American Standard TMM4A0A18S21SA, TMM4A0A24S21SA, TMM4A0B30S21SA, TMM4A0B36S31SA Installer's Manual

WALL-MOUNT AIR HANDLERS

1.5-3TON COOLING

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

Important: This Document is customer property and is to remain with this unit.

Installer’s Guide

Section 1. Features

1.1 Standard Features

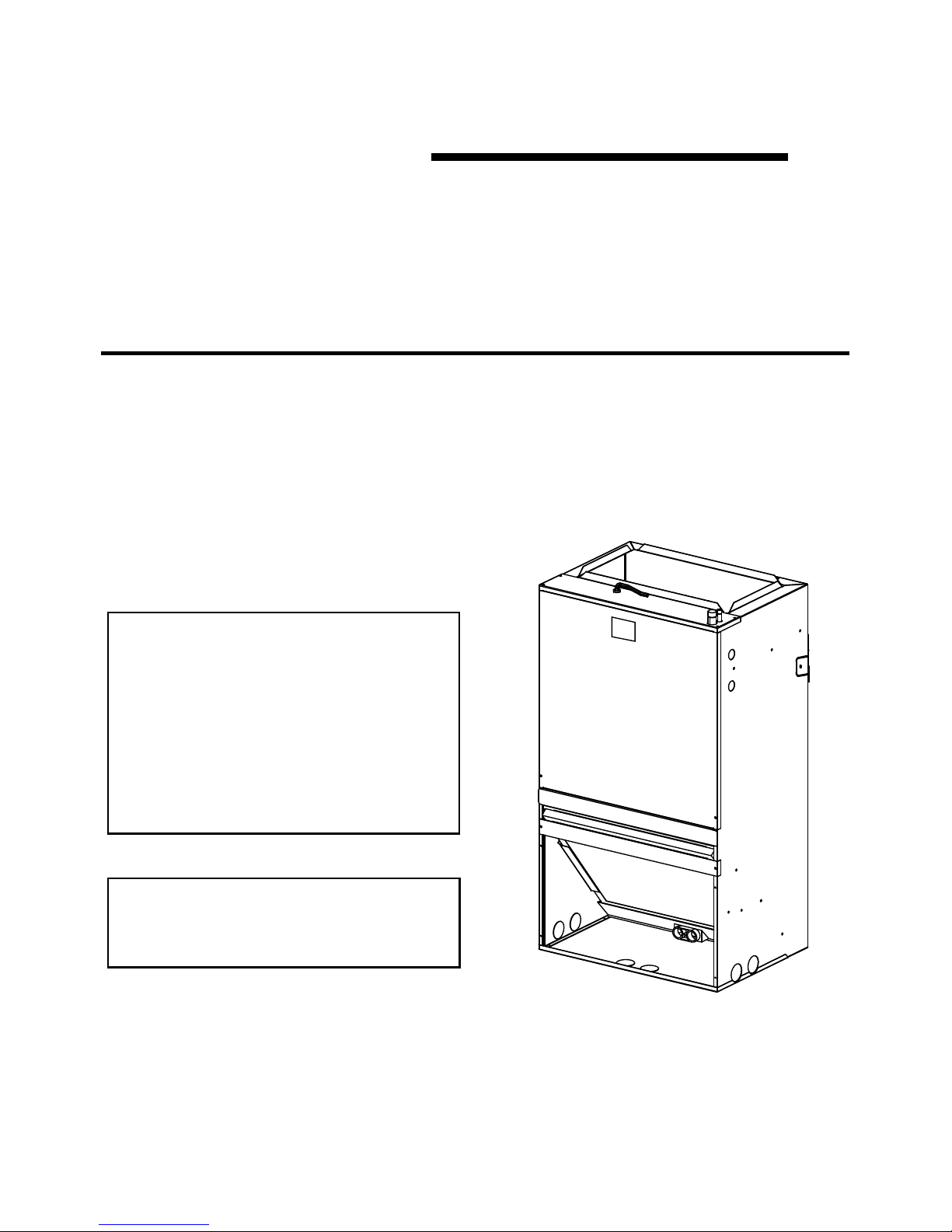

The TMM4A series wall mount air handler is designed for installation in a closet, utility room, alcove

and can be wall mounted. These versatile units are applicable to air conditioning applications. Field

installed electric resistance heaters are available.

