American Dish ET-AF-3 Installation Manual

American Dish Service

INSTALLATION INSTRUCTIONS

Model ET-AF-M/ET-AF-3 (Gravity-Drain)

Available in 90, 120, 150-second Time Cycles

Undercounter, Single-Rack, Chemical Sanitizer, Dump & Fill Dishmachine

Listed by UL #E68594, NSF/ANSI 3, ASSE 1004 #933, LA Test Labs File M-840044, Mass. License P3-0111-306

1

If you have questions, call 800-922-2178 or visit our website at www.AmericanDish.com

The electrical power supplied to this machine is an imminent hazard that could result in severe

bodily injury or death if not properly installed or hooked up correctly. When working in the control

box or on electrical parts, always disconnect power and tag-out before servicing. Replace cover

to control box and other protective covers when fi nished servicing this equipment.

READ Manufacturer’s Manual before Using this Product. For your safety read and observe all

cautions shown throughout these instructions. While performing installations described in this

booklet, wear approved Personal Protective Equipment, including Safety Eye-Wear.

Copyright ADS Installation Manual Model ET-AF Gravity, Revision 3.0 , 6/7/2013

2

CHEMICALS— There are potentially hazardous situations when working with industrial cleaning

chemicals for dishmachines. See chemical manufacturer’s safe practices and MSDS sheets for

handling and installing chemicals and supply containers.

#1 BEFORE YOU BEGIN— American Dish Service provides this information as a service to our

customers. Keep all instructions for future reference. ADS reserves the right to alter or update

this information at any time. Should you desire to make sure that you have the most up-to-date

information, we would direct you to the appropriate document on our web site:

www.americandish.com. Set out below are the specifi cations and requirements that you must use

and follow to properly install the type or types of equipment listed above. It is your obligation as

the customer to ensure that the machine is installed safely and properly, and when completed,

the machine is left in proper and safe working order. Electrical, Plumbing, and Chemical hookup

should be performed by a qualifi ed professional who will ensure that the equipment is installed

in accordance with all applicable Codes, Ordinances, and Safety requirements. Failure to follow

the installation instructions could void the warranty. ADS assumes no liability or control over the

installation of the equipment. Product failure due to improper installation is not covered under the

ADS Warranty.

#2 FLUSH OUT—Do not install spray arm until machine is fl ushed with water. When this machine

is turned on, fi rst fi ll by pushing and holding the button marked FILL until water inside the pan

reaches the water level decal on the outside of the pan, then push the button on front door marked

START to complete one cycle. Do this before installing the spray arm. Dump the fl ush water out

before installing spray arm by pushing the button marked DRAIN. Draining the water will fl ush

installation debris from the tank and pump; this prevents damage to the spray arm bearing.

#3 WATER HEATERS— or boilers must provide the minimum temperature of 120°F required by the

machines listed above, which have a minimum demand of 60 gallons per hour. The recommended

temperature range for optimal performance is 130-140°F. These specifi cations are for the

dishmachine only, which typically accounts for 70% of a restaurant’s hot water demand.

#4 IMPORTANT—The models of dishmachine listed in this document must be installed with space

around the outside to allow for servicing of the motor as well as a 4” space behind the machine

from the wall. It should not be built into wooden cabinets.

#5 INSPECT FOR DAMAGE—If you receive a damaged dishmachine, do not sign “Clear” but write

“damaged” on the documents.

#6 LOOSE ELECTRICAL CONNECTIONS—Damage to equipment can occur if the following

precautions are not observed. Before connecting power to the machine, check all electrical

terminals in the control box. Screws can loosen in transit. Loose connections on high amp load

terminals such as the pump motor will cause wire burning and component damage during

operation and will not be covered under ADS warranty.

#7 “CLEAN CIRCUIT” means the electrical circuit breaker for the dishmachine supplies no other

outlets, machines, or lights. GFCI outlets are not recommended for commercial dishmachines;

ADS recommends that a single-rack machine be installed with the wire connection (hard-wired)

directly from the circuit breaker. If a plug and socket are used to provide electrical power to a

dishmachine in a commercial kitchen, then according to electrical code it must be a GFCI, but not

all GFCIs are the same. They must be rated for the draw of the circuit.

