Page 1

Reference Manual

Advanced Signal Calibrator

ASC-400

Page 2

Reference Manual

Advanced Signal Calibrator

JOFRA ASC-400

Copyright 2014 AMETEK Denmark A/S

Page 3

About this manual….

The structure of the manual

This reference manual is aimed at users who are familiar with AMETEK signal calibrators,

as well as those who are not. The manual is divided into 12 chapters, which describe how

to set up, operate, service and maintain the signal calibrator. The technical specifications

are described and accessories may be ordered from the list of accessories.

Safety symbols

This manual contains a number of safety symbols designed to draw your attention to

instructions, which must be followed when using the instrument, as well as any risks

involved.

Warning

Conditions and actions that may compromise the safe use of the instrument and

result in considerable personal or material damage.

Caution…

Conditions and actions that may compromise the safe use of the instrument and

result in slight personal or material damage.

Note…

Special situations, which demand the user’s attention.

128797 03 2015-04-22 2

Page 4

List of contents

1.0 Introduction ..................................................................................................................................... 5

1.1 Warranty ..................................................................................................................................................... 6

1.2 Receiving the Advanced Signal Calibrator ................................................................................................. 6

1.3 Dimensioning drawing ................................................................................................................................ 7

2.0 Safety instructions .......................................................................................................................... 8

3.0 Calibrator Interface ....................................................................................................................... 10

3.1 Input/Output Connections ......................................................................................................................... 10

3.2 Keypad - Functions ................................................................................................................................... 11

3.3 Main display - Functions ........................................................................................................................... 11

3.4 Upper display (Read-back display) - Functions ........................................................................................ 12

3.5 Lower display (Primary display) – Functions ............................................................................................ 12

4.0 Operating the calibrator ................................................................................................................ 13

4.1 Basic operation (Setup) ....................................................................................................... ..................... 13

4.2 The principle of navigating through a Setup ............................................................................................. 14

4.3 System Settings ........................................................................................................................................ 15

4.3.1 Power Saver (Auto off) ................................................................................................................. 16

5.0 Using measure modes (lower display) ........................................................................................ 18

5.1 Measuring volts ......................................................................................................................................... 18

5.2 Measuring frequency ................................................................................................................................ 19

5.3 Measuring mA ........................................................................................................................................... 20

5.4 Measuring Temperature ........................................................................................................................... 21

5.4.1 Using Thermocouples (TC) .......................................................................................................... 21

5.4.2 Using Resistance-Temperature-Detectors (RTDs) ...................................................................... 22

5.5 Measuring Pressure .................................................................................................................................. 25

5.5.1 Zeroing with Absolute Pressure Modules (APM S, H and Mk.II) ................................................. 26

5.5.2 Using the BARO Module (optional) .............................................................................................. 26

6.0 Using Source modes (Lower Display) ......................................................................................... 28

6.1 Sourcing mA (internal loop power supply) ................................................................................................ 28

6.2 mA Sink (external loop power supply) ...................................................................................................... 29

6.3 Sourcing Voltage ....................................................................................................................................... 30

6.4 Sourcing Frequency .................................................................................................................................. 31

6.5 Sourcing a Pulse Train ............................................................................................................................. 31

6.6 Sourcing mV ............................................................................................................................................. 32

6.7 Sourcing Thermocouples .......................................................................................................................... 33

6.8 Sourcing Ohms/RTDs ............................................................................................................................... 34

6.9 Custom RTD ............................................................................................................................................. 35

6.10Using Auto Output functions ..................................................................................................................... 36

6.10.1 Using the Step function ................................................................................................................ 36

6.10.2 Using the Ramp function .............................................................................................................. 37

7.0 Using Isolated Measure Modes (Upper Display) ........................................................................ 39

7.1 Measuring mA (external loop supply) ....................................................................................................... 39

7.2 Measuring current with internal loop power .............................................................................................. 40

7.3 Measuring Voltage .................................................................................................................................... 41

7.4 Measuring Pressure .................................................................................................................................. 41

8.0 Using the Upper and Lower Display for Calibration and Testing ............................................ 43

8.1 Performing a Temperature Switch Test .................................................................................................... 43

8.2 Performing a Pressure Switch Test .......................................................................................................... 45

8.3 Testing an Input or Indicating Device ....................................................................................................... 47

8.4 Calibrating an I/P Device .......................................................................................................................... 47

8.5 Calibrating a Transmitter (Signal Converter) ............................................................................................ 49

8.6 Calibrating a Pressure Transmitter (loop powered 4-20 mA) ................................................................... 50

128797 03 2015-04-22 3

Page 5

8.7 Using Scaled Current or Voltage when testing or calibrating a T/I Transmitter ..................................... 52

8.8 Using Percent Error when testing or calibrating a T/I Transmitter ............................................................ 53

9.0 Maintenance ................................................................................................................................... 54

9.1 Returning the calibrator to service ............................................................................................................ 54

9.2 Replacing batteries ................................................................................................................................... 56

9.3 Storing ....................................................................................................................................................... 57

9.4 Cleaning .................................................................................................................................................... 57

10.0 Errors .............................................................................................................................................. 58

11.0 Technical specifications ............................................................................................................... 59

12.0 List of accessories ........................................................................................................................ 67

128797 03 2015-04-22 4

Page 6

1.0 Introduction

Congratulations on your new AMETEK JOFRA Advanced Signal Calibrator!

With the AMETEK JOFRA Advanced Signal Calibrator, you have chosen an extremely

effective instrument, which we are sure will perform according to your expectations.

This ASC-400 signal calibrator is a handheld, battery or DC adaptor powered instrumen t

that measures and sources electrical and physical parameters.

During the past several years, we have acquired extensive knowledge of industrial

signal calibration. This expertise is reflected in our products, which are all designed for

daily use in an industrial environment. Please note that we would be very interested in

hearing from you if you have any ideas or suggestions for changes to our products.

This reference manual applies to the following instrument:

JOFRA ASC-400

The calibrator has the following features and functions:

A dual colour display.

The upper display is used for the measurement of volts, current, pressure, %error,

scaling and switch test

The lower display can be used to measure and source volts, millivolts, current, pressure,

resistance, resistance temperature detectors (RTDs), thermocouples, frequency, and

resistance, and to source pulse trains.

A thermocouple (TC) input/output terminal with automatic and manual reference-junction

(co l d j u n c t i o n ) temperature compensation.

An interactive and intuitive user interface

USB interface for remote control

Isolated read back for transmitter calibration.

A BARO option turning any gauge measuring APM into an absolute measuring

device.

Extended and comprehensive pressure measurement capabilities with JOFRA

advanced pressure modules (APM)

ISO-9001 certified

AMETEK Denmark A/S was ISO-9001 certified in September 1994 by Bureau Veritas

Certification Denmark.

CE-label

Your new signal calibrator bears the CE label and conforms to the EMC

Directive.

128797 03 2015-04-22 5

Page 7

Technical assistance

Please contact the dealer from whom you acquired the instrument if you require

technical assistance.

1.1 Warranty

This instrument is warranted against defects in workmanship, material and design for

two (2) years from date of delivery to the extent that AMETEK will, at its sole option,

repair or replace the instrument or any part thereof which is defective, provided,

however, that this warranty shall not apply to instruments subjected to tampering or,

abuse, or exposed to highly corrosive conditions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS

OR IMPLIED AND AMETEK HEREBY DISCLAIMS ALL OTHER WARRANTIES,

INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE OR MERCHANTABILITY. AMETEK SHALL NOT BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT

LIMITED TO, ANY ANTICIPATED OR LOST PROFITS.

This warranty is voidable if the purchaser fails to follow any and all instructions,

warnings or cautions in the instrument’s User Manual.

If a manufacturing defect is found, AMETEK will replace or repair the instrument or

replace any defective part thereof without charge; however, AMETEK’s obligation

hereunder does not include the cost of transportation, which must be borne by the

customer. AMETEK assumes no responsibility for damage in transit, and any claims for

such damage should be presented to the carrier by the purchaser.

1.2 Receiving the Advanced Signal Calibrator

When you receive the instrument…

1) Unpack and check the signal calibrator and the accessories carefully.

2) Check the parts according to the list shown below.

If any of the parts are missing or damaged, please contact the dealer who sold you

the signal calibrator.

You should receive:

1 ASC-400 Calibrator

1 electronic Reference manual on USB memory stick

2 sets of test leads and test clips (black and red)

1 carrying soft bag

1 USB cable

6 x AA batteries

1 Calibration certificate (International traceable)

When reordering, please specify the part numbers according to the list of accessories,

section 12.0

128797 03 2015-04-22 6

Page 8

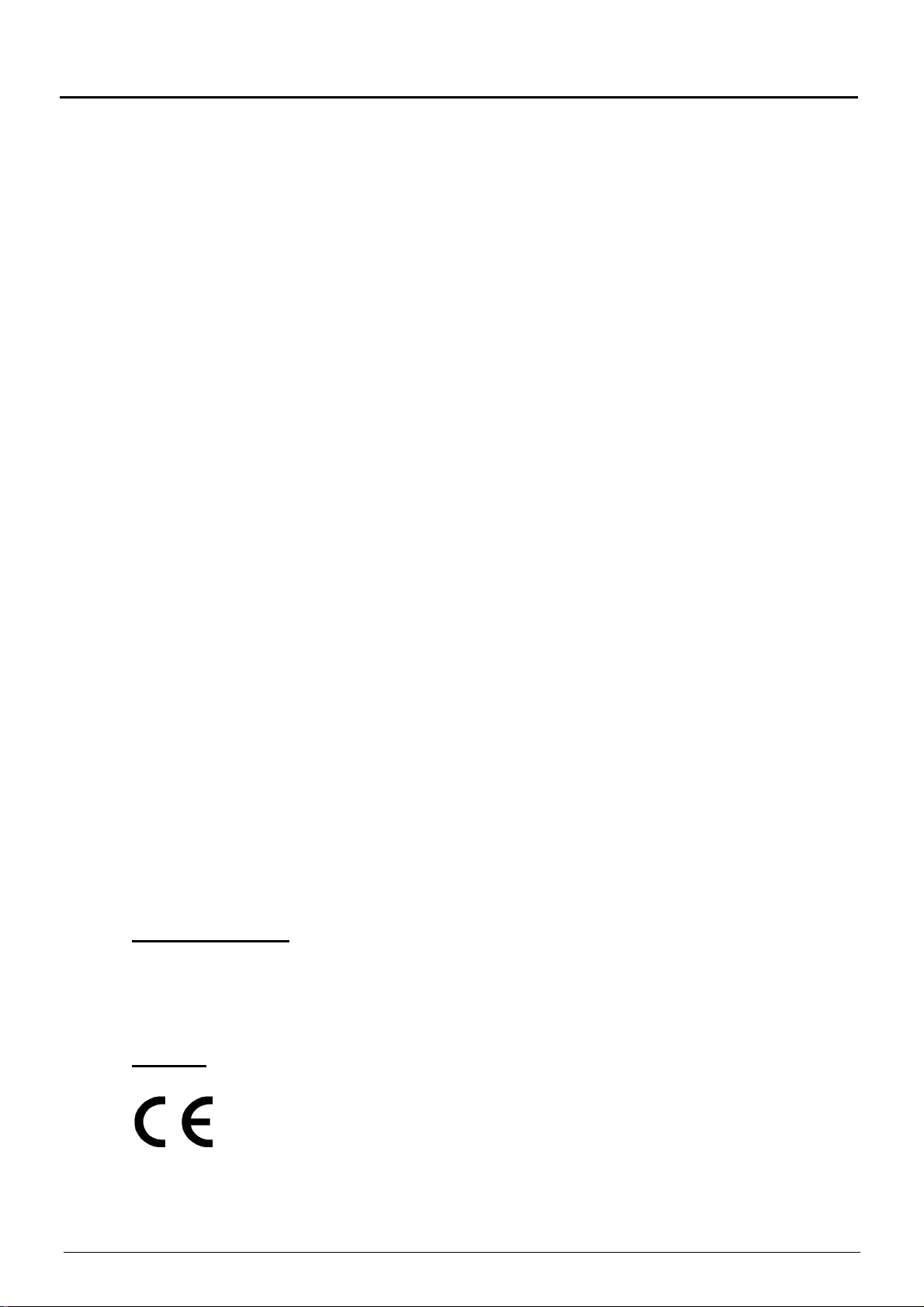

1.3 Dimensioning drawing

55 mm96 mm

220 mm

128797 03 2015-04-22 7

Page 9

2.0 Safety instructions

Read this manual carefully before using the instrument!

Please follow the instructions and procedures described in this manual. They are

aimed at allowing you to make the best of your signal calibrator and avoid any

personal injuries and/or damage to the instrument.

Disposal – WEEE Directive

The signal calibrator contains Electrical and Electronic circuits and must be properly

recycled or disposed of (in accordance with the WEEE Directive 2002/96/EC).

Warning

The signal calibrator is designed to calibrate and measure low voltage process signals.

To ensure the safety of the operator and the instrument, DO NOT connect the signal

calibrator to input voltages above 30 Volts.

