Page 1

M470039-01

Rev A

Contact Information

Telephone: 800 733 5427 (toll free in North Americ a )

858 450 0085 (direct)

Fax: 858 458 0267

Email:

Domestic Sales: domorders.sd@ametek.com

International Sales: intlorders.sd@ametek.com

Customer Service: service.ppd@ametek.com

Web:

www.programmablepower.com

OPERATION MANUAL

This manual covers:

PLA Series Programmable Air-cooled Electronic Loads

PLW Series Programmable Water-cooled Electronic Loads

Page 2

_______________________________________________

12

Page 3

WARRANTY IN FORMATION

CERTIFICATION

AMETEK Programmable Power, Inc. (“AMETEK”), certifies that this product met its published specifications at

time of shipment from the factory.

Contact Information

Telephone: 800 733 5427 (toll free in North Americ a )

858 450 0085 (direct)

Fax: 858 458 0267

Email:

Domestic Sales: domorders.sd@ametek.com

International Sales: intlorders.sd@ametek.com

Customer Service: service.ppd@ametek.com

Web:

www.programmablepower.com

Warranty Period:

AMREL DC Loads: One Year

WARRANTY TERMS

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the

Product stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect in

material or workmanship with in the applicable warranty period stat e d ab ove, then AMETEK may,

at its option: repair or replace the Product; or issue a credit note for the defective Product; or

provide the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in

accordance with the return procedure specified below. AMETEK will, at its expense, deliver the

repaired or replaced Product or parts to the Buyer. Any warranty of A METEK will not apply if the

Buyer is in default under the Purchase Order Agreement or where the Product or any part

thereof:

• is damaged by misuse, accident, negligenc e or f ailure to maintain the same as

specified or required by AMETEK;

• is damaged by modifications, alterations or attac hments thereto which are not

authorized by AMETEK;

• is installed or operated contrary to the instructions of AMETEK;

• is opened, modified or disassembled in any way without AMETEK’s consent; or

• is used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty

until the Buyer has made all payments to AMETEK provided for in the Purchase Order Agreement.

PRODUCT RETURN PROCEDURE

1. Request a Return Material Authorization (RMA) number from the repair facility (must be

done in the count ry in which it wa s p urchased):

• In the USA, contact the AMETEK Repair Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427 (toll free North America)

858-450-0085 (direct)

• Outside the United States, contact the nearest Authorized Service Center

(ASC). A full listing can be found either through your local distributor or our

website, www.programmablepower.com, by clicking Support and going to the

Service Centers tab.

2. When requesting an RMA, have the following information ready:

• Model number

• Serial number

• Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject to

an evaluation fee and applicable freight charges.

Page 4

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., i s a global l eader in the design and

manufacture of precision, programmable power supplies for R&D, test and measurement, process

control, power bus simulation and power conditioning applications across diverse industri al segments.

From bench top supplies to rack-mounted industrial power subsystems, AM E TEK Programmable Power

is the proud manufacturer of AMREL brand power suppli es.

AMETEK, Inc. is a leadi ng global m anufacturer of electronic instr uments and electromec hanic al dev ices

with a nnualized sales of $2. 5 billion. The Company has over 11,000 c olleagues working at more than 80

manufacturing facilities and more than 80 sales and service centers in the United St ates and around the

world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc. AMREL is a trademar k owned by AMETEK, Inc. Other

trademarks, registered trademarks, and product names are the property of their respective owners and

are used herein for identification purposes only.

Notice of Copyright

Manual © 2003-2011 AMETEK Programmable Power, Inc. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL

OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES,

WHETHER SPECIA L, DIRECT, INDIREC T, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE O UT

OF THE USE OF SUCH INFORM ATION. THE USE OF AN Y SUCH INFORMATION W ILL BE ENTIRELY AT

THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH

STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE AC CURACY

CANNOT BE GUARANTEED. APPRO VED AMETEK CONT ENT IS CO NTAI NED WITH TH E ENGLISH

LANGUAGE VERSION, WHICH IS POSTED AT WWW.PROGRAMM ABLEP OWER.COM.

Contact Information

Telephone: 800 733 5427 (toll free in North America) 858 450 0085 (direc t)

Fax: 858 458 0267

Email:

Domestic Sales :

International Sales :

Customer Service :

Web: www.programmablepower.com

domorders.sd@ametek.com

intlorders.sd@ametek.com

service.ppd@ametek.com

Page 5

_________________________________________________________________________________________

SAFETY SUMMARY

NOTE: The following general safety precautions must be observed during all phases of operation of this instrument.

Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of

design, manufacture, and intended use of the instrument. AMETEK Programmable Power, Inc. assumes no liability for the customer’s

failure to comply with these requireme

WARNING

Servicing instructions are for use by service-trained personnel. To avoid dangerous electrical shock, do not perform any

servicing unless you are qualified to do so. Some procedures described in this manual are performed with power supplied

to the instrument while its protective covers are removed. If contacted, the energy available at many points may result in

personal injury.

ENVIRONMENTAL CONDITIONS

This instrument is intended for indoor use in an installation category II, pollution degree 2 environment. It is designed to

operate at maximum relative humility of 95% and at altitudes of up to 2000 meters. Refer to the specifications for the ac

mains voltage requirements and ambient operating temperature range.

BEFORE APPLYING POWER

y that the product is set to the appropriate line voltage, the correct line fuse is installed, and all safety precautions are

Verif

taken.

GROUND THE INSTRUMENT

Before switching on the instrument, the protective earth terminal of the instrument must be connected to the protective

conductor of the main power cord. The mains plug shall be inserted only in an outlet socket that is provided with a

protective earth contact. This protective action must not be negated by the use of an extension cord that does not have a

protective conductor. Any interruption of the protective grounding or disconnection of the protective earth terminal will

cause a potential shock hazard that could result in personal injury.

nts.

FUSES

Only fuses with the required rated current, voltage, and specified type should be used. Do not use repaired fuses or shortcircuited fuse holder. To do so could cause a shock or fire hazard.

AVOID ACCESS TO LIVE CIRCUITS

Operating personnel must not remove the instrument cover. Component replacement and internal adjustments must be

made by qualified service personnel. Do not replace components with the power cable connected. Under certain

conditions, dangerous voltage may exits even with the power cable removed, to avoid injuries, always disconnect power,

discharge circuits and remove external voltage sources before touching components.

AVOID TROUBLESHOOTING ALONE

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is

present. Any adjustment, maintenance, and repair of this instrument while it is opened and under voltage should be

avoided as much as possible. If this is unavoidable, adjustment, maintenance, and repair should be carried out by only

qualified personnel who are aware of the hazard involved.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Because of the danger of introducing additional hazards, do not install substitute parts or perform an unauthorized

modification to the instrument. Return the instrument to an American Reliance Service Department for service and repair

to ensure that safety features are maintained.

iii

Page 6

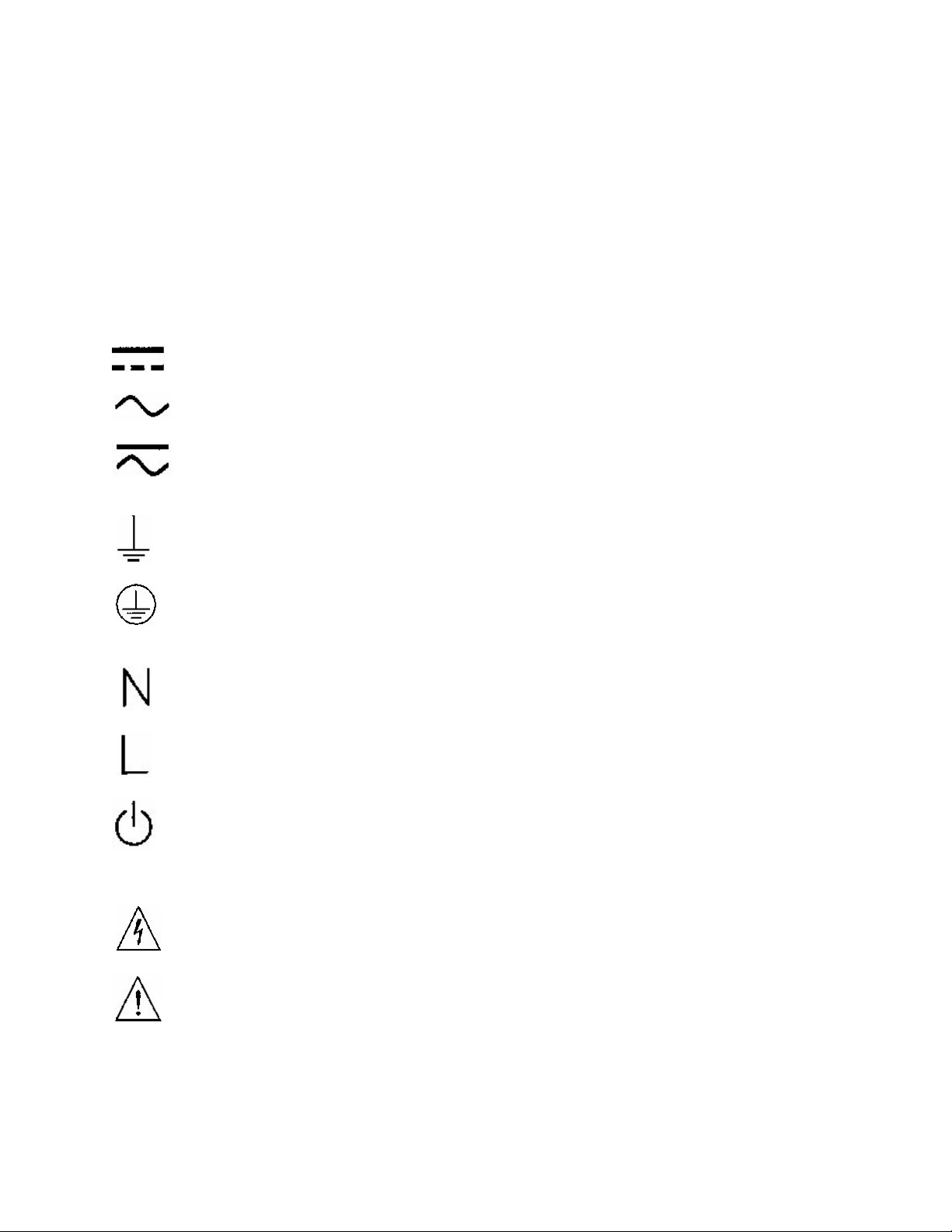

SAFETY SYMBOLS

WARNING The WARNING symbol denotes a hazard. It calls attention to a procedure, practice, or the like, which,

if not correctly performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING symbol

until the indicated conditions are fully understood and met.

CAUTION The CAUTION symbol denotes a hazard. It calls attention to an operating procedure, or the like,

which, if not correctly performed or adhered to, could result in damage to or destruction of parts or all of the products.

Do not proceed beyond a CAUTION symbol until the indicated conditions are fully understood and met.

SAFETY SYMBOL DEFINITIONS

Symbol Description

------------------------------------------------------------------------------------------------------------

Direct current.

Alternating current.

Both direct and alternating current.

Earth (ground) terminal.

Protective earth (ground) terminal.

Terminal for Neutral conductor on permanently installed equipment.

Terminal for Line conductor on permanently installed equipment.

Standby (supply)

Units with this symbol are not completely disconnect the unit from AC

mains, either disconnect the power cord or have a qualified electrician

install an external switch.

Warning, risk of electric shock.

