Page 1

P/N M330000-01

Revision G

December 2019

Copyright © 2019

AMETEK Programmable Power

All rights reserved

Asterion Series

AC/DC Power Source

1U Models

User Manual

Page 2

Page 3

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 3

About AMETEK

AMETEK Programmable Power, Inc., a business unit of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement, process

control, power bus simulation and power conditioning applications across diverse industrial segments.

From bench top supplies to rackmounted industrial power subsystems, AMETEK Programmable Power

is the proud manufacturer of Elgar, Sorensen, California Instruments and Power Ten brand power

supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical devices

with annualized sales of $5 billion. The Company has over 18,000 colleagues working at more than 180

manufacturing facilities and more than 100 sales and service centers in the United States and around

the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc. California Instruments is a trademark owned by

AMETEK, Inc. Other trademarks, registered trademarks, and product names are the property of their

respective owners and are used herein for identification purposes only.

Notice of Copyright

Asterion Series User Manual © 2019 AMETEK Programmable Power, Inc. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC. (AMETEK):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL

OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES,

WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE

OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE

ENTIRELY AT THE USER’S RISK, AND

(c) GIVES NOTIFICATION THAT, IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE

ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK CONTENT IS WITHIN THE ENGLISH

LANGUAGE VERSION, WHICH IS POSTED AT WWW.POWERANDTEST.COM.

Part Number

M330000-01

Revision and Date

Revision G, December 2019

Contact Information

Telephone:

800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax:

858 458 0267

Email:

sales.ppd@ametek.com

repair.ppd@ametek.com

Web:

www.powerandtest.com

Page 4

Asterion Series User Manual – 1U Models California Instruments

4 M330000-01, REV-G

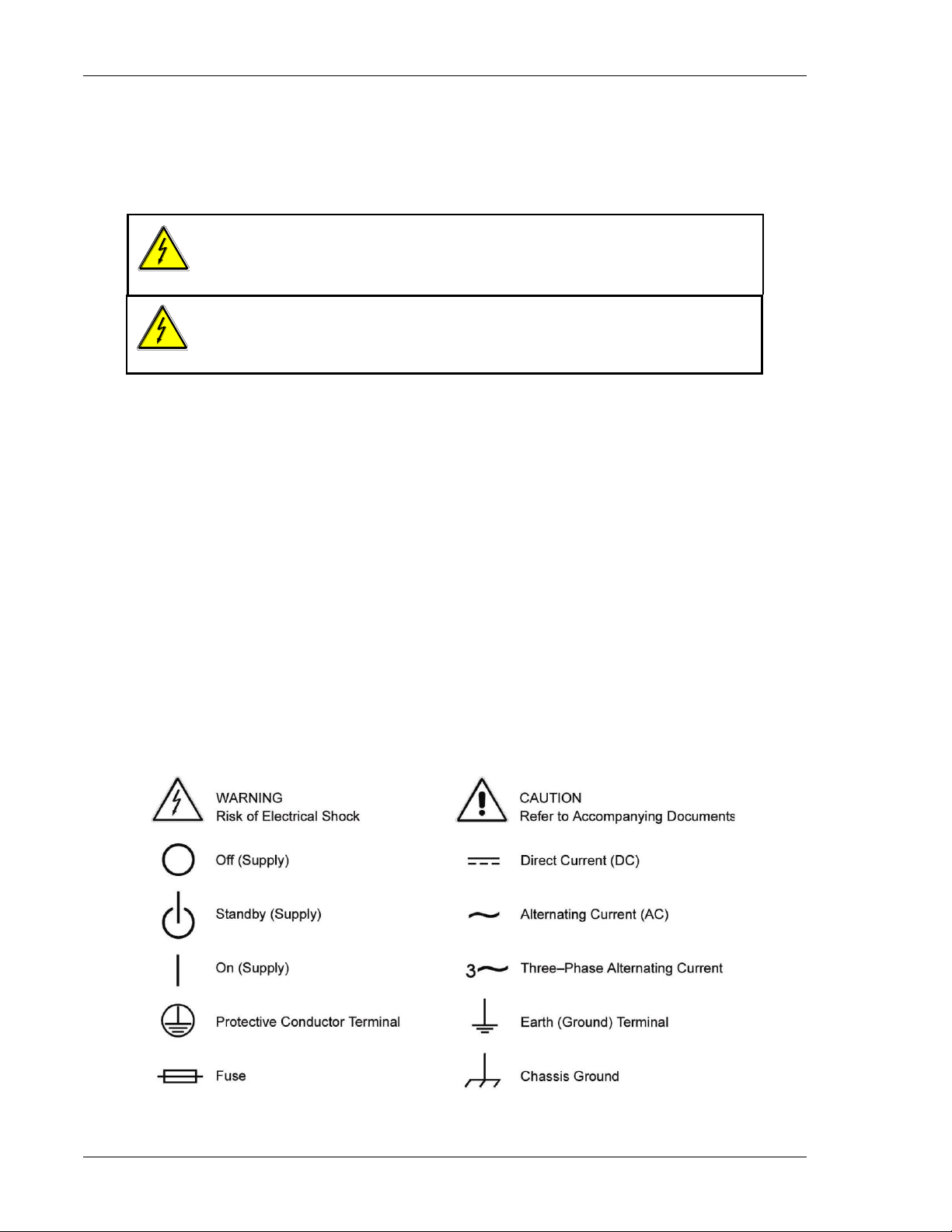

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your particular

application.

WARNING

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating at a

high voltage relative to chassis ground.

WARNING

The equipment used contains ESD sensitive parts. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

Only qualified personnel, who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC input power line ground is connected properly to the unit safety ground chassis.

Similarly, other AC power ground lines, including those to application and maintenance equipment, must

be grounded properly for both personnel safety and equipment protection.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must ensure

that the output power lines are labeled properly as to the safety hazards and that any inadvertent contact

with hazardous voltages is prevented.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety glasses

and protective clothing during open cover checks to avoid personal injury by any sudden component

failure.

AMETEK Programmable Power Inc., San Diego, California, USA, or any of the subsidiary sales

organizations, cannot accept any responsibility for personnel, material or inconsequential injury, loss or

damage that results from improper use of the equipment and accessories.

Safety Symbols

Page 5

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 5

Product: Asterion Series Power Source

Warranty Period: 1 Year

Warranty Terms

AMETEK Programmable Power, Inc. (AMETEK), provides this written warranty covering the Product

stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect in material or

workmanship within the applicable warranty period stated above, then AMETEK may, at its option: repair

or replace the Product; or issue a credit note for the defective Product; or provide the Buyer with

replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in accordance

with the return procedure specified below. AMETEK will, at its expense, deliver the repaired or replaced

Product or parts to the Buyer. Any warranty of AMETEK will not apply if the Buyer is in default under the

Purchase Order Agreement or where the Product, or any part thereof, is as follows:

• damaged by misuse, accident, negligence or failure to maintain the same as specified or

required by AMETEK;

• damaged by modifications, alterations or attachments thereto which are not authorized by

AMETEK;

• installed or operated contrary to the instructions of AMETEK;

• opened, modified, or disassembled in any way without consent from AMETEK;

• used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty until the

Buyer has made all payments to AMETEK provided for in the Purchase Order Agreement.

Product Return Procedure

Request a Return Material Authorization (RMA) number from the repair facility (must be done in the

country in which it was purchased):

• In the USA, contact the AMETEK Customer Service Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

• Outside the United States, contact the nearest Authorized Service Center (ASC). A full

listing can be found either through your local distributor, or on our website,

www.powerandtest.com, by tapping Support button or going to the Service Centers tab.

When requesting an RMA, have the following information ready:

• Model number

• Serial number

• Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK to be in specification is subject to an

evaluation fee and applicable freight charges.

Page 6

Asterion Series User Manual – 1U Models California Instruments

6 M330000-01, REV-G

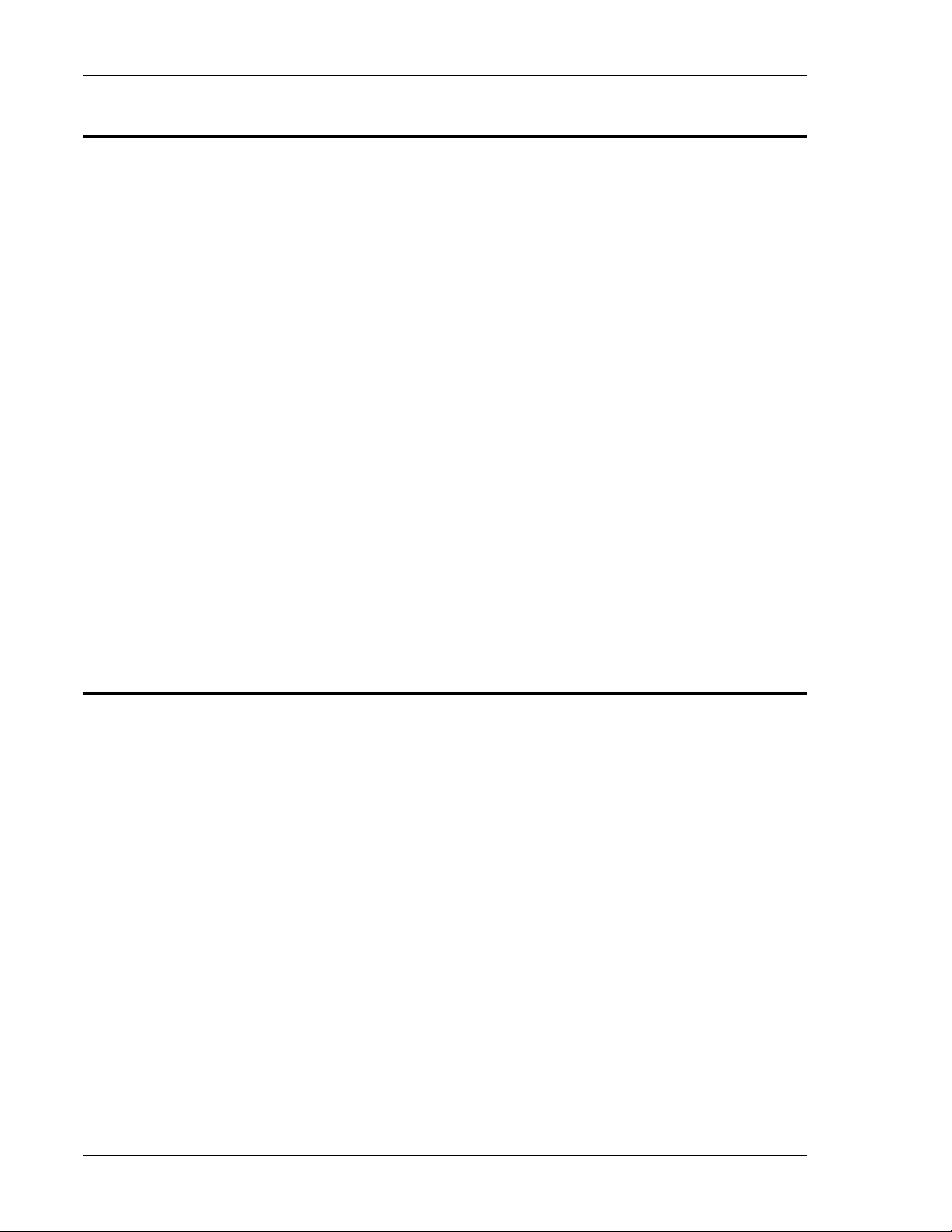

Table of Contents

1. Introduction ................................................................................................................................ 13

1.1 General Description ............................................................................................................................ 13

1.2 Asterion Series Models ....................................................................................................................... 14

2. Specifications ............................................................................................................................. 15

2.1 Electrical Characteristics ..................................................................................................................... 15

2.1.1 AC/DC Output Specifications .................................................................................................. 15

2.1.3 iX2TM Constant-Power Mode Output Characteristic ................................................................ 18

2.1.4 AC Input Specifications ........................................................................................................... 19

2.1.5 AC Output Measurements ...................................................................................................... 20

2.1.6 DC Output Measurements ...................................................................................................... 21

2.1.7 Harmonics Measurements ...................................................................................................... 21

2.1.8 Protection Function Characteristics ........................................................................................ 22

2.2 Environmental Specifications .............................................................................................................. 22

2.3 Mechanical Specifications ................................................................................................................... 23

2.4 Regulatory Agency Compliance .......................................................................................................... 23

2.5 Remote Control Analog/Digital Signal Characteristics ........................................................................ 24

2.6 Remote Control Digital Interface Characteristics................................................................................. 25

2.7 Operational Characteristics ................................................................................................................. 26

2.8 Front Panel Controls/Indicators ........................................................................................................... 27

2.9 Rear Panel Connectors ....................................................................................................................... 28

2.10 Firmware/Software Options ................................................................................................................. 29

3. Installation .................................................................................................................................. 31

3.1 Unpacking ........................................................................................................................................... 31

3.1.1 Contents of Shipment ............................................................................................................. 31

3.2 Mechanical Installation ........................................................................................................................ 32

3.2.1 Rackmounting ......................................................................................................................... 33

3.3 Outline Drawings ................................................................................................................................. 35

3.4 Rear Panel Protective Covers ............................................................................................................. 35

3.5 Input/Output Connections ................................................................................................................... 38

3.6 AC Input Connection ........................................................................................................................... 39

3.6.1 AC Input Overcurrent Protection ............................................................................................. 39

3.6.2 AC Input Safety Disconnect Device ........................................................................................ 39

3.6.3 AC Input Connector ................................................................................................................ 39

3.6.4 1-Phase AC Input Operation ................................................................................................... 40

3.6.5 3-Phase AC Input Operation ................................................................................................... 40

3.7 AC/DC Output Connection ................................................................ .................................................. 41

3.8 Remote Sense .................................................................................................................................... 42

3.9 Noise and Impedance Effects ............................................................................................................. 42

3.10 Wire Gauge Selection ......................................................................................................................... 43

3.10.1 Wire Size .............................................................................................................................. 43

3.11 Rear Panel User Interface Connectors ............................................................................................... 45

3.11.1 External Input/Output Control Signal Connector ................................................................... 45

3.11.2 Summary Fault Signal (DFI) ................................................................................................. 47

3.11.3 Remote Inhibit Signal ............................................................................................................ 48

3.11.4 External Interface Signal Connector ..................................................................................... 48

3.11.5 Command Monitor and Trigger Output Connectors .............................................................. 49

3.11.6 Clock and Lock Connectors (Option) .................................................................................... 49

3.11.7 Master/Auxiliary System Interface Connectors ..................................................................... 50

3.11.8 RS-232C Serial Interface Connector .................................................................................... 51

3.11.9 USB Interface ....................................................................................................................... 52

3.11.10 LAN Interface (Ethernet) ..................................................................................................... 53

3.12 Multiple Chassis System Configurations ............................................................................................. 54

3.12.1 Multi-Phase System .............................................................................................................. 54

3.12.2 Parallel System ..................................................................................................................... 55

Page 7

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 7

4. Operation .................................................................................................................................... 57

4.1 Front Panel Operation ......................................................................................................................... 57

4.1.1 Front Panel Controls and Indicators, Enhanced 1U Models ................................................... 58

4.1.2 Front Panel Controls and Indicators, ATE 1U Models ............................................................. 59

4.2 Basic Output Programming ................................................................................................................. 60

4.2.1 Front Panel Display Navigation ............................................................................................... 60

