American Dryer Corp. AD-75 User Manual

AD-75

(DSI Gas/Electric/Steam)

Installation/Operator’s Manual

WARNING: For your safety the information in this manual must be followed to minimize the risk of fire or explosion or to prevent property damage, personal injury or death.

Do not store or use gasoline or other flammable vapor and liquids in the vicinity of this or any other appliance.

WHAT DO YOU DO IF YOU SMELL GAS

*Do not try to light any appliance.

*Do not touch any electrical switch; do not use any phone in your building.

*Clear the room, building or area of all occupants.

*Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

*If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

AVERTISSEMENT: Assurez-vous de bien suivre les instructions données dans cette notice pour réduire au minimum le risque d’incendie ou d’explosion ou pour éviter tout dommage matériel, toute blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni d’autres vapeurs ou liquides inflammables dans le voisinage de cet appareil ou de tout autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DEGAZ:

*Ne pas tenter d’allumer d’appareil.

*Ne touchez à aucun interrupteur. Ne pas vous servir des téléphones se trouvant dans le bâtiment où vous vous trouvez..

*Évacuez la pièce, le bâtiment ou la zone.

*Appelez immédiatement votre fournisseur de gaz depuis un voisin. Suivez les instructions du fournisseur.

*Si vous ne pouvez rejoindre le fournisseur de gaz, appelez le service des incendies.

L’installation et l’entretien doivent être assurés par un installateur ou un service d’entretien qualifié ou par le fournisseur de gaz.

For replacement parts, contact the distributor from which the dryer was purchased or

American Dryer Corporation

88 Currant Road

Fall River MA 02720-4781

Telephone: (508) 678-9000 / Fax: (508) 678-9447 E-mail: techsupport@amdry.com

020698JEV/tf |

ADC Part No. 113035 |

Retain This Manual In A Safe Place For Future Reference

American Dryer Corporation products embody advanced concepts in engineering, design, and safety. If this product is properly maintained, it will provide many years of safe, efficient, and trouble-free operation.

ONLY qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation/operator's manual included with the dryer.

The following “FOR YOUR SAFETY” caution must be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence ni d’autres vapeurs ou liquides inflammables dans le voisinage de cet appareil ou de yout autre appareil.

We have tried to make this manual as complete as possible and hope you will find it useful. ADC reserves the right to make changes from time to time, without notice or obligation, in prices, specifications, colors, and material, and to change or discontinue models.

Important

For your convenience, log the following information:

DATE OF PURCHASE |

|

MODEL NO. |

AD-75

DISTRIBUTORS NAME

Serial Number(s)

Replacement parts can be obtained from your distributor or the ADC factory. When ordering replacement parts from the factory, you can FAX your order to ADC at (508) 678-9447 or telephone your orders directly to the ADC Parts Department at (508) 678-9000. Please specify the dryer model number and serial number in addition to the description and part number, so that your order is processed accurately and promptly.

The illustrations on the following pages may not depict your particular dryer exactly. The illustrations are a composite of the various dryer models. Be sure to check the descriptions of the parts thoroughly before ordering.

“IMPORTANT NOTE TO PURCHASER”

Information must be obtained from your local gas supplier on the instructions to be followed if the user smells gas. These instructions must be posted in a prominent location near the dryer.

IMPORTANT

YOU MUST DISCONNECT and LOCKOUT THE ELECTRIC SUPPLYand THE GAS SUPPLY or THE STEAM SUPPLY BEFORE ANY COVERS or GUARDS ARE REMOVEDFROMTHEMACHINETOALLOWACCESS FORCLEANING,ADJUSTING, INSTALLATION, or TESTING OFANY EQUIPMENT per OSHA (Occupational Safety and HealthAdministration) STANDARDS.

“Caution: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper operation.”

«Attention: Lor des opérations d’entretien des commandes étiqueter tous fils avant de les déconnecter. Toute erreur de câblage peut étre une source de danger et de panne.»

CAUTION

DRYER(S) SHOULD NEVER BE LEFT UNATTENDED WHILE IN OPERATION.

WARNING

CHILDREN SHOULD NOT BEALLOWED TO PLAYON OR NEAR THE DRYER(S). CHILDREN SHOULD BE SUPERVISED IFNEAR DRYER(S) IN OPERATION.

FOR YOUR SAFETY

DO NOT DRYMOPHEADS IN THE DRYER.

DO NOT USE DRYER IN THE PRESENCE OF DRYCLEANING FUMES.

WARNING

UNDER NO CIRCUMSTANCES should the door switch or the heat circuit devices ever be disabled.

WARNING

The dryer must never be operated with any of the back guards, outer tops, or service panels removed. PERSONALINJURY or FIRE COULD RESULT.

WARNING

DRYER MUST NEVER BE OPERATED WITHOUT THE LINT FILTER/SCREEN IN PLACE...EVEN IF AN EXTERNAL LINT COLLECTION SYSTEM IS USED.

IMPORTANT

PLEASE OBSERVEALLSAFETYPRECAUTIONS displayed on the equipment and/or specified in the installation/operator's manual included with the dryer.

Dryer(s) must not be installed or stored in an area where it will be exposed to water and/or weather.

The wiring diagram for the dryer is located in the front electrical control box area.

Table of Contents |

|

SECTION I |

|

IMPORTANT INFORMATION ............................................................................... |

3 |

RECEIVING and HANDLING ..................................................................................... |

3 |

SAFETY PRECAUTIONS ........................................................................................... |

4 |

SECTION II |

|

SPECIFICATIONS/COMPONENT IDENTIFICATION .................................... |

6 |

SPECIFICATIONS ....................................................................................................... |

6 |

COMPONENT IDENTIFICATION.............................................................................. |

8 |

SECTION III |

|

INSTALLATION PROCEDURES ......................................................................... |

10 |

LOCATION REQUIREMENTS ................................................................................. |

10 |

UNPACKING/SETTING UP ...................................................................................... |

11 |

DRYER ENCLOSURE REQUIREMENTS ............................................................... |

12 |

FRESH AIR SUPPLY ................................................................................................. |

13 |

EXHAUST REQUIREMENTS .................................................................................. |

14 |

ELECTRICAL INFORMATION ................................................................................ |

19 |

GAS INFORMATION ................................................................................................ |

27 |

STEAM INFORMATION ........................................................................................... |

30 |

PREPARATION FOR OPERATION/START-UP ..................................................... |

36 |

PREOPERATIONAL TESTS ..................................................................................... |

37 |

PREOPERATIONAL INSTRUCTIONS.................................................................... |

39 |

SHUT DOWN INSTRUCTIONS ............................................................................... |

40 |

SECTION IV |

|

SERVICE/PARTS INFORMATION ...................................................................... |

41 |

SERVICE ..................................................................................................................... |