Caution (refer to accompanying documents).

iv

Page 7

TABLE OF CONTENTS

ONE: FEATURES AND OPERATION OVERVIEW 1-1

INTRODUCTION 1-1

PLW MODEL NUMBER DESCRIPTION 1-1

PLA MODEL NUMBER DESCRIPTION 1-2

FEATURES AND OPTIONS 1-2

GENERAL INFORMATION AND OPERATING NOTES 1-3

OPERATING MODES 1-3

PROGRAMMING MODE PARAMETERS 1-4

INPUT CONTROL 1-5

TRANSIENT OPERATION 1-5

TRIGGER OPERATION 1-6

PROTECTION FEATURES 1-6

FRONT PANEL OPERATION QUICK GUIDE 1-10

LCD STATUS ENUCIATOR 1-10

LCD DESCRIPTION 1-10

FRONT PANEL KEYPAD DESCRIPTION 1-11

HOT KEY DESCRIPTION 1-11

ENCODER OPERATION 1-12

MODE AND MENU NAVIGATION 1-13

FRONT PANEL MENU TREE 1-14

EXTERNAL PROGRAMMING PORT 1-18

REMOTE INHIBIT (RI) & DRY CONTACTS ALARM PIN DEFINITION 1-19

INPUT VOLTAGE LIMIT 1-20

INPUT CURRENT LIMIT 1-20

INPUT POWER LIMIT 1-20

DIMENSIONAL DRAWING & DESCRIPTIONS 1-22

PLW 2U MODEL 1-22

PLA 2U MODEL 1-24

PLA 3U MODEL 1-26

PLW 4U & HIGHER MODEL 1-27

PLA 4U AND HIGHER MODEL 1-28

TWO: INSTALLATION 2-1

INTRODUCTION 2-1

BASIC SET UP PROCEDURE 2-1

INSPECTION, CLEANNING, AND PACKAGING 2-1

RETURNING ELECTRONIC LOAD TO THE MANUFACTURER 2-2

PACKAGING FOR SHIPPING OR STORAGE 2-3

LOCATION, MOUNTING, AND VENTILATION 2-3

FUSE REPLACEMENT 2-4

AC INPUT POWER CONNECTION 2-4

AC INPUT CONNECTOR AND VOLTAGE SELECTION 2-5

AC INPUT CORD 2-5

LOAD WIRING 2-5

REAR PANEL INLET & OUTLET PIPE INSTALLATION (PLW ONLY) 2-6

COOLANT WITH ANTI-FREEZE (GLYCOL) PRECAUTIONS 2-7

PREVENTION OF WATER FREEZING, AND OXIDIZATION CONDITIONS 2-8

LOAD WIRING LENGTH FOR OPERATION WITH SENSE LINES 2-9

NOISE AND IMPEDANCE EFFECTS 2-9

LOAD CONNECTIONS 2-9

INPUT TERMINAL 2-9

INPUT TERMINAL CONNECTOR 2-10

LOCAL SENSE CONFIGURATION 2-10

REMOTE SENSE CONFIGURATION 2-11

PARALLEL CONNECTION 2-11

v

Page 8

TRIGGER OPERATION 2-12

ZERO-VOLT LOADING CONNECTION 2-13

THREE: LOCAL OPERATION 3-1

INTRODUCTION 3-1

VOLTAGE AND CURRENT METERING INFORMATION 3-1

OPERATING STATUS INFORMATION 3-1

LOCAL AND GPIB OPERATION INFORMATION 3-2

MODE MENU OPERATION AND RANGE SETTING 3-2

MAIN LEVEL LOCAL OPERATION 3-3

ENCODER OPERATION 3-4

MENU FUNCTION 3-5

LOAD CONTROL MENU 3-5

STEP PARAMETERS 3-7

MEASURE SENSE 3-7

PORT 0 3-7

EXTERNAL CONTROL 3-7

SHORT CONTROL 3-8

CROSS MODE 3-8

CROSS RANGE 3-8

RSF DETECT 3-8

TRIGGER SOURCE 3-8

PROTECTION 3-9

V-ON PROTECTION (UVL) 3-9

MAX/MIN SETTING FUNCTION 3-9

CALIBRATION PARAMETERS 3-10

OSCILLATE 3-10

OSC DETECTION DISABLE AND DELAY FEATURES 3-10

BOOT INPUT 3-10

LOAD PROFILE MENU 3-10

DISPLAY MENU 3-10

C OPERAND FOR BATTERY TESTING 3-10

STABLE READ BACK – MEAS. BUFFER 3-10

SYSTEM FUNCTIONS MENU 3-11

GPIB FUNCTION 3-11

RS-232 FUNCTION 3-11

SYNTAX MODE 3-11

EOS CODE 3-11

BUZZER 3-11

PANEL LOCK 3-11

ETHERNET FUNCTION 3-12

USB FUNCTION 3-13

AUTHENTICATE MENU 3-24

SERIAL NUMBER 3-24

INTERFACE 3-24

CODE 3-24

TRANSIENT OPERATION 3-24

ENTERING TRANSIENT MODE VALUES 3-25

TRANSIENT FREQUENCY, SLEW RATE AND DUTY CYCLE PROGRAMMING 3-25

LOCAL TRANSIENT OPERATION 3-26

CONTINUOUS MODE 3-26

TOGGLE MODE 3-27

PULSE MODE 3-28

TRIGGER MODE 3-29

STEP MODE 3-30

STEP OPERATION SET-UP 3-30

STEP FUNCTION 3-31

STEP COUNT 3-31

STEP MODE 3-31

vi

Page 9

ENTERING STEPPING MODE VALUE 3-31

FOUR: REMOTE OPERATION 4-1

INTRODUCTION 4-1

INTRODUCTION TO GPIB & RS-232 (SCPI) COMMANDS 4-1

OVER VIEW SCPI LANGUAGE 4-1

LANGUAGE DICTIONARY 4-2

COMMANDS STRUCTURE 4-2

SCPI (GPIB & RS-232) PROGRAMMING COMMANDS SET 4-3

COMMON COMMANDS 4-12

COMMAND LIST 4-13

FIVE: CALIBRATION 5-1

INTRODUCTION 5-1

CALIBRATION SERVICE ENVIRONMENT AND PRECAUTIONS 5-1

CALIBRATION REQUIRED EQUIPMENT 5-1

CONFIGURATION 5-2

CALIBRATION PARAMETERS 5-2

LOCAL CALIBRATION PROCEDURES 5-3

RE-INSTALLING CALIBRATION DATA 5-8

APPENDIX A: PEL & PLA/PLW COMMAND COMPATIBILITY TABLE A-1

APPENDIX B: HEAT-SINK TEMPERATURE VS. GPM CURVES B-1

APPENDIX C: NEW ELOAD FEATURES C-1

APPENDIX D: SPECIFICATION & POWER CURVE (see attached)

vii

Page 10

Page 11

ONE: FEATURES AND OPERATION OVERVIEW

INTRODUCTION

The PLA and PLW Series Programmable DC Electronic Load from AMETEK Programmable Power, Inc offers a compl ete solution to

the electronic load system requirements. This instrument was designed to assist in the development and testing of new

products, as well as is being a standard instrument for automatic test systems and evaluation of dc power supplies,

batteries, and power components. Other applications include use as a power circuit breaker or crowbar, high current

function or pulse generator, fuel-cell and photovoltaic cell test, and de-energizing super conducting magnets. This

instrument uses advanced power MOSFETs to dissipate the input power. The electronic load consumes minimum power

to control maximum input power handling capability. Complex circuits are used to control the power balance and

dissipation of the MOSFET. This control circuit also supports the Constant Voltage (CV), Constant Current (CC),

Constant Resistance (CR), and Constant Power (CP) modes of operation. It comes with Standard Commands for

Programmable Instrument (SCPI) commands, remote monitoring of input voltage and currents is a standard features. The

electronic load can be used either on your bench or in a standard 19 in. (483 mm) rack: occupies 3.5” ~ 8.75” (2U ~ 5 U)

of vertical rack space. Designed for continuous use in standalone or systems applications, this electronic load is typically

used to evaluate DC equipment, control circuits, or burn-in power applications.

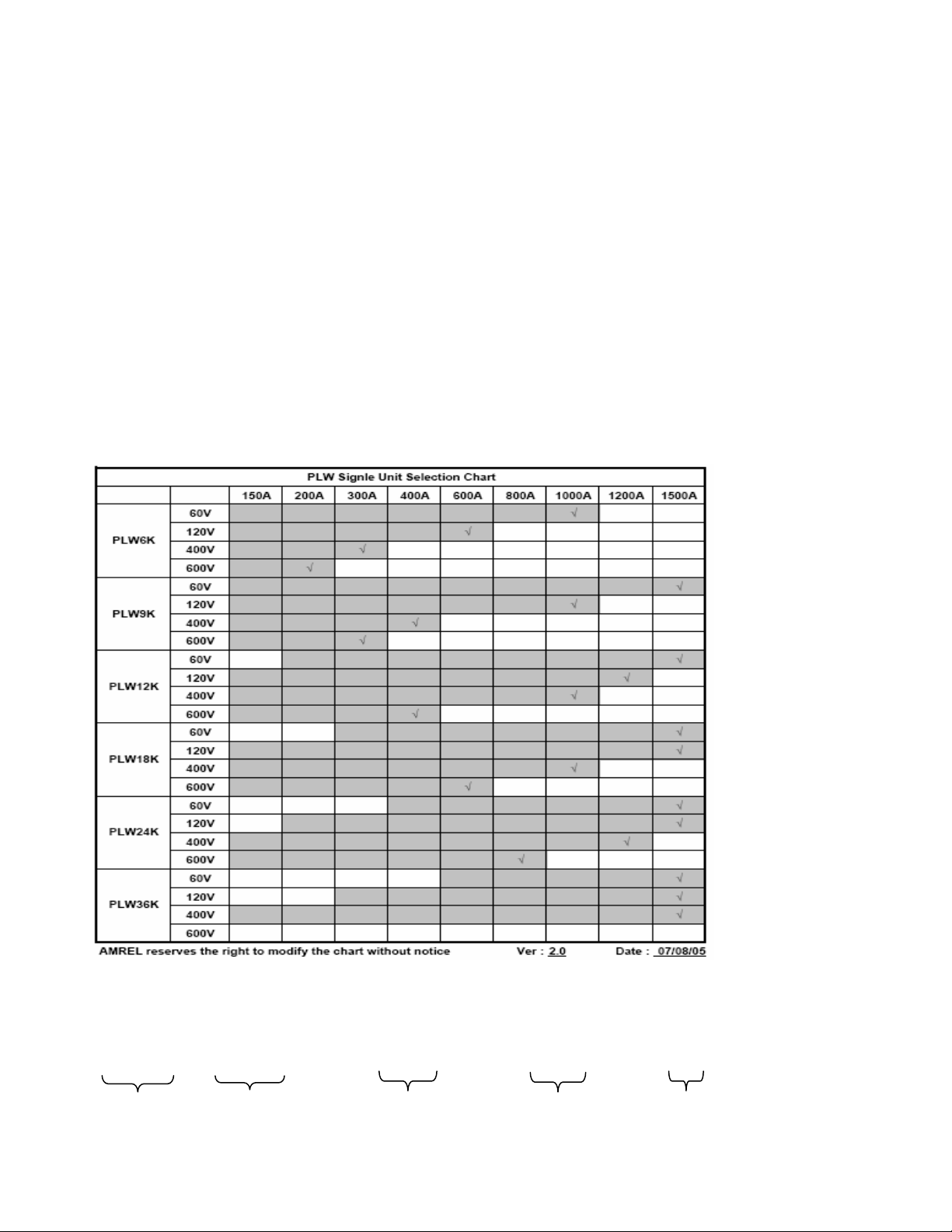

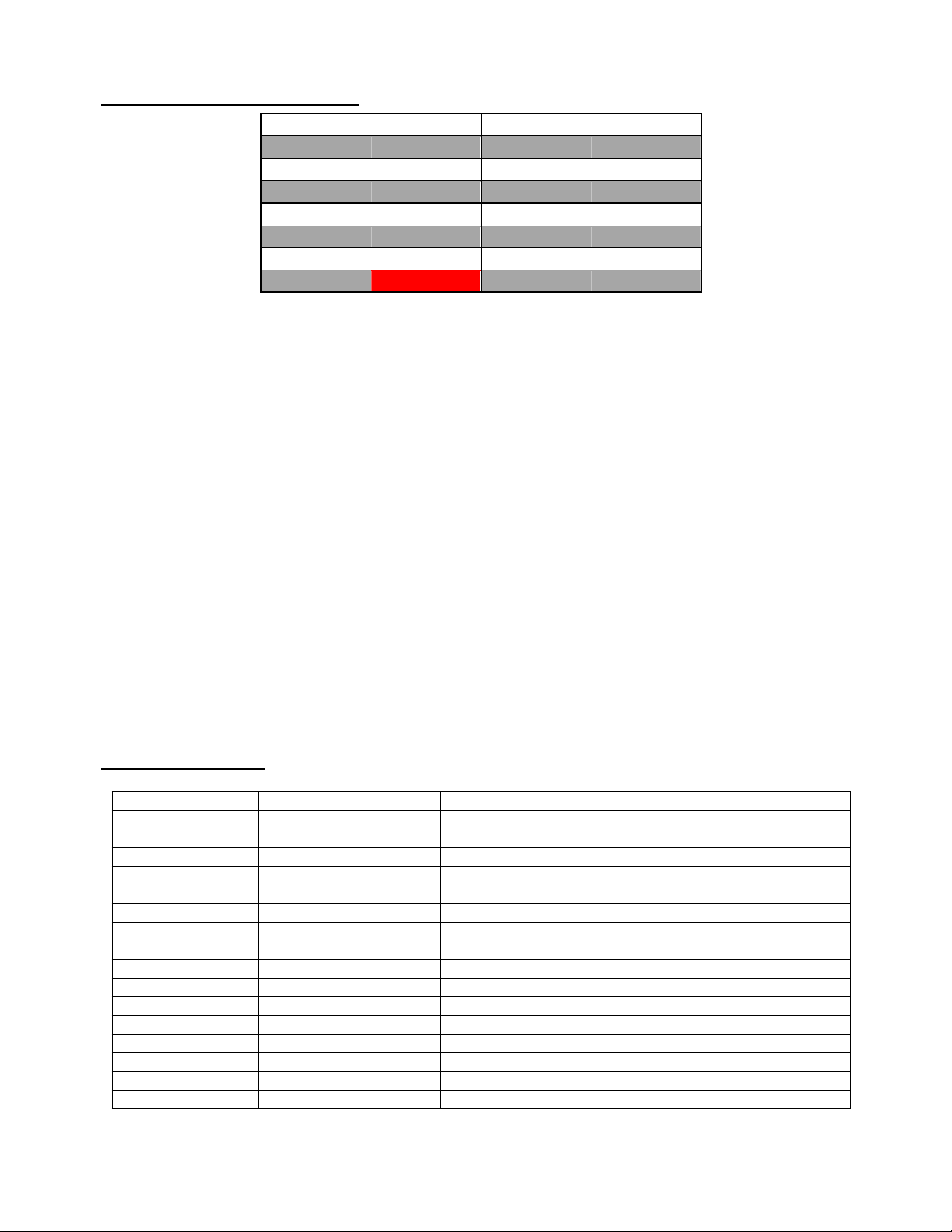

TABLE 1.1a – PLW GENERAL VOLTAGE AND CURRENT RANGES

Note: ¥ - Max Voltage & Current Rated Model; Gray Highlight – Available Model Combinations