18-GF07D1-1

• FRONT OR BOTTOM RETURN AIR.

• PAINTED FINISH ON GALVANIZED STEEL

• STURDY POLYCARBONATE DRAIN PANS

- The TMM4A wall mount air handler has factory

installed drain pans and is shipped for upflow

applications only.

•

208/230 VAC OPERATION

1.2 Optional Accessories

• 5, 7.5 and 10 kW SINGLE PHASE ELECTRIC

HEATERS

- Circuit breakers are standard on all single

phase 5, 7.5 and 10 kW heaters.

•

STUD OR WALL MOUNTING TABS

•

FULLY INSULATED CABINET

•

3/4'' NPT PRIMARY AND SECONDARY DRAINS

TMM4A0A18S21SA

TMM4A0A24S21SA

TMM4A0B30S21SA

TMM4A0B36S31SA

2

SAFETY HAZARD! This information is intended for use by

individuals possessing adequate backgrounds of electrical

and mechanical experience. Any attempt to repair a central air

conditioning product may result in personal injury and/or

property damage. The m anufacturer or seller cannot be

responsible for the interpretation of this information, nor can it

assume any liability in connection with its use.

Important: These instructions do not cover all variations in systems

nor provide for every possible contingency to be met in connection

with the installation. Should further information be desired or should

particular problems arise which are not covered sufficiently for the

purchaser ’s purposes, the m atter should be referred to your

installing dealer or local distributor.

Note: The manufacturer recommends installing ONLY A.H.R.I.

approved, matched indoor and outdoor systems. Some of the

benefits of installing approved matched indoor and outdoor split

systems are maximum efficiency, optimum performance, and the

best overall system reliability.

Important: Installation of this unit shall be made in accordance with

the National Electric Code, NFPA No. 90A and 90B, and any other

local codes or utilities requirements.

Note: The small air handlers have been evaluated in accordance

with the Code of Federal Regulations, Chapter XX, Part 3280 or the

equivalent. “SUITABLE FOR MOBILE HOME USE.”

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

HAZARDOUS VOLTAGE!

Disconnect all electrical power, including remote disconnects

before installing or servicing. Follow proper lockout/tagout

procedures to ensure the power can not be inadvertently

energized. Failure to disconnect power before servicing could

result in death or serious injury.

CAUTION

CORROSION HAZARD! To prevent shortening its service life,

the air handler should not be used during the finishing phases

of construction. The low return air temperatures can lead to

the formation of condensate. Condensate in the presence of

chlorides and fluorides from paint, varnish, stains, adhesives,

cleaning compounds , and cement creates a corrosive

condition which may cause rapid deterioration of the cabinet

and internal components.

CAUTION

SAFETY HAZARD! Sharp Edge Hazard. Be careful of sharp

edges on equipment or any cuts made on sheet metal while

installing or servicing. Personal injury may result.

LIVE ELECTRICAL COMPONENTS! During installation,

testing, servicing, and troubleshooting of this product, it may

be necessary to work with live electrical components. Failure

to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

EXPLOSION HAZARD!

Do not store corrosive or combustible materials, gasoline, or

other flammable vapors or liquids near the unit. Failure to

follow this warning could result in property damage, serious

personal injury, or death.

ELECTRICAL HAZARD!

Grounding Required! Follow proper local and state electrical

code on requirements for grounding. Failure to follow this

warning could result in property damage, serious personal

injury, or death.

HAZARDOUS VAPORS! Do not install an air handler with a

non-ducted return in the same closet, alcove, or utility room

as a fossil fuel device. Hazardous vapors can be distributed

throughout the conditioned space and equipment damage can

result.