41 |

PARTS ......................................................................................................................... |

41 |

SECTION V |

|

WARRANTY INFORMATION .............................................................................. |

42 |

RETURNING WARRANTY CARD(S) ..................................................................... |

42 |

PARTS ......................................................................................................................... |

42 |

RETURNING WARRANTY PARTS ......................................................................... |

42 |

SECTION VI |

|

ROUTINE MAINTENANCE .................................................................................. |

44 |

CLEANING ................................................................................................................. |

44 |

ADJUSTMENTS ......................................................................................................... |

46 |

SECTION VII |

|

PROCEDURE FOR FUNCTIONAL CHECK OF REPLACEMENT |

|

COMPONENTS ....................................................................................................... |

47 |

MICROPROCESSOR.......................................................................................... |

47 |

DIRECT SPARK IGNITION (D.S.I.) SYSTEM..................................................... |

48 |

SECTION VIII |

|

REVERSING SPIN/DWELL ADJUSTMENTS .................................................. |

49 |

SECTION IX |

|

TECHNICAL INFORMATION (DATA LABEL) ................................................ |

50 |

SECTION X |

|

TROUBLESHOOTING ........................................................................................... |

52 |

SECTION I

IMPORTANT INFORMATION

A. RECEIVING and HANDLING

The dryer is shipped in a protective stretch wrap cover with protective cardboard corners and top cover (or optional box) as a means of preventing damage in transit. Upon delivery, the dryer and/or packaging, and wooden skid should be visually inspected for shipping damage. If any damage whatsoever is noticed, inspect further before delivering carrier leaves.

Dryers damaged in shipment.

1.ALL dryers should be inspected upon receipt and before they are signed for.

2.If there is suspected damage or actual damage, the trucker's receipt should be so noted.

3.If the dryer is damaged beyond repair, it should be refused. Those dryers which were not damaged in a damaged shipment should be accepted, but the number received and the number refused must be noted on the receipt.

4.If you determine that the dryer was damaged after the trucker has left your location, you should call the delivering carrier's freight terminal immediately and file a claim. The freight company considers this concealed damage. This type of freight claim is very difficult to get paid and becomes extremely difficult when more than a day or two passes after the freight was delivered. It is your responsibility to file freight claims. Dryer/parts damaged in transit cannot be claimed under warranty.

5.Freight claims are the responsibility of the consignee, and ALL claims must be filed at the receiving end. ADC assumes no responsibility for freight claims or damages.

6.If you need assistance in handling the situation, please contact the ADC Traffic Manager at (508) 678-9000.

IMPORTANT: The tumbler section of the dryer must be transported and handled in an upright position at all times.

3

B. SAFETY PRECAUTIONS

WARNING: For your safety, the information in this manual must be followed to minimize the risk of fire or explosion or to prevent property damage, personal injury, or loss of life.

WARNING: The dryer must never be operated with any of the back guards, outer tops, or service panels removed. PERSONAL INJURY or FIRE COULD RESULT.

1.DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

2.Purchaser/user should consult the local gas supplier for proper instructions to be followed in the event the user smells gas. The instructions should be posted in a prominent location.

3.WHAT TO DO IF YOU SMELL GAS..

a.DO NOT try to light any appliance.

b.DO NOT touch any electrical switch.

c.DO NOT use any phone in your building.

d.Clear the room, building, or area of ALL occupants.

e.Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

f.If you cannot reach your gas supplier, call the fire department.

4.Installation and service must be performed by a qualified installer, service agency, or gas supplier.

5.Dryer(s) must be exhausted to the outdoors.

6.Although ADC produces a very versatile machine, there are some articles that, due to fabric composition or cleaning method, should not be dried in it.

WARNING: Dry only water-washed fabrics. DO NOT dry articles spotted or washed in dry cleaning solvents, a combustible detergent, or "all purpose" cleaner.

EXPLOSION COULD RESULT.

WARNING: DO NOT dry rags or articles coated or contaminated with gasoline, kerosene, oil, paint, wax. EXPLOSION COULD RESULT.

WARNING: DO NOT dry mop heads. Contamination by wax or flammable solvents will create a fire hazard.

WARNING: DO NOT use heat for drying articles that contain plastic, foam, sponge rubber, or similarly textured rubber materials. Drying in a heated basket (tumbler) may damage plastics or rubber and also may be a fire hazard.

4

7.A program should be established for the inspection and cleaning of lint in the heating unit area, exhaust duct work, and inside the dryer. The frequency of inspection and cleaning can best be determined from experience at each location.

WARNING: The collection of lint in the burner area and exhaust duct work can create a potential fire hazard.

8.For personal safety, the dryer must be electrically grounded in accordance with local codes and/or the National Electric Code ANSI/NFPA NO. 70-LATEST EDITION.

NOTE: Failure to do so will VOID THE WARRANTY.

9.UNDER NO CIRCUMSTANCES should the dryer door switches, lint door switch, heat safety circuit ever be disabled.

WARNING: PERSONAL INJURY or FIRE COULD RESULT.

10.This dryer is not to be used in the presence of dry cleaning solvents or fumes.

11.Remove articles from the dryer as soon as the drying cycle has been completed.

WARNING: Articles left in the dryer after the drying and cooling cycles have been completed can create a fire hazard.

12.DO NOT operate steam dryers with more than 125 PSI steam pressure. Excessive steam pressure can damage steam coil and/or harm personnel.

13.Replace leaking flexible hoses or other steam fixtures immediately. DO NOT operate the dryer with leaking flexible hoses. PERSONAL INJURY MAY RESULT.

14.The normal PH level for copper type steam coils must be maintained between a value of 8.5 to 9.5. For steel type steam coils the PH level must be maintained between a value of 9.5 to 10.5. These limits are set to limit the acid attack of the steam coils.

IMPORTANT: Coil failure due to improper PH level will VOID THE WARRANTY.

