Page 1

INSTALLATION & USER'S MANUAL

Advanced Clean

SpaLet™

Side Panel

Remote Panel

Thank you for purchasing this product.

After reading this manual, please keep it in a place where you can refer to it easily.

BE SURE TO FOLLOW THE SAFETY PRECAUTIONS.

Failure to follow the safety precautions may result in serious accidents in some circumstances.

Each of these items are extremely important for safety, and should be strictly observed.

In the event that an accident occurs as a result of improper usage, American Standard

will assume no responsibility for damages.

©2017 AS America Inc.

SPALET is a trademark of AS America, Inc.

760230-110

Page 2

INSTALLATION

TABLE OF CONTENTS

1. Important Safeguards ........................................................... 3

2. Product Description ............................................................. 5

3. Installing This Product ......................................................... 6

Installation Requirements ....................................................................6

Contents .............................................................................................................. 6

Ground Fault Circuit Breaker .......................................................................... 7

Power Supply ..................................................................................................7

Grounding ....................................................................................................... 7

Installation Location ........................................................................................ 7

Water Supply .................................................................................................. 7

Checking the Bathroom .................................................................................. 7

Measure the size of the Toilet ......................................................................... 8

Conditions for using Water Supply Hose ........................................................ 8

Illustrated Parts Breakdown ................................................................ 9

Overview .........................................................................................................9

Strainer ........................................................................................................... 9

Operating Panel ............................................................................................ 10

Installation .......................................................................................... 11

Operational Check .............................................................................. 16

4. Operation Manual / Table of Contents ................................17

2

Page 3

1. IMPORTANT SAFEGUARDS

When using electrical products, especially when children are present, the basic safety precautions should

always be observed.

READ ALL THE INSTRUCTIONS BEFORE USING THIS PRODUCT

The following safety terms are used in this manual to warn against different

hazardous situations:

DANGER– To reduce the risk of electrocution:

1. Do not place or store product where it can fall or be pulled into a tub or sink.

2. Do not place in or drop into water or other liquid.

3. Do not reach for a product that has fallen into water. Unplug immediately.

WARNING

To reduce the risk of burns, electrocution,

fire or injury to persons:

1. When small children, elderly persons, persons with limited mobility or people with

illness are using this product, ensure that the proper operating procedures are

followed at all times to ensure the user's safety.

2.

When you are using this product for a long period of time, set the seat

temperature to "Off".

For the following persons, be sure to set the seat temperature to "Off" when they are

using this product.

(Children, elderly persons, persons with illness, persons with limited mobility, persons

with sensitive skin, persons who are taking medicines that cause drowsiness,

persons who are intoxicated, or persons who are extremely fatigued.)

* Using the toilet for a long period of time without setting the seat temperature to "Off"

may result in low temperature burns.

Low Temperature Burns

A low temperature burn may occur when the skin has been in contact for some time

with an object at relatively low temperature (about 104 °F [40 °C]). Susceptibility to

burns also depends on an individual's skin sensitivity and other factors.

3. This product should be used only as described in this manual. Do not use

attachments that are not recommended by the manufacturer.

4. Never operate this product if it has a damaged cord or plug, if the plug is loose in the

outlet, if it is not working properly, or if it has been dropped or damaged. If the plug

is inserted or disconnected by holding the cord, the plug or cord may be damaged

resulting in fire or electric shock.

5. Keep the cord away from heated surfaces.

contunued on page 4

3

Page 4

6. Never block the air openings of the product. If lint or hair, etc. is stuck in the air

openings, remove it immediately.

7. Never use while sleeping or feeling drowsy.

8. Never drop or insert any object into any opening or hose.

9. Connect this product to a properly grounded outlet only. See Grounding Instructions.

10. This product should only be connected to a potable water supply line. Failure to do so

will cause problems in the operation.

11. Do not pull out or insert the power plug with wet hands.

12. Disconnect the power plug periodically and clean it with a dry cloth.

Dust accumulated on the power plug may cause fire.

13. Do not use outdoors or operate where aerosol (spray) products are being used or

where oxygen is being administered.

To reduce the risk of minor injury or property damage:

1. This product should only be connected to a 120 V AC, 60 Hz GFCI-protected outlet.

2. For care of the plastic parts, our company recommends the use of a mild liquid or an

all-purpose cleaner. Avoid using abrasive products (such as powdered cleansers) and

chlorine-based products (such as bleach), as these products can damage the

anti-bacterial properties of the plastic components.

3. If the toilet seat or the body cover is damaged, pull the power plug out of the outlet.

4. Do not stand on the toilet seat lid, as it may break.

5. Do not lean back against the lid during use, as this may damage or break the lid.

6. Install this product according to this installation manual. Improper installation may

result in electrocution, fire, or a water leak.

7.

Do not forcefully pull on the bidet nozzle or turn it as this may cause it to fail.

8. Do not apply unnecessary force to the water supply hose as it could result in

damage and cause water to leak

9. To prevent the toilet seat and toilet seat lid from slamming down, a damping

mechanism is provided to lower them gradually. If the toilet seat or toilet seat lid is

closed abruptly or too forcefully, this product could be damaged or fail.

SAVE THESE INSTRUCTIONS

4

4

Page 5

2. Product Description

This product incorporates a set of features to improve personal toilet hygiene and comfort. These

features include rear cleansing, front cleansing and a seat heater as well as the required controls for

these features.

This product includes a seat unit (with heated toilet seat, toilet seat lid, warm water tank, and power

cord), hardware for installing the seat unit on a toilet and connecting it to the water supply and this

installation and user's manual.

This product incorporates the following features:

rear cleansing with water flow strength controls

•

front cleansing with water flow strength controls

•

seat heater with heat level control

•

rear and front cleansing water temperature control

•

seat and water temperature indicators

•

rear and front nozzle self-cleaning

•

stop button for rear cleansing, front cleansing

•

Note:

When transporting the product, take care not to inadvertently bump or drop it.

•

This product has been already inspected using tap water. A small amount of water

•

may be detected when installing the unit; this should not be a cause for concern.

5

Page 6

3. Installing This Product

Installation Requirements

Before installing this product, ensure that each of the following installation

requirements are met.

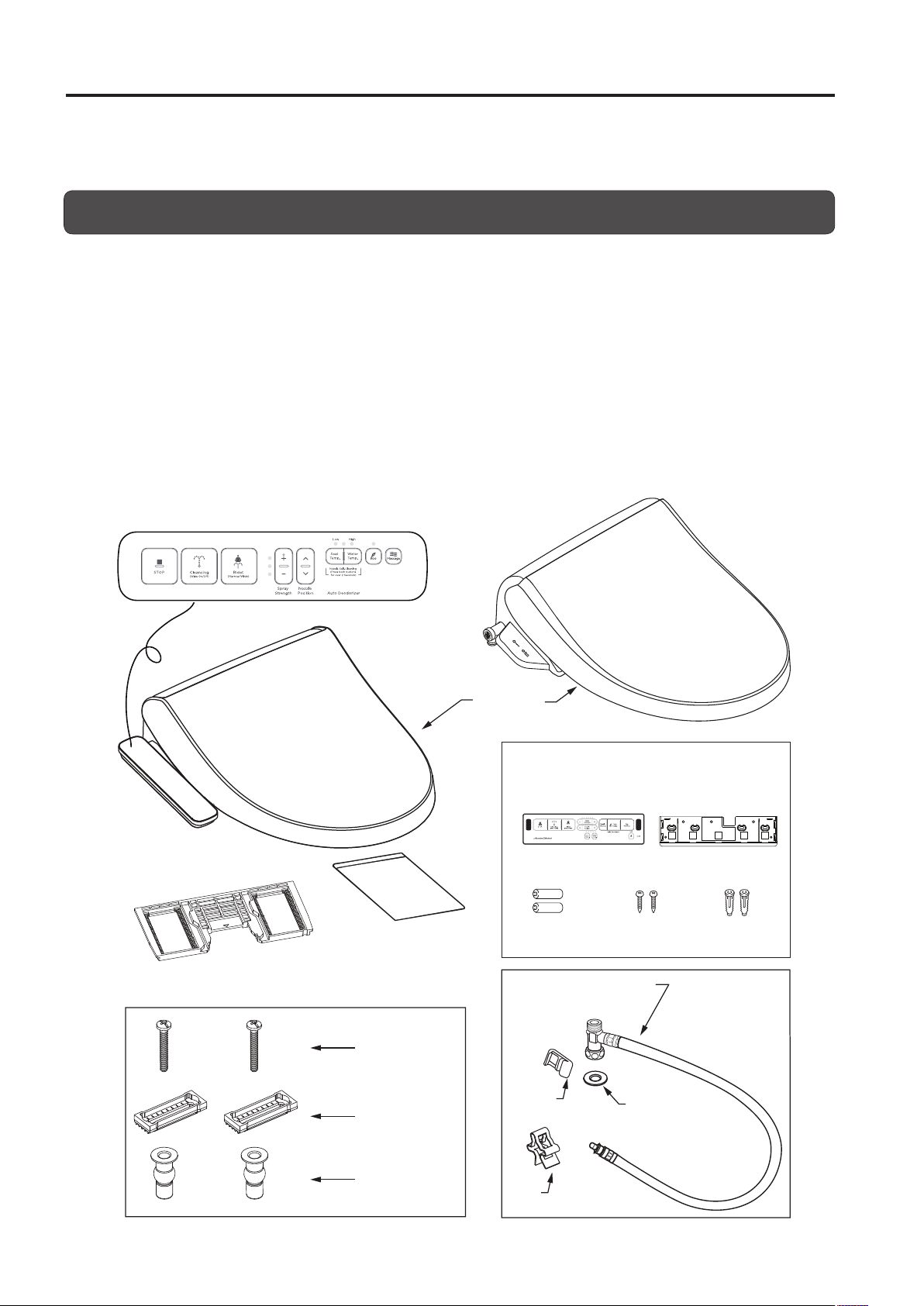

Contents

Remove the parts from the box and make sure all the parts in the parts list (below) are present. Inspect

the parts carefully to make sure they are in good condition.

If any part is damaged or missing, do not install this product. Contact a customer service representative

for the part(s) you need.

The following parts are included:

Seat unit (with heated toilet seat, toilet seat lid and power cord)

•

Mounting plate

•

Manual

•

Mounting bolts, brackets, and bushings (2 pieces each)

•

Seat unit water supply hose (with 1 clip and 1 washer)

•

Side Panel

Seat unit

FOR REMOTE VERSION ONLY:

Remote control

•

Bracket

•

Batteries

•

Wood screw

•

Plastic anchors

•

*Remote control unit and bracket are

packed in the box.

Mounting plate

(This plate attaches to the seat unit.)

Mounting bolt

Bracket

Bushing

Manual

Remote control unit

For remote control unit

Batteries (2)

Water supply hose

(w/ T-junction)

Plastic

Clip

Clip

Wood

screws

Washer

Bracket

Plastic

anchors

6

Page 7

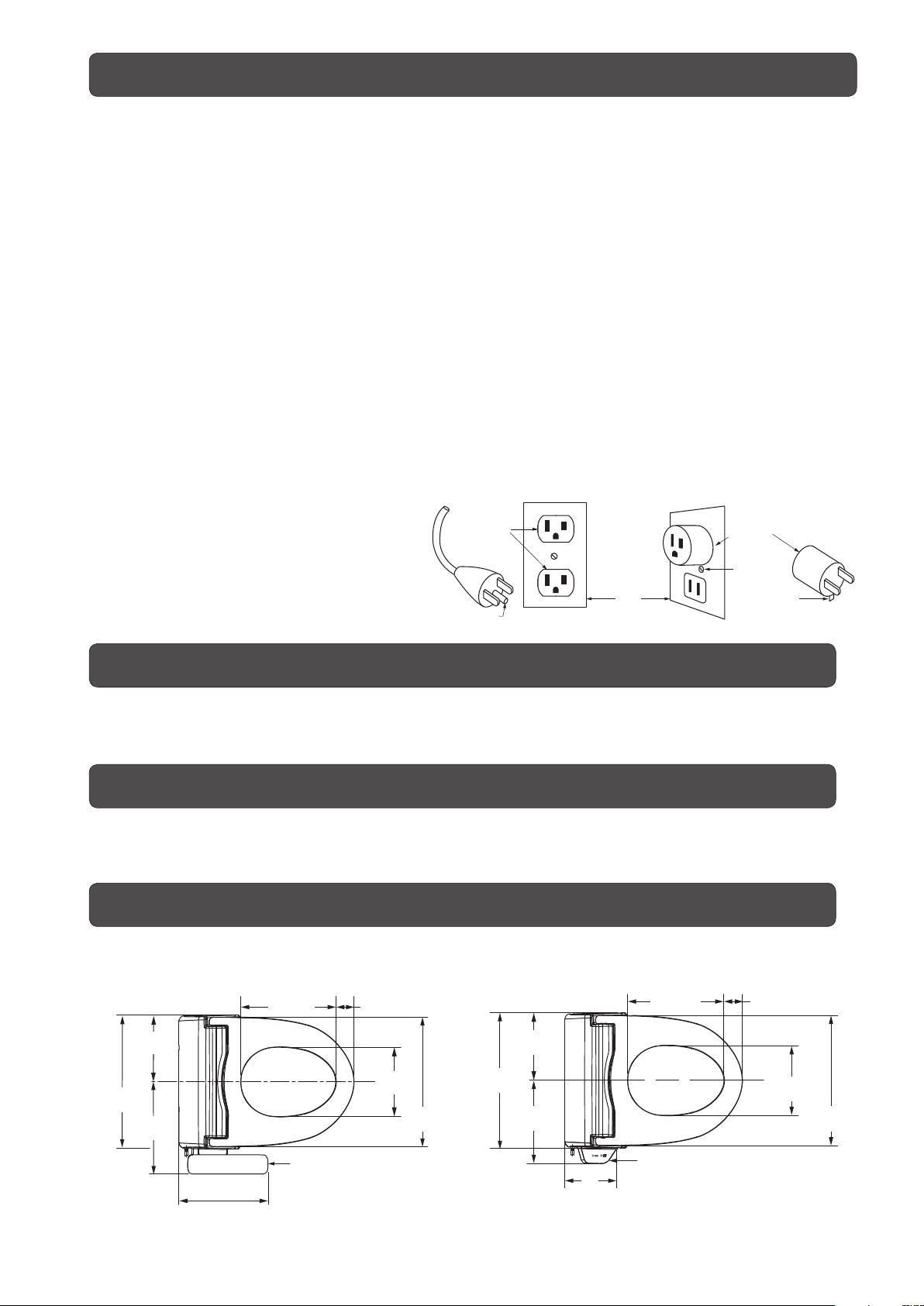

GROUNDING INSTRUCTIONS

Remote receiver

11-1/4"

(286mm)

2-3/16"

(56mm)

11-1/4"

(286mm)

2-3/16"

(56mm)

7-11/16"

(195mm)

7-11/16"

(195mm)

9-1/2"

(241mm)

6"

(152mm)

7-15/16"

(202mm)

14-7/8"

(378mm)

Side Panel

7-15/16"

(202mm)

10-9/16"

(269mm)

10 - 9/16"

(269mm)

14-7/8"

(378mm)

15-3/8"

(391mm)

15-3/8"

(391mm)

This product should be grounded. In the event of an electrical short circuit, grounding reduces the risk

of electric shock by providing an escape wire for the electric current. This product is equipped with a

cord having a grounding wire with a grounding plug. The plug must be plugged into an outlet that is

properly installed and grounded.