WARNING

THIS PRODUCT CONTAINS FIBERGLASS WOOL

INSULATION! FIBERGLASS DUST AND CERAMIC FIBERS

ARE BELIEVED BY THE STATE OF CALIFORNIA TO

CAUSE CANCER THROUGH INHALATION. GLASSWOOL

FIBERS MAY ALSO CAUSE RESPIRATORY, SKIN, OR EYE

IRRITATION.

PRECAUTIONARY MEASURES

• Avoid breathing fiberglass dust

• Use a NIOSH approved dust/mist respirator

• Avoid contact with the skin or eyes. Wear long-sleeved,

loose fitting clothing, gloves, and eye protection.

• Wash clothes separately from other clothing, rinse washer

thoroughly.

• Operations, such as sawing, blowing, tear-out, and spraying

may generate fiber concentrations requiring ad ditional

respiratory protection. Use the appropriate NIOSH approved

respirator in these situations.

FIRST AID MEASURES

EYE CONTACT: FLUSH EYES WITH WATER TO REMOVE DUST

IF SYMPTOMS PERSIST, SEEK MEDICAL ATTENTION.

SKIN CONTACT: WASH AFFECTED AREA GENTLY WITH SOAP

AND WARM WATER AFTER HANDLING.

Section 2. Safety Information

WARNING

Make sure the blower motor support is tight

(3-motor mount bolts) then check to see if

wheel is secured to motor shaft before

operating unit.

BLOWER MOTOR

SHIPPING BOLT

3

Carefully unpack the unit and inspect the contents for damage. If

any damage is found at the time of delivery, proper notification and

claims should be made with the carrier.

Check the rating plate to assure model number and voltage, plus

any kits match with what you ordered. The manufacturer should be

notified within 5 days of any discrepancy or parts shortage.

The small air handler should be centrally located and may be

installed in a closet, alco ve, utility room , basement. Minimum

clearances must be met.

The air handler comes standard with two different options for

mounting, wall mount or frame mount. Both mounting options require

the unit to be level from side to side and from front to back in order to

allow condensate to properly drain from the unit. Failure to do this will

result in condensate to leak out from the unit potentially causing

structural damage to the surrounding support structures, dry wall,

carpet, etc. around the unit. Also, both mounting structures require

the ability to accommodate a minimum of 150 lb load. Failure to do

this will cause damage to the support structure and potentially

damage the unit.

