American Dish ADC-44 Service Manual

Effective Date: February 15,2000

American Dish Service

MODELS ADC44 ADC66

CONVEYOR DISHWASHERS

SERVICE MANUAL

900 Blake Street

Edwardsville, Kansas 66111

(913)-422-3700

IMPORTANT:

American Dish Service provides this information as a service to our customers. Keep all instructions for

future reference. Although ADS will make every effort to make sure the information in this service manual

is correct and up-to-date, ADS does not certify that this is the case, and should you decide to utilize this

manual, you do so at your own risk. ADS reserves the right to alter or update this information at any time

with out notice. Should you desire to make sure that you have the most up-to-date information, we would

direct you to the appropriate document on our web site: www.AmericanDish.com. The instructions

and guidelines in this owners manual are given with the assumption that the dishwasher

has been installed, operated, and maintained properly and in accordance with all applicable

Codes, Ordinances, and Safety requirements. Failure to install, operate, and maintain the

machine in this manner will void the ADS Warranty. ADS assumes no liability or control

over the installation, maintenance(service), or operation of the equipment. Product failure due to improper installation, maintenance, and operation is not covered under the ADS

Warranty.

WARNING:

During the operation of all dishmachines, chemicals, high voltage electricity, and normal operational functions can cause harm, bodily injury, or worse if proper installation, operation, and maintenance are not

observed. It is imperative that the operator(s) are trained in the operation and made aware of the hazards

that can exist. This is the responsibilty of the owner of this equipment. When installing, operating, or

maintaining your dishwasher you must follow all applicable safety requirements, including the wearing of

approved personal protective equipment.

2

Table of Contents

Page Description

I………..NSF Data Plate

2……….Installation Instructions

3……….Dishtable Requirements

4……….Dispensers

4……….Machine Operation

5……….Motors

6……….Motor Replacement

8……….Hi Temp Design

8……….Problem Evaluation

10……...Preventive Maintenance

11……...Conveyor Basic Requirements

11……...Conveyor Warranty Statement

13……...Bulletins, “Most Common Problems”

33……...Troubleshooting Guide

ILLUSTRATIONS

43………Sequence Switches (Tray Track)

44………Water Control (“fl oats”)

45………Spray Arm End Cap

46………Control Box Layout (1 & 3 Phase)

47………Service Drop for Electrical Power

48………Elements of Cleaning Process

PARTS

49……...Parts Kits

52……...Parts Price List

SPECIFICATIONS

62……...Specifi cation Sheet for 44”

63……...Specifi cation Sheet for 66”

64……...Phase Specifi cation, 1 phase

65……...Phase Specifi cation, 3 phase

66……...Booster Heater Specifi cations

67……...Drawing Sheet for 44”

68……...Drawing Sheet for 66”

69……...Loader (soil table) Option

71……...Wire Diagram (control box)

72...……Wire Diagrams (ladder chart)

73……...Operational Chart

3

ADC-44/-66

COMMERCIAL RACK CONVEYOR DISHMACHINE

MANUFACTURED BY AMERICAN DISH SERVICE

Listing date 2/19/97

NSF Operational Requirements for

NSF DATA PLATE

MODEL ADC-44, Multi-tank, rack conveyor dishmachine

as manufactured by AMERICAN DISH SERVICE

Hot water sanitizing

Final sanitizing rinse minimum temperature: 180 F

Pumped rinse tank minimum temperature: 160 F

Wash tank minimum temperature: 160 F

Final rinse minimum pressure: 20 psi

Maximum conveyor speed: 6.8 ft./min.

Chemical sanitizing

Final rinse minimum temperature: 120 F

Pumped rinse tank minimum temperature: 120 F

Wash tank minimum temperature: 140 F

Final rinse minimum pressure: 20 psi

Sanitizer required: 50 ppm available chlorine

Maximum conveyor speed: 6.8 ft./min.

NSF DATA PLATE

NSF Operational Requirements for

MODEL ADC-66, Multi-tank, rack conveyor dishmachine

as manufactured by AMERICAN DISH SERVICE

Listing date 6/15/99

Final sanitizing rinse minimum temperature: 180 F

Hot water sanitizing

Pumped rinse tank minimum temperature: 160 F

Wash tank minimum temperature: 160 F

Final rinse minimum pressure: 20 psi

Maximum conveyor speed: 6.8 ft./min.

Chemical sanitizing

Final rinse minimum temperature: 120 F

Pumped rinse tank minimum temperature: 120 F

Wash tank minimum temperature: 140 F

Final rinse minimum pressure: 20 psi

Sanitizer required: 50 ppm available chlorine

Maximum conveyor speed: 6.8 ft./min.

