American Dryer Corp AD-200 PHASE 7 User Manual

AD-200 Phase 7

Service Manual

with Tilt Options

American Dryer Corporation

88 Currant Road

Fall River, MA 02720-4781

Telephone: (508) 678-9000 / Fax: (508) 678-9447

E-mail: techsupport@amdry.com

022500DMG/tcosta ADC Part No. 450039

Retain This Manual In A Safe Place For Future Reference

American Dryer Corporation products embody advanced concepts in engineering, design, and safety. If this product is

properly maintained, it will provide many years of safe, efficient, and trouble-free operation.

ONLY qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation/operator's manual

included with the dryer.

The following FOR YOUR SAFETY caution must be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors or liquids

in the vicinity of this or any other

appliance.

We have tried to make this manual as complete as possible and hope you will find it useful. ADC reserves the right to make

changes from time to time, without notice or obligation, in prices, specifications, colors, and material, and to change or

discontinue models.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser dessence

ni dautres vapeurs ou liquides

inflammables dans le voisinage de cet

appareil ou de yout autre appareil.

Important

For your convenience, log the following information:

DATE OF P URCHASE MODEL NO.

DISTRI BUTORS NAM E

Serial Number(s)

AD-200 Phase 7 Tilting

Replacement parts can be obtained from your distributor or the ADC factory. When ordering replacement parts from the

factory, you can FAX your order to ADC at (508) 678-9447 or telephone your orders directly to the ADC Parts Department at

(508) 678-9000. Please specify the dryer model number and serial number in addition to the description and part number, so

that your order is processed accurately and promptly.

IMPORTANT NOTE TO PURCHASER

Information must be obtained from your local gas supplier on the instructions

to be followed if the user smells gas. These instructions must be posted in a

prominent location near the dryer.

IMPORTANT

YOU MUST DISCONNECT and LOCKOUT THE ELECTRIC

SUPPLY and THE GAS SUPPLY or THE STEAM SUPPLY BEFORE ANY

COVERS or GUARDS ARE REMOVED FROM THE MACHINE TO

ALLOW ACCESS FOR CLEANING, ADJUSTING, INSTALLATION, or

TESTING OF ANY EQUIPMENT per OSHA (Occupational Safety and Health

Administration) STANDARDS.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPOR AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

DO NOT DRY MOP HEADS IN THE DRYER.

DO NOT USE DRYER IN THE PRESENCE OF DRY CLEANING FUMES.

CAUTION

DRYERS SHOULD NEVER BE LEFT UNATTENDED WHILE IN

OPERATION.

WARNING

CHILDREN SHOULD NOT BE ALLOWED TO PLAY ON OR NEAR

THE DRYERS.

CHILDREN SHOULD BE SUPERVISED IF NEAR DRYER(S) IN

OPERATION.

WARNING

The dryer must never be operated with any of the back guards, outer tops,

or service panels removed. PERSONAL INJURY or FIRE COULD

RESULT.

WARNING

DRYER MUST NEVER BE OPERATED WITHOUT THE LINT

FILTER OR SCREEN IN PLACE, EVEN IF AN EXTERNAL LINT

COLLECTION SYSTEM IS USED.

IMPORTANT

PLEASE OBSERVE ALL SAFETY PRECAUTIONS displayed on the

equipment and specified in the installation and operator's manual included

with the dryer.

Dryers must not be installed or stored in an area where it will be exposed to

water or weather.

The wiring diagram for the dryer is located in the front electrical control box area.

Table of Contents

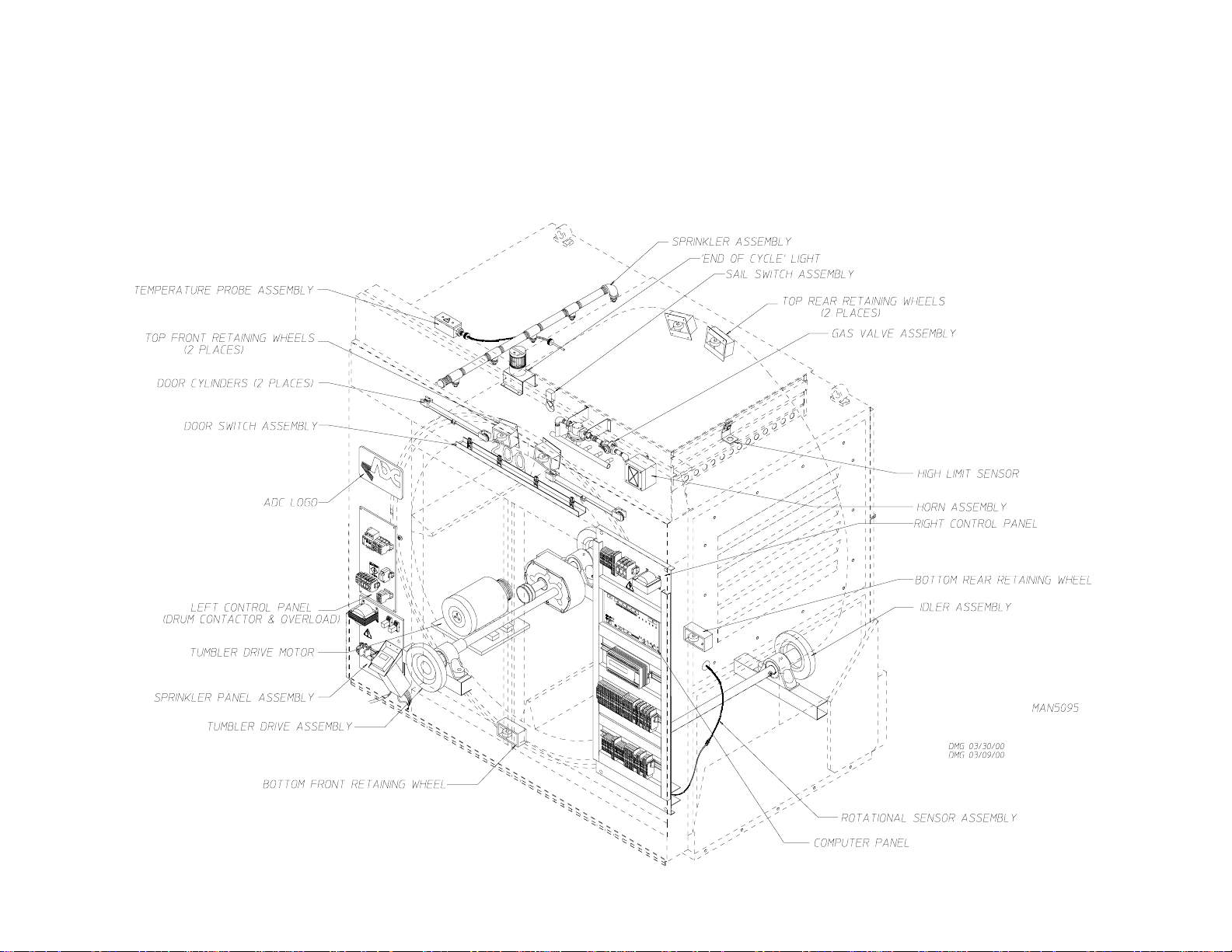

AD-200 REFERENCE GUIDE (Tumbler [Basket] Section)................................. 3

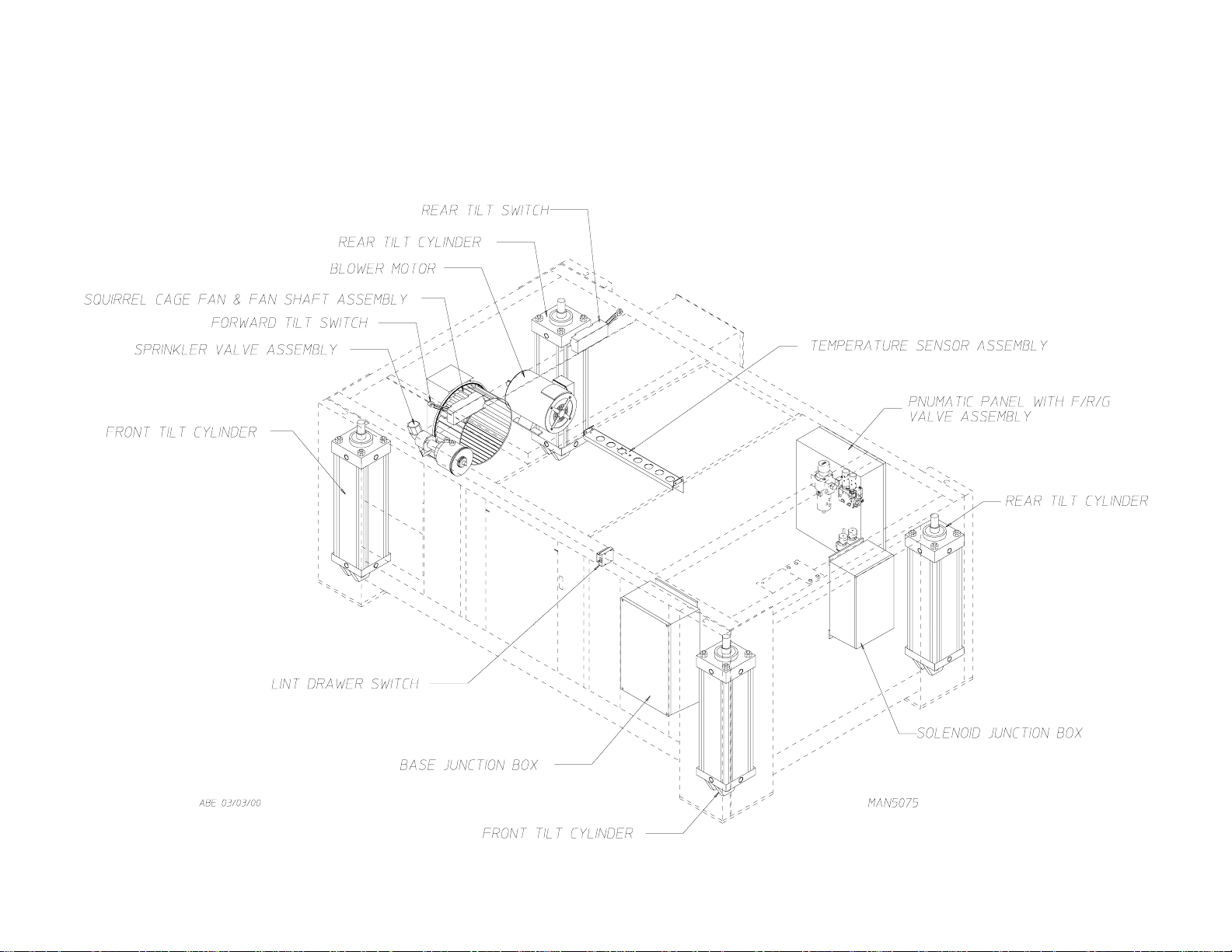

AD-200 REFERENCE GUIDE (Base Section) ...................................................... 4

SECTION I

SAFETY PRECAUTIONS ........................................................................................ 5

SECTION II

ROUTINE MAINTENANCE.................................................................................... 7

A. Cleaning ..................................................................................................................................... 7

B. Lubrication ................................................................................................................................. 9

C. Adjustments ............................................................................................................................. 10

SECTION III

SPECIFICATIONS and DIMENSIONS ............................................................... 11

A. Specifications (Gas and Steam Models) .................................................................................... 11

B. Dimensions ............................................................................................................................... 12

SECTION IV

INSTALLATION REQUIREMENTS .................................................................... 15

A. Enclosure/Air Supply/Exhaust Requirements .............................................................................. 15

B. Electrical and Gas Requirements ............................................................................................... 16

C. Operational Service Check Procedure ...................................................................................... 16

SECTION V

COMPONENT DESCRIPTION/REPLACEMENT ...........................................17

A. Heat Section ............................................................................................................................. 17

B. Troubleshooting The Direct Spark Ignition (DSI) System ........................................................... 23

C. Natural Gas and L.P. (Liquid Propane) Gas Conversion Instructions .......................................... 40

D. Steam Coil System Operation ................................................................................................... 41

E. Sprinkler System Description .................................................................................................... 46

F. Tilting System Description ......................................................................................................... 52

G. Air Jet Assembly ....................................................................................................................... 58

H. Blower (Squirrel Cage Fan) Motor Assembly ............................................................................ 60

I. Filter/Regulator Assembly ......................................................................................................... 67

J. Door Systems ........................................................................................................................... 68

K. Control and Electrical System ................................................................................................... 74

L. Tumbler (Basket) System .......................................................................................................... 87

SECTION VI

PHASE 7 OPL SYSTEM DIAGNOSTICS ...........................................................96

A. Diagnostic (L.E.D. Display) Fault Messages .............................................................................. 96

B. I/O Board Input and Output L.E.D. Indicators .......................................................................... 97

SECTION VII

TROUBLESHOOTING .........................................................................................102

SECTION VIII

PROCEDURE FOR FUNCTIONAL CHECK OF REPLACEMENT

COMPONENTS ................................................................................................110

AD-200 Reference Guide

(Tumbler [Basket] Section)

3

AD-200 Reference Guide

(Base Section)

4

SECTION I

SAFETY PRECAUTIONS

CAUTION: The dryer should never be left unattended while in operation.