To avoid possible electric shock or personal injury:

Do not apply more than the rated voltage. See specifications for supported ranges.

Follow all equipment safety procedures.

Ne v e r t o u c h the pr o b e t o a voltag e so u r c e w he n t he te s t l ea ds ar e plugged into the

current terminals.

Do not use the calibrator if it is damaged. Before you use the calibrator, inspect the

case. Look for cracks or missing plastic. Pay particular attention to the insulation

surrounding the connectors.

Select the proper function and range for your measurement.

Make sure the battery cover is closed and latched before you operate the calibrator.

Remove test leads from the calibrator before you open the battery door.

Inspect the test leads for damaged insulation or exposed metal. Check tes t leads

continuity. Replace damaged test leads before you use the calibrator.

When using the probes, keep your fingers away from the probe contacts. Keep your

fingers behind the finger guards on the probes.

Connect the common test lead before you connect the live test lead.

When you disconnect test leads, disconnect the live test lead first.

Do not use the calibrator if it operates abnormally. Protection may be impaired. When

in doubt, have the calibrator serviced.

Do not operate the calibrator around explosive gas, vapour, or dust.

When using a pressure module, make sure the process pressure line is shut off

and depressurized before you connect it or disconnect it from the pressure module.

Disconnect test leads before changing to another measure or source function.

When servicing the calibrator, use only specified replacement parts.

To avoid false readings, which could lead to possible electric shock or personal injury,

replace the battery as soon as the battery indicator appears.

To avoid a violent release of pressure in a pressurized system, shut off the valve and

slowly bleed off the pressure before you attach the pressure module to the

pressure line.

To avoid personal injury or damage to the calibrator, use only the specified

replacement parts and do not allow water into the case.

128797 03 2015-04-22 8

Page 10

Caution…

To avoid possible damage to the signal calibrator or to the equipment under

test:

Disconnect the power and discharge all high-voltage capacitors before testing

resistance or continuity.

Use the proper jacks, function, and range for your measurement or sourcing

application.

If the message changes to "OL" the range limit is exceeded and the pressure source

must immediately be removed from the APM to prevent damage to the pressure

transducer inside.

To avoid damaging the pressure module from overpressure, never apply pressure

above the rated maximum printed on the module.

To avoid damaging the plastic lens and case, do not use solvents or abrasi ve

cleansers.

When using the switch test function, make sure that no other equipment, such as

heavy loads or sources, is connected in the test loop.

Note…

The product liability only applies if the instrument is subject to a manufacturing

defect. This liability becomes void if the user fails to follow the maintenance

instructions described in this manual or uses unauthorized spare parts.

128797 03 2015-04-22 9

Page 11

3.0 Calibrator Interface

ying

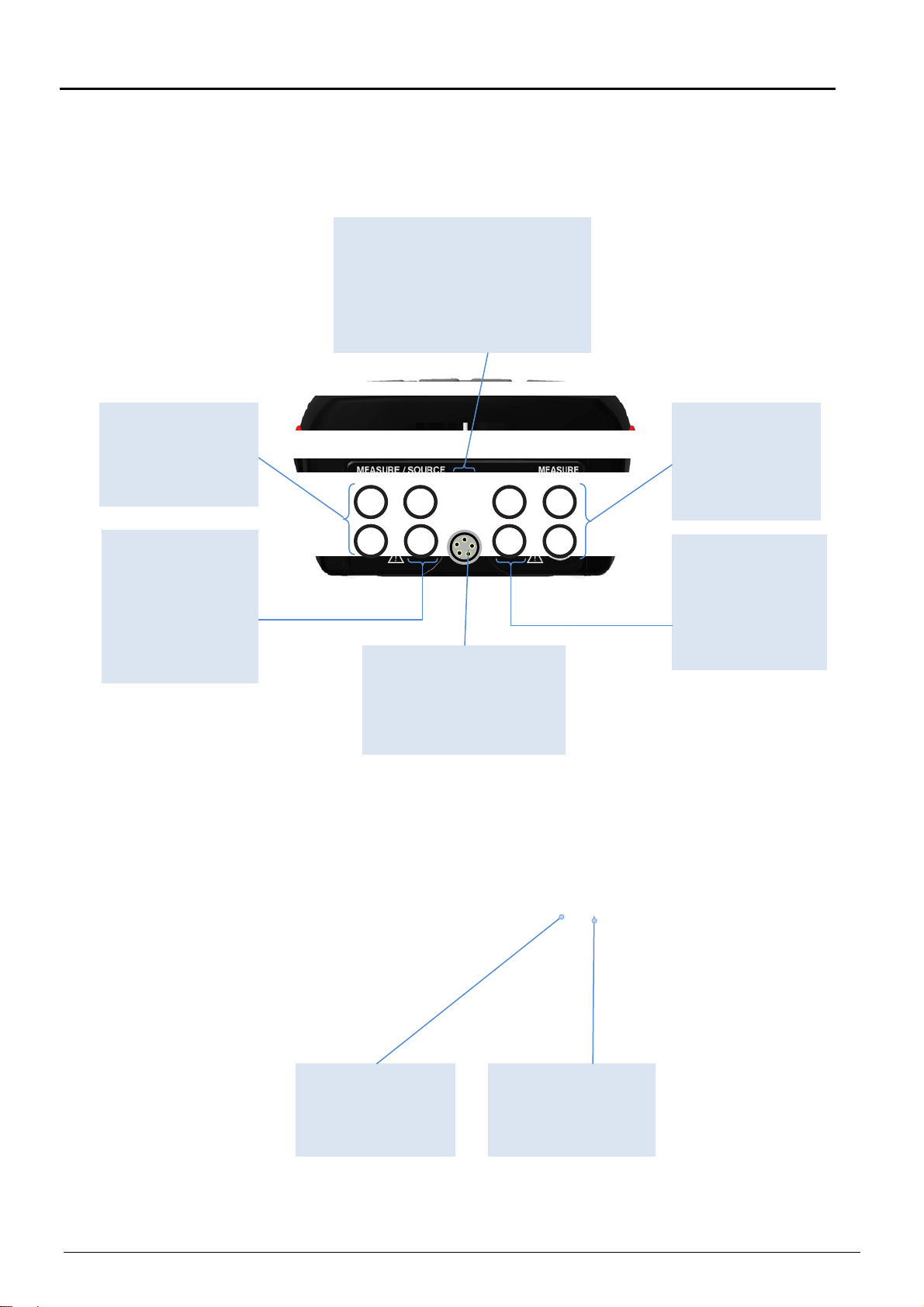

3.1 Input/Output Connections

Measure / Source

mA

Input terminals for

sourcing and

measuring current.

Measure / Source

V, Ω/RTD, Hz

Input terminals for

sourcing and

measuring voltage,

frequency, pulse

train, resistance

and RTDs.

TC mV input / output

Terminal for measuring or

simulating thermocouples and mV.

Accepts miniature polarized

thermocouple plugs with flat in-line

blades spaced 7.9 mm (0.312 in)

center to center.

Pressure module

connector (APM)

Connects calibrator to a

pressure module for

pressure measurements.

USB connection

Connects calibrator

to a PC for remote

control.

Charger Connector

Connects to optional

power supply /

battery charger.

Measure / V mA

Input terminals for

measuring ,

switch test,

current, voltage

and suppl

Measure Ω/RTD,

4w, 3/4w

Input terminals for

performing RTD

measurements

with 3-wire or 4wire setups.

128797 03 2015-04-22 10

Page 12

3.2 Keypad - Functions

Power key/

Backlight key

Turn the calibrator on and

off. Press the button for

five seconds to turn it off.

Adjust the backlight

intensity.

Arrow Keys

Have different functions

depending on the mode of

operation. In navigation

mode, they move the

cursor in the desired

direction.

In edit mode, they roll in

the list of options or if

entering a number, the

arrow left and arrow right

move the cursor one

character in the desired

direction.

Zero key

Zero Pressure Module

reading.

Function keys

F1, F2, F3, F4

To operate the menu bar

at the bottom of the

calibrator display, use the

F-keys.

Back key

Cancel a selection / edit or

return to previous menu.

Action key / Enter key

Action function: Open and

close edit fields or a menu

button. The action key also

accepts the selected

option or entered value.

Enter function: Accept

selected options or

entered values. When a

value is entered with the

Enter Key the cursor

selects the next value field

in the list.

Numeric Keypad

Allows user to enter

Numeric values in both

upper and lower display.

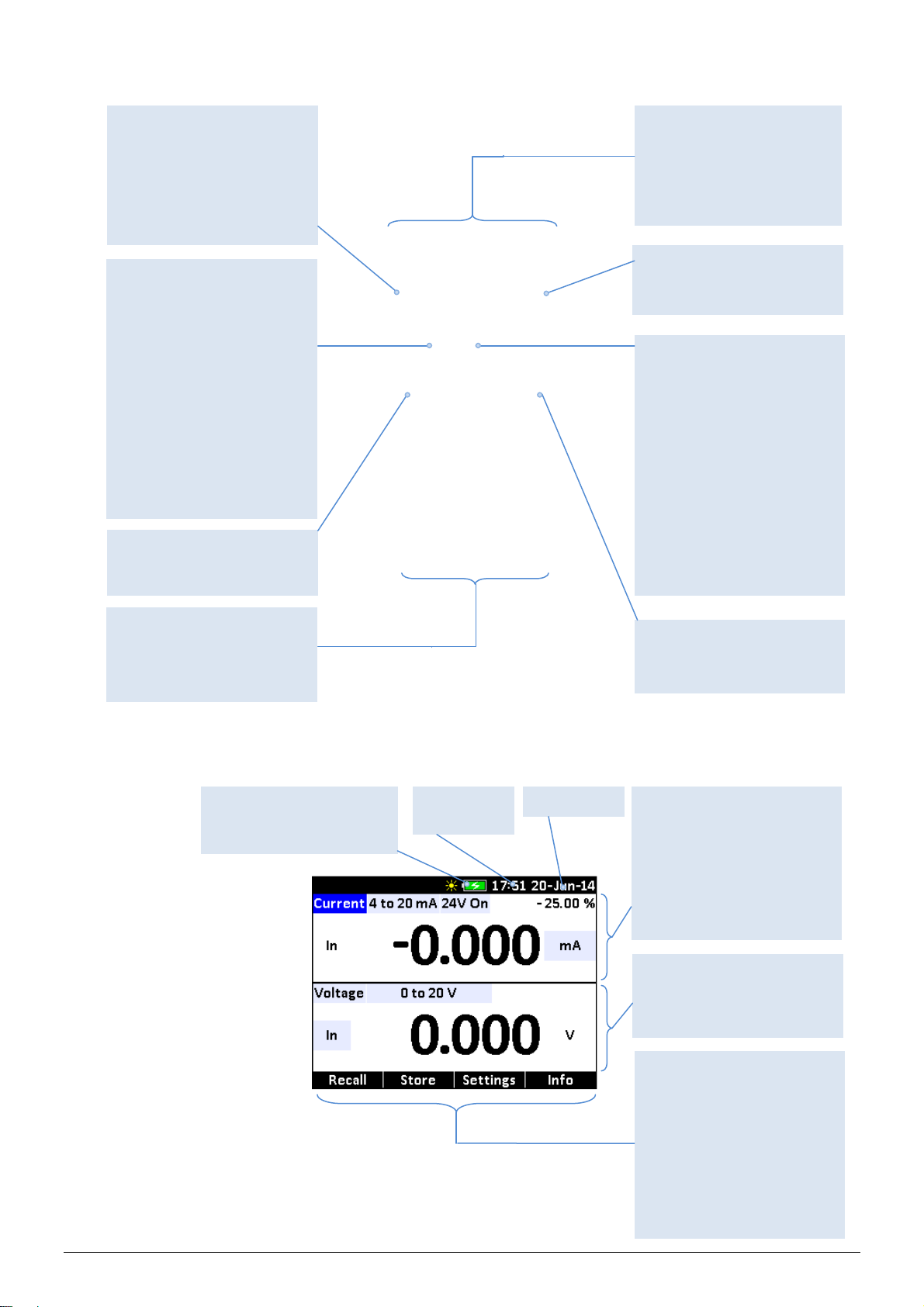

3.3 Main display - Functions

Remaining power and

attached power adapter

Real Time

Clock display

Configuration key

Opens and closes

configuration mode.

Date displayBattery icon.

Upper display

The upper display is used

for measuring DC voltage,

DC current with and

without loop power,

pressure, percent, error,

scaled value, switch test.

Lower display

The lower display can be

used for both measuring

and sourcing.

Horizontal menu bar

The menu bar is used to

setup both the upper and

the lower display to perform

the desired function. The

function keys (F1, F2, F3

and F4) are used to

navigate through all the

levels and choices of the

menu bar.

128797 03 2015-04-22 11

Page 13

(opt.)

