Reference Manual

Advanced Signal Multi-scanner

JOFRA ASM-801/802/803 A/B

Copyright 2009 AMETEK Denmark A/S

About this manual….

The structure of the manual

This reference manual is aimed at users who are familiar with

AMETEK multi-scanners, as well as those who are not. The

manual is divided into 11 chapters, which describe how to set

up, operate, service and maintain the Multi-scanner. The

technical specifications are described and accessories may be

ordered from the list of accessories.

Safety symbols

This manual contains a number of safety symbols designed to

draw your attention to instructions, which must be followed

when using the instrument, as well as any risks involved.

Warning

Events, which may compromise the safe use of

the instrument and result in considerable

personal or material damage.

Caution…

Events, which may compromise the safe use of

the instrument and result in slight personal or

material damage.

Note…

Special situations, which demand the user’s

attention.

2 02-10-2009 125614 02

List of contents

1.0

Introduction ..............................................................................5

2.0 Safety instructions...................................................................7

3.0 Receiving the multi-scanner ...................................................9

3.1 Multi-scanner models.................................................................. 11

3.1.1 A Model version.............................................................. 12

3.1.2 B Model version.............................................................. 14

4.0 Setting up the multi-scanner.................................................15

4.1 Preparing the multi-scanner........................................................ 16

4.2 Connecting sensors to the multi-scanner ................................... 17

4.2.1 Connecting RTDs ........................................................... 18

4.2.2 Connecting Thermocouples and Voltages Sources....... 18

4.2.3 Connecting 4-20mA Transmitters................................... 20

4.3 Cascading the multi-scanner ...................................................... 21

4.4 Connecting A-models to other instruments ................................ 22

5.0 Operating the multi-scanner .................................................23

5.1 Manual operation ........................................................................ 23

5.2 Operation with JOFRACAL......................................................... 24

6.0 Remote operation...................................................................25

6.1 Setting up the RS-232 Port for Remote Control ........................ 25

6.2 Units............................................................................................ 26

6.2.1 Temperature units .......................................................... 26

6.2.2 Electrical units ................................................................ 26

6.3 Commands.................................................................................. 26

6.3.1 *CLS ............................................................................... 26

6.3.2 *ESE <reg val>............................................................... 26

6.3.3 *ESE? ............................................................................. 27

6.3.4 *ESR?............................................................................. 27

6.3.5 *IDN? .............................................................................. 27

6.3.6 *OPC .............................................................................. 27

6.3.7 *OPC? ............................................................................ 28

6.3.8 *RST ............................................................................... 28

6.3.9 *SRE <reg val>............................................................... 28

6.3.10 *SRE? ............................................................................ 28

6.3.11 *STB?............................................................................. 28

6.3.12 *TST? ............................................................................. 28

6.3.13 *WAI ............................................................................... 29

6.3.14 SYSTEM_IDN? .............................................................. 29

125614 02 02-10-2009 3

6.3.15 SYS_CONF.................................................................... 29

6.3.16 SYS_CONF?.................................................................. 29

6.3.17 TEMP_UNIT................................................................... 30

6.3.18 TEMP_UNIT?................................................................. 30

6.3.19 CH_CONF...................................................................... 30

6.3.20 CH_CONF? (@<channel>)............................................ 32

6.3.21 VAL? (@<ch_list >) ........................................................ 33

6.3.22 CH_SCAN (@<ch_list>) ................................................ 33

6.3.23 CH_SCAN_STOP .......................................................... 33

6.3.24 CH_SCAN? .................................................................... 33

6.3.25 CAL_DATE..................................................................... 33

7.0 Maintenance............................................................................34

7.1 Storing......................................................................................... 34

7.2 Cleaning...................................................................................... 34

7.3 Returning the multi-scanner to service ....................................... 34

8.0 Errors.......................................................................................37

9.0 Adjusting the multi-scanner..................................................39

9.1 Adjusting and calibrating the instrument..................................... 39

9.2 Introduction to AMETRIM Software.......................................... 39

9.2.1 Installing the AMETRIM Software ..................................40

9.2.2 Connecting the PC and the ASM-80x ............................ 40

9.2.3 Starting the AMETRIM Software .................................... 40

9.2.4 Run calibration/adjustment............................................. 42

9.2.5 To calibrate the ASM-80x............................................... 45

9.2.6 To adjust and calibrate (as left) the ASM-80x ................ 46

9.2.7 To calibrate (as found), adjust and calibrate (as left) the

ASM-80x......................................................................... 48

9.2.8 Setup Printer................................................................... 49

10.0 Technical specifications.......................................................50

11.0 List of accessories.................................................................60

4 02-10-2009 125614 02

1.0 Introduction

Congratulations on your new AMETEK JOFRA

Advanced Signal Multi-scanner!

With the AMETEK JOFRA Multi-scanner, you have chosen an

extremely effective instrument, which we hope will perform according

to your expectations. During the past several years, we have acquired

extensive knowledge of industrial temperature calibration. This

expertise is reflected in our products, which are all designed for daily

use in an industrial environment. Please note that we would be very

interested in hearing from you if you have any ideas or suggestions

for changes to our products.

This reference manual applies to the following instruments:

JOFRA ASM-801 A

JOFRA ASM-801 B

JOFRA ASM-802 A

JOFRA ASM-802 B

JOFRA ASM-803 A

JOFRA ASM-803 B

ISO-9001 certified

AMETEK Denmark A/S was ISO-9001 certified in September 1994

by Bureau Veritas Certification Denmark.

125614 02 02-10-2009 5

CE-label

Technical assistance

Please contact the dealer from whom you acquired the instrument if

you require technical assistance.

Your new multi-scanner bears the CE label and

conforms to the EMC Directive.

Warranty

According to current terms of sale and delivery.

This warranty only covers defects in manufacture and becomes void if

the instrument has been subject to unauthorized intervention and/or

misuse.

6 02-10-2009 125614 02

2.0 Safety instructions

Read this manual carefully before using

the instrument!

Please follow the instructions and procedures described in

this manual. They are aimed at allowing you to make the

best of your multi-scanner and avoid any personal injuries

and/or damage to the instrument.

Disposal – WEEE Directive

The multi-scanner contains Electrical and Electronic

circuits and must be properly recycled or disposed of (in

accordance with the WEEE Directive 2002/96/EC).

Warning

The multi-scanner has been designed to calibrate and

measure low voltage signals. To ensure the safety of the

operator and the instrument, DO NOT connect the multi-

scanner to input voltages above 30 Volts.

To avoid possible electric shock or personal injury:

The multi-scanner must not be used for any purposes

other than those described in this manual.

Do not operate the multi-scanner in environments of

explosive gas, vapour, or dust.

Do not apply more than the rated voltage. See

specifications for supported ranges.

Select the proper function and range for your

measurement.

Do not use the multi-scanner if it operates abnormally.

Protection may be impaired. When in doubt, get the

multi-scanner serviced.

Disconnect test leads before changing to another

measure or source function.

125614 02 02-10-2009 7

During set-up, make sure that there is correlation

between the software set-up, and the actual distribution

of the sensors connected to the multi-scanner. The

software cannot detect misplacements of sensors.

When servicing the multi-scanner, only use specified

replacement parts.

Caution…

To avoid possible damage to the multi-scanner or to

the equipment under test:

Disconnect the power and discharge all high-voltage

capacitors before testing resistance or continuity.

Use the proper connectors, function and range for your

measurement.

When using the switch test function, make sure that no

other equipment, such as heavy loads or sources, is

connected in the test loop.

Note…

The product liability only applies if the instrument is

subject to a manufacturing defect. This liability becomes

void if the user fails to follow the maintenance instructions

described in this manual or uses unauthorized spare parts.