WARNING: For your safety, the information in this manual must be followed to minimize the risk of

fire or explosion or to prevent property damage, personal injury, or loss of life.

WARNING: The dryer must never be operated with any of the back guards, outer tops, or

service panels removed. PERSONAL INJURY or FIRE COULD RESULT.

1. DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

2. Purchaser/user should consult the local gas supplier for proper instructions to be followed in the event the

user smells gas. The instructions should be posted in a prominent location.

3. WHAT TO DO IF YOU SMELL GAS...

a. DO NOT try to light any appliance.

b. DO NOT touch any electrical switch.

c. DO NOT use any phone in your building.

d. Clear the room, building, or area of ALL occupants.

e. Immediately call your gas supplier from a neighbors phone. Follow the gas suppliers instructions.

f. If you cannot reach your gas supplier, call the fire department.

4. Installation and service must be performed by a qualified installer, service agency, or gas supplier.

5. Dryer(s) must be exhausted to the outdoors.

6. Although ADC produces a very versatile machine, there are some articles that, due to fabric composition or

cleaning method, should not be dried in it.

WARNING: Dry only water-washed fabrics. DO NOT dry articles spotted or washed in dry

cleaning solvents, a combustible detergent, or all purpose cleaner.

EXPLOSION COULD RESULT.

WARNING: DO NOT dry rags or articles coated or contaminated with gasoline, kerosene, oil, paint,

or wax.

EXPLOSION COULD RESULT.

5

WARNING: DO NOT dry mop heads. Contamination by wax or flammable solvent will create a fire

hazard.

WARNING: DO NOT use heat for drying articles that contain plastic, foam, sponge rubber, or

similarly textured rubberlike materials. Drying in a heated tumbler (basket) may damage

plastics or rubber and also may be a fire hazard.

7. A program should be established for the inspection and cleaning of lint in the burner area, exhaust duct

work, and area around the back of the dryer. The frequency of inspection and cleaning can best be

determined from experience at each location.

WARNING: The collection of lint in the burner area and exhaust duct work can create a potential fire

hazard.

8. For personal safety, the dryer must be electrically grounded in accordance with local codes and/or the

National Electrical Code ANSI/NFPA NO. 70-LATEST EDITION or in Canada, the Canadian Electrical

Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION.

NOTE: Failure to do so will VOID THE WARRANTY.

9. UNDER NO CIRCUMSTANCES should the dryer door switches, lint drawer switch, or heat safety

circuit, ever be disabled.

WARNING: PERSONAL INJURY or FIRE COULD RESULT.

10. This dryer is not to be used in the presence of dry cleaning solvents or fumes.

11. Remove articles from the dryer as soon as the drying cycle has been completed.

WARNING: Articles left in the dryer after the drying and cooling cycles have been complete can

create a fire hazard.

12. READ and FOLLOW ALL CAUTION and DIRECTION LABELS ATTACHED TO THE DRYER.

WARNING: YOU MUST DISCONNECT and LOCKOUT THE ELECTRIC SUPPLY and

THE GAS SUPPLY or THE STEAM SUPPLY BEFORE ANY COVERS or

GUARDS ARE REMOVED FROM THE MACHINE TO ALLOW ACCESS

FOR CLEANING, ADJUSTING, INSTALLATION, or TESTING OF ANY

EQUIPMENT per OSHA (Occupational Safety and Health Administration)

STANDARDS.

IMPORTANT: Label ALL wires prior to disconnection when servicing the microprocessor controller

(computer) and the ignition module. WIRING ERRORS CAN CAUSE

IMPROPER and DANGEROUS OPERATION.

6

SECTION II

ROUTINE MAINTENANCE

A. CLEANING

A schedule should be established for periodic inspection, cleaning, and removal of lint from various areas of the

dryer, as well as throughout the duct work system. The frequency of cleaning can best be determined from

experience at each location. Maximum operating efficiency is dependent upon proper air circulation. The

accumulation of lint can restrict this airflow. If the guidelines in this section are met, an ADC dryer will provide

many years of efficient, trouble-free, and - most importantly - safe operation.

WARNING: LINT FROM MOST FABRICS IS HIGHLY COMBUSTIBLE. THE

ACCUMULATION OF LINT CAN CREATE A POTENTIAL FIRE HAZARD.

WARNING: KEEP DRYER AREA CLEAR and FREE FROM COMBUSTIBLE

MATERIALS, GASOLINE, and OTHER FLAMMABLE VAPORS and

LIQUIDS.

NOTE: REMOVE POWER FROM THE MACHINE BEFORE PERFORMING ANY

MAINTENANCE IN THE MACHINE.

NOTE: Suggested time intervals shown are for average usage which is considered six (6) to eight (8)

operational (running) hours per day.

SUGGESTED CLEANING SCHEDULE

EVERY THIRD or FOURTH LOAD

Clean the lint screen. A clogged lint screen will cause poor dryer performance. The lint screen is located in the

lint drawer in the base of the dryer. Pull out the lint drawer, brush the lint off the lint screen, and remove the lint.

Inspect the lint screen and replace if torn.

NOTE: The frequency of cleaning the lint screens can best be determined from experience at each

location.

WEEKLY

Open the hinged panels on each side of the tumbler (basket) section and remove any lint accumulation from the

tumbler (basket) drive motor, drive shafts, gear reducer, drive belts, drive wheels, and drive shaft bearings.

Slide the lint basket ALL the way out of the dryer and clean any lint accumulation off of the temperature sensor

bracket, which is located above the lint basket.

7

WARNING: TO AVOID THE HAZARD OF ELECTRICAL SHOCK, DISCONTINUE

ELECTRICAL SUPPLY TO THE DRYER.

MONTHLY

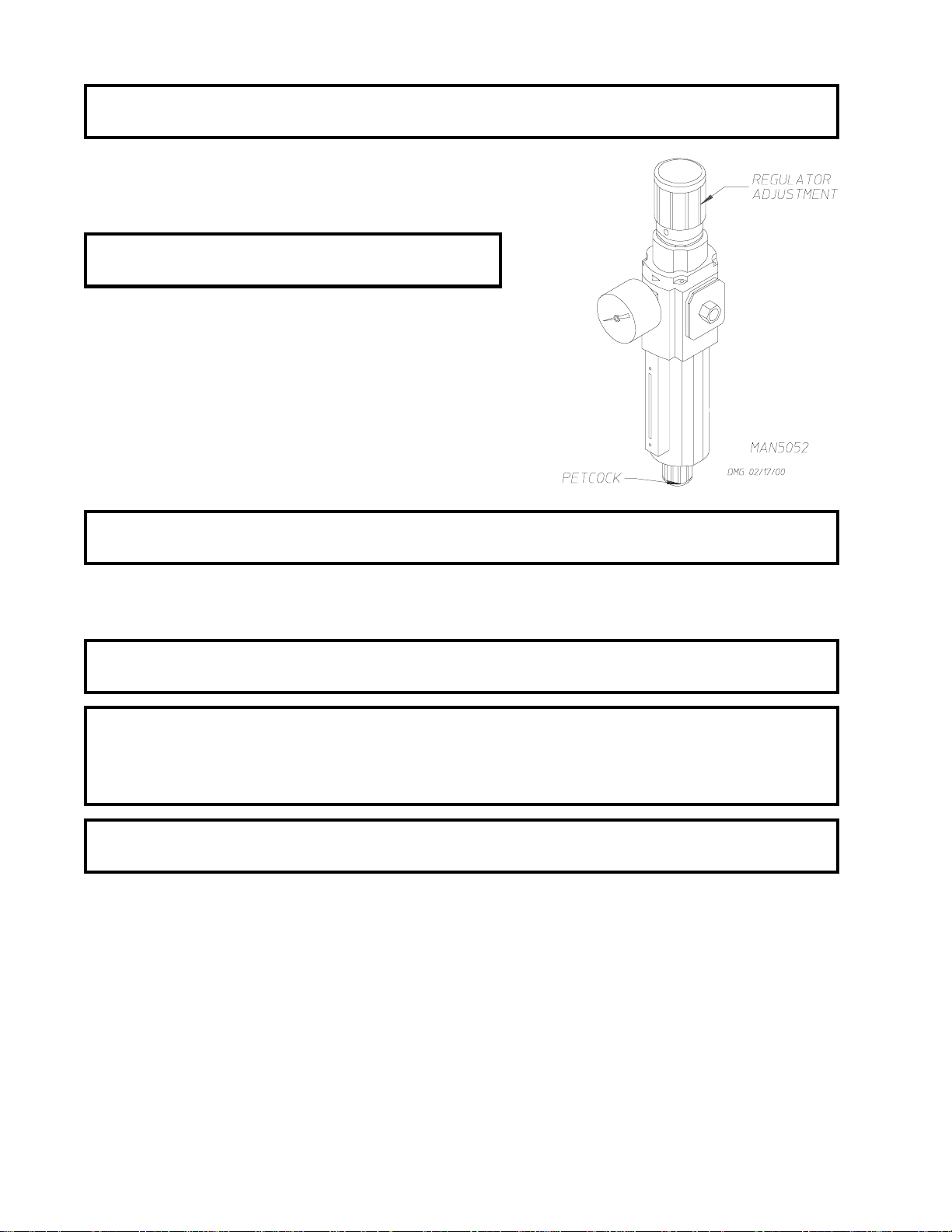

Empty the compressed air filter bowl.

NOTE: REGULATOR PRESSURE IS TO BE SET

AT 80 PSI (5.51 BARS).

Clean any lint accumulation from the gas valve and burner area

at the top of the dryer, the fan (impellor) motor, and the fan

(impellor) bearings located in the dryer base.

EVERY 6 MONTHS

STEAM MODELS - Clean the steam coil fins. We suggest

using compressed air and a vacuum

cleaner with brush attachment.

NOTE: When cleaning steam coil fins, be careful not to bend the fins. If fins are bent,

straighten by using a fin comb, which is available from any local air conditioning supply house.

Inspect and remove any lint accumulation in customer furnished exhaust duct work system and from the dryers

internal exhaust ducting.

NOTE: THE ACCUMULATION OF LINT IN THE EXHAUST DUCT WORK CAN

CREATE A POTENTIAL FIRE HAZARD.

NOTE: DO NOT OBSTRUCT THE FLOW OF COMBUSTION and VENTILATION AIR.

CHECK CUSTOMER FURNISHED BACK DRAFT DAMPERS IN THE EXHAUST

DUCT WORK. INSPECT and REMOVE ANY LINT ACCUMULATION WHICH CAN

CAUSE THE DAMPER TO BIND or STICK.

NOTE: When cleaning the dryer cabinet(s), avoid using harsh abrasives. A product intended for the

cleaning of appliances is recommended.

Clean off any lint accumulation on top of the temperature probe and the hi-limit switch located above the lint

basket.

