Page 1

Linear Displacement Transducer

Installation Manual

957SSI Brik

Series 957SSI Brik™

™

ABSOLUTE PROCESS CONTROL

KNOW WHERE YOU ARE... REGARDLESS

Page 2

Contents

Chapter 1: Overview .................................... 2

Chapter 2: Installing .................................... 5

2.1 Installing to a Mounting Bracket ....... 5

2.2 Magnet Position ............................... 6

Chapter 3: Wiring ........................................ 7

3.1 Wiring Connections .......................... 7

3.2 Features ......................................... 16

3.3 Troubleshooting ............................. 16

3.4 Specications ................................. 17

3.5 Part Numbering System ................. 18

NOTE: Ametek has checked the accuracy of this manual

at the time it was approved for printing. This manual may

not provide all possible ways of installing and maintaining the LDT. Any errors or additional possibilities to the

installation and maintenance of the LDT will be added in

subsequent editions. Comments for the improvement of

this manual are welcome.

Ametek reserves the right to revise and redistribute the

entire contents or selected pages of this manual. All rights

to the contents of this manual are reserved by Ametek.

Unpacking

Carefully remove the contents of the shipping carton and

check each item on the packing slip before destroying the

packing materials. Any damage must be reported to the

shipping company. If you do not receive all of the parts,

contact Ametek at 800-635-0289 (US and Canada) or

248-435-0700 (International).

Most probes are shipped

in a Tube. To remove the

metal end cap, use a large,

at blade screw driver or a

metal rod and tap on the

inner edge of the cap until

it pivots. Grab the cap and

pull it out. Use caution as the edge of the metal cap may

be sharp.

Chapter 1: 957SSI Overview

The 957SSI Brik™ is a magnetostrictive Linear Displacement Transducer (LDT) for highly accurate continuous

machine positioning in a variety of industrial applications.

The 957SSI Brik™ provides a Serial Synchronous Interface output signal that is proportional to the position of the

magnet assembly along the length of the probe.

This sensor is built to withstand the most severe environmental conditions and is completely absolute. This means

that power loss will not cause the unit to lose position information or require re-zeroing. The non-contact design allows this device to be used in highly repetitive applications

without mechanical wear.

Features

The 957SSI has auto-tuning capability. This is the ability to

sense a magnet other than the standard slide magnet and

adjust its signal strength accordingly.

There is an indicator LED that is located at the connector

end of the probe and provides visual status information regarding the operation of the probe. Green indicates proper

or normal operation. Red indicates the loss of the magnetic signal or a probe failure. When the probe is in the

normal mode of operation, the LED will remain illuminated

green continuously.

LED Colors*

Green Magnet is present and within the active range.

Red Fault, the LDT has lost its signal from the magnet or the

magnet has moved into the Null Zone or Dead Band.

*Refer to diagnostics on page 16 for a complete list of LED colors

and functions.

NOTE: The series number on your LDT is a record of all

the specic characteristics that make up your unit. This

includes what interface type it has, its output signal and

range, the type of connector the unit uses, and stroke

length. For a translation of the model number, see Section 3.5 Part Numbering System.

If you have an RMA warranty claim, pack the probe in a

shipping tube or with stiff reinforcement to prevent the

probe from being bent in transit.