8 02-10-2009 125614 02

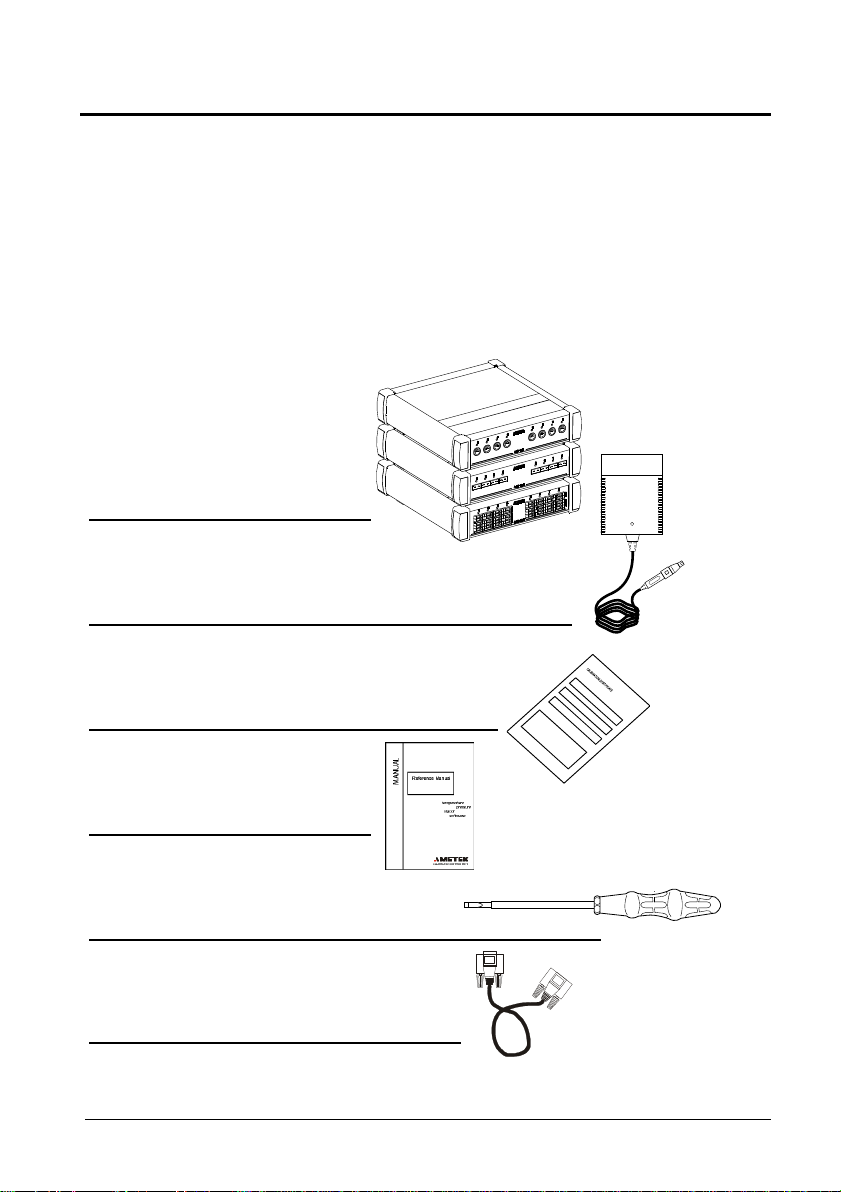

3.0 Receiving the multi-scanner

When you receive the instrument…

Unpack and check the multi-scanner and the accessories

carefully.

Check the parts according to the list shown below.

If any of the parts are missing or damaged, please contact the

dealer who sold you the multi-scanner.

You should receive:

1 multi-scanner

1 power supply

1 traceable certificate

1 reference manual

1 screw driver (ASM-801 only)

1 RS 232 serial cable

125614 02 02-10-2009 9

1 CD-ROM containing the software package

“JOFRACAL”.

When reordering, please specify the part numbers according

to the list of accessories, section. 11.0

10 02-10-2009 125614 02

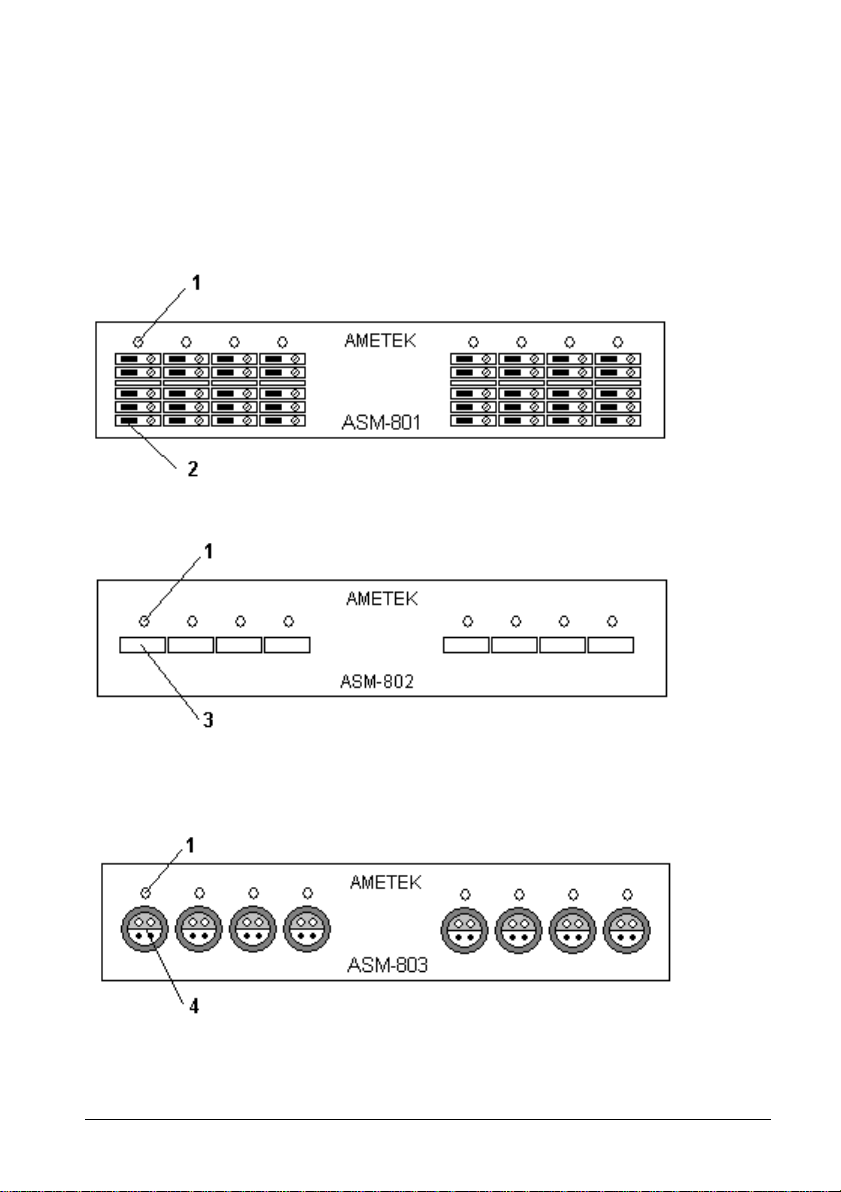

3.1 Multi-scanner models

The Advanced Signal Multi-scanner is available in 3 different models;

801, 802 and 803 in two different model versions – A and B.

Model ASM-801 with Multi input

Model ASM-802 with Mini-Thermocouple input

Model ASM-803 with LEMO input

125614 02 02-10-2009 11

Pos. Description

LED indicating which channel is being read. LED channel 1

1

will flash once a second when the Multi-scanner is ready

for operation.

2

Screw connection, max. wire size 2,5mm

2

Miniature thermocouple connector from OMEGA, type

3

.

SMP-U-F

Connector from LEMO, type ERA.1S.304.CLL

4

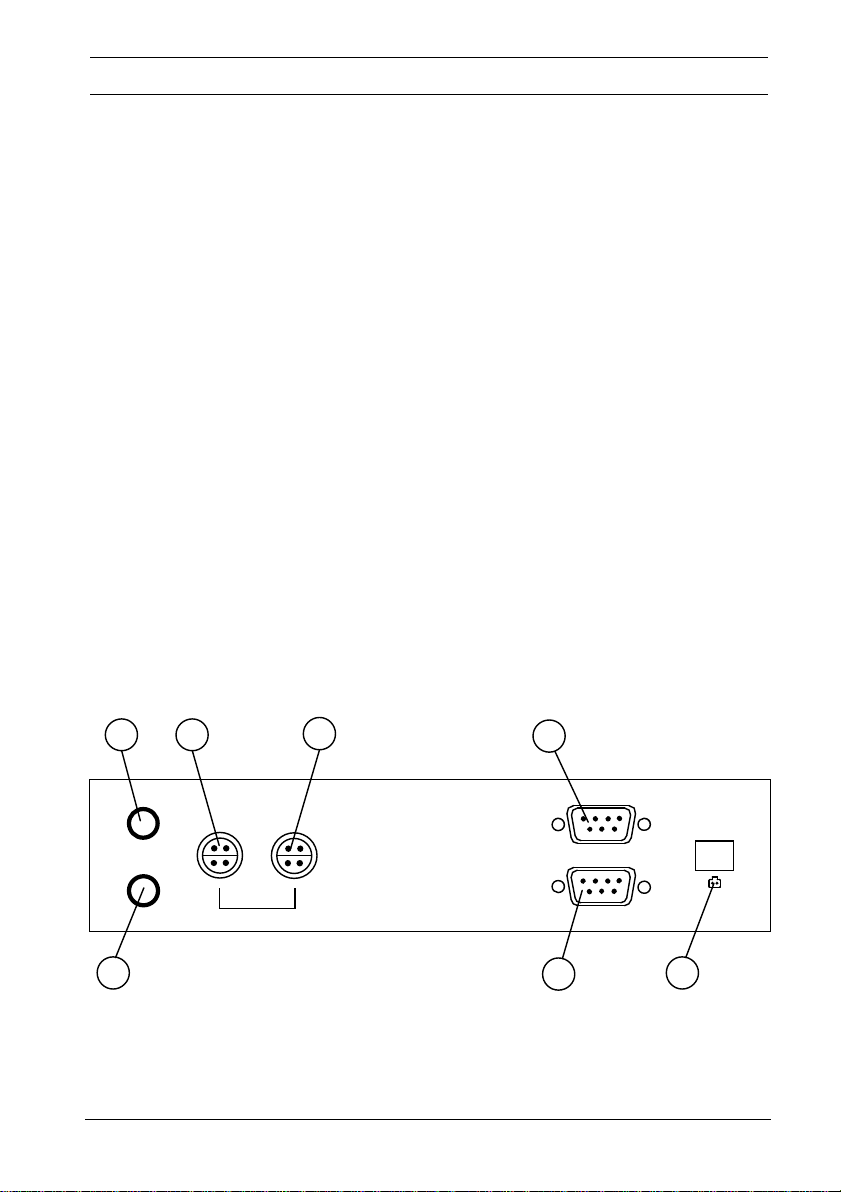

3.1.1 A Model version

The A version operates by connecting selected channels to a single

output channel. In order to collect measurements a measuring device

is connected to the output channel.