4.2.2 Selecting Output Characteristics and Adjusting Parameters ................................................... 60

4.3 Basic Functional Test .......................................................................................................................... 61

4.4 Output Power Characteristic ................................................................................................................ 63

4.4.1 Front Panel Touch-Screen Display ......................................................................................... 63

4.4.2 Touch-Screen Numeric Keypad .............................................................................................. 64

4.4.3 Rotary Encoder ....................................................................................................................... 64

4.5 Menu Structure .................................................................................................................................... 67

4.6 Front Panel Display Menus ................................................................................................................. 70

4.6.1 DASHBOARD Screen Top-Level Menu .................................................................................. 73

4.6.2 OUTPUT PROGRAM Screen Top Level Menus ..................................................................... 75

4.6.3 MEASUREMENTS Screen Top-Level Menus ......................................................................... 80

4.6.4 TRANSIENTS Screen Top-Level Menu .................................................................................. 87

4.6.5 CONFIGURATION Screen.................................................................................................... 102

4.6.6 CONTROL INTERFACE Screen ........................................................................................... 109

4.6.7 APPLICATIONS Screen ....................................................................................................... 115

4.6.8 SYSTEM SETTINGS Screen ................................................................................................ 115

5. Waveform Management .......................................................................................................... 119

5.1 Standard Waveforms ......................................................................................................................... 119

5.2 Creating Custom Waveforms ............................................................................................................ 119

5.2.1 Viewing Custom Waveforms on the Display ......................................................................... 120

5.3 RMS Amplitude Restrictions .............................................................................................................. 120

5.4 Frequency Response Restrictions ..................................................................................................... 121

5.5 Transient List Waveforms .................................................................................................................. 121

6. Standard Measurements ......................................................................................................... 123

6.1 Parameter Measurements ................................................................................................................. 123

6.1.1 Accuracy Considerations ...................................................................................................... 124

6.2 Advanced Measurements .................................................................................................................. 124

6.2.1 Harmonic Analysis ................................................................................................................ 124

6.2.2 Acquiring FFT data ............................................................................................................... 124

6.2.3 Analyzing FFT Data .............................................................................................................. 125

6.3 Output Voltage Waveform Acquisition ............................................................................................... 126

6.3.1 Acquiring Output Voltage Waveform ..................................................................................... 126

6.3.2 Analyzing Acquired Waveforms ............................................................................................ 127

6.4 Triggering Measurements.................................................................................................................. 127

6.4.1 Trigger Mode ......................................................................................................................... 127

6.4.2 Trigger source ....................................................................................................................... 128

6.4.3 Trigger delay ......................................................................................................................... 128

7. Transient Programming .......................................................................................................... 131

7.1 Using Transient Modes...................................................................................................................... 131

7.1.1 Step Transients ..................................................................................................................... 132

7.1.2 Pulse Transients ................................................................................................................... 132

7.1.3 List Transients ....................................................................................................................... 133

7.2 Programming Slew Rates .................................................................................................................. 134

7.3 Switching Waveforms in Transient Lists ............................................................................................ 135

7.4 Saving Transient List Programs ........................................................................................................ 136

8. Calibration ................................................................................................................................ 137

8.1 Calibration Equipment ....................................................................................................................... 137

8.2 Calibration Procedures ...................................................................................................................... 137

8.2.1 Preparation for Calibration .................................................................................................... 137

8.2.2 Output Voltage AC Zero Alignment, AC-Mode ................................ ...................................... 138

Page 8

Asterion Series User Manual – 1U Models California Instruments

8 M330000-01, REV-G

8.2.3 Output Voltage DC Zero Alignment, DC-Mode ..................................................................... 138

8.2.4 Output Voltage Gain Initial Alignment, AC-Mode and DC-Mode ........................................... 138

8.2.5 Output Voltage Measurement AC Gain Alignment, AC-Mode .............................................. 139

8.2.6 Output Voltage Measurement DC-Positive Gain Alignment, DC-Mode ................................ 139

8.2.7 Output Voltage Measurement DC-Negative Gain Alignment, DC-Mode ............................... 140

8.2.8 Output Current Measurement AC Low-Range Gain Alignment, AC-Mode ........................... 140

8.2.9 Output Current Measurement AC High-Range Gain Alignment, AC-Mode ........................... 141

8.2.10 Output Current Measurement AC Low-Range Offset Alignment, AC-Mode ....................... 141

8.2.11 Output Current Measurement AC High-Range Offset Alignment, AC-Mode ....................... 142

8.2.12 Output Current Measurement DC-Positive Low-Range Gain Alignment, DC-Mode ........... 142

8.2.13 Output Current Measurement DC-Positive High-Range Gain Alignment, DC-Mode........... 142

8.2.14 Output Current Measurement DC-Negative Low-Range Gain Alignment, DC-Mode .......... 143

8.2.15 Output Current Measurement DC-Negative High-Range Gain Alignment, DC-Mode ......... 143

8.2.16 Output Current Measurement Low-Range Offset Alignment, DC-Mode ............................. 144

8.2.17 Output Current Measurement High-Range Offset Alignment, DC-Mode ............................ 144

8.2.18 Output Phase Alignment, Output Relative to External SYNC ............................................. 145

8.2.19 Output Phase Alignment, Auxiliary Unit Relative to Master Unit (LKS Option Only) ........... 146

8.2.20 Alignment of External Programming Signal for Output Voltage Waveform/Amplitude ........ 146

8.2.21 Alignment of External Programming Signal for Output Voltage Amplitude, DC Output....... 147

8.2.22 Alignment of External Programming Signal for Output Voltage Amplitude, AC output ....... 148

8.2.23 Alignment of Interharmonics Output (413 Option Only) ...................................................... 149

9. Service ...................................................................................................................................... 151

9.1 Cleaning ............................................................................................................................................ 151

9.2 Basic Troubleshooting ....................................................................................................................... 151

9.2.1 Excessive Output Voltage ..................................................................................................... 151

9.2.2 Poor Output Voltage Regulation ........................................................................................... 151

9.2.3 FAULT LED is On ................................................................................................................. 151

9.2.4 Distorted Output.................................................................................................................... 152

9.2.5 Unit Shuts Down after Short Interval ..................................................................................... 152

9.2.6 No Output and Front Panel Display/LEDs are Off................................................................. 152

9.2.7 No Output and Front Panel Display/LEDs are On................................................................. 152

9.2.8 Setting of AC/DC Mode or Voltage Range is Not Accepted .................................................. 152

9.2.9 Parallel Group Faults When Master Output Switch is Turned On ......................................... 152

10. Error and Status Messages ..................................................................................................... 153

Index ................................................................................................................................................. 159

Page 9

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 9

List of Figures

Figure 1-1. Asterion Series Front View, 1U Models (With Rackmount Brackets) ................................................ 13

Figure 2-1. iX2TM Constant-Power: Output Current Versus Voltage, AST 751/AST 1501 ................................... 18

Figure 2-2. iX2TM Constant-Power: Output Current Versus Voltage, AST 501 .................................................... 18

Figure 3-1. Rackmounting, 1U Models ................................................................................................................ 34

Figure 3-2. Rear Panel Protective Cover Installation........................................................................................... 35

Figure 3-3. Installation Drawing, Enhanced 1U Models....................................................................................... 36

Figure 3-4. Installation Drawing, ATE 1U Models ................................................................................................ 37

Figure 3-5. Rear Panel View, 1U Models, (with GPIB and LKM/LKS options) .................................................... 38

Figure 3-6. AC Input Connector and Safety-Ground ........................................................................................... 39

Figure 3-7. AC/DC Output Connector and Functional-Ground ............................................................................ 41

Figure 3-8. External Input/Output Control Connector .......................................................................................... 45

Figure 3-9. External Interface Signal Connector ................................................................................................. 48

Figure 3-10. External Command Monitor and Trigger Output Connectors .......................................................... 49

Figure 3-11. External Clock/Lock Interface Connectors (Option) ........................................................................ 49

Figure 3-12. External Master/Auxiliary System Interface Connectors ................................................................. 50

Figure 3-13. RS-232C Interface Connector ......................................................................................................... 51

Figure 3-14. USB Interface Connector ................................................................................................................ 52

Figure 3-15. LAN Interface 8P8C Modular Connector ......................................................................................... 53

Figure 3-16. Connections for 3-Phase Master/Auxiliary Group, 1U Models ........................................................ 55

Figure 3-17. Connections for 1-Phase Parallel Group, 1U Models ...................................................................... 56

Figure 4-1. Front Panel, Enhanced 1U Models ................................................................................................... 57

Figure 4-2. Front Panel, ATE 1U Models ............................................................................................................ 57

Figure 4-3. Functional Test Setup ....................................................................................................................... 62

Figure 4-4. iX2TM Constant-Power Output Characteristic ................................................................ .................... 63

Figure 4-5. HOME Screen ................................................................................................................................... 64

Figure 4-6. DASHBOARD Screen Menu with Voltage Selection-Field Active ..................................................... 64

Figure 4-7. Touch-Screen Numeric Keypad ........................................................................................................ 64

Figure 4-8. Rotary Encoder ................................................................................................................................. 65

Figure 4-9. Output Program Menu Selection-Fields with Voltage Highlighted ..................................................... 66

Figure 4-10. Highlighted Voltage Selection-Field with Value Window ................................................................. 66

Figure 4-11. Power-On Screens .......................................................................................................................... 70

Figure 4-12. HOME Screen Pages ...................................................................................................................... 71

Figure 4-13. DASHBORD Screen Top-Level Menu ............................................................................................ 73

Figure 4-14. Real-Time, Immediate Output Parameter Adjustment .................................................................... 74

Figure 4-15. Default Screen ................................................................................................................................ 74

Figure 4-16. OUTPUT PROGRAM Screen Top-Level Menu-1/2 ........................................................................ 75

Figure 4-17. MEASUREMENTS Screen Top-Level Menu-1/2/3 ......................................................................... 80

Figure 4-18. HARMONICS Menu ........................................................................................................................ 83

Figure 4-19. HARMONICS Menu, Table View .................................................................................................... 85

Figure 4-20. HARMONICS Menu, Bar Graph View ............................................................................................. 85

Figure 4-21. TRACE CAPTURE Screen ............................................................................................................. 86

Figure 4-22. TRACE Screen, Plus-Magnifier and Zoom Cursors ........................................................................ 86

Figure 4-23. TRACE Screen, Zoom View ............................................................................................................ 87

Figure 4-24. TRANSIENTS Screen Top-Level Menu .......................................................................................... 87

Figure 4-25. SETTINGS Menu ............................................................................................................................ 88

Figure 4-26. SETTINGS Screen, TRIGGER Sub-Menu ...................................................................................... 89

Figure 4-27. VIEW Menu, With Empty Buffer ...................................................................................................... 90

Figure 4-28. VIEW Menu, With Transient List Entry ............................................................................................ 90

Figure 4-29. VIEW Menu, ADD Sub-Menu .......................................................................................................... 90

Figure 4-30. VIEW Menu, VOLTAGE DROP Sub-Menu ..................................................................................... 93

Figure 4-31. VIEW Menu, VOLTAGE SWEEP/STEP Sub-Menu ........................................................................ 94

Figure 4-32. VIEW Menu, VOLTAGE SURGE/SAG Sub-Menu .......................................................................... 95

Figure 4-33. VIEW Menu, FREQUENCY SWEEP/STEP Sub-Menu ................................................................... 96

Figure 4-34. VIEW Menu, FREQUENCY SURGE/SAG Sub-Menu ..................................................................... 97

Figure 4-35. VIEW Menu, VOLT/FREQ SWEEP/STEP Sub-Menu ..................................................................... 98

Figure 4-36. VIEW Menu, VOLT/FREQ SURGE/SAG Sub-Menu ....................................................................... 99

Figure 4-37. VIEW Menu, DELAY Sub-Menu .................................................................................................... 100

Figure 4-38. RUN Menu .................................................................................................................................... 101

Figure 4-39. CONFIGURATION Screen Top-Level Menu ................................................................................. 102

Figure 4-40. CONFIGURATION Menu, PROFILES Sub-Menu ......................................................................... 103

Page 10

Asterion Series User Manual – 1U Models California Instruments

10 M330000-01, REV-G

Figure 4-41. PROFILES Menu, NAME Sub-Menu ............................................................................................ 103

Figure 4-42. CONFIGURATION Menu, PONS Menu-1/2 ................................................................................. 104

Figure 4-43. CONTROL INTERFACE Screen................................................................................................... 109

Figure 4-44. CONTROL INTERFACE Menu, ANALOG Sub-Menu ................................................................... 110

Figure 4-45. CONTROL INTERFACE Menu, GPIB Sub-Menu ......................................................................... 110

Figure 4-46. CONTROL INTERFACE Menu, RS232 Sub-Menu ....................................................................... 110

Figure 4-47. CONTROL INTERFACE, LAN Menu ............................................................................................ 112

Figure 4-48. CONTROL INTERFACE, LAN CONFIGURE Sub-Menu .............................................................. 112

Figure 4-49. CONTROL INTERFACE REMOTE INHIBIT Menu ....................................................................... 114

Figure 4-50. APPLICATIONS Screen, Output Impedance Example ................................................................. 115

Figure 4-51. SYSTEM SETTINGS Screen ........................................................................................................ 115

Figure 4-52. SYSTEM SETTINGS Menu, LCD Menu ....................................................................................... 116

Figure 5-1. HARMONICS Screen, Waveform Information ................................................................................ 120

Figure 6-1. HARMONICS Menu ........................................................................................................................ 124

Figure 6-2. FFT data in Tabular Format ............................................................................................................ 125

Figure 6-3. FFT data in Bar Graph Format ....................................................................................................... 125

Figure 6-4. Waveform Display on TRACE Screen ............................................................................................ 126

Figure 6-5. TRACE Screen, Zoom View Cursors .............................................................................................. 126

Figure 6-6. TRACE Screen, Expanded Zoom View .......................................................................................... 127

Figure 6-7. HARMONICS Menu, Triggering ...................................................................................................... 128

Figure 6-8. Post-Trigger (Positive Delay) .......................................................................................................... 129

Figure 6-9. Pre-Trigger (Negative Delay ........................................................................................................... 129

Figure 7-1. Output Transient Modes ................................................................................................................. 132

Figure 7-2. Pulse Transients ............................................................................................................................. 133

Figure 7-3. List Transients ................................................................................................................................ 133

Figure 7-4. Switching Waveforms in a Transient List Transient Execution ....................................................... 135

Figure 7-5. RUN Menu: Start and Abort Fields ................................................................................................. 135

Figure 7-6. CONFIGURATION Menu, PROFILES Selection ............................................................................ 136

Figure 8-1. AUX Generator PWA Potentiometer, R9 ........................................................................................ 149

