Ametek MGC-LOW, MGC-HIGH Operating Manual

User Manual

Portable Pressure Calibration Set

MGC-LOW, MGC-HIGH

Copyright 2004 AMETEK DENMARK A/S

About this manual….

• The structure of the manual

This user manual is aimed at users who are familiar with

Ametek pressure calibration systems, as well as those who are

not. The manual is divided into 9 chapters which describe how

to set up, operate, service and maintain the pressure calibration

system. The technical specifications are described and

accessories may be ordered from the list of accessories.

• Safety symbols

This manual contains a number of safety symbols designed to

draw your attention to instructions which must be followed when

using the instrument, as well as any risks involved.

Warning

Events which may compromise the safe use of

the instrument and result in considerable

personal or material damage.

Caution…

Events which may compromise the safe use of

the instrument and result in slight personal or

material damage.

Note…

Special situations which demand the user’s

attention.

2 24-08-2004 124945 00

List of contents

Introduction ..............................................................................4

1.0

2.0 Safety instructions ...................................................................6

3.0 Identifying your pressure calibration system.......................8

3.1 Model description.......................................................................... 8

3.2 Receipt of the pressure calibration system .................................. 9

4.0 Operating instructions...........................................................11

4.1 Operating the MGC-LOW ........................................................... 11

4.1.1 Media to be used............................................................ 13

4.1.2 After calibration .............................................................. 14

4.2 Operating the MGC-HIGH .......................................................... 15

4.2.1 Media to be used............................................................ 18

4.2.2 After calibration .............................................................. 18

4.3 Operating the optional Lloyds valve system with clamp............. 19

5.0 Errors.......................................................................................22

5.1 Re-calibration.............................................................................. 23

6.0 Returning the pressure calibration set for service ............24

7.0 Maintenance............................................................................26

7.1 Cleaning...................................................................................... 26

8.0 Technical specifications........................................................27

9.0 List of accessories .................................................................30

124945 00 24-08-2004 3

1.0 Introduction

Congratulations on your new Ametek Portable

Pressure Calibration Set!

With the Ametek Portable Pressure Calibration Set, you have chosen

an extremely effective pressure system which we hope will live up to

all your expectations. Over the past many years, we have acquired

extensive knowledge of industrial precision pressure calibration. This

expertise is reflected in our products which are all designed for daily

use in an industrial environment. Please note that we would be very

interested in hearing from you if you have any ideas or suggestions

for changes to our products.

This user manual applies to the following systems:

• MGC-LOW, System 1

• MGC-LOW, System 2

• MGC-LOW, System 3

• MGC-HIGH, System 1

• MGC-HIGH, System 2

• MGC-HIGH, System 3

• MGC-HIGH, System 4

ISO-9001 certified

)

4 24-08-2004 124945 00

Ametek Denmark A/S was awarded the

ISO-9001 certificate in September 1994 by

BVQI - Bureau Veritas Quality International.

) CE-label

Your new pressure calibration system bears

the CE label and conforms to the EMC

directive and the Low-voltage Directive.

) Technical assistance

Please contact the dealer from whom you acquired the pressure

calibration system if you require technical assistance.

) Guarantee

According to current terms of sale and delivery.

This guarantee only covers defects in manufacture and becomes

void if the pressure calibration system has been subject to

unauthorised intervention and/or misuse.

124945 00 24-08-2004 5

2.0 Safety instructions

Read this manual carefully before using

the pressure system!

Please follow the instructions and procedures described in

this manual. They are designed so that you get the most

out of your pressure system and avoid any personal

injuries and/or damage to the system.

Warning……

About the handling:

• Avoid knocking, bumping or dropping the pressure

system. This can cause permanent damage to the

system and loss of accuracy.

About the use:

• The pressure system must not be used for any

purposes other than those described in this manual and

for any application other than precision pressure

calibration jobs.

• The pressure system should only be used by TRAINED

PERSONNEL.

• Never subject the pressure gauges to overpressure. In

case of overpressure the gauge should not be used for

calibration purposes.

• None of our calibration systems are cleaned or

prepared for OXYGEN OBJECTS so DO NOT USE our

systems for this purpose.

• Do not disconnect any parts from the system when

pressurised.

• Do not connect any external pressure source to this

instrument. This unit is designed to test pressure

measuring devices connected to the manifold only.

Pressure from an external source can result in

explosion of the liquid reservoir and possible personal

injuries.

6 24-08-2004 124945 00

Note…

The product liability only applies if the pressure system is

subject to a manufacturing defect. This liability becomes

void if the user fails to follow the maintenance instructions

set out in this manual or uses unauthorised spare parts.

124945 00 24-08-2004 7

3.0 Identifying your pressure calibration

system

3.1 Model description

MGC-LOW

The JF Model MGC-LOW consists of 2 dual scaled precision

pressure gauges with ±1% F.S.

• System 1 : 0 – 6 BAR & Kg / cm² and 0 – 16 BAR & Kg / cm²

• System 2 : 0 – 16 BAR & Kg / cm² and 0 – 40 BAR & Kg / cm²

• System 3 : 0 – 40 BAR & Kg / cm² and 0 – 100 BAR & Kg / cm²

MGC-HIGH

The JF Model MGC-HIGH consists of 3 or 4 dual scaled precision

pressure gauges with ±0.6% F.S.

