Page 1

Keyboard Operator’s Manual

AD2089

Part Number 8200-0710-01 B0

REV 1

Page 2

Notice

The information in this manual was current when published. The manufacturer reserves the right to revise and improve its products.

All specifications are therefore subject to change without notice.

Copyright

Under copyright laws, the contents of this manual may not be copied, photocopied, reproduced, translated or reduced to any

electronic medium or machine-readable form, in whole or in part, without prior written consent of Sensormatic Electronics. ©

Copyright 1997-2005, Sensormatic Electronics Corporation.

American Dynamics

6795 Flanders Drive

San Diego, CA 92121-2903 U.S.A.

Customer Service

Thank you for using American Dynamics products. We support our products through an extensive worldwide network of dealers. The

dealer through whom you originally purchased this product is your point of contact if you need service or support. Our dealers are

empowered to provide the very best in customer service and support. Dealers should contact American Dynamics at (800) 507-6268

or (561) 912-6259 or on the Web at www.americandynamics.net.

Trademarks

Intellex® is a registered trademark of Sensormatic Electronics Corporation. IntelleCord™ and Smart Search™ are trademarks of

Sensormatic Electronics Corporation. Windows® is a registered trademark of Microsoft Corporation. PS/2® is a registered trademark

of International Business Machines Corporation. Sony® is a registered trademark of Sony Corporation.

Trademarked names are used throughout this manual. Rather than place a symbol at each occurrence, trademarked names are

designated with initial capitalization. Inclusion or exclusion is not a judgment on the validity or legal status of the term.

ii

Page 3

Warnings

WARNING: TO REDUCE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER. NO USER

SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

DO NOT INSTALL THIS PRODUCT IN HAZARDOUS AREAS WHERE HIGHLY

COMBUSTIBLE OR EXPLOSIVE PRODUCTS ARE STORED OR USED.

The lightning flash/arrowhead symbol, within an equilateral triangle, alerts the user to the presence of a shock hazard within the

product’s enclosure.

CAUTION: Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the battery manufacturer. Dispose of used batteries according to the

battery manufacturer’s instructions.

VORSICHT : ZUR VERMEIDUNG EINES STROMSCHLAGES DARF DAS GEHÄUSE NICHT ENTFERNT WERDEN. ES ENTHÄLT

KEINE VOM BENUTZER ZU WARTENDEN TEILE. ÜBERLASSEN SIE DIE WARTUNG NUR QUALIFIZIERTEM

FACHPERSONAL.

CAUTION: Es besteht die Gefahr einer Explosion, wenn die Batterie nicht ordnungsgemäß

ausgetauscht wird.

WARNING: THIS EQUIPMENT IS A CLASS 1 LASER PRODUCT INCORPORATING A CLASS 1

LASER DIODE AND IT COMPLIES WITH FDA RADIATION PERFORMANCE

STANDARDS, 21 CFR SUBCHAPTER J AND THE CANADIAN RADIATION EMITTING

DEVICES ACT, REDR C1370.

Rack Mounting

Consult with the supplier of your equipment rack for adequate rack mounting means, with proper consideration for the weight of this

product.

Consult with the manufacturer of your rack regarding the proper hardware and procedure of mounting this product in a safe and

useable fashion

Avoid uneven loading or mechanical instability when rack-mounting units.

Make sure that units are installed to get enough air flow for safe operation.

The maximum temperature for rack-mounted units is 40° C.

Avoid uneven loading or mechanical instability when rack-mounting units.

Check product label for power supply requirements to assure that no overloading of supply circuits or overcurrent protection occurs.

Mains grounding must be reliable and uncompromised by any connections.

WARNING: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPLY WITH THE LIMITS FOR

A CLASS “A” DIGITAL DEVICE, PURSUANT TO PART 15 OF THE FCC RULES. THESE

LIMITS ARE DESIGNED TO PROVIDE REASONABLE PROTECTION AGAINST

HARMFUL INTERFERENCE WHEN THE EQUIPMENT IS OPERATED IN A COMMERCIAL

ENVIRONMENT. THIS EQUIPMENT GENERATES, USES AND CAN RADIATE RADIO

FREQUENCY ENERGY AND, IF NOT INSTALLED AND USED IN ACCORDANCE WITH

THE INSTRUCTION MANUAL, MAY CAUSE INTERFERENCE TO RADIO

COMMUNICATIONS. OPERATION OF THIS EQUIPMENT IN A RESIDENTIAL AREA IS

LIKELY TO CAUSE HARMFUL INTERFERENCE IN WHICH CASE THE USER WILL BE

REQUIRED TO CORRECT THE INTERFERENCE AT THEIR OWN EXPENSE.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate

the equipment.

NOTE: This product was FCC verified under test conditions that included the use of shielded I/O cables

and connectors between system component s. To be in compliance with FCC regulations, the user

must use shielded cables and connectors for all except power and alarm cables.

This digital apparatus does not exceed the Class A limits for radio noise emissions as set out in the Radio Interference Regulations

(ICES-003) of the Canadian Department of Communications.

iii

Page 4

License Information

READ THIS LICENSE AGREEMENT BEFORE OPENING THE DISK P ACKAGE, INST AL LING THE SOFTWARE, OR USING YOUR

SYSTEM.

THIS LICENSE AGREEMENT DEFINES YOUR RIGHTS AND OBLIGATIONS. BY BREAKING THE SEAL ON THIS PACKAGE,

INSTALLING THE SOFTWARE, OR USING YOUR SYSTEM, YOU AGREE TO ALL OF THE TERMS AND CONDITIONS OF THIS

AGREEMENT. IF YOU DO NOT AGREE TO ALL OF THE TERMS AND CONDITIONS OF THIS AGREEMENT, YOU MAY, WITHIN

30 DAYS, RETURN THIS PACKAGE, ALL THE DOCUMENTATION, AND ALL ACCOMPANYING MATERIAL(S) TO THE POINT OF

PURCHASE FOR A REFUND.

SOFTWARE LICENSE

The software includes the Intellex API, modular programs and source codes provided as samples, the Intellex API manual and any

electronic documentation; and is provided to you by installing the software on a computer hard drive. The software is licensed, not

sold.

GRANT OF LICENSE

The purchase of Intellex API software constitutes a license agreement between Sensormatic and you. This license agreement

permits you and only you to use the software. By purchasing the Intellex API license agreement, you may use the API software and

accompanying modular programs with their source codes. This license agreement does not grant you the right to resell nor distribute

the API nor the modular programs and their source codes or additional copies of them to another entity. The software is only licensed

for use with Intellex equipment. There are no restrictions on instituting a licensing program internal to your organization with regard to

the software products that you develop using the API; however, no software programs that you develop using the Intellex API or the

modular programs can be sold nor distributed by you to other entities as accessory products for Intellex product line without

authorization from Sensormatic.

OTHER RIGHTS AND LIMITATIONS

• A demonstration copy of the Software is considered purchased and is covered by this license agreement.

• The purchase order is your proof of license to exercise the rights granted herein and must be retained by you.

• Y ou may not de-compile, disassemble, or reverse engineer any of the executables; including, but not limited to the library files, for

which you were not given the source code. The modular programs are excluded from this restriction and you may re-compile, reassemble, or alter any component of the source codes that are provided to you.

• You may not sub-license, rent or lease the software; nor permanently transfer the software to another party by delivering the

original media material comprising the software package as well as this license to the other party.

• Sensormatic reserves the right to revoke this agreement if you fail to comply with the terms and conditions of this agreement. In

such an event, you must destroy all the Intellex API software on and/or loaded from the purchased CD ROM, any API software

downloaded from the web or sent on “patch” media, all of the modular programs you modified and all the software programs that

you developed using the Intellex API.

• The software may contain software from third parties that is licensed under a separate End User License Agreement (EULA).

Read and retain any license documentation that may be included with the Software. Compliance with the terms of any third party

EULA is required as a condition of this agreement.

Failure to comply with these restrictions will result in automatic termination of this license and will make available to Sensormatic

other legal remedies.

COPYRIGHT

The software is a proprietary product of Sensormatic and is protected by both the United States and International copyright laws.

UPGRADES

If the software is an upgrade from another software version, or an upgrade of a component of a package of software programs that

you licensed you may use or transfer the software only as specified in this agreement.

LIMITED WARRANTY

Sensormatic warrants that the recording medium on which the software is recorded, and the documentation provided with it, will be

free of defects in materials and workmanship under normal use for a period of ninety (90) days from the date of delivery to the first

user. Sensormatic further warrants that for the same period, the software provided on the recording medium under this license will

substantially perform as described in the user documentation provided with the product when used with the specified hardware and

development environment.

CUSTOMER REMEDIES

Sensormatic’s entire liability and your exclusive remedy under this warranty will be, at Sensormatic’s option, to a). attempt to correct

software errors with efforts we believe suitable to the problem, b). replace at no cost the recording medium, software or

documentation with functional equivalents as applicable, or c). refund the license fee and terminate this agreement. Any replacement

item will be warranted for the remainder of the original warranty period. No remedy is provided for failure of the diskette or Software if

such failure is the result of accident, abuse, alteration or misapplication. Warranty service or assistance is provided at the original

point of purchase.

