American Dryer Corp. AD-400 User Manual

AD-400

Pre-Installation Manual

Volume II

American Dryer Corporation

88 Currant Road

Fall River, MA 02720-4781

Telephone: (508) 678-9010 / Fax: (508) 678-9447

ADC Part No. 450102

✓

Table of Contents

Installation / Service........................................................................................................................................ 1

Section I [Important Information]......................................................................................................... 2

Receiving and Handling.................................................................................................................. 2

Safety Precautions............................................................................................................................. 3

Specifications/Dimensions

Section n [Installation].............................................................................................................................. 7

Moving the Dryer into Position...................................................................................................... 7

Internal Electrical Conduit, Air and Water Hose Connections.................................................. 9

Leveling the Dryer______________________________________________________________ 13

Service Connections........................................................................................................................... 13

Section III [Pre-startup]........................................................................................................................... 20

Preparation for operation................................................................................................................ 20

.............................................................................................................

5

Section rV [Routine Maintenance]......................................................................................................... 21

Section V [Service / Parts / Information]............................................................................................... 23

Service

Parts..................................................................................................................................................... 23

Section VI [Warranty Information]....................................................................................................... 24

Returning Warranty Card(s)........................................................................................................... 24

Warranty............................................................................................................................................ 24

Returning Warranty Parts............................................................................................................... 24

Section VII [Description]......................................................................................................................... 26

Tumbler Support and Drive System.............................................................................................. 26

Main Air Blower / Heat Reclaimer System................................................................................... 28

Automatic Lint Removal System.................................................................................................... 30

Compressed Air System................................................................................................................... 32

Gas Burner and Ignition System..................................................................................................... 35

Safety Devices.................................................................................................................................... 47

................................................................................................................................................ 23

«8»

Installation / Service

NOTE: This manual covers the ADG-400 and ADS-400. Refer to the sections and information concerning

your particular model.

Section I

ft

I

fi'Av

Important Information

A. RECETVTNG AND HANDLING

The dryer is shipped in a protective wrap cover as a means of preventing damage in transit Upon

delivery, the dryer and protective packaging should be visually inspected for shipping damage. If any

damage whatsoever is noticed, inspect further before delivering carrier leaves.

Dryers Damaged in Shipment

1. The dryer should be inspected upon receipt and before it is signed for.

2. If there is suspected damage or actual damage, the trucker's receipt should be so noted.

3. If the dryer is damaged beyond repair, it should be refused. Those dryers which were not damaged in

a damaged shipment should be accepted, but the number received and number refused must be noted

on the receipt.

S

p

f

4. If you determine that the dryer was damaged after the trucker has left your location, you should call

the delivering carrier's freight terminal immediately and file a claim. The freight company considers

this concealed damage. This type of freight claim is very difficult to get paid and becomes extremely

difficult when more than a day or two passes after the freight was delivered. It is your responsibility

to file freight claims. Dryers/parts damaged in transit cannot be claimed under warranty.

Freight claims are the responsibility of the consignee, and all claims must be filed at the receiving end.

ADC assumes no responsibility for freight claims or damages.

5. If you need assistance in handling the situation, please contact the traffic manager at American Dryer

Corp. (ADC) at (508) 678-9000.

IMPORTANT; The dryer tumbler section must be transported and handled in an upright

position at all times.

Him

B. SAFFTY PRECAUTIONS

1. Warning: For your safety, the information in this manual must be followed to minimize the risk of fire

or explosion or to prevent property damage, personal injury, or loss of life.

2. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

3. Purchaser/user should consult the local gas supplier for proper instructions to be followed in the

event the user smells gas. The instructions should be posted in a prominent location.

4. What to do if you smell gas:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Qear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

5. Installation and service must be performed by a qualified installer, service agency, or the gas supplier.

6. Dryer must be exhausted to the outdoors.

7. Although ADC produces a very versatile machine, there are some articles that, due to fabric

composition or cleaning method, should not be dried in it.

WARNING: Dry only water-washed fabrics. Do not dry articles spotted or washed in dry

cleaning solvents, a combustible detergent, or "all purpose" cleaners. Fire or explosion could

result.

WARNING; Do not dry rags or articles coated or contaminated with gasoline, kerosene, oil,

paint, wax, or grease. Fire or explosion could result.

WARNING: Do not dry mop heads. Contamination by wax or flammable solvents will create a

fire hazard.

WARNING: Do not use heat for drying articles that contain plastic, foam, or sponge rubber, or

similarly textured rubber like materials. Drying in a heated tumbler may damage plastics or

rubber and also may be a fire hazard.

8. A program should be established for the inspection and cleaning of the lint in the gas burner area,

exhaust duct work, inside the dryer and in the base of the dryer. The frequency of inspection and

cleaning can best be determined from experience at each location.

WARNING: The collection of lint in the burner area and exhaust duct work can create a

jx)tential fire hazard.

9. For personal safety, the dryer must be electrically grounded in accordance with local codes and/or the

National Electric Code ANSI/NFPA No. 70-Latest Edition.

I NOTE: Failure to do so will void warranty.

10. Under no circumstances should the dryer door switches, airflow switches, or heat circuit safety

devices ever be disabled.

I WARNING: Personal injury or fire could result.

11. This dryer is not to be used in the presence of dry cleaning solvents or fumes.

12. Remove articles from the dryer as soon as the drying and cool down cycles have been completed.

WARNING: Articles left in the dryer after the drying and cool down cycles have been

completed can create a fire hazard.

13. Do not operate steam dryers with more than 125 psi steam pressure. Excessive steam pressure can

14. Replace leaking flexible steam hoses or other steam fixtures immediately. Do not operate dryer with

15. Read and follow all caution and direction labels attached to dryer.

I

damage steam coil or harm personnel.

leaking flexible hoses. Personal injury may result.