• System 1 : 0 – 6 BAR & Kg / cm², 0 – 16 BAR & Kg / cm² and

0 – 40 BAR & Kg / cm²

• System 2 : 0 – 10 BAR & Kg / cm², 0 – 40 BAR & Kg / cm²,

0 – 100 BAR & Kg / cm² and 0 – 300 BAR & Kg / cm²

• System 3 : 0 – 10 BAR & Kg / cm², 0 – 40 BAR & Kg / cm² and

0 – 100 BAR & Kg / cm²

• System 4 : 0 – 10 BAR & Kg / cm², 0 – 40 BAR & Kg / cm² and

0 – 300 BAR & Kg / cm²

Both models are supplied with a hydraulic hand pump fitted with

hose, valve and couplings all delivered in a handy carrying case.

The precision pressure gauges are all dual scaled in BAR and kg/cm²

and are designed for marine use.

The calibrator is easy to operate and the hydraulic pump very rapidly

produces the required testing pressure. The calibrator quickly shows

the user if there is an indication error on a pressure gauge or valve

and how large it is. When the size of the error is known, it is possible

to compensate for it or note it – and thereby only replace faulty

pressure indicators.

8 24-08-2004 124945 00

3.2 Receipt of the pressure calibration system

The pressure calibration system is delivered as standard in a carrying

case and should always be placed in the case after use.

When you receive the pressure calibration system…

• Carefully unpack and check the pump, the pressure gauges and

the accessories.

• Check the parts off against the list shown below.

If any of the parts are missing or damaged, please contact the

dealer who sold the pressure calibration system.

You should receive:

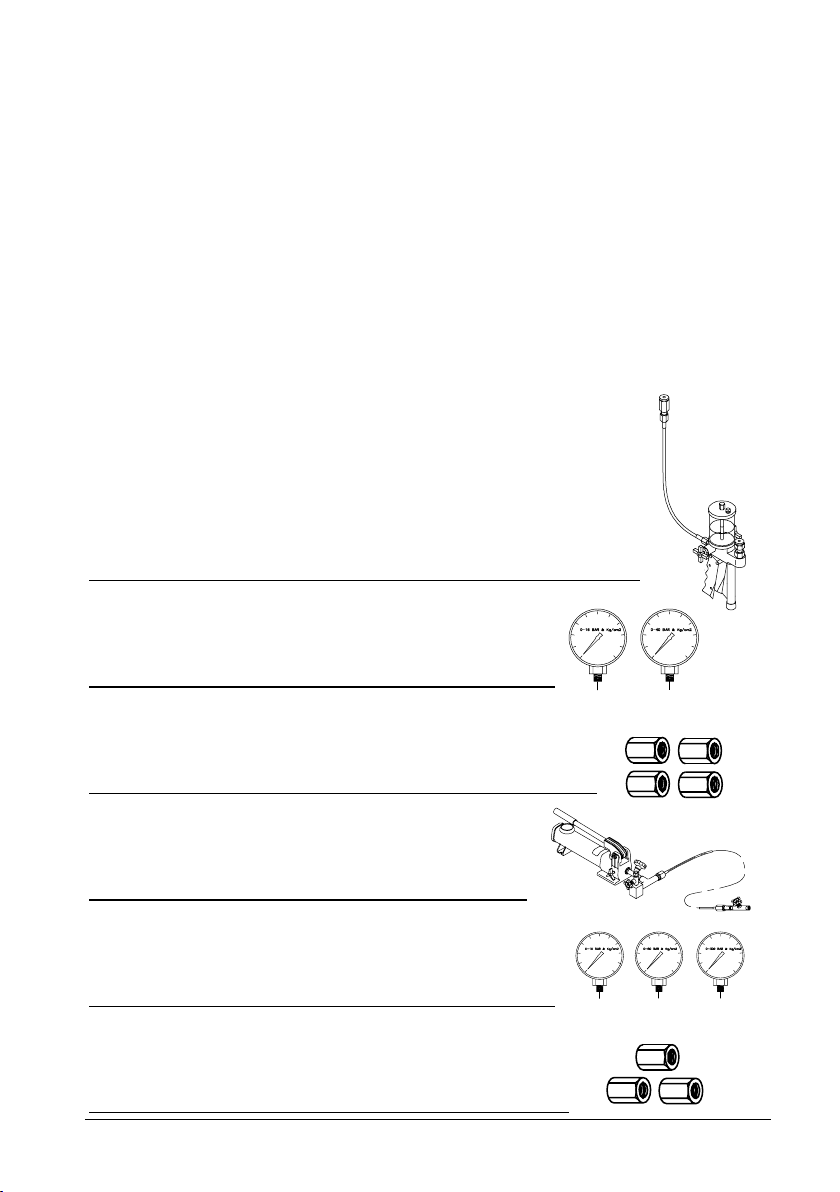

• 1 pump system T-620 incl. 0.5 m hose (MGC-LOW)

• 2 precision pressure gauges (3/8” BSP)

(MGC-LOW)

• 4 adapters (1/4” x 1/4” BSP, 1/4” x 3/8” BSP,

1/2” x 1/4” BSP, 1/4" x 3/4" BSP) (MGC-LOW)

• 1 pump system P-142 incl. 0.5 m hose

(MGC-HIGH)

• 3 precision pressure gauges (3/8” BSP)

(MGC-HIGH)

• 3 adapters (1/4” x 1/4” BSP, 1/2” x 1/4”

BSP, 1/4" x 3/4" BSP) (MGC-HIGH)

124945 00 24-08-2004 9

• 1 plug 1/4" BSP

• 2 bonded seal 1/4" BSP

• 1 traceable certificate per gauge

• 1 user manual

10 24-08-2004 124945 00

Loading...

Loading...