PLW MODEL NUMBER DESCRIPTION

PLW 36K – 400 – 300 E

Model Type Power Rating Voltage Rating Current Rating E-Package Suffix

1-1

Page 12

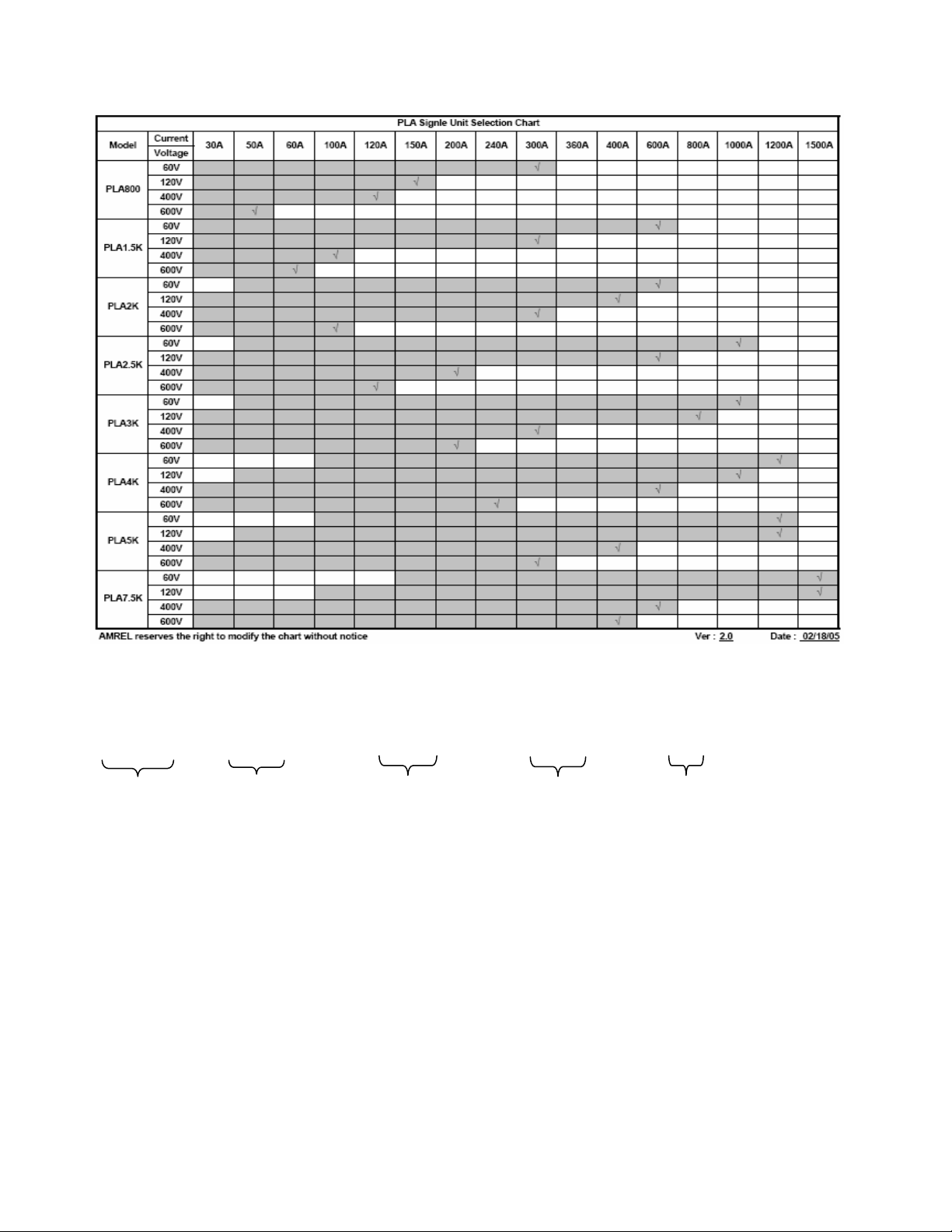

TABLE 1.1b – PLA GENERAL VOLTAGE AND CURRENT RANGES

Note: ¥ - Max Voltage & Current Rated Model; Gray Highlight – Available Model Combinations

PLA MODEL NUMBER DESCRIPTION

PLA 5K – 400 – 300 E

Model Type Power Rating Voltage Rating Current Rating E-Package Suffix

FEATURES AND OPTIONS

x Four constant operating modes: Constant current (CC), constant voltage (CV), constant resistance (CR), and

constant current (CP) mode operation.

x Local control and remote programming for pulse amplitude, pulse width, and pulse cycle.

x Trig-In/Trig-Out and measurement functions.

x GPIB, RS-232, Ethernet, and USB interface programming with SCPI command language.

(Ethernet and USB are available as part of the E-Package).

x Front panel control with keypad and rotary encoder (Tune Mode) for accurate setting.

x Built in pulse generator for continuous, pulsed, and toggled transient operation.

x Seven programmable protection modes: Over Voltage Protection (OVP), Under Voltage Protection (UVP),

Over Current Protection (OCP), Under Current Protection (UCP), Over Power Protection (OPP), and Under

Power Protection (UPP).

x Fan speed control for reduced acoustic noise under light load conditions.

-10Vdc analog programmable.

x 0

x Simple closed-case calibration.

x Highest power density: up to 18KW in 2U height

1-2

Page 13

x Fan speed control for reduced acoustic noise under light load conditions (PLA Only)

x 0-10Vdc analog programmable

x Simple closed-case calibration

x Highest power density: up to 18KW in 2U height (PLW Only)

x Field-upgradeable capability for GPIB, RS232, USB and Ethernet

x Three ranges for each operating mode; Auto or Manual

x External analog programming control for each mode and range

x Panel lock capability

x Program the Slew rise time and Slew fall time independently

x 50us transient time at CC mode; 500us transient time at CV mode

x Anti-Oscillation controls: System bandwidth controls

x Oscillation detection and protection

x Anti-Saturation controls: Under Voltage Lockout

x 16 bits programming and read back capability

x Cross mode and Cross range capability; default off

x Remote Inhibit and Dry contact Fault output

x Pulse power capability with Over Power Protection

x Field-upgradeable firmware

x Self-diagnostic capability

x Redundant Over Temperature Protection

x Four Step profiles; 32 step points for each profile

x Soft-Start Functionality

x Convenient and efficient Hot Keys for mode and Transient Mode Selection, Input and Transient On/Off

Control, Slew Rate Settings, Front panel trigger, and Short.

x Independent Large Numerical Voltage and Current LED display

x Power Interruption (Current Interruption) for Impedance Measurement of Fuel Cells and Batteries

GENERAL INFORMATION AND OPERATING NOTES

Operating Modes:

The four modes of operation are:

Constant Current (CC):

The eLOAD will sink a current in accordance with the programmed value regardless of the input voltage.

Note 1: Never use CC mode for testing a constant current source. The regulation of the two units will fight for control of

the current and an unstable oscillation will result.

Note 2: During CC mode, the eLOAD can operate under the fastest transient time.

Constant Voltage (CV):

The eLOAD will attempt to sink enough current to control the source voltage to the programmed value. It acts

as a shunt voltage regulator when operating in the CV mode.

Note 1: Never use CV mode for testing a constant voltage source. The regulators of the two devices will buck each other

trying to gain control of the voltage which will lead to an unstable condition.

Note 2: In CV mode, the transient time will be adjusted to a slower setting to ensure stable operation.

Constant Resistance (CR):

The eLOAD will sink a current linearly proportional to the input voltage according to the programmed value.

1-3

Page 14

Constant Power (CP):

The eLOAD will dissipate the power in accordance with the programmed value. It will automatically adjust the

current level inversely in response to a change in voltage.

Note: If the source voltage decays to zero volts the load will attempt to draw max rated current. If the OCP limit of the

eLOAD is greater than the current limit of the voltage source, the voltage source will be latched to the CC state. Otherwise

the OCP will trip to shutdown the load.

Programming Mode Parameters:

When programmed to a mode, the eLOAD remains in that mode until the mode is changed or until a fault

condition, such as an over power or over temperature occurrence. The current, voltage, resistance and power

mode parameters can be programmed without mode limitations. When a mode is selected via the front panel

or the digital interfaces, the associated parameters will then take effect at the instance of turning the input on.

Cross Mode:

According to the AMREL eLOAD design, the eLOAD has four operating modes: CC, CV, CR, and CP. As part

of our factory default settings, when switching from one mode to another mode in manual range (i.e. CV Low

to CC High), the final switched state will have the input turned off. If an application requires the input to stay

on when switching modes, the option “cross mode” must be changed from “input off” to “input remain.” By

changing the option, the load will switch between modes while keeping the input on, to accommodate for the

different applications of the DUT.

Note: Cross mode operation will work under both “manual” and “auto” range control mode.

Ranges:

Parameters may be programmed in any of the three overlapping ranges. The low range provides better

resolution at low settings. The range can be set using the front panel or via SCPI command. For auto-range

control: when you program a value, the eLOAD automatically selects the range that corresponds to the value

you program. If the value falls in a region where ranges overlap, the eLOAD selects one with the highest

resolution. In manual-range control: the programmed values will be limited by the current range setting, an

OUT OF RANGE message will appear on the front panel display when an invalid value is entered. When a

range is selected, the associated parameters (preset value or value from memory) will take into effect.

Cross Range Operation:

According to AMREL eLOAD design specification, the eLOAD has three overlapping operating ranges in each

mode. As part of our factory default settings, when switching from one range to another range in manual

mode (i.e. CV Low to CV High), the final switched state will have the input turned off. If an application requires

the input to stay on when switching ranges, the option “cross range” must be changed from “input off” to “input

remain.” By changing the option, the load will switch ranges while keeping the input on, to accommodate for

the different applications of the DUT. The cross range feature allows the user to effectively switch between

ranges based on the application needed by the DUT.

Note: Cross range operation will work under both “manual” and “auto” range control mode.

Immediate (Main) Level:

The immediate level can be set at front panel or via the digital interfaces. If the selected mode is active (Input

on), the new setting immediately changes the input at a rate determined by the soft-start turn-on sequence of

the unit. If the eLOAD is not in the selected mode, the new setting is saved until that mode is activated.

Transient Level:

The transient level can be set at front panel or via digital interfaces. The eLOAD input will switch between the

main level and the transient level when transient operation is turned on. During transient operation, the load

will switch from the immediate level to the transient level determined by the programmed slew time.

1-4

Page 15

Triggered Level:

The level can be preset (stored in the eLOAD) allowing the input to be updated when a trigger is received.

The trigger level can only be changed via digital interfaces, and can be programmed to any value within the

mode’s range settings.

Slew Rate:

The slew rate determines the rate at which the input to the eLOAD changes to a new programmed value,

usually defined as Adc/μs. Slew time (positive and negative) is the amount of time it takes for the eLOAD to

change from the immediate (main) level to the triggered/transient level. To better accommodate user

applications, the positive and negative edge of the slew time can be set independently via the front panel or

through digital remote programming.

Input Control:

Short On/Off:

The eLOAD can simulate a short circuit at its input by activating the load with full-scale current. The short

circuit can be toggled on/off at the front panel or via the digital interfaces while Short On/Off is enabled. The

short on/off switch-over uses the slew rate setting of the active mode and range. The actual value of the

electronic short is dependent on the active mode and range when the short is activated. In CV mode it is

equivalent to setting zero volts. In CC mode it is equivalent to setting full-scale current for the present current

range. In CR mode it is equivalent to programming the minimum resistance for the present resistance range.

Important Notes:

1) Activating the short operation in CV mode may cause the load to draw excessive current that will trigger the

software current limit, which will turn the input off (Protection Mode).

2) It is dangerous to activate short operation when testing batteries or other DUT without current limit. The eLOAD

will act as a near-short current sink, and drain Maximum Current. Severe damages can occur to both the DUT

and eLOAD.

Turning the short circuit on does not affect the programmed settings, and the load input will return to the

previously programmed values when the short is turned off.

Input On/Off:

The eLOAD’s input can be toggled on/off at the front panel, or via the digital interfaces. Turning the input off

(zero current) does not affect the programmed settings. The input will return to the previously programmed

settings when the input is activated again.

Transient Operation:

Utilizing an internal transient generator, the eLOAD provides a robust set of transient operation modes to

periodically switch the eLOAD between two load levels. Transient operation can be activated using the front

panel or via the digital interfaces. Before you turn on the transient operation, you want to set the desired mode

of operation as well as all of the parameters associated with transient operation under varying combinations of

load levels, frequency, duty cycle, and slew rate. Transient operation may be used in CC, CR, CV or CP

modes and can be continuous, pulsed, triggered, stepped or toggled. During transient operation, the eLOAD

will switch from the immediate level to the transient level determined by the programmed slew time.