4

INSTALLATION INSTRUCTIONS

SEE INSTALLATION MANUAL

5

TABLES

The greatest source of service calls for conveyor accounts come from incorrect table application. Not all

table types are suitable for conveyors. An existing conveyor may have improper tables. The conveyor

has no doors and must operate with either side open. Tables are needed to control water fl ow. Water

loss problems are due to improper tables and the placement of sinks and drains.

1. It is recommended that sinks and drains be a minimum of 20” from the edge of the table lip. No drains

in clean table. If a drain is closer than 20” it must be removed or a new table installed. These close-sink

tables are for door-type equipment and harm the operation of conveyors. This is best considered be-

fore the installation during an account survey.

2. The tables must slant toward the machine so water can return to the tanks. Otherwise, the water will

be lost and the machine’s design for self-scrapping will be canceled out. This will also cause the auto-fi ll

to activate repeatedly, thus increasing water and chemical usage and robbing fi nal rinse pressure.

The economical answer: tables are made to serve the machine, not the reverse.

3. When the tables are fi nally put in place, ANCHOR the table to the dishmachine using the 1/4” -20 SS

hex bolts supplied in the machine package. There is a diagram for the position of the bolts along with two

new drill bits. This is important, if you anchor the tables you will eliminate many service problems.

4. The table lip should not extend down into the machine far enough to rub on the conveyor bar. If this

should happen cut a half-round in the table lip above the conveyor bar for clearance and fasten down the

table securely on the machine. There should be no space between the table and the machine’s lip. Rea-

son: If the elevation of the table were raised above the level of the tank lip, then the geometry of the conveyor dogs, switches, and racks will be changed. To compensate for a raised table several items must be

altered and adjusted. This will create a major problem for the machine’s control and conveyor systems.

It is recommended that the tables be attached to the machine according to these instructions.

TABLE LAYOUT

A 90 degree exit or a “horse shoe” layout are popular ideas because of the space saved but they cause

operational problems. Even with the safety clutch, the diffi culty of a short table or 90 degree causes constant jams. In most cases the ADS table limit switch is a better solution for shutting down machine operation when racks load up on the table. Curve or “bands” installed on the clean table are a common sight,

their purpose is to take square racks around the corner. Few accomplish this goal—moving racks around

a corner is extremely diffi cult. The usual experience is after reaching ¾ of the arch, the rack sits diagonal

and blocks the following rack. It must be pulled out to continue. This layout reduces a conveyor’s output

to nearly that of a corner machine.

RULE: The Installation is KEY to reduced service problems.

