Page 1

Smart choice for power

Xantrex Technology Inc.

Programmable Products

9250 Brown Deer Road

San Diego, CA 92121

USA

858 450 0085 Phone

858 458 0257 Fax

www.programmablepower.com

SLH-Series AC High

Power Electronic

Load

Operating and Programming

Manual

M540073-01 Rev C www.programmablepower.com

Page 2

Page 3

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and

controls with products from small mobile units to utility-scale systems for wind, solar,

batteries, fuel cells, microturbines, and backup power applications in both gridconnected and stand-alone systems. Xantrex products include inverters, battery

chargers, programmable power supplies, and variable speed drives that convert, supply,

control, clean, and distribute electrical power.

Trademarks

SLH-Series AC High Power Electronic Load is a trademark of Xantrex International.

Xantrex is a registered trademark of Xantrex International.

Other trademarks, registered trademarks, and product names are the property of their

respective owners and are used herein for identification purposes only.

Notice of Copyright

SLH-Series AC High Power Electronic Load

December 2007 Xantrex International. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC.

(“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF

ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL,

WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY

SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN

ENGLISH, ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE

TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED XANTREX

CONTENT IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION WHICH IS POSTED

AT WWW.PROGRAMMABLEPOWER.COM.

Operating and Programming Manual ©

Date and Revision

December 2007 Revision B

Part Number

M540073-01

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

i

Page 4

This page intentionally left blank.

ii

Page 5

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

WARNING

Only

qualified personnel

perform installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance

equipment

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting

any cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS

TO HUMAN SAFETY may be normally generated on the output terminals. The customer/user

must ensure that the output power lines are labeled properly as to the safety hazards and that

any inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of

the electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use

safety glasses during open cover checks to avoid personal injury by any sudden component

failure.

must

Hazardous voltages may be present when covers are removed.

Qualified personnel must use extreme caution when servicing this

equipment. Circuit boards, test points, and output voltages also may

be floating above (below) chassis ground.

who deal with attendant hazards in power supplies, are allowed to

be grounded properly for both personnel and equipment safety.

SAFETY SYMBOLS

iii

Page 6

This page intentionally left blank.

iv

Page 7

Important Safety Instructions

This manual has been written expressly for the Sorensen SLH series of electronic loads, which

have been designed and certified to meet the Low Voltage and Electromagnetic Compatibility

Directive Requirements of the European Community.

Since the goal of the Low Voltage Directive is to ensure the safety of the equipment operator,

universal graphic symbols have been used both on the unit itself and in this manual to warn the

operator of potentially hazardous situations (see Safety Information page).

v

Page 8

This page intentionally left blank.

vi

Page 9

CONTENTS

SECTION 1 FEATURES, FUNCTIONS, AND SPECIFICATIONS ....1-1

1.1 General Description ......................................................................................... 1-1

1.2 Power Contours ............................................................................................... 1-1

1.3 Operating Modes ............................................................................................. 1-4

1.4 Features and Functions ................................................................................... 1-5

1.5 Accessories ..................................................................................................... 1-5

1.6 Specifications................................................................................................... 1-5

1.7 Regulatory Compliance ................................................................................... 1-7

1.8 System Block Diagram .................................................................................... 1-7

SECTION 2 INSTALLATION AND MAINTENANCE .......................2-1

2.1 INSPECTION................................................................................................... 2-1

2.1.1 Line Voltage......................................................................................... 2-1

2.1.2 Grounding Requirements..................................................................... 2-2

2.1.3 Environmental Requirements .............................................................. 2-2

2.1.4 Rack Mount.......................................................................................... 2-2

2.1.5 Tilt Adjustment ..................................................................................... 2-3

2.1.6 Service or Repair ................................................................................. 2-3

2.2 Connections..................................................................................................... 2-3

2.2.1 Voltage Sensing Input (Vsense) BNC Connector. ............................... 2-3

2.2.2 RS-232C Connection........................................................................... 2-4

2.2.3 GPIB Connection ................................................................................. 2-4

2.3 Maintenance .................................................................................................... 2-5

2.3.1 Cleaning............................................................................................... 2-5

v

Page 10

Contents

SECTION 3 OPERATION.............................................................. 3-1

3.1 Front Panel Controls and Indicators.................................................................3-1

3.2 Set-up Procedures ...........................................................................................3-5

3.3 Normal Operation.............................................................................................3-9

3.3.1 CC Mode: .............................................................................................3-9

3.3.2 Crest Factor Selection:.........................................................................3-9

3.3.3 CR Mode ............................................................................................3-10

3.4 STORE / RECALL Function and Sequence Operation ..................................3-12

3.4.1 STORE Procedure: ............................................................................3-12

3.4.2 RECALL Procedure............................................................................3-12

3.4.3 AUTO SEQUENCE Procedures.........................................................3-12

3.5 Initial Settings of SLH-series AC/DC Electronic Load ....................................3-14

3.6 Protection Features........................................................................................3-15

3.6.1 Over Voltage ......................................................................................3-16

3.6.2 Over Current ......................................................................................3-16

3.6.3 Over Power ........................................................................................3-16

3.6.4 Over Temperature..............................................................................3-16

SECTION 4 GPIB/RS-232 PROGRAMMING OPERATION ............. 4-1

4.1 Introduction ......................................................................................................4-1

4.2 SLH-series GPIB COMMAND LIST .................................................................4-1

4.2.1 Setting Commands...............................................................................4-1

4.2.2 Query Commands ................................................................................4-2

4.3 Command Syntax Abbreviations......................................................................4-3

4.4 GPIB/RS-232 Command Description...............................................................4-6

4.4.1 Setting Commands...............................................................................4-6

4.4.2 Query Commands ..............................................................................4-12

APPENDIX A SLH-series AC/DC Load Wave Form Data Bank .......................................... A-1

APPENDIX B SLH-series AC/DC Load R.201 Edition Wave Form Data Bank ................... B-1

APPENDIX C Setting the AC or DC Electronic Load........................................................... C-1

APPENDIX D Installation Guide and Specification Addendum for SLH-Series Electronic

Loads: Master/Slave Configurations............................................................. D-1

LIST OF FIGURES

Figure 1-1 SLH-500-4-1200 Electronic Load Power Curve ......................................... 1-1

Figure 1-2 SLH-500-6-1800 Electronic Load Power Curve ......................................... 1-2

Figure 1-3 SLH-300-12-1200 Electronic Load Power Curve ....................................... 1-2

Figure 1-4 SLH-300-12-1800 Electronic Load Power Curve ....................................... 1-3

vi

Page 11

Contents

Figure 1-5 SLH-300-18-1800 Electronic Load Power Curve ........................................1-3

Figure 1-6 Characteristics of CC Mode ........................................................................1-4

Figure 1-7 Characteristics of CR Mode ........................................................................1-4

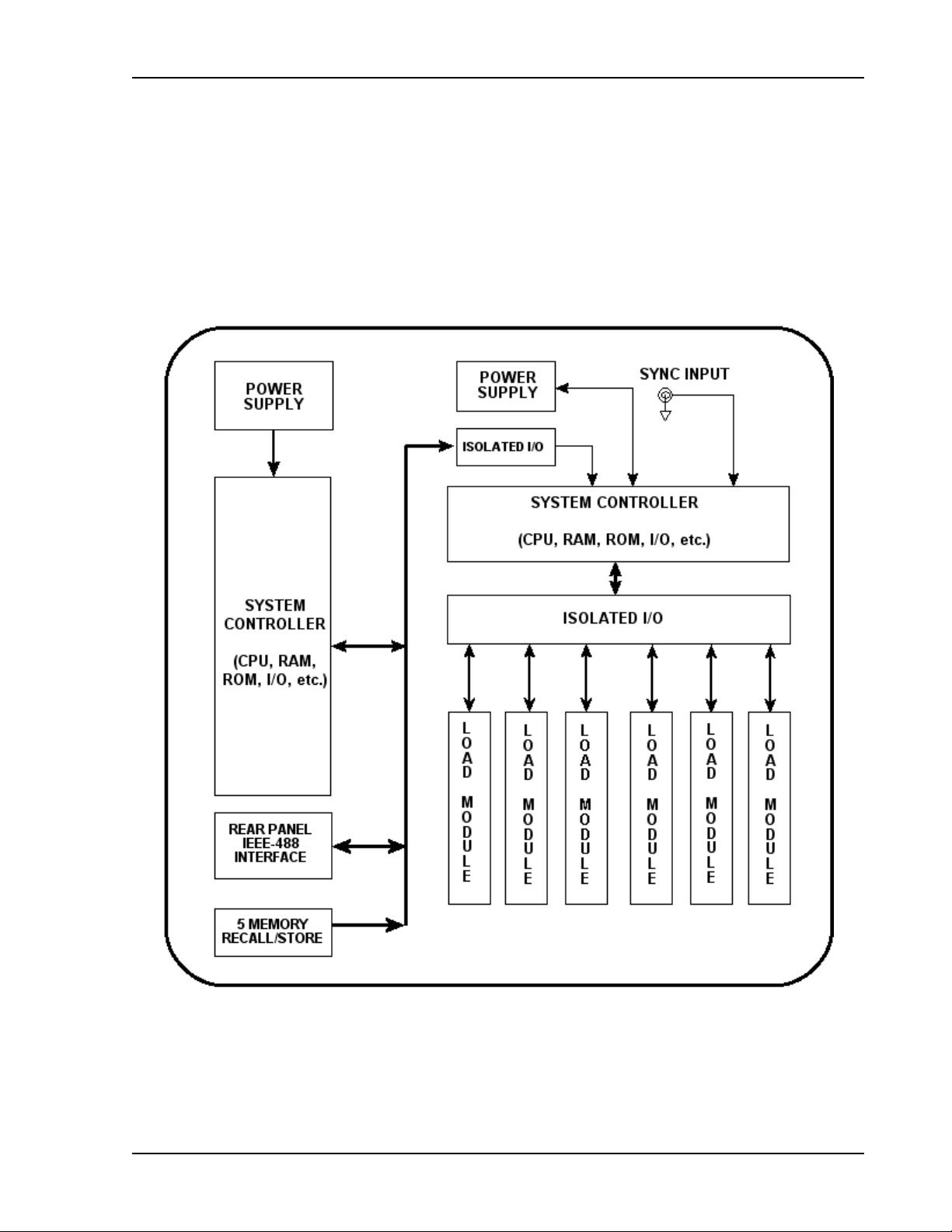

Figure 1-8 System Block Diagram................................................................................1-7

Figure 2-1 Setting Switch .............................................................................................2-1

