Page 1

ADG-464

Installation/Operator's Manual

WARNING: For your safety the

information in this manual must be

followed to minimize the risk of fire or

explosion or to prevent property damage,

personal injury or death.

Do not store or use gasoline or other flammable

vapor and liquids in the vicinity of this or any

other appliance.

WHAT DO YOU DO IF YOU SMELL GAS

* Do not try to light any appliance.

* Do not touch any electrical switch; do not use

any phone in your building.

* Clear the room, building or area of all

occupants.

* Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

* If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

AVERTISSEMENT: Assurez-vous de bien

suivre les instructions données dans cette

notice pour réduire au minimum le risque

d’incendie ou d’explosion ou pour éviter tout

dommage matériel, toute blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR

DE GAZ:

* Ne pas tenter d’allumer d’appareil.

* Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones se trouvant dans

le bâtiment où vous vous trouvez..

* Évacuez la pièce, le bâtiment ou la zone.

* Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

* Si vous ne pouvez rejoindre le fournisseur

de gaz, appelez le service des incendies.

L’installation et l’entretien doivent être assurés

par un installateur ou un service d’entretien

qualifié ou par le fournisseur de gaz.

081199SL/cms

For replacement parts, contact the reseller from which the dryer

was purchased or

American Dryer Corporation

88 Currant Road

Fall River MA 02720-4781

Telephone: (508) 678-9000 / Fax: (508) 678-9447

E-mail: techsupport@amdry.com

www.amdry.com

ADC Part No. 112193

Page 2

Retain This Manual In A Safe Place For Future Reference

American Dryer Corporation products embody advanced concepts in engineering, design, and safety. If this product is

properly maintained, it will provide many years of safe, efficient, and trouble-free operation.

ONLY qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation manual included with

the dryer.

The following “FOR YOUR SAFETY ” caution must be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors or

liquids in the vicinity of this or

any other appliance.

We have tried to make this manual as complete as possible and hope you will find it useful. ADC reserves the right to make

changes from time to time, without notice or obligation, in prices, specifications, colors, and material, and to change or

discontinue models. The illustrations included in this manual may not depict your particular dryer exactly.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables dans le voisinage de cet

appareil ou de yout autre appareil.

Important

For your convenience, log the following information:

DATE OF PURCHASE________________________________ MODEL NO. __________________________________________

RESELLER’S NAME ________________________________________________________________________________________

Serial Number(s) ________________________________________________________________________________________

ADG-464

________________________________________________________________________________________

________________________________________________________________________________________

Replacement parts can be obtained from your reseller or the ADC factory. When ordering replacement parts from the factory,

you can FAX your order to ADC at (508) 678-9447 or telephone your order directly to the ADC Parts Department at (508)

678-9000. Please specify the dryer model number and serial number in addition to the description and part number, so that

your order is processed accurately and promptly.

“IMPORTANT NOTE TO PURCHASER”

Information must be obtained from your local gas supplier on the instructions

to be followed if the user smells gas. These instructions must be posted in a

prominent location near the dryer.

Page 3

IMPORTANT

YOU MUST DISCONNECT and LOCKOUT THE ELECTRIC SUPPLY and THE STEAM

SUPPLY BEFORE ANY COVERS or GUARDS ARE REMOVED FROM THE

MACHINE TO ALLOW ACCESS FOR CLEANING, ADJUSTING, INSTALLATION,

or TESTING OF ANY EQUIPMENT per OSHA (Occupational Safety and Health

Administration) STANDARDS.

«Attention: Lor des opérations d’entretien

“Caution: Label all wires prior to

disconnection when servicing controls. Wiring

errors can cause improper operation.”

des commandes étiqueter tous fils avant

de les déconnecter. Toute erreur de

câblage peut étre une source de danger et

de panne.»

CAUTION

DRYERS SHOULD NEVER BE LEFT UNATTENDED WHILE IN OPERATION.

WARNING

CHILDREN SHOULD NOT BE ALLOWED TO PLAY ON OR NEAR THE DRYERS.

CHILDREN SHOULD BE SUPERVISED IF NEAR DRYERS IN OPERATION.

FOR YOUR SAFETY

DO NOT DRY MOP HEADS IN THE DRYER.

DO NOT USE DRYER IN THE PRESENCE OF DRY CLEANING FUMES.

WARNING

UNDER NO CIRCUMSTANCES should the door switch or the heat circuit devices

ever be disabled.

Page 4

WARNING

The dryer must never be operated with any of the back guards, outer tops, or service

panels removed. PERSONAL INJURY or FIRE COULD RESULT.

WARNING

DRYER MUST NEVER BE OPERATED WITHOUT THE LINT FILTER (SCREEN) IN

PLACE, EVEN IF AN EXTERNAL LINT COLLECTION SYSTEM IS USED.

IMPORTANT

PLEASE OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or

specified in the installation/operator's manual included with the dryer.

Dryers must not be installed or stored in an area where it will be exposed to water or weather.

The wiring diagram for the dryer is located in the front electrical control box area.

Page 5

Table of Contents

SECTION I

Important Information......................................................................................................................... 3

A. Receiving and Handling ................................................................................................................. 3

B. Safety Precaution .......................................................................................................................... 4

SECTION II

Specifications/Dimensions ................................................................................................................... 6

A. Specification ................................................................................................................................ 6

B. Dimensions .................................................................................................................................. 7

SECTION III

Installation Procedures........................................................................................................................ 8

A. Reassembly of Dryer.................................................................................................................... 8

B. Location Requirement .................................................................................................................11

C. Internal Air, Electrical and Water Connections ............................................................................ 12

D. External Supply Connections ...................................................................................................... 19

E. Electrical Requirements.............................................................................................................. 22

F. Fresh Air Supply Requirements ................................................................................................... 25

SECTION IV

Pre Start-up........................................................................................................................................ 26

A. Preparation for Operation .......................................................................................................... 26

SECTION V

Routine Maintenance ........................................................................................................................ 27

A. Cleaning .................................................................................................................................... 27

SECTION VI

Component System Descriptions ...................................................................................................... 29

A. Tumbler Support and Drive System ............................................................................................ 29

B. Main Air Blower and Heat Reclaimer System ............................................................................. 32

C. Compressed Air System ............................................................................................................ 34

D. Gas Burner and Ignition System.................................................................................................. 37

E. Safety Devices ........................................................................................................................... 46

Page 6

SECTION VII

Service and Parts Information .......................................................................................................... 48

A. Service ....................................................................................................................................... 48

B. Parts ........................................................................................................................................... 48

SECTION VIII

Warranty

Information........................................................................................................................................ 49

A. Returning Warranty Cards .......................................................................................................... 49

B. Parts .......................................................................................................................................... 49

C. Returning Warranty Parts ........................................................................................................... 49

SECTION IX

Troubleshooting ................................................................................................................................. 51

Troubleshooting TOC ..................................................................................................................... 51

Page 7

SECTION I

IMPORTANT INFORMATION

A. RECEIVING and HANDLING

The dryer is shipped in a protective stretch wrap cover with protective cardboard corners and top cover (or

optional box) as a means of preventing damage in transit. Upon delivery, the dryer and packaging, and wooden

skid should be visually inspected for shipping damage. If any damage whatsoever is noticed, inspect further

before delivering carrier leaves.

Dryers damaged in shipment.

1. ALL dryers should be inspected upon receipt and before they are signed for.

2. If there is suspected damage or actual damage, the trucker's receipt should be so noted.

3. If the dryer is damaged beyond repair, it should be refused. Those dryers which were not damaged in a

shipment should be accepted, but the number received and the number refused must be noted on the

receipt.

4. If you determine that the dryer was damaged after the trucker has left your location, you should call the

delivering carrier's freight terminal immediately and file a claim. The freight company considers this

concealed damage. This type of freight claim is very difficult to get paid and becomes extremely difficult

when more than a day or two passes after the freight was delivered. It is your responsibility to file freight

claims. Dryer or parts damaged in transit cannot be claimed under warranty.

5. Freight claims are the responsibility of the consignee, and ALL claims must be filed at the receiving end.

ADC assumes no responsibility for freight claims or damages.

6. If you need assistance in handling the situation, please contact the ADC Traffic Manager at (508) 678-9000.

IMPORTANT : The tumbler section of the dryer must be transported and handled in an upright

position at all times.

3

Page 8

B. SAFETY PRECAUTIONS

WARNING : For your safety, the information in this manual must be followed to minimize the risk of

fire or explosion or to prevent property damage, personal injury, or loss of life.

WARNING : The dryer must never be operated with any of the back guards, outer tops, or

service panels removed. PERSONAL INJURY or FIRE COULD RESULT.

1. DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

2. Purchaser or user should consult the local supplier for proper instructions to be followed in the event the user

smells gas. The instructions should be posted in a prominent location.

3. WHAT TO DO IF YOU SMELL GAS ...

a. DO NOT try to light any appliance.

b. DO NOT touch any electrical switch.

c. DO NOT use any phone in your building.

d. Clear the room, building or area of ALL occupants.

e. Immediately call your gas supplier from a neighbor’s phone. Follow the gas suppliers’s instructions.

f. If you cannot reach your gas supplier, call the fire department.

4. Installation and service must be performed by a qualified installer, service agency or gas supplier.

5. Dryers must be exhausted to the outdoors.

6. Although ADC produces a very versatile machine, there are some articles that, due to fabric composition or

cleaning method, should not be dried in it.

WARNING : Dry only water-washed fabrics. DO NOT dry articles spotted or washed in dry cleaning

solvents, a combustible detergent or “all purpose” cleaner.

EXPLOSION COULD RESULT.

WARNING : DO NOT dry rags or articles coated or contaminated with gasoline, kerosene, oil, paint

or wax.

EXPLOSION COULD RESULT.

WARNING : DO NOT dry mop heads. Contamination by wax or flammable solvents will create a fire

hazard.

WARNING : DO NOT use heat for drying articles that contain plastic, foam, sponge rubber or similarly

textured rubber materials. Drying in a heated basket (tumbler) may damage plastics

or rubber and also may be a fire hazard.

4

Page 9

7. A program should be established for the inspection and cleaning of lint in the burner area, exhaust duct

work, and inside the dryer. The frequency if inspection and cleaning can best be determined from experience

at each location.

WARNING : The collection of lint in the burner area and exhaust duct work can create a potential fire

hazard.

8. For personal safety, the dryer must be electrically grounded in accordance with local codes and/or the

NATIONAL ELECTRIC CODE ANSI/NFPA NO. 70-LATEST EDITION, or in Canada, the CANADIAN

ELECTRICAL CODES PARTS 1 & 2 CSA C22.1-1990 or LATEST EDITION.

NOTE: Failure to do so will VOID THE WARRANTY.

9. UNDER NO CIRCUMSTANCES should the dryer door switches, lint drawer switches, heat safety

circuit, or tilt switches ever be disable.

WARNING: PERSONAL INJURY or FIRE COULD RESULT.

10. This dryer is not to be used in the presence of dry cleaning solvents or fumes.

11. Remove articles from the dryer as soon as the dryer cycle has been completed.

WARNING : Articles left in the dryer after the drying and cooling cycles have been completed can

create a fire hazard.

12. READ and FOLLOW ALL CAUTION and DIRECTION LABELS ATTACHED TO THE DRYER.

WARNING: YOU MUST DISCONNECT and LOCKOUT THE ELECTRICAL SUPPLY and

THE GAS SUPPLY BEFORE ANY COVERS or GUARDS ARE REMOVED

FROM THE MACHINE TO ALLOW ACCESS FOR CLEANING,

ADJUSTING, INSTALLATION OR TESTING OF ANY EQUIPMENT per

OSHA (Occupational Safety and Health Administration) STANDARDS.

The lightening flash with an arrow head within an

equilateral triangle, is intended to alert the user to the

presence of non-insulated “dangerous voltage” within

the products enclosure that may be sufficient in

magnitude to constitute a risk of electrical shock to

any person.

The Exclamation point “!” within an equilateral triangle

is intended to alert the user to the presence of

important operating and maintenance (servicing)

instructions in the literature accompanying the

appliance.

5

Page 10

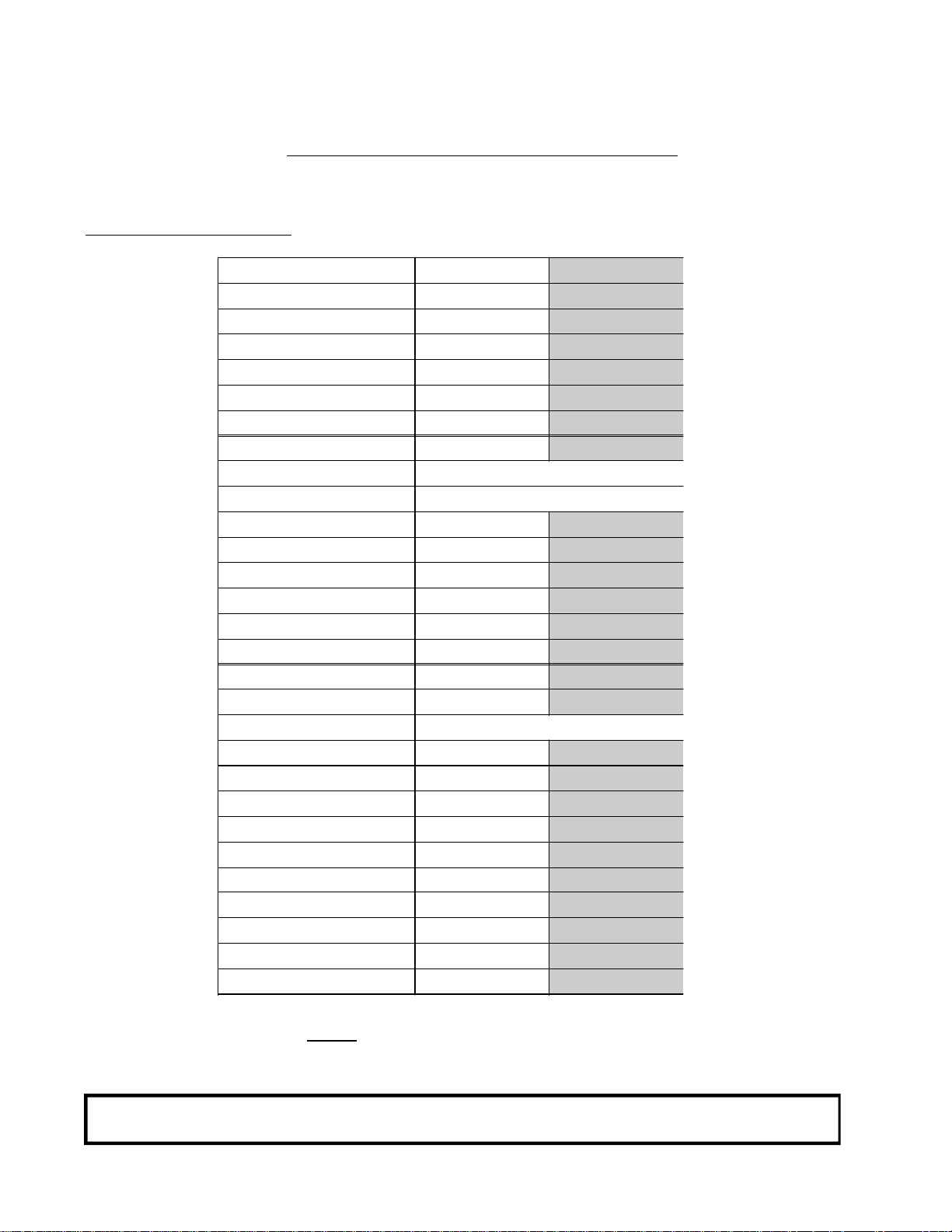

A. SPECIFICATIONS

MAXIMUM CAPACITY (DRY WEIGHT) 460 LBS . 208.66 KG

TOTAL WEIGHT 9,550 LBS. 4,331.8 KG

TOTAL SHIP PING WEIGHT 9,800 LBS. 4,445.21 KG

TILT HEIGHT 137-1/4" 348.6 CM

OPERATING HEIGHT 114-1/2" 290.83 CM

FULL TILT DEPTH 117-1/2" 298.45 CM

OPERATING DEPTH 95" 241.3 CM

WIDTH 122" 309.88 CM

TILT LOAD (REAR TILT) 15°

TILT UNLOAD (FRONT TILT) 15°

UNLOADING HEIGHT FROM FLOOR 43-3/4" 111.12 C M

LOADING HEIGHT FROM FLOOR 65-5/8" 166.69 CM

DOOR OPENING 53-1/4" X 49" 135.26 CM X 124.46 CM

TUMBLER (BASKET) DIAMETER 69-1/8" 175.58 CM

TUMBLER (BASKET) DEPTH 80-5/16" 203.99 CM

TUMBLER (BASKET) VOLUME 175 CU. FT. 4.96 CU. M

MINIMUM LOAD SIZE 250 LBS. 113.4 KG

MAXIMUM LOAD SIZE 460 LBS . 208.66 KG

BURNER TYPE ON/O FF

HEAT INPUT* 2,800,000 BTU/HR. 705,588 KC AL/HR.