6

DISPENSERS

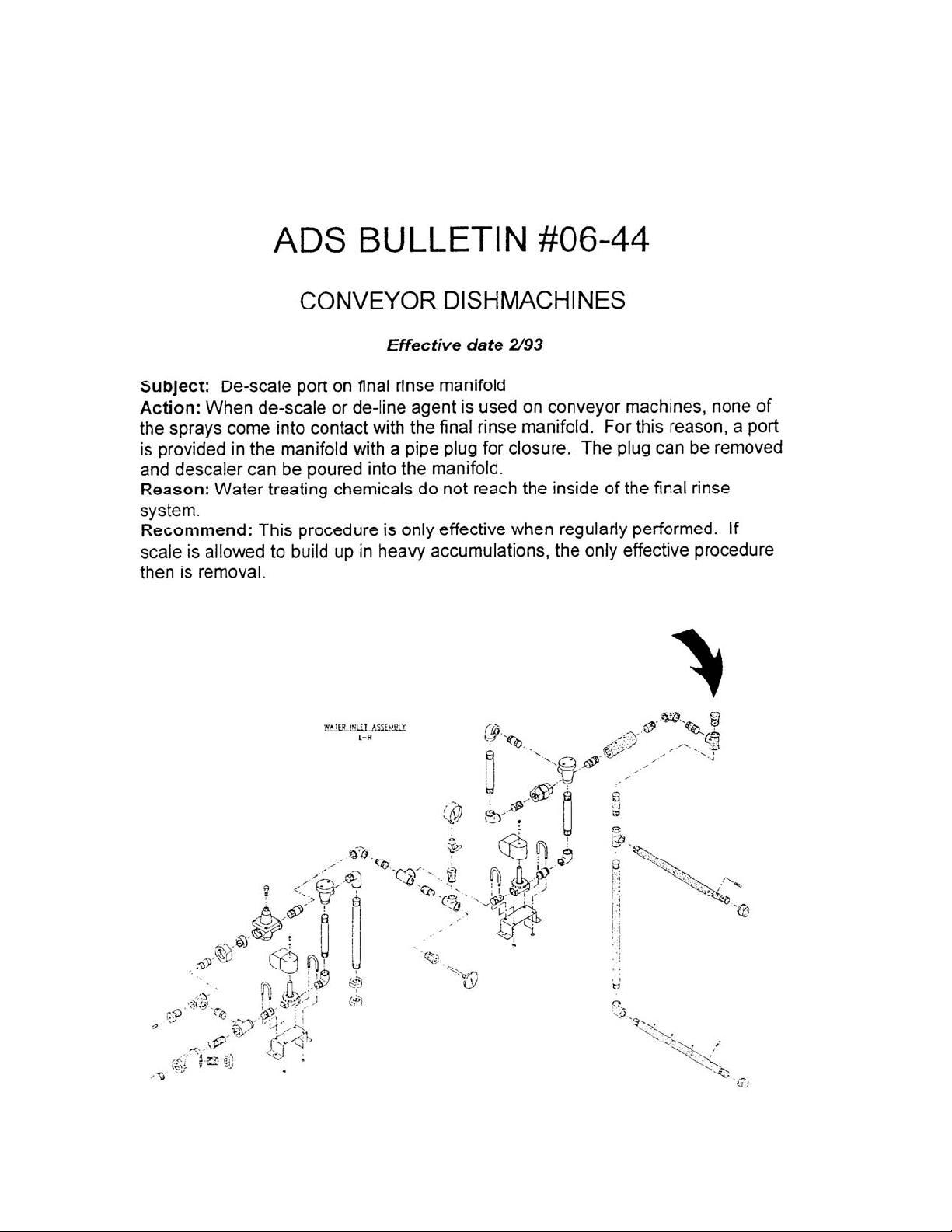

1. The fi nal rinse manifold has two ports (1/8” IPS, female) provided in the mixing chamber chemical checkvalves. The dispenser’s electrical connection points are provided in the control box. There are two signals.

For the 44 3-phase, a 208/240v signal labeled RINSE and a 208/240v signal labeled DETERGENT. They

are located in the lower left hand area of the control box, as you face the machine. The 110v CONTROL

(1amp) circuit produced by the transformer does not have the capacity to run a dispenser. It is highly recommended that no device be attached to the control circuit of the machine, such as dispensers and hood

fans. Use the factory provided dispenser terminals in the control box. For the 66 3-phase, a 110v signal

is provided and labeled for dispenser control in the lower left hand corner of the control box, as you face it.

This 110v power is available because of the neutral line and L1 of the incoming power.

2. The wash tank has a 7/8” hole provided for a chemical probe. It is located at the front of the tank adjacent to the pump fi lter and pump discharge manifold. There is also a 7/8” hole for the detergent inlet located

in the wash section above the scrap trays on the side of the well between the wash and rinse tanks. This

can be accessed behind the heater power box located in front of the rinse tank pump.

3. Do not mount the dispenser on top of the control box.

4. Secure all chemical lines and attachment points. Make sure that chemical lines do not run over the top

of electrical devices or inlet plumbing. (A leaking sanitizer line can destroy the stainless cabinet and machine components)

7

MACHINE OPERATION

After the machine is operational and the tables are cleared, remove all packing material (heater supports)

then wash out the tanks, give attention to any installation debris left over. Now, fi ll the machine by turning

on the master switch. The Conveyor will automatically fi ll with water to an operational level. IMPORTANT:

Adjustment of the water diverter plate is required to fi ll the tanks in proper sequence. It is found inside

the hood on the back wall at the top. Slotted holes allow movement side to side. The rule: make sure the

rinse tank always fi lls last by adjusting the stream fi lling the rinse tank to approximately the size of a pencil.

After the pump motors start, the machine will fi ll once more to compensate for the water used by the pumps.

This is normal operation.

Place a rack at the opening of the soil side of the machine and push it in until it catches on the fi rst dog. The

machine will take the rack through, operate the pumps, conveyor, heaters, fi nal rinse and then exit the rack

and shut down until another rack is put into the machine.