Apart from being controlled from a connected computer, the A version

can also be operated manually.

Depending on the type of measuring device connected to the

instrument, there is a certain settling time between channel shifts.

a

c

d

e

CHANNEL SELECT

UP

DOWN

ANALOG BUS

IN OUT

SLAVE

PC / MASTER

30V DC 0.5A

_

+

b

f

g

12 02-10-2009 125614 02

Pos. Description

Manual channel select; UP.

a

Manual channel select; DOWN

b

Holding down a and b will reset the instrument.

ANALOG BUS IN. If multiple multi-scanners are connected

c

in series, the analogue line out of the next instrument must

be connected here. For applications, see section 4.3.

ANALOG BUS OUT. Connect the measuring device here

d

or if multiple multi-scanners are connected in series,

connect the instrument in front to the ANALOG BUS OUT.

SLAVE. If multiple multi-scanners are connected in series,

e

the RS232 master line of the succeeding instrument must

be connected here. For applications, see section 4.3.

PC/Master. Connect the controlling computer here, or if

f

multiple multi-scanners are connected in series, connect

the instrument in front to the PC/MASTER.

30V DC 0.5A. Power supply connection.

g

Use only mains adapter supplied by AMETEK in order to

comply with the requirements in EN61326 (1997).

125614 02 02-10-2009 13

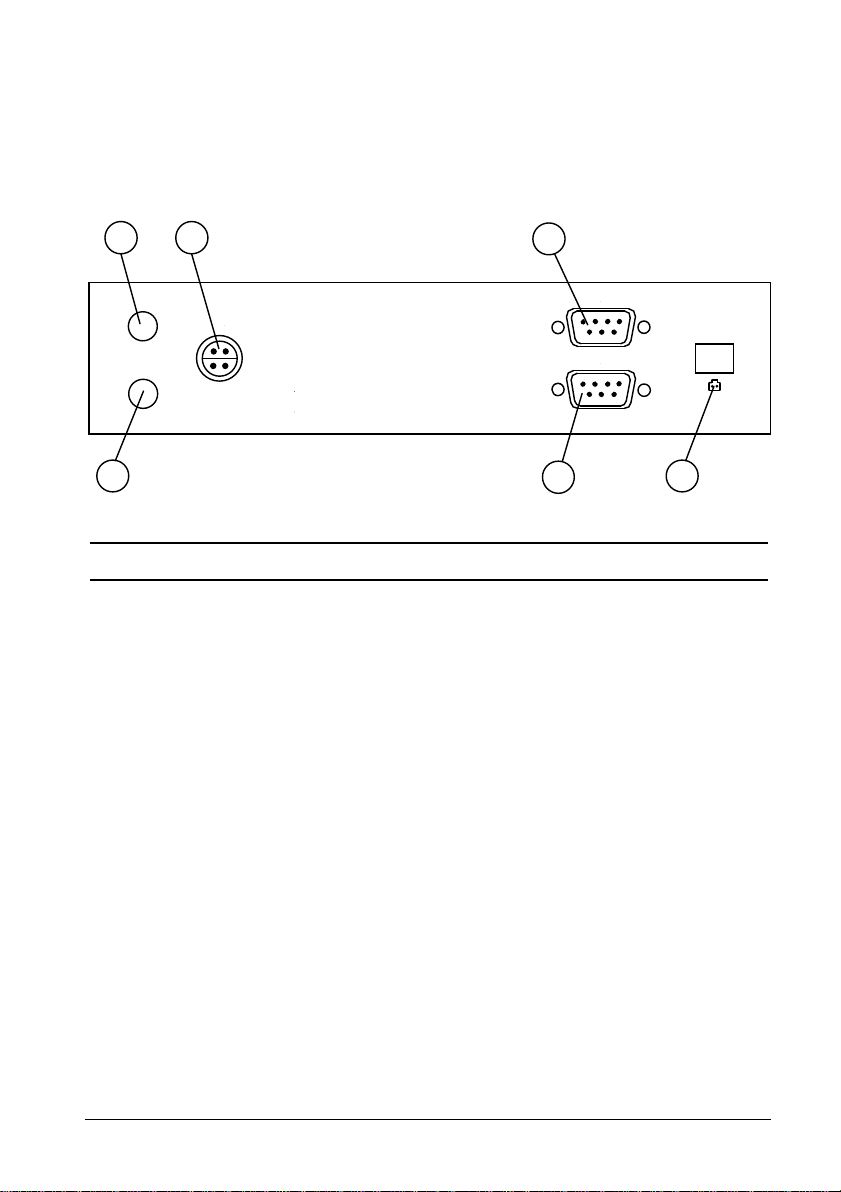

3.1.2 B Model version

The B version has the same functions as the A version, but it differs

as it is not necessary to include a measuring instrument to the set-up,

as the multi-scanner has built-in measuring capabilities.

a

c

e

ANALOG BUS

IN

SLAVE

PC / MASTER

30V DC 0.5A

_

+

b

f

g

Pos. Description

a + b

Holding down a and b will reset the instrument.

ANALOG BUS IN. If multiple multi-scanners are connected

c

in series, the analogue line out of the next instrument must

be connected here. For applications, see section 4.3.

SLAVE. If multiple multi-scanners are connected in series,

e

the RS232 master line of the succeeding instrument must

be connected here. For applications, see section 4.3.

PC/Master. Connect the controlling computer here or if

f

multiple multi-scanners are connected in series, connect

the instrument in front to the PC/MASTER.

30V DC 0.5A. Power supply connection.

g

Use only mains adapter supplied by AMETEK in order to

comply with the requirements in EN61326 (1997).

14 02-10-2009 125614 02

4.0 Setting up the multi-scanner

Warning

The multi-scanner must not be used for any purposes

other than those described in this manual.

Do not connect the multi-scanner to input voltages

above 30 Volts.

Do not operate the multi-scanner in environments of

explosive gas, vapour, or dust.

Do not apply more than the rated voltage/current. See

specifications for supported ranges.

Select the proper function and range for your

measurement.

Caution…

In case of resistive measurements, it is very important that

no capacities are present in the circuit loop. If present, they

must be discharged, before wires are connected to the

instrument.

When commencing the switch test, which is in fact a

resistive measurement, the thermostats must not be

connected to any other voltage source.

125614 02 02-10-2009 15

4.1 Preparing the multi-scanner

Connect RS232 cables and analog signal cables before the

DC power is applied.

Place the multi-scanner on an even stable surface where you intend

to use it. Make sure that the scanner is not subjected to temperature

fluctuations e.g. draught or sunlight.

Caution…

The multi-scanner can be set up to supply transmitters with

LED channel 1 flashes once every second when the multi-scanner is

ready.

24V max. 27mA.

When changing the set-up from one type of sensor to

another, especially when changing from transmitters to

other types of sensors, make sure that the multi-scanner is

reset.

The order in which the sensors are connected to the multiscanner makes no difference. When setting up the

instrument, via the control software, it is possible to choose

individually which channels to use. But what matters is

that there is consistency between where to connect the

sensor to the instrument and what to write in the controlling

software. Inconsistency would result in faulty

measurements or even possible damage to the sensors.

A constantly lit LED indicates which channel is currently being read.

Notice that the shifting of the internal relays can be heard when

setting up the multi-scanner and between channel shifts. This is not

an error.

16 02-10-2009 125614 02

4.2 Connecting sensors to the multi-scanner

A

E

Warning

Disconnect test leads before changing to another measure

or source function.

Caution…

For correct connection of sensors to the multi-scanner use the

diagrams below.

To avoid possible damage to the multi-scanner or to

the equipment under test:

Disconnect the power and discharge all high-voltage

capacitors before testing resistance or continuity.

Use the proper connectors, function and range for your

measurement.

When using the switch test function, make sure that no

other equipment, such as heavy loads or sources, is

connected in the test loop.