15. READ and FOLLOW ALL CAUTION and DIRECTION LABELS ATTACHED TO THE DRYER.

WARNING: YOU MUST DISCONNECT and LOCKOUTTHE ELECTRIC SUPPLY and THE GAS SUPPLY BEFORE ANY COVERS or GUARDSARE REMOVED FROM THE MACHINE TO ALLOW ACCESS FOR CLEANING, ADJUSTING, INSTALLATION, or TESTING OFANY EQUIPMENT per OSHA (Occupational Safety and Health Administration)

STANDARDS.

5

SECTION II

SPECIFICATIONS/COMPONENT IDENTIFICATION

A. SPECIFICATIONS

0$;,080 &$3$&,7< 'U\ :HLJKW |

|

|

OEV |

NJ |

|||||||||||

%$6.(7 ',$0(7(5 |

|

|

|

|

|

|

|

FP |

|||||||

%$6.(7 '(37+ |

|

|

|

|

|

|

|

|

FP |

||||||

02725 +RUVHSRZHU |

|

|

|

|

|

+3 |

NZ |

||||||||

'225 23(1,1* 'LDPHWHU |

|

|

|

|

FP |

||||||||||

%$6.(7 92/80( |

|

|

|

|

|

FX IW |

FX P |

||||||||

'5<(56 3(5 &217$,1(5 |

|

|

|

|

|

|

|

|

|||||||

'5<(56 3(5 758&. |

|

|

|

|

|

|

|

|

|

||||||

|

92/7$*( $9$,/$%/( |

|

|

|

Y ‘ +] |

||||||||||

Gas |

$3352; :(,*+7 8QFUDWHG |

|

|

OEV |

NJ |

||||||||||

$3352; :(,*+7 &UDWHG |

|

|

OEV |

NJ |

|||||||||||

+($7 ,1387 |

|

|

|

|

EWXK |

NFDO KU |

|||||||||

$,5)/2: |

|

|

|

|

|

|

FIP |

FPP |

|||||||

|

|

|

|

|

|

|

|||||||||

|

,1/(7 3,3( &211(&7,21 |

|

|

) 3 7 |

|

|

|||||||||

|

|

|

|

29(1 6,=( |

|

|

|

|

|

|

|

|

|

||

|

.: |

|

|

|

%78+ |

.&$/ +5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

+] |

+] |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Electric |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

DRAW |

|

|

|

$33/,(' 92/7$*( 3+$6( |

|

|

|

||||||

.: |

|

‘ |

‘ |

‘ |

‘ |

|

‘ |

‘ |

|

‘ |

|||||

|

|

AMP |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

APPROXIMATE |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

||||||||||

|

92/7$*( $9$,/$%/( |

|

|

|

Y ‘ +] |

||||||||||

|

$3352; :(,*+7 8QFUDWHG |

|

|

OEV |

NJ |

||||||||||

Steam**** |

$3352; :(,*+7 &UDWHG |

|

|

OEV |

NJ |

||||||||||

$,5)/2: |

|

|

|

|

|

|

FIP |

FPP |

|||||||

&2035(66(' $,5 92/80( |

|

|

FIK |

FPK |

|||||||||||

$,5 &211(&7,21 |

|

|

|

) 3 7 |

|

|

|||||||||

67($0 &2168037,21 |

|

|

%2,/(5 +3 |

|

|

|

|||||||||

|

|

1250$/ /2$' |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

||||||

OEV KU |

|

NJ KU |

|

|

|

|

|

|

|

||||||

23(5$7,1* 67($0 35(6685( |

|

6833/< |

5(7851 |

||||||||||||

|

|

||||||||||||||

|

|

&211(&7,21 |

&211(&7,21 |

||||||||||||

|

|

|

|

|

|

|

|

||||||||

|

SVL PD[ |

|

EDU |

|

|

|

|

|

|

||||||

*For non-reversing models.

**A minimum of 3/4" pipe must be supplied to the gas inlet for each dryer.

***Contact factory for electrical information not listed. 3-Phase figures shown are for 3-wire service.

****Steam unit must be supplied with clean, dry, regulated air at 80 psi (+/- 10 psi).

*****Size of piping to dryer varies with installation conditions. Contact factory for assistance.

Shaded areas are stated in metric equivalents.

NOTE: ADC RESERVES THE RIGHT TO MAKE CHANGES IN SPECIFICATIONS AT ANY TIME, WITHOUT NOTICE or OBLIGATION.

6

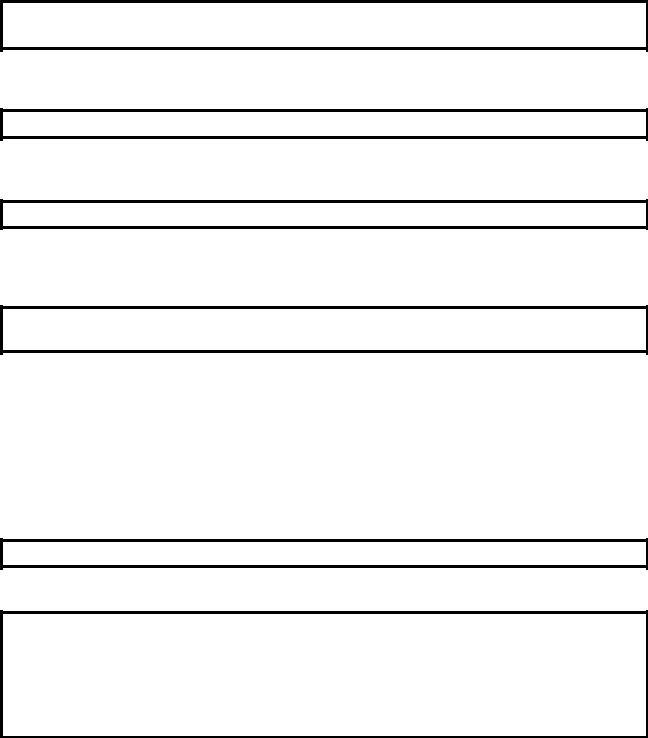

Specifications

ADG-75D(Gas)

ADE-75 (Electric)

ADS-75 (Steam)

NOTE: ADC RESERVES THE RIGHT TO MAKE CHANGES IN SPECIFICATIONS AT ANY TIME, WITHOUT NOTICE or OBLIGATION.