Copyright ADS Installation Manual Model ET-AF Gravity, Revision 3.0 , 6/7/2013

Reference NEC Article 210.8 GFCI Protection (B) Other Than Dwelling Units (2) Commercial and

Institutional Kitchens. All 15 and 20A, 125V receptacles installed in kitchens, even those that do not

supply the countertop surface, must be GFCI protected.

#8 This equipment is considered an item of heavy use. It is not rated for outdoor use.

ELECTRICAL SECTION

The electrical power supplied to this machine is an imminent hazard that could result in

severe bodily injury or death if not properly installed or hooked up correctly.

Electrical—ET-AF-M/ET-AF-3 Gravity- Drain (120 volt, 20 amp)

A time cycle of 90-seconds is the shortest time available for this model and is compliant with NSF listing.

To change to a longer time cycle, the entire cam timer assembly must be changed because of the motor

gearing.

3

Control box with cover removed Showing controls on lower door

The power supply for 120 volts, 20amps, shall consist of two #10-12-gauge wires and one suitable green

ground wire. The 20 amp breaker or 20 amp fuse must be on a clean circuit for only this machine. ADS

has provided a junction box with a 7/8” hole for the 1/2” conduit that will bring the building’s electrical

power to the machine. This junction box is attached to the lower frame of the machine, below the control

box when the door is closed.

Remove the junction box cover, attach the conduit and connect a black 120 volt supply wire to the black

wire in the junction box. Connect a white neutral supply wire to the white wire in the junction box. When

powered up, test the neutral wire to a ground source with a volt meter, it should read 0 to 6 volts. Test the

black wire to a ground source, it should read 110-120 volts. Attach a building ground wire to the ground

lug located in the junction box and tighten all wires. Replace the junction box cover.

Copyright ADS Installation Manual Model ET-AF Gravity, Revision 3.0 , 6/7/2013

Optional buzzer for low level chemical alarm Optional chemical alarm pressure switch

4

Power junction box for incoming 120v power Wash motor contactor to the left of the cam timer

motor

1.5 HP Motor, arrow 1 arrow 2 point to L1 and

Neutral connect points

IT IS RECOMMENDED THAT THIS EQUIPMENT BE INSTALLED USING A NEW CIRCUIT BREAKER.

This machine does not use a booster heater.

Copyright ADS Installation Manual Model ET-AF Gravity, Revision 3.0 , 6/7/2013

5

PLUMBING SECTION

#1 TANKLESS water heaters can be problematic for commercial dishmachines. The ADS model

ET-AF dishmachine requires the full cycle amount of water (1.7 gallons) supplied within 7 seconds.

It has been the experience of ADS that tankless supply systems require multiple units plumbed in

sequence with a recirculation loop to achieve proper pressure and temperature.

Check with the tankless water heater manufacturer, they may recommend a storage tank to

guarantee proper fl ow and line pressure to the machine. Failure to provide adequate water

quantity, pressure and temperature to the machine will cause the machine to function improperly

and is not the responsibility of ADS. Improperly installing ADS equipment in this manner could

void the warranty. All costs associated with providing an adequate water supply to the machine is

the sole responsibility of the user.

#2 HOODS—Follow all local plumbing and mechanical codes. IMC 2012, section 507.2.2 requires

Type II hoods for all commercial dishwashers except where the heat and moisture loads are

incorporated into the building’s HVAC systems or dishwashing equipment designed with separate

heat and moisture removal systems. An undercounter-type, chemical sanitizing dishwasher is

rated at 6450 Btu/h by table 5E, ASHRAE Research Project #1362, 8/5/2008. ADS DOES NOT