Page 11

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 11

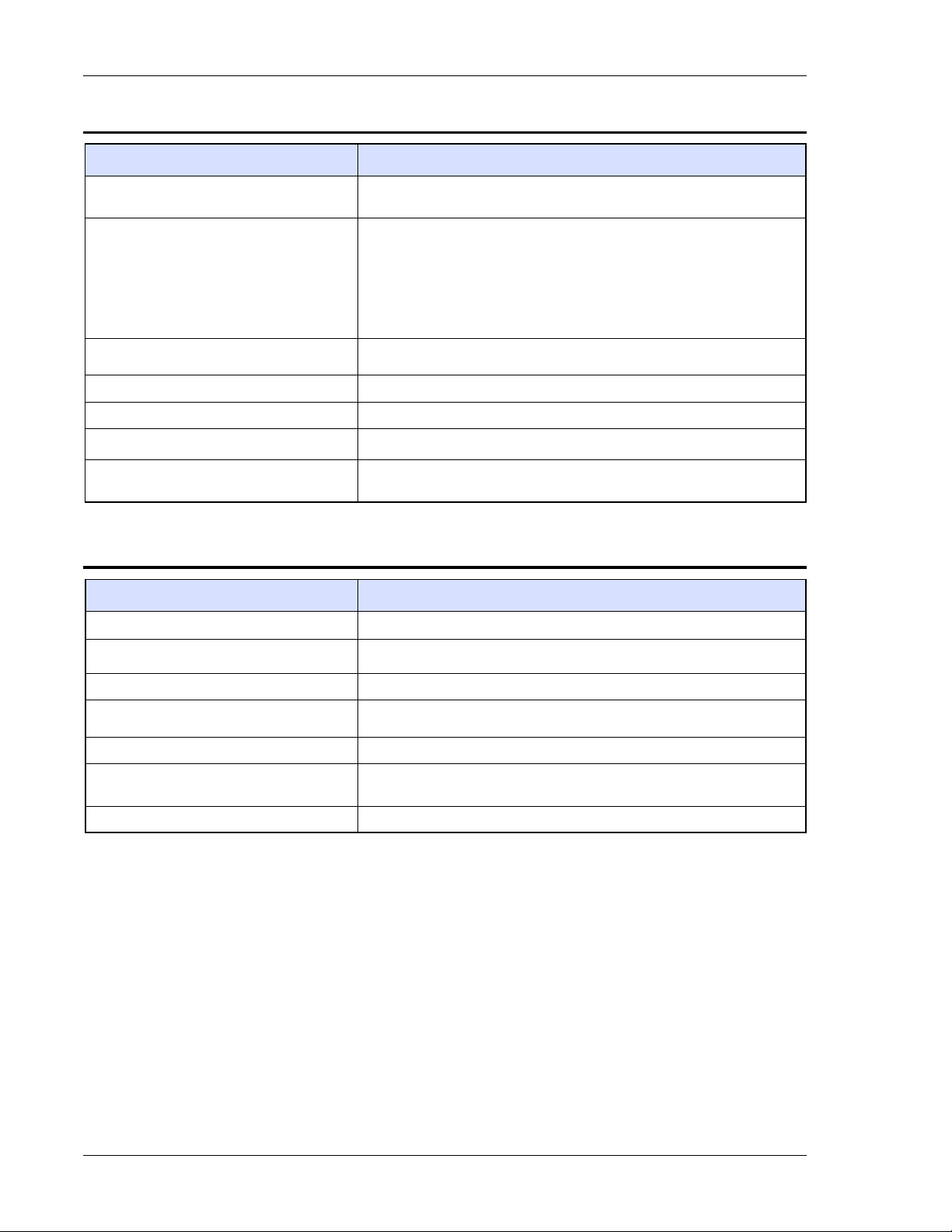

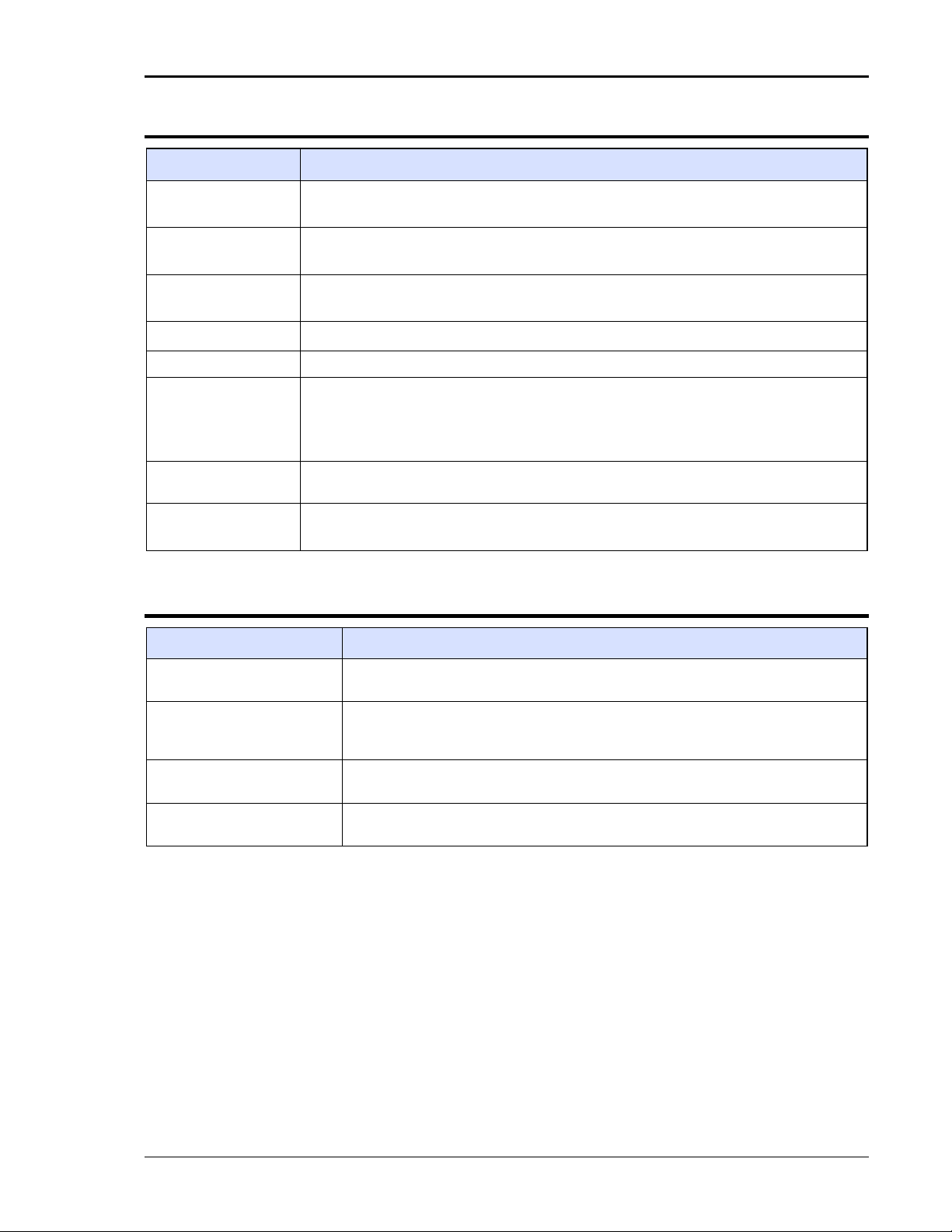

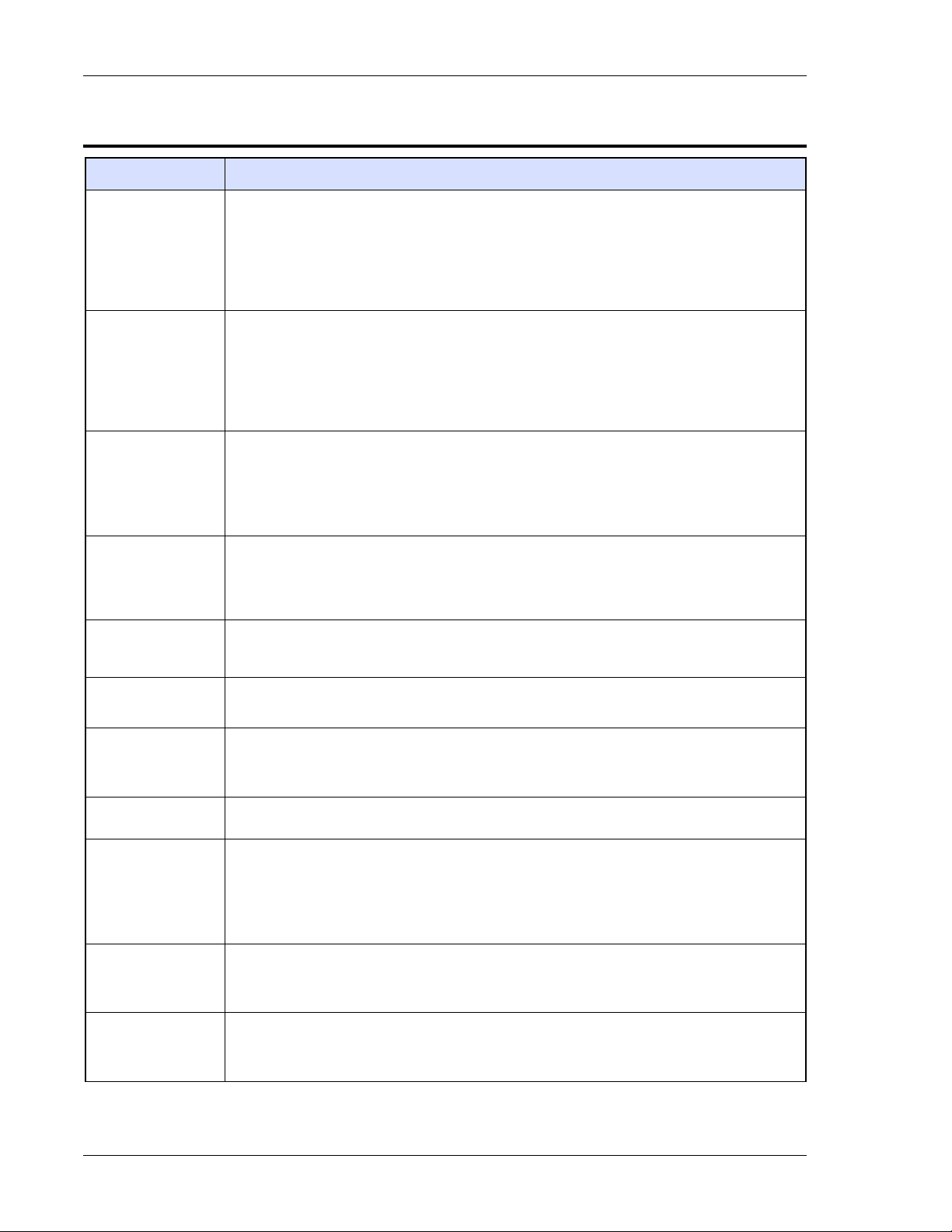

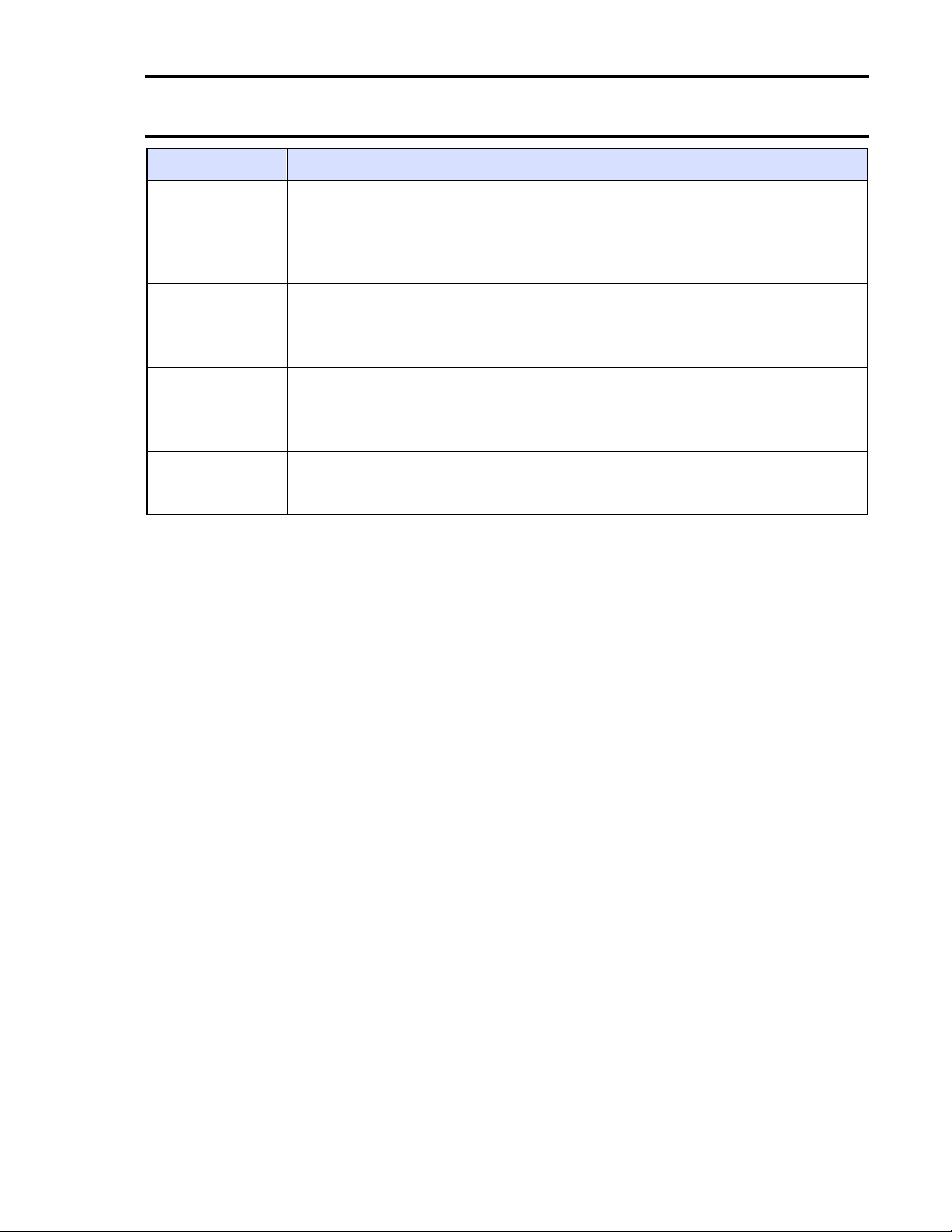

List of Tables

Table 3-1. AC Input Connector Pinout and Safety-Ground ................................................................................. 40

Table 3-2. AC Input Connector Type ................................................................................................................... 40

Table 3-3. AC/DC Output Connector Pinout and Functional-Ground .................................................................. 41

Table 3-4. AC/DC Output Connector Type and Functional-Ground .................................................................... 41

Table 3-5. Minimum Wire Size ............................................................................................................................ 43

Table 3-6. Wire Resistance and Voltage Drop, 20°C .......................................................................................... 44

Table 3-7. External Input/Output Control Connector Type .................................................................................. 45

Table 3-8. External Input/Output Control Functions ............................................................................................ 46

Table 3-9. External Input/Output Control Connector Pinout ................................................................................ 47

Table 3-10. External Interface Signal Connector Type ........................................................................................ 48

Table 3-11. External Command Monitor and Trigger Output Characteristics ...................................................... 49

Table 3-12. External Clock/Lock Interface Characteristics (Option) .................................................................... 50

Table 3-13. External Master/Auxiliary System Interface Connector Type ........................................................... 50

Table 3-14. External Master/Auxiliary System Interface Characteristics ............................................................. 51

Table 3-15. RS-232C Interface Connector Type ................................................................................................. 51

Table 3-16. RS-232C Interface Connector Pinout ............................................................................................... 51

Table 3-17. USB Interface Connector Pinout ...................................................................................................... 52