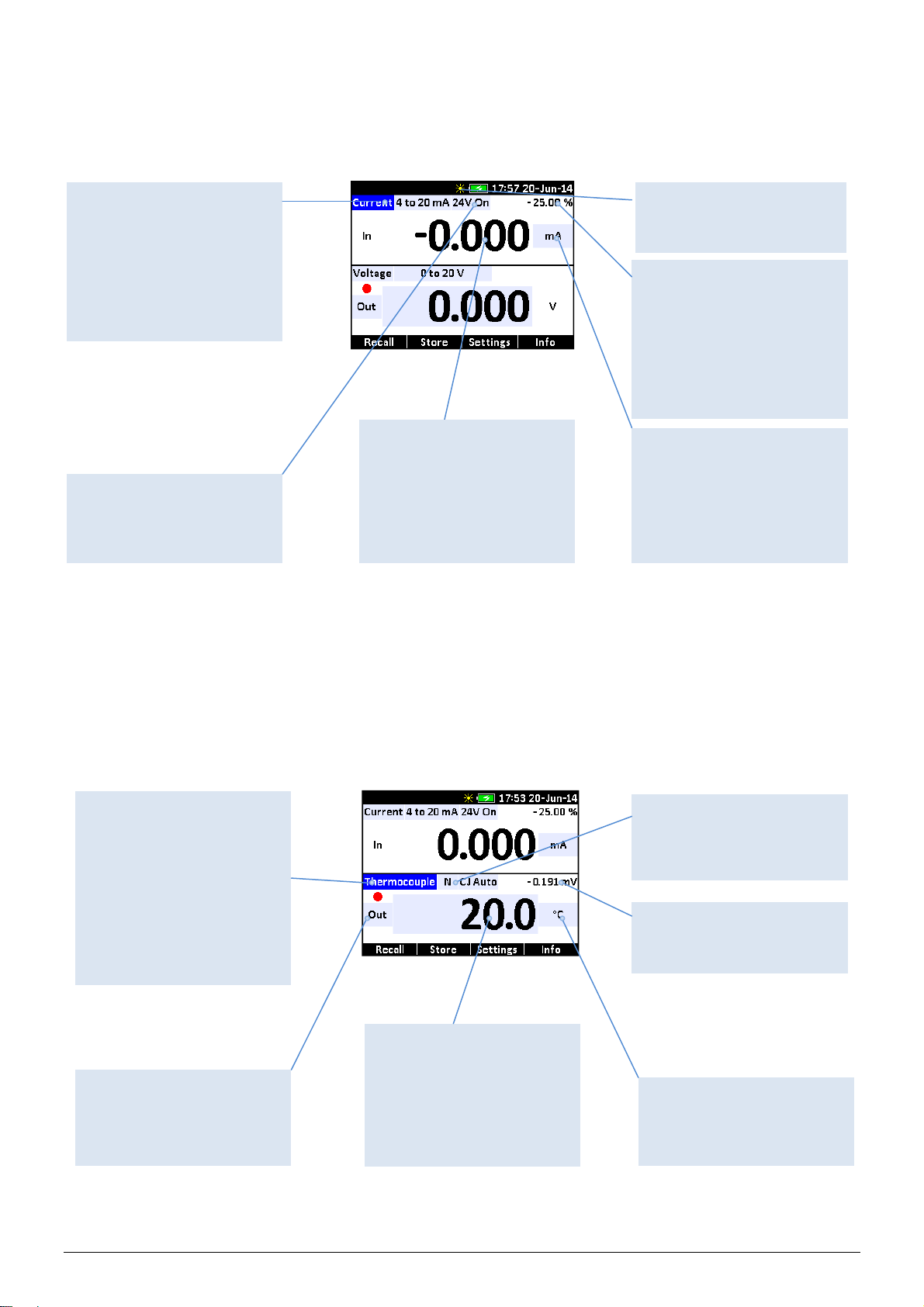

3.4 Upper display (Read-back display) - Functions

Primary Parameters

Determine what parameter is

goin g t o b e measure d.

The available options for the

upper display are : CURRENT,

VOLTAGE, SWITCH TEST,

PRESSURE and LEAK TEST.

Additional parameters

Selection and selection of

parameters relevant to the

choice of primary parameter

Numeric display

Displays the numeric values

of the signa l being

measured.

An “OL” reading indicates an

out of range or overload

condition.

Backlight Intensity

Indicates Low, Medium or

High intensity on backlight

Secondary upper display

Shows where in the preset

span the measured value

falls. Fixed for mA at 4 (0%)

and 20 (100% ). Also shows

mA value for percent error,

mA or Volts value for scaling

and leak rate for pressure.

Units

Shows what unit the

measurement value is in.

Available options are : mA,

SCALING, %ERROR, VOLT

and PRESSURE UNITS.

3.5 Lower display (Primary display) – Functions

Primary Parameters

Determine what parameter is

goin g to be measured or

sourced.

The available options for the

upper display are : CURRENT,

VOLTAGE, THERMOCOUPLE, RTD, OHMS,

FREQUENCY, PULSE,

PRE S S U R E and BARO

Input / Output

Switches / indicates lower

display input mode (read),

and output mode (source).

Numeric display

Displays the numeric values

of the signa l being

measured, or sourced.

An “OL” reading indicates an

out of range or overload

condition.

128797 03 2015-04-22 12

Additional parameters

Selection and selection of

parameters relevant to the

choice of primary parameter.

Native Value

0 to 100 % in mA out mode

and leak rate for pressure.

Units

Shows what unit the

measurement or source

value is in.

Page 14

4.0 Operating the calibrator

4.1 Basic operation (Setup)

Warning

Please inspect the Safety Instructions in section 2.0 before using the instrument.

Caution…

Please inspect the Safety Instructions in section 2.0 before using the instrument.

Connect USB cable and APM before switching on the instrument, or before applying

DC power.

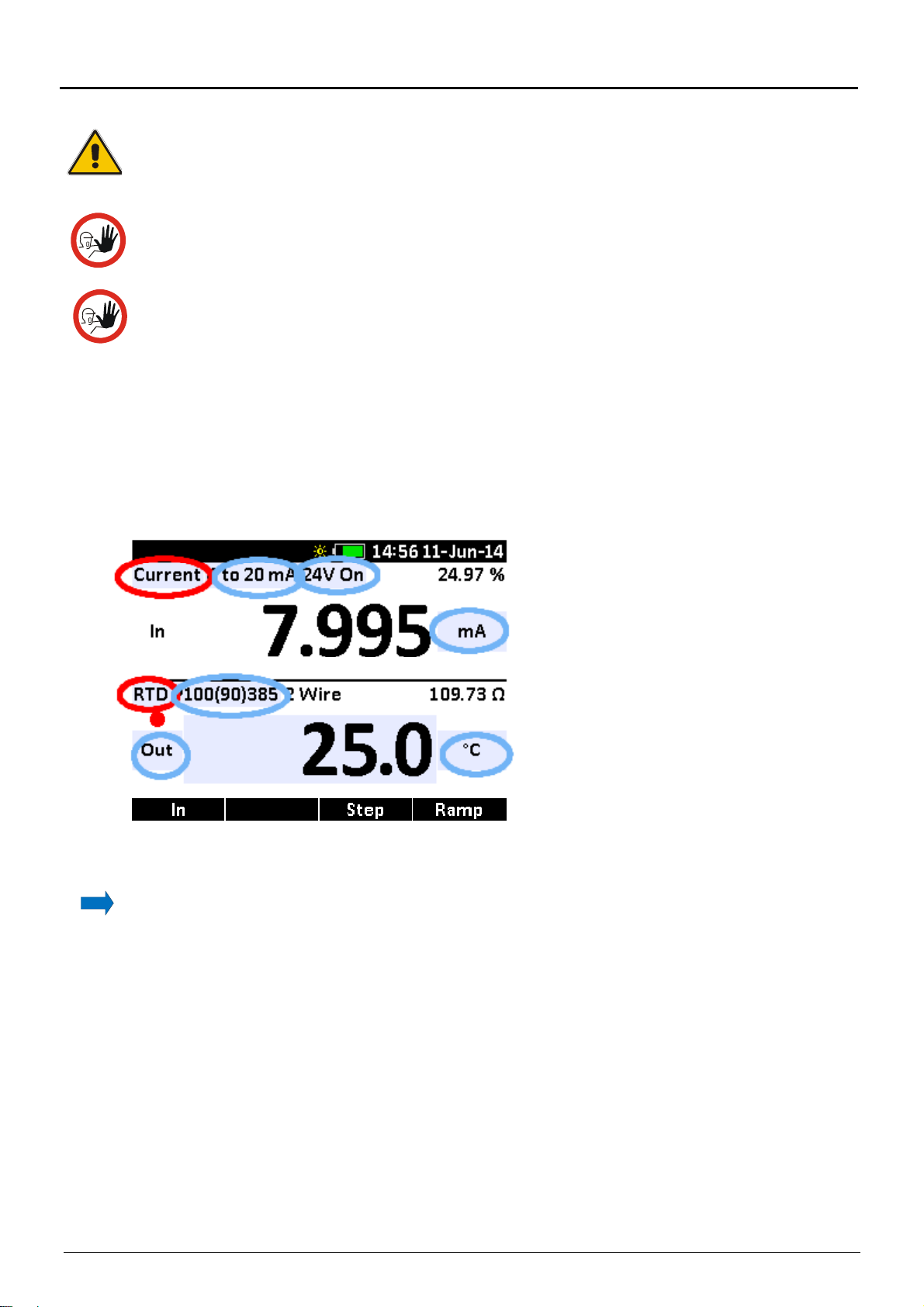

1. Select mode for upper and lower display (RED markers).

2. Select the related options and functions for the selected modes (BLUE markers)

Note…

the light blue fields; they indicate a parameter / function that can be selected

or altered in edit mode. This works like a build in user manual, indicating the

changeable parameters for the selected mode at all times.

128797 03 2015-04-22 13

Page 15

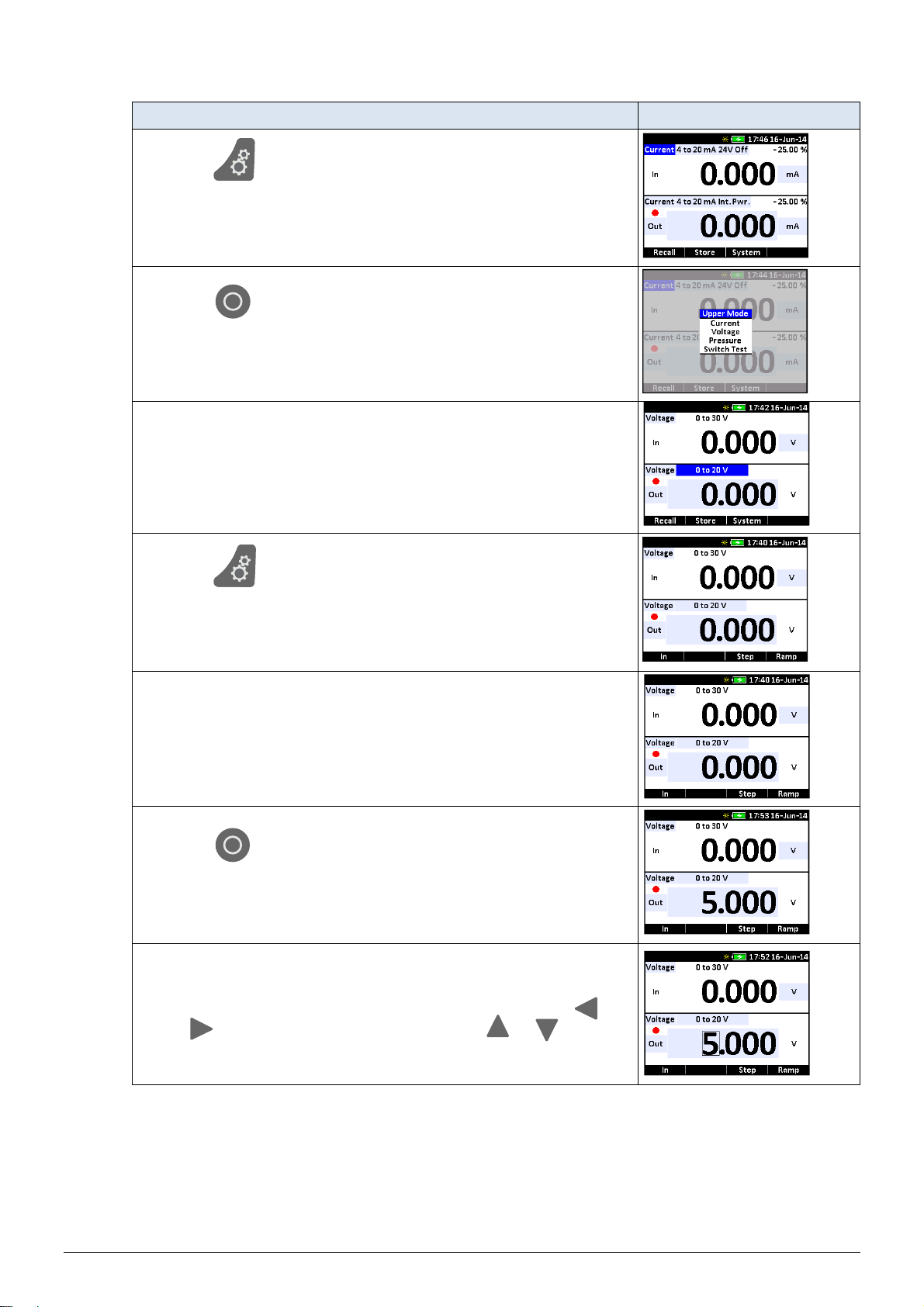

4.2 The principle of navigating through a Setup

ACTION SCREEN DISPLAYED

1. Press to access edit mode.

2. Use the (ARROW) keys to move between the

parameter fields.