8

B. LUBRICATION

MONTHLY

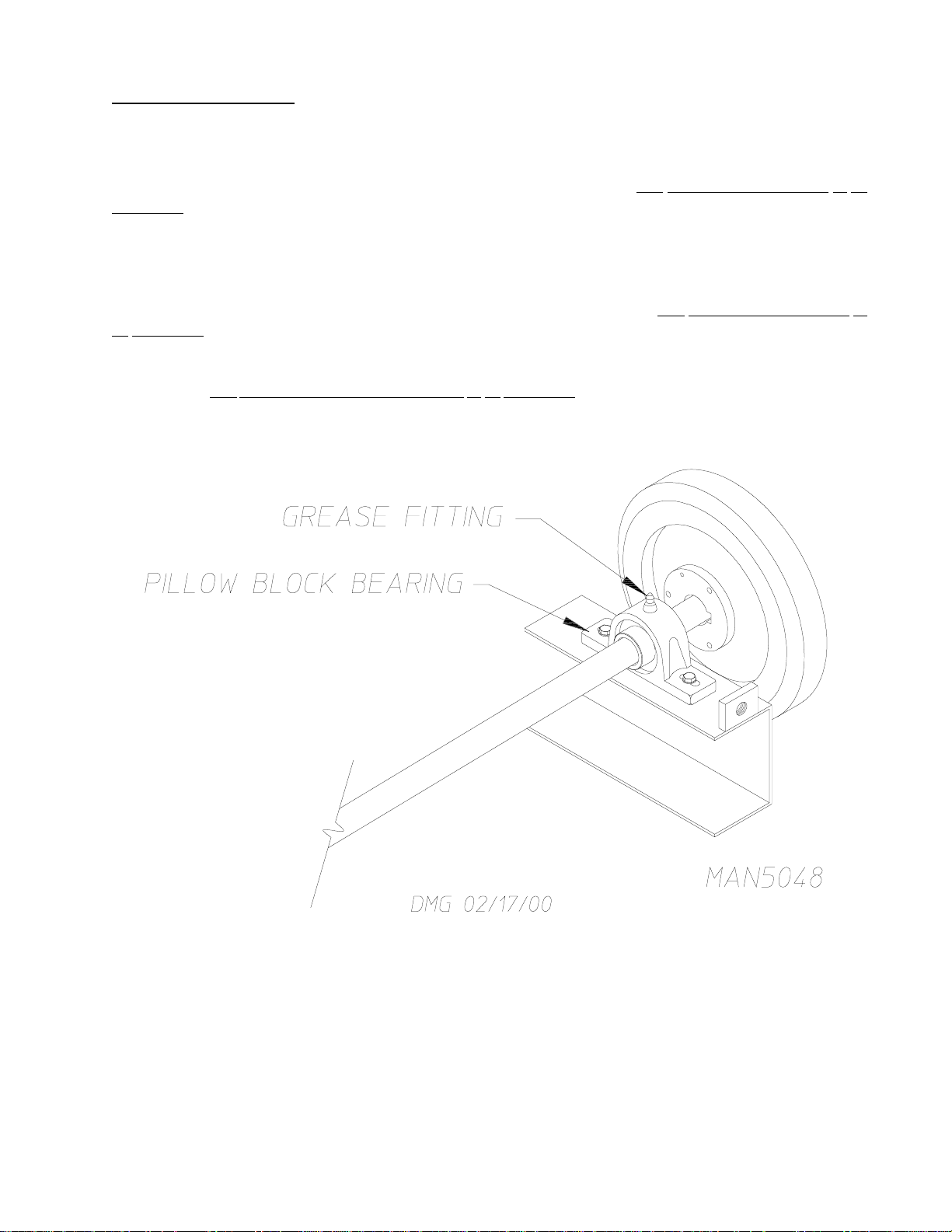

The two (2) bearings that support the impellor/fan shaft must be lubricated.

equivalent. Generically, this grease would be described as an NLGI Grade 2 multipurpose industrial grease with

a lithium thickener and mineral base oil.

EVERY 3 MONTHS

The four (4) bearings that support the drive and idler shafts must be lubricated. Use Shell Alvania #2 grease or

its equivalent. Generically, this grease would be described as an NLGI Grade 2 multipurpose industrial grease

with a lithium thickener and mineral base oil.

Apply grease (

ONLY).

Use Viscosity Shell Alvania #2 grease or its equivalent) to the tilting hinges (on 1-Way Tilt Models

Use Shell Alvania #2 grease or its

9

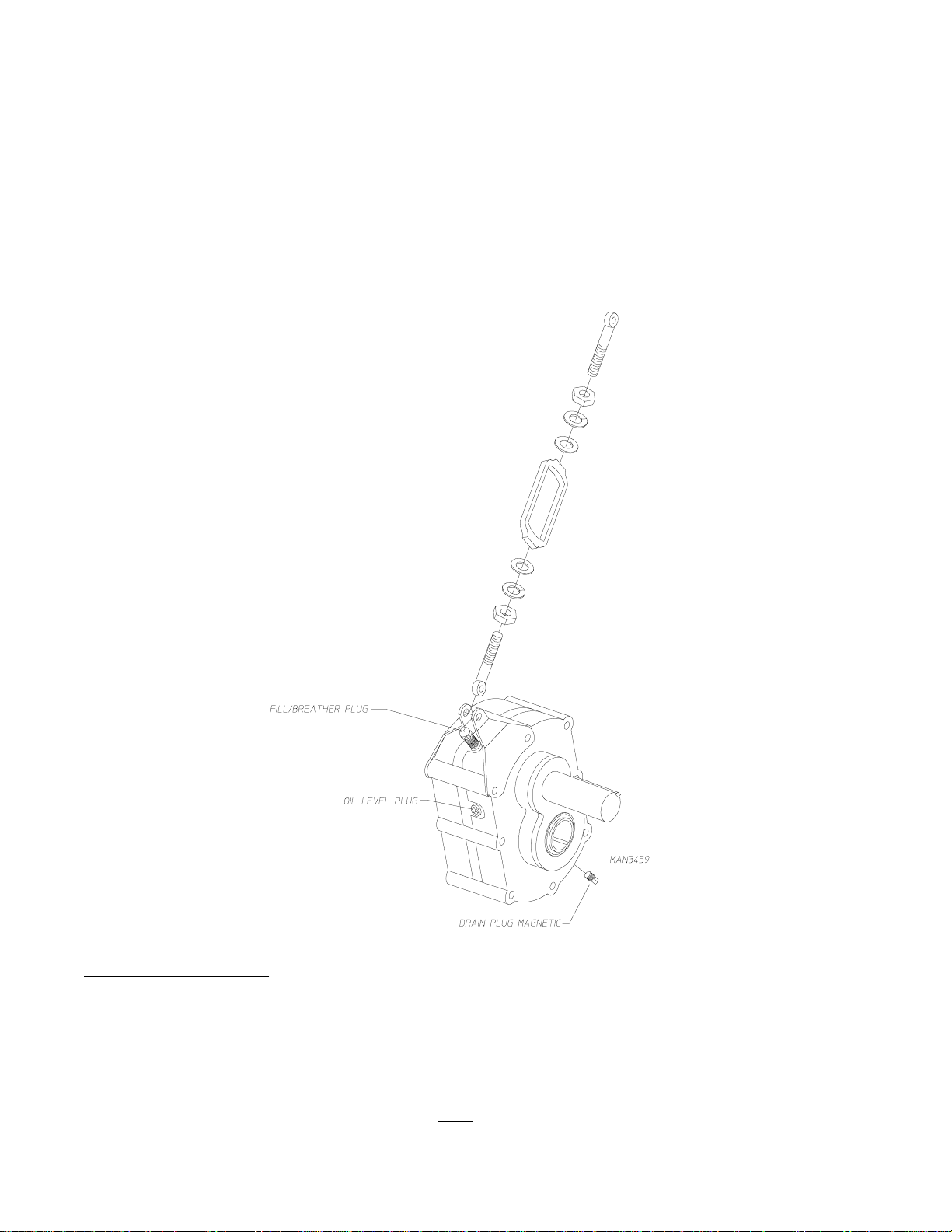

EVERY 6 MONTHS

Change gear oil in tumbler shaft gear reducer.

1. Remove the drain plug (located at the bottom rear of the reducer).

2. After oil is completely drained, replace the drain plug.

3. Remove the vent plug and pour in

its equivalent.

1.4 liters of Mobil Oil DTE HH5G (I.S.O. viscosity grade 460), SAE 90, or

C. ADJUSTMENTS

7 DAYS AFTER INSTALLATION and EVERY 6 MONTHS THEREAFTER

Inspect bolts, nuts, screws, (bearing set screws), nonpermanent gas connections (i.e., unions, shut-off valves,

orifices), and grounding connections. Fan (impellor) V-belts, along with the motor and drive belts should be

examined and replaced if necessary. Tighten loose V-belts when necessary. Complete operational check of

controls and valves. Complete operational check of ALL safety devices (i.e., door switches, lint drawer switch,

sail switch, burner, and hi-limit thermostats).

10

SECTION III

SPECIFICATIONS and DIMENSIONS

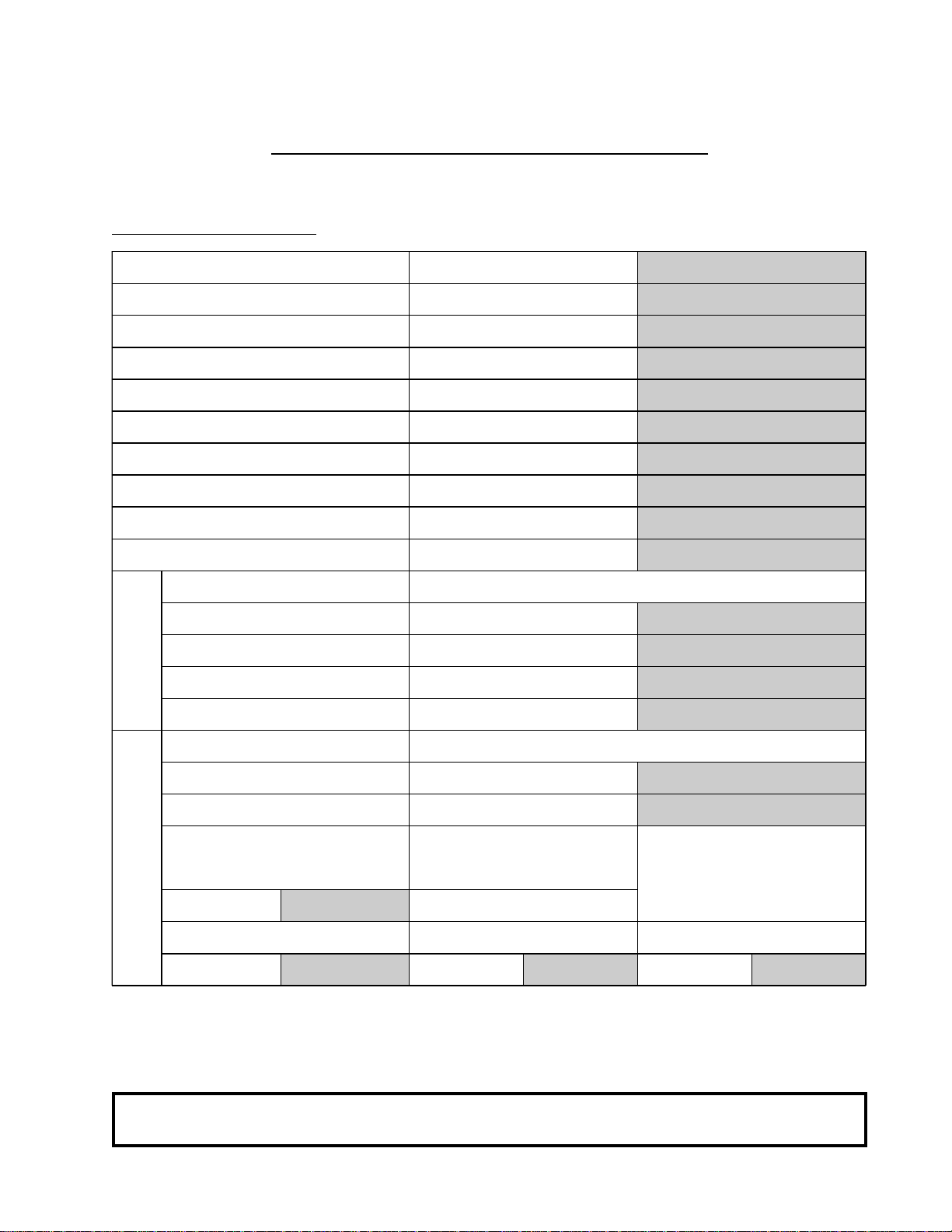

A. SPECIFICATIONS (Gas and Steam Models)

M

AXIMUM CAPACITY (DRY WEIGHT

T

UMBLER (BASKET) DIAMETER

T

UMBLER (BASKET) DEPTH

T

UMBLER (BASKET) VOLUME

D

RIVE MOTOR

) 200 lbs. 90.9 kg

62-1/2” 158.75 cm

42” 106.7 cm

74.5 cu. ft. 2.11 cu.m.