Table 3-18. LAN Interface 8P8C Modular Connector Pinout ............................................................................... 53

Table 4-1. Front Panel Controls and Indicators, Enhanced 1U Models ............................................................... 58

Table 4-2. Front Panel Controls and Indicators, ATE 1U Models ........................................................................ 59

Table 4-3. HOME Screen-1 Menu Structure ....................................................................................................... 67

Table 4-4. Home Screen-2 Menu Structure ......................................................................................................... 68

Table 4-5. HOME Screen-2 Menu Structure (continued) ..................................................................................... 69

Table 4-6. HOME Screen-3 Menu Structure ....................................................................................................... 70

Table 4-7. HOME Screen-1, Screen-2, Screen-3 Menu Content ........................................................................ 72

Table 6-1. MEASUREMENTS Screen Parameters ........................................................................................... 123

Table 6-2. MEASUREMENTS Parameter Value Derivation .............................................................................. 124

Table 8-1. Calibration Equipment ...................................................................................................................... 137

Table 8-2. Load Values for Output AC Current Alignment ................................................................................. 145

Table 8-3. Load Values for Output DC Current Alignment ................................................................................ 145

Table 10-1. Error and Status Messages ................................ ................................ ............................................ 157

Page 12

Asterion Series User Manual – 1U Models California Instruments

Page 13

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 13

1. Introduction

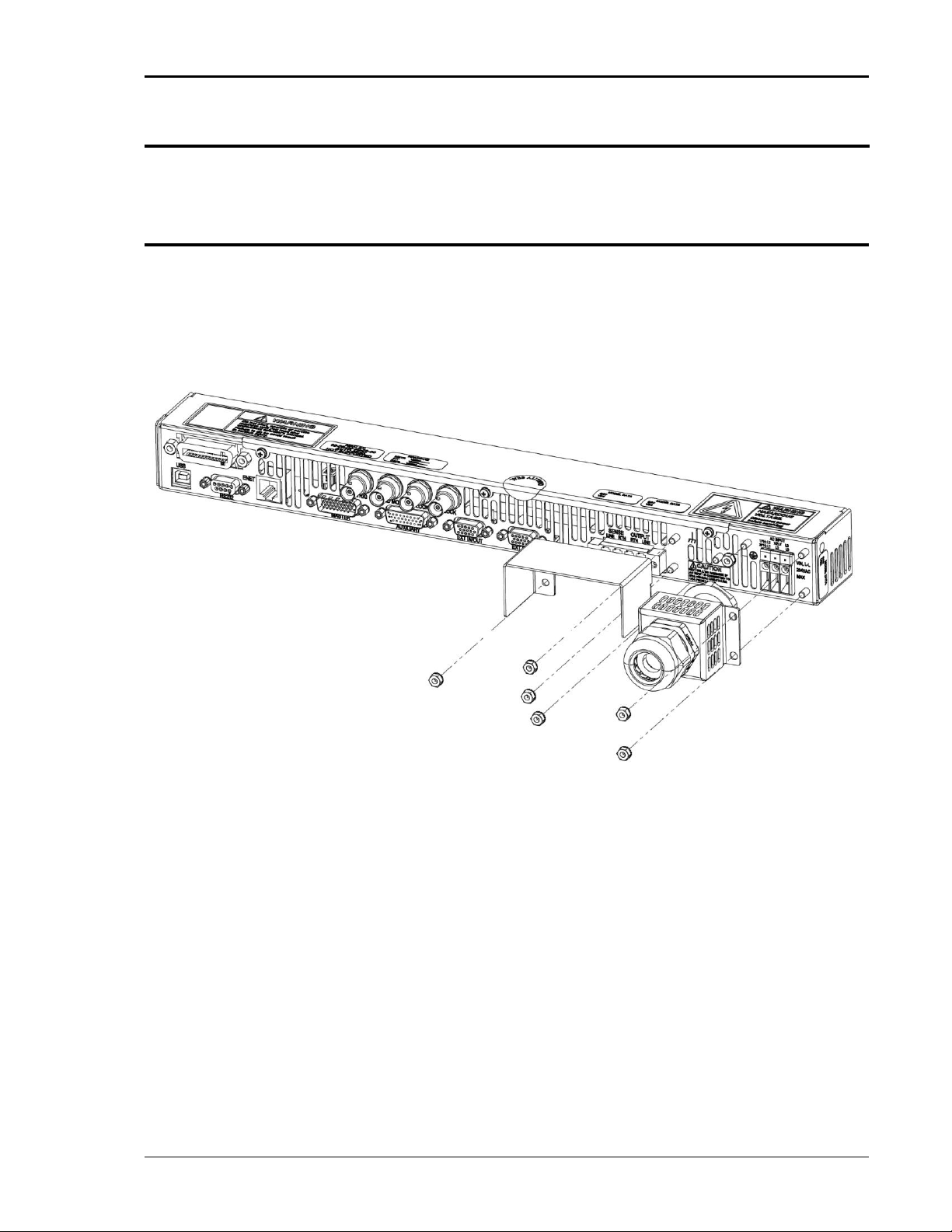

This instruction manual contains information on the installation, operation, and calibration of the

Asterion Series power source models with 1-phase output in 1U chassis. The Asterion Series is the

latest generation of switched-mode power sources that provide precise output having high accuracy, low

distortion, and fast dynamic response. With extensive programmability and user interface, it offers a rich

feature set and functionality: AC and DC output capability, wide output frequency range, arbitrary and

harmonic waveform generation, sequencing of transient lists, digital power analyzer measurements,

real-time waveform display, and the capability to be configured in systems comprised of multi-phase and

parallel groups.

Figure 1-1. Asterion Series Front View, 1U Models (With Rackmount Brackets)

1.1 General Description

The Asterion Series power sources are available in 1U chassis at power levels of 500 VA, 750 VA, and

1500 VA. Two AC output voltage ranges are provided, 0-200 VAC/0-400 VAC, with a frequency range of

16 Hz-1200 Hz (with up to 5000 Hz as an option), two DC output ranges, 0-250 VDC/0-500 VDC, and a

combined AC+DC mode. A wide range of AC and DC loads could be powered, including reactive loads

(inductive and capacitive) running at full rated apparent power, and non-linear loads drawing current with

high crest factor, up to 7:1.

The output has an iX2TM constant-power characteristic that provides greater output current at reduced

output voltage: up to 2X at 50% of full-scale voltage. Wide-range AC input is accepted, including

100/115/230/240 VAC, 1-phase/3-phase, and 50/60/400 Hz input frequency. Power factor correction of

the AC input exhibits a sinusoidal current waveform with low input current harmonics. Up to six 1U units

could be connected in parallel or in multi-phase groups, with outputs of up to 9 kVA.

Multiple remote digital communications interfaces are available: standard LAN (Ethernet), USB, and

RS-232C, or the optional IEEE-488 (GPIB) interface. The Asterion Virtual Panels program provides a

convenient graphical user interface, and the SCPI command set allows access to the full

programmability and functionality. Extensive remote analog and discrete digital control interfaces are

also provided for specialized control applications. The front panel display has capability for control,

programming, and measurements of the power source, and features a menu-based interface with

touch-screen data/command entry.

Waveform generation includes standard sine wave and square wave, and extensive programmability to

produce complex waveforms based on harmonics or arbitrary parameter value/time relations. A transient

generator could combine sequences of voltage, frequency, and wave shape to simulate real-world AC or

DC disturbances, and automate a complex profile of power stimulus to the unit under test.

The power analyzer utilizes DSP-based digitization of output parameters to implement measurement

functions spanning single parameter values (voltage/current/frequency), power characteristics

(true/apparent power, crest factor, power factor), and advanced computation using fast Fourier transform

(FFT) derivation of the harmonics and distortion contained in the voltage and current waveforms.

Real-time display of output waveforms is possible through the front panel display or the

Asterion Virtual Panels.

Page 14

Asterion Series User Manual – 1U Models California Instruments

14 M330000-01, REV-G

1.2 Asterion Series Models

AST 150 1 A 1 B – E 0 0 0A 00

Series

Asterion

Output Power

050 = 500 W 225 = 2250 W

075 = 750 W 300 = 3000 W

150 = 1500 W 450 = 4500 W

Output Phases

1 = 1-phase; 2 = 2-phase; 3 = 3-phase

Product Family

A = AC, Standard

B = AC, Low Aubile Noise

Number of Chassis

Number of chassis = 1, 2, 3, etc.

Input Voltage

B = universal, 100-240 VAC

Front Panel

E = Enhanced; A = ATE

Interface Options

0 = none

1 = GPIB

2 = GPIB - MC

Avionics Test Options

0 = none 6 = B787 - MC

1 = B787 7 = AMD - MC

2 = AMD 8 = B787 & AMD - MC

3 = B787 & AMD 9 = AVSTD - MC

4 = AVSTD A = AVALL - MC

5 = AVALL

Frequency and Clock/Lock Options

0A = None 2C = HF & LKS

1A = HF 2D = LF & LKM

1B = LF 2E = LF & LKS

1C = FC 2F = FC & LKM

1D = LKM 2G = FC & LKS

1E = LKS 3A = HF & FC & LKM

2A = HF & FC 3B = HF & FC & LKS

2B = HF & LKM

Other Options

0A = None 1G = 1399 - MC 2G = 411 - 1399 3B = MB - 411 - 413 - MC

1A = 411 2A = 411 - 413 2H = 413 - 1399 3C = MB - 411 - 1399

1B = 413 2B = MB - 411 2I = MB - 1399 3D = MB - 41 - 1399 - MC

1C = MB 2C = MB - 413 2J = 411 - 1399 - MC 3E = MB - 413 - 1399

1D = 411 - MC 2D = 411 - 413 - MC 2K = 413 - 1399 - MC 3F = MB - 413 - 1399 - MC

1E = 413 - MC 2E = MB - 411 - MC 2L = MB - 1399 - MC 4A = MB - 411 - 413 - 1399

1F = 1399 2F = MB - 413 – MC 3A = MB - 411 - 413 4B = MB - 411 - 413 - 1399 - MC

Page 15

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 15

2. Specifications

Unless otherwise noted, the specifications are valid under the following conditions:

1. Ambient temperature of 25 5C, after a 30-minute warm-up, and at fixed AC input line and load;

2. Individual unit and individual output phase, with sine wave output, and into a resistive load;

3. For system configurations, specifications are for phase output, line-to-neutral; phase angle

specifications are valid under balanced resistive load conditions.