BLOWER MOTOR 25 HP 18.64 KW

TUMBLER (BASKET) MOTORS (2) 5 HP (2) 5.6 KW

BURNER BLOWER MOTOR 1-1/2 HP 1.12 KW

BLOWER MAXIMUM AIRFLOW 13,000 CFM 368 C M. M

MAXIMUM DUCT BACK PRESSURE 1.25" (W.C.) 3.1 MBAR

MINIMUM DUCT PRESS URE 24" 60.96 CM

COMPRESS ED AIR PRESSURE REQUIRED 80 PS I (± 10 P SI) 5.63 KG/C M (±.70)

COMPRESS ED AIR VOLUME REQUIRED 20 CF/HR .57 CM/HR

COMPRESS ED CONNECTION 3/8" N.P.T. .95

Shaded areas are stated in metric equivalents.

SECTION II

SPECIFICATIONS/DIMENSIONS

* Gas pressure into the dryer cannot exceed 13” water column (W.C.) -32.34 m bar-. If the gas pressure

is higher than 13” W.C., (32.34 m bar) an external regular must be installed.

NOTE: ADC reserves the right to make changes in specifications at any time, without notice or

obligation.

6

Page 11

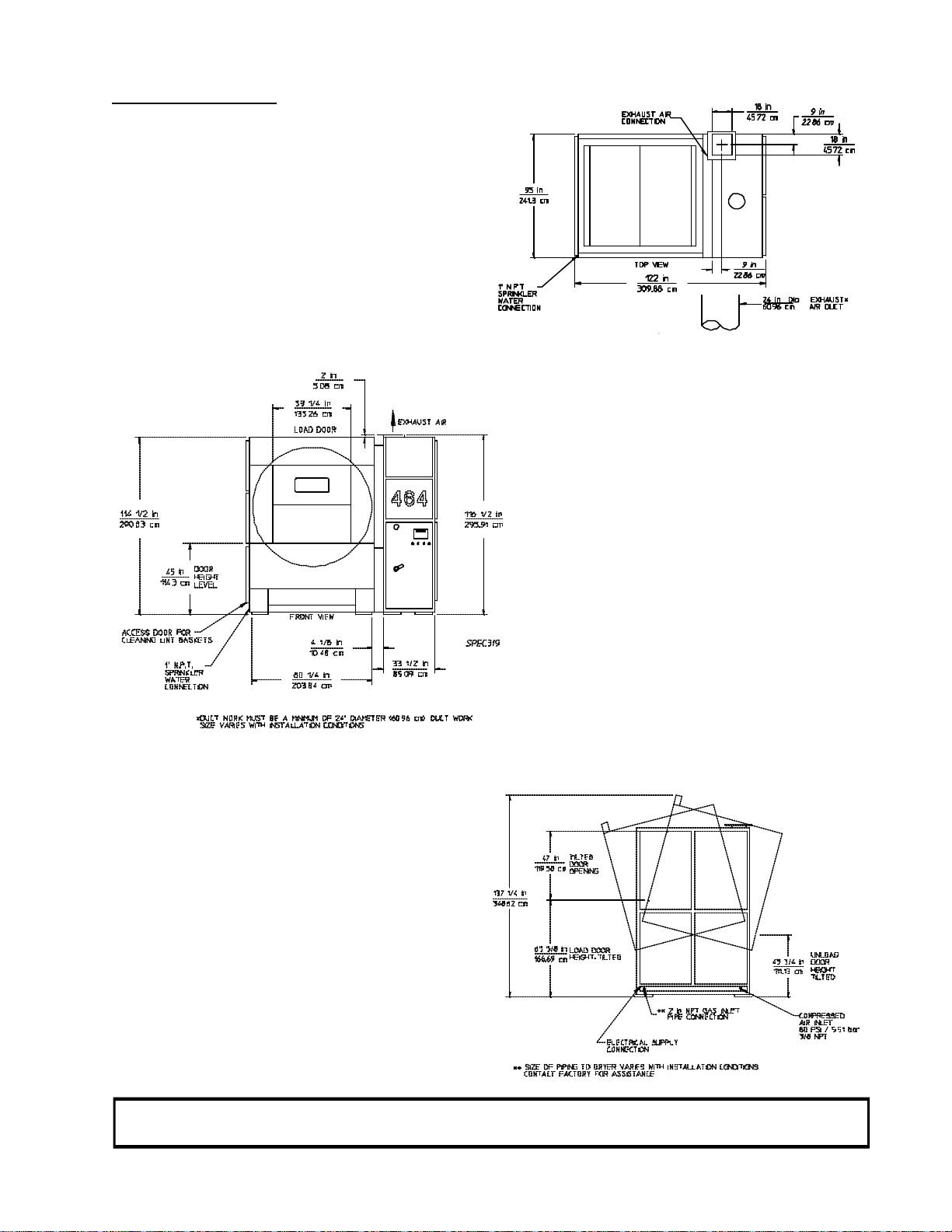

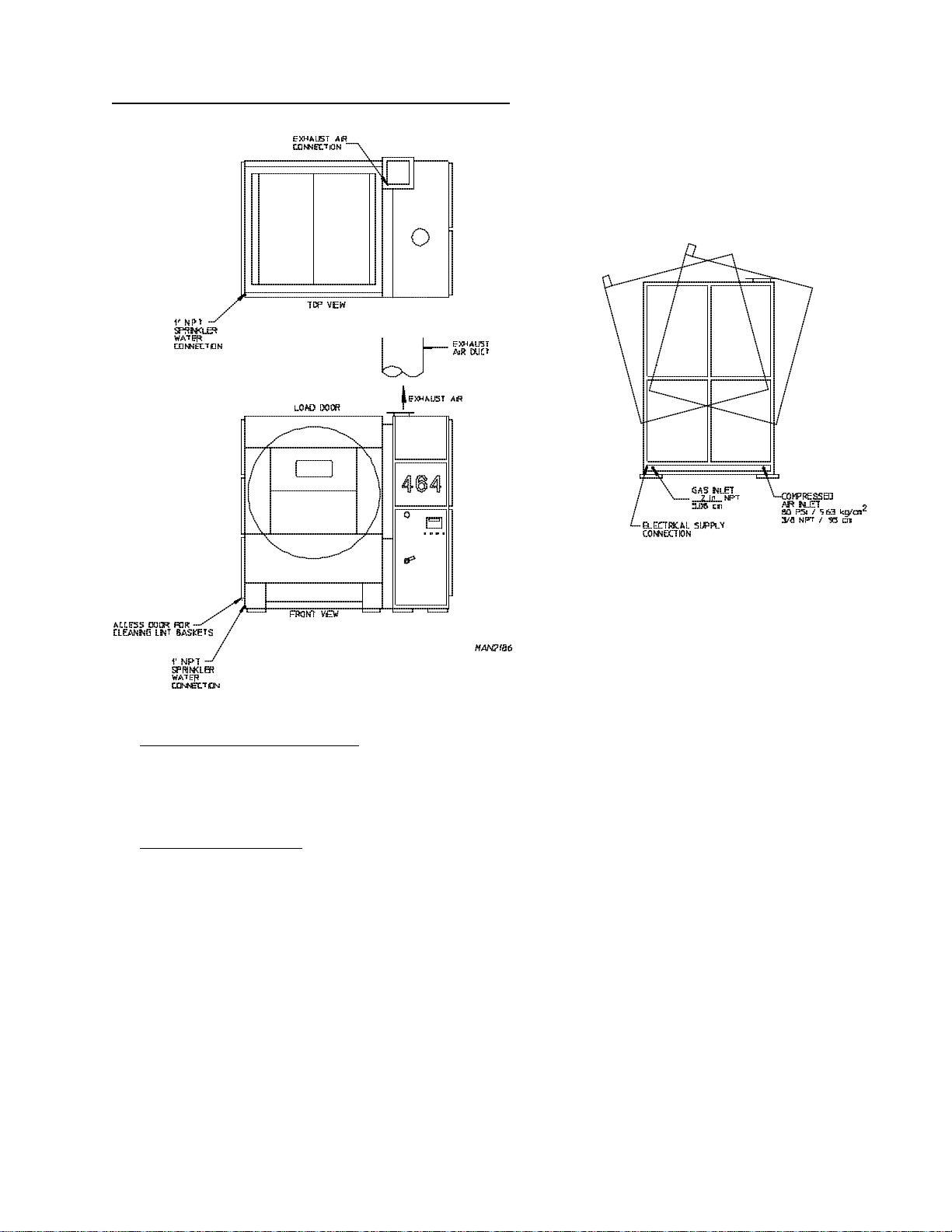

B. DIMENSIONS

NOTE: ADC reserves the right to make changes in specifications at any time, without notice or

obligation.

7

Page 12

SECTION III

INSTALLATION PROCEDURES

Installation should be performed by competent technicians in accordance with local and state codes. In the

absence of these codes, the installation must conform to applicable AMERICAN NATIONAL STANDARDS:

National Fuel Gas Code ANSI.Z223.1-LATEST EDITION or National Electric Code ANSI/NFPA NO. 70LATEST EDITION or in Canada, the installation must conform to applicable Canadian Standards: CAN/CGAB149.1-M91 (Natural Gas) or CAN/CGA-B149.2-M91 (L.P. Gas) or LATEST EDITION (for General

Installation and Gas Plumbing) or Canadian Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST

EDITION (for Electrical Connections)

A. REASSEMBLY OF DRYER

IMPORTANT : Always keep the tumbler (basket) section of the dryer in an upright position when

moving it.

1. Reassembly Instructions for Dryer Shipped in Two (2) Pieces

In this method of shipment, the tumbler section and the tumbler base section are shipped as one unit and the

heat console section is the second.

a. Reassemble Tumbler (Basket) and Tumbler (Basket) Base Section To The Heat Console Section

Move both pieces into position by lifting them with cables through the eyebolts located at the top of each

of the two sections. These pieces may also be moved into place with a fork (lift) truck by lifting the pieces

from underneath. The tumbler and tumbler base section weighs about 6,400 pounds (2,903 kg) and the

heat console section weighs about 4,100 pounds (1,860 kg). Once the sections are in position, the seven

(7) clearance holes on the tumbler (basket) base section (four [4] in the front and three [3] in the rear)

must be aligned with the seven (7) #3/8-16 tapped holes in the heat console section. Use the three (3)

#8-16 x 2” long bolts along with the tapered shims supplied to bolt the two sections together.

b. Reattach The Control Pendant Arm

Position the control pendant arm to the top front of the heat console section by aligning the clearance holes

in the arm with the 1/4-20 tapped holes on the top of the heat console section. Use the 1/4-20 x 3” long

bolts supplied with the machine to attach the arm to the console.

c. Reconnect The Internal Air, Electric Connections, and Water Connections (refer to page 12 through

page 19)

8

Page 13

2. Reassembly Instructions For Dryers Shipped In Three (3) Pieces

When the dryer is shipped in three pieces, the tumbler and the tumbler base sections are shipped as two (2)

separate pieces. The heat console section is shipped as the third piece.

a. Reassemble The Tumbler (Basket) Base Section To The Heat Console Section

Move the heat console section into position by using cables through the eye bolts located at the top of the

section or by using a fork truck and lifting the section from underneath. The tumbler (basket) base section

is now moved into position with a fork (lift) truck. The seven (7) clearance holes located on the right side

of the tumbler (basket) base section (four [4] holes in front and three [3] at the back of the section) must

be aligned with the seven (7) 3/8-16 tapped holes on the left side of the heat console section. Use the

3/8-16 x 3” long bolts and the tapered shims supplied with the unit to bolt the section together.

b. Reassemble The Tumbler (Basket) Section Over The Tumbler (Basket) Base

Slowly lower the tumbler (basket) section over the tumbler base. The four (4) large slots located on the

bottom of the tumbler (basket) section (one slot at each corner of the tumbler [basket] section) must be

aligned with the top of the pistons in the tumbler base section. Use the four (4) 1-1/4-12 x 3-1/2” long bolts

supplied with the unit to secure the tumbler (basket) section to the tumbler (basket) base section.

c. Reattach The Control Pendant Arm

Position the control pendant arm to the top front of the heat console section by aligning the clearance

holes in the arm with the 1/4-20 tapped holes on the top of the heat console section. Use the 1/4-20 x 3”

long bolts supplied with the machine to attach the arm to the console.

d. Reconnect The Internal Air, Electric Connections, and Water Connections (refer to page 12 through

page 19).

3. Reassembly Instructions for Dryer Shipped in Four Pieces

In this method of shipment the tumbler section, tumbler (basket) base, lower heat console, and upper heat

console are ALL shipped as separate sections.

a. Reassemble The Heat Console Section

Apply silicone (provided with unit) to the flanges of the lower heat console section. Lift the upper heat

console section by use of cables through the eyebolts located on the top of the upper console section.

