American Dish JDS12T Installation Manual

American Dish Service

INSTALLATION INSTRUCTIONS

Model JDS12 (T) or (R) “Muffl er” Booster

(T) 12kW, 240v, 3-ph, (R) 12kW, 208v, 3-ph

Manufactured by Hubbell Electric Heater Company for use on American Dish Service dishwashers

If you have questions, call 800-922-2178 or visit our website at www.AmericanDish.com

The electrical power supplied to this machine is an imminent hazard that will result in severe

injury or death if not avoided. When working in the control box or on electrical parts, always

disconnect power and tag-out before servicing. Replace cover to control box and other protective

covers when fi nished servicing this equipment.

1

READ Manufacturer’s Manual before Using this Product. For your safety read and observe all

cautions shown throughout these instructions. While performing installations described in this

booklet, wear approved Personal Protective Equipment, including Safety Eye-Wear.

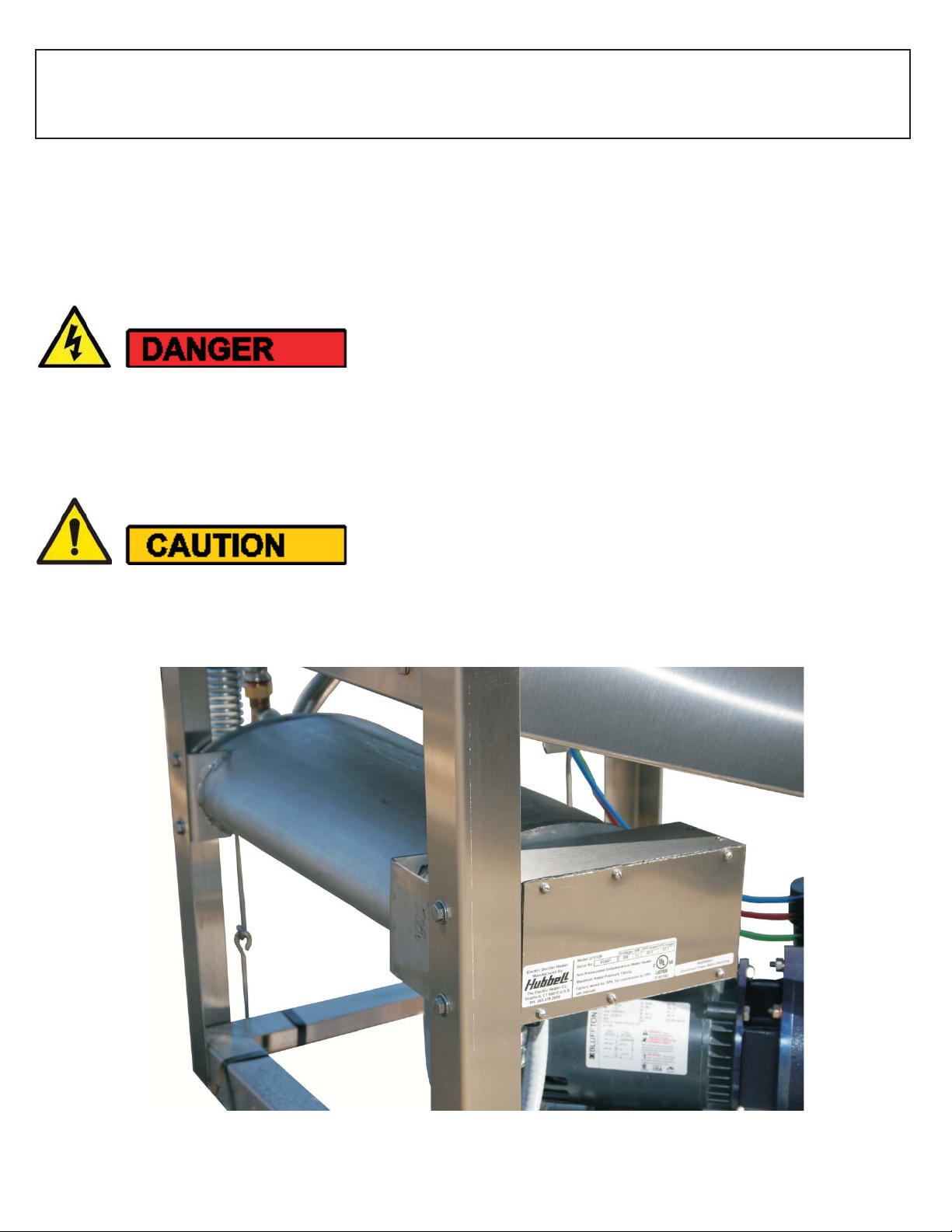

Showing the JDS12 Booster

The following text reprinted by permission from Hubbell Electric Heater Company’s Operating and

Maintenance Manual for JDS12T (240v) and JDS12R (208v).