SPECIFY BUILDING HVAC VALUES

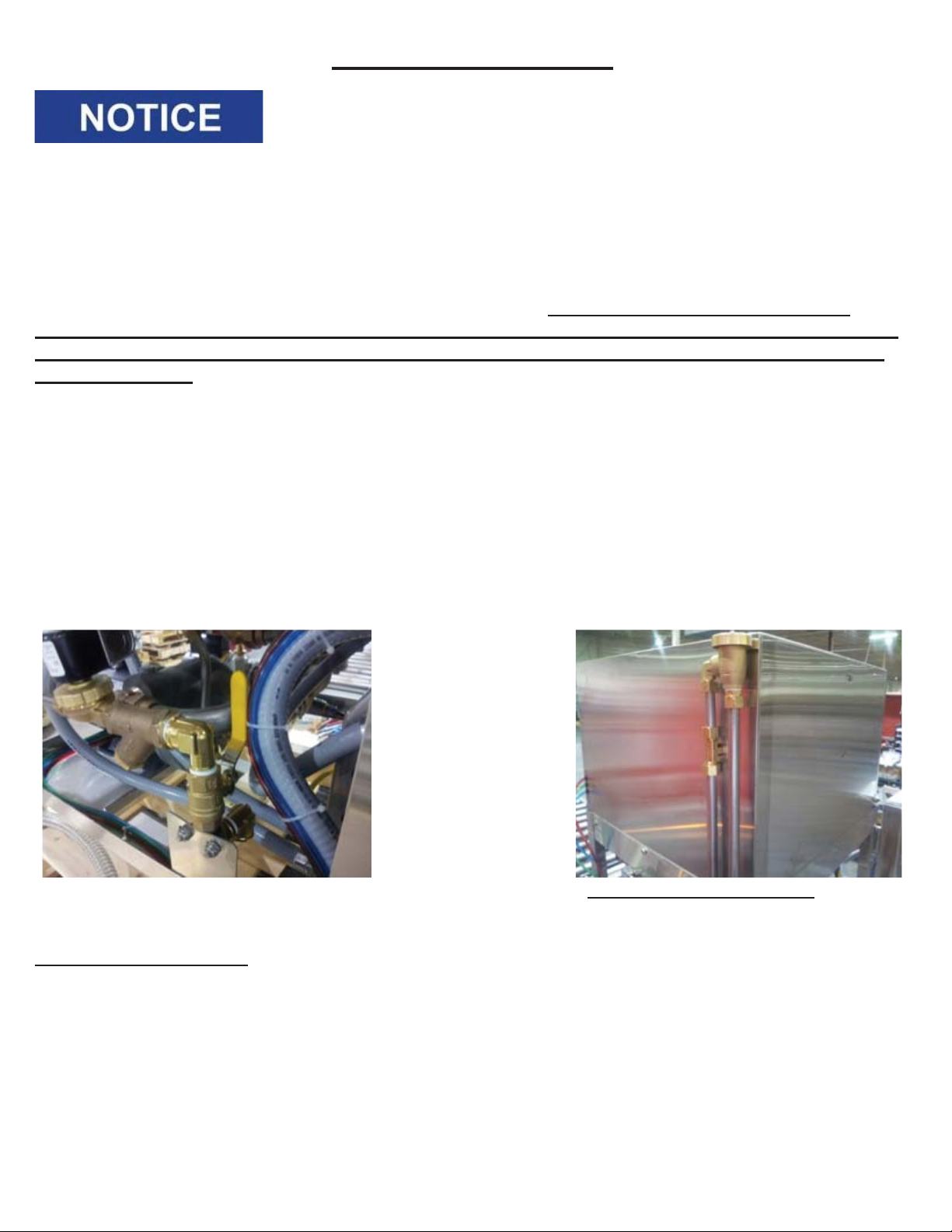

#3 DRAIN SIZE—The gravity drain model uses 1.5” female pipe to exit the sump.

Showing ½” female pipe inlet, ball valve, y-line

fi lter, H2O solenoid

ASSE approved vacuum breaker (backfl ow

preventer)

Hot Water Connection

WATER HEATER—Flush the building’s water lines before connecting to the dishmachine. Prior to

connecting plumbing, level the machine by adjusting the feet at the bottom of each leg up or down. Water

heaters or boilers must provide the minimum temperature of 120°F required for this model of

dishmachine, which demands a minimum of 60 GPH for ET-AF-M or ET-AF-3. Temperatures above

150°F exceed the operational design limits for these models. These models cannot be converted to high

temp sanitizing by adding a booster.

Copyright ADS Installation Manual Model ET-AF Gravity, Revision 3.0 , 6/7/2013

Loading...

Loading...