American Standard TUY060R9V3W, AUY120R9V5W, AUY080R9V3W, TUY100R9V4W, TUY120R9V5W Service Facts

...

Service Facts

Gas Furnace – Var. Speed Blower –

Var. Speed Inducer – Two Stage Heat –

X341119P12

Direct Vent

Models: * - First letter may be “A” or “T”

*UY060R9V3W *DY060R9V3W

*UY080R9V3W *DY080R9V3W

*UY100R9V4W *DY100R9V4W

*UY120R9V5W *DY120R9V5W

IMPORTANT — This document contains a wiring diagram and service information. This is customer property and is to

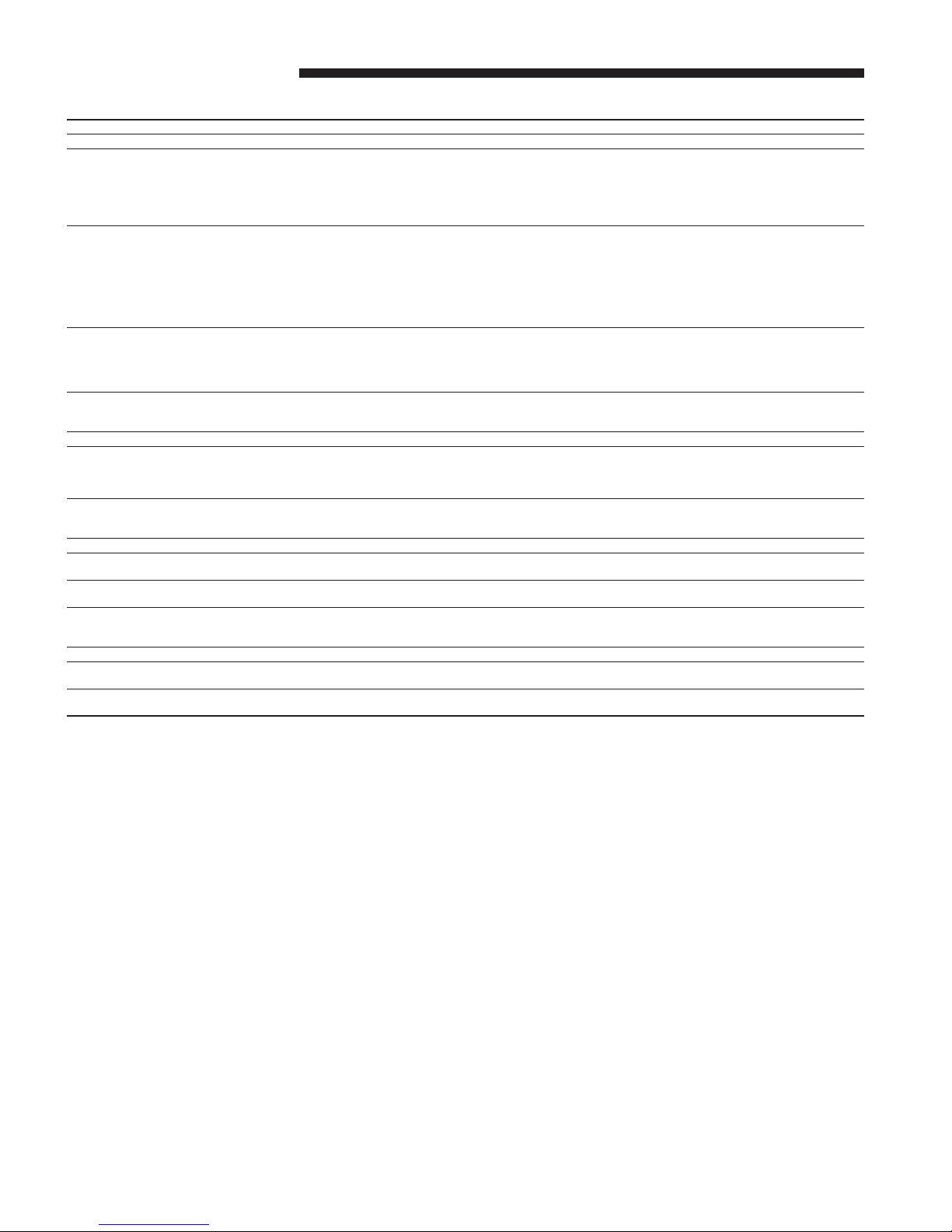

MODEL

TYPE

RATINGS 2

1st Stage Input BTUH

1st Stage Capacity BTUH (ICS)

2nd Stage Input BTUH

2nd Stage Capacity BTUH (ICS)

Temp. rise (Min.-Max.) °F.

BLOWER DRIVE

Diameter - Width (In.)

No. Used

Speeds (No.)

CFM vs. in. w.g.

