Page 1

AD-95/ML-95

Service Manual

American Dryer Corporation

88 Currant Road

Fall River, MA 02720-4781

Telephone: (508) 678-9000 / Fax: (508) 678-9447

E-mail: techsupport@amdry.com

072298SL/cj

ADC Part No. 450188

Page 2

Retain This Manual In A Safe Place For Future Reference

American Dryer Corporation products embody advanced concepts in engineering, design, and safety. If this product is

properly maintained, it will provide many years of safe, efficient, and trouble-free operation.

ONLY qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation/operator's manual

included with the dryer.

The following FOR YOUR SAFETY caution must be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors or liquids

in the vicinity of this or any other

appliance.

We have tried to make this manual as complete as possible and hope you will find it useful. ADC reserves the right to make

changes from time to time, without notice or obligation, in prices, specifications, colors, and material, and to change or

discontinue models.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser dessence

ni dautres vapeurs ou liquides

inflammables dans le voisinage de cet

appareil ou de yout autre appareil.

Important

For your convenience, log the following information:

DATE OF P URCHASE MODEL NO.

DISTRI BUTORS NAM E

Serial Number(s)

Replacement parts can be obtained from your distributor or the ADC factory. When ordering replacement parts from the

factory, you can FAX your order to ADC at (508) 678-9447 or telephone your orders directly to the ADC Parts Department at

(508) 678-9000. Please specify the dryer model number and serial number in addition to the description and part number, so

that your order is processed accurately and promptly.

The illustrations on the following pages may not depict your particular dryer exactly. The illustrations are a composite of the

various dryer models. Be sure to check the descriptions of the parts thoroughly before ordering.

IMPORTANT NOTE TO PURCHASER

Information must be obtained from your local gas supplier on the instructions

to be followed if the user smells gas. These instructions must be posted in a

prominent location near the dryer.

Page 3

IMPORTANT

YOU MUST DISCONNECT and LOCKOUT THE ELECTRIC SUPPLY and THE GAS

SUPPLY or THE STEAM SUPPLY BEFORE ANY COVERS or GUARDS ARE

REMOVED FROM THE MACHINE TO ALLOW ACCESS FOR CLEANING, ADJUSTING, INSTALLATION, or TESTING OF ANY EQUIPMENT per OSHA (Occupational

Safety and Health Administration) STANDARDS.

«Attention: Lor des opérations dentretien

Caution: Label all wires prior to

disconnection when servicing controls. Wiring

errors can cause improper operation.

des commandes étiqueter tous fils avant

de les déconnecter. Toute erreur de

câblage peut étre une source de danger et

de panne.»

CAUTION

DRYERS SHOULD NEVER BE LEFT UNATTENDED WHILE IN OPERATION.

WARNING

CHILDREN SHOULD NOT BE ALLOWED TO PLAY ON OR NEAR THE DRYER(S).

CHILDREN SHOULD BE SUPERVISED IF NEAR DRYERS IN OPERATION.

FOR YOUR SAFETY

DO NOT DRY MOP HEADS IN THE DRYER.

DO NOT USE DRYER IN THE PRESENCE OF DRY CLEANING FUMES.

WARNING

UNDER NO CIRCUMSTANCES should the door switch or the heat circuit devices ever

be disabled.

Page 4

WARNING

The dryer must never be operated with any of the back guards, outer tops, or service

panels removed. PERSONAL INJURY or FIRE COULD RESULT.

WARNING

DRYER MUST NEVER BE OPERATED WITHOUT THE LINT FILTER/SCREEN IN

PLACE, EVEN IF AN EXTERNAL LINT COLLECTION SYSTEM IS USED.

IMPORTANT

PLEASE OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment and/or

specified in the installation and operator's manual included with the dryer.

Dryers must not be installed or stored in an area where it will be exposed to water or

weather.

The wiring diagram for the dryer is located in the front electrical control box area.

Page 5

Table of Content

SECTION I

Important Information...................................................................................................................................... 3

A. Safety Precautions .......................................................................................................................................... 3

SECTION II

Maintenance ...................................................................................................................................................... 4

A. Cleaning .......................................................................................................................................................... 4

B. Adjustments ..................................................................................................................................................... 5

C. Lubrication ...................................................................................................................................................... 5

SECTION III

Installation Requirements ............................................................................................................................... 6

A. Enclosure, Air Supply, and Exhaust Requirements ......................................................................................... 6

B. Electrical and Gas Requirements .................................................................................................................... 6

C. Operational Service Check Procedure ........................................................................................................... 7

SECTION IV

Desciption of Parts ........................................................................................................................................... 8

A. Computer Panel (Microprocessor) ................................................................................................................. 8

B. Reversing Relay Panel.................................................................................................................................... 9

C. HSI Module (for Gas Models ONLY) .......................................................................................................... 10

D. Gas Burner Assembly................................................................................................................................... 10

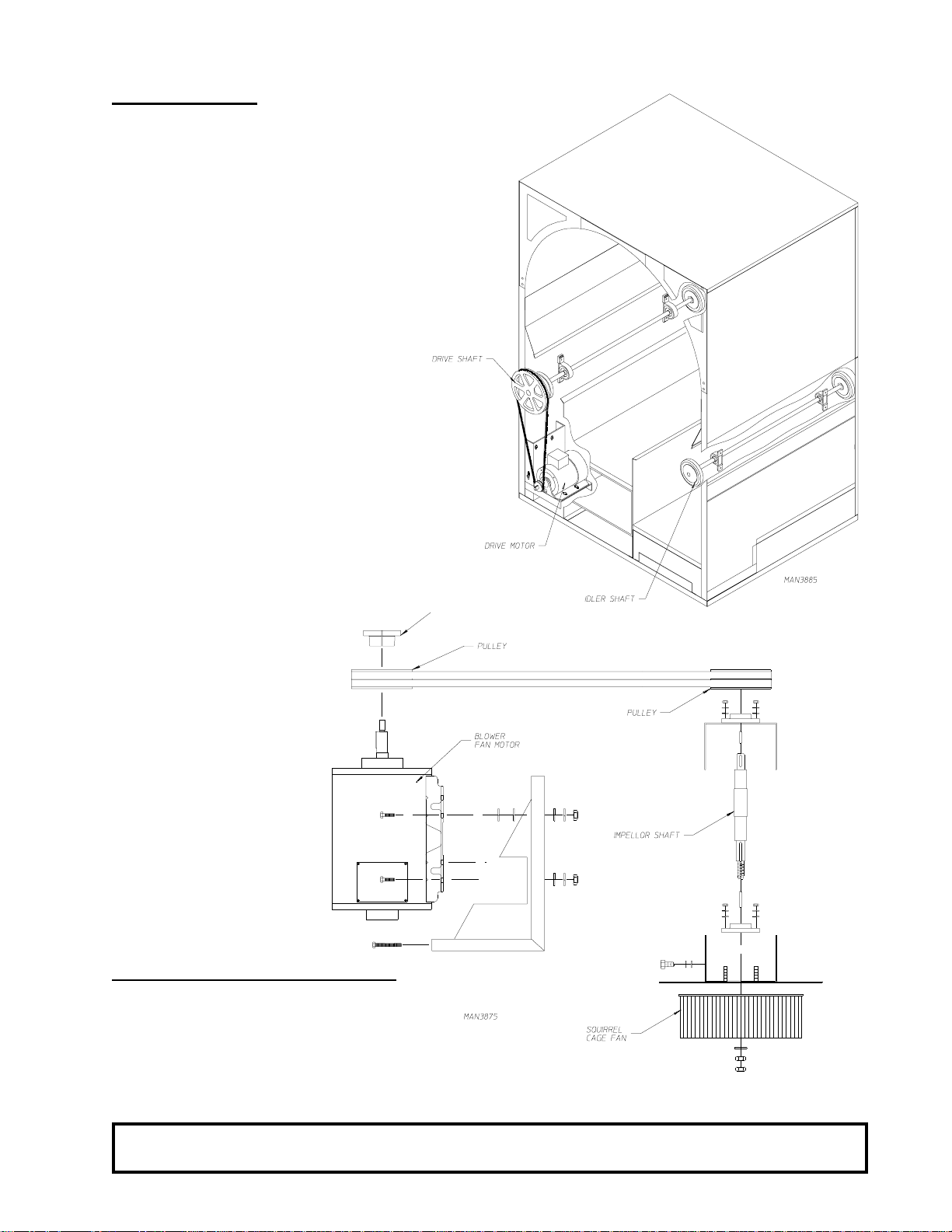

E. Drive Motor................................................................................................................................................... 11

F. Blower Motor and Impellor .......................................................................................................................... 11