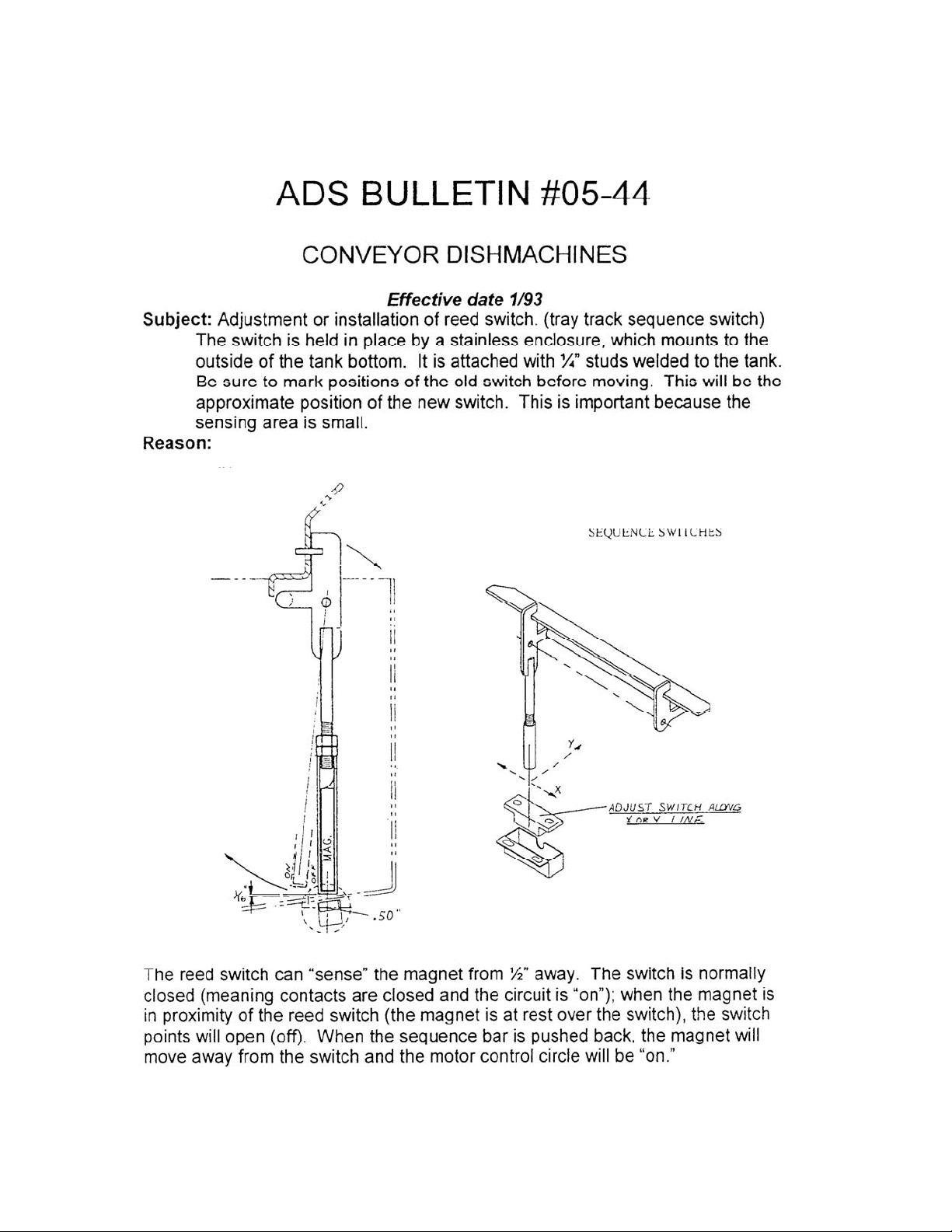

WHAT TURNS THE MACHINE ON AND OFF

The conveyor motor, wash motor and rinse motor are all sequenced by the actual dish rack. There is no

timer or control unit that causes the machine to run. Everything is keyed off the dish rack. The sequence

bars located in the front tray track are used to tell the machine what to do. The reed switches are normally

closed (they always TURN ON THE MOTORS), when a magnet comes within ½” of the reed, it will turn OFF.

When the magnet swings away from the switch, the motor turns on. NOTE: an easy way to test the reed

switch is by placing a strong hand held magnet (automotive tool) next to the reed, if it turns off that means

the switch is good and the problem is alignment with the machine’s bar magnet.

The heaters are controlled by the thermostats and the level control switches. If there is no water in the

tanks when the machine is turned on, the level control switches will turn off the heaters and open the fi ll

solenoid. When the tanks are full the switches will shut off the water and then turn on the heaters. If the incoming water is hotter than the settings on the thermostats, the thermostats will shut the heaters down until

the water temperature drops below the set point. NOTE: To increase the temperature, turn the thermostat

center rod counter clock-wise. (turn left to increase temp)

The dish rack acts as 1/2 of the conveyor mechanism. The center dogs pull against the ladders of each

rack. If the rack or its ladder is damaged the conveyor system will work less effectively. Damaged or broken

racks should be replaced. They cause problems such as racks staying in the machine or riding back a forth

on the conveyor bar. Both of these problems will cause excessive water, chemicals, and energy use. The

rack is 1/2 of the conveyor system.

A test to see if the machine’s tray track and tables are set up right is to place a rack on the soil table then

push it through the machine and on to the clean table. It should slide easily across all points. If the rack

should stick between the two tray tracks, they will need to be moved wider apart. The track is attached at

three points, adjust all three to maintain alignment. (Never adjust the front tray track; always make the

adjustment to the rear tray track)

CAUTION:

Disconnect power to the machine before servicing and tag-out power.