Motor HP

R.P.M.

Volts / Ph / Hz

COMBUSTION FAN - Type

Drive - No. Speeds

Motor HP - RPM

Volts / Ph / Hz

FLA

FILTER — Furnished?

Type Recommended

Hi Vel. (No.-Size-Thk.)

VENT — Size (in.)

HEAT EXCHANGER

Type -Fired

-Unfired

Gauge (Fired)

ORIFICES — Main

Nat. Gas. Qty. — Drill Size

L.P. Gas Qty. — Drill Size

GAS VALVE

PILOT SAFETY DEVICE

Type

BURNERS — Type

Number

POWER CONN. — V /Ph / Hz 4

Ampacity (In Amps)

Max. Overcurrent Protection (Amps)

PIPE CONN. SIZE (IN.)

DIMENSIONS

Crated (In.)

WEIGHT

Shipping (Lbs.) / Net (Lbs)

1 Central Furnace heating designs are certified by AGA and CSA.

2 For U.S. applications, above input ratings (BTUH) are up to 2,000 feet, derate 4% per 1,000 feet for elevations above 2,000 feet above sea level.

For Canadian applications, above input ratings (BTUH) are up to 4,500 feet, derate 4% per 1,000 feet for elevations above 4,500 feet above sea level.

3 Based on U.S. government standard tests.

4 The above wiring specifications are in accordance with National Electrical Code; however, installations must comply with local codes.

remain with this unit. Please return to service information pack upon completion of work.

WARNING

*UY060R9V3W

Upflow / Horizontal

39,000

3

3

37,000

60,000

56,000

35 - 65

DIRECT

10 x 8

Variable

See Fan Performance Table

1/2

Variable

115/1/60

Centrifugal

Direct - Variable

1/50 - 5000

33 - 110/3/60 - 180

1.0

Yes

High Velocity

1 - 17x25 - 1 in.

2 Round

Aluminized Steel - Type I

3 — 45

3 — 56

Redundant - Two Stage

Hot Surface Igniter

Multiport Inshot

115/1/60

11.1

1/2

H x W x D

41-3/4 x 19-1/2 x 30-1/2

158 / 146

DISCONNECT POWER BEFORE SERVICING

PRODUCT SPECIFICATIONS

*UY080R9V3W

Upflow / Horizontal

52,000

48,000

80,000

73,000

35 - 65

DIRECT

10 x 8

1

See Fan Performance Table

20

3

15

1

Variable

1/2

Variable

115/1/60

Centrifugal

Direct - Variable

1/50 - 5000

33 - 110/3/60 - 180

1.0

Yes

High Velocity

1 - 17x25 - 1 in.

2 Round

Aluminized Steel - Type I

20

4 — 45

4 — 56

Redundant - Two Stage

Hot Surface Igniter

Multiport Inshot

4

115/1/60

11.1

15

1/2

H x W x D

41-3/4 x 19-1/2 x 30-1/2

168 / 156

1

*UY100R9V4W

Upflow / Horizontal

65,000

60,000

100,000

93,000

35 - 65

DIRECT

10 x 10

1

Variable

See Fan Performance Table

1

Variable

115/1/60

Centrifugal

Direct - Variable

1/50 - 5000

33 - 110/3/60 - 180

1.0

Yes

High Velocity

1 - 20x25 - 1 in.

3 Round

Aluminized Steel - Type I

20

5 — 45

5 — 56

Redundant - Two Stage

Hot Surface Igniter

Multiport Inshot

5

115/1/60

13.5

20

1/2

H x W x D

41-3/4 x 23 x 30-1/2

197 / 185

*UY120R9V5W

Upflow / Horizontal

78,000

72,000

120,000

112,000

40 - 70

DIRECT

10 x 10

1

Variable

See Fan Performance Table

1

Variable

115/1/60

Centrifugal

Direct - Variable

1/50 - 5000

33 - 110/3/60 - 180

1.0

Yes

High Velocity

1 - 24x25 - 1 in.

3 Round

Aluminized Steel - Type I

20

6 — 45

6 — 56

Redundant - Two Stage

Hot Surface Igniter

Multiport Inshot

6

115/1/60

15.2

20

1/2

H x W x D

41-3/4 x 26-1/2 x 30-1/2

206 / 193

B - FURNACES

NOTICE: Since the manufacturer has a policy of continuous product and product data improvement,

it reserves the right to change design and specifications without notice.

© 2005 American Standard Inc. All Rights Reserved

Page B-651-438

W.M. 1/05R

Service Facts

PRODUCT SPECIFICA TIONS

MODEL

TYPE

RATINGS 2

1st Stage Input BTUH

1st Stage Capacity BTUH (ICS)

2nd Stage Input BTUH

2nd Stage Capacity BTUH (ICS)

Temp. rise (Min.-Max.) °F.