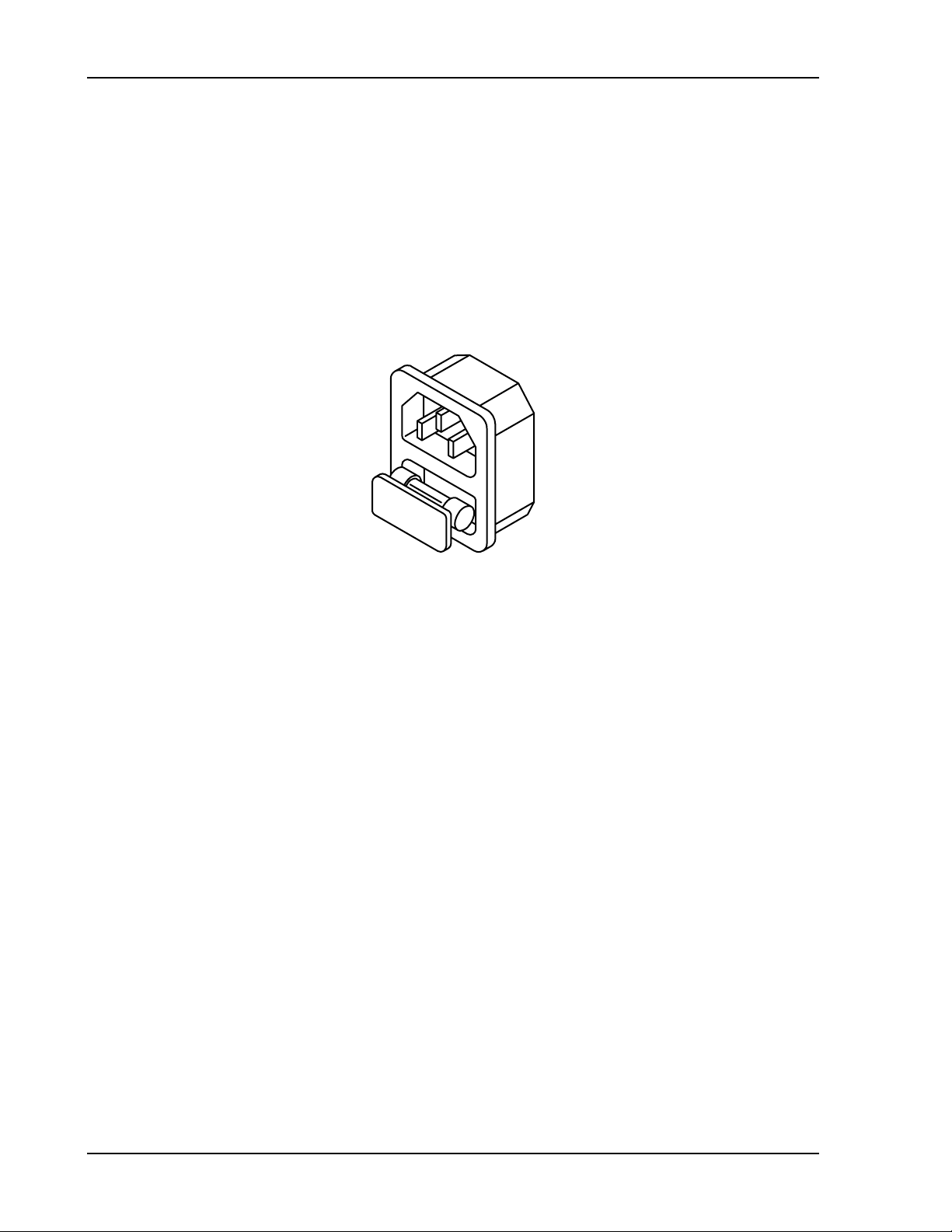

Figure 2-2 Fuse Holder in AC Line Input Connector ....................................................2-2

Figure 2-3 Connection Method for Small Load Current Condition................................2-3

Figure 2-4 Typical Connection for SLH-series High Power AC/DC Electronic Load ....2-3

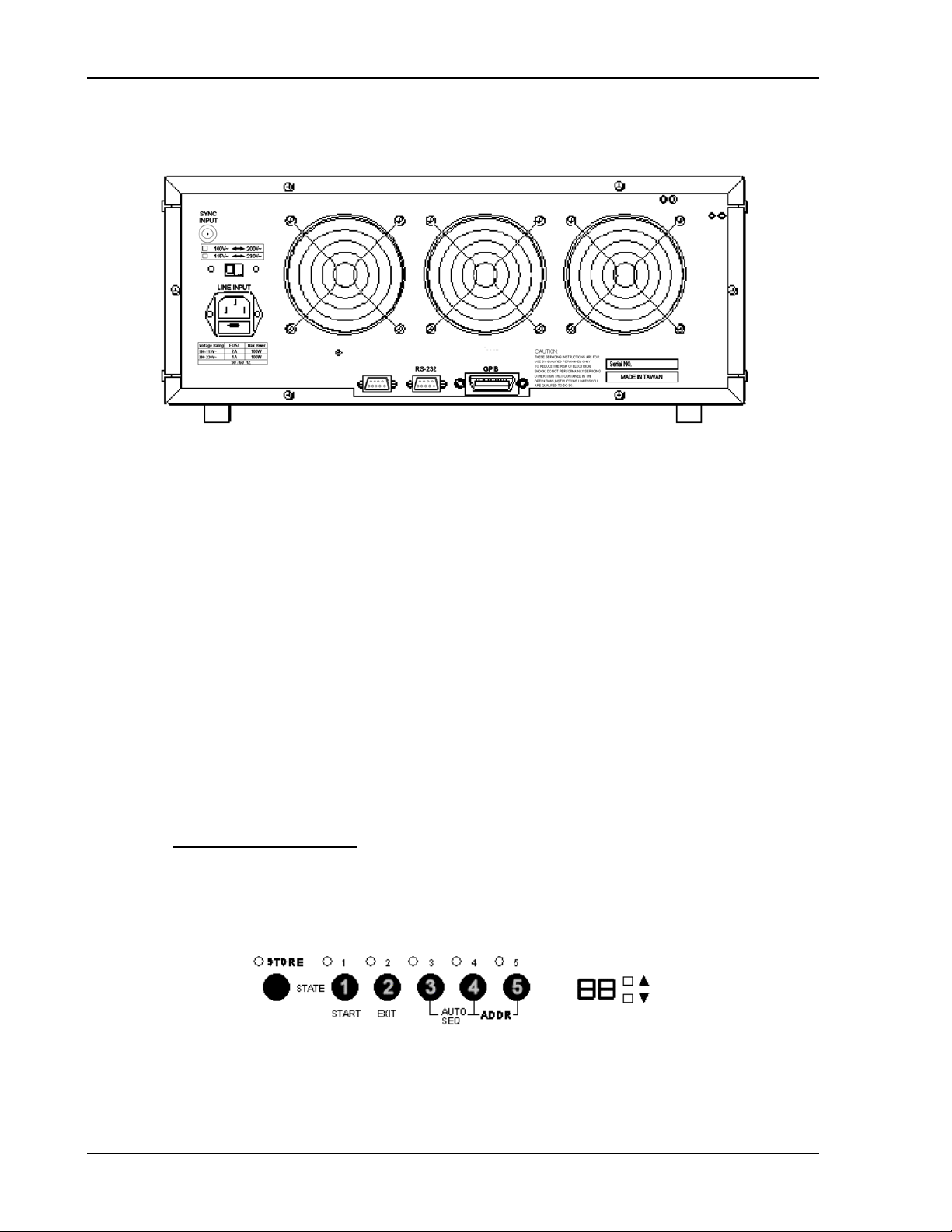

Figure 2-5 Close-up, Front Panel State Keys...............................................................2-4

Figure 2-6 SLH-series Rear Panel ...............................................................................2-4

Figure 3-1 Front Panel of SLH-series High Power AC/DC Electronic Load .................3-1

Figure 3-2 Front Panel Button Functions for SLH-series AC Unit ................................3-5

Figure 3-3 Illustration of Sync.......................................................................................3-6

Figure 3-4 SLH-series AC Electronic Load Operation Flow Chart ...............................3-8

Figure 3-5 STORE/RECALL and Sequencing Keypad...............................................3-12

Figure 3-6 Auto Sequence Function Set-Up and Operation Flowchart ......................3-13

Figure 4-1 Protection Status Register ........................................................................4-14

Figure 4-2 Error Status Byte Register ........................................................................4-14

LIST OF TABLES

Table 1-1 SLH-series AC/DC Specification ..................................................................1-6

Table 3-1 Built in Crest Factor Settings by Bank andKkey Selection ...........................3-7

Table 3-2 SLH-series AC Electronic Load Factory Settings.......................................3-15

Table 3-3 SLH-series Protection Setting Values ........................................................3-16

Table 4-1 GPIB Setting Command Summary...............................................................4-1

Table 4-2 GPIB Query Command Summary ................................................................4-2

Table 4-3 GPIB Command Terminator.........................................................................4-3

Table 4-4 GPIB/RS-232 Setting Command Summary .................................................4-4

Table 4-5 GPIB/RS-232 Preset Query Command Summary with Applicable Module

Types ...........................................................................................................4-4

Table 4-6 State Command Summary ...........................................................................4-4

Table 4-7 System Commands - All Modules ................................................................4-5

Table 4-8 Measure and Limit Commands ....................................................................4-5

Table 4-9 Global Commands........................................................................................4-5

Table 4-10 Waveform Information ..............................................................................4-10

vii

Page 12

Contents

This page intentionally left blank.

viii

Page 13

FEATURES, FUNCTIONS,

AND SPECIFICATIONS

1.1 GENERAL DESCRIPTION

SLH-Series High Power, AC/DC Electronic Load is used to test the specification

characteristics of AC/DC high power suppliers and the service life characteristics of

batteries.

The load works with GPIB interface and front panel manual operation.

SECTION 1

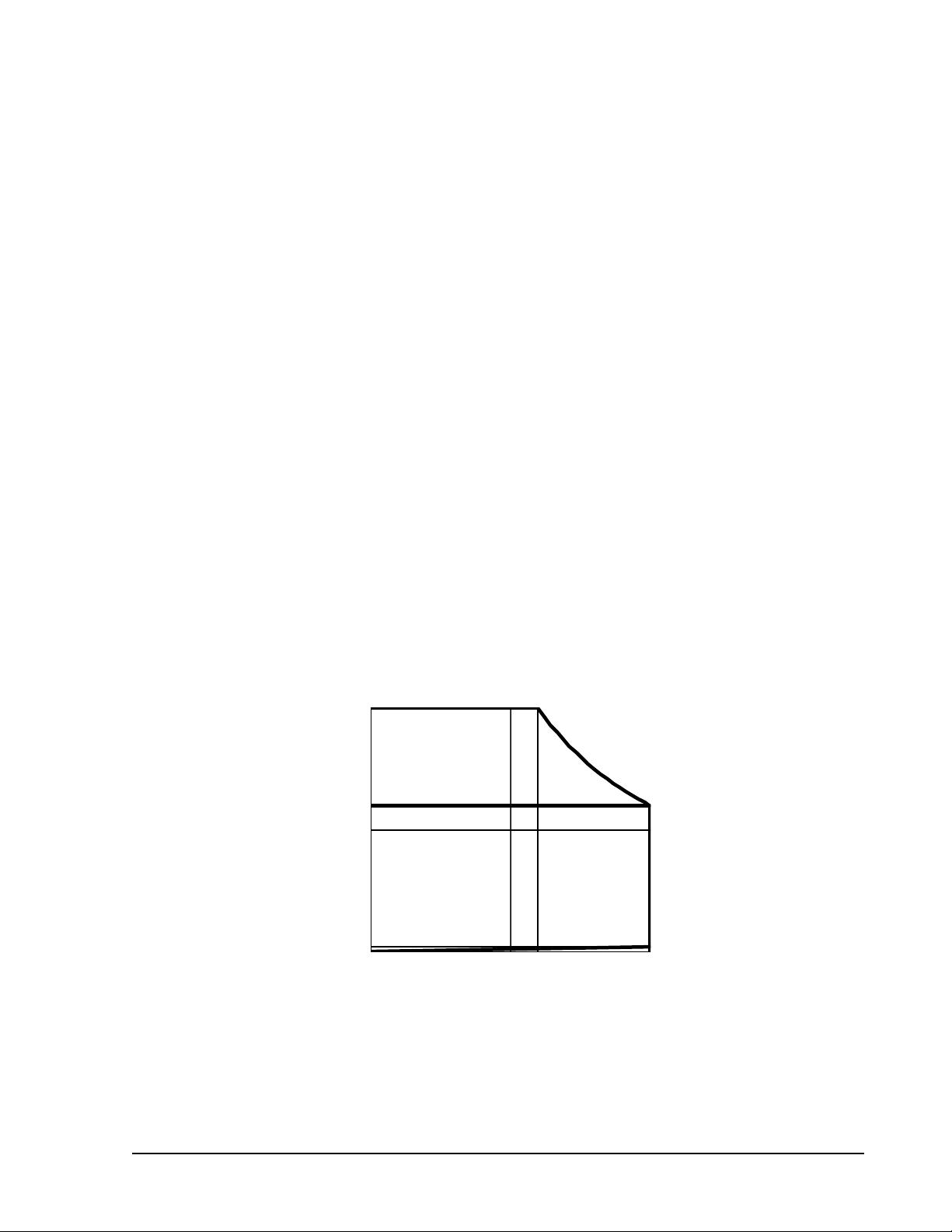

1.2 POWER CONTOURS

The power contours of the SLH-Series AC/DC Electronic Loads are shown in the

following figures.