3 HP 2.24 kw

LOWER MOTOR (GAS/STEAM

B

D

OOR OPENING

D

OOR SILL HEIGHT - LEVEL

C

OMPRESSED AIR

C

OMPRESSED AIR CONNECTION

V

OLTAGE AVAILABLE

H

EAT INPUT

A

PPROX. WEIGHT (UNCRATED

A

IRFLOW

Gas*

I

NLET PIPE SIZE

V

OLTAGE AVAILABLE

A

PPROX. WEIGHT (UNCRATED

A

IRFLOW

S

TEAM CONSUMPTION

) 7-1/2 HP/15 HP 5.6 kw/11.2 kw

36-3/4” W

IDE

x 43” H

IGH

93.3 cm x 109.2 cm

37-1/4” 94.6 cm

80 PSI 5.51 bars

3/8” F.P.T. ---

208-460v 3ø 3, 4w 50/60 Hz

750,000 btu/hr 189,000 kcal/hr

)3,369 lbs. 1,528 kg

5,300 cfm 150 cmm

1-1/4” 3.18 cm

208-460v 3ø 3, 4w 50/60 Hz

)3,719 lbs. 1,687 kg

6,500 cfm 184 cmm

B

OILER

HP

ORMAL LOAD

N

890 lbs/hr 404.5 kg/hr 27

Steam*

O

PERATING STEAM PRESSURE

S

TEAM SUPPLY

S

TEAM RETURN

125 PSI max 8.79 kg/sq cm 1-1/2” 3.81 cm 3/4” 19 .05 mm

Shaded areas are stated in metric equivalents

* Dryer must be provided with a clean, dry, regulated 80 PSI +/- 10 PSI (5.51 bars +/- 0.68 bars) air supply

(equivalent volume = 9 cfh [0.26 cmh]).

NOTE: ADC reserves the right to make changes in specifications at any time, without notice or

obligation.

11

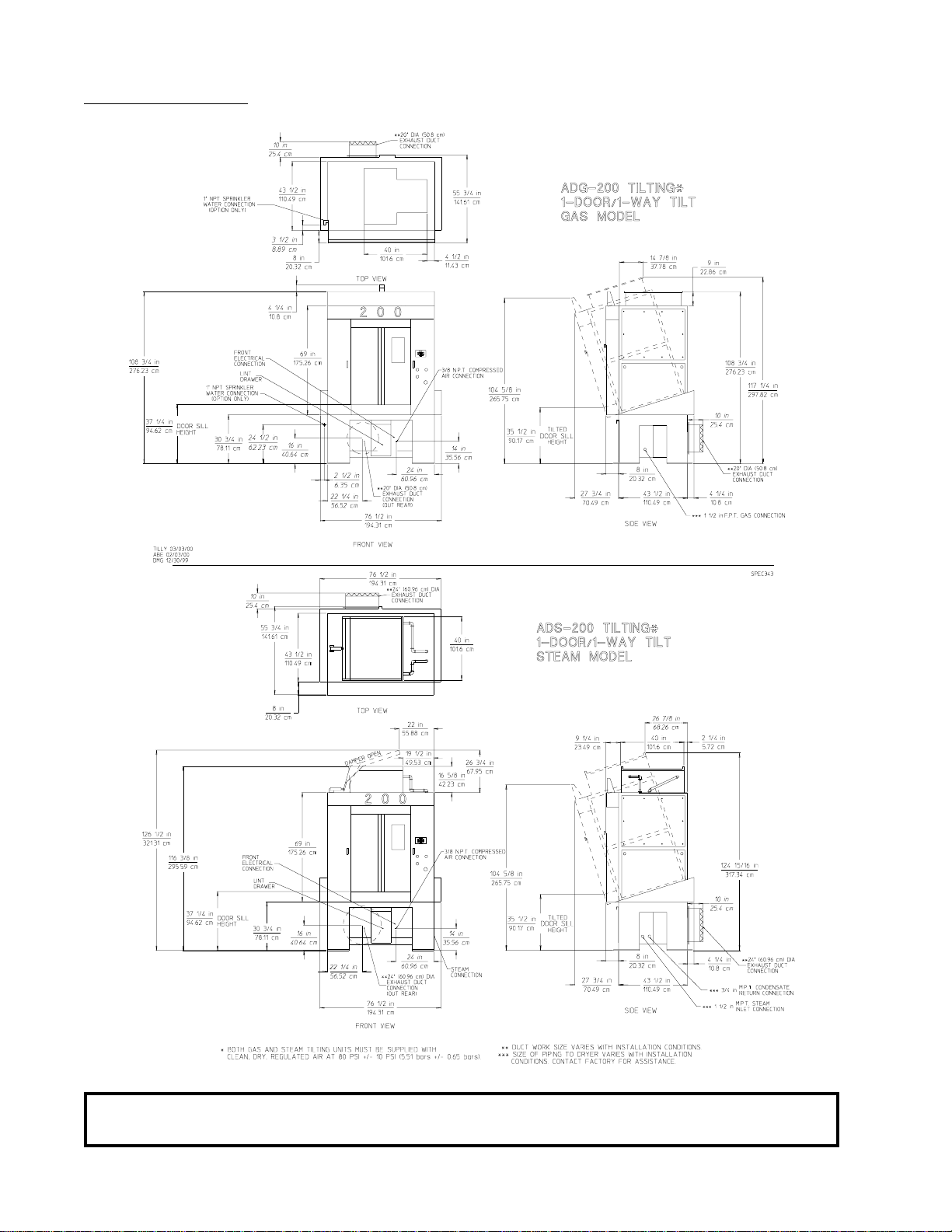

B. DIMENSIONS

NOTE: ADC reserves the right to make changes in specifications at any time, without notice or

obligation.

12

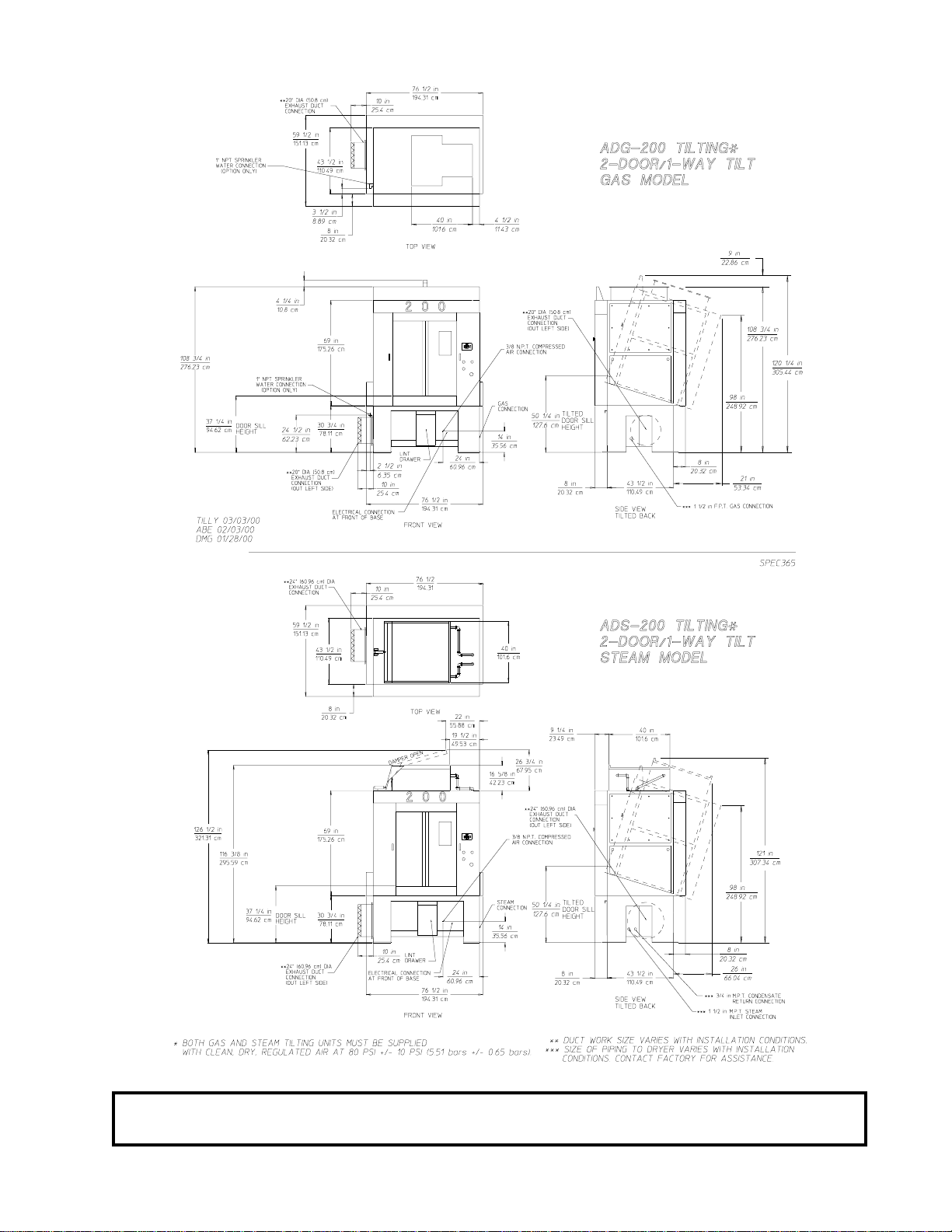

NOTE: ADC reserves the right to make changes in specifications at any time, without notice or

obligation.

13

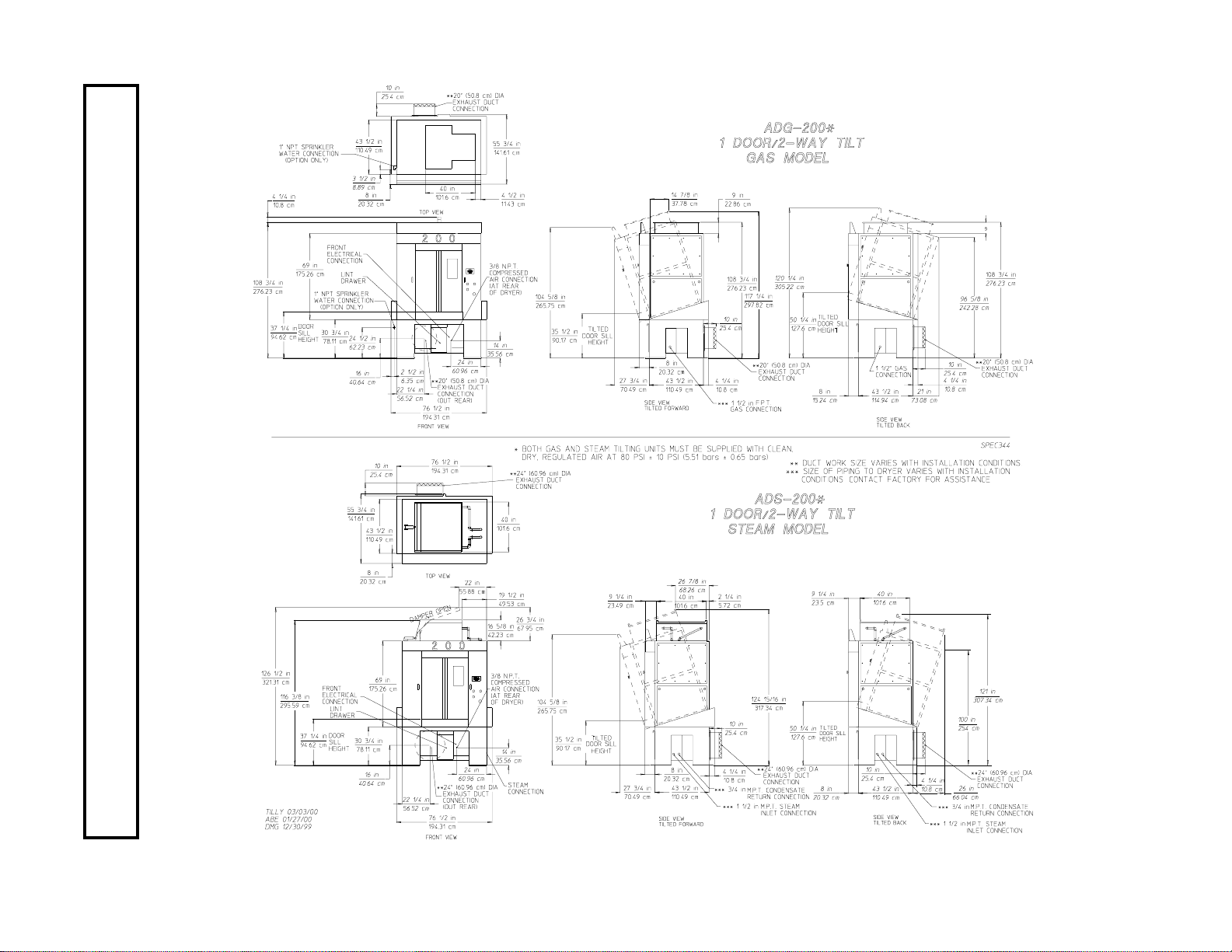

14

NOTE: ADC reserves the right to make changes in specifications at any time, without notice or

obligation.

