American Metal Ware FDD2500 Installation Manual

Model FDD2500

Operator Manual

Daily Cleaning

1.

CAUTION: When cleaning the unit, do not use cleansers, liquid bleach, powders or any other substance that contains

chlorine. These products promote corrosion of stainless steel and plastic parts. Use of these products will void the warranty.

Empty drip pan as needed and wash daily in a dish detergent.

Wipe down all surfaces of the dispense spouts, product storage cabinet, splash panel and drip tray areas with a clean

soft cloth using a mixture of one ounce Ivory liquid detergent (or equivalent) to one gallon of fresh water. Follow by

wiping down all surfaces of the dispense spouts, product storage cabinet, splash panel and drip tray areas with a clean

soft cloth moistened with fresh water and allow to air dry.

2.

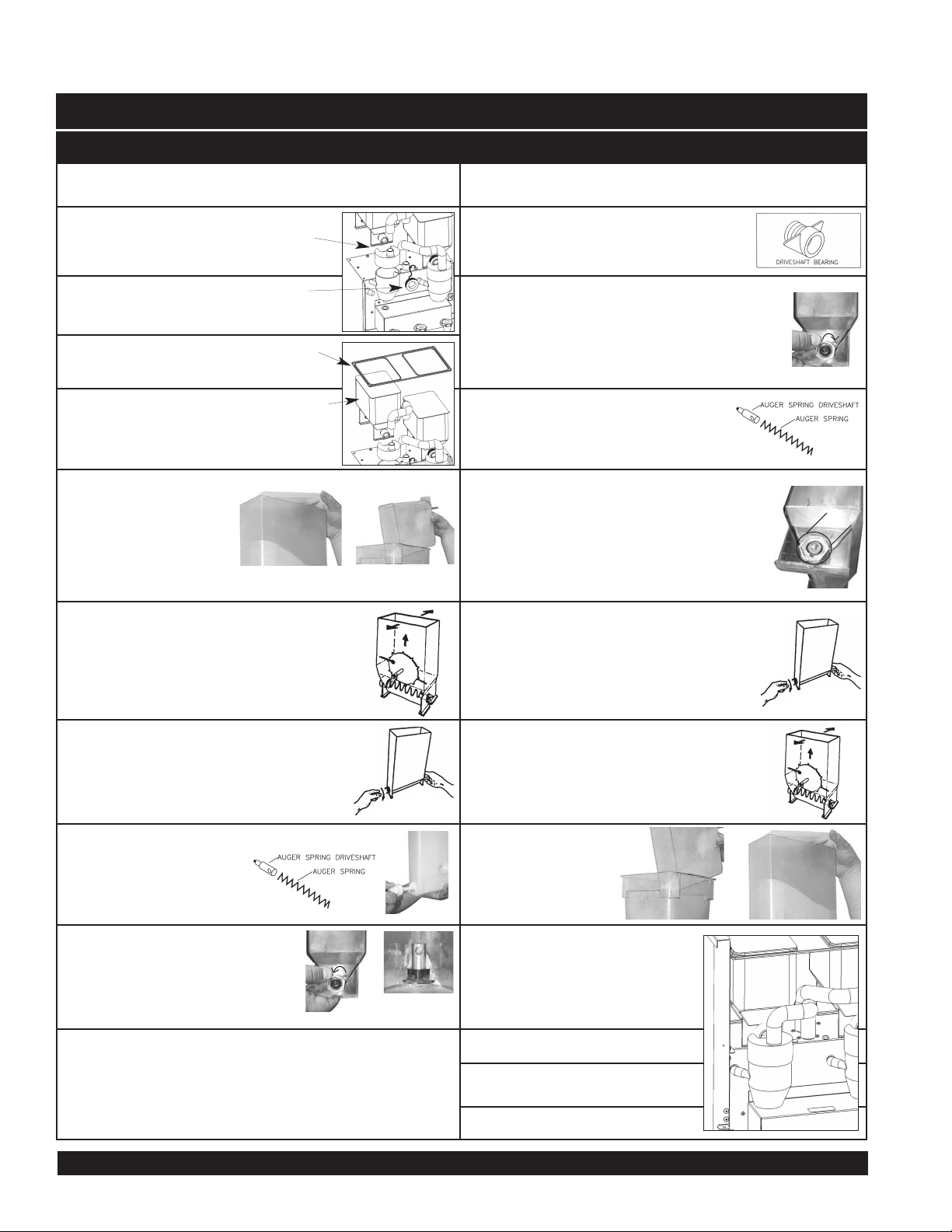

Rinse out the funnel by placing the rinse switch (located to the right of the dispensing valves

when the door is open) in the ON position. Dispense one to two cupfuls until the water is

clear. Short bursts of dispensing may also help clean the chambers. When

complete, return the rinse switch to the OFF position.