2

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 3

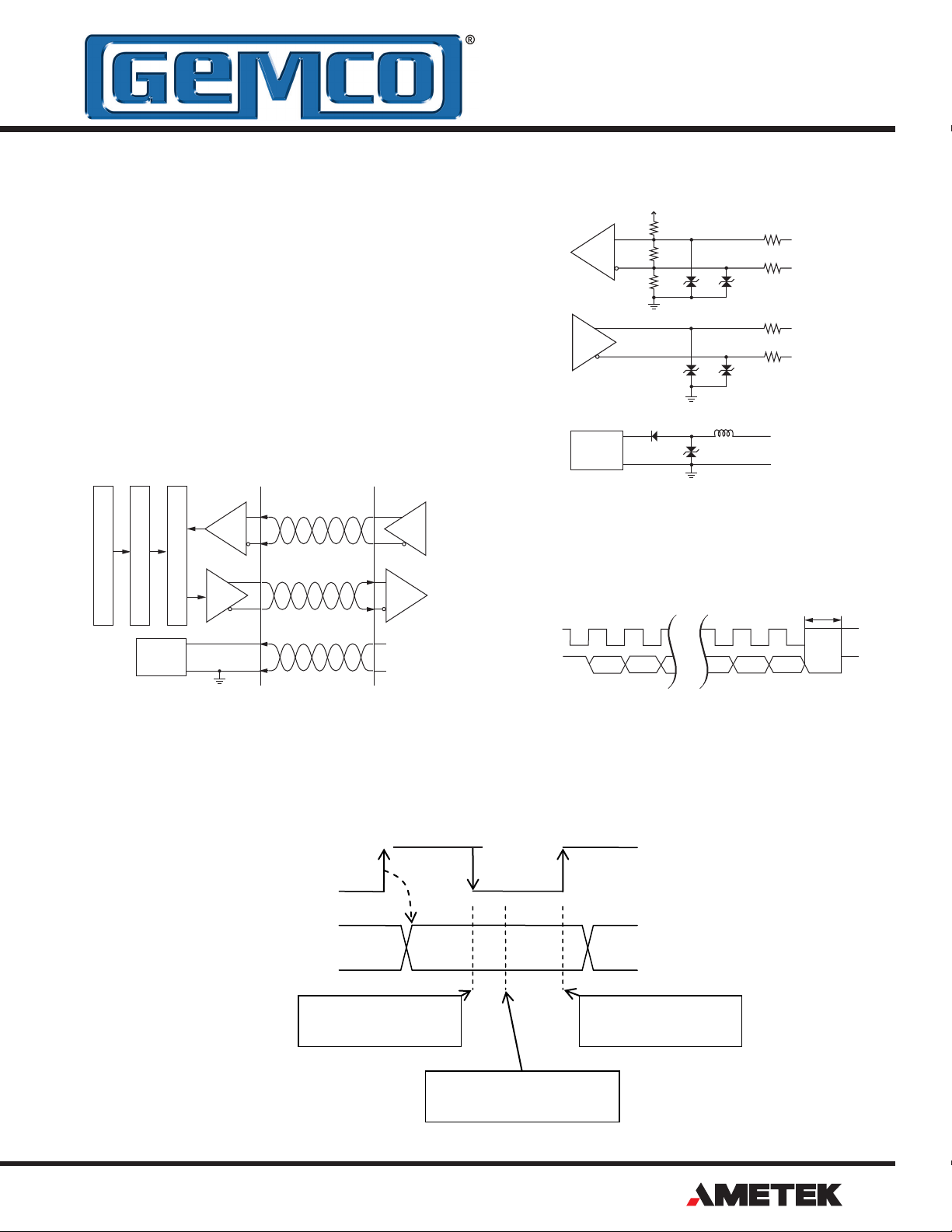

SSI (Serial Synchronous Interface)

CLOCK

DATA

SAMPLING AT

SAMPLING AT

RISING EDGE

SAMPLING

BETWEEN EDGES

SSI Sensor Input

The displacement value (position) is encoded into a 24, 25

or 26 Bit format and transmitted at high speeds. Synchronization in a closed loop system is made easy. A clock pulse

train from a controller is used to shift out sensor data: one

bit of position data is transmitted to the controller for one

clock pulse received by the sensor. The absolute position

data is continually updated by the sensor and converted

by the shift register into serial information.

SSI Logic Diagram

SSI Clock (+)

SSI Clock (-)

Position Measurement

Output Data Format Conversion

Input

Power

Supply

SSI Shift Register and Controller

SSI Data (+)

SSI Data (-)

+7 to 30 V

0V

+5V

RS-422

RS-422

Input

Power

Supply

4.7KΩ

470Ω

4.7KΩ

SSI Timing Diagram

Clock (+)

Data (+)

12V 12V

12V 12V

33V

Ferrite

Filter

10Ω

SSI Clock (+)

10Ω

SSI Clock (-)

10Ω

SSI Data (+)

10Ω

SSI Data (-)

Power Supply (+)

Common

Clock Interval

LSBMSB

Min. 16 µs

Note: Based on Gemco cable P/N 01533149 (Turck P/N RF50610-30M).