SECTION IV

INSTALLATION REQUIREMENTS

Installation should be performed by competent technicians in accordance with local and state codes. In the

absence of these codes, installation must conform to applicable American National Standards: National Fuel

Gas Code ANSI.Z223.1-LATEST EDITION and/or National Electrical Code ANSI/NFPA NO. 70-LATEST

EDITION, or in Canada, the Canadian Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION.

A. ENCLOSURE/AIR SUPPLY/EXHAUST REQUIREMENTS

NOTE: The following information is very brief and general. For detailed description, refer to the

AD-200 Phase 7 Tilting Installation/Operators Manual (ADC Part No. 113109) included

with the dryer.

Bulkheads and partitions around the dryer should be made of noncombustible materials. Allowances should be

made for the opening and closing of the control door and lint door. Also, allowances should be made in the rear

for ease of maintenance. (Refer to the AD-200 Phase 7 Tilting Installation/Operators Manual [ADC Part No.

113109] for recommended distances and minimum allowances required.)

When the dryer is operating, it draws in room air, heats it, passes this air through the tumbler (basket), and

exhausts it out of the building. Therefore, the room air must be continually replenished from the outdoors. If the

make-up air is inadequate, drying time and drying efficiency will be adversely affected. Ignition problems and sail

switch fluttering problems on gas dryers may result, and you also could have premature motor failure from

overheating. The air supply must be given careful consideration to insure proper performance of each dryer.

IMPORTANT: Make-up air must be provided from a source free of dry cleaning fumes. Make-up

air that is contaminated by dry cleaning fumes will result in irreparable damage to

motors and other dryer components.

Exhaust duct work should be designed and installed by a competent technician. Improperly sized duct work will

create excessive back pressure which will result in slow drying, increased use of energy, and shut down of the

burner by the airflow (sail) switch, burner hi-limit or lint chamber hi-heat protector thermostat. (Refer to the

AD-200 Phase 7 Tilting Installation/Operators Manual [ADC Part No. 113109] for more details.)

CAUTION: IMPROPERLY SIZED or INSTALLED EXHAUST DUCT WORK CAN

CREATE A POTENTIAL FIRE HAZARD.

15

B. ELECTRICAL and GAS REQUIREMENTS

It is your responsibility to have ALL electrical connections made by a properly licensed and competent electrician

to assure that the electrical installation is adequate and conforms with local and state regulations or codes. In the

absence of such codes,

requirements of the National Electrical Code ANSI/NFPA NO. 70-LATEST EDITION, or in Canada, the Canadian

Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION.

IMPORTANT: Failure to comply with these codes or ordinances and/or the requirements stipulated

The dryer installation must meet the American National Standard, National Fuel Gas Code ANSI Z223.1LATEST EDITION, or in Canada, the Canadian Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST

EDITION (for Electrical Connections) as well as, local codes and ordinances, and must be done by a qualified

technician.

NOTE: Undersized gas piping will result in ignition problems and slow drying and can create a safety

hazard.

The dryer must be connected to the type of gas (natural or L.P. [liquid propane]) indicated on the dryer data

label. If this information does not agree with the type of gas available, contact the distributor who sold the dryer

or contact the factory.

ALL electrical connections, material, and workmanship must conform to the applicable

in this manual can result in personal injury or component failure.

The gas input ratings shown on the dryer data label are for elevations up to 2,000 feet (609.6 meters), unless

elevation requirements of over 2,000 feet (609.6 meters) were specified at the time the dryer order was placed

with the factory. The adjustment for dryers in the field for elevations over 2,000 feet (609.9 meters) are made by

changing the burner orifices. If this adjustment is necessary, contact the distributor who sold the dryer or contact

the factory.

NOTE: Any burner changes must be made by a qualified technician.

C. OPERATIONAL SERVICE CHECK PROCEDURE

After performing any service or maintenance function, an operational check should be performed to insure that

ALL components are performing properly.

1. Make a complete operational check of ALL the operating controls to insure that the timing is correct,

temperature selection switches are functioning properly.

2. Make a complete operational check of ALL safety related circuits, door switches, hi-limit thermostat, sail

switch, cycling thermostats, etc.

16

SECTION V

COMPONENT DESCRIPTION/REPLACEMENT

A. HEAT SECTION

The AD-200 dryer uses three (3) types of heat sources: natural gas, liquid propane (L.P.) gas, and steam. Natural

gas and L.P. gas

heat specified on the nameplate.

1. ADG-200 (gas) dryers utilize a Direct Spark Ignition (DSI) module to monitor that a flame is established. If

for some reason the flame signal is lost, the DSI module will shut off the gas valve and not retry ignition (no

try to restart the flame). A spark of approximately 14,000 volts is used to establish a flame. The DSI

module will turn the gas valve on and ignitor/flame-probe will spark for 8-seconds attempting a flame. Each

time the dryer calls for heat the microprocessor controller (computer) will send a 24 VAC signal through the

exhaust hi-limit, sail switch, and oven hi-limit. At that point, the DSI module will try for ignition.

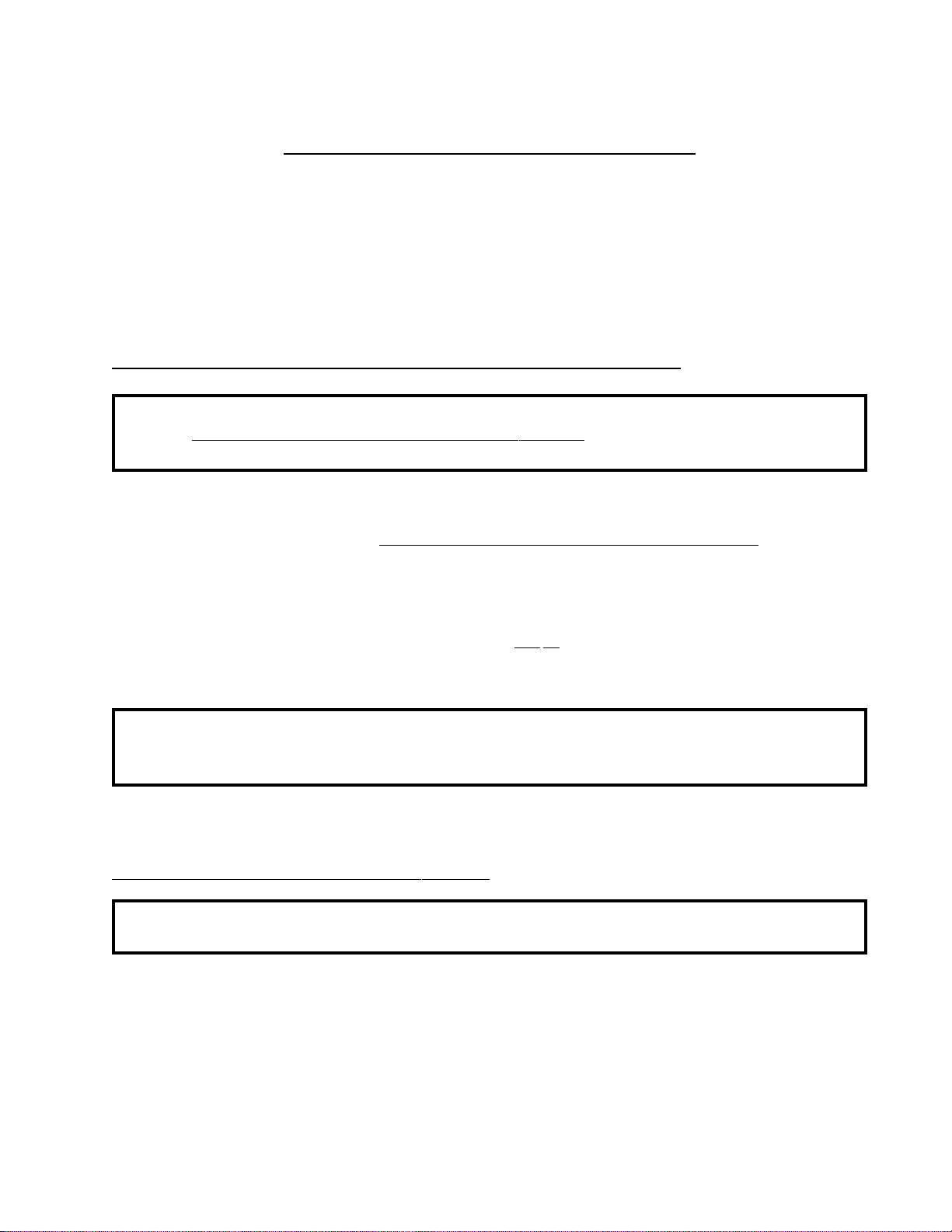

DIRECT SPARK IGNITION (DSI) SYSTEM COMPONENTS/FUNCTIONS

are not directly replaceable. The gas valves need to be modified to use other than the type of

Johnson (DSI) Control Module P/N 128935

ADC (DSI) Control Module P/N 128973

17

Johnson (DSI) Control Module

P/N 128935

a. The Direct Spark Ignition

(DSI) Module is a 24 VAC

device designed to be the

controller of the DSI system.

When activated by the dryer

controls, this module constantly

monitors and controls the

functions of the DSI system

(i.e., spark activation, gas valve

off and on, flame verification,

etc.). Additionally, the DSI

Module has self diagnostic

capabilities.

24 VAC Direct Spark Ignition (DSI) Module

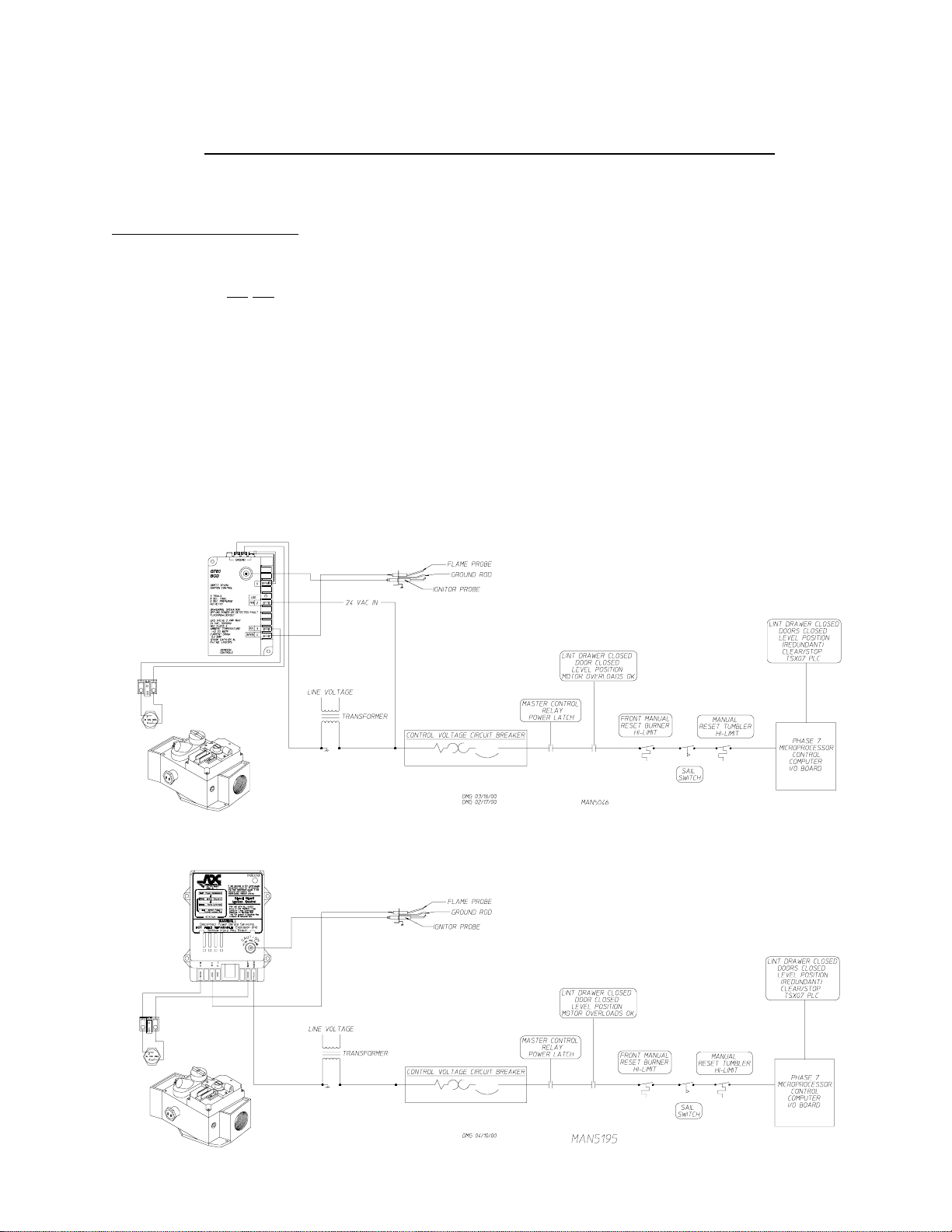

b. The Ignitor/Flame-Probe Assembly is located in the burner

flame area and is used to ignite the gas by use of a high voltage

spark (approximately 14,000 volts) and to provide feedback

information to the DSI Module as to whether the burner flame

is evident (on).