WARNING: Do not use a water jet to clean machine. Risk of electric shock.

Cleaning

Weekly Cleaning

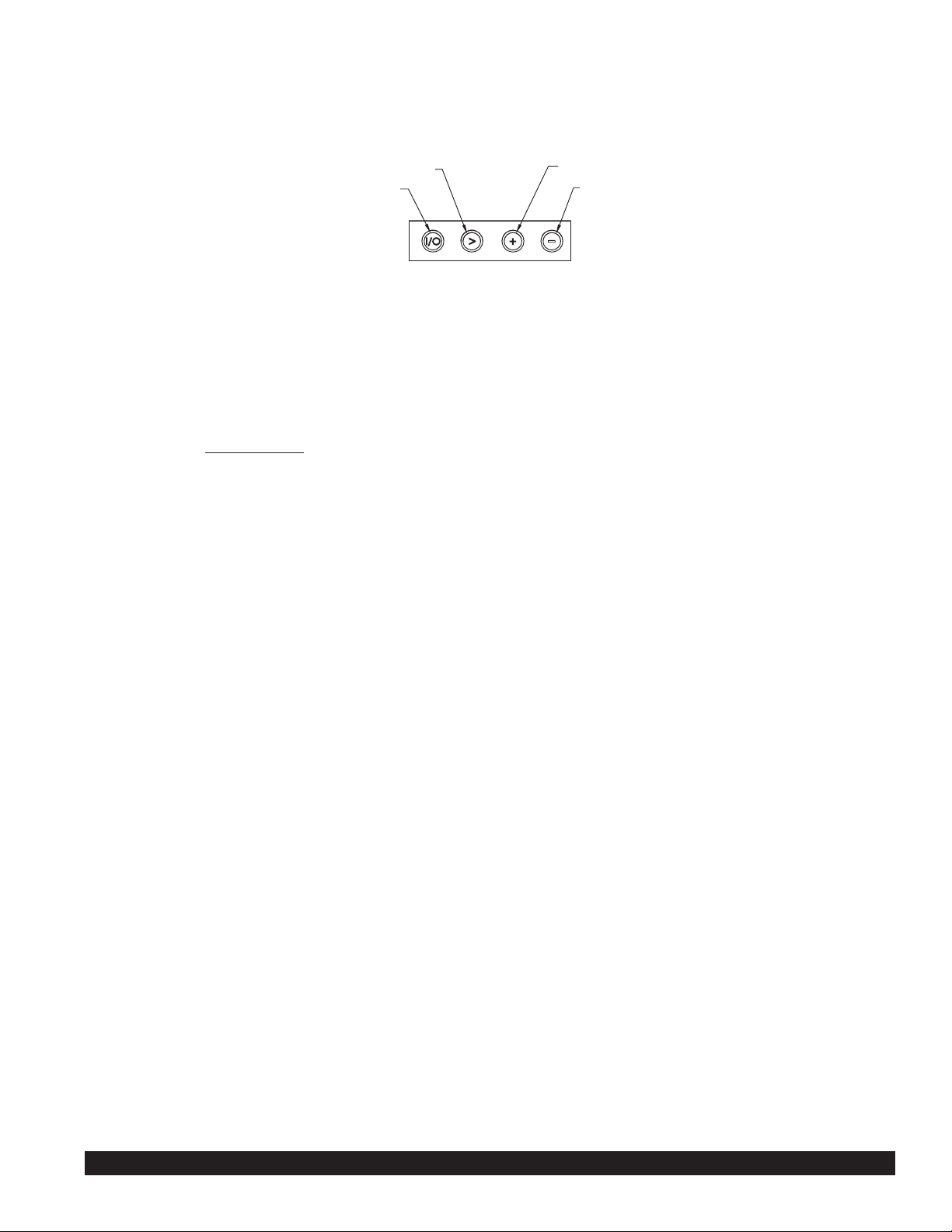

Cleaning the Funnel – Disassembly Cleaning the Funnel – Reassembly

1.