500

300

250

Voltage (V)

10

0

024

Figure 1-1 SLH-500-4-1200 Electronic Load Power Curve

2.4

Current (A)

M540073-01 Rev C 1-1

Page 14

Features, Functions and Specifications SLH-Series AC High Power Electronic Load

00

500

300

250

Voltage (V)

10

0

036

Current (A)

3.6

Figure 1-2 SLH-500-6-1800 Electronic Load Power Curve

300

2

150

Voltage (V)

100

5

0

0612

4

Current (A)

8

Figure 1-3 SLH-300-12-1200 Electronic Load Power Curve

1-2 M540073-01 Rev C

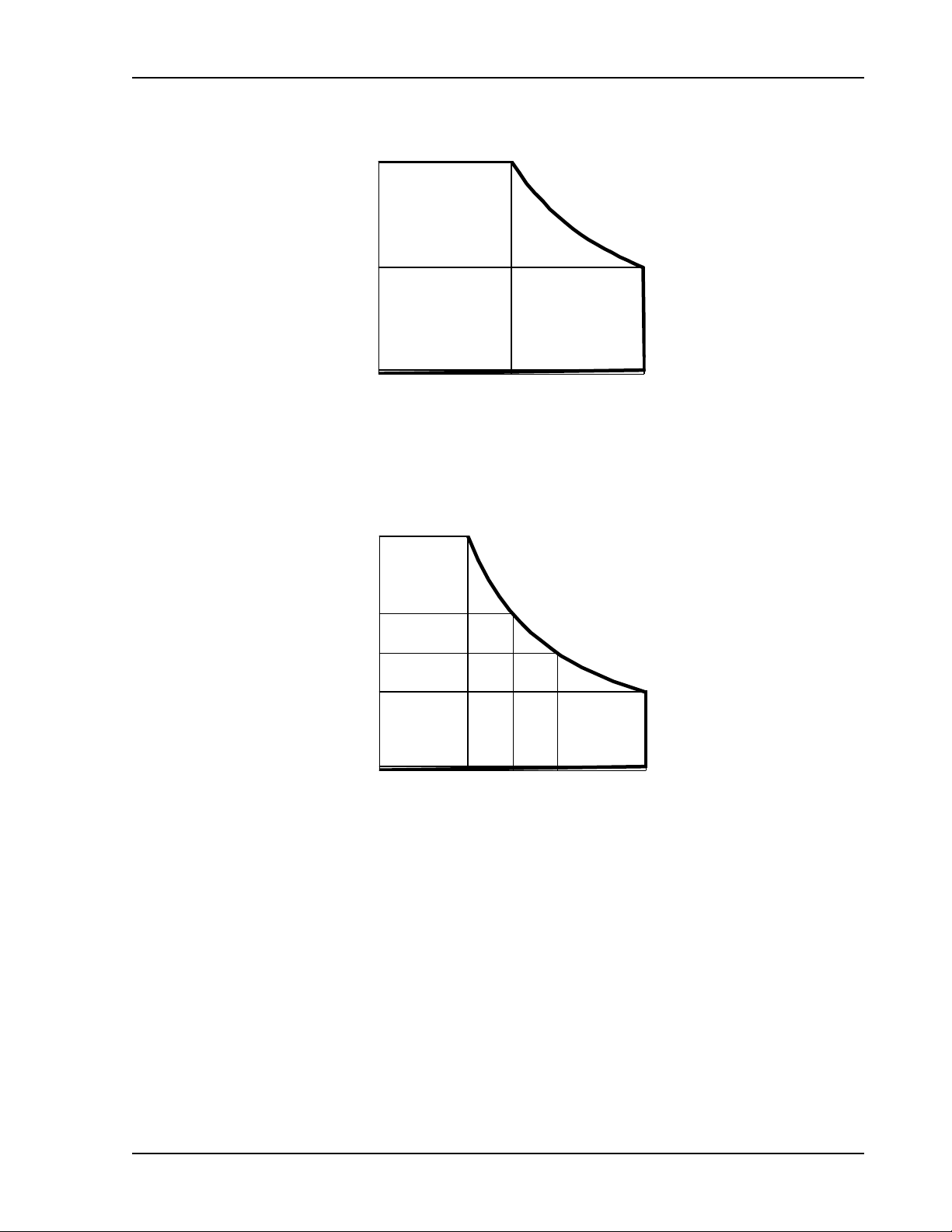

Page 15

SLH-Series AC High Power Electronic Load Features, Functions and Specifications

300

150

Voltage (V)

5

0

0612

Current (A)

Figure 1-4 SLH-300-12-1800 Electronic Load Power Curve

300

200

150

Voltage (V)

100

5

0

0918

6

Current (A)

12

Figure 1-5 SLH-300-18-1800 Electronic Load Power Curve

M540073-01 Rev C 1-3

Page 16

Features, Functions and Specifications SLH-Series AC High Power Electronic Load

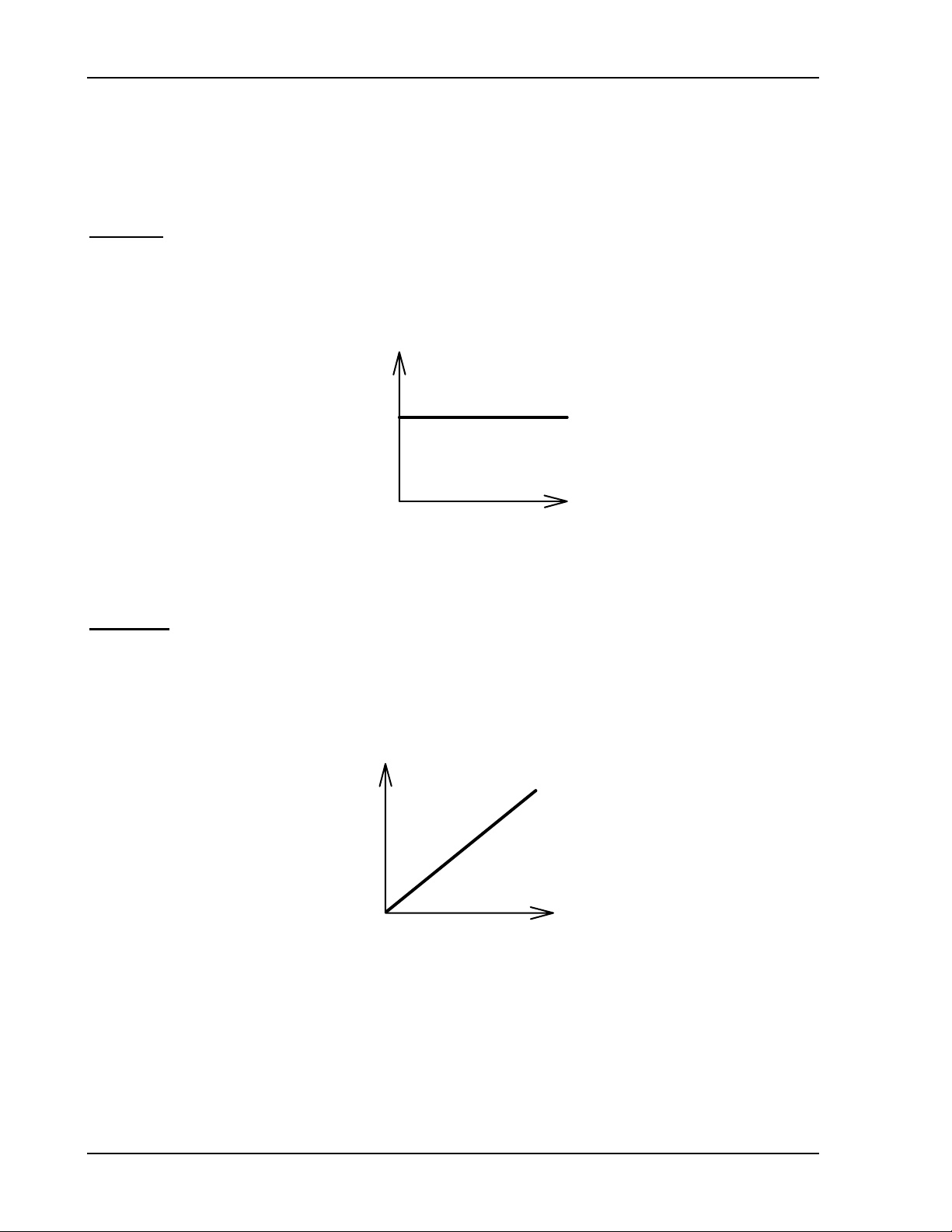

1.3 OPERATING MODES

The work mode of SLH-series High Power AC Electronic Load includes Constant

Current (CC) and Constant Resistance (CR).

CC Mode

:

During CC mode, the load current input into SLH-series High Power, AC Electronic Load

depends on the current setting regardless of the input voltage, i.e., the

current setting remains unchanged.

I

CC

CURRENT SETTING

LOAD

CURRENT

V

INPUT VOLTAGE

Figure 1-6 Characteristics of CC Mode

CR Mode:

During C.R. mode, the load current input into SLH-series High Power AC/DC Electronic

Load depends on the resistance setting. At this time, the load current is in direct proportion

to input voltage, e.g. the resistance setting remains unchanged. Please refer to Fig. 1.7

below

I

LOAD

CURRENT

RESISTANCE

SETTING

V

INPUT VOLTAGE

Figure 1-7 Characteristics of CR Mode

The load setting of SLH-series High Power AC/DC Electronic Load and the load condition

setting of the front panel can be made through front panel manual operation or through

GPIB commands. The load voltage and current can be transmitted to the computer through

GPIB bus. For operation of GPIB, please refer to Section 4 GPIB Operation

1-4 M540073-01 Rev C

Page 17

SLH-Series AC High Power Electronic Load Features, Functions and Specifications

1.4 FEATURES AND FUNCTIONS

• Interface function of full GPIB control, including setting of load condition and read-

back of Vmeter and Ameter

• Dual High Accuracy/High Resolution 4 ½ digit Vmeter and Ameter

• In CC mode, frequency width can reach to 400Hz with the set table range of 1KHz

• In CC mode, the settable Crest Factor can be set to Maximum 3.5

• Automatic judging ability for GO/NG

• Switch-able automatic voltage sensing ability.

