American Dish ADC-44 Installation Manual

American Dish Service

INSTALLATION INSTRUCTIONS

Model ADC-44 or ADC-66

208/240V, 3-ph, 60a or 90a for 66

High Temp or Chemical Sanitizer Conveyor Dishmachines

Listed by UL #E68594, NSF/ANSI 3, ASSE 1004 #301, LA Test Labs File M-920011, Mass. License P3-0111-306

1

If you have questions, call 800-922-2178 or visit our website at www.AmericanDish.com

The electrical power supplied to this machine is an imminent hazard that could result in severe

bodily injury or death if not properly installed or hooked up correctly. When working in the control

box or on electrical parts, always disconnect power and tag-out before servicing. Replace cover

to control box and other protective covers when fi nished servicing this equipment.

Copyright ADS Installation Manual Model ADC-44/66 3-PH, Revision 3.0, 6/7/2013

READ Manufacturer’s Manual before Using this Product. For your safety read and observe all

cautions shown throughout these instructions. While performing installations described in this

booklet, wear approved Personal Protective Equipment, including Safety Eye-Wear.

CHEMICALS— There are potentially hazardous situations when working with industrial cleaning

chemicals for dishmachines. See chemical manufacturer’s safe practices and MSDS sheets for

handling and installing chemicals and supply containers.

#1 BEFORE YOU BEGIN— American Dish Service provides this information as a service to our

customers. Keep all instructions for future reference. ADS reserves the right to alter or update

this information at any time. Should you desire to make sure that you have the most up-to-date

information, we would direct you to the appropriate document on our web site:

www.americandish.com. Set out below are the specifi cations and requirements that you must use

and follow to properly install the type or types of equipment listed above. It is your obligation as

the customer to ensure that the machine is installed safely and properly, and when completed,

the machine is left in proper and safe working order. Electrical, Plumbing, and Chemical hookup

should be performed by a qualifi ed professional who will ensure that the equipment is installed

in accordance with all applicable Codes, Ordinances, and Safety requirements. Failure to follow

the installation instructions could void the warranty. ADS assumes no liability or control over the

installation of the equipment. Product failure due to improper installation is not covered under the

ADS Warranty.

2

#2 HEAVY USE ITEM— A conveyor dishmachine is often run at full capacity. The machine is not

rated for outdoor use.

#3 FLUSH OUT INITIAL FILL WATER— Do not install spray arms until machine is fl ushed with

water. When this machine is connected to power, it will normally fi ll with water . Do this without

installing the spray arms. Place a rack inside the machine so all the pumps will run. Afterward,

drain all the water from the tanks, install all spray arms, and refi ll the machine. To drain, pull the

pump fi lter out of the sump and the stand tube from the rinse tank (for the 66, also pull the large

scrap basket from the power scrapper tank).

#4 CLEARANCES—Dishmachines must be installed to allow for servicing of motors and conveyor

systems. Do not install chemical dispensers on the top of the control box, machine, or booster.

#5 WATER HEATERS—or boilers must provide the minimum temperature of 120°F required by the

machines listed above, which have a minimum hourly demand of 120 gallons per hour. For HOT

WATER SANITIZING, a booster heater must be installed to achieve the 180°F minimum for the fi nal

rinse. This booster will require a rise of 70°. These specifi cations are for the dishmachine only,

which typically accounts for 70% of a restaurant’s hot water demand.

#6 INSPECT FOR DAMAGE—If you receive a damaged dishmachine, do not sign “Clear” but write

“Damaged” on the documents.

Copyright ADS Installation Manual Model ADC-44/66 3-PH, Revision 3.0, 6/7/2013

#7 TABLES— are critical to proper dishmachine operation. No table drains (quick drains) or sinks

within 20” of the dishmachine on soil table. No sinks or drains on clean tables. Slant tables

toward the machine and anchor to the machine lip with ¼” bolts supplied. Table lip must not rub

on the conveyor bar. If needed, cut out a half-round in the table lip for clearance of the conveyor

bar. Tray tracks are not adjustable up or down because of the switch activators. Fasten tables to

the machine so they are level with the tray track. Curves or “bands” on clean table seldom work

correctly, we recommend using ADS table limit switch (kit 288-1044) for short exit tables.