Open the door and remove the large tube

from the funnel cover, then remove the

cover.

1.

Place funnel into position, then

connect hoses.

2.

Remove the mixing funnel by removing silicone tube at the side, then remove funnel.

2.

Place funnel cover on funnel and connect

large tube.

3.

PARTS IN CONTACT WITH FOOD MUST BE WASHED,

RINSED, SANITIZED, AND AIR DRIED.

Cleaning (cont.)

Weekly Cleaning (cont.)

Cleaning Hoppers – Disassembly Cleaning Hoppers – Reassembly

CAUTION: Do not wash hopper without first

disassembling.

IMPORTANT: All components must be completely dry prior

to reassembly.

1.

Open door, disconnect large hose from

funnel cover and then lift off funnel

cover.

11.

Place driveshaft bearing inside hopper

with threads going through hole in the

rear of the hopper.

2.

Lift off ring heater and set aside.

12.

Secure the bearing by attaching the palnut

to the bearing outside rear hopper opening.

Use one hand inside the hopper to push

the bearing outward while turning the

palnut clockwise.

3.

Lift open lid and remove coffee spill

pan.

4.

Remove the hopper from the cabinet.

3.

Install the auger spring driveshaft

and the auger spring by inserting the

flat end of the spring into the

hole in the auger spring driveshaft.

5.

Remove the hopper

cover and empty

hopper contents.

4.

Insert assembly into lower front hopper

opening, making sure the threaded end of

the auger spring driveshaft completely

inserts into the plastic driveshaft bearing in

the rear of the hopper. The driveshaft

bearing threads should be accessible

from the outside rear of the hopper.

6.

Remove the auger pinwheel by pulling it

forward while stretching out the sides of

the hopper.

5.

Place the washer over the driveshaft

bearing threads followed by securing

the drivelink onto the driveshaft bearing

by turning counterclockwise. Secure

the auger spring with one hand while

attaching the drivelink with the other.

7.

Remove the drivelink and washer at

the rear of the hopper by holding the

auger spring with one hand at the front

of the hopper while turning the drivelink

clockwise with the other hand.

6.

Replace the auger pinwheel making sure

the pins are securely positioned inside the

locator holes in the hopper.

8.

Remove the auger

spring and auger spring

driveshaft by pulling out

through the lower front opening of the hopper.

7.

Carefully fill

the hopper

with product

and replace

the cover.

9.

Remove the palnut at the

rear of the hopper by turning

it counterclockwise then remove

the driveshaft bearing from the

inside of the hopper.

8.

Reinstall hopper into the

machine, making sure it is

properly aligned.

10.

All parts in contact with food must be washed, rinsed,

sanitized, and air dried.

1

Install ring heater to front spout.

Open lid and install coffee

spill pan.

11.

Driveshaft

Bearing

PULL

Auger Spring

Driveshaft

9.

10.

Install funnel cover with large

tube attached.