The lightening flash with an arrow head symbol within an equilateral triangle,

is intended to alert the user to the presence of uninsulated "dangerous voltage"

within the products enclosure that may be sufficient in magnitude to constitute

a risk of electric shock to persons.

The exclamation pointwithin an equilateral triangle is intended to alert the

user to the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

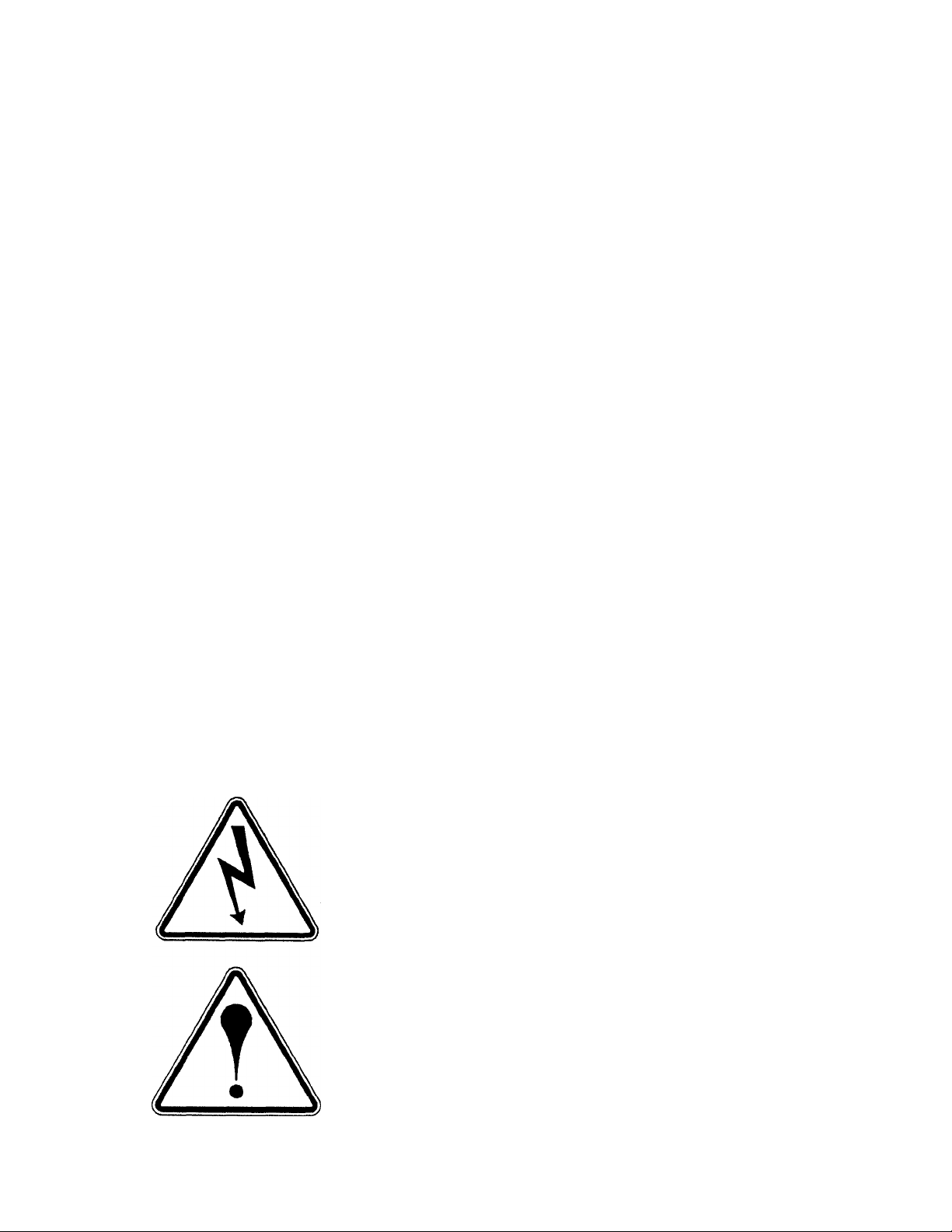

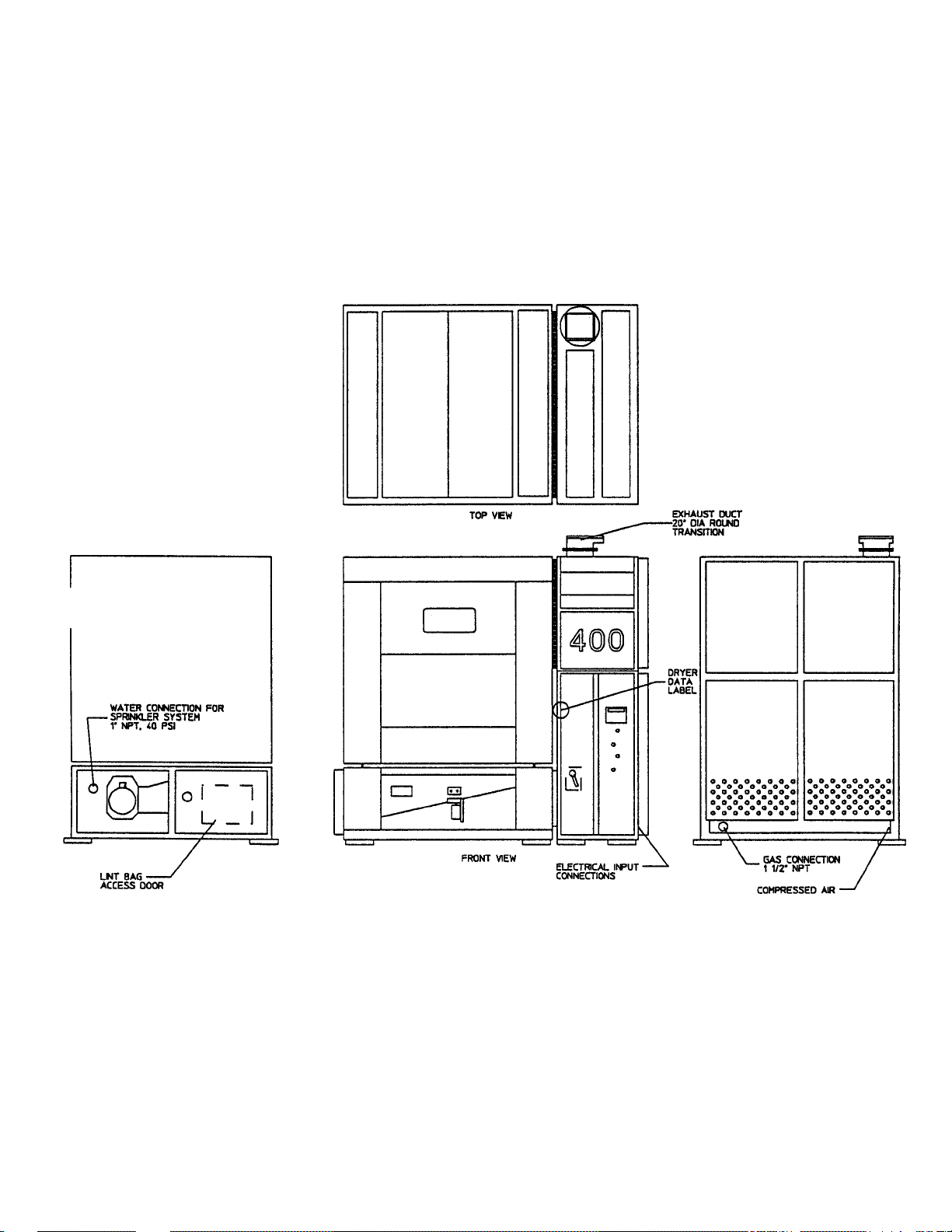

C. SPECIFICATIONS/DIMENSIONS

Note: Values for 240 volts, 3 phase, 60 Hz are measured; all other ratings are ca

Service Voltage Phase

208 3

240

380 3

416 3

460 3

3

Gas/Steam Electrical Service Specifications

Wire Service

3/4 86

3/4

3/4

3/4 43

3/4

Approx. Amp

Draw

75

47 75

39

Dual Element

Fuse

150 150

125

70

70

culated.

Circuit Breaker

150

100

90

90

Specifications

Total weight

Total weight crated

Tilt height

Operating height

Full tilt height

Operating depth

Width

Tilt load (rear tilt)

Tilt load (front load)

Unloading height from floor

Loading height from floor

Door opening

Basket diameter

Basket depth

Basket volume

Minimum load size

Maximum load size

Gas burner type

Maximum heat input, gas dryers

Minimum heat input, gas dryers

Blower motor

Basket motors (2 motors)

Burner blower motors

Maximum airflow

Maximum exhaust duct back pressure

Minimum exhaust duct diameter

Compressed air required

AD-400

400 lbs.

9,800 lbs

10,100 lbs

136.25"

114.25"

95"

80.875" 205.42 cm

123"

16 degrees

6 degrees

43" 10922 cm

64"

55"x49"

68.75" 174.63 cm

66.375" 16859 cm

143 cu ft.

200 lbs

400 lbs

Hi/Lo

1,600,000 btu/h 403,200 kcal/hr

40,000 btu/h 10,080 kcal/hr

25 hp

two 5 hp

3/4 hp

9,C^cfm

1.25" (wc)

20"

