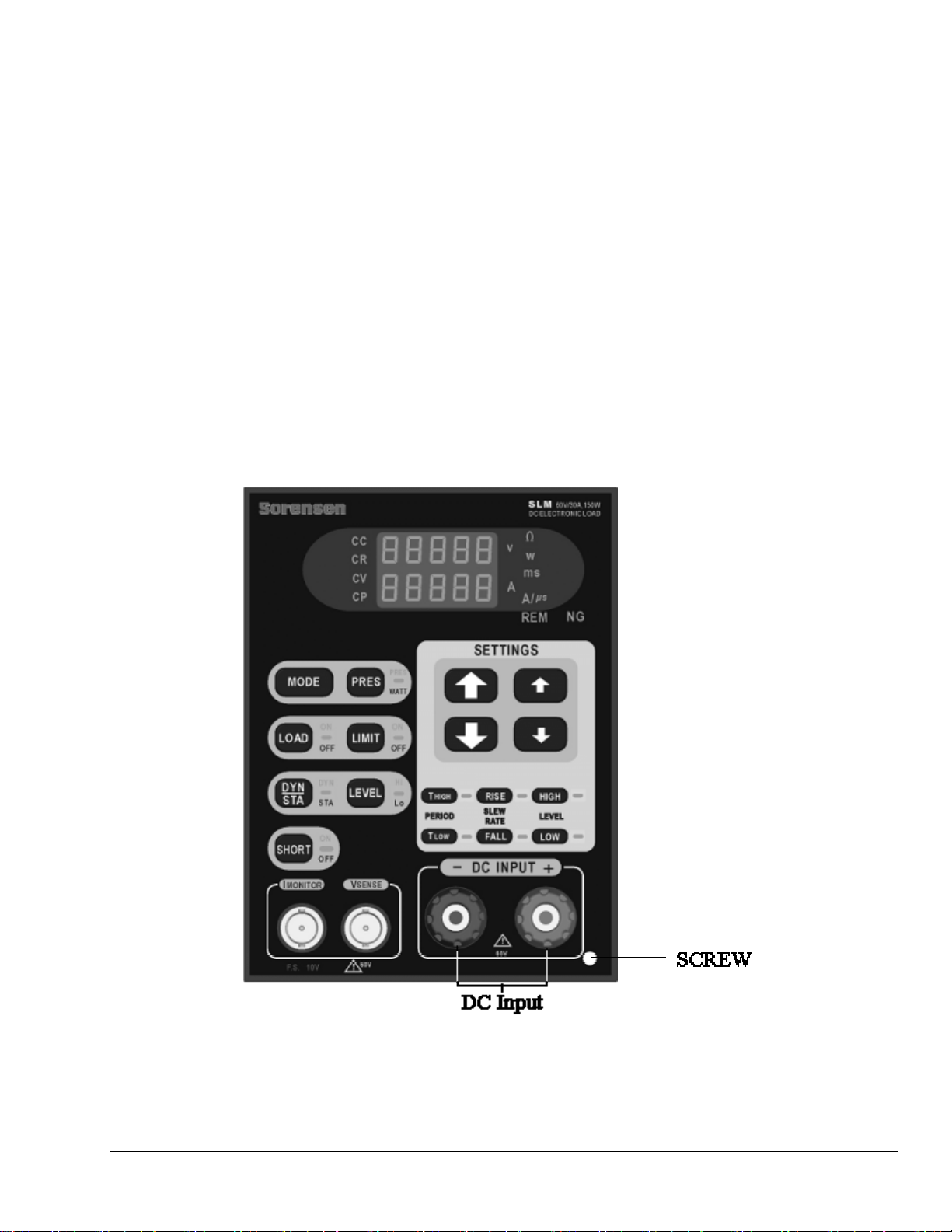

Figure 2-1 Binding Post and Screw on SLM-Series DC Plug-in Load Module

M540071-01 Rev C 2-1

Page 24

Installation Sorensen SLM-Series DC Load

2.1 Installation and Removal of SLM-Series DC Plug in

Module

CAUTION:

Only qualified personnel should do installation and removal.

Unless the SLM mainframe and the SLM-series DC electronic load module were purchased separately,

the load module should be installed in the mainframe before shipment from Xantrex.

Installation and removal procedures for the SLM-series load module are listed below.

2.1.1 Installation

1 Turn the SLM mainframe power OFF before inserting any load module, or damage may

occur to the plug-in module circuitry.

2. Align the upper and lower grooves of the mainframe with the upper and lower guides of the

selected compartment.

3. Push the module in and press firmly on the binding posts (labeled, “DC Input” in Figure 2-1)

of the front panel to seat the circuit board into the interconnecting jack.

4. Using a screwdriver, tighten the screw on the lower right corner of the SLM-series load

module front panel. The screw location is shown in Figure 2-1.

5. DO NOT turn the mainframe power ON until after all of the electronic modules are completely

installed.

Figure 2-2 Plug-in Installation and Removal

2-2 M540071-01 Rev C

Page 25

Sorensen SLM-Series DC Load Installation

2.1.2 Removal

CAUTION: PREVENT DAMAGE TO THE MODULE CIRCUITRY. Do NOT remove the

plug-in module while the mainframe is under power.

1. Turn the SLM mainframe power OFF.

2. Using a screwdriver, loosen the screw on the lower right corner of the front panel.

3. Turn the adjustment knob of the black binding post counter-clockwise until it is fully loosened.

4. Pull on the black adjustment knob of binding post until the interconnecting jack at the rear of

the load module disengages.

5. Finish pulling the SLM-series DC load module out from the mainframe.

2.2 Connections

2.2.1 Input Binding Post and Wire Considerations

The output of the device under test (DUT) can be connected to the load by one of five methods, each

described in the following subsections. The positive (+) and negative (-) binding posts should be

connected to the wires/cables according to the following guidelines. A major consideration in making

input connection is the wire size. The minimum wire size is required to prevent overheating and to

maintain good regulation. It is recommended that the wires be large enough to limit the voltage drop

to less than 0.5V per lead.

Note: When using Constant Resistance mode, Vsense inputs should be used to keep cable

resistance from affecting measurements and regulation.