Beware of moving gear and drive arm on conveyor.

Heaters will remain hot immediately after emptying of machine.

Turn machine off before opening for inspection.

8

MOTORS

It is recommended that pump motors be replaced as a unit. This is classifi ed as “pump motor complete,

less cover.” The reasoning is as follows: conveyors are generally placed in high volume accounts, which

have little space or time for major repairs. The simplest procedure is to remove the four housing bolts, disconnected the electrical connection and replace with a new unit. This can be accomplished without extensive service knowledge and down time for the restaurant. If there is a problem with the seal, shaft, or impeller the resulting time investment could cause disruption.

The performance profi le of conveyors, meaning maintenance items are usually left undone, tend to produce

service events of major proportion. This problem can best be managed by a little preparation. The primary

events include conveyor gearbox, heater/circuit breaker, wash/rinse pumps, and damaged or broken parts.

Any of these assemblies can be replaced and operations returned to normal within 30 minutes if the assemblies are readily available. ADS has kits or lists of major items and they can be purchased in assembled

form.

Once a replacement is speedily made, the faulty part can be returned to the shop. At the shop there is

enough time and resources to effect an adequate repair; the repaired part then becomes the replacement

assembly for the next event. This is the fastest way to service the high volume conveyor business. Expecting service people to repair assemblies can place an account in a down condition. It can lead to multiple-day events. All necessary resources are simply not available at the restaurant and overnighting unexpected parts can add days before they are up again. So assemblies are recommended for key areas such

as conveyor drives, pump assemblies, and plumbing manifolds.

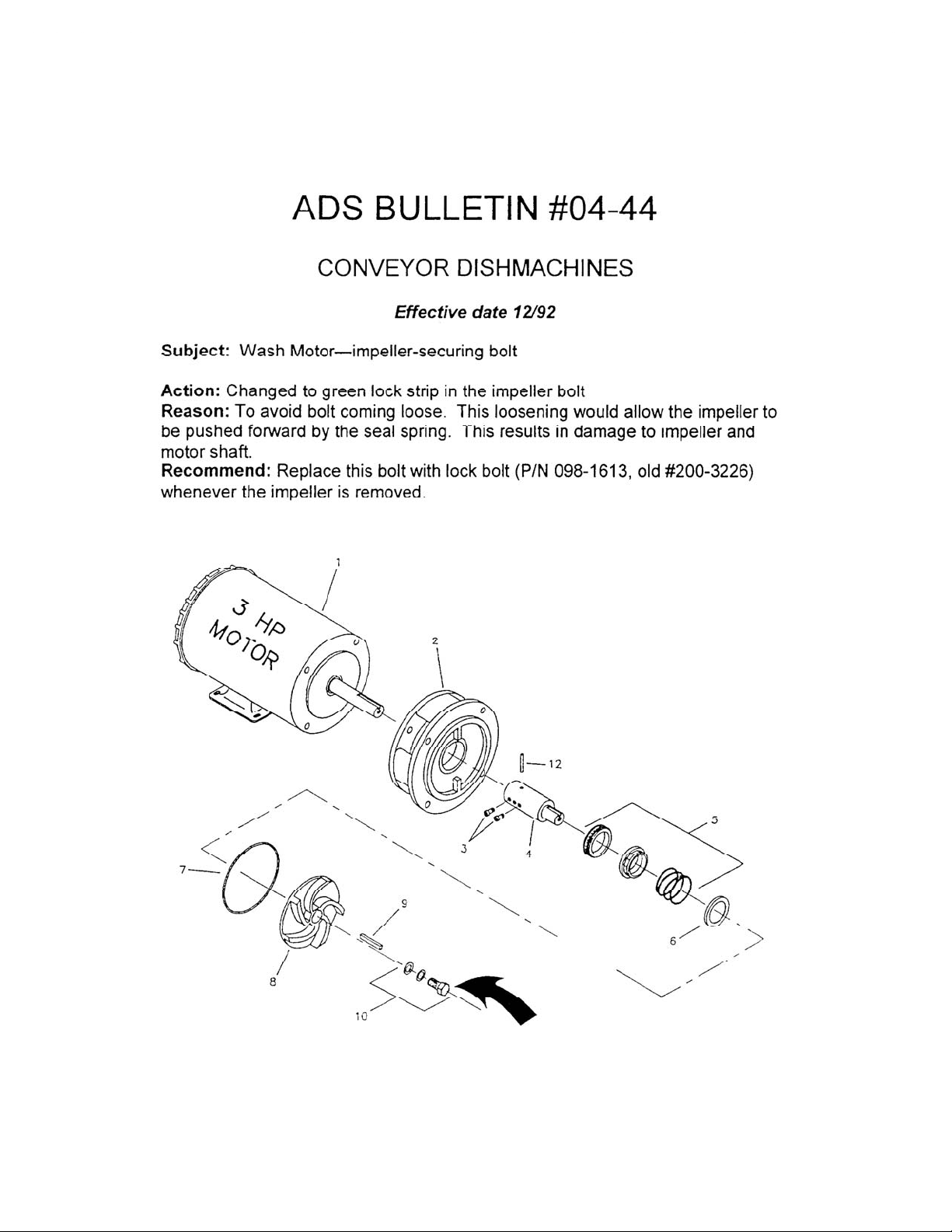

3HP MOTOR REPLACEMENT (Wash Pump)