New data is placed on the "data" signal 605nS after the rising edge of the "clock" signal. This time, plus the data caused

by cable length, must be considered when determining the setup times (frequency) of the controller.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

3

Page 4

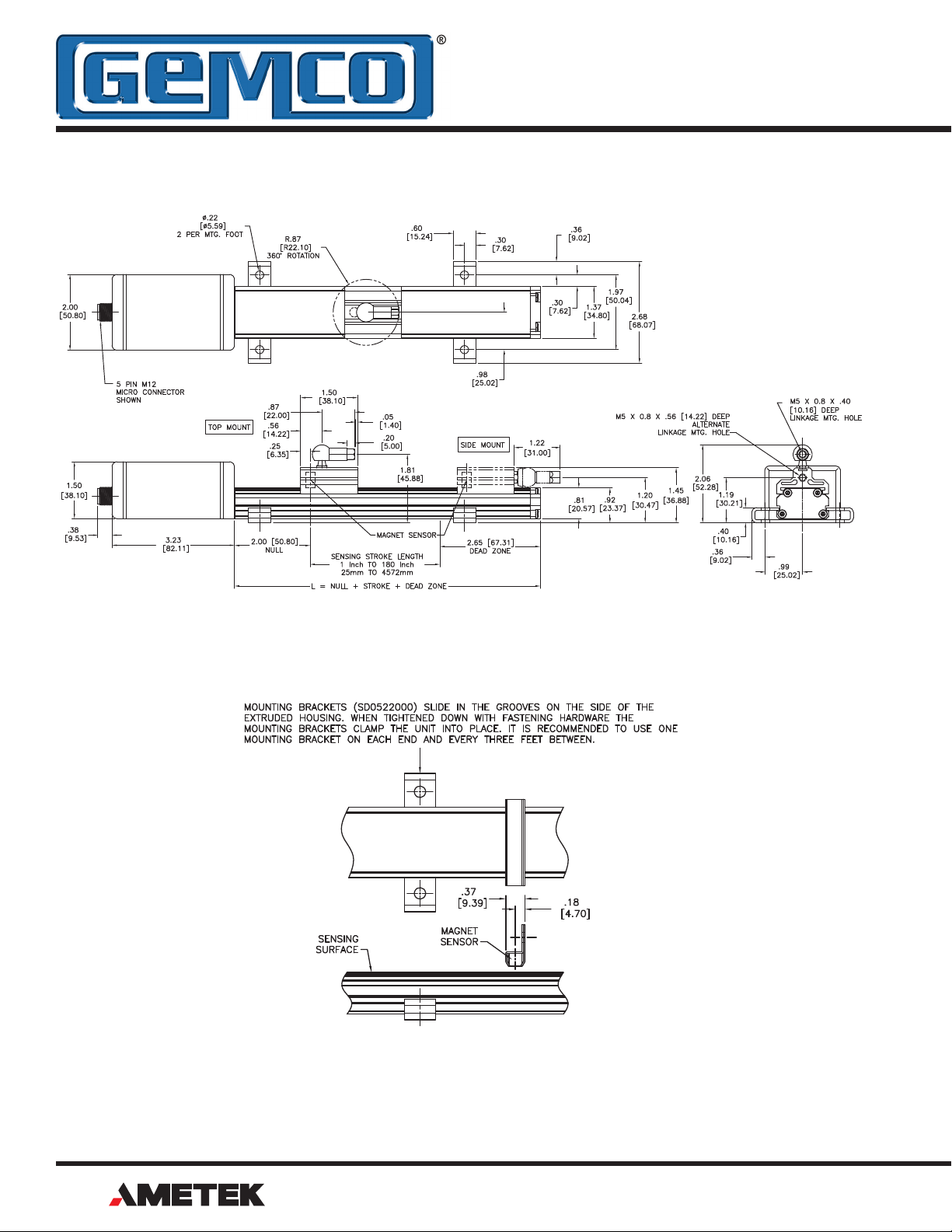

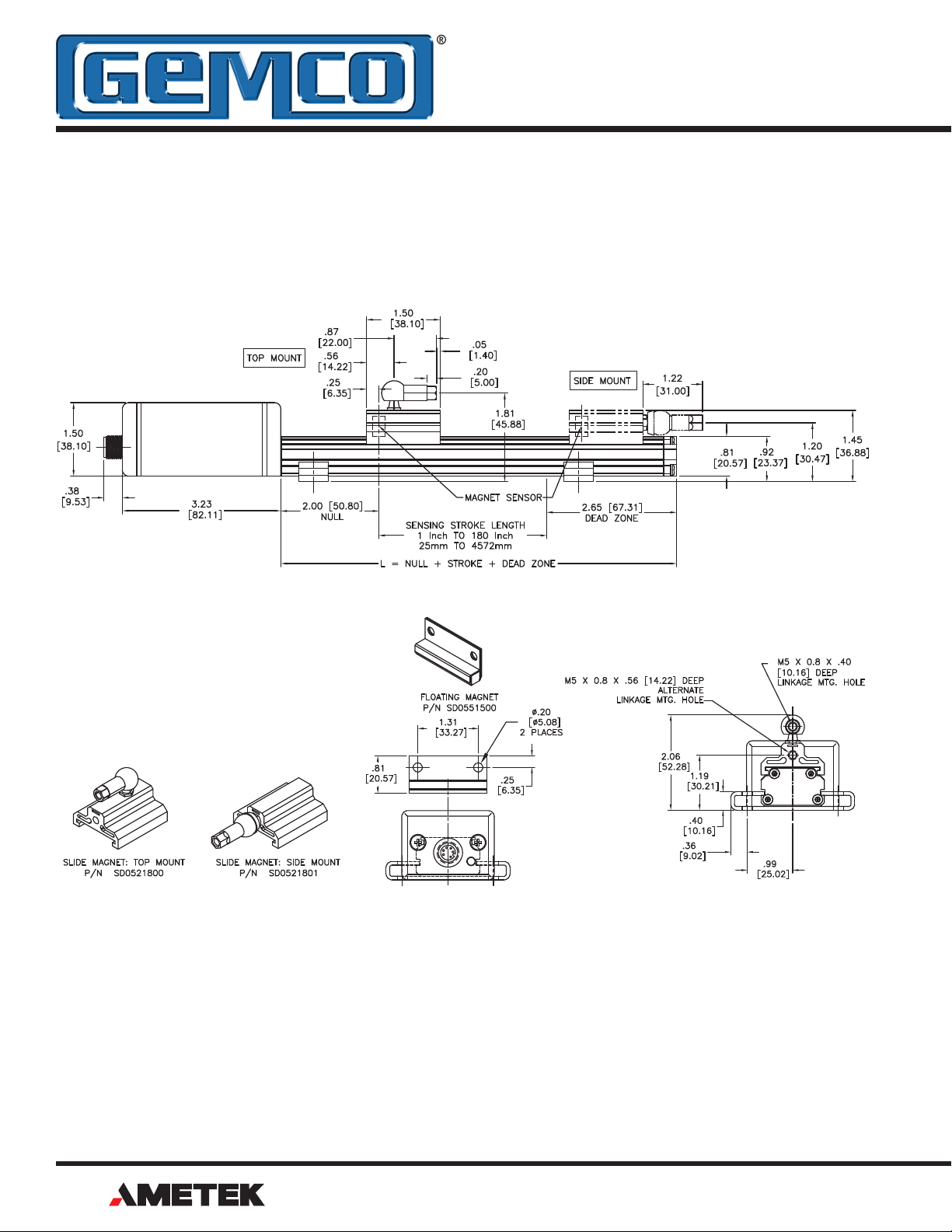

957SSI Brik™ with Magnet Sensor

Figure 1-1 957SSI Dimension Drawing for Reference

Figure 2-1 Mounting Bracket (SD0522000)

4

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 5

Chapter 2: Installing the LDT

Units can be ordered in span lengths up to 180 inches

long in .1 inch increments. The optional slide magnet is designed to move effortlessly along the transducer in guide

tracks, or the standard oating magnet assembly can be

positioned up to 1/4” above the unit. A variety of hardware

is available for attaching the magnet slide to the moving

portion of the process.

The 957 Brik™ has a few truly unique features. One feature is the LDT’s auto-tuning capability, the ability to sense

a magnet other than the standard slide magnet and adjust

its signal strength accordingly.

Mounting

The transducer can be mounted vertically or horizontally

using the supplied SD0522000 mounting brackets. The

mounting brackets slide in the grooves on the lower part

of the extrusion and clamp down when tightened. It is recommended to use one mounting bracket on each end and

every three feet between.