DANGER– Improper use of the grounding plug can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not connect the grounding wire to either

at blade terminal. The wire with insulation having an outer surface that is green with or without yellow

stripes is the grounding wire.

Check with a qualified electrician or serviceman if the grounding instructions are not completely

understood, or if in doubt as to whether the product is properly grounded.

This product is for use on a nominal 120 V circuit, and has a grounding plug that looks like the plug

illustrated in sketch A. A temporary adapter, which looks like the adapter illustrated in sketches B and

C, may be used to connect this plug to a 2-pole receptacle as shown in sketch B if a properly grounded

outlet is not available. The temporary adapter should be used only until a properly grounded outlet

(sketch A) can be installed by a qualied electrician. The green colored rigid ear, lug, and the like

extending from the adapter must be connected to a permanent ground such as a properly grounded

outlet box cover. Whenever the adapter is used, it must be held in place by the screw.

If it is necessary to use an extension cord,

use only a three wire extension cord that

has a three-blade grounding plug, and

a three-slot receptacle that will accept

the plug on the product. Replace or

repair a damaged cord.

GROUNDED

OUTLET

GROUNDING PIN

A B C

GROUNDING

METHODS

GROUNDED

OUTLET

BOX

ADAPTER

METAL

SCREW

TAB FOR

METAL SCREW

Installation Location

In order to prevent damage to the electronic components, install this product at a location that

minimizes the possibility of it getting wet. In extremely humid conditions, provide adequate ventilation by

operating an exhaust fan or opening a window or door.

Water Supply

Use only the tap water line to supply water to this product. The use of any other type of water i.e. ground

water or well water may reduce functionality of product.

The tap water pressure must be 8.5 to 106.7 psi

(0.06 to 0.74 MPa, 0.6 to 7.5 kgf/cm2).

Checking the Bathroom

The dimensions required for mounting this product on a toilet are shown in the gure below. Check to

make sure there is sufficient space inside the bathroom and that there are no obstructions.

7

Page 8

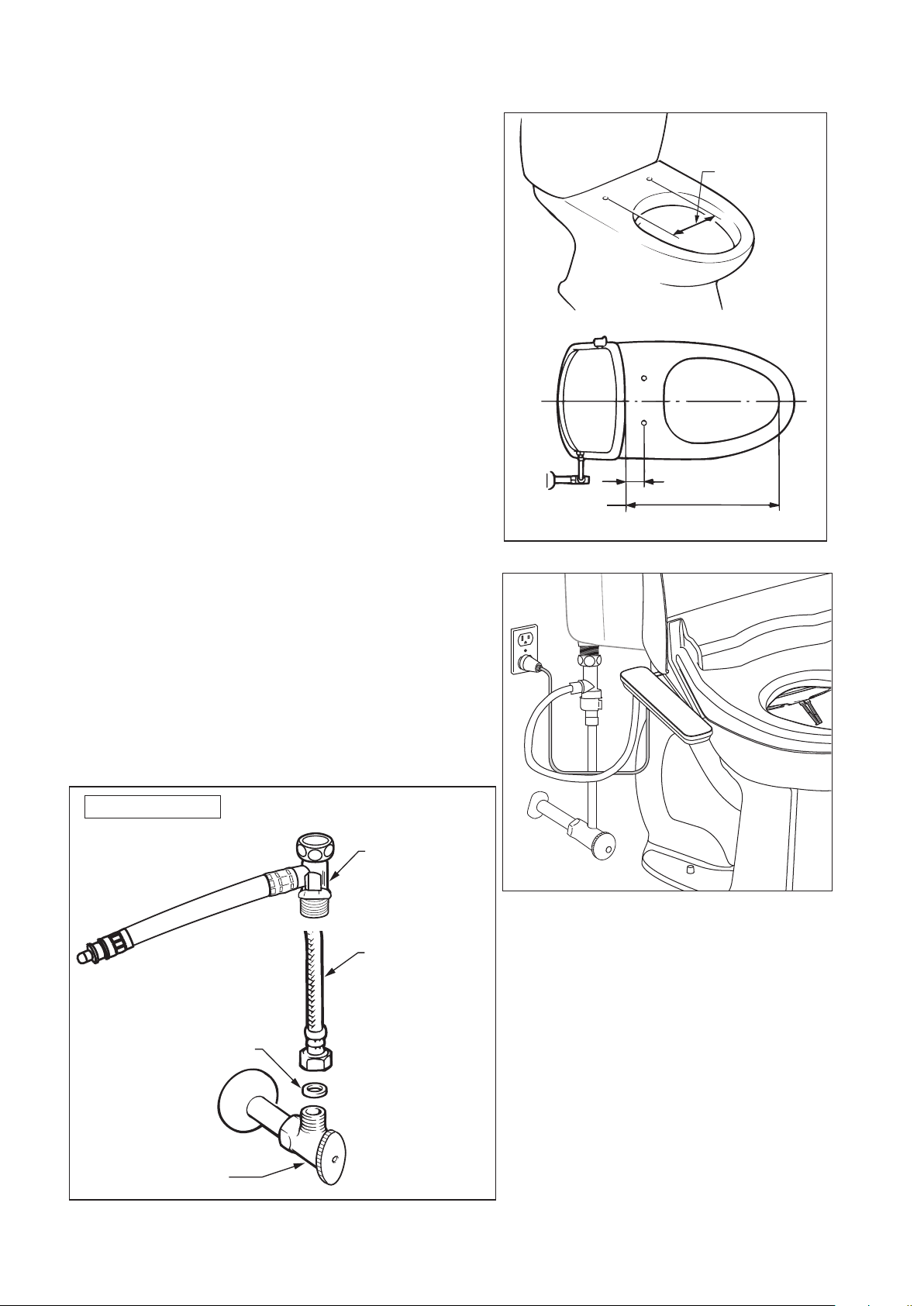

1. Measure the size of the toilet.

Depending on the size of the toilet, it may not be

possible to mount this product on it.

Make sure the toilet's dimensions are as shown in

the gure on the right.

2. Conditions for using water supply

hose (included)

17-5/16"-19-5/8"

(440-500 mm)

5-1/8" to 8-1/2"

(130 to 215 mm)

1-1/8" (30 mm)

or more

The length of the water supply hose included with this

product is 37-3/8" (950 mm), but a length of 31-1/2"

(800 mm) from the junction tting to the seat unit's

water supply socket is appropriate. (Refer to the gure

on the right)

Installation Figure

Water supply hose

(w/ T junction)

Toilet Water

supply hose

Seal washer

Water supply

valve

8

Page 9

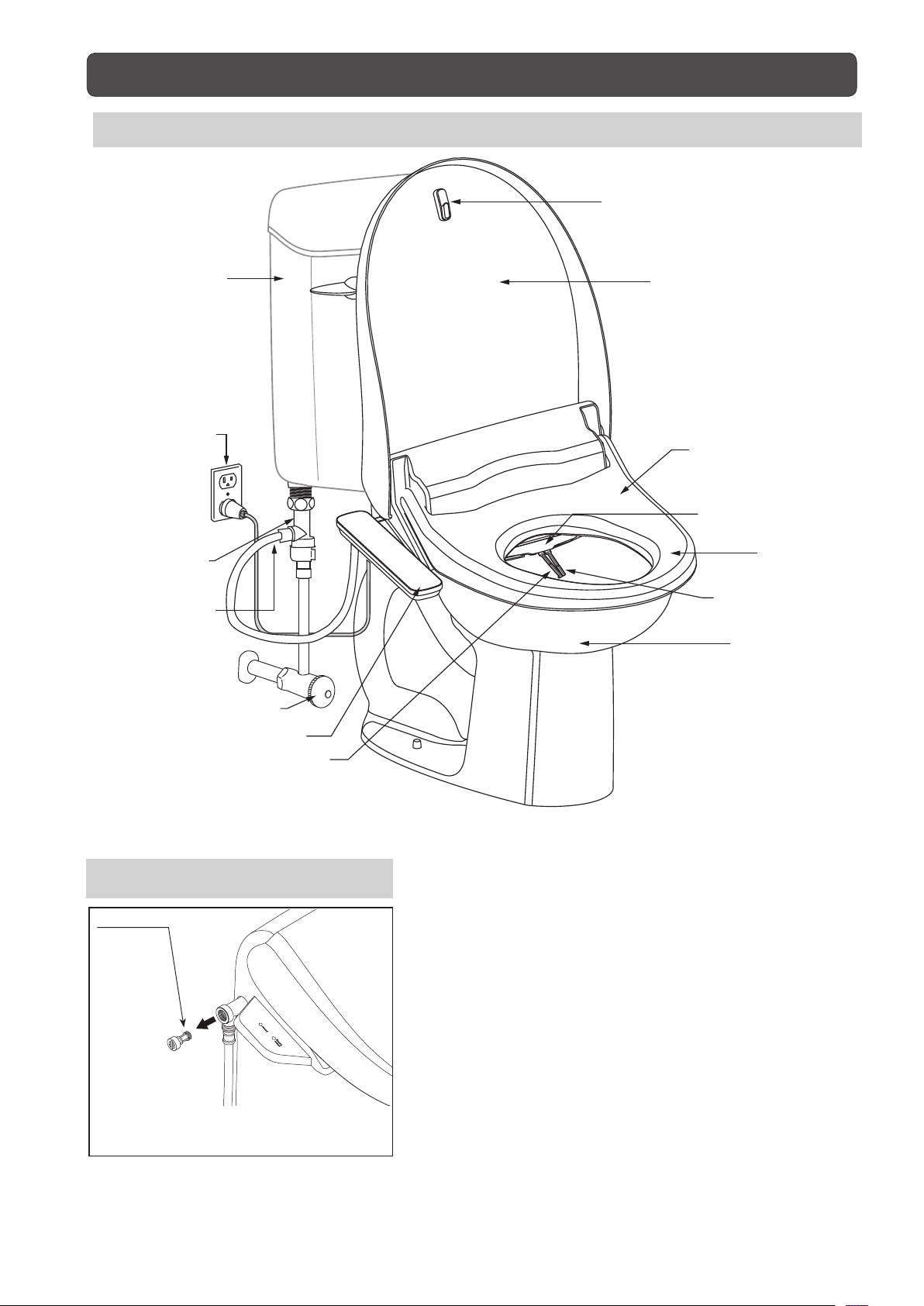

Illustrated Parts Breakdown

Overview

Lid Bumper

Toilet

Tank

Power Plug

T-Junction

Water Hose

(with T-Junction)

Water Valve

Lid

Seat Sensor

(built-in)

Nozzle Shutter

Seat

Nozzle

(posterior cleansing)

Bowl

Control Panel

Nozzle

(feminine cleansing)

Strainer

Strainer

* The strainer removes impurities

and debris from the tap water.