80 psi 5.63 kg/cm^

Metric Equivalents

182 kg

4,454.5 kg

4,590.9 kg

346.08 cm

290.20 cm

241.30 cm

312.42 cm

16 degrees

6 degrees

16256 cm

134.70 cm X 124.46 cm

4.03 cum

90.72 kg

181.44 kg

Hi/Lo

18.65 kw

two 3.73 kw

.56 kw

255 cmm

3.1 mbar

50.80 cm

Section II

Installation

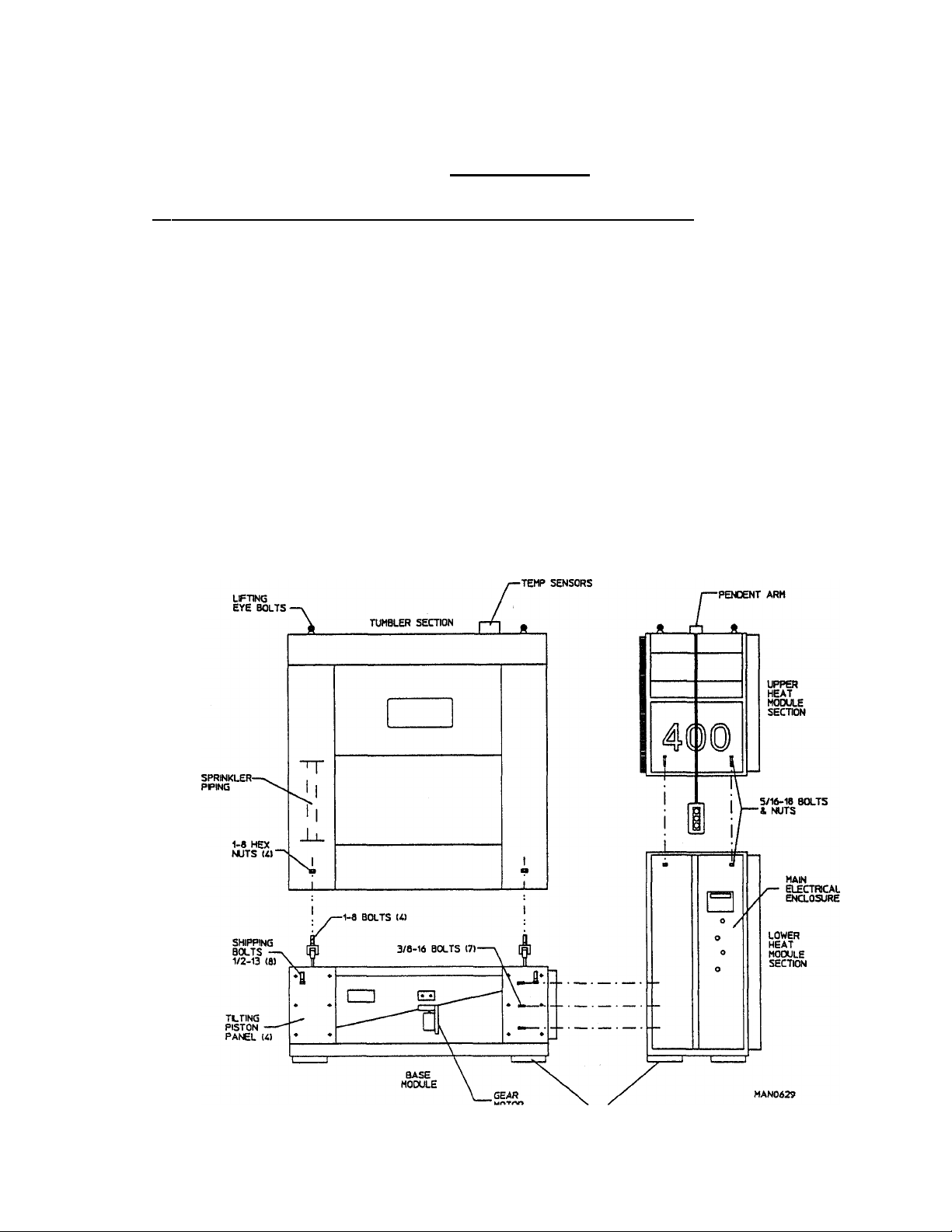

A. MOVTNG THE DRYER INTO POSITION/REASSEMBLY

The AD-400 dryer is shipped brokert down into either two, three, or four pieces.

1. Two-Piece Shipment

In this method of shipment, the tumbler section and base module are shipped as one piece, and the

burner section comprises the second piece. Move both pieces into position by lifting them with cables

through the eyebolts on top. These pieces may also be moved by lifting from underneath with a fork

truck. The tumbler section/base module weighs about 6,600 poimds, and the Burner Section weighs

about 3,200 pxDunds. Put the sections together and match the seven (7) clearance holes in the base module

right side channels with the seven (7) 3/8-16 tapped holes in the left side of the burner module. Use the

3/8-16 bolts provided with the dryer to bolt the two sections together. Remove the eight (8) 1/2-13

shipping bolts that fasten the tumbler section to the base. Remove the four (4) tilting piston panels to gain

access to these shipping bolts.

2. Three-Piece Shipment

The tumbler section is shipped separately from the base module, and the burner section is shipped as the

third piece.

Move the base module into position with a fork truck. Lift the tumbler section onto the base module by

cables through the lifting eye bolts on top of the tumbler section. There is a 1-inch bolt in each comer of

the base module. These must pass through the 1-1/8-inch diameter holes in each comer of the tumbler

section bottom so that the tumbler section sits flat on the four (4) base piston clevis blocks. Use the four

(4) sets of 1-inch nuts and washers provided to bolt the basket section to the base.

Make sure that the front of the tumbler section lines up with the front of the base module. The small gear

motor sits on the base module front. The sprinkler piping is on the left side of the tumbler section.

Bolt the bumer/heater section to the base module as per the instructions in the previous two-piece

shipment section.

3. Four-Piece Shipment

The tumbler section is shipped apart from the base module, and the burner section is broken down into

two separate pieces.

Apply a bead of silicone to the top flanges of the lower bumer/heater section. A tube of silicone is

included with the dryer. Lift the uppjer bumer/heater section onto the lower bumer/heater section by

cables through the lifting eye bolts on top of the upper bumer/heater section. Bolt these sections together

with the 5/16-18 hardware provided. Assemble the rest of the dryer using the information provided in

the previous sections.

4. Additional Reassembly

The pjendant arm now can be rebolted to the top of the burner section. Pass the 5/16-18 bolts through the

pendant arm tube and screw them into the weld nuts located on the top of the burner section.