ELECTRICAL SECTION

The electrical power supplied to this machine is an imminent hazard that could result in

severe bodily injury or death if not properly installed or hooked up correctly.

#1 Before powering up the machine, CHECK ALL ELECTRICAL SCREW TERMINALS in the control

box on top of the machine, power box, and both heater boxes located under the tanks. Screws

can loosen in transit. Loose connections on high amp load terminals will cause wire burning

and component damage during operation and will not be covered under ADS warranty. The term

“Clean Circuit” means the electrical circuit breaker supplies no other devices, motors, machines,

or lights.

3

#2 ADS Conveyor models DO NOT INCLUDE an internal booster heater. Boosters must be

installed separately, ADS recommends a 27 kW for 155 GPH at a 70°rise.

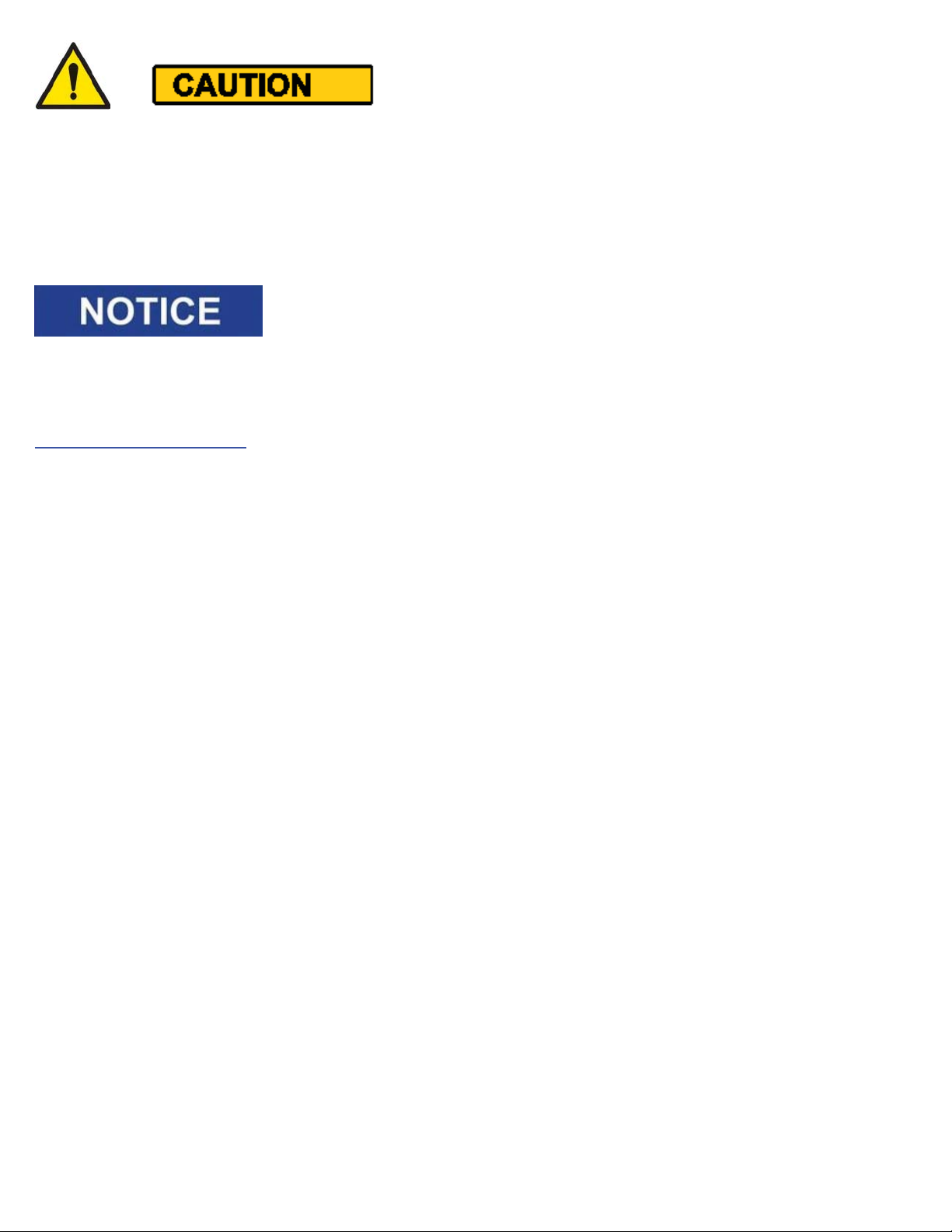

ADC-44 conveyor control box for 3-phase power Main distribution block for 44’s incoming 3-phase

Electrical ADC-44, 208v/240v, 3-ph, 60a

ORDERING INSTRUCTIONS—Machines with heaters are voltage specifi c, order according to actual

voltage at the installation (see kW chart in appendix)

The power supply of 208 volts, 60 amps must consist of three 6-gauge wires and a suitable ground. The

60 amp breaker or fuses must be on a clean circuit to the machine. ADS has provided a conduit hole

(1 3/8”actual size) for 1” conduit for the electrical service into the back of the control box. Attach the

6-gauge wires to the main distribution block in the control box to terminals marked L1, L2, & L3. Attach a

building ground wire to the main distribution block marked GND and tighten all wires.

Copyright ADS Installation Manual Model ADC-44/66 3-PH, Revision 3.0, 6/7/2013

4

FOR 240 VOLT OR DELTA SYSTEMS—attach the high leg (200 volt line) to L3. Attach your 120 volt lines

to L1 and L2. If power is 240v, see kW rating chart at the back of the manual for correct heater sizing and

available ADS heater elements.

3-Phase MOTOR ROTATION—Remove front panels and check rotation of motors. A rotational arrow is

placed on the wash pump motor. If this motor is running in reverse of the arrow, turn off main power and

switch the incoming power wires on L1 & L2. This step will correct the rotation of the other motors at the

same time. Verify proper rotation and tighten all wires.