Ferro-magnetic material, which is material readily magnetized, should be placed no closer than .25” from the sensing surface of the LDT.

Magnet Assembly

Magnet choices are the Floating Magnet or the Slide Magnet assemblies. When using the Floating Magnet assembly SD0551500, the magnet should be installed within ¼”

of the sensing surface. The magnet assembly should also

be installed in such a manner that it remains an even distance from the aluminum extrusion throughout the entire

stroke. Improperly installed magnets can result in output

signal non-linearity, or loss of Magnet signal.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

5

Page 6

2.2 Magnet Position

The sliding magnet is designed to move along the extrusion.

The magnet can be slide mounted (Part # SD0521801) or

top mounted (Part # SD0521800). Refer to gure 2-2.

Figure 2-2 Magnet Sensor

6

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 7

Chapter 3: Wiring

!

3.1 Wiring Connections

Once the LDT has been installed, wiring connections can

be made. There are two groups of connections you will

need to make. They are as follows:

• Power Supply Connections (including ground and

shield)

• LDT Input/Output Connections

Power Supply/Ground Connections

The 957SSI is available with many different connector/wiring options. Refer to part numbering on unit in question

for proper wiring. See Section 3.5 for part numbering and

gures 3.3 - 3.8 for wiring details.

The 957SSI standard cable is a 6 Pin, 12mm, cordset.

It has 6 conductors of 24ga, with an aluminum/polyester/aluminum foil with drain wire plus an overall braid of tinned copper shield. Cable O.D. is .23

(5.7mm ). To reduce electrical noise, the shield must be

properly used. Connect the cable’s shield to the controller

system GND.

In order for the 957SSI to operate properly, the LDT’s external power supply must provide a voltage between +7

to +30 VDC. The power supply must be rated at 150mA

minimum. The power supply should provide less than 1%

ripple and 10% regulations. (The power supply should be

dedicated to the LDT to prevent noise from external loads

from affecting the position readings.)

Cable lengths

AMETEK recommends that the maximum cable length be

10 meters. Cables greater than 33 feet are available; however, proper care must be taken during installation.

Any extension to the existing cabling should be mounted in a junction box free of any other cabling, the cable

should be a twisted shielded pair with a braided shield.

The shield should pass straight thru this enclosure and not

tied to ground. When grounding the LDT, a single earth

ground should be connected to the power supply common.

The LDT power supply common should be connected to

the power supply common (-) terminal. The LDT’s shield

should be tied to the earth ground at the power supply.

Cable length limitations are based on SSI clock frequencies. Apply good industry practices for long cable

runs - keep cable away from high power AC lines and all

motor drive cables.

Always observe proper grounding techniques such as single point grounding and isolating high voltage (i.e. 120/240

VAC) from low voltage (7-30 VDC cables). Whenever possible, this cable should be run in conduit by itself. The

power supply common, the cable shield and a good earth

ground should be connected together at the location of

the power supply common. See gure 3-1 Power Supply

Wiring.

WARNING Do not route the Brik™

output cable near high voltage

sources.

UNIPOLAR

Single ended

power supply

+7 to +30 VDC

+ COM

Power+ Common

Figure 3-1 Power Supply Wiring

Controller Data Sampling

Cable Length

6 ft 1.83 m 750 kHz 1500 kHz

30 ft 9.14 m 650 kHz 1300 kHz

100 ft 30.48 m 500 kHz 1000 kHz

150 ft 45.72 m 400 kHz 800 kHz

300 ft 91.44 m 270 kHz 540 kHz

600 ft 182.88 m 160 kHz 320 kHz

1200 ft 365.76 m 90 kHz 180 kHz

Falling

Edge

Rising Edge

Cable Connectors

The 975SSI is available with various cable connection options. See gure 3-2 for standard options. Should a different connector be required for an application, please contact the factory at 800-635-0289.

Note: Minimum SSI clock frequency rate is 70 kHz.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

7

Page 8

Figure 3-2 Standard Cable Connector Options 957SSI

8

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 9

Startup

1. Verify connections

The 957SSI is reverse polarity protected; however, components can be damaged from improper connections or

over voltage. Before applying power verify connections

are correct.