7

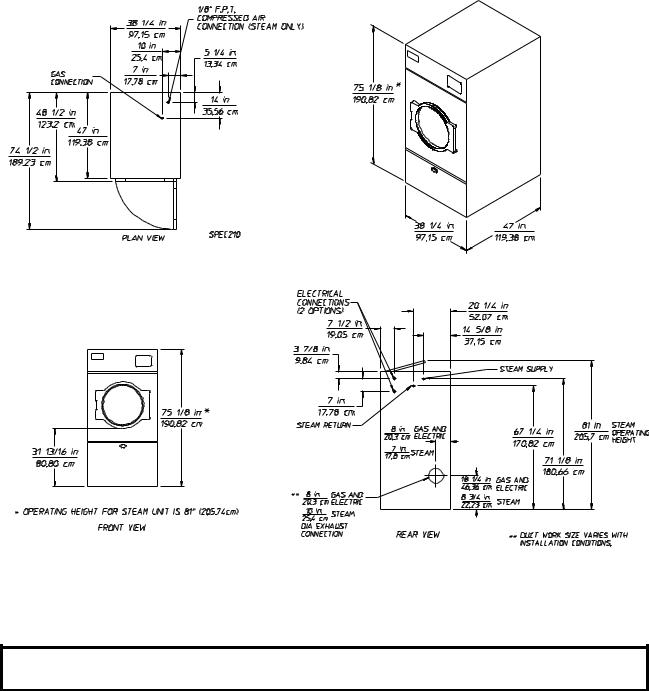

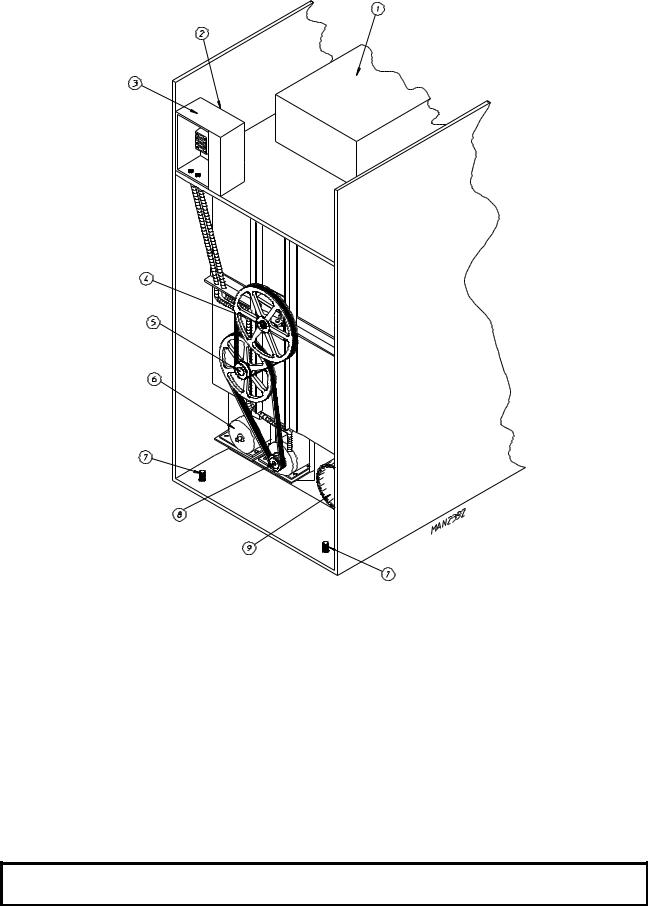

B.COMPONENT IDENTIFICATION

1.DRYER FRONT VIEW

Illus. No. Description

1Controls

2Control (top access) Door Assembly

3 |

Main Door Assembly |

4Lint Compartment Area (lint screen located behind door)

5Data Label and Installation Label (located behind control [service] door)

8

2. DRYER REAR VIEW

Illus. No. Description

1Heating Unit

21/8" Compressed Air Supply Inlet

(behind Electric Service Relay Box for steam units ONLY)

3* Electric Service Relay Box

4Tumbler Bearing Mount Assembly

5Idler Bearing Mount Assembly

6 |

Blower Motor Assembly |

7Leveling Leg (rear)

8 |

Basket (Drive) Motor Assembly (Reversing Models ONLY) |

9Dryer Exhaust

* Electric service connections for Gas & Steam Models are made in this box.

NOTE: 1/8-inchCompressedAirSupplyInlet(forSteamModelsONLY)islocated behindtheElectricServiceRelayBox.

9

SECTION III

INSTALLATION PROCEDURES

Installation should be performed by competent technicians in accordance with local and state codes. In the absence of these codes, the installation must conform to applicable American National Standards: National Fuel Gas Code ANSI.Z223.1-LATEST EDITION and/or National Electric Code ANSI/NFPA NO. 70-LATEST EDITION.

A. LOCATION REQUIREMENTS

Before installing the dryer, be sure the location conforms to local codes and ordinances. In the absence of such codes or ordinances the location must conform with the National Fuel Gas Code ANSI.Z223.1-LATEST EDITION.

1.The dryer must be installed on a sound level floor capable of supporting its weight. It is recommended that carpeting be removed from the floor area that the dryer is to rest on.

2.The dryer must not be installed or stored in an area where it will be exposed to water and/or weather.

3.The dryer is for use in noncombustible locations.

4.Provisions for adequate air supply must be provided as noted in this manual (refer to Fresh Air Supply in Section D).

5.Clearance provisions must be made from combustible construction as noted in this manual (refer to Dryer Enclosure Requirements in Section C).

6.Provisions must be made for adequate clearances for servicing and for operation as noted in this manual (refer to Dryer Enclosure Requirements in Section C).

7.Dryer must be exhausted to the outdoors (refer to Exhaust Requirements in Section E).

8.Dryer must be located in an area where correct exhaust venting can be achieved as noted in the manual (refer to Exhaust Requirements in Section E).

IMPORTANT: Dryer should be located where a minimum amount of exhaust duct will be necessary.

10

B. UNPACKING/SETTING UP

Remove protective shipping material (i.e., plastic wrap, and/or optional shipping box) from dryer.

IMPORTANT: Dryer must be transported and handled in an upright position at all times.

The dryer can be moved to its final location while still attached to the skid or with the skid removed. To un-skid the dryer, locate and remove the four (4) bolts securing the base of the dryer to the wooden skid. Two (2) are at the rear base (remove the back panel for access), and two (2) are located in the bottom of the lint chamber. To remove the two (2) bolts located in the lint chamber area, remove the lint door.

With the skid removed, to make it easier to slide the dryer into its final position, slightly lower ALL four (4) leveling legs, so that the dryer will slide on the legs instead of the base frame.