Continuous Transient Operation

The built-in transient generator produces a pulse train to control the eLOAD in dynamic (transient) operations.

Adjustable parameters include, rise/fall time, frequency and duty cycle. In CONTINUOUS transient operation,

the eLOAD switches between the immediate (main) level and transient level according to parameter settings.

Pulsed Transient Operation

Generate a load change that returns to its original state after a time period SINGLE key or SCPI commands.

1-5

Page 16

Toggled Transient Operation

Toggled transient mode allows the eLOAD input to alternate between two pre-defined load levels as in

Continuous Mode except that the transient points can be triggered instead of an internal transient generator.

STEP Operation:

Step mode lets you generate complex sequences of input changes with rapid, precise timing, which may be

synchronized with internal or external signals. You can program up to 32 settings (or steps) in the profile, the

time interval (dwell) that each setting is maintained, the number of times that the list will be executed, and the

setting’s change in response to the triggers. The step data can be stored in Profile 0, 1, 2 or 3 via either the

front panel or the digital interfaces. Use RCL command to recall the saved state.

Trigger Operation:

The eLOAD has various triggering modes to allow synchronization with other test equipment or events.

Triggering a preset level

Transfers all pending preset levels to the actual level. For the presently active mode, the new level appears at

the input. For the modes which are not presently active, the present levels will not take effect at the input until

the applicable mode becomes active. However you must first initiate the trigger function by executing the

TRIG:IMMED command.

Triggering a transient pulse

A trigger signal will generate a transient pulse of programmable width when pulsed transient operation is in

effect. Triggers can be sent from the front panel by pressing the TRIGGER key or via Remote Interface.

Triggering to a toggle level

A trigger signal will change the input between the main level and the transient level when TOGGLE mode is in

effect. Triggers can be sent from the front panel using the TRIGGER key or via Remote Interface.

Protection Features:

The eLOAD includes the following protection features:

Over Voltage (OV):

The eLOAD has an Over Voltage Protection (OV) set at 105% of the full voltage rating. If the input voltage

exceeds 105% of the over voltage threshold, the input will shut off and an alarm message “OV” will display.

Over Current (OC):

The eLOAD has an Over Current Protection (OC) set at 110% of the full current rating. If the input current

exceeds 110% of the over current threshold, the input will shut off and an alarm message “OC” will display.

Over Power (OP):

The eLOAD has an Over Power Protection function set at 105% (PLW Models) and 110% (PLA Models) of full

Power Rating. If the accumulated energy based on operating voltage and current exceeds the over power

threshold, the input will shut down and display the alarm message “OP”.

Over Temperature (OTP):

The eLOAD utilizes a redundant over-temperature protection structure, which comprises of a temperature

sensor and a thermal switch. Both are designed to force off the eLOAD input during abnormal operating

temperatures. The OTP control algorithm will maintain the eLOAD in its normal temperature range, and in the

case of an OTP condition, the input will be forced off.

1-6

Page 17

Reverse Voltage (RCP):

The eLOAD has the internal parallel diodes to short the input in the presence of a reversed DC voltage input.

The front panel display with the alarm message “RCP” will indicate this condition has been detected.

Remote Sense Fault (RSF):

If the connection to the sense leads is not proper when operating under remote sense mode, the input will be

forced off with the alarm message “RSF”; Remote Sense Fault. Two common errors that can result in “RSF”

failure are while the “Measure Sense” is set to remote, the sense leads are not connected or if the leads are

connected and the connection is lost. The latter can become a serious problem in CP mode. In Constant

Power mode, the eLOAD will maintain the set wattage by balancing the voltage and current. If the remote

sense leads are disconnected, the V

of the load will sense zero voltage and sink the amount of current

MON

needed to keep the same power level until OC or other protection are triggered. The “RSF” protection will

trigger if the voltage deviation between the actual measured voltage and remote sense voltage exceeds a set

limit, forcing the input off until the conditions is cleared. Please refer to page 2-8 for voltage deviation limits.

The “RSF” detection can be disabled via Menu Æ Local ControlÆ RSF Detection Æ OFF.

Note: “RSF” error signal has precedence over OC with remote sense enabled, and will trigger if connection is lost.

Unregulated state (UNR):

The “UNR” message cautions that the power stage of the eLOAD is operating at its minimum resistance or

equivalent to it being shorted (marginal region for the load). Another indication is that the load is being

operated improperly, i.e. not enough supply current/voltage or incorrect calibration data.

Supply Current and Voltage Below Main Level

A common cause for the eLOAD entering into the unregulated state is when the eLOAD is supplied with

insufficient voltage and current, not allowing it to reach the programmed current, voltage, power or resistance

level. For example, if the input is off in CV mode and the main level of the load is set at 3 volts and the power

supply is programmed for 2 volts. An “UNR” alarm message will appear when turning the input on. The

message is caused by the lack of voltage needed to bring the main to 3 volts, and the voltage and current

readings will be unstable during this state. The same condition will occur for CC mode, if the needed current is

lower than the supplied current. To fix the problem, increase the voltage or current above the needed main

value. The “UNR” threshold is set as 1% deviation from the maximum value in that mode and/or range.

CR and CP Mode

In CR and CP mode, if the voltage or current is below the needed value to reach a certain resistance or

wattage, an “UNR” alarm message will appear. For example, in order to obtain 300 watts the input current

value multiplied by the input voltage value will need to equal 300 watts, otherwise an error will occur. For CR

mode, the input voltage value divided by the input current value will need to equal the resistance value

entered. To fix the problem, increase the voltage or current above the needed power or resistance. The

“UNR” threshold for constant power mode is set as 0.3% deviation from the maximum value in that mode

and/or range. The constant resistance mode has a higher fluctuation in its value, so it will have a higher

“UNR” deviation range.

Note: When testing power supplies, a sudden current sink by the eLOAD in CP mode may cause the power supply to

latch in CC mode. At that time, the eLOAD will sink no current and display “UNR”. Simply power cycle the power supply

and repeat the application with a higher voltage setting to prevent the power supply from entering an uncontrollable state.

Insufficient Voltage for Normal eLOAD Regulation

The eLOAD requires a minimum voltage (compliance voltage) in order for proper regulation in any operating

mode and the eLOAD will become unregulated in the case of insufficient supplied voltage. Important factors

such as large line voltage drop, and “dc + ac” input voltages will contribute to drive the eLOAD into an UNR

state. Please take precautions to ensure proper operating voltage is supplied.

Re-Calibration

Verify that the supply current and voltage is sufficient for the operating condition. If the “UNR” message still

occurs, check the current or voltage read back and compare it with the main value setting (CC mode: current;

CV mode: voltage) to make sure the difference is below 1%. If the difference is above 1% for CC/CV mode,

1-7

Page 18

30% for CR mode or 0.3% for CP mode, that particular mode will need to be recalibrated. As a factory default,

all loads are calibrated to its optimal condition. Please verify the calibration inaccuracy carefully or contact

$0(7(.33'Technical Support before re-calibrating the unit.

Precautions for Testing Batteries

As a precaution, when testing batteries prevent from operating in CV mode and make sure that the load does

not enter the unregulated state. If a battery is connected to a short circuited load (UNR state), the load will

draw max current and may cause permanent damage to the load, battery under test and possibly start a fire.

Under Voltage Lockout Protection (UVL):

The programmable under voltage lockout feature allows the user to set a trip point between zero and full-scale

voltage (V-On Voltage Threshold). The input will remain off until the input voltage is greater than the preprogrammed value or the V-On Voltage threshold. For the V-On (UVL) feature, there are two modes that can

be set. In “continuous” mode, the UVL detection will remain active, and each time the voltage drops below the

set threshold voltage, the UVL protection will shut off the input. Under “input on” mode, the UVL detection will

only trigger once to shut down the input and will reset each time the input is cycled. The only way to clear a

UVL protection message is to increase the input voltage beyond the V-On threshold. As a recommended

setting, the V-On threshold should be set equivalent to at least the unit’s min. operating/compliance voltage.

Oscillation Protection (OSC):

The eLOAD offers oscillation protection to prevent the system or DUT from being damaged during unstable

operating conditions. If the oscillation exceeds the frequency threshold for longer than the programmed

oscillation delay, the input will shutdown and an alarm message “OSC” will display. For applications that are

oscillatory in nature, the OSC protection can be disabled. Please refer to the menu tree for further disabling

procedures.

Anti-Oscillation (system bandwidth control):

In addition to the “OSC” protection, the eLOAD has four selectable bandwidth controls: Default, OSC1, OSC2

and OSC3 (DISABLE to disable OSC protection), that will adjust the system speed to resolve potential

oscillation problems. The slew time ranges will vary according to the range selected. At Default state, it has the

widest bandwidth and fast transient time. At OSC1 state, it has the normal bandwidth and transient time. At

OSC2 and OSC3 state, they have the slower transient time in order to have the better stability. The selection

of different bandwidth ranges allows for higher speed or slower stable applications.

Self-Test Failure:

The self-test assures early detection of hardware problems and forces the input off when a failure does occur.

The appropriate bit(s) in the status registers are set when any of the above protection features are active. The

front panel display will indicate which condition(s) have been detected.

Resetting Latched Protection

All of the protection features remain latched (set) when they are tripped. The latched protection features can

be reset via the front panel PROT (CLEAR) key or the digital interfaces. The condition that caused the

protection feature to trip must be removed or it will trip again as soon as it is reset.

Bias Voltage Protection (VPP & VNP)

For the eLOAD to operate properly it requires an internal +12 V

and -12VDC voltage to bias different parts of

DC

the system. In the case that the +12V bias voltage malfunctions, a “VPP” error message will appear indicating

a voltage positive power error. If the -12V bias voltage malfunctions, a “VNP” error will appear indicating a

voltage negative power error. For either of these error messages, please contact AMREL Technical Support.

The eLOAD most likely had a serious internal malfunction that caused the system to shutdown.

Note: For VPP and VNP failures, please refrain from repairing the unit, for it may inflict further damage.

1-8

Page 19

In Fault Protection (INF)

If the eLOAD is forced to sustain too much power, current or voltage in a short amount of time, the internal

power stage may have been damaged. If the damage is serious enough, the system hardware will shutdown

and the display will show an “In_Fault” error message. When this message occurs, please contact $0(7(.33'

customer service. The eLOAD most likely has a power stage malfunction and will no longer operate normally.

Note: For INF failure, please refrain from repairing the unit, for it may inflict further damage.

User-Defined Over Current, Voltage, and Power Protection:

Over Voltage (OVP):

OVP is a programmable voltage trip point. Limits can be programmed to “shut down” the eLOAD input if the

voltage exceeds pre-programmed value (default to off). The default programmable over voltage (OVP) trip

point is 105% of full voltage rating

Over Current (OCP):

Over Current Protection (OCP) is a programmable current trip point. Limits can be programmed to “shut down”

the eLOAD input if the current exceeds pre-programmed value for longer than the pre-set time interval (default

to off). The default programmable over current (OCP) trip point is 105% of full current rating.

Over Power (OPP):

The over power protection (OPP) is a programmable power trip point. If the input power exceeds the OPP limit,

the eLOAD input will shutdown and display an OPP alarm message. The default programmable over power

trip point is 110% of full power rating for PLW Models and 105% of full power rating for PLA Models.

User-Defined Under Current, Voltage, and Power Protection

For flexible customer application, AMREL’s eLOAD provides a user-defined under current (UCP), under

voltage (UVP) and under power protection (UPP). For applications that require a minimum voltage, current or

power level for normal operation, the input will shut off when the level drops below the set value.

Custom Max/Min Value Setting

The maximum and minimum value for each mode and range is programmable. To prevent accidental

erroneous settings, the Max/Min will limit the programmable values.

Note: The max and min value settings must be within the limits of each individual range and mode

Low Voltage (LV) Protection

When the input voltage drops below 1% of the maximum voltage, a “LV” message will appear to indicate the

eLOAD is operating under a low voltage condition. During “LV” mode, the load will automatically switch to a

slower slew time to soften high in-rush currents by limiting the speed of the current rise. The “LV” message

notifies the user of a change in the slew time, so they can modify their settings to ensure proper test operation.

Self-Diagnostic Capability

Based on the system error message displayed on the front panel, certain troubleshooting analysis can be

concluded and may be fixed accordingly. The error messages or alarms displayed due to “over limit” faults or

erroneous operation will trigger an internal relay that shuts off the system input. For more serious failures,

such as “VPP”, “VNP” or “INF,” the system has permanently shutdown and will need to be shipped back to $0(7(.33'

for repair. There are other fault prote

depth analysis of the system errors, please refer to the

error bit for the different types of error. Utilizing any of the interfaces, the fault condition can be diagnosed

based on the returned error bit.

ctions that could occur under different applications, for an in-

protection features section. The eLOAD also provides

1-9

Page 20

FRONT PANEL OPERATION QUICK GUIDE

LCD Status Enunciator

LIQUID CRYSTAL DISPLAY:

1

2

3

CC 40.000A LOCAL

FIGURE 1.1 LIQUID CRYSTAL DISPLAYS

Important Notes:

1) The LCD displays real time input Voltage/Current & mode status. These messages are viewed in either local or

2) The Front Panel and Remote read back provide 4 digits of display after the decimal point. Any numbers

AUTO LOW 600A

4

remote mode.

th

exceeding the 4

digit will be rounded to the next significant digit and displayed as the read back value.