2. Turning on power

Note that the system may execute uncontrolled movement

when power is rst applied when the 957SSI is part of a

closed loop system whose parameters have not yet been

congured.

Position Update

The position of the magnet on the extrusion is precisely

determined by a time of ight method. The 957SSI converts this position value to a 24, 25, or 26 bit Binary or

Gray code data stream where it is transmitted to the host

controller via SSI. All displacement outputs are absolute

and do not lose their position after loss of power.

Position update frequencies are available up to 6500

measurements per second (Length dependant) in Asynchronous mode, and are controller dependant in the Synchronous mode. However, if the controller interrogates

the 957LDT quicker than the LDT can provide data, the

957SSI Brik™ LDT will automatically switch to the Asynchronous mode and supply the host controller with the

most up to date positional information.

NOTE: The data in this mode will always be one update

cycle old.

Asynchronous Update Mode

The 957SSI Brik™ LDT takes measurements at its preset

internal interrogation rate (length dependant) and provides

information when requested from the host controller.

NOTE: If the controller or interface module does not specify Synchronous mode, we recommend using the LDT in

the Asynchronous mode.

Direction

The 957 can be congured increasing, decreasing, position, or velocity. Option “F” (Measure Direction Forward)

will increase counts as the magnet moves from the head

of the LDT to the tip. Option “R” will be exactly opposite.

The zero position will be located at the end of the blue

housing. This is an area where it is physically impossible

to detect a magnetic signal. If the 957SSI is in the “Measure Direction Reverse” option, the zero point will be at the

far tip of the LDT, again a position that the magnet cannot

be detected. If the velocity option is selected, the unit will

output velocity and not displacement.

Synchronous Update Mode

A clock pulse train from the host controller is used to shift

out sensor data, one bit of positional data is transmitted

to the controller for each clock pulse received by the sen-

sor. The rst clock pulse edge from the host controller

signals the LDT to make a measurement. The positional

data from this measurement will be used during the next

controller update cycle.

SSI Clock

Controller

Update

Synchronous

Asynchronous

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Update

Position

Internal

Repitition

Update

Position

Update

Position

Update

Position

Update

Position

Update

Position

Update

Position

Resolution

The resolution of the positional output is selectable in the

part number and can be ordered in English (Imperial) or

metric units. Selections 1 thru B are valid options. Refer

to section 3.5 Part Numbering for further details.

®

9

Page 10

Figure 3-3: Wiring for Connector

Option "S", 6 Pin 12 mm

10

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 11

Figure 3-4: Wiring for Connector

Option "C", Integral Cable Assembly

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

11

Page 12

Figure 3.5 Wiring Diagram

Option "H", High Temperature Integral

Cable Assembly

12

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 13

Figure 3-6:

Wiring for Connector

Option "E", 10 pin MS connector

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

13

Page 14

Figure 3-7:

Option "M", 7 Pin DIN

Wiring for Connector

14

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 15

Figure 3-8: Wiring for Connector

Option "B", 8 Pin DIN

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

15

Page 16

3.2 Features

3.3 Troubleshooting for 957SSI

Automatic Gain Control

The Automatic Gain Control feature will automatically

search and nd the magnet on power up. If power is applied without a magnet on the LDT, the LED will turn RED

indicating no magnet signal is detected. Turn power off

and place magnet within the active stroke area. Re-apply

power.

Accessories

P/N Description

949029L6 6 Foot, 6 Pin, Straight, 12mm Cable

949030L6 6 Foot, 6 Pin, Right Angle, 12mm Cable

SD0554600L6 6 foot, 8 Pin, Straight Cable, for Option B

SD0558500L6 6 Foot, 7 Pin, Straight Cable for Option M

SD0521800 Slide Magnet, Top Swivel

SD0521801 Slide Magnet, Top Swivel

SD0551500 Large Floating Magnet

SD0522000 Mounting Foot

Consult factory for complete accessory offerings.

Diagnostics

The 957SSI is equipped with a tri-color LED next to the connector to help while troubleshooting. The chart below explains the possible LED colors and the faults they represent.

If there is ever a loss of magnet, the LED will turn red and

the unit will transmit a position of zero.

Troubleshooting describes common problems that may

occur when installing the LDT and offers possible solutions to these problems. If, after reading this appendix,

you are unable to resolve a problem, contact our technical support department at 800-635-0289.