3. Press to access the various Parameter lists to

choose from.

4. Start by selecting upper or lower display.

5. Use the (ARROW) keys to move between the

parameter fields and make more changes…

6. Press to accept the selections and leave the

edit mode.

7. Use the numeric keys to enter an output value (if output

if chosen).

8. Press to accept the value.

9. Or use the (ARROW) keys to enter “fine adjust”

mode.

Move the value-frame to the right or left using the

or keys. Modify the digits using the or keys.

128797 03 2015-04-22 14

Page 16

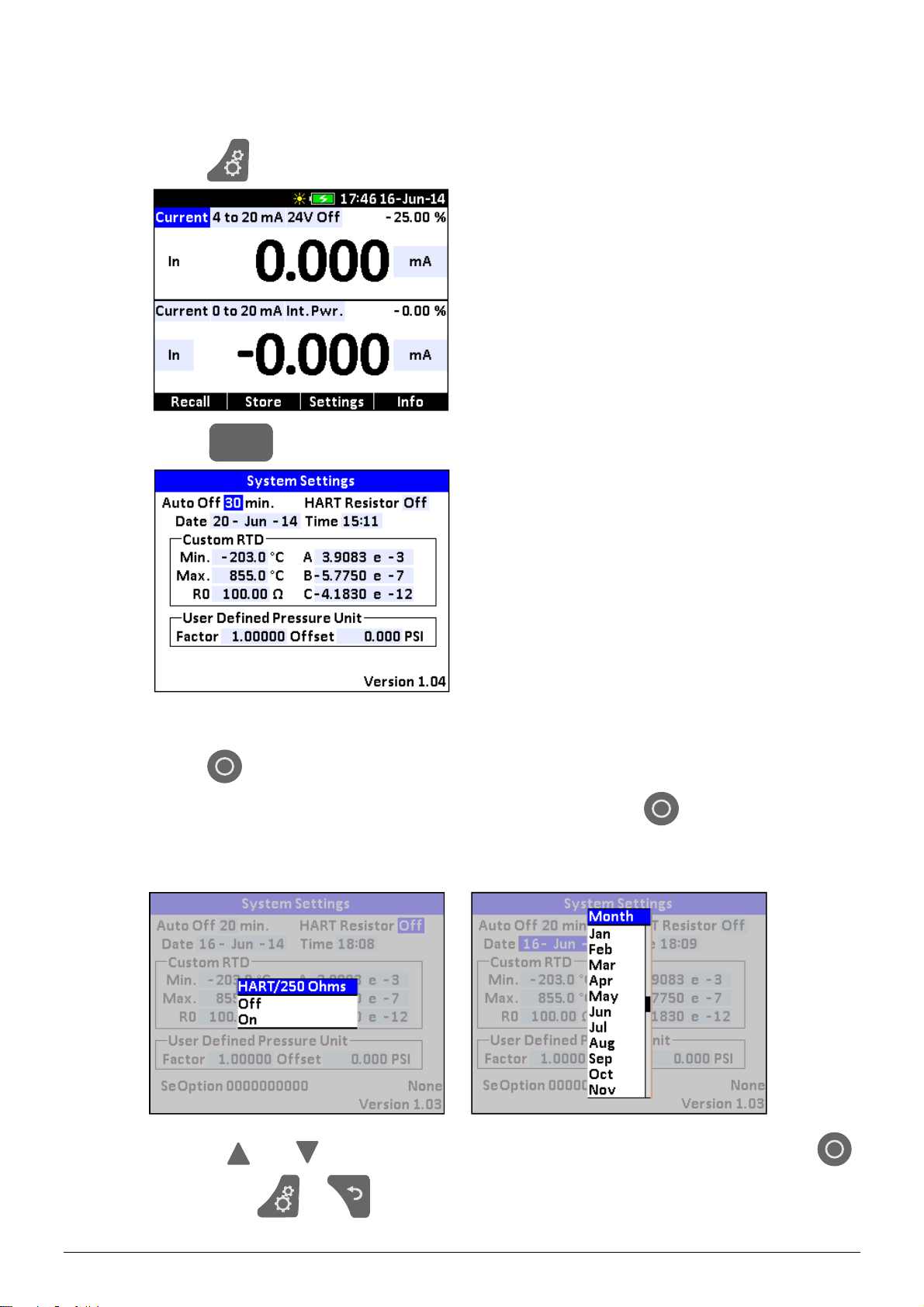

4.3 System Settings

The System Settings setup can be accessed at any stage of operation:

1. Press to display the Horizontal menu bar.

2. Press (System) to access the System Settings.

F3

3. Use the (ARROW) keys to move between the setting fields.

4. Press to open a setting field for editing.

5. Use the numeric keys to enter the desired value and press to accept the value.

When entering the HART Resistor ON/OFF field and Date field horizontal lists

appear.

6. Use the and keys to scroll in the lists and select from the lists by pressing .

7. Press either or to exit the System Settings.

128797 03 2015-04-22 15

Page 17

8. The calibrator resumes normal operation after a few seconds. It will return to the

setup last used.

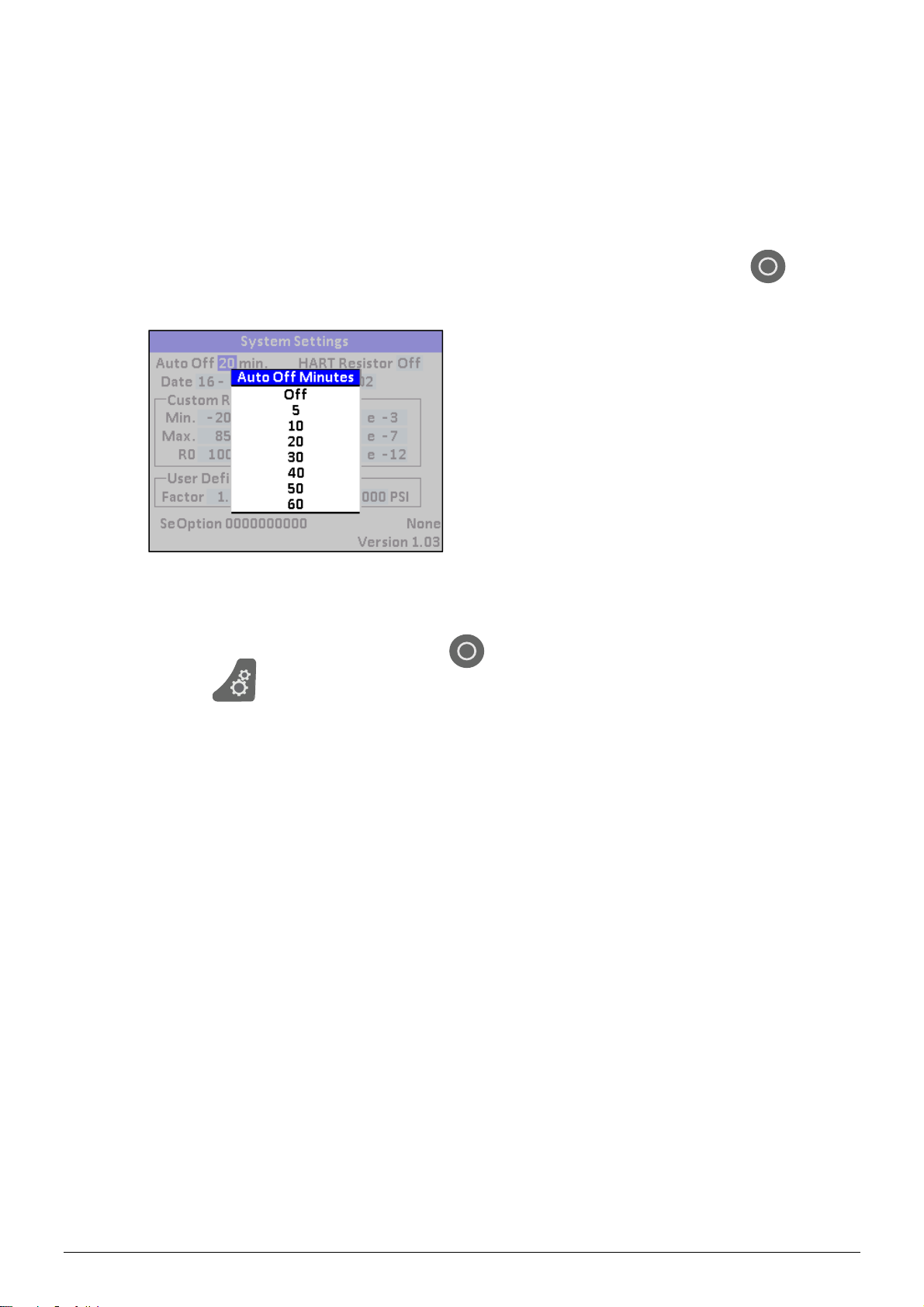

4.3.1 Power Saver (Auto off)

The ASC-400 calibrator automatically turns off 5 to 60 minutes after the last keystroke.

To reduce or increase this time or to disable this feature, do as follows:

1. In the System Settings setup enter the “Auto Off” setting field and press to

access the Auto Off Minutes list.

2. The list displays the turn-off time in minutes.

Off disables the power saver and the calibrator will be permanently off.

3. Select the turn-off time by pressing .

4. Press to exit the System Settings.

128797 03 2015-04-22 16

Page 18

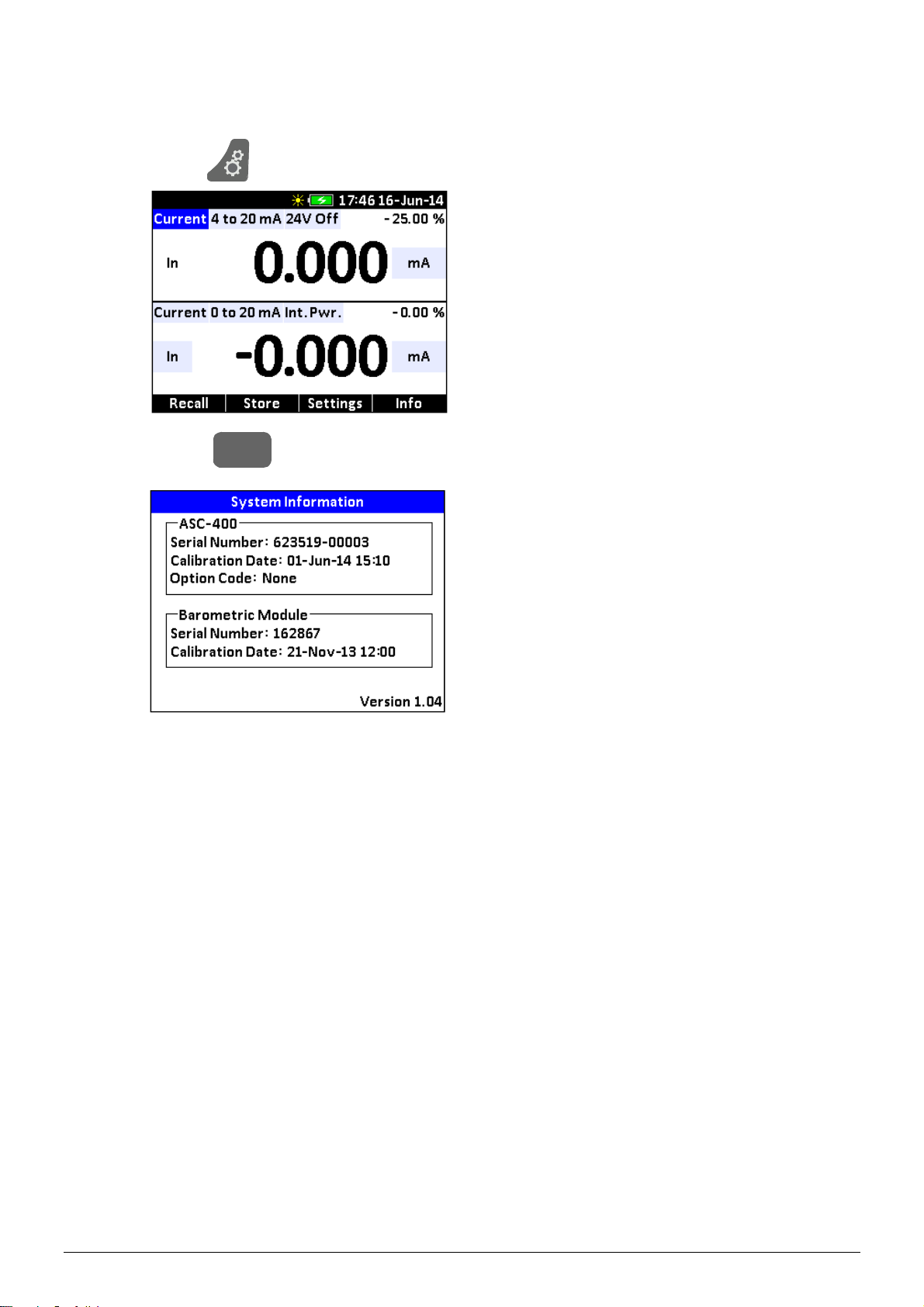

4.4 System Information

The System Information can be accessed at any stage of operation:

1. Press to display the Horizontal menu bar.

2. Press (Info) to access the System Information.

F4

128797 03 2015-04-22 17

Page 19

5.0 Using measure modes (lower display)

5.1 Measuring volts

The electrical parameter volts can be measured using the lower display.