WARNING/CAUTION

1. Tank is to be completely fi lled with water and all air is to be vented before energizing.

2. Due to the rigors of transportation, all connections should be checked for tightness before heater is

placed in operation

3. The refractory material in the heating elements may absorb some moisture during transit, periods of

storage, or when subjected to a humid environment. This moisture absorption may result in a

cold insulation resistance of less than twenty (20) megohms. If this heater has been subjected to

the above condition, each heating element must be checked for insulation resistance before

energizing.

4. Keep away from live electrical circuits. Do not perform any maintenance, make any adjustments,

or replace any components inside the control panel with the high voltage power supply turned on.

Under certain circumstances, dangerous potentials may exist even when the power supply is off.

To avoid casualties, always turn the power supply safety switch to off, turn the charge or ground the

circuit before performing any maintenance or adjustment procedure.

5. The unit is designed to operate at atmospheric pressure only. Do not install any valves in the outlet

line and ensure that the outlet line is open to atmosphere.

2

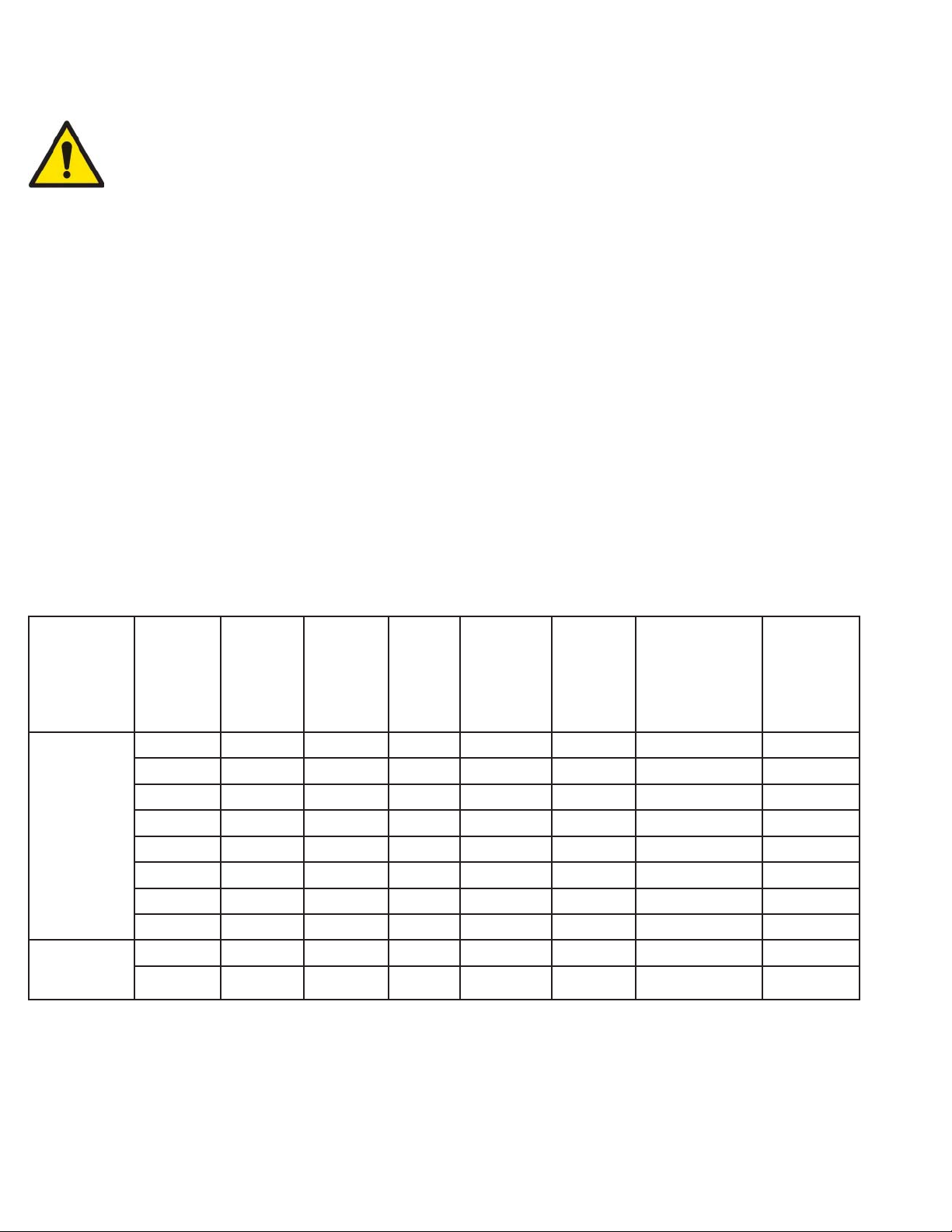

Specifi cations

Model Volts Ph

208 1 9 43.3 92.4 50 8 3/4"

220 1 10.1 45.8 103.4 50 8 3/4"

230 1 11 47.9 113 50 8 3/4"

JDS12T

JDS12R

240 1 12 50 123 60 6 3/4"

208 3 9 25 92.4 30 10 1/2"

220 3 10.1 26.5 103.4 30 10 1/2"

230 3 11 27.7 113 30 10 1/2"

240 3 12 28.9 123 30 10 1/2"

208 1 12 57.7 123 60 6 3/4"

208 3 12 33.3 123 40 8 3/4"

Power

(kW) Amps

Recovery

(GPH) @

40F Rise

Min.

Feed

Breaker

or Fuse

Size

Power Feed

Wire Size

(75C Cu

(THHN)

Conduit

Size

Power feed wire sizing is based on using 75° C Cu THHN wire with feeder branch protection rated at 100%

for a non-continuous load.

INST ALLA TION AND ST ART -UP

WARNING/CAUTION

Do not turn on the electric power supply to this equipment until heater is completely fi lled with

water and all air has been released. If the heater is NOT fi lled with water when the power is