CAUTION: PREVENT DAMAGE TO THE LOAD. Do NOT apply voltage or current with

power switched OFF. Turn ON the power switch to the load PRIOR to applying voltage or

current to the input terminals (i.e., before turning on the power supply under test).

Plug Connectors

This is the most popular way to connect the input of electronic load to the device under test. It is

recommended the load current be less than 20A

the plug is rated to 20A. The maximum wire gauge should be limited to AWG14.

in this connection since the current rating of

Hook Terminals

The hook terminal provides a good contact to the binding post and can be used anytime. The

maximum wire gauge should be limited to AWG10.

Direct Insertion into Binding Posts

This is the most convenient way to connect the load input to the DUT. The maximum wire gauge

AWG14 can be used in this application.

M540071-01 Rev C 2-3

Page 26

Installation Sorensen SLM-Series DC Load

Plug Connectors and Hook Terminals

This method is recommended when input current is greater than 20A.

Plug Connectors and Direct Insertion

This method is also recommended when input current is greater than 20A.

2.2.2 Typical Connections

SLM DC

SLM DC

SLM DC

SLM DC

Electronic Load

Electronic Load

Electronic Load

Electronic Load

Power Source

Power Source

Power Source

-+

-+

-+

-+

A. Local Sense Connection B. Remote Sense Connection

Figure 2-3 Typical Connections for SLM-Series DC Series Load Module

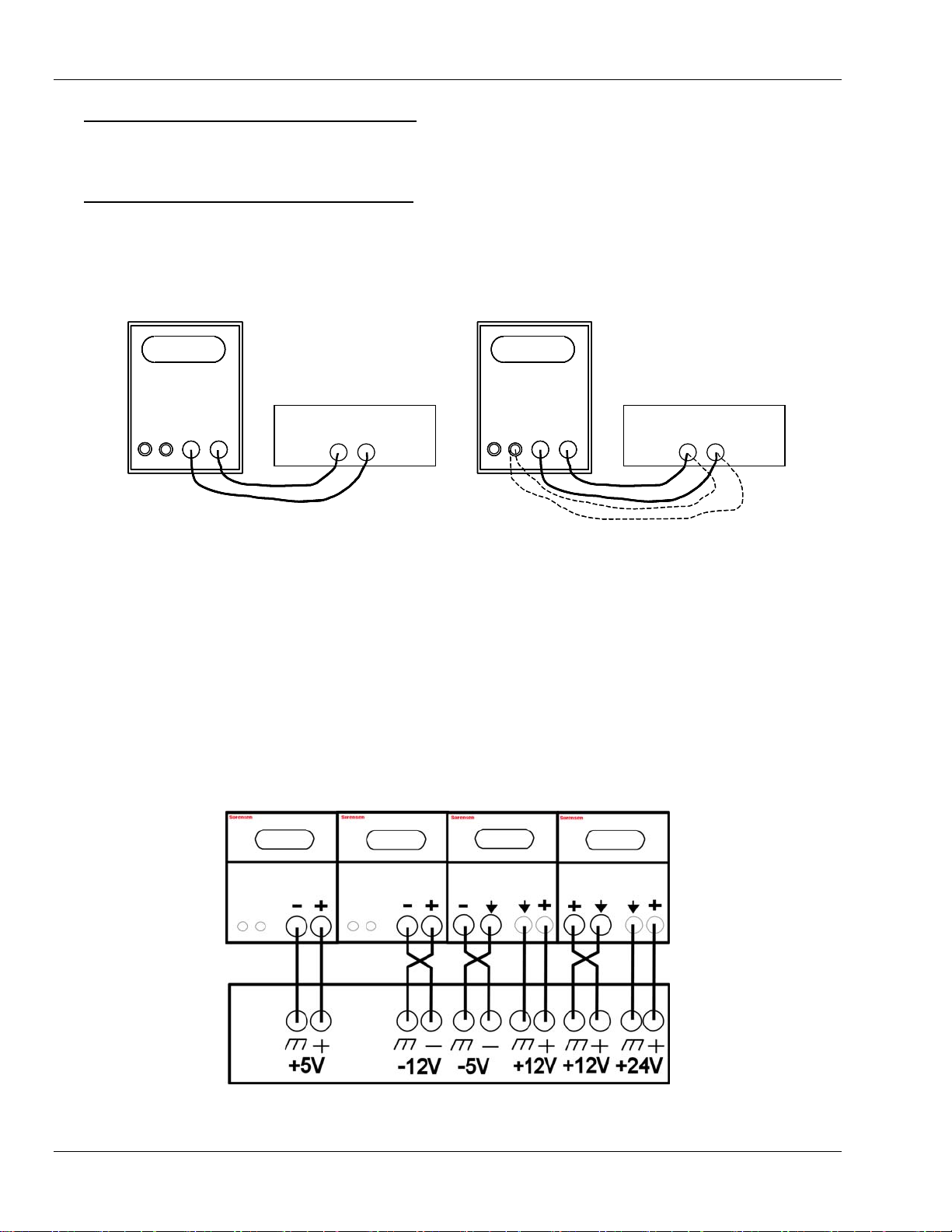

2.2.3 The Connection for a Multiple Output Power Supply

Rule for a multiple output power supply connection to the SLM-series DC electronic loads:

The potential of positive input (Red binding post) must be higher than the potential of

negative input (Black binding post) of SLM-series DC electronic load.

Figure 2-4 is an example of +5V, -5V, +12V, -12V and +24V six outputs power supply connected

to a SLM-series DC electronic load.

+ -

+ -

+ -

SLM DC

SLM DC

SLM DC

SLM DC

Electronic Load

Electronic Load

Electronic Load

Electronic Load

-+

-+

-+

-+

Power Source

Power Source

Power Source

+ -

+ -

+ -

Figure 2-4 SLM-Series DC Plug-in Load and Multiple Output Power Supply Connection

2-4 M540071-01 Rev C

Page 27

Sorensen SLM-Series DC Load Installation

2.3 Maintenance

2.3.1 Cleaning

WARNING:

To avoid electrical shock or damage to the meter, do not get water inside the case.

Periodically wipe the case with a damp cloth and detergent; do not use abrasives or solvents.