9

Page 10

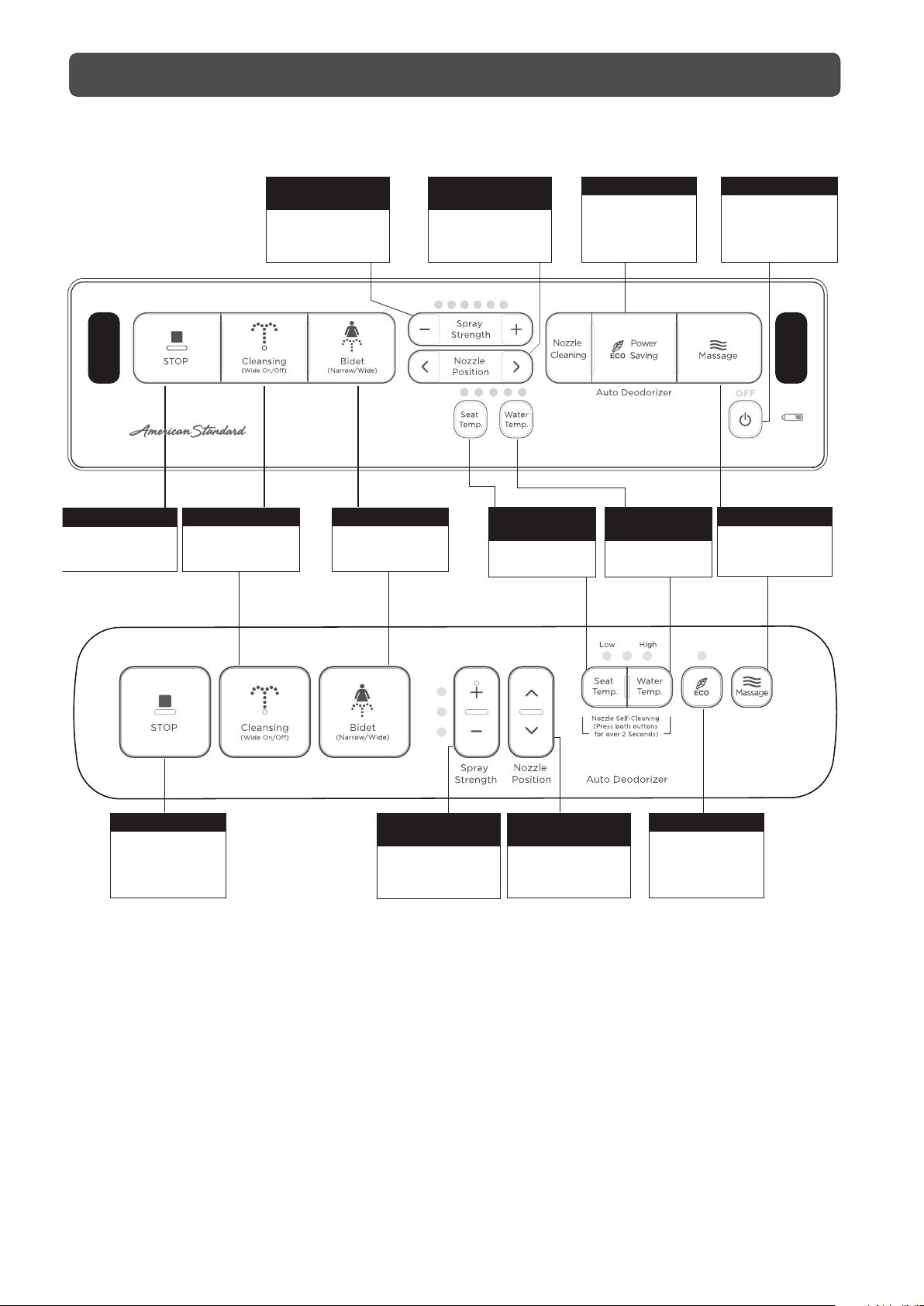

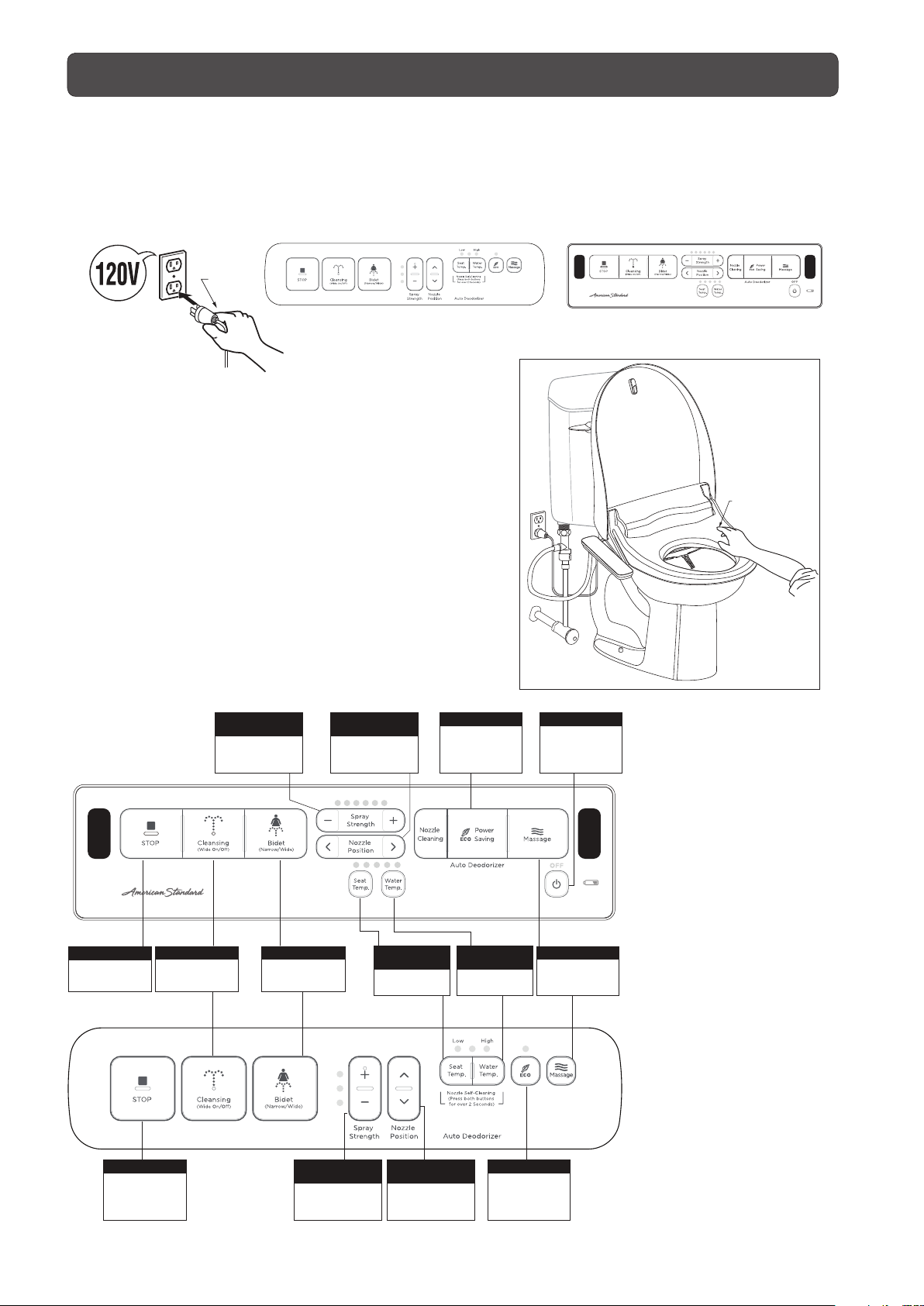

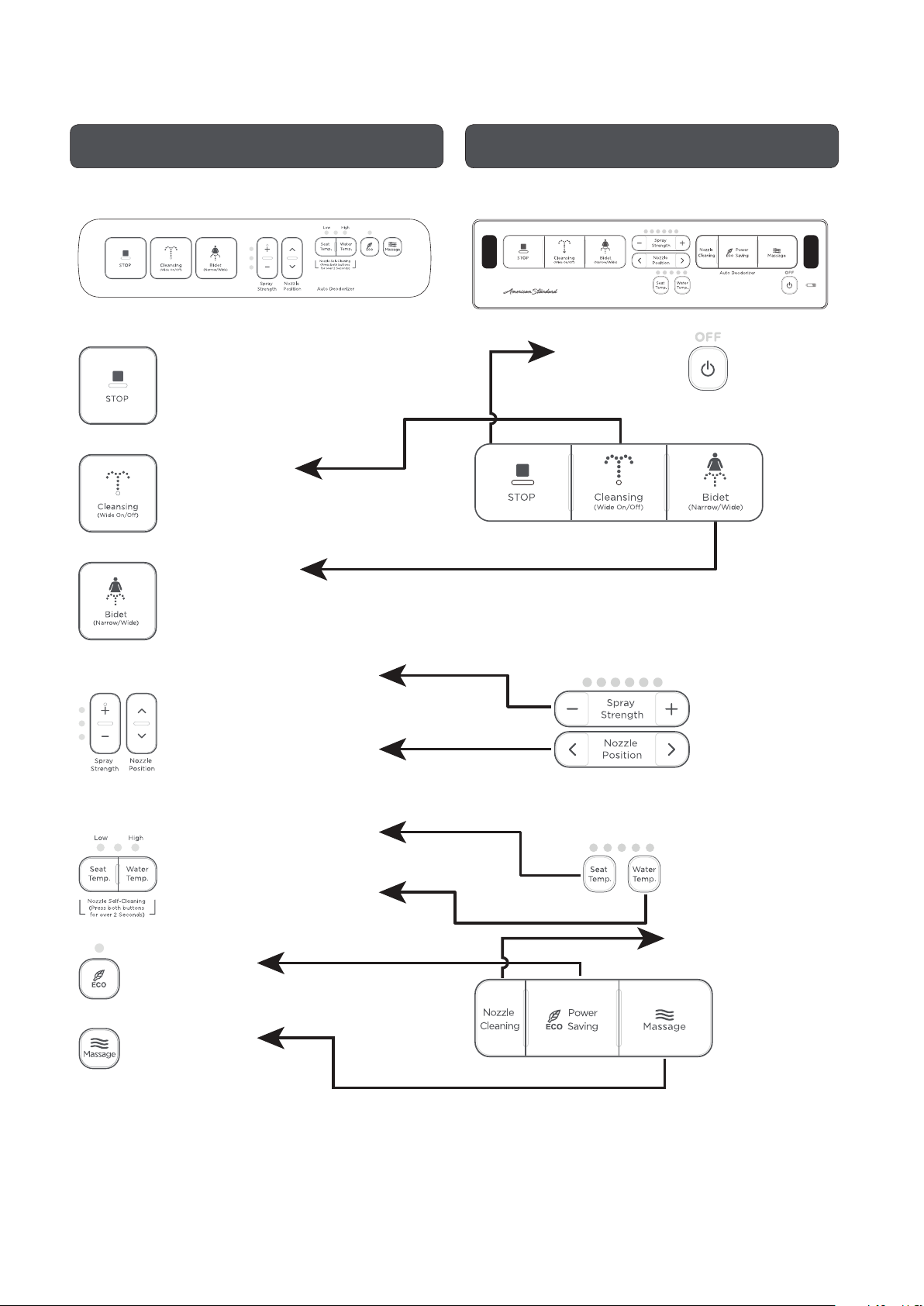

Operating Panel

Remote

STOP

Stops cleansing

functions

CLEANSING

Use for Posterior

Side Panel

Cleansing.

SPRAY

STRENGTH

Adjusts Feminine

and Posterior

spray strength

BIDET

Use for Feminine

Cleansing.

NOZZLE

POSITION

There are 5 modes

for nozzle position

adjustment

SEAT

TEMPERATURE

Adjusts seat

temperature

ECO

Power saving

WATER

TEMPERATURE

Adjusts water

temperature

POWER

Controls POWER

to the seat

MASSAGE

Massage cleaning

(only for posterior)

POWER

Controls POWER

to the seat and

stops cleansing

functions

SPRAY

STRENGTH

Adjusts Feminine

and Posterior

spray strength

10

NOZZLE

POSITION

There are 5 modes

for nozzle position

adjustment

ECO

Power saving

Page 11

Installation

1. Required tools

Have the following tools for installing this product:

adjustable end wrench, Phillips head screwdriver,

flat-blade screwdriver.

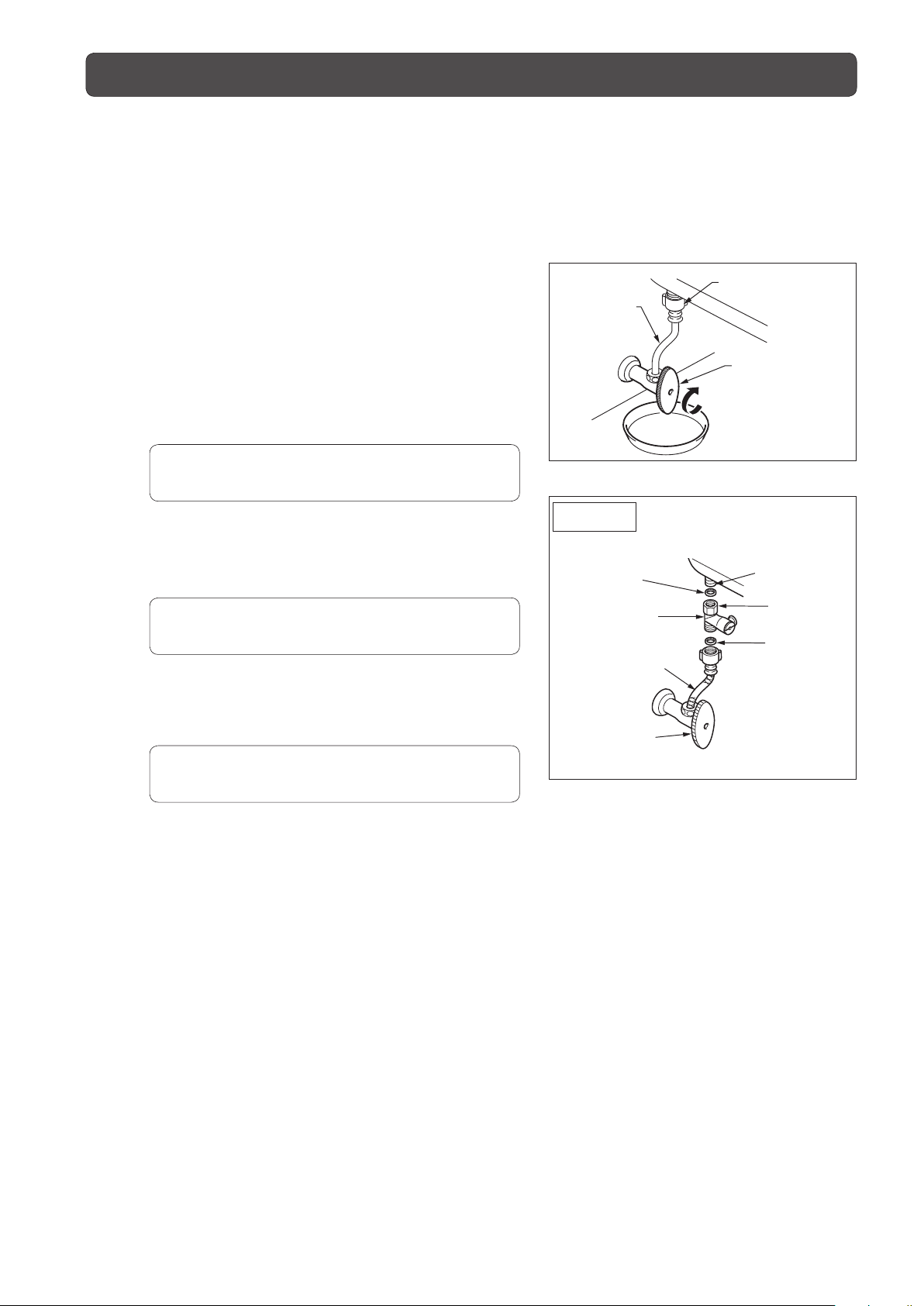

2. Install the junction fitting

1) Close the toilet water shutoff valve fully.

2) Flush the toilet and empty all the water from the

tank.

3) Place a wash bowl or other container

underneath the tank water supply hose. Then

loosen the box nut on the tank inlet side and

remove it.

CAUTION

•

Be careful not to damage the water supply hose.

4) Place the packing in the junction fitting box nut

and connect the tank inlet to the junction fitting.

CAUTION

•Donotovertightenthenut.

5) Insert the packing in the tank water supply hose

box nut and connect the tank water supply hose

to the junction fitting.

Tank Water

Supply Hose

Installation

Figure

Packing

Junction

Tank Water

Supply Hose

Water Shutoff

Bowl Cock Side

Box Nut

Water Shutoff Valve

Close

Tank Inlet

Box Nut

Fitting

Packing

Valve

CAUTION

•Donotovertightenthenut.

