American Standard TUC100B948AO User Manual

32-5034-04

User’s Information Guide

Gas Furnaces — Non-Condensing

Fan Assisted Combustion System

Upflow / Horizontal and Downflow / Horizontal

!

WARNING

▲

If the information in this manual is not followed exactly,

a fire or explosion may result causing property

damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier,

call the fire department.

— DO NOT RELY ON SMELL ALONE TO DETECT

LEAKS. DUE TO VARIOUS FACTORS, YOU MAY

NOT BE ABLE TO SMELL FUEL GASES.

• U.L. recognized fuel gas and CO detectors are

recommended in all applications, and their

installation should be in accordance with the

manufacturer's recommendations and/or local

laws, rules, regulations, or customs.

— Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

!

WARNING

▲

DO NOT USE THIS UNIT IF ANY PART HAS BEEN UNDER

WATER. IMMEDIATELY CALL A QUALIFIED SERVICE

TECHNICIAN TO INSPECT THE FURNACE AND TO REPLACE ANY PART OF THE CONTROL SYSTEM AND ANY

GAS CONTROL WHICH HAS BEEN UNDERWATER.

GENERAL INFORMATION

Understand the signal words DANGER, WARNING, AND

CAUTION. These words are safety alert words. DANGER

indicates the most serious hazards which

severe personal injury or death. WARNING indicates hazards

could result in personal injury or death. CAUTION is

which

used to indicate unsafe practices which could result in minor

injury or property damage.

will result in

Contents

Dangers, Warnings & Cautions 1 General Information 1 To Start the Furnace 2 Proper Maintenance 4 The Problem Solver 6 Regular Dealer Maintenance 7 Warranty 9

IMPORTANT FACTS

The flow of combustion and ventilating air must not be

obstructed from reaching the furnace. Air openings provided

in the casing of the furnace must be kept free of obstructions

which would restrict airflow, thereby affecting efficiency and

safe operation of your furnace.

Also, air openings provided to the area in which the furnace

is installed and the space around the furnace shall not be

blocked or obstructed. Keep this in mind should you choose to

remodel the area which contains your furnace. If additional

insulation is added after the furnace is installed, the area

around the furnace must be inspected to ensure it is free and

clear of insulation. If this furnace is installed in an attic or

other insulated space it must be kept free and clear of all insulating materials as some insulating materials are combustible.

Furnaces must have air for proper performance. There must

be a free flow of fresh air sufficient for efficient combustion

and safe ventilation of your furnace.

The combustion air for your furnace must be fresh uncontaminated air. Paints, varnishes, laundry bleaches, detergents, many household cleaners, water softening salts,

adhesives, and all such products release fumes containing

compounds which could lead to early heat exchanger and

vent system deterioration. Do not store these types of

products near your furnace.

Never store gasoline, combustible materials, or other flammable liquids or vapors near your furnace.

Carbon monoxide, fire or smoke can cause serious bodily

injury, death, and/or property damage.

User’s Information

A variety of potential sources of carbon monoxide can be

found in a building or dwelling such as gas-fired clothes

dryers, gas cooking stoves, water heaters, furnaces and

fireplaces. The U.S. Consumer Product Safety Commission

recommends that users of gas-burning appliances install

carbon monoxide detectors as well as fire and smoke detectors,

listed by a nationally recognized agency (e.g. Underwriters

Laboratories or International Approval Services), to help

alert dwelling occupants of the presence of fire, smoke or

unsafe levels of carbon monoxide.

NOTE:

The manufacturer of your furnace does not test any detectors and makes no representations regarding any brand or

type of detector.

!

WARNING

▲

BODILY INJURY CAN RESULT FROM HIGH VOLTAGE

ELECTRICAL COMPONENTS, FAST MOVING FANS, AND

COMBUSTIBLE GAS. FOR PROTECTION FROM THESE

INHERENT HAZARDS DURING INSTALLATION AND

SERVICING, THE ELECTRICAL SUPPLY MUST BE DISCONNECTED AND THE MAIN GAS VALVE MUST BE

TURNED OFF.

Installing and servicing heating equipment can be hazardous

due to gas and electrical components. Only trained and

qualified personnel should install, repair or service heating

equipment.

Untrained personnel can perform basic maintenance functions such as cleaning and replacing filters. All other operations must be performed by trained service personnel.