To make the desired measurements, follow the principle of navigating through the

functions described in the guidelines in section 4.2 and proceed as follows:

1. Select “Voltage” from the Lower Mode list.

2. Select the desired Range from the Range list.

3. Select the desired Test Mode (in) from the Test Mode list.

4. Accept the selections and leave the edit mode.

5. Connect the leads, as shown in Figure 1.

Figure 1

Measuring Volts

128797 03 2015-04-22 18

Page 20

5.2 Measuring frequency

The electrical parameter frequency can be measured using the lower display.

To make the desired measurements, follow the principle of navigating through the

functions described in the guidelines in section 4.2 and proceed as follows:

1. Enter edit mode.

2. Select “Frequency” from the Lower Mode list.

3. Select the desired Test Mode (In) from the Test Mode list.

4. Enter the desired trigger level (Trig. V) value using either the ARROW keys or the

numeric keys.

5. Select the desired unit from the Units list.

6. Accept the selections and leave edit mode.

7. Connect the leads, as shown in Figure 2.

Figure 2

Measuring Frequency

128797 03 2015-04-22 19

Page 21

5.3 Measuring mA

The electrical parameter mA can be measured using the lower display.

Follow the principle of navigating through the functions as described in the guidelines in

section 4.2 to make the desired mA measurements:

1. Enter edit mode.

2. Select “Current” from the Lower Mode list.

3. Select the desired Test Mode (In) from the Test Mode list.

4. Select the desired Range from the Range list.

5. Select the desired power source from the Power Source list.

6. Select mA or % from the Units list.

7. Accept the selections and leave edit mode.

8. Connect the leads, as shown in Figure 3.

Figure 3

Measuring mA

128797 03 2015-04-22 20

Page 22

5.4 Measuring Temperature

5.4.1 Using Thermocouples (TC)

The ASC-400 supports the following thermocouple types:

B, BP, C, E, J, K, L, N, R, S, T, U, XK

The characteristics of all the types are described in section 11 – Technical

Specifications.

The ASC-400 has 3 cold junction Modes to choose from:

CJ Auto Automatic CJ compensation, CJ temperature inside the

connector is measured by a high accuracy RTD.

CJ Off With CJ in OFF Mode, the calibrator will measure the difference

between the thermocouple at the junction and at its TC input

terminal (equivalent to 0ºC CJ).

CJ Manual With CJ in Manual Mode it is possible to set the desired CJ

temperature to be used for temperature calculation.

Note…

CJ Off Mode should only be used when calibration is being done using an

external ice bath.

CJ Manual mode should be used when the cold junction temperature is known,

but different from 0 º C .

To use the thermocouple to measure temperature, follow the principle of navigating

through the functions described in the guidelines in section 4.2 and proceed as follows:

1. Attach the thermocouple leads to the TC mini plug, and insert the plug into the

input/output of the ASC-400 calibrator, as shown in Figure 4.

2. Enter edit mode.

3. Select “Thermocouple” from the Lower Mode list.

4. Select the desired Test Mode (In) from the Test Mode list.

5. Select TC function from the TC Type list.

6. Select CJ Mode from the list.

7. If CJ Manual is selected a CJ temperature value must be entered using either the

ARROW keys or the numeric keys.

8. Select the temperature unit from the Units list.

128797 03 2015-04-22 21

Page 23

9. Accept the selections and leave edit mode.

Figure 4

Measuring Temperature using

Thermocouple Terminals

Note…

For best accuracy wait minimum 2 to 5 minutes for the temperature between the

mini plug and the calibrator to stabilize before any measurements are taken .

Use the appropriate type of TC connector, using a wrong type of mini TC connector will

cause additional CJ error.

The ASC-400 calibrator can also measure the mV of a Thermocouple, which can be

used along with a table in case the corresponding TC type is not supported by the

calibrator.

To select mV do as follows:

1. Select “Voltage” from the Lower Mode list.

2. Select “-10 to 75 mV” from the Range list.

In this mode the CJ compensation is turned off.

Note…

The TC wire used must match the thermocouple type being calibrated.

5.4.2 Using Resistance-Temperature-Detectors (RTDs)

The supported types of RTDs are shown in Section 11 - Specifications.

RTDs are characterized by their 0°C resistance, R0. The ASC-400 calibrator accepts

two, three, and four wire inputs, with four wire input being the most accurate.

To use the RTD option, follow the principle of navigating through the functions described

in the guidelines in section 4.2 and proceed as follows:

1. Enter edit mode.

2. Select “RTD” from the Lower Mode list.

3. Select “In” from the Test Mode list.

4. Select RTD type from the RTD Type list.

5. Select a wire connection from the Num. Wires list. 4-wire allows for the most precise

measurement.

6. Accept the selections and leave edit mode.

128797 03 2015-04-22 22

Page 24

7. Attach RTD leads, as shown in Figure 5

Figure 5

Measuring RTD temperature

2, 3 or 4 wire connections

RTD

2 wire

RTD

3 wire

RTD 4 wire

128797 03 2015-04-22 23

Page 25

Resistance can also be measured using this function:

1. Select “Resistance” from the Lower Mode list.

2. Proceed as in the above guidelines.

This option can be used to measure ohms or a type resistive temperature sensor, which is

not programmed into the ASC-400 calibrator.

128797 03 2015-04-22 24

Page 26

5.5 Measuring Pressure

Warning

To avoid a violent release of pressure in a pressurized system, shut off the valve and

slowly bleed off the pressure before you attach the pressure module to the pressure

line.

Caution…

To avoid damaging the pressure module from overpressure, never apply pressure

above the rated maximum printed on the module.

To avoid damaging the pressure module from corrosion, use it only with specified

materials. Refer to the pressure module documentation for material compatibility.

To measure pressure, follow the principle of navigating through the functions described

in the guidelines in section 4.2 and proceed as follows:

1. Connect the pressure module to the ASC-400 calibrator, as shown below in Figure

6.

Note…

The APM might take a while to start up. The module is a complete pressure

measuring system with a microcontroller system inside.

The calibrator can measure pressure on both the upper and the lower display. This

makes it possible to measure pressure in two different units at the same time.

2. Select either the upper or lower display to work from.

3. Select “Pressure” from the Upper or Lower Mode list.

4. Select type of pressure, Gauge or Absolute (If barometer is mounted in ASC-400).

5. Select the desired measuring unit from the Units list.

6. Zero the pressure module (see section 5.5.1 for using the zeroing function).

7. Leak rate is automatically calculated in the selected pressure unit / minute.

128797 03 2015-04-22 25

Page 27

APM pressure module

Figure 6

Connections for Measuring

Pressure

5.5.1 Zeroing with Absolute Pressure Modules (APM S, H and Mk.II)

To zero, adjust the calibrator to read a known pressure, such as barometric pressure.

To adjust the calibrator, follow the principle of navigating through the functions described

in the guidelines in section 4.2 and proceed as follows:

1. Select either the upper or lower display to work from.

2. Select “Pressure” from the Upper or Lower Mode list.

3. Press to activate the Zeroing.

ZERO

4. The calibrator stores the Barometric zero offset in non-volatile memory.

The zero offset is stored for one absolute pressure module at a time. If a new

absolute module is connected this process must be repeated.

5.5.2 Using the BARO Module (optional)

1. The BARO barometer option in the ASC-400 calibrator has 2 functions.

Working as a high accuracy barometer

Applying the barometric pressure value to the measurement of a pressure

module (APM) allowing any gauge APM to be used for absolute measurements.

This system is superior to ordinary absolute sensors, as the working sensor is

gauge and can be zeroed at any time, compensating for potential drift.

128797 03 2015-04-22 26

Page 28

2. If the BARO option is mounted, the pressure type field becomes active and

pressure type can be selected.

128797 03 2015-04-22 27

Page 29

6.0 Using Source modes (Lower Display)

The ASC-400 calibrator can generate calibrated signals for testing and calibrating process

instruments. The calibrator can source voltages, currents, resistances, frequencies,

pulses, and the electrical output of RTD and thermocouple temperature sensors.

6.1 Sourcing mA (internal loop power supply)

To source a current, follow the principle of navigating through the functions described in

the guidelines in section 4.2 and proceed as follows:

1. Select “Current” from the Lower Mode list.

2. Select “Int. Pwr.” from the Power Source list.

3. Select “Out” from the Test Mode list.

4. Connect leads to the mA terminals, as shown in Figure 7.

5. Enter the desired current using either the ARROW keys or the numeric keys.

UUT 900 ohms max. (650 ohms with HART resistor turned on)

-

+

UUT

Figure 7

Connections for Sourcing

Current

128797 03 2015-04-22 28

Page 30

g

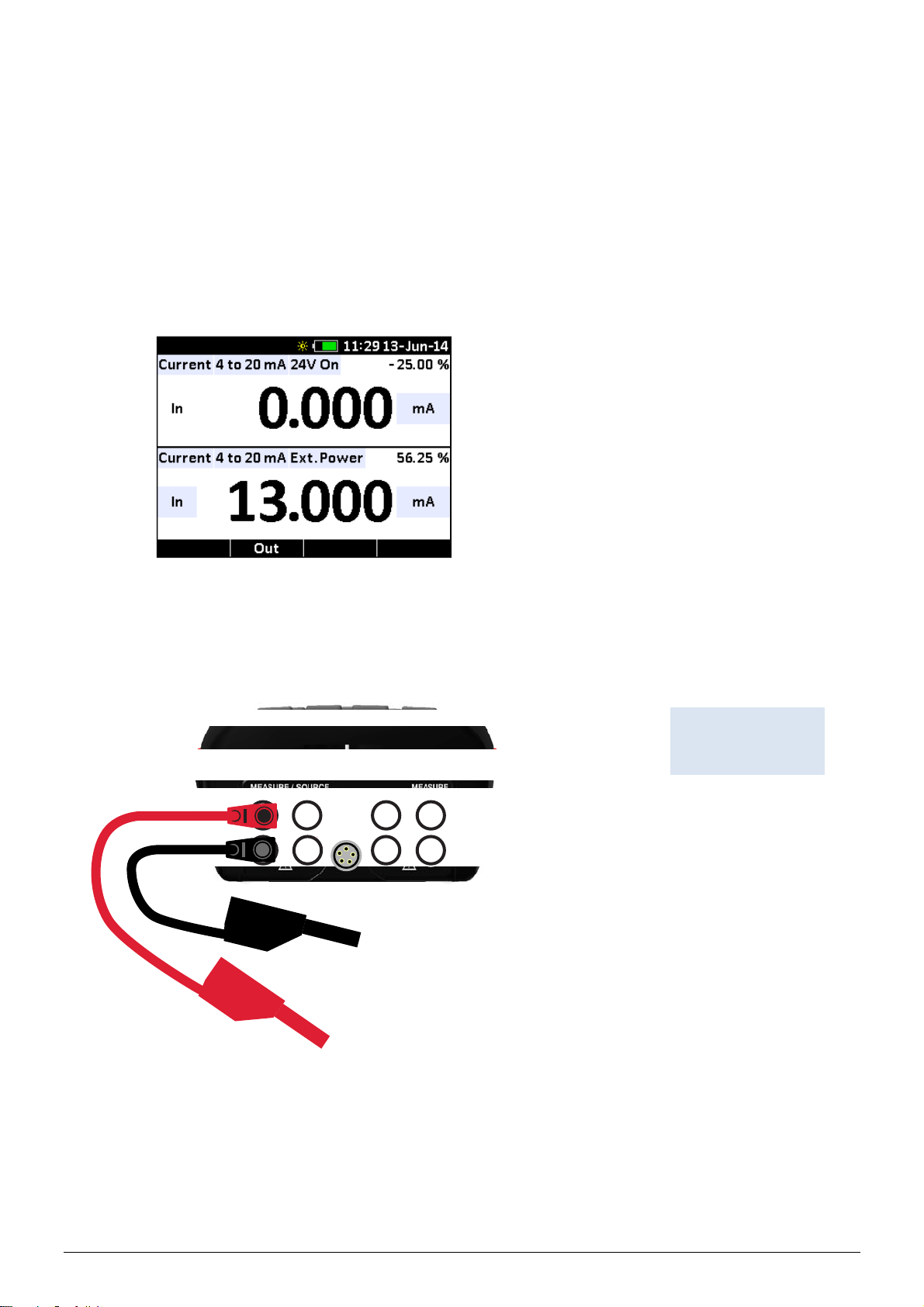

6.2 mA Sink (external loop power supply)