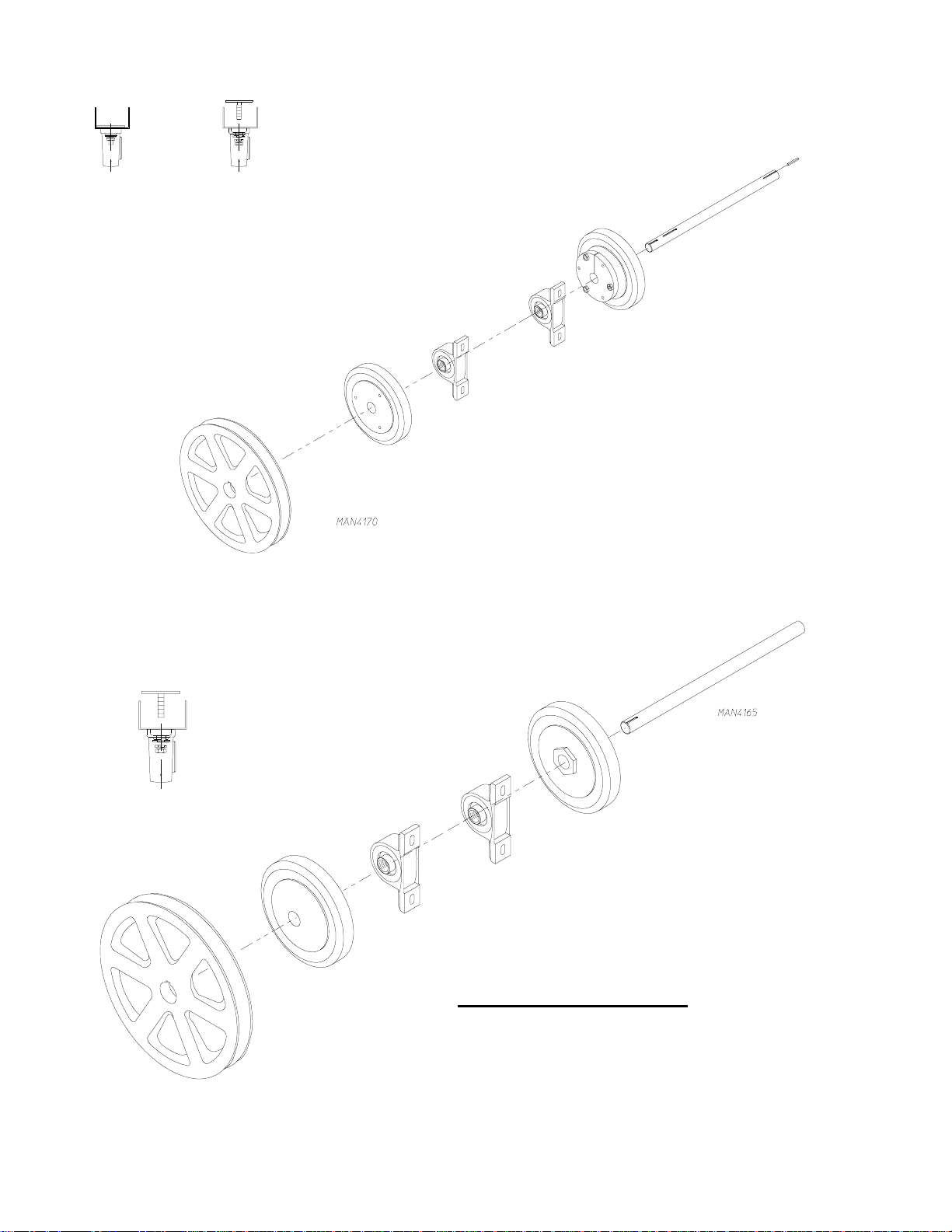

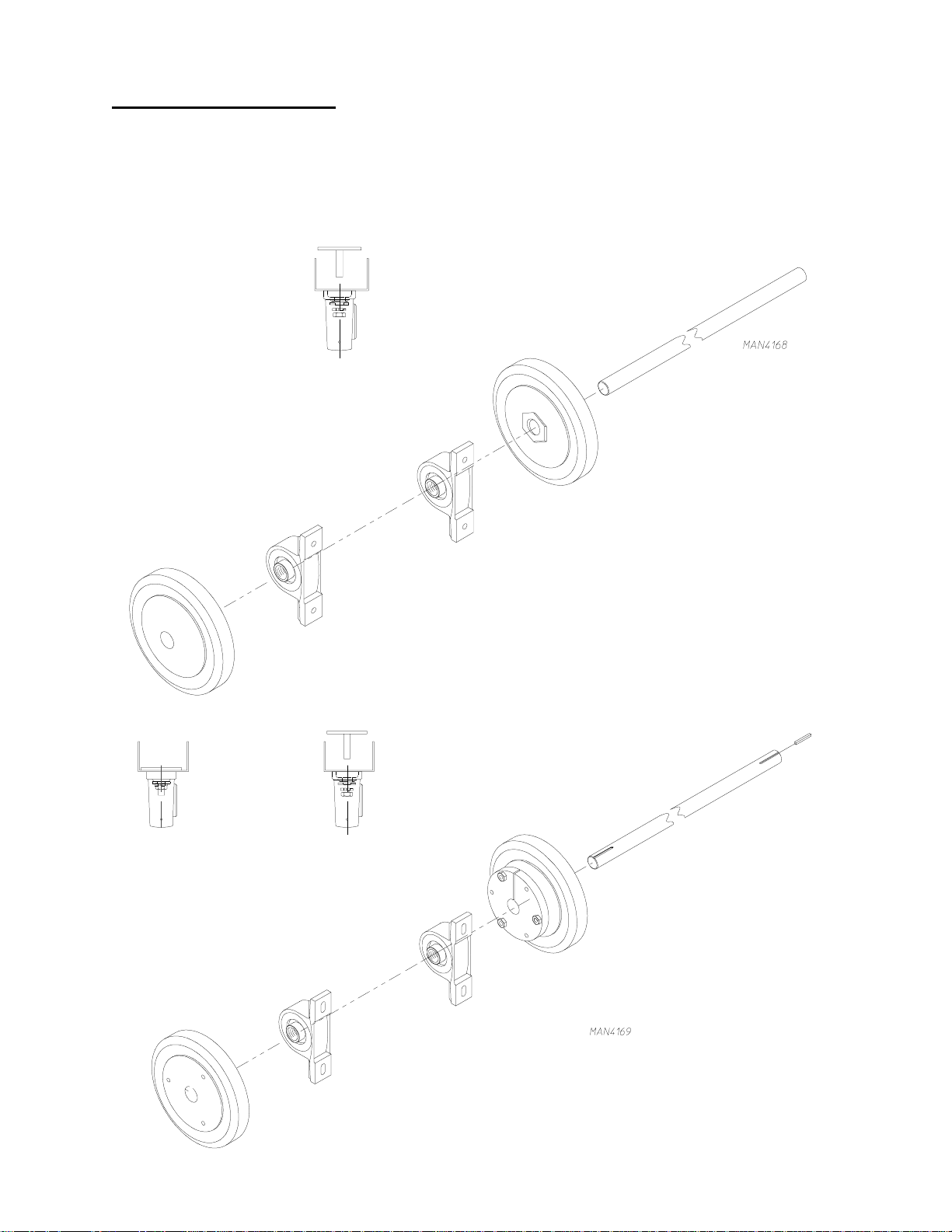

G. Drive Shaft Assembly.................................................................................................................................... 12

H. Idler Shaft Assembly .................................................................................................................................... 13

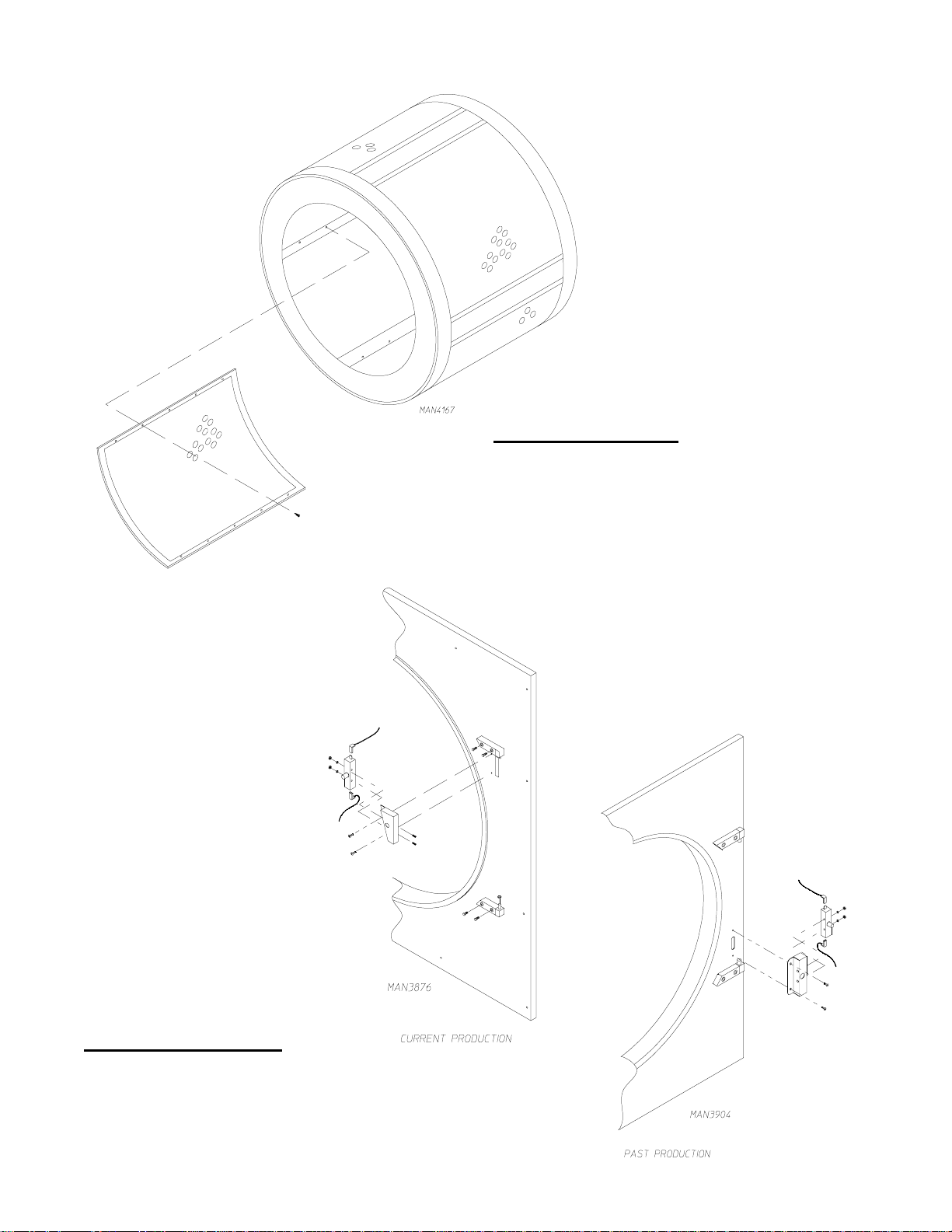

I. Basket (Tumbler) .......................................................................................................................................... 14

J. Main Door Switch ......................................................................................................................................... 14

K. Sail Switch (for Gas Models ONLY)............................................................................................................ 15

L. Hi-Limit (for Gas Models ONLY) ................................................................................................................ 15

M. Automatic Reset Thermostat ....................................................................................................................... 16

N. Lint Screen ................................................................................................................................................... 16

O. Lint Drawer Switch ...................................................................................................................................... 17

SECTION V

Servicing .......................................................................................................................................................... 18

A. Computer Controls ........................................................................................................................................ 18

B. Ignition Controls ............................................................................................................................................ 20

C. Thermostats .................................................................................................................................................. 23

D. Sail Switch Assembly (for Gas Models ONLY) ........................................................................................... 24

E. Front Panel and Main Door Assemblies ....................................................................................................... 25

F. Pulleys .......................................................................................................................................................... 28

G. Basket Assembly ........................................................................................................................................... 32

H. Bearings ........................................................................................................................................................ 33

I. V-Belts .......................................................................................................................................................... 33

J. Motors ........................................................................................................................................................... 34

K. Impellor ......................................................................................................................................................... 37

L. Lint Drawer Assembly .................................................................................................................................. 37

Page 6

SECTION VI

Troubleshooting .............................................................................................................................................. 38

SECTION VII

Phase 6 OPL System Diagnostics ................................................................................................................ 41

A. Diagnostic (L.E.D. Display) Failure Codes .................................................................................................. 41

B. LED Display Indicators ................................................................................................................................ 43

C. L.E.D. Codes ................................................................................................................................................ 48

D. Computer Logic and Wiring Diagram........................................................................................................... 50

SECTION VIII

Technical Information .................................................................................................................................... 56

A. Motor Plate (High and Low Voltage) ........................................................................................................... 56

B. Data Label .................................................................................................................................................... 57

C. Using a Manometer ...................................................................................................................................... 58

D. Tool List ........................................................................................................................................................ 59

Page 7

SECTION I

Important Information

A. Safety Precautions

1. DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

2. Purchaser or user should consult the local gas supplier for proper instructions to be followed in the event the

user smells gas. The instructions should be posted in a prominent location.

3. Dryer must be exhausted to the outdoors.

4. Although ADC's dryer is a very versatile machine, there are some articles, that due to fabric composition or

cleaning method, should not be dried in it.

WARNING: Dry only water-washed fabrics. DO NOT dry articles spotted or washed in dry

cleaning solvents, a combustible detergent, or "all-purpose" cleaners. Fire or

explosion could result.

WARNING: DO NOT dry rags or articles coated with gasoline, kerosene, paint, or wax. Fire or

explosion could result.

WARNING: DO NOT dry mop heads. Contamination by wax or flammable solvents will create

a fire hazard.

WARNING: DO NOT use heat for drying articles that contain plastic, foam, sponge rubber, or

similarly textured rubberlike materials. Drying in a heated tumbler may damage plastic

or rubber and also may be a fire hazard.

5. A program should be established for the inspection and cleaning of lint in the burner area and exhaust duct

work. The frequency of cleaning can best be determined from experience at each location.

WARNING: The collection of lint in the burner area and exhaust duct work can create

a potential fire hazard.

6. For personal safety, the dryer must be electrically grounded in accordance with local codes and the National

Electric Code ANSI/NFPA No. 70-LATEST EDITION.

NOTE: Failure to do so will void the warranty.

7. Under no circumstances should the dryer door, lint drawer switches or heat safety devices ever be disabled.

WARNING: PERSONAL INJURY OR FIRE COULD RESULT.

8. Articles should never be left unattended for an extended period of time in the basket after completion of the

drying and cooling cycles.

9. This dryer is not to be used in the presence of dry cleaning solvents or fumes.

10. Read and follow

WARNING: CHILDREN SHOULD NOT BE ALLOWED TO PLAY ON OR IN THE DRYERS

ALL caution and direction labels attached to dryer.

CHILDREN SHOULD BE SUPERVISED IF NEAR DRYERS IN OPERATION.

3

Page 8

SECTION II

Routine Maintenance

A. Cleaning

A program and schedule should be established for periodic inspection, cleaning, and removal of lint from various

areas of the dryer, as well as throughout the duct work system. The frequency of cleaning can best be determined

from experience at each location. Maximum operating efficiency is dependent upon proper air circulation. The

accumulation of lint can restrict this airflow. If the guidelines in this section are met, an ADC dryer will provide

many years of efficient, trouble free, and most importantly safe operation.

WARNING: LINT FROM MOST FABRICS IS HIGHLY COMBUSTIBLE. THE

ACCUMULATION OF LINT CAN CREATE A POTENTIAL FIRE HAZARD.

WARNING: KEEP DRYER AREA CLEAR AND FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS.

NOTE: Suggested time intervals shown for average usage which is considered six (6) to eight (8)

operational (running) hours per day.

Clean lint drawer and screen every third load.

NOTE: Frequency can best be determined at each location.

Daily (beginning) of each work shift.

Clean lint from the drawer and screen. Inspect lint screen and replace if torn.

Weekly

Clean lint accumulation from lint chamber, thermostat and microprocessor temperature sensor (sensor bracket)

area.