• Protection functions include Over-Voltage, Over-Current, Over-Power and Over-

Temperature

• Cooling fan control device with revolution change function

1.5 ACCESSORIES

• Vsense Input BNC Connector 1 PC

• Banana Terminal (Black) 1 PC

• Banana Terminal (Red) 1 PC

• Hook-Type Terminal 2 PC

• SLH-series High Power AC/DC Electronic Load Operation Manual 1 PC

1.6 SPECIFICATIONS

LINE

AC INPUT

MAX. POWER

CONSUMPTION

DIMENSIONS (W*H*D)

WEIGHT

FREQUENCY

FUSE

100V/115V±10% 200V/230V±10%

50/60 HZ

T2A/250V

(5 x 20mm)

440mm x 177mm x 445mm

13 Kg

T1A/250V

(5 x 20mm)

100 W

M540073-01 Rev C 1-5

Page 18

Features, Functions and Specifications SLH-Series AC High Power Electronic Load

NOTE: The following specifications apply 25°±5°:

MODEL SLH-500-4-1200 SLH-500-6-1800 SLH-300-12-

SLH-300-18-1800

1200/1800

INPUT RATINGS

Power (VA) 1200 VA 1800 VA 1200/1800 VA 1800 VA

Current (Ampere) 4 Arms 6 Arms 12 Arms 18 Arms

Voltage (Volt) 300 Vrms/500 Vdc 300 Vrms/500 Vdc 300Vrms 300Vrms

Frequency

CC MODE

DC, 40 - 70Hz (CC Mode) ; DC - 70Hz (CR Mode)

Range 0-2 / 2-4 A 0-3 / 3-6 A 0-6 / 6-12 A 0-9 / 9-18 A

Resolution 0.5 / 1 mA 0.75 / 1.5 mA 1.5 / 3 mA 2.25 / 4.5 mA

Accuracy

Low Current

Range

0 - 0.2 A 0 - 0.3 A 0 - 0.6 A 0 - 0.9 A

±0.5% of (setting + range)

Accuracy ± 2% of (setting + range)

Crest Factor √2 - 3.5 (Maximum current = 2 x Rated Current)

Maximum Peak

Current

CR MODE

Range 1

(I>0.5% of rating)

Range 2

(I>50% of rating)

4-1/2 DVM

8A 12A 24A 18A

50 - 200,000 Ω 33.33 - 133,000 Ω 20 - 80,000 Ω 13.3 - 53,333 Ω

12.5 - 50 Ω 8.33 - 33.33 Ω

5 - 20 Ω

3.33 - 13.33 Ω

Range 0-500V 0-500V 300 V 300 V 300 V

Resolution 0.1 V 0.1 V 0.1 V 0.1 V 0.1 V

Accuracy

4-1/2 DAM

±(0.5% of reading + 0.2% of range)

Range 0-4 A 0-6 A 0-12 A 0-12 A 0-18 A

Resolution 1 mA 1 mA 1 mA 1 mA 1 mA

Accuracy

±(0.5% of reading + 2% of range) ; ±0.5% of (reading + range) @ 50/60Hz

4-1/2 WATT

METER

Range

Resolution

Accuracy

VA METER

0-1200W 0-1800 W 0-1200W 0-1800 W 0-1800 W

0.1 W

± (0.5% of reading)± 3W

Vrms×Arms

Table 1-1 SLH-series AC/DC Specifications

1-6 M540073-01 Rev C

Page 19

SLH-Series AC High Power Electronic Load Features, Functions and Specifications

1.7 REGULATORY COMPLIANCE

• Certified to UL 61010-1, CSA C22.2 No. 61010.1 and IEC/EN 61010-1

• CE Compliant:

o Low Voltage Directive (73/23/EEC) using EN 61010-1, and

o EMC Directive (89/336/EEC) using EN 61326

• FCC Compliant to 21 CFR, Subpart J.

1.8 SYSTEM BLOCK DIAGRAM

Figure 1-8 System Block Diagram

M540073-01 Rev C 1-7

Page 20

Features, Functions and Specifications SLH-Series AC High Power Electronic Load

This page intentionally left blank.

1-8 M540073-01 Rev C

Page 21

INSTALLATION AND MAINTENANCE

2.1 INSPECTION

The SLH-series High Power, AC/DC Electronic Load was carefully inspected before

shipment. If instrument damage has occurred during transport, please inform

Sorensen's sales and service office or representative.

Your SLH-series High Power AC/DC Electronic Load was shipped with a power cord

for the type of outlet used at your location. If the appropriate cord was not included,

please contact your nearest Sorensen sales office to obtain the correct cord. Refer to "

check line voltage " to check the line voltage selection and fuse type.

SECTION 2

2.1.1 Line Voltage

The SLH-series High Power AC/DC Electronic Load can operate with 115/230VAC

input as indicated on the rear panel label (or 100/200VAC for Japan units). Make

sure that the factory check mark corresponds to your nominal line voltage. If not

correctly marked, perform the following procedures:

1. With the mainframe power OFF, disconnect the power cord.

2. Refer the drawing on the rear panel in Fig 2-1, set the switches to the proper

voltage as described in the following:

SYNC INPUT

RANGE

115

Figure 2-1 Setting Switch

M540073-01 Rev C 2-1

Page 22

Installation and Maintenance SLH-Series AC High Power Electronic Load

3. Mark the correct voltage on the rear panel of SLH-series High Power AC/DC

Electronic Load.

4. Check the rating of the line fuse and replace it with the correct fuse if

necessary.

5. The line fuse is located below the AC line receptacle see Fig 2-2. With the

power cord removed, use a small screwdriver to extract the fuse holder from

under the AC socket. Replace the fuse with the appropriate type as indicated in

Table 1-1. These fuses are slow-blow fuses.

6. Reinstall fuse holder and connect the power cord.

Figure 2-2 Fuse Holder in AC Line Input Connector

2.1.2 Grounding Requirements

The SLH-series High Power AC/DC Electronic Load is equipped with a threeconductor cable which plugs in an appropriate receptacle to ground the instrument's

cover.

2.1.3 Environmental Requirements

• For indoor use only

• Installation Category II (over voltage)

• Pollution Degree 2

• Altitude up to 2000 meters (with power derating)

• Relative Humidity 80% RH Max

• Ambient Operating Temperature 0-40°C, with ideal being 25°C ± 5°C

2.1.4 Rack Mount

The SLH-series High Power AC/DC Electronic Load is designed to permit mounting

in a standard 19 inches rack for system application.

2-2 M540073-01 Rev C

Page 23

SLH-Series AC High Power Electronic Load Installation and Maintenance

2.1.5 Tilt Adjustment

The SLH-series High Power AC/DC Electronic Load is equipped with tilt stands on its

two front feet, which can be flipped forward to provide an inclined viewing angle of

the front panel for bench-top use.

2.1.6 Service or Repair

If the instrument is damaged, please attach a tag to the instrument, identifying the owner

and indicating the required service. Follow the procedures detailed on Page iii of this

manual.

2.2 CONNECTIONS

PREVENT DAMAGE TO THE LOAD. Do NOT apply voltage or current with power

switched OFF. Turn ON the power switch to the load PRIOR to applying voltage or

CAUTION

2.2.1 Voltage Sensing Input (Vsense) BNC Connector.

current to the input terminals (i.e., before turning on the power supply under test).

To solve the conductor voltage drop under a big load current, Vsense-CLIP cable

can be used to connect with the specific point to be measured thus obtaining the

specific voltage value. See Figure 2-3 and Figure 2-4.

Figure 2-3 Connection Method for Small Load Current Condition.

Either front or rear connection may be used.

Figure 2-4 Typical Connection for SLH-series High Power AC/DC Electronic Load

Operation and Programming Manual 2-3

Page 24

Installation and Maintenance SLH-Series AC High Power Electronic Load

2.2.2 RS-232C Connection

Figure 2-5 SLH-series Rear Panel

2.2.3 GPIB Connection

The GPIB connector on the rear panel (Figure 2-5) connects the SLH-series High

Power AC/DC Electronic Load to the controller and to other GPIB devices. An GPIB

system can be connected in any configuration (star, linear, or both) with the following

provisions:

• The maximum number of devices including the controller is no more than 15.

• The maximum length of all cables is no more than 2 meters times the number of

devices connected together, up to 20 meters maximum.

Ensure that the lock screws are firmly hand-tightened; use a screwdriver only for the

removal of screws. The GPIB address of the Load is factory set to 05.

GPIB Address Setting:

Set the GPIB address on the front panel (see Figure 2-6) by pressing

STATE 4+STATE 5 keys simultaneously. Press UP or DOWN on the

BANK keys (white buttons to right) to select the address number (0-31).

Press STATE 2 to exit GPIB address setting mode.

Figure 2-6 Close-up, Front Panel State Keys

2-4 M540073-01 Rev C

Page 25

SLH-Series AC High Power Electronic Load Installation and Maintenance

2.3 MAINTENANCE

2.3.1 Cleaning

Avoid electrical shock or damage to the meter: do not get water

inside the case.

WARNING!

Periodically wipe the case with a damp cloth and detergent; do not use abrasives or

solvents.

Operation and Programming Manual 2-5

Page 26

Installation and Maintenance SLH-Series AC High Power Electronic Load

This page intentionally left blank.

2-6 M540073-01 Rev C

Page 27

SECTION 3

OPERATION

3.1 FRONT PANEL CONTROLS AND INDICATORS

This section describes the front panel and its manual operation of the SLH-series High

Power AC/DC Electronic Load. For calibration procedures, please refer to the SLHseries High Power Load Calibration Manual. For GPIB control, please refer to Section

4, GPIB Remote Operation, of this manual.

Figure 3-1 Front Panel of SLH-series High Power AC/DC Electronic Load

M540073-01 Rev C 3-1

Page 28

Operation SLH-Series AC High Power Electronic Load

1 Model Label

Shows load model series and its voltage, current and power specifications.

2 NG LED

• When lit, indicates “No Go” (fail) when Vmeter, Ameter, Wattmeter or VA meter

exceeds the upper or lower limit set.

• When not lit, indicates “Go” (no fail).

3 MODE key and CC, CR LEDs

The MODE key toggles between Constant Current (CC LED on) or Constant Resistance

(CR LED on) operating modes.

4 REM LED

Indicates remote operation:

• When lit, the unit is under remote control and cannot be operated through the front panel

keys. (Remote controller releases control by GPIB command).

• When not lit, the unit is under local control and can be manually operated using the front

panel keys.

5 Upper Digital Meter (DM)

Multi-purpose display, depending on selected mode:

• Under general conditions, functions as a 4 ½ digital voltmeter to display the voltage at

the load input end or Vsense BNC input end.

• During WATT ON condition, functions as a wattmeter to display the power of the load.

• Under LIMIT ON condition, displays the upper limit of:

o Voltmeter with the unit as “Vrms”.

o Ammeter with the unit as “Arms”.

o Wattmeter with the unit as “W”.

o VA meter with the unit as “VA”.

• During protection condition, displays “oVP” for over-voltage.

• During FREQ ON (see 15) condition, displays:

o “FrEq” (frequency),

o “bAn” (bank), or

o “Sync” (Sync)

6 Lower Digital Meter (DM)

• Under general conditions, functions as a 4 ½ digital ammeter to display the load current

actually flowing into the electronic load.

• In Preset ON (see 7) mode, displays the set value whether by front panel manual

operation or by remote control.

• In CC Mode (see 3), displays the set value of CC Level A and B in “Arms”.

• In CR Mode (see 3), displays the set value of CR Level A and B in “Ω”.

• During protection condition, displays:

o “oCP” for over-current,

o “oPP” for over-power, or

o “oTP” for over-temperature

• During LIMIT ON condition (see 11), displays the lower limit of:

o Voltmeter with the unit as “Vrms”.

o Ammeter with the unit as “Arms”.

o Wattmeter with the unit as “W”.

o VA meter with the unit as “VA”.

3-2 M540073-01 Rev C

Page 29

SLH-Series AC High Power Electronic Load Operation

• During FREQ ON condition (see 15):

o For frequency (“FrEq”) setting, displays DC, 0.1 - 70.0, Auto.

o For bank (“bAn”) selection, displays 0 - 10.

o For sync (“Sync”) selection, displays “ON”, OFF”.

7 PRES key and ON/OFF LED

Key toggles Preset mode and its LED on and off.

• During Preset OFF, PRES ON/OFF LED not lit:

o upper DM displays the voltage input to electronic load as “Vrms” (Vrms LED lit)

o lower DM displays the current flowing into electronic load as “Arms” (Arms LED

lit)

• During Preset ON, PRES ON/OFF LED lit,

o both upper and lower DMs will have different displays depending on which mode

is active:

Constant Current mode (CC LED on), lower DM displays the setting value

of Level A/B load current as “Arms”, (Arms LED lit).

Constant Resistance mode (CR LED on), lower DM displays the setting

value of Level A/B load resistance as “Ω”, (Ω LED lit).

8 LOAD key and ON/OFF LED

Key toggles Load and its LED on and off.

• Load OFF (LED not lit), electronic load returns to the condition set originally.