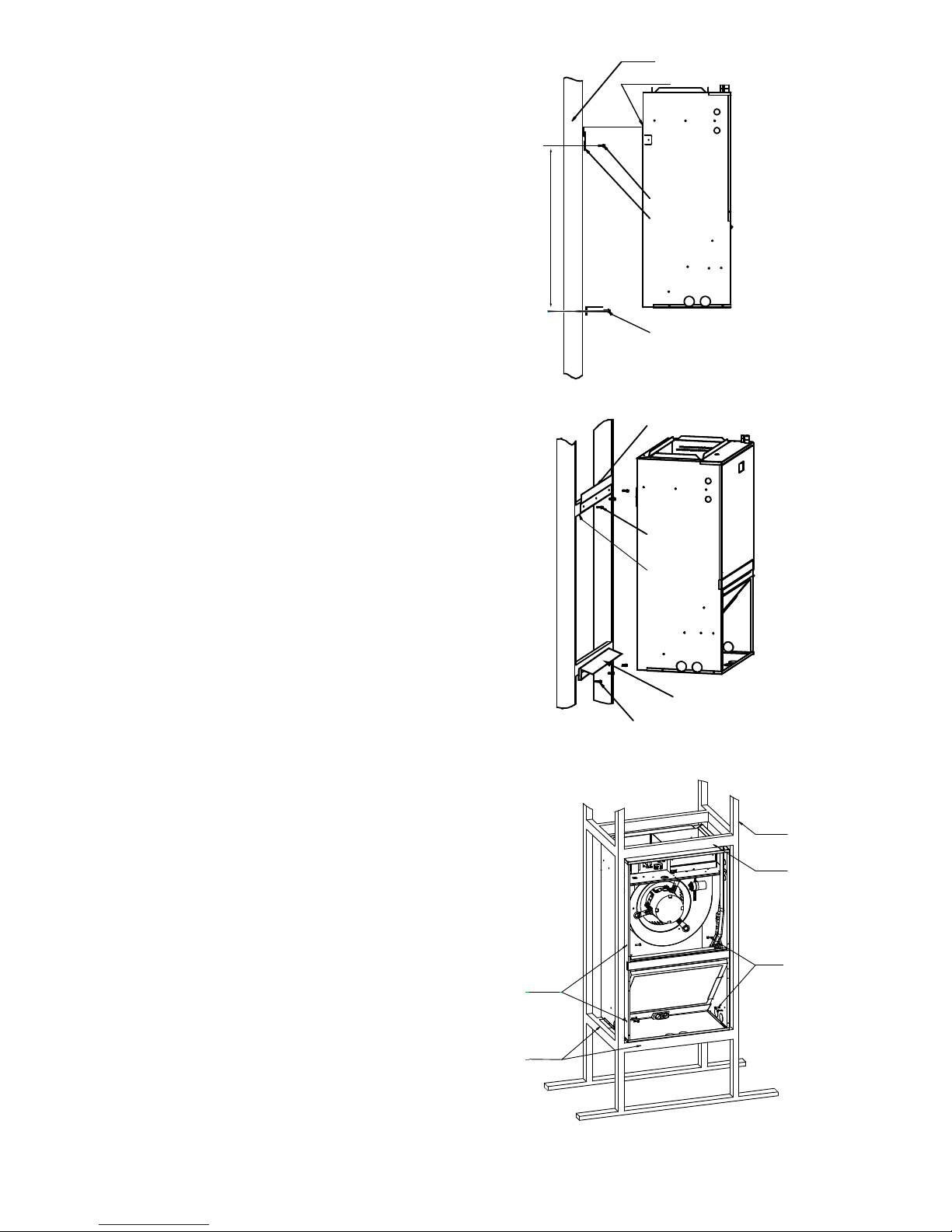

The air handler comes standard with an upper and lower wall mount

bracket. Reference Figure 3-1 for more detail.

1. Remove lower wall mounting bracket from the back of the unit by

removing one screw which attaches the bracket to the air handler.

Note: Discard the screw after you have removed the wall mounting

bracket.

2. Install bracket on the wall by using 3 wood screws (not provided).

Make sure the bracket is level in order to provided proper drainage

from the unit. Note: Do not attach the wall mounting bracket into

unsupported dry wall. Make sure that the wood screws are going into

a structure that can suppport a minimum of 150 lb load.

3. Lift the air handler above the wall mounting bracket and attached

the unit to the installed bracket. Reference Figure 3-1.

4. Install the additional bottom plate for extra support for this type

mounting (see figure 3-1).

Note: The additional plate is shipped in the bottom of the shipping

carton (only for 30/36k unit).

3.2.1 WALL MOUNT

Fig. 3-2 FRAME MOUNT

The air handler comes with 8 clearance holes 4 on each side. These

holes are used to mount the air handler inside of a frame structure

(see Figure 3-2). When mounting in this fashion, make sure that the

wood screws are mounted from within the air handler and not outside

of the unit. Installing the screws from the outside of the unit, And

notice don’t damage to the coil.

For ensure the proper installation for frame mount, Select the enough

solid and level site. Ensure enough space required for installation and

maintenance(See Figure. 3-3)

3.2.2 FRAME MOUNT

PROVIDED WALL

MOUNT BRACKET

WALL MOUNT PLATE

WOOD SCREWS

SUPPORTING 2˝X4˝

STRUCTURE

WALL STRUCTURE

WOOD SCREWS

WOOD SCREWS

PROVIDED WALL

MOUNT BRACKET

NOTE: MOUNTING WALL AND SUPPORTING

STRUCTURE MUST BE ABLE TO SUPPORT A

MINIMUM OF 150 LBS.