The ASC-400 calibrator can supply a variable test current into a mA loop to calibrate or

debug installed mA loops

Follow the principle of navigating through the functions described in the guidelines in

section 4.2 and proceed as follows:

1. Select “Current” from the Lower Mode list.

2. Select “Ext. Pwr.” from the Power Source list.

3. Connect the loop, as shown in Figure 8.

UUT

-

+

LOOP

POWER

SUPPLY

30 VDC

Figure 8

Connections for mA loop

calibration/debu

128797 03 2015-04-22 29

Page 31

6.3 Sourcing Voltage

y

To source voltage, follow the principle of navigating through the functions described in

the guidelines in section 4.2 and proceed as follows:

1. Select “Voltage” from the Lower Mode list.

2. Select “0 to 20 V” from the Range list.

3. Select “Out” from the Test Mode list.

4. Connect leads to the voltage source terminals, as shown in Figure 9.

5. Enter the desired voltage using either the ARROW keys or the numeric keys.

-

+

UUT

Figure 9

Connections for Sourcing

Voltage and Frequenc

128797 03 2015-04-22 30

Page 32

6.4 Sourcing Frequency

To source a signal, follow the principle of navigating through the functions described in

the guidelines in section 4.2 and proceed as follows:

1. Select “Frequency” from the Lower Mode list.

1. Select “Out” from the Test Mode list.

2. Select the desired frequency unit from the Units list.

3. Connect leads to the frequency output terminals, as shown in Figure 9.

4. Enter the desired frequency using either the ARROW keys or the numeric keys.

5. The amplitude can be changed by entering the Output Volt peak to peak (Out. Vpp)

setup field. Use either the ARROW keys or the numeric keys to change the

amplitude.

6.5 Sourcing a Pulse Train

The ASC-400 calibrator can generate a pulse train with a selectable number of pulses

at a desired frequency and output level.

For example, setting the frequency to 10Hz and the number of pulses to 99999 would

produce 99999 pulses for a period of 10 seconds.

To source a pulse, use the same connection as for frequency, and follow the principle of

navigating through the functions described in the guidelines in section 4.2 and proceed

as follows:

1. Select “Pulse” from the Lower Mode list.

2. Select the desired frequency unit from the Units list.

3. The amplitude of the pulse can be changed by entering the Output (Out. Vpp) setup

field. Use either the ARROW keys or the numeric keys to change the amplitude.

4. Enter the desired number of pulses (Count) using either the ARROW keys or the

numeric keys.

5. Press (Start) to start and stop the signal.

F4

128797 03 2015-04-22 31

Page 33

6.6 Sourcing mV

To source an mV, follow the principle of navigating through the functions described in

the guidelines in section 4.2 and proceed as follows:

1. Connect the thermocouple leads to the appropriate polarized TC mini plug, and

insert the plug into the TC terminals on the calibrator, as shown in Figure 10.

2. Select “Voltage” from the Lower Mode list.

3. Select “-10 to 75 mV” from the Range list.

4. Select “Out” from the Test Mode list.

5. Enter the desired mV using either the ARROW keys or the numeric keys.

Note…

CJ compensation is not active in this mode.

128797 03 2015-04-22 32

Page 34

6.7 Sourcing Thermocouples

To source a thermocouple, follow the principle of navigating through the functions

described in the guidelines in section 4.2 and proceed as follows:

1. Connect the thermocouple leads to the appropriate polarized TC mini plug, and

insert the plug into the TC terminals on the calibrator, as shown in Figure 10.

2. Select “Thermocouple” from the Lower Mode list.

3. Select the desired thermocouple type from the TC Type list.

4. Select the desired CJ mode from the CJ Mode list.

If CJ Manual is selected, enter CJ temperature.

5. Select the desired temperature unit from the Units list.

6. Select “Out” from the Test Mode list.

7. Enter the temperature using either the ARROW keys or the numeric keys.

Note…

The TC wire and connector used must match the TTX / signal converter input

Figure 10

Connections for Thermocouple

temperature and mV output.

(showing additional mA loop from

TTX / signal converter)

128797 03 2015-04-22 33

Page 35

6.8 Sourcing Ohms/RTDs

To source an RTD, follow the principle of navigating through the functions described in

the guidelines in section 4.2 and proceed as follows:

1. Select “RTD” or “Resistance” from the Lower Mode list.

2. Select the desired RTD type from the RTD Type list (only when selecting “RTD” from

the Lower Mode list).

3. Select the desired temperature unit from the Units list (only when selecting “RTD”

from the Lower Mode list).

4. Select “Out” from the Test Mode list.

5. Connect the calibrator to the instrument being tested, as shown in Figure 11.

6. Enter the temperature or the resistance using either the ARROW keys or the

numeric keys.

Note…

The ASC-400 calibrator simulates a 2-wire RTD. To connect 3- or 4-wire

transmitter, use stacked test leads, as shown in Figure 12.

Figure 11

Connections for Outputting RTDs

(always 2-wire)

(showing additional mA loop

from TTX / signal converter)

128797 03 2015-04-22 34

Page 36

3-wire connection 4-wire connection

Figure 12

Using a 3- or 4-wire

Connection for RTDs

6.9 Custom RTD

The ASC-400 offers the possibility of entering a custom curve-fit PRT into the calibrator for

sourcing and measuring.

Follow the principle of navigating through the functions described in the guidelines in

section 4.2 and proceed as follows:

1. Select “Custom” from the RTD Type list. The option is found at the bottom of the list.

2. Press (System) to access the System Settings.

F3

3. Enter the desired values in the Custom RTD setting fields using either the ARROW

keys or the numeric keys and accept the values.

4. Leave the System Settings setup.

5. Attach the custom RTD leads as shown in Figures 11 or 12.

The custom function uses the Calendar-Van Dusen equation for outputting and

measuring custom RTDs.

128797 03 2015-04-22 35

Page 37

The coefficient C is only used for temperatures below 0°C. Only A and B coefficients are

needed for the range above 0°C, so coefficient C should be set to 0.

The R0 is the resistance of the probe at 0°C.

The ITS 90 coeffici ents for PT385, PT3926, and PT3616 are shown in Table 1.

Table 1

RTD Coefficients

RTD Range (°C) R0 Coefficient A Coefficient B Coefficient C

PT385

PT385

PT3926

PT3926

PT3916

PT3916

-200 to 0 100 3.9083 x 10-3 -5.775 x 10-7 -4.183 x 10-12

0 to 850 100 3.9083 x 10-3 -5.775 x 10-7 Below 0 100 3.9848 x 10-3 -5.87 x 10-7 -4 x 10-12

Above 0 100 3.9848 x 10-3 -5.87 x 10-7 Below 0 100 3.9692 x 10-3 -5.8495 x 10-7 -4.2325 x 10-12

Above 0 100 3.9692 x 10-3 -5.8495 x 10-7 -

6.10 Using Auto Output functions

The ASC-400 calibrator has two Auto Output functions:

Step

Ramp

6.10.1 Using the Step function

To use the Step function, follow the principle of navigating through the functions

described in the guidelines in section 4.2 and proceed as follows:

1. Select the desired lower mode from the Lower Mode list. Auto Output options are

not available for Pulse, Pressure and Baro modes.

2. Select “Out Step” from the Test Mode list.

128797 03 2015-04-22 36

Page 38

3. If TC or RTD is selected, choose the type and temperature units first, to get proper

step values.

F3

4. Selection of Step is also possible using the function key (Step) for quick,

menu free access.

5. Select the desired step size from the Step Size list. The ASC-400 will step from the

0% set source value to the 100% set source value in 10%, 20% or 25%increments.

The step time is adjustable from 1 to 999 seconds.

6. Exit the edit mode menu when all the selections have been made.

F3

7. Press (Step) to access the MANUAL Step menu.

or

F4

8. Press (Auto) to start auto stepping, using the selected step time.

F2

9. Pres either (–Step) or (+Step) to Step up- or downwards.

F4

10. In AUTO step, press (Stop) to stop the auto stepping.

11. To cancel Step or Auto step mode, press (Back).

6.10.2 Using the Ramp function

F3

F1

To use the Ra mp function, follow the principle of navigating through the functions

described in the guidelines in section 4.2 and proceed as follows:

1. Select the desired lower mode from the Lower Mode list. Auto Output options are

not available for Pulse, Pressure and Baro modes.

2. Select “Out Ramp” from the Test Mode list.

128797 03 2015-04-22 37

Page 39

3. If TC or RTD is selected, choose the type and temperature units first, to get proper

ramp values.

F4

4. Selection of Ramp is also possible using the function key (Ramp) for quick,

menu free access.

5. Select the desired 0% and 100% values. The ASC-400 will ramp from the 0% set

source value to the 100% set source value in the selected time (5 to 999 seconds).

6. Exit the edit mode menu when all the selections have been made.

7. Press (Start) to begin auto rapping.

F4

8. When ramping, press (Stop) to stop ramping.

F4

F1

9. To cancel Ramp mode, press (Back).

128797 03 2015-04-22 38

Page 40

7.0 Using Isolated Measure Modes (Upper Display)

7.1 Measuring mA (external loop supply)

The current output of a transmitter, or any other 0 to 24 mA current, can be measured

using the upper display.

To make the desired measurements, follow the principle of navigating through the

functions described in the guidelines in section 4.2 and proceed as follows:

1. Select “Current” from the Upper Mode list.

2. Select the primary parameters to be measured and accept the selections.

3. Connect the leads to the isolated inputs of the calibrator, as shown in Figure 13.

Figure 13

mA current measurement

connection (upper window)

128797 03 2015-04-22 39

Page 41

7.2 Measuring current with internal loop power

To test/calibrate a 2-wire, loop powered transmitter, as stand alone, use the loop power

function. This function activates a 24V supply in series with the current measuring

circuit. To use this option, follow the principle of navigating through the functions

described in the guidelines in section 4.2 and proceed as follows:

1. Select “Current” from the Upper Mode list.

2. Select “24V On” from the 24V Power list.

3. Connect the ASC-400 calibrator to transmitter current loop terminals, as shown in

Figure 14.

Figure 14

Connection using build in

loop supply in ASC-400

128797 03 2015-04-22 40

Page 42

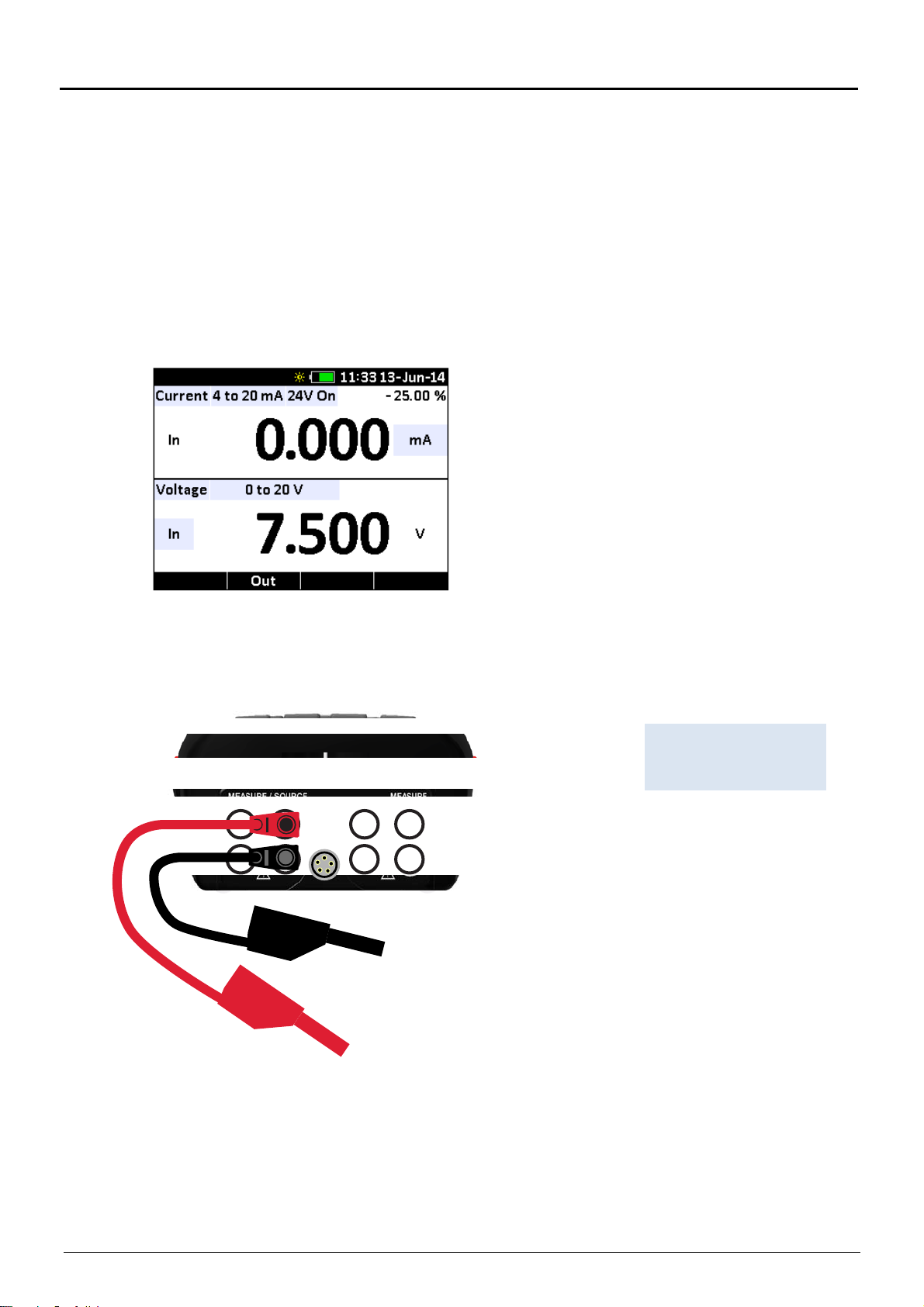

7.3 Measuring Voltage

The voltage output of a transmitter can be measured using the upper display.

