Page 1

1080 N. Crooks Road, Clawson, MI 48017-1097

Phone: 248-435-0700 Toll Free: 800-635-0289

Fax: 248-435-8120 www.AMETEKAPT.com

INSTALLATION MANUAL

Copyright 2005 by AMETEK AUT OMATION & PROCESS TECHNOLOGIES.

All Rights Reserved. Made in the USA.

L

INEAR

D

ISPLACEMENT

T

RANSDUCERS

956 BLOK

LOW PROFILE SENSOR HOUSING

Other Products

Applications

956LC 956S

956A 956D

956DQ

Includes 956 BLOK

Programming Instructions

and Accessory Guide

956 Series

ABSOLUTE PROCESS CONTROL

KNOW WHERE YOU ARE... REGARDLESS

956.M4R

6/05.Z163

Page 2

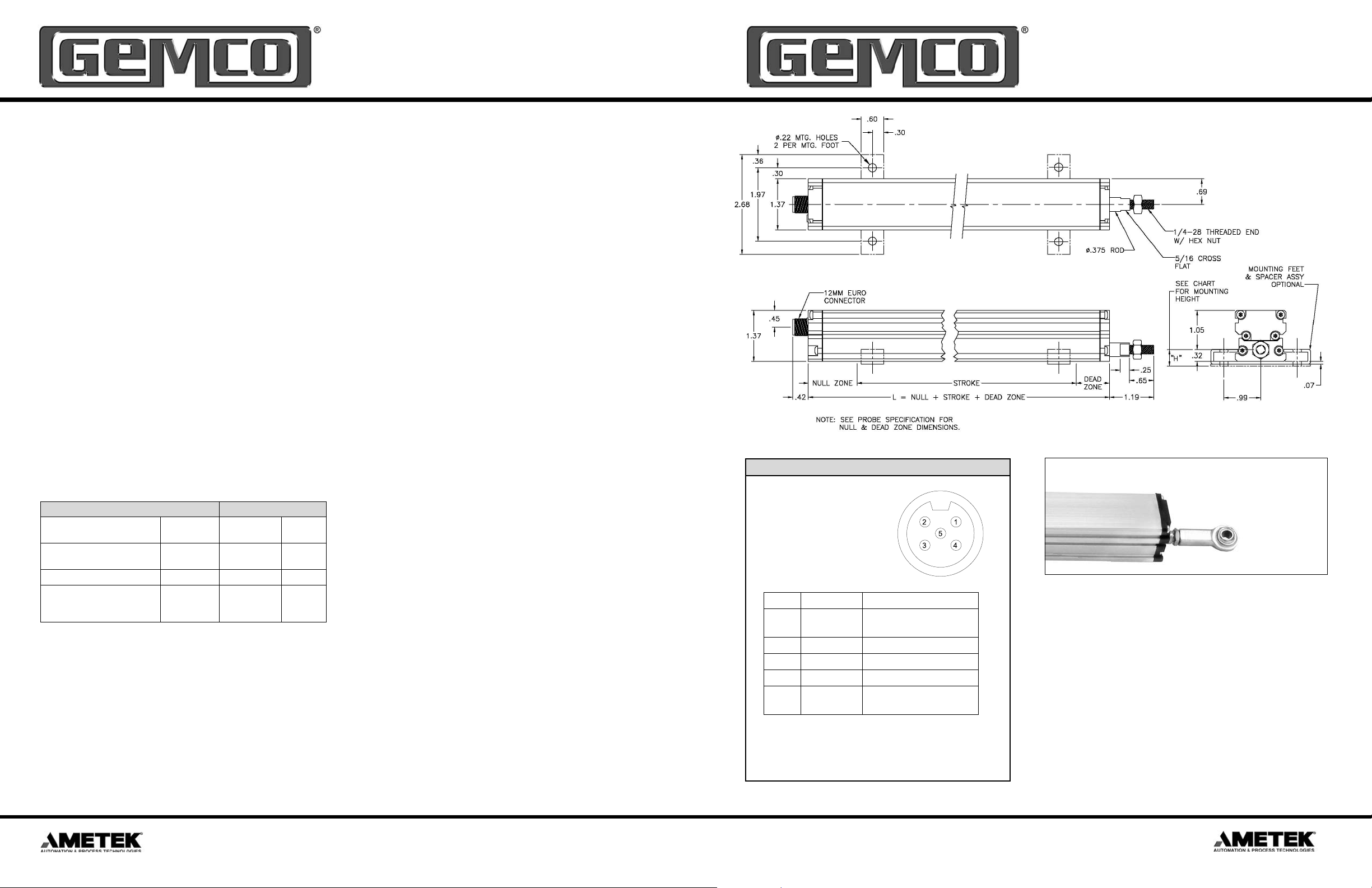

Mounting

The 956 BLOK is available with three optional

mounting heights. When using the standard

SD052200 mounting feet, the distance from the

bottom of the foot to the center of the piston rod is

.315”.