PROVIDED AIR HANDLER

MOUNTING BRACKET

Fig. 3-1 WALL MOUNT

WOOD SCREWS

31.5˝

Section 3. Installation Instructions

3.1 Unpacking

3.2 Location

WALL STRUCTURE

SUPPORTING

2"X4" STRUCTURE

WOOD SCREWS

SUPPORTING

2"X4" STRUCTURE

STUD ATTACHMANT

HOLES

4

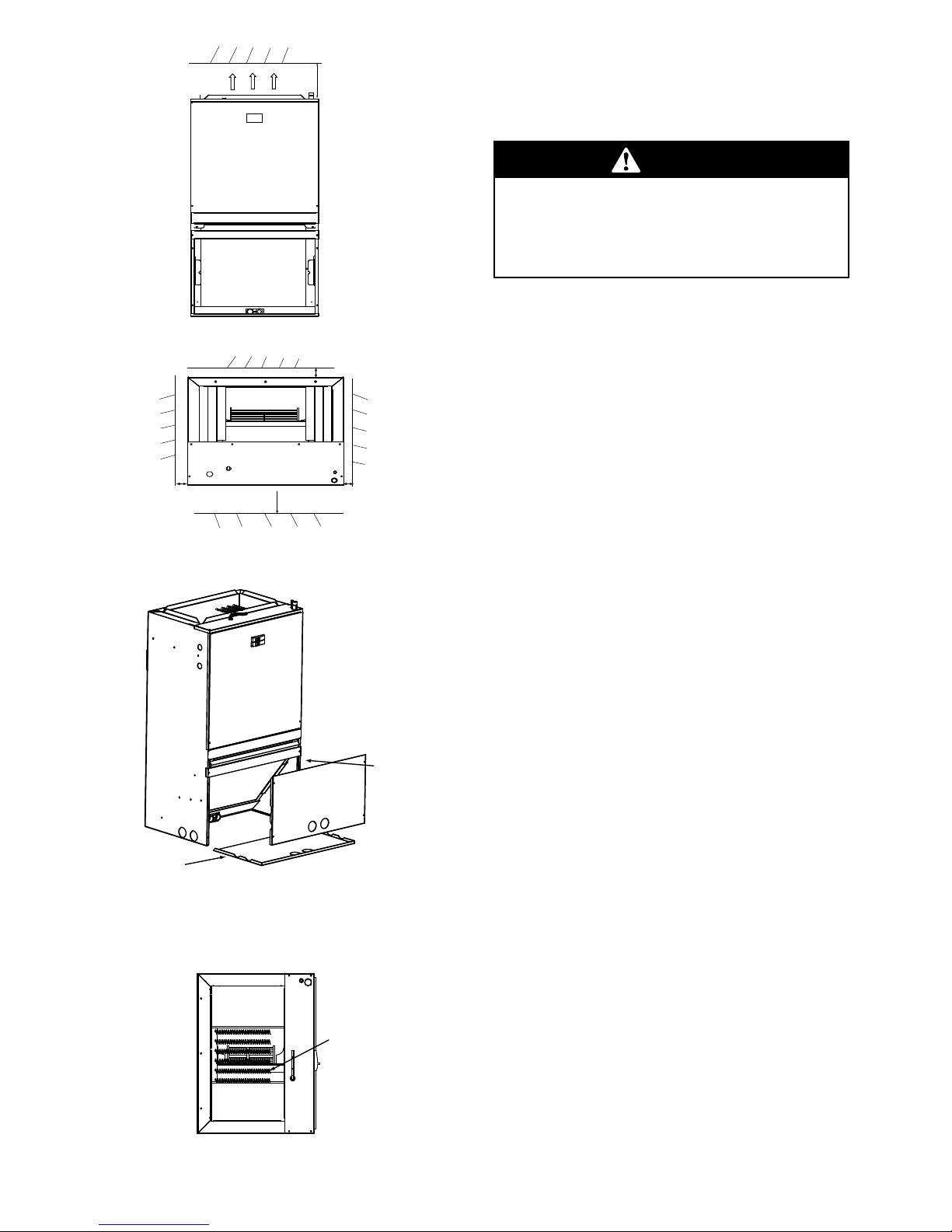

REMOVE BOTTOM COIL

PANEL OFF PLATE

INSTALL FRONT

COIL PANEL

Fig. 3-4 DIFFERENT AIR SUPPLY

3.2.3 CONFIGURATIONS

Fig.3-3 Space for frame mount

≥0"

Fig. 3-5 HEATER ELEMENTS INSTALLATION

ELECTRIC HEATER KITS

Bottom Return Conversion: Divert the return air from the factory

standard front return to a bottom return.Remove the cross brace

when converting cabinet to bottom return.

3.3 Duct Work

3.4 Condensate Drain

Field ductwork must comply with the National Fire Protection

Association NFPA 90A, NFPA 90B an d any applicable local

ordinance.

WARNING

Do not, under any circumstances, connect return ductwork to any

other heat producing device such as fireplace insert, stove, etc.

Unauthorized use of such devices may result in fire, carbon

monoxide poisoning, explosion, personal injury or property

damage.

Sheet metal ductwork run in unconditioned spaces must be insulated

and covered with a vapor barrier. Fibrous ductwork may be used if

constructed and installed in accordance with SMACNA Construction

Standa rd on Fibrous Glass Ducts. Ductwork must comply with

National Fire Protection Association as tested by U/L Standard 181

for Class I Air Ducts. Check local codes for requirements on

ductwork and insulation.

• Duct system must be designed within the range of external static

pressure the unit is designed to operate against. It is important that

the system airflow be adequate. Make sur e supply and return

ductwork, grills, special filters, accessories, etc. are accounted for in

total resistance. See airflow performance tables in this manual.