Parts and controls of this furnace are unique. Should service

or modification be required, be sure your servicer uses only

factory authorized parts, kits, or accessories for this furnace.

If you experience a problem with the operation of your

furnace, check the “Problem Solver” section of this manual

before you call for a possibly unneeded service call.

!

WARNING

▲

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer to

the installation instructions provided with the furnace and

this manual. For assistance or additional information consult a qualified installer, service agency or the gas supplier.

To Start the Furnace

Lighting instructions.

Your furnace does not use a continuously burning pilot flame.

Therefore, manually lighting your furnace is not required.

Your furnace is equipped with an automatic ignition system.

It uses a hot surface ignition device that automatically lights

the burners each time the thermostat signals the furnace to

start.

!

WARNING

▲

Do not attempt to manually light the furnace.

1. Please read all safety information in this book before

operating furnace.

2. Set thermostat to lowest setting. Turn off all electric

power to furnace.

3. Remove the furnace front panel to gain access to the

main gas valve.

4. Turn gas cock knob clockwise or the toggle switch located

on the main gas valve inside the unit to “OFF” position

(see illustration on next page). If external gas cock is

used, turn to “OFF” position (see illustration on next

page). Allow 5 minutes for any gas within the unit to

escape. LP gas being heavier than air may require forced

ventilation. If you smell gas STOP! Follow the “What To

Do If You Smell Gas” instructions on the front cover of

this book. If you don’t smell gas, go to next step.

5. Turn gas cock knob counterclockwise or the toggle switch

to “ON” marker (see illustration on next page).

6. Replace the furnace front access panel.

7. Turn on main electrical supply and set thermostat to

desired setting. Combustion blower will start and

ignition device will start to heat up. After approximately

15 seconds main gas valve will open and burners will

ignite.

8. When thermostat is satisfied, main burners will

extinguish.

9. If main burners fail to ignite, lower thermostat setting or

disconnect electrical supply, wait 5 minutes, raise

thermostat setting above indicated temperature.

10. If furnace will not light, turn “OFF” all gas and electricity to unit and call servicer or gas supplier.

For complete shutdown.

Turn gas cock knob on main gas valve to “OFF” position.

Disconnect electrical supply to unit.

!

CAUTION

▲

If this is done during the cold weather months, provisions

must be taken to prevent freeze-up of all water pipes and

water receptacles.

Whenever your house is to be vacant, arrange to have

someone inspect your house for proper temperature. If your

furnace should fail to operate, damage could result, such as

frozen water pipes.

Flame Roll-out Device.

All models are equipped with a fusible link located near the

burners. In case of flame roll-out, the link will open (melt)

and cause the circuit to open which shuts off all flow of gas.