NO OTHER WARRANTIES

The above warranty is in lieu of all other warranties, express or implied, including, but not limited to the implied warranties of

merchantability and fitness for a particular purpose. No oral or written information or advice given by Sensormatic, its representatives,

distributors or dealers shall create any other warranty, and you may not rely on such information or advice.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES

In no event will Sensormatic be liable to you for damages, including any loss of profits, loss of data or other incidental or

consequential damages arising out of your use of, or inability to use, the Software or its documentation. This limitation will apply even

iv

Page 5

Contents

AD2089 Keyboard Controller

About the AD2089 Keyboard Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

AD2089 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

AD2089 Keyboard Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Connection and Setup of the AD2089

Supplied Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Connecting to a Switching System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Connections for Cable Distance of Seven Feet or Less . . . . . . . . . . . . . . . . . . .5

Connections for Cable Distance of Greater than Seven Feet . . . . . . . . . . . . . . .5

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Keyboard Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Setting Keyboard Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Built-in Keyboard Operations Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Contents

Using the AD2089 in Operate Mode

User Numbers and Passcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Monitor Mode Operations (keyswitch in “operate” position) . . . . . . . . . . . . . . . . .15

Selecting Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Calling a Camera to View on a Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Controlling a Camera's Pan and Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Locking and Unlocking a Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Controlling Camera Zoom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Controlling Camera Focus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Controlling the Camera Iris . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Controlling Camera Flip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Auto Focus / Auto Iris. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Calling Presets (Shots) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Running System Tours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Holding a Tour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Re-Starting a Tour on Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Changing Tour Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Calling Salvos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Auxiliary Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Acknowledging Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Viewing Satellite Sites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Running Patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Running a Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

User’s Guide vii

Page 6

Contents

Playback Mode Operations (keyswitch in operate position) . . . . . . . . . . . . . . . . .21

Selecting DVRs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Programming with the AD2089

Using the AD2089 in Program Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Setting Presets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Setting Scratch Pad Tours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Programming Patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Defining Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Clearing Patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Arming a Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Disarming a Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Programming Macros. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Deleting Macros. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Using the AD2089 in Menu Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Specifications 29