11

Page 12

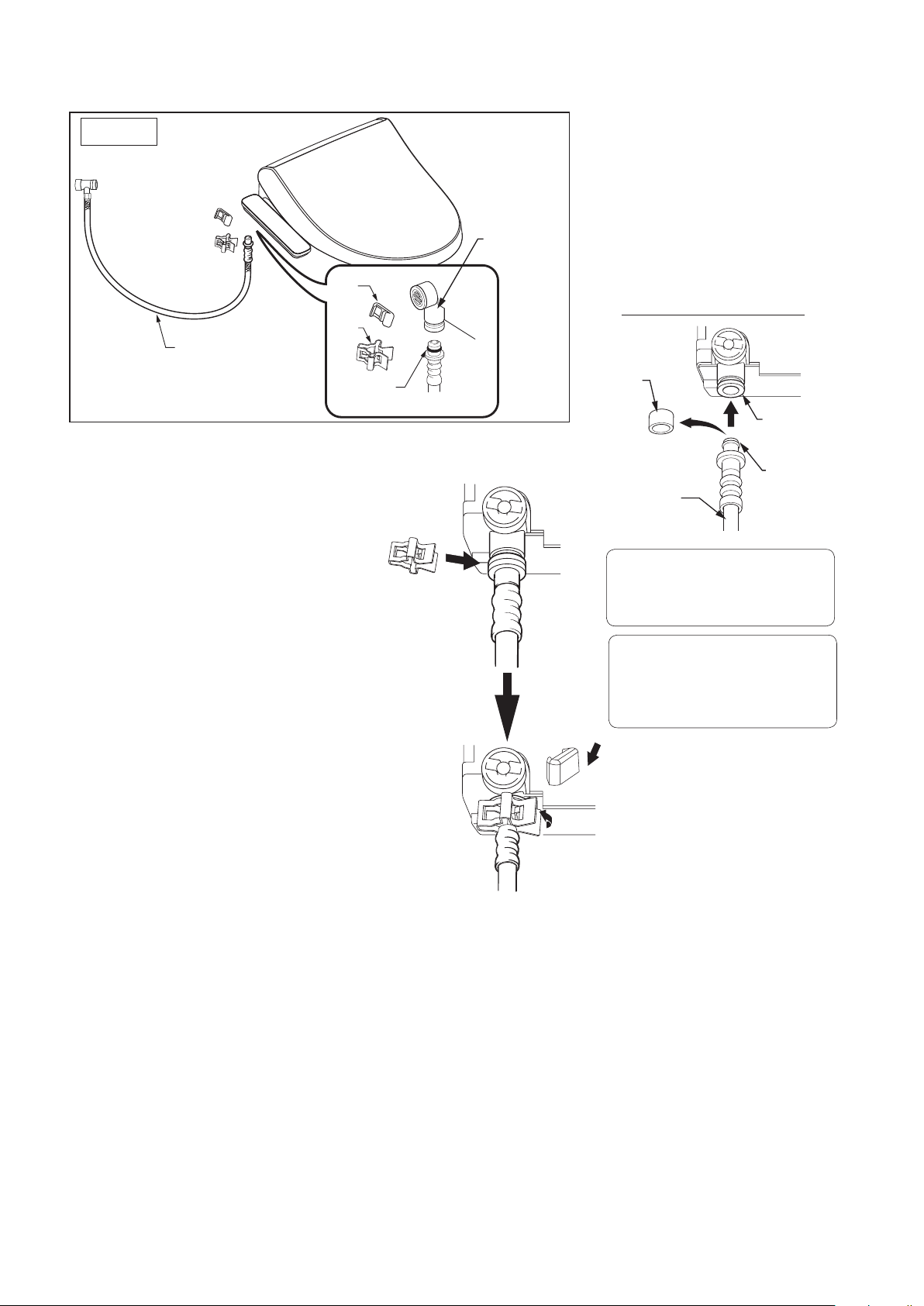

3. Installation of water supply hose to the bidet

1)

Installation

Figure

Remove the protective cover

from the end of the water supply

hose, and pull out the cap from

the water supply connection

socket.

Plastic

Clip

Clip

Water supply

hose

3) Insert the attachment clip onto the

water supply hose to attach it to the

bidet and water supply connection

socket.

* The attachment clip can be attached in

any direction.

O-ring

Water supply

joint

2) Connect the water supply hose

for the bidet to the water supply

connection socket.

WATER SUPPLY

CONNECTION SOCKET

Protective

Cover

Water

supply

socket

Water supply

hose for

O-ring

the seat

CAUTION

•

Be careful not to damage the O-ring.

* A damaged O-ring may cause water to leak.

CAUTION

•Firmlyinserttheclip.

* If the clip is not rmly inserted,

it may cause water leaks.

4) Bend the clip end and firmly clip

together both the feeding hose for

the bidet and the feeding socket.

After you install the clip, twist it in

both directions to verify that it is

firmly attached, then attach the

final attachment clip over the

primary clip to secure in place.

5) Insert the clip until you feel the clip

edge click.

* If not firmly inserted, it may cause

water leaks

12

Page 13

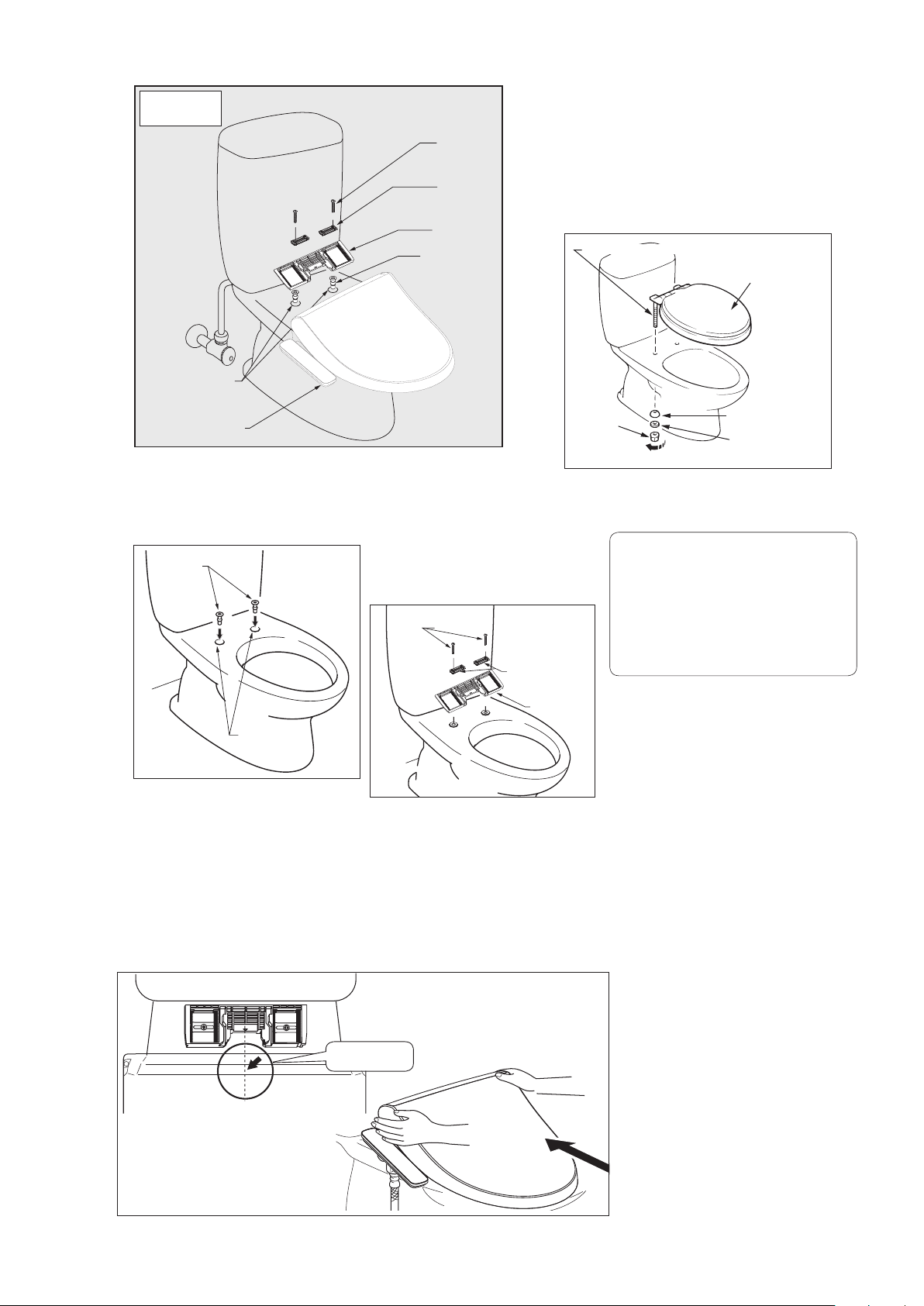

4. Installation of the bidet

Mounting bolts

for the toilet

Mounting

brackets

Mounting plate

Installation

Figure

Body

mounting

bolt

Bracket

Mounting

plate

Bushing

Seat

mounting hole

E-bidet

(2) Install the slide plate onto the seat.

1) Insert the bushings into

the seat mounting holes.

Bushings

2) Insert the mounting

bracket into the mounting

plate and use the mounting

bolts to attach the slide

plate to the seat.

(1) Remove the existing seat.

1) Remove the nuts from the seat

mounting bolts, the slip washers,

and rounded packing.

2) Raise the seat and remove it by

lifting the seat mounting bolts.

Seat mounting bolts

Existing seat

Nut

Loosen

Rounded packing

Slip washer

References

•Sometoiletseatsmayrequire

different methods of removal that

differ from our explanation.

Seat mounting

holes

(3) Install the bidet.

1) Place the bidet on the toilet and align the seat to the

mounting plate.

2) Slightly raise the front side of the bidet, slide it until the

slide plate is fully inserted, and then press the locking

lever to secure the bidet.