© 2002 American Standard Inc. All Rights Reserved 32-5034-04

User’s Information

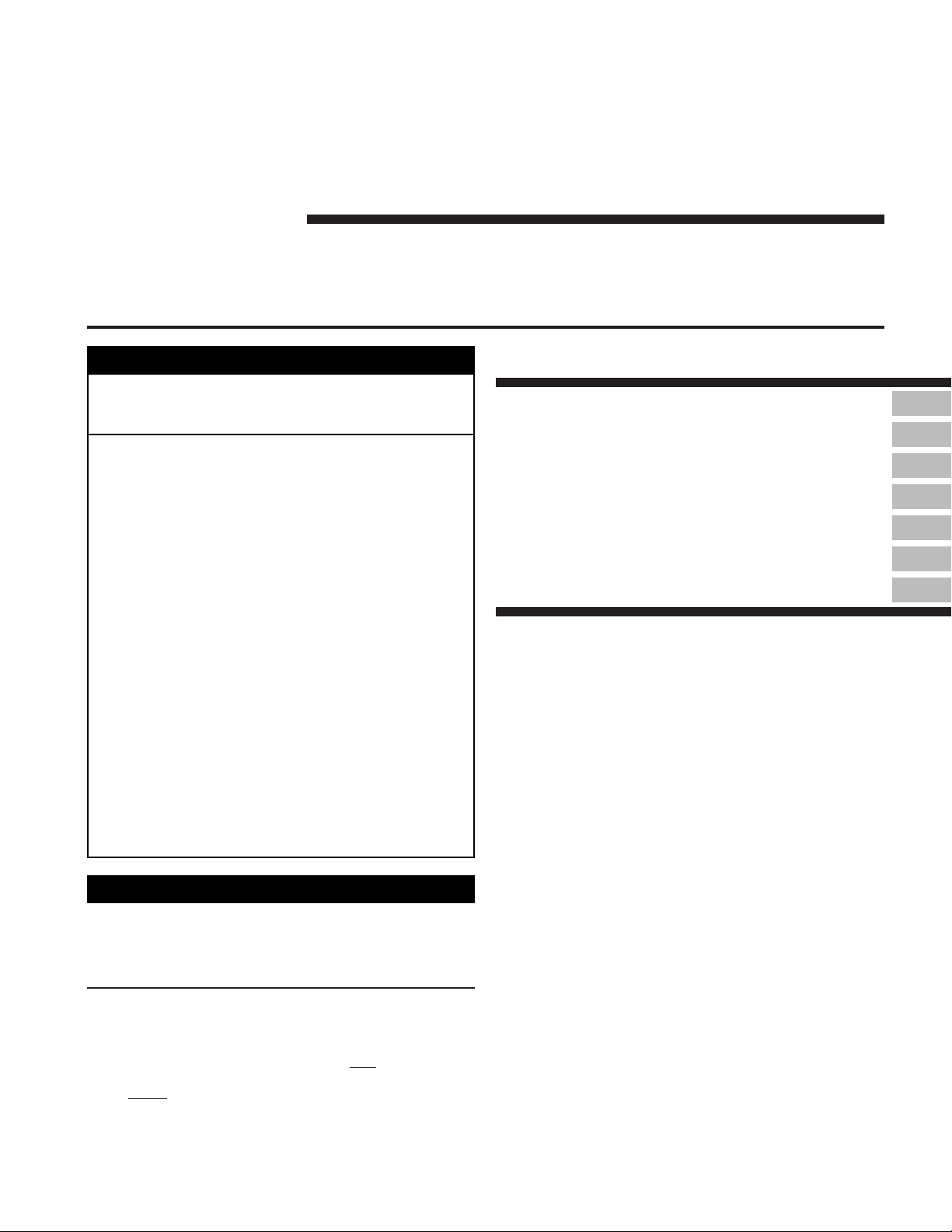

Outlet Pressure Boss

Swi

let Pressure

Boss

Adj

ust

GROUND

UNION JOINT

Outlet Pressure Boss

Your furnace may

have a “Knob Switch”

or a “Toggle Switch”

to turn the gas

ON or OFF.

SWITCH TOGGLES

“ON” OR “OFF”

Inlet Pressure

Boss

(opt.)