Troubleshooting 30

Typical System Connections 31

AD2089 Keyboards to AD1024 System with Network Client/DVMS Control . . . .31

AD2089 Keyboard to AD1024 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

AD2089 Keyboard to AD1024 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

AD2089 Keyboard to AD2150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

AD2089 Keyboard to AD2150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

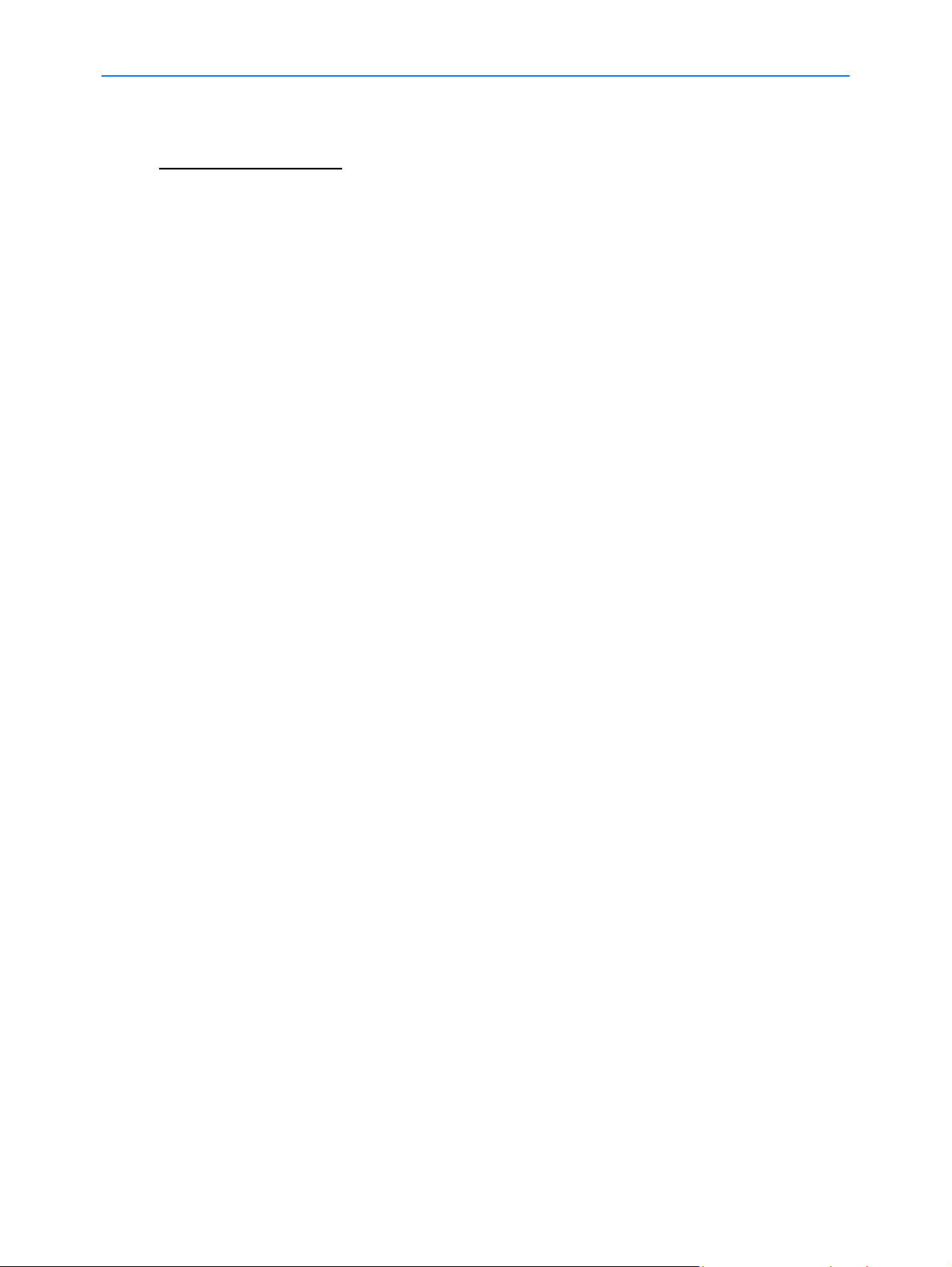

AD2089 Keyboard to AD168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

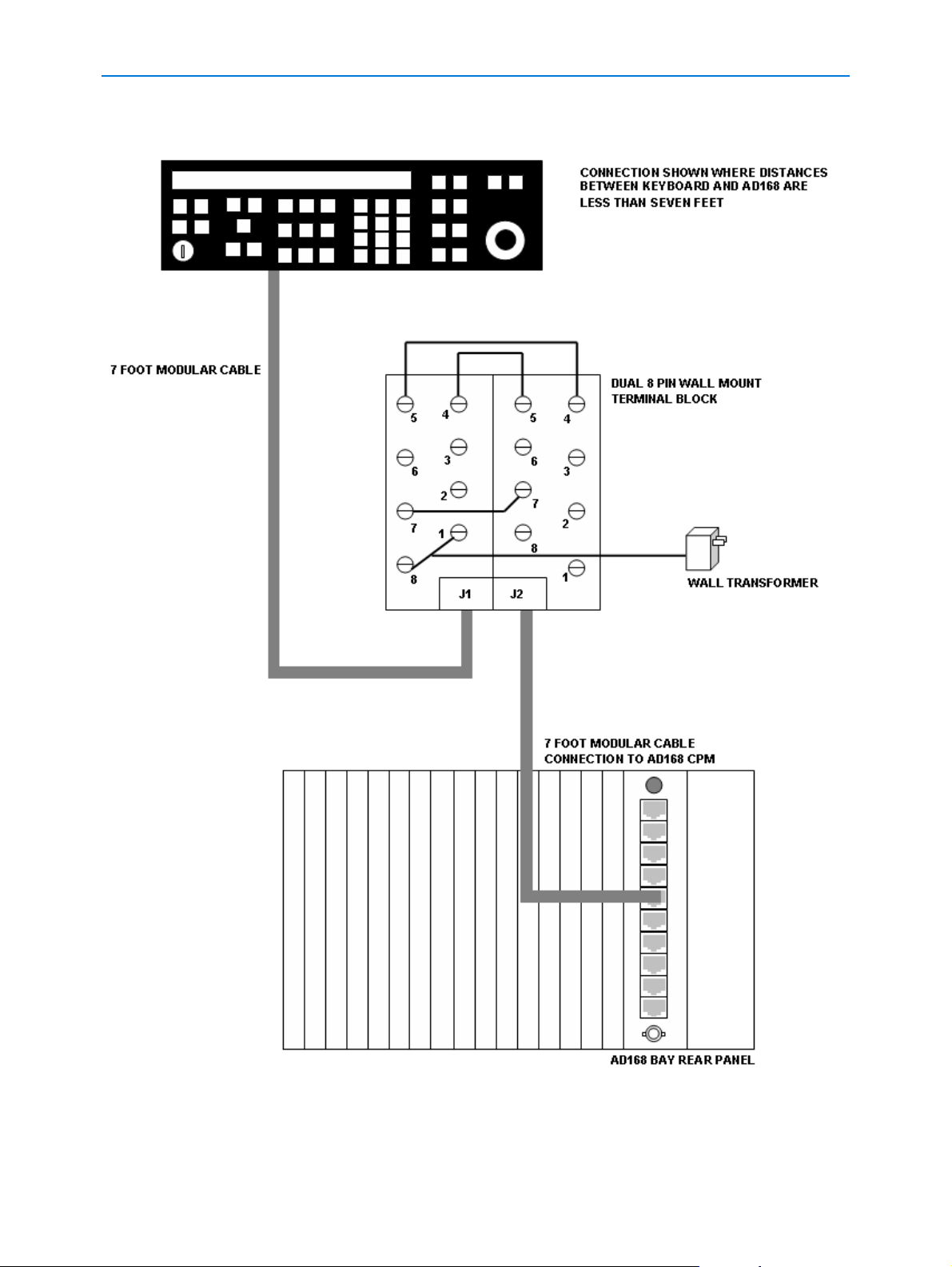

AD2089 Keyboard to AD168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

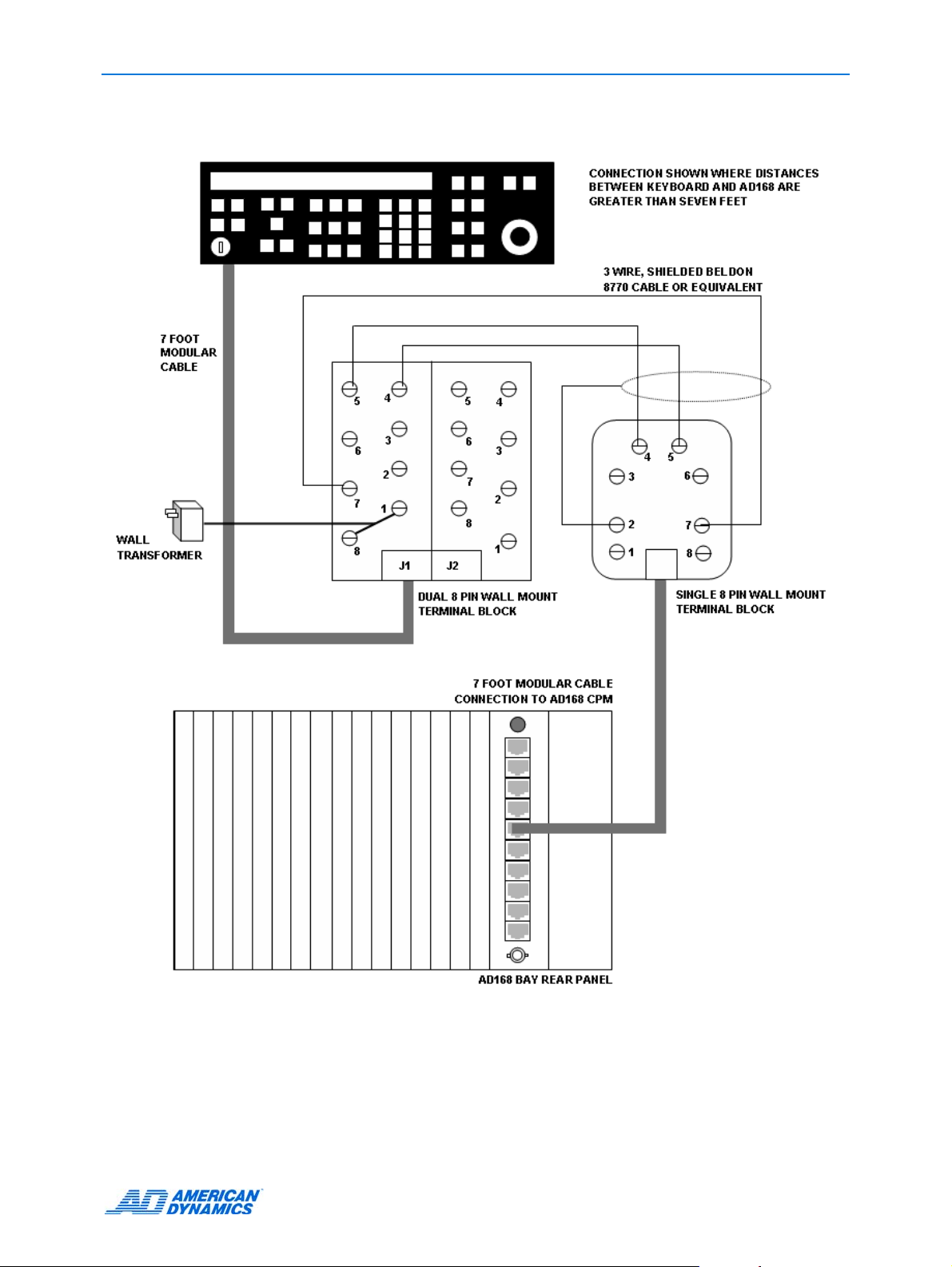

AD2089 to MegaPower 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Built-in Test Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Software License Agreement 40

Monitor Arming Commands 43

viii Intellex® Digital Video Management System

Page 7

Macro Key Labels

Macro Programming Worksheets

Macro Programming Workskeet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Contents

User’s Guide ix

Page 8

Contents

x Intellex® Digital Video Management System

Page 9

AD2089 Keyboard Controller

About the AD2089 Keyboard Controller

This chapter describes the features of the AD2089 keyboard. It also describes the location and

function of the keyboard's front panel components.

AD2089 Features

The AD2089 video control station is fully compatible with the American Dynamics MegaPower

CPU and MegaPower 1024 when used in conjunction with Network Client 4.04 (or later) and

Intellex DVMS or Ultra digital video recorders.

Note

In addition to controlling the matrix switchers through Network Client, the AD2089 will work directly

with the MegaPower 48, MegaPower 168, and MegaPower 1024 matrix switcher/controller

systems but will not support the AD2089 DVMS functions.

The AD2089 enables the user to view and control cameras and video recorders at local and

remote facilities, and to control auxiliary devices such as door locks and lights. Additionally, the

operator can acknowledge alarms with the unit. The aforementioned functions are accomplished

in the keyboard’s Operate Mode. Operators with key privileges can also perform programming

functions with the AD2089. These functions include programming of presets (targets), patterns,

scratchpad tours, and macros. Macros are user pr ogrammed functions mad e up of as many as 21

keystrokes that are executed with a single keystroke. Operators ca n also arm and di sarm monitors

for display of system alarms. These functions are accomplished in the Program Mode. Menu

programming enables operators to set up the parameters of American Dynamics switching

systems. System setup is accomplished in the Menu Mode.

A summary listing of AD2089 features follows:

• site ID - selects a site for satellite switching

• monitor/camera selection - provides selection for viewing and control

• pan/tilt and lens control - pan, tilt, and zoom control through joystick positioning. Focus and

iris adjustments through lens control keys

• video recorder control and operation – enables selection of video r ecorders and execution of

the following functions: Play, Stop, Fast-Forward, Rewind, Record, Pause, and Eject

• macro key programming and operation – up to 1000 macros divided among eight macro keys

enable multi-step operation with a single keystroke

• joystick “Flip” push-button - enables user to flip cameras 180≡ from established position

• tour functions - enables programming, running, and control of camera sequences

• salvo functions - enables programming and simultaneous callup of multiple camera scenes

• alarm functions - supports monitor alarm arming, disarming, and alarm acknowledgment

• pattern and preset functions - enables programming and display of patterns and presets

(shots)

• selectable baud rate - 1200, 2400, 4800, 9600, 19,200, 38,400 bps (1200 default)

• selectable LED brightness - enables eight different brightness levels

1

Page 10

AD2089 Keyboard Controller

• selectable speaker volume - enables eight different volume levels

• auto focus/auto iris capability - supported when used with DeltaDome units

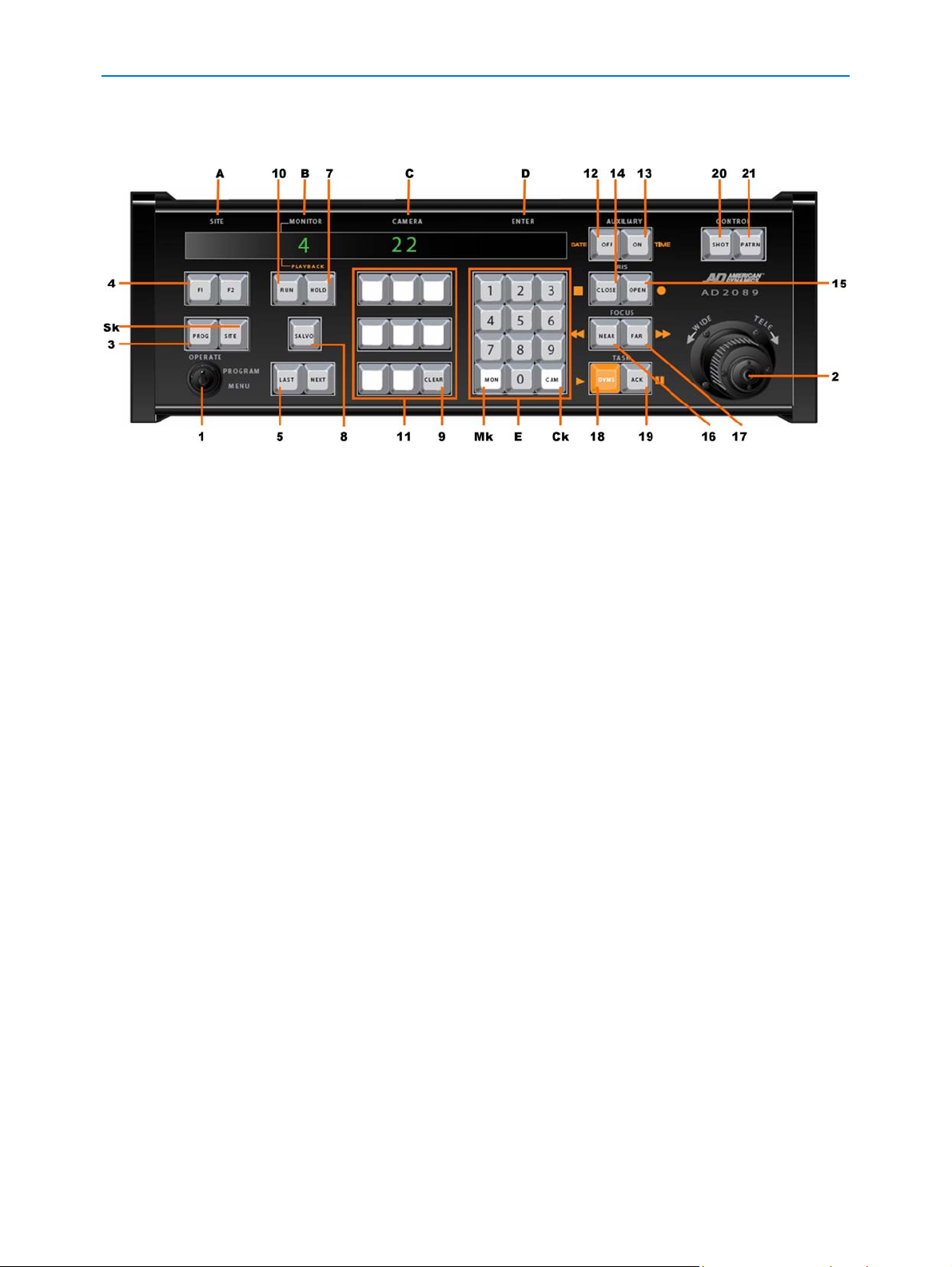

AD2089 Keyboard Overview

The AD2089 keyboard is comprised of the following elements:

ASite - shows the number of the site entered with the keypad when the SITE key (Sk) is

pressed.

B Monitor/DVMS - shows the number of the monitor or DVR entered when the MON (Mk) or

DVMS key is pressed.

CCamera - shows the number of the camera entered with the keypad when the CAM key

(Ck) is pressed.

DEnter - shows the number entered on the NUMERIC KEYPAD (E).

E Numeric Keypad - has keys ranging from 0 - 9 that enable the user to select specific

cameras, monitors, salvos, tours, presets, patterns, auxiliaries, recorders, sites and

macros.

1 Keyswitch - enables the user to switch the Operate, Program or Menu modes of operation.

When the keyswitch is set to Menu position, the p age and cursor navigation fun ctions of

the multi-function keys are activated.

2 Joystick - enables the user to pan, tilt, zoom and flip the camera under keyboard control.

3 PROG key - enables the user to set scratch-pad tours and patterns, as well as a number of

other switching system functions.

4 F1 & F2 keys - special functions keys used to implement basic system commands and

DeltaDome control F1 & F2 keys - special functions keys used to implement basic system

commands and DeltaDome control

5 LAST key - calls the prior camera displayed in a sequence (tour).

6 NEXT key - calls the next camera displayed in a sequence (tour).

7 HOLD key - Holds the current camera in a sequence (tour).

8 SALVO key - calls a specified salvo whose number is entered on the numeric keypad.

9 CLEAR key - clears data entered on the numeric keypad

10 RUN key - runs system and scratch pad tours.

11 MACRO keys – Each of the eight macro keys calls a specified macro whose number is entered

on the numeric keypad.

2 AD2089 Operator’s Manual

Page 11

AD2089 Keyboard Controller

Multi-Function Keys

12 OFF/Page Left key/ Stop - turns off auxiliary device in Monitor Operate mode. Displays page

to the left in Menu mode. In Playback Oper ate mode, DATE allows you to select a specific date

for playback. On the Numbers Keypad, enter a 4-digit date (mmdd) and press DATE. As a

shortcut, you can enter a 2-digit date (dd).

13 ON/Page Right key/ Record - turns on auxillary device in Monitor Operate mode. Displays

place to the right in Menu mode. In Playback Operate mode, TIME allows you to select a

specific time for playback. Once you have selected a date, enter a 4-digit time (hhmm), press

TIME and then press PLAY. As a shortcut, you can enter a 2-digit time (hh).

14 CLOSE/Page Up key/ Pause - closes iris in Monitor Operate mode. Displays prior page up in

Menu mode. S tops playing recorded video and resumes live video in Playback Operate mode.

15 OPEN/Page Down key/ Play - Opens iris in Monitor Operate mode. Displa ys prior page down

in Menu mode. Saves a downloaded clip to a preconfigured database in Playback Operate

mode.

16 NEAR /Left Arrow key/ Rewind - adjusts focus of near objects in Monitor Operate mode.

Moves cursor left one character in Menu mode. Rewinds video at fast speed in Playback

Operate mode. Each time button is pressed, video speed increases (up to 5x).

17 FAR/Right Arrow / Fast Forward key - adjusts focus of far objects in Monitor Operate mode.

Moves cursor right one character in Menu mode. Plays video at fast spee d in Playback Operate

mode. Each time button is pressed, video speed increases (up to 5x). If play is paused,

pressing this button will skip video forward one frame.

18 DVM S/U p Arrow /Pl ay ke y – enables selection of Playback Operate mode. Initiates playback

of a selected camera or of a camera that is already displayed on a selected monitor. Pressing

the play button will put the keyboard into Playback Shifted mode. If playback is already in

progress but has been paused, pressing the play button will resume playback. If playback is in

progress and is still playing, the duration of playback is increased by one play-back interval and

is re-downloaded.

19 ACK key /Down Arrow /Eject Key- acknowledges alarms, runs tours, sets and repeats

alarms. Pauses an image in Playback Operate mode.

20 PRESET/Enter key - calls presets in Operate mode. Sets presets in Program mode. Stores

entered menu data.

21 PATRN/Exit key - runs and repeats patterns in Operate mode. Sets patterns in Program mode.

Exits Menu mode.

3

Page 12

Connection and Setup of the AD2089

Connection and Setup of the AD2089

This chapter describes the power and data connections between the AD2089 keyboard and the

switching system being used. It also describes the setup of communications protocols and other

keyboard parameters. Additionally, it describes built-in test procedures used to verify the

operational integrity of the keyboard.

Supplied Equipment

The AD2089 is supplied with the following equipment and accessories:

• Wall Transformer (specified for national and local electrical requirements)

• One dual eight pin, wall-mount terminal block, with three jumper wires

• One single eight pin, wall-mount terminal block

• Two seven foot, eight conductor modular cables

• Eight clear key caps and four white key caps for the AD2089 macro key section

• Pre-printed macro key labels

• One extractor tool for macro key removal

The transformer is connected from the wall to the terminal block. Power is then routed thr ough the

dual terminal block to the keyboard's eight pin RJ-45 port via the seven foot cable.

Connecting to a Switching System

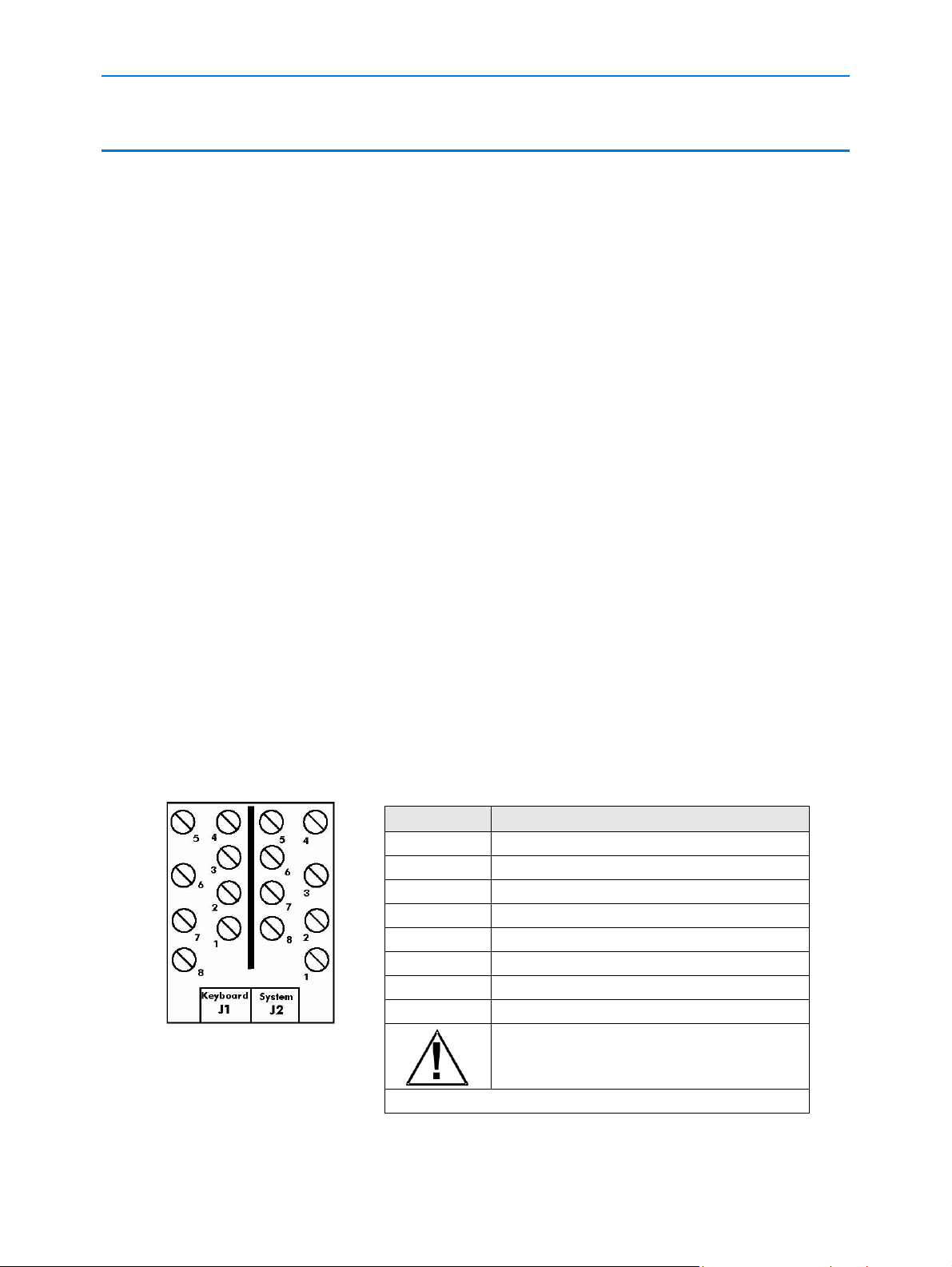

The dual terminal block consists of two single eight-screw terminal blocks located on the left and

right sides of the block interior (see illustration below). Each of the eight terminal screws in a

connector set are routed to an RJ-45 connector at the bottom of the block.

The J1 connector is connected to the AD2089 keyboard via one of the seven foot mo dular ca bles.

The J2 connector is connected to the switching system via the other seven foot modular cable.

Additional information showing typical system connections is included in Appendix C of this

manual. Pin definitions for both the keyboard (J1) and system (J2) sides of the terminal block are

listed in the table below

Screw Function

1 Transformer Power In (J1 Only)

2Shield

3 Not Used

4 RS-232 RCD

5 RS-232 XMIT

6 Not Used

7 Ground

8 Transformer Power In (J1 Only)

Dual Terminal Block

Power and Data Connections Only

Not for Connection to Telephone Lines

Dual Terminal Block Screw Designations

4 AD2089 Operator’s Manual

Page 13

Connection and Setup of the AD2089

Connections for Cable Distance of Seven Feet or Less

For switching system connections where keyboard-to-system cable distance is seven feet or less,

make the following connections using the jumpers included with the dual terminal block

J1 Pins J2 Pins

⇐

⇐

5 (xmit)

4 (rcd)

7 (ground)

4 (rcd) ⇐

5 (xmit)

7 (ground)

After connecting the jumpers, connect one of the seve n foot modular cables from the J2 ( system)

jack of the dual terminal block, to the appropriate RS-232 port on the switching system. Connect

the other seven foot modular cable from the J1(keyboard) jack of the dual terminal block, to the

RJ-45 jack of the keyboard.

Connections for Cable Distance of Greater than Seven Feet

For switching system connections where keyboard-to-system cable distance is greater than seven

feet, the following components are required.

• Dual terminal block supplied with the AD2089

• A three-wire, shielded, 18 AWG cable supplied by the installer

• Single terminal block supplied with the AD2089

Use the three-wire cable to connect the keyboard and switching system terminal blocks. The

following table provides the connection points

Dual Block (J1 Side) Screws Single Block Screws

⇐

⇐

5 (xmit)

4 (rcd)

7 (ground)

4 (rcd) ⇐

5 (xmit)

7 (ground)

The cable shield connects to Pin 2 of the single terminal block

After connecting the three-wire cable to the respective terminal blocks, connect one of the seven

foot modular cables supplied with the AD2089 from the J1(keyboard) jack of the dual terminal

block to the RJ-45 jack of the keyboard. Connect the other seven foot modular cable from the RJ45 jack of the single terminal block to the appropriate RS-232 port on the switching system.

Power Connections

Depending on national and local electrical requirements, the AD2 089 is su ppli ed with eith er a 12 0

VAC or a 230 VAC transformer. The 230 VAC transformer is supplied with a Euro-style IEC 320

type inlet. An appropriate detachable cord sh ould be connected between the IEC 3 20 inlet and the

power source.

Connect the output leads from the wall transformer to screws 1 and 8 on the J1(keyboard) side of

the dual terminal block. All power to the AD2089 is supplied from this connection.

CAUTION!

DO NOT INSERT THE WALL TRANSFORMER

INTO THE POWER SOURCE UNTIL ALL

CONNECTIONS HAVE BEEN VERIFIED

Note

Typical system and test connections are illustrated in Appendix C of this manual.

5

Page 14

Connection and Setup of the AD2089

Installation Precautions

The keyboard unit is susceptible to high electrostatic discharge potenti als. Care should be taken to

locate the unit so as to reduce the likelihood of accidental contact with ESD potentials, such as

walking on a carpet under very dry conditions.

Should accidental contact occur, and the keyboard unit experiences loss of camera control,

momentarily remove power to the unit. This will re-establish communication with the connected

unit or system, and reset the camera status.

This installation should be made by qualified service personnel, and should conform to all local

electrical codes. Safeguards must be taken to avoid unintentional operation by employees and

maintenance personnel working about the premises, by falling objects, by customers, by building

vibration, and by similar causes.

6 AD2089 Operator’s Manual

Page 15

Connection and Setup of the AD2089

Keyboard Setup

The AD2089 keyboard communicates via RS-232 protocol. Keyboard setup up the keyboard

involves setting the keyboard's baud rate, LED brightness, speaker volume, and PTZ motion

control.

Setting Keyboard Parameters

The operator can set the following four keyboard parameters:

• Baud Rate – 1200 (default), 2400, 4800, 9600, 19,200, and 38,400 bps

• LED Brightness - eight brightness levels

• Speaker Volume - eight volume levels

• Pan/Tilt/Zoom Motor Control – two control options can be set automatically or manually

To Enter Setup Mode

1 Turn the three-position keyswitch to the MENU position.

2 Press the F1 key. "SETUP BAUD =" appears in the CAMERA display. The current value of the

baud rate appears in the ENTER display.

To Change the Baud Rate

1 Press the NEXT key to cycle through the available baud rate settings in the forward direction:

1200, 2400, 4800, 9600, 19,200, and 38,400. Press the LAST key to cycle through in the

reverse direction. The factory default setting is 1200 baud.

2 When the appropriate baud rate appears in the display, press the PROG key to save the

selection. You now have the option to either set the brightness level using the following

procedure, or exit setup mode by pressing the F1 key, turning the keyswitch to OPERATE,

MENU, and then back to OPERATE again.

To Set the Brightness Level

1 After baud rate selection has been completed, the message "L EDS =" appears in the CAMERA

display . The brightness level (an integ er from 1 to 8) appears in the ENTER display . The intege r

1 signifies minimum brightness. The integer 8 signifies maximum brightness. 8 is the factory

default setting.

2 To change the currently di splayed brightness level, cycle through the levels using the NEXT or

LAST keys to move in forward or reverse direction respectively. Each time the level changes,

the intensity of the displayed characters changes as well.

3 When the appropriate integer appears in the ENTER display, press the PROG key to save the

selection. You now have the option to either set the speaker volume level using the following

procedure, or exit setup mode by pressing the F1 key, turning the keyswitch to OPERATE,

MENU, and then back to OPERATE again.

To Set the Speaker Volume

1 After LED brightness level selection has been completed, the message "SOUND" appears in

the CAMERA display. The speaker volume level ("Off" or integer values from 1 to 7) appear s in

the ENTER display . "Of f" indicates the spea ker is disabled. The in teger 1 signifies the minimum

volume level. The integer 7 signifies the maximum volume level. 7 is the factory default setting.

7

Page 16

Connection and Setup of the AD2089

2 To change the currently displayed volume level, cycle through the levels using the NEXT or

LAST keys to move in forward or reverse direction respectively. Each time the level changes, a

short tone sounds indicating the new level.

3 When the appropriate level appears in the ENTER display, press the PROG key to save the

selection. You now have the option to either set the PTZ motion control option using the

following procedure, or exit the setup mode by pressing the F1 key, turning the keyswitch to

OPERATE, MENU, and then back to OPERATE again.

To Set the Pan / Tilt / Zoom Motion Control Option

Depending on the particular switching system that is used with the AD2089 keyboard, the pan, tilt,

and zoom (PTZ) motions of the system cameras are controlled by one of two methods: Repeat or

Make/Break. Detailed descriptions of these two methods are beyond the scope of th is manual, but

a system administrator will be advised of the appropriate method to use, and will make the

appropriate setting accordingly.

1 After speaker volume level selection has been completed, the letters "rpt =" appear in the

CAMERA display. "AUTO" will appear in the ENTER display. “AUTO” indicates that the

switching system being used will automatically select either the Repeat or Make/Break control

method.

2 You can step through the “AUTO”, "OFF" and "ON" states by using the NEXT or LAST keys. If

"OFF" is displayed, the Repeat method will be set off . If "ON" is displayed the Repeat method

will be set on. The AD168 system operates with Repeat set to OFF. American Dynamics

systems that operate with Repeat set to ON include AD1650B, AD1024, AD2052, AD2150, and

AD2350. Consult with your system administrator about the appropriate setting for your system.

3 When the appropriate state appears in the ENTER display, press the PROG key to save the

selection. Y ou now have the option to either set the baud rate using the procedure indicated on

page 2-3, or exit the setup mode by pressing the F1 key, turning the keyswitch to OPERATE,

MENU, and then back to OPERATE again.

Resetting Keyboard Parameters

1 To reset baud rate, LED brightness level, speaker volume level, and the PTZ motion control

option to factory default settings, first unplug the keyboard's wall transformer.

2 Press and hold the F1 and PROG keys simultaneously while plugging the transformer back in.

8 AD2089 Operator’s Manual

Page 17

Connection and Setup of the AD2089

Built-in Keyboard Operations Test

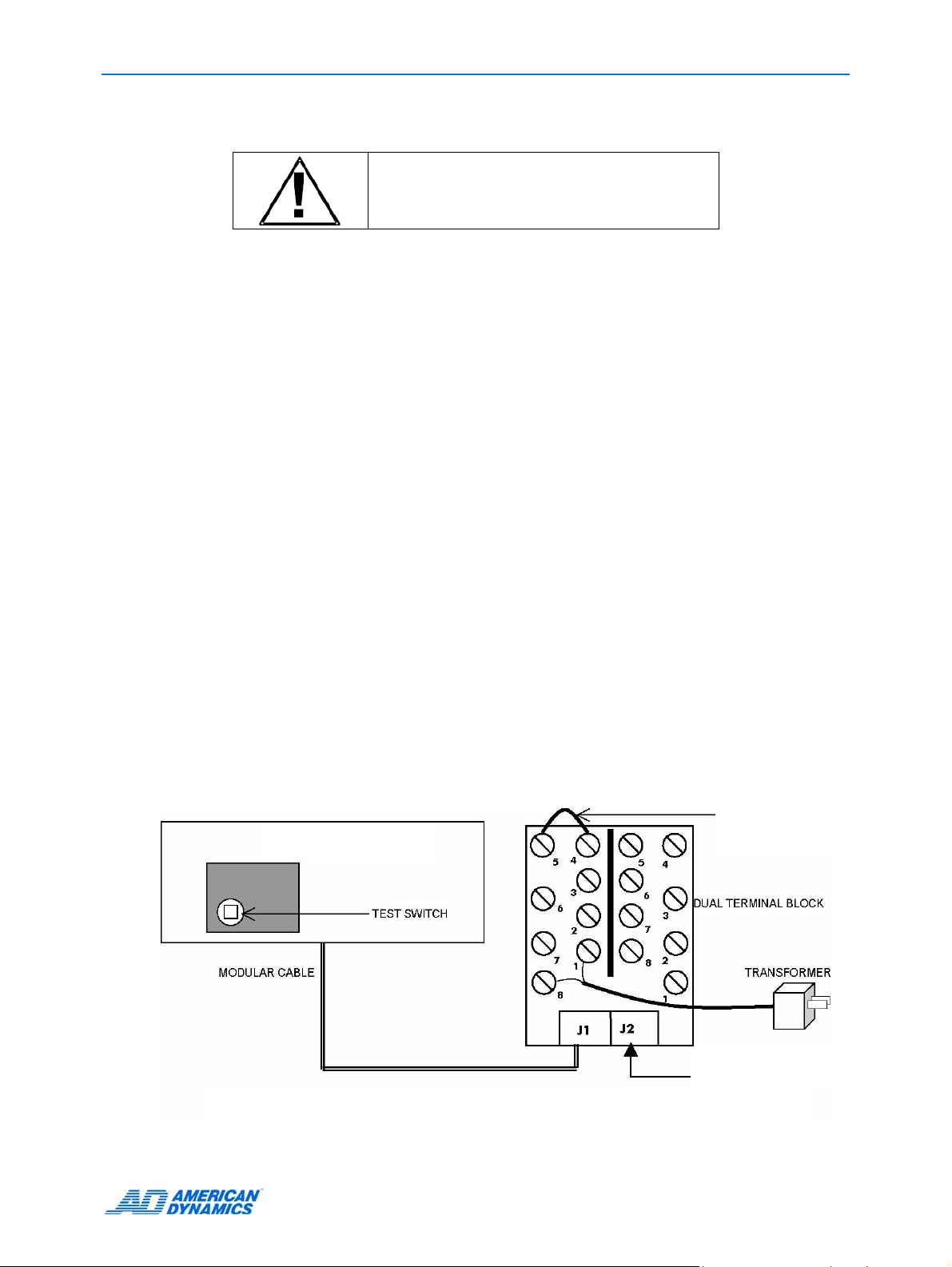

CAUTION !

The following procedures expose internal

electrical components and should be performed

by qualified service personnel only.

The AD2089 has built-in test capability to verify the operational integrity of the unit's hardware and

firmware. Built-in test functions include the following:

• speaker test

•LED lamp test

• LED brightness test

• LED seven segment test

• joystick calibration / speed test

• key functionality test

• keyswitch test

• serial communications test

• ROM checksum test

Procedure to Initiate Built-In Test

1 Unplug the keyboard's wall transformer.

2 Disconnect the matrix switching system's modular cable from the dual terminal block (J2).

3 Connect a jumper wire to pins 4 and 5 on the J1 side of the dual terminal block.

4 Detach the bottom plate of the keyboard by removing the four screws.

5 Press and hold down the button labeled "test switch", while simultaneously plugging in the wall

transformer.

XMIT/RCD SELF-TEST

JUMPER CONNECTION

AD2089 Keyboard

Underside

DO NOT CONNECT TO

SYSTEM DURING

BUILT-IN-TEST

Each test is performed in sequence. Press the test switch button to adva nce to the next

test procedure. To quit the test sequence, unplug and then re-plug the wall transformer

9

Page 18

Connection and Setup of the AD2089

Speaker Test

The speaker test performs an audible check of the keyboard's speaker. A series of audio tones

step through the frequency range of the speaker. During this test the CAMERA display shows the

message "SOUND". The speaker test is repeated automatically, until the test switch button is

pressed to advance to the LED lamp test.

LED Lamp Test

The LED lamp test simultaneously illuminates all segments of all LEDs in the four keyboard

display sections. Press the test switch button to advance to the LED brightness test.

LED Brightness Test

In this test, all LEDs are stepped through the eight levels of intensity. The eight step sequence

repeats continuously until the test switch button is pressed to advance to the seven segment LED

test.

Seven Segment LED Test

This test simultaneously illuminates one of the seven segments for all 18 of the display LEDs for a

brief interval. The next segment then illuminates, and then the next, and so on. The seven

segment illumination cycle repeats continuously until the test switch button is pressed to advance

to the joystick calibration / speed test.

Joystick Calibration / Speed Test

This test checks the joystick’s calibration, speed, and position. Codes representing these

parameters appear in the keyboard’s ENTER, CAMERA, and MONITOR/DVMS displays.

When the joystick is in the center or “hands-free” position, dash marks appear in the ENTER

display. The number “128” appears once in the MONITOR/DVMS display, and twice in the

CAMERA display.

SITE MONITOR CAMERA ENTER

- - 1 2 8 1 2 8 1 2 8 - -

The dashes in the ENTER display indicate that no pan or tilt commands are being transmitted.

“128” in the MONITOR/DVMS display indicates that the joystick is not being twisted in a clockwise

or counter-clockwise direction. Twisting clockwise zooms in. Twisting counter-clockwise zooms

out.

The left-most “128” in the CAMERA display indicates the hands-free position for panning. The

right-most “128” indicates the hands-free position for tilting.

Note

Due to variations in components and voltage sources, the center and endpoint numeric values for

each keyboard may vary by small amounts.

If the dashes are not displayed when the joystick is physically centered (when the operator

releases the joystick), then the joystick is not properly calibrated. Contact American Dynamics

Technical Support Center at 1-800-442-2225.

When the joystick is moved in any direction away from the center position, the dashes in the

ENTER display are replaced by a four-digit movement code:

10 AD2089 Operator’s Manual

Page 19

Connection and Setup of the AD2089

Enter Display

(Joystick in Motion)

8 L 1 d

pan speed (1-8)

pan direction (left or right)

tilt speed (1-8)

tilt direction (up or down)

• From left to right, the first digit represents the pan speed. Speed is directly proportional to the

distance from the joystick’s center position. “1” represents the slowest pan speed, and is

therefore the position closest to the center. “8” represents the fastest pan speed, and is therefore

the position furthest from the center.

• The second digit (left to right) represents the panning direction (left or right, "L" or "r").

• The third digit (left to right) shows the tilt speed (up or down, "U" or "d"). Speed is directly

proportional to the distance from the joystick’s center position. “1” represents the slowest tilt

speed, and is therefore the position closest to the center. “8” represents the fastest tilt speed,

and is therefore the position furthest from the center.

• The fourth digit (left to right) shows the tilt direction (up or down, “U” or “d”)

When the joystick is moved left or right, or forwards or backwards, the numbers on the CAMERA

display change. Moving the joystick to the left or forwards increases the numeric value s. Moving to

the right or backwards decreases the numeric values. Zero is the lower limit for numeric values.

“255” is the upper limit.

CAMERA display: 128 1 28

When the joystick is twisted clockwise or counter-clockwise, the numbers on the MONITOR/DVMS

display change. Twisting clockwise performs the zoom-in or telephoto function. When twisting

clockwise, an “I” (for zoom in) should appear before the digits, and the digits will increase. Twisting

counter-clockwise performs the zoom-out or wide function. When twisting counter-clockwise, a

“O”(for zoom out) should appear before the digits, and the digits will decrease. Zero is the lower

limit for numeric values. “255” is the upper limit.

Monitor/Playback display:

l

202

Clockwise Motion

Monitor/Playback display:

O

102

Counter- Clockwise Motion

Key Functionality Test

This test performs a visual and audible check of keyboard key actions. When the test is started,

each of the keyboard LED display sections shows a number representing the number of keys in

that section of the keyboard. The numbers displayed are as follows:

Display

Number of Keys

Selection

SITE 4

MONITOR/DVMS 5

CAMERA 9

ENTER 23

11

Page 20

Connection and Setup of the AD2089

Note

The count in the ENTER display includes the keys in the ENTER, MULTI-FUNCTION, and

CONTROL sections of the keyboard, as well as the “flip” button on the joystick.

To verify proper operation, each key on the AD2089 keyboard must be pressed once. The keys

can be pressed in any order. When a key is pressed.

• An audible tone is sounded, verifying key recognition by the keyboard's microprocessor.

• The number in the associated display decrements by one. Pressing the same key multiple

times will not decrement the count by more than one (although the audible tones will

continue).

• When all keys have been pressed (including the joystick flip button), each display section will

show a zero.

Press the test switch button to advance to the keyswitch test.

Keyswitch Test

This test performs a visual check of the keyswitch positions. When the test is started, the ENTER

display shows the current keyswitch position (OPERATE, PROGRAM, or MENU), and the SITE

display shows the number 0, 1, or 2 corresponding to the respective keyswitch position.

Rotate the keyswitch to all three positions, and verify that each of the three locations provides the

appropriate message and number. Following verification of the keyswitch positions, press the test

switch button to advance to the serial communications test.

Serial Communications Test

This test provides a communications check of the keyboard's RS-232 serial port. The test requir es

a loop back connection of the XMIT pin to the RCV pin on the keyb oard output por t, or o n the dual

terminal block (pin 4 connected to pin 5 on the J1 side only). During this test procedure the

CAMERA display shows the message “SERIAL”.

A sequence of test characters is sent from the microprocessor's transmit port to be verified at the

processor's receive port.

• If the test sequence is verified as correct, a double tone sounds on the speaker.

• If the test sequence is not verified, or if the test connection is incorrect, a single tone sounds

on the speaker.

After completing the serial communications test, press the test switch button to advance to the

ROM Checksum test.

ROM Checksum Test

In this test a software checksum of the ROM contents is calculated for comparison with a known

checksum value. The known value is printed on a label on the AD2089 microprocessor. The label

is visible on the bottom of the unit, adjacent to the test switch button.

When the test is run, the CAMERA display shows the checksum mess ag e CS =, and the ENTER

display shows the four digit computed value of the checksum. Verify that the displayed checksum

value matches the checksum printed on the label.

12 AD2089 Operator’s Manual

Page 21

Connection and Setup of the AD2089

When the ROM checksum test is completed, the built-in test sequence will return to the speaker

test when the test switch button is pressed.

To exit the built-in test mode, unplug the wall transformer, remove the test jumper from the dual

terminal block, return the jumpers to their original positions, re-connect to the system, and then replug the transformer.

13

Page 22

Using the AD2089 in Operate Mode

Using the AD2089 in Operate Mode

This chapter describes how to call cameras to view on workstation monitors, and explains how to

control the movement of pan/tilt cameras, and how to zoom, focus, and adjust the iris of a camera

lens. The chapter discusses how to run tours, patterns, and macros, and how to call a salvo. There

is also an explanation on how to select a DVR and control the various DVR functions. In addition,

procedures are provided for acknowledging alarms, and controlling auxiliary devices such as door

locks and lights.

User Numbers and Passcodes

Depending on the setup of the switching system being used, an operator may have to e nter a user

code and passcode on the AD2089 keyboard in order to gain system access. If a user code is

required, the letters “UC” appear in the CAMERA display to prompt the operator. After entering the

appropriate user code, the operator is prompted by the letters “PSC” in the CAMERA display. After

entering the appropriate passcode, the operator has system access.

Consult with your system administrator to verify the appropriate user number and passcode for

your keyboard.

Logging On to the System

To log on to the system:

1 Enter your user code (assigned by the system administrator) on the numeric keypad

2 Press the ACK key

The system prompts for the user passcode by displaying "PSC" in the CAMERA display.

3 Enter the assigned passcode (maximum of six digits) on the numeric keypad.

If an incorrect passcode is entered, press the CLEAR key, and then repeat step 3.

4 Press the ACK key.

If the passcode is accepted, the CAMERA display window clears. This confirms that th e keyboar d

is communicating with the system, and that a monitor can be "called" to the keyboard.

Logging Off from the System

When a user shift is completed, it is advisable to log off from the keyboard to insure system

security.

To log off from the system:

1 Press [99], [F1].

Selection of Monitor or DVMS Mode of Operation

The 2089 can be operated in one of two modes – Monitor or Playback. The current mode of

operation is indicated by a dash appearing on the Monitor/DVMS display. If the dash is positioned

directly beneath the display’s monitor label, the unit is in Monitor mode. If the dash is positioned

directly above the display’s Playback label, the unit is in Playback mode.

• To select Playback mode, press the DVMS key.

14 AD2089 Operator’s Manual

Page 23

Using the AD2089 in Operate Mode

• To select Monitor mode, press the MON key.

If the user does not enter a number prior to pressing either the DVMS or Monitor keys, the

keyboard “remembers” the number of the last DVMS or monitor selected prior to toggling to the

alternate mode.

Monitor Mode Operations (keyswitch in “operate” position)

Selecting Monitors

Workstation monitors display the video from the cameras and dom es installed in local an d/ or

satellite facilities. Each monitor has an identification number documented by the system

administrator.

To select a monitor:

1 Enter the monitor identification number on the numeric keypad (the number will appear in the

ENTER display).

2 Press the MON key. (the monitor identification number will appear in the MONITOR/DVMS

display window. The ENTER display will clear). This monitor has now been called to the

keyboard. Camera video can now be viewed on the called monitor. W

Note

When the monitor key is pressed a horizontal line segment appears below the monitor display

label.

Calling a Camera to View on a Monitor

After a monitor has been called to the control of the AD2089 (see page 3-1), a camera can be

called to view on the monitor. Each system camera has a unique identification number

documented by the system administrator.

To call a camera:

1 Enter the camera identification number on the numeric keypad (the number appears in the

ENTER display).

2 Press the CAM key (the number clears from the ENTER display, and appears in the CAMERA

display).

The selected video input now appears on the monitor screen. After calling a camera to the

selected monitor, any other camera can be called to the monitor by repeating the two step

procedure described above.

Controlling a Camera's Pan and Tilt

Once an appropriately equipped camera has been called to view on a monitor, the operator can

manually control the camera's movement. Pan is the side-to-side movement of the camera. Tilt is

the up and down movement of the camera.