A

B

C

D

E

B

C

B

C

D

125614 02 02-10-2009 17

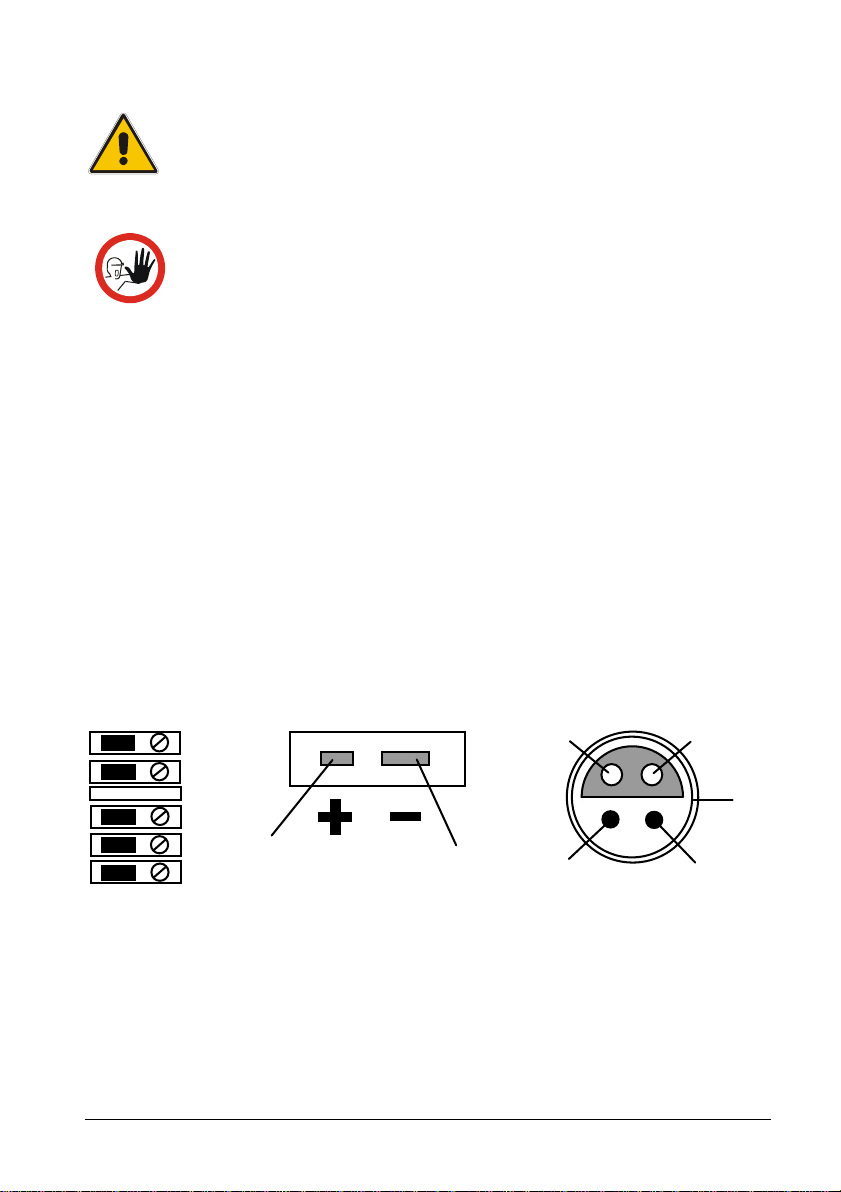

4.2.1 Connecting RTDs

A B -

2-wire

3-wire

4-wire

C D -

See section 10.0; Technical specifications for supported types of

RTDs. The calibrator accepts 2-, 3-, and 4-wire inputs, with the 4-wire

input being the most accurate.

4.2.2 Connecting Thermocouples and Voltages Sources

See section 10.0; Technical specifications for supported types of

thermocouples. The multi-scanner has a cold junction compensation

function. Normally this function should be ON and the actual

temperature of the thermocouple can be measured.

With CJC OFF, the multi-scanner will measure the difference

between the thermocouple at the junction and at its TC input terminal.

18 02-10-2009 125614 02

Note…

The multi-scanner is also able to measure the mV of a thermocouple,

which can be used along with a table if the corresponding TC type is

not supported by the multi-scanner.

For best accuracy wait, as a minimum, 5 minutes after

connecting the sensors, before any measurements are

taken. Do not apply heat to the plugs while measuring the

TC e.g. by touching them.

125614 02 02-10-2009 19

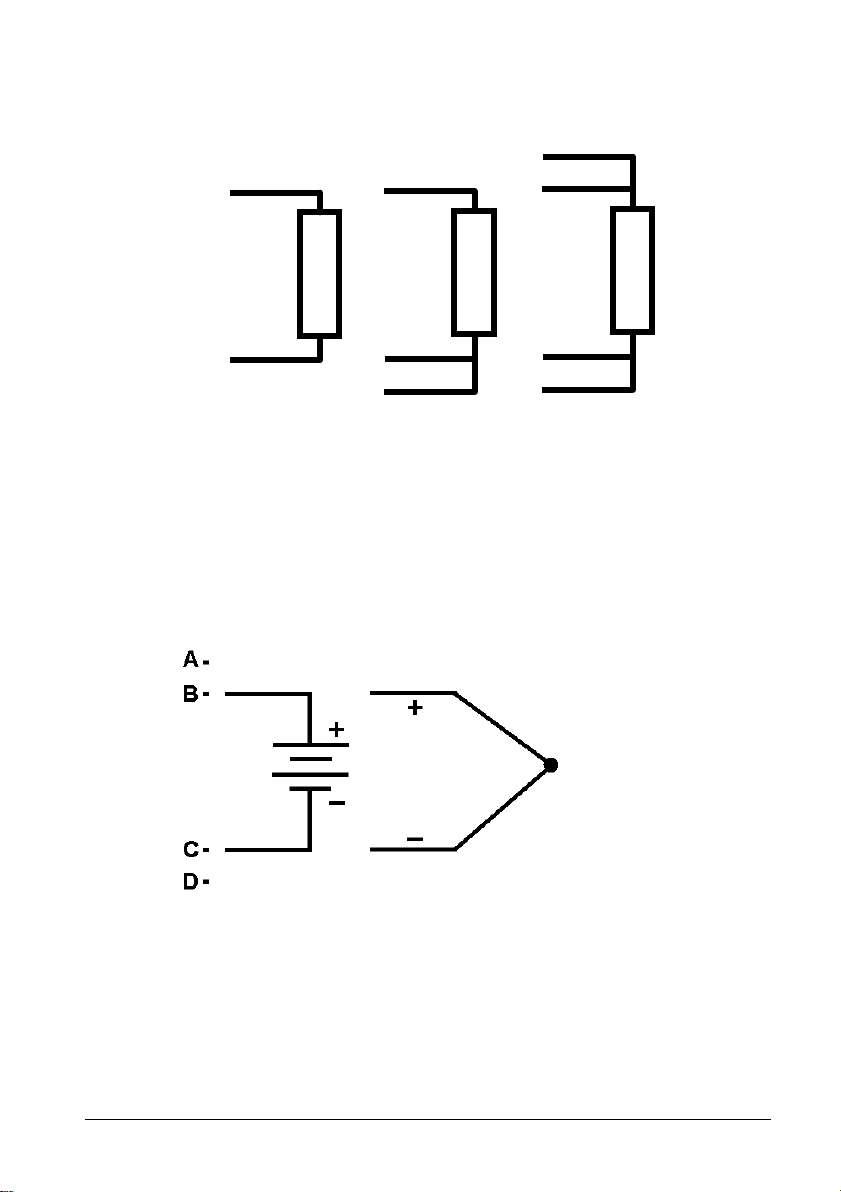

4.2.3 Connecting 4-20mA Transmitters

Connection a Connection b

Measuring current with loop power

In order to test a 2-wire loop powered transmitter, which is

disconnected from wiring, use the loop power function. This function

activates a 24V supply, in series with the current measuring.

Connect as shown on figure “Connection a”.

Measuring current without loop power

Transmitters with built-in supply or transmitters using external supply

are connected as shown on figure “Connection b”.

Measuring ground

E -

20 02-10-2009 125614 02

4.3 Cascading the multi-scanner

It is possible to connect up to 3 multi-scanners in series and build a

system, which enables you to measure up to 24 sensors

simultaneously.

The first multi-scanner to be placed after the PC can be either an Aor a B-model. Succeeding multi-scanners have to be A-models. It is

not possible to connect multiple B-models in series.

When the DC power has been connected to the multi-scanners and

the proper RS232 connection has been established between all the

instruments, the LED’s on channel 1 on all instruments involved will

flash simultaneously.

First model is a B-model, succeeding multi-scanners are Amodels

First model is an A-model, succeeding multi-scanners are Amodels

125614 02 02-10-2009 21

4.4 Connecting A-models to other instruments

A

E

The output from the ASM A-model is a LEMO ERA.1S.304.CLL

connector. For correct connection to other instruments, use the

diagram below.

For connecting A-models to other instruments, different cables can be

supplied.

Part no. 125534 Cable with male LEMO/LEMO connector can be

used to connect an ASM A-model to e.g. a JOFRA DTI-1000 or

JOFRA AMC-900.

Part no. 125587 Cable with mini compensation/LEMO connector can

be used to connect an ASM A-model to e.g. a JOFRA ASC300,

JOFRA AMC-900 JOFRA ATC-B models or other instruments with

mini compensation thermocouple connectors.

Part no. 122823 Cable with banana/LEMO connector can be used to

connect an ASM A-model to e.g. a JOFRA ASC300, JOFRA AMC900, JOFRA ATC-B models or other instruments with a safety 4 mm

banana sockets. For correct connection, use the diagram below.

For connecting A-models to other ASM's, use 125618, cable kit.

B

C

Brown

White

Yellow

Green

Red

Red

Black

Black

D

Green

A

B

C

D

E

22 02-10-2009 125614 02

5.0 Operating the multi-scanner

5.1 Manual operation

A-models

The push buttons on the back of the A-models can be used for

manual channel shift. When LED 1 is flashing no channel is selected.

These buttons will enable the user to operate the instrument without

using a connected computer.

Supplying transmitters is not possible during manual operation.

Press both push buttons for two seconds and the multi-scanner will

reset itself.

Warning

Do not use the multi-scanner if it operates abnormally.

Protection may be impaired. When in doubt, get the

multi-scanner serviced.

When servicing the multi-scanner, only use specified

replacement parts

Push buttons for manual channel shift

CHANNEL SELECT

UP

DOWN

ANALOG BUS

IN OUT

125614 02 02-10-2009 23

B-models

Push buttons for resetting

the instrument

ANALOG BUS

IN

The push buttons on the back of the B-models can only be used to

reset the instrument.

Press both push buttons down for two seconds and the multi-scanner

will reset itself.

5.2 Operation with JOFRACAL

Both A- and B-models are operated by means of the sensor test and

calibration software, AMETEK Denmark A/S JOFRACAL. The

program is included on the enclosed CD.