To increase bearing life and improve efficiency, the dryer should be tilted slightly to the rear.

The basket (tumbler) is supported during shipping by a wooden block. REMOVE THIS BLOCK BEFORE STARTING THE DRYER.

IMPORTANT: For microprocessor (computer) models, this wooden block must be removed before connecting power to the dryer or irreparable damage to the basket (tumbler) will result.

The lint coops of ALL AD-75 dryers are supported during shipping by a bracket. REMOVE THIS BRACKET BEFORE STARTING THE DRYER.

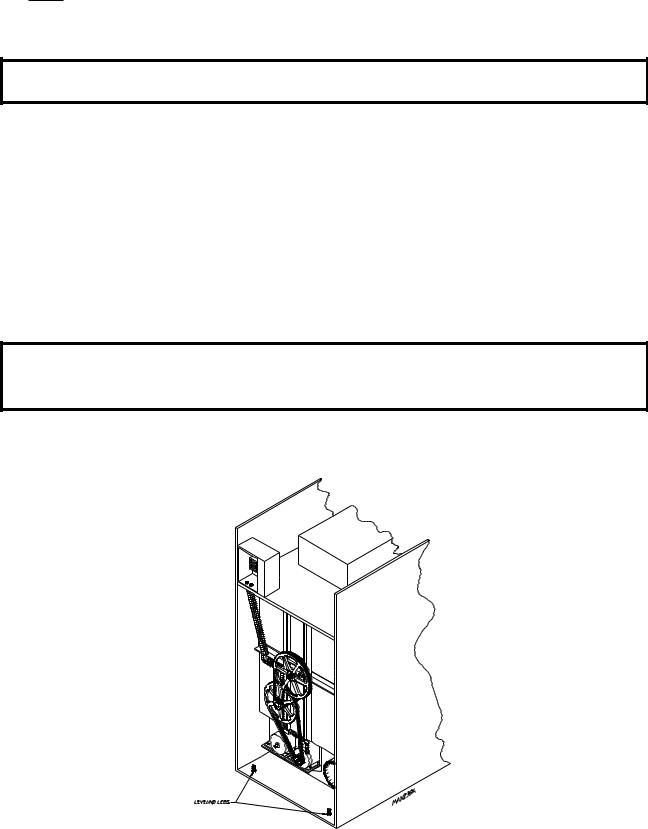

1. LEVELING DRYER

The dryer is equipped with four (4) leveling legs, one at each corner of the base. Two (2) are located at the rear of the dryer base, and two (2) are located in the lint chamber (coop).

To increase bearing life and improve efficiency, the dryer should be tilted slightly to the rear.

11

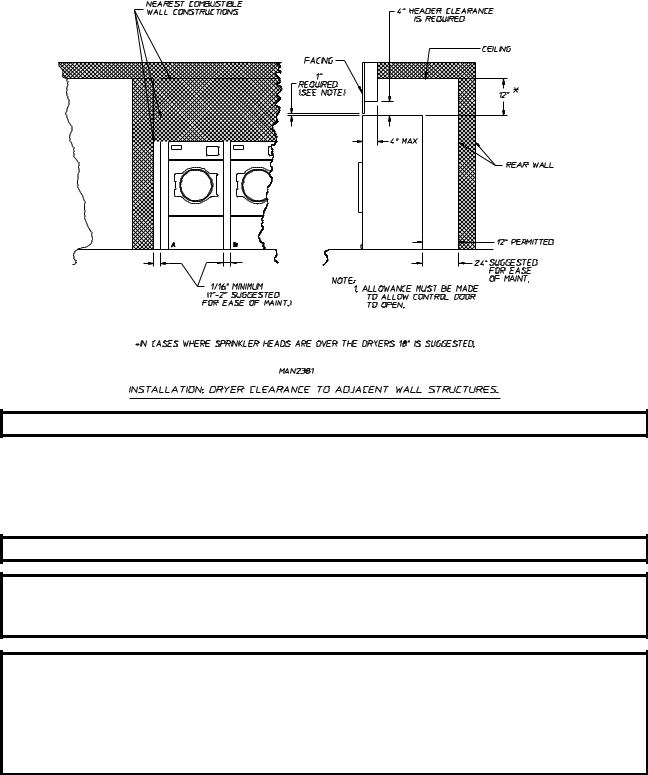

C. DRYER ENCLOSURE REQUIREMENTS

Bulkheads and partitions should be made of noncombustible materials and must be located a minimum of twelve (12) inches (18-inches or more is recommended for ease of installation, maintenance,andservice)abovethedryeroutertop,exceptalongthefrontofthedryerwhichmaybepartially closed in if desired. The clearance between the bulkhead header and the dryer must be a minimum of four (4) inches and mustnot extend more than four (4) inches to the rear of the front. The bulkhead facingmust notbe closed in all the way to the top of the dryer. Aone (1) inch clearance is required.

NOTE: Allowancesmustbemadeforopeningthecontroldoor.

Dryers may be positioned side wall to side wall. However, a 1/16" minimum allowance must be made for openingandclosingofthecontroldoorandthelintdoor. Itissuggestedthatthedryerbepositionedabouttwo(2) feet away from the nearest obstruction for ease of installation, maintenance, and service (to be measured from the back guard.) (Refer to the illustration above for details.)

NOTE: Airconsiderationsareimportantforproperandefficientoperation.

IMPORTANT: Eventhoughaminimumofonly12-inchesisrequired,18-inchesormore issuggested.Theadditionalclearanceisadvantageousforeaseof installationandservice.

IMPORTANT: Whenfiresprinklersystemsarelocatedabovethedryers,aminimumof 18-inchesabovethedryerconsole(module)isrequired. Dryersmaybe positionedsidewalltosidewallhowever,a1/16-inchminimum allowanceisrequiredbetweendryers(orwall)foreaseofinstallationand maintenance. Allowancesmustbemadefortheopeningandclosingsof thecontroldoorandthelintdoor.