On/Off Swi

tch

Regulator

Adj

ust

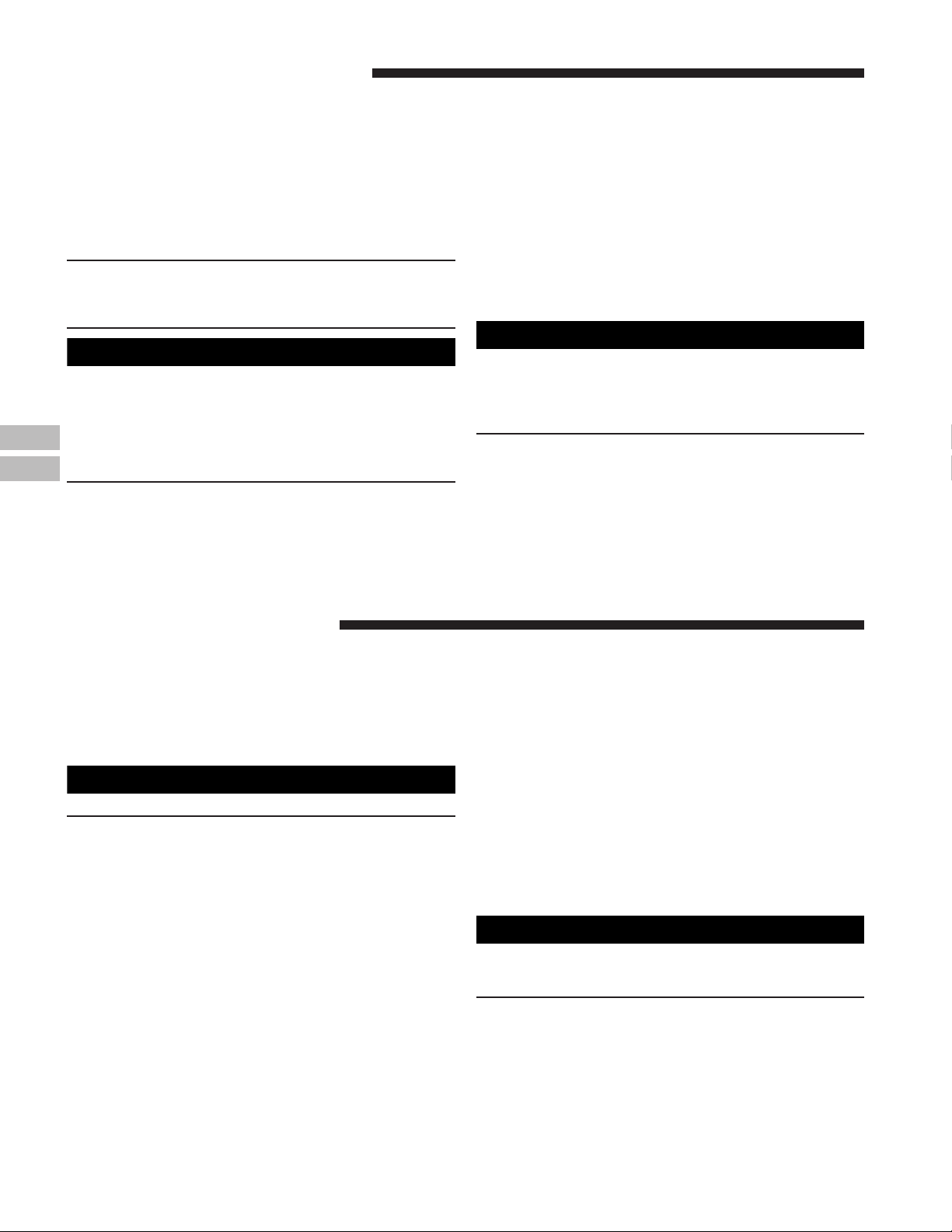

NOTE THE LOCATION OF THE MANUAL MAIN GAS SHUT-OFF VALVE FOR YOUR FURNACE.

Have your installer or servicer show you the location if you have any questions.

UPFLOW FURNACE Manual Main Gas Shut-off Valve May Be Located on the Left or Right Side

HORIZONTAL FURNACE Manual Main Gas Shut-off Valve May Be Located on the Top or Bottom Side

TOP VIEW OF RIGHT SIDE PIPING

32-5034-04 3

User’s Information

Proper Maintenance

Reduces Energy Use

A clean filter saves money.

When the furnace circulates and filters the air in your home,

dust and dirt particles build up on the filter. Excessive

accumulation can block the airflow, forcing the unit to work

harder to maintain desired temperatures.

And the harder your unit has to work, the more energy it

uses. So you pay more any time your system is running with

a dirty filter.

!

CAUTION

▲

Never operate your unit for either heating or cooling with

filters removed.

Help ensure top efficiency by cleaning the filter once a month.

If you have an upflow furnace, you can wash or change the

filter once a month. Clean it twice a month during seasons

when the unit runs more often.