• Load ON (LED lit), electronic load is at the condition set originally and is ready to be

loaded with the load current of the AC/DC input power source.

9 WATT key and ON/OFF LED

Key toggles Watt mode and its LED on and off.

• Watt ON (LED lit) indicates the Watt VA condition of actual loading.

• Watt OFF (LED not lit) means Watt OFF, e.g., to indicate the voltage and current

condition of actual loading.

• During Preset OFF (see 7) condition:

o upper DM displays the value in Watts consumed for electronic loading (“W” LED

is lit);

o lower DM displays the value in VA flowing into electronic load (“VA” LED lit).

• During Preset ON (see 7) condition, both upper and lower 4-½ digit monitors will have

different displays with the change of working mode as follows:

o CC Mode, the setting value of Level A/B load current displayed on the lower DM

with the unit as “Arms” and corresponding LED lit.

o CR Mode, the setting value of Level A/B load resistance displayed on the lower

DM with the unit as “Ω” and corresponding LED lit.

10 LEVEL key and A/B LED

Key toggles between A (Level A), LED off, and B (Level B), LED ON to set the values of

groups A/B for rapid switching load current or resistance.

11 LIMIT key and ON/OFF LED

Key toggles between Limit ON (LED lit) and Limit OFF (LED not lit) condition:

• Upper DM displays upper limit of:

o Voltmeter with the unit as “Vrms”.

o Ammeter with the unit as “Arms”.

o Wattmeter with the unit as “W”.

M540073-01 Rev C 3-3

Page 30

Operation SLH-Series AC High Power Electronic Load

o VA meter with the unit as “VA”..

• Lower DM displays the lower limit of:

o Voltmeter with the unit as “Vrms”.

o Ammeter with the unit as “Arms”.

o Wattmeter with the unit as “W”.

o VA meter with the unit as “VA”.

(See 13 for upper and lower limit adjustment).

12 SENSE key and ON/OFF LED

Controls whether or not the input to the voltmeter is made from the AC input end (Sense

LED OFF) or from the Vsense end (Sense LED ON). The DM displays the voltage from

either.

13 Load Current Coarse Tuning/Fine Tuning, Increase/Decrease Keys

• During PRESET ON (see 7):

o The larger arrows () coarse tune the value by larger increments/decrements.

o The smaller arrows ( ) fine tune the value by smaller increments/decrements.

• During LIMIT ON (see 11):

o 3.1.13.2.1 :Upper limit value Up/Down Key.

o 3.1.13.2.2 :Lower limit value Up/Down Key.

• When FREQ (see 15) LED lit:

o “FrEq” displayed in upper DM, keys adjust the frequency value by coarse

(larger) increments/decrements, and the keys adjust the frequency value by

fine (smaller) increments/decrements.

o “bAn” displayed in upper DM,: is Fine Tuning Up Key is Fine Tuning

Down Key.

o “Sync” displayed in upper DM, is ON Key is OFF Key.

14 √2, 2.0, 2.5, 3.0, 3.5 keys and their respective LEDs:

Each key only functions in CC mode and has no effect in CR mode.

These keys are selected to change the current C.F. (Peak Factor) of CC mode. When

changing BANK (see 15) settings, these keys will define different C.F. values.

15 FREQ key and LED

Key scrolls from FREQ to BANK to SYNC (displayed in DM) to off (LED not lit).

• Frequency and Bank can only be set in CC MODE

o FREQ (For Frequency Setting) : Setting Range: DC, 0.1 - 70.0 Hz, Auto.

o BANK (For Bank Setting ) : 0 - 10 totaling 11 banks (Not valid for DC).

• SYNC (Current Bank Sync Signal Selection):

o ON is external Sync

o OFF is internal Sync.

16 AC/DC Load Input Connector

Must not exceed the rated specification of the voltage and current of the SLH-series High

Power AC/DC Electronic Load.

Avoid damage to internal circuit and connector: Upon wiring, please refer to

CAUTION

Section 3.2.

3-4 M540073-01 Rev C

Page 31

SLH-Series AC High Power Electronic Load Operation

17 Vsense BNC, Voltage Sensing Input BNC Connector.

To solve the conductor voltage drop under a big load current, Vsense-CLIP cable can be used

to connect with the specific point to be measured thus obtaining the specific voltage value.

The control keys are summarized in Figure 3-2.

SLH AC Loads

Button Functions

MODE

CC: Constant Current

CR: Constant Resistance

SENSE

ON: Vsense input voltage

OFF: Input terminal voltage

PRESet

ON

OFF

WATT

ON: Watt Displayed

on Upper Monitor

VA Displayed

on Lower Monitor

OFF: Vrms Displayed

on Upper Monitor

Arms Displayed

on Lower Monitor

LIMIT

G/NG RMS Volt Limits

G/NG RMS Current Limits

G/NG Power Limits [W]

G/NG Power Limits [VA]

FREQ

FREQ

Frequency Setting

Bank

Crest factor

bank setting

Sync

Figure 3-2 Front Panel Button Functions for SLH-series AC Unit

3.2 SET-UP PROCEDURES

The following set up procedures are summarized in Figure 3-4.

Pass / Fail Limits, Go/No GO Limits

(If pass/fail limits are not desired, skip to Frequency Setting below).

The limits set the value range within which the inputs must fall for the NG LED to remain off

and sets the NG register to 0 (pass) or 1 (fail).

LEVEL

HIGH

LOW

LOAD

ON

OFF

Voltage:

Press the LIMIT key until the LIMIT LED is on and the “Vrms” LED (5) is lit. The upper

digital meter (DM) displays the upper voltage limit; the lower DM displays the lower voltage

limit. Use the coarse

keys to set the upper limit and the fine ↑↓ keys to set the lower

limit.

Current:

Press the LIMIT key until the LIMIT LED is on and the “Arms” LED (5) is lit. The upper DM

displays the upper current limit; the lower 5-digit display shows the lower current limit. Use

the coarse keys to set the upper limit and the fine ↑↓ keys to set the lower limit.

Power:

Press the LIMIT key until the LIMIT LED is on and the “W” LED (5) is lit. The upper DM

displays the upper power limit; the lower DM displays the lower power limit. Use the coarse

keys to set the upper limit and the fine ↑↓ keys to set the lower limit.

M540073-01 Rev C 3-5

Page 32

Operation SLH-Series AC High Power Electronic Load

VA:

Press the LIMIT key until the LIMIT LED is on and the “VA” LED (5) is lit. The upper DM

displays the upper VA limit; the lower DM displays the lower VA limit. Use the coarse

to set the upper limit and the fine ↑↓ keys to set the lower limit.

Vsense Input:

The “SENSE” key toggles external Vsense on (LED lit) and off (LED not lit).

Frequency Setting:

The range for setting the frequency of SLH-Series AC electronic Load AC/DC module is

from DC-70Hz. Specifications apply 40-70Hz.

Press the FREQ key (15) until its LED lights and “FrEq” appears on the upper DM.

Use the coarse/fine

/↑↓ keys to set the frequency to the desired value, to DC or to Auto.

• If the frequency setting is less than 0.1 Hz, the frequency setting value will set

automatically to DC.

• In Auto, the load automatically synchronizes to the zero crossing of the voltage input

at the terminals.

• After setting the frequency, set the SYNC trigger to OFF to make the frequency valid.

Current Synchronization

(Figure 3-3)

External SYNC Signal (SYNC ON)

The user can input a SYNC signal to the Analog Programming Input BNC connector on

the back plate.

Based on this external SYNC signal, the SLH-Series AC Electronic Load, the phase of

load current will synchronize to the zero crossing of the external signal.

The external SYNC signal must have be a 50% duty cycle.

Press the “FREQ” key until “Sync” appears on the upper DM.

Press any

↑↓ key to toggle the external sync on and off.

Internal SYNC signal (SYNC OFF)

The internal SYNC signal source of SLH-Series AC electronic load is taken from the

voltage signal at the terminal inputs.

The load current signal will synchronize to the voltage zero crossing of the input

terminals.

EXT+

EXT-

Input

Zero Crossing

SYNC "OFF"

330Ω

SYNC "ON"

+5V

SYNC

SYNC

Figure 3-3 Illustration of Sync

3-6 M540073-01 Rev C

Page 33

SLH-Series AC High Power Electronic Load Operation

Crest Factor

The SLH-Series AC electronic load module provides 11 built-in sets totaling 55

waveforms. The waveforms are stored in memory banks (0-10) with 5 selections per

bank as shown in Table 3-1. (See Appendix for waveform details). Selection of crest

factor is through the √2, 2.0, 2.5, 3.0 and 3.5 keys in addition to the bank selection.

Sine Wave

1 1.5 1.6 1.7 1.8 1.9

2 2.0 2.1 2.2 2.3 2.4

3 2.5 2.6 2.7 2.8 2.9

4 3.0 3.1 3.2 3.3 3.4

Square Wave 5 1.0 1.1 1.2 1.3 1.4

6 1.5 1.6 1.7 1.8 1.9

7 2.0 2.1 2.2 2.3 2.4

8 2.5 2.6 2.7 2.8 2.9

9 3.0 3.1 3.2 3.3 3.4

DC 10 √2dc 2dc 2.5dc 3.0dc 3.5dc

BANK √2 2.0 2.5 3.0 3.5

0 √2 2.0 2.5 3.0 3.5

Table 3-1 Built in Crest Factor Settings by Bank andKkey Selection

When Frequency is set to DC (see Frequency Setting above), the waveform information

shall be fixed at DC level and the “bAn” bank selection will not appear in the FREQ key

menu.

• Press FREQ key (15). The associated LED will light. The first selection is for

frequency, as described in the section, “Frequency Setting” above.

• Verify that the frequency does not read “dc”. If it does, use the ↑↓ keys to

adjust the frequency from “dc”.

• Press the “FREQ” key until “bAn” appears on the upper DM.

• Use the ↑↓ keys to select the desired bank.

• Press the “FREQ” key two times to exit setting mode.

• Press the appropriate √2, 2.0, 2.5, 3.0 and 3.5 keys to select the desired crest

factor. The associated LED will light.

Display Setting

In normal operation, the DMs display RMS voltage and RMS current. To display power

in Watts (upper DM) and VA (lower DM), press the “WATT” key until the associated LED

(W or VA) is lit.

Press the “WATT” key again to return to normal display mode.

M540073-01 Rev C 3-7

Page 34

Operation SLH-Series AC High Power Electronic Load

DESCRIPTION DISPLAY CONTROL

LIMIT

Set

G/NG Voltage

Limits

Set

G/NG Current

Limits

Set

G/NG Power

Limits

Set

G/NG VA

Limits

SENSE

FREQ

Set frequency.

MIN=dc,

Max.=Auto

LED ON: VRMS, LIMIT

Upper 4½-digit: Upper

Limit Setting

Lower 4½-digit: Lower

Limit Setting

LED ON: ARMS, LIMIT

Upper 4½-digit: Upper

Limit Setting

Lower 4½-digit: Lower

Limit Setting

LED ON: W, LIMIT

Upper 4½-digit: Upper

Limit Setting

Lower 4½-digit: Lower

Limit Setting

LED ON: VA, LIMIT

Upper 4½-digit: Upper

Limit Setting

Lower 4½-digit: Lower

Limit Setting

LEDs ON: SENSE

LED ON: FREQ

Upper 4½-digit: "FrEq"

Lower 4½-digit: dc,

frequency setting, auto

Sets upper limit

↑↓ Sets lower limit

Sets upper limit

↑↓ Sets lower limit

Sets upper limit

↑↓ Sets lower limit

Sets upper limit

↑↓ Sets lower limit

↑↓

Any setting button

toggles sense on/off

↑↓

Course/fine setting

Set BANK Number

for Crest Factor

Waveform

Set SYNC source

ON=External

OFF=Input Terminal

or Vsense

WATT

Setup Complete

LED ON: FREQ

Upper 4½-digit: "bAn"

Lower 4½-digit: Bank

number setting 0-10

LED ON: FREQ

Upper 4½-digit: "Sync"

Lower 4½-digit: On/off

LED ON: WATT

Upper 4½-digit: "W"

Lower 4½-digit: "VA"

↑ ↓

High Bank# / Lower

Bank#

↑↓

Any button

toggles on/off

↑↓

Any button

toggles on/off

Figure 3-4 SLH-series AC Electronic Load Operation Flow Chart

3-8 M540073-01 Rev C

Page 35

SLH-Series AC High Power Electronic Load Operation

3.3 NORMAL OPERATION

3.3.1 CC Mode:

Two levels can be set to allow for quick switching between two current levels. One

crest factor setting (see Crest Factor Selection next) applies to both levels. Although

the levels are referenced “high” and “low,” the setting level does not require one to

be higher than the other.