M540071-01 Rev C 2-5

Page 28

Installation Sorensen SLM-Series DC Load

This page intentionally left blank.

2-6 M540071-01 Rev C

Page 29

SECTION 3

OPERATION

This section describes the front panel function and operation of each SLM-series DC load module.

Refer to the SLM mainframe operation manual for descriptions of the memory Store/Recall and of GPIB

and RS-232 remote programming.

3.1 Front Panel Controls and Indicators

3.1.1 Description

Figure 3-1 SLM-Series DC Plug-in Module Front Panel

M540071-01 Rev C 3-1

Page 30

Operation Sorensen SLM-Series DC Load

1 Module Label

Shows the load model name and its maximum ratings.

2 NG LED

Lights to indicate "No Go" (fail) when Vmeter, Ameter, or Wattmeter exceeds the upper or

lower limit set. Off, not lit, indicates "Go" (no fail).

3 CC, CR, CV, CP LEDs and MODE Key

• LEDs indicate which mode is in operation:

◦ CC = Constant Current

◦ CR = Constant Resistance

◦ CV = Constant Voltage

◦ CP = Constant Power

• The MODE key switches from one mode to the next.

4 REM LED

Indicates remote operation:

• When lit, the unit is under remote control and cannot be operated through the front

panel keys. (Remote controller releases control by GPIB command).

• When off, the unit is under local control and can be manually operated using the front

panel keys.

5 Upper 5-Character Digital Meter (DM) and Associated LEDs

The DM is for multi-purpose display, depending on selected mode:

• In PRESet OFF mode, displays voltage of DC input terminal or VSENSE BNC input.

• In PRESet ON mode, displays values being programmed for CV, CR, or CP (value for

CC is displayed in lower DM).

• In WATT On mode, displays load Watt meter.

• In LIMIT ON mode:

◦ displays GO/NG upper limit values for voltage, current, and power

◦ displays SENSE to indicate V

SENSE control

◦ displays voltage settings for LOAD ON or for LOAD OFF

Associated LEDs indicate the displayed value's unit:

• V = Value displayed is in Volts

• A = Value displayed is in Amps

• Ω = Value displayed is in Ohms

• W = Value displayed is in Watts

• ms = Value displayed is in milliseconds

• A/μs (or mA/μs) = Value displayed is in Amps per microsecond (or milliamps per

microsecond)

3-2 M540071-01 Rev C

Page 31

Sorensen SLM-Series DC Load Operation

6 Lower 5-Character Digital Meter (DM) and Associated LEDs

Multi-purpose display, depending on selected mode:

• In PRESet OFF mode, displays:

◦ actual load current when SHORT status is OFF

◦ short circuit current when SHORT status is ON

• In PRESet ON mode, displays values being programmed for:

◦ CC

HIGH/TLOW when in Dynamic mode

◦ T

◦ RISE/FALL slew rates when in Dynamic mode

• In LIMIT ON mode, displays:

◦ oVP (over voltage), oCP (over current), oPP (over power), or

oTP (over temperature) when in protection mode

◦ GO/NG low limit values for voltage, current, and power

◦ Auto or On setting for V

SENSE control

◦ either Ld-on or Ld-off to indicate whether Load voltage setting mode is On or

Off

Associated LEDs indicate the displayed value's unit:

• V = Value displayed is in Volts

• A = Value displayed is in Amps

• Ω = Value displayed is in Ohms

• W = Value displayed is in Watts

• ms = Value displayed is in milliseconds

• A/μs (or mA/μs) = Value displayed is in Amps per microsecond (or milliamps per

microsecond)

7 PRES Key and ON/WATT LED

• PRES key sequentially selects Preset ON, Watt ON and Preset OFF

• LEDs indicate which is selected at any given time:

◦ Preset On = LED is lit amber

◦ Watt On = LED is lit green

◦ Preset Off = LED is not lit

8 LOAD Key and ON/OFF LED

• LOAD key toggles ON/OFF the DC load. (Does not affect the programmed settings).

• LED indicates the status of the Load function:

◦ LED lit indicates the Load function is ON and ready to sink current from the DC

input.

◦ LED not lit indicates the Load function is OFF.

M540071-01 Rev C 3-3

Page 32

Operation Sorensen SLM-Series DC Load

9 LEVEL Key and Hi/Lo LED

• LEVEL key toggles between the High or Low levels for programming the high and low

level load values for CC, CR, CV, CP when in those modes. (See Key 16 for setting

the Level values. (These High/Low level load values can be programmed while in

Static mode but not in Dynamic mode. See Key 10, DYN/STA, next).

• LED indicates whether the Load value being programmed is High level or Low level:

◦ LED lit = high (HI) level

◦ LED not lit = low (Lo) level

Section 3.2.3 provides guidelines for programming the values.

10 DYN / STA Key and LED

• DYN/STA key toggles between Dynamic and Static modes only when in Constant

Current mode or Constant Power mode. (When in Constant Resistance and Constant

Voltage modes, the SLM-series DC load module automatically adjusts to Static mode

because Dynamic mode is not available for either).

• LED indicates whether the SLM-series DC load module is in Dynamic or Static mode:

◦ LED lit = Dynamic

◦ LED not lit = Static

11 SHORT Key and ON/OFF LED

• The SHORT key toggles the short circuit of DC input terminal On and Off.

• LED indicates the ON/OFF status of the short circuit

◦ LED lit = ON

◦ LED not lit = OFF

12 LIMIT Key and LED

• The Limit key sequentially selects the following parameters to program their settings:

◦ OFF

◦ GO/NG Upper/Lower Voltage limit

◦ GO/NG Upper/Lower Current limit

◦ GO/NG Upper/Lower Power limit

◦ Vsense Auto/ON

◦ Load ON voltage

◦ Load OFF voltage

◦ Range: Auto/RangeII

◦ iStart

◦ iStop

◦ iStep

◦ Pstart

◦ Pstop

◦ Pstep

◦ V threshold

3-4 M540071-01 Rev C

Page 33

Sorensen SLM-Series DC Load Operation

◦ Test Mode: Normal, OCP, OPP

◦ returns to OFF and the loop repeats

• The LED indicates whether limits are being programmed or not:

◦ LED lit = Limit programming ON

◦ LED not lit = Limit programming OFF

13 Coarse/Fine, Increment/Decrement (inc/dec) Keys

These keys are used in two different ways, depending on whether one or both 5-character

DMs are displaying a value:

• When only one value is displayed, such as for setting Load On voltage, these keys

increase or decrease the value as follows:

◦ The larger arrows, × Ø, make coarse (large) adjustments to the displayed

value.