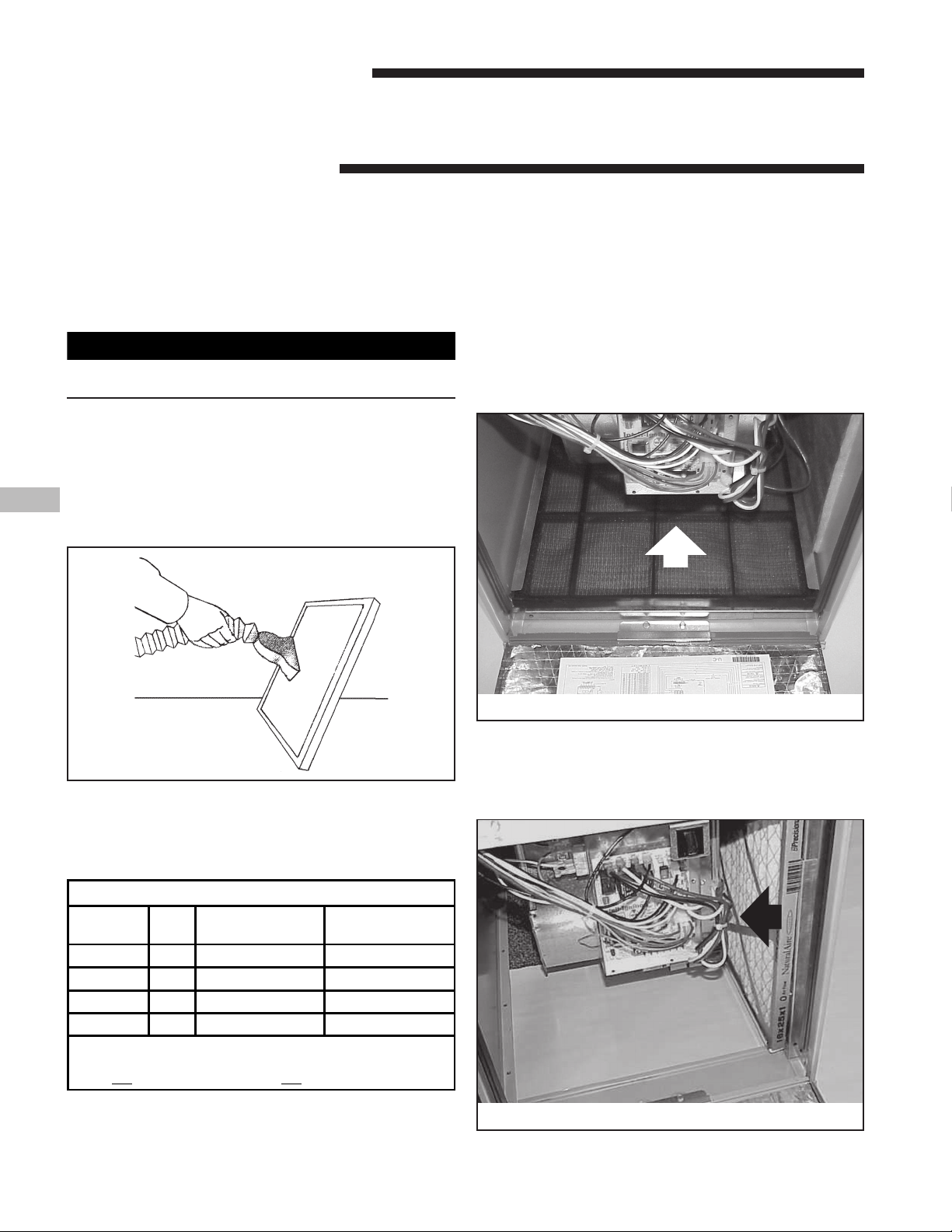

Your furnace came from the factory with a cleanable filter.

You can clean the filter with a vacuum, OR you can wash it

with a household detergent. Good quality, high velocity

filters may be used for replacements in upflow furnaces.

Replacing your filter.

When replacing your furnace filters, use a high velocity type

filter. On upflow furnaces, standard size 1" thick high

velocity filters will fit into the patented filter rack which will

automatically adjust in width to fit. Filters are available

from your dealer.