12

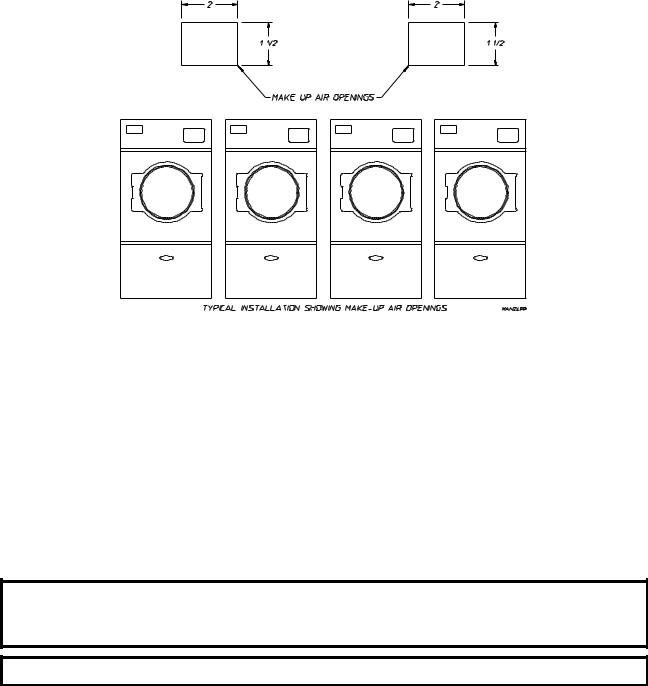

D. FRESH AIR SUPPLY

When the dryer is operating, it draws in room air, heats it, passes this air through the basket (tumbler), and exhausts it out of the building. Therefore, the room air must be continually replenished from the outdoors. If the make-up air is inadequate, drying time and drying efficiency will be adversely affected. Ignition problems and sail switch "fluttering" problems may result, as well as premature motor failure from overheating.

Air supply (make-up air) must be given careful consideration to assure proper performance of each dryer. An unrestricted source of air is necessary for each dryer. An air flow of 1,200 cfm (cubic feet per minute) must be supplied to each gas and electric dryer and 1,350 cfm (cubic feet per minute) must be supplied to each steam dryer. As a general rule, an unrestricted air entrance from the outdoors (atmosphere) of a minimum of 1-1/2 square feet is required for each dryer.

To compensate for the use of registers or louvers used over the openings, this make-up air must be increased by approximately thirty-three percent (33%). Make-up air openings should not be located in an area directly near where exhaust vents exit the building.

It is not necessary to have a separate make-up air opening for each dryer. Common make-up air openings are acceptable. However, they must be set up in such a manner that the make-up air is distributed equally to ALL the dryers.

EXAMPLE: For a bank of four (4) dryers, two (2) unrestricted openings measuring 2 feet by 1-1/2 feet (6 square feet) is acceptable.

Allowances must be made for remote or constricting passageways or where dryers are located at excessive altitudes or predominantly low pressure areas.

IMPORTANT: Make-upairmustbeprovidedfromasourcefreeofdrycleaningsolvent fumes. Make-upairthatiscontaminatedbydrycleaningsolventfumes willresultinirreparabledamagetomotorsandotherdryercomponents.

NOTE: ComponentfailureduetodrycleaningsolventfumeswillVOIDTHEWARRANTY.

13

E.EXHAUST REQUIREMENTS

1.General Exhaust Duct WorkInformation

Exhaust duct work should be designed and installed by a qualified professional. Improperly sized duct work will create excessive back pressure which results in slow drying, increased use of energy, overheating of the dryer, and shutdown of the burner by the airflow (sail) switches, burnerhi-limits,orbasket(tumbler)hi-heatthermostats.

CAUTION: DRYER MUST BEEXHAUSTED TO THE OUTDOORS.

CAUTION: IMPROPERLY SIZED OR INSTALLED EXHAUST DUCT WORK CAN

CREATE A POTENTIAL FIRE HAZARD.

The duct work should be laid out in such a way that the duct work travels as directly as possible to the outdoors with as few turns as possible. Single or independent dryer venting is recommended.

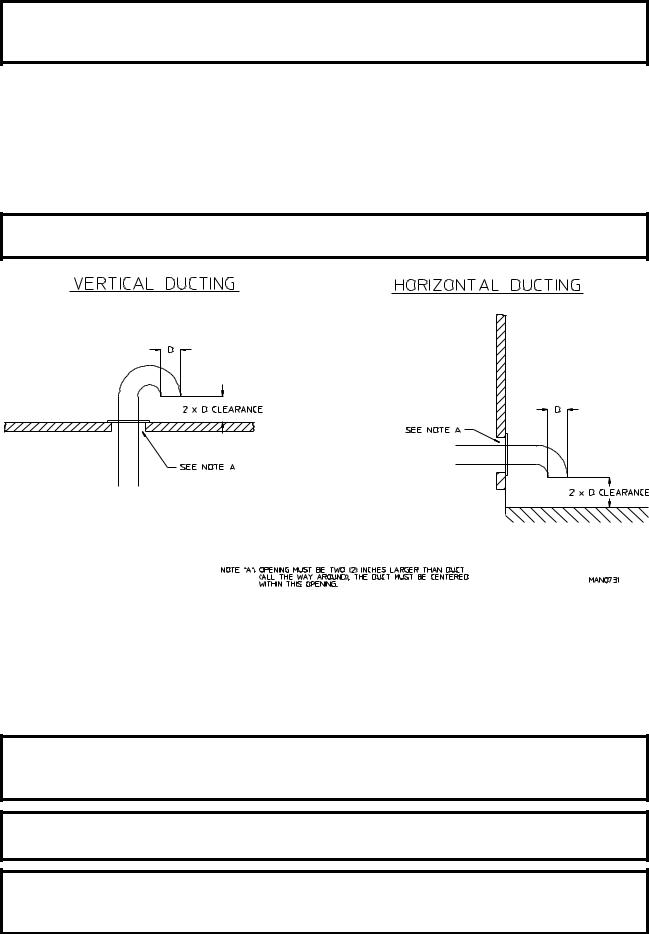

Horizontal Venting:

When single dryer venting is used, the length of duct work, from the dryer to the outside exhaust outlet, should not exceed fifteen (15) feet. The minimum diameter of this duct work must be at least 10-inches (even thoughthedryerexhaustductforgasandelectricunitsisonly8-inches).Inthecaseofmultiple(common)dryer venting, the distance from the last dryer to the outside exhaust outlet should not exceed fifteen (15) feet. The shapeoftheductworkisnotcriticalsolongastheminimumcross-sectionalareaisprovided. Itissuggestedthat the use of 90° turns be avoided; use 30° and/or 45° angles instead. The radius of the elbows shouldpreferably be1-1/2timesthediameteroftheduct. Includingbasket(tumbler)/dryerelbowconnectionsorelbowsusedfor outside protection from the weather, no more than two (2) elbows should be used in the exhaust duct run. If more than two (2) elbows are used, the cross sectional area of the duct work must be increased. ALL duct work should be smooth inside with no projections from sheet metal screws or other obstructions which will collectlint. Whenaddingducts,theducttobeaddedshouldoverlaptheducttowhichitistobeconnected. ALL duct work joints must betaped to prevent moisture and lint from escaping into the building. Inspection doors shouldbeinstalledatstrategicpointsintheexhaustductworkforperiodicinspectionandclean-outoflintfrom theductwork.