◦ The smaller arrows, ↑↓, make fine (small) adjustments to the displayed value.

• When two values are displayed (one in upper 5-digit display and one in lower 5-digit

display), such as for setting upper and lower limits, these keys increase or decrease

the values as follows:

◦ The larger arrows, × Ø, increase or decrease the value in the upper 5-digit

display.

◦ The smaller arrows, ↑↓, increase or decrease the value in the lower 5-digit

display.

HIGH / TLOW PERIOD Keys and LEDs

14 T

• The THIGH and TLOW keys are used to program the duration of high and low load

current levels, respectively.

• The LEDs indicate which time period (THIGH or TLOW) is being programmed.

15 RISE / FALL SLEW RATE Keys and LEDs

• The Rise and Fall keys are used to program the speed of load current changes from

low level to high level (Rise) and from high level to low level (Fall).

• The LEDs indicate which slew rate (Rise or Fall) is being programmed.

16 HIGH / LOW LEVEL Keys and LEDs

• These two keys are used to program the High and Low loads for current, resistance,

voltage, or power, depending on which mode is set (CC, CR, CV, or CP). (Follow

guidelines in the Operation-Setup section that follows).

• The LEDs indicate which level (HIGH or LOW) is being programmed.

-/+ DC INPUT Binding Posts

17

The negative (left) and positive (right) terminal of load input connector

• +: Connect to the positive and ground output for a positive output power supply

• -: Connect to the negative and ground output for a negative output power supply.

NOTE: Before testing, ensure that the voltage and current do not to exceed the maximum

M540071-01 Rev C 3-5

Page 34

Operation Sorensen SLM-Series DC Load

r

rating of each SLM-series DC load module and the connection method utilized (see

Section 2.2.1).

Also check the polarity of DC input connection before testing.

SENSE

18 V

Measures the specific voltage points through the V-sense BNC - CLIP cable.

NOTE: Avoid High Voltage Hazards - refer to Section 2.2.2 for cautions and warnings about

connections.

MONITOR

19 I

Sends the load current waveform output to an oscilloscope to evaluate the current waveform

of a power supply under test.

See Section 1 for voltage/current relationship of I-Monitor outputs in SLM-series DC series

modules.

3.1.2 Summary Chart

The front panel controls are summarized in Figure 3-2.

SLM DC Loads

Button Functions

MODE (3)

CC: Constant Current

CR: Constant Resistance

CV: Constant Voltage

CP: Constant Powe

PRESet (7)

PRESET

DWM/DAM Display

DVM/DAM

LIMIT (12)

G/NG Volt Limits

G/NG Curr. Limits

G/NG Power Limits

Vsense

AUTO

ON

Load On Voltage

Load Off Voltage

Range

AUTO

Rang II

iStart

iStop

iStep

PStart

PStop

Pstep

Vthreshold

Test

Normal

OCP

OPP

LEVEL (9)

HI

LO

LOAD (8)

ON

OFF

DYN/STA (10)

DYNamic

STAtic

SHORT (11)

Figure 3-2 Organization of Front Panel Controls of SLM-Series DC Plug-in Module

ON

OFF

3-6 M540071-01 Rev C

Page 35

Sorensen SLM-Series DC Load Operation

3.2 Operation – Setup and OCP/OPP Tests

The SLM series DC loads have six operating modes: Constant Current (CC), Constant Voltage (CV),

Constant Power (CP), Constant Resistance (CR), all selected with the MODE key, Shorts mode,

selected with the SHORT key, and Dynamic mode, selected with the DYN/STA key. (Dynamic mode

allows controlled current transitions between two states in CC or CP modes only).

Note: For the remainder of this Section, the bolded number within parentheses following a front panel

key name, refers to the labels in Figure 3-1.

3.2.1 Overview of Front Panel Operation

Limits must be set up before selecting a mode in which to operate. The LIMIT key (12) is used to set

the Go/No Go upper and lower limits for voltage, for current and for power. It is also used to set the

system configuration for V-sense control, for Load ON voltage and for Load OFF voltage.

After setting up the initial LIMIT parameters (see Section 3.2.2), use the MODE key (3) to enter CC, CR,

CV, or CP mode and set up the applicable parameters in each mode. Use the HIGH and LOW keys

(16) to set the load level values for each mode. If programming values in Dynamic (10) mode (again,

for CC and CP modes only), the T

HIGH, TLOW (14), and RISE, FALL (15) values must also be set.

Then, select the high or low programmed Load level by pressing the LEVEL key (9), and last, press the

LOAD key (8) to apply load to the input terminals.

3.2.2 Initial Setup (LIMIT Key)

Pass / Fail Limits, Go/No GO Limits

If pass/fail limits are not desired, skip this step. This step is to set the upper and lower limit values

within which the inputs must fall in order to pass the test. (Pass is indicated when the NG register

is set to 0 and the NG LED (2) remains not lit). If the inputs fall outside those values, i.e., they are

less than the lower limit value or higher than the upper limit value, the test is a “fail” or No Go. (Fail

is indicated when the NG register is set to 1 and the NG LED is lit).

Voltage: Press the LIMIT key until its corresponding ON LED (12) is lit and the “V” LED (5) is lit.

The upper 5-digit display shows the upper voltage limit; the lower 5-digit display shows the

lower voltage limit. Use the larger × Ø increment/decrement arrows to set the upper limit and

the smaller ↑↓ increment/decrement arrows to set the lower limit.

Current: Press the LIMIT key until its corresponding ON LED is lit and the “A” LED (5) is lit.

The upper 5-digit display shows the upper current limit; the lower 5-digit display shows the lower

current limit. Use the larger × Ø increment/decrement arrows to set the upper limit and the

smaller ↑↓ increment/decrement arrows to set the lower limit.