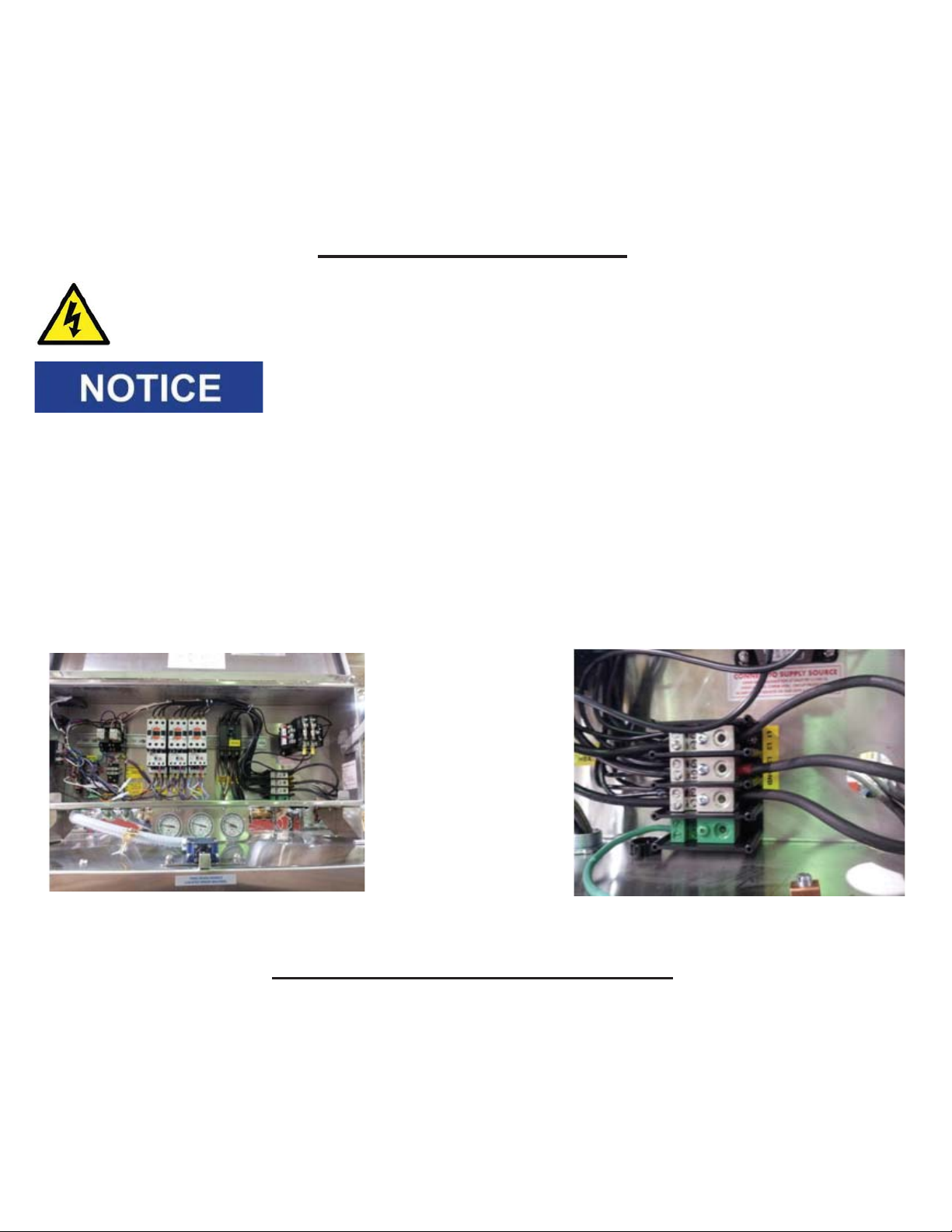

ADC-66 conveyor control box for 3-phase power Main distribution block for 66’s incoming 3-ph,

note Neutral

Electrical ADC-66, 208v/240v, 3-ph, 90a, w/10-gauge neutral

ORDERING INSTRUCTIONS—Machines with heaters are voltage specifi c, order according to

actual voltage at the installation (see kW chart in appendix)

The power supply (208 volt, 90 amps) must consist of three 3-gauge wires, a 10-gauge neutral, and a

suitable ground. The 90 amp breaker or fuses must be on a clean circuit to the machine. ADS has

provided a conduit hole (1 3/4”actual size) for 1 1/4” conduit for electrical service in the back of the control

box. Attach the 3-gauge wires to the main distribution block in the control box, to terminals marked L1,

L2, & L3. Attach 10-gauge neutral and ground wire to their proper locations on the main distribution block

and tighten all wires.

FOR 240 VOLT OR DELTA SYSTEMS— attach the high leg (200 volt line) to L3. Attach your 120 volt

lines to L1 and L2. If power is 240v, see kW rating chart at the back of the manual for correct heater

sizing and available ADS heater elements.

3-Phase MOTOR ROTATION—Remove front panels and check rotation of motors. A rotational arrow is

placed on the wash pump motor. If this motor is running in reverse of the arrow, turn off main power and

switch the incoming power wires on L1 & L2. This step will correct the rotation of the other motors at the

same time. Verify proper rotation and tighten all wires.

IT IS RECOMMENDED THAT THIS EQUIPMENT BE INSTALLED USING A NEW CIRCUIT BREAKER.

Copyright ADS Installation Manual Model ADC-44/66 3-PH, Revision 3.0, 6/7/2013

5

PLUMBING SECTION

#1 TANKLESS WATER HEATERS can be problematic for commercial dishmachines. The ADS

models ADC-44/66 dishmachines require heated water 120 gallons per hour at 20 psi as measured

at the fi nal rinse manifold, with a minimum temperature of 120°F. It has been the experience of

ADS that tankless supply systems require multiple units plumbed in sequence with a recirculation

loop to achieve proper pressure and temperature.