WARNING: To avoid the hazard of electrical shock, discontinue electrical supply to dryer.

90 Days

Remove lint from basket, drive motors and surrounding areas. Remove lint from gas valve burner area with a

dusting brush or vacuum cleaner attachment.

NOTE: To prevent damage, avoid cleaning or touching ignitor and flame-probe assembly.

Remove lint accumulation from inside control box and at rear area behind control box.

6 Months

Inspect and remove lint accumulation in customer-furnished exhaust duct work system and from dryer's internal

exhaust ducting.

4

Page 9

WARNING: THE ACCUMULATION OF LINT IN THE EXHAUST DUCT WORK CAN CREATE

A POTENTIAL FIRE HAZARD.

WARNING: Do not obstruct the flow of combustion and ventilation air. Check customer furnished back

draft damper in exhaust duct work. Inspect and remove any lint accumulation which can

cause damper to bind or stick.

NOTE: A back draft damper that is sticking partially closed can result in slow drying and shutdown of the

heat circuits safety switches or thermostats.

NOTE: When cleaning dryer cabinets, avoid using harsh abrasive. A product intended for cleaning

appliances is recommended.

B. Adjustments

Seven Days after Installation and every 6 Months

Inspect bolts, nuts, screws (bearing set screws), nonpermanent gas connections (union, shut-off valves, orifices,

and ground connections). Motor and drive belts should be examined. Cracked or seriously frayed belts should be

replaced. Tighten loose V-belts when necessary. Complete operational check of controls and valves. Complete

operational check of all safety devices (door switch, lint drawer switch, sail switch, burner and hi-limit thermostats).

C. Lubrication

The motor bearings, idler bearings, and basket (tumbler) bearings are permanently lubricated. No lubrication is

necessary.

The impeller (fan) shaft bearing should be lubricated every three (3) months.

5

Page 10

SECTION III

Installation Requirements

Installation should be performed by competent technicians in accordance with local and state codes. In the

absence of these codes, installation must conform to applicable AMERICAN NATIONAL STANDARDS:

National Fuel Gas Code ANSI Z223.1-LATEST EDITION or National Electric Code ANSI/NFPA No. 70LATEST EDITION, or Canadian Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION

(for Electrical Connections).

A. Enclosure, Air Supply, and Exhaust Requirements

NOTE: The following information is very brief and general. For detailed description, refer

to the AD-95 Installation Manual supplied with dryer. (ADC P/N 112197)

Bulkheads and partitions around the dryer should be made of noncombustible materials. Allowances should

be made for the opening and closing of the control door and lint door. (Refer to appropriate installation manual for

recommended distances and minimum allowances required.)

When the dryer is operating, it draws in room air, heats it, passes this air through the basket (tumbler), and

exhausts it out of the building. Therefore, the room air must be continually replenished from the outdoors. If the

makeup air is inadequate, drying time and drying efficiency will be adversely affected. Ignition problems and sail

switch "fluttering" problems on gas dryers may result, and you also could have premature motor failure from

overheating. The air supply must be given careful consideration to insure proper performance of each dryer.

IMPORTANT: Makeup air must be provided from a source free of dry cleaning fumes. Makeup air

that is contaminated by dry cleaning fumes will result in irreparable damage to motors

and other dryer components.

Exhaust duct work should be designed and installed by a competent technician. Improperly sized duct work will

create excessive back pressure which will result in slow drying, increased use of energy, and shutdown of the

burner by the airflow (sail) switch, burner hi-limit or lint chamber hi-heat protector thermostat. (Refer to appropriate

Installation Manual for more detail.)

CAUTION: IMPROPERLY SIZED OR INSTALLED EXHAUST DUCT WORK CAN

CREATE A POTENTIAL FIRE HAZARD.

B. Electrical and Gas Requirements

It is your responsibility to have ALL electrical connections made by a properly licensed and competent

electrician to assure the electrical installation is adequate and conforms with local and state regulations or codes.

In the absence of such codes, ALL electrical connections, material, and workmanship must conform to the

applicable requirements of the National Electric Code ANSI/NFPA No. 70-LATEST EDITION, or Canadian

Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION (for Electrical Connections).

IMPORTANT: Failure to comply with these codes or ordinances and the requirements

stipulated in this manual can result in personal injury or component failure.

6

Page 11

The dryer installation must meet the AMERICAN NATIONAL STANDARD, NATIONAL FUEL GAS CODE

ANSI Z223.1-LATEST EDITION, as well as, local codes and ordinances, and must be done by a qualified

technician, or Canadian Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION

(for Electrical Connections).

NOTE: Undersized gas piping will result in ignition problems and slow drying and can create a safety

hazard.

The dryer must be connected to the type of gas (natural or L.P.) indicated on the dryer data label. If this

information does not agree with the type of gas available, contact the distributor who sold the dryer or contact the

factory.

The gas input ratings shown on the dryer data label are for elevations up to 2,000 feet, unless elevation requirements of over 2,000 feet were specified at the time the dryer order was placed with the factory. The adjustment

for dryers in the field for elevations over 2,000 feet are made by changing the burner orifices. If this adjustment

is necessary, contact the distributor who sold the dryer or contact the factory.

NOTE: Any burner changes must be made by a qualified technician.

C. Operational Service Check Procedure

1. Turn on electric power to the dryer.

2. To start dryer:

a. Display will read "READY"

b. Press "E" touch pad on the keyboard of microprocessor controller (computer).

c. The dryer will start and display will show "dRYING MANUAL CYCLE, 30 MIN REMAIN,"

then display the drum temp.

NOTE: Pressing touch pads A, B, C, D and F will also start the dryer. Six (6) preprogrammed drying

cycles (A through F) have been stored in the computer's memory. (See computer operator's

manual for details.)

3. Make a complete operational check of all the operating controls to assure that the timing is correct,

temperature selection switches are functioning, etc.

4. Make a complete operational check of all safety-halted circuits: door switches, hi-limit thermostat, sail

switch, cycling thermostats, etc.

5. For gas dryers a gas pressure test should be taken at the gas valve pressure tap of each dryer to assure

that the water column pressure is correct and consistent.

NOTE: Water column pressure requirements (measured at the pressure tap on the gas valve body):

Natural Gas - 3.5 to 4 inch water column

L.P. Gas - 10.5 to 11 inch water column.

6. If computer program changes are required, refer to the Phase 6 OPL Operator's Manual (ADC P/N

113022) for details.

7. The dryer should be operated through one complete cycle to assure that no further adjustments are neces-

sary and that all components are functioning properly.

8. Check the electric service phase sequence. While the dryer is operating, check to see if the blower wheel

is rotating in the proper direction. Looking from the front, the blower wheel should spin in the clockwise

direction. If so, the phasing is correct. If the phasing is incorrect, reverse two (2) leads at connections L1,

L2 or L3 of power supply to the dryer.

7

Page 12

SECTION IV

Description of Parts

prior to February 11, 1998

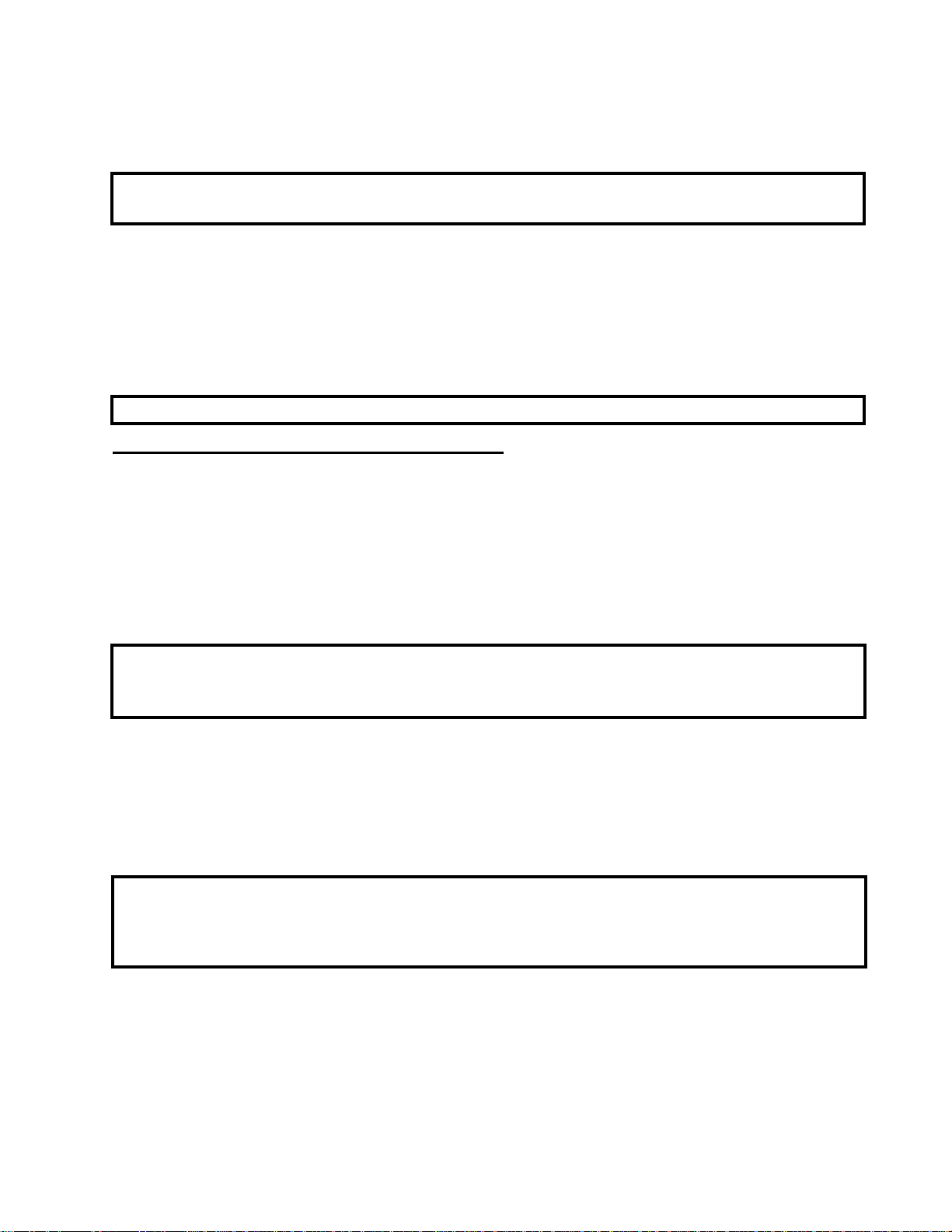

A. Control Panel (Microprocessor)

Lifting the control door will reveal the control panel assembly. Opening the control panel will allow access to

the major components which include the computer board

and keypad. The keypad inputs to the computer what

temperature and program has been selected. The computer controls the entire operation of the machine. It

accepts inputs and gives outputs throughout the machine.