2.1 Electrical Characteristics

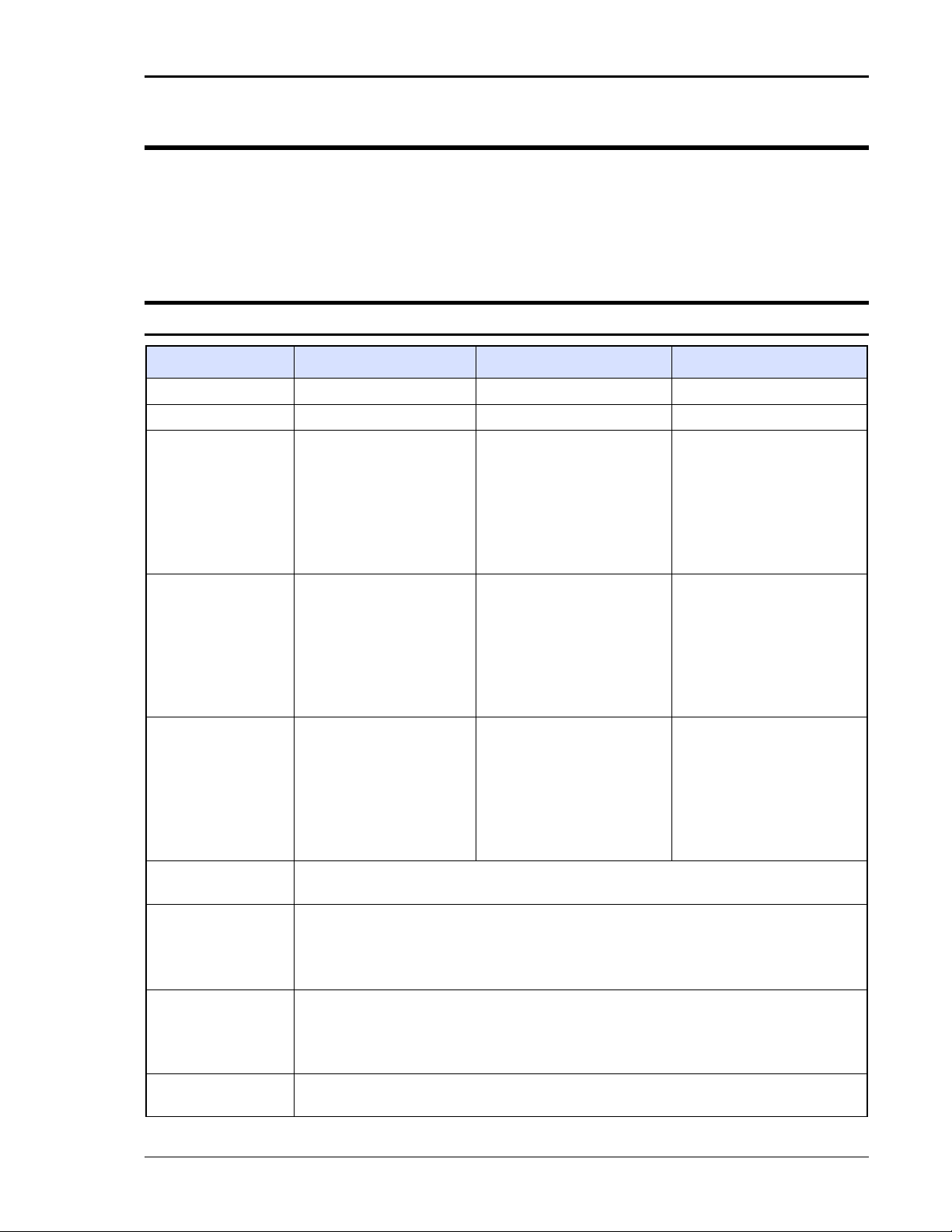

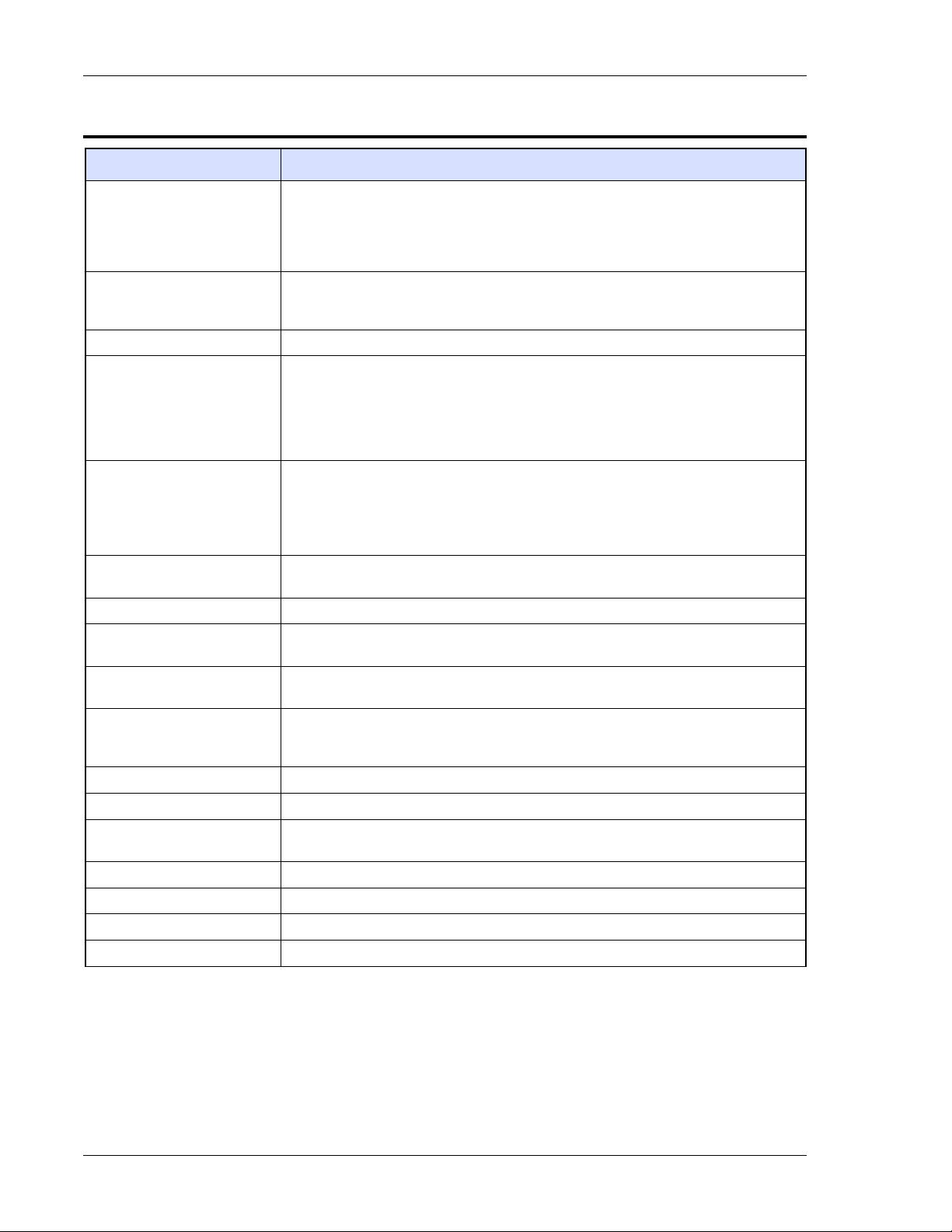

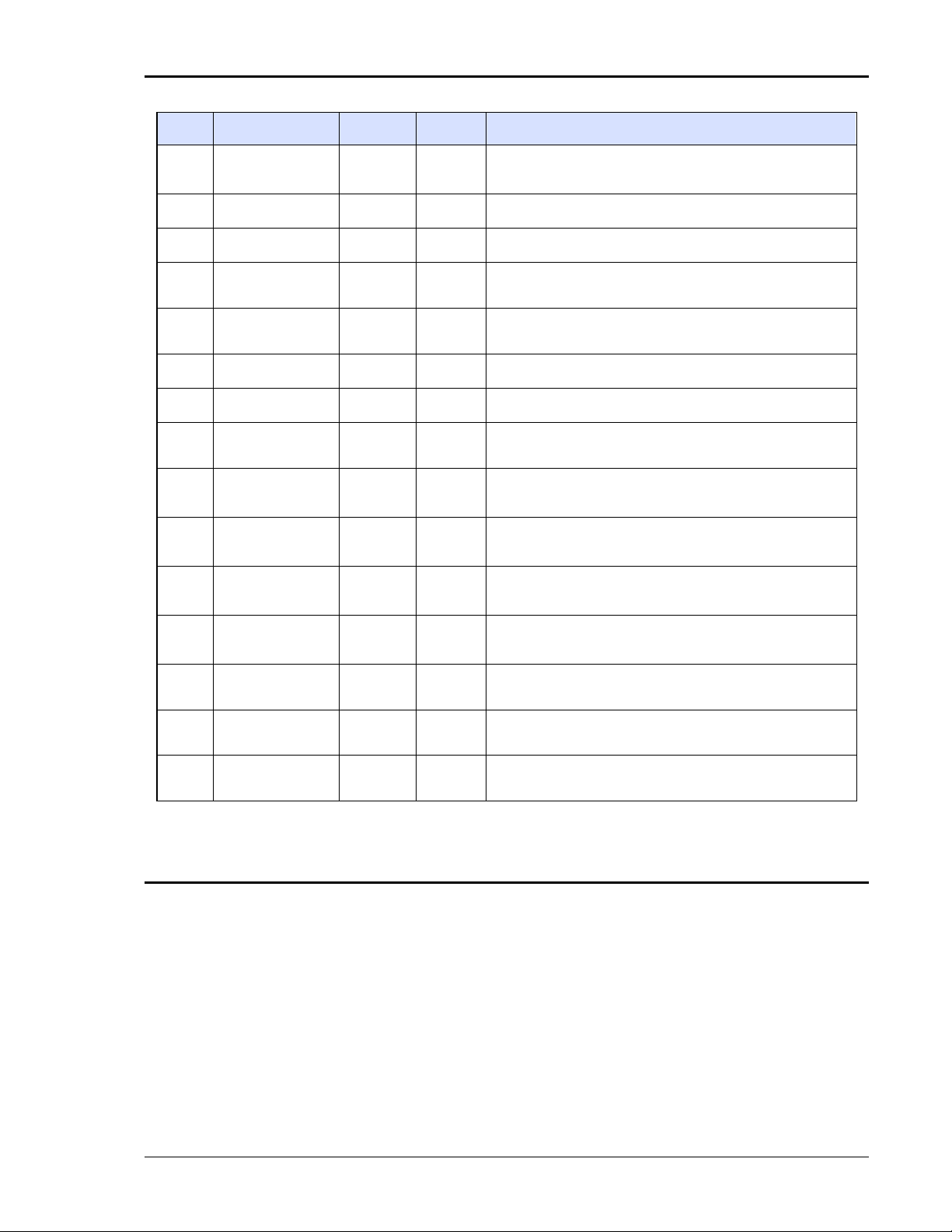

2.1.1 AC/DC Output Specifications

Model

AST 501

AST 751

AST 1501

Enclosure

1U

1U

1U

Output Phase

1-Phase

1-Phase

1-Phase

Output Power

500 VA/ 500 W

750 VA/ 750 W;

Low Audible Noise Models:

derate power above 30 °C at

12 W/°C.

1500 VA/ 1500 W;

derate output power with AC

input line-to-line voltage:

from 1,500 W at 103.5 VAC

to 1,300W at 90 VAC;

Low Audible Noise Models:

derate power above 30 °C at

25 W/°C.

AC and AC+DC

Output Current,

Full-Scale

Low-Range:

2.5 A(RMS) at 200 VAC;

iX2TM, 5.0 A(RMS)

maximum at 100 VAC.

High-Range:

1.25 A(RMS) at 400 VAC;

iX2TM, 2.5 A(RMS)

maximum at 200 VAC.

Low-Range:

3.75 A(RMS) at 200 VAC;

iX2TM, 7.5 A(RMS) maximum

at 100 VAC.

High-Range:

1.875 A(RMS) at 400 VAC;

iX2TM, 3.75 A(RMS)

maximum at 200 VAC.

Low-Range:

7.5 A(RMS) at 200 VAC;

iX2TM, 15 A(RMS) maximum

at 100 VAC.

High-Range:

3.75 A(RMS) at 400 VAC;

iX2TM, 7.5 A(RMS)

maximum at 200 VAC.

DC Output Current,

Full-Scale

Low-Range:

2.0 ADC at 250 VDC;

iX2TM, 4.0 ADC maximum

at 125 VDC.

High-Range:

1.0 ADC at 500 VDC;

iX2TM, 2.0 ADC maximum

at 250 VDC.

Low-Range:

3.0 ADC at 250 VDC;

iX2TM, 6.0 ADC maximum at

125 VDC.

High-Range:

1.5 ADC at 500 VDC;

iX2TM, 3.0 ADC maximum at

250 VDC.

Low-Range:

6.0 ADC at 250 VDC;

iX2TM, 12 ADC maximum at

125 VDC.

High-Range:

3.0 ADC at 500 VDC;

iX2TM, 6.0 ADC maximum at

250 VDC.

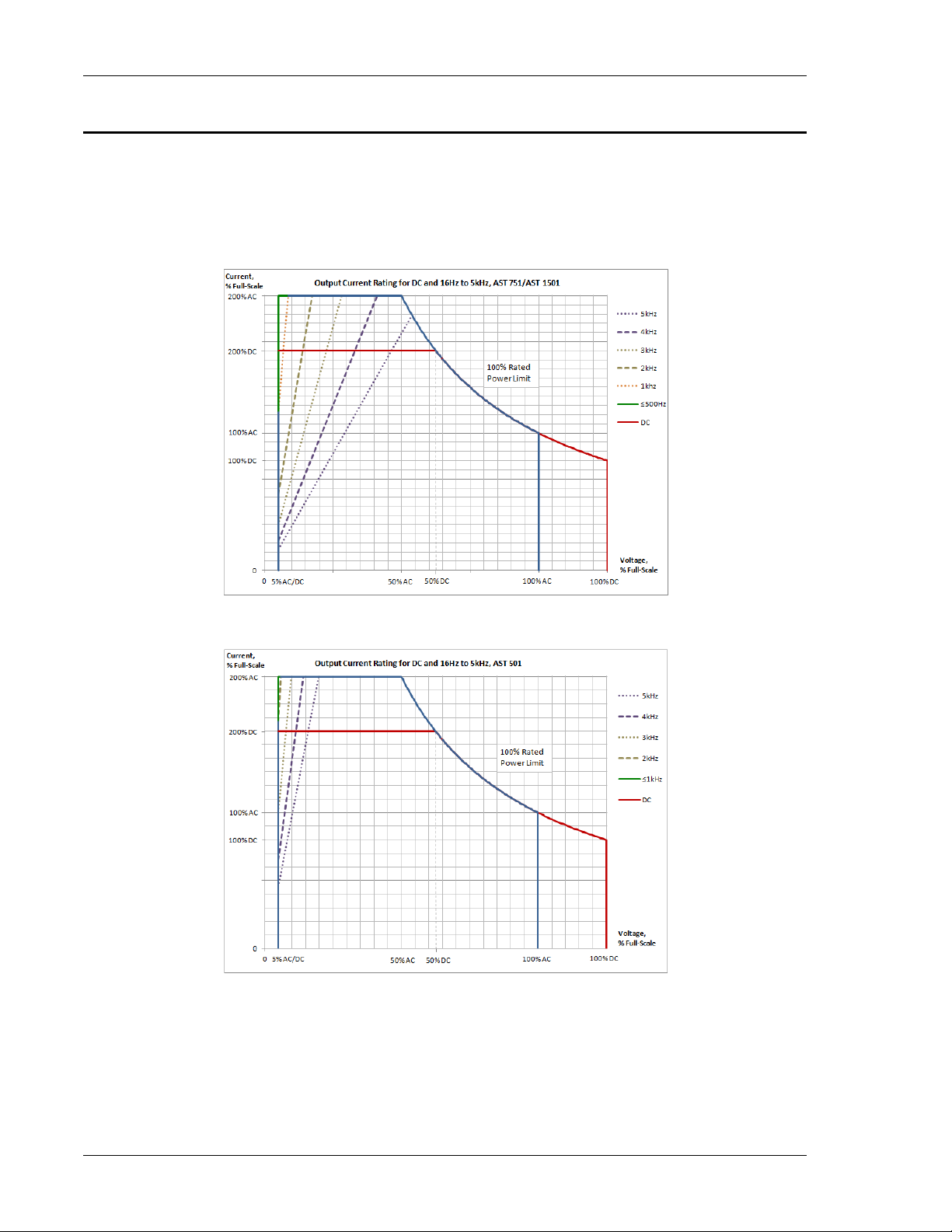

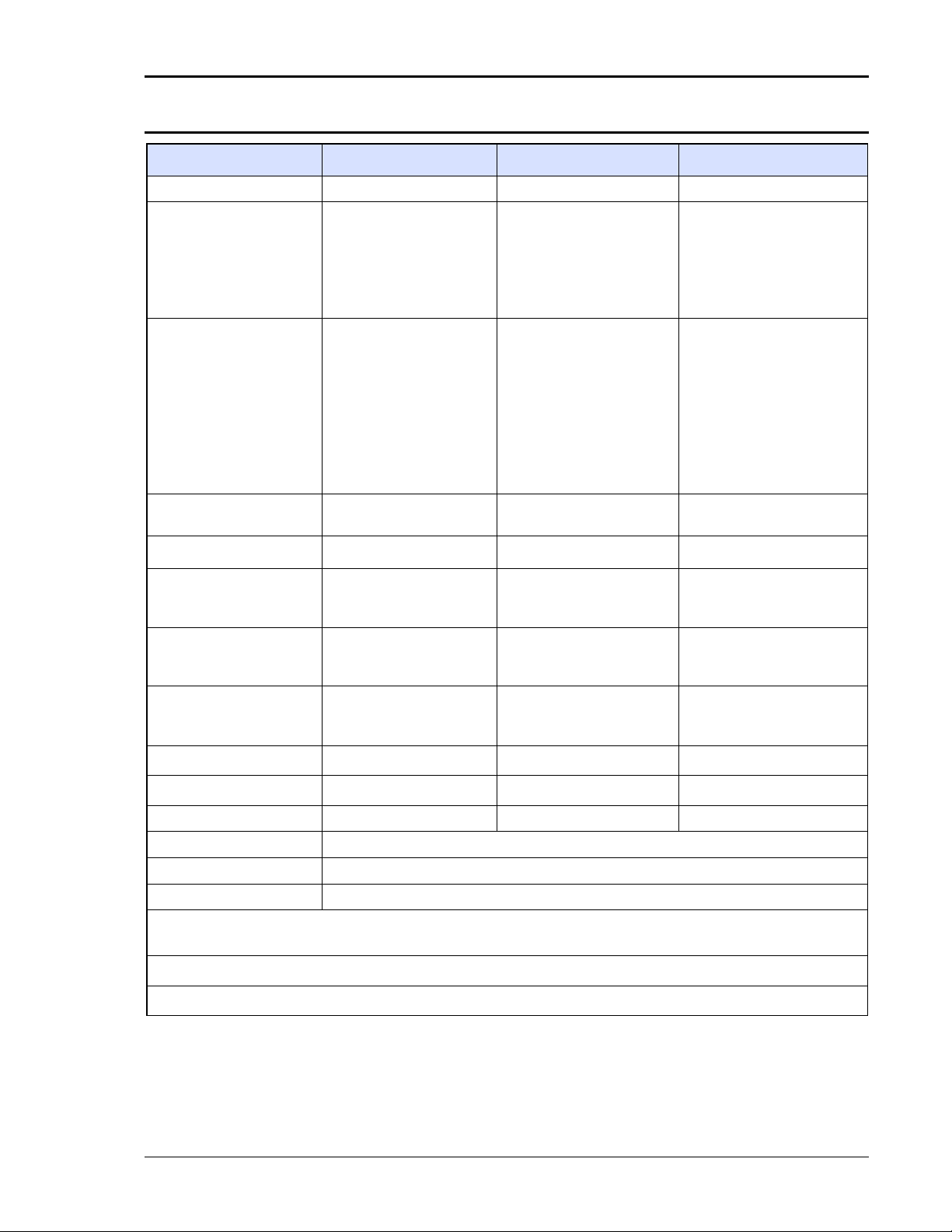

Output Current,

Maximum

iX2TM, 200% of the full-scale RMS current at ≤50% of full-scale voltage. Refer to Figure

2-1 and Figure 2-2 for graphs of current rating as a function of output frequency.

iX2TM

Constant-Power

Mode

Constant-Power output capability in each output voltage range with full rated output

power from 50% of full-scale output voltage to 100% of full-scale; the output current

increases to 200% of rated current at 50% full-scale output voltage from 100% rated

current at 100% of full-scale voltage. Refer to Figure 2-1 and Figure 2-2 for graphs of

current rating as a function of output frequency.