BLOWER DRIVE

Diameter - Width (In.)

No. Used

Speeds (No.)

CFM vs. in. w.g.

Motor HP

R.P.M.

Volts / Ph / Hz

COMBUSTION FAN - Type

Drive - No. Speeds

Motor HP - RPM

Volts / Ph / Hz

FLA

FILTER — Furnished?

Type Recommended

Hi Vel. (No.-Size-Thk.)

VENT — Size (in.)

HEAT EXCHANGER

Type -Fired

-Unfired

Gauge (Fired)

ORIFICES — Main

Nat. Gas. Qty. — Drill Size

L.P. Gas Qty. — Drill Size

GAS VALVE

PILOT SAFETY DEVICE

Type

BURNERS — Type

Number

POWER CONN. — V / Ph / Hz 4

Ampacity (In Amps)

Max. Overcurrent Protection (Amps)

PIPE CONN. SIZE (IN.)

DIMENSIONS

Crated (In.)

WEIGHT

Shipping (Lbs.) / Net (Lbs)

1 Central Furnace heating designs are certified by AGA and CSA.

2 For U.S. applications, above input ratings (BTUH) are up to 2,000 feet, derate 4% per 1,000 feet for elevations above 2,000 feet above sea level.

For Canadian applications, above input ratings (BTUH) are up to 4,500 feet, derate 4% per 1,000 feet for elevations above 4,500 feet above sea level.

3 Based on U.S. government standard tests.

4 The above wiring specifications are in accordance with National Electrical Code; however, installations must comply with local codes.

3

3

*DY060R9V3W

Downflow / Horizontal

39,000

36,000

60,000

56,000

35 - 65

DIRECT

10 x 8

1

Variable

See Fan Performance Table

1/2

Variable

115/1/60

Centrifugal

Direct - Variable

1/50 - 5000

33 - 110/3/60 - 180

1.0

Yes

High Velocity

2 - 14x20 - 1 in.

2 Round

Aluminized Steel - Type I

20

3 — 45

3 — 56

Redundant - Two Stage

Hot Surface Igniter

Multiport Inshot

3

115/1/60

11.1

15

1/2

H x W x D

41-3/4 x 19-1/2 x 30-1/2

160/ 146

*DY080R9V3W

Downflow / Horizontal

52,000

48,000

80,000

74,000

35 - 65

DIRECT

10 x 8

1

Variable

See Fan Performance Table

1/2

Variable

115/1/60

Centrifugal

Direct - Variable

1/50 - 5000

33 - 110/3/60 - 180

1.0

Yes

High Velocity

2 - 14x20 - 1 in.

2 Round

Aluminized Steel - Type I

20

4 — 45

4 — 56

Redundant - Two Stage

Hot Surface Igniter

Multiport Inshot

4

115/1/60

11.1

15

1/2

H x W x D

41-3/4 x 19-1/2 x 30-1/2

168 / 158

1

*DY100R9V4W

Downflow / Horizontal

65,000

60,000

100,000

94,000

35 - 65

DIRECT

10 x 10

1

Variable

See Fan Performance Table

3/4

Variable

115/1/60

Centrifugal

Direct - Variable

1/50 - 5000

33 - 110/3/60 - 180

1.0

Yes

High Velocity

2 - 16x20 - 1 in.

3 Round

Aluminized Steel - Type I

20

5 — 45

5 — 56

Redundant - Two Stage

Hot Surface Igniter

Multiport Inshot

5

115/1/60

13.5

20

1/2

H x W x D

41-3/4 x 23 x 30-1/2

185 / 175

*DY120R9V5W

Downflow / Horizontal

78,000

72,000

120,000

112,000

40 - 70

DIRECT

10 x 10

1

Variable

See Fan Performance Table

1

Variable

115/1/60

Centrifugal

Direct - Variable

1/50 - 5000

33 - 110/3/60 - 180

1.0

Yes

High Velocity

2 - 16x20 - 1 in.