5

LCD DESCRIPTION

Mode Indicator: Constant Voltage (CV), Constant Current (CC), Constant Resistor (CR), and Constant Power (CP).

1)

2) Main Setting Indicator: Main Voltage, Current, Resistance and Power Setting.

3) Local Mode/Remote Mode Indicator: Local, INSC, GPIB, RS232, ETHER, and USB.

4) Operating Range Indicator: Auto, Manual Low, Manual Middle, and Manual High.

5) Max Range Setting Indicator: Displays maximum value for the specified range.

1-10

Page 21

Front Panel Keypad Description

x

R

R

MENU

7 8 9 LOCAL

4 5 6 RANGE

1 2 3 STEP

0

FIGURE 1.2 FRONT PANEL KEYPAD

Key “0” Numeric entry key for number 0.

Key “.” Numeric entry key for decimal dot.

Key “1” Numeric entry key for number 1.

Key “2” Numeric entry key for number 2.

Key “3” Numeric entry key for number 3.

Key “4” Numeric entry key for number 4.

Key “5” Numeric entry key for number 5.

Key “6” Numeric entry key for number 6.

Key “7” Numeric entry key for number 7.

Key “8” Numeric entry key for number 8.

Key “9” Numeric entry key for number 9.

CLEA

Key “CLEAR” Clears partially set commands and

return the unit to the metering mode. By

pressing the "Clear" with no entry will

display "AMREL Model number and

software version.

Note: If the model name exceeds 16 digits, the displayed

model name will truncate. Please refer to the model name

label or use *IDN? Command to query back model name

Key “RANGE” Selects between auto, manual low,

Key “LOCAL” Returns from remote PC control to local

Key “STEP” Allows programming of time duration

Key “ENTER” Enters the values in the set mode and

ENTE

manual middle and manual high range.

operation and status indicator will

change from RMT to LCL. The Local

key also accesses all eLOAD menu

options and parameters for configuring

desired settings.

and value settings for step operation

returns the unit to the metering mode.

Hot Key Description

HOT KEYS OFF SOLID ON FLASHING ON

INPUT

SHORT

STEP

PULSE

CC

CR

CP

19CV

CONT

TOGGLE

SINGLE

TRIGGER

PEAK

FREQ

DUTY

SLEW

INPUT OFF INPUT ON Press to Short

SHORT OFF SHORT ON Press to Short

STEP OFF STEP ON Press Input to Start Step

PULSE OFF PULSE ON Press Input to Start Pulse

CC Mode Disabled CC Mode Enabled N/A

CR Mode Disabled CR Mode Enabled N/A

CP Mode Disabled CP Mode Enabled N/A

CV Mode Disabled CV Mode Enabled N/A

Continuous Disabled Continuous Enabled N/A

Toggle Disabled Toggle Enabled N/A

Single Disabled Single Enabled N/A

N/A N/A Trigger Transient Operation

Setting not Enabled Adjust Trans. Value N/A

Setting not Enabled Adjust Trans. Freq. N/A

Setting not Enabled Adjust Trans. Duty N/A

Setting not Enabled Adjust +/- Slew Rate N/A

TABLE 1.2 – HOT KEY DESCRIPTION

1-11

Page 22

Encoder Operation

BUTTON or

SETTING

Main Level Setting

Screen in Main Value

Edit Mode

Main Level Setting

Screen With Input On

PEAK Hot Key Pressed

DUTY Hot Key Pressed

SLEW Hot Key Pressed

MENU Button Pressed

RANGE Button

Pressed

STEP Button Pressed

ENCODER

ACTION FUNCTION

Press & Hold Change Input Value

Tap Change Decimal Position

Rotate Left Decrement Value

Rotate Right Increment Value

Press & Hold Modify/Enter Value

Tap Modify/Enter Value

Rotate Left Decrement Value (real-time)

Rotate Right Increment Value (real-time)

Press & Hold Change Input Value

Tap Change Decimal Position

Rotate Left Decrement Value

Rotate Right Increment Value

Press & Hold Modify/Enter Value

Tap Change Decimal Position

Rotate Left Decrement Value

Rotate Right Increment Value

Press & Hold Make Selection/Modify/Enter Value

Tap Change Decimal Position

Rotate Left

Rotate Right

Press & Hold Select Menu Option

Tap Exit to Previous Menu

Rotate Left Scroll Through Selection

Rotate Right Scroll Through Selection

Press & Hold Select Mode & Range Type

Tap Select Mode & Range Type

Rotate Left Scroll Through Selection

Rotate Right Scroll Through Selection

Press & Hold Make Selection/Modify/Enter Value

Tap Change Decimal Position

Rotate Left

Rotate Right

TABLE 1.3 – ENCODER OPERATION

Scroll Through Selection/Increment

Value

Scroll Through Selection/Decrement

Value

Scroll Through Selection/Increment

Value

Scroll Through Selection/Decrement

Value

Note: Press “Clear” to exit from any menu or edit mode

1-12

Page 23

Mode and Menu Navigation

Mode and Menu Navigation

1) In meter mode, press CV, CC, CR, or CP Hot Keys to make a mode selection.

2) In meter mode, press RANGE from the Front Key Pad to enter into range selection mode.

3) Press RANGE again to make a range selection from Low, Middle, High or Auto.

4) The first row displays the currently selected mode and main value

5) The second row displays the currently selected range.

6) Press “ENTER” key to confirm range, and go back to meter mode.

7) Press “CLEAR” key to go back to meter mode.

8) Press encoder, same as CLEAR key.

9) Press and hold encoder, similar to ENTER key.

Function selection mode

1) In meter mode, press FREQ, DUTY, or SLEW Hot Keys to enter into an edit mode.

2) Press SLEW to make a selection between rise time and the fall time.

3) Press DUTY to configure the duty cycle.

4) Press FREQ to configure the frequency.

5) Rotate 43 the encoder to edit value by each decimal place.

6) Press “CLEAR” key to go back to meter mode.

7) Press encoder, same as CLEAR key.

8) Press and hold encoder to enter and accept a value.

Menu mode

1) Press LOCAL/MENU key, or press and hold encoder to enter into menu mode.

2) Rotate 43 the encoder to select menu item.

3) Press “ENTER” or press and hold the encoder to accept the setting.

4) Press “CLEAR”, or press encoder to go back to meter mode.

Note: Please refer to the front panel menu tree section for detailed menu selections.

Panel Lock

1) When LCD is in “Menu Mode”, select “PANEL LOCK” can set PANEL ENABLE, and PANEL PASSSWORD.

2) When “PANEL ENABLE” is set to OFF, power off the PD unit and power on again, the local panel is disabled.

All other keys are locked except “LOCAL” key. When these keys are pressed, LCD displays “LOCAL

LOCKED”.

3) Press “LOCAL” key, users must enter PASSWORD. If the PASSWORD is correct, the LCD goes back to

normal state. Press “ENTER” key and “LOCAL” key in the same time locks all the keys again.

4) If users forget the password, they can use “555555” as default password.

List step edit mode

1) When LCD display is in meter mode, press STEP key from Front Key Pad to enter into step edit mode.

2) Press STEP key to make a selection between Time edit or Value edit of a step.

3) Press and hold the encoder to enter and accept the setting of a step.

4) Rotate 43 the encoder to select step point one by one.

5) Press “VALUE (9)” key to edit step value.

6) Press “CLEAR” key to go back to meter mode.