Center aligned

13

Page 14

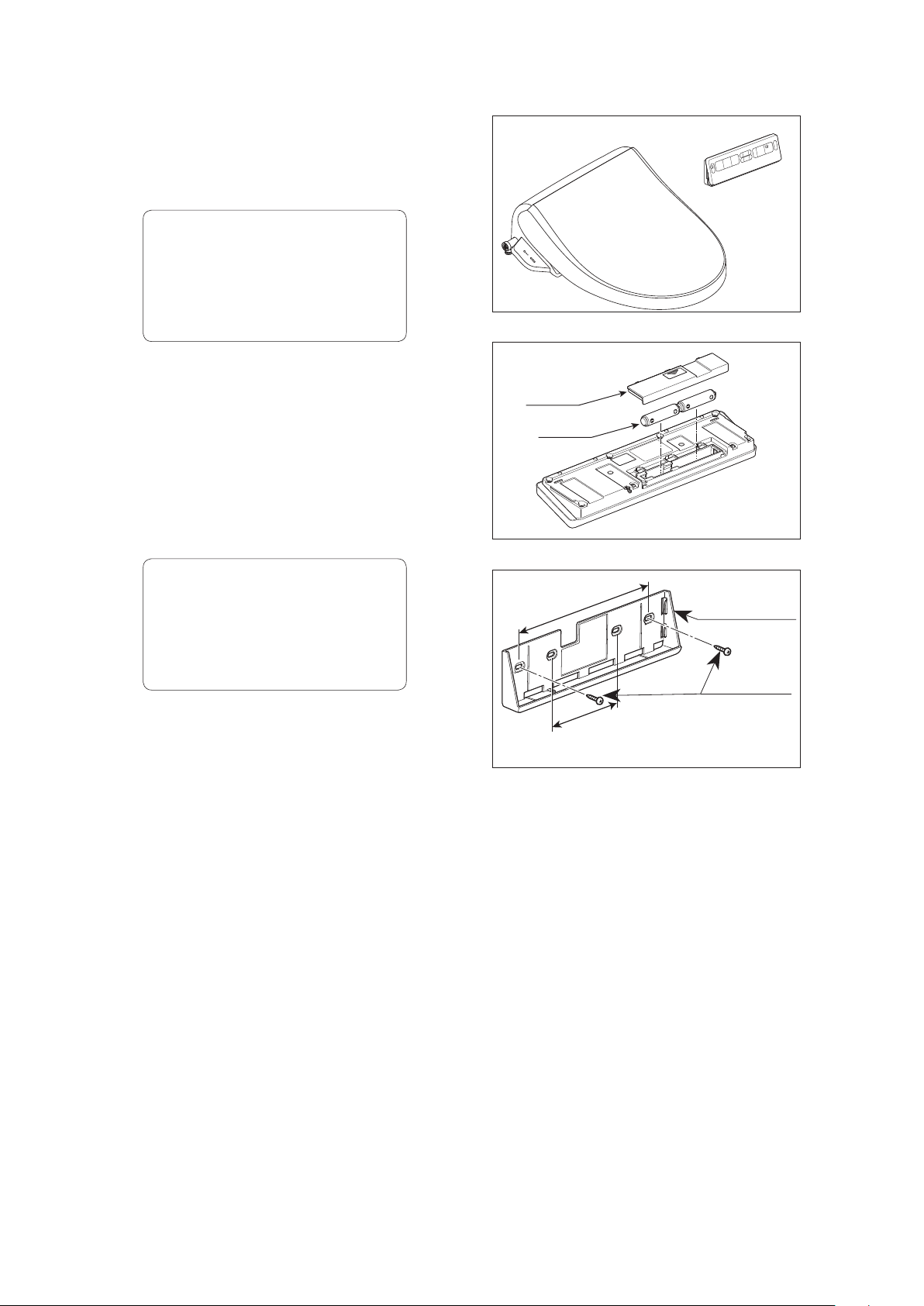

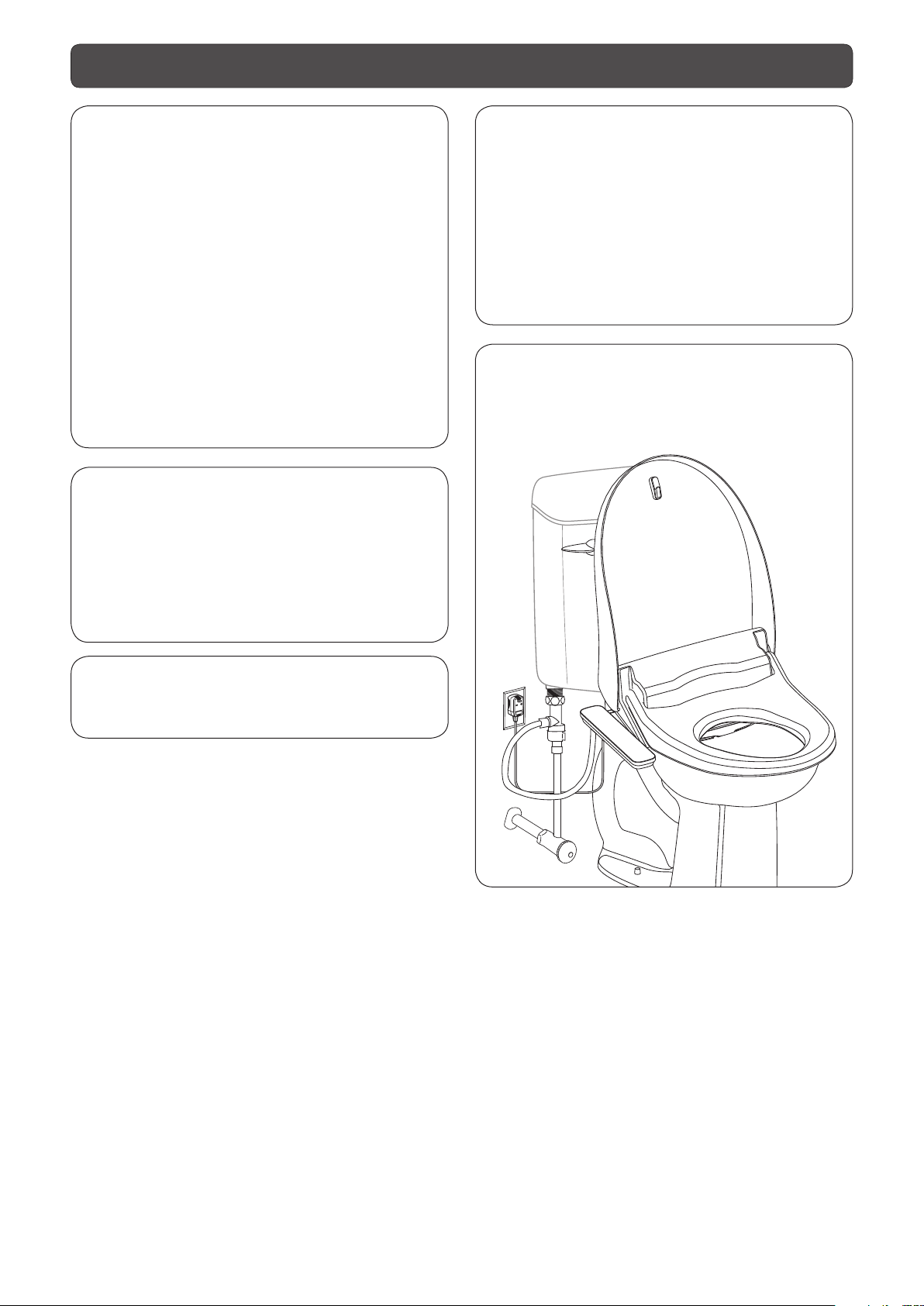

5. Install the remote control unit

* For Remote Version Only

(1) Open the back cover of the

remote control unit and insert the

2 size AA batteries.

CAUTION

• Insert each battery so its positive

pole touches a positive connector

in the battery compartment and its

negative pole touches a negative

connector.

(2) Position the bracket on the wall

in the location you chose for

the remote control unit. Mark the

location of the mounting holes on

the wall. Fasten the bracket to the

wall, drilling holes and using the

fasteners appropriate for the wall

material, as described below.

Back Cover

Battery

CAUTION

• Leave enough space above the

top of the remote control unit to

allow the unit to be removed and

replaced.

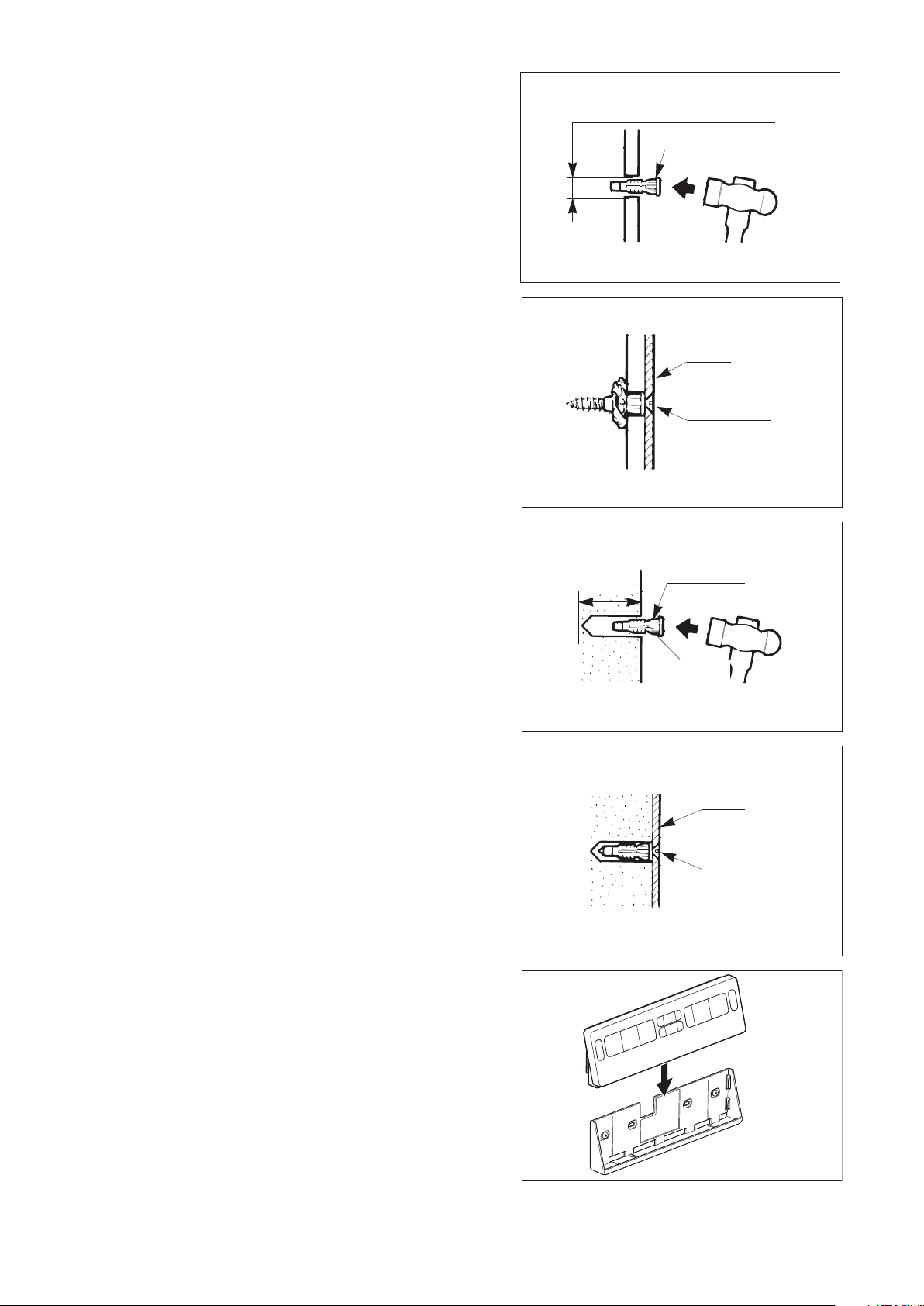

If mounted in plywood paneling

0.20 in. (5 mm) or greater in

thickness:

Fasten the bracket to the wall with the

mounting screws.

200mm

100mm

Bracket

Mounting Screw

14

Page 15

If mounted either in plywood

paneling 0.20 in. (5 mm) or less in

thickness or in gypsum board:

1) In plywood paneling, drill holes with a

diameter of 0.24 in. (6 mm); in gypsum

board, drill holes with a diameter of 0.20

in. (5 mm):

2) Using a hammer, gently drive the

plastic anchors into the holes.

3) Fasten the bracket securely to the

anchors using mounting screws. As you

tighten the screws, they are hard to turn

at first, then gradually get easier to turn,

and then are hard to turn again.

Plywood paneling : 0.24 in. (6 mm)-dia.

Gypsum board : 0.20 in. (5 mm)-dia.

Plastic Anchor

Bracket

Mounting Screw

If mounted in concrete:

1) Drill holes with a diameter of 0.24 in.

(6 mm) and a depth of approximately

1.30 in. (33 mm).

2) Using a hammer, gently drive the

plastic anchors into the holes.

3) Fasten the bracket securely to the

anchors using mounting screws.

1.30 in.

(33 mm)

Plastic Anchor

0.24 in.

(6 mm)-dia.

Bracket

Mounting Screw

(3) Align the remote control unit with the

bracket and then push it down onto the

bracket.

Remote

Bracket

15

Page 16

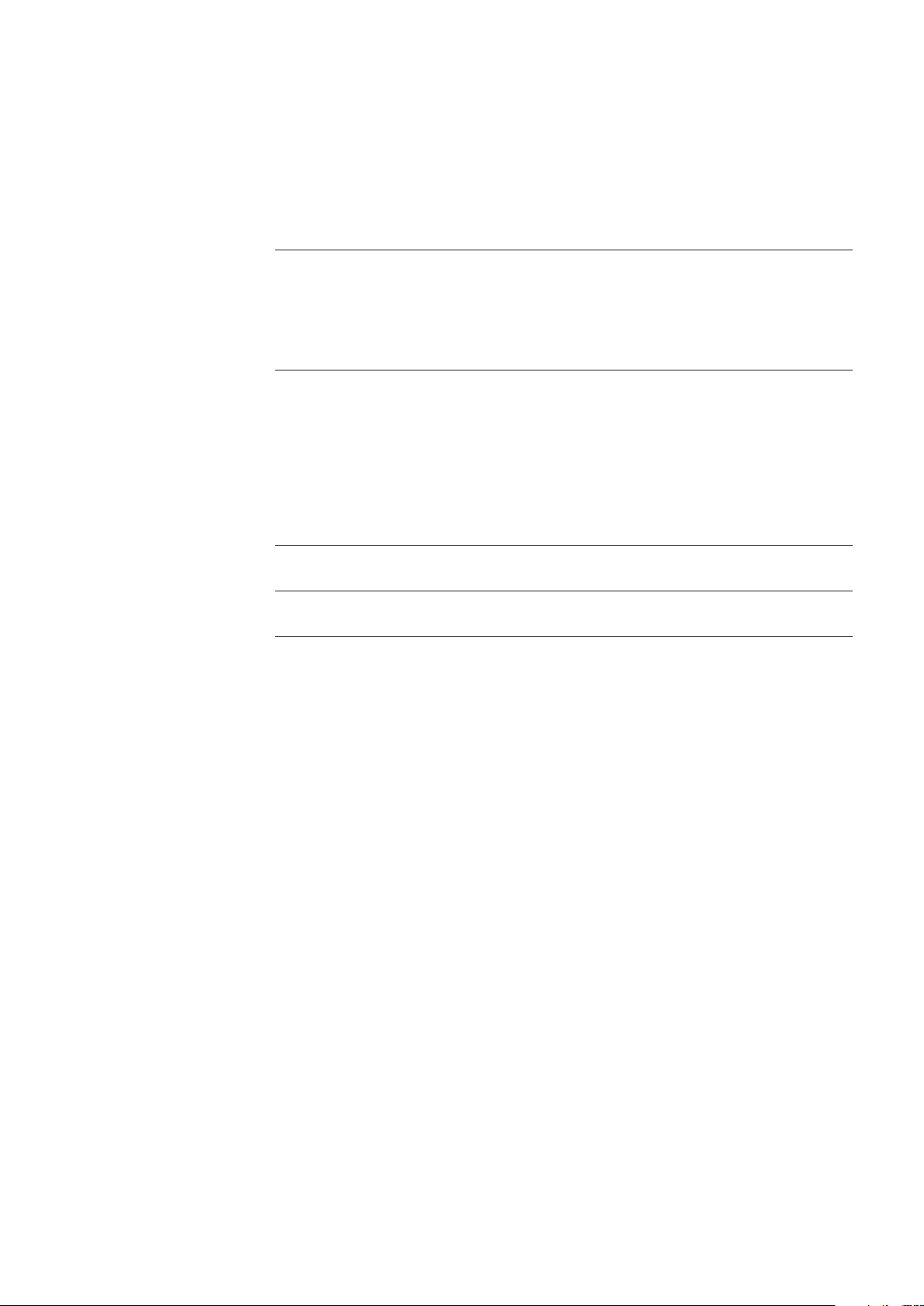

Operational Check

Operational Check

Follow the procedure below after the installation work has

been completed.

1. Insert the power plug into the outlet.

Confirm that the LED on the seat unit is lit.

Power

plug

2.Check the Feminine and

Posterior cleansing spray.

(1) Check the cleansing operation.

1) With your forearm resting on the toilet seat, press the

cleansing button.

The shower automatically stops two minutes after the

switch is turned on.

2) When the nozzle extends, cover the tip of the nozzle

with your hand to catch the spray.

3) Press the STOP button to stop the cleansing spray.

Remote Control VersionSide Panel Version

Press here

on seat

(2) Perform the same check using the

front cleansing spray function.

SPRAY

STRENGTH

Adjusts feminine

and posterior

Remote

STOP

Stops cleansing

functions

CLEANSING

Use for posterior

cleansing.

spray strength

Use for feminine

Side Panel

BIDET

cleansing.

NOZZLE

POSITION

There are 5 modes

for nozzle position

adjustment

SEAT

TEMPERATURE

Adjusts seat

temperature

ECO

Power saving

WATER

TEMPERATURE

Adjusts water

temperature

POWER

Controls power

to the seat

MASSAGE

Massage cleaning

(only for posterior)

POWER

Controls power

to the seat and

stops cleansing

functions

SPRAY

STRENGTH

Adjusts feminine

and posterior

spray strength

NOZZLE

POSITION

There are 5 modes

for nozzle position

adjustment

16

ECO

Power saving

Page 17

OPERATIONAL MANUAL

TABLE OF CONTENTS

Additional Important Information.....................................................................................18

Product Functions .......................................................

Side Panel / Remote Control...........................................................................................19

Preparations Before Use ...........................................................................

How to Use the Basic Functions

How to Use the Convenient Functions

................................................................

...........................................................................

....

......................19

.............

....................

........20

21

24

Maintaining This Product ......................................................................28

Cleaning the Seat Unit.........................................................................

Cleaning the Nozzles..................................................................................................... 28

Changing the Nozzle Tip ................................................................................................ 28

Cleaning & Maintenance of the Deodorizing Screen..................................................... 29

Cleaning the Inlet Strainer ..............................................................................................30

Cleaning Areas Covered by the Toilet Seat Lid & Unit............................................

Change Batteries for the Remote Control .......................................................................32

Troubleshooting .............................................................

Specifications .............................................................................

Warranty information & After-sales Support ..............................

..........

................28

.....

..................33

.....

...

......35

......

.....31

...36

17

Page 18

Additional Important Information

•Thecapacityofthewarmwatertankis0.88L.

Water temperature gradually drops when rear

cleansing or front cleansing is used. If the water

drops below a comfortable temperature, press

the stop button and wait about 3 minutes for the

water to reheat.