Power: Press the LIMIT key until its corresponding ON LED is lit and the “W” LED (5) is lit.

The upper 5-digit display shows the upper power limit; the lower 5-digit display shows the lower

power limit. Use the larger × Ø increment/decrement arrows to set the upper limit and the

smaller ↑↓ increment/decrement arrows to set the lower limit

M540071-01 Rev C 3-7

Page 36

Operation Sorensen SLM-Series DC Load

VSENSE: Press the LIMIT key until SEnSE appears on the display. Use any of the arrow keys

to toggle between AUTO or ON.

• In AUTO, if the external VSENSE voltage (through the BNC connection) is greater than

1V for SLM-series DC 60V modules or 3V for 250, 500V modules; the voltage

displayed on the 5-digit DVM is from the V

SENSE input. Otherwise, when the voltage

on the BNC is equal to or less than the minimum voltage, the 5-digit DVM measures

the DC input terminals of the load module.

• In VSENSE ON mode, the 5-digit voltage meter displays the voltage of VSENSE BNC

input.

LOAD ON: Press the LIMIT key until Ld-on appears on the lower 5-digit DM display. Use the

coarse/fine adjust keys to set the LOAD ON voltage, which is displayed on the upper 5-digit DM.

The LOAD ON voltage must be higher than the LOAD OFF voltage. (If the LOAD ON voltage

is set lower than the LOAD OFF voltage, the load will reset the LOAD ON voltage equal to the

LOAD OFF voltage).

LOAD OFF: Press the LIMIT key until LdoFF appears on the lower 5-digit DM display. Use the

coarse/fine adjust keys to set the LOAD OFF voltage, which is displayed on the upper 5-digit

DM. The LOAD OFF voltage must be lower than the LOAD ON voltage. (If the LOAD OFF

voltage is set higher than the LOAD ON voltage, the load will reset the LOAD OFF voltage equal

to the LOAD ON voltage).

Range Auto/Fixed Range 2: There are two programming ranges in Constant Current and

Constant Resistance modes. Range selection can be automatic or fixed in Range 2, as set by

the LIMIT key. Ranges are described in the following examples:

Constant Current mode: (SLM-60-60-300 example)

Range 1 (6A) indicates low load current operating range; Range 2 (60A) indicates high load

current operating range. The detailed specifications of load current range are listed in

Table 1-1. The current range automatically changes according to the programmed load

current. Range 1 is selected automatically if the programmed load current is less than the

maximum current of Range 1 (6A), and will set to Range 2 automatically when the

programmed current is higher than the maximum current of Range 1 (6A).

Constant Resistance mode:

Range 1 indicates low load resistance operating range (high resistance, low current), Range

2 indicates high load resistance operating range (low resistance, high current). The

detailed resistance range specifications are shown in Table 1-1. The resistance range

automatically changes according to the programmed load resistance.

The SLM-series electronic load will set Range 1 automatically if the programmed load

resistance is higher than the minimum load resistance of Range 1, and will set to Range 2

when the programmed load resistance is lower than the minimum load resistance of Range

1.

The normal operating mode for programming values is for the load to automatically select

low or high range (CC or CR modes only). However, in the use of the analog input, the

load can be programmed in Range 2 at all times.

3-8 M540071-01 Rev C

Page 37

Sorensen SLM-Series DC Load Operation

Press the LIMIT key until rAnGE appears on the upper 5-digit display. Use the inc/dec

arrows to set AUTO or rAn2. rAn2 forces the load to Range 2 for CC and CR mode, as

defined in Table 3-2.

Over Current Test (OCP Test)

An OCP test automatically steps the current from a start current (iStAr) to a stop current (iStOP) in

equal increments (iStEP). When the voltage falls below a threshold voltage (Uth), the test stops and

the current setting is saved.

The LIMIT key steps through each of the first three setup parameters. The threshold voltage setting

appears after the OPP test parameters.

After setting the four parameters (start, stop, step and threshold), refer to Test Mode instructions to set

the OCP test mode, store and run the test.

Over Power Test (OPP Test)

An OPP test automatically steps the current from a start power (PStAr) to stop power (PStOP) in equal

increments (PStEP). When the voltage falls below a threshold voltage (Uth), the test stops and the

power setting is saved.

Each press of the LIMIT key steps through settings for the four setup parameters.

After setting the four parameters, set the OPP test mode, store and run the test.

Test Mode

Test modes are Normal, OCP and OPP. All modes except OCP and OPP are “normal” mode.

Press the LIMIT key until tESt appears on the display. Use the inc/dec arrows to set Normal, OCP or

OPP modes.

If OCP or OPP mode is selected, store the setting in the chassis memory as described in the SLM-4 or

SLM-1 programming manuals.

To run an OCP or OPP test, perform a recall operation where the test was saved (see SLM-1 or SLM-4

manual).

To return to Normal mode, press the LIMIT key until tESt appears on the display. Use the down

arrows until “nor” appears on the display.

Please see Figure 3-3 for flowchart.

M540071-01 Rev C 3-9

Page 38

Operation Sorensen SLM-Series DC Load

LIMIT

FUNCTION DISPLAY CONTROL

1

LIMIT

Set

G/NG Voltage

Limits

Set

G/NG Current

Limits

Set

G/NG Power

Limits

Set Vsense Mode

Set

LOAD On

Voltage

Set

LOAD OFF

Voltage

Set

Range to Auto or

Range II

Set

Start Current for

OCP Test

Set

Stop Current for

OCP Test

1

LED ON: V, LIMIT

Upper 5 Digit: Upper

Limit

Lower 5 Digit:: Lower

Limit

LED ON: A, LIMIT

Upper 5 Digit: Upper

Limit

Lower 5 Digit:: Lower

Limit

LED ON: W, LIMIT

Upper: Upper Limit

Setting

Lower: Lower Limit

Setting

LEDs ON: LIMIT

Upper: "SEnSE"

Lower: Auto / On

LEDs ON: V, LIMIT

Upper: Voltage Setting

Lower: "Ld-on"

LEDs ON: V, LIMIT

Upper: Voltage Setting

Lower: "Ld-oFF"