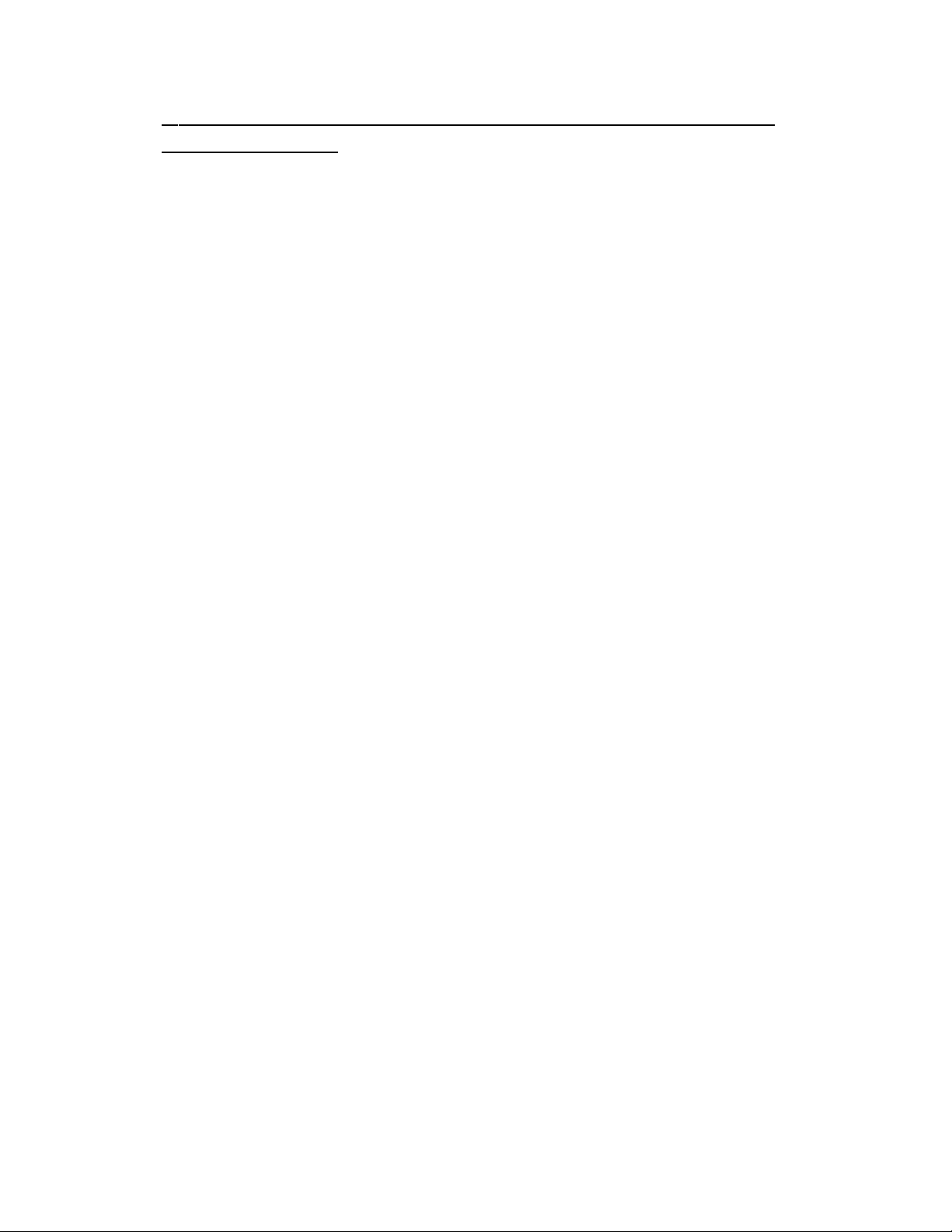

B. INTERNAL F.T.FCTRTCAL CONDUTT. AIR AND WATER HOSE

RECONNECTIONS

Because the dryer is shipped in sections, wiring and hose connections must be reattached.

1. Air Hoses

These air hose reconnections must be completed:

a. Front Tilt Piston Lines

This reconnection is made at the front of the dryer in the space between the base and

lower bumer/heater section. Connect the red marked 3/8 poly flo tube into the red

marked brass elbow. Connect the black marked tube into the black marked brass elbow.

b. Rear Tilt Piston Lines

This reconnection is made at the rear of the dryer in the space between the base and

lower bumer/heater section. Connect the red marked 3/8 poly flo tube into the red

marked 3/8 poly flo tube union. Do the same for the black marked tube and union.

c. Sprinkler Valve Lines

The 1/4-inch aluminum tube reconnection is made at the rear of the dryer in the space

between the base and lower bumer/heater section. Connect the 1 /4-inch aluminum tube

into the 1/4-inch aluminum tube union.

d. Load Door Piston Lines

These reconnections are made inside the lower burner section. Open the lower

bumer/heater section access doors and reconnect the red marked 1/4-inch poly flo tubes

into the red-marked 1 /4-inch poly flo unions. Do the same with the black marked tubes.

2. Water Hose

a. Sprinkler water hose

If the tumbler section was shipped apart from the base module, reconnect the 1-inch

sprinkler water pipe union located on the left side of the base. This will reconnect the

1-inch mbber hose on the base into the mating 1-inch piping on the tumbler section.

3. Electrical Conduit Recormections

If the dryer was shipped in two (2) pieces, the following electrical conduits and plugs must be

reconnected.

LEFT SIDE VIEW

.BURNER FAN

MOTOR CONOUT

HOSE AND ELECTRIC CONDUIT RECONNECTIONS

MAN0709

• Tumbler and Base Input Signal Plugs

These two (2) large plugs are shipped with the base module. They must be fed through the large hole in

the rear of the lower burner section and plugged into the mating plugs mounted on the floor of the

bumer/heater section.

• Lint Fan Motor Conduit

This conduit is shipped in the bottom of the bumer/heater section and must be fed through the rear of

the base module and reconnected into the lint fan motor's junction box. Reconnect the conduit wire

marked LI to the motor wire marked LI. Do the same for L2 and L3. Also reconnect the ground wire.

• Left Side Tumbler Drive Motor Conduit

This conduit is shipped in the bottom of the bumer/heater section and must be fed through the rear of

the base and reconnected to the left side tumbler drive motor junction box. sitting behind the motor.

Reconnect the conduit red wire to the junction box red wire. Do the same for orange and blue. Also

reconnect the ground wire.