•Thewatertemperaturerangeispresettothe

following temperatures:

Low: Approx. 90 °F (32 °C),

Medium: Approx. 93 °F (34 °C),

High: Approx. 97 °F (36 °C).

It takes approximately 10 minutes to heat cold

water (at about 41 °F [5 °C]) to the appropriate

temperature (about 100 °F [38 °C]).

This product is designed to use the tap water

pressure to extend the nozzles and spray water

through them. When the tap water pressure is

extremely low, the nozzles may not spray water

at all when the water pressure is set to the

lowest setting. If this occurs, adjust the Spray

Strength.

Before and after cleansing and when the water

temperature adjustment button is pressed, etc.,

water is sprayed from the nozzle. This occurs by

design and is not a cause for concern.

If water sprays while under any other

configuration, or sprays constantly, close the

water shutoff valve and remove the power plug

from the wall outlet. Then, contact cutomer

service.

This product is equipped with a seat sensor that

prevents the water from spraying if nobody is

sitting on the toilet seat. This prevents activation

if the Bidet button is pressed when the toilet seat

is unoccupied.

When the toilet is new, a slight odor may come

from the deodorizer. This will go away in a short

time.

18

Page 19

Product Functions

Side Panel

STOP

Power On/Off

Stop function

CLEANSING

For posterior cleansing only.

Press twice for oscillating function.

BIDET

For feminine cleansing.

Press twice for oscillating function.

Press twice for super oscillating function.

Remote

STOP

Stop function

POWER

Power On/Off

SPRAY STRENGTH

Adjusts spray strength for

cleansing and bidet settings.

NOZZLE POSITION

Nozzle position adjustment

for optimal cleansing.

SEAT TEMPERATURE

Adjust warm seat temperature

WATER TEMPERATURE

Adjust warm water temperature

ECO

Power saving Mode

MASSAGE

Massage cleaning

(only for posterior)

NOZZLE CLEANING

Nozzle self-cleaning.

FOR DETAILED FUNCTIONS SEE OPERATION SECTION

19

Page 20

Press the STOP button to turn the power ON or OFF.

*

If the power is ON, the power LED on the indicator panel will light up.

be on.

STOP

(Turning the power on/off)

Performing the following operations before using the bidet allows you to use

the toilet comfortably.

Adjust the temperature of the toilet

seat using the Seat Temp. switch.

Adjust the temperature of the bidet

using the Water Temp. switch.

For Side Panel:

The water temperature can be set to one of 3

settings: HI, MID and LO.

For Remote Control:

The water temperature can be set to one of 5

settings

Set it to your preferred temperature.

* The indicator LED cycles through the temperature

settings each time the temperature button is pressed.

* The indicator LED stays on to indicate water

temperature level.

* 2 additional settings above default, for side panel only

For Side Panel:

The seat temperature can be set to one of 3

default settings: HI, MID and LO.

For Remote Control:

The seat temperature can be set to one of 5 settings.

Set it to your preferred temperature.

* The indicator LED cycles through the temperature

settings each time the temperature button is pressed.

* The indicator LED goes out after several seconds.

* 2 additional settings above default, for side panel only

• The toilet seat will not become warm instantly. To achieve

a comfortable seat temperature, set the seat to the desired

temperature about 10 to 15 minutes prior to use.

• This product is equipped with an ECO function that

automatically switches the seat heater off when it is

not occupied.

• The default setting for the seat temperature is "MID". The seat

temperature can be increased or decreased incrementally.

Reference

Preparations Before Use

Seat Temp.

Remote Control

Side Panel

Water Temp.

20

Page 21

How to Use the Basic Functions

Cleansing

Water is sprayed from the posterior

cleansing nozzle.

Press the Cleansing button.

1

Side Panel

Press the STOP button to stop

3

the spraying.

Bidet

Water is sprayed from the feminine

cleansing nozzle.

Press the Bidet button.

1

Press the [+] or [-] Spray Strength

2

button to adjust the shower strength.

* An automatic self-stop function is included

which stops both rear and front cleansing

automatically after 2 minutes.

Remote Control

For Panel Control:

There are 3 levels of spray strength.

For Remote Controlt:

There are 6 levels of spray strength.

Adjust the spray strength as desired.

* The indicator LED cycles through the spray strength

settings each time the button is pressed.

* The indicator LED goes out after several seconds

2 additional settings above default: press STOP and

CLEANSING buttons simultaneously for 2 seconds.

Press here

on seat

21

Page 22

Massage Cleansing

Water pressure alternates between high and low during rear cleansing, providing a massaging effect.

Side Panel

Press the Massage button during

posterior cleansing.

1

Remote Control

To stop the massage spray, press

the Massage button again.

2

22

Page 23

Deodorizing

Deodorizing starts when a person

1

sits on the toilet seat.

*

This product is equipped with a deodorizer cartridge which

absorbs odors from the toilet.

Deodorizing automatically stops

2

after you stand up.

Stops after 5 seconds

To disable the deodorizer

Press the STOP and Bidet buttons

simultaneously for 2 seconds.

*

When the deodorizer feature is disabled, the power

LED on the seat unit flashes momentarily. At this

point, the deodorizer will no longer activate when a

user is detected.

* The restore the deodorizer function, press the

STOP and Bidet buttons simultaneously for

2 seconds.

Only for Side Panel

Press the buttons simultaneously for 2 seconds.

Only for Remote Control

23

Page 24

How to Use the Convenient Functions

ECO button

One-Touch Power Save: Reduces power consumption by turning off the water and seat heater for 8 hours.

.sruoh 8 retfa derotser yllacitamotua era sgnittes rewop ehT

One-touch power save (8 hours)

Press the ECO button.

For side panel, the power save ECO LED

1

lights up.

For remote control, the power save ECO LED

lights up on the seat next to the power LED.

Only for Side Panel Only for Remote Control

Only for Side Panel

For example: when one-touch power save is set for 10:00

Water/Seat Temperature

Customer Set

Temperature

Power Save

Temperature

OFF

8:00

Set

10:00

12:00 2:00

8 hours

4:00

Reheat

6:00

8:00

10:00 12:00

* For Side Panel:

When the One-Touch Power

Save function is running,

the ECO LED lights up.

* For remote control:

the ECO LED lights up

on the seat

Only for Remote Control

* Once 8 hours have passed, the power settings will automatically return to their original state. The power

ashing to off.

*

The one-touch power save is not automatically repeated everyday, but can be set any number of times in a day.

To cancel the ECO mode function, press

the ECO button again.

2

(The ECO power save LED will go out.)

* You can use the toilet even when the ECO save function is operating. However, you may feel that

the water is cold as the heater for water and the toilet seat is turned off. If desired, you may turn off

the ECO save function.

* Even when the ECO save function is not operating, leaving the toilet lid closed is an effective way to

conserve energy.

24

Page 25

High Efficiency Power Savings

When the product is not in use, it lowers the temperature of warm water and seat to control

power consumption until the product is put back into use.

Press [Water Temp] and [Power Saving] button, and hold for 2 seconds or more.

Power saving indicator flashs once activated.

SET

Warm WaterSeat Temperature

Setting

Temperature

Power Saving

Temperature

OFF

OFF

In Use

BACK

Flash 2 times

per second

Power

Saving

How to cancel high efficiency power saving function

Press [Water Temp] and [Power Saving] button, and hold for 2 seconds or more.

Power saving indicator of displayed part turns off.

(Reference)

When the unit is in the Power Save mode, the temperature of the water and seat will start out a bit cool,

but will warm up while in use.

Even when the Power Saving function is not operating, leaving the toilet lid closed is an effective way

to conserve energy.

25

Page 26

Other convenient functions

(For side panel version of bidet seat only)

Seat Temp. expand from 3 to 5 modes

Press Seat Temp. and Nozzle position UP (arrow up) for

2 seconds to expand the seat temperature adjustments

from 3 to 5 modes.

• Aftersetting,allindicatorswillashonce.

• TheLowandMidindicatorwillbothlightupwhenseat

temperature is in the middle of Low and Mid.

Mid and High indicator will both light up when seat

temperature is in the middle of Mid and High temperature.

Resume initial setting

Press Seat Temp and Nozzle Position UP for 2 seconds.

• Aftersetting,allindicatorswillashonce.

* The seat heater automatically turns ON when you stand up.

Water Temp. expand from 3 to 5 modes

Press Water Temp. and Nozzle position DOWN (arrow down)

for 2 seconds to expand the water temperature adjustments

from 3 to 5 modes.

• Aftersetting,allindicatorswillashonce.

• TheLowandMidindicatorwillbothlightupwhenwater

temperature is in the middle of Low and Mid.

Mid and High indicator will both light up when water

temperature is in the middle of Mid and High temperature.

Indicator

Indicator

3 modes

Seat temp.

Low Low

Mid Low mid

High Mid

3 modes

Warm Water temp.

Low

Mid

High

Indicator

Indicator

5 modes

Seat temp.

Mid high

High

5 modes

Warm Water temp.

Low

Low mid

Mid

Mid high

High

Resume initial setting

Press Water Temp. and Nozzle Position DOWN for 2 seconds.

• Aftersetting,allindicatorswillashonce.

Spray Strength expand from 3 to 5 modes

Press Water Temp. and Spray Strength " "

for 2 seconds to expand the spray strength

adjustments from 3 to 5 modes.

• Aftersetting,allindicatorswillashonce.

• TheLowandMidindicatorwillbothlightupwhenspray

strength is in the middle of Low and Mid ow.

Mid and High indicator will both light up when spray

strength is in the middle of Mid and High ow.

Resume initial setting

Press Water Temp. and Spray Strength " " for 2 seconds.

• Aftersetting,allindicatorswillashonce.

Press the buttons simultaneously for 2 seconds.

3 modes

Indicator Spray Strength Indicator Spray Strength

Low

Mid

High

5 modes

Low

Low mid

Mid

Mid high

High

26

Page 27

If freezing weather or long term absence is

Turn clockwise.

anticipated, drain the water.

(1) Turn the water shutoff valve clockwise to shut off the

water supply to the tank.

(For draining in cold areas, operate the indoor drain plug.)

(2)

Press the flush lever on the tank to drain water from the tank.

(3) Remove the power plug from the outlet.

(4) Drain the water from the warm water tank and the water

supply hose connected to the seat unit.

(5)

Push the lock lever on the right side of the seat unit and slide the

seat unit forward to remove it from the toilet bowl.

(6)

Remove the strainer located on the left side of the seat unit. Place

a wash bowl or similar item underneath the strainer.

(7) Tilt the seat unit to the left to drain the water from the water

supply hose through the strainer hole.

(8)

After the water has been drained, firmly attach the strainer.

(9)

Turn the drain plug located on the bottom of the seat unit to the

left (counterclockwise) 90 degrees to loosen it.

(10) Tilt the seat unit forward, pull out the drain plug and completely

drain out the water from the warm water tank.

(11)

After the water has been drained, push and turn the drain plug

to the right (clockwise) 90 degrees to tighten it.

(12) Place the seat unit on the toilet bowl. Slide the seat unit

backward to secure the seat unit.

Lock Lever

Strainer

CAUTION

When removing the strainer,

be sure to close the water

shutoff valve. When attaching

the strainer, firmly tighten it

until the end of the strainer

is hidden in the seat unit.

* Water can leak from

the strainer.

End

Warm Water Tank Drain Plug

Right side of seat unit

* Remove the warm water tank drain plug when

draining the water from the warm water tank

27

Drainage Valve of

warm water tank

.

Page 28

Maintaining This Product

Cleaning the Seat Unit Cleaning the Nozzles

Periodically, wipe off the seat unit with

a soft cloth dampened with water.

a) Bidet Seat must be powered ON to clean

nozzle tip.

b) For side panel type, under non-seated

situation to clean nozzles manually, press

"Seat Temp" and "Water Temp" buttons at the

same time for over 2 seconds.

For remote type, under non-seated situation

to clean nozzles manually, press "Nozzle

Cleaning" button for over 2 seconds.

c) Grasp the nozzle tip and pull out. Use a soft

sponge to clean any accumulated debris.

Changing Nozzle Tips

a) Ensure bidet is powered ON.

b)

For side panel type, under non-seated situation to clean

nozzles manually, press "Seat Temp" and "Water Temp"

buttons at the same time for over 2 seconds.

For remote type, under non-seated situation

to clean nozzles manually, press "Nozzle

Cleaning" button for over 2 seconds.

c) Grasp the nozzle tips and pull out.

d) Push new tips onto the nozzle ends.

28

Page 29

Cleaning & Maintenance of the Deodorizing Screen

Cleaning the Deodorizing Screen

1. Disconnect the power plug from the outlet

and shut off the water supply at the valve.

2. Remove the seat from the toilet.

3. Pull the screen from under the left hand

side of the seat.

4. Remove the dirt from the screen using a

toothbrush or other small brush.

5. Install the strainer back into the base

plate of the toilet seat.

6. Install the seat back onto the bowl.

7. Plug the seat back into the power outlet.

29

Page 30

Cleaning the Inlet Strainer

If the water pressure weakens over time, clean the strainer using the following procedure.

Cleaning the Inlet Strainer

1. Close the water shutoff valve to cut off

the water supply.

NOTE: Since the water shutoff valve is adjusted

beforehand, keep track of the turns so that you can

return to the original position.

2.

Turn the strainer located on the bottom

left of the seat unit using a screwdriver or

similar tool and remove it.

When the strainer is removed, a small amount of water

will pour out. Place a wash bowl or similar container

underneath to catch the water.

Strainer

Turn counterclockwise.

3. Remove the dirt adhering

to the inside of the strainer

by rinsing it with water.

4. Install the strainer, tightening it fully with a

screwdriver or similar tool.

End

Tighten the strainer until

the end is completely

inside the seat unit.

5. Open the water shutoff valve by turning

the water shutoff valve back to its original

position.

6. Finally, perform an operational check.

30

Page 31

Cleaning Areas Covered by the Toilet Seat Lid & Unit

Turn clockwise.

Water

shutoff valve

Slide

forward

Lock lever

3a

3b

Slide

forward

Wipe o here.

CAUTION

When cleaning this product, be sure to unplug the power plug from the wall outlet.

Removing the toilet seat lid

1. Move the pin hole on the right side

of the toilet seat lid to the outside and

remove it from the pin.

Toilet seat lid

Move to the outside.

Pin hole

Pin

2. Hold the toilet seat up on the right

side and slide it to the left, removing it

from the pin on the left side.

CAUTION

If you try to pull hard to remove the toilet seat

lid, it could crack or break.

Slide

Lift up

Removing the seat unit

3a. Push the lock lever on the right side of the seat unit.