as of February 11, 1998

8

Page 13

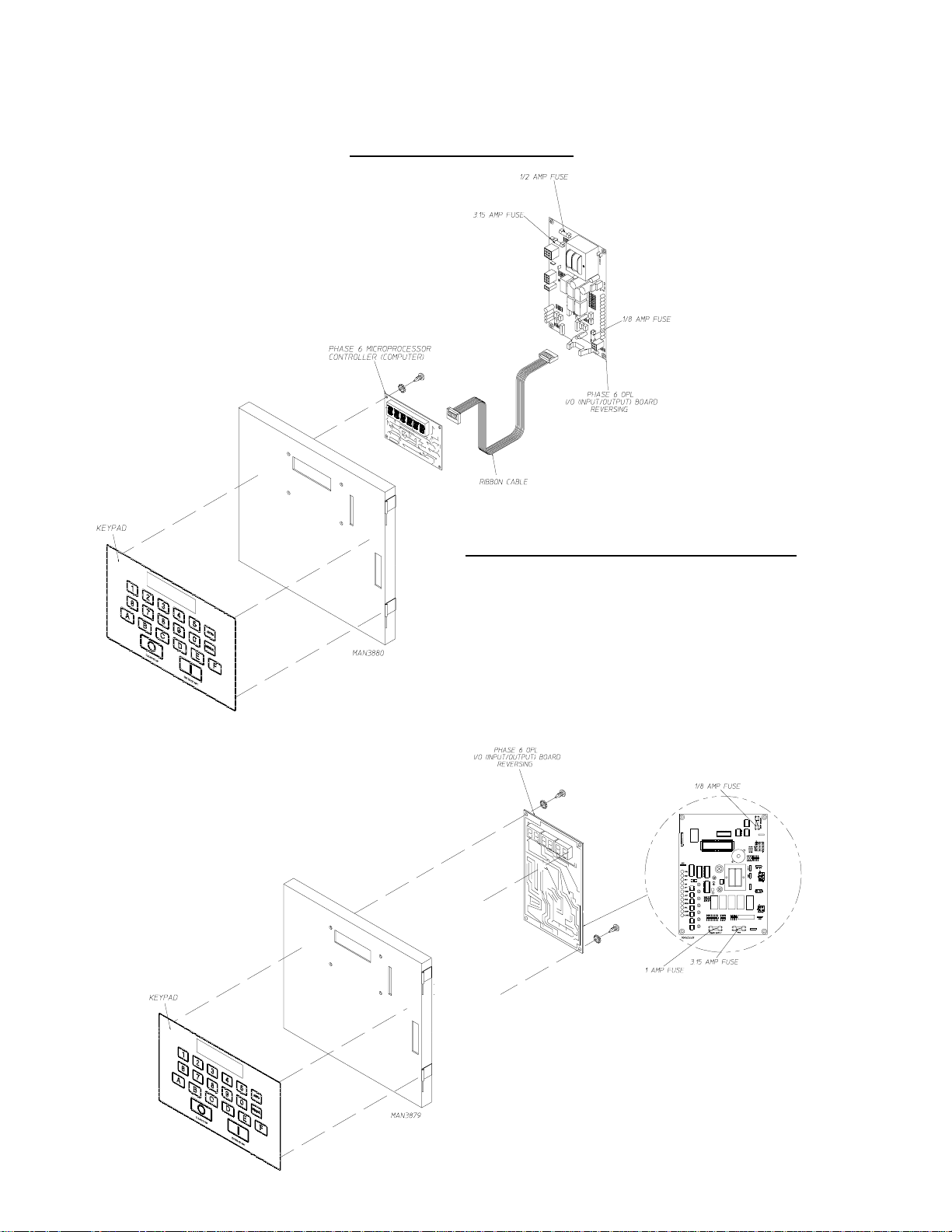

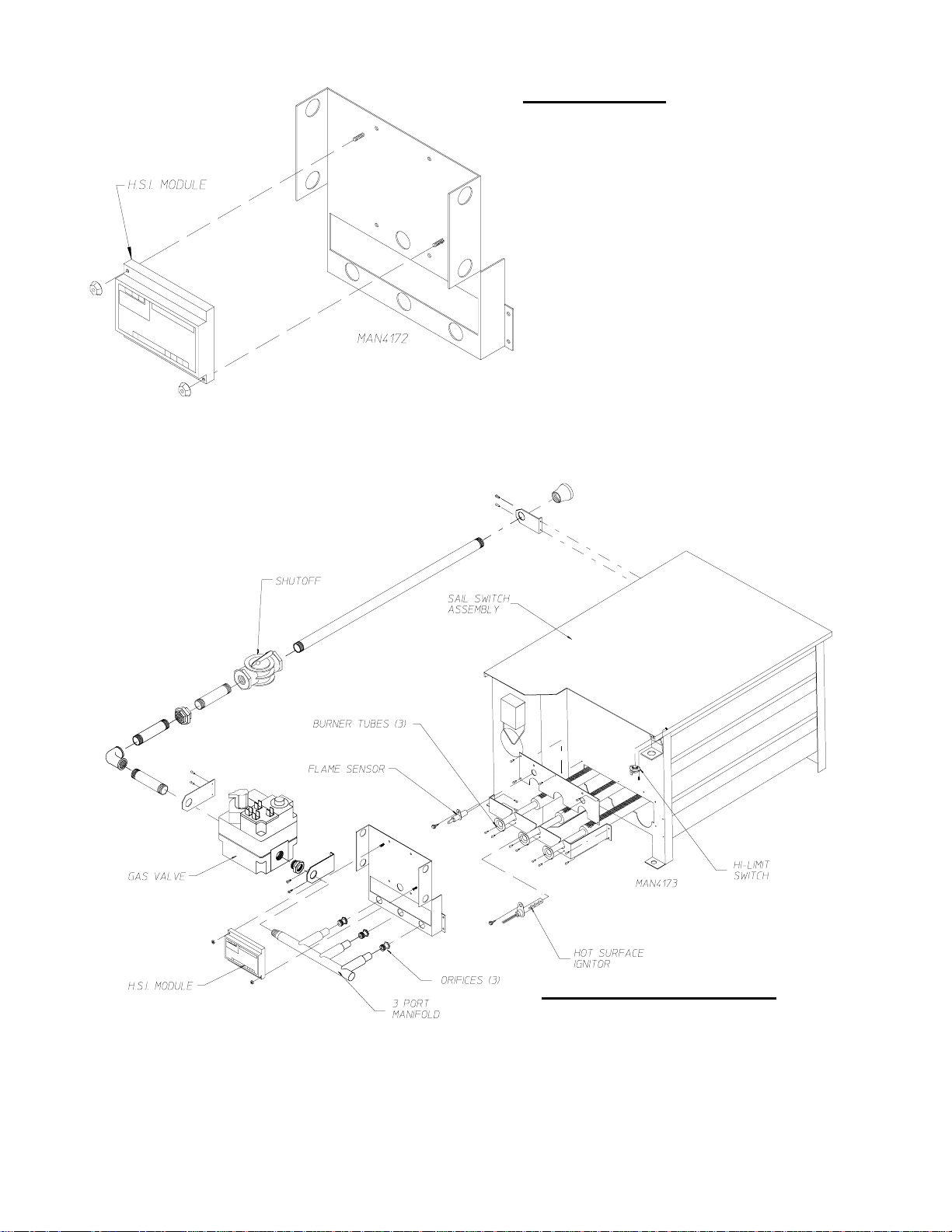

...with circuit breaker

B. Reversing Relay Panel

Lifting the control door will reveal the reversing relay

box. Located on the back of the relay box is the reversing relay panel. Included on this panel is a four (4) position terminal block, blower overload, blower contactor,

reversing contactor, 24VAC transformer, fuse or circuit

breaker, ground lug and an arc suppressor (A.S.) board.

...with fuses

9

Page 14

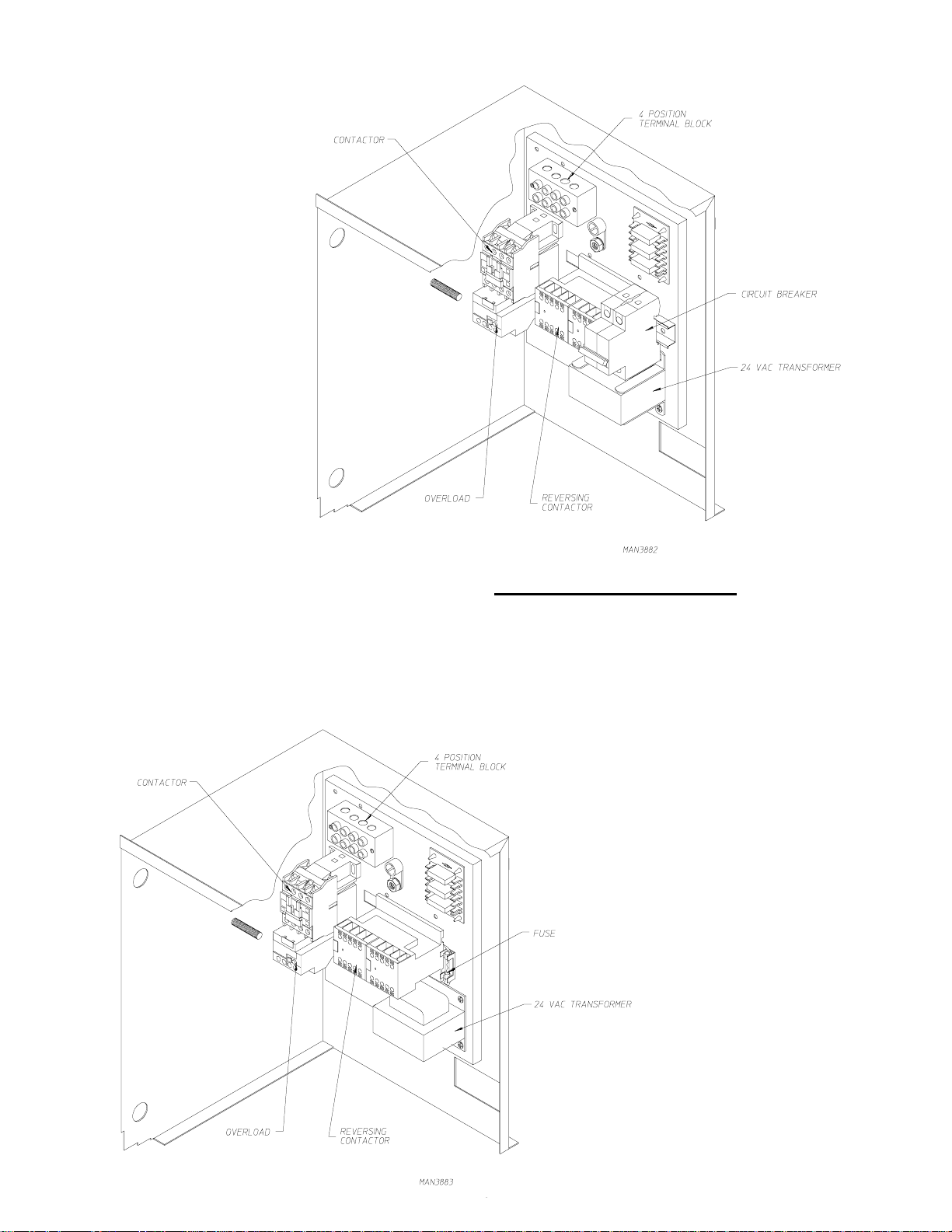

C. HSI Module (Gas Models

Only)

The HSI system consists of a microprocessorbased control module, along with a hot surface

ignitor probe and a flame probe assembly. The

hot surface ignitor is a silicon carbide ignitor that

upon application of 24VAC will glow bright

orange for the inter-purge time period. Upon

ignition, the resistance in the flame sensor

electrode changes and the information is sent

to the HSI module via the sensor probe lead

connection to the module. Once the resistance

is changed and sensed, the HSI module will

sustain the gas flow (provide 24VAC power to

the gas valve).

10

D. Gas Burner Assembly

Gas-heated dryers are equipped with a gas

burner assembly consisting of three (3) burner

tubes, gas valve, glo bar, flame sensor, sail

switch, and hi-limit thermostat. The inlet

piping enters through the rear of the dryer on

the left-hand side (viewing from the front)

and runs to the front of the dryer where the

gas valve is located.

Page 15

E. Drive Motor

The TEFC (totally enclosed, fan-cooled) drive motor is located in the front left corner (viewing from

front) behind the front panel of the dryer. It sits

on an adjustable base so the motor can be easily

adjusted to the left or right, up or down, forward

or backward. The drive motor is a 1/2 HP motor

and operates on 208 to 460 volts, 50/60 hertz, 3phase.

F. Blower Motor and Impeller

The impeller is shaft driven. The blower motor drives the shaft on which the impeller is

mounted. This enables the impeller to run at

a higher RPM, thereby producing a higher

airflow (CFM).

NOTE: The bearing on this type of blower assembly should be greased according to the maintenance

section of this manual.

11

Page 16

taperlock

trantorque

G. Drive Shaft Assembly

(Viewing from the front of the dryer.) Behind front panel

on the left side of the dryer, you can view the drive shaft

assembly which consists of a 9" drive pulley, two (2) 6"

wheels, two (2) trantorques, on models manufactured prior

to December 15, 1997; or with two (2) taperlock bearings, on models manufactured after December 15, 1997;

and two (2) 1" pillow block bearings.

12

Page 17

H. Idler Shaft Assembly

(Viewing from the front of the dryer.) Behind the front panel on the right side of the dryer you will view the

idler shaft assembly which consists of two (2) 6" wheels, two (2) transtorque on models manufactured

prior to December 15, 1997; or with two (2) taperlock bearings on models manufactured after December

15, 1997; and two (2) 1" pillow block bearings.

transtorque

taperlock

13

Page 18

I. Basket (Tumbler)

The basket consists of a basket (tumbler) weldment

which have four (4) ribs and four (4) removable

perforated panels which are mounted to the rib

sections of the basket (tumbler) weldment with

1/4-20 x 1/4" socket button head screws.