AC and AC+DC

Output Voltage,

Full-Scale

Low-Range: 0 to 200 V(RMS); High-Range: 0 to 400 V(RMS)

HF Option: derate full-scale output voltage from 4 kHz to 5 kHz, as follows,

Low Range, Vout ≤ 800 V-kHz / Fout, with Fout in kHz;

High Range, Vout ≤ 1600 V-kHz / Fout, with Fout in kHz.

DC Output Voltage,

Full-Scale

Low-Range: 0 to 250 VDC; High-Range: 0 to 500 VDC

Page 16

Asterion Series User Manual – 1U Models California Instruments

16 M330000-01, REV-G

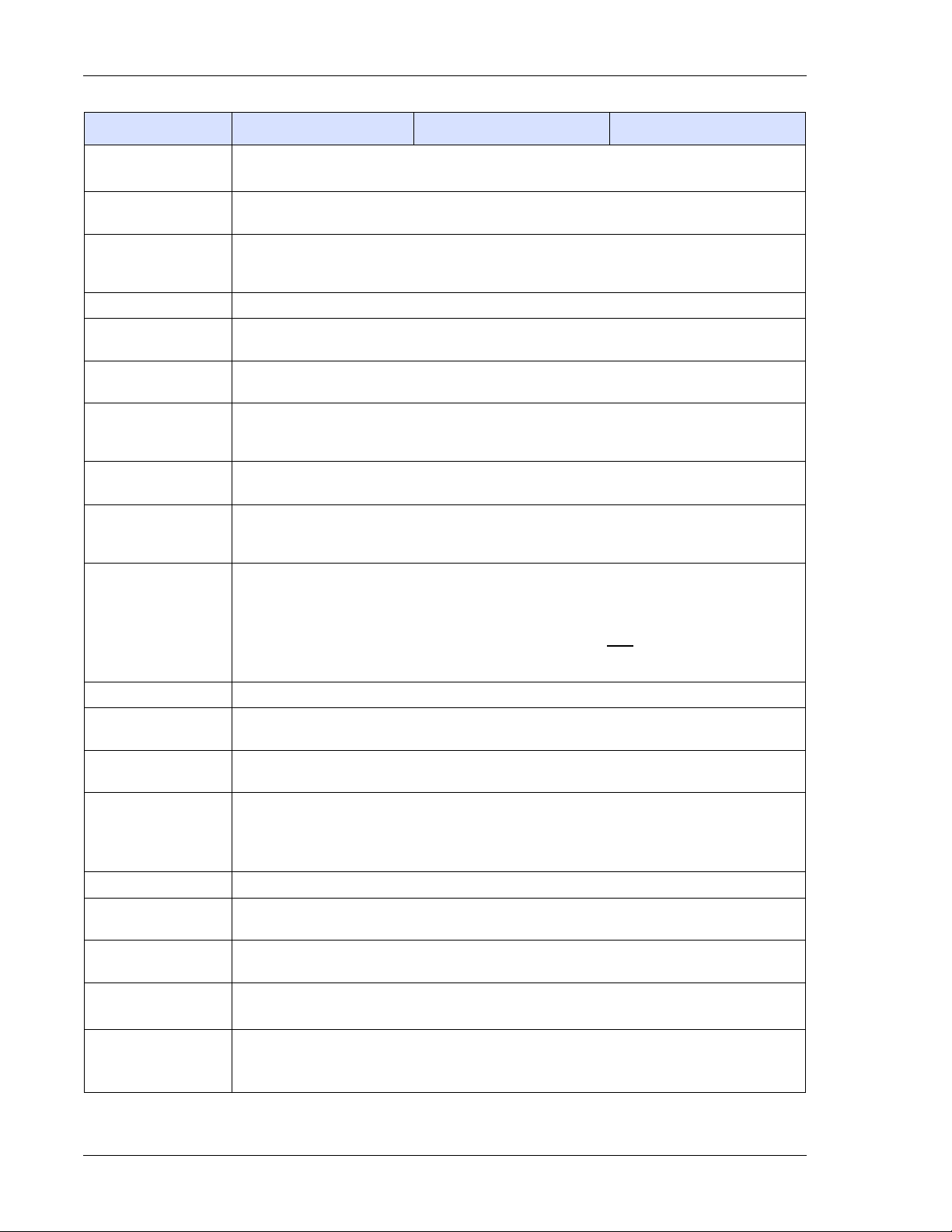

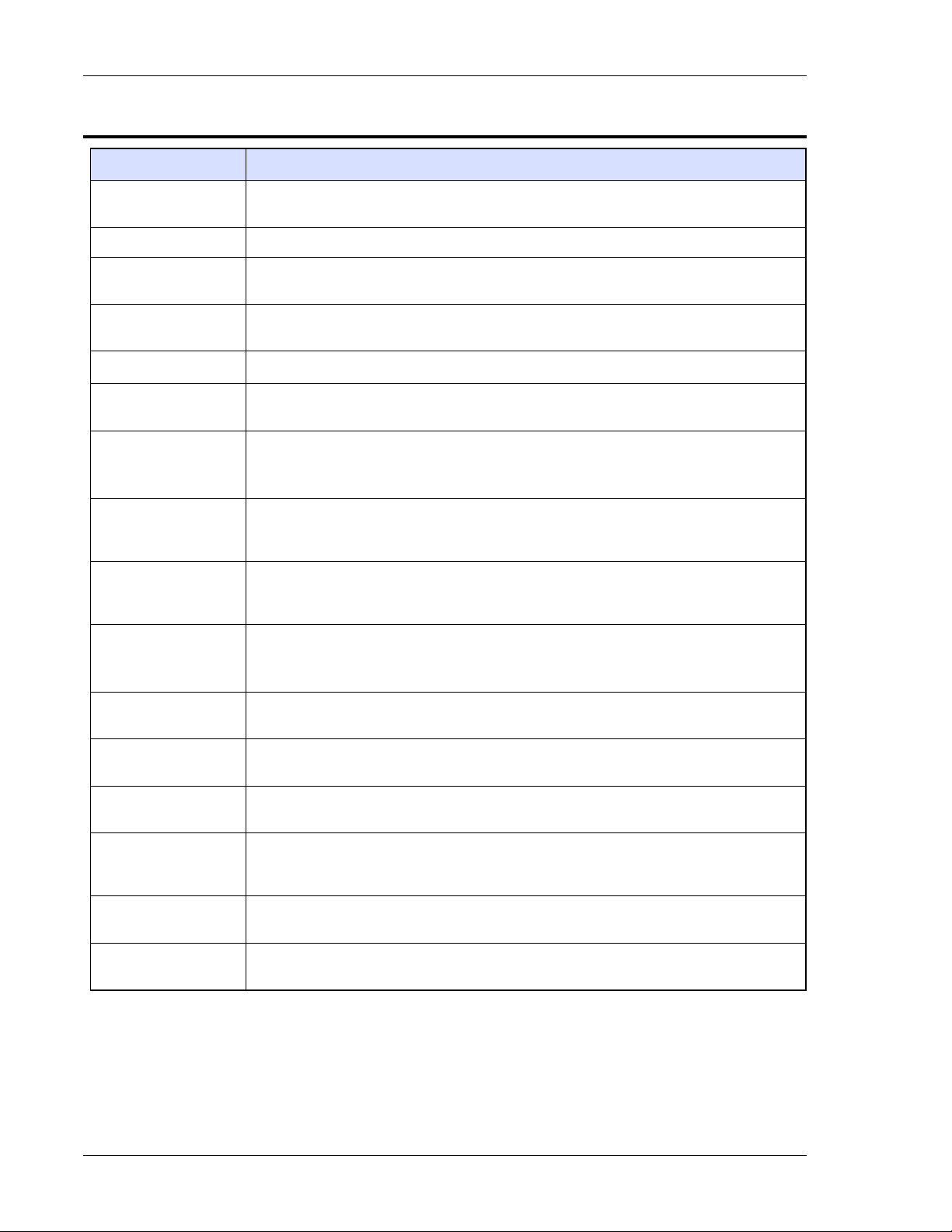

Model

AST 501

AST 751

AST 1501

DC Offset Voltage,

typical

±20 mVDC, ≥40 Hz

Output Float

Voltage

566 V(PK), maximum from either output terminal to chassis

Voltage

Programming

Accuracy

±(0.1% of actual + 0.2% of full-scale) for DC, and AC 16 Hz to 1.2 kHz; >1.2 kHz, add

±0.2% of full-scale/kHz; add ±0.1% of full scale for AC+DC mode. Valid from 5% to 100%

of full-scale; with sense leads connected.

Voltage Resolution

≤0.02 V, AC, DC, and AC+DC mode

Voltage Temp.

Coefficient, typical

≤100 ppm/°C of full-scale

Voltage Stability,

Typical

±0.1% of full-scale over 8 hours; with constant line, load, and temperature;

with sense leads connected

Voltage Distortion

0.25% maximum, 16 Hz to 100 Hz; 0.5% maximum, >100Hz to 500 Hz; and

1% maximum, >500 Hz to 1.2 kHz, plus 0.5%/kHz to 5 kHz; at full linear load or no load;

valid for output voltage >5% of full-scale at full load, and >15% of full-scale at no load.

Voltage Slew Rate,

typical

≥10 V/µs, with full-scale programmed voltage step

Current

Programming

Range

Programmable from zero to 200% of full-scale rating in each output range. Refer to

Figure 2-1 and Figure 2-2 for graphs of current rating as a function of output frequency.

Current

Programming

Accuracy

±(0.3% of actual + 0.5% of maximum) for DC, and AC 16 Hz to 1.2 kHz; add ±0.1% of

maximum for AC+DC mode. Valid from 5% to 100% of maximum.

HF option: for High-Range, add 1.2% of maximum/kHz above 1.2 kHz; for Low-Range,

add 0.1% of maximum/kHz above 1.2 kHz. Valid from 20% to 100% of maximum.

For multi-chassis configurations, multiply the accuracy by √1.5𝑛, where 𝑛 is number of

chassis.

Line Regulation

±0.015% of full-scale voltage, for a ±10% input line change; DC, or 40 Hz to 5 kHz.

Load Regulation

±0.025% of full-scale voltage, for 100% of rated resistive load change; DC, or 40 Hz to

1.2 kHz; above 1.2 kHz, add ±0.015% of full-scale/kHz.

V/I Programming

Overrange, Typical

1% of full-scale

Noise Level, typical

AC output: 450 mV(RMS), low-range; 750 mV(RMS), high-range;

at ≥40 Hz output frequency; bandwidth, 20 kHz to 1 MHz;

DC output: 400 mV(RMS), low-range; 700 mV(RMS), high-range;

bandwidth, 20 Hz to 1 MHz.

Remote Sense

5 V(RMS), maximum total output lead drop

Crest Factor

AST 751, AST 1501: 5:1 of full-scale current per output range (ratio of peak to RMS);

AST 501: 7:1 of full-scale current per output range (ratio of peak to RMS).

Output Power

Factor

0, lagging to 0, leading

Frequency,

Range

Standard models: DC, and 16 Hz to 1.2 kHz;

LF option: DC, and 16 Hz to 550 Hz; HF option: DC, and 16 Hz to 5 kHz.

Frequency

Accuracy,

(FC option)

Standard models: ±(0.01% of actual + frequency resolution/2);

FC option: ±0.25%.

Page 17

Asterion Series User Manual – 1U Models California Instruments

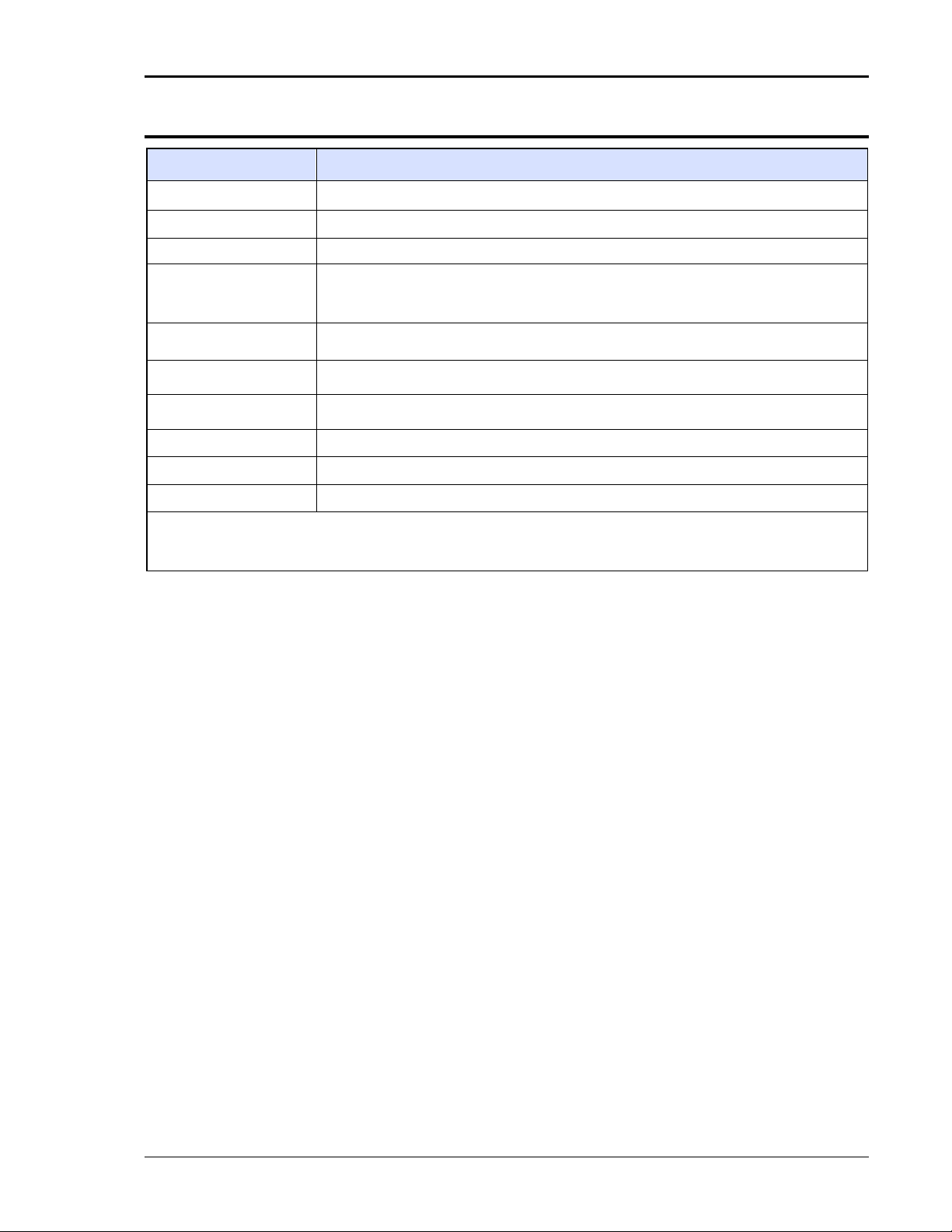

M330000-01, REV-G 17

Model

AST 501

AST 751

AST 1501

Frequency

Resolution

Standard: 0.01 Hz resolution, 16-81.91 Hz; 0.1 Hz resolution, 82-819.1 Hz;

1 Hz resolution, 820-5000 Hz;

with LKM/LKS option: 1 Hz resolution, 16-5000 Hz.