1. Press the MODE button (3), until the CC LED (3) is lit.

2. Press the PRES button (7) to view the programmed values. The load has a

high and low setting to allow for quick changes in load setting.

a. To set the low level, press the LEVEL button (10) until the associated

LED is not lit (or do not press the button if the load is already in low

state). Use the ↑↓ buttons (13) to adjust to the desired level.

b. To set the high level, press the LEVEL button until the associated LED

is lit (or do not press the button if the load is already in high state). Use

the ↑↓ buttons to set the desired level.

3. To exit the preset mode, press the PRES button until the associated LED turns

3.3.2 Crest Factor Selection:

The SLM Series AC/DC electronic load module provides 11 built-in sets totaling 55

waveforms. The waveforms are stored in memory banks (0-10) with 5 selections per

bank as shown in Table 3-1. Please refer to Appendix for details of waveforms.

When Frequency is set to DC (see Frequency section above), the waveform

information shall be fixed at DC level and the “bAn” bank selection will not appear in

the FREQ button menu.

1. Press FREQ button (15). The associated LED will light. Verify that the

frequency does not read “dc”. If it does, use the ↑↓ buttons to adjust the

frequency from “dc”.

2. Press the “FREQ” button until “bAn” appears on the upper display.

3. Use the

4. Press the “FREQ” button two times to exit setting mode.

5. Press the appropriate √2, 2.0, 2.5, 3.0 and 3.5 key to select the desired crest

factor. The associated LED will light.

6. Press the LEVEL key to select the desired level CC mode. When the LED is

lit, the HIGH level is selected and when unlit, the LOW level is selected.

7. Press the LOAD button (8) to toggle the load off or on.

↑↓ buttons to select the desired bank, as defined in Table 3-1.

• Press the LEVEL button at any time to switch between the settings.

• Use the

• Press the PRES key to view the set values.

M540073-01 Rev C 3-9

↑↓ keys any time to change the current.

Page 36

Operation SLH-Series AC High Power Electronic Load

3.3.3 CR Mode

Two levels can be set to allow for quick switching between two current levels. One

crest factor setting (see section 3-2) applies to both levels. Although the levels are

referenced “high” and “low,” the setting level does not require one to be higher than

the other.

In CR mode, the value setting is inverse to the increment/decrement arrows; i.e., the

↑ keys decrease the resistance setting, and the ↓ keys increase the resistance

setting.

1. Press the MODE button, until the CR LED is lit (3).

2. Press the PRES button (7) to view the programmed values.

a. To set the low level, press the LEVEL button (10) until the associated

LED is not lit (or do not press the button if the load is already in low

state). Use the ↑↓ buttons (13) to adjust to the desired level.

b. To set the high level, press the LEVEL button until the associated LED is

lit (or do not press the button if the load is already in high state). Use

the ↑↓ buttons to set the desired level.

c. To exit the preset mode, press the PRES button until the LED is no

longer lit.

3. Select the desired CR level by pressing the LEVEL button (10). When the

LED is lit, the HIGH level is selected and when unlit, the LOW level is

selected.

4. Press the LOAD button (8) to toggle the load off or on

• Press the LEVEL button at any time to switch between the settings.

• Use the

• Press the PRES key to view the set values.

↑↓ keys any time to change the resistance.

3-10 M540073-01 Rev C

Page 37

SLH-Series AC High Power Electronic Load Operation

Normal Operating

Modes

Press MODE

Button until desired

mode is illuminated

CC, CR

MODE

Toggle PRESet

viewing off

(LED off )

Toggle between

HIGH (amber LED)

and LOW (LED off)

Preset desired

values

Set LO level

Activate and Set HI

level

PRES

LEVEL

NO

PRES

↑↓

Course/fine setting

LEVEL

↑↓

Course/fine setting

CC Mode?

YES

FREQ

Set FREQ

DC, AC 0.1-70,

Auto

FREQ

Set BANK Number

for Crest Factor

Waveform

FREQ

↑↓

Course/fine setting

↑ ↓

High Bank# / Lower

Bank#

Turn load ON

(LED ON/amber)

Turn load off

(LED off)

Set SYNC source

ON=External

OFF=Input Terminal

or Vsense

FREQ

LOAD

LOAD

↑↓

Any button

toggles sense on/off

Exit FREQ/BANK/

SYNC Setup

Figure 3-5. AC Electronic Load Operation Flow Char

M540073-01 Rev C 3-11

Page 38

Operation SLH-Series AC High Power Electronic Load

3.4 STORE / RECALL FUNCTION AND SEQUENCE

OPERATION

The six front panel function keys of the SLH-series High Power Load are designed for

high testing throughput. Five operation states (keys 1 through 5 in Figure 3-6) can be

stored in the non-volatile memory of SLH-series electronic load. Each state saves or

recalls the load setup, the status and the electronic load level.

Figure 3-6 STORE/RECALL and Sequencing Keypad

3.4.1 STORE Procedure:

The STORE function stores up to five states of SLH-series load settings. If you store

2 different states in the same state key, the most recent input will replace the

previous state.

a. Set the load status and the load level from load module.

b. Press the STORE key to start the store process; its LED begins flashing.

You have ten seconds to select and press a STATE key (next) in which to

store the status and level that you’ve set.

c. Press one of the STATE 1-5 keys; the corresponding LED will light, the load

status and level of the load are stored into the non-volatile memory. Once the

STORE procedure is complete, the STORE LED is no longer lit.

Notes:

If more than one state is stored in the same State key, the last one entered will be

treated as an update and will overwrite the previously input state.

After pressing the STORE key, the front panel keys on the SL-series electronic load

module are still active. However, the STATE LED will turn off if any key on any load

module is pressed. This indicates that the front panel state of the load module is

not the same as stored state.

3.4.2 RECALL Procedure

Press one of the STATE 1 through 5 keys to recall the stored state; its corresponding

LED will be lit.

3.4.3 AUTO SEQUENCE Procedures

There are two modes that can be activated while in AUTO SEQUENCE: EDIT MODE

and TEST MODE. To enter AUTO SEQUENCE, simultaneously press STATE KEYS 3

and 4 (S3 and S4). To activate EDIT MODE, press the STORE key. To enter TEST

MODE, press the START key. Please refer to the flow chart in Figure 3-7. A brief

description of each mode follows the flow chart.

3-12 M540073-01 Rev C

Page 39

SLH-Series AC High Power Electronic Load Operation

Bank LED

Display

Step Number

Bank Number

"t1" when

STORE button

is held

t1 test time,

when STORE

is released

"t2" when

STORE button

is held

Press

STORE Button

Select Memory

Location: Press

Bank Up/Down,

State 1-5

Press STORE

Button

Press BANK Up/

Down to select t1

time in 0.1sec

Press STORE

Button

EDIT

S3+S4 Buttons

Simultaneously

BANK Up/Down

Keys to select

sequence number

EDIT Seq or

RUN Seq

Press

EXIT Button

Start

Press

Press

YES

1

RUN

Press

START Button

Testing

Exit?

Bank LED

Display

Test sequence

number nx

Test

sequence

number nx

Memory Bank

and State

under test

t2 delay time,

when STORE

is released

YES

Press

EXIT Button

1

NO

End? Step = Step + 1

YES

Pass/Fail

Press Exit Key

1

NO

FAIL

YES

Press BANK Up/

Down to select t2

time in 0.1sec

Is Step=16 (F)

NO

End?

NO

Press STORE

Button

Step=Step+1

PASS

Display GO Display NG

Figure 3-7 Auto Sequence Function Set-Up and Operation Flowchart

GO / NG

M540073-01 Rev C 3-13

Page 40

Operation SLH-Series AC High Power Electronic Load

EDIT MODE

To enter the EDIT mode of the Sequence function, press State3 + State4 keys

simultaneously (State 3 and State 4 LEDs are On, indicating Auto Sequence function is

now active). Use the BANK Up/Down keys to select the sequence to be edited, then

press the STORE key to begin the editing process.

The EDIT MODE flow chart is described below:

• Nine Auto Sequences (n1-n9) can be edited within the SLH mainframe.

• Each Auto Sequence has up to 16 test steps, where each step is pulled from any

one of 150 Stored memory sets (30 Bank memory locations in each of 5 State

locations).

• Each test step has t1 (test time, or duration of test step) and t2 (delay time), the

unit of time is 100mS, the range is 0.1S - 9.9S in 100mS resolution. SLH will

check each module GO/NG at the end of t1 (test time), the next step will be

started after t2 (delay time).

• The test step sequence can include up to 16 steps, and can be terminated by

pressing the EXIT key (State 2) if fewer than 16 steps are required.

TEST MODE

To enter the TEST Mode of Sequence function, press State 3 + State 4 keys

simultaneously; (State 3 and State 4 LEDs are On, indicating Auto Sequence function is

now active). Use the BANK Up/Down keys to select the sequence test to be run, then

press the START key to run the test sequence.

• After pressing the START key, the SLH controls all the installed modules to recall

the memory correspond to the memory stored in Auto-sequence (n1~n9).

• Each test sequence starts from (Step 0 - t1 - t2), then (step 1 - t1 - t2), and so on

until either it completes the last step or is stopped by pressing the EXIT (State 2)

key.

• The two-digit BANK LED will display “GO” (flash) if all test steps in all modules

pass, and will show “NG” (flash) if there is at least one failure during the test.

• At that point, the user can either press the Start key to continue with another test,

or press EXIT (State 2) key to quit the Auto-Sequence function.

3.5 INITIAL SETTINGS OF SLH-SERIES AC/DC ELECTRONIC

LOAD

The initial setting parameters of SLH-series High Power AC/DC Electronic Load are

described in Table 3-2.

Last Setting

All SLH-series High Power AC/DC Electronic Loads have the function for

simplifying the setting procedures. This function is called “Last Setting” e.g., All

SLH-series High Power AC/DC Electronic Load, undergone the initial inspection

program procedure (Power on), can be immediately changed back to the setting

3-14 M540073-01 Rev C

Page 41

SLH-Series AC High Power Electronic Load Operation

condition prior to Machine OFF thus simplifying the procedures for re-setting after

machine being turned off.

Reset

If the Load’s memory data have been damaged in some way, for example, due to

unstable power source or noises, there may be an error, such as the display

screen showing something different from the actual condition. The Reset

function corrects the errors.

To reset the SLH-series High Power AC/DC Electronic Load, simultaneously

press the SENSE and the PRES keys. The front panel monitor will display

firmware version and initialize the setting parameters of SLH-series High Power

AC/DC Electronic Load as shown in Table 3-2 until the key is released.