Page 2 Model FDD2500

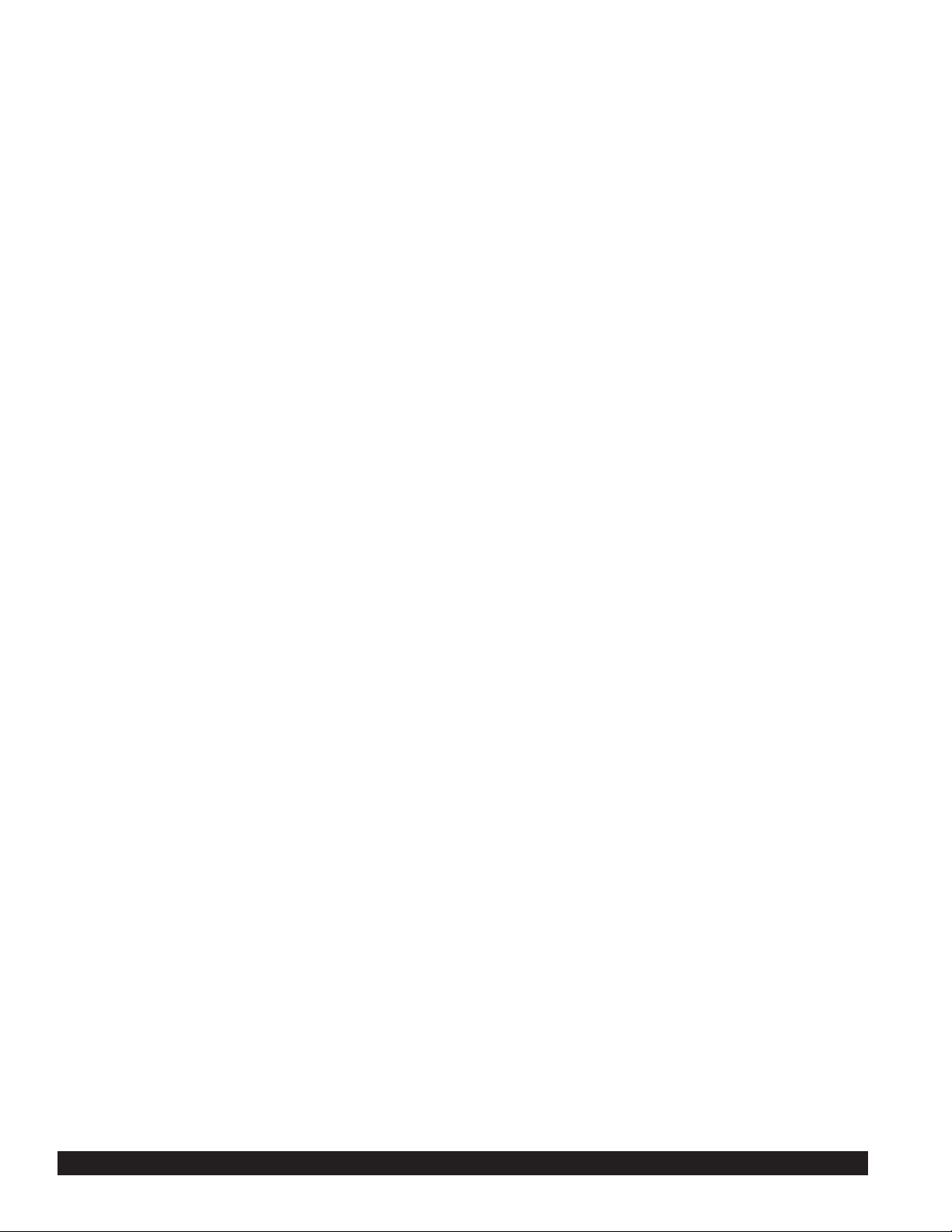

PROGRAMMING MACHINE FROM TOUCHPADS

Tools Required: None

MACHINE PROGRAMMING: The machine operating parameters can be changed from the touchpad and LCD display

without opening up the machine. (See illustration below).

To enter Programming Mode:

Press and hold (>) and (+) at the same time for approximately 5 seconds.

Tip: Use the eraser end of two pencils to press the buttons if you are having difficulty entering programming mode.

To Exit programming mode at anytime:

• Wait 20 seconds without pressing a button.

• The display will prompt “Exit?”

• Press (+) or (-) to toggle between YES and NO.

• After selecting YES, you MUST press (>) to SAVE changes, or wait for ready message and machine

will exit without saving.

Tip: To verify changes successfully save, re-enter programming mode and check settings.

1) Press (>) to select Language. (1A)

Press (+) to choose English, Spanish, German, or French.

2) Press (>) to set the Time of day on the machine.

Press (+) or (-) to change the time.

3) If password is activated, enter password now.

a) Press (+) to enter first number.

b) Press (>), then (+) to enter second number.

c) Press (>), then (+) to enter third number.

4) Press (>) to change Password settings. (2B)

Press (+) or (-) to toggle between ON (enable password) and OFF (disable password).

If ON is selected, press (>) to change password.

a) Press (>) to enter new password. (following steps 3 a, b, c)

b) Press (>) to confirm new password. (following steps 3 a, b, c)

5) Press (>) to program Dispense Settings. (to change Portion Sizes) (2E) (For FDD2500-**-3A models only)

a) Press (+) for message “Select Dispense Button”. (5A)

b) Press the dispense button for the dispense head you wish to adjust the settings. LCD will display L, M,

or R for left, middle, or right dispense head to acknowledge your selection.

c) Once the dispense head is selected, press (+) or (-) to change the amount of time (portion size) for the

beverage being dispensed.