3 Round

Aluminized Steel - Type I

20

6 — 45

6 — 56

Redundant - Two Stage

Hot Surface Igniter

Multiport Inshot

6

115/1/60

15.2

20

1/2

H x W x D

41-3/4 x 26-1/2 x 30-1/2

206 / 196

2 Page B-651-438

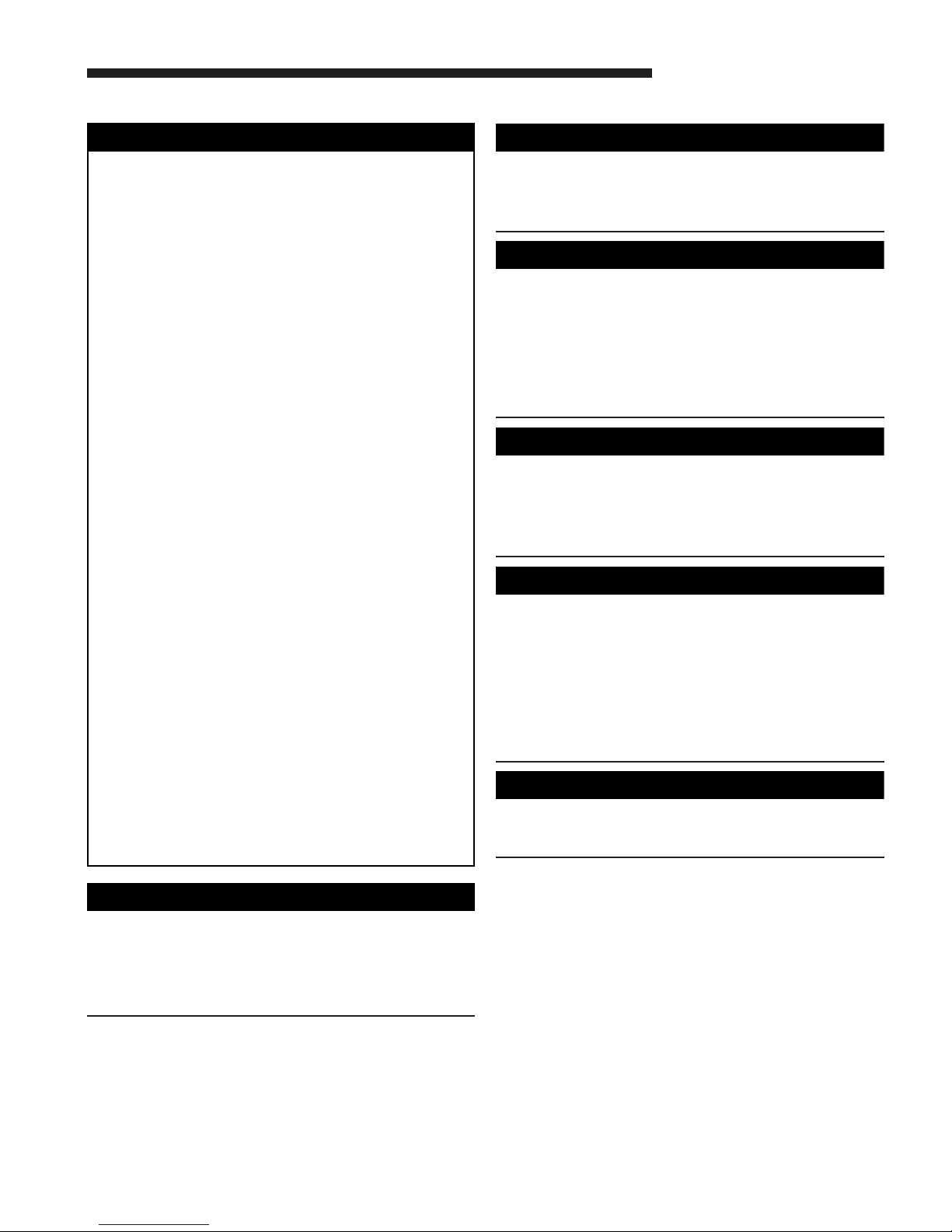

SAFETY SECTION

Service Facts

!

WARNING

▲

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being

placed into operation could result in carbon monoxide

poisoning or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and

horizontal pitch, as required in the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the CAN/CGA B149

Installation Codes and these instructions. Determine

that there is no blockage or restriction, leakage,

corrosion and other deficiencies which could cause an

unsafe condition.

3. As far as practical, close all building doors and

windows and all doors between the space in which the

appliance(s) connected to the venting system are

located and other deficiencies which could cause an

unsafe condition.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not

connected to the venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts, so

they are operating at maximum speed. Do not operate

a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance

being inspected into operation. Adjust the thermostat

so appliance is operating continuously.

7. If improper venting is observed during any of the above

tests, the venting system must be corrected in

accordance with the National Fuel Gas Code,

ANSI Z221.1/NFPA 54 and/or CAN/CGA B149

Installation Codes.

8. After it has been determined that each appliance

connected to the venting system properly vents where

tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas-fired

burning appliance to their previous conditions of use.

!

WARNING

▲

CARBON MONOXIDE POISONING HAZARD

Failure to follow the installation instructions for the venting

system being placed into operation could result in carbon

monoxide poisoning or death.

!

WARNING

▲

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in

serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a com-

mercially available soap solution made specifically for the

detection of leaks to check all connections. A fire or

explosion may result causing property damage, personal

injury, or loss of life.

!

WARNING

▲

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in

serious injury, death or property damage.