LEDs ON: LIMIT

Upper: "rAnGE"

Lower: AUto / rAn2

LEDs ON: A, LIMIT

Upper: "iStAr"

Lower: Current

Setting

LEDs ON: A, LIMIT

Upper: "iStOP"

Lower: Current

Setting

×Ø Sets upper limit

↑↓ Sets lower limit

×Ø Sets upper limit

↑↓ Sets lower limit

×Ø Sets upper limit

↑↓ Sets lower limit

Any up/down button toggles

Auto / On

×Ø ↑↓ Coarse/fine setting

×Ø ↑↓ Coarse/fine setting

Any up/down button toggles

Auto / On

×Ø ↑↓ Coarse/fine setting

×Ø ↑↓ Coarse/fine setting

Current Step Size

for OCP Test

Start Power for

Stop Power for

Power Step Size

for OPP Test

Threshold Voltage for

OCP/OPP Tests

No

Load Module

Setup Complete

Set

Set

OPP Test

Set

OPP Test

Set

Set

Set

Test Mode

Is OCP or OPP

Test Selected

?

LEDs ON: A, LIMIT

Upper: "iStEP"

Lower: Current

Setting

LEDs ON: A, LIMIT

Upper: "iStEP"

Lower: Current

Setting

LEDs ON: W, LIMIT

Upper: "PStAr"

Lower: Power

Setting

LEDs ON: W, LIMIT

Upper: "PStOP"

Lower: Power

Setting

LEDs ON: W, LIMIT

Upper: "PStEP"

Lower: Power

Setting

LEDs ON: LIMIT

Upper: ""

Lower: nor / OCP /

OPP

Yes

Store Setup in

Chassis Memory

Load Module

Setup Complete

×Ø ↑↓ Coarse/fine setting

×Ø ↑↓ Coarse/fine setting

×Ø ↑↓ Coarse/fine setting

×Ø ↑↓ Coarse/fine setting

×Ø ↑↓ Coarse/fine setting

Coarse or fine up button: moves

from "nor" --> "OCP" --> "OPP"

Coarse or fine down button: moves

down from "OPP" --> "OCP"--> "nor"

OCP mode: current stepped

test will be run

OPP mode: power stepped

test will be run

"nor" mode: normal mode, all

standard modes -- CC, CR,

CV, CP, Dynamic, Shorts -will be run

1. Press chassis "STORE" button.

2. Use Bank Up/down buttons and

State 1-5 buttons to store setup, per

SLM-4 or SLM-1 manual.

Figure 3-3 Flowchart for Load Module General Setup Parameters and OCP and OPP Tests

Press the LIMIT button to enter setup mode. To skip setup of any parameter, scroll past by

pressing the LIMIT key to advance to the next parameter. When setup is complete, press LIMIT key

until its LED is no longer lit.

(

indicates pressing LIMIT button to advance to next parameter).

3-10 M540071-01 Rev C

Page 39

Sorensen SLM-Series DC Load Operation

3.2.3 Normal Operating Modes

In the following instructions, the numbers within parentheses refer to the front panel

components of the SLM-series DC plug-in-module, as labeled in Figure 3-1.

CC Mode

CC mode can be either static (fixed DC level) or dynamic (two levels with timing and slew rates

programmed). Dynamic mode is described later in this Section 3.2.3. In static mode, two

levels can be set to allow for quick switching between two current levels.

1. Press the MODE key (3), until the CC LED (3) is lit.

2. Press the PRES key (7) to view the programmed values. The high level must be higher

than the low level; the load will not allow the HIGH level to be lower than the LOW level.

a. To set the high level, press the HIGH key (16). Use the inc/dec arrows to set the

desired level.

b. To set the low level, press the LOW key (16). Use the inc/dec arrows to set the desired

level.

3. To exit the Preset mode, press the PRES key until its LED is green (power/watts displayed)

or not lit (volts displayed).

4. Press the LEVEL key to select the desired level CC mode by. When the LEVEL LED is lit,

the HIGH level is selected and when not lit, the LOW level is selected.

5. Press the LOAD key (8) to toggle the load off or on. Press the LEVEL key at any time to

switch between the HIGH and LOW level settings. The value for current can be changed at

any time using the inc/dec arrows. The values set can be viewed by pressing the PRES

key.

CR Mode

CR mode static (fixed DC level) can be set in two levels to allow for quick switching between

two resistance levels. High and low levels are referenced to the resulting current level, thus

the ×↑keys will decrease the resistance setting and the Ø↓ keys will increase the resistance

setting.

1. Press the MODE (3) key, until the CR LED is lit (3).

2. Press the PRES key (7) to view the programmed values. The HIGH level must be set to a

lower resistance than the LOW level; the load will not allow the HIGH level to be higher than

the LOW level.

a. To set the high level, press the HIGH key (16). Use the inc/dec arrows to set the desired

level.

b. To set the low level, press the LOW key (16). Use the inc/dec arrows to set the desired

level.

3. To exit the Preset mode, press the PRES key until its LED is green (power/watts displayed)

or not lit (volts displayed).

M540071-01 Rev C 3-11

Page 40

Operation Sorensen SLM-Series DC Load

4. Press the LEVEL key (9) to select the desired CR level. When the LEVEL LED is lit, the

HIGH level (lower resistance) is selected and when not lit, the LOW level is selected (higher

resistance).

5. Press the LOAD key (8) to toggle the load off or on. Press the LEVEL key (9) at any time

to switch between the settings. The current can be changed at any time using the inc/dec

arrows. The value set can be viewed by pressing the PRES key.

CV Mode

CV mode operates in static mode only.

1. Press the MODE key (3) until the CV LED (3) is lit.

2. Press the PRES key (7) to view the programmed values. The high level must be higher

than the low level; in setting the values, the load will not allow the HIGH level to be lower

than the LOW level.

a. To set the high level, press the HIGH key (16). Use the inc/dec arrows to set the desired

level.

b. To set the low level, press the LOW key (16). Use the inc/dec arrows to set the desired

level.

3. To exit the Preset mode, press the PRES key (7) until its LED is green (power/watts

displayed) or not lit (volts displayed).