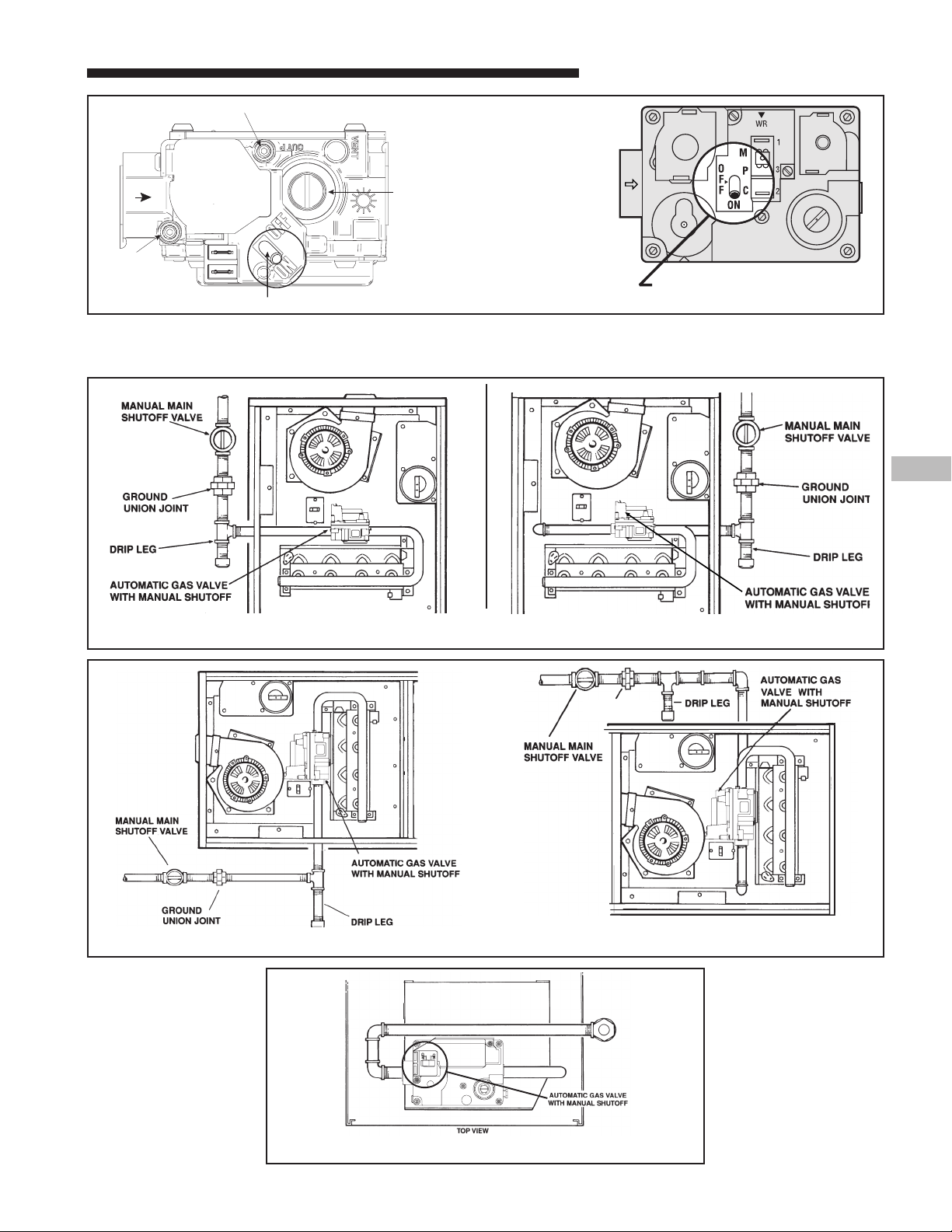

How to remove your filter.

The upflow furnace blower door has a hinge at the bottom

which allows the door to tilt forward for filter servicing or

replacement without the door being removed. The furnace

filter in the bottom or side configuration can be removed by

simply turning the two latches on the blower door 1/4 turn

and tilting the door forward.

Airflow

With the new patented filter rack on the upflow models, all

cleaning or replacing of filters is quick and easy. Clean filters

guarantee optimum performance of your system.

FACTORY SUPPLIED UPFLOW FURNACE

UPFLOW FURNACE RETURN AIR FILTERS

CABINET

WIDTH

14-1/2" 1 14" X 25" X 1" 17-1/2" X 25" X 1"

17-1/2" 1 17" X 25" X 1" 17-1/2" X 25" X 1"

21" 1 20" X 25" X 1" 17-1/2" X 25" X 1"

24-1/2" 1 24" X 25" X 1" 17-1/2" X 25" X 1"

*NOTE - On 5 ton airflow models, if the airflow requirement

exceeds 1800 CFM, these models will require filters on both

sides; OR

1 side and the bottom; OR just the bottom.

RETURN AIR FILTERS

QTY*

CABINET

BOTTOM FILTER

CABINET

SIDE FILTER

Blower Door Hinge and Bottom Filter Rack Installation

The blower door may be removed if necessary by tilting the

door outward 2 to 3 inches, then pulling up. The door will

slide out of the hinge for removal. For replacement, simply

insert the blower door bottom into the space between the

furnace base front and the hinge, then tilt inward and latch.

Airflow

Typical Upflow Right Side Return Filter Installation

4 32-5034-04

Loading...

Loading...