1-13

Page 24

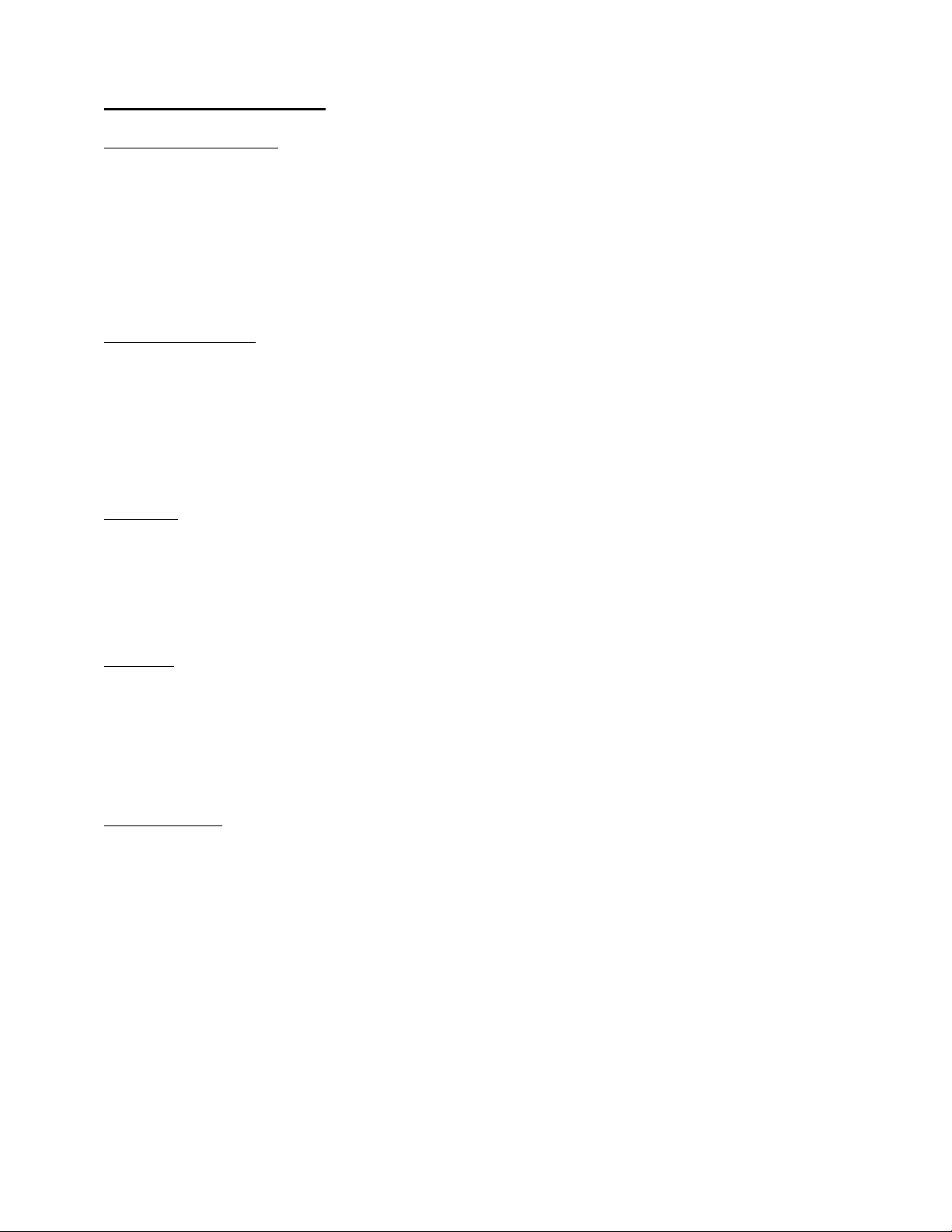

Front Panel Menu Tree

MENU

All Words in Bold are Factory Default Settings

LOAD CONTROL STEP PARAM. Æ MODE Æ STEP

Æ STEP AUTO

Æ STEP ONCE

Æ COUNT Æ 1 ~ INFINITY

MEASURE SENSE Æ LOCAL

Æ REMOTE

PORT0 Æ OFF

Æ ON

EXT. CONTROL Æ OFF

Æ ON

SHORT CONTROL Æ OFF

Æ ON

CROSS MODE Æ INPUT OFF

Æ INPUT REMAIN

CROSS RANGE Æ INPU

T OFF

Æ INPUT REMAIN

RSF DETECT Æ ON

Æ OFF

TRIGGER Æ SOURCE Æ HOLD

Æ BUS

Æ EXTERNAL

Æ ETHERNET

Æ DELAY Æ 00000mS

PROTECTION Æ OV-PROTECTION Æ OV STATE Æ OFF

Æ ON

Æ OV LIMIT Æ 1.05*V

MAX

Æ OV DELAY Æ 01000mS

Æ UV-PROTECTION Æ UV STATE Æ OFF

Æ ON

Æ UV LIMIT Æ 000.000V

Æ UV DELAY Æ 01000mS

Æ OC-PROTECTION Æ OC STATE Æ OFF

Æ ON

Æ OC LIMIT Æ1.05* I

MAX

Æ OC DELAY Æ 01000mS

Æ UC-PROTECTION Æ UC STATE Æ OFF

Æ ON

Æ UC LIMIT 000.000A

Æ UC DELAY 01000mS

Æ OP-PROTECTION Æ OP STATE Æ OFF

1-14

Page 25

Æ ON

Æ

Æ OP LIMIT Æ1.05*P

MAX

Æ OP DELAY Æ 01000ms

Æ UP-PROTECTION Æ UP STATE Æ OFF

Æ ON

Æ UP LIMIT Æ 000.000W

Æ UP DELAY Æ 01000ms

Æ V-ON CONTROL Æ V-ON STATE Æ INPUT ON

Æ CONTINUE

Æ V-ON THRESHOLD

Æ 01.000V

MAX/MIN LIMIT Æ MAX VOLTAGE Æ V

MAX

Æ MIN VOLTAGE Æ 000.000V

Æ MAX CURRENT Æ I

MAX

Æ MIN CURRENT Æ 000.000A

Æ MAX RESIST. Æ R

Æ MIN RESIST. Æ R

Æ MAX POWER Æ P

MAX

MIN

MAX

Æ MIN POWER Æ 000.000W

CAL. PARAM. Æ MEASURE LOW Æ 06400 COUNT

Æ MEASURE HIGH Æ 32000 COUNT

Æ TRAN. OFFSET Æ 06400 COUNT

OSCILLATE Æ OSC. CONTROL Æ DEFAULT

Æ OSC1

Æ OSC2

Æ OSC3

Disable

Æ OSC. DELAY Æ 0000ms

BOOT INPUT Æ OFF

Æ ON

INPUT CONTACTOR Æ CONTROL Æ DISABLE

Æ PORT0 + @ ON

Æ PORT0 - @ ON

ÆDELAY Æ 50ms ~ 500ms

PROFILE RECALL Æ 0 Æ - DONE -

Æ 1 Æ - DONE Æ 2 Æ - DONE Æ 3 Æ - DONE SAVE Æ

0 Æ - DONE Æ 1 Æ - DONE Æ 2 Æ - DONE Æ 3 Æ - DONE RESET Æ ENTER TO RESET Æ - DONE -

DISPLAY METER MODE Æ V+I

Æ V+P

Æ

Æ V+R

Æ I+P

V+C

1-15

Page 26

Æ I+C

Æ

Æ I+R

Æ R+P

Æ R+C

Æ P+C

Æ V+T

Æ I+T

Æ R+T

Æ P+T

Æ C+T

‘C’ VALUE Æ 001.000A

MEAS. BUFFER Æ 8

Æ 16

Æ 32

Æ 64

Æ 128

Æ 256

SYSTEM GPIB ADDRESS Æ 12

RS-232 SPEED Æ 2400

Æ 4800

Æ 9600

Æ 19200

Æ 38400

Æ 57600

Æ 115200

SYNTAX

EOS CODE Æ CR+LF

Æ NULL

Æ CR

BUZZER Æ ON

Æ OFF

PANEL LOCK Æ PANEL ENABLE Æ ON

Æ OFF

Æ PANEL PASSWD Default: 555555

ETHERNET Æ ADDRESS 0.0.0.0

Æ NETMASK 0.0.0.0

Æ GATEWAY 0.0.0.0

AUTHENTICATE SERIAL NO. Æ 000B87XXXXXX

INTERFACE Æ GPIB ETHER USB

CODE Æ _______

MODE

PLA/PLW

Æ PEL

Æ LF

1-16

Page 27

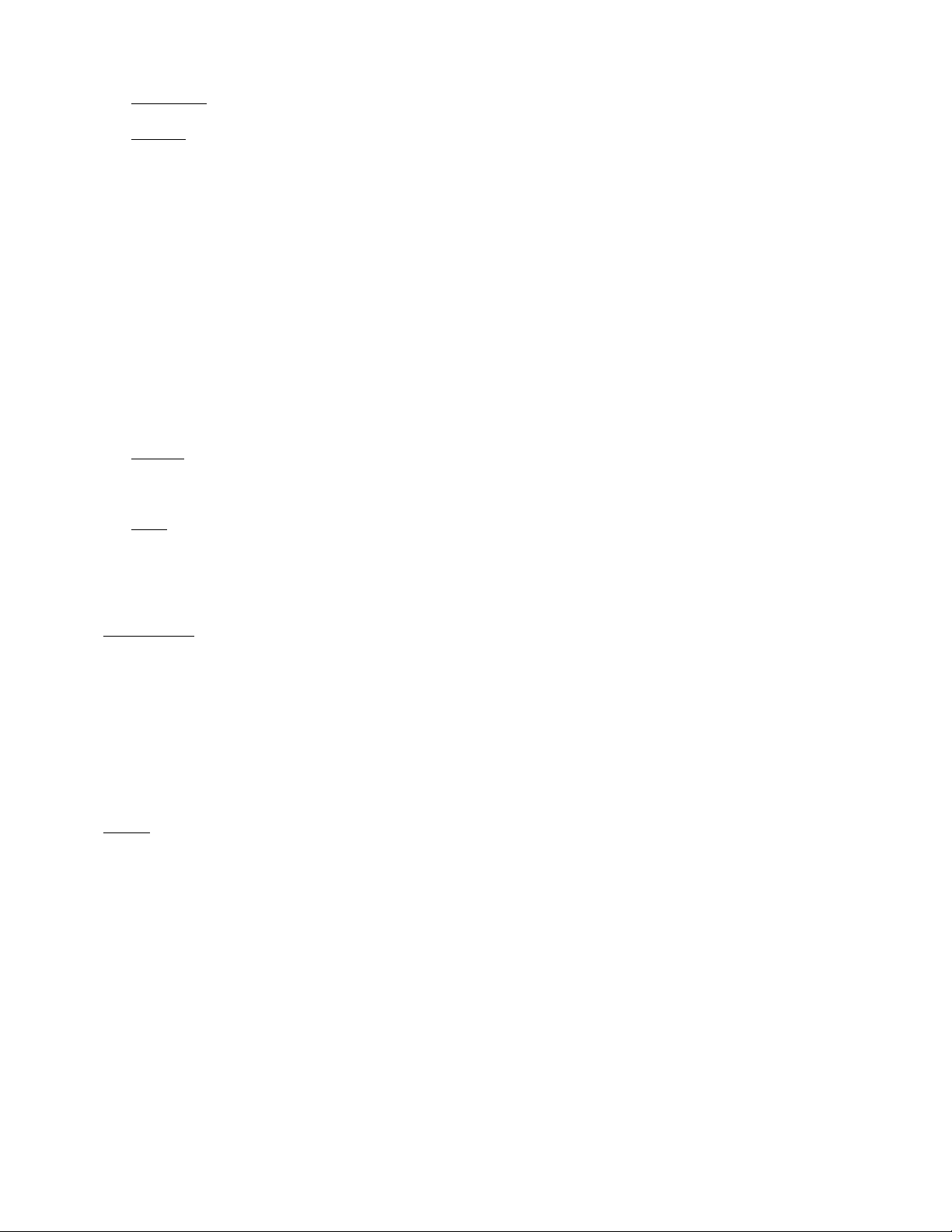

HOT KEYS

ON/OFF

“FLASHING”

ON

“FLASHING”

ON

“FLASHING”

ON

ON

Note: “Flashing” stands for a blinking light displayed on the key being pressed

RANGE

STEP

ÆINPUT OFF

ÆSHORT OFF

ÆSTEP OFF

ÆPULSE OFF

“FLASHING”

ÆAUTO

ÆMANU LOW

ÆMANU MID

ÆMANU HI

ÆSTEP ÆTIME Æ 00000 ms

ÆVALUE Æ 000.000V/A/ȍ/W

(PRESS ENCODER TO ENTER.)

ÆENCODER RIGHT Æ +1 for Point of step (increment step# by 1)

ÆENCODER LEFT Æ -1 for point of step (decrement step# by 1)

MODE/MAIN

ÆON

Æ CC ÆOFF

ÆCR ÆOFF

ÆON

ÆCP ÆOFF

ÆON

ÆCV ÆOFF

ÆON

By default the range is set to AUTO RANGE and mode is set to CCL

PULSE

ÆFALL Æ5ms

ÆCONT ÆON

ÆOFF

ÆTOGGLE ÆON

ÆOFF

ÆSINGLE ÆON

ÆOFF

ÆTRIGGER ÆBLINK

ÆOFF

ÆPEAK Æ001.000A

ÆFREQ Æ20Hz

ÆDUTY Æ50%

ÆSLEW ÆRISE Æ5ms

1-17

Page 28

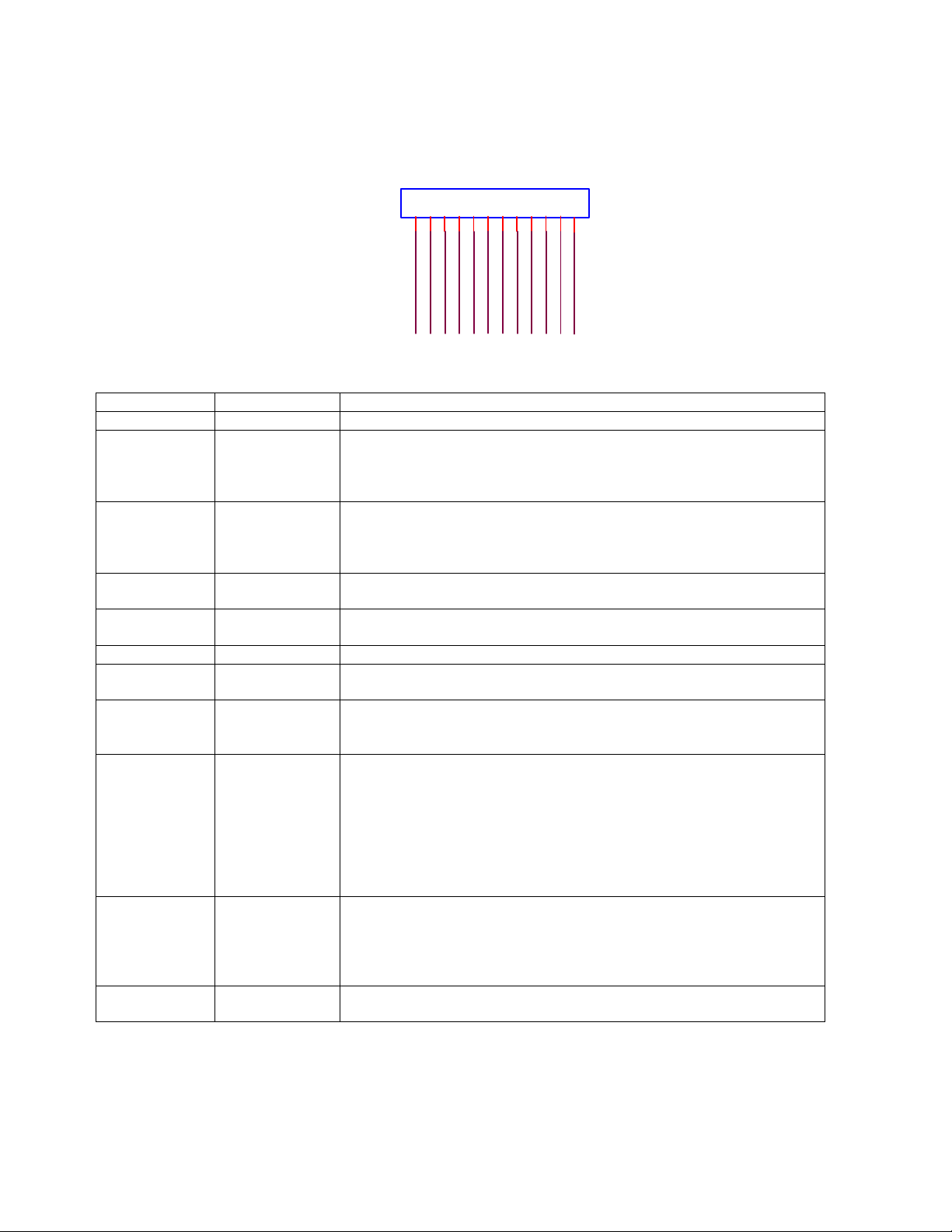

EXTERNAL PROGRAMMING PORT

The external programming port provides remote sense inputs, input voltage monitoring, input current monitoring, external

trigger input, external trigger output, and analog programming signal.

External Program Port

Terminal Block

10

11

12

9

9

10

11

12

5

6

7

8

5

6

7

8

1

2

3

4

4

3

2

1

DGND

TRIGOU T

TRI GI N

IMON

NC

PORT

VMON

FAULT

+S

-S

External Prog

AGND

1 + S Positive remote sense.

2 -S Negative remote sense.

3 EXT_GND Analog Ground. Provides common (reference) connection for EXT_PRG

(PIN 4), VMON (PIN 5), and IMON (PIN 6). When an external

programming function is not used, connect this point to Analog pin 4 to

prevent EMI Noise.

4 EXT_PRG External analog programming input signal. The electronic load can be

programmed externally by 0-10Volts DC or DC + AC voltage (AC voltage

must be biased to above 0V). When external analog programming function

is not used, connect this point to AGND pin 3 to prevent EMI Noise.

5 VMON Input voltage monitoring signal. Generates a 0-10Volt output signal that is

linearly proportional to the electronic load’s 0 to full-scale voltage.

6 IMON Input current monitoring signal. Generates a 0-10Volt output signal that is

linearly proportional to the electronic load’s 0 to full-scale current.