Vertical Venting:

When single dryer venting is used the length of the duct work from the dryer to the outside exhaust outlet should not exceed twenty (20) feet. The minimum diameter of this duct work must be at least 12-inches (even though the dryer exhaust duct for gas and electric units is only 8-inches) In the case of multiple (common)dryerventing,thedistancefromthelastdryertotheoutsideexhaustoutletshouldnotexceedtwenty (20) feet. The shape of the duct work is not so critical so long as the minimum cross sectional area is provided. It is suggested that the use of 90º turns be avoided; use 30º and/or 45º bends instead.. The radius of the elbows should preferably be 1-1/2 times the diameter of the duct. ALL duct work should be smooth inside with no projectionsfromsheetmetalscrewsorotherobstructionswhichwillcollectlint. Whenaddingducts,theductto beaddedshouldoverlaptheducttowhichitistobeconnected. ALLductworkjointsmustbetapedtoprevent moistureandlintfromescapingintothebuilding. Inspectiondoorsshouldbeinstalledatstrategicpointsinthe exhaustductworkforperiodicinspectionandclean-outoflintfromtheductwork.

IMPORTANT: Exhaustbackpressuremeasuredbyamanometerintheexhaustduct

shouldnotexceed0.3-inchesofwatercolumn.

IMPORTANT: Minimumductworkdiameterforhorizontalventingis10-inchesandfor

verticalventingtheminimumis12-inches..

14

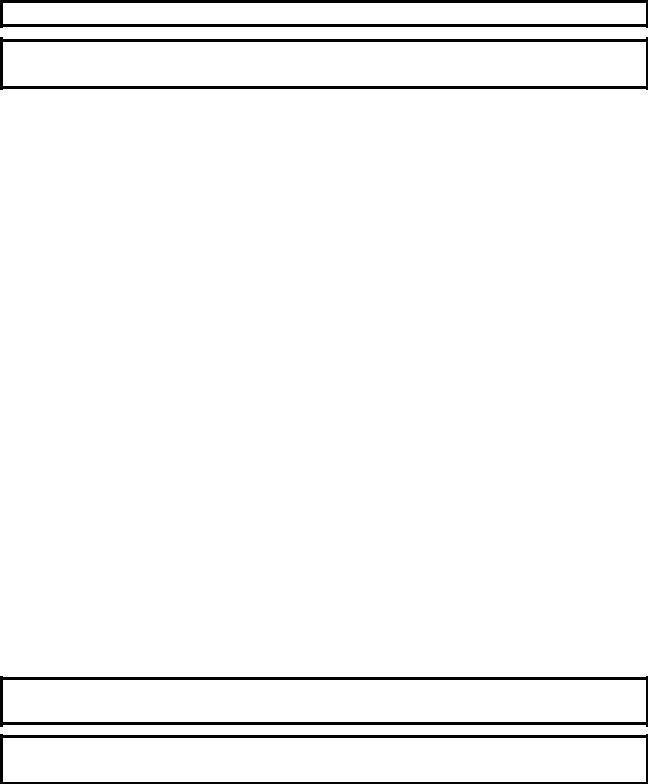

NOTE: Wheretheexhaustductworkpassesthroughawall,ceiling,orroofmadeof combustiblematerials,theopeningmustbe2-incheslarger(allthewayaround) thantheduct. Theductmustbecenteredwithinthisopening.

a.Outside Duct Work Protection

1)To protect the outside end of horizontal duct work from the weather, a 90° elbow bent downward should be installed where the exhaust exits the building. If the duct work travels vertically up through the roof, it should be protected from the weather by using a 180° turn to point the opening downward. In either case, allow at least twice the diameter oftheductbetweentheductopeningandthenearestobstruction.

IMPORTANT: DONOTusescreensorcapsontheoutsideofopeningofexhaustduct

work.

2.Single Dryer Venting

Where possible, it is suggested to provide a separate exhaust duct for each dryer. The exhaust duct should be laid out in such a way that the duct work travels as directly as possible to the outdoors with as few turns as possible. It is suggested that the use of 90° turns in the ducting be avoided; use 30° and/or 45° angles instead. The shape of the exhaust duct work is not critical so longastheminimumcrosssectionareaisprovided.

IMPORTANT: Minimumductsizeforadryerthatisventedhorizontallyis10-inchesfor

aroundductoranequivalentof80squareinches. TheDUCTSIZEMUSTNOT

BE REDUCED ANYWHERE DOWN STREAM OF THE DRYER

IMPORTANT: Exhaustbackpressuremeasuredbyamanometerateachbasket

(tumbler)exhaustductareashouldnotexceed0.3-inchesofwatercolumn.

IMPORTANT: Minimumductsizeforadryerthatisventedverticallyis12-inchesfora

roundductoranequivalentof120squareinches. TheDUCTSIZEMUSTNOT

BE REDUCED ANYWHERE DOWN STREAM OF THE DRYER.

15

IMPORTANT: Forextendedductworkruns,thecrosssectionareaoftheductworkcanonlybe increasedtoanextent. Whentheductworkapproachesthemaximumlimitsnotedin thismanual,aprofessionalheatingventingairconditioning(HVAC)firmshouldbe consultedforproperventinginformation.

ALL duct work should be smooth inside with no projections from sheet metal screws or other obstructions which will collect lint. When adding ducts, the duct to be added should overlap the duct to which it is to be connected. ALL duct work joints must be taped to prevent moisture and lint from escaping into the building. Inspection doors should be installed at strategic points in the exhaust duct work for periodic inspection and clean-out of lint from the ductwork.