General Checks

Make sure that the magnet is located within the LDT’s active stroke area. Magnet assemblies should be positioned

so that they can move freely over the entire area of the

active stroke without binding.

NOTE: Ferromagnetic material (material readily mag-

netized) should be located no closer than 0.25” from the

sensing surface of the LDT. This includes mounting brackets, magnet spacers, magnet brackets, and mounting

screws. Ferromagnetic material can distort the magnetic

eld, causing adverse operation or failure of the LDT.

Check all LDT wires for continuity and/or shorts. It is preferable that the cable between the LDT and the interface

device be one continuous run. If you are using a junction

box, it is highly recommended that the splice junction box

be free of AC and/or DC transient-producing lines. The

shield should be carried through the splice and terminated

at the interface device end.

Power Supply Check

957 LED Output Summary

Output 957SSI

Flashing Red Flash memory corrupt

Flashing Red/Green EE memory corrupt

Flashing Yellow Communication/programming mode

Fast Flashing Yellow Clock input held asserted at power up

Solid Red No magnet signal detected

Green/Red Blip

(1s to 0.12s)

Solid Green Normal probe operation; magnet signal

Solid Yellow No SSI clock pulses detected

Yellow/Red Blip

(1s to 0.12s)

Green/Yellow Blip

(1s to 0.12s)

Max Gain but signal detected and within range

and SSI clock operational

SSI clock pulses do not match

LDT SSI data length

LDT data not Synchronous with controller

(if LDT is programmed for Synchronous mode)

Alarm Bit

The 957SSI can be congured to output a fault bit

should there be a problem with the LDT.

16

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

This will help you to determine if your power supply is

adequate for the LDT to operate properly, or if the LDT’s

cable has a short or open.

In order for the 957SSI to operate properly, the external

power supply must provide a voltage level between 7 to 30

VDC. A power supply providing voltage above this speci-

ed range may damage the LDT. A power supply providing power below this specied range will not be sufcient

to power the LDT. When powering more than one Brik™

on a single power supply, remember that each Brik™ typically requires 1.3 watts of power. The amount of current

draw will vary based on the input voltage, as well as other

operating parameters. To approximate the current draw

for a particular LDT, divide the LDT wattage by the input

voltage. For example, 1.3 watt divided by 24 VDC equals

55mA.

Page 17

If your LDT is not operating properly, the LDT’s cable may

have an open or short, or the power supply is not supply-

ing sufcient power. To verify this, perform the following

steps:

1. Turn the power supply off.

2. Remove the mating connector from the LDT.

3. Turn the power supply on.

4. Using a digital voltmeter, check from the Power Supply Common to the Power Supply + on the mating

end of the cable for a level between +7 and +30

VDC.

If reading is between 7 and 30 VDC, turn power supply off

and go to step 7. If reading is below 7 VDC, either your

power supply is not providing enough power or the LDT’s

cable possibly has a short/open. Readings of no voltage

or minimal voltage (less than 5 volts) may be due to short/

5. Turn the power supply off.

6. Check the continuity of the individual wires of the

cable between the power supply and the LDT. Check

for continuity from one end of the cable to the other.

Also verify that no shorts exist between pins.

7. Reconnect the mating connector to the LDT.

8. Turn power supply on.

9. Using a digital voltmeter, check the power supply’s

“+” and “-” terminals for a voltage between 7 and 30

VDC.

Low voltage readings may indicate a power supply with a

wattage (current) rating that is too low. (Each LDT requires

approximately 1.3 watts). If the cabling checks out in step

6 and your voltage is below 7 VDC, check your power supply current rating. If voltage is between 7 to 30 VDC and

the LDT is still inoperative, contact factory.

open in the cable. If reading is NOT between 7 and 30

VDC, go to step 5. If reading is above 30 VDC, adjust power supply or replace.

* See Section 3.4: Specications for more information on

power consumption.