turned on, the heating elements will burn out.

The unit is designed to operate at atmospheric pressure only. Do not install any valves in the

outlet line and ensure that the outlet line is open to atmosphere.

Installation or service of this unit requires ability equal to that of a licensed tradesman in the fi eld.

The installation must conform to these instructions and any local authority having jurisdiction.

Grounding and electrical wiring connected to the unit must also conform to the latest version of

the National Electric Code NFPA-70.

PIPING INSTALLATION

3

Connect the warm water inlet (lower connection) and hot water outlet (upper connection) to the ½”

FNPT connections at the back of the unit. Tefl on tape should be used on all NPT Threaded pipe

connections.

FILLING THE HEA TER

Open the valve to the booster water inlet and allow the heater and piping system to completely fi ll,

as indicated by a steady fl ow of water through the dishwasher rinse nozzles.

NOTE: Flush the tank at full fl ow for 10 minutes prior to putting into service.

ELECTRICAL INSTALLATION

Enter the enclosure through the factory cut KO’s with properly sized feeder leads, See

Specifi cations. Single-phase installations require two (2) leads. Three-phase installations are

intended for use with a 3-wire delta system plus ground. No neutral is required. For a 4-wire plus

ground system, install 3 legs of power plus the ground and terminate the neutral leg.

Install these power leads into the box lugs on the magnetic contactor, as required.

Connect incoming ground wire to ground lug supplied.

All other electrical connections are made at the factory; therefore, no other electrical connections

are necessary.

Check all connections, including factory connections for tightness.

OPTIONAL FIELD CONVERSION FROM SINGLE TO THREE PHASE OR VICE-VERSA

(See Drawing on page 9)

For 3-phase wiring the elements should be wired as follows: One RED wire and one BLUE wire

to terminal 1 of the contactor, one RED wire and one YELLOW wire to terminal 2 of the contactor,

and one Blue wire and one YELLOW wire to terminal 3 of the contactor.

Loading...

Loading...