ADC (DSI) Control Module

P/N 128973

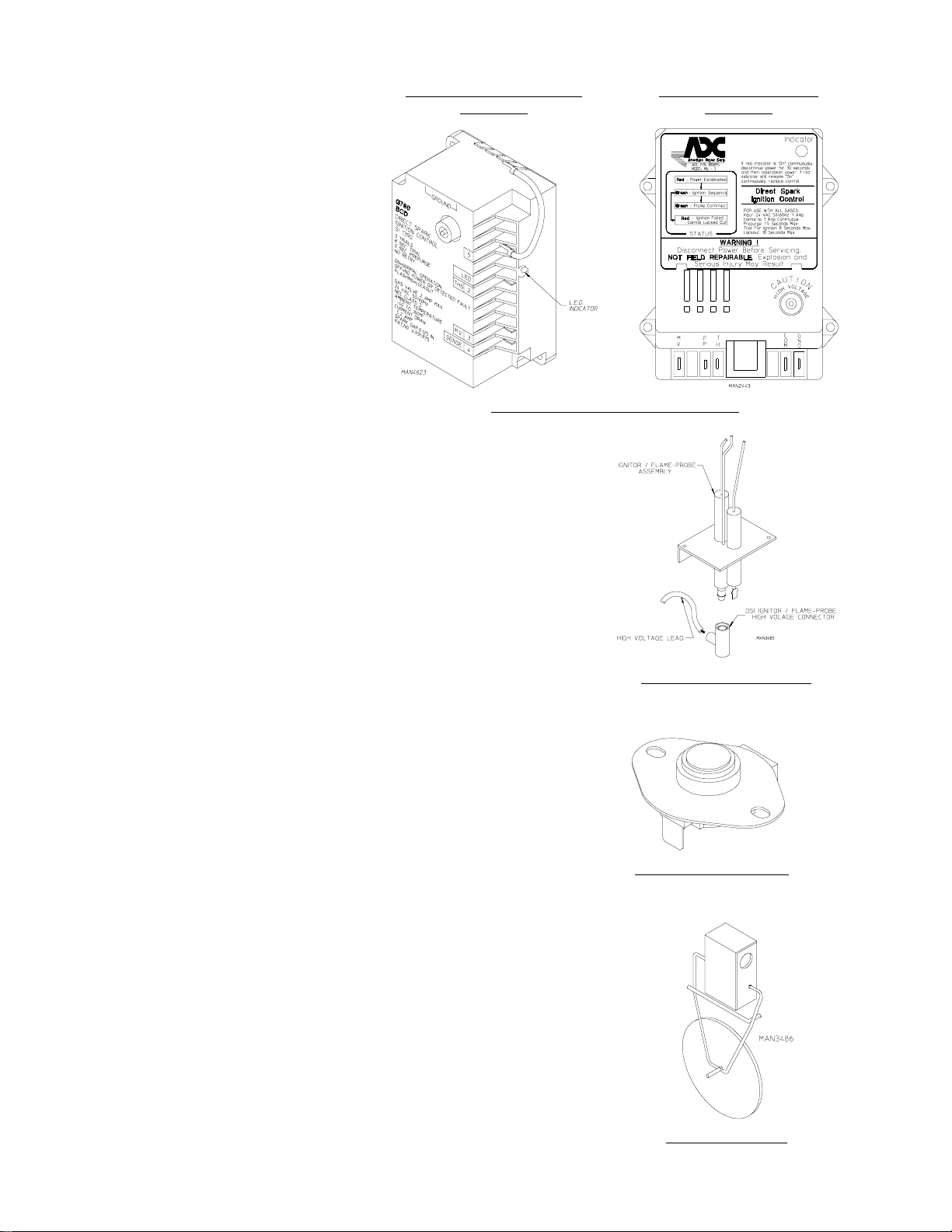

c. The Manual Reset Burner Hi-Limit Switch is a thermostat

type switch located in the burner. Its function is to discontinue

heat (flame) in the event of an over temperature situation (above

330º F [166º C]). For dryers manufactured as of May 26,

1998, the hi-limit must be manually reset once the device trips.

d. The Sail Switch Assembly is located on the Burner Assembly,

downstream of the flame tubes. Its function is to detect whether

or not there is sufficient airflow through the dryer.

Ignitor/Flame-Probe Assembly

MAN3484

330º F (166º C) Thermostat

18

Sail Switch Assembly

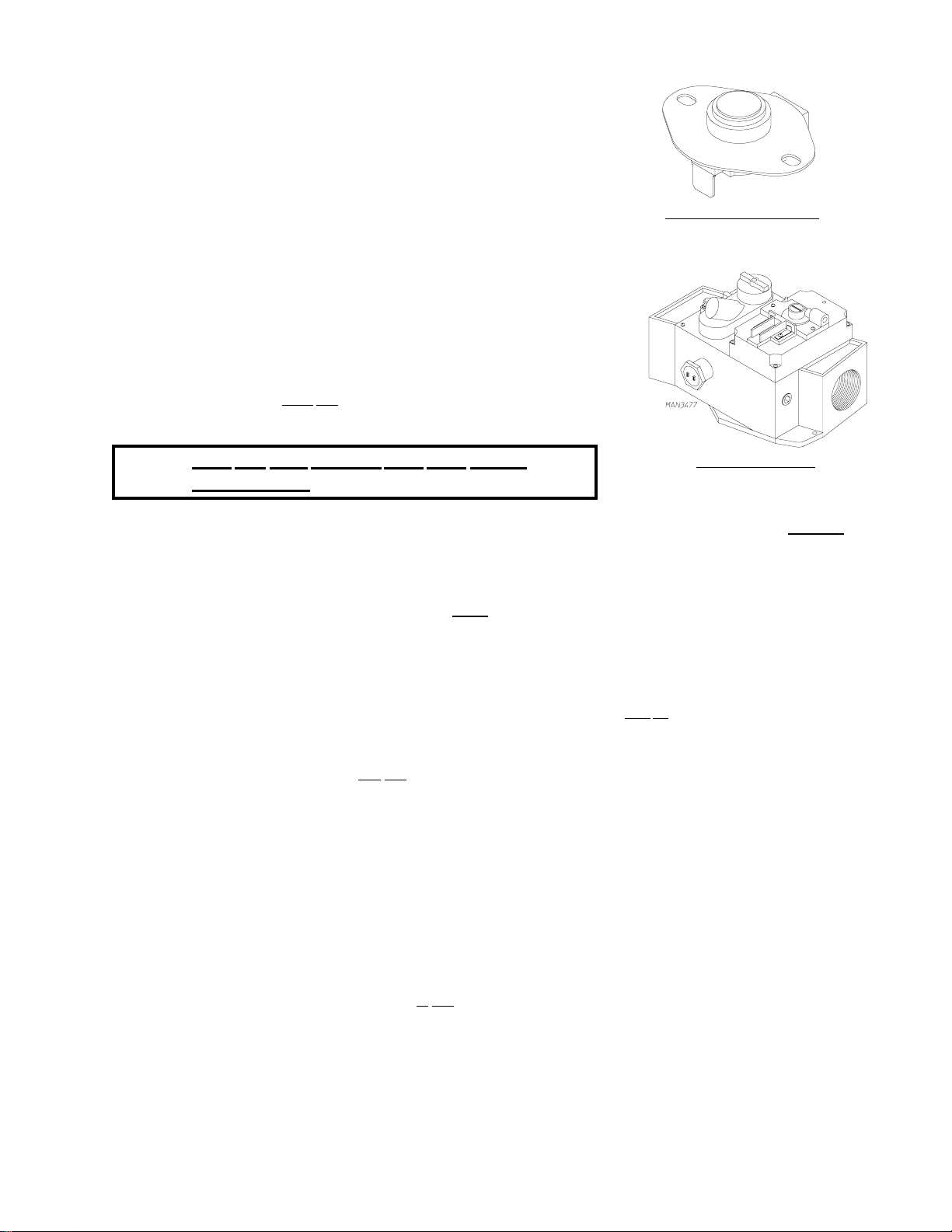

e. The Manual Reset Tumbler (Basket) Hi-Limit Switch is a

thermostat type switch located above the Lint Basket. Its function

is to discontinue heat (flame) in the event of an over temperature

situation (above 225º F [107º C]).

f. The gas valve used in the ADG-200 is of the redundant type

which means that the gas valve is actually two (2) gas valves in

one; one (1) in series with the other. This is a safety feature

which provides protection against gas flow in the event that one

(1) of the valves

does not seat properly. The valve also regulates

the incoming gas pressure.

MAN3484

225º F (107º C) Thermostat

NOTE: THE DSI GAS VALVES ARE NOT FIELD

Redundant Gas Valve

REPAIRABLE.

g. Normal Operation of the Direct Spark Ignition (DSI) System (refer to the illustration on page 17).

1) The DSI System consists of a microprocessor-based control module, along with an Ignitor/FlameProbe Assembly. This control utilizes a high voltage synchronous spark ignitor and a rectified flame

sensor probe signal to locally control ALL basic functions in the gas burner.

On a call for heat by the dryers controls, 24 VAC is applied to the DSI module at which time the

modules L.E.D. (light emitting diode) indicator will light red indicating that power has been

established to the module. Almost immediately (up to approximately 1.5-seconds [prepurge]) the

indicator will light green, the gas valve opens and the spark burst will be evident (on) for approximately

8-seconds. The burner flame should now be established/confirmed.

If at this time the flame has not been established and confirmed, the DSI module will LOCKOUT

and the modules L.E.D. indicator will light red and stay on continuously. Burner Ignition Control

Fault will display. To clear this fault press the CLEAR/STOP key.

Once the burner flame is established and confirmed, the DSI module indicator will light green, and

the burner system will continue through a normal heating cycle, where the DSI system will cycle on

and off as required by the dryers controls.

During the normal heating cycle, should a FLAME-OUT occur (i.e., severe air turbulence forces

the flame away from the Ignitor/Flame-Probe Assembly), the DSI module will shut the gas valve off

and immediately try to reestablish the burner flame. The DSI module will attempt to light the

burner ONLY ONCE. If flame is not established, the DSI module will LOCKOUT and Burner

Ignition Control Fault will display. To clear this fault press the CLEAR/STOP key.