1. Remove the power plug from the

wall outlet.

2. Close the water shutoff valve to

cut off the water supply.

4. Carefully place the seat unit on the rim of the

toilet bowl.

5. To reinstall seat, slide it back on mounting pad.

3b. Pull from base of seat, slide the seat forward by grasping at base,

raise it slightly and remove from toilet.

* When removing this

product, slide the unit

slowly without holding

the toilet seat or toilet

seat lid. Do not use

excessive force.

CAUTION

When cleaning the toilet bowl, take care not to splash

the seat unit with detergent. Before installing the seat

unit, wipe the detergent off from the toilet bowl using a

cloth damped with water.

31

Page 32

Change Batteries for the Remote Control

When batteries are about to run out, the battery indicator LED

display begins to flash.

The indicator only flashes when batteries are low.

The batteries included were used in testing of product and

may not have the normal lifecycle.

The lighting in the room area may make it difficult to see

the low battery LED flashing.

Change new batteries for the remote control; as follows.

Cautions

The + and - of the battery shall comply with the marks on the remote control

Do not mix the new battery with the used ones.

Use alkaline batteries.

Do not touch the switches or buttons on the remote control when

changing batteries.

Change Batteries for the Remote Control

Pull the remote control up and

take it out from the bracket.

Remote

Control

Bracket

Open the rear cover of the battery

compartment and place 2-AA batteries

e

Buckle

Alkaline Dry

Battery

Rear

Cover

Place the cover back and the remote control into the bracket.

32

Page 33

Troubleshooting

You can easily correct some of the problems with this product. Before requesting repairs, please check the

following items.

If you are unable to correct the problem using the troubleshooting procedures shown below, please contact

your local customer service representative.

All functions

Symptom

The system will not operate

at all.

Electricity is not being supplied to

the power outlet.

The power switch is off. The LED

on the indicator panel is off.

The power plug is not plugged into

the wall outlet.

Cause

Check for a power failure or tripped breaker,

etc.

Press the STOP button for 2 seconds to verify

the LED lights on the seat unit light up.

Plug the power plug into the wall outlet.

Posterior cleansing and Feminine cleansing

Symptom

The water shutoff valve is closed. Turn the water shutoff valve counterclockwise.

Cause

Remedy

Remedy

Water does not

spray out.

Symptom

Spray water is not warm.

The inlet strainer is clogged. Clean the inlet strainer.

Tap water pressure is low. Spray

strength is set to “Lo”.

The seat sensor is not engaged. Sit back fully on the toilet seat.

Cause

Water temperature is not set to an

appropriate temperature.

The Cleansing or bidet function

was used for a long period of time.

ECO mode is activated. Disable ECO mode.

Set the spray strength to a higher level.

Remedy

Adjust the water temperature to the

appropriate level.

The water takes about 3 minutes to warm

back.

33

Page 34

Heated Toilet Seat

Symptom

The toilet seat is not warm.

Others

Symptom

The seat unit becomes

loose

Cause

Seat temperature is not set to an

appropriate level.

ECO mode is activated. Disable power save.

Cause

The seat unit is not locked. Push the seat unit until it locks in position.

Adjust the seat temperature to the appropriate

level.

Remedy

Remedy

WARNING: A damaged or overheated power plug or cord, or a loose or overheated wall

outlet, could cause injury or damage the product. If this occurs, remove the

power plug from the wall outlet, contact us, and discontinue using this product

until the situation has been corrected.

34

Page 35

Specifications

Product Type Remote Control Side Panel Control

Rated Voltage AC120V 60Hz

Rated Power 300W±10%

Inlet Water

Pressur Range

Ambient Temperature Range 32°F~104°F (0°C~40°C

Min. 9 psi (0.06MPa) Flow pressure

Max. 108 psi (0.75MPa) Hydrostatic pressure

Cleansing

Remote

Heated

Seat

Deodorizer

Power

Saving

Other

Convinient

Functions

Product Dimension

Water Inlet Type Direct inlet flow

Heating Type Warm water storage tank

Rear Cleansing Volume

Front Cleansing Volume

Water Temperature

One Touch Cleansing

Oscillating

Massage

Nozzle Position

Adjustment

Heating Power 230W±10%

Safety Device Temp.sensor, Temp fuse, High Temp. sensor switch

Dimension

Power Source 2*1.5v AAA batteries

Surface Temperature

Heating Power 57W±10%

Safety Device Temp. sensor, fuse

Deodorizing Method Chemstorption by activated carbon deodorizer

Deodorizing Perfprmance Auto Deodorizing : 3.8CFM (0.11m³/min)

One Touch Power Saving

Super Power Saving

Nozzle Self Clean

Nozzle Manual Clean

Nozzle Shutter

Seat Heating Auto Off

Sitting Sensor

Anti-microbial Material

L 21-1/16" x W 17-3/16" x H 6-7/8"

(L 536mm*W 436mm*H 173mm)

0.42~1.27 pint/min (0.25~0.6L/min)

(6 adjustment levels)

water pressure 29psi (0.2 Mpa)

0.96~1.27 pint/min (0.45~0.6L/min)

(6 adjustment levels)

water pressure 29psi (0.2 Mpa)

OFF (Water temperature) Low-about

90°F (32°C); Relatively Low-about 93°F

(34°C); Mid-about 97°F (36°C); Relatively

High-about 100°F (38°C); High-about

104°F (40°C)(5 adjustment levels)

(Rear cleansing only)

•

L263mm*W32.5mm*H71mm

L10-3/8"*W1-1/4"*H2-13/16"

Room temperature/ about 82°F - 104°F

(28°C—40°C) 5 adjustable levels

Nozzle, Seat, Side control panel/ Remote control panel

L 21-1/16" x W 18-9/16" x H 6-7/8"

(L 536mm*W 472mm*H 173mm)

0.42~1.27 pint/min (0.25~0.6L/min)

(3/5 adjustment levels)

water pressure 29psi (0.2 Mpa)

0.96~1.27 pint/min (0.45~0.6L/min)

(6 adjustment levels)

water pressure 29psi (0.2 Mpa)

OFF (Water temperature)

Low-about 90°F (32°C);

Mid-about 97°F (36°C);

High-about 104°F (40°C)

(3/5 adjustment levels)

•

•

•

Room temperature/ about 82°F - 114°F

(28°C—40°C) 3/5 adjustable levels

(8hr)

•

•

•

•

•

•

•

—

Soft Close Seat & Cover

Quick Detach Cover

Quick Detach Main Body

•

•

•

35

Page 36

For residents of the United States, warranty

information may also be obtained by calling

AS AMERICA, INC. ONE YEAR LIMITED WARRANTY

If inspection of this AS America, Inc. (“American Standard”) plumbing product, within one year after its initial

purchase, confirms that it is defective in materials or workmanship, American Standard will repair or, at its

option, exchange the product for a similar model.

This limited warranty applies only to the original purchaser and installation of these products. In the event of a

limited warranty claim, proof of purchase will be required—save sales receipt.

This limited warranty does not apply to local building code compliance. Since local building codes vary

considerably, the purchaser of this product should check with a local building or plumbing contractor to ensure

local code compliance before installation.

This limited warranty is void if the product has been moved from its initial place of installation; if it has been

subjected to faulty maintenance, abuse, misuse, accident or other damages; if it was not installed in accordance

with American Standard's instructions; or if it has been modified in a manner inconsistent with the product as

shipped by American Standard.

American Standard's option to repair or exchange the product under this limited warranty does not cover any

labor or other costs of removal or installation. IN NO EVENT WILL AMERICAN STANDARD BE LIABLE FOR

THE COST OF REPAIR OR REPLACEMENT OF ANY INSTALLATION MATERIALS, INCLUDING BUT NOT

LIMITED TO, TILES, MARBLE, ETC. American Standard will not be responsible for any other incidental or

consequential damages attributable to a product defect or to the repair or exchange of a defective product, all

of which are expressly excluded from this limited warranty. This limited warranty does not cover any liability for

consequential or incidental damages, all of which are hereby expressly disclaimed, or the extension beyond the

duration of this limited warranty of any implied limited warranties, including those of merchantability or fitness

for an intended purpose. (Some states or provinces do not allow the exclusion or limitation of implied limited

warranties, so this exclusion may not apply to you.)

This limited warranty gives you specific legal rights. You may have other statutory rights that vary from state to

state or from province to province, in which case this limited warranty does not affect such statutory rights.

In the United States:

American Standard Brands

1 Centennial Ave.

Piscataway, New Jersey 08854

Attention: Director of Customer Care

In Canada:

AS Canada, ULC

5900 Avebury Rd.

Mississauga, Ontario

Canada L5R 3M3

Toll Free: (800) 387-0369

www.americanstandard.ca

In Mexico:

American Standard B&K Mexico

S. de R.L. de C.V.

Via Morelos #330

Col. Santa Clara

Ecatepec 55540 Edo. Mexico

Toll Free: 01-800-839-1200

www.americanstandard.com.mx

Page 37

WALK-IN BATH INSTALLATION

INSTRUCTIONS AND OWNER’S MANUAL

Page 38

CONGRATULATIONS!

You are now the owner of a walk-in bathtub from the most trusted name in plumbing.

We thank you for your purchase. Your American Standard ® walk-in bath is a true

investment in your health and peace of mind.

Customer Support: (866) 423-0800

1

Page 39

OWNERS MANUAL

TABLE OF CONTENTS

UNPACKING THE UNIT………………………………………………………………. Page 3

RESPONSIBILITIES OF THE INSTALLER…………………………………………… Page 4

TESTING YOUR TUB BEFORE INSTALLATION…………………………………… Page 5

INSTALLATION PREPARATION…………………………………………………….. Page 6

ELECTRICAL INSTALLATION………………………………………………………. Page 7

INSTALLATION PROCEDURES…………………………… ………………………... Page 8-17

SAFETY INSTRUCTIONS ……………………………… ……………………………. Page 18

OPERATING INSTRUCTIONS…………………………… ………………………….. Page 19-20

CLEANING & MAINTENANCE……………………………………………………..... Page 21

WARRANTY…………………………………………………………………………..... Page 22

TROUBLESHOOTING………………………………………………………………..... Page 23-25

2

Page 40

OWNERS MANUAL

UNPACKING THE UNIT

1. FIRST, inspect the carton for damage: CAREFULLY DOCUMENT AND

PHOTOGRAGH ALL PERCEIVED DAMAGE. Report all damage claims to

customer service at 1-866-423-0800.

2. DO NOT LIFT THE TUB BY THE PLUMBING

which the installer is responsible. All Walk-In Tubs are water tested before they

leave our factory and the bathtub you have purchased has passed inspection.

3. Immediately inspect the unit for damage even if there is no carton damage. All

product damage must be reported within 72 hours of receipt from American

Standard®. Once the unit is installed, surface damages will be assumed to be

installation-related if not reported prior to installation. Installers are also responsible

for damage that occurs once the unit is placed in its niche.

NOTE: Remove all packaging material except for the protective plastic. This has

been placed on the tub at the factory to eliminate abrasions from handling. This

should only be removed at final clean up.

4. Inspect the plumbing for any fittings that may have loosened in transit.

5. Read the following instructions completely before installing this product. If the

home-owner or installer has any questions, please call us at 1-866-423-0800.

6. You must follow all the instructions in this manual.

FAILURE TO READ AND COMPLY WITH ALL INSTRUCTIONS CAN RESULT IN

PRODUCT DAMAGE OR INJURY TO BOTH INSTALLER AND HOMEOWNER. IT

WILL ALSO RESULT IN ASSUMPTION OF ALL LIABILITY BY SAID INSTALLER.

. Doing so can result in leaks, for

3

Page 41

OWNERS MANUAL

RESPONSIBILITIES OF THE INSTALLER

The Installer must inspect and water test the product prior to installation to ensure the unit is free of defect

and /or damage. In the event of a problem, the unit must not be installed. If the packaging or product has

been damaged, please call immediately at 1-866-423-0800.

This product has been listed by INTERTEK / ETL and IAPMO / C UPC. The product has been tested and

complies with the following standards and guidelines: IAPMO /C UPC, UL-1795, ANSI Z-124.1.2,

ASME A 112.19.7, ASME A 112.19.15 & CSA B-45. The installer is responsible for compliance to

state and local codes.

This product is designed to be installed by a licensed tradesperson. Licensed plumbers and electricians

should be employed to insure proper installation. Installer assumes all liabilities for installation

procedures.

Although American Standard® has taken reasonable precautions to ensure that the Quick Drain

suitable for residential plumbing; it is the responsibility of the installer to insure that the plumbing is

acceptable for use of the Quick Drain TM. American Standard® does not accept responsibility for

damage arising from use of the Quick Drain TM.

Only accessories authorized by manufacturer should be used with this product.

TM

is

IMPORTANT SAFETY INSTRUCTIONS

INSTRUCTIONS PERTAINING TO RISK OF FIRE,

ELECTRICAL SHOCK OR INJURY TO PERSONS

SAVE THESE INSTRUCTIONS!

WARNING! ALL INSTRUCTIONS LISTED IN THIS MANUAL SHOULD BE READ AND

FOLLOWED CAREFULLY. ALL PRECAUTIONS PERTAINING TO RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS MUST BE UNDERSTOOD AND

EXPLAINED TO OWNER.

TO REDUCE THE RISK OF INJURY, CHILDREN OR PERSONS WITH INFIRMITIES

MUST NOT BE PERMITTED TO USE THIS PRODUCT WITHOUT CLOSE AND

CONTINUOUS SUPERVISION.

4

Page 42

OWNERS MANUAL

TESTING YOUR WALK-IN TUB BEFORE INSTALLATION

1. All American Standard® walk-in baths are 100% water tested at the factory and have passed inspection.

Transportation and mishandling may loosen fittings and cause leaks. It is therefore necessary to test the

bathtub while there is access to all sides of the bath.

2. The unit needs to be filled with water and inspected for leaks along the door as well as the whirlpool and

air systems if equipped. The inspection needs to be performed with and without the whirlpool and / or air

systems operating. It is best to test the unit outside by filling with a garden hose.