SEAL REPLACEMENT PROCEDURE

1. Turn off power to the machine. Tag-out power to the machine. Empty water from the wash tank and

open petcock on wash pump motor.

2. Remove the two mounting bolts that secure motor to frame.

3. Take out the four 3/8” bolts that hold rear pump housing to the front pump cover.

4. Slide motor and rear pump housing out of the pump cover. Place the unit on the fl oor and open the rear

access plate on the motor.

5. Disconnect the three lead wires that are attached to terminals L1, L2, and L3. Remove the conduit from

the motor.

6. Remove the impeller by taking out the secure bolt. The impeller slides off the keyway. If it does not slide

off easily, gently tap it from behind. Heavy blows from a hammer will damage the impeller and shaft alignment.

7. Remove the four 3/8” bolts that hold the rear pump housing to the motor.

Carefully slide the housing off the motor; paying particular attention to the shaft seal. The graphite section

(black face) is the part that slides on the 1.5” dia. collar that slides over the 7/8” dia. motor shaft. The ceramic section (white race) is the part that seats in the housing. Slide the graphite section off. Be careful not

to crack the ceramic when the pump housing is removed from the motor.

Important Note: The older 3hp motor shaft extension with the pinned and set screws adapter is not fi eld

repairable or serviced. The 7/8” shaft is an updated version and supersedes the 5/8” shaft extension.

8. To assemble, reverse the order above. If you are replacing the seal make sure the rubber boot and ceramic (white) are fully seated at the bottom of the pump housing. If the ceramic uses an “O” ring instead

of a boot, the operation is still the same. Seat the ceramic all the way in the housing. Make sure the

shaft is clean. Put the boot and ceramic section in the housing fi rst. It will be helpful to use some hand

soap or dishsoap to slide the boot with the white ceramic section into the pump housing.

9

A round wooden dowel works best for applying even pressure to seat the seal into the housing. The

smooth surface will face out toward you; the grooved side will face the housing toward the motor end. Do not put grease or oil on the seal. Inspect the graphite section; make sure there are no

cracks or chips on the face of the black graphite or white ceramic. Slide this black part onto the motor

shaft (1.5” collar) and install the spring and retainer shield. The retainer shield is important, without it the

spring steel will cut into the impeller. Place the impeller on next. The keyway and slot should be free

from damage or distortion. If the shaft keyway slot is enlarged, the motor will need replacement. If the

impeller is also damage in the key slot, it must be replaced.

Important Note: the impeller “lock bolt” must be replaced as a new part each time the pump is disassembled. Part # 098-1613.

9. When the pump assembly is placed back into the pump cover, properly seat the pump gasket (“o” ring)

and use some dishsoap to avoid pinching the o-ring.

1/3HP MOTOR REPLACEMENT (Rinse Pump)

Same as the Wash Pump except the motor shaft attaches to an auxiliary shaft. Motor shaft diameter is 5/8”

and the auxiliary shaft w/seal is 3/4” instead of 7/8.” Impeller screws on right-hand threads instead of a keyway and bolt. When setting up the auxiliary shaft, slide forward until it touches the pump cover, then back

off 1/8”. This pump has an open-face impeller.

1.5HP MOTOR REPLACEMENT on ADC-66 (Power Scrapper Pump)

Same as the Wash Pump except the motor shaft and seal are 5/8” diameter and the pump gasket is also an

“o” ring. Impeller screws on instead of a keyway and bolt. This motor, as it is used on the 66, is always wire

220v, single phase. It is, however, the standard 1.5 hp ADS motor for low-temp machines. This pump has

an open-face impeller.