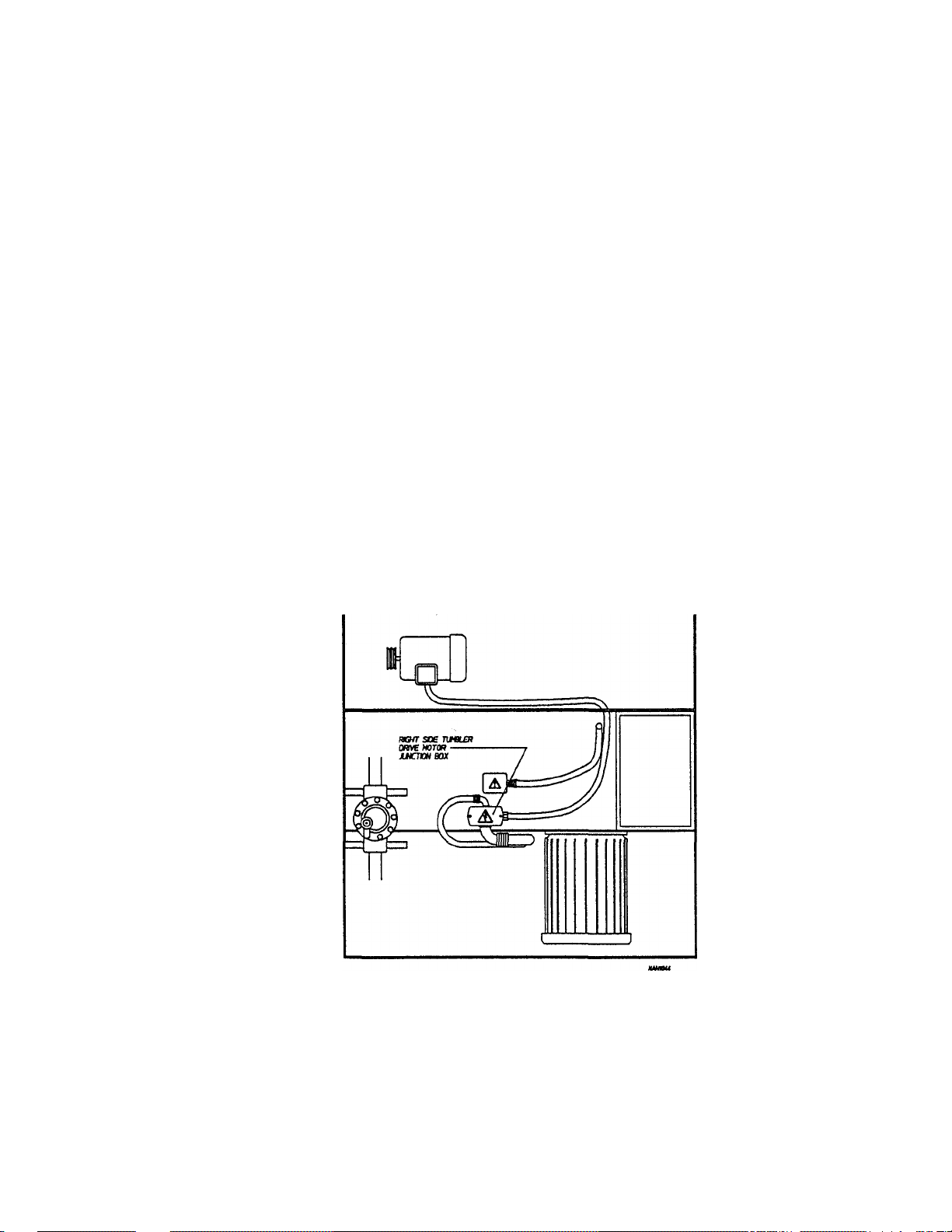

• Right Side Tumbler Drive Motor Conduit

This conduit is shipped along side the right side tumbler drive motor. Locate and route this conduit into

the bumer/heater section and reconnect into its junction box located on the bumer/heater section blower

motor housing, (see drawing below) Reconnect the conduit's wires to the junction box wires, matching

the colors. Also, reconnect die ground.

• Lint Screen Motor Conduit

This conduit is shipped inside the main electrical enclosure in the lower bumer/heater section. Feed this

conduit through the bottom front of the base and reconnect it into the lint screen motor junction box.

This motor is single phase. Connect the conduit wire to the motor wires, matching the colors. Reconnect

the ground wire also.

n

Pendant Arm and Light/Siren Cable Plugs

Reconnect the pendant arm cable plug, the light/siren cable plug. These are located on top of the

bumer/heater section of the dryer.