Parameter

MODE CC CC CC CC CC

LOAD OFF OFF OFF OFF OFF

LEVEL LOW LOW LOW LOW LOW

SENSE OFF OFF OFF OFF OFF

PRES OFF OFF OFF OFF OFF

WATT OFF OFF OFF OFF OFF

Upper Pass / Fail Limits

V LIMIT 600.0 V 600.0 V 400.0 V 400.0 V 400.0 V

A LIMIT 5.000 A 8.000 A 15.00 A 15.00 A 20.00 A

WLIMIT 1250.0 W 2000.0 W 1250.0 W 2000 W 2000 W

VALIMIT 1250.0 VA 2000.0 VA 1250.0 VA 2000 VA 2000 VA

Lower Pass/Fail Limits

V, A, W, VA 0.0 0.0 0.0 0.0 0.0

C.F √2 √2 √2 √2 √2

FREQ 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz

BANK 0 0 0 0 0

SYNC OFF OFF OFF OFF OFF

CC LEVEL

LOW

CC LEVEL

HIGH

CR LEVEL

LOW

CR LEVEL

HIGH

SLH-500-4-1200 SLH-500-6-1800 SLH-300-12-1200 SLH-300-12-1800 SLH-300-18-1800

0.0000 A 0.0000 A 0.0000 A 0.0000 A 0.0000 A

0.0000 A 0.0000 A 0.0000 A 0.0000 A 0.0000 A

20E4 Ω 133E3 Ω 80E3 Ω 80E3 Ω

20E4 Ω 133E3 Ω 80E3 Ω 80E3 Ω

53E3 Ω

53E3 Ω

Table 3-2 SLH-series AC Electronic Load Factory Settings

3.6 PROTECTION FEATURES

There are four protection functions for the SLH-series High Power Electronic Load:

Over-Voltage, Over-Current, Over-Power and Over-Temperature. When the electronic

load exceeds the normal work area range, one of these four functions will activate.

This feature turns OFF the load to protect it from damage. The lower digital meter

M540073-01 Rev C 3-15

Page 42

Operation SLH-Series AC High Power Electronic Load

flashes the protection status, indicating which protection function is active. These

functions are described below:

3.6.1 Over Voltage

The over voltage protection (OVP) point is preset in the SLH-series High Power

AC/DC Electronic load. Table 3- shows the OVP trip values for the various models in

the series. When OVP occurs, the lower digital meter (DM) flashes "oVP". Once the

over voltage condition is reset, the lower DM resumes normal display.

Model OVP

SLH-500-4-1200

SLH-500-6-1800

SLH-300-12-1200

SLH-300-12-1800

SLH-300-18-1800

525.0 V

525.0 V

315.0 V

315.0 V

315.0 V

Table 3-3 SLH AC-series Protection Setting Values

OCP

4.20 A

6.30 A

12.60 A

12.60 A

18.90 A

OPP

1260 VA

1890 VA

1260 VA

1890 VA

1890 VA

3.6.2 Over Current

The over current protection (OCP) point is preset in the SLH-series High Power

AC/DC Electronic load. Table 3- shows the OCP trip values for the various models

in the series. When OCP occurs, the lower digital meter (DM) flashes "oCP". Once

the over current condition is reset, the lower DM resumes normal display.

3.6.3 Over Power

The over power protection (OPP) point is preset in the SLH-series High Power

AC/DC Electronic load. Table 3- shows the OPP trip values for the various models in

the series. When OPP occurs, the lower digital meter (DM) flashes "oPP". Once the

over power condition is reset, the lower DM resumes normal display.

3.6.4 Over Temperature

SLH-series High Power AC/DC Electronic load is provided with a temperature

sensor. Over temperature protection (OTP) is tripped when the heat dissipater

temperature exceeds about 85±5, and the lower DM flashes “oTP”. Once the

over temperature condition is reset, the lower DM resumes normal display.

When OTP occurs, check the ambient working temperature and ventilation. The air

outlet on requires a distance of greater than 6 in / 15 cm from any obstruction, for

proper ventilation.

3-16 M540073-01 Rev C

Page 43

GPIB/RS-232 PROGRAMMING

4.1 INTRODUCTION

The rear panel of SLH-series is designed for automated and/or remote testing from a

computer through a GPIB or RS-232 interface. This feature can be used as an

automatic load/cross load regulation and centering voltage testing for a switching

power supply or a rechargeable battery charge/discharge characteristic testing.

SECTION 4

OPERATION

4.2 SLH-SERIES GPIB COMMAND LIST

4.2.1 Setting Commands

Function Command Format

SET AUTO FREQUENCY

DETECT ON/OFF

SET SYNC ON/OFF SYNC{SP}{0|1|OFF|ON}{;|NL}

SET SENC ON/OFF SENS{SP}{0|1|OFF|ON}{;|NL}

SET WATT ON/OFF WATT{SP}{0|1|OFF|ON}{;|NL}

SET BANK BANK{SP}{d}{;|NL} d:0 ~ 10

SET WAVE WAVE{SP}{m}{;|NL}} m:1 ~ 5

SET FREQUENCY PREQ{SP}{NR2}{;|NL} NR2:###.#####

SET VOLTAGE LOW LIMIT VL{SP}{NR2}{;|NL}

SET VOLTAGE HIGH LIMIT VH{SP}{NR2}{;|NL}

SET CURRENT LOW LIMIT IL{SP}{NR2}{;|NL}

SET CURRENT HIGH LIMIT IH{SP}{NR2}{;|NL}

SET WATT LOW LIMIT WL{SP}{NR2}{;|NL}

SET WATT HIGH LIMIT WH{SP}{NR2}{;|NL}

SET VA LOW LIMIT VAL{SP}{NR2}{;|NL}

SET VA HIGH LIMIT VAH{SP}{NR2}{;|NL}

SET CURRENT CURR:{LOW|HIGH|A|B}{SP}{NR2}{;|NL} NR2:###.#####

SET RESISTANCE RES:{LOW|HIGH|A|B}{SP}{NR2}{;|NL}

SET LOAD ON/OFF LOAD{SP}{0|1|OFF|ON}{;|NL}

SET LEVEL LOW/HIGH LEV{SP}{0|1|LOW|HIGH}{;|NL}

SET PRESENT ON/OFF PRES{SP}{0|1|OFF|ON}{;|NL}

SET MODE MODE{SP}{0|1|2|CC|CR|CV}{;|NL}

SET CLEAR STATE CLER{;|NL}

SET STORE STATE STORE{SP}{m}{;|NL} m:1 ~ 5

SET RECALL STATE RECALL{SP}{m}{;|NL} m:1 ~ 5

AFREQ{SP}{0|1|OFF|ON}{;|NL}

Table 4-1 GPIB Setting Command Summary

M540073-01 Rev C 4-1

Page 44

GPIB/RS232 Programming Operation SLH-Series AC High Power Electronic Load

REMARK :

1. CURRENT ENGINEERING UNIT : A

2. VOLTAGE ENGINEERING UNIT : V

3. RESISTANCE ENGINEERING UNIT : Ω

4.2.2 Query Commands

Function Command Syntax ECHO

AUTO FREQUENCY

DETECT ON/OFF

SYNC SYNC?{;|NL} 1:ON, 0:OFF

SENS ON/OFF SENS?{;|NL} 1:ON, 0:OFF

WATT ON/OFF WATT?{;|NL} 1:ON, 0:OFF

BANK BANK?{;|NL} 0 ~ 10

WAVE WAVE?{;|NL} 1 ~ 5

FREQUENCY FREQ?{;|NL} ###.####

VOLTAGE LOW LIMIT VL?{;|NL} ###.####

VOLTAGE HIGH LIMIT VH?{;|NL} ###.####

CURRENT LOW LIMIT IL?{;|NL} ###.####

CURRENT HIGH LIMIT IH?{;|NL} ###.####

WATT LOW LIMIT WL?{;|NL} ###.####

WATT HIGH LIMIT WH?{;|NL} ###.####

VA LOW LIMIT VAL?{;|NL} ###.####

VA HIGH LIMIT VAH?{;|NL} ###.####

MEASURE POWER MEAS:POW?{;|NL} ###.####

MEASURE VA MEAS:VA?{;|NL} ###.####

No Good INDICATER NG?{;|NL} 0:OFF, 1:ON

CURRENT CURR:{LOW|HIGH|A|B}?{;|NL} ###.####

RESISTANCE RES:{LOW|HIGH|A|B}?{;|NL} ###.####

LOAD ON/OFF LOAD?{;|NL} 1:ON, 0:OFF

LEVEL LOW/HIGH LEV?{;|NL} 0:LOW/A, 1:HIGH/B

PRESET ON/OFF PRES?{;|NL} 1:ON, 0:OFF

MODE CC/CR MODE?{;|NL} 0:CC, 1:CR

NAME NAME?{;|NL} 325x

PROTECT STATE PROT?{;|NL} 0 ~ F(hex)

ERROR STATE ERR?{;|NL} 0 ~ F(hex)

CURRENT METER MEAS:CURR?{;|NL} ±###.####

VOLTAGE METER MEAS:VOLT?{;|NL} ±##.####

GLOB. CURRENT METER GLOB:MEAS:CURR?{;|NL} ##.###, ##.###, ##.###, ##.###

GLOB. VOLTAGE METER GLOB:MEAS:VOLT?{;|NL} ##.###, ##.###, ##.###, ##.###

AFREQ?{;|NL} 1:ON, 0:OFF

Table 4-2 GPIB Query Command Summary

REMARK :

1. CURRENT ENGINEERING UNIT:A

2. VOLTAGE ENGINEERING UNIT:V

3. RESISTANCE ENGINEERING UNIT:Ω

4-2 M540073-01 Rev C

Page 45

SLH-Series AC High Power Electronic Load GPIB/RS232 Programming Operation

4.3 COMMAND SYNTAX ABBREVIATIONS

SP :Space, the ASCII code is 20 Hexadecimal.

; :Semicolon, Program line terminator, the ASCII code is OA Hexadecimal.

NL :New line, Program line terminator, the ASCII code is OA Hexadecimal.

N :Integer from 1 to 8.

NR2 :Digits with decimal point. It can be accepted in the range and format of ##.#####.

Example: 30.12345, 5.0

Description of GPIB Programming Command Syntax.

{ } :The contents of the { } symbol must be used as a part or data of the GPIB

command, it can not be omitted.

[ ] :The contents of the [ ] symbol indicates that the command is optional, depending

on the testing application.

| :This symbol means to make a choice between one or the other. For example

“HIGH|LOW” means it can only use HIGH or LOW as the command, but one of

the choices must be used.

Terminator :The program line terminator character must be sent after the GPIB

command; the available command terminator characters that can be accepted in

the SLH are listed in Table 4-3.

LF

LF WITH EOI

CR, LF

CR, LF WITH EOI

Table 4-3 GPIB Command Terminator

A terminator informs GPIB that it has reached the end of statement. Normally,

this is sent automatically by your GPIB programming statements. In this manual,

the terminator is assumed at the end of each example line of code. If it needs to

be indicated, it is shown by symbol (nl); which stand for “new line” and represents

ASCII code byte the OA Hexadecimal or 10 decimal.

Semicolon ”;“ :The semicolon “;” is a back-up command, the semicolon allows you to

combine command statements on one line to create command message.

Table 4-4 presents a summary of the GPIB/RS-232 Setting commands, and Table 4-5

summarizes the GPIB/RS-232 preset Query commands with applicable module types. Table

4-6 is a summary of State commands, the System commands are in Table 4-7, Measure and

Limit commands are in Table 4-8, and the Global commands are in Table 4-9.