7 NC No Connection

8 FAULT Fault signal output. A TTL compatible signal that becomes active (high)

when any of the protections are triggered.

9 PORT Digital port output. Port can be activated via front panel operation or by

SCPI command PORT 0|1 |off|on. PORT becomes active (high) when the

PORT is on.

10 TRIG_IN Negative Edge Triggered External trigger signal input. A TTL compatible

signal is used to activate the electronic load. TRIG_IN is used to change to

a preset mode or switch between settings in transient mode, such as trigger

the step mode, trigger mode, continuous mode, toggle mode, step auto

mode, step once mode, or pulse mode.

NOTE: IN ORDER TO ENABLE THE TRIG_IN PORT FOR USE, THE

TRIGGER SOURCE MUST BE SET TO EXTERNAL.

11 TRIG_OUT External trigger signal output. A TTL compatible signal that is activated

via the Trig-in or GPIB command *TRG. This output follows the state of

the TRIG_IN input. External trigger output is used for triggering

oscilloscopes, power supplies, or other electronic loads that have external

trigger input.

12 EGND Earth Ground. Provides the common (reference) connection for TRIG_IN

(PIN 10), TRIG_OUT (PIN 11), Fault (PIN 8), and PORT (PIN 9).

1-18

Page 29

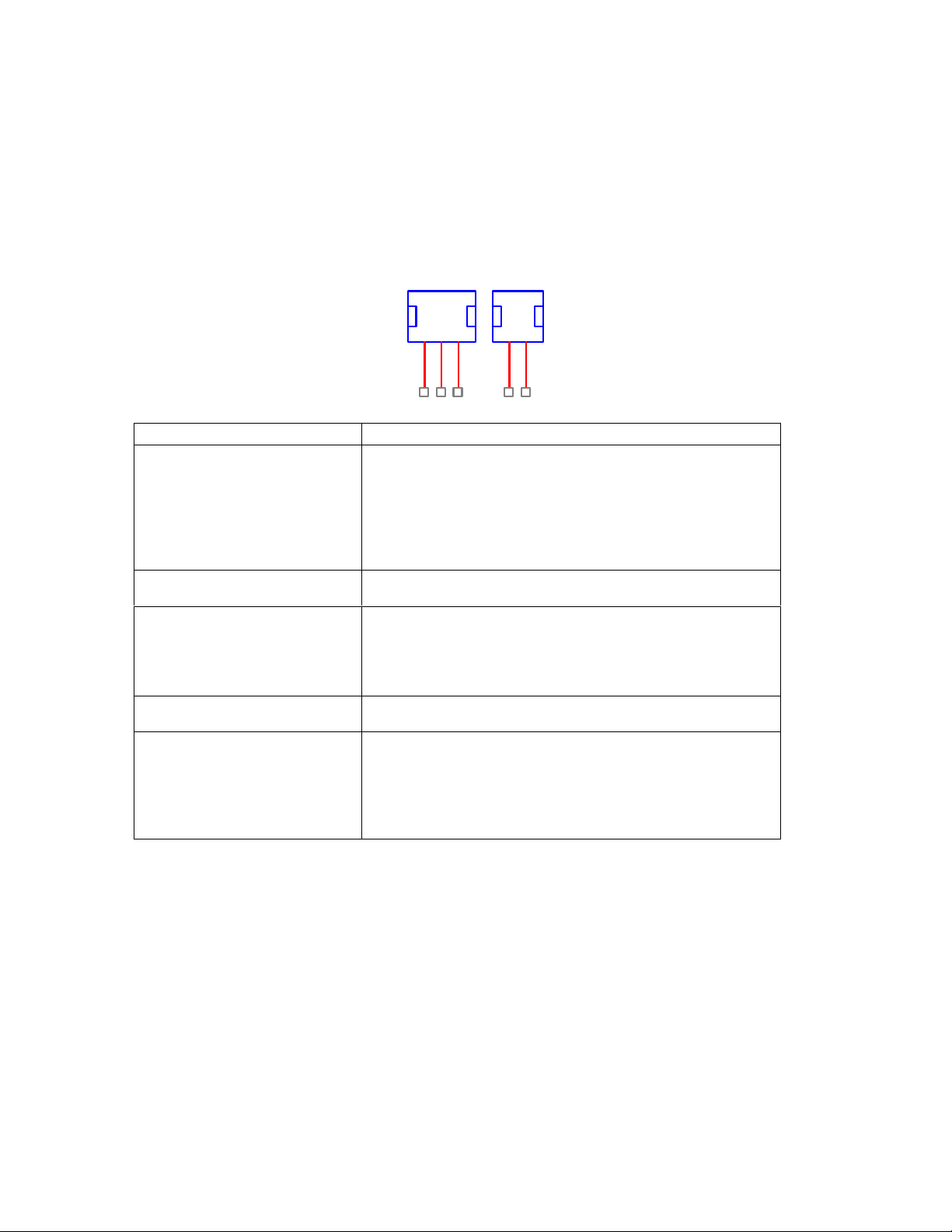

REMOTE INHIBIT (RI) & DRY CONTACTS ALARM PIN DEFINITION

In the case of fault conditions, the eLOAD provides an externally short-activated emergency shut-off port

(Remote Inhibit) that will disengage the eLOAD operation. For added protection, normal and deviant

conditions can be identified by the Dry Contacts Alarm, which utilizes Normal Open (RY_NO) and

Normal Close (RY_NC) relays as alarm indicators for customization of external protection systems. In the

case of a protection or AC power loss, the RY_NO will short (closed) and RY_NC will be opened to

indicate a fault/deviant condition, either contact can be used to trigger an external alarm.

1

3

4

5

2

Pin Number Pin Definition

1 – RI+ Remote Inhibited (RI) is used as an emergency switch to disable

the system. RI can be connecting to a switch or an open collector

device that shorts the RI pin to common (EGND) whenever it is

necessary to disable input of the unit. Once RI is activated, it

will turn off the dc output. In order to re-activate the unit, the

connection between common and RI pin needs to be open again,

and it will have 3 seconds delay.

2 – RI- The EGND return path for RI+ pin. Shorting RI+ and RI- (Pin 1

& Pin 2) will trigger RI protection.

3 – RY_NC Dry Contacts alarm: a fault alarm is declared if there is a loss of

AC power or protections are triggered. The fault alarm outputs

provide a normally closed relay configuration that provides

user’s flexibility and isolation required to an external controller

or an external alarm panel. The delay is 3 second

4 – RY_CO Relay Common. Provides the common (reference) connection

only for RY_NC or RY_NO

5 – RY_NO Dry Contacts alarm: a fault alarm is declared if there is a loss of

AC power or protections are triggered. The fault alarm outputs

provide a normally open relay configuration that provides user’s

flexibility and isolation required to an external controller or an

external alarm panel. The delay is 3 second.

1-19

Page 30

INPUT VOLTAGE LIMIT

The programmable electronic load can handle voltages within nominal values and surge voltages less than 5% above

nominal value. The Over-voltage protection will be tripped when the input voltage exceeds 5% of nominal value. For

CV mode application, the input power source should have current limit capability to prevent exceeding the electronic

load’s input current range.

Two over voltage protection features have been provided. 1) Over voltage protection to limit maximum current to 5%

above nominal value. 2) Software selectable, the user can set and read back the input protection voltage level.

WARNING

High voltage and high current operation may result in a fault condition, shutting down the Load input. Ensure that the

maximum voltage and current applied to the electronic load does not exceed the power rating.

INPUT CURRENT LIMIT

The nominal current values are indicated in the specification datasheet. During Load bank operation in CV (Constant

Voltage) mode, limiting the input current at high voltages become a critical factor. The internal structure of the Load

Bank and the Over-Current protection will limit the maximum current to less than 5% above nominal rated current.

However, the combined input current and voltage can easily exceed the maximum rated power. If the power overload

condition persists over a time period, the accumulated over-power energy will trigger the hardware OP protection, and

control the input current to not exceed 120% of max rated power. For CC mode operation, the input power source should

be a CV source or operate in CV mode, to avoid potential unstable conditions caused by two Constant Current Control

loops. As for over power conditions in CC mode, please limit the input voltage to pre

down the Load input.

vent the OP fault condition shutting

Two over current protection features have been provided. 1) Over current protection to limit maximum current to 5%

above nominal value. 2) Software selectable, the user can set and read back the input protection current level.

WARNING

High voltage and high current operation may result in a fault condition, shutting down the Load input. Ensure that the

maximum voltage and current applied to the electronic load does not exceed the power rating.

INPUT POWER LIMIT

The programmable electronic load is designed to handle power up to 110% of Max Power Rating, with input voltage and

current below the max rated specifications. As a recommendation, the input power source should not exceed the max

rated power, to avoid fault conditions shutting the Load input off. As indicated in the specification sheet, Constant Power

mode requires a current limit for each range (CPL, CPM, and CPH), which cannot exceed the corresponding current range

max value (CCL, CCM, and CCH).

WARNING

Anticipate the Maximum output of the power source carefully and consider the worst-case scenario. The maximum

power range of the load should be higher than the output power of the source. High voltage and high current operation

may result in a fault condition, shutting down the Load input.

For CP mode application, the programmable electronic load can be set to maximum power dissipation with the following

limitations. Input must be within maximum voltage and current ratings. For example, PLA1.2K-120-200, the max rated

values are 120V/200A/1200W. Therefore, the maximum power will be limited to a combination of “voltage x current

values” equating to 1,200W. Thus, CP mode is limited by the hardware's maximum current, voltage and power ratings.

1-20

Page 31

Maximum Current – Max A

V

in

MaxV Maximum Voltage – Max V

Maximum Power – Max KW

LowV

Low-Mid Max A I

in

The theory of the CP operation comes from the divider circuit built in the load. Because of the nonlinear characteristic of

the divider, the input voltage, input current, and power setting will limit the CP mode of operation. The CP mode will not

allow the load to operate beyond the full range of the Constant Power setting.

1-21

Page 32

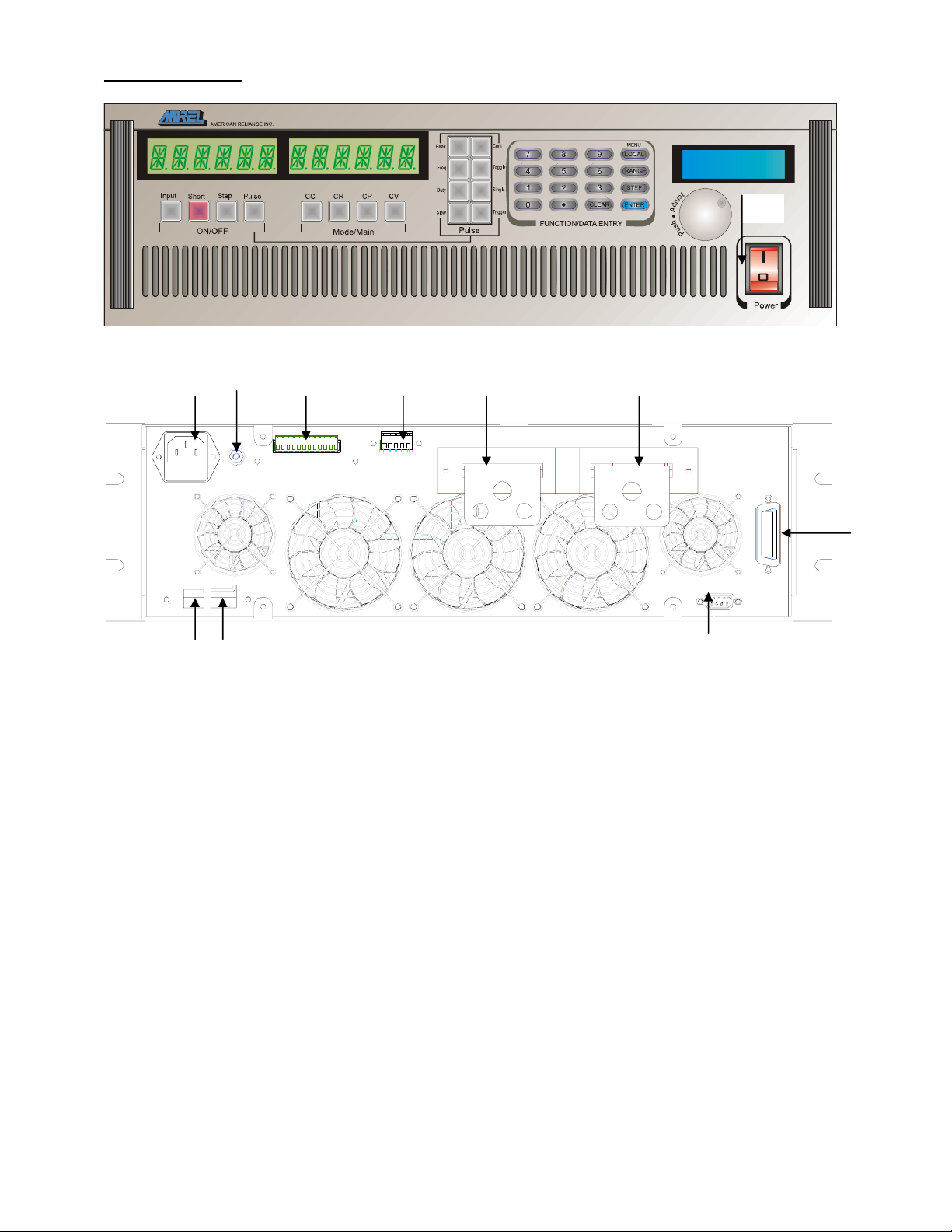

DIMENSIONAL DRAWINGS & DESCRIPTIONS

PLW 2U MODEL

Note: Please refer to the Specifications for detailed unit dimensions

Front Panel

1

22

2 3

21

20

5 6 798

19 18

16

17

12

1110

13

14

15

1.Input ON/OFF Button

2.Short ON/OFF Button

3.Step ON/OFF Button

4.Pulse (Transient) ON/OFF Button

5.Constant Current Mode Selection

6.Constant Resistance Mode Selection

7.Constant Power Mode Selection

8.Constant Voltage Mode Selection

9.Slew Rate Duty Cycle Setting

10. Slew Rate Rising/Falling Time Setting

11. Manual Trigger Button

12. Single

13. Front Panel Keypad

14. Encoder

15. Power ON/OFF Button

16. LCD Display

17. Toggle Transient Operation Selection

18. Continuous Transient Operation

Selection

19. Transient Level Setting

20. Transient Frequency Setting

21. Current & Warning Signal LED Display

22. Voltage LED Display

1-22

Page 33

32

26

25

2324

27

34

33

35 36

31

PLW 2U REAR PANEL

Rear Panel

23. ( – ) Negative input terminal.