Frequency Temp.

Coefficient, typical

10 ppm/ºC of full-scale range

Phase

Programming

Range

0.0º to 360.0º, relative to external synchronization signal; in multi-phase group, Auxiliary

unit output voltage is relative to the Master unit output voltage, with the Master unit

voltage as reference 0°.

Phase Accuracy

±1º, 16 Hz to 100 Hz; ±2º >100 Hz to 1.2 kHz, plus ±1º/kHz above 1.2 kHz

Phase

Programming

Resolution

±0.4º

Page 18

Asterion Series User Manual – 1U Models California Instruments

18 M330000-01, REV-G

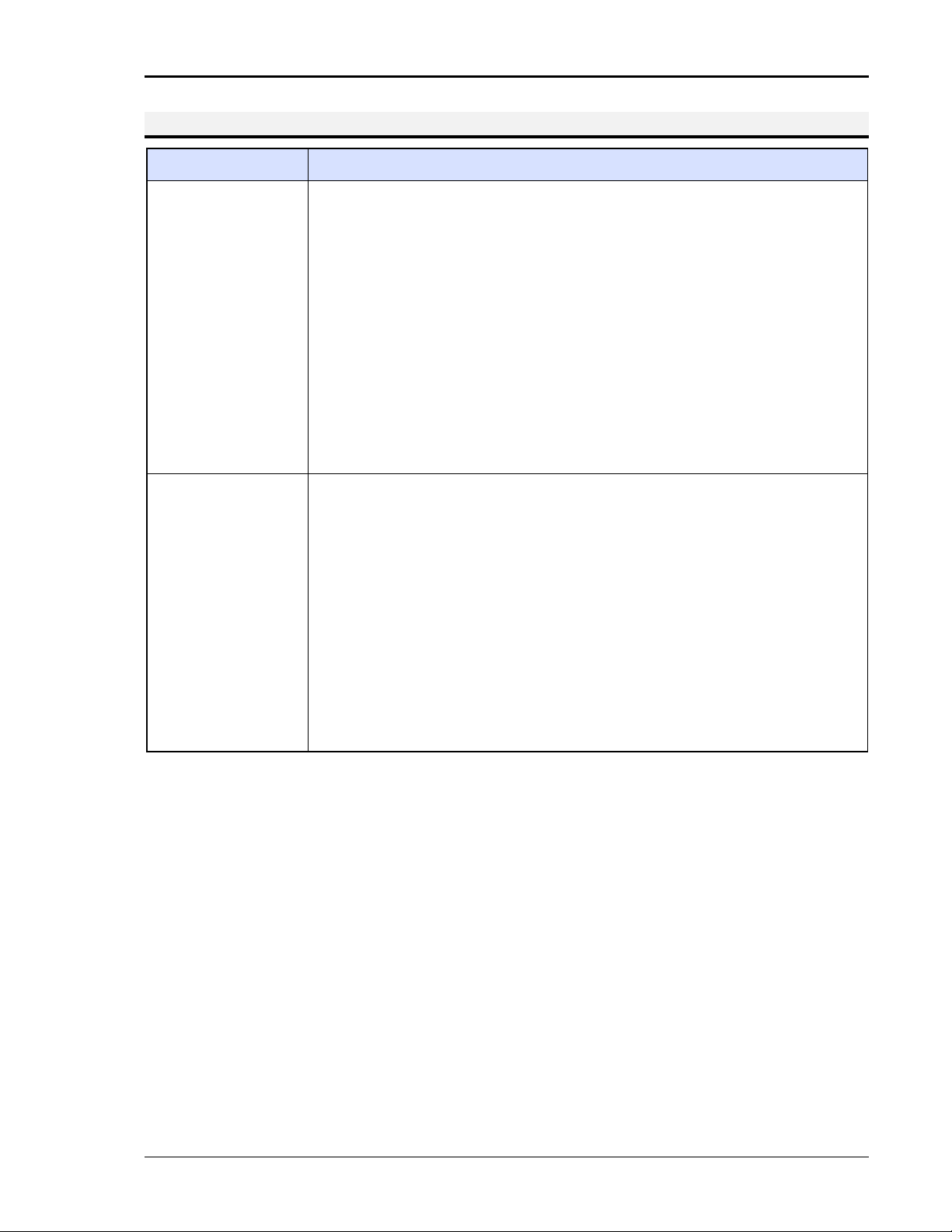

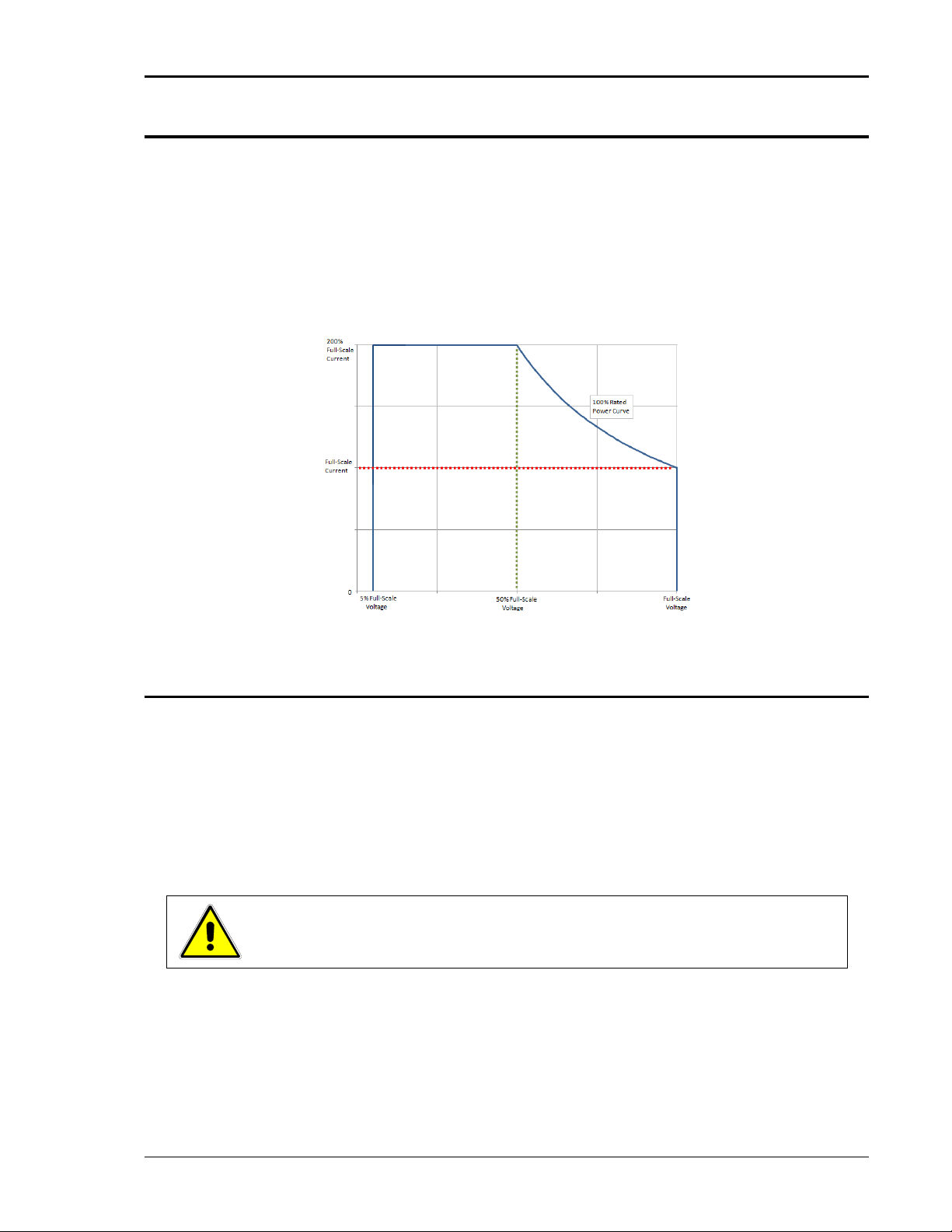

2.1.3 iX2

TM

Constant-Power Mode Output Characteristic

The iX2TM Constant-Power mode has an output characteristic where full rated output power is available

from 50% of full-scale output voltage to 100% of full-scale output voltage, as depicted in the graphs of

Figure 2-1 and Figure 2-2. The output current versus output voltage follows a constant-power relation

where the output current would be 200% of the full-scale value when the output voltage is 50% of

full-scale. The current ratings are also a function of output frequency, as shown in Figure 2-1 above

500 Hz for the AST 751 and AST 1501 models, and in Figure 2-2 above 1 kHz for the AST 501 models.

Figure 2-1. iX2TM Constant-Power: Output Current Versus Voltage, AST 751/AST 1501

Figure 2-2. iX2TM Constant-Power: Output Current Versus Voltage, AST 501

Page 19

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 19

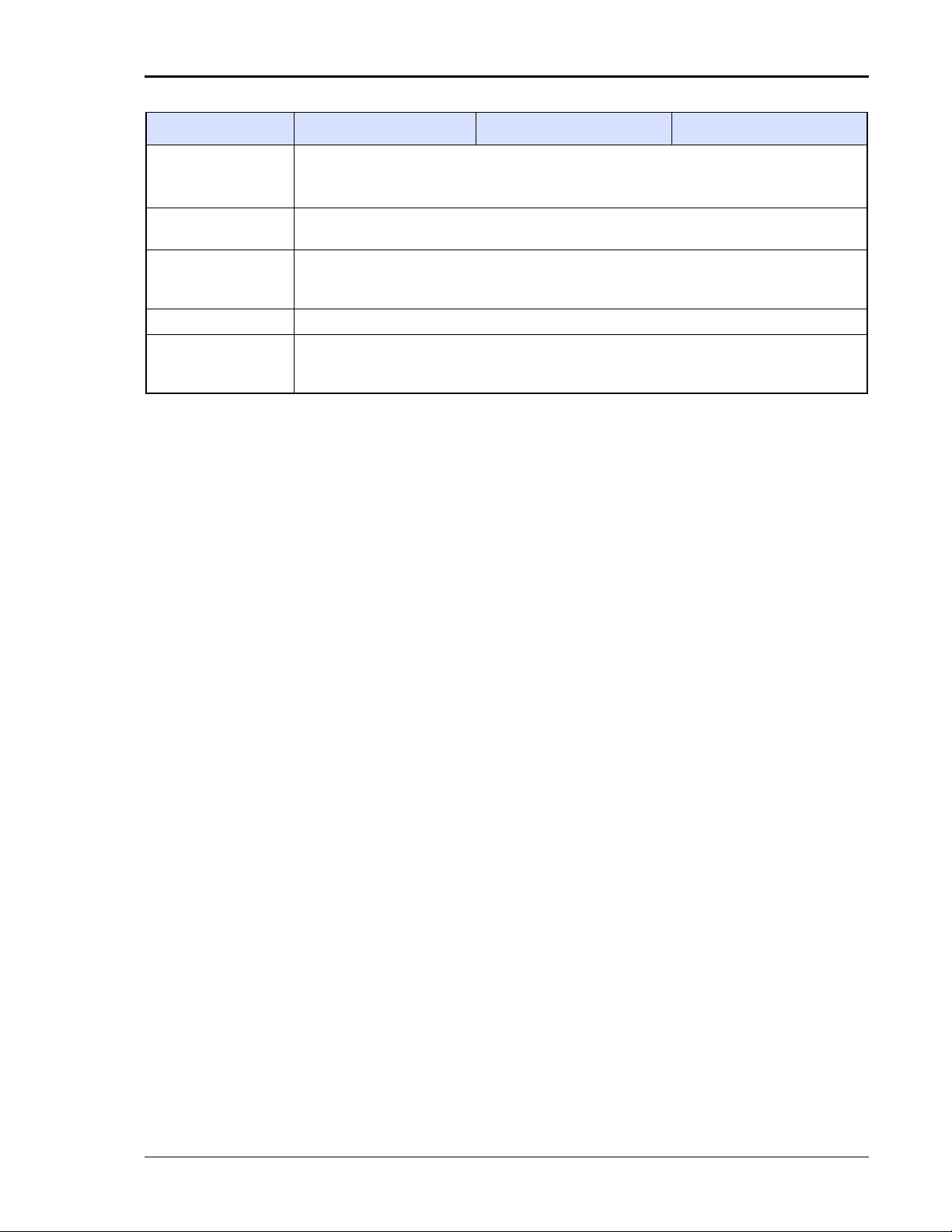

2.1.4 AC Input Specifications

Model

AST 501

AST 751

AST 1501

Enclosure

1U

1U

1U

Input Voltage,

Nominal Rating

100VAC-120VAC

low-input range, and

200-240 VAC high-input

range;

1-Phase and 3-Phase,

line-neutral or line-line.

100VAC-120VAC

low-input range, and

200-240 VAC high-input

range;

1-Phase and 3-Phase,

line-neutral or line-line.

100VAC-120VAC low-input

range, and

200-240 VAC high-input

range;

1-Phase and 3-Phase,

line-neutral or line-line.

Input Voltage,

Operating Range

90-132 VAC low-input

range, and

180VAC-264VAC

high-input range.

.

90-132 VAC low-input

range, and

180VAC-264VAC

high-input range.

90-132 VAC low-input

range, and

180VAC-264VAC

high-input range;

derate output power for

operation with 1-Phase AC

input and line-to-line

voltage: from 1,500 W at

103.5 VAC to 1,300W at

90 VAC.

Input Frequency,

Nominal Rating

50 Hz, 60 Hz, 400 Hz

50 Hz, 60 Hz, 400 Hz

50 Hz, 60 Hz, 400 Hz

Input Frequency Range

47-440 Hz

47-440 Hz

47-440 Hz

Input Current,

maximum with

1-Phase input

7.6 A(RMS) at 90 VAC

11 A(RMS) at 90 VAC

20 A(RMS) at

90 VAC to 103.5 VAC

Input Current,

maximum with

3-Phase input

4.4 A(RMS) at 90 VAC,

line-to line

6.5 A(RMS) at 90 VAC,

line-to line

13 A(RMS) at 90 VAC,

line-to line

Efficiency1, typical

AST 1501: 75%;

AST 751: 72%;

AST 501: 69%.

AST 1501: 75%;

AST 751: 72%;

AST 501: 69%.

AST 1501: 75%;

AST 751: 72%;

AST 501: 69%.