Check with the tankless water heater manufacturer, they may recommend a storage tank to

guarantee proper fl ow and line pressure to the machine. Failure to provide adequate water

quantity, pressure and temperature to the machine will cause the machine to function improperly

and is not the responsibility of ADS. Improperly installing ADS equipment in this manner could

void the warranty. All costs associated with providing an adequate water supply to the machine is

the sole responsibility of the user.

#2 DRAIN SIZE—Gravity drain lines are 2” pipe size. Do not use reducing adapters for drain lines,

always use same diameter pipe or larger. Close pump petcocks if equipped.

#3 A PRESSURE REDUCING valve with by-pass should be installed before the booster heater if

the line pressure is 50 psi or above. This is according to booster manufacturer’s instructions.

#4

BURN HAZARD from hot water from pump sprays or plumbing leaks.

ELECTRICAL SHOCK HAZARD on bare electrical terminals in the thermostat boxes,

#5

power box, fl oat switch boxes, and control box.

#6 HOODS—Follow all local plumbing and mechanical codes. IMC 2012, section 507.2.2 requires

Type II hoods for all commercial dishwashers except where the heat and moisture loads are

incorporated into the building’s HVAC systems or dishwashing equipment designed with separate

heat and moisture removal systems. A conveyor-type, hot-water sanitizing dishwasher is rated

at 21,720 Btu/h by table 5E, ASHRAE Research Project #1362, 8/5/2008. ADS DOES NOT SPECIFY

BUILDING HVAC VALUES.