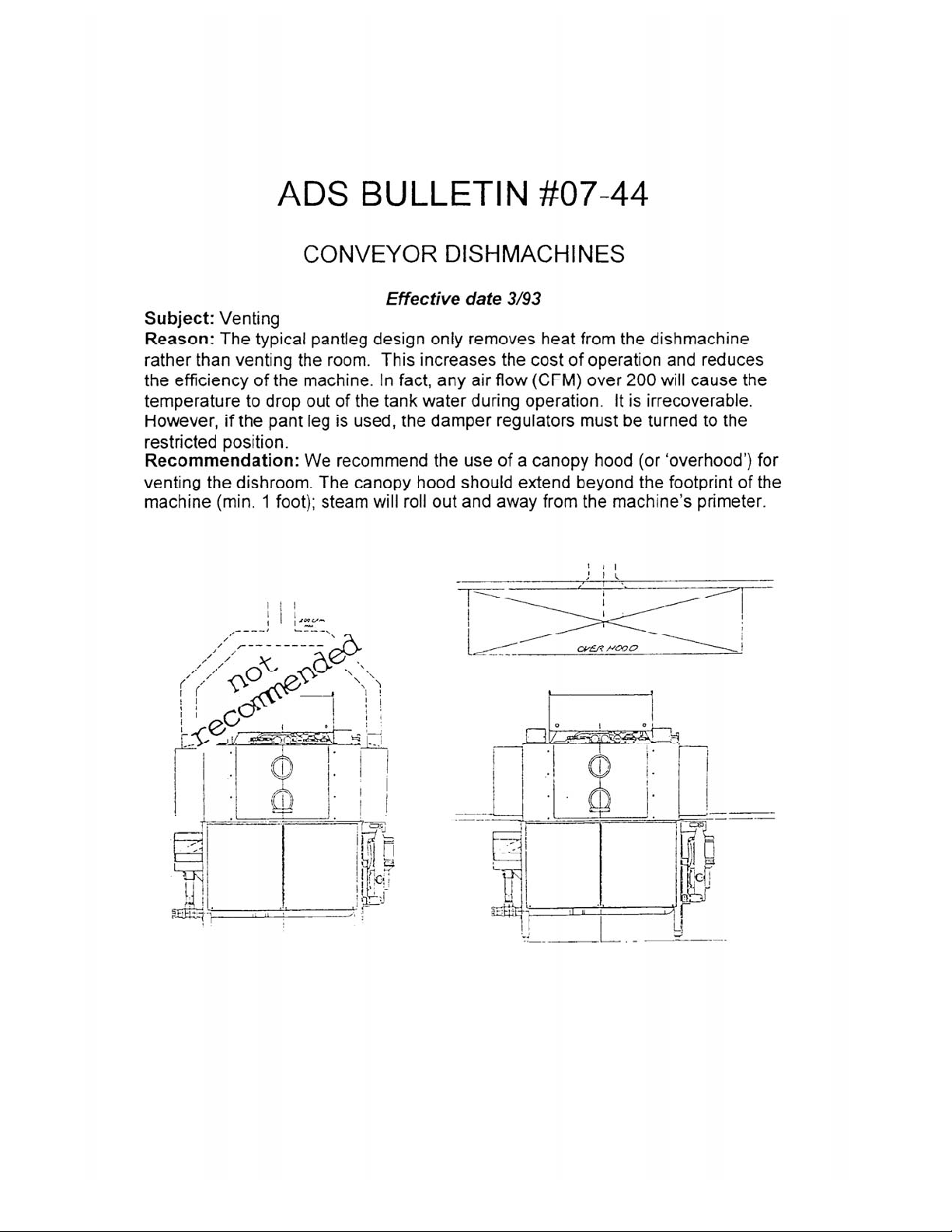

HI TEMP DESIGN IN CONVEYORS

The term “Hi Temp” refers to the sanitation process of the dishmachine. Or, in other words, the type of

process used to achieve an acceptable kill rate in bacteria. There are typically two methods, chemical or

thermal sanitizing. In high temperature sanitizing, the surface of the dishware must reach a temperature of

165F for a minimum of ten seconds. It is assumed that a minimum of 3600 HUE ensures adequate sanitization. One second of 165F corresponds to 346.8 HUE points (although 160F only provides 91.9 points and

140F only 1 point); this is an ascending scale, which tops out at 165F. This is accomplished by spraying

180F water over the dishware during the fi nal rinse. This elevates the surface temperature to 165F during

10 seconds, which temperature reduces organisms by 99.999%. HUE points are also added for seconds

spent in hot wash water but the value only reaches a few hundred points. This is the Heat Unit Equivalent

(H.U.E.) test required for NSF certifi cation (Reference: Mallmann, A Study of Mechanical Dishwashing, University of Michigan, 1947).