NOTE: Wheretheexhaustductpassesthroughawall,ceiling,orroofmadeofcombustiblematerials, theopeningmustbe2-incheslarger(allthewayaround)thantheduct. Theductmustbe centeredwithinthisopening.

a.Outside Duct Work Protection

1)To protect the outside end of horizontal duct work from the weather, a 90° elbow bent downward should be installed where the exhaust exits the building. If the duct work travels verticallyupthroughtheroof,itshouldbeprotectedfromtheweatherbyusinga180°turntopoint theopeningdownward. Ineithercase,allowatleasttwicethediameteroftheductbetweentheduct openingandthenearestobstruction.

IMPORTANT: DONOTusescreensorcapsontheoutsideofopeningofexhaustductwork.

16

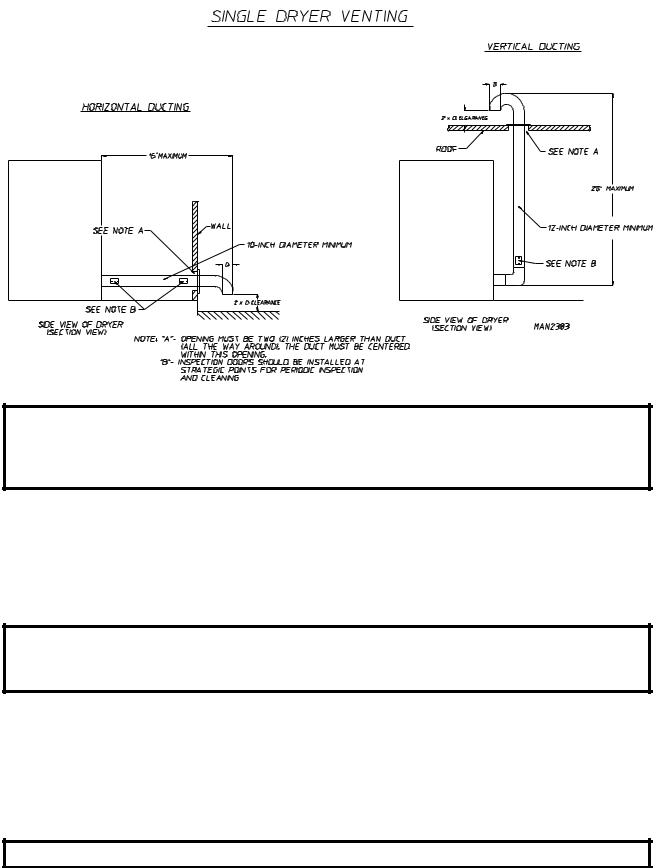

3. MultipleDryer(common)Venting

If it is not feasible to provide separate exhaust ducts for each dryer, ducts from individual dryers may be channeledintoa"commonmainduct." Theindividualductsshouldenterthebottomorsideofthemainduct atananglenotmorethan45ºinthedirectionofairflowandshouldbespacedatleast38-1/4inchesapart. The main duct should be tapered, with the diameter increasing before each individual duct (10-inch minimum)isadded.

IMPORTANT: Nomorethanfour(4)dryersshouldbeconnectedtomaincommonduct.

Themainductmaybeanyshapesolongastheminimumcrosssectisprovided. Theillustrationonpagexx showstheminimumcrosssectionareaformultipledryerroundorsquareventing. Thesefiguresmustbe increased 10 square inches when rectangular main ducting is used, and the ration of duct width to depth should not be greater than 3-1/2 to 1. These figures must be increased in proportion if the main duct run from the last dryer to where it exhausts to the outdoors is unusually long (over fifteen [15] feet) or has numerous(morethan two[2]elbowsinit). Incalculatingductworksize,thecrosssectionareaofasquare or rectangular duct must be increased twenty (20) percent for each additional fifteen (15) feet. The diameter of a round exhaust must be increased ten (10) percent for each additional fifteen (15) feet. Each 90º elbow is equivalent to an additional thirty (30) feet and each 45º elbow is equivalent to an additional fifteen (15) feet.

IMPORTANT: Forextendedductworkruns,thecrosssectionareaoftheductworkcanonlybe increasedtoanextent. Maximumproportionalductworkrunscannotexceedfifteen (15)feetwithtwo(2)elbows. Whentheduckworkapproachesthemaximumlimits asnotedinthismanual,aprofessionalHVACfirmshouldbeconsultedforproper venting. HVACshouldbeconsultedforproperventinginformation.

Theductworkshouldbesmoothinsidewithnoprojectionsfromsheetmetalscrewsorotherobstructions whichwillcollectlint. Whenaddingducts,theducttobeaddedshouldoverlaptheducttowhichitistobe connected. ALL duct work joints must be taped to prevent moisture and lint from escaping into the building. Inspection doors should be installed at stategic points in the exhaust duct work for periodic inspectionandclean-outoflintfromtheductwork.

NOTE: Wheretheexhaustpassesthroughawall,ceiling,orroofmadeofcombustiblematerials, theopeningmustbe2-incheslarger(allthewayaround)thantheduct. Theductmustbe centeredwithinthisopening.

a.OutsideDuctWorkProtection

1)Toprotecttheoutsideendofhorizontalductworkfromwheather,a90ºelbowbentdownwardshouldbe installed where the exhaust exits the building. If the duct work travels vertically up through the roof, it should be protected from the wheather by using a 180º turn to point the opening downward. In either case, allow at least twice the diameter of the duct between the duct opening and the nearest obstruction.

IMPORTANT: DONOTusescreensorcapsontheoutsideofopeningofexhaustductwork.

17

18

F. ELECTRICAL INFORMATION

1. ELECTRICAL REQUIREMENTS

It is your responsibility to have all electrical connections made by a properly licensed and competent electrician to assure that the electrical installation is adequate and conforms with local and state regulations or codes. In the absence of such codes, ALL electrical connections, material, and workmanship must conform to the applicable requirements of the National Electrical Code ANSI/NFPA NO.70-LATEST EDITION..

IMPORTANT: Failure to comply with these codes or ordinances, and/or the requirements stipulated in this manual can result in personal injury or component failure.

NOTE: Component failure due to improper installation will VOID THE WARRANTY.

Each dryer should be connected to an independently protected branch circuit. The dryer must be

connected with copper wire only. The copper conductor wire/cable

DO NOT use aluminum wire which could cause a fire hazard. must be of proper ampicity and insulation in accordance with

electric codes for making all service connections.

NOTE: The use of aluminum wire will VOID THE WARRANTY.

IMPORTANT: A separate circuit servicing each dryer must be provided.

19

Loading...

Loading...