• Design the duct system in accordance with “ACCA” Manual “D”

Design for Residential Winter and Summer Air Conditioning and

Equipment Selection. Latest editions are available from: “ACCA” Air

Conditioning Contractors of America, 1513 16th Street, N.W.,

Washington, D.C. 20036. If duct system incorporates flexible air

duct, be sure pressure drop Information (straight length plus all

turns) shown in “ACCA” Manual “D” is accounted for in system.

• Supply plenum is attached to the 3/4” duct flanges supplied with

the unit.

IMPORTANT: If an elbow is included in the plenum close to the unit,

it must not be smaller than the dimensions of the supply duct flange

on the unit.

• IMPORTANT: The front flange on the return duct if connected to

the blower casing must not be screwed into the area where the

power wiring is located. Drills or sharp screw points can damage

insulation on wires located inside unit.

The unit is supplied with primary and auxiliary condensate drains

that have 3/4” NPT connections. Both drains must be trapped

outside the unit and piped in accordance with applicable building

codes. Do not reduce the drain line size less than the connection

size on the drain pan. Condensate should be piped to an open drain

or to the outside. All drains must pitch downward away from the unit

a minimum of 1/4” per foot of line to ensure proper drainage.

Insulate the primary drain line to prevent sweating where dew point

temperatures may be met. (Insulation is optional depending on

climate and application needs.)

• Secure the supply and return ductwork to the unit flanges, using

proper fasteners for the type of duct used and tape the duct-to-unit

joint as required to prevent air leaks.

Important: If cleanout Tee is used, standpipe must be sealed/capped.

Top view of the indoor unit clearance(including air duct).

》20"

≥0"

≥24"

≥0"

Front of unit

AIRFLOW

Loading...

Loading...