24. ( + ) Positive input terminal.

25. Relay connector.

26. External programming port.

27. Standard GPIB interface connector.

28. Standard RS-232 interface connector.

29. Standard RJ45 for Ethernet (LAN).

30. Standard USB interface connector.

29 30

28

31. Chassis / Line ground lug screw.

32. AC power inlet with external fuse holder.

33. Water inlet

34. Water outlet

35. Water valve power connector

36. Auxiliary master/slave connector

(future option).

1-23

Page 34

PLA 2U MODEL

22 21

19 18

16

20

12

1110

1

2 3 4

9

5 6 7 8

Note: Please refer to the Specifications for detailed unit dimensions

17

13

14

15

Front Panel Descriptions

1. Input ON/OFF Button

2. Short ON/OFF Button

3. Step ON/OFF Button

4. Pulse (Transient) ON/OFF Button

5. Constant Current Mode Selection

6. Constant Resistance Mode Selection

7. Constant Power Mode Selection

8. Constant Voltage Mode Selection

9. Slew Rate Duty Cycle Setting

10. Slew Rate Rising/Falling Time Setting

11. Manual Trigger Button

12. Single

13. Front Panel Keypad

14. Encoder

15. Power ON/OFF Button

16. LCD Display

17. Toggle Transient Operation Selection

18. Continuous Transient Operation Selection

19. Transient Level Setting

20. Transient Frequency Setting

21. Current & Warning Signal LED Display

22. Voltage LED Display

1-24

Page 35

25

26

23

24

32

31

PLA 2U REAR PANEL

Rear Panel Descriptions

23. ( + ) Positive input terminal.

24. ( – ) Negative input terminal.

25. Relay connector.

26. External programming port.

27. Standard GPIB interface connector.

28

2729

30

28. Standard RS-232 interface connector.

29. Standard RJ45 for Ethernet (LAN).

30. Standard USB interface connector.

31. Chassis / Line ground lug screw.

32. AC power inlet with external fuse holder.

1-25

Page 36

PLA 3U MODEL

PLA 3U FRONT PANEL

NOTE: All front panel descriptions are the same for 2U, 3U, 4U, and 6U.

14

10

7

9

8

4

PLA3U REAR PANEL

1. ( – ) Negative input terminal.

2. ( + ) Positive input terminal.

3. Relay connector.

4. External programming port.

5. Standard GPIB interface connector.

3

12

5

6

6. Standard RS-232 interface connector.

7. Standard RJ45 for Ethernet (LAN).

8. Standard USB interface connector.

9. Chassis / Line ground lug screw.

10. AC power inlet with external fuse holder.

1-26

Page 37

PLW 4U & HIGHER MODELS

Note: Please refer to the Specifications for detailed unit dimensions

PLW 4U & HIGHER FRONT PANEL

NOTE: All front panel descriptions are the same for 2U and higher models.

10

69

5

4

3

12

GPIB

VALVE

VALVE

13 14

115/230V 50/60Hz

AC

FLUID

INLET

11

RS-232

PLW 4U & HIGHER REAR PANEL

Note: Please refer to the Specifications for detailed unit dimensions

1. ( – ) Negative input terminal.

2. ( + ) Positive input terminal.

3. Relay connector.

4. External programming port.

5. Standard GPIB interface connector.

6. Standard RS-232 interface connector.

7. Standard RJ45 for Ethernet (LAN).

9. Chassis / Line ground lug screw.

10. AC power inlet with external fuse holder.

11. Water inlet

12. Water outlet

13. Water valve power connector

14. Auxiliary master/slave connector

(future option).

8. Standard USB interface connector.

EXTERNAL PROGRAMMING

DC INPUT

AUX1

AUX2

AUX3

PORT

FLUID

OUTLET

(-)

(+)

NO

NC

CO

RY RI

ETHE RNET

12

USB

8

7

6

1-27

Page 38

PLA 4U AND HIGHER MODELS

PLA 4U & HIGHER FRONT PANEL

NOTE: All front panel descriptions are the same for 2U and higher models.

9

10

4

2

1

3

5 6

7 8

PLA 4U & HIGHER REAR PANEL

Note: Please refer to the Specifications for detailed unit dimensions

1. ( – ) Negative input terminal.

2. ( + ) Positive input terminal.

3. Relay connector.

4. External programming port.

5. Standard GPIB interface connector.

6. Standard RS-232 interface connector.

7. Standard RJ45 for Ethernet (LAN).

8. Standard USB interface connector.

9. AC power inlet with external fuse holder.

10. Interconnect AC power

11. Auxiliary master/slave connector

(future option).

11

1-28

Page 39

9

10

4

8

2

1

5

6

3

7

ALTERNATE PLA 4U & HIGHER REAR PANEL

1. ( – ) Negative input terminal.

2. ( + ) Positive input terminal.

3. Standard RJ45 for Ethernet (LAN).

4. External programming port.

5. Standard GPIB interface connector.

6. Standard RS-232 interface connector.

11

7. Standard USB interface connector.

8. Relay connector.

9. AC power inlet with external fuse holder.

10. Interconnect AC power

11. Auxiliary master/slave connector

(future option).

1-29

Page 40

12

Page 41

TWO: INSTALLATION

INTRODUCTION

This section provides recommendations and procedures for inspecting, installing, and testing the electronic load.

BASIC SETUP PROCEDURE

Use Table 2.1 to summarize the basic setup procedure and an overall view of the subsections. Use the procedure as a

quick reference if you are familiar with the installation requirements for the programming electronic load. If you want

more information, each step in the procedure refers to subsequent sections, which contain more details. Execute each step

in the sequence provided.

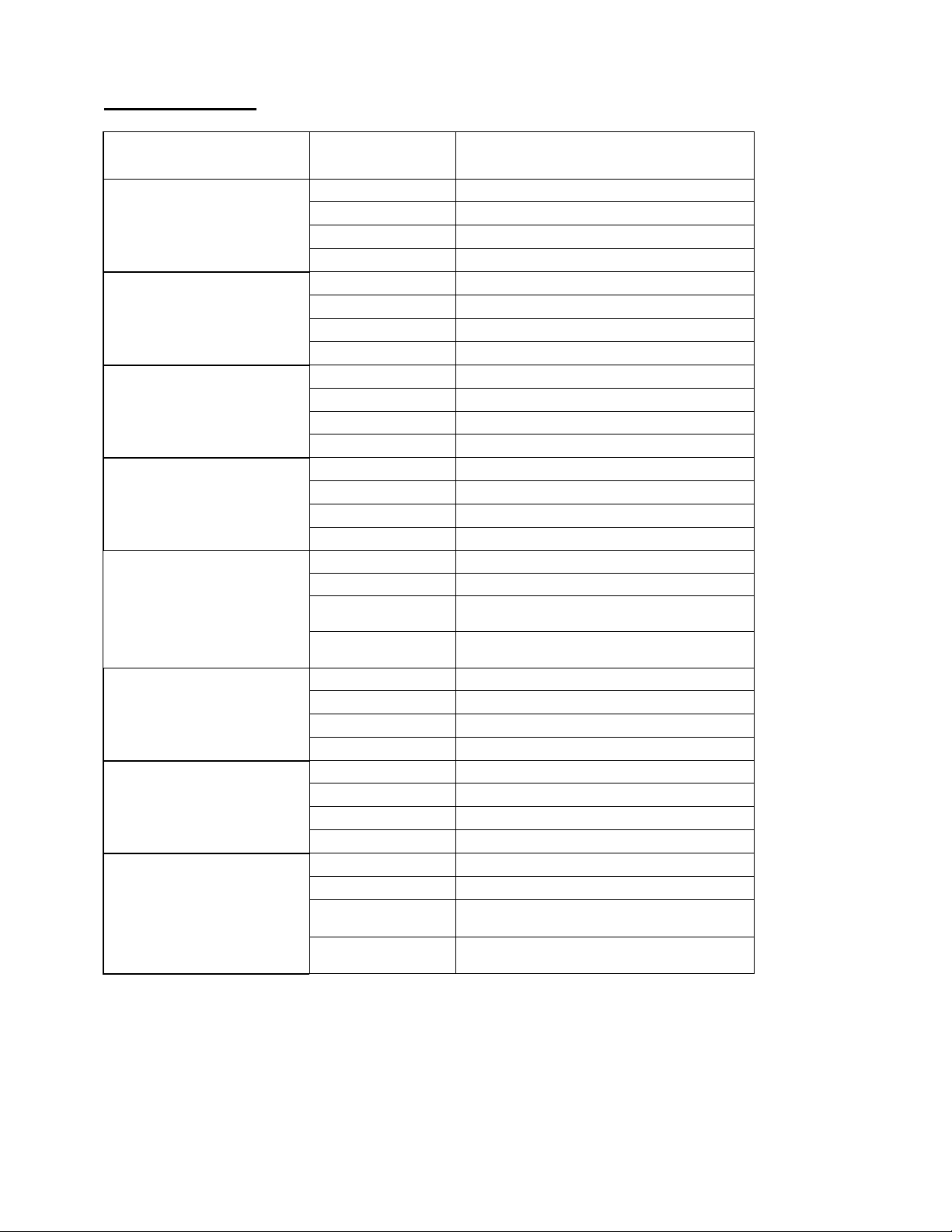

TABLE 2.1 BASIC SETUP PROCEDUE

-------------------------------------------------------------------------------------------------------------------------------------Step# Description Action Reference

------------------------------------------------------------------------------------------------------------------------------------- 1 Inspection Perform an initial physical Inspection, cleaning,

inspection of the load. and packaging.

------------------------------------------------------------------------------------------------------------------------------------- 2 Installation Install the instrument on Location, mounting,

bench or rack mount, and ventilation.

ensuring adequate ventilation.

------------------------------------------------------------------------------------------------------------------------------------- 3 Input power Connect AC input power AC input power

connection.

------------------------------------------------------------------------------------------------------------------------------------- 4 Test Perform functional tests for Functional test.

CV mode, CC mode, and

front panel controls.

------------------------------------------------------------------------------------------------------------------------------------- 5 Source Connect the source. Source connection.

------------------------------------------------------------------------------------------------------------------------------------- 6 Sense Connect sensing lines. Local and Remote sense.

--------------------------------------------------------------------------------------------------------------------------------------

INSPECTION, CLEANING, AND PACKAGING

x INITIAL INSPECTION: When you first receive your unit, perform a quick physical check.

1. Inspect the instrument for cracks, scratches, broken switches, connectors, and display.

2. Make sure there is not damage on the AC power cord; the AC input cover is installed properly and with the

strain relief.

3. Make sure there is no loose component in the unit that may cause by the long distance shipping.

If the unit is damaged, save all the packing materials and notify the carrier immediately.

x MAINTENANCE: No routine servicing of the electronic load is required except for periodic cleaning.

Whenever the instrument is removed from operation, first use a low pressure air to blow dust from in and around

components on the printed circuit board, clean the front panel with dry cloths or with a weak solution of soap

and water, clea

the low-pressure air to blow it again.

n the metal surfaces with naphtha or an equivalent solvent when used in high humility. Then use

2-1

Page 42

RETURNING ELECTRONIC LOAD TO THE MANUFACTURER

Return Material Authorization Policy for warranty and non-warranty service:

Before returning a product directly to AMETEK Programmable Power, Inc. you must obtain a Return Materia

number and the correct manufactory Ship To: address. Products must also be shipped prepaid. Product shipments will be

refused and returned at sender expense if they are unauthorized shipped without RMA # clearly marked on the outside of

the shipping box, shipped “COD”, or if they are shipped to the wrong location.