3. If the pump/blower/lights/heater does not operate:

Failure to perform these tests before installation will make the installer liable for future repair costs.

a. Place the tub on a completely flat surface in an area where it may be drained after testing.

b. Using a clean rag and warm water wipe down seal to insure it is free of debris.

c. Seal the drain hole (this can be done with tape) and fill the tub to at least three inches above the

highest jet, or to the bottom of the safety bar if no jets are present.

d. Allow the water to stand in tub for 30 minutes and then inspect all plumbing and seals for

leaks.

e. Using appropriately rated three-prong extension cords, all plugged in to separate outlets,

operate all electrical components (air blower, water pump, and heater if applicable) for another

30 minutes and inspect for leaks again. Inspect the unions around the pump and heater.

f. If a leak persists at a union after tightening, it may have been over-tightened or might have a

displaced O-ring. Disassemble it and make sure the O-ring was seated properly. Do the same if

a leak persists at the heater. Verify that the heater threads match the pipe threads.

g. Ensure that all jets are open and working, some jets are adjustable for both flow rate and

direction of flow. The jet water flow rate is adjusted by turning either the outside ring or the

inside nozzle clockwise or counterclockwise. Some jets are not adjustable at the jet face, but

can be adjust by the “Leg’s Only Massage”. The “Legs Only Massage” Valve is located near

the seat. (If equipped.) .

a. Check the breaker to ensure that power is on and make sure that any cables and / or air lines

connecting the control boxes to the switches and pumps are firmly attached. Verify the correct

electrical circuit and amps of the electrical cord.

b. Go to Trouble Shooting Guidelines. (See pages 23-25.)

c. Do not

dry operation of pumps is not covered under the warranty period. (See pg. 22.)

run any pumps unless the tub is filled with water to the proper level. Damage due to

5

Page 43

OWNERS MANUAL

INSTALLATION PREPARATION

1. Check the floor area where the tub is to be installed.

a. Clean area of any debris or trash.

b. Use a 5 or 6-foot level and determine if the floor is level. If the floor is not level,

adjust all leveling feet to perfectly level the tub.

Note: It is important that all leveling feet are completely touching the floor and

level for the door system to work properly.

2. Check to ensure that the drain piping has been “roughed-in” at the proper location. See

specification sheets (installation detail) included in this manual.

3. Ensure that the proper electrical service has been installed at the pump location. See electrical

Requirements in the manual. (See page 7.)

6

Page 44

OWNERS MANUAL

ELECTRICAL INSTALLATION

All electrical wiring must be installed in accordance with the National Electrical Code and with all

local codes. All wiring shall be done by a qualified electrician. Run one, two or three branch circuits

(as required) from the main electrical service panel to the pump area of the framing structure to

provide power to the unit.

Electrical components have specific wiring requirements. Refer to the matrix below for the electrical

supply requirements for the whirlpool bathtub and factory installed components.

Branch circuits must be rated for 110 – 120 volts. Use 12 Gauge, 3 conductor cable for the circuits.

If the length run exceeds 100 feet, check with local codes for requirements. Install moisture proof

junction box(s) 6” above the floor at the pump end of the framing for each circuit.

DO NOT INSTALL THE JUNCTION BOX(S) WHERE IT CAN BE REACHED WHILE SITTING OR

STANDING IN THE TUB OR TOUCHING THE FAUCETS.

QUICK DRAIN™, LIGHTS, WHIRLPOOL, AIR SPA, COMBO & HEATER

ELECTRIAL REQUIREMENTS

This section lists the factory installed components of the Whirlpool and/or Air Spa Systems.

Note the required number of circuits and their rating for the Whirlpool & Air Spa unit you are planning to install.

ELECTRICAL REQUIREMENTS FOR FACTORY INSTALLED COMPONENTS

Electrical Rating

Systems

Soaker w / Quick Drain™ 15 Amp GFCI

Soaker w / Light 15 Amp GFCI

Soaker w / Quick Drain™ w / Light 15 Amp GFCI

Whirlpool or Air Spa 15 Amp GFCI

Whirlpool or Air Spa w / Light 15 Amp GFCI

Whirlpool or Air Spa w/ Quick Drain™ 15 Amp GFCI 15 Amp GFCI

Whirlpool or Air Spa w/ Light & Quick Drain™ 15 Amp GFCI 15 Amp GFCI

Whirlpool & Air Spa (Combo) 15 Amp GFCI 15 Amp GFCI

Whirlpool & Air Spa (Combo) w/ Light 15 Amp GFCI 15 Amp GFCI

Whirlpool & Air Spa (Combo) w/ Quick Drain™ 20 Amp GFCI 15 Amp GFCI

Circuit 1

Electrical Rating

Circuit 2

Dedicated

Circuit

Whirlpool & Air Spa (Combo) w/ Light & Quick Drain™ 20 Amp GFCI 15 Amp GFCI

Whirlpool Inline Heater - Dedicated Circuit

All electrical connections must be carried out by a certified electrician in accordance with local electrical

requirements and codes.

15 Amp GFCI

7

Page 45

OWNERS MANUAL

INSTALLATION PROCEDURES

▲ WARNING: When installing whirlpool massage baths, air spa baths, combo baths, or Quick Drain™

equipped baths, the following precautions must be followed:

▲ WARNING: Danger: Risk of electrical shock; connect components to separate circuits, EACH protected

by a ground fault circuit interrupter (GFCI)

▲ WARNING: Installation must provide access for servicing the pump and motor (all American

Standard® walk-in baths come with access panels for the pump, motor and faucet).

1. Install tub waste/overflow according to instructions included with the provided kits. The Gel Coat Series

requires the installation of a door drain with check valve. The check valve and tubing must be installed

horizontal to the floor. Some installations will require the purchase of additional fittings.

2. American Standard Faucet Installation # 9FHS-CH

Review the installation instructions packed with the faucet set.

Mask off the tub’s deck with a protective tape.

Locate and mark the center line of the overflow fitting

Locate and mark 1 ½” line either side of the tub’s center line to establish the overflow clearance.

Follow the drill template and faucet installation instructions.

3. Other Faucet Model and / or Brand

Review the installation instructions packed with the faucet set.

Mask off the tub’s deck with a protective tape.

Locate and mark the center line of the overflow fitting

Locate and mark 1 ½” line either side of the tub’s center line to establish the overflow clearance.

Verify the first two component mounting clearance on either side of the waste overflow as well as

above and below the tub’s deck.

Verify the remaining component mounting clearance on both sides of the overflow as well as above

and below the tub’s deck.

It is recommended the hand held shower be installed on the corner closest to the wall to prevent water

from leaking off the deck and on to the floor.

4. Install the optional in-line water heater per manufacturer’s instructions.

5. Standard Walk-In Bath Installation - After framing is complete, set product in place to check fit and make

certain that the tub can be properly leveled. (Caution: If the bathtub is not resting on all leveling feet, water

will not drain properly and this may cause the door to leak). Secure tub frame to the studs using metal

straps. (Not provided.)

5a. Fire-Rated Drywall – If fire-rated drywall is specified, the finished fire-rated wall must be in place before

the tub is installed. The dimensions of the framing structure must be increased by the thickness of firerated drywall.

8

Page 46

OWNERS MANUAL

INSTALLATION PROCEDURES

WARNING: Never allow the weight of the tub to be supported by wood support stringers and do not use

integral tile flange (if equipped) to screw or nail in place, as this will result in product failure and will

void the warranty.

6. Verify the product is completely level by checking tub deck surface and ensure all leveling feet are

touching the ground.

7. Electrical connection is made by simply plugging each cord into the GFCI outlet.

8. After plumbing and electrical connections have been made, the tub and door seal should be cleaned of dirt

and debris. Use warm water and a non abrasive cleaner for clean up.

9. Installation is not complete until the bathtub has been water-tested in place and does not leak.

9

Page 47

OWNERS MANUAL

g

Alcove Installation

`

Faucet and Pump

Access Panels

IMPORTANT

Do not use tile flange to

screw or nail tub in place.

Integral Flange

Non Integral Flange

Model A B C D E F G

2651.11X

2848.10X

2848.11X

3051.11X

3052.10X

3151.10X

3060.10X

3260.21X

50 ½” 26 ¼” 37 ½” 9 ½” 11 ½” 15 ½” N/A

48” 28” 38” 10 ¾” 14” 16 ¾” N/A

48” 28” 37 ½” 10” 14½” 16” N/A

50 ½” 30 ½” 37 ½” 9 ½” 14½” 15 ½” N/A

51 ½” 29 ¾” 42” 12 ½” 14½” 17” N/A

50 ½” 31 ¼” 37 ½” 10” 14 ½” 15 ¾” 38”

59 ½” 29 ¾” 37 ½” 31 ¼” 14½” 15 ¼” 38”

59 ½” 32 37 11 ½” 16” 20½” N/A

Tubs installed in an alcove installation require a raised flange to prevent water from seeping past the tub and into the wall. Tubs

without a raised flange shall be installed with a tile flange kit such as model: 9FLNG or a similar type. The flange kit is a long

plastic strip that is fits onto the rim of the tub to provide the leak protection needed.

The tile flange should be installed on the tub before it is placed in the alcove. Install the tile flange along all sides of the tub where

the wall will be. Measure to fit and miter cut the flange corners. The flange should be attached to the tub with a silicone adhesive.

Warnin

: Never attempt to nail or screw thru the tub as this will result in product failure and will void the warranty.

Drain Overflow

10

Page 48

OWNERS MANUAL

Acrylic Extension Kit Installation

The Acrylic Extension Kit is designed to accommodate all acrylic walk-in tubs to fit within a 60” alcove

pocket. The top panel measures 30” x 20” (depth x width) and the front panel 37 ½” x 20” (height x width).

The panels must be trim to fit the unit within the 60” alcove.

Step 1

Temporary locate the tub within the alcove walls.

Level the tub along the deck and apron.

Measure and record the distance from the tub and apron to the adjacent alcove wall.

Steps 2, 3, & 4

Mask off and mark the trim lines for the top and front extension panels.

Using a high speed carbide tooth blade, cut along the trim lines

Mark a horizontal line that is parallel to the tub’s deck along the back and adjacent wall of the alcove.

Mark a vertical line that is parallel to tub’s apron on the adjacent wall of the alcove.

Install three wood stringers approximately 3/8” below the horizontal and vertical lines.

Verify the fit of the front panel and then the top panel to the alcove opening.

Shimming may be required to achieve a level fit.

11

Page 49

OWNERS MANUAL

Acrylic Extension Kit Installation

Steps 5 & 6

Remove the tub from the alcove and install the front and then top panel with the self tapping fasteners.

Steps 7 & 8

Apply the temporary clamps to help support the front and top panels while re-locating the tub back into

the alcove.

Remove temporary clamps, check level, shim if necessary, and seal in panels with silicone.

12

Page 50

OWNERS MANUAL

Gelcoat Extension Kit Installation

The Gel Coat Extension Kits are designed for each unit to fit within a 60” alcove packet. The top and end

panels have integral flange for easy of installation.

Step 1

Temporary locate the tub within the alcove walls.

Level the tub along the deck and apron.

Measure the distance from the tub and apron to the alcove wall.

Verify the fit of both front and top extension panels.

Step 2

Mark a horizontal line that is parallel to the tub’s deck along the back and adjacent wall of the alcove.

Mark a vertical line that is parallel to tub’s apron on the adjacent wall of the alcove.

Install three wood stringers approximately 3/8” below the horizontal and vertical lines.

13

Page 51

OWNERS MANUAL

Gelcoat Extension Kit Installation

Step 3

Remove the tub from the alcove.

Install the front and then the top panel with the tub brackets.

Step 4

Apply the temporary clamps to help support the panels while re-locating the tub back into the alcove.

Remove temporary clamps, check level, shim if necessary, and seal in panels with silicone.

___ ___

14

Page 52

OWNERS MANUAL

Drain Overflow Installation

Drain / Overflow Information

A drain / overflow assembly is provided with the tub must be installed on the bath, water tested

and connected to the sanitary system of the house. Some drain / overflow kits are packed with

the waste flange, strainer, overflow cover, and fasteners, packed separately within the kit to

protect the trim finish. Follow the installation instructions provided with the drain / overflow

kit. After the drain is fully installed, test the unit for proper drainage. If the unit does not drain

properly, rectify the condition before proceeding with installation. American Standard is not

responsible for the removal or re-installation costs.

Note: All gel coat models require additional installation of the door drain to the waste overflow.

Connection of the Quick Drain

Quick Drain System requires the connection to a minimum 1 ½” sanitary drain line.

Use UPC Approved PVC Glue, Primer, and Schedule 40 1 ½” pipe.

Do not change or modify the location and or piping of the Back Flow Manifold

The sanitary tee is installed directly above the drain tee with clearance not greater than 1”.

Dry fit the drain overflow assembly to the sanitary drainage pipe and check for proper fit.

Glue the Quick Drain Fittings, pipe and drain overflow assembly to the sanitary drainage pipe.

NOTE: Water tight installation of the waste / overflow is the installer’s responsibility. Drain leakage is

excluded from Safety Tubs warranty of this product.

We have taken reasonable precautions to ensure the Quick Drain is suitable for residential

plumbing. It is the responsibility of the installer to insure the sanitary system is acceptable for the

use of the Quick Drain. We do not accept responsibility for damage arising from the use of the

Quick Drain.

15

Page 53

OWNERS MANUAL

Threshold Drain Installation

Threshold Drain Information

All gel coat walk-in bathtubs are provided with a threshold door drain. All acrylic walk-in

bathtubs feature the “Patented T5 Door System” which does not require the threshold drain.

Connection of the Door Drain

Door Drain requires the connection to a minimum 1 ½” sanitary drain line.

Use UPC Approved PVC Glue, Primer, and Schedule 40 1 ½” pipe.

The door drain, check valve, and 3/8” vinyl tubing are installed on the walk-in bathtub

The door drain coupling has an integral 3/8” barb for connection of the door drain line.

The drain coupling must be located between the drain tee and shoe along the tub’s drain line.

The 3/8” barb on the drain coupling must be positioned parallel to the sub floor.

Connect the door drain assembly and drain coupling with 3/8” vinyl tubing.

Verify the coupling barb, check valve, and 3/8” tubing are horizontal to the floor.

Glue all components and tubing in place use PVC Glue.

16

Page 54

OWNERS MANUAL

Inline Heater Installation

Whirlpool In-Line Heater

All whirlpool systems are deigned with an In-Line Heater Blank. The threads and union set on the

heater blank and heaters are specifically designed for our system. All other heaters and heater blanks

will not interchanges with our system.

The heaters are equipped with a preset pressure switch which will not allow the heater to turn on if

the pump is not running with water flowing through the whirlpool system. The heater includes an

exclusive High Limit Switch. This safety circuit will not false trip from the hot tap water. It will

turn off the heater is the thermostat fails. If your whirlpool is equipped with adjustable jets, or other

flow control systems, the pre-set pressure switch may not activate the heater. To assure proper heater

operation, all jets may need to fully open with the pump operating at or near maximum flow.

Installation of the In-Line Heater

Verify there is a dedicated 120 volt, 15 Amp Circuit with a GFCI outlet available.