19

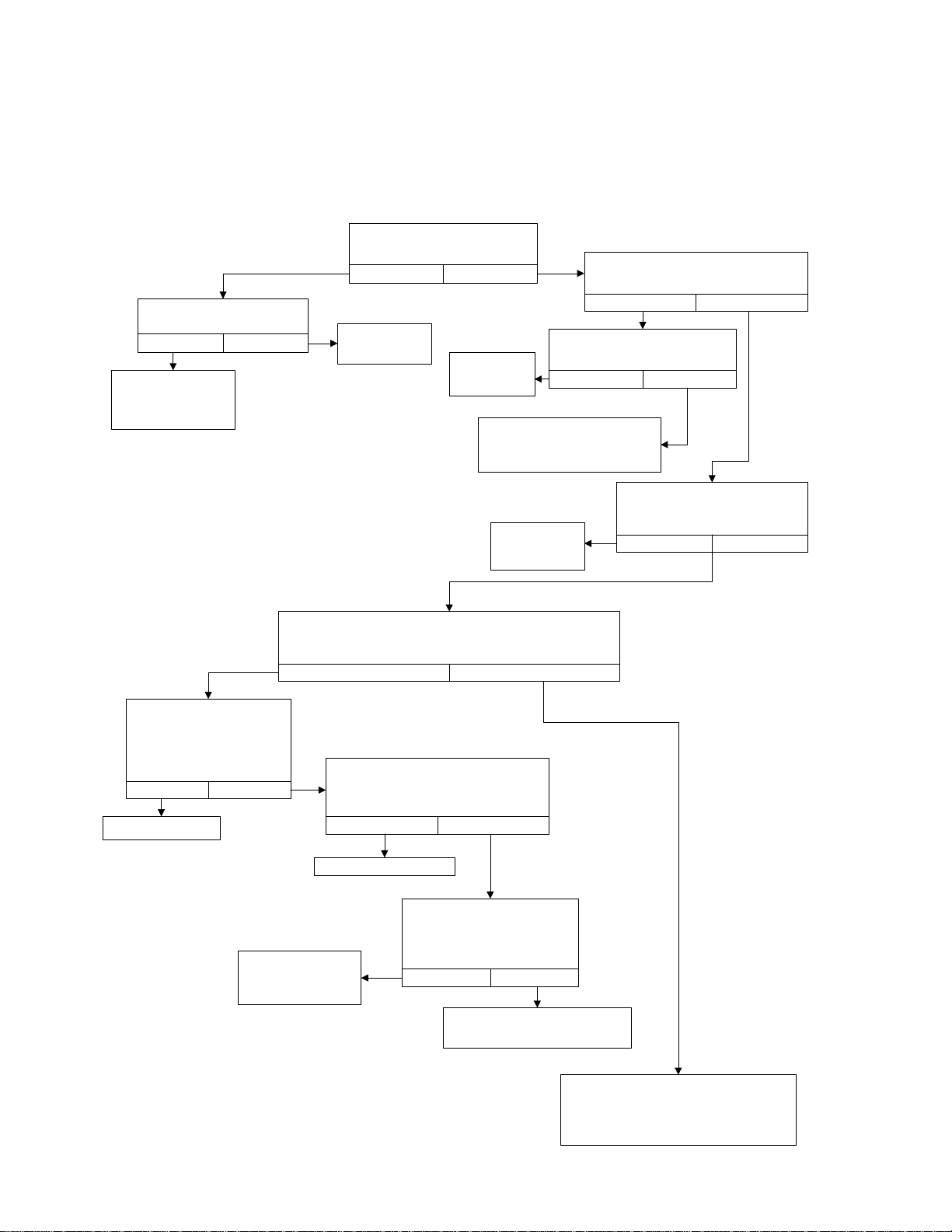

h. Troubleshooting Flow Chart - Quick Reference...

First Visual Check

No Spark And System Does Not Work

Is 24 VAC available

at transformer?

No Yes

Is power available

to primary?

No Yes

Determine why

voltage is not

present.

Replace

Transformer.

Contacts.

Is 24 VAC present from terminal

Are thermostat contacts and

Close

Check continuity of wiring to

determine why voltage does

limit control contacts closed?

No Yes

not exist at THS2.

Install

Jumper.

THS2 to ground?

No Yes

Is jumper installed

from terminal 5 to

ground?

No Yes

Turn off supply voltage.

Check high voltage cable.

Is it securely attached to

spark transformer?

No Yes

Correct

Johnson Control

module G760/761

Open thermostat contacts for 30 seconds.

Close contacts and wait for prepurge (if applicable)

period. Is spark present now?

No Yes

Is condition of high voltage

cable good (not brittle,

burnt, or cracked)?

No Yes

Replace

Is spark electrode

ceramic cracked

or is electrode

Replace

grounded out?

No Yes

Replace electrode

assembly.

20

System was in lockout.

Observe a complete operating

cycle to determine why

control locked out.

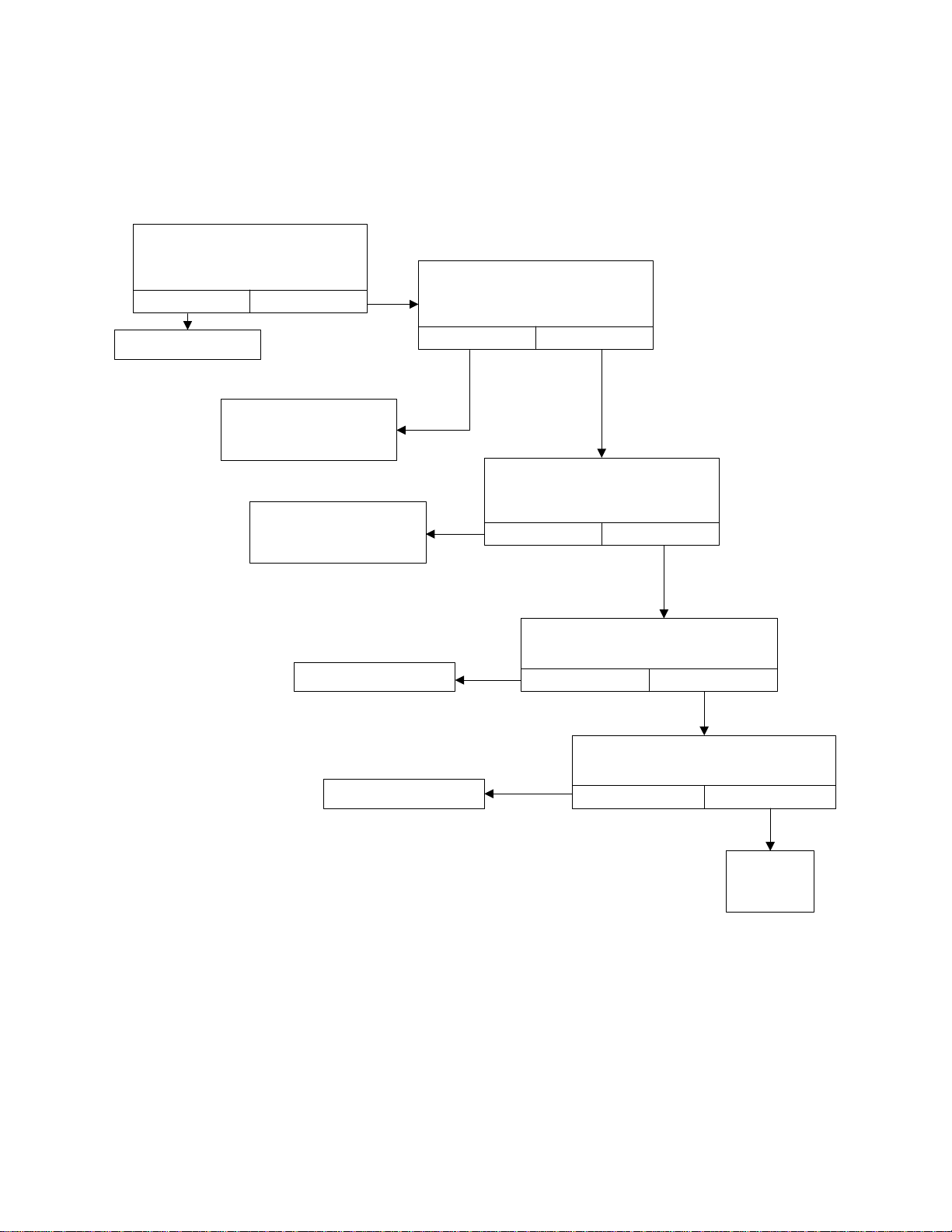

i. Troubleshooting Flow Chart - Quick Reference...

Second Visual Check

Spark Present But Main Burner Does Not Come On*

Is main valve wiring securely

attached to terminal M.V.3

and ground?

No Yes

Correct

Replace

Johnson Control

module G760/761

Determine

why continuity

does not exist.

Is 24 VAC present

between terminals M.V.3

and ground ?

No Yes

Check for continuity in

wiring from M.V.3 to gas

valve, and gas valve to GR.

No Yes

Correct

Correct

Is inlet gas pressure per

manufacturer’s specifications?

No Yes

Is Spark gap .125 in.

and in gas stream?

No Yes

Replace

gas valve.

21

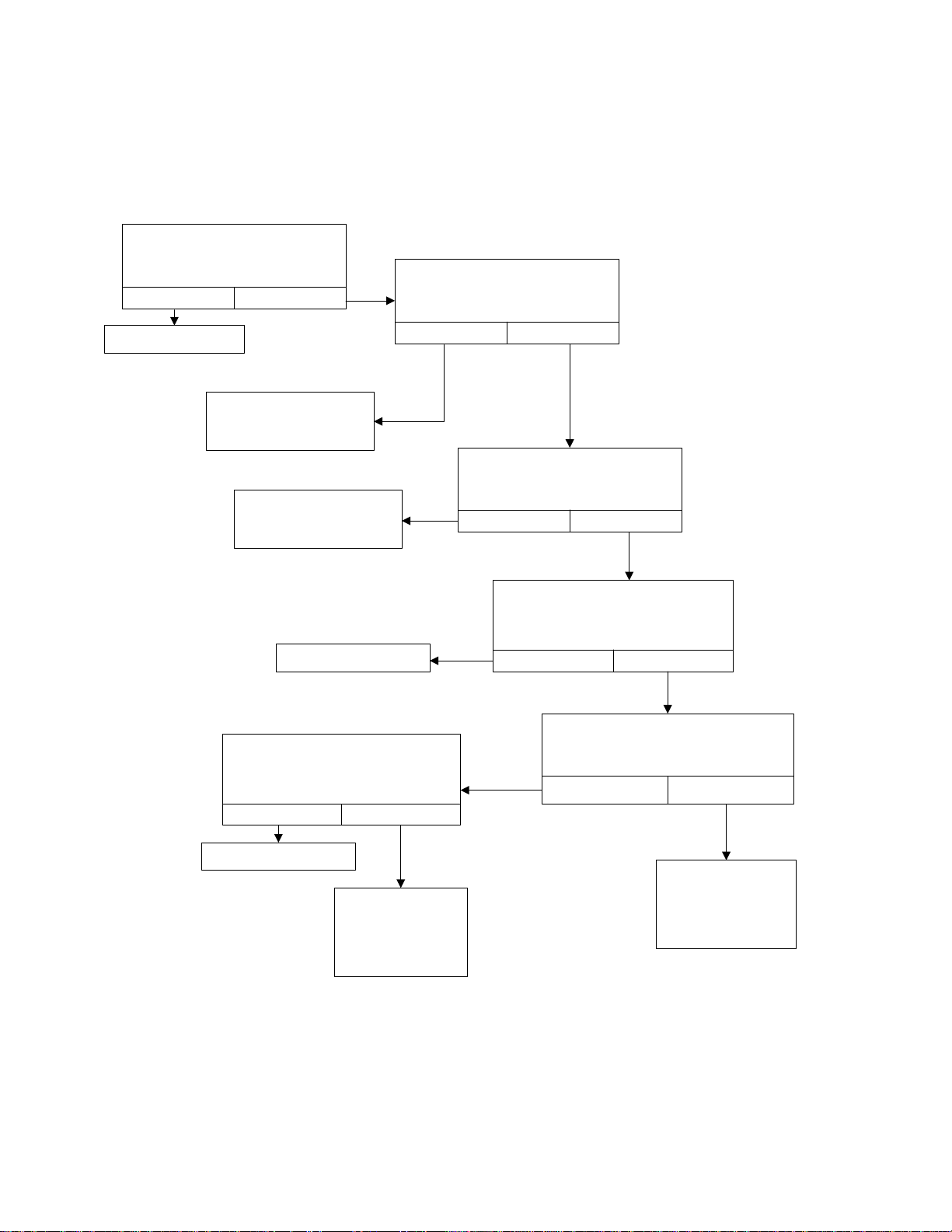

j. Troubleshooting Flow Chart - Quick Reference...

Third Visual Check

Main Burner Lights But Will Not Stay On

Is flame sensor cable

securely attached

to terminal 4?

No Yes

Correct

Replace

sensor

cable.

Correct or

replace

sensor.

Does continuity exist

from control

to flame sensor?

No Yes

Is flame sensor corroded

or is ceramic cracked?

No Yes

Correct

Is flame sensor

positioned per

manufacturer’s specifications?

No Yes

Correct

Replace

Johnson Control

module

G760/761

Does continuity exist in

ground path from burner

to control?

No Yes

Check flame sensing current

during trial. Is current

greater than 0.3

No Yes

Johnson Control

µ

A DC?

Replace

module

G760/761

22

B. TROUBLESHOOTING THE DIRECT SPARK IGNITION (DSI) SYSTEM

NOTE: The troubleshooting information provided in this manual is intended for use by qualified service

technicians only. OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment

or specified in the AD-200 Phase 7 Tilting Installation/Operators Manual (ADC Part No.

113109) included with the dryer.

IMPORTANT: UNDER NO CIRCUMSTANCES SHOULD ANY SAFETY or HEAT

CIRCUIT DEVICES EVER BE DISABLED.