M540073-01 Rev C 4-3

Page 46

GPIB/RS232 Programming Operation SLH-Series AC High Power Electronic Load

Setting Preset Numeric Command Remark

[PRESet:] BANK{SP}{d}{;|NL}

[PRESet:] WAVE{SP}{m}{;|NL }

[PRESet:] FREQ{SP}{NR2}{;|NL}

[PRESet:] CC:{HIGH|LOW}{SP}{NR2}{;|NL}

[PRESet:] CR:{HIGH|LOW}{SP}{NR2}{;|NL}

d=0~30

M=0~5

40.0~70.0Hz

Table 4-4 GPIB/RS-232 Setting Command Summary

Query Preset Numeric Command RETURN

[PRESet:] BANK{SP}{?}{;|NL}

[PRESet:] WAVE{SP}{?}{;|NL}

[PRESet:] FREQuency{?}{;|NL}

(PRESet:] CC:{HIGH|LOW}{?}{;|NL} ###.####

[PRESet:] CR:{HIGH|LOW}{?}{;|NL}

0~10

1~5

40.0~70.0

###.####

Table 4-5 GPIB/RS-232 Preset Query Command Summary

STATE Command RETURN

[STATe:] LOAD{SP}{ON|OFF}{;|NL}

[STATe:] LOAD{?}{;|NL}

[STATe:] MODE{SP}{CC|CR|CV|CP}{;|NL}

[STATe:] MODE{?}{;|NL}

[STATe:] PRESet{SP}{ON|OFF}{;|NL}

[STATe:] PRESe{?}{;|NL}

[STATe:] SENSe{SP}{ON|OFF}{;|NL}

[STATe:] LEVEl{SP}{HIG|LOW}{;|NL}

[STATe:] LEVEl{?}{;|NL}

[STATe:] SYNCronize{SP}{ON|OFF}{;|NL}

[STATe:] SYNCronize{?}{;|NL}

[STATe:] WATT{SP}{ON|OFF}{;|NL}

[STATe:] WATT{?}{;|NL}

[STATe:] CLEar{;|NL}

[STATe:] ERRor{?}{;|NL}

[STATe:] NG{?}{;|NL}

[STATe:] PROTect{?}{;|NL}

0=OFF, 1=ON::

0=:CC, 1=:CR

2=:CV, 3=:CP

0=OFF, 1=ON::

0:=LOW,

1:=HIGH

0=OFF, 1=ON::

0=OFF, 1=ON::

Dddddddd

0:=OK, 1:=NG

Dddddddd

Table 4-6 State Command Summary

4-4 M540073-01 Rev C

Page 47

SLH-Series AC High Power Electronic Load GPIB/RS232 Programming Operation

COMMAND NOTE RETURN

[SYStem:] RECall{SP}{m[,n]}{;|NL} M=1~5 n=1~30

[SYStem:] STORe{SP}{m[,n]}{;|NL} M=1~5 n=1~30

[SYStem:] REMOTE{;|NL} Only RS232 cmd

[SYStem:] LOCAL{;|NL} Only RS232 cmd 0=:OFF, 1=:ON

[SYStem:] NAME{?}{;|NL} “XXXXX”

Table 4-7 System Commands

COMMAND RETURN

MEASure:CURRent {?}{;⎢NL}

MEASure:VOLTage {?}{;⎢NL}

MEASure:PWR {?}{;⎢NL}

MEASure:VA {?}{;⎢NL}

LIM:CURRent:{HIGH|LOW}{SP}{NR2}{;|NL}

LIM:CURRent:{HIGH|LOW}{?}{;|NL}

LIM:POWer:{HIGH|LOW}{SP}{NR2}{;|NL}

LIM:POWer:{HIGH|LOW}{?}{;|NL}

LIM:VA:{HIGH|LOW}{SP}{NR2}{;|NL}

LIM:VA:{HIGH|LOW}{?}{;|NL}

LIM:VOLTage:{HIGH|LOW}{SP}{NR2}{;|NL}

LIM:VOLTage:{HIGH|LOW}{?}{;|NL}

###.####

###.####

###.####

###.####

###.####

###.####

###.####

###.####

Table 4-8 Measure and Limit Commands

COMMAND RETURN

GLOBal:[STATe:] PRESet{SP}{ON|OFF}{;|NL}

GLOBal:[STATe:] LOAD{SP}{ON|OFF}{;|NL}

GLOBal:[STATe:] MODE{SP}{ON|OFF}{;|NL}

GLOBal:[STATe:] LEVEL{SP}{A|B}{;|NL}

GLOBal:MEASure:CURRent{?}{;|NL} ###.##

GLOBal:MEASure:VOLtage{?}{;|NL} ###.##

Table 4-9 Global Commands

REMARKS:

1. d : 0 - 9

2. GLOB : GLOBAL (ALL CHANNELS ACTIVE AT SAME TIME)

3. CURRENT ENGINEERING UNIT : A

4. VOLTAGE ENGINEERING UNIT : V

5. RESISTANCE ENGINEERING UNIT : Ω

6. PERIOD ENGINEERING UNIT : mS

7. SLEW-RATE ENGINEERING UNIT : A/μS

Note: The RS-232 command set is the same as the GPIB command set.

M540073-01 Rev C 4-5

Page 48

GPIB/RS232 Programming Operation SLH-Series AC High Power Electronic Load

4.4 GPIB/RS-232 COMMAND DESCRIPTION

4.4.1 Setting Commands

CURRENT Level

Purpose:

The load current setting in Constant Current mode.

Command Syntax:

CC:{LOW|HIGH}{SP}{NR2}{;|NL}

Description:

CC:{LOW|HIGH}{SP}{NR2}{;|NL}

Sets the current level of Electronic Load modules.

CC:{SP}{NR2}{;|NL}

This command is used to set the load current level for CC static mode of SLH-series

electronic load module.

Note:

a. The load current data must include the decimal point; otherwise, this command

will not execute. The load current level can be programmed up to the sixth place

after the decimal point.

b. If the programmed load current level is over the maximum rated specification, the

full scale current will be sent to the load module.

c. Engineering units for load current is Amps.

Example:

CC:LOW 1.8 set LOW level load current to 1.8 A.

CC:HIGH 25.123456 set HIGH level load current to 25.123456 A.

RESISTANCE Level

Purpose:

The load resistance setting in Constant Resistance mode.

Command Syntax:

CR:{HIGH|LOW}{SP}{NR2}{;|NL}

Description:

CR:{HIGH|LOW}{SP}{NR2}{;|NL}

This command is used to set the LOW/HIGH load resistance level of the electronic load.

Note:

a. The load resistance data must include the decimal point; otherwise, this

command will not execute. The load resistance level can be programmed up to

the sixth place after the decimal point.

b. If the programmed load resistance level is over the maximum rated specification,

the full scale resistance will be sent to the load module.

c. Engineering unit for load resistance is Ohms.

Example:

CR:LOW 0.123 set LOW level load resistance to 0.123 OHM.

CR:HIGH 3.456789 set HIGH level load resistance to 3.456789 OHM.

4-6 M540073-01 Rev C

Page 49

SLH-Series AC High Power Electronic Load GPIB/RS232 Programming Operation

LOAD

Purpose:

Turn the Electronic load module input ON or OFF.

Command Syntax:

LOAD{SP}{0FF|ON}{NL}

Description:

This command sets the Electronic load to sink current from power source.

For Example :

LOAD OFF ; All loads are at input OFF condition.

LOAD ON ; Set the load to LOAD ON status, this load is ready to sink current from the

power source.

LOAD 0; Set the load to LOAD OFF.

LEVEL HIGH/LOW

Purpose:

Select Low or High level in static mode, of DC electronic loads, or LEVEL A/B of AC

electronic loads.

Command Syntax:

[GLOB:] LEVE {SP}{HIGH|LOW}{NL}

Description:

LEVE LOW is Set LOW current level in CC mode or LOW resistance level in CR mode.

LEVE 1 is Set HIGH current level in CC mode or HIGH resistance level in CR mode.

PRESET ON/OFF

Purpose:

Set the upper or lower digit multi-function meter to display the programming load level.

Command Syntax:

PRES{SP}{0|1|OFF|ON}{NL}

Description:

PRES ON is set to preset on status.

MODE

Purpose:

Select the operating mode of Electronic load module.

Command Syntax:

MODE{SP}{0|1|CC|CR}{NL}

Description:

MODE CC ; set the presently operating mode to Constant Current mode.

MODE 1 ; set the presently operating mode to Constant Resistance mode.

CLEAR status register

Purpose:

CLEar the PROT and ERR status byte registers.

Command Syntax:

All Modules: CLER{NL}

M540073-01 Rev C 4-7

Page 50

GPIB/RS232 Programming Operation SLH-Series AC High Power Electronic Load

Description:

CLER ; clear the PROT and ERR status byte register, the PROT and ERR status byte

register will indicate “0” after executing the CLER command.

STORE

RECALL

Purpose:

STORE the load level and load status into the memory of the SL-series electronic LOAD.

Command Syntax:

STOR{SP}{m}{;|ML}

Description:

Parameter m is 1~5 for 5 different states withSL-series electronic load module's load status

and load current into the non-volatile memory.

Example:

STORE 1; store the AC electronic load module's load status and load current into the

memory 1.

Purpose:

Recall the state of load level and status, is stored by the GPIB/RS232 STORe command.

Command Syntax:

REC{SP}{m}{;|NL}

Description:

This command is used to recall the memory state, is stored into memory by the GPIB/RS232

STORe command, up to 5 states can be recalled for AC electronic load modules, and up to

150 states can be recalled for DC electronic load modules.

Example:

REC 1; Recall the state of load level and status that is stored in memory 1 by GPIB/RS232

STOR command.

SYNCHRONOUS ON/OFF

Purpose:

To set synchronous function ON/OFF of AC electronic loads.

Command Syntax:

SYNC{SP}{0|1|OFF|ON}{;|NL}

Description:

1. External synchronous signal (SYNC ON): Using external synchronous signal as the

synchronous triggering signal of the electronic load thus making the load current

synchronous with the voltage.

2. Internal synchronous signal (SYNC OFF): Using the signal at the terminal of the input

connector thus generating synchronous signal through the internal zero-crossing circuit

and isolated circuit.

Example:

SYNC ON ; To set external synchronization.

SYNC OFF ; To set internal synchronization.

4-8 M540073-01 Rev C

Page 51

SLH-Series AC High Power Electronic Load GPIB/RS232 Programming Operation

WATT Meter ON/OFF

Purpose:

To set display of power meter of AC series electronic load.

Command Syntax:

WATT{SP}{0|1|OFF|ON}{;|NL}

Description:

This command is to set the power meter display. This command must be used in

conjunction with PRES:OFF. When setting to ON, the top monitor will change from voltmeter

to Watt meter while the monitor at the bottom will change from ammeter to Volt-Ameter (VA)

and the unit is “W” and “VA” respectively. When setting to OFF, the Watt meter on the top

will change back to voltmeter while the VA meter at the bottom will change back to ammeter

and the unit is “Vrms” and “Arms” respectively.

Example:

PRES OFF

WATT ON ; to display WATT, VA meter.

WATT OFF ; to display Voltage, Current meter.

WAVEFORM BANK

Purpose:

To set waveform bank for AC electronic load modules.

Command Syntax:

BANK{SP}{d}{;|NL} d:0-10

Description:

This command is to set the desired waveform bank.

1. waveform bank 0-4 are sine wave.

2. waveform bank 5-9 are square wave.

3. waveform bank 10 is DC.

4. There are five (5) waveforms for each of eleven (11) waveform banks for a total of 55

waveforms. Waveform information is shown in Table 4-10.

Example:

BANK 1, to set waveform bank 1.

BANK 10, to set waveform bank 10.

M540073-01 Rev C 4-9

Page 52

GPIB/RS232 Programming Operation SLH-Series AC High Power Electronic Load

Sine Wave 0 √2 2.0 2.5 3.0 3.5

1 1.5 1.6 1.7 1.8 1.9

2 2.0 2.1 2.2 2.3 2.4

3 2.5 2.6 2.7 2.8 2.9

4 3.0 3.1 3.2 3.3 3.4

Square Wave 5 1.0 1.1 1.2 1.3 1.4

6 1.5 1.6 1.7 1.8 1.9

7 2.0 2.1 2.2 2.3 2.4

8 2.5 2.6 2.7 2.8 2.9

9 3.0 3.1 3.2 3.3 3.4

DC 10 √2dc 2dc 2.5dc 3.0dc 3.5dc

Waveform

Bank

Table 4-10 Waveform Information

m=1 m=2 m=3 m=4 m=5

WAVEFORM

Purpose:

To set waveform for AC electronic load modules.

Command Syntax:

WAVE{SP}{m}{;|NL} m:1-5

Description: