Ametek RTC-125A, RTC-157A, RTC-158A, RTC-159A, RTC-187A Operating Manual

...

User Manual

Reference/Professional Temperature Calibrator

Jofra RTC-125/157/158/159/187/250/700 A/B/C

Jofra PTC-125/155/350/425/660 A/B/C

User Manual

Reference/ Professional Temperature Calibrator

JOFRA RTC-156/157/158/159/187/250/700 A/B/C

JOFRA PTC-125/155/350/425/660 A/B/C

Copyright 2012 AMETEK Denmark A/S

2 2018-03-13 128206 06

List of contents

1.0 Introduction ............................................................................ 5

1.1 List of equipment received ........................................................ 6

2.0 Safety instructions ................................................................. 8

3.0 Setting up the calibrator ...................................................... 15

3.1 Before use ............................................................................... 15

3.1.1 Setting up a dry-block calibrator .................................... 18

3.1.2 Setting up a liquid bath calibrator (RTC-158/250 only) .. 20

3.2 During use ............................................................................... 24

3.3 Programming intelligent sensors ................................................ 25

3.4 Keyboard ..................................................................................... 25

3.5 Main screen display .................................................................... 27

3.6 Standard connections ................................................................. 31

3.7 Input modules (B and C versions only) ....................................... 32

3.8 Stability of temperature values ................................................... 33

4.0 Operating the Calibrator ...................................................... 34

4.1 Operating principle ...................................................................... 34

4.1.1 Horizontal Menu ............................................................. 35

4.1.2 Vertical Menu ................................................................. 35

4.4.3 Parameter Fields ............................................................ 36

4.4.4 Working with lists ........................................................... 38

4.5 Starting the calibrator .................................................................. 40

4.6 Setting the temperature .............................................................. 40

4.7 Calibration (optional - PTC) ........................................................ 41

4.7.1 Running a calibration ..................................................... 42

4.7.2 Viewing calibration results ............................................. 46

4.7.3 Displaying calibration information .................................. 47

4.7.4 Deleting workorders ....................................................... 49

4.8 Switch test menu ........................................................................ 50

4.8.1 Running a switch test ..................................................... 50

4.8.2 Showing switch test results ............................................ 52

4.9 Auto step menu ........................................................................... 54

4.9.1 Running an Auto step calibration ................................... 54

4.9.2 Auto Step test results ..................................................... 57

4.10 Sensor Setup menu .................................................................... 58

4.10.1 Setting the additional stability time (A version) .............. 58

4.10.2 Setting the parameters for TRUE – reference sensor (B

and C versions only) ...................................................... 59

4.10.3 Setting the parameters for DLC– dynamic load

128206 06 2018-03-13 3

compensation – (RTC, B and C versions only) .............. 61

4.10.4 Setting the parameters for SUT– Sensor under test (B

versions only) ................................................................. 61

4.10.5 Viewing the Reference and DLC data (B and C versions

only) ............................................................................... 64

4.11 Calibrator Setup menu ................................................................ 65

4.11.1 Setting the temperature parameters .............................. 65

4.11.2 Setting the temperature resolution ................................. 67

4.11.3 Setting the sound, volume and operating mode ............ 68

4.11.4 Setting calibration interval .............................................. 68

4.11.5 Changing the date and time ........................................... 68

4.11.6 Choosing a language (optional) ..................................... 69

4.11.7 Saving a setup ............................................................... 69

4.11.8 Loading a setup ............................................................. 70

4.11.9 Resetting the instrument setup to factory defaults......... 70

4.11.10 Network Configuration (for service use only) ................. 71

4.12 Selecting the stirrer speed (RTC-158/250 only) ........................ 72

4.13 Information Screen ..................................................................... 73

4.14 About the calibrator ..................................................................... 74

5.0 Setting the mains voltage and replacing the main fuses ... 75

6.0 After use................................................................................ 77

6.1 Storing and transporting the calibrators ...................................... 77

6.2 Handling the dry-block calibrator ................................................ 78

6.3 Handling the liquid-bath calibrator (RTC- 158/250 only) ............ 79

4 2018-03-13 128206 06

1.0 Introduction

This user manual applies to the following instruments:

Reference Temperature Calibrators

• JOFRA RTC-156 A - Temperature calibrator

• JOFRA RTC-156 B - Temperature calibrator with sensor and

reference inputs

• JOFRA RTC-156 C - Temperature calibrator with reference input

• JOFRA RTC-157 A - Temperature calibrator

• JOFRA RTC-157 B - Temperature calibrator with sensor and

reference inputs

• JOFRA RTC-157 C - Temperature calibrator with reference input

• JOFRA RTC-158 A - Temperature calibrator

• JOFRA RTC-158 B - Temperature calibrator with sensor and

reference inputs

• JOFRA RTC-158 C - Temperature calibrator with reference input

• JOFRA RTC-159 A – Temperature calibrator

• JOFRA RTC-159 B – Temperature calibrator with sensor and

reference inputs

• JOFRA RTC-159 C - Temperature calibrator with reference input

• JOFRA RTC-187 A - Temperature calibrator

• JOFRA RTC-187 B - Temperature calibrator with sensor and

reference inputs

• JOFRA RTC-187 C - Temperature calibrator with reference input

• JOFRA RTC-250 A - Temperature calibrator

• JOFRA RTC-250 B - Temperature calibrator with sensor and

reference inputs

• JOFRA RTC-250 C - Temperature calibrator with reference input

• JOFRA RTC-700 A - Temperature calibrator

• JOFRA RTC-700 B - Temperature calibrator with sensor and

reference inputs

• JOFRA RTC-700 C - Temperature calibrator with reference input

Professional Temperature Calibrators

• JOFRA PTC-125 A - Temperature calibrator

• JOFRA PTC-125 B - Temperature calibrator with sensor and

reference inputs

• JOFRA PTC-125 C - Temperature calibrator with reference input

• JOFRA PTC-155 A - Temperature calibrator

128206 06 2018-03-13 5

• JOFRA PTC-155 B - Temperature calibrator with sensor and

reference inputs

• JOFRA PTC-155 C - Temperature calibrator with reference input

• JOFRA PTC-350 A - Temperature calibrator

• JOFRA PTC-350 B - Temperature calibrator with sensor and

reference inputs

• JOFRA PTC-350 C - Temperature calibrator with reference input

• JOFRA PTC-425 A – Temperature calibrator

• JOFRA PTC-425 B – Temperature calibrator with sensor and

reference inputs

• JOFRA PTC-425 C - Temperature calibrator with reference input

•

• JOFRA PTC-660 A - Temperature calibrator

• JOFRA PTC-660 B - Temperature calibrator with sensor and

reference inputs

• JOFRA PTC-660 C - Temperature calibrator with reference input

These instruments are temperature calibrators designed to calibrate

temperature sensors and thermostats.

The RTC-156/157/159/187/700 A/B/C instruments and the PTC-series

are all designed as dry-block calibrators, where as the RTC-158/250

A/B/C instruments are designed to be used both as dry-block

calibrators and liquid baths.

Read this manual carefully before using the instrument and ensure that

all safety instructions and warnings are observed.

1.1 List of equipment received

When you receive the instrument, the following should be enclosed:

• 1 calibrator

• 1 mains cable

• 2 sets of test cables (2 black, 2 red –B versions only)

• 1 software package “JOFRACAL” and reference manual

• 1 USB cable

• 1 tool for insertion tube

• 1 traceable certificate (A versions)

• 2 traceable certificates (C versions)

• 3 traceable certificates (B versions)

6 2018-03-13 128206 06

• 1 set of silicone plugs for insulation plugs (RTC156/157/158/159/187/250 and PTC-125/155 only)

• 1 insulation collar (RTC-156 only)

• 1 protection shield (RTC-700 and PTC-660 only)

RTC-158/250 A/B/C only (liquid bath) - OPTIONAL

• 1 liquid bath kit consisting of :

Caution

Do not use the RTC-158 insulation plug (black POM) with

the RTC-250 instrument due to the risk of melting.

Always use the correct - yellow/brown PEEK - insulation

plug with the RTC-250 instrument.

- 1 sensor basket

- 2 lids for transportation / calibration

- 1 stirring magnet

- 1 stirring magnet remover

- 1 liquid drainage syringe

- 1 bottom shield

- 1 silicone oil

- 1 oil material safety data sheet

128206 06 2018-03-13 7

2.0 Safety instructions

menus displayed when using a B

-

version.

Read this manual carefully before using the

instrument!

In order to avoid any personal injuries and/or damage to

the instrument all safety instructions and warnings must be

observed.

The screen menus shown in this manual represent the

Disposal – WEEE Directive

These calibrators contain Electrical and Electronic circuits

and must be recycled or disposed of properly (in

accordance with the WEEE Directive 2012/19/EU).

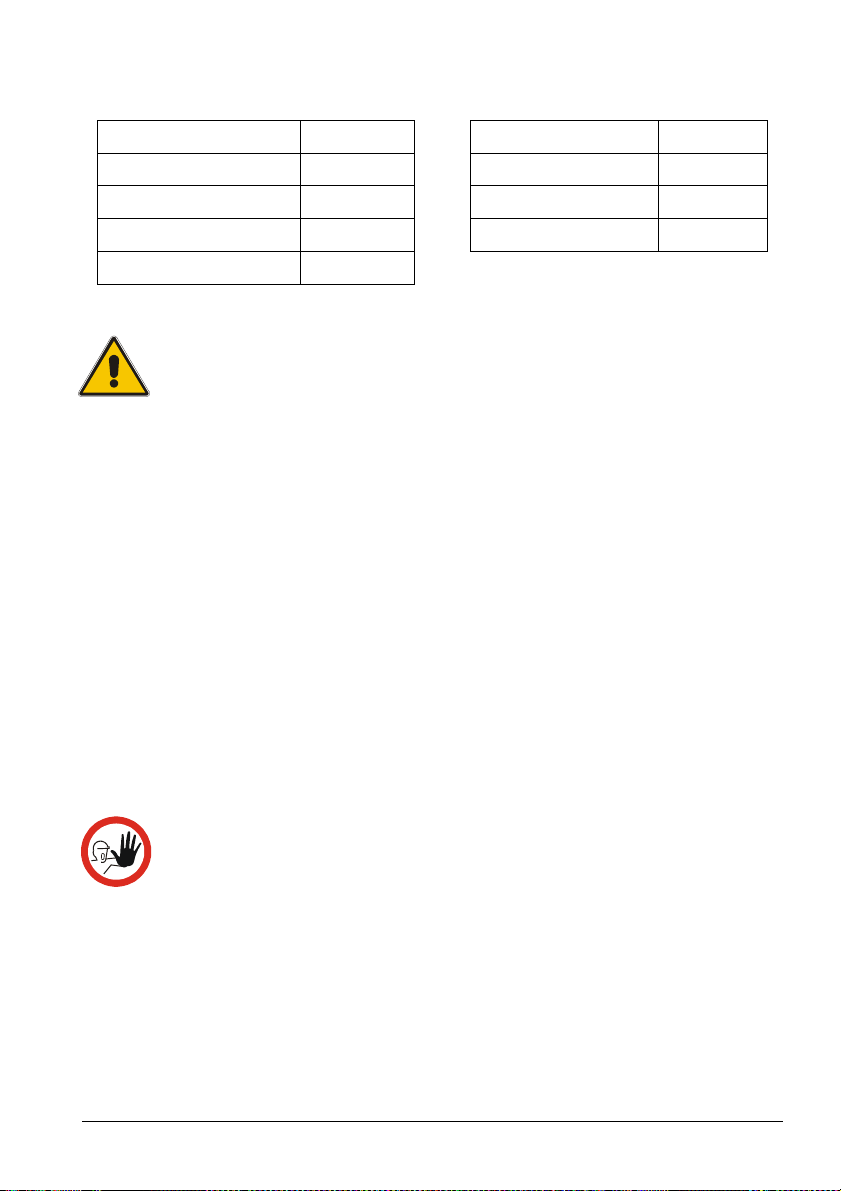

Warning

About the use:

• The calibrator must not be used for any purposes other

than those described in this manual, as it might cause a

hazard.

• The calibrator has been designed for indoor use only

and is not to be used in wet locations.

• The calibrator is not to be used in hazardous areas,

where vapour or gas leaks, etc. may constitute a

danger of explosion.

• The calibrator is not designed for operation in altitudes

above 2000 meters.

• The calibrator is a CLASS I product and must be

connected to a mains outlet with a protective earth

connection. Ensure the ground connection of the

calibrator is properly connected to the protective earth

before switching on the calibrator. Always use a mains

power cable with a mains plug that connects to the

protective earth.

8 2018-03-13 128206 06

• To ensure the connection to protective earth any

extension cord used must also have a protective earth

conductor.

• Only use a mains power cord with a current rating as

specified by the calibrator and which is approved for the

voltage and plug configuration in your area.

• Before switching on the calibrator make sure that it is

set to the voltage of the mains electricity supply.

• Always position the calibrator to enable easy and quick

disconnection of the power source (mains inlet socket).

• The calibrator must be kept free within an area of 20

cm on all sides and 1 metre above the calibrator due to

fire hazard.

• After transport or storage in humid conditions or if the

calibrator has not been heated up to minimum 100°C

within the last 10 days, the instrument needs to be

operated with a well temperature of at least 140°C for 2

hours before it can be assumed to meet all safety

requirements of EN61010-1 (PTC-350/425/660 and

RTC-250/700 only).

• If the calibrator is wet or has been in a wet

environment, do not apply power until the moisture has

been removed for example by storage at 50°C in a low

humidity environment for at least 4 hours.

• Never use heat transfer fluids such as silicone, oil,

paste, etc. in the dry-block calibrators. These fluids may

penetrate the calibrator and cause electrical hazard,

damage or create poisonous fumes.

• The calibrator must be switched off before any attempt

to service the instrument is made. There are no user

serviceable parts inside the calibrator.

• When cleaning the well or the insertion tube,

REMEMBER to wear goggles when using compressed

air in the dry-block calibrator and cleaning oil in the

liquid bath calibrator.

• Use protection shield when calibrating at high

temperatures (RTC-700 and PTC-660)

128206 06 2018-03-13 9

• The RTC-159 and PTC-125 contains R-1270 and R704 under pressure. The calibrator must under no

conditions be stored at ambient temperatures above

50°C ( 122°F) or operated at ambient temperatures

above 40°C (104°F). Doing so may cause a hazard.

About the front panel:

• For B and C versions only, the sockets on the input

module must NEVER be connected to voltages

exceeding 30V with reference to ground.

• Thermostats must not be connected to any other

voltage sources during test.

About insertion tubes, insulation plugs, well and

sensor:

ever leave hot insertion tubes which have been

• N

removed from the calibrator unsupervised – they may

constitute a fire hazard or personal injury.

If you intend to store the calibrator in the optional

carrying case after use, you must ensure that the

instrument has cooled down to a temperature

below 100°C/212°F before placing it in the carrying

case.

• Never place a hot insertion tube in the optional carrying

case.

About the fuses:

• The fuse box must not be removed from the power

control switch until the mains cable has been

disconnected.

• The two main fuses must have the specified current

and voltage rating and be of the specified type. The

use of makeshift fuses and the short-circuiting of fuse

holders are prohibited and may cause a hazard.

About the liquid bath (RTC-158/250 A/B/C only):

•

For liquid bath ensure that the sensor is absolutely

clean and dry as a few drops of water in the well (liquid

baths) might cause a steam explosion.

10 2018-03-13 128206 06

• Do not pour cold fluid into a hot well – it might cause

an explosion.

• AMETEK Denmark A/S does not take any

responsibility, if the well is filled with other fluids than

those recommended.

• Liquid baths should only be operated by trained

personal.

• Heat transfer fluids must only be used in calibrators

prepared as a liquid bath. If these fluids are heated

above specified temperature they will create noxious or

toxic fumes. Proper ventilation must be used.

• To avoid hazards from treating fluids in a wrong

manner, always reduce the "Max. SET-temperature

allowed” in the CALIBRATOR SETUP MENU according

to the specifications of the fluid to be used.

If using a calibrator outside of the fluids specifications

there is a risk of fire hazards, personal Injury or

chemical release.

By reducing the "Max. SET-temperature allowed”, the

calibrator cannot be used outside this temperature

range.

Be aware of the flash point, the boiling point and other

fluid properties applicable to the usage when setting the

Max. SET-temperature. Read the MSDS (Material

Safety Data Sheet) of the liquid before use.

• Always remove the liquid from the calibrator before

transportation.

• Product information on the fluid must be carefully

investigated before use.

• Do not handle hot fluid.

• If the oil is heated beyond the flash point, it may

constitute a fire hazard.

• Do not pour water or any other fluids into a bath filled

with hot oil, because only a few drops of water might

cause a steam explosion, if poured into above 100°C

hot oil.

• Do not under any circumstances pour water on burning

oil. It might cause a dangerous steam explosion.

128206 06 2018-03-13 11

insert h

as

cooled

down to less than 50°C/122°F.

Caution – Hot surface

This symbol is engraved in the grid plate.

• Do not touch the grid plate, the well or the insertion

tube when the calibrator is heating up – they may be

very hot and cause burns.

• Do not touch the lid or the spill tray when the calibrator

is heating up – they may be very hot and cause burns

(RTC-158/250 A/B/C only).

• Do not touch the tip of the sensor when it is removed

from the insertion tube/well – it may be very hot and

cause burns.

• Do not touch the handle of the calibrator during use – it

may be very hot and cause burns.

• Over 50°C/122°F

If the calibrator has been heated up to temperatures

above 50°C/122°F, you must wait until the instrument

reaches a temperature below 50°C/122°F before you

switch it off.

• Do not remove the insert from the calibrator before the

12 2018-03-13 128206 06

Caution – Cold surface

Below 0°C/32°F

(applies only to the RTC-156/157/158/159/187 A/B/C and

PTC-125/155 A/B/C models)

• Do not touch the well or insertion tube when these are

below 0°C/32°F - they might create frostbite.

• If the calibrator has reached a temperature below

0°C/32°F, ice crystals may form on the insertion tube

and on the well. This, in turn, may cause the material

surfaces to oxidize.

To prevent this from happening, the insertion tube and

the well must be dried. This is done by heating up the

calibrator to min. 100°C/212°F until all water left has

evaporated.

Remove the insulation plug while heating up.

• It is very important that humidity in the well and insertion

tube is removed to prevent corrosion and frost

expansion damages.

Caution…

About the use:

• Do not use the instrument if the internal fan is out of

order.

• Before cleaning the calibrator, you must switch it off,

allow it to cool down and remove all cables.

About the liquid bath (RTC-158/250 A/B/C only):

• Be careful not to overfill the well with oil.

• Avoid getting silicone oil on the clothes. It is impossible

to wash off.

• The oil level rises several centimetres when the

temperature is rising. Please read instructions in

section 3.1.2 about oil level. To stop overflow switch off

the main power and the oil level will decrease when

cooled down.

• Carefully wipe off all silicone oil from the sensor under

test to avoid spreading of the silicone oil.

• Be careful to select the right oil for the right task. Using

other than the recommended oils might cause damage

to the calibrator or degrade the performance.

• Remove excess hot fluid with the outmost care, as it

might be very hot.

• Do not attempt to remove hot fluid with the liquid

drainage tube, as it might melt.

About the well, insertion tube and sensor:

The well and the insertion tube must be clean and dry

•

before use.

• Do not pour any form of liquids into the well. It might

damage the well or cause a hazard.

• Do not use any alkali, acid or ionic fluids in the

aluminium well as it might be damaged.

128206 06 2018-03-13 13

• Scratches and other damage to the insertion tubes

manual or uses unauthorized spare parts.

should be avoided by storing the insertion tubes

carefully when not in use.

• The insertion tube must never be forced into the well.

The well could be damaged as a result, and the

insertion tube may get stuck.

• Before using new insertion tubes for the calibration, the

insertion tubes must be heated up to maximum

temperature – 250°C (482°F) / 700°C (1292°F) (RTC250/700 A/B/C only) and 350°C (662°F) / 425°C

(797°F) / 660°C (1220°F) (PTC-350/660 A/B/C only) for a period of minimum 30 minutes.

• The insertion tube must always be removed from the

calibrator after use.

The humidity in the air may cause corrosion oxidation

on the insertion tube inside the instrument. There is a

risk that the insertion tube may get stuck if this is

allowed to happen.

• If the calibrator is to be transported, the insertion tube

must be removed from the well to avoid damage to the

instrument.

• The tip of the sensor should rest at the bottom of the

sensor basket for optimum results (liquid baths only).

• Be careful not to submerge the handle or wire inlet of

the sensor-under-test in the fluid, as this might damage

the sensor (liquid baths only).

14 2018-03-13 128206 06

Note…

The product liability o

subject to a manufacturing defect. This liability becomes

void if the user fails to follow the instructions set out in this

nly applies if the instrument is

3.0 Setting up the calibrator

3.1 Before use

The RTC/PTC-B-versions have a precision reference input. To achieve

the high precision, a set of sensor coefficients relating to the specific

sensor must be present in the RTC/PTC. Before use of the RTC/PTC,

ensure that the correct coefficients in the RTC/PTC are equal to those

from the sensors calibration certificate. This is done with the included

PC software JOFRACAL. Please read how to do in the chapter

“Reference Sensors” in the JOFRACAL user manual.

Warning

• The calibrator must not be used for any purposes other

than those described in this manual, as it might cause a

hazard.

• The calibrator has been designed for indoor use only

and is not to be used in wet locations.

• The calibrator is not to be used in hazardous areas,

where vapour or gas leaks, etc. may constitute a danger

of explosion.

• The calibrator is not designed for operation in altitudes

above 2000 meters.

• The calibrator is a CLASS I product and must be

connected to a mains outlet with a protective earth

connection. Ensure the ground connection of the

calibrator is properly connected to the protective earth

before switching on the calibrator. Always use a mains

power cable with a mains plug that connects to the

protective earth.

• To ensure the connection to protective earth any

extension cord used must also have a protective earth

conductor.

• Only use a mains power cord with a current rating as

specified by the calibrator and which is approved for the

voltage and plug configuration in your area.

128206 06 2018-03-13 15

• Before switching on the calibrator make sure that it is

set to the voltage of the mains electricity supply.

• Always position the calibrator to enable easy and quick

disconnection of the power source (mains inlet socket).

• The calibrator must be kept free within an area of 20

cm on all sides and 1 metre above the calibrator due to

fire hazard.

• Never use heat transfer fluids such as silicone, oil,

paste, etc. in the dry-block calibrators. These fluids may

penetrate the calibrator and cause electrical hazard,

damage or create poisonous fumes.

• Use protection shield when calibrating at high

temperatures (RTC-700 and PTC-660)

• The RTC-159 and PTC-125 contains R-1270 and R-704

under pressure. The calibrator must under no

conditions be stored at ambient temperatures above

50°C ( 122°F) or operated at ambient temperatures

above 40°C (104°F). Doing so may cause a hazard.

About the front panel:

For B and C versions only, the sockets on the input

•

module must NEVER be connected to voltages

exceeding 30V with reference to ground. Thermostats

must not be connected to any other voltage sources

during test.

About the liquid bath (RTC-158/250 A/B/C only):

• For liquid bath ensure that the sensor is absolutely

clean and dry as a few drops of water in the well (liquid

baths) might cause a steam explosion.

• Do not pour cold fluid into a hot well – it might cause

an explosion.

• AMETEK Denmark A/S does not take any

responsibility, if the well is filled with other fluids than

those recommended.

• Liquid baths should only be operated by trained

personal.

• Heat transfer fluids must only be used in calibrators

prepared as a liquid bath. If these fluids are heated

16 2018-03-13 128206 06

above specified temperature they will create noxious or

toxic fumes. Proper ventilation must be used.

• To avoid hazards from treating fluids in a wrong

manner, always reduce the "Max. SET-temperature

allowed” in the CALIBRATOR SETUP MENU according

to the specifications of the fluid to be used.

If using a calibrator outside of the fluids specifications

there is a risk of fire hazards, personal Injury or

chemical release.

By reducing the "Max. SET-temperature allowed”, the

calibrator cannot be used outside this temperature

range.

Be aware of the flash point, the boiling point and other

fluid properties applicable to the usage when setting the

Max. SET-temperature. Read the MSDS (Material

Safety Data Sheet) of the liquid before use. The Max.

SET-temperature must never exceed (liquid flash point –

50°C).

• Product information on the fluid must be carefully

investigated before use.

• Do not handle hot fluid.

• If the oil is heated beyond the flash point, it may

constitute a fire hazard.

• Do not pour water or any other fluids into a bath filled

with hot oil, because only a few drops of water might

cause a steam explosion, if poured into above 100°C

hot oil.

• Do not under any circumstances pour water on burning

oil. It might cause a dangerous steam explosion.

Note…

The instrument must not be exposed to draughts.

128206 06 2018-03-13 17

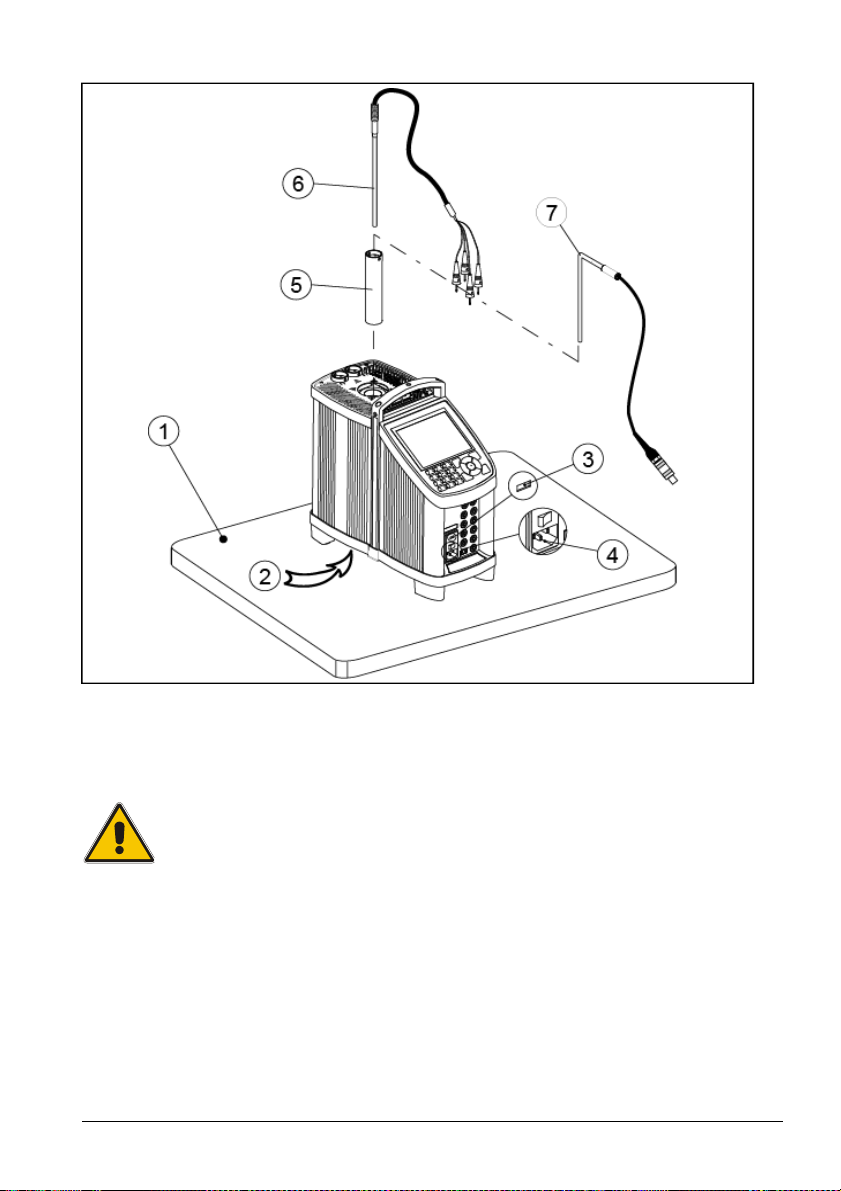

3.1.1 Setting up a dry-block calibrator

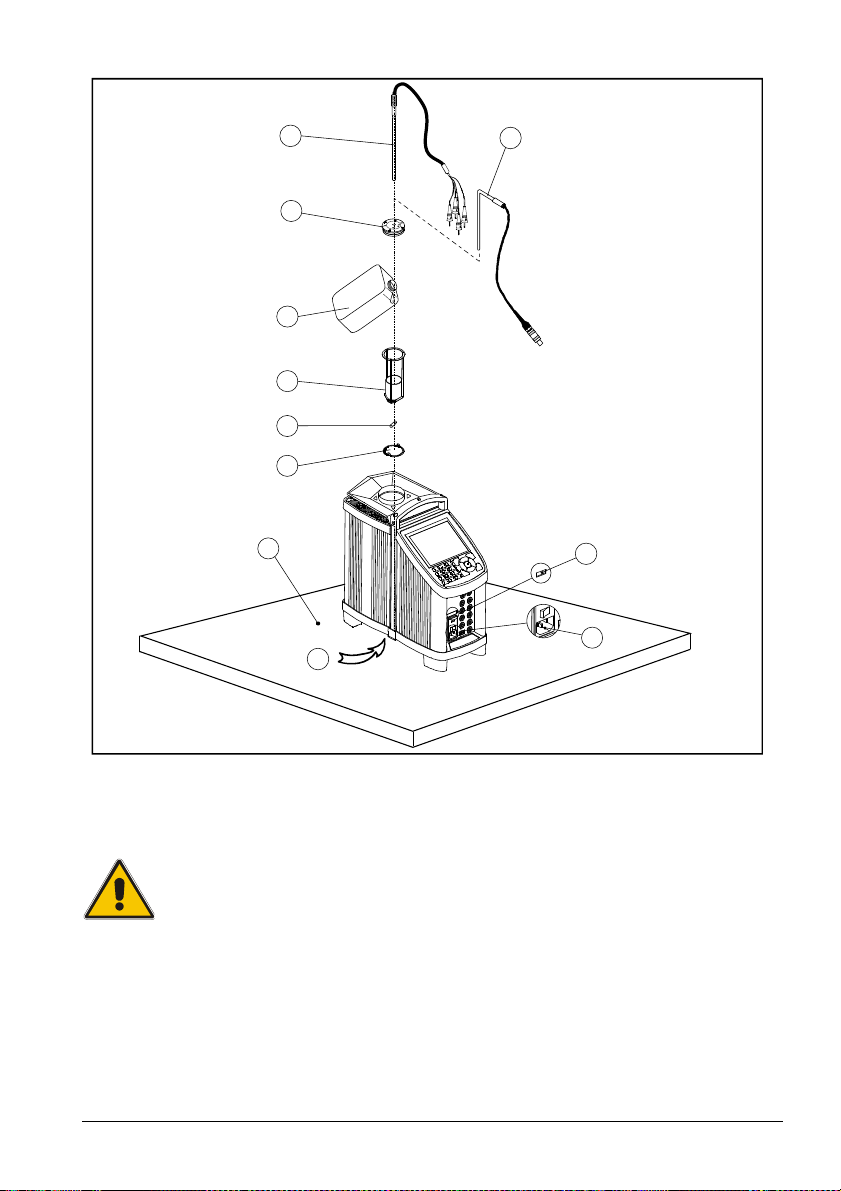

ig. 1a – This image shows the RTC-model

F

Follow the instructions below before using the calibrator (cf. fig. 1a)

Warning

Always position the calibrator to enable easy and quick

disconnection of the power source (mains inlet socket).

1. Place the calibrator on an even horizontal surface where you

intend to use it (pos. 1).

18 2018-03-13 128206 06

Caution…

• The well

must

be clean before use.

flammable substances, etc.

2. Ensure a free supply of air to the internal fan located at the

• Do not use the instrument if the internal fan is out of

order.

bottom of the instrument (pos. 2)

The area around the calibrator should be free of draught, dirt,

3.

4. Check that the earth connection for the instrument is present

5.

6.

Check that the voltage setting, shown on the power control

switch (pos. 3), is identical to the mains voltage used.

and attach the cable below the power control switch (pos. 4).

Select an insertion tube (pos. 5) with a boring diameter

matching the sensor (pos. 6) to be calibrated. Ensure that

both the well and the insertion tube are clean. Insert the tube

into the well.

Place the sensor (pos. 6) and the reference sensor – if

available (pos. 7) in the insertion tube (pos. 5) as shown in fig.

a.

1

128206 06 2018-03-13 19

3.1.2 Setting up a liquid bath calibrator (RTC-158/250 only)

silicone oil, if spilled.

10

11

9

6

l

i

O

5

4

3

1

7

2

8

Fig. 1b

ollow the instructions below before using the calibrator (cf. fig. 1b)

F

Warning

Always position the calibrator to enable easy and quick

disconnection of the power source (mains inlet socket).

1. Place the calibrator on an even horizontal surface where you

intend to use it. Place it in a way that will minimize the risk of

tilting (pos. 1). It is recommended to cover the surface with a

disposable cover in order to protect the surface against the

20 2018-03-13 128206 06

It is also recommendable to have a sufficient amount of

adjusted to the actual job.

disposable paper towels within reach.

Caution…

2.

3.

• Do not use the instrument if the internal fan is out of

order. Ensure a free supply of air to the internal fan

located at the bottom of the instrument (pos. 2).

• The well must be clean before use.

The area around the calibrator should be free of draught, dirt,

flammable substances, etc.

Place the parts from the liquid bath kit in the well in the

following order:

• Bottom shield (pos. 3) – It is very important that the

bottom shield is placed in the well before any calibration

is attempted, as the bottom shield protects the well from

being damaged during calibration.