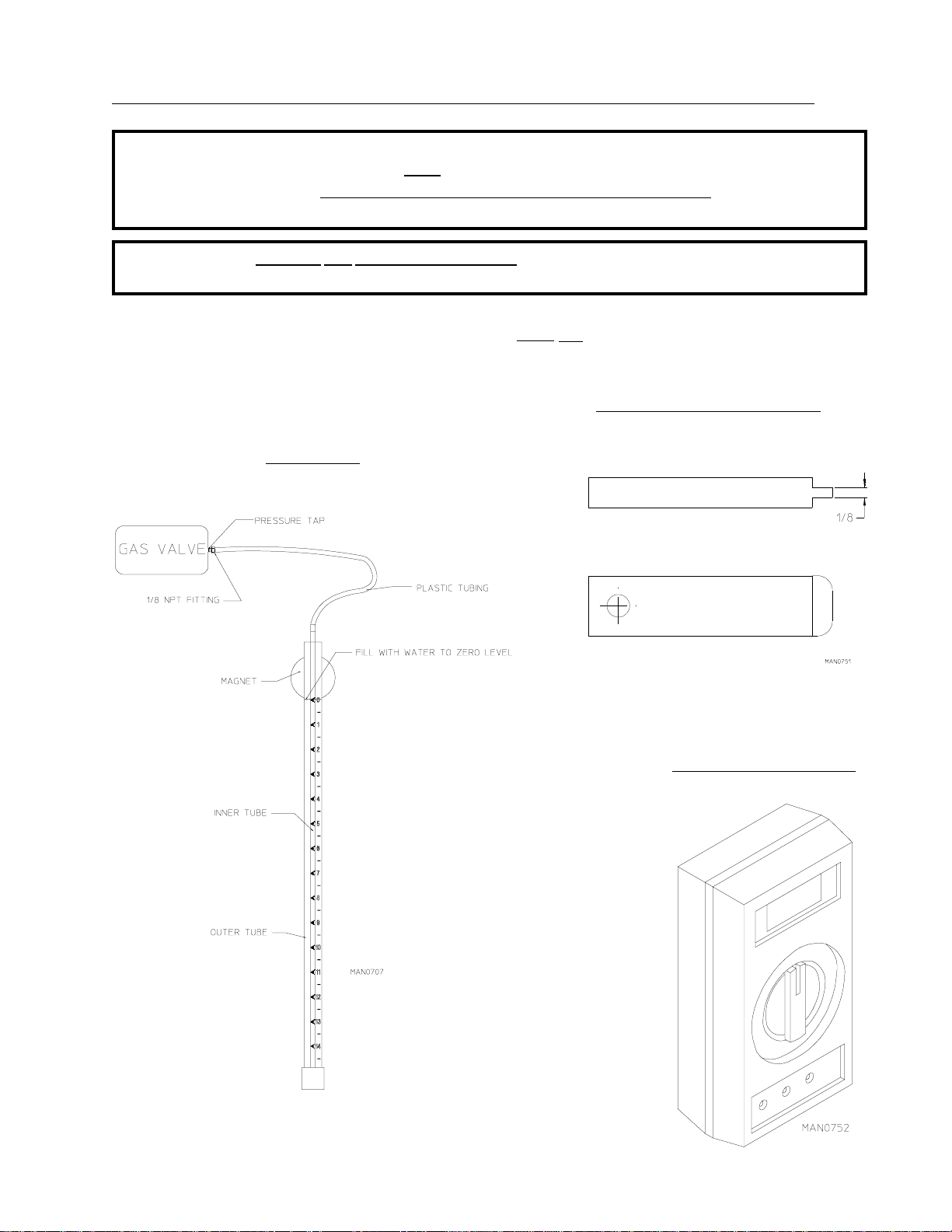

THE FOLLOWING PIECES OF TEST EQUIPMENT WILL BE REQUIRED TO TROUBLESHOOT

THIS SYSTEM WITH MINIMAL TIME AND EFFORT

DSI IGNITOR GAP FEELER GAUGE

(1/8 [3.175 mm])

Used For Checking Gap Between Ignitor/

MANOMETER

Used To Measure Gas Pressure In Inches

Of Water Column (W.C.)

Flame-Probe Assembly and Spark Electrode

Available From ADC

Available From ADC

MULTIMETER/VOLTMETER

For Measuring Voltage

23

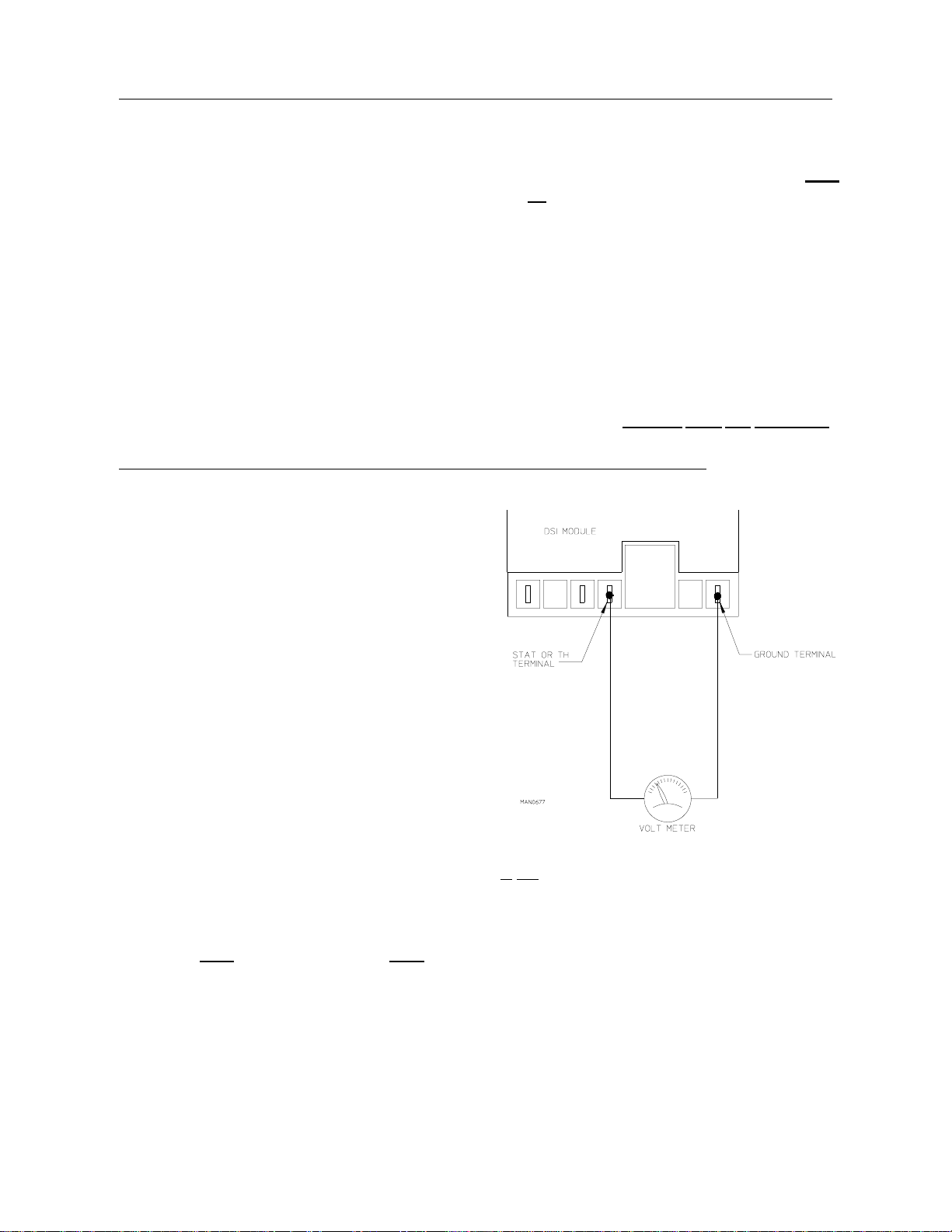

1. Direct Spark Ignition (DSI) Troubleshooting Terms (definitions) ADC (DSI) Control Module P/N 128973

a. DSI MODULE RED L.E.D. INDICATOR LIGHT - This red L.E.D. (light emitting diode) light is

located in the upper right corner of the DSI

module (refer to the top illustration on page

18). This is a diagnostic indicator that

simplifies the operational and troubleshooting

procedures of the DSI system.

b. LOCKOUT MODE - DSI module red L.E.D. indicator light stays on continuously. This indicates

there is a system fault and most likely the fault is the DSI module itself.

c. FLAME-OUT - Burner flame shut down by the DSI module due to lack of flame verification. This

condition occurs only after ignition is evident but is lost. The DSI system will immediately

attempt to relight the burner.

d. RECYCLE - Flame has been sensed but lost. Initiate a new sequence (

2. Troubleshooting and System Basic Diagnosis ADC (DSI) Control Module P/N 128973

a. Preliminary Steps

The following steps must be performed to

minimize the time required to isolate cause

of fault.

1) DSI module L.E.D. indicator light is off (no

red or green light).

a) Check for voltage (approximately 24

VAC) across the DSI model terminals

TH and GND...

If voltage (approximately 24 VAC) is

evident, then, there is a malfunction within

the DSI module itself, and it must be

replaced.

THERE ARE NO RETRIES).

If there is no voltage present, then problem is not the DSI module or the ignition system, the

problem is elsewhere in the dryer (i.e., dryers heat circuit [sail switch, hi-limit circuits, etc.]).

2) DSI module L.E.D. indicator lights red for approximately 1.5-seconds (prepurge). This indicates

that ALL the controls (including ALL the safety circuits) are functioning and power is being supplied

to the DSI module.

3) DSI module L.E.D. indicator lights green. This indicates a normal heating cycle. This also

indicates that the preliminary diagnostics of the module has confirmed that the DSI module is functional.

4) DSI module L.E.D. indicator lights red continuously...LOCKOUT MODE. This indicates that

there is a system fault and most likely the fault is internal to the DSI module. To make sure, open

and close the main door. Restart the dryer...if the module LOCKS OUT (red L.E.D. indicator

light stays on continuously) again, replace the DSI module.

24

If the dryer repeatedly has DSI module LOCKOUT failures, the cause may be due to high

voltage not getting into the DSI module ignitor probe assembly.

5) Check to insure that the red high voltage wire (between the ignitor spark electrode and the DSI

module)

terminal and the Ignitor/Flame-Probe Assembly). If the wires are touching one another, separated

and secure in place AWAY FROM ONE ANOTHER.

6) Check to insure that the dryer is properly grounded and that the ground connections (GND) to the

DSI module are secure.

7) If the problem persists, it is most likely to be in the external components (not the DSI module), or

wiring, due to a FLAME-OUT...proceed as follows:

is not wrapped around the sensor probe wire (the wire between the DSI module FP

NOTE: Preliminary steps - DO NOT OMIT - to minimize the time required to troubleshoot this

system.

a) Disconnect the electrical power to the dryer.

b) Visually check the DSI module components for visual damage.

c) Check wiring for loose connections, nicks, or cracking at the ceramic insulator, or shorting of the

sensor to the burner.

d) Inspect the DSI Ignitor/Flame-Probe Assembly...

...check electrode for visible cracking at the ceramic insulator or shorting of sensor to burner

...check to insure that the flame sensor rod is positioned over the flame area

...check for carbon deposits on the flame sensor rod

...check to insure that there is a 1/8 (3.175 mm) +/- 1/32 (+/- 0.79248 mm) gap between the

ground rod and the ignitor spark electrode

b. After performing these inspections and making corrections - if any - restore power to the dryer...start

the dryer and operate through one (1) complete cycle to insure that ALL components are functioning

properly. If a no heat condition persists refer to the Troubleshooting Flow Charts on page 27, page

28, and page 29.

1) To effectively use this information or the flow charts, each step must be completed in sequence,

performing whatever test are suggested. After the completion of each test, the guide will direct the

Service Technician to the next logical step in the troubleshoot sequence based on the outcome of the

previous check.

2) Components should be replaced only after each step has been completed and replacements after

each step has been completed and replacement is suggested in the flow chart. However, the

experienced technician realizes that a loose connection or broken or shorted wire may be at fault

where electrical components are concerned...and not necessarily the suspected component itself.

25

c. Three Visual Checks

1) Does the DSI Ignitor/Flame-Probe Assembly start sparking?

If not, refer to the FIRST VISUAL CHECK on

2) Does the main burner ignite?

If not, refer to the SECOND VISUAL CHECK on page 28.

3) Does the main burner remain lit after ignition has been established (FLAME-OUT)?

If not, refer to the THIRD VISUAL CHECK on

page 27.

page 29.

26

Loading...

Loading...