To make the desired measurements, follow the principle of navigating through the

functions described in the guidelines in section 4.2 and proceed as follows:

1. Select “Voltage” from the Upper Mode list.

2. Select the primary parameters to be measured and accept the selections.

3. Connect the leads to the isolated inputs of the calibrator, as shown in Figure 13.

7.4 Measuring Pressure

Warning

To avoid a violent release of pressure in a pressurized system, shut off the valve and

slowly bleed off the pressure before you attach the pressure module to the pressure

line.

Caution…

To avoid damaging the pressure module from overpressure, never apply pressure

above the rated maximum printed on the module.

To avoid damaging the pressure module from corrosion, use it only with specified

materials. Refer to the pressure module documentation for material compatibility.

To measure pressure, follow the principle of navigating through the functions described

in the guidelines in section 4.2 and proceed as follows:

1. Connect the pressure module (JOFRA APM) to the ASC-400 calibrator, as shown in

Figure 15.

The calibrator can measure pressure on both the upper and the lower display. This

makes it possible to display the pressure value in two different pressure units at the

same time.

2. Select either the upper or lower display to work from.

3. Select “Pressure” from the Upper or Lower Mode list.

4. Select the desired measuring unit from the Units list

128797 03 2015-04-22 41

Page 43

5. Zero the pressure module (see section 5.5.1 for using the zeroing function).

Figure 15

Measuring on a Pressure

Transmitter (PTX)

Pressure transmitter

APM pressure module

128797 03 2015-04-22 42

Page 44

8.0 Using the Upper and Lower Display for Calibration and Testing

8.1 Performing a Temperature Switch Test

The ASC-400 calibrator can detect switch state changes and link the results in any

source/simulate mode (except pulse), performing an automatic or semi automatic switch

calibration, on a great variety of pressure, temperature and electrical level switches.

An example is given below for calibrating a temperature switch, measuring the

temperature with an external RTD sensor, using an external temperature source.

RTD Probe

Temperature

Switch

To perform a switch test, follow the principle of navigating through the functions

described in the guidelines in section 4.2 and proceed as follows:

1. Select the upper display and select “Switch Test” from the Upper Mode list.

2. Connect the ASC-400 calibrator to the switch using the switch terminals. The polarity

of the terminals does not matter.

3. The upper display shows no read outs at neither “Closed”, “Opened” nor “Dead

band”

Figure 16

Temperature Switch Test

128797 03 2015-04-22 43

Page 45

4. Raise the temperature slowly until the switch opens.

5. Lower the temperature slowly until the switch closes.

6. The upper display will now show :

the temperature when the switch closed

the temperature that the switch opened at

the dead band between the temperatures readings.

7. To perform another test clear the data by selecting “Reset” using the edit mode.

128797 03 2015-04-22 44

Page 46

8.2 Performing a Pressure Switch Test

The ASC-400 calibrator can detect contact state changes and capture the results in any

source/simulate mode (except pulse). The calibrator records switch state and pressure

measurement, at the time of switch change, after the test, the result is displayed in a

convenient and easy to use format.

An example is given below for a pressure switch test.

Pressure Switch

To perform a switch test, follow the principle of navigating through the functions

described in the guidelines in section 4.2 and proceed as follows:

1. Select the upper display and select “Switch Test” from the Upper Mode list.

2. Connect the ASC-400 calibrator to the switch using the pressure switch terminals.

The polarity of the terminals does not matter.

Hand Pump

Figure 17

Pressure Switch Test

APM Module

128797 03 2015-04-22 45

Page 47

3. Connect the pump to the ASC-400 calibrator and the pressure switch.

4. Make sure the vent on the pump is open. Zero the pump if necessary.

Note…

Zero the APM if necessary. Close the vent after zeroing the calibrator.

5. The upper display shows no read outs at neither “Closed”, “Opened” nor “Dead

band”

6. Apply pressure with the pump slowly until the switch opens.

Note…

In the switch test mode the display update rate is increased to help capture

changing pressure inputs. Even with this enhanced sample rate pressurizing

device under test should be done slowly to ensure accurate readings.

7. Vent the pump slowly until the pressure switch closes.

8. The upper display will now show :

the pressure when the switch closed

the pressure that the switch opened at

the dead band between the pressure readings.

128797 03 2015-04-22 46

Page 48

8.3 Testing an Input or Indicating Device

To test and calibrate actuators, recording, and indicating devices using the source

functions, follow the principle of navigating through the functions described in the

guidelines in section 4.2 and proceed as follows:

1. Select the lower display and select the desired primary parameter from the Lower

Mode list.

2. Select “Out” from the Test Mode list (input/output control).

3. Connect the leads to the device and the ASC-400 calibrator as shown in Figure 18.

Figure 18

Connections for Testing an

Output Device

Input / Measure Device

8.4 Calibrating an I/P Device

To calibrate a device that controls pressure, follow the principle of navigating through

the functions described in the guidelines in section 4.2 and proceed as follows:

1. Select the upper display and select “Pressure” from the Upper Mode list.

2. Select the lower display and select “Current” from the Lower Mode list.

3. Connect the ASC-400 calibrator to the device as shown in Figure 19.

The calibrator will simulate the transmitter current and measure the output pressure.

4. Enter a current using either the ARROW keys or the numeric keys.

3 mA max. current

128797 03 2015-04-22 47

Page 49

Figure 19

Calibrating an I/P Device

Pressure Device

APM pressure module

128797 03 2015-04-22 48

Page 50

8.5 Calibrating a Transmitter (Signal Converter)

To calibrate a transmitter both the upper and the lower displays will be used; one for

measuring the output, and one for sourcing the input. This section covers all but the

pressure transmitters. A RTD temperature transmitter is used in this example.

Follow the principle of navigating through the functions described in the guidelines in

section 4.2 and proceed as follows:

1. Select the lower display and select “RTD” from the Lower Mode list.

2. Select “Out” from the Test Mode list (input/output control).

3. Select “RTD” from the RTD Type list.

4. Select the upper display and select “Current” from the Upper Mode list.

5. Select “4 to 20mA” from the Range list.

6. To turn the loop power on, select “24V On” from the 24V Power list (loop power).

7. Connect the ASC-400 calibrator to the transmitter as shown in Figure 20.

8. Enter output values using the numeric keys or fine adjust using the ARROW keys.

9. Adjust the transmitter as necessary.

To calibrate different transmitter types, follow the above steps with the exception of

selecting the appropriate input type on the lower display.

Figure 20

Calibrating a Transmitter

128797 03 2015-04-22 49

Page 51

8.6 Calibrating a Pressure Transmitter (loop powered 4-20 mA)

To calibrate a pressure transmitter both the upper and the lower displays will be used;

upper for measuring the output, and lower for pressure measurement.

Follow the principle of navigating through the functions described in the guidelines in

section 4.2 and proceed as follows:

1. Select the lower display and select “Pressure” from the Lower Mode list.

2. Select the upper display and select “Current” from the Upper Mode list.

3. Select “4 to 20mA” from the Range list.

4. To turn the loop power on, select “24V On” from the 24V Power list.

5. Connect the ASC-400 calibrator to the transmitter and the pressure module as

shown in Figure 21.

6. Zero the pressure module.

7. Test the transmitter at 3 or more points of the span to prove hysteresis.

8. Adjust the transmitter as necessary.

128797 03 2015-04-22 50

Page 52

Figure 21

Calibrating a Pressure

Transmitter

APM pressure module

Hand pump

128797 03 2015-04-22 51

Page 53

8.7 Using Scaled Current or Voltage when testing or calibrating a T/I Transmitter

The ASC-400 calibrator has the ability to read current or voltage on the upper display

that is scaled to and displayed in the same units of the lower display.

Follow the principle of navigating through the functions described in the guidelines in

section 4.2 and proceed as follows:

1. Select the lower display and select “RTD” from the Lower Mode list.

2. Select “Out step” from the Test Mode list (input/output control).

3. Select “RTD” from the RTD Type list.

4. Set the 0%, the 100% span points and the time using either the ARROW keys or the

numeric keys

5. Select the upper display and select either “Current” or “Voltage” from the Upper

Mode list.

6. Select power mode, internal or external power. (Current only)

7. Select “Scaling” from the Units list.

8. From the Scaling Menu set the 0% and 100% point for the upper and lower displays

using either the ARROW keys or the numeric keys.

128797 03 2015-04-22 52

Page 54

8.8 Using Percent Error when testing or calibrating a T/I Transmitter

The ASC-400 calibrator features a function which can calculate signal or pressure vs.

milliamp error as a percentage of the 4 to 20 mA loop span.

Follow the principle of navigating through the functions described in the guidelines in

section 4.2 and proceed as follows:

1. Select the lower display and select “RTD” from the Lower Mode list.

2. Select “Out step” from the Test Mode list (input/output control).

3. Select “RTD” from the RTD Type list.

4. Set the 0%, the 100% span points and the time using either the ARROW keys or the

numeric keys

5. Select the upper display and select either “Current” or “Voltage” from the Upper

Mode list.

6. Select power mode, internal or external power. (Current only)

7. Select “%Error” from the Units list.

8. From the %Error Menu set the 0% and 100% point for the upper and lower displays

using either the ARROW keys or the numeric keys.

128797 03 2015-04-22 53

Page 55

9.0 Maintenance

Only qualified service personnel should perform calibration, repairs, or service not covered by

this manual.

For maintenance procedures not described in this manual, or if the ASC-400 calibrator needs

repair, please contact AMETEK Denmark Service Department as described below in section 9.1

“Returning the calibrator to service”.

9.1 Returning the calibrator to service

If the calibrator continuously malfunctions, verify that the instrument is being operated as

described in this manual and return it to the manufacturer for repair/service.

If the calibrator needs repair and is under warranty, see the warranty statement section 1.1 for

terms. If the warranty has lapsed, the calibrator can be repaired and returned for a fixed fee.

When returning the instrument please enclose a fully completed service information form.

Simply copy the “Service info” form from the following page and fill in the required information.

The calibrator should be returned in the original packing.

Warning

To avoid possible electric shock, personal injury or sudden release of pressure, review

“Safety Instructions” Section 2.0 before proceeding.

Note…

AMETEK Denmark’s liability ceases if:

parts are replaced/repaired using spare parts, which are not identical to those

recommended by the manufacturer.

non-original parts are used in any way when operating the instrument.

AMETEK Denmark’s liability is restricted to errors originated from the factory.

128797 03 2015-04-22 54

Page 56

Service info

Customer data: Date:

Customer name and address:__________________________ _________________________________________

Attention and dept.:_______________________________________ ____________________________________

Fax no./phone no.:____________________________________________________________________________

Your order no.:_______________________________________________________________________________

Delivery address:_____________________________________________________________________________

Distributor name:__________________________________________________________________________ ____

Instrument data:

Model and serial no.:___________________________________________________________________________

Warranty claimed Yes:___________ No:___________ Original invoice no.:________________________

_____________________________________________________________________________________________________

Temp. Sensor Service request: This instrument is sent for

calibration input (please check off):

___ Calibration as left ___ Check

___ Calibration as found and as left ___ Service

___ Accredited calibration as left ___ Repair

___ Accredited calibration as found and as left.

_____________________________________________________________________________________________________

Diagnosis data/cause for return:

Diagnosis/fault description:______________________________________________________________________

_____________________________________________________________________________________________________

_____________________________________________________________________________________________________

_____________________________________________________________________________________________________

_____________________________________________________________________________________________________

Special requests:__________________________________ _______ ____ ____ _______ ____ _______ ____ ______

_____________________________________________________________________________________________________

_____________________________________________________________________________________________________

_____________________________________________________________________________________________________

_____________________________________________________________________________________________________

Safety precautions: if the product has been exposed to any hazardous substances, it must be

thoroughly decontaminated before it is returned to AMETEK Denmark A/S. Details of the hazardous

substances and any precautions to be taken must be enclosed.