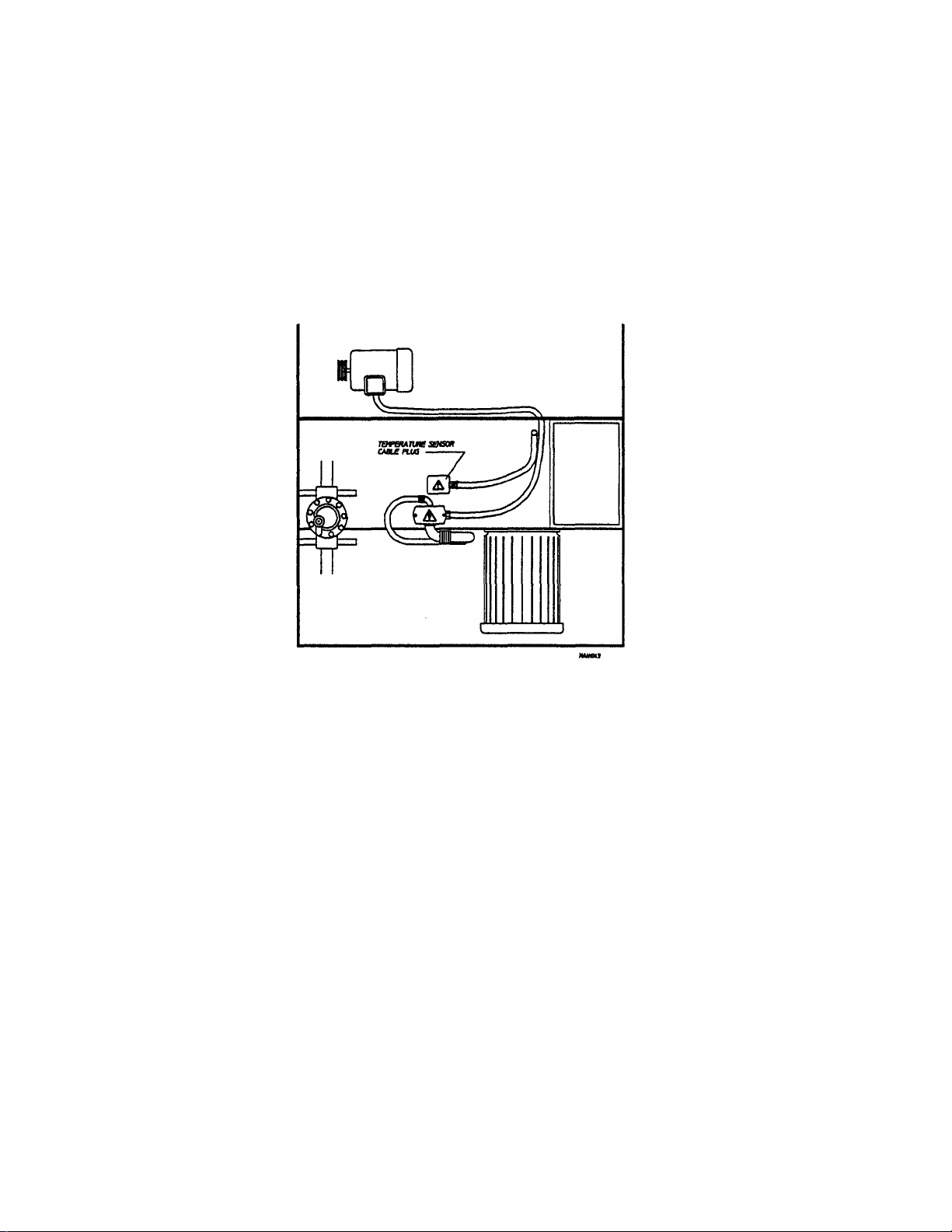

Temperature Sensor Cable Plug

This cable is shipped along side the right hand side lumber drive motor. Locate and route this cable into

the bumer/heater section and reconnect onto its mating receptacle and latch together, (see drawing

below)

If the tumbler section was shipped apart from the base module, then the basket junction box cable

plug will be shipped with the base near the lint fan motor. Pull this plug and cable up through the

large hole in the floor of the tumbler section and reconnect the plug into the basket junction box. This

cable will be pulled up whenever the tumbler tilts, so be sure it has enough slack to it.

If the burner section was shipped in two (2) pieces, then the burner fan motor conduit must be

reconnected to the burner fan motor. The spark plug and flame rod cables must be plugged back into

the spark plug and flame rod on the burner box. Also, reconnect the front panel conduit plug located

behind the upper burner section front panel.

V

...

)

12

C. LEVELING THE DRYER

The dryer weighs 9,800 pouitds. It must be installed on a level floor that can support its weight.

Place a large level on all four sides of the dryer base to ensure it is level. If shimming is required, place

9-1/2-inch by 9-1/2-inch square pieces of sheet metal under the mounting pads of the dryer.

The dryer must be lagged to the floor through the holes in the mounting pads.