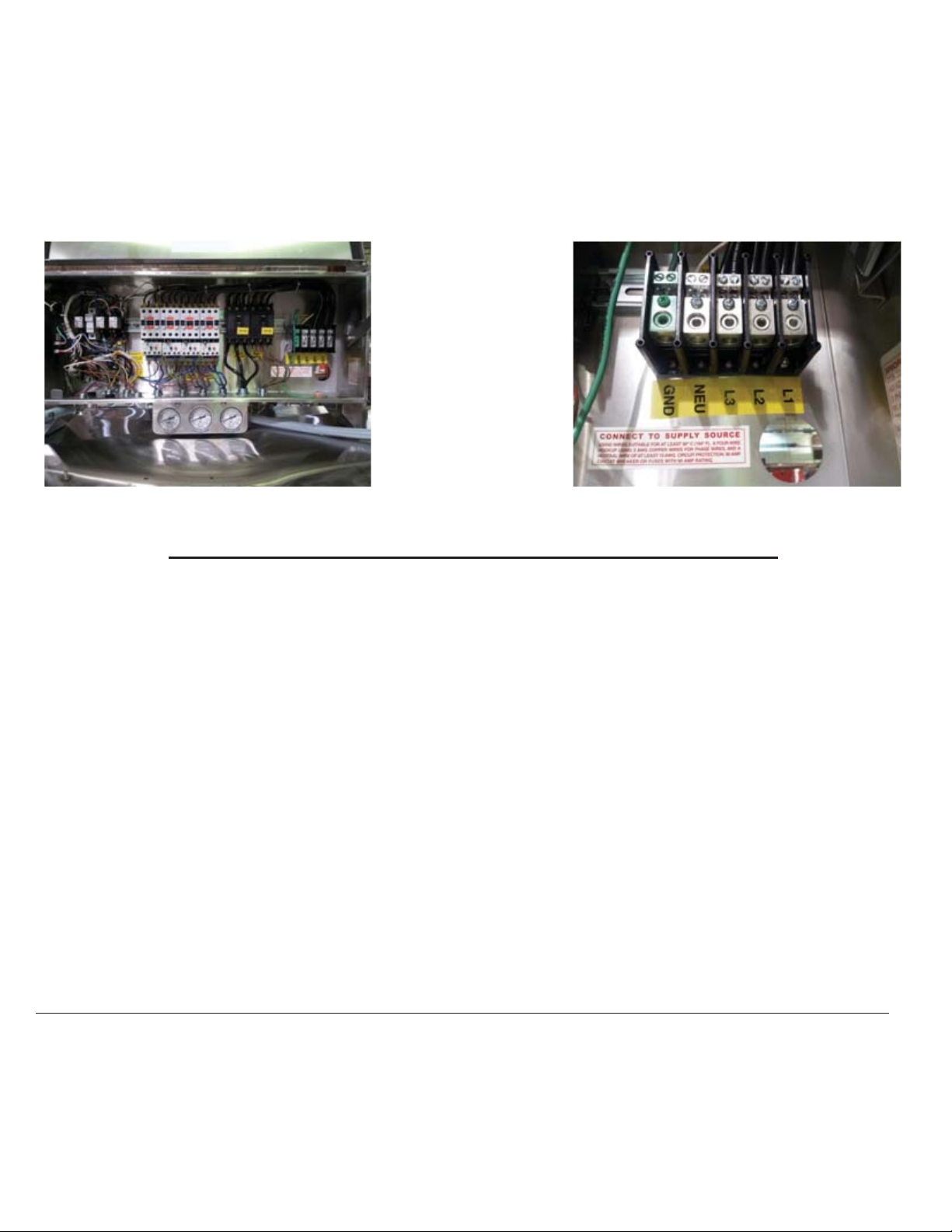

Hot water inlet manifold, single point ¾” pipe,

PR valve

Flush building’s water lines before connecting to dishmachine.

Copyright ADS Installation Manual Model ADC-44/66 3-PH, Revision 3.0, 6/7/2013

Final rinse manifold with pressure gauge, 20 psi

fl ow req.

6

DUAL SANITIZING MODE

Hot Water Sanitizer Connection

For high temp sanitizing this line will come from a stand-alone booster heater. Connect ¾” MPT water

supply line to the 90° elbow of the dishmachine’s inlet manifold. The requirement at the dishmachine

is 180° F minimum at 20 PSI during fi nal rinse fl ow, 120 GPH. This is measured at the pressure gauge

mounted next to the pressure reducing valve in the inlet plumbing on top of the machine’s hood. To adjust

pressure, turn adjustment screw atop the valve counter-clockwise to decrease pressure.

Chemical Sanitizer Connection

For chemical sanitizing this line will come directly from the building’s water heater. Connect ¾” MPT water

supply line to the 90° elbow of the dishmachine’s inlet manifold. The requirement at the dishmachine

is 120° F minimum at 20 PSI during fi nal rinse fl ow, 120 GPH. This is measured at the pressure gauge

mounted next to the pressure reducing valve in the inlet plumbing on top of the machine’s hood. To adjust

pressure, turn adjustment screw atop the valve counter-clockwise to decrease pressure. A dispenser with

three product pumps is required for chemical sanitizing (chlorine pump).