4. Press the LEVEL key (9) to select the desired level CV mode. When the LED is lit, the

high level is selected; when the LED is not lit, low level is selected.

5. Press the LOAD key (8) to toggle the load off or on. Press the LEVEL key (9) at any time

to switch between the settings. The current can be changed at any time using the inc/dec

arrows. The value set can be viewed by pressing the PRES key.

CP Mode

CP mode can be either static (fixed DC level) or dynamic (two levels with timing and current

slew rates programmed). Dynamic mode is described next. In static mode, two levels can be

set to allow for quick switching between two current levels.

1. Press the MODE key (3), until the CP LED (3) is lit.

2. Press the PRES key (7) to view the programmed values. The high level must be higher

than the low level; in setting the values below, the load will not allow the HIGH level to be

lower than the LOW level.

a. To set the high level, press the HIGH key (16). Use the inc/dec arrows to set the desired

level.

b. To set the low level, press the LOW key (16). Use the inc/dec arrows to set the desired

level.

3. To exit the Preset mode, press the PRES key (7) until its LED is green (power/watts

displayed) or not lit (volts displayed).

3-12 M540071-01 Rev C

Page 41

Sorensen SLM-Series DC Load Operation

4. Press the LEVEL (9) key to select the desired level CP mode. When the LED is lit, the

high level is selected; when the LED is not lit, low level is selected.

5. Press the LOAD (8) key to toggle the load off or on. Press the LEVEL key at any time to

switch between the high and low settings. The power can be changed using the inc/dec

arrows. The value set can be viewed by pressing the PRES key (7) until the amber LED is

lit.

Dynamic Mode

Dynamic mode allows fast state switching in either current or power mode. It controls the dwell

time and current slew rate, as well as the high and low values.

Figure 3-4 Dynamic Mode Waveform and Definition Parameters

1. Press the MODE key (3), until the desired mode LED (3) is lit, CP or CC only.

2. Set high and low values:

a. Press the PRES key (7) until its amber LED is lit and the programmed values are

displayed. The high level must be higher than the low level; in setting the values below,

the load will not allow the HIGH level to be lower than the LOW level.

b. To set the high LEVEL, press the HIGH key (16). Use the inc/dec arrows to set the

desired level.

c. To set the low LEVEL, press the LOW key (16). Use the inc/dec arrows to set the

desired level.

3. Set the current RISE and FALL slew rates:

a. Press the RISE key (15). Use the inc/dec arrows to set the desired RISE rate.

Note: In CP mode, the rise rate is limited to Range 1.

b. Press the FALL key (15). Use the inc/dec arrows to set the desired FALL rate.

Note: In CP mode, the rise rate is limited to Range 1.

4. Set the dwell time (PERIOD):

a. Press the T

b. Press the T

HIGH key (14). Use the inc/dec arrows to set the desired high state time.

LOW key (14). Use the inc/dec arrows to set the desired low state time.

M540071-01 Rev C 3-13

Page 42

Operation Sorensen SLM-Series DC Load

5. Operating in Dynamic Mode:

a. Press the MODE key (3), until the desired mode LED (3) is lit, CP or CC only.

b. Press the DYN/STA key (10) until its amber LED is lit.

c. Press the LOAD key (8) to turn the load on (amber LED is lit).

Shorts Mode

Shorts mode puts the load in minimum resistance/maximum current state.

1. To turn on shorts mode, press the SHORT key (11) until its LED is lit. This overrides any

selection made with the MODE key. When the LOAD key is toggled to ON, the load

simulates a short by sinking maximum rated current at minimum resistance.

2. To exit shorts mode, press the SHORT key (11) until its LED is not lit.

3-14 M540071-01 Rev C

Page 43

Sorensen SLM-Series DC Load Operation

Normal Operating Mode Flowchart

Normal Operating

Modes

Press MODE

SHORT

Shorts MODE?YES NO

MODE

PRES

HIGH

Button until

desired mode is

illuminated CC,

CR, CV, CP

Toggle PRESet

viewing off (LED

off or green)

Toggle between

HIGH (amber

LED) and LOW

(LED off)

Toggle between

HIGH (amber

LED) and LOW

(LED off)

YES

PRES

LEVEL

LOAD

NO

DYN/STA

×Ø ↑↓

Coarse/fine setting

×Ø ↑↓

Coarse/fine setting

LOW

×Ø ↑↓

Coarse/fine setting

CR or CV

Mode?

YES

Dynamic

Toggle dynamic

mode (LED on)

and static mode

(LED off)

If only one value is

desired, set HIGH

to maximum rated

value. Use LOW

to set desire value.

YES

THIGH

×Ø ↑↓

Coarse/fine setting

RISE

×Ø ↑↓

Coarse/fine setting

Turn load off

(LED off)

LOAD

TLOW FALL

×Ø ↑↓

Coarse/fine setting

Figure 3-5 Normal Operating Mode Flowchart

M540071-01 Rev C 3-15

Page 44

Operation Sorensen SLM-Series DC Load

3.2.4 Initial Setting of SLM-Series DC Load Modules

Table 3-1 lists the factory, or initial, load value settings of the SLM-series DC electronic load when it is

initially powered ON once it first arrives from the factory.

Item

Basic Settings

CC LOW [amps] 0.0000 0.0000 0.000 0.0000 0.0000

CC HIGH [amps] 0.0000 0.0000 0.000 0.0000 0.0000

CR HIGH [Ω] 15000. 7500. 3750. 18750. 18750.

CR LOW [Ω] 15000. 7500. 3750. 18750. 18750.