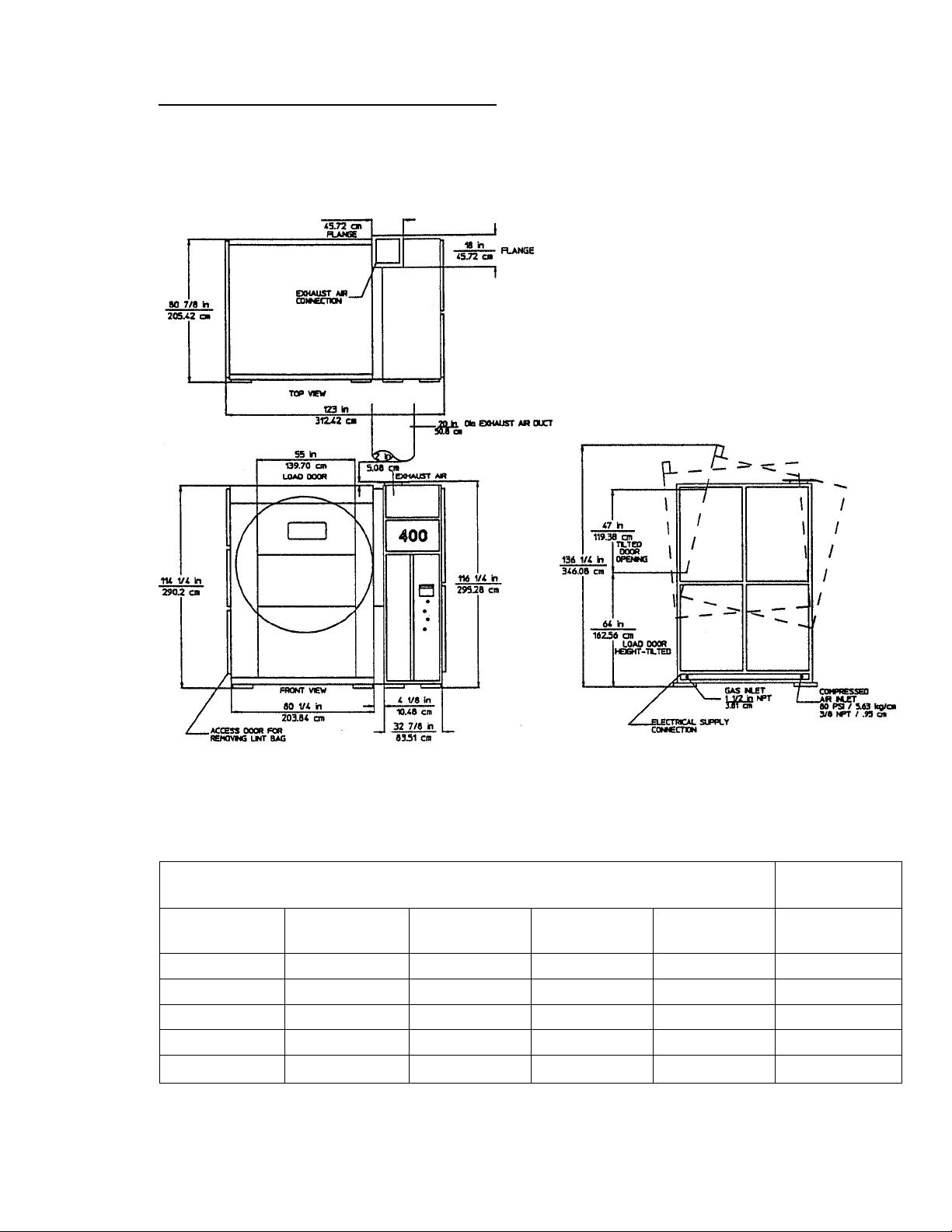

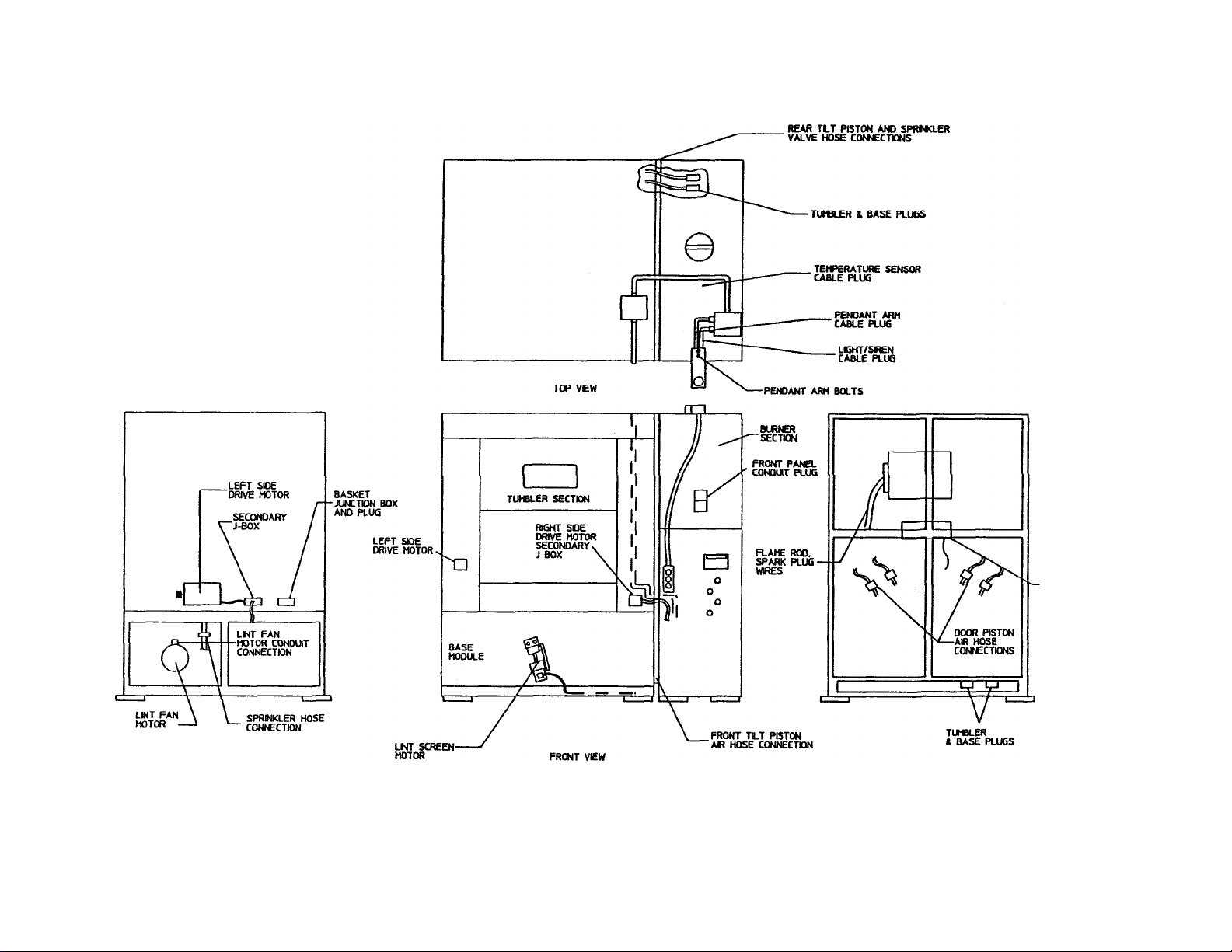

D. SERVICE CONNECTIONS

1. Electrical Service

The electrical power is connected to the dryer at the high voltage section of the control cabinet. On the

AD-400 dryer, this section is located at the bottom left of the front enclosure.

The AD-400 must be supplied with two (2) independent input power lines. One electric service feeds the

dryer itself, and the other, the safety sprinkler system. Both input lines must be independent of each

other and individually protected by their own individual fused disconnects.

I NOTE: The AD-400 will not operate without pewer fed to the safety sprinkler system.

Feed the electrical service cables to the dryer using the pre-punched knockouts at the bottom section of

the electrical cabinet right wall.

Connect the input power lines to the power distribution terminals mounted at the bottom on the panel

inside the enclosure.

Connect the ground wires directly to the ground lug located at the same approximate location.

Before turning the power on to the dryer, measure the supply voltage to ensure that it matches the dryer's

sp>ecified input voltage. This input voltage is marked on the aluminum data plate located on the inner

right wall of the electrical cabinet door.

AD-400

Gas/Steam Electrical Sp>ecifications

Voltage (V) Phase

208

240

380

416

460

3

3

3

3

3 3,4

Wires Current (A)

3,4

3,4

3,4

3,4

86 150

75

47

43 70

39 70

Fuses

125

75

Breakers

150

150

100

90

90

13

SERVICE CONNECTIONS

14

CONNECTION

3/8* NPT

80 PSI

MAN0632

Loading...

Loading...