J. Main Door Switch

The main door switch is mounted to the front panel

behind the main door. When the main door opens,

the switch will also open, preventing the dryer from

operating. The main door switch is a safety device

and should never be disabled.

14

Page 19

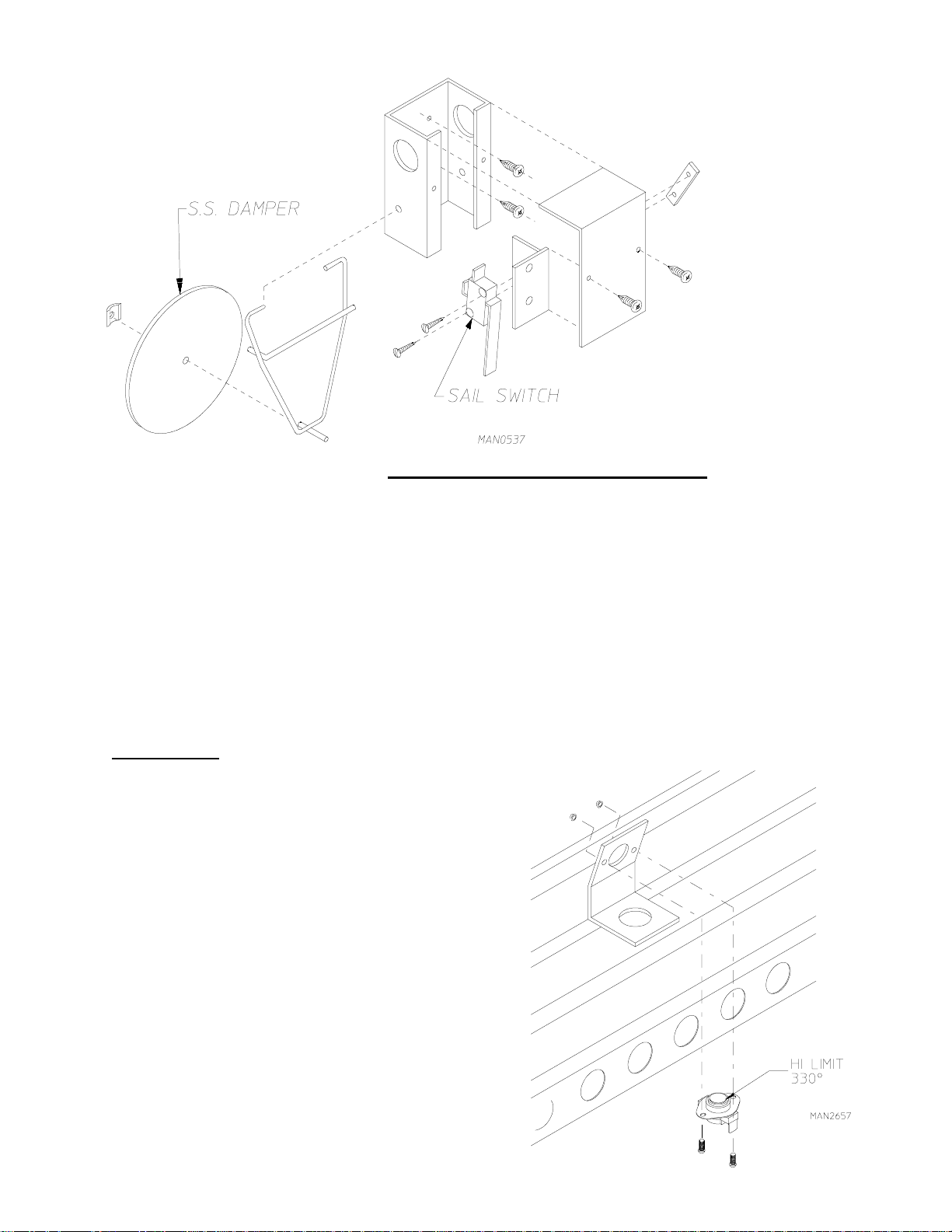

K. Sail Switch (Gas Models Only)

The sail switch is located on the front of the burner box. A sail switch

consists of a round damper plate on a lever arm which is in contact with

an electric switch. When the fan or air blower comes on, it draws air

through the gas burner. This creates a negative pressure inside the

burner box, and this negative pressure pulls in the round damper and

activates the sail switch. If there is improper air flow, the damper will

not pull in, preventing the burner from starting. The display will also

read "no airflow flow" with an audio indication. Improper airflow can be

caused by improperly designed exhaust ducting where the duct run is

too long or has too many sharp bends in it. It can also be caused by a

lack of makeup air.

L. Hi-Limit (Gas Models Only)

Prior to May 26, 1998. The high limit thermostat is an

automatic reset disc-type thermostat set at 330º F and

located near the burner. If the burner flame gets too hot,

this thermostat will shut off the burner. This is generally

caused by low airflow through the dryer. In a hi-limit

situation the display will read "bURNER SAFETY FAIL"

with an audio indication.

As of May 26, 1998. The high limit thermostat is a

manual reset disc-type thermostat set at 330º F and located near the burner. If the burner flame gets too hot,

this thermostat will shut off the burner. This is generally

caused by low airflow through the dryer. In a hi-limit

situation the display will read "bURNER SAFETY FAIL"

with an audio indication. The manual reset thermostat

must be reset manually or the 24VAC burner circuit will

never be complete. This will cause the phase 6 to continue to go off on "bURNER SAFETY FAIL" with an

audio indication.

15

Page 20

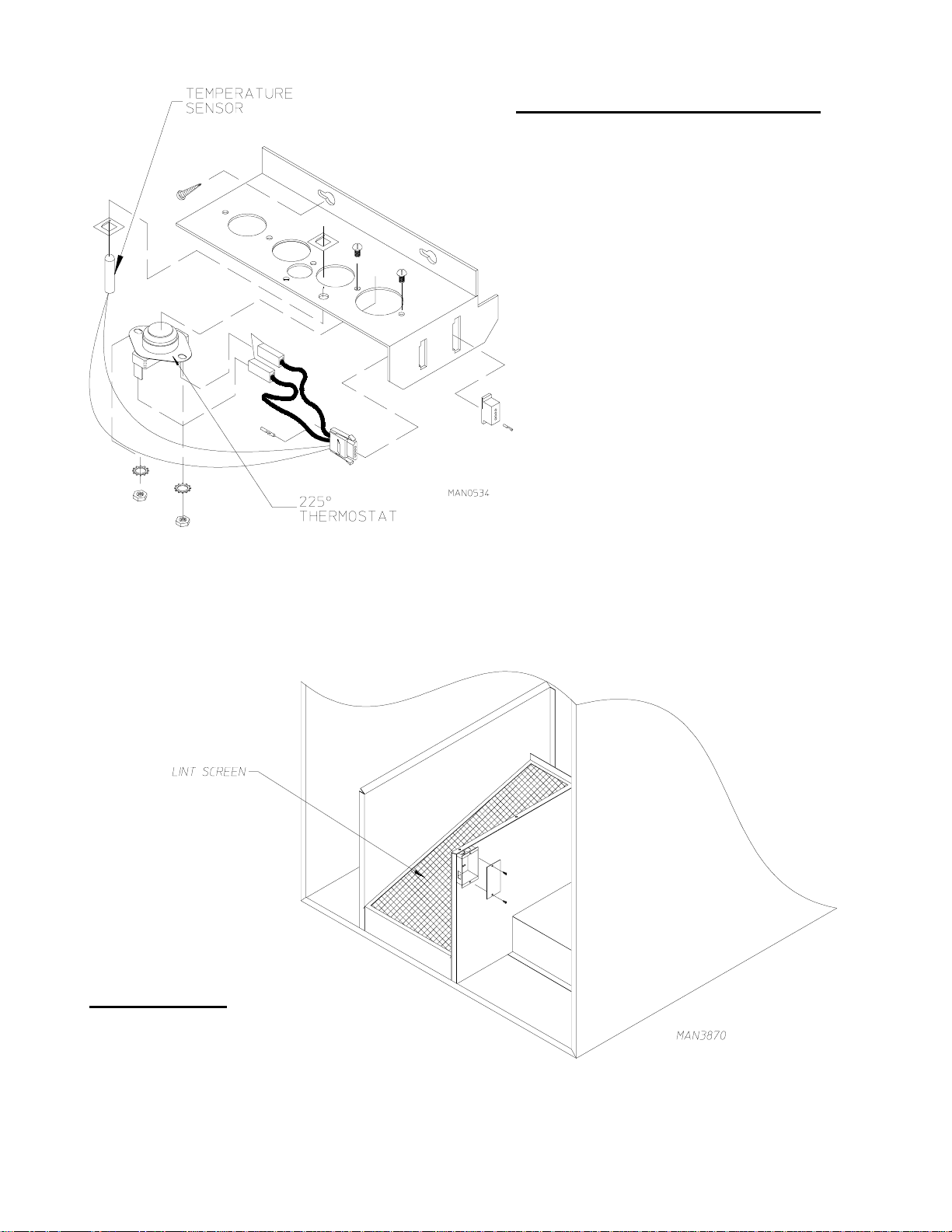

M. Automatic Reset Thermostat

This is located inside the dryer in the lint compartment above the lint screen. This thermostat

senses the heated air after it passes through the

basket. If the air temperature gets too hot, the

thermostat will shut off the burner. The dryer

will not run until the air temperature cools down.

At this time, the thermostat will reset. Basket

and blower will run but the dryer will not heat. If

the temperature sensor opens the display will read

"TEMP SENSOR FAIL CHECK TEMP SENSOR FUSE" with an audio indication. If the thermostat opens the display will read "dRUM

SAFETY FAIL" with an audio indication.

N. Lint Screen

The lint screen is located in the front of the dryer

behind the lint door it is a non-removable framed

screen which is screwed into the lint coupe. To

clean the lint off the screen simply brush the screen

clean. The lint screen must be kept clean in order

for the dryer to operate properly and efficiently.

Inspect the screen for tears and replace as needed.

16

Page 21

O. Lint Drawer Switch

The lint door switch is located in the lint compartment and attached to the side of the lint coupe. The lint door switch ensures

that the dryer will operate only when the lint door is completely

closed. This is a safety device and should never be disabled.

17

Page 22

SECTION V

Servicing

Introduction

ALL electrical and mechanical service or repairs should be made with the electrical power to the dryer

disconnected (power off).

WARNING: PERSONAL INJURY COULD RESULT

The information provided in this section should not be misconstrued as a device for use by an untrained person

making repairs. Service work should be performed by competent technicians in accordance with local, state,

and federal codes. When contacting the factory for assistance, always have the dryer model and serial numbers

available.

CAUTION: Observe

manual before and while making repairs.

Before considering replacement, make sure that ALL connectors are in place and making proper contact.

ALL safety precautions displayed on the dryer or specified in this

A. Computer Controls

To Replace Input/Output Board Reversing (Prior to February 11, 1998)

1. Discontinue power to the dryer.

2. Disconnect the nine (9) pin connector, six (6) pin connector, four (4) pin connector and a two (2) pin

connector from the computer panel by squeezing the clip on the pin connector and pulling the plug away

from the board.

3. Disconnect the green ground wire from the board

4. Disconnect the ribbon cable assembly from the input/output board reversing.

5. Remove the two (2) screws securing the input/output board to the sheet metal control panel. Remove

the board by pulling the other two corners off the clinch studs.

6. Install new reversing input/output board by reversing this procedure.

To Replace Display Board

1. Discontinue power to the dryer.

2. Unplug keyboard ribbon from the rear of the computer.

3. Unplug ribbon cable assembly from the rear of the computer.

4. Remove the two (2) screws securing the computer to the computer box door. Remove the computer by

pulling the other two corners off the clinch studs.

5. Install new display by reversing this procedure.

To Replace Computer Board

1. Disconnect power to dryer.

2. Unplug keyboard ribbon from rear of computer.

3. Unplug all wiring harnesses connected to the computer board.

4. Remove the two (2) screws securing the computer to the

computer panel. Remove the computer by pulling the other

two corners off the clinch studs.

5. Install new computer by reversing this procedure.

18

Page 23

To Replace Keyboard Label Assembly

1. Discontinue power to dryer.

2. Unplug keyboard ribbon from rear of computer.

3. Slowly peel off and remove keyboard label assembly from control panel.

4. Peel paper backing off new keyboard label assembly.

5. Holding the new keyboard label assembly close to the panel, insert the keyboard ribbon through the

rectangular slot in the control panel. Align label assembly into

position by matching the red viewing window on the label

to the rectangular cutout in the panel and gently press into

place.