• Stirring magnet (pos. 4) – It is very important that the

stirring magnet is in place and spinning before any

calibration is attempted. The stirring magnet ensures

minimum temperature gradient in the fluid. The magnets

teflon cover will over time be worn down, leaving the

magnet flat on one side. This will reduce the spinning

ability. A magnet with a flat side must therefore be

replaced.

• Sensor basket (pos. 5) – It is very important to place

the sensor basket in the well, as it ensures that the

sensors encounter maximum temperature stability and

ensures that the stirring magnet is not blocked.

• Silicone oil (pos. 6) – Fill the well with oil according to

the tables of recommended oil volume listed in the

tables below. The recommended volumes must be

The sensor basket (pos. 4) is marked with an optimum

fluid level mark (100%). When filling the well with fluid and

placing the sensors, this mark must never be exceeded.

128206 06 2018-03-13 21

RTC-250 A/B/C RTC-158 A/B/C

50 cSt oil

10 cSt oil

For recommended

For recommended

0°C - 50°C

50°C - 100°C

100°C - 150°C

150°C - 200°C

200°C - 250°C

100%

95%

90%

85%

80%

-20°C - 50°C

50°C - 100°C

100°C - 120°C

120°C - 155°C

100%

95%

90%

85%

Warning

• Do not handle hot fluid.

• Do not pour cold fluid into a hot well – it might cause an

explosion

• Do not pour water or any other fluids into a bath filled

with hot oil, because only a few drops of water might

cause a steam explosion, if poured into e.g. above 100°C

hot oil.

• If the fluid is heated beyond the flash point, it may

constitute a fire hazard.

• AMETEK Denmark A/S does not take any responsibility,

if the well is filled with other fluids than those

recommended.

If the fluid has caught fire, switch off the main power to prevent further

heating of the fluid. Flames are best extinguished by cowering the well

with a non-flammable lid.

Caution…

• Be careful not to overfill the well with oil.

The oil level rises several centimetres when the

temperature is rising to maximum. To stop the overflow

switch off the main power and the oil level will decent.

• Do not attempt to remove hot fluid with the liquid drainage

syringe, as it might melt.

4. Check that the voltage setting, shown on the power control

switch (pos. 7), is identical to the mains voltage used.

22 2018-03-13 128206 06

5. Plug in the mains cable below the power control switch (pos.

section 4.6.

rises, to prevent o

verflow.

sensor.

8) and check that the earth connection is present. Switch on

the calibrator.

6. Start the stirring magnet by following the procedure in section

4.12.

Warning

Always set the “Max. SET-temperature” of the calibrator

according to the specified temperature range of the liquid.

The “Max. SET-temperature” must never exceed the flash

point or the boiling point of the liquid.

7. Select a SET-temperature according to the tables of

recommended oil volume by following the procedure in

8. Carefully monitor the oil level in the well, as the temperature

9. Place the calibration lid (pos. 9) onto the well. Holes with a

boring diameter matching the sensors to be calibrated must be

drilled into the lid before using it.

10. Place the sensor (pos. 10) and the reference sensor – if

Start the calibration of either the dry-block calibrator or the liquid bath

calibrator following the calibration procedure in this manual.

128206 06 2018-03-13 23

available (pos. 11) - to be calibrated vertically into the well. It

is recommended to use the optional support rod set for a

correct position during calibration.

Caution…

• The tip of the sensor should rest at the bottom of the

sensor basket for optimum results.

• Be careful not to submerge the handle or wire inlet of the

sensor-under-test in the fluid, as this might damage the

3.2 During use

below 0°C/32°F

– they

might

create frostbite.

to the calibrator or

degrade the performance.

Caution – Hot surface

This symbol is engraved in the grid plate.

• Do not touch the grid plate, the well or the insertion

tube while the calibrator is heating up – they may be

very hot and cause burns.

• Do not touch the lid or the spill tray when the calibrator

is heating up – they may be very hot and cause burns

(liquid baths only).

• Do not touch the tip of the sensor when it is removed

from the insertion tube – it may be very hot and cause

burns.

• Do not touch the handle of the calibrator during use –

it may be very hot and cause burns.

• Do not remove the insert from the calibrator before the

insert has cooled down to less than 50°C/122°F.

Caution – Cold surface

• If the calibrator has reached a temperature below

0°C/32°F, ice crystals may form on the insertion tube

and on the well. This, in turn, may cause the material

surfaces to oxidize.

To prevent this from happening, the insertion tube and

the well must be dried. This is done by heating up the

calibrator to min. 100°C/212°F until all water left has

evaporated.

Remove the insulation plug while heating up.

It is very important that humidity in the well and

insertion tube is removed to prevent corrosion and frost

expansion damages.

• Do not touch the well or insertion tube when these are

Caution…(liquid baths only)

24 2018-03-13 128206 06

• Be careful to select the right fluid for the right task. Using

other than the recommended fluids might cause damage

Loading...

Loading...