For introduction and use of the program, the user is advised to read

the user manual included on the CD. All possibilities and limits of the

program are described in the manual.

24 02-10-2009 125614 02

6.0 Remote operation

The ASM can be remotely controlled using a PC terminal, or by a

computer program running the calibrator in an automated system. It

uses an RS-232 serial port connection for remote operation. With this

connection the user can write programs on the PC, with Windows

languages like Visual Basic to operate the calibrator, or use a

Windows terminal, such as Hyper Terminal, to enter single

commands.

6.1 Setting up the RS-232 Port for Remote

Control

Note: The RS-232 connection cable should not exceed 15m unless

the load capacitance measured at connection points is less than

2500pF.

Serial parameter values:

115200 baud

8 data bits

1 stop bit

no parity

Xon/Xoff

EOL (End of Line) character or CR (Carriage Return) or

both

To set up remote operation of the calibrator on the Windows Hyper

Terminal, connected to a COM port on the PC, use the following

procedure:

1. Start Hyper Terminal (located in Accessories/

Communications of the Windows Start menu)

2. Select New Connection.

3. For Name enter ASM-80x. Select the serial port that the unit

is connected to.

4. Enter the above information for port settings.

125614 02 02-10-2009 25

5. Select ASCII setup from File/Properties/Settings and mark

these choices:

Echo typed characters locally

Wrap lines that exceed terminal width

6. Select Ok

7. To see if the port works enter *IDN?. This command will

return information on the unit.

6.2 Units

6.2.1 Temperature units

CEL = °C

KEL = K

FAR = °F

6.2.2 Electrical units

V = volts

OHMS = ohms

A = amps

Hz = Hertz

MV = 10

KOHMS = 10

-3

V

3

OHMS

6.3 Commands

6.3.1 *CLS

SCPI standard command (Clear Status).

Clears the ESE, ESR, SRE and STB registers, i.e. set them to 0.

6.3.2 *ESE <reg val>

SCPI standard command (standard Event Status Enable).

26 02-10-2009 125614 02

Set the Event Status Enable register, which is a 8-bit register, i.e. a

value between 0 and 255 must be specified as argument

6.3.3 *ESE?

SCPI standard command (standard Event Status Enable query).

Outputs the value of the Event Status Enable register.

6.3.4 *ESR?

SCPI standard command (standard Event Status Register query).

Outputs the value of the Event Status Register.

This implementation supports the following bits in the ESR register (if

enabled with the ESE register):

Power ON (PON, bit 7): This bit is set to 1 after power up.

Command Error (CME, bit 5): This bit is set when an unknown

command has been received or a known command with

wrong arguments has been received.

EXE (bit 4): This bit is set when an error during the execution

of a command has occurred.

Operation Complete (OPC, bit 0): Is set whenever a command

has been executed.

The events in the ESR register are cleared after a read.

6.3.5 *IDN?

SCPI standard command (Identification query). Return information for

the unit in the format <manufacture>,<model>,<serial#>,<version>,

e.g.:

AMETEK,ASM801A,123456-12345, 1.00

6.3.6 *OPC

SCPI standard command (Operation Complete).

Because the system only implements sequential commands this

command will immediately set the OPC bit in the Event Status

Register when the command is executed.

125614 02 02-10-2009 27

6.3.7 *OPC?

SCPI standard command (Operation Complete query).

Because the system only implements sequential commands this

command will immediately output a “1” when the command is

executed.

6.3.8 *RST

SCPI standard command (Reset). In this implementation the

execution of this commands correspond to a power off/on.

6.3.9 *SRE <reg val>

SCPI standard command (Service Request Enable).

Set the Service Request Enable register, which is a 8-bit register, i.e.

a value between 0 and 255 must be specified as argument.

6.3.10 *SRE?

SCPI standard command (Service Request Enable query).

Outputs the value of the Service Request Enable register.

6.3.11 *STB?

SCPI standard command (Status Byte query).

Outputs the value of the Status Byte register. In this implementation

only the ESB bit (Event Summary Bit) is used, i.e. the MAV bit

(Message Available) and RQS/MSS bit is always set to 0.

The ESB bit is set if one of the enabled events in the ESR register

has occurred since last read of the STB register. The ESB bit is

always cleared after a read.

6.3.12 *TST?

SCPI standard command (Self-Test). In this implementation no selftest is performed when executing this command, i.e. this command

always return OK.

28 02-10-2009 125614 02

6.3.13 *WAI

SCPI standard command (Wait-to-continue).

Because the system only implements sequential commands this

command has no functionality.

6.3.14 SYSTEM_IDN?

Returns IDN-information for all ASM-units connected in a format like

the *IDN-command. However, it is extended with the box number (fist

field) and calibration date (last field), e.g.:

1,AMETEK,ASM801B,123456-11111,0.01,2005-06-28

2,AMETEK,ASM802A,123456-22222,0.01,2005-06-28

3,AMETEK,ASM803A,123456-33333,0.01,2005-06-28

6.3.15 SYS_CONF

SYS_CONF <Freq.> Hz,<Speed>

<Freq> = 50, 60

<Speed> = 1,2,3,4

Sets up A/D converter speed/filters in all connected units. The speed

parameter is only used by B-models. However, the speed parameter

must always be specified.

Default settings at power up is 50 Hz and speed 1.

6.3.16 SYS_CONF?

Returns the actual SYS_CONF configuration.

Example 50 Hz, 3

If the connected units have different configurations “ERROR” will be

returned.

125614 02 02-10-2009 29

6.3.17 TEMP_UNIT

TEMP_UNIT <temp. unit>

<temp. unit> = CEL, FAR, KEL

Sets temperature unit in all connected units. Default setting at power

up is CEL.

6.3.18 TEMP_UNIT?

Returns temperature unit: <temp. unit> = CEL, FAR, KEL

If the connected units have different configurations “ERROR” will be

returned.

6.3.19 CH_CONF

Configures the channels.

CH_CONF DCV (@<ch_list>)

Sets the selected for measuring voltage.

Example: CH_CONF DCV (@2)

CH_CONF DCV, <Range low> V, <Range high> V, <Temperature

low> <temp. unit>, <Temperature high> <temp. unit>

(@<ch_list>)

Sets the selected for measuring voltage transmitter (T/V)

<Range low> = V_LOW_XX = 0.000 [V] (default value)

<Range high> = V_HIGH_XX = 10.000 [V] (default value)

<Temperature low> = V_TEMP_LOW_XX = 0 [°C] (default value)

<Temperature high> = V_TEMP_HIGH_XX = 100 [°C] (default value)

CH_CONF MA (@<ch_list>)

Sets the selected channels for measuring current

CH_CONF MA, <Range low> A, <Range high> A, <Temperature

low> <temp. unit> , <Temperature high> <temp. unit>

(@<ch_list>)

Sets the selected channels for measuring current transmitter (T/I)

30 02-10-2009 125614 02

<Range low> = MA_LOW_XX = 0.004 [A] (default value)

<Range high> = MA_HIGH_XX = 0.020 [A] (default value)

<Temperature low> = MA_TEMP_LOW_XX = 0 [°C] (default value)

<Temperature high> = MA_TEMP_HIGH_XX = 100 [°C] (default

value)

CH_CONF MV (@<ch_list>)

Sets the selected for measuring mV.

CH_CONF <TC type>, <CJC type>, <Manuel CJC temperature>

<temp. unit>, <A>, <B>, <C> (@<ch_list>)

Sets the selected channels for measuring thermocouple

<TC type> can be : J, K, T, E, R, S, B, XK, BP, L, U, N,

CUSTOM J,

CUSTOM K,

CUSTOM T,

CUSTOM E,

CUSTOM R,

CUSTOM S,

CUSTOM B,

CUSTOM XK,

CUSTOM BP,

CUSTOM L,

CUSTOM U,

CUSTOM N

<CJC type> can be : INT, EXT, MAN

<Manuel CJC temperature> is only used with <CJC type> = MAN

<A>, <B>, <C> is only used for CUSTOM types for calculating a

compensated thermocouple voltage before converting to temperature:

Ucomp [V] = A + B * Utc[V] + C * Utc[V] * Utc[V].

CH_CONF <RTD type>, <wires>, <Custom Serial. No.>,

<R0/RTPW>, <A/ALR>, <B/BLR>, <C/C1LR>, <C2LR>, <C3LR>,

<C4LR>, <C5LR>,<AHR>, <BHR>, <CHR>, <DHR>, <W660>

(@<ch_list>)

Sets the selected channels for measuring RTD

125614 02 02-10-2009 31

<RTD type> can be: Ohms 400

Ohms 4000

CUSTOM

CUSTOM ITS-90

CUSTOM CvD

P10(90)385

P50(90)385

P100(90)385

P200(90)385

P500(90)385

P1K(90)385

P100(90)392

H120(90)672

M50(90)428

M100(90)428

YSI(90)400

<wires> can be: 2, 3, 4

<Custom Serial. No.>, <R0/RTPW>, <A/ALR>, <B/BLR>, <C/C1LR>

is only used for <RTD type> = Custom CvD.

<Custom Serial. No.>, <R0/RTPW>, <A/ALR>, <B/BLR>, <C/C1LR>,

<C2LR>, <C3LR>, <C4LR>, <C5LR>,<AHR>, <BHR>, <CHR>,

<DHR>, <W660> is only used for <RTD type> = Custom ITS-90.