Position the upper heat console over the lower heat console section. Use the 5/16-18 hardware provided

with the machine to secure the sections together.

b. Reassemble The Tumbler (basket) Base Section To The Heat Console Section

Move the heat console section into position by using cables through the eyebolts located at the top of the

section or by using a fork (lift) truck and lifting the section from underneath. The tumbler (basket) base

section is now moved into position with a fork (lift) truck. The seven (7) clearance holes located on the

right side of the tumbler (basket) base section (four [4] holes in the front and the three [3] at the back of

the section) must be aligned with the seven 3/8-16 tapped holes on the left side of the heat console

section. Use the 3/8-16 x 2” long bolts and the tapered shims supplied with the unit to bolt the sections

together.

9

Page 14

c. Reassemble The Tumbler (Basket) Section To The Tumbler (Basket) Base

Lift the tumbler (basket) section with a cable through the eye bolts on top of the section. Slowly lower

the tumbler (basket) section over the tumbler base. The four (4) large slots located on the bottom of the

tumbler (basket) section (one slot at each corner of the tumbler section) must be aligned with the tapped

holes in the cylinder cleaves located at the top of the tumbler (basket) section. Use the four (4)

1-1/4-12 x 3-1/2’ long bolts supplied with the unit to secure the tumbler (basket) section to the tumbler

(basket) base section.

d. Reattach The Control Pendant Arm

Position the control pendant arm on the top front of the heat console section by aligning the clearance

holes in the arm over the 1/4-20 taped holes in the top of the heat console section. Use the 1/4-20 x 3”

long bolts supplied with the unit to attach the arm to the console.

e. Reconnect The Internal Air, Electric Connections, and Water Connections (refer to page 12 through

page 19).

10

Page 15

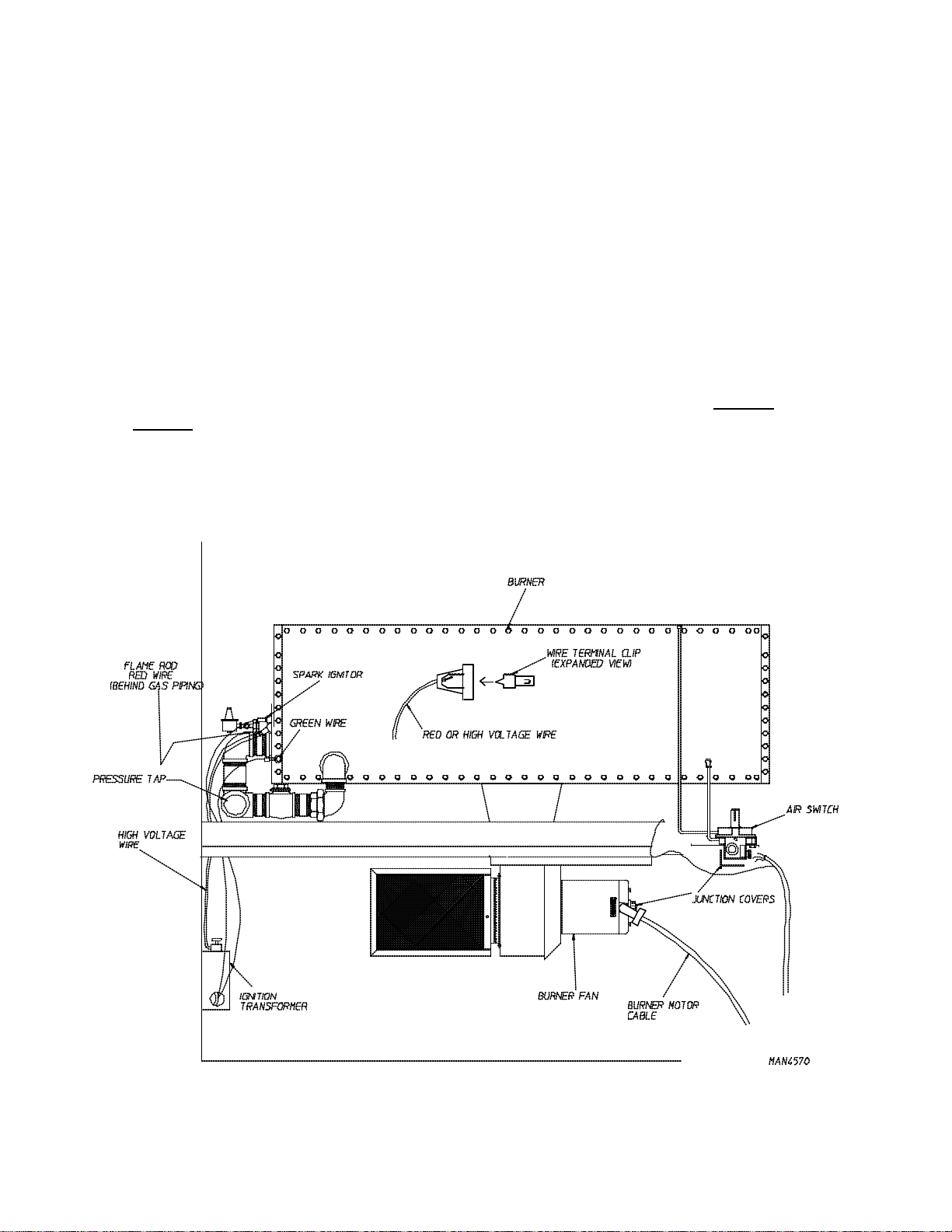

B. LOCATION REQUIREMENTS

The model ADG-464 dryer requires 36-inches (91.44 cm) of space on each side of the dryer and 36-inches

(91.44 cm) of space behind the unit for ease of maintenance and tilting. The dryer must be leveled for proper

operation. If shimming is required, put (24.13 cm) 9-1/2” x 9-1/2” (24.13 cm) metal shims under the base feet.

The dryer must be lagged to the floor.

IMPORTANT: Dryer should be located where a minimum amount of exhaust duct will be necessary.

1. The dryer must be installed with a proper exhaust duct connecton to the outside.

2. The dryer must be installed with provisions for adequate combustion and make-up air supply.

CAUTION: This dryer produces combustible lint and must be exhausted to the outdoors. Every 6

months, inspect the exhaust ducting and remove any lint build up.

11

Page 16

C. INTERNAL AIR, ELECTRIC and WATER CONNECTIONS

1. Air

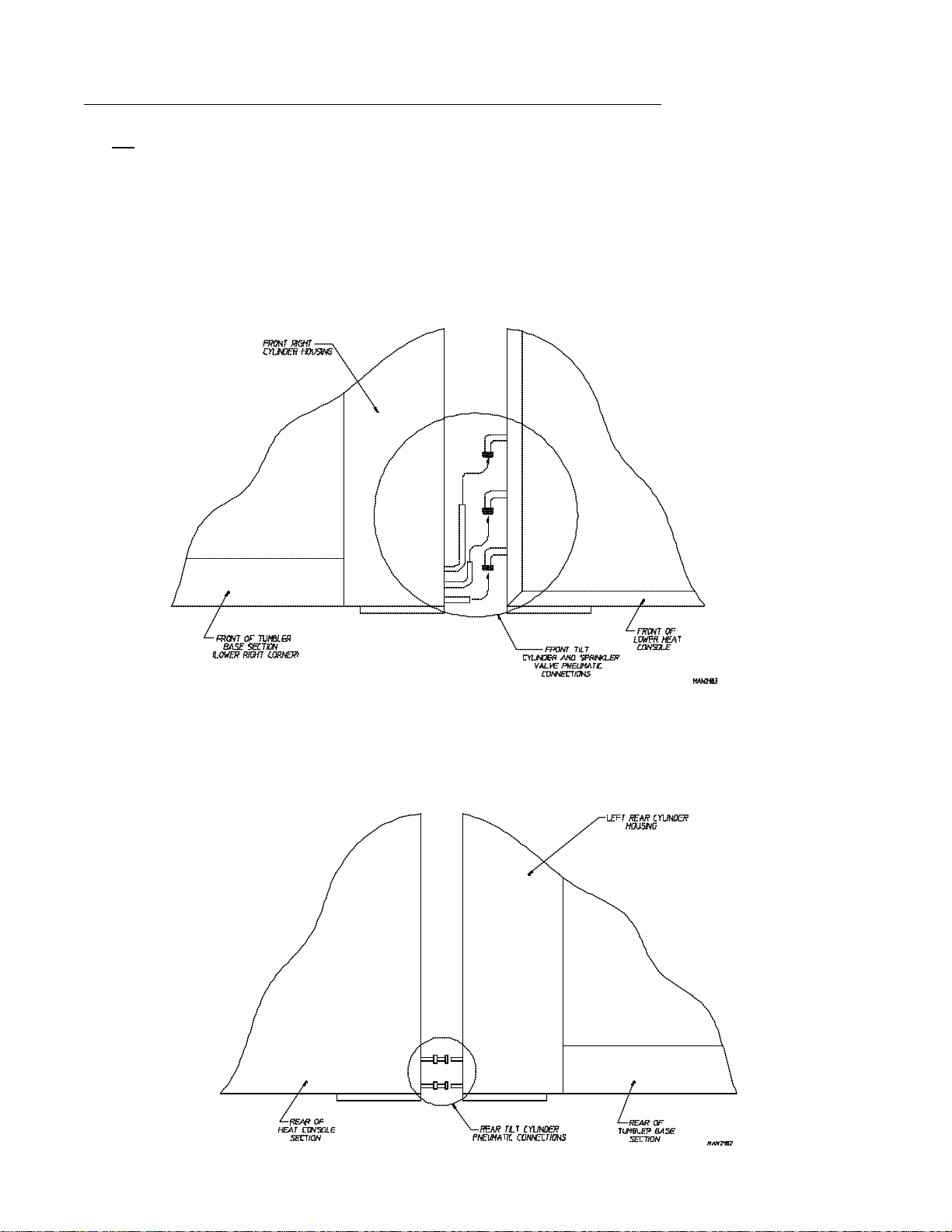

a. Front Tilt Piston and Sprinkler lines

This connection is made at the front of the dryer in the area between the lower heat console section and

the tumbler (basket) base section. To connect the sprinkler air line insert the 1/4” aluminum tubing into the

1/4” brass compression fitting and tighten the fitting nut. To connect the 3/8” poly-flo tubing to the

corresponding brass fittings, match the marked number on the tube with the number on the brass fitting.

After inserting the corresponding tubes into the brass fittings. Tighten the brass fitting nuts.

b. Rear Tilt Piston Lines

This connection is made at the rear of the dryer in the space between the lower heat console section and

the tumbler (basket) base section. Insert the 3/8” poly-flo tube coming from the tumbler (basket) base

section to the 3/8” brass fitting marked with the corresponding number. Do the same to the second tube

and brass fitting. Tighten the brass fitting nuts.

12

Page 17

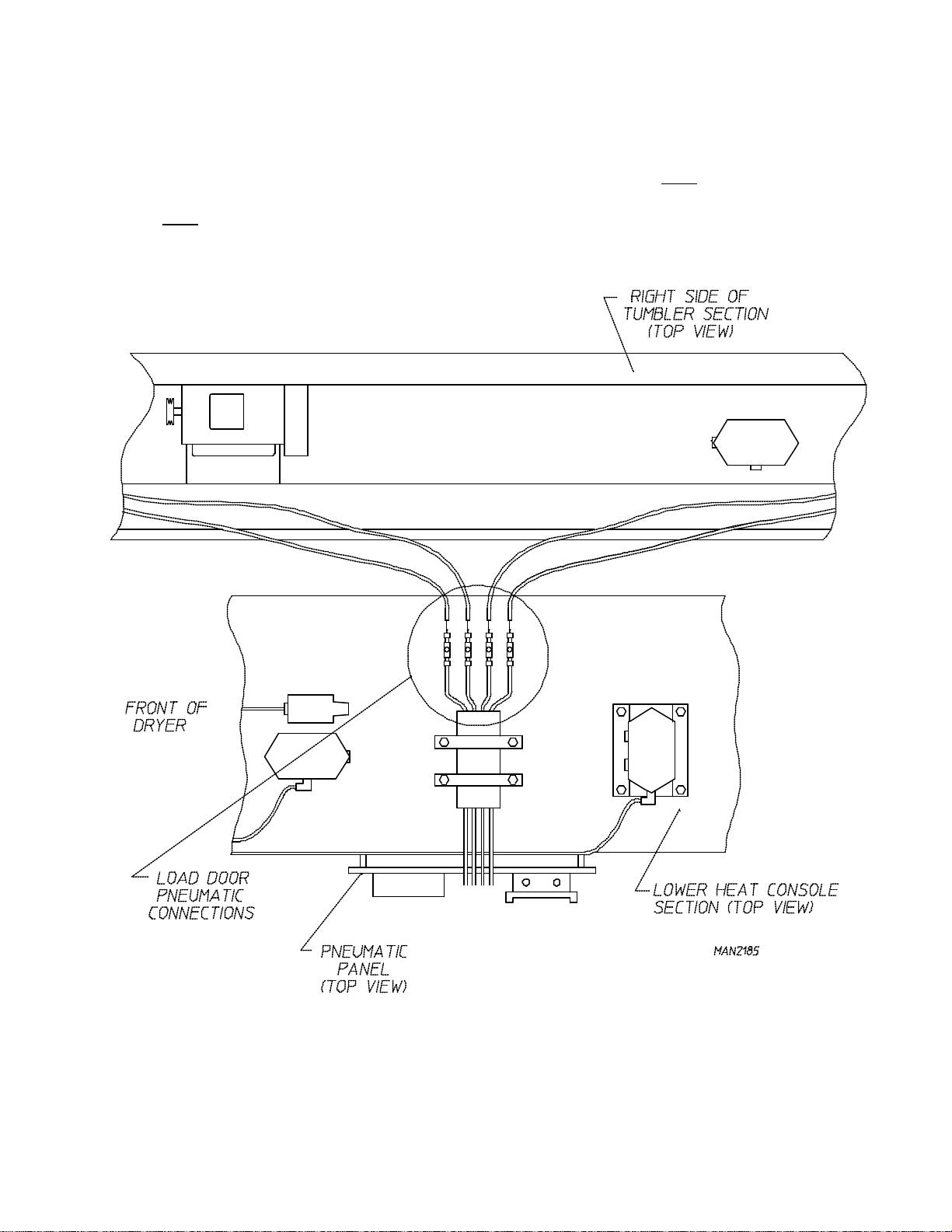

c. Load Door Piston Lines

The load door cylinder pneumatic connections are made in the lower heat console section, in the area

behind the pneumatic panel. To connect the 1/4” poly-flo tubing into the corresponding needle valves,

match the number on the line with the number on the needle valve. Insert ALL of the tubing (two [2] on

a 1-Door model, four [4] on a 2-Door model) into their corresponding valves. Give a moderate pull on

ALL of the air lines to make sure that the connection are complete.