Power Factor2, typical

0.98; active PFC

0.98; active PFC

0.98; active PFC

Hold-Up Time

3

, typical

≥10 ms

≥10 ms

≥10 ms

Inrush Current, typical

30 A (PK) at 264 VAC

30 A (PK) at 264 VAC

30 A (PK) at 264 VAC

1-PH Input

2 wire + ground; 264 VAC, maximum

3-PH Input

3 wire + ground; 264 VAC, maximum line-to-line

Isolation Voltage

2200 VAC, input to output; 1350 VAC, input to chassis

1

At full load and DC or 16 Hz to 1.2 kHz output frequency, with AC input voltage of 115 V(RMS) or 230 V(RMS),

and 50/60 Hz input frequency

2

At full load, with 1-phase AC input voltage of 115 V(RMS) or 230 V(RMS), and 50/60 Hz input frequency

3

At full load and with AC input voltage of 115 V(RMS) or 230 V(RMS)

Page 20

Asterion Series User Manual – 1U Models California Instruments

20 M330000-01, REV-G

2.1.5 AC Output Measurements

Parameter

Specification

1

Voltage Range, Full-Scale

AC and AC+DC output: 0-500 V(RMS)

Voltage Accuracy

±(0.1% of actual + 0.2% of full-scale) for AC 16 Hz to 1.2 kHz; >1.2 kHz,

add ±0.2% of full-scale/kHz; add ±0.1% of full-scale for AC+DC mode. Valid

from 5% to 100% of full-scale; with sense leads connected.

Voltage Resolution

20 mV

Current Range, Maximum

AST 501, AST 751: 7.5 A(RMS); AST 1501: 15 A(RMS).

Current Accuracy

±(0.3% of actual + 0.5% of maximum) for AC, 16 Hz to 1.2 kHz; add ±0.1%

of full-scale for AC+DC mode. Valid from 5% to 100% of maximum.

HF Option: High-Range, add 1.2% of maximum/kHz; Low-Range, add 0.1%

of maximum/kHz. Valid from 20% to 100% of maximum.

Current Resolution

2 mA

Peak Current Range, Maximum

AST 501, AST 751: ± 0-18.75 A(PK); AST 1501: ± 0-37.5 A(PK).

Peak Current Accuracy

±(0.5% of actual 0.7% of maximum) for AC 16 Hz to 1.2 kHz; add ±0.1% of

maximum for AC+DC mode. Valid from 5% to 100% of maximum.

HF Option: High-Range, add 1.2% of maximum/kHz above 1.2 kHz;

Low-Range, add 0.1% of maximum/kHz above 1.2 kHz. Valid from 20% to

100% of maximum.

Peak Current Resolution

5 mA

Frequency Range

16 Hz to 5.0 kHz

Frequency Accuracy

±(0.01% of actual + frequency resolution/2)

Frequency Resolution

0.01 Hz: 16-81.91 Hz; 0.1 Hz: 82.0-819.1 Hz; 1 Hz: 820-5.0 kHz

Phase Range

0-360°

Phase Accuracy

±1°, 16 Hz to 100 Hz; ±2°, >100 Hz to 1.2 kHz; ±5°, >1.2 kHz

Phase Resolution

0.1°, 16-100 Hz; 1°, >100 Hz to 5 kHz

Real Power Range, Full-Scale

Output power rating of model.

Real Power Accuracy

±(0.4% of actual + 0.7% of full-scale) for AC 16 Hz to 1.2 kHz; >1.2 kHz,

add ±0.4% of full-scale/kHz; add ±0.2% of full-scale for AC+DC mode.

Real Power Resolution

1 W

Apparent Power Range,

Full-Scale

Output power rating of model.

Apparent Power Accuracy

±(0.4% of actual + 0.7% of full-scale) for AC 16 Hz to 1.2 kHz; >1.2 kHz,

add ±0.4% of full-scale/kHz; add ±0.2% of full-scale for AC+DC mode.

Apparent Power Resolution

1 VA

Power Factor Range, Full-Scale

0-1

Power Factor Accuracy

±2% of full-scale

Power Factor Resolution

0.01

1

Accuracy specifications apply above 100 counts of resolution; for multi-chassis configurations, multiply the

output current and power by the number of chassis, and their accuracy specifications by √1.5𝑛, where 𝑛 is

number of chassis; power factor accuracy applies for PF > 0.5 and output apparent power > 50% of maximum

rating; frequency measurement specifications valid for output voltage >5% of full-scale in each range.

Page 21

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 21

2.1.6 DC Output Measurements

Parameter

Specification1

Voltage Range, Full-Scale

±500 VDC

Voltage Accuracy

±(0.1% of actual + 0.2% of full-scale); valid from 5% to 100% of

full-scale; with sense leads connected.

Voltage Resolution

25 mV

Current Range, Maximum

AST 501, AST 751: 6 ADC; AST 1501: 12 ADC.

Current Accuracy

±(0.5% of actual + 0.5% of maximum); valid from 5% to 100% of

maximum.

Current Resolution

2 mA

Peak Current Range, maximum

AST 501, AST 751: ± 0-18.75 A(PK); AST 1501: ± 0-37.5 A(PK).

Peak Current Accuracy

±(0.5% of actual + 0.7% of maximum); valid from 5% to 100% of

maximum.

Peak Current Resolution

5 mA

Power Range, Full-Scale

Output power rating of model.

Power Accuracy

±(0.4% of actual + 0.7% of full-scale)

Power Resolution

1 W

1

Accuracy specifications apply above 100 counts of resolution; for multi-chassis configurations, multiply the output

current and power by the number of chassis, and their accuracy specifications by √1.5𝑛, where 𝑛 is number of

chassis.

2.1.7 Harmonics Measurements

Parameter

Specification1

Frequency, Fundamental

16-81.91 Hz, 82.0-819.1 Hz, 820-960 Hz

Fundamental Frequency Resolution

0.01 Hz: 16-81.91 Hz; 0.1 Hz: 82.0-819.1 Hz; 1 Hz: 820-960 Hz

Harmonic Frequency

32 Hz to 48 kHz; 2nd to 50th harmonic

Fundamental Voltage Accuracy

±(0.2% of actual + 0.3% of full-scale) for 16 Hz to 960 Hz.

Fundamental Voltage Resolution

20 mV

Harmonic Voltage Accuracy

±(0.2% of actual + 0.3% of full-scale + 0.3% of full-scale/kHz).

Harmonic Voltage Resolution

20 mV

Fundamental Current Accuracy

±(0.4% of actual + 0.6% of maximum) for 16 Hz to 960 Hz.

Fundamental Current Resolution

2 mA

Harmonic Current Accuracy

±(0.4% of actual + 0.6% of maximum + 0.4% of maximum/kHz).

Harmonic Current Resolution

2 mA

1

Accuracy specifications apply above 100 counts of resolution; for multi-chassis configurations, multiply the

current accuracy by √1.5𝑛, where 𝑛 is number of chassis. Voltage and current measurements are valid from 5%

to 100% of maximum in each range.

Page 22

Asterion Series User Manual – 1U Models California Instruments

22 M330000-01, REV-G

2.1.8 Protection Function Characteristics

Function

Characteristic

Output Overvoltage Protection (OVP)

Programmable to 115% of full-scale output voltage;

exceeding OVP threshold results in shutdown of output.

Output Current Limit Protection

User-selectable constant-current mode or current-limit mode, with

programmable current setpoint;

in constant-current mode, output current is regulated to setpoint;

in current limit mode, exceeding current-limit setpoint results in

shutdown of output;

current-limit delay: programmable from 100 ms to 10 s.

Output Short-Circuit Protection

Instantaneous and RMS current-limit

AC Input Overcurrent Protection

Internal fuses in each phase for fault isolation; not user replaceable

AC Input Undervoltage Protection

Automatic shutdown for insufficient AC input voltage

AC Input Transient Protection

Protection to withstand EN61326-1, Class-A surge levels

Overtemperature Protection (OTP)

Internal temperature monitors cause shutdown of output if

temperature thresholds are exceeded

2.2 Environmental Specifications

Parameter

Specification

Operating Temperature

0°C to 40°C (32° F to 104° F)

Storage Temperature

-40°C to 85°C ( -40°F to 185° F)

Altitude

2000 m (6,562 ft)

Relative Humidity

5-95 %, non-condensing

Vibration

MIL-PRF-28800F, Class 3; 5-500 Hz per Paragraph 4.5.5.3.1

Shock

MIL-PRF-28800F, Class 3; 30G half-sine with 11ms duration per

Paragraph 4.5.5.4.1

Transportation Integrity

ISTA Test Procedure 1A

Page 23

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 23

2.3 Mechanical Specifications

Parameter

Specification

Dimensions

H, 1.75” (44.45 mm); W (front panel), 19.0” (483mm); D, 23.0” (584mm);

H, 1.75” (44.45 mm); W (chassis), 16.9” (483mm); D, 23.0” (584mm).

Unit Weight

AST 501/751: 19 lb / 8.6 kg;

AST 1501: 22 lb / 10 kg.

Shipping Weight

AST 501/751: 29 lb / 13.2kg;

AST 1501: 32 lb / 14.5 kg.

Chassis Material

Steel with plastic front panel

Chassis Finish

Galvanized Zinc, G90

Installation

Protective covers are provided for AC input and AC/DC output;

bench-top: removable feet for the chassis;

rackmount: per ANSI-EIA-310-D, with front panel mounting flange brackets and chassis

provisions for mounting rack slides; slides and flange brackets/handles options available.

Cooling

Force-air cooling; linear, variable fan speed control; air intake at front/sides and exhaust

at rear.

Acoustic Noise

Standard: 65 dBA, maximum; measured at 1 m with A-weighting;

Low Audible Noise: 59 dBA, maximum; measured at 1 m with A-weighting.

2.4 Regulatory Agency Compliance

Parameter

Specification

EMC

CE marked for EMC Directive 89/336/EEC per EN61326-1:2013, Class-A for

emissions and immunity as required for the EU CE Mark.

Safety

CSA NRTL certified for US and Canada to CAN/CSA-C22.2 No. 61010-1-12,

UL 61010-1 Third Edition. CE marked for LVD compliance 2006/95/EC to

EN 61010-1 Third Edition as required for the EU CE mark.

CE Mark LVD Categories

Installation Overvoltage Category: ΙΙ; Pollution Degree: 2; Class II equipment;

indoor use only.

RoHS

CE marked for compliance with EU Directive 2011/65/EU for Restriction of

Hazardous Substances in Electrical and Electronic Equipment.

Page 24

Asterion Series User Manual – 1U Models California Instruments

24 M330000-01, REV-G

2.5 Remote Control Analog/Digital Signal Characteristics

Function

Characteristics

External Analog

Programming of

Output Voltage

Waveform

Signal input for output voltage waveform programming by external analog reference;

AC or DC input signal: 0V to user-selectable maximum range value within ±2.5 V(PK) to

±10 V(PK), corresponding to maximum range of 1.77 V(RMS) to 7.07 V(RMS), for zero to

full-scale RMS output voltage; with AC waveform, from 16 Hz to 5 kHz (option dependent);

programming accuracy, ±2% of full-scale output;

input impedance, 40 kΩ, typical.

External Analog

Programming of

Output Voltage

Amplitude (RPV)

Signal input for output voltage amplitude programming; waveform is set by internal

controller reference;

DC input signal: 0V to user-selectable maximum range value within 2.5 VDC to10 VDC, for

zero to full-scale RMS of internally programmed output voltage waveform;

programming accuracy, ±2% of full-scale output;

input impedance, 40 kΩ, typical.

External Analog

Programming

Modulation of

Output Voltage

Signal input for output voltage modulation; waveform is set by internal controller reference;

AC or DC input signal with 0V to ±7.07 V(PK), 0-5 V(RMS) for 0-20% of full-scale output

voltage amplitude modulation;

programming accuracy, ±2% of full-scale output;

input impedance, 40 kΩ, typical.

Trigger Output

Signal output with dual function: user-selectable as either function trigger or list trigger;

function trigger provides a pulse for any programmable change in output voltage or

frequency; list trigger provides a pulse if programmed as part of list transients;

logic level, active-low pulse with duration of 500 µs, typical.

Output Voltage

Monitor Outputs

Signal output for monitoring the waveform of the command signal of the output amplifier;

0-5 V(RMS), typical, signal range for zero to full-scale output voltage.

Trigger Input

Signal input for external trigger for execution of programmed values or transient lists;

logic level, TTL-compatible.

Synchronization

Signal (SYNC)

Input

Signal input for external square wave to control the output frequency and phase, with

waveform generated by the internal reference;

logic level, TTL-compatible.

Remote Inhibit

Input

Signal input to turn the output off/on; logic level, TTL-compatible; user-selectable as

active-high or active-low.

Summary Fault

Switch Output

Switch output indicating that a Summary Fault (DFI) condition is present;

normally-closed, bidirectional AC/DC solid-state switch;

closed-circuit for fault or when unit is turned off (open-circuit for no fault present);

switch ratings: ±12V, maximum peak voltage; 0.1A, maximum current; 2.5Ω, maximum

closed resistance; 6µA, maximum open-circuit leakage current at 12V.

LKM (Option)

Signal outputs for Master Clock and Lock signals used in synchronizing two or more power

sources;

logic level, TTL-compatible.

LKS (Option)

Signal inputs for Auxiliary Clock and Lock signals used in synchronizing two or more power

sources;

logic level, TTL-compatible.

Page 25

Asterion Series User Manual – 1U Models California Instruments

M330000-01, REV-G 25

2.6 Remote Control Digital Interface Characteristics

Interface

Characteristic

LAN

Ethernet 10BASE-T and 100BASE-T over twisted-pair cables compliant with IEEE 802.3;

Connector: 8P8C modular jack.

USB

Serial interface compliant to USB 2.0;

Connector: Type-B receptacle.

RS-232C

Serial interface compliant to RS-232C;

Protocol: data bits, 7 with parity and 8 without parity; stop bits, 2; baud rate, 9600 to

115200; handshake, CTS and RTS;

Connector: Subminiature-D, 9-contact receptacle.

IEEE-488 (Option)

Parallel interface complies with IEEE-488.1, IEEE-488.2, and the SCPI command

specification;

command execution response time, 10 ms, typical;

connector: IEEE-488.1 compliant.

Firmware Upgrade

Firmware could be upgraded through the LAN (units built starting September 2018), USB,

or RS-232 interfaces.

Upgrade through IEEE-488 is not supported.

Page 26

Asterion Series User Manual – 1U Models California Instruments

26 M330000-01, REV-G

2.7 Operational Characteristics

Parameter

Characteristic

Parallel Operation

Multi-chassis configurations could be formed with up to six units paralleled in

1-phase or 3-phase groups, using one master unit and up to five units operating

as auxiliary units. Setup of the multi-chassis configuration is automatically

accomplished when the chassis are interconnected with the interface cables, and

require no user setup, except to wire the outputs.

Output Relays

Isolation and range relays are provided internally to automatically configure the

outputs, turn the output on/off, and disconnect the load from the output amplifier

when in the off state.

Non-Volatile Memory

16 complete instrument setups and transient lists, 100 events per list.

Transient Generator

Output could be controlled to produce transient events with 500 µs programming

resolution:

Voltage: drop, step, sag, surge, sweep;

Frequency: step, sag, surge, sweep;

Voltage and Frequency: step, sweep.

Reliability

MTBF: > 110,000 hr;

calculation method: Telecordia SR-332, Issue 3; method: Method I (Parts

Count), Case 2 (Temp 40°C, Stress 50%, Burn-in 4 hr); ambient temperature:

40°C; temperature variation: 10°C; environment: Ground, Fixed, Controlled; duty

cycle: 100%; stress factor: 50%; quality level: 1; upper confidence level: 90%

Calibration

Calibration interval is 1 year; calibration is firmware-based through the digital

interface or Asterion Virtual Panels.

Fault Identification

On-board diagnostics identify when an assembly has experienced a fault.

XLOAD,

Output Characteristic