<Custom Serial. No.> can be up to 16 characters.

CUSTOM activates the stored values for either CUSTOM CVD or

CUSTOM ITS-90.

CH_CONF SWITCH (@<ch_list>)

Set the selected channels to be a switch sensor.

6.3.20 CH_CONF? (@<channel>)

Returns the configuration of the current channel.

- DCV

- DCV, <Range low> V, <Range high> V, <Temperature low> <temp.

unit>, <Temperature high> <temp. unit>

32 02-10-2009 125614 02

- MA

- MA, <Range low> A, <Range high> A, <Temperature low> <temp.

unit> , <Temperature high> <temp. unit>

- MV

- <TC type>, <CJC type>, <Manuel CJC temperature> <temp. unit>

- <RTD type>, <wires>, <Custom Serial. No.>, <R0/RTPW>,

<A/ALR>, <B/BLR>, <C/CLR>, <AHR>, <BHR>, <CHR>, <DHR>,

<W660>

- SWITCH

6.3.21 VAL? (@<ch_list >)

Returns the value of the selected channels. Before this command

could be used the specified channels must be selected with the

CH_SCAN command. The value returned is based on the last

periodic scan.

For A-models the returned value is the CJC-temperature. The value

can have the following units : ohms, mV, V, mA, CEL, FAR, KEL.

For sensortype = SWITCH the returned value is =0 or 1 where

1=OPEN and 0=CLOSED.

6.3.22 CH_SCAN (@<ch_list>)

Starts scanning of the selected channels.

6.3.23 CH_SCAN_STOP

Stop scanning.

6.3.24 CH_SCAN?

Returns a list of the selected channels.

6.3.25 CAL_DATE

Used for downloading calibration date in all units connected. The data

must be in the format YYYY-MM-DD, e.g. 2005-06-28. Year must be

in the range 2005..2099.

125614 02 02-10-2009 33

7.0 Maintenance

7.1 Storing

It is not necessary to store away the multi-scanner after use.

The instrument can be part of a continuous set-up, as long as it is

kept in a dry, clean place.

7.2 Cleaning

Clean the outer surface of the instrument by using water and a soft

cloth. A mild detergent can be used along with the water.

Caution…

Before cleaning the multi-scanner, you must switch it off.

Caution…

The cloth must be firmly wrung to avoid any water

penetrating the instrument and causing damage.

7.3 Returning the multi-scanner to service

If the multi-scanner continuously malfunctions, verify that the

instrument is being operated as described in this manual and return it

to the manufacturer for repair/service.

When returning the instrument please enclose a fully completed

service information form. Simply copy the “Service info” form on page

36 and fill in the required information.

The multi-scanner should be returned in the original packing.

34 02-10-2009 125614 02

Only qualified service personnel should perform calibration, repairs,

or service not covered by this manual.

Note…

AMETEK Denmark’s liability ceases if:

parts are replaced/repaired using spare parts, which are

not identical to those recommended by the

manufacturer.

non-original parts are used in any way when operating

the instrument.

AMETEK Denmark’s liability is restricted to errors originated

from the factory.

125614 02 02-10-2009 35

Service info

Customer data: Date:

Customer name and address:___________________________________________

Attention and dept.:___________________________________________________

Fax no./phone no.:____________________________________________________

Your order no.:_______________________________________________________

Delivery address:_____________________________________________________

Distributor name:_____________________________________________________

Instrument data:

Model and serial no.:__________________________________________________

Warranty claimed Yes:____ No:_____ Original invoice no.:_________________

___________________________________________________________________

Temp. Sensor Service request: This instrument is sent for

calibration input (please check off):

___ Calibration as left ___ Check

___ Calibration as found and as left ___ Service

___ Accredited calibration as left ___ Repair

___ Accredited calibration as found and as left.

___________________________________________________________________

Diagnosis data/cause for return:

Diagnosis/fault description:_____________________________________________

___________________________________________________________________

Special requests:_____________________________________________________

___________________________________________________________________

Safety precautions: if the product has been exposed to any hazardous substances, it must be

thoroughly decontaminated before it is returned to AMETEK Denmark A/S. Details of the

hazardous substances and any precautions to be taken must be enclosed.

36 02-10-2009 125614 02

8.0 Errors

If the power is lost to the entire test set-up or part of it, it is highly

recommended to restart the calibration.

GENERAL ERRORS

Error description Solution

Warning

During set-up, make sure that there is correlation between

the software set-up, and the actual distribution of the sensors

connected to the multi-scanner. The software cannot detect

misplacements of sensors.

LED channel 1 does not flash :

Faulty readout :

No contact with the multi-

scanner :

125614 02 02-10-2009 37

Check the power supply

Switch the multi-scanner off and on

again

If the error still occurs, return the

multi-scanner to the manufacturer for

service

Check that the connected sensors are

correctly connected and that they are

properly polarised

Check that the software is set up

correctly

Switch the multi-scanner off and on

again

If the error still occurs, return the

multi-scanner to the manufacturer for

service

Check the power supply

Check the RS232 connection. Use

only the supplied cable

Switch the multi-scanner off and on

again - and set up the software again

If the error still occurs, return the

multi-scanner to the manufacturer for

service

When using Hyper Terminal or similar

terminal programs, and communications

fails, check that the program has been set

up correctly.

Faulty readout from

thermocouples:

Check that the correct type has been

selected during setup

Check that the sensors have been

correctly polarised and connected

Check that the correct type of cold

junction has been selected

manually/automatically

Check that the multi-scanner is not

subjected to direct or indirect heat

sources

ERRORS – SERIES CONNECTED MULTI-SCANNERS

Error description Solution

LED’s does not flash

simultaneously on all channel

1’s :

Faulty readout :

Check the RS232 connection. Use

only the supplied cables

Switch the multi-scanners off and on

again

Check that the connected sensors are

correctly connected and that they are

properly polarised

Check that the software is set up

correctly

Check that analog connection

between the multi-scanners has been

properly established

Switch the multi-scanners off and on

again, and set up the software again

38 02-10-2009 125614 02

9.0 Adjusting the multi-scanner

9.1 Adjusting and calibrating the instrument

You are advised to return the instrument to AMETEK Denmark A/S or

an accredited laboratory at least once a year for calibration and

adjustment.

Alternatively, you can calibrate/adjust the instrument yourself

using the AMETRIM Adjust and Calibration Software.

9.2 Introduction to AMETRIM Software

This software is supplied on the JOFRACAL CD-ROM. It can be run

directly from this CD-ROM and requires no special installation.

It is possible to make a disk containing the AMETRIM software. From

this disk AMETRIM can be installed on the hard disk of the computer,

but the disk has to be in the disk drive when running the software.

To use the software, you need:

PC hardware requirements

IBM compatible PC with 486 or higher processor (Pentium

MHz recommended).

32 MB of RAM (64 MB recommended).

40 MB available hard-disk space.

Standard VGA monitor (800 x 600, 256 colours), (1024 x 768

recommended).

CD-ROM drive.

One vacant RS 232 Serial Port.

PC software requirements

Microsoft Windows

Windows

®

2000, Microsoft Windows® ME, Microsoft Windows®

®

98, Microsoft Windows® NT 4.0, Microsoft

XP.

System font: MS Sans Serif and Arial.

TM

200

125614 02 02-10-2009 39

9.2.1 Installing the AMETRIM Software

The software comes on a CD-ROM and is ready to run – no

installation is required. Simply insert the CD-ROM and run the ATCadjustment program.

9.2.2 Connecting the PC and the ASM-80x

Caution…

1. Ensure that both the PC and the ASM-80x are switched

off at the mains. Failure to do so may result in your

equipment being damaged.

2. Connect the serial cable provided to the “RS 232” port on

the front of the ASM-80x and to the COM port on the PC.

3. Switch on the PC and the ASM-80x.

9.2.3 Starting the AMETRIM Software

Note…

Before starting this software, the PC and the ASM-80x

must be connected together and the ASM-80x switched on.

40 02-10-2009 125614 02

Use the normal Windows procedure to start the AMETRIM

software.

If you are unsure of how to start software programs, refer to

your Windows Help

In the main menu select “Run Program” to start the

calibration.

Select “ASM-80x” and “Comport” in the “Device Quick

Connect” dialog box and press “Connect”.

125614 02 02-10-2009 41

If the ASM-80x is not switched on or is not connected to the

selected port, then the software returns to the AMETRIM

adjustment software main menu.

As the software starts, it detects the type of instrument

connected to the PC and reads its serial number.

This information plus the COM port the calibrator is

connected to is displayed at the bottom of the AMETRIM

window.

If the calibrator is not switched on or is not one of the

models covered by this manual, then the software closes

automatically.

9.2.4 Run calibration/adjustment

This option allows you to check the accuracy of the ASM-80x

electrical inputs. You will require a calibrated reference signal source.

42 02-10-2009 125614 02

For Cold Junction compensation, you will also require a stable

temperature source, for example an ice bath, and a conversion table

to provide the sensor’s corresponding V value for the bath’s

temperature.

Note…

Before calibrating/adjusting the inputs, the ASM-80x must

have been turned on for at least half an hour.