6. Connect keyboard ribbon to the computer.

7. Reestablish power to dryer.

To Replace Microprocessor Temperature Sensor

Probe

1. Discontinue power to the dryer.

2. Open lint door.

3. Remove microprocessor sensor bracket assembly from

dryer.

a. Disconnect sensor bracket harness connector.

b. Loosen the two (2) Phillips head screws which

secure bracket assembly to dryer and remove

bracket from dryer.

NOTE: Do not remove screws.

4. Disassemble sensor probe from bracket assembly by removing the top push-on fastener securing the

probe from bracket. Use a small screwdriver to slowly pry the fastener off.

5. Disconnect the two (2) orange wires from the high heat (225º F) thermostat, and remove modular bracket

connector, wires, and probe from bracket assembly.

6. Install new sensor probe assembly (ADC P/N 811710) by reversing procedure.

7. Reestablish power to the dryer.

NOTE: If, when power is reestablished, the computer display reads "TEMP SENSOR FAIL CHECK

TEMP SENSOR FUSE," check for a loose connection in the wiring.

19

Page 24

B. Ignition Controls

To Remove Hot Surface Ignitor (see

burner illustration on page 10)

1. Discontinue power to dryer.

2. Disconnect wire from S1 and GND on the HSI

module.

3. Disassemble ignitor from burner by removing the

one (1) self tapping screw.

4. Reverse procedure for installation of new ignitor.

To Remove Flame Sensor Probe

1. Discontinue power to dryer.

2. Disconnect the red wire from the flame sensor probe which goes to S2 on the HSI module.

3. Disassemble flame sensor probe from burner by removing the one (1) self tapping screw.

4. Reverse procedure for installation of new flame sensor probe.

HSI Ignitor Flame Sensor Probe

NOTE: Before reestablishing power to dryer visually check the following (see illustration)

A. That the hot surface ignitor wires are connected to S1 and GND on the HSI module.

B. Do not wrap the hot surface ignitor wires and the flame electrode wire together. Improper operation may

result. They may run alongside each other.

20

Page 25

To Replace Gas Valve (See burner illustration on page 10)

1. Discontinue power to dryer.

2. Close shut-off valves in gas supply line.

3. Disconnect gas valve wiring.

NOTE: Identify location of each wire for correct reinstallation.

4. Break union connection before gas valve.

5. Loosen and remove four (4) screws securing pipe brackets to burner.

6. Remove valve and manifold assembly from dryer.

7. Remove valve mounting bracket, manifold and piping from gas valve.

8. Reverse procedure for installing new gas valve.

WARNING: Test all connections for leaks by brushing on a soapy water solution. NEVER TEST FOR

LEAKS WITH A FLAME.

To Replace Main Burner Orifices

1. Refer to "To Replace Gas Valve" and follow steps 1 through 6.

2. Unscrew main burner orifices and replace.

NOTE: Use extreme care when removing and replacing orifices. These orifices are made of brass and

are easily damaged.

3. Reverse the removal procedure for reinstalling.

NOTE: Test all connections for leaks by brushing on a soapy water solution. NEVER TEST FOR

LEAKS WITH A FLAME.

To Test and Adjust Gas (Water Column) Pressure

There are two (2) types of devices commonly used to measure column pressure. They are spring and mechanicaltype gauges and manometers. The spring and mechanical-type gauge is not recommended, because it is easily

damaged and not always accurate. A manometer is simply a glass or transparent plastic tube with a scale in

inches. When filled with water and pressure applied, the water in the tube rises showing the exact water column

pressure.

NOTE: Manometers are available from the factory by ordering ADC P/N 122804.

1. To test gas water column (W.C.) Pressure:

a. Connect water column test gauge connection to gas valve pressure tap

(1/8" NPT). This pressure tap is located on the outlet (manifold) side

of the valve.

b. Start dryer. With burner on, the correct water column reading in

inches would be:

Natural Gas - 3.5 Inches Water Column

L.P. Gas - 10.5 Inches Water Column

2. To adjust water column pressure (natural gas only, L.P. gas must be

regulated at source):

21

Page 26

a. Remove the slotted vent cap on the top of the valve.

b. Turn the slotted adjustment screw located on the top of the valve next to the terminals. Turn clockwise to

increase manifold pressure and counterclockwise to decrease.

NOTE: If correct W.C. pressure cannot be achieved, problems may be due to an undersized gas supply line,

a faulty or underrated gas meter, etc.

To Convert Natural Gas to L.P. Gas

NOTE: All dryers are sold as natural gas, unless otherwise specified at the time the dryer order was placed.

For L.P. gas the dryer must be converted as follows.

1. Refer to "Replace Gas Valve" and follow steps 1 through 6.

A. For models with 3/4" White-Rodgers valve.

1. Remove top vent cap.

2. Insert spring and pin.

3. Replace vent cap.

2. Unscrew main burner orifices and replace with L.P. orifices.

NOTE: Use extreme care when removing orifices. They are made of brass and are easily damaged.

3. Reverse the procedure for reinstalling valve assembly to the dryer.

WARNING: Test all connections for leaks by brushing a on soapy water solution. NEVER TEST FOR

LEAKS WITH A FLAME.

NOTE: There is no regulator provided in an L.P. dryer. The column pressure must be regulated at the

source (L.P. tank) or an external regulator must be added to each dryer.

To Replace Burner Tubes

1. Refer to "Replace Gas Valve" and follow steps 1 through 6.

2 Remove four screws securing the HSI module mounting

bracket.

3. Remove front flanges of the burner tubes to the burner

tube rest.

4. Remove the screws securing the burner tube rest

to the oven and remove this rest.

5. Remove screws securing burner box cover plate to the

oven and remove the cover.

6. Remove burner tubes by sliding them out.

7. Replace by reversing procedure.

WARNING: Test all connections for leaks by brushing on a soapy water solution. NEVER TEST FOR

LEAKS WITH A FLAME.

22

Page 27

To Replace HSI Module

1. Discontinue power to the dryer.

2. Remove the wires connected to the terminal strip at the bottom

of the module. (Mark correct location of each wire to aid in

replacement on new module.)

3. Remove the four (4) pal nuts securing the module to the

mounting bracket.

4. Replace module by reversing procedure.

5. Reestablish power to dryer.

C. Thermostats

To Replace Burner Hi-Limit Thermostat (Gas

Models Only)

1. This thermostat is an important safety device as an added

protection against failure of the air flow (sail switch) to open in

the event of motor failure or reduced airflow conditions.

IMPORTANT: Under no circumstances should heat circuit

safety devices ever be disabled.

NOTE: Models manufactured as of 1998 are equipped with a

manual reset hi-limit thermostat.

1. Discontinue power to dryer.

2. Disconnect wires from hi-limit thermostat.

3. Remove the two (2) screws, washers and nuts securing

thermostat to the bracket. Remove thermostat.

4. Reversing procedure for installing new thermostat.

5. Reestablish power to dryer.

To Replace Lint Compartment Hi-Heat Protector (225º) Thermostat

This thermostat is part of the "sensor bracket assembly" and is secured to the underside of the basket wrapper in

the lint compartment. As a safety device, this thermostat will open (shut off) the heating unit circuit if an

excessive temperature occurs. The dryer motor will remain on, even if the thermostat is open.

1. Disconnect power to dryer.

2. Open lint door.

3. Locate sensor bracket assembly and loosen the two (2) Phillips head

screws securing bracket assembly to the tumbler wrapper.

NOTE: Do not remove the screws.

23

Page 28

4. Remove bracket assembly by slightly sliding bracket toward the rear of the dryer and to the left.

5. Disconnect sensor bracket harness connector and remove bracket assembly from dryer.

6. Disconnect the two (2) orange wires from the thermostat.

7. Disassemble thermostat from bracket assembly by removing the two (2) mounting screws, washers and

nuts.

8. Reverse this procedure for installing a hi-heat protector thermostat.

9. Reestablish power to the dryer.

D. Sail Switch Assembly (Gas Models Only)

The sail switch is a heat circuit safety device which controls the burner circuit only. When the dryer is operating

and there is proper airflow, the sail switch damper pulls in and closes the sail switch. Providing all the other heatrelated circuits are functioning properly, ignition should now be established. If an improper airflow occurs, the sail

switch damper will release, and the circuit will open.

To Replace Sail Switch

1. Discontinue power to dryer.

2. Remove the two (2) screws which hold the sail switch box cover to sail switch box.

3. Disconnect the two (2) wires from the switch.

4. Disassemble sail switch from mounting bracket by removing the two (2) screws securing switch in place.

5. Reverse this procedure for installing new sail switch. Adjust sail switch described in the next section.

To Adjust Sail Switch

With the dryer operating at a high temperature setting, pull the sail switch away from the burner. The sail switch

should open and extinguish the burner. Let the sail switch damper return to the burner wall. The sail switch

should close to restart the burner ignition cycle. If the sail switch circuit does not operate as described, bend the

actuator arm of the sail switch accordingly until proper operation is achieved. To check proper "open" position of

sail switch, open main door, manually depress main door switch and start dryer. With the main door open and the

dryer operating, the sail switch should be open, and the burner should not come on.

24

Page 29

CAUTION: Do not abort this switch by taping or screwing sail switch damper to burner. PERSONAL

INJURY OR FIRE COULD RESULT.

E. Front Panel and Main Door Assemblies

To Replace Main Door Switch

1. Discontinue power to dryer.

2. Open main door.

3. Remove the two (2) Phillips head screws holding the main door switch bracket assembly in place.

4. Disconnect wiring from switch assembly.

5. Reverse this procedure for installing new door switch assembly.

6. Reestablish power to dryer.

IMPORTANT: Under no circumstances should the door switch be disabled.

To Replace Main Door Assembly

1. Open main door.

2. Holding the door upward remove the two (2) screws from the top hinge block.

3. Lift the door up to remove.

4. Reverse this procedure for reinstalling new main door assembly.

To Install New Main Door Glass as of October 24, 1997

1. Remove main door assembly from dryer (follow main door removal procedure).

2. Lay main door on flat surface with the back of the door facing down.

3. Remove the four 10-32 acorn nuts securing the glass to the door.

4. Remove glass and clean all old sealant off main door. This area must be clean for correct bonding.

5. Place a bead of silicone around the edge door and lightly press glass into place.

25

Page 30

IMPORTANT: Do not press hard or silicone thickness between the glass and door will be reduced,

resulting in poor bonding.

6. The door assembly should now be put in an area where it will not be disturbed for at least 24 hours.

Depending on the conditions, the curing time of this adhesive is 24 to 36 hours.

7. After 24-hour curing period, install main door on dryer by reversing step 1.

IMPORTANT: Do not press hard or silicone thickness between the glass and door will be reduced,

resulting in poor bonding.

6. Reinstall the four 10-32 acorn nuts that where removed in step #3.

As of October 24, 1997

26

Prior to October 24, 1997

Page 31

7. The door assembly should now be put in an area where it will not be disturbed for a few hours. This

will give the silicone a chance to harden.

NOTE: Once the silicone is cured you may want to trim any excess silicone on the inside of the main

door assembly.

8. After the curing period install the main door on the dryer by reversing step no. 1.

To Install new Main Door Glass prior of October 24, 1997

1. Remove main door assembly from dryer (follow main door removal procedure).

2. Lay main door on flat surface with back of door face down.

3. Remove glass and clean all old sealant off main door. This area must be completely clean for correct

bonding.

4. Apply a narrow bead of silicone (ADC P/N 170730) all around main door area where glass will rest.

5. Install glass onto door and adhesive. Slightly press glass into place.

IMPORTANT: Do not press hard or silicone thickness between the glass and door will be reduced, resulting

in poor bonding.

NOTE: Once the silicone is cured you may want to trim any excess silicone on the inside of the main door

assembly.

6. After the curing period install the main door on the dryer by reversing step #1.

To Replace Front Panel

1. Discontinue power to dryer.

2. Remove bottom lint door assembly.

3. Disconnect the four emergency stop wires located in the front left electrical box.

4. Remove the front panel by removing the screws.

IMPORTANT: When pulling the front panel off, the door switch harness in the upper right hand

corner must be unplugged.

NOTE: The main door assembly can be removed to make the panel removal easier. Refer to

"replace main door assembly" directions.