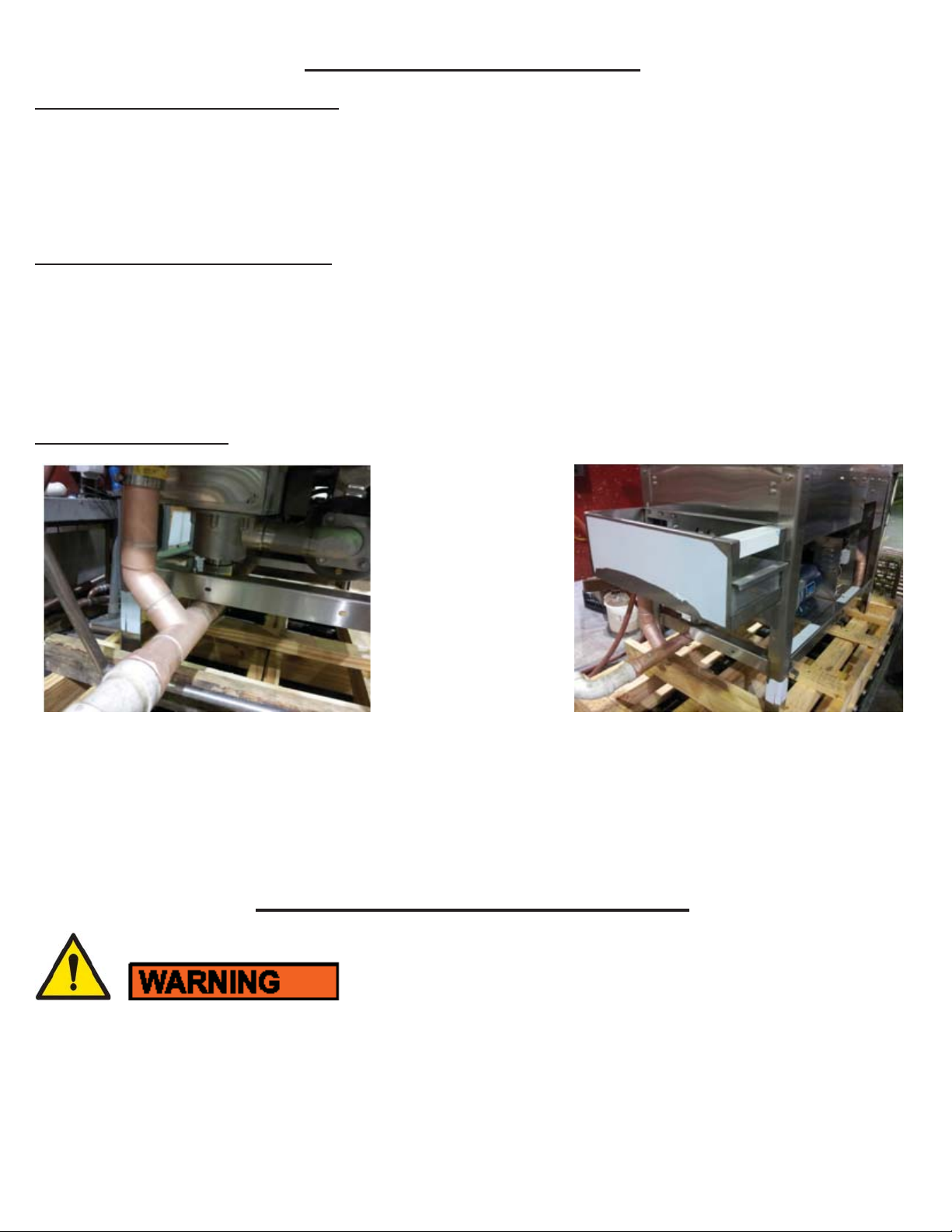

Drain Requirements

Showing 2” drain manifold exiting sump & scrap

box

ADS provides a 2” copper common drain that exits on the soil side of the dishmachine under the scrap

box (ADC-66 drain exits both sides). To prevent clogging, run drain lines as straight as possible. Do not

plumb with tight radius elbows or 180° bends. Use of fl oor sinks for drains can cause fl ooding. Do not

use reducing adapters for drain lines, always use 2” diameter pipe or larger. Always run gravity drain lines

downhill.

Scrap box and tray

DISPENSER HOOK-UP SECTION

You must wear approved safety eye-wear before connecting chemical equipment. Commercial

cleaning chemicals are harmful and can cause damage to the plumbing and stainless steel of the

dishmachine. Do not mount dispensers on the control box or run chemical lines over controls or

plumbing. Always secure chemical lines and check regularly for leaks. If not properly handled,

chemicals can cause serious bodily injury. In the event of chemical contact to skin or eyes; wash

immediately with fresh water and seek medical attention.

Copyright ADS Installation Manual Model ADC-44/66 3-PH, Revision 3.0, 6/7/2013

Loading...

Loading...