3.4 Specications

Specications

Connector Interface 6 Pin 12mm

Integral cable ass'y, 7 Pin or 8 Pin

DIN

Displacement 1” to 180" Vibration 30 Gs

Dead Band 2.65" (67.31 mm) standard Update Time Measuring Length 300 750 1000 2000 5000mm

Null Zone 2.00" (50.8 mm) standard Approvals CE (EMC) Non-linearity < 0.01% or +/- 0.005”, whichever

Enclosure Rating IP67, IEC 600529 Input Voltage 7 to 30 VDC Diagnostics Tri-Color LED beside connector/

Measured Variables Single Magnet Displacement, Consult

Factory for Velocity or Differential

Operation

Shock 1000 Gs

Current

Draw

IEC 60068-2-27

IEC 60068-2-6

Measurements/sec. 4.0 2.4 2.0 1.1 0.5k

1.3 watts, (53mA at 24 VDC) typical* Operating

Output Type 24, 25 or 26 Bit, Binary or Gray

Code (optional parity and error

bit), Position Updates

Resolution English or Metric Units

Metric: 1, 5, 10, 20 micron (5

micron standard)

English: .00005", .0001", .0005",

.001"

Consult Factory for Others.

Hysteresis 0.008”

is greater, (+/- 0.003" Typical)

cable exit, See 'LED Output Summary Table' on page 13

Temperature -40° to 185° F ( -40° to 85° C)

Interface Specications Input SSI Clock

Output Data Pulse

Resistance

SSI Clock Frequency Minimum 70 kHz Maximum 150 kHz

NOTE: Specications subject to change and are based on a typical 48” stroke. *1.3 watt typical at 1ms interrogation time. Faster interrogation times increase power consumption.

RS-422, 470 Ohm termination

resistance

RS-422, 2.0V min. @ 100 Ohm

termination

Storage

Temperature

Repeatability Equal to Output Resolution

-40° to 221° F

(-40° to 105° C)

Cable Specications

Cable Type Gauge Jacket Temp Bend Radius

Connector Options "S", "M", "B", "C" 24 PVC -50° to 105° C Moving Applications - 2.36"

High Temp Integral Cable "H" option 22 Teon -70° to 200° C Moving Applications - 4.6"

Connector Option "E" 22 Polyurethane -50° to 105° C Moving Applications - 2.3"

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Fixed applications - 1.18"

Fixed applications - 2.3"

Fixed applications - 1.2"

®

17

Page 18

3.5 Part Numbering System

Brik

Extrusion

VP957 0120 1

Units of Measure

Output Type

S SSI

Stroke Length

1" to 180". Insert stroke length to 0.1 inch. Enter as

a four-place number. Example: A 12.0” stroke enters

as 0120.

OR

Insert stroke in millimeters to 5mm. Enter as a fourplace number. Example: 305mm stroke entered as

0305M.

E Inches

M Metric

Connector Option

S Standard M12 6 Pin

Integral Cable Assembly. Insert length

C_

in feet. Example: C6 = 6 foot cable. *

M 7 Pin DIN, MTS Style D70

B 8 Pin DIN, Balluff S32

High Temp., Integral cable assembly

200° C Teon Cable. Insert length

H_

in feet.

Example: H6= 6 foot High Temp Teon

Cable.

Environmental 10 Pin MS connector

E

compatible with SD0439700 cable

assemblies

* If stroke is in inches, cable is in feet.

If Stroke is in metric, cable is in

meters.

SS

Data Length

1 24 Bits

2 25 Bits

3 26 Bits

Data Format

B Binary

G Gray

Position Update

S Synchronous

A Asynchronous

Direction

F Measures Direction Forward

R Measures Direction Reverse

V Velocity

B

S

F

1

Options

X None

A

Resolution

1 .005mm

2 .01mm

3 .05mm

4 .1mm

5 .02mm

6 .002mm

7 .001mm

8 .00005"

9 .0001"

A .0005"

B .001"

NOTE: Contact our Technical Support at 1-800-635-0289 for custom congurations.

XE

Alarm Bit 25,

Parity 26

18

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 19

Part Number

Serial Number

Purchase Order Number

Sales Order Number

Comments

NOTES:

Page 20

Other Products

®

MADE IN AMERICA

Copyright 2013 by AMETEK AUTOMATION & PROCESS TECHNOLOGIES. All Rights Reserved. Made in the USA.

1080 North Crooks Road, Clawson, MI 48017

Phone: 248-435-0700 Toll Free: 800-635-0289

Email: apt.orders@ametek.com Web: www.ametekapt.com

957.M0R

10/13.Z400

Loading...

Loading...