When replacing linear potentiometers we offer a

mounting kit which will include two standard feet and

the necessary spacer to accommodate either a .45”

or .75” mounting height. The part number for the

spacer kit is SD0545100.

The mounting feet simply slide into the groves on the

BLOK extrusion and clamp down when tightened.

The 956 BLOK comes standard with a ¼”-28 UNC

thread and a fl at across the piston for attaching it to

a moving member of the machine. Optional rod ends

are available for ease of mounting and alignment.

When the 956 BLOK leaves the factory it is

programmed for the specifi c stroke length. However,

the mechanical stroke of the piston is greater than the

specifi ed stroke length to help prevent damage that

could occur to the unit if over-stroked.

When the piston is fully retracted, the magnet

assembly will be at 3/8” (.375”) into the Null Zone.

When mounting, or if you plan to re-program the unit,

it is very important to stay out of this area.

To determine the usable portion of the unit, fully

retract the piston assembly, then pull it out 3/8” and

mark this location on the piston with either a pencil

or a marker. From this point, extend the piston by the

active stroke length specifi ed in the part number on

the product label. Again, mark this location on the

piston.

The area between the two marks on the piston is the

sensors active stroke range. To re-program the units

active stroke, please refer to the programming guide

located in the 955 manual.

Preface

The 956 BLOK is a housing option available for all 955

BRIK Style Linear Displacement Transducers.

In this manual you will fi nd all necessary dimension and

mounting drawings. Wiring and programming details

along with electrical specifi cations can be located in the

955 Installation & Programming Manual.

Introduction

The 956 BLOK is an exclusive two chamber industrial

rod and barrel style enclosure for the GEMCO 955 Linear

Displacement Transducers. The electronics are isolated

in a chamber that has an IP67 or optional IP68 rating.

The piston is housed in the second chamber which has

an IP65 rating. The units are available up to a stroke

length of 36 inches. The 316 stainless steel rod or piston

is .375” in diameter and has ¼”-28 threads extending

from the extrusion for easy installation. The opposing end

of the rod is a piston with a magnet permanently affi xed

that slides easily through a Rulon bearing assembly. As

the magnet is moved it is sensed by the electronics in the

other chamber and converted to a useable output.

Caution

!

U

Disconnect power before servicing.

The GEMCO 956 BLOK LDT contains no

serviceable components. Consult factory for

repair or replacement.

NOTE: The 956S BLOK is NOT FM approved for

Class I Div II applications.

Accessories Compatible LDTs

Description Catalog

Number

956A,

S, LC

955D,

QD

Mounting Foot

(order two per probe)

SD0522000 X X

Rod End (Shaft) 04-570256 X X

Mount feet for .45” or .75”

mounting Includes two

mounting feet & spacers

SD0545100 X X

Ametek Automation & Process Technologies has

checked the accuracy of this manual at the time it was

approved for printing. However, this manual may not

provide all possible ways of installing and maintaining

the LDT. Any errors found in this manual or additional

possibilities to the installation and maintenance of

the LDT will be added in subsequent editions. Any

comments you have for the improvement of this manual

are welcomed.

AMETEK reserves the right to revise and redistribute

the entire contents or selected pages of this manual.

All rights to the contents of this manual are reserved by

AMETEK.

Wiring Diagram 955A Only

Euro Connector

(Micro 12 mm single

keyway)

Pin # Wire Color Function

1 Brown Customer Supplied

Power (+VDC)

2 White Program Input

3 Blue Power Supply Common

4 Black Position Output

5 Gray Analog Output

Common

Note: Refer to your specifi c model number

and application manual for the correct wire

diagram and pin location.

Optional Rod End.

Part # 04-570256

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com 1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Loading...

Loading...