15

Page 24

Using the AD2089 in Operate Mode

The AD2089 joystick controls the panning and tilting of cameras connected to the switching

system. As the joystick is moved to the left or right, and is moved towards or away from the

operator, the camera will pan and/or tilt accordingly.

For cameras with variable speed pan/tilt capability, camera movement speed is proportional to the

positioning of the joystick. The further from the stationary center position the joystick travels, the

faster the camera will move. There are eight independent speed levels for the up, down, left, and

right directions.

Center the joystick when the camera has been positioned appropriately.

Locking and Unlocking a Camera

After calling a pan/tilt camera to view and control on a system monitor, an operator can prevent

other operators from controlling the movements of the called camera. This is referred to as

“locking” the camera.

To lock a camera:

1 Enter the camera identification number on the numeric keypad (the number appears in the

ENTER display).

2 Press [2], [F1]. This locks the called camera.

To unlock a camera:

1 Enter the camera identification number on the numeric keypad (the number appears in the

ENTER display).

2 Press [1], [F1]. This unlocks the called camera.

Controlling Camera Zoom

Zoom refers to the apparent action of moving closer to or farther away from an object, as seen

through the camera lens. Zoom functions are controlle d by twisting the control knob of the threevector joystick. Twisting to the right (“TELE”) enables the camera to zoom in. Twisting to the left

(“WIDE”) enables the camera to zoom out.

Controlling Camera Focus

Focus refers to the action of adjusting th e clarity of the ca mera image d isplayed on the m onitor. To

focus the camera on a distant object, press the FAR key. To focus on a closer object, press the

NEAR key.

Controlling the Camera Iris

Normally, the brightness of a picture is controlled by the camera's auto gain and the auto/manual

iris functions. However, there may be times when you would like the picture on the monitor to

appear darker or lighter. To brighten the picture, press the iris OPEN key. To darken the picture,

press the iris CLOSE key.

16 AD2089 Operator’s Manual

Page 25

Using the AD2089 in Operate Mode

Controlling Camera Flip

To “flip” the camera under keyboard control 180× from its current position (for uninterrupted

surveillance of subjects who pass directly beneath the camera, press the button on the top of the

joystick knob. The flip feature is active with the AD168 system.

Note

On suitably equipped domes with the auto-flip function turned on, the dome flips automatically

when the subject passes directly beneath the camera.

Auto Focus / Auto Iris

SpeedDome Ultra dome units are designed with Auto Focus and Auto Iris capability. When the

AD2089 keyboard is used to control S peedDome Ultra units, focus and iris control can be

performed manually by using the NEAR and FAR keys for focus control, and the OPEN and

CLOSE keys for iris control. After performing manual control, the user can return to auto control

mode by pressing the OPEN and CLOSE keys simultaneously.

Calling Presets (Shots)

A preset is a memorized location or scene that a pan/tilt camera can display on operator d emand.

Presets are also referred to as shots or targets. Depending on the matrix switching system used,

the operator will have the option of calling a certain number of presets, each with its own unique

identification number. Presets are positioned and stored in memory in the Program mode, which

will be discussed in the next chapter. Once they are programmed, presets are called to view in the

Operate mode.

To call a preset:

1 After calling a pan/tilt camera to view (see page 3-2), enter the preset identification number on

the numeric keypad (the preset number appears in the ENTER display).

2 Press the PRESET key to call the preset of the camera under control (the ENTER display

clears). The selected video now appears on the monitor screen with appropriate p an, tilt, zoom,

and focus adjustments.

Note

When the AD2089 is used with a switching system using AD SpeedDomes in conjunction with an

AD2083-02A code translator, the PRESET key can be used for a range of commands beyond the

definition and calling of presets. Consult the AD2083-02A manual for a complete listing of these

commands.

Running System Tours

A tour is a dynamic sequence of camera views, each of which appears on a selected monitor

screen for a specified dwell time, and each of which can have a pre-programmed preset status,

auxiliary status, and connect next designation. System tours are also referred to as universal

tours. System tours are programmed in the Menu mode.

Additionally, there are monitor or "scratch-pad" tours, which are temporary tours programmed for

the operator's currently selected monitor. Scratch-pad tours are set up in the Program mode, and

will be discussed in the next chapter.

To run a system (universal) tour:

1 Enter the appropriate monitor identification number on the numeric keypad (the monitor

number will appear on the ENTER display).

17

Page 26

Using the AD2089 in Operate Mode

2 Press the MONITOR/DVMS key to gain control of the monitor. The monitor number will appear

in the MONITOR/DVMS display. The ENTER display will clear.

3 Enter the system tour number to be associated with the monitor under control. The tour n umber

will appear in the ENTER display.

4 Press the RUN key, and then press the ACK key within three seconds to run the designated

system tour.

Holding a Tour

A tour can be stopped and held on a single camera entry by pressing the HOLD key. While a tour

is on hold, all keyboard control actions (pan, tilt, lens adjustment, and auxiliary on/off functions)

can be performed on the held camera.

Note

When a tour is paused the NEXT and LAST key can be used to step throu gh the cameras views in

forward or reverse order.

Re-Starting a Tour on Hold

To re-start a tour on hold, Press the RUN key.

Changing Tour Direction

To change the direction of a running tour, press the NEXT or LAST key, depending on which is

appropriate in a given situation.

Calling Salvos

A salvo is the simultaneous display of multiple camera scenes on a group of numerically

contiguous monitors. The number of allowable entries in a salvo is dependent on the particular

switching system being used. Each system salvo has a unique identification number that defines

the set of contiguous monitors. Salvos are programmed in the Menu mode or through system

setup software, but are called to workstation monitors in th e Operate mode.

To call a salvo:

1 Enter the identification number of the first (lowest numbered) monitor of the contiguous monitor

group on the numeric keypad. The monitor number will appear in the ENTER display.

2 Press the MONITOR/DVMS key to gain control of the monitor. The monitor number will appear

in the MONITOR/DVMS display. The ENTER display will clear.

3 Enter the salvo identification number on the numeric keypad. The salvo number will appear in

the ENTER display.

4 Press the SALVO key to call the salvo to the monitor group. The ENTER display will clear.

Auxiliary Control

An auxiliary is a relay that switches devices such as lights, door locks, and audible alarms. Such

auxiliary relays are said to be momentary or latched. Either type can be controlled by the AD2089

keyboard using the auxiliary ON and auxiliary OFF keys.

A momentary auxiliary remains active as long as its control key is pressed. An example of

momentary auxiliary action is a door that remains unlocked as long the auxiliary ON key is

pressed. When the key is released, the door returns to its locked state.

18 AD2089 Operator’s Manual

Page 27

Using the AD2089 in Operate Mode

A latched auxiliary remains active until it is deactivated using the appropriate off switch. An

example of a latched auxiliary is a light. When the auxiliary ON key is pressed (and released), the

light is turned on. When the auxiliary OFF key is pressed (and released), the light is turned off.

Acknowledging Alarms

When a monitor is armed for an alarm contact, the video input (camera view) associated with that

alarm contact is displayed on the monitor when the alarm is activated. If the monitor is armed for

manual clearance, any alarm displayed on the monitor can be acknowledged (cleared) by an

AD2089 operator.

To acknowledge (clear) an alarm:

1 Call the monitor that is displaying alarm video.

2 Press the ACK key.

If the monitor is sequencing multiple alarmed video inputs, hold or step to (using the next or last

keys) the appropriate alarmed video input, and press the ACK key to clear the alarm. Continue to

step to and ACK each alarm until all appropriate alarms have been cleared.

Alarm signaling capability will vary depending on which switching system is connected to the

AD2089. Consult your switching system manual to determine the particulars of the alarm interface.

Viewing Satellite Sites

A site is a complete matrix switcher / controller system, providing both local and remote control of

resources in a satellite network. If your workstation supports satellite site switching capabilities, the

SITE key accesses satellite sites.

To gain access to a satellite site:

1 Enter the site number on the numeric keypad. The site number will appear in the ENTER

display.

2 Press the SITE key. Call the appropriate monitor and camera. The site number will appear in

the SITE display . The ENTER display will clear.

3 Call remote site monitors and cameras by the procedures discussed earlier in this chapter (see

page 3-1).

Running Patterns

A pattern is a sequential series of pan, tilt, zoom, and focus commands defined for SpeedDome

series domes. A pattern is programmed in real time, which means that the dome remembers each

pattern segment in the actual time it takes the operator to execute a command. For example, if,

during a pattern sequence, the dome focuses on a door for 30 seconds, the door scene will appear

for 30 seconds when the pattern is called to run. Patterns are set in the Program mode, which is

discussed in the following chapter. Patterns are run in the Operate mode.

Note

Pattern command sequences can vary depending on the switching system and accessorie s used.

Consult the appropriate product manual(s) if necessary.

To run a pattern:

1 Call the camera that the pattern will run on (see page 3-2).

2 Enter the pattern number on the numeric keypad. The pattern number will appear in the

ENTER display.

19

Page 28

Using the AD2089 in Operate Mode

3 Press the PATRN key (P-1, P-2, or P-3 appear in the ENTER display) and then press the RUN

key. The camera will sequence through the pattern movements once.

To repeat a pattern:

1 Follow the procedure described immediately above to run a pattern.

2 After pressing the PATRN key (P-1, P-2, or P-3 appear in the ENTER display), press the ACK

key to repeat the pattern.

To hold a pattern:

1 Follow the procedure to run a pattern.

2 After pressing the PATRN key, press the HOLD key to bring the ca mera or dome to the st ar ting

point of the pattern and hold there.

Running a Macro

A macro is a sequence of keyboard inputs of up to 21 keystrokes, that is executed by typing the

macro’s numeric identifier (up to four digits), and pressing the macro’s designated key. A macro

can be made up of all Monitor mode inputs, all DVMS mode inputs, or a combination of both .

To run a macro:

1 Type the macro’s numeric identifier.

2 Press the macro key (the macro is executed).

Procedures and examples of macro programming are covered in the following chapter.

20 AD2089 Operator’s Manual

Page 29

Using the AD2089 in Operate Mode

Playback Mode Operations (keyswitch in operate position)

Selecting DVRs

To initiate DVR control, the operator performs the following actions:

1 Type a DVR number of up to four digits on the numeric keypad. [####]

2 Press the DVMS key

In Playback mode, a horizontal line segment appears above the PLAYBACK display label

When DVMS mode is selected, the multi-function keys (labeled “auxiliary”, “iris”, “focus”, and

“task”) switch to their DVMS functions (Play, Record, Eject, Pause, Stop, Fast Forward, and

Rewind).