In order to calibrate the inputs the following calibrated signals must be

used:

Nominal values Accepted range

RTD Input:

50Ω (20 to 70Ω)

176Ω (150 to 200Ω)

360Ω (330 to 390Ω)

1760Ω (1500 to 2000Ω)

3600Ω (3300 to 3900Ω)

mA inputs:

0 mA (-1 to +1 mA)

10 mA (9 to 11 mA)

20 mA (18 to 22 mA)

V Inputs:

0 V (-1 to +1 V)

5 V (3 to 7 V)

10 V (9 to 11 V)

mV inputs:

0 mV (-1 to +1 mV)

35 mV (25 to 45 mV)

70 mV (63 to 77 mV)

Cold Junction compensation: T-type thermocouple and a

reference junction, for example an

ice bath.

125614 02 02-10-2009 43

The number and type of electrical inputs to be checked is userdefinable. You can also define if you want to check the inputs by just

measuring them, adjust and calibrate or to measure, adjust and then

calibrate the electrical inputs.

Cold Junction compensation requires a special setup, using a

calibrated thermocouple and temperature source, for example an ice

bath. This and the measurement principles are shown briefly below:

Container with ice

0°C reference

Principle sketch

If at any point you do not wish to continue, click Stop. The software

exits this option and returns to the Main Menu.

44 02-10-2009 125614 02

In AMETRIM main menu, click Run calibration/adjustment.

By clicking the Calibration dates button, you can view the

last calibration date.

9.2.5 To calibrate the ASM-80x

125614 02 02-10-2009 45

Click the radio button Only measuring.

Use the check box list to select the inputs to be measured.

For A-models, only CJ-Comp. Can be selected.

Use the check box list to select the input types to be

measured.

Connect the reference signal source to the appropriate

channel when prompted.

Click Start and follow the instructions on screen.

The software starts measuring the first of the selected inputs.

Ensure that the correct reference signal source is connected

when prompted.

When all the selected inputs have been measured a new

dialogue appears.

Type a unique name for the measurements. Click As found

and ensure that the date is correct. This information will

appear in a measurement report displayed on screen.

9.2.6 To adjust and calibrate (as left) the ASM-80x

Click OK to view the measurement report.

Note…

These results are not saved electronically. If you require a

record of these measurements, click Print while it is

displayed.

When you are finished viewing or printing the report, click

Close. This returns you to the first dialogue in the

Temperature adjustment option.

If you do not require any further measurements, click Done

to return to the Main Menu.

Note…

If you select Cold Junction compensation, either you must

also select the mV (TC) Input or be sure that the mV(TC)

range is calibrated.

Click the radio button Adjust/Calibrate.

Use the check box list to select the inputs to be measured.

If you have selected more than one check box, the

measurements occur in the same order as they appear in the

check box list.

46 02-10-2009 125614 02

Connect the reference signal source to the appropriate

channel (when prompted).

Click Start and follow the instructions on screen.

Each input has several pre-set input values. Ensure that the

reference signal source is adjusted correctly when

prompted.

For Cold Junction compensation, ensure the corresponding

V value for the calibrated junction temperature is entered

(0V @ 0C).

The software measures the pre-set values for the selected

input, adjusts the settings and then re-calibrates the

calibrator’s inputs. All this is done before moving on to the

next selected input.

When all the selected inputs have been measured, adjusted

and re-calibrated a new dialogue appears.

125614 02 02-10-2009 47

Type a unique name for the measurements. Click As left

and ensure that the date is correct. This information will

appear in a measurement report displayed on screen.

Click OK to view the measurement report.

Note…

These results are not saved electronically. If you require a

record of these measurements, click Print while the report

is displayed.

When you are finished viewing or printing the report, click

Close. This returns you to the first dialogue in the

Temperature adjustment option.

9.2.7 To calibrate (as found), adjust and calibrate (as left) the

ASM-80x

If you do not require any further measurements, click Done

to return to the Main Menu.

Note…

If you select Cold Junction compensation, either you must

also select the mV (TC) Input or be sure that the mV(TC)

range is calibrated.

Click the radio button Measure/Adjust/Calibrate.

Use the check box list to select the inputs to be measured.

If you have selected more than one check box, the

measurements occur in the same order as they appear in

the check box list.

Connect the reference signal source to the appropriate

channel (when prompted).

Click Start and follow the instructions on screen.

Each input has several pre-set input values. Ensure that the

reference signal source is adjusted correctly when

prompted.

For Cold Junction compensation, ensure the corresponding

V value for the calibrated junction temperature is entered

(0V @ 0C).

48 02-10-2009 125614 02

The software measures the pre-set values for the selected

input, adjusts the settings and then re-calibrates the

calibrator’s inputs. All this is done before moving on to the

next selected input.

When all the selected inputs have been measured, adjusted

and re-calibrated a new dialogue appears.

Type a unique name for the measurements. Click As left

and ensure that the date is correct. This information will

appear in a measurement report displayed on screen.

Click OK to view the measurement report.

Note…

These results are not saved electronically. If you require a

record of these measurements, click Print while the report

is displayed.

When you are finished viewing or printing the report, click

Close. This returns you to the first dialogue in the

Temperature adjustment option.

9.2.8 Setup Printer

This option provides a standard Windows procedure which enables

you to edit the settings for the current printer or change to another

printer.

If you are unsure how to use these settings, refer to your Windows

Help.

125614 02 02-10-2009 49

If you do not require any further measurements, click Done

to return to the Main Menu.

10.0 Technical specifications

Input specifications1

1

All specifications are given with an ambient temperature of 23±3°C /

73.4±5.4°F

ASM-801 B / ASM-803 B and B+A/B+A +A combinat ions only

Description Value

Signal range : 0 – 24mA

Internal power supply : 24V, max. 28mA

Display resolution : 0.0001mA / 0.001°C / 0.001°F

Accuracy : ±(0.010% of rdg. + 0.010% of F.S.)

Temperature coefficient,

outside 23±3°C /

73.4±5.4°F : 7 ppm/°C

Input impedance : <10

ASM-801 B / ASM-802 B / ASM-803 B and B+A/B+A+A combinations only

Description Value

Signal range : 0 – 12V

Display resolution : 0.0001V / 0.001°C / 0.001°F

Accuracy : ±(0.005% of rdg. + 0.010% of F.S.)

Temperature coefficient,

outside 23±3°C /

73.4±5.4°F : 5 ppm/°C

Input impedance : >1M

50 02-10-2009 125614 02

ASM-801 B / ASM-802 B / ASM-803 B and B+A/B+A+A combinations only

Description Value

Signal range : -10mV – 78mV

Display resolution : 0.0001mV / 0.001°C / 0.001°F

Accuracy : ±(0.005% of rdg. + 0.005% of F.S.)

Temperature coefficient,

outside 23±3°C /

73.4±5.4°F : 5 ppm/°C

Input impedance : >1M

ASM-801 B / ASM-803 B and B+A/B+A +A combinat ions only

Description Value

Signal range : 0 - 400

0 - 4000

Internal power supply : Excitation current 0.8mA (0-400) / 0.15mA (0-4000)

Display resolution : 0.0001 / 0.001°C / 0.001°F

0.001 / 0.001°C / 0.001°F

Accuracy : 0-400 (PT10/PT50/PT100)

4-wire : ±(0.002% of rdg. + 0.002% of F.S.)

3-wire: ±(0.002% of rdg. + 0.002% of F.S. + 50m)

2-wire: ±(0.002% of rdg. + 0.002% of F.S. + 100m)

0-4000 (PT500/PT1000)

4-wire : ±(0.002% of rdg. + 0.005% of F.S.)

3-wire: ±(0.002% of rdg. + 0.005% of F.S. + 50m)

2-wire: ±(0.002% of rdg. + 0.005% of F.S. + 100m)

Temperature coefficient,

outside 23±3°C /

73.4±5.4°F : 0 - 400 : 5 ppm/°C

0 - 4000 : 10 ppm/°C

125614 02 02-10-2009 51

ASM-801 B / ASM-803 B and B+A/B+A +A combinat ions only

Description Value

Signal type : Switch test

Signal range : on : 0 – 1k / off : >3k

Internal power supply : 2.5V (open)

A-models when used with other equipment

Description Value

RTD 4-wire : 2.5 ppm rdg. (0 - 400)

15 ppm rdg. (400 - 4000)

RTD 3-wire : 2.5 ppm rdg. +50 m (0 - 400)

15 ppm rdg. +50 m (400 - 4000)

mA : 1 ppm rdg. (0 – 24mA)

mV, V : 2uV

All models

Description Value

Accuracy automatic cold

Junction compensation;

ASM-801/802 A/B : ±0.20°C (±0.36°F) @ ambient temp. 20°C to 26°C

(68°F to 78.8°F)

ASM-803 A/B : ±0.50°C (±0.9°F) @ ambient temp. 20°C to 26°C

(68°F to 78.8°F)