13

Page 18

2. Electric

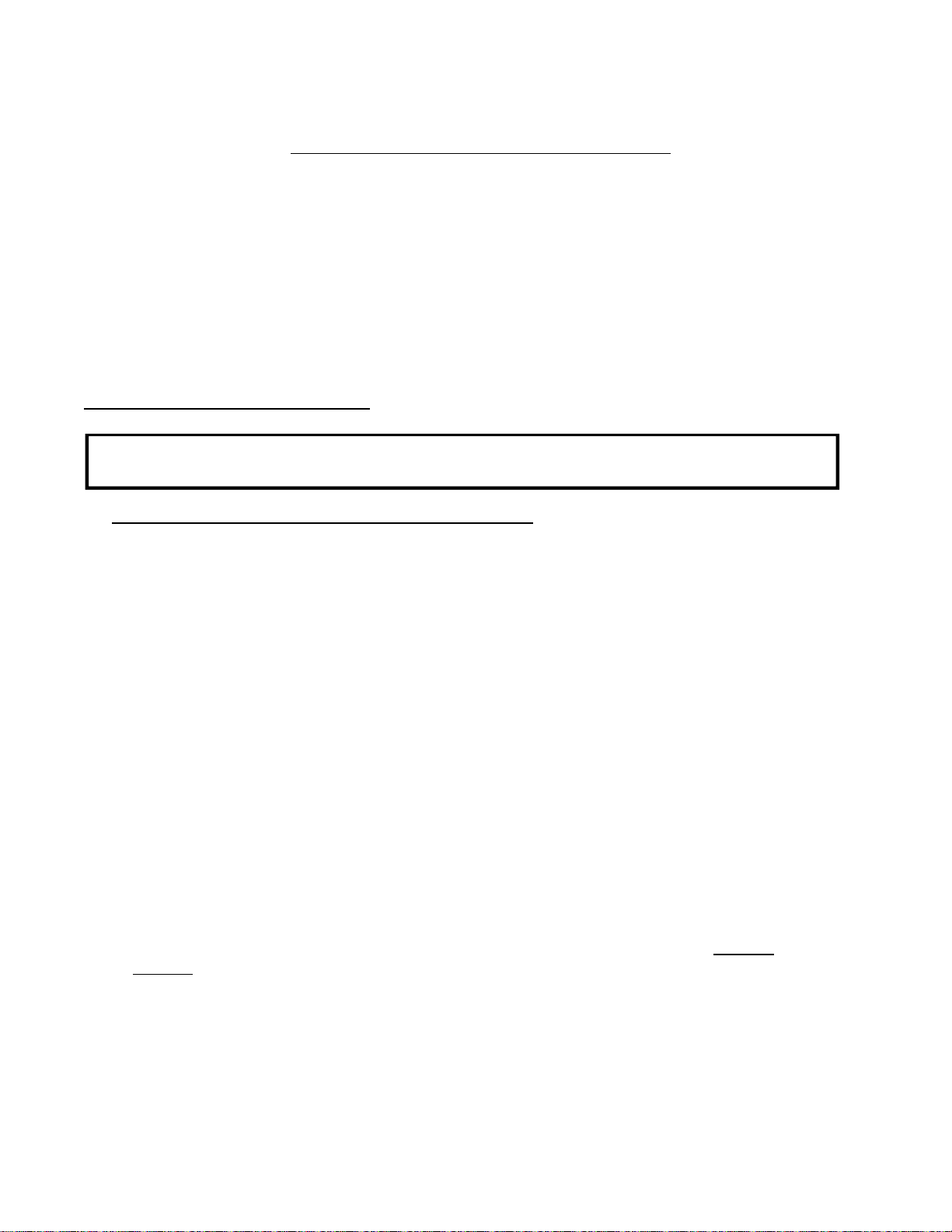

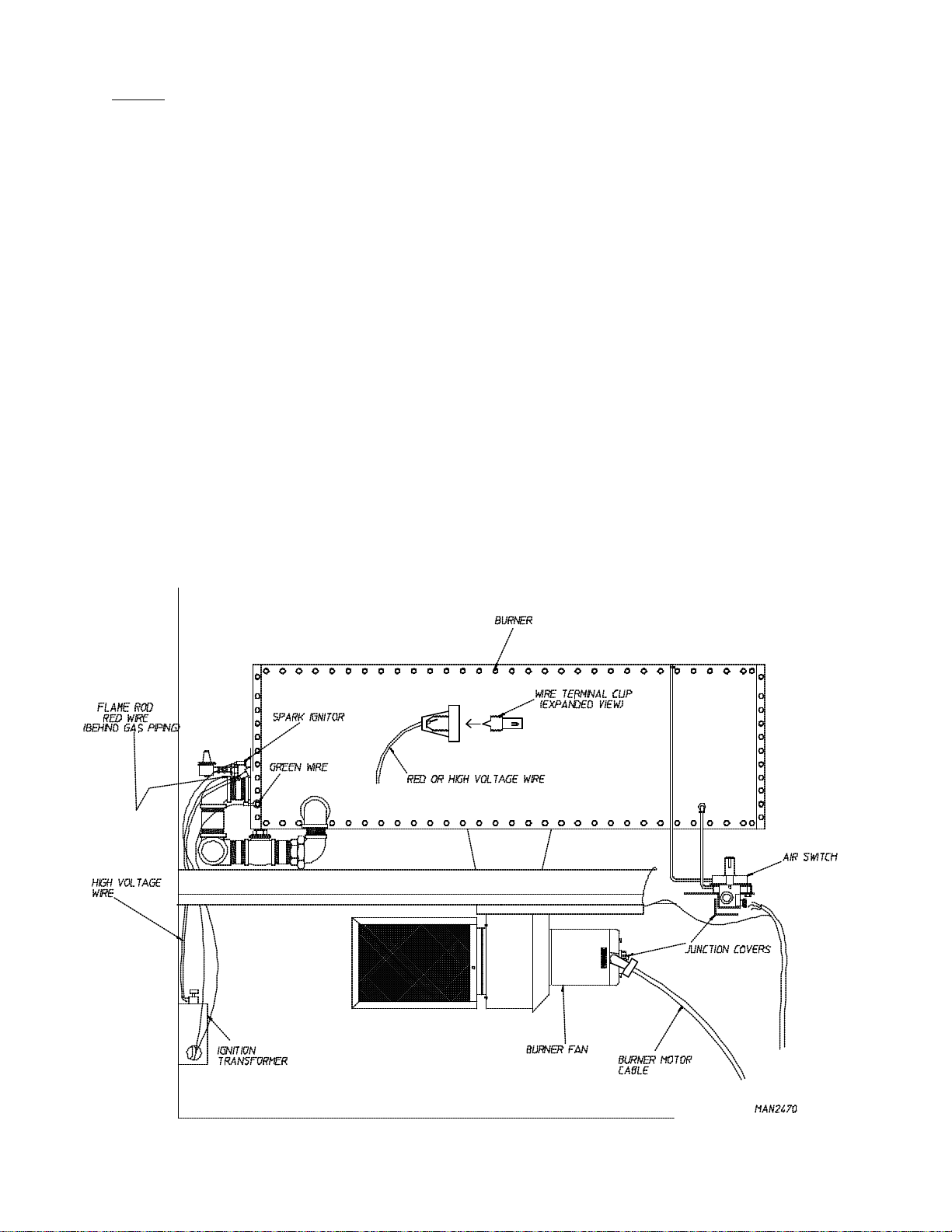

a. Burner Switch and Air Switch

These connections are made between the upper heat module and the lower heat module section. To

connect the burner, there are three (3) wires that come from the ignition transformer through (2) holes on

the bottom of the upper heat module. The green and red wires are fed through the hole closest to the

doors and the high voltage wire gets put through the hole nearest the tumbler. The green wire has a ring

terminal that gets mounted to the burner assembly. The red and high voltage wires need to have the

provided connectors installed on the ends of the wires. Take stripped end of the wire and put it through the

end of the black cap, then, tighten the metal end clip. The red wire goes on the flame probe behind the

pilot line and the high voltage wire goes on the spark plug (spark plug closest to the front).

b. Burner Fan

The burner fan connections are made in the back of the burner fan motor. Remove the two (2) screws

that hold the cover to the junction box of the motor. The burner fan cable with the four (4) conductors in

it can be found next to the heat reclaimer piston. Connect the 90° end connector of the cable to the motor

junction box with the lock nut. After the cable is mechanically fastened to the motor begin to connect the

wires with the same color tape identifiers together. (CAUTION: There may be more than two [2]

connections at one junction) with wire and PVC electrical tape.

The green wire is ground and gets connected to the ground lug in the motor. Replace the two (2) screws

and the cover for the burner motor junction area.

14

Page 19

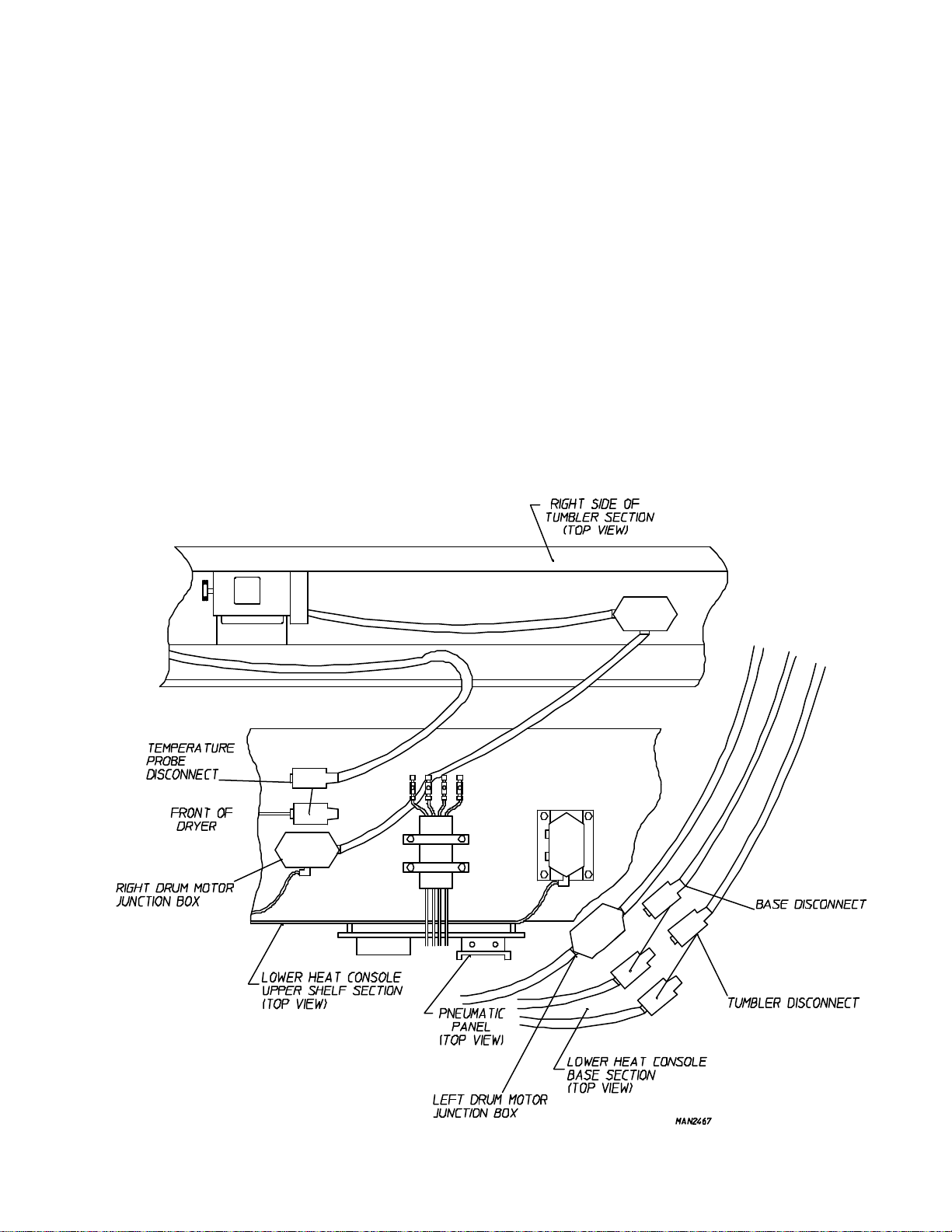

c. Tumbler (Basket) Motors

The disconnects for the two (2) tumbler (basket) motors are located in the lower heat console. The right

drum (tumbler/basket) motor disconnect is located in the lower heat console on the upper shelf towards

the left. The left drum (tumbler/basket) motor disconnect is located in the base of the lower heat console

to the right. On both cables the mechanical connections should be made to the respective junction box.

Remove the two (2) screws that hold down the cover of each junction box. Insert cable end in the junction

box and fasten with lock nut. Then begin to connect the four (4) wires with the same color tape identifiers

together with the four (4) wires already in the junction box. Make these connections with wire nuts and

PVC electrical tape. Replace the cover and the cover (2) screws that hold down the cover to the junction

box.

d. Temperature Probe, Base, and Tumbler (Basket) Disconnects

The disconnects are located in the lower heat console. The temperature probe disconnect is located on

the upper shelf towards the left. The base disconnect and the tumbler (basket) disconnect are located on

the base towards the right. Check identifying tapes to ensure proper assignments of connectors to the

proper base. Check for proper keying and connect disconnect to the proper base. Engage hold downs on

base and verify that the clamps are properly locked.

15

Page 20

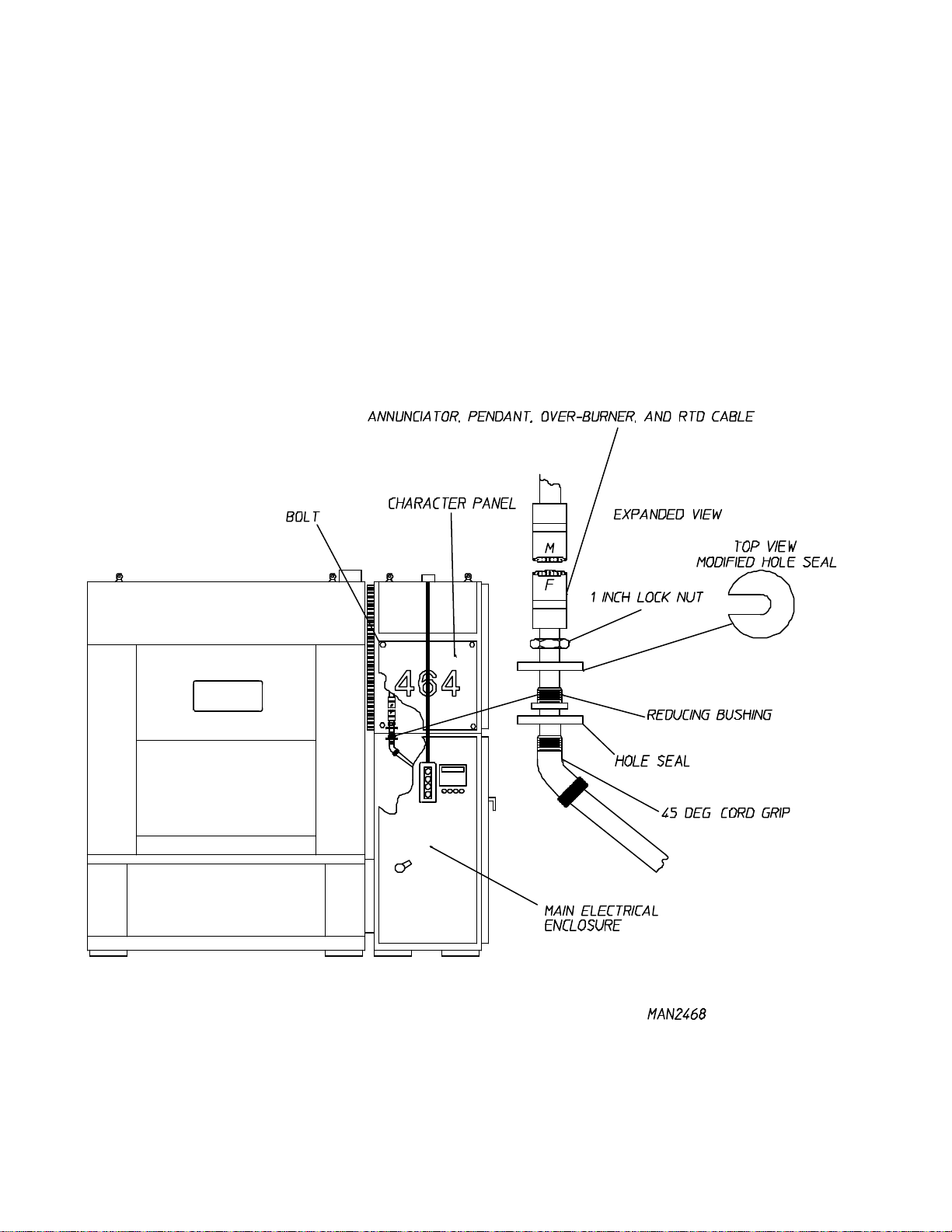

e. Annunciator, Pendent, Over-Burner, and RTD (Resistive Temperature Device) Cable

Remove the four (4) bolts that hold on the character (464) panel. Open the door to the main electrical

enclosure, the female end of the RTD (Resistance Temperature Device) cable will be found there. Loosen

the 1-inch lock nut and remove the modified hole seal. Put the female end of the RTD cable through the

hole in the top of the electrical enclosure. Connect the male end and the female end of the RTD cable

together, pull the cable up until the threads of the reducing bushing can be seen through the hole into where

the character (464) panel was. Next, get the 1-inch lock nut on by a few threads, slip the modified hole

seal under the lock nut holding the 45° cord grip connector, then tighten the 1-inch lock nut. Replace the

character (464) panel and tighten the four (4) bolts.

16

Page 21

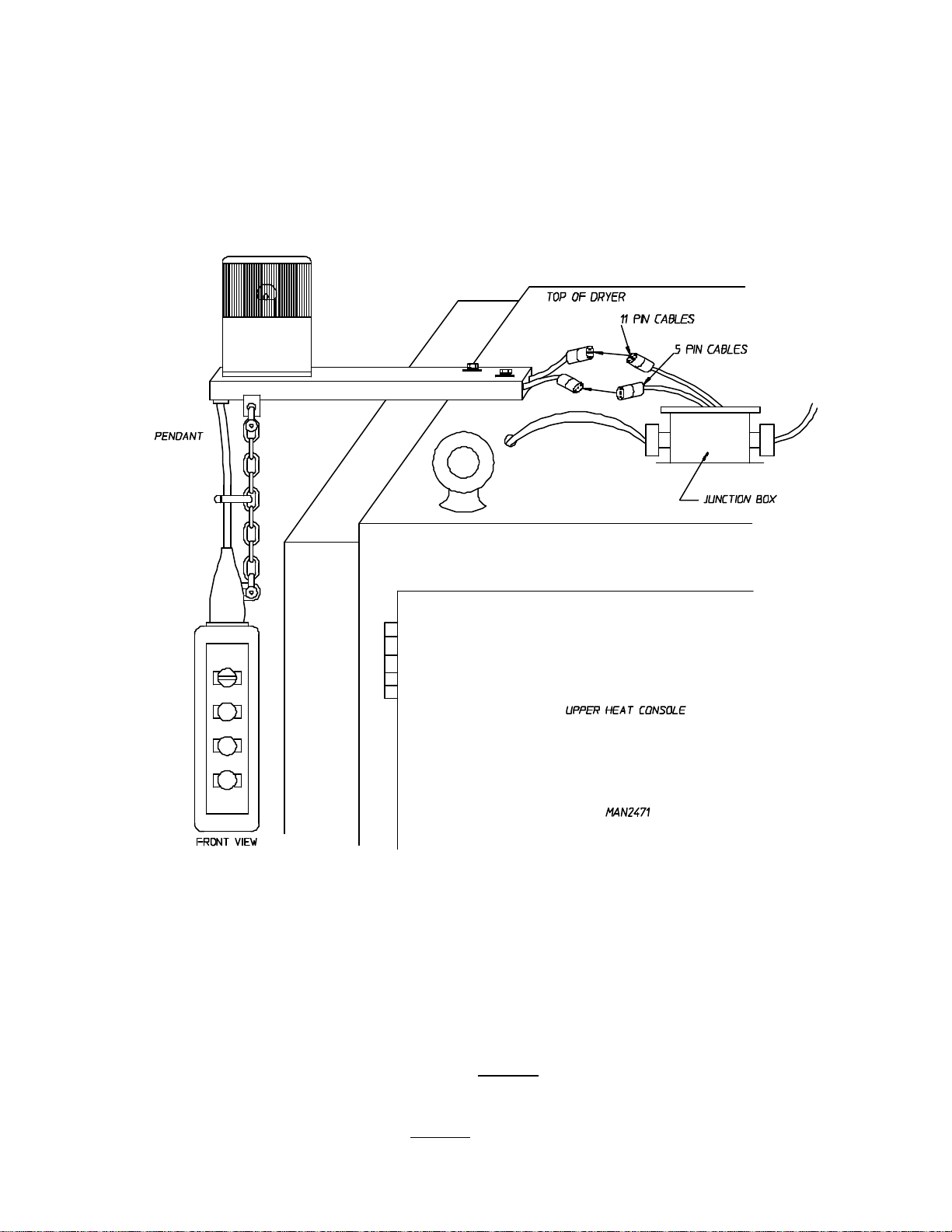

d. Pendent

On the top of the heat console section of the dryer near the pendent, there is a junction box with four (4)

cables coming out of it. Two (2) of the cables from the junction box have connectors on the end, a 5-pin

connector and an 11-pin connector. Coming out of the pendent should be two (2) cables, one with a 5pin connector and the other with an 11-pin connector. Match up the four (4) cables into assigned pairs,

check keying and connect the male and female connection together.

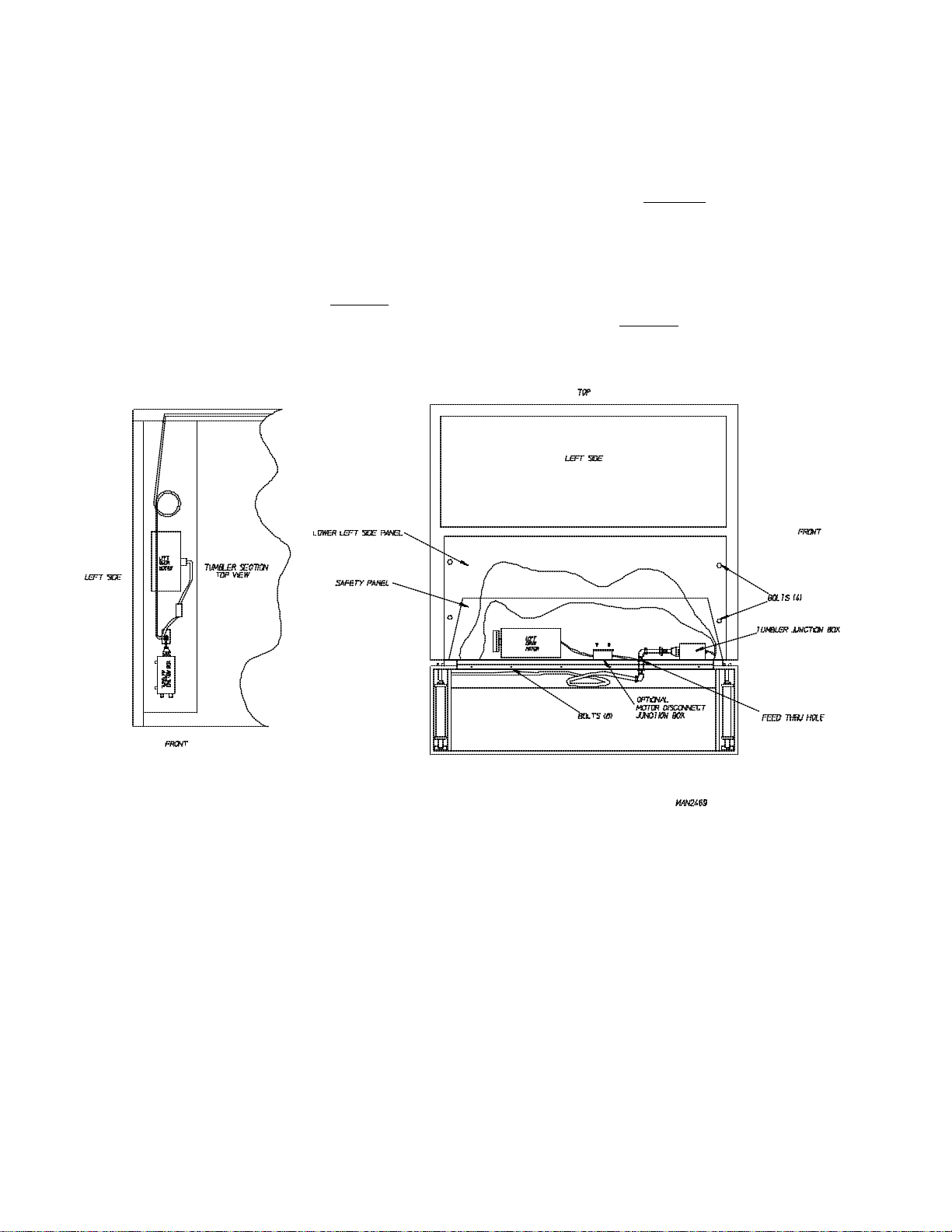

e. Tumbler Junction Box Disconnect

Remove the four (4) bolts that hold on the lower left side panel, then remove the panel. The safety panel

is next to be removed. This is done by removing the six (6) bolts on the bottom of the safety panel where

the tumbler (basket) section and the base meet. Reach into the feed through hole in the base of the

tumbler (basket) section, there will be two (2) cables there. Pull both cables through the hole into the

tumbler (basket) section. The cable with the connector on the end is for the tumbler (basket) junction

box, the other cable is for the left drum motor. Leave that cable in the tumbler (basket) section (it will be

covered in Section f [Left Drum Motor] on page 18). Check keying between the plug and tumbler

(basket) junction box. Insert plug into connector on the junction box and engage locking clasps. Leave

the lower left side panel and the safety panel off the machine until left drum motor is reconnected (refer

to Section f [Left Drum Motor] on page 18).

17

Page 22

f. Left Drum Motor

There are two (2) different ways that the left drum motor is connected with or without the motor

disconnect junction box. The junction box is used when the connections to the left motor are made on the

back side of the motor, nearest to the tumbler (basket). When connecting the motor, bring the left drum

motor cable (refer to Section e [Tumbler Junction Box Disconnect] on page 17) and mechanically

connect it to the junction box on the motor or the external junction box with the lock nut. There will be four

(4) wires in the cable, match them with the PVC electrical tape. There should be one (1) green wire

remaining, which is used for the ground connection. Replace the screws that go on the cover of the

junction box. Bolt the safety panel back in place using the six (6) bolts removed in Section e (Tumbler

Junction Box Disconnect) on page 17, then bolt the lower left side panel back in to place using the four (4)

bolts also removed in Section e (Tumbler Junction Box Disconnect) on page 17.

18

Page 23

D. EXTERNAL SUPPLY CONNECTIONS

1. Optional Sprinkler Water Supply

A 40 PSI (2.75 bar) supply of water must be connected into the 1” N.P.T. sprinkler connection located on

the left side of the tumbler (basket) base on dryer models with a sprinkler system.

2. Compressed Air Supply

A minimum of 20 cubic feet per hour (cfh) (.566 cu. m./hr) at 80 PSI (5.51 bar) of dry, clean and regulated

compressed air must be supplied to the dryer.

The compressed air supply must be connected into the 3/8” F.P.T. fitting which is located in the rear corner

of the lower heat console section.

19

Page 24

3. Gas Piping

The gas connection to the dryer is made into the 2-inch F.P.T. shut-off valve located in the bottom front

corner of the lower heat console.

The gas pressure supplied to the dryer must be between 7-inches (17.41 m bar) and 13-inches (32.34 m

bar) water column (W.C.) for natural gas or between 10.5-inches (26.12 m bar) water column (W.C.) for

L.P. (liquid propane) gas.

If the facilities gas pressure is higher than these values, an external pressure regulator must be installed

prior to the dryer to reduce the gas pressure to within the appropriate range.

The dryer must be connected to either natural or L.P. (liquid propane) gas indicated on the dryer data label

located on the inner right wall of the electric cabinet. If your gas supply does not match the type of gas for

which the dryer was built, contact your distributor or the ADC factory.

1. The installation must conform with local codes or, in the absence of these local codes, with the National

Fuel Gas Code, ANSI Z223.1 or the CAN.CGA-B149, Installation Codes.

2. The dryer and it’s individual shutoff valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa.)

Pipe joint compounds that resist the action of natural and L.P. (liquid propane) gas must be used.

Test ALL pipe connections for leaks by brushing on a soapy water solution.

WARNING: NEVER TEST FOR LEAKS WITH A FLAME!!!

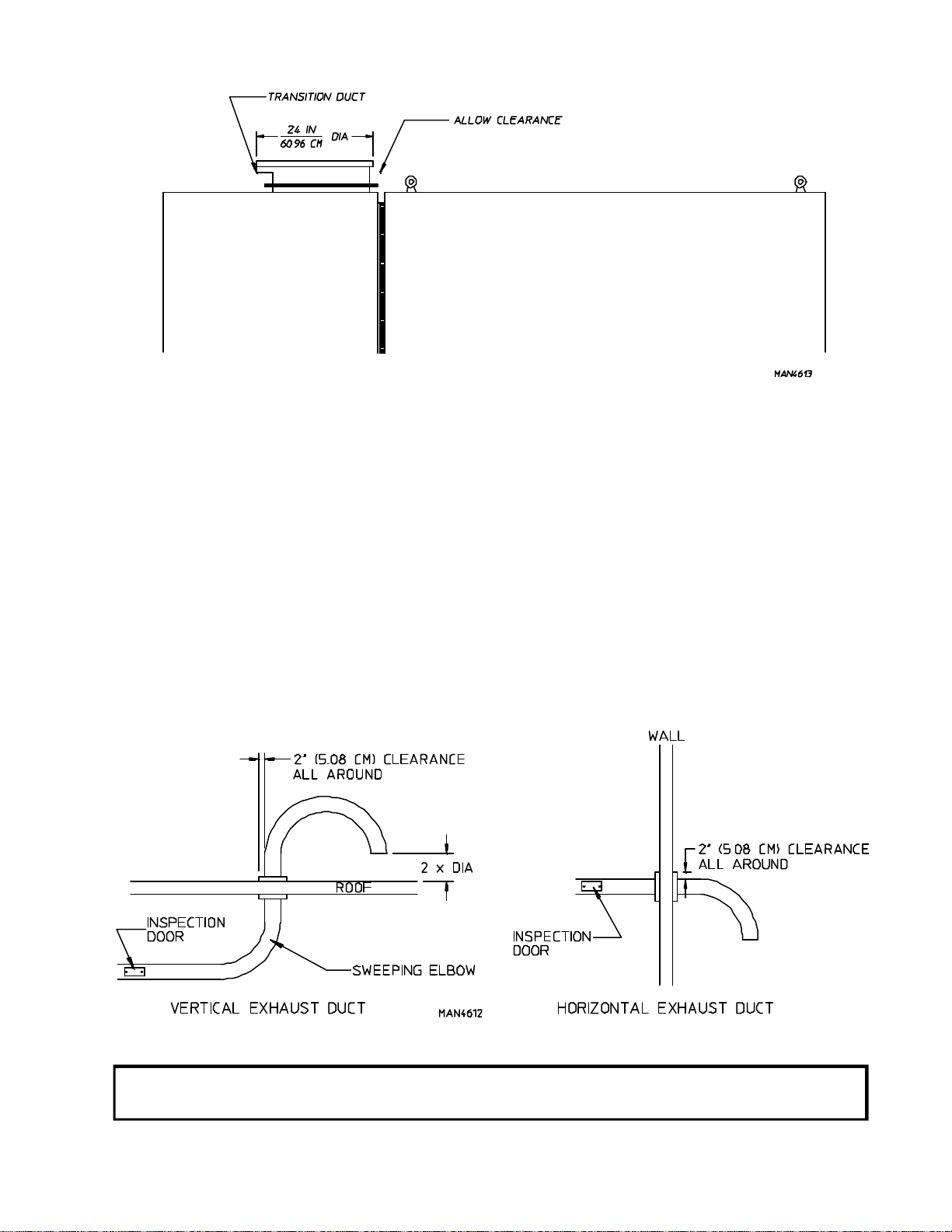

4. Exhaust Air Ducting

The dryer’s exhaust air must be vented to the outdoors by the shortest route possible with the number of

elbows kept to a minimum. The duct should be designed and installed by qualified technicians.

Improperly designed duct work reduce the airflow through the dryer, causing improper and unsafe drying

conditions. The static pressure of the air in the duct work must not exceed 1.25-inch water column

(3.1 millibar). The dryer exhaust 11,600 cfm (cubic feet per minute) - 328.5 cmm (cubic meters per

minute) - of air during the drying cycle, 13,000 cfm (cubic feet per minute) - 368 (cubic meters per minute) during cool down. Ducting must be sized for the 13,000 cfm 368 cmm (cubic feet per minute) of airflow.

The exhaust vent connection is located on top of the burner and heater section of the dryer. It has rectangle

cross-section and is flanged.

A sheet metal transition piece is supplied to connect a 24-inch (60.96 cm) diameter exhaust duct to the

dryers’ exhaust vent connection. Care must be taken in locating this transition piece so that the tilting

tumbler (basket) does not hit the transition piece.

The duct wire connecting the vent to the outdoors must be a minimum of 24-inches (60.96 cm) in diameter

for a round duct or 625 square inches (15.87 square meters) for a rectangular duct (22-inches by 22-inches

square duct [55.88 cm x 55.88 cm] would be sufficient).

20

Page 25

The duct work must be smooth on the inside with no projections from sheet metal screws or other

obstructions which would collect lint. Inspection doors must be installed at strategic points in the duct work

for periodic lint removal.

Use smooth sweeping elbows instead of sharp 90º elbows. The radius of an elbow should be at least

1-1/2 times the duct diameter.

When the exhaust duct goes through a combustible wall on a roof, leave a 2-inch (5.08 cm) clearance space

between the exhaust ducting and the wall or roof.

When adding ducts, the duct that leaves the building must be protected from the weather. For horizontal

ducting use a 90º turned downward . For vertical duct work use a 180º turned downward. In either case,

allow at least twice the diameter of the duct between the duct opening and nearest obstruction. (If the duct

is rectangular, leave twice the smallest face dimension.)

IMPORTANT : DO NOT use screen or caps on the outside opening of the exhaust duct work.

Screens will clog with lint and caps will restrict the exhaust airflow.

21

Page 26

E. ELECTRICAL REQUIREMENTS

1. Electrical Requirements

It is your responsibility to have ALL electrical connections made by a properly licensed and competent

electrician to assure that the electrical installation is adequate and conforms with local and state regulations

or codes. In the absence of such codes, ALL electric connections, materials and workmanship must

confirm to the applicable requirements of the National Electrical Code ANSI/NFPA NO. 70-LATEST

EDITION or in Canada, the CANADIAN ELECTRICAL CODES PARTS 1 & 2 CSA C22.1-1990 or

LATEST EDITION.

IMPORTANT : Failure to comply with these codes or ordinances or requirements stipulated in this

manual can result in personal injury or component failure.

NOTE: Component failure due to improper installation will VOID THE WARRANTY.

Each dryer should be connected to an independently protected branch circuit. The dryer must be

connected with copper wire ONLY. DO NOT use aluminum wire which could cause a fire hazard.

The copper conductor wire or cable must be of proper ampacity and insulation in accordance with electric

codes for making ALL service connects

NOTE: The use of aluminum wire will VOID THE WARRANTY.

22

Page 27

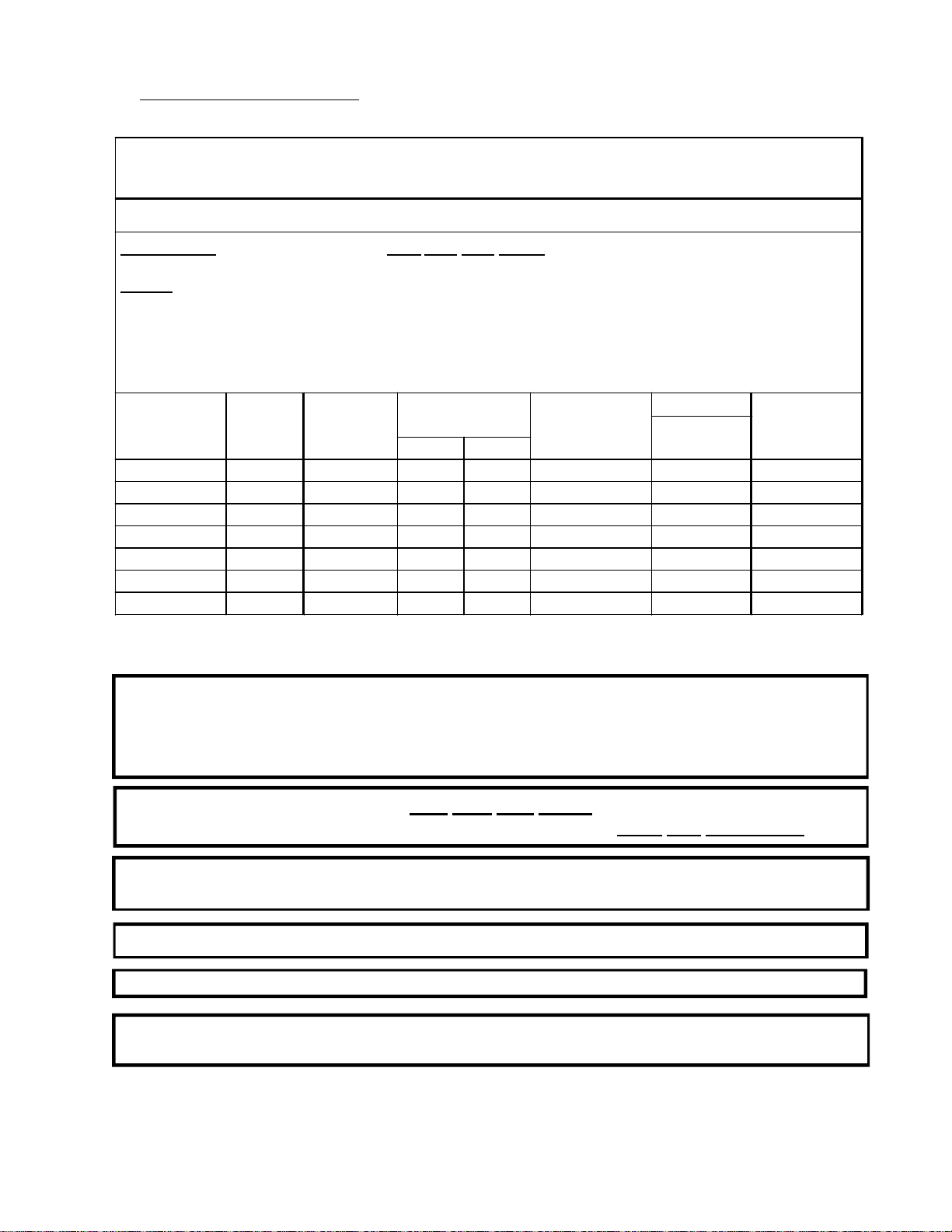

2. Electrical Service Specifications

ELECTRICAL SERVICE SPECIFICATIONS (PER DRYER)

ADG-464

IMPORTANT:

NOTES: A.

B.

C.

SERVICE

VOLTAGE

208

240 3Ø 3 104 109

380 3Ø 3/4 -- 60

400 3Ø 3/4 -- 60

416 3Ø 3/4 -- 57

460 3Ø 3/4 52 --

480 3Ø 3/4 52 --

* AWG Stranded Wire Type...size wire as per National Electrical Code or local codes.

208 VAC AND 240 VAC ARE NOT THE SAME. When ordering, specify exact voltage.

When fuses are used they must be dual element, time delay, current limiting, class RK1 or RK5 ONLY.

Calculate/determine correct fuse value, by applying either local and/or National Electrical Codes to listed

appliance amp draw data.

Circuit breakers are thermal-magnetic (industrial) motor curve type ONLY. For others, calculate/

verify correct breaker size according to appliance amp draw rating and type of breaker used.

Circuit breakers for 3-phase (3Ø) dryers must be 3-pole type.

PHASE

3Ø 3/4 107 --

WIRE

SERVICE

APPROX.

AMP DRAW

60 Hz 50 Hz

MINIMUM

WIRE SIZE

*

*

*

*

*

*

*

FUSING

Dual Element

Time Delay

150 150

150 150

90 90

90 90

90 90

80 80

80 80

CIRCUIT

BREAKER

IMPORTANT : The dryer must be connected to the electric supply shown on the data label that is

affixed to the right side of the main electrical enclosure. In the case of 208 VAC or

240 VAC, the supply voltage must match the electric service specifications of the

data label exactly.

WARNING : 208 VAC and 240 VAC ARE NOT THE SAME. Any damage done to the dryer

components due to improper voltage will automatically VOID THE WARRANTY.

IMPORTANT : For proper sprinkler and dryer operation, sprinkler must be powered by a “separate

or dedicated” single-phase (1ø) multi-wire branch circuit at dryer’s nameplate voltage.

NOTE: For 4-wire service, cap the neutral.

NOTE: Contact the factory for electrical information not listed.

NOTE: ADC reserves the right to make changes in specifications at any time, without notice or

obligation.

23

Page 28

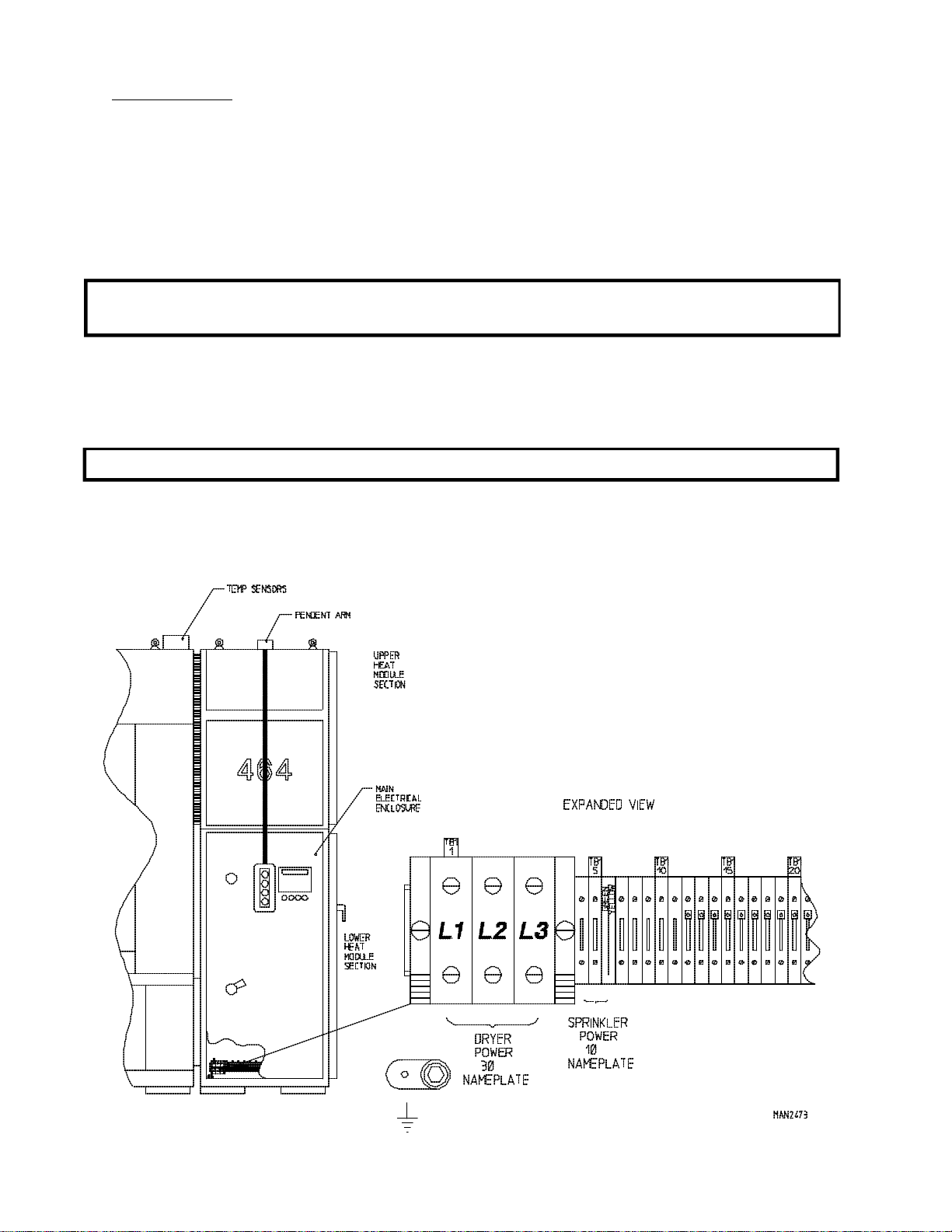

3. Electrical Service

The electrical power is connected the dryer at the high voltage section of the control cabinet. On the

ADG-464 dryer, this section is located at the bottom left of the main electrical enclosure.

The ADG-464 dryer must be supplied with two (2) independent input power lines. One is 3-phase ( 3ø)

electric service that feeds the dryer itself, and the other is 1ø electric service that feeds the safety sprinkler

system. Both input lines must be independent of each other and individually protected by their

individual fused disconnect.

NOTE: The ADG-464 with sprinkler option will not operate without an independent power source

fed to the Safety Sprinkler System.

Feed the electrical service cables to the dryer using the pre-punched knockouts at the bottom section of the

electrical cabinet right wall.

Connect the ground wires directly to the ground lug located at the same approximate area.

NOTE: The sprinkler operates off of single-phase (1ø) nameplate voltage of the dryer.

Before turning power on to the dryer, measure the supply voltage to ensure that it matches the dryer’s

specified input voltage. This input voltage is marked on the aluminum data plate located on the inner right

wall of the electrical cabinet.

24

Page 29

F. FRESH AIR SUPPLY REQUIREMENTS

When the dryer is operating, it draws in room air, heats this air through the tumbler (basket), and exhausts it out

of the building. Therefore, the room air must be continually replenished from the outdoors. If makeup air is

inadequate, drying time and efficiency will be adversely affected, and safety will be compromised. Premature

component failure may result.

Air supply (make-up air) must be given careful consideration to assure proper performance of each dryer. An

unrestricted source of air is necessary for each dryer. An airflow of 13,000 cfm per minute (368 cmm) (cubic

meters per minute) must be supplied to each dryer. As a general rule, an unrestricted air entrance from the

outdoors (atmosphere) of a minimum twenty (20) square feet (6.096 m2) is required for each dryer.

To compensate for the use of registers or louvres used over the openings, the makeup air area must be increased

by approximately thirty-three percent (33%). Makeup air openings should not be located in an area directly

near where exhaust vents exit the building.

Allowances must be made for remote or constricting passageways or where dryers are located at excessive

altitude or predominantly low pressure areas. The dryer must be installed with provisions for adequate combustion

and make-up air supply.

IMPORTANT : Makeup air must be provided from a source free of dry cleaning solvent fumes.

Makeup air that is contaminated by dry cleaning solvent fumes will result in irreparable

damage to the motors and other dryer components.

NOTE: Component failure due to dry cleaning solvent fumes will VOID THE WARRANTY.

25

Page 30

SECTION IV

PRE START-UP

A. PREPARATION FOR OPERATION

1. The supply voltage must match the dryer voltage as stated on the aluminum dryer data label which is located

on the inner right wall of the electrical cabinet.

2. A separate fused power supply must be connected into safety sprinkler circuit power connection.

3. Open ALL steam supply lines and condensate return line shut-off valves.

4. A compressed air supply of 80 PSI (5.51 bar) must be connected into the dryer’s fitting located at the rear

corner of the lower heat console section.

5. The dryer exhaust duct must be vented to the outdoors.

6. A water supply of 40 PSI (2.75 bar) must be connected into the 1-inch sprinkler pipe connection.

7. The dryer must be lagged to the floor and leveled for proper operation.

8. A fresh air supply from the outdoors of 13,000 cfm (368 cmm) must be available to the dryer.

9. ALL service doors must be closed and all access panels and tilt guards must be installed on the dryer.

26

Page 31

SECTION V

ROUTINE MAINTENANCE

A. CLEANING

A program or schedule should be established for periodic inspection, cleaning, and removal of lint from various

areas of the dryer, as well as throughout the duct work system. The frequency of this cleaning can best be

determined from experience at each location. Maximum operating efficiency is dependent upon proper air

circulation. The accumulation of lint can restrict this air flow. If the guidelines in this section are met, an ADC

dryer will provide many years of efficient, trouble free and safe operation.

WARNING: LINT FROM MOST FABRICS IS HIGHLY COMBUSTIBLE. THE

ACCUMULATION OF LINT CAN CREATE A POTENTIAL FIRE HAZARD.

WARNING: KEEP DRYER AREA CLEAR AND FREE FROM COMBUSTIBLE

MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND

LIQUIDS.

NOTE: Suggested time intervals shown are for average usage which is considered six (6) to eight (8)

operational (running) hours per day.

NOTE: Remove power from the machine before performing any maintenance in the machine (cleaning

the lint drawers and both steam coil lint screens are the only exceptions).

IMPORTANT: Dryer produces combustible lint and must be exhausted to the outdoors. Every 6

months, inspect the exhaust ducting and remove any lint build up.

SUGGESTED CLEANING SCHEDULE

EVERY THIRD OR FOURTH LOAD

Clean lint accumulation for lint drawers.

Clean lint accumulation from the burner lint screens.

NOTE: The frequency of cleaning the lint screens can best be determined from experience at each

location.

WEEKLY

Clean any lint accumulation from inside the heat console.

WARNING: TO AVOID THE HAZARD OF ELECTRICAL SHOCK, DISCONTINUE

ELECTRICAL SUPPLY TO THE DRYER.

27

Page 32

MONTHLY

Grease the four (4) tumbler shaft pillow bearings with DC-44 (Dow Corning) grease or equivalent. DC-44

is a lithium grease that conforms to NLGI Grade 2 and has a temperature range of 40º F (4.4º C) to 400º F

(204.4º C).

Empty the compressed air filter bowl and add oil to the compressed air lubricator bowl. Use a petroleum

based non-detergent lightweight oil, SAE 10/150SSU , which will readily break up into a mist, such as Mobil

DTE Light Oil or equivalent. DO NOT USE SYNTHETIC OILS.

EVERY 90 DAYS

Clean any lint accumulation on main blower wheel.

Remove lint from around the tumbler drive motors and main blower (fan) motor.

Main blower (fan) shaft bearings must be lubricated. Use a #3 grease or equivalent.

EVERY 6 MONTHS

Remove the gear oil in both tumbler drive shaft gear reducers. Replace with 1.4 liters (in each gear reducer)

of Mobil Oil DTE HH5G (I.S.O. viscosity grade 460) or equivalent.

Main blower fan and drive motor belts should be examined. Cracked or seriously frayed belts should be

replaced. Tighten belts when necessary.

Inspect and remove lint accumulation in customer furnished exhaust duct work system.

Open access door on top of tumbler and remove lint accumulation from tumbler brush.

NOTE: THE ACCUMULATION OF LINT IN THE EXHAUST DUCT WORK CAN

CREATE A POTENTIAL FIRE HAZARD.

NOTE: When cleaning the dryer cabinets, avoid using harsh abrasive. A product intended for the

cleaning or appliances is recommended.

28

Page 33

SECTION VI

COMPONENT SYSTEM DESCRIPTIONS

A. TUMBLER (BASKET) SUPPORT and DRIVE SYSTEM

IMPORTANT : Always keep the tumbler (basket) section of the dryer in an upright position when

moving it.

1. Tumbler (Basket)

The tumbler is made of five (5)14-gauge stainless steel perforated panels, five (5) stainless steel lifting ribs,

and two (2) outer tumbler rings. The tumbler (basket) is a completely welded assembly so the perforated

panels are not removable.

2. Tumbler (Basket) Support System

The tumbler (basket) sits on four (4) 11-inch diameter heavy-duty rubber roller wheels which supports and

drives the tumbler. The rubber wheels are molded into each of four (4) steel hubs. The steel hubs are

fastened to the 2-inch diameter drive shafts by taper lock bushings. Each drive shaft is supported by two (2)

2-inch diameter heavy duty roller bearings. The position of the tumbler (basket) is adjusted by moving these

bearings in or out with the four (4) bearings adjustment bolts.

29

Page 34

3. Tumbler and Basket Drive System

There are two (2) 5 HP tumbler drive motors. Each motor drives one of the 2-inch diameter tumbler drive

shafts, and the motors spin simultaneously so that all four (4) sets drive wheels work together to spin the

tumbler (basket).

Each motor is connected to the drive shaft by two (2) “A” section V-belts, driving a shaft-mounted (5.6 to 1

ratio) gear reducer. This produces a tumbler shaft speed of 200 RPM to 205 RPM and a tumbler (basket)

speed of 31.5 RPM. Proper tension is maintained on the V-belts by tightening the gear reducer turnbuckle

support. The oil in each gear reducer must be replaced every six (6) months by 1.4 liters of I.S.O. viscosity

Grade 460 gear oil.

4. Servicing the Drive System

a. Removing a Drive Wheel

The drive wheels a removed through the front and back panels of the dryer, not through the slides. The

front loading door and back loading door panels are hinged at the top. Remove the bolts holding these

panels to tumbler section frame and swing the panel out. The two (2) 1/4-inch poly-flo tubes connected

to the load door piston have to be removed to allow the panel to swing up far enough out to get access to

the drive wheels. Likewise, the following electrical disconnections must be performed (refer to

page 31).

30

Page 35

1) Front Panel Electrical Connections:

a) Front Position Switch Disconnect Plug;

The front door position switch disconnect plug is located on the left side of the front doors.

Disconnect this plug and feed the cable through the right hand side of the tumbler section.

b) Intake Temperature Probe Disconnect Plug;

The intake temperature probe disconnect plug is located in the burner and heater section, just

above the 25 HP motor. Disconnect this plug and route through the hole located on the right of the

front panel.

2) Rear Panel Electrical Connection Plug;

a) Rear Panel Controls Disconnect Plug;

The rear panel controls disconnect plug is located behind the rear panel controls. Disconnect this

plug and feed through hole towards the left hand drum motor section.

b) Rear Door Position Switch Disconnect Plug;

The rear door position switch disconnect plug is located on the left side of the rear doors. Disconnect

this plug and feed the cable through the right hand side of the tumbler section.

Put a block of wood under the tumbler; loosen and back out the tumbler shaft support bearings so

that the drive wheel lines up with the large hole in the frame. The drive wheel taper lock bushing

can now be loosened and removed through the hole in the frame, and the drive wheel pulled out of

the dryer through this hole. Before backing out the tumbler shaft bearings mark their position on

the frame to make reassembly easier.

5. Tumbler (Basket) Retaining Wheels

There are eight (8) 4-7/16 diameter retaining wheels which stabilize the tumbler’s (basket’s) position from

front to back. Four (4) of these are mounted on the front panel of the dryer (two [2] on the left side and two

[2]) on the right side), and four (4) are mounted on the rear panel (two [2]) on the left side and two [2] on the

right side). Access to these wheels is obtained by removing the vertical front and rear panel covers.

31

Page 36

B. MAIN AIR BLOWER and HEAT RECLAIMER SYSTEM

The fan which moves the exhaust air through the ADG-464 dryer is a 22-inch diameter, squirrel cage

wheel that is driven at 1,100 rpm by a 25 HP motor. This fan moves a maximum of 13,000 cfm (368 cmm) air

through the dryer.

32

Page 37

The dryer is equipped with a pneumatically operated heat reclaimer damper, which when opened, will recirculate

approximately fifteen percent (15%) of the dryer’s exhaust air.

The heat reclaimer damper is closed until ignition of flame has been established. Then, the damper piston is

actuated, opening the dampers recirculating fifteen percent (15%) of the exhaust air back over the gas burner

and into the tumbler (basket). The damper remains open for the rest of the drying cycle. On cool down, the

damper closes, exhausting ALL of the 13,000 cfm (368 cmm) which ensures a fast cool down of the load.

HEAT RECLAIMER ADJUSTMENT

1. REMOVE ELECTRICITY FROM THE UNIT.

2. LOOSEN HEAT RECLAIMER ADJUSTMENT NUTS

ON ALL FOUR (4) CORNERS OF THE HEAT

RECLAIMER PISTON.

3. THE DISTANCE BETWEEN THE TOP OF THE PLATE

TO THE BOTTOM OF THE NUTS MUST BE 1-3/16”

-3.00 cm- (see drawing below) IN ORDER TO OBTAIN

THE NUTS CLOSEST TO THE PISTON MUST BE

LOOSENED TO ONE PISTON WITH THE DAMPER

CLOSED. SNUG THE NUTS UP TO THE PLATE.

4. TIGHTEN TOP HEAT RECLAIMER NUTS DOWN

ONTO THE BOTTOM HEAT RECLAIMER NUTS.

33

Page 38

C. COMPRESSED AIR SYSTEM

The compressed air system of the ADG-464 dryer consists of a number of pneumatic pistons located throughout

the dryer, an FRL (Filter/Regulator/Lubricator) assembly, and pneumatic control panel.

1. Air Pistons:

The pistons are actuated by solenoid and flow control valves that are under computer control. The pneumatic

pistons are used to:

• Tilt the dryer for loading and unloading.

• Open and close load and unload doors.

• Operate heat reclaimer.

• Operate the cool down damper and the intake air damper.

2. Filter/Regulator/Lubricator (FRL) Assembly

The compressed air supply to the dryer is connected into the 3/8-inch F.P.T. fitting located on the rear corner

of the lower heat console. This is connected to the FRL (Filter/Regulator/Lubricator) assembly which is

located at the bottom rear of the lower heat console section.

The FRL (Filter/Regulator/Lubricator) assembly performs three (3) functions;

a. The filter removes most solids and liquid particles from the compressed air stream and traps them in its

bowl where this waste can be readily removed through the drain valve at the bottom of the bowl.

The filter bowl should be cleaned monthly.

b. For dryers manufactured prior to February 26, 1997 ...

The lubricator injects a mist of oil into the compressed

air steam so that the pistons and solenoid valves will

function smoothly.

The oiling rate can be adjusted by turning the oil

adjustment screw on top of the lubricator.

Oil is added to the bowl should be refilled on a

monthly basis with any petroleum-based, nondetergent lightweight oil (SAE 10/150 SSU) which

will readily break up into a mist. DO NOT USE SYNTHETIC OIL or OILS CONTAINING

ADDITIVES or SOLVENTS.

c. The regulator will maintain a nearly constant outlet air pressure of 80 PSI (5.51 bar) so that the dryer’s air

pistons will function normally despite upstream air pressure variation.

NOTE: For complete operation and maintenance information on the Filter/Regulator/Lubricator (FRL)

assembly, refer to the manufacturer data sheets accompanying this manual.

Dryers manufactured as of February 26, 1997 have their pneumatic components pre-lubricated.

34

Page 39

3. Pneumatic Control Panel

The pneumatic control panel of a two-way tilt dryer has two (2) tilting solenoid valves, one to control the front

set of tilting pistons and a second to control the rear set of tilting pistons. A 1-Way Tilt dryer has only one (1)

tilting solenoid valve.

Each valve has five (5) 1/2-inch F.P.T. ports and two (2) electric solenoids, one on each side of the valve.