128797 03 2015-04-22 55

Page 57

9.2 Replacing batteries

The battery icon indicates how much power is remaining.

If the batteries discharge too deeply the calibrator will automatically shut down to avoid battery

leakage and false measurements.

All stored data will be preserved.

Caution…

Always set the charger switch in “Alkaline” position when alkaline batteries are installed

The ASC-400 calibrator uses six AA batteries.

Use ONLY AA size Alkaline batteries or optional NiMH rechargeable batteries.

Ensure the battery type switch is in the right position (Alkaline or rechargeable).

(factory setting).

1. Unscrew the captive screw to gain access to the battery compartment.

Figure 22

Replacing batteries

2. Replace the batteries taking care to note polarity for their proper installation.

Position for

Alkaline

batteries

Position for

Rechargeable

batteries

3. Remount battery cover and the captive screw.

128797 03 2015-04-22 56

Page 58

9.3 Storing

It is not necessary to store away the ASC-400 calibrator after use.

The calibrator can be part of a continuous set-up, as long as it is kept in a dry, clean place.

Alternatively the calibrator can be stored in the soft bag delivered with the instrument.

9.4 Cleaning

Caution…

Before cleaning the calibrator, you must switch it off.

Periodically wipe the case of the calibrator with a damp soft cloth. A mild detergent can be used

with the water.

Caution…

The soft cloth must be firmly wrung to avoid any water penetrating the calibrator

and causing damage.

Do not use solvents or abrasive cleansers. They might damage the display and

case.

128797 03 2015-04-22 57

Page 59

10.0 Errors

If the power is lost to the entire test set-up or part of it, it is highly recommended to restart the

calibration.

GENERAL ERRORS

Error description Solution

Warning

During set-up, make sure that there is correlation between the software set-up, and the

actual distribution of the sensors connected to the calibrator. The software cannot

detect misplacements of sensors.

ASC-400 does not turn on :

Faulty readout :

No contact with the ASC-400 :

When using Hyper Terminal or similar terminal programs, and co mmunications

Faulty readout from

thermocouples:

Check the batteries

Check the power supply

If the error still occurs, return the ASC-400 to the manufacturer for service

Check that the connected sensors are correctly connected and that they are

properly polarised

Check that the ASC-400 is set up correctly

Switch the ASC-400 off and on again

If the error still occurs, return the ASC-400 to the manufacturer for service

Check the power supply

Check the USB connection. Use only the supplied cable

Switch the ASC-400 off and on again - and set up the software again

If the error still occurs, return the ASC-400 to the manufacturer for service

fails, check that the program has been set up correctly.

Check that the correct type has been selected during setup

Check that the sensors have been correctly polarised and connected

Check that the correct type of cold junction has been selected

manually/automatically/off

Check that the ASC-400 is not subjected to direct or indirect heat sources

128797 03 2015-04-22 58

Page 60

11.0 Technical specifications

g

play

(

)

All specifications are given with an ambient temperature of 23 ±5°C / 73 ±9°F

Mechanical specifications

Description Value

Operating temperature :

Storage temperature :

Dimension LxWxH :

Case protection:

Humidity:

Display:

Weight incl. Batteries :

Unit in soft case :

Weight incl. Test leas and test chips :

Shipping size :

Shipping weight :

-10 to 50°C / 14 to 122°F

-20 to 60°C / -4 to 140°F

220x96x55 mm / 8.66x3.78x2.17 in

IP40

0% to 80% R.H. non-condensin

2.8" 320*240 TFT colour dis

584 g / 20.6 oz

235x95x115 mm / 9.25x3.74x4.53 in

933 g / 32.91 oz

275x100x175 mm / 10.83x3.94x6.89 in

1233 g /43.49 oz

Electrical specifications

Description Value

Mains adapter:

Batteries :

Battery lifetime, Alkaline, backlight low:

Battery lifetime, Alkaline, backlight high,

12 mA: loop power:

attery charge current. Use only NiMH cells

ith capacity larger than 1700 mAh.:

(opt i o n) 9VDC/500mA - 230VAC/115VAC

6 x AA batteries

1.5V AA… Alkaline (non rechargeable) or AA NiMh

rechargeable

30 hours

13 hours

85 mA

RS232 communication interface :

Connector :

Communication type :

Display update rate:

Temperature coefficient:

-10°C to 18°C and 28°C to 50°C:

Thermocouple mV

TC mV read

TC mV source

Maximum output current is 3 mA Output impedance 0.010 ohm. Input impedance 10 Mohm.

128797 03 2015-04-22 59

Mini USB female (B)

USB 2.0 / ASCII

2.5/second (mA, V, resistance, RTD, TC)

10/second (pressure, switch-test)

0.003%FS/°C / 0.0017%FS/°F (mA, V, resistance)

0.001%rdg/°C / 0.0006%rdg/°F (frequency)

Range Accuracy ±

Min Max 12 months

-10.000 mV 75.000 mV 0.015% rdg +10µV

-10.000 mV 75.000 mV 0.015% rdg +10µV

Page 61

Thermocouple Cold junction

Range Accuracy ±

Min Max 12 months

CJC compensation

CJC outside above

Volt V

Read (Isolated)

Read (non-isolated)

Source

18°C / 64°F 28°C / 83°F 0.2°C / 0.36°F

0.05°C/°C

0.05°F/°F

Range Accuracy ±

Min Max 12 months

0.000 V 30.000 V 0.01% rdg +2mV

0.000 V 20.000 V 0.01% rdg +2mV

0.000 V 20.000 V 0.01% rdg +2mV

Maximum output current in voltage ranges is 3 mA Output impedance <1 ohm . Input resistance 1 Mohm.

Frequency Pulse

CPM read

Hz read

0.050 10.000 0.05% rdg + 0.001Hz

10.000 100.00 0.05% rdg + 0.01Hz

100.00 1000.0 0.05% rdg + 0.1Hz

1000.0 10000 0.05% rdg + 1Hz

Range Accuracy ±

Min Max 12 months

2.0 600.0 0.05% rdg + 0.1CPM

KHz read

CPM source

Hz source

KHz source

Pulse (source only)

Rate : 1 Hz to 10KHz

1.000 10.000 0.05% rdg +0.001KHz

2.0 600.0 0.05% rdg

0.050 1000.0 0.05% rdg

1000.0 10000 0.06% rdg

1.000 10.000 0.06% rdg

1 99999

Input voltage amplitude range on frequency is 1 to 20 V, Trigger level 0.2 to 10 volt. Minimum pulse width 10 µS.

Output amplitude is adjustable from 1 to 20 V and is a square wave with a 50% duty cycle.

For output frequency, a slight negative offset of approximately -0.1 V is present to assure zero crossing.

Ohm

Ohm read (low)

Ohm read (high)

Ohm source (low)

@ 0.1 to 0.2 mA

@ 0.2 to 0.5 mA

@ 0.5 to IE max

Range Accuracy ±

Min Max 12 months

0.00 400.00 0.015% rdg + 0.03 ohm

400.0 4000.0 0.015% rdg + 0.3 ohm

5.0

5.0

5.0

400.00

400.00

400.00

0.015% rdg +0.10 ohm

0.015% rdg +0.05 ohm

0.015% rdg +0.03 ohm

Ohm source (high)

@ 0.05 to 0.1 mA

@ 0.1 to IE max

400.0

400.0

4000.0

4000.0

0.015% rdg +0.5 ohm

0.015% rdg +0.3 ohm

True Ohm Measurement current (pulsed) 0.25 mA.

3W measurement current match 1% Source exitation current IEXI(max) = 2.0 V / R, IEXI must never exceed 3 mA.

Pulsed current (source) Unit is compatible with smart transmitters and PLCs with pulse > 5 ms.

128797 03 2015-04-22 60

Page 62

Current – mA and loop

Description Value

Range mA:

Loop power for transmitter:

Isolated input:

Current mA

Read (Isolated)

Read (non-isolated)

Source

Hart resistor 250 ohm (On/Off in software). Maximum loop resistance source @ 24 mA (Hart on/ Hart off) 6 50 ohm

/ 900 ohm.

mA source voltage input range (external power/HART resistor off) 1V ‐ 30V.

0 to 24 mA

Yes, 24 VDC / ±10%

Yes

Range Accuracy ±

Min Max 12 months

0.000 mA 24.000 mA 0.010% rdg +2

0.000 mA 24.000 mA 0.010% rdg +2µA

0.000 mA 24.000 mA 0.010% rdg +2

µ

A

µ

A

128797 03 2015-04-22 61

Page 63

Thermocouple - TC

Description Value

TC types:

Cold junction compensation ON/OFF

Control:

TC Type

B

BP

C

E

J

K

L

N

R

S

T

128797 03 2015-04-22 62

Temperature

resolution

Source Measure

0,1 0,1

0,1 0,1

0,1 0,1

0,1 0,01

0,1 0,01

0,1 0,01

0,1 0,01

0,1 0,01

0,1 0,1

0,1 0,1

0,1 0,01

B, BP, C, E, J, K, L, N, R, S, T, U, XK

Yes

Temperature range 12 month accuracy

°C °F °C °F

Min. Max. Min. Max.

250 300 482 572 4,02 7,24

300 400 572 752 3,36 6,05

400 600 752 1112 2,47 4,45

600 800 1112 1472 1,60 2,88

800 1000 1472 1832 1,39 2,51

1000 1820 1832 3308 1,07 1,93

0 1200 32 2192 0,89 1,61

1200 2000 2192 3632 1,39 2,51

2000 2500 3632 4532 1,96 3,53

0 200 32 392 0,75 1,35

200 800 392 1472 0,64 1,16

800 1200 1472 2192 0,78 1,41

1200 1600 2192 2912 0,97 1,75

1600 2000 2912 3632 1,24 2,24

2000 2316 3632 4200,8 1,70 3,06

-200 -100 -328 -148 0,46 0,83

-100 0 -148 32 0,26 0,47

0 400 32 752 0,20 0,36

400 1000 752 1832 0,30 0,54

-210 -150 -346 -238 0,59 1,07

-150 0 -238 32 0,34 0,62

0 660 32 1220 0,26 0,47

660 1200 1220 2192 0,36 0,65

-200 -100 -328 -148 0,72 1,30

-100 0 -148 32 0,35 0,63

0 400 32 752 0,30 0,54

400 800 752 1472 0,37 0,67

800 1000 1472 1832 0,42 0,76

1000 1372 1832 2501,6 0,53 0,96

-200 -100 -328 -148 0,37 0,67

-100 900 -148 1652 0,26 0,47

-200 -100 -328 -148 1,08 1,95

-100 0 -148 32 0,50 0,90

0 1000 32 1832 0,41 0,74

1000 1300 1832 2372 0,49 0,89

-50 0 -58 32 2,72 4,90

0 200 32 392 1,89 3,41

200 660 392 1220 1,17 2,11

660 1600 1220 2912 0,95 1,71

1600 1768,1 2912 3214,58 1,07 1,93

-50 0 -58 32 2,51 4,52

0 200 32 392 1,86 3,35

200 400 392 752 1,21 2,18

400 1600 752 2912 1,10 1,98

1600 1768,1 2912 3214,58 1,23 2,22

-200 -100 -328 -148 0,70 1,26

-100 0 -148 32 0,38 0,69

0 200 32 392 0,26 0,47

Page 64

200 400 392 752 0,22 0,40

U

XK

Does not include thermocouple wire error and CJC.

0,1 0,01

0,1 0,01

-200 0 -328 32 0,54 0,98

0 600 32 1112 0,26 0,47

-200 -100 -328 -148 0,43 0,78

-100 0 -148 32 0,23 0,42

0 400 32 752 0,18 0,33

400 800 752 1472 0,24 0,44

128797 03 2015-04-22 63

Page 65

Resistance - RTD

Description Value

RTD types:

Pt10/50/100/200/400/500/1000, Cu10/50/100, Ni120,

YSI400

Response time:

Connection:

4-wire RTD

Type

Pt10(90)385

Pt50(90)385

Pt100(90)385

Pt200(90)385

Pt400(90)385

Pt500(90)385

Pt1K(90)385

P50(90)391

P100(90)391

P100(90)392

M10(90)427

M50(90)428

M100(90)428

M100(90)617

Temperature

resolution

Source Measure

0,1 0,1

0,1 0,01

0,1 0,01

0,1 0,01

0,1 0,01

0,1 0,01

0,1 0,01

0,1 0,01

0,1 0,01

0,1 0,01

0,1 0,1

0,1 0,01

0,1 0,01

0,1 0,01

Less than 5 mSec

2, 3 and 4-wire

Temperature range 12 month accuracy

°C °F °C °F

Min. Max. Min. Max.

-200 100 -328 212 0,85 1,53

100 400 212 752 0,98 1,77

400 660 752 1220 1,12 2,02

660 850 1220 1562 1,23 2,22

-200 100 -328 212 0,22 0,4

100 400 212 752 0,29 0,53

400 660 752 1220 0,35 0,63