5. Disconnect the emergency stop assembly from the old panel and reinstall on the new panel.

6. Disconnect other door switch wiring switch from the old panel and reinstall on the new front panel.

7. Reinstall the new front panel by reversing steps 1 through 3.

8. Reestablish power to dryer.

To Replace Main Door Hinge Block

1. Discontinue power to dryer.

2. Follow procedure for removal of main door assembly for top hinge removal.

3. Remove the two screws from the bottom hinge block.

4. Reassemble by reversing removal procedure.

27

Page 32

5. Reestablish power to dryer.

F. Pulleys

To Replace Drive Shaft Pulley

1. Discontinue power to dryer.

2. Remove front panel from dryer (Follow front

replacement directions on page 27.)

3. Loosen v-belts. Rotate pulley and roll v-belts

out of grooves.

4. Remove set screw from the 9" pulley.

5. Remove pulley and key.

NOTE: A gear puller may be required to

remove pulley.

6. Reverse this procedure for replacement.

NOTE: Pulley must be aligned for proper

operation.

To Replace Drive Motor Pulley

1. Discontinue power to dryer.

2. Remove front panel from the dryer. Follow front panel replacement directions on page 27.

3. Loosen v-belts. Rotate pulley and roll v-belt out of groove.

4. Remove set screw from the drive motor pulley.

5. Remove pulley and key.

NOTE: A gear puller may be required to remove pulley.

6. Reverse this procedure for replacement.

NOTE: Pulleys must be aligned for proper operation.

Tumbler Wheel Replacement on Drive Assembly (taper lock models)

1. Discontinue power to dryer.

2. Remove front panel from dryer. (Follow front panel replacement directions on page 27.)

3. Remove the ten (10) 1/4-20 x 1/4" socket button head screws from the perfed basket side.

4. Remove wrapper assembly.

5. Loosen v-belts. Rotate pulley and v-belts out of the groove.

6. Block the basket (tumbler) assembly in position.

7. Mark the position of pillow block bearing then remove the bolts from the pillow block bearings.

8. Remove the drive shaft assembly through the front of the machine.

9. Remove the set screw from the 9" pulley.

28

Page 33

10. Remove the pulley and key.

NOTE: A gear pulley may be required to remove the pulley.

11. Remove cap screws from bushing.

12. Insert cap screws in the tapped removal holes and tighten evenly until bushing becomes loose on shaft.

13. Remove the bushing, tumbler wheel and key.

14. Reverse this procedure for replacement.

IMPORTANT: Tighten screws evenly and progressively. Never allow the sheave to be drawn in

contact with the flange of the bushing. This gap should measure from 1/8" to 1/4".

Proper cap screw torque is 30 ft-lbs. If greater tightening forces are applied, excess

pressure will be created in the hub of the mounted sheave which may cause it to crack.

Tumbler Wheel Replacement on Drive Assembly (transtorque models)

1. Discontinue power to dryer.

2. Remove front panel from the dryer. (Follow front panel replacement directions on page 27.)

3. Remove the ten (10) 1/4-20 x 1/4" socket button head screws from the perfed basket side.

4. Remove wrapper assembly.

5. Loosen v-belts. Rotate pulley and v-belts out of groove on the pulley. For a more detailed description,

follow steps replacement of drive belt.

6. Block the basket (tumbler) assembly in position.

7. Mark the position of the pillow block bearings, then remove the bolts from the pillow block bearings.

8. Remove the drive shaft assembly through the front of the machine.

9. Remove the set screw from the 9" pulley.

10. Remove the pulley and key.

NOTE: A gear pulley may be required to remove the pulley.

11. Remove the transtorque from the wheel assembly.

29

Page 34

NOTE: One wrench must be on the transtorque and one on the axle. The wrench on the transtorque

should have pressure applied in a counterclockwise direction.

12. Remove the bushing trantorque and tumbler wheel.

13. Reverse these procedures for replacement.

Tumbler Wheel Replacement on Idler Assembly (taper lock models)

1. Disconnect power to the dryer.

2. Remove the front panel from the dryer. (Follow front panel replacement directions on page 27.)

3. Remove the ten (10) 1/4-20 x 1/4" socket button head screws from the perfed basket side.

4. Remove the wrapper assembly.

5. Block the basket tumbler assembly in position.

6. Mark the position of the pillow block bearings. Then remove the bolts from the pillow block bearing.

7. Remove the idler shaft assembly through the front of the machine.

8. Remove the cap screws from bushing.

9. Insert cap screws in the tapped removal holes and tighten evenly until bushing becomes loose on shaft.

10. Remove the bushing, tumble wheel and key.

11. Reverse this procedure for replacement.

30

Page 35

IMPORTANT: Tighten screws evenly and progressively. Never allow the sheave to be drawn in

contact with the flange of the bushing. This gap should measure from 1/8" to 1/4".

Proper cap screw torque is 30 ft-lbs. If greater tightening forces are applied, excess

pressures will be created in the hub of the mounted sheave which may cause it to crack.

Tumbler Wheel Replacement on Idler Assembly (trantorque models)

1. Discontinue power to the dryer.

2. Remove the front panel form the dryer. (Follow front panel replacement directions on page 27.)

3. Remove the ten (10) 1/4-20 x 1/4" socket button head screws from the perforated basket side.

4. Remove the wrapper assembly.

5. Block the basket (tumbler) assembly in position.

6. Mark the position of the pillow block bearings. Then remove the bolts from the pillow block bearings.

7. Remove the idler shaft assembly through the front of the machine.

8. Remove the transtorque from the wheel assembly.

NOTE: One wrench must be on the transtorque and one on the axle. The wrench on the transtorque

should have pressure applied in a counterclockwise direction.

9. Remove the bushing (transtorque) and tumbler wheel.

10. Reverse these procedures for replacement.

To Replace Blower Shaft Pulley

1. Discontinue power to the dryer.

2. Remove the ten (10) 1/4-20 x 1/4" socket button head screws from the perforated basket side and remove

the basket panel.

3. Remove the inside right wrapper.

4. Loosen v-belts. Rotate pulley and roll v-belts out of the groove.

5. Remove cap screw from bushing.

6. Insert cap screws in tapped removal holes and tighten evenly until bushing becomes loose on shaft.

7. Remove bushing, pulley and key.

8. Reverse this procedure for replacement.

31

Page 36

IMPORTANT: Tighten screws evenly and progressively. Never allow the sheave to be drawn in

contact with the flange of the bushing. This gap should measure from 1/8" to 1/4".

Proper cap screw torque is 30 ft-lbs. If greater tightening forces are applied, excess

pressures will be created in the hub of the mounted sheave which may cause it to crack.

To Replace Blower Motor Pulley

1. Discontinue power to the dryer.

2. Remove the ten (10) 1/4 - 20 x 1/4" socket button head screws from the perforated basket side and remove

the basket panel.

3. Remove the inside right wrapper.

4. Loosen v-belts, rotate pulley and roll v-belts out of groove.

5. Remove cap screws from the bushings.

6. Insert cap screws in tapped removal holes and tighten evenly until bushing becomes loose on shaft.

7. Remove bushing, pulley and key.

8. Reverse this procedure for replacement.

IMPORTANT: Tighten screws evenly and progressively. Never allow the sheave to be drawn in

contact with the flange of the bushing. This gap should measure from 1/8" to 1/4".

Proper cap screw torque is 30 ft-lbs. If greater tightening forces are applied, excess

pressures will be created in the hub of the mounted sheave which may cause it to crack.

Basket Assembly

NOTE: Dryer must be level prior to basket alignment.

1. Discontinue power to the dryer.

2. Remove the perforated basket (tumbler) panel.

3. Remove wrapper panel to access the drive and idler shaft.

32

Page 37

4. Place a level on the shafts to verify if level.

5. Measure distance between basket and wrapper 1/2" to 3/4" gap should be derived.

6. Loosen the 8 bolts on the pillow block bearings and turn the adjustment screw clockwise or counterclockwise to increase or decrease the gap between the basket and wrapper.

7. Measure the length of the adjustment bolts and all should be equal.

8. Place a level on the shaft to verify it is level if any adjustment has been made.

9. Check the basket drive belt for proper tension. Adjust if necessary.

10. Replace the wrapper panels.

11. Replace the perforated basket (tumbler) panel.

To Replace Idler Shaft Pillow Block Bearing

1. Refer to tumbler wheel replacement on idler assembly page 30.

2. Complete steps 1 through 11.

3. Remove both set screws from each pillow block bearing.

4. Remove pillow block bearing from shaft.

5. Reverse this procedure for replacement.

NOTE: Once the shaft assembly has been installed into dryer. Return pillow block bearings to the marked

position and tighten set screws.

6. Refer to basket assembly section page 32 for shaft and basket alignment.

To Replace Drive Assembly Pillow Block Bearing

1. Refer to tumbler wheel replacement on drive assembly page 28.

2. Complete steps 1 through 14.

3. Remove both set screws from each pillow block bearing.

4. Remove pillow block bearings from shaft.

5. Reverse this procedure for replacement.

NOTE: Once the shaft assembly has been installed into dryer. Return pillow block bearing to the marked

position and tighten set screws.

6. Refer to basket assembly section page 32 for shaft and basket alignment.

V-belt Adjustment (Motor to Drive Axle)

1. Discontinue power to dryer.

2. Remove front panel. Follow front panel replacement directions on page 27.

3. Loosen the four (4) bolts holding the drive motor mount to the side of the dryer.

4. Loosen the jam nuts on the adjustment screw on the top of the motor mount.

5. Turn the adjustment screw to lower the motor mount (to tighten the belts) or raise the motor mount (to loosen

the belts.)

6. Check the vertical plane of the motor and idler pulleys for parallel adjustment.

7. If realignment is required, loosen motor pulley and bushing, and move motor pulley to proper position.

33

Page 38

8. Retighten motor mount bolts and jam nuts.

9. Assemble front panel lint door assemblies back to dryer.

10. Reestablish power to dryer.

To Replace Drive Motor V-Belts

1. Discontinue power to the dryer.

2. Remove front panel. Follow front panel replacement instructions on page 27.

3. Loosen tension on v-belt so that it can easily be rolled off pulley. This can be done by loosening the four

bolts holding the motor to the side of the dryer. As well as the adjustment bolt on top.

4. Replace v-belt.

5. Retighten v-belt and adjust tension and alignment per

previous instructions.

J. Motors

To Replace Drive Motor

1. Discontinue power to dryer.

2. Remove front panel from dryer. Follow front

panel replacement instructions on page 27.

3. Remove drive belt.

4. Disconnect wiring harness from motor.

5. Remove bolts holding motor to mount

and replace with new motor. Do not

tighten bolts.

6. Remove pulley from old motor and install on

new motor. By removing the set screw from

the drive motor pulley.

NOTE: A gear puller may be required to

remove pulley.

7. Align motor pulley with drive assembly pulley and tighten set screw holding motor pulley.

8. Replace belts and adjust belt tension.

9. Retighten bolts.

10. Reestablish power to dryer.

To Replace Impeller Motor (Fan Shaft Drive)

1. Discontinue power to the dryer.

2. Remove lint door and front panel from dryer.

3. Remove the perforated panel inside the basket (tumbler).

4. Remove the wrapper assembly under the basket.

34

Page 39

5. Loosen the tension on the blower motor v-belts by loosening the jam nuts and then the adjustment bolt.

6. Remove the bolts securing the motor mount assembly to the dryer cabinet and remove the motor mount

assembly from the dryer.

NOTE: The motor mount assembly will not be able to be removed to far due the wiring harness

still connected.

7. Disconnect the wiring harness from motor.

8. Remove motor pulley from old motor and install on new motor.

NOTE: Be sure to take measurements of the pulley location on the old motor and in this way the belt will

be aligned.

9. Remove the old motor from the motor mount and install the new motor on the mount.

10. Reconnect the wiring harness to the motor.

11. Install motor mount assembly back into the dryer and replace bolts into proper holes finger tight.

12. Replace belts and adjust belt tension.

NOTE: Be sure that the belt alignment is still proper.

13. Retighten bolts

14. Reestablish power to dryer.

To Replace Blower Motor V-belts

1. Remove the ten (10) 1/4 - 20 x 1/4" socket button head screws from the perforated basket side and remove

the basket panel.