To tilt the dryer back, a 120 volt signal is applied to the front pistons solenoid connector #S5, and no voltage

is applied to the solenoid connector #S8. The internal spool in the valve will move and 80 PSI (5.51 bar) of

air will enter the bottom port of the front tilting pistons, extending the front tilting piston rods and tilting the

dryer back for loading. The top piston ports are bled to the atmosphere. To level the dryer after loading, the

voltage signals are reversed. No voltage is applied to the “S5” solenoid, and 120 volts are applied to the “S8”

solenoid. The valve spool will now move so that 80 PSI (5.51 bar) of air is applied at the top piston ports,

while the bottom piston ports are bled to the atmosphere. The piston rods will now retract, leveling the dryer.

On 2-Way Tilt dryers, the rear tilting piston solenoid valve acts in the same manner.

The tilting piston valves are 3-position valves. This means that, if no voltage is applied to both positions

“S5” and “S8” ALL five (5) valve ports are blocked. If the dryer is tilting or leveling and power to the dryer

is shut off, the pistons will lock in position, holding the dryer in a partially tilted position.

The dryer can be made to tilt faster or slower by adjusting the pistons 3/8” flow control valves which are

located on the pneumatic control panel.

35

Page 40

4. Internal and External Pilot Air Supply

On two-way tilt dryers, a pneumatic safety circuit is incorporated to prevent both front and rear tilting pistons

from extending their rods at the same time. When 120 volts is supplied to the “S5” side of the front tilting

piston solenoid valve coil, the round internal spool in the core of the solenoid will move, allowing 80 PSI (5.51

bar) air to flow into the bottom ports of the front tilting pistons, while the top ports of these pistons are bled to

the atmosphere. In addition to this 120 volt electrical signal, the spool also requires a 30 PSI (2.06 bar) supply

of compressed air to change its position. This pilot air can either be supplied internally, tapped off the 80 PSI

(5.51 bar) air supply connected to port no.1 through holes in the body of the solenoid valve or it can be

supplied externally through the 1/8-inch F.P.T. connection located on either end of the solenoid valve. If no

pilot air is supplied to the solenoid valve. Then the spool cannot move, even with voltage supplied to the

solenoid valve coil.

This can be used to prevent both sets of tilting pistons from extending their rods at the same time. When the

front tilting piston rods are extended, 80 PSI (5.51 bar) air is connected to the bottom piston ports, while the

top piston ports are bled to the atmosphere. So, by tapping the external pilot air supply to the rear tilting rods

are extended, then there is no pilot pressure available to the rear tilting piston solenoid valve so that its spool

cannot move and the rear tilting piston rods cannot extend if a 120 volt signal is sent to its “12” side solenoid

valve coil.

The external pilot air supply to the front tilting piston is tapped off the rear tilting piston top port air line so that

whenever the rear piston rods are extended, there is no pilot air supplied to the front tilting piston solenoid

valve and the front tilting piston rods cannot extend. On the solenoid valve supplied on the dryer, the “12” side

valve is externally piloted, while “14” side valve is internally piloted.

A valve can easily be checked for internal or external piloting by removing the two (2) screws which hold the

solenoid operator onto the valve. For an internal pilot air to be supplied to the valve spool. For an external

pilot, the solid sealing disc must be positioned on top of the internal port.

5. Loading Doors and Heat Reclaimer, Cool Down and Intake Air Damper

These solenoid valves are located in the 6-station manifold block on the pneumatic control panel. Each door

piston is controlled by two (2) 2-port/2-position solenoid valve. The heat reclaimer is controlled by one (1)

2-port/2-position solenoid valves.

The three (3) pistons that control the heat reclaimer damper, cool down damper, and intake air damper are

controlled by a single 3-way double acting solenoid valve.

To open the front loading door, a 120 volt signal is applied to “S1,” the coil of the valve that supplies air to the

load door or the heat reclaimer’s bottom port. The valve will open, and 80 PSI (5.51 bar) of air is supplied to

the bottom port of the piston. The piston rod will extend, and the door will open. No voltage is applied to

“S2,” the coil of the valve that controls the air supply to the door pistons top port so that this line is bled to the

atmosphere.

To close the front loading door or heat reclaimer damper, the voltage signals are reversed, and the loading

door will close.

36

Page 41

D. GAS BURNER and IGNITION SYSTEM

The ADG-464 dryer gas burner system operates an on/off gas rate sequences to accurately control the tumbler’s

(basket’s) drying temperature. Maximum firing rate is 2,800,000 Btu/hr (705,588 kcal/hr).

Upon a call from heat, the dryer computer sends a 120 volt signal to the burner controller module (BCM) which

initiates and controls the ignition sequences. The burner controller module (BCM) insures that ALL the safety

switches are closed before turning on the combustion air burner fan, then checks to ensure that the burner fan

air switch has closed. The pilot gas flame is then established, the flame rod (which sits in this pilot flame) comes

in contact with the flame and signals the BCM. The main motorized gas valves open in sequence and full

operational flame is achieved.

The burner controller module (BCM) has five (5) LED’s (light emitting diodes) on its cover and two (2) neon’s on

the mounting base for ease of troubleshooting, as well as dip switches inside for ease of programming.

The burner controller module (BCM) controls ALL of the gas burner ignition components, except for the

motorized gas valve. When the drying set point temperature is reached, the dryer’s computer closes the top

motorized gas valve, shutting off full flame.

37

Page 42

1. Major Burner Components

a. Burner Controller Module (BCM)

The BCM (burner controller module) provides effective burner flame safeguard control through adjust

able purge and trial-for-ignition timing. The BCM insures that ALL dryer safety switch circuits are

closed, delays ignition to allow the combustion chamber to vent, and insures that a healthy pilot flame is

established before opening the main gas valves. Five (5) LED’s (light emitting diodes) on the cover of

the BCM allow for easy troubleshooting. Dip switches on the back of the module allow for easy

programming.

1) Dip Switches Selections

a) Loosen the two (2) screws on the burner control module cover and pull the module cover off of its

base. The dip switches are on the back of the cover.

Switch #1 - Recycling Mode

With this switch in the “ON” position, the burner will recycle the ignition sequence once during

each drying cycle after a burner fan air switch or main flame failure, but only if the failure occurs

more than 35-seconds after ignition. If this switch is “OFF”, the burner will lock out at once.

Switch #2 - Intermittent Pilot

This switch is “ON” for intermittent pilot or “OFF” for interrupted pilot. ADC utilizes intermittent

pilot so that the pilot flame stays lit during the entire drying cycle. With interrupted pilot, the pilot

flame would go out once the main flame is established. This is used mainly on oil burners lit by a

gas pilot.

Switch #3 - Trail-for-Ignition (TFI) Time

When this switch is “ON” a trial-for-ignition TFI of ten (10) seconds is set. If it is in the “OFF”

position, the (TFI) is 5-seconds. The trial for Ignition time is the length of time that the pilot is given

to light. A 10-second TFI is best for the dryer.

Switch #4, Switch #5, Switch #6, Switch #7, Switch #8 - Purge Time

Switch #8 is in the “ON” position, and switch #4, switch #5, switch #6, and switch #7 are in the

“OFF” position. This gives a purge time of 0-seconds.

38

Page 43

2) L.E.D. (light emitting diode) and Neon Displays of the BCM (Burner Controller Module)

a) Operating Interlock - L.E.D. (light emitting diode) is lit when:

ALL safety interlock switches are closed applying a 120 VAC signal to terminal #7 of the burner

controller module (BCM).

b) Operating Interlock - L.E.D. (light emitting diode) is not lit when:

One or more safety interlock switches are open. If any safety interlocks switch is open the burner

ignition sequence will not be attempted.

c) Air Failure - L.E.D. (light emitting diode) is lit if:

• Air switch is not closed within 10 seconds of start-up of blower

• Air switch is open during firing cycle.

d) System Unsafe - L.E.D. (light emitting diode) is lit if:

• A dryer safety device, connected in series with terminal #7, is opened. These safety devices

include the door switches, tilt switches, tumbler (basket) stop motion detector, high temperature

limit switches, airflow switches, and high or low gas pressure switch.

• A loose connection on the flame rod or spark plug.

• ALL purge time dip switches are in the off position.

• Flame is detected out of sequence.

• Inductance (H) is detected on sensor wires.

• Wiring fault on terminal #3, terminal #4, and terminal #5.

• Internal controller failure.

• Air switch closed before start-up.

e) Flame Signal - L.E.D. (light emitting diode) is lit when:

The flame rod is in contact with the pilot flame and the BCM (burner controller module) converts

a microampere (µ) current between the flame rod and ground into a 3 volt DC to 11 volt DC signal

that can be measured on the BCM. Insert one (1) probe of a DC volt meter into the flame signal

port and put the other probe to ground. The meter will read out the 3 volt DC to 11 volt DC flame

signal. If the flame signal L.E.D. (light emitting diode) flickers on and off, this is a result of a weak

flame signal which can be caused by an intermittent wiring connection between the flame rod and

the BCM, a faulty ground connection, bad ground of the dryer, weak pilot flame, and dirty or

defective flame rod.

f) Burner Controller Power On Indicator - Neon is lit when;

Burner controller has its supply voltage of 120 VAC.

g) Burner for Air Switch Status Indicator - Neon is lit when;

Air switch is closed after start-up of the blower (fan) and the interlocks are ALL closed.

39

Page 44

h) Burner Fan Air Switch Status Indicator - Neon is not lit;

• Air switch is not closed after start-up of burner fan.

• Door interlocks are open.

• Combustion burner screen is clogged.

• A door on the dryer is open.

i) Test and Reset Button

When this button is pushed in, the burner controller module (BCM) will halt the ignition sequence,

once the pilot flame is established. This allows the pilot flame to be adjusted.

3) Flame Rod and Spark Plug

The pilot flame is lit by the spark plug, while flame sensing is done through the flame rod. The spark

plug is energized when the pilot solenoid valve opens, igniting the pilot flame. The flame rod sits in the

pilot flame and sends a 3 volt DC to 11 volt DC signal to the BCM (burner controller module) when it

is in contact with the pilot flame. The pilot flame should be about the size of a tennis ball and should

heat the flame rod so it is red hot.

4) Burner Fan System

The burner fan provides additional combustion air for proper gas combustion. The fan provides

approximately 900 cfm (cubic feet per minute) - 274 cmm - of air through the burner box. The

airflow is obtained when the air pressure is measured at the air pressure tap on the gas burner box

approximately 1.25-inches W.C. (water column) -3.1 millibar-. The combustion air system is

comprised of the components described on page 41 and page 42.

40

Page 45

a) Burner Fan Air Switch

The differential in air pressure is measured by the burner fan air switch, which is located next to the

burner fan motor. If the combustion air is inadequate, this switch will prevent ignition. The setting

of this switch is adjustable, and it should be set at 12 to 15 millimeters (.4 - .6 inches water column

[W.C.]) - .995 - 1.49 mbar.

b) Burner Fan and Motor

The combustion air is produced by a 6-1/4-inch (15.88 cm) squirrel cage fan which is attached to a

1-1/2 HP, 3,600 RPM motor. The motor must spin counterclockwise (CCW) as viewed from the

rear of the motor.

c) Combustion Air Lint Filter

The combustion air lint filter is made of a fine mesh stainless steel screen which must be cleaned

regularly. This screen prevents any lint from entering the burner box.

41

Page 46

d) Combustion Air Damper

To produce the required combustion airflow, this damper can be adjusted. Remove the screen to

get access to the damper. Moving the damper closer to the blower inlet opening will reduce the

combustion airflow, and moving it away from the blower inlet opening will increase the airflow.

To measure the combustion airflow, attached a manometer to the air pressure tap on the burner

box. The air pressure

mbar)

5) Pilot Gas Supply Line

a) The pilot gas supply line consists of a manual shut-off valve, pressure regulator, electric solenoid

valve, back-loaded pressure regulator, and an adjustable gas cock.

b) The gas pressure in this line should be approximately 3.5-inches water column (W.C.) - 8.70

mbar - for natural gas and 1.5-inches water column (W.C.) (3.73 mbar) for L.P. (liquid propane)

gas. This will provide a bushy pilot flame, which produces a signal through the flame rod that is

converted to a 3 DC to 11 volts DC in the burner controller module (BMC).

(1) This flame can be adjusted in two (2) ways.

(a) Pilot Inlet Pressure Regulator

should measure 1.25 to 1.50 inches water column (W.C.) (3.1 to 3.73

Remove the cap and turn the slotted adjustment screw clockwise (CW) for more gas and

counterclockwise (CCW) for less gas.

(b) Adjustable Pilot Gas Cock

Remove the cap and turn the slotted adjustment screw clockwise (WC) for less gas and

counterclockwise (CCW) for more gas.

(2) The pilot line contains a back-loaded pressure regulator with an impulse line connected to the

gas burner inlet. The regulator will maintain a constant pilot supply pressure in the burner due

to an increase in temperature. DO NOT adjust this regulator.

6) Main Gas Supply Line

The main gas supply line consists of a pressure regulator, two (2) motorized shut-off valves, Hi/Lo gas

pressure switch, and manual shut-off valve.

The gas pressure at the burner should be 2.5-inches water column (W.C.) - 6.22 mbar - for natural

gas and 1.25 inches water column (W.C.) - 3.1 mbar - for L.P. (liquid propane) gas. This pressure is

measured by a manometer at the pressure tap which is located above the top manual shut off valve.

a) Motorized Gas Valve

The two (2) 2-inch F.P.T. motorized valve are “ON/OFF” gas flow control valves. The valves

motors operate on 120 VAC and are electrically “cascaded” so that upper valve will not open until

lower valve has fully opened. A limit switch inside the lower motorized valve provides the signal

that the valve is fully opened. These valves will open only when the burner controller module

(BCM) is receiving a signal from the flame rod proving that the pilot flame is established.

42

Page 47

Top Motorized Gas Valve

The valve sets the gas rate of 2,800,000 btu/hr (705,588 kcal/hr). To achieve this rate, the has

pressure must be set for 2.5-inches water column (W.C.) - 6.22 mbar - for natural gas and 1.25

inch water column (W.C.) - .3.1 mbars - for L.P. (liquid propane) gas. To adjust. loosen the pan

head screw located on the front of the top motorized valve, while holding the valve body, turn the

flow adjustment clockwise (CW) for less gas and counterclockwise (CCW) for more gas. Retighten

the pan head screw when correct gas flow is achieved. There is a switch located on the back of

the top gas valve that verifies valve closure. The burner controller module (BCM) will go into a

system unsafe error and the burner will not begin a burner sequence.

b) Sequence of Operation

With dryer power on, a 120 volt signal is sent to terminal #1 and terminal #2 of the BCM (burner

controller module). A power indicator light has been added to the controller base for troubleshooting.

(1) Drying cycle is started

(2) Dryer computer calls for heat.

(3) The BCM (burner controller module) checks that ALL of the dryer’s safety circuits are

closed (terminal #7 of the BCM). If this is the case, then the “green” “operating interlocks”

L.E.D. (light emitting diode) on the BCM will light. If a safety switch is open, the “green”

L.E.D. will not light, and the “red” “SYSTEM UNSAFE” L.E.D. will light. The ignition

sequence will stop.

43

Page 48

If ALL safety switches are closed, the burner controller module (BCM) will start the

burner fan motor (BCM terminal #8).

The BCM (burner controller module) waits 10-seconds to allow the blower motor to get up