Temperature coefficient : 0.05°C/°C (0.05°F/°F) outside 20°C to 26°C

52 02-10-2009 125614 02

TC Type

From To From To

B

E

J

K

Temperature range 12 month accuracy

°C °F °C °F

250 320 482 608 1,31 2,35

320 420 608 788 0,99 1,77

420 660 788 1220 0,65 1,17

660 800 1220 1472 0,56 1,01

800 1000 1472 1832 0,44 0,78

1000 1200 1832 2192 0,41 0,74

1200 1400 2192 2552 0,39 0,70

1400 1600 2552 2912 0,38 0,60

1600 1820 2912 3308 0,40 0,72

-250 -200 -418 -328 0,74 1,34

-200 -100 -328 -148 0,18 0,32

-100 0 -148 32 0,09 0,17

0 155 32 311 0,06 0,11

155 320 311 608 0,06 0,12

320 420 608 788 0,07 0,12

420 660 788 1220 0,08 0,14

660 800 1220 1472 0,09 0,16

800 1000 1472 1832 0,10 0,19

-210 -100 -346 -148 0,23 0,41

-100 0 -148 32 0,10 0,18

0 155 32 311 0,08 0,14

155 320 311 608 0,09 0,16

320 420 608 788 0,09 0,17

420 660 788 1220 0,09 0,17

660 800 1220 1472 0,09 0,17

800 1000 1472 1832 0,11 0,21

1000 1200 1832 2192 0,13 0,23

-250 -200 -418 -328 0,94 1,69

-200 -100 -328 -148 0,27 0,49

-100 0 -148 32 0,14 0,24

0 155 32 311 0,10 0,19

155 320 311 608 0,11 0,20

320 420 608 788 0,11 0,20

420 660 788 1220 0,13 0,23

660 800 1220 1472 0,14 0,24

800 1000 1472 1832 0,15 0,28

1000 1200 1832 2192 0,17 0,31

1200 1372 2192 2501,6 0,20 0,36

125614 02 02-10-2009 53

TC Type

From To From To

N

R

S

T

Temperature range 12 month accuracy

°C °F °C °F

-250 -200 -418 -328 1,37 2,47

-200 -100 -328 -148 0,41 0,74

-100 0 -148 32 0,20 0,35

0 155 32 311 0,15 0,27

155 320 311 608 0,13 0,23

320 420 608 788 0,12 0,22

420 660 788 1220 0,13 0,23

660 800 1220 1472 0,14 0,25

800 1000 1472 1832 0,15 0,27

1000 1200 1832 2192 0,16 0,29

1200 1300 2192 2372 0,17 0,31

-50 0 -58 32 1,30 2,35

0 155 32 311 0,78 1,40

155 320 311 608 0,47 0,84

320 420 608 788 0,40 0,73

420 660 788 1220 0,39 0,70

660 800 1220 1472 0,35 0,63

800 1000 1472 1832 0,36 0,64

1000 1200 1832 2192 0,34 0,61

1200 1400 2192 2552 0,34 0,60

1400 1600 2552 2912 0,35 0,62

1600 1768 2912 3214,4 0,41 0,74

-50 0 -58 32 0,98 1,76

0 155 32 311 0,78 1,40

155 320 311 608 0,49 0,89

320 420 608 788 0,45 0,81

420 660 788 1220 0,41 0,73

660 800 1220 1472 0,40 0,72

800 1000 1472 1832 0,39 0,70

1000 1200 1832 2192 0,38 0,69

1200 1400 2192 2552 0,38 0,69

1400 1600 2552 2912 0,39 0,71

1600 1768 2912 3214,4 0,46 0,83

-250 -200 -418 -328 0,65 1,17

-200 -100 -328 -148 0,27 0,49

-100 0 -148 32 0,15 0,26

0 155 32 311 0,10 0,18

155 320 311 608 0,08 0,15

320 400 608 752 0,08 0,14

54 02-10-2009 125614 02

RTD Type Temperature 12 months accuracy

°C °F °C °F

From To From To

PT10(90)385 -200 -80 -328 -112 0,198 0,357

-80 0 -112 32 0,210 0,378

0 100 32 212 0,224 0,403

100 155 212 311 0,225 0,405

155 320 311 608 0,234 0,422

320 420 608 788 0,250 0,450

420 660 788 1220 0,263 0,473

660 800 1220 1472 0,292 0,525

PT50(90)385 -200 -80 -328 -112 0,042 0,076

-80 0 -112 32 0,046 0,083

0 100 32 212 0,051 0,091

100 155 212 311 0,052 0,093

155 320 311 608 0,057 0,102

320 420 608 788 0,062 0,112

420 660 788 1220 0,069 0,124

660 800 1220 1472 0,078 0,141

PT100(90)385 -200 -80 -328 -112 0,023 0,041

-80 0 -112 32 0,026 0,046

0 100 32 212 0,029 0,052

100 155 212 311 0,030 0,054

155 320 311 608 0,034 0,062

320 420 608 788 0,038 0,069

420 660 788 1220 0,044 0,080

660 800 1220 1472 0,052 0,093

PT200(90)385 -200 -80 -328 -112 0,247 0,445

-80 0 -112 32 0,262 0,471

0 100 32 212 0,278 0,500

100 155 212 311 0,279 0,502

155 320 311 608 0,290 0,522

320 420 608 788 0,309 0,556

420 660 788 1220 0,323 0,582

660 800 1220 1472 0,358 0,645

PT500(90)385 -200 -80 -328 -112 0,101 0,182

-80 0 -112 32 0,108 0,194

0 100 32 212 0,116 0,208

100 155 212 311 0,117 0,210

155 320 311 608 0,123 0,222

320 420 608 788 0,133 0,239

420 660 788 1220 0,141 0,254

660 800 1220 1472 0,158 0,285

125614 02 02-10-2009 55

RTD Type Temperature 12 months accuracy

°C °F °C °F

From To From To

PT1000(90)385 -200 -80 -328 -112 0,052 0,094

-80 0 -112 32 0,056 0,102

0 100 32 212 0,062 0,111

100 155 212 311 0,063 0,113

155 320 311 608 0,068 0,122

320 420 608 788 0,074 0,133

420 660 788 1220 0,081 0,145

660 800 1220 1472 0,092 0,165

Cu (M)

50(90)428 -200 -80 -328 -112 0,039 0,070

-80 0 -112 32 0,042 0,076

0 100 32 212 0,045 0,081

100 155 212 311 0,045 0,081

155 200 311 392 0,046 0,083

Cu (M)

100(90)428 -200 -80 -328 -112 0,021 0,038

-80 0 -112 32 0,023 0,041

0 100 32 212 0,026 0,047

100 155 212 311 0,026 0,047

155 200 311 392 0,027 0,049

56 02-10-2009 125614 02

Electrical specifications

All models

Description Value

Power supply [VAC],

Input : 90 – 254V, 45 – 65Hz

Output : 30V ±2% regulated DC, max. 30W

Power

consumption, [VA] : 21 VA (AC) / 15W

Communication Interface,

Standard : RS232

Transmission rate : 115200 Baud

User interface,

Update rate : B-model : Scan rate 1 : 1 ch/sec. (V, mA, mV)

0.5 ch/sec. (RTD)

Scan rate 2 : 2 ch/sec. (V, mA, mV)

1ch/sec. (RTD)

Scan rate 3 : 3 ch/sec. (V, mA, mV)

1.5 ch/sec. (RTD)

Scan rate 4 : 5 ch/sec. (V, mA, mV)

2.5 ch/sec. (RTD)

125614 02 02-10-2009 57

Mechanical specifications

All models

Description Value

Weight : 2.3 kg. / 5.07 lb.

Dimensions

LxWxH : 250 x 249 x 69 mm / 9.8 x 9.8 x 2.7 inch

Operating temp. : 0 - 40°C/ 32 - 104°F

Storage temp. : -20 - 50°C/ -4 - 122°F

Humidity range : 0-90% Rh

Protection class : IP30

RTD sensor types : CUSTOM ITS-90, CUSTOM CvD, P10(90)385

P50(90)385, P100(90)385, P200(90)385,

P500(90)385, P1K(90)385, P100(90)392,

H120(90)672, M50(90)428, M100(90)428, YSI(90)400

TC sensor types : B, E, J, K, L, N, R, S, T, U, BP, XK

58 02-10-2009 125614 02

Additional specifications - directives observed

EMC directives 89/336 / EEC

EN61326:1997/A1:2001/A2: 2001/A3:2003 : Electrical equipment for measurement,

control and laboratory use – EMC requirements

EN61000-4-3:2002+A1 : 3V/m

EN61000-4-6:1996+A1: 3Vrms

EN61000-4-2:1995+A1+A2: 4kV contact / 8kV air

EN61000-4-4:1995+A1+A2: 1kV

EN61000-4-5:1995+A1: 1kV (L-N) / /2kV (L-PE, N-PE)

EN61000-4-11:1994+A1: 100%, 20ms

EN55022:1998+A1+A2: 0.15MHz – 30 MHz Class B conducted mains

EN55022:1998+A1+A2: 30MHz – 1000 MHz Class B radiated e. m.

field

125614 02 02-10-2009 59

11.0 List of accessories

All parts listed in the list of accessories is available from the factory

through our dealers.

Please contact your dealer for assistance if you require parts, which

do not appear in the list.

List of accessories

Accessories Part no.

Alu. carrying case incl. box 125634

Reference manual 125614

Cable with banana/LEMO connection 122823

Cable (1150mm) with male LEMO/LEMO connection 125534

Cable with mini compensation/LEMO connection 125587

Cable with male LEMO/LEMO connection 125592

Screwdriver, VDE insulated, LK 125594

Kit with RS232 cable and cable (650mm) with male

LEMO/LEMO connection 125618

Thermocouple male plug type K (ASM-802) 120517

Thermocouple male plug type N (ASM-802) 120514

Thermocouple male plug type T (ASM-802) 120515

Thermocouple male plug type Cu-Cu (ASM-802) 120519

Power supply ASM 125542

Loose LEMO connection with strain relief (ASM-803) 125620

4 core cable w/shield for Pt100 (ASM-803) 60E151

Edge port converter with 4 RS232 ports 125002

RS232 serial cable, 3 metres 105366

JOFRACAL PC software 124915

60 02-10-2009 125614 02

Loading...

Loading...