Improper servicing could result in dangerous operation,

serious injury, death, or property damage.

!

WARNING

▲

BODILY INJURY CAN RESULT FROM HIGH VOLTAGE

ELECTRICAL COMPONENTS, FAST MOVING FANS, AND

COMBUSTIBLE GAS. FOR PROTECTION FROM THESE

INHERENT HAZARDS DURING INSTALLATION AND

SERVICING, THE ELECTRICAL SUPPLY MUST BE

DISCONNECTED AND THE MAIN GAS VALVE MUST BE

TURNED OFF. IF OPERA TING CHECKS MUST BE

PERFORMED WITH THE UNIT OPERATING, IT IS THE

TECHNICIAN’S RESPONSIBILITY TO RECOGNIZE THESE

HAZARDS AND PROCEED SA FELY.

!

CAUTION

▲

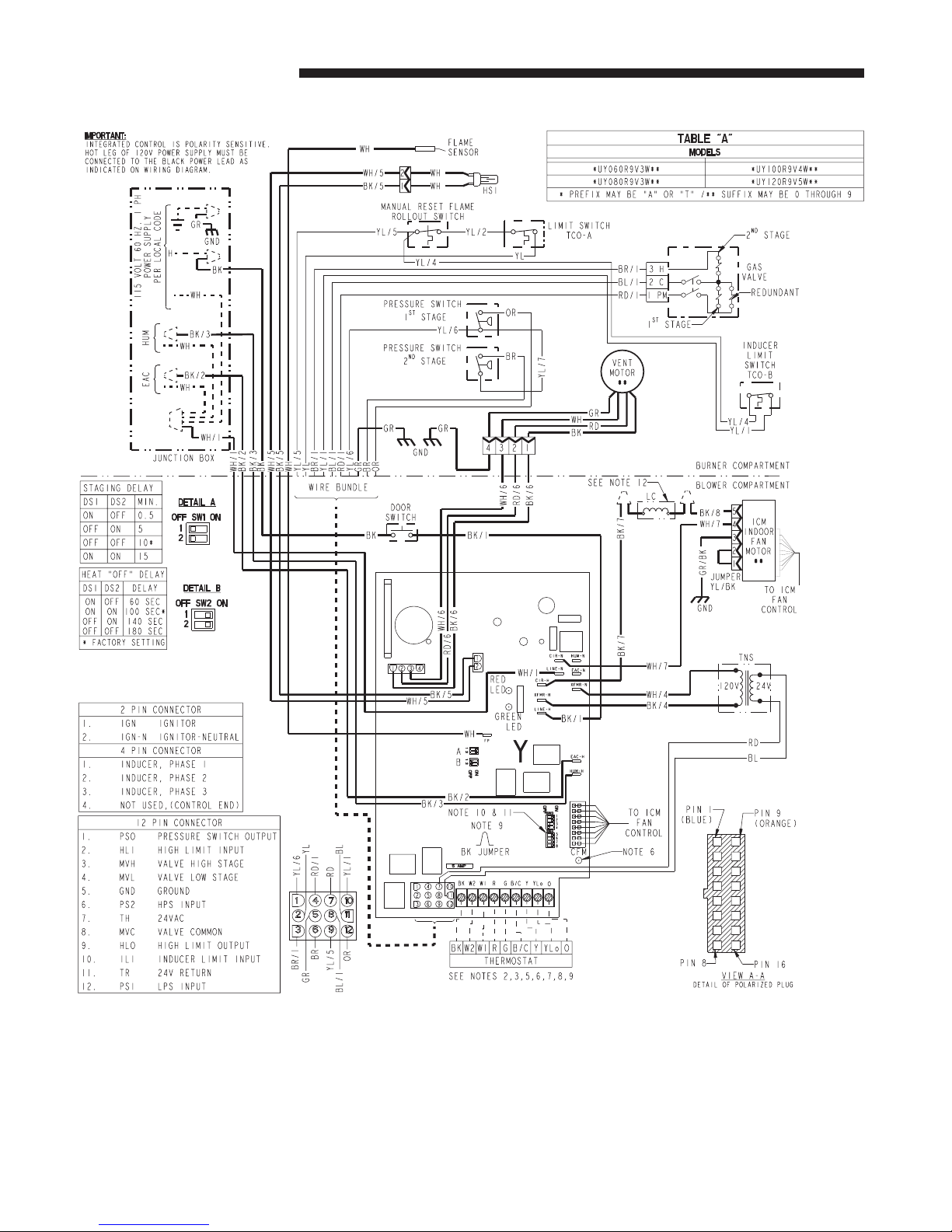

The integrated furnace control is polarity sensitive. The hot

leg of the 115 VAC power must be connected to the BLACK

field lead.

!

WARNING

▲

The cabinet must have an uninterrupted or unbroken

ground according to National Electrical Code, ANSI/

NFPA 70 - “latest edition” and Canadian Electrical Code,

CSA C22.1 or local codes to minimize personal injury if an

electrical fault should occur. A failure to follow this warning could result in an electrical shock, fire, injury, or death.

Page B-651-438 3

Service Facts

SEQUENCE OF OPERA TION

Thermostat call for heat (2-stage thermostat)

Call for 1st stage only:

W1 thermostat contacts close signaling the control module to

run its self-check routine. After the control module has

verified that the 1st stage pressure switch contacts are open

and the limit switch(es) contacts are closed, the draft blower

will be energized.

As the induced draft blower comes up to speed, the pressure

switch contacts will close and the ignitor warm up period will

begin. The ignitor will heat for approx. 20 seconds, then the

gas valve is energized in 1st stage to permit gas flow to the

burners.

The flame sensor confirms that ignition has been achieved

within the 4 second ignition trial period.

As the flame sensor confirms that ignition has been achieved,

the delay to fan ON period begins timing and after approx. 45

seconds the indoor blower motor will be energized at low

speed and will continue to run during the heating cycle.

Call for 2nd stage after 1st stage:

W2 thermostat contacts close signaling a call for 2nd stage

heat. After a 30 second delay, the induced draft blower will

be energized on high speed and the 2nd stage pressure

switch contacts will close. The gas valve is energized in

2nd stage and the indoor blower motor in high speed.

2nd stage satisfied, 1st stage still called:

W2 thermostat contacts open signaling that 2nd stage

heating requirements are satisfied.

The induced draft blower is reduced to low speed allowing

the 2nd stage pressure switch contacts to open and the gas

valve is reduced to 1st stage. The indoor blower motor is

reduced to low speed.

1st stage satisfied:

W1 thermostat contacts open signaling that 1st stage

heating requirements are satisfied. The gas valve will close

and the induced draft blower will be de-energized. The

indoor blower motor will continue to run for the fan off period

(Field selectable at 60, 100, 140 or 180 seconds), then will be

de-energized by the control module.

Thermostat call for heat (1-stage Thermostat)

W1/W2 (jumpered) thermostat contacts close signaling a call

for heat. 1st stage sequence of operation remains the same as

above. 2nd stage heat will energize after the stage delay

timer (field selectable at .5, 5, 10 or 15 minutes) has expired.

Thermostat satisfied:

W1/W2 (jumpered) contacts open signaling the control

module to close the gas valve. The induced draft blower is

switched to low speed and de-energized after the post purge

timer has expired. The indoor blower motor will continue to

operate after the flames are extinguished and then is

switched to low heat speed for the FAN-OFF period.

!

WARNING

▲

Should overheating occur, or the gas supply fail to shut off,

shut off the gas valve to the unit before shutting off the

electrical supply. Failure to follow this warning could result

in property damage, personal injury, or death.

Indoor blower operation with thermostat fan switch “ON”:

Fan is R-G.

R-W energized, fan continues to run without interruption.

Heat Low speed if it is a two stage furnace.

Heat speed if it is a single stage furnace.

INDOOR BLOWER TIMING

Heating: The integrated furnace control module controls

the indoor blower. The blower start is fixed at 45 seconds

after ignition. The FAN-OFF period is field selectable by

dip switches SW-2, #1 and #2 at 60, 100, 140, or 180

seconds. The factory setting is 100 seconds.

W1-W2 stage delay (jumpered together) is field selectable by

dip switch SW-1, #1 and #2 at .5, 5, 10 or 15 minutes. The

factory setting is 10 minutes. (See wiring diagram).

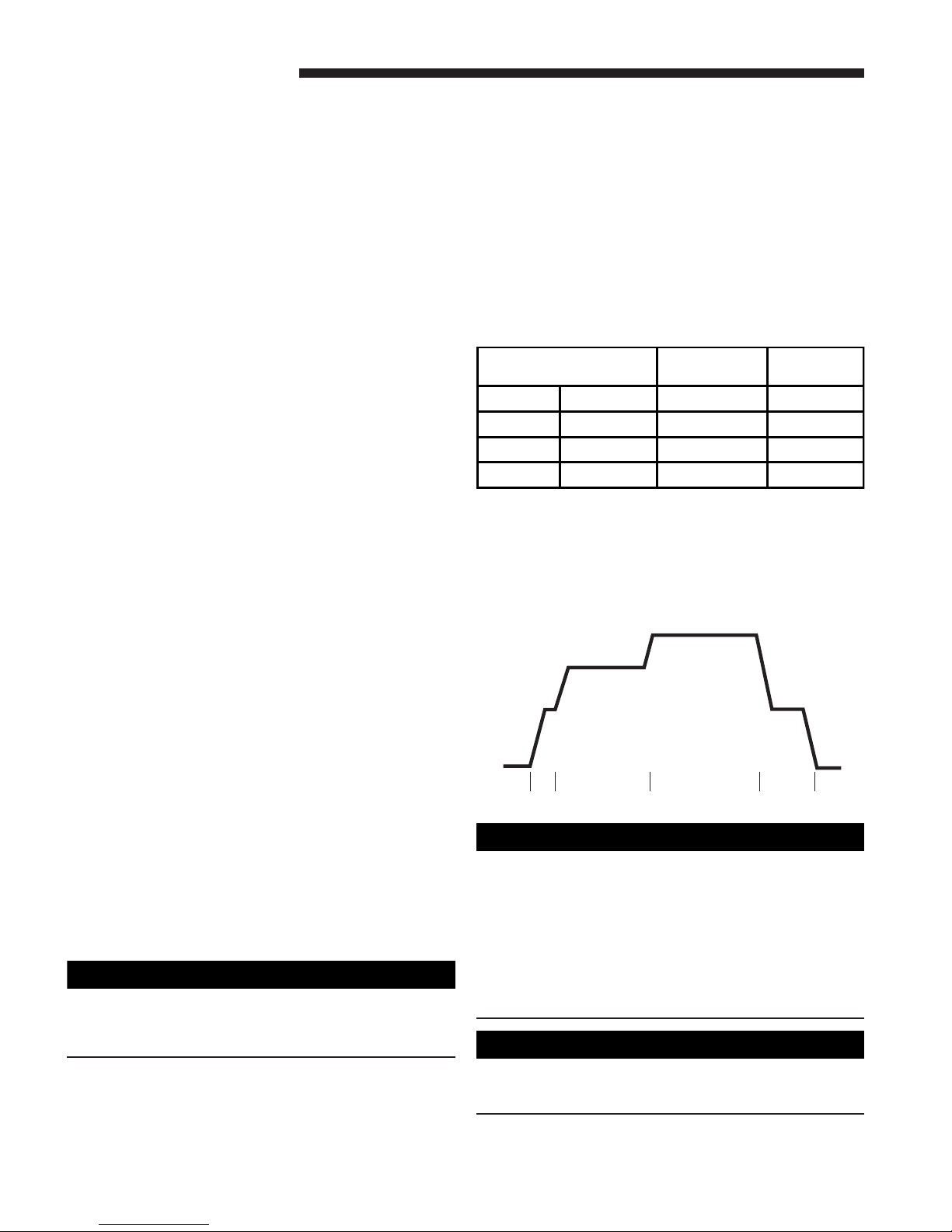

Cooling: The fan delay-off period is set by dip switches on

the Integrated Furnace Control. The options for cooling

delay off is field selectable by dip switches #5 and #6.

The following table and graph explain the delay-off settings:

COOLING OFF - DELAY OPTIONS

SWITCH SETTINGS SELECTION

5 - OFF 6 - OFF NONE SAME

5 - ON 6 - OFF 1.5 MINUTES 100% *

5 - OFF 6 - ON 3 MINUTES 50%

5 - ON 6 - ON ** 50 - 100%

* - This setting is equivalent to BAY24X045 relay benefit

** - This selection provides ENHANCED MODE, which is a

ramping up and ramping down of the blower speed to provide

improved comfort, quietness, and potential energy savings.

See Wiring Diagram notes on the unit or in the Service Facts

for complete wiring setup for ENHANCED MODE. The graph

which follows, shows the ramping process.

100% if necessary

80%

Dehumidify

50%

Fast Coil Cooling

OFF

1

minute

BODILY INJURY CAN RESULT FROM HIGH VOLTAGE

ELECTRICAL COMPONENTS, FAST MOVING FANS, AND

COMBUSTIBLE GAS. FOR PROTECTION FROM THESE

INHERENT HAZARDS DURING INSTALLATION AND

SERVICING, THE ELECTRICAL SUPPLY MUST BE

DISCONNECTED AND THE MAIN GAS VALVE MUST BE

TURNED OFF. IF OPERATING CHECKS MUST BE PERFORMED WITH THE UNIT OPERATING, IT IS THE

TECHNICIAN’S RESPONSIBILITY TO RECOGNIZE THESE

HAZARDS AND PROCEED SAFELY.

The integrated furnace control is polarity sensitive. The hot

leg of the 115 VAC power must be connected to the BLACK

field lead.

7.5

minutes

!

▲

▲

WARNING

!

CAUTION

NOMINAL

AIRFLOW

50%

Efficiency

OFF

3

minutes

4 Page B-651-438

PERIODIC SERVICING REQUIREMENTS

Service Facts

!

WARNING

▲

Disconnect power to the unit before removing the blower

door. Allow a minimum of 10 seconds for IFC power supply

to drain to 0 volts. Failure to follow this warning could

result in property damage, personal injury or death.

!

WARNING

▲

CARBON MONOXIDE POISONING HAZARD

Failure to follow the service and/or periodic maintenance

instructions for the furnace and venting system, could

result in carbon monoxide poisoning or death.

1. GENERAL INSPECTION – Examine the furnace

installation annually for the following items:

a. All flue product carrying areas external to the furnace

(i.e. chimney, vent connector) are clear and free of

obstruction. A vent screen in the end of the vent (flue)

pipe must be inspected for blockage annually.

b. The vent connector is in place, slopes upward and is

physically sound without holes or excessive corrosion.

c. The return air duct connection(s) is physically sound,

is sealed to the furnace and terminates outside the

space containing the furnace.

d. The physical support of the furnace should be sound

without sagging, cracks, gaps, etc., around the base so

as to provide a seal between the support and the base.

e. There are no obvious signs of deterioration of the furnace.

2. FILTERS – Filters should be cleaned or replaced (with

high velocity filters only), monthly and more frequently

during high use times of the year such as midsummer

or midwinter.

3. BLOWERS – The blower size and speed determine the

air volume delivered by the furnace. The blower motor

bearings are factory lubricated and under normal

operating conditions do not require servicing. If motor

lubrication is required it should only be done by a

qualified servicer. Annual cleaning of the blower wheel

and housing is recommended for maximum air output,

and this must be performed only by a qualified servicer

or service agency.

4. IGNITER – This unit has a special hot surface direct

ignition device that automatically lights the burners.

Please note that it is very fragile and should be handled

with care.

!

CAUTION

▲

Do not touch igniter. It is extremely hot.

5. BURNER – Gas burners do not normally require

scheduled servicing, however, accumulation of foreign

material may cause a yellowing flame or delayed

ignition. Either condition indicates that a service call is

required. For best operation, burners must be cleaned

annually using brushes and vacuum cleaner.

Turn off gas and electric power supply. To clean burners,

remove burner box cover (6 to 8 screws) and top burner

bracket. Lift burners from orifices.

NOTE:

Be careful not to break igniter when removing burners.

Clean burners with brush and/or vacuum cleaner. Reassemble parts by reversal of the above procedure. The

burner box must be resealed when replacing box cover.

NOTE:

On LP (propane) units, some light yellow tipping of the

outer mantle is normal. Inner mantle should be bright blue.

Natural gas units should not have any yellow tipped flames.

This condition indicates that a service call is required. For

best operation, burners must be cleaned annually using

brushes and vacuum cleaner.

NOTE:

On LP (propane) units, due to variations in BTU content and

altitude, servicing may be required at shorter intervals.

!

WARNING

▲

CARBON MONOXIDE POISONING HAZARD

Failure to follow the service and/or periodic maintenance

instructions for the furnace and venting system, could

result in carbon monoxide poisoning or death.

6. HEAT EXCHANGER/FLUE PIPE – These items must be

inspected for signs of corrosion, and/or deterioration at the

beginning of each heating season by a qualified service

technician and cleaned annually for best operation. To

clean flue gas passages, follow recommendations below:

a. Turn off gas and electric power supply.

b. Inspect flue pipe exterior for cracks, leaks, holes or

leaky joints. Some discoloration of PVC pipe is normal.

c. Remove burner compartment door from furnace.

d. Inspect around insulation covering flue collector box.

Inspect induced draft blower connections from

recuperative cell and to the flue pipe connection.

e. Remove burners. (See 4.)

f. Use a mirror and flashlight to inspect interior of heat

exchanger, be careful not to damage the igniter, flame

sensor or other components.

g. If any corrosion is present, contact a service agency.

Heat exchanger should be cleaned by a qualified

service technician.

h. After inspection is complete replace burner box cover,

burners, and furnace door.

i. Restore gas supply. Check for leaks using a soap

solution. Restore electrical supply. Check unit for

normal operation.

7. COOLING COIL CONDENSATE DRAIN - If a cooling

coil is installed with the furnace, condensate drains

should be checked and cleaned periodically to assure

that condensate can drain freely from coil to drain. If

condensate cannot drain freely water damage could

occur. (See Condensate Drain in Installer’s Guide.)

!

CAUTION

▲

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation.

Verify proper operation after servicing.

!

WARNING

▲

NEVER USE AN OPEN FLAME TO TEST FOR GAS LEAKS:

AN EXPLOSION COULD OCCUR, CAUSING INJURY OR

DEA TH.

Page B-651-438 5

Service Facts

*UY WIRING DIAGRAM

6 Page B-651-438

Loading...

Loading...