6) Press (>) to change Whipper Settings. (5A1)

a) Press the dispense button for the dispense head you wish to adjust the settings. LCD will display L, M,

or R for left, middle, or right dispense head to acknowledge your selection.

b) Once the dispense head is selected, press (+) or (-) to toggle between ON (turn whipper ON) and OFF

(turn whipper OFF).

7) Press (>) to return to Dispense Settings. (2E)

Repeat steps 6 & 7 for remaining heads.

8) Press (>) to modify Drink Strength. (7A)

a) Press (>) to Select a Dispense Button. (7B)

b) Press the dispense button for the dispense head that you want to change the drink strength for.

c) Press (+) or (-) to modify the auger speed which changes the drink strength (0-100% of maximum auger

speed in 1% increments).

Note: A faster speed will result in a stronger drink and a slower speed will result in a weaker drink.

PROCEED

POWER ON/OFF

(STANDBY)

INCREMENT UP

INCREMENT DOWN

Model FDD2500 Page 3

Programming Machine from Touchpads (cont.)

9) Press (>) to modify Auger Delay.

a) Press (>) and select dispense button.

b) Press the dispense button for the dispense head that you want to change the auger ON delay time.

c) Press (+) or (-) to modify the time in tenths of a second.

10) Press (>) to modify Auger Off Delay.

a) Press the dispense button for the dispense head that you want to change the auger OFF delay time.

b) Press (+) or (-) to modify the time in tenths of a second.

11) Press (>) to change Heater settings. (8A)

Press (+) or (-) to toggle between ON (water tank heater ON) and OFF (water tank heater OFF).

12) Press (>) to modify Water Tank Temperature. (7A)

Press (+) or (-) to increase or decrease water tank temperature.

13) Press (>) to modify Low Temp/No Brew settings. (7B)

Press (+) or (-) to toggle between ON (will not allow drinks to dispense if water temperature is below

programmed temperature) and OFF.

a) If turned ON press (>) to modify Minimum Dispensing Temp.

b) Press (+) or (-) to increase or decrease Minimum Dispensing Temp.

14) Press (>) to change Sleep Mode settings. (8A)

Press (+) or (-) to toggle between OFF and ON (forces the water tank temperature to a programmed temperature

after a programmed time of inactivity – used for energy savings).

a) If turned ON, press (>) to change Sleep Mode Settings.

b) Press (+) or (-) to increase or decrease the amount of time the unit is inactive before going into sleep mode.

c) Press (>) to change sleep mode water tank temperature setting.

d) Press (+) or (-) to increase or decrease the water tank temperature during sleep mode.

15) Press (>) to view Manual Dispense mode. (9A)

(Models with manual Free-Flow Tomlinson handles cannot be changed to portion control.)

16) Press (>) for Sales Mode. (14A) (This option for future use. “Free” is currently the default setting.)

17) Press (>) to retrieve Sales Data. (15A)

18) Press (>) to view Total Dispense data (number of drinks dispensed per head). (15B)

Press the dispense buttons that you want to retrieve information about.

After viewing each head’s data, proceed to next step.

19) Press (>) to view Total Brews data. (15E)

LCD will display total number of drinks dispensed by the unit.

20) Press (>) for Clear Data options. (16A)

Press (+) or (-) to toggle between YES (resets sales data counter to “0”) and NO.

Important: After selecting YES and then pressing (>) all data will be cleared immediately.

21) Press (>) to view Dispenser Type. (17A)

LCD will display type of dispenser.

22) Press (>) to display Date Code information. (18A)

LCD will display manufacture date.

23) Press (>) to display Software Version on controller. (19A)

Displays current software version stored in controller memory.

24) Press (>) to Retrieve Error Codes. (20A)

Press (+) or (-) to toggle through and review all error codes. The LCD will display the number of times each

error code has occurred. Error Codes:

SC1: No Water Pressure

SC2: Reset Power (Error has occurred that requires power to be reset).

SC3: Low Water Level (Inlet valve ON for more than 5 minutes.)

Page 4 Model FDD2500

Loading...

Loading...