The DVMS number appears in the MONITOR/DVMS display.

3 Select a DVMS function by pressing the appropriate key.

DVMS FUNCTION KEY LABEL

STOP OFF

RECORD ON

PAUSE CLOSE

PLAY OPEN

REWIND NEAR

FAST FORWARD FAR

EJECT ACK

To return to the monitor mode of operation, press the MON key. The switching system will

remember the number of the last DVMS selected prior to toggling the mode.

21

Page 30

Programming with the AD2089

Programming with the AD2089

This chapter provides step-by-step instru ctio ns for keyboard operations performed with the

keyswitch in the PROGRAM position. The chapter also includes a discussion of operations

available with the keyswitch set in the MENU position.

Using the AD2089 in Program Mode

When operating with the keyswitch in the PROGRAM position, you can set presets, scratch-pad

tours, patterns, and macros. You can also arm and disarm monitors.

Setting Presets

To set a pr eset:

1 Call a monitor and camera to the keyboard (see Chapter 3).

2 Turn the three-position keyswitch to the PROGRAM position.

3 Using the joystick, move the camera to the appropriate position. Make the appropriate lens

adjustments.

4 Enter the preset identification number on the numeric keypad (the number appears in the

ENTER display).

5 Press the PRESET key (the ENTER display will clear).

Setting Scratch Pad Tours

To set a scr atc h pad tour:

1 Call a monitor to the keyboard (see Chapter 3).

2 Turn the three-position keyswitch to the PROGRAM position.

3 Enter "62" on the numeric keypad. Press the PROG key to clear any previously programmed

scratch pad tour.

4 Enter the first camera identification number of the tour (the number will appear in the ENTER

display).

5 Press the CAMERA key (the ENTER display will clear).

6 Enter the appropriate dwell time number (1-60) on the numeric keypad (the num ber ap pears in

the ENTER display). Press the PROG key (the ENTER display will clear).

Repeat steps 3 through 6 until all the cameras in the tour have been pr ogrammed.

7 Press the RUN key to run the scratch pad tour.

Programming Patterns

You can program up to three patterns per programmable dome. The length and complexity of a

pattern are limited by two variables:

• number of camera commands

•time

22 AD2089 Operator’s Manual

Page 31

Programming with the AD2089

Each time you move the camera in any direction (with zoom, focus, or iris adjustments), you issue

a command to the camera. The three patterns for a dome can collectively consist of up to 98

camera commands.

There is also a pattern time limit. A single pattern cannot have a duration longer than 400 seconds.

How ever many commands have been issued , a p att ern wi ll stop recording once the time limit has

elapsed.

Note

pattern command sequences can vary depending on the switching system and accessorie s used.

Consult the appropriate product manual( s) if ne cessar y. The following pattern commands may not

be compatible with your particular system requirements.

Defining Patterns

To define a pattern:

1 Turn the three-position keyswitch to the PROGRAM position.

2 Enter the pattern identification number on the numeric keypad (the number will appear in the

ENTER display).

3 Press the PATRN key (the ENTER display will show “P-1”, “P-2”, or “P-3”).

4 Press the PROG key. Using the joystick and lens keys, maneuver the called camera to define

the pattern.

5 Press the ACK key to save the pattern (the ENTER display will clear).

Clearing Patterns

To clear a pattern, overwrite the old pattern with a newly defined pattern. Follow the steps listed in

Defining Patterns, above, to define a new pattern.

Arming a Monitor

When a monitor is armed, the camera video associated with an alarm for that monitor appears

when an alarm has been triggered. To arm a monitor, do the following:

1 Call the monitor to be armed (see Chapter 3).

2 Turn the three-position keyswitch to the PROGRAM position.

3 Enter the arming type identification number on the numeric keypad (the number will appear in

the ENTER display).

Note

For information about arming identification numbers, consult Appendix E in this manual.

4 Press the F2 key. The ENTER key will clear, and the selected monitor screen displays the

arming type code for five seconds.

Disarming a Monitor

When a monitor is disarmed, the camera video from alarms is not displayed when an alarm has

been triggered. To disarm a monitor, do the following:

1 Call the monitor to be disarmed (see Chapter 3).

2 Turn the three-position keyswitch to the PROGRAM position.

3 Press [316], [F2].

23

Page 32

Programming with the AD2089

Programming Macros

There are eight keys on the 2089 keyboard used for macros. A macro performs a sequence of

switching system operations by entering a numeric identifier and pressing a sin gle macro key. The

macro key caps have user-selected labels which identify locations or general functions.

A macro can consist of up to 21 keystrokes. Up to a 1000 different macros can be divided among

the eight keys.

To program a macro:

1 Turn the three-position keyswitch to the PROGRAM position.

2 Enter the number of the macro (range = 1-1000).

Note

Each macro key can have multiple switching sequences and therefore multiple numbers

associated with the key. The maximum number of switching sequences that can be assigned to

the eight macro keys = 1000. Numbering for each key can st art at “1”, but it is not necessary to

assign numbers in exact sequence.

3 Press the macro key to be programmed. The macro number appears in the CAMERA display

and a keystroke counter starting at 21 appears in the MONITOR/DVMS display.

4 Enter the keystrokes that comprise the macro.

5 After entering the macro keystrokes, press the macro key to conclude the pr og ra m m ing

sequence.

Macro Examples

Example 1: [1], [Blackjack] = {1], [0], [0], [0], [CAMERA], [1], [0], [PRESET] [Blackjack].

Example 1 contains eight keystrokes. Pressing “1” on the numeric keypad, and then pressing the

macro key “Blackjack” calls camera 1000 with preset 10 to the currently selected monitor. Bear in

mind, the macro key “Blackjack” is not limited to one macro sequence, nor is it confined to one

particular kind of switching function. See Examples 2 and 3 following.

Example 2: [2], [Blackjack] = [1], [0], [RUN], [ACK], [HOLD],[Blackjack]

Once programmed, selecting “2, Blackjack” calls Tour 10, and holds the tour on its first entry. The

operator can then step through the tour manually by using the NEXT or LAST keys.

Example 3: [3], [Blackjack] = [1], [0], [SALVO], [Blackjack]

Once programmed, selecting “3, Blackjack” calls Salvo 10, which could consist of multiple views of

the same blackjack table, or multiple views of different blackjack tables.

Example 4: [5], [ALT] = [6], [CAM], [10], [PRESET], [ALT]

Once programmed, selecting “5, ALT” calls Camera 6 with Preset 10 to the selected monitor. This

preset provides an alternate view of the same subject that Camera 5 is viewing.

Note

Here is an example where the number of the macro provides a clue as to the camera being

referenced.

Advanced Macro Examples

In the following examples the “0” key is used as a software shortcut. The “0” key defines a numeric

entry as being the value previously displayed within the MONITOR/DVMS or CAMERA display.

Example 1 (“Quick Switch”): [(] = [1], [MON], [0], [CAM], [(]

24 AD2089 Operator’s Manual

Page 33

Programming with the AD2089

Once programmed, entering a camera number and then pressing the [z] macro key, causes the

selected camera to switch to Monitor 1. The symbol “z” represent s a mo nitor and enable s a macro

quick switch. This macro will enable an operator to reduce the number of keystrokes required to

call a camera to a monitor, while also unburdening the operator from having to remember the

number of the monitor that has to be addressed. This application is for operators who consistently

utilize certain monitors at their workstations.

Example 2 (“Quick ACK”):

[10], [ALM] = [1], [0], [MON], [ACK], [0], [MON], [ALM]

Once programmed, selecting [10], [ALM] causes Monitor 10 which is an armed monitor, to be

called. If an alarm was displayed on the monitor , it would then be cleared automatically, and then

the monitor in use prior to the alarm would be re-called. The application of this macro is for

operators working with multiple monitors who want to quickly acknowledge alarms.

Synchronization of Macro Programming

Synchronization is the term used to describe the transfer of macros from o ne keyboard to another.

Thus, if a system includes multiple keyboards, some or all of which are to have the same macr os,

it is only necessary to program the macros once on a single keyboard, and then copy the macros

to the other system keyboards through the synchronization proce ss.

Synchronization is accomplished by using battery backed RAM in the system CPU to temporarily

hold a set of macros. The user then performs a “PUT” or a “GET”. A “PUT” transfers macros from

the programmed keyboard to the system CPU. A “GET” transfers macro s from the CPU to another

keyboard.

To synchronize macros with other AD2089 keyboards, the operator must perform the following

actions:

Keyboard to CPU Transfer

1 Set the keyboard and corresponding AD1024 port to the appropriate baud rate.

2 Initiate the macro transfer from keyboard to CPU by pressing [998], [F2]. The LED display will

show the following message:

3 To proceed with the transfer, press ACK. To cancel the action press CLEAR. Pressing any

other key will generate a beep indicating an invalid keystroke. If ACK is selected, the LED

display will show the following message:

4 The number in the ENTER display indicates the percentage of macros successfully transferred

to the keyboard. The number starts at 0 and increases in increments of 10, up to 100 percent.

With the keyboard set to 9600 baud and connected directly to the CPU, the transfer will take up

to three minutes. With the keyboard set at 1200 baud and connected through a Port Expander

set at 4800 baud, the transfer will take up to 12 minutes. During the transfer, any keystroke will

generate a beep (invalid keystroke). When the transfer is complete (the number “100” appears

in the ENTER display), the ENTER display will then show the following message:

25

Page 34

Programming with the AD2089

After the word “done” appears, pressing any key will remove the word from the LED display.

CPU to Keyboard Transfer

1 Set the receiving keyboard and the CPU to the appropriate baud rates.

2 Initiate the 1024 CPU to keyboard transfer by pressing [999] [F2]. The LED display will show

the following message:

3 To proceed with the transfer, press ACK. To cancel the action press CLEAR. Pressing any

other key will generate a beep indicating an invalid keystroke. If ACK is selected, the LED

display will show the following message:

4 The number in the ENTER display indicates the percentage of macros successfully transferred

to the keyboard. The number starts at 0 and increases in increments of 10, up to 100 percent.

With the keyboard set to 9600 baud and connected directly to the CPU, the transfer will take up

to three minutes. With the keyboard set at 1200 baud and connected through a Port Expander

set at 4800 baud, the transfer will take up to 12 minutes. During the transfer, any keystroke will

generate a beep (invalid keystroke). When the transfer is complete (the number “100” appears

in the ENTER display), the ENTER display will then show the following

After the word “done” appears, pressing any key will remove the word from the LED display.

Deleting Macros