2. Remove the right side wrapper.

3. Remove the blower motor belt by loosening the 3/8" bolt with locking nuts.

4. Reinstall new belts by reversing steps 1 though 3.

To Replace Front Thruster Wheels

1. Discontinue power to the dryer.

35

Page 40

2. Remove the front panel. Follow front panel removal instructions on page 27 for removal.

3. Remove thruster wheel assembly.

4. Remove the wheel from thruster wheel bracket.

5. Reverse steps 1 through 5 for installing the new thruster wheel.

To Replace Rear Thruster Wheels on Bolted Brackets Front Access

1. Discontinue power to the dryer.

2. Remove the front panel. Follow front panel removal instructions on page 27.

3. Remove the two (2) front thruster wheel brackets.

4. Remove the basket (tumbler) from the dryer.

IMPORTANT: Be careful of the rotational sensor located underneath the basket. I the basket hits this

sensor it will break. You may want to remove this sensor first.

5. Remove the rear thruster wheels.

6. Reverse steps 1 through 6 for installation of the new thruster wheels.

Rear Access

1. Discontinue power to the dryer.

2. Remove thruster wheel cover.

3. Remove the two (2) bolts securing the thruster wheel bracket to the rear of the machine.

4. Remove the nut securing the thruster wheel to the bracket and remove the thruster wheel.

5. Reverse steps 1 through 4 for installation of the new thruster wheel.

To Replace Rear Thruster Wheels on Welded Thruster Wheel Bracket Models

1. Discontinue power to the dryer.

2. Remove the front panel. Follow front panel removal instruction on page 27.

3. Remove the two (2) front thruster wheel brackets.

4. Remove the basket (tumbler) from the dryer.

IMPORTANT: Be careful of the rotational sensor located underneath the basket. If the basket hits

this sensor, it will break. You may want to remove this sensor for extra caution.

5. Remove the rear thruster wheels.

6. Reverse steps 1 through 6 for installation of the new thruster wheels.

K. Impeller

1. Discontinue power the dryer.

2. Remove the perforated basket (tumbler) panel.

3. Remove right wrapper assembly.

4. Remove v-belts from blower motor and impeller assembly.

36

Page 41

5. Remove the four (4) nuts mounting the impeller assembly to the blower housing.

6. Remove the two (2) set screws and two (2) left hand jam nuts that hold the impeller on the shaft.

7. Remove the impeller, washers and key.

8. Reverse this procedure and reestablish power to the machine.

L. Lint Screen Assembly

To Replace Lint Screen

1. Discontinue power to the dryer.

2. Open lint door.

3. Remove lint screen by removing the screws from the lint screen frame.

NOTE: It may be easier to remove a perforated basket panel for easier access to the lint screen

screws.

4. Replace lint screen and secure frame to the lint coupe.

5. Close lint door.

To Replace Lint Door Switch

1. Disconnect power to dryer.

2. Remove lint door panel.

3. Disconnect both 4-pin connectors at the rear of the lint switch cover.

4. Remove the two (2) screws holding the lint switch cover on.

5. Remove lint switch cover and disconnect the two (2) terminals of the switch.

6. Remove switch by pressing tabs together and pushing switch out.

7. Install new switch by reversing these procedures.

37

Page 42

SECTION VI

Troubleshooting

The information provided will help isolate the most probable components associated with the difficulty described.

The experienced technician realizes that a loose connection or broken or shorted wire may be at fault where

electrical components are concerned -- not necessarily the suspected component itself.

ELECTRICAL PARTS SHOULD ALWAYS BE CHECKED FOR FAILURE BEFORE BEING RETURNED TO THE FACTORY.

The information provided should not be misconstrued as a device for use by an untrained person in making

repairs. Only properly licensed technicians should service the equipment

OBSERVE ALL SAFETY PRECAUTIONS DISPLAYED ON THE EQUIPMENT OR SPECIFIED

IN THIS MANUAL WHILE MAKING REPAIRS.

Refer to section "Electrical Troubleshooting" for a detailed troubleshooting procedure for electrical components.

1. No display on computer.

A. Open circuit breaker switch or blown fuse.

B. Tripped blower motor overload.

.

C. Bad wiring connection.

D. Bad transformer.

E. Emergency stop button is depressed.

F. Faulty microprocessor (computer controller).

2. Computer will not accept key pad entries.

A. Key pad ribbon is not plugged into computer securely.

B. Faulty keypad.

C. Faulty microprocessor (computer controller).

3. Dryer will not start, but computer display indictors are on.

A. Failed contactors.

B. Failed arc suppressor (A.S.) board

C. Failed microprocessor (computer).

D. Failed motors.

4. Drive motor runs, burner is on, but basket will not turn.

A. Broken, damaged or loose v-belt.

B. Belts contaminated (oil, grease, etc.).

C. Loose or broken pulley.

5. Dryer operates but is taking too long to dry.

A. Improperly programmed microprocessor.

B. An inadequate exhaust duct work system.

38

Page 43

C. Restriction in exhaust system.

D. Insufficient makeup air.

E. Poor housekeeping. Dirty or clogged lint screen.

F. Washing machine extractors are not performing properly.

G. An exceptionally cold/humid or low barometric pressure atmosphere.

H. The supply gas may have a low heating valve, check with local gas supplier.

I. Failed temperature sensor (temperature calibration is incorrect).

J. Failed microprocessor (computer) controller.

9. Thermal overload for drive motor is tripping.

A. Either an exceptionally low or high voltage supply.

B. Motor bearing failure.

C. Motor vents are blocked with lint.

D. Failed motor.

E. Failed overload.

F. Out of balance impeller (fan).

G. Insufficient makeup air.

10. Overload for impeller (fan) motor is tripping.

A. Either an exceptionally low or high voltage supply.

B. Motor bearing failure.

C. Motor vents are blocked with lint.

D. Failed motor.

E. Failed overload.

F. Insufficient makeup air.

11. Burner hi-limit safety thermostat is tripping.

A. Insufficient exhaust duct work, size or restriction in exhaust system.

B. Insufficient makeup air.

C. Lint screen needs cleaning.

D. Damaged impeller.

NOTE: For models with the manual reset hi-limit thermostat see page 23.

12. Display reads "Temp Sensor Failure Check Temp Sensor Fuse." Dyer Sensor Circuit Failure.

A. Check 1/8 amp fuse on computer.

B. Faulty microprocessor temperature sensor probe.

39

Page 44

C. Open circuit in either one of two (2) wires leading from the sensor probe to the computer

1. Connection at sensor bracket assembly connector.

2. Connection at computer harness connector.

D. Faulty microprocessor (computer) controller.

13. Dryer does not start. Display reads "main door" or "lint door" with an audio indication.

A. Main door is open.

B. Lint drawer is open.

C. Faulty main door or lint door switch.

D. Open circuit in either main door or lint drawer switch harnesses.

E. Faulty 24 V transformer

14. There is excessive vibration coming from the basket.

A. Basket is out of adjustment.

B. Drive shaft or idler shaft is out of alignment.

C. Bad pillow block bearing.

D. Bad tumbler wheel.

E. Drive motor and shaft not aligned.

F. Bad retaining wheel.

40

Page 45

SECTION VII

PHASE 6 OPL SYSTEM DIAGNOSTICS

IMPORTANT: You must disconnect and lock out electric, gas or steam supply before any covers or

guards are removed from the machine to allow access for cleaning, adjusting, installation

or testing of any equipment per OSHA (Occupational Safety and Health Administration)

standards.

ALL major circuits, including door, microprocessor temperature sensor, heat and motor circuits are monitored.

The Phase 6 OPL microprocessor controller (computer) will inform the user, via the L.E.D. display of certain

failure codes, along with indicators both in L.E.D. display and at the output of each relay (and door switch circuit)

to easily identify failures.

A. DIAGNOSTIC (L.E.D. DISPLAY) FAILURE CODES

1. SAIL SWITCH FAIL- This routine will prevent start up on the machine unless the sail switch is in the

correct position. If the sail switch is closed prior to start up the display will read "SAIL SWITCH FAIL"

along with an audio indication.

2. No AIR FLOW- If the sail switch opens during cycle operation the display will read "No AIR FLOW"

along with an audio indication. The machine will continue to run with no heat for three (3) minutes or

until the temperature drops below 100º F. Upon failure the machine will shut down and display "No AIR

FLOW" with an audio indication.

3. bURNER SAFETY FAIL- Routine monitors the temperature above the burner. If the Burner Hi-

Limit switch opens the display will read "bURNER SAFETY FAIL." The machine will run with no heat

for three (3) minutes or until the temperature drops below 100º F. Upon failure the machine will shut

down and display "bURNER SAFETY FAIL" with an audio indication.

4. dRUM SAFETY FAIL- This routine monitors the tumbler temperature if the tumbler Hi-Limit switch

opens prior or during the cycle while the heat was on the machine will display "dRUM SAFETY FAIL."

The machine will continue to run with no heat for three (3) minutes or until the temperature drops below

100º F. Upon failure the machine will shut down and display "dRUM SAFETY FAIL" with an audio

indication.

5. No HEAT- This routine monitors the burner ignition. If the burner mis-ignites (does not light) the HSI

(hot surface ignition) module will check to see of the microprocessor program has any retries left. The

standard retry count is two (2). If the module notices that there are retries left it will purge for one (1)

minute then try to ignite the burner again. The HSI module will try this for a total of three (3) times or

until there are no retries left. If the burner does not ignite after three attempts the L.E.D. display will

display the error code "no heat" with an audio indication. When this occurs the machine will run with no

heat for three (3) minutes or until the temperature drops below 100º F.

IMPORTANT: For other countries, such as Australia, the retry count may not apply due to local approvals.

6. bURNER CONTROL FAIL- This routine monitors the ignition control's gas valve output response.

If the valve output signal is not present from the ignition control within the valve time limits the

Phase 6 microprocessor controller (computer) determines the ignition control has failed. If this occurs

when the cycle is active the machine will display "bURNER CONTROL FAIL." If the tumbler

temperature is above 100º F the machine will continue to display "bURNER CONTROL FAIL." The

machine will run with no heat for three (3) minutes or until the temperature drops below 100º F. If the

tumbler temperature is below 100º F upon failure the machine will shut down and display "bURNER

CONTROL FAIL" with an audio indication.

41

Page 46

7. bURNER FLAME FAIL- This routine allows two (2) Flame out retries to occur before proceeding

into the error. The count of two (2) will be established every time the call for heat was to occur. Only

if it reaches the count of two (2) before the tumbler temperature has reached the set temperature will

this error be triggered. The machine will run with no heat for three (3) minutes or until the temperature

drops below 100º F. If the tumbler temperature is below 100º F upon failure, the machine will shut

down and display "bURNER FLAME FAIL" with an audio indication. This process will occur every

time the heat output is active.

8. MAIN DOOR- This monitors the door circuit. If the machine was not active and the main door was

opened the display would read "REAdY." If a program attempt was made with the main doors open

the display will read "MAIN dOOR" with an audio indication. If the machine is active and the main

door was opened the display would read "MAIN dOOR" with no audio indication and the dryer will

shut down. Once the main door has closed the display would read "PRESS START" press the

"ENTER/START" key and it will continue the programmed cycle.

9. LINT dOOR- This monitors the lint drawer and door circuit. If the machine was not active and the

lint drawer and door was opened the display would read "REAdY." If a program attempt was made

with the lint drawer and door open the display would read "LINT dOOR" with an audio indication. If

the machine is active and the lint drawer and door was opened the display would read "LINT dOOR"

with no audio indication and the dryer will shut down. Once the lint door was closed the display

would read "PRESS START" press the "ENTER/START" key and it will continue the programmed

cycle.

10. TEMP SENSOR FAIL CHECK TEMP SENSOR FUSE- This routine monitors the tumbler

temperature. When the temperature sensor or fuse opens with the machine not active the display will

read "TEMP SENSOR FAIL CHECK TEMP SENSOR FUSE" with an audio indication. If the

machine was active at the time that the temperature sensor or fuse opened the display would read

'TEMP SENSOR FAIL CHECK TEMP SENSOR FUSE." If the tumbler temperature is above

100º F the machine will continue to display "TEMP SENSOR FAIL CHECK TEMP SENSOR

FUSE" with an audio indication and run with no heat for three (3) minutes or until the temperature

drops below 100º F. If the tumbler temperature is below 100º F upon failure the machine will shut

down and display "TEMP SENSOR FAIL CHECK TEMP SENSOR FUSE" with an audio indication. The display will continue to read "TEMP SENSOR FAIL CHECK TEMP SENSOR FUSE" an