CV HIGH [volts] 60.00 60.00 00.00 250.0 500.0

CV LOW [volts] 60.00 60.00 60.00 250.0 500.0

CP LOW [watts] 0.000 0.000 0.000 0.000 0.000

CP HIGH [watts] 0.000 0.000 0.000 0.000 0.000

Dynamic Settings

FALL [A/μs] 0.0625 0.1250 0.2500 0.0500 0.0250

RISE [A/μs] 0.0625 0.1250 0.2500 0.0500 0.0250

THIGH [ms] 0.0500 0.0500 0.0500 0.0500 0.0500

TLOW [ms] 0.0500 0.0500 0.0500 0.0500 0.0500

SLM-60-15-75 SLM-60-30-150 SLM-60-60-300 SLM-250-10-300 SLM-500-10-300

Go/No Go Limits

V HIGH 60.00 60.00 60.00 300.0 600.0

V LOW 0.000 0.000 0.000 0.000 0.000

CURR. HIGH 15.000 30.00 60.00 12.000 6.000

CURRENT LOW 0.000 0.000 0.000 0.000 0.000

POWER HIGH 75.00 150.0 300.0 300.0 200.0

POWER LOW 0.000 0.000 0.000 0.000 0.000

System Settings

V SENSE Auto Auto Auto Auto Auto

LD-ON [volts] 1.000 1.000 1.000 2.000 4.000

LD-OFF [volts] 0.5 0.5 0.5 0.150 0.300

Table 3-1 SLM-Series DC Electronic Load Factory Settings for Power On

3.2.5 Analog Programming Input

The Electronic Load has an analog programming 9-pin input on the rear panel of SLM

mainframe, labeled CH1, CH2, CH3, and CH4 respectively. See the SLM Mainframe

Operations Manual for connection instructions. CC and CP modes can be programmed with

a 0 to 10V analog signal (arbitrary waveform or arbitrary waveform + dc) connected to the

analog programming input.

Example: SLM-60-60-300. The 0 to 10V Analog signal can program the 0 to

full-scale input Range 1n the CC mode (0 to 6A range when load current setting

is less than 6A, or 0 to 60A range when load current setting is higher than 6A) or

in the CP mode (0 to 300W). To be operated only in the high range (Range 2).

The analog programming signal can act alone or it can be summed with the programmed

3-16 M540071-01 Rev C

Page 45

Sorensen SLM-Series DC Load Operation

value via GPIB, RS-232, or the front panel. Figure 3-6 shows the analog programming signal

(4 Vac, 500Hz) summed with the 24A programmed setting in CC mode.

LOAD CURRENT

36A

24A

12A

2mS

Figure 3-6 Analog Programming Load Current in CC Mode Operation

Caution: The analog input is always active. Even if the load is in the “OFF”

state at the front panel or through remote control, the load will draw current when

voltage is applied to the analog input.

ANALOG V

6V

4V

2V

T

3.2.6 Load Coarse/Fine Increase/Decrease Adjustment Key

The load current step change or resolution is shown in Table 3-2 for each load module.

Pressing and holding any one of the four arrow keys for more than 1 second speeds the step change;

either release the arrow key to stop at a value, or wait for the adjustment to reach the maximum or

minimum load current setting.

SLM-60-15-75 RANGE 1 RANGE 2

COARSE/FINE LOAD

CURRENT ADJUSTMENT

KEY

CC Mode 4.0 mA 0.4 mA 40.0 mA 4.0 mA

CR Mode 6.666mS 0.0666mS 0.1066Ω 1.066mΩ

CV Mode 0.16V 16mV 0.16V 16mV

CP Mode 0.2W 0.02W 0.2W 0.02W

SLM-60-30-150 RANGE 1 RANGE 2

COARSE/FINE LOAD

CURRENT ADJUSTMENT

KEY

CC Mode 8.0 mA 0.8 mA 80 mA 8.0 mA

CR Mode 13.33mS 0.133mS 53.33mΩ 0.533mΩ

CV Mode 0.16V 0.016V 0.16V 0.016V

CP Mode 0.4W 0.04W 0.4W 0.04W

(Continued)

×Ø

×Ø

↓↑

↓↑

×Ø

×Ø

↓↑

↓↑

M540071-01 Rev C 3-17

Page 46

Operation Sorensen SLM-Series DC Load

SLM-60-60-300 RANGE 1 RANGE 2

COARSE/FINE LOAD

CURRENT ADJUSTMENT

KEY

CC Mode 16.0 mA 1.6 mA 160 mA 16 mA

CR Mode 26.66mS 0.266mS 26.66mΩ 0.266mΩ

CV Mode 0.16V 0.016V 0.16V 0.016V

CP Mode 0.8W 0.08W 0.8W 0.08W

SLM-250-10-300 RANGE 1 RANGE 2

COARSE/FINE LOAD

CURRENT ADJUSTMENT

KEY

CC Mode 2.68 mA 0.268 mA 26.8 mA 2.68 mA

CR Mode 1.067mS 0.0107mS 0.667Ω 6.67mΩ

CV Mode 666.7mV 66.67mV 666.7V 66.67mV

CP Mode 0.8W 0.08W 0.8W 0.08W

SLM-500-10-300 RANGE 1 RANGE 2

COARSE/FINE LOAD

CURRENT ADJUSTMENT

KEY

CC Mode 2.68 mA 0.268 mA 26.8 mA 2.68 mA

CR Mode 0.053mS 0.0053mS 133.3Ω 13.33mΩ

CV Mode 1.333V 133.3mV 1.333V 133.3mV

CP Mode 0.8W 0.08W 0.8W 0.08W

×Ø

×Ø

×Ø

↓↑

↓↑

↓↑

×Ø

×Ø

×Ø

↓↑

↓↑

↓↑

Table 3-2 Resolution of Range 1/2 vs Coarse/Fine Load Current Setting Keys

3.2.7 I-Monitor

The I-Monitor BNC monitors the Electronic load's input current or short current. An isolated amplifier

output 0V to 10V full-scale signal indicates the zero to full-scale current for each Electronic load module.

The isolated voltage is 250V between load module and I-Monitor BNC output, and it has the same

ground potential with mainframe (i.e., GPIB ground potential).

The isolated I-Monitor feature eliminates the grounding problem while connecting I-Monitor BNC and

measuring power supply output voltage to oscilloscope simultaneously, because dual oscilloscope

channels are not isolated.

This feature is also useful in testing multiple output power supplies that have simultaneous positive and

negative polarity output, because the I-Monitor output is isolated from each load module or each power

supply output. It eliminates grounding problems while monitoring the current signal from the I-Monitor

BNC connector.

3-18 M540071-01 Rev C

Page 47

Sorensen SLM-Series DC Load Operation

3.2.8 Protection Features