The ADC conveyors are rated in both methods of sanitizing, and NSF lists these dishmachines as dual

sanitizers. This means the machine design can serve in both roles without modifi cation. The fi nal rinse

manifold will accomplish the task of applying chemical sprays or high temperature sprays with the same

water consumption rates and systems. The only difference is in the type of chemical dispenser application

(min. 50 ppm chlorine) or the boosted incoming hot water (min. 180F) for fi nal rinse. (Reference: ANSI/NSF

Standard 3, 1996)

10

QUESTIONS TO EVALUATE OPERATION OF CONVEYOR MACHINE

1. Will the machine fi ll with water when it is turned on for the fi rst time during a new work period? If it does

not fi ll, is the “ON” light illuminated when the master switch is turned on? If not, the machine will need

electrical service. [Service]

2. When the machine fi lls with water, what is the incoming water temperature? It should be 120F for

Chemical Sanitizing and 160F for Hot Water Sanitizing. This requirement is supplied by the building’s

primary water heating source. [Building maintenance]

3. After the machine has fi lled with water, a rack of dishes can be pushed into the machine on the “soil

table” side. The wash pump and the conveyor should begin operation. If they do not, look at the inspection door, is it fully closed? Look at the table limit switch, does a rack or other item block it? These

switches must be closed for the operation to begin. [Operator]

4. Does the machine continually fi ll, causing the primary water-heating source to run out of hot water? This

condition will be a result of water escaping from one or both of the tanks.

The rinse tank is likely to pump out water via a bent defl ector fi n on the pumped rinse spray arm.

This can be remedied by bending the fi n back in line, so that the sprays are falling straight down and

pumping straight up (12:00 o’clock & 6:00 o’clock). This problem most often occurs as a result of

striking the spray arm against a table or trash can.

For the wash tank, the likely cause will be water cascading out on the soil-table. This is remedied by

correct installation of the tables. The scrap sink must be no closer to the entrance of the machine

than 20 inches; and the tables must pitch into the machine so that water fl ow on the table surface

will return to the machine. Quick drains or table scuppers are not used on “stage washers.” [Installation]

NOTE: Autofi ll should not operate during normal use, its only operation is at the fi rst of the shift when the

machine is off and empty. Intermediate fi lling is an indication of installation problems.

5. Is the fi nal rinse water at the correct temperature? 120F min. for Chemical, and 180F min. for Hot Wa-

ter. The correct fi nal rinse temperature is critical to operational temperature. [Building maintenance]

6. When the last rack exits the machine, will the conveyor and fi nal rinse shut down? If not, open the

inspection door and check the rack guide sequence switches (magnet bars, which hang down from the

rack guide). Look for a glass or bowel that may be holding the bar from hanging straight down (at 6:00

o’clock). [Operator]

If a surging sound is coming from the wash pump, check the pump fi lter and tank

1. trays. They may be fi lled with debris. Clean the fi lters and trays, refi ll the machine. [Operator]

2. When racks do not travel completely through the machine, examine the bottom of all the dishracks. If

the “ladder” bars are missing or broken, the rack must not be used. The dishrack is part of the conveyor

system and must be intact and complete. [Operator]

3. Chemical supply is provided by the chemical company. [Service]

4. The curtains must be in good repair and properly placed in the machine to retain temperature in the

wash environment. If the curtains were left out, the air would circulate through the machine and rapidly

cool the water sprays. [Operator]

11

5. Dish and glass appearance is often referred to as “results.” If the results are poor, there are several factors, which affect the outcome of the washing process.

First is procedure. If the dishes are not placed so the sprays can reach them, the results will be poor. If

large amounts of soil are left on dishware, this will eventually overwhelm the process (any size tank can

be overfi lled with soil).

Second is temperature and water condition. If water temperature is too low or too high it will cause

problems. Hard water with high mineral levels will build up a white substance in the watered areas of the

”

machine. A 1/16

layer of build-up on the surface of a heater element will reduce its effi ciency by twenty

percent (that’s like turning a 10kw heater into an 8kw). If there are scale producing elements such as

TDS, carbonates, silicates, calcium, sodium and other minerals results will suffer. This is especially true

of well water. A good test is to take clean glasses, hand buff them, turn off all chemical feeders, wash

the glasses 4 or 5 times in clear water in the machine. If they come out spotty or cloudy, you have a

water problem not a machine or chemical problem. It is important to treat hard water before it is used in

conveyor equipment. [Building]

Third, installation problems are the # 1 cause of operational disruptions and will affect performance. If

the machine is improperly installed no amount of tuning or adjustment can compensate for the lack of

essential items. The installer must return and correct the omitted elements of the installation.

12

ADC-44/-66

Preventive Maintenance Schedule

Three General areas must be inspected

1) Sequence switch mechanism in tray track

2) Water control mechanism

3) Conveyor system

SEQUENCE SWITCH MECHANISM

1) Free moving

2) 1/16” clearance on pivot bolts

3) Magnet adjustment is approximately 1/16” from tank fl oor

4) Pump motor will activate only after 1/8-1/4” movement of sequence bar. This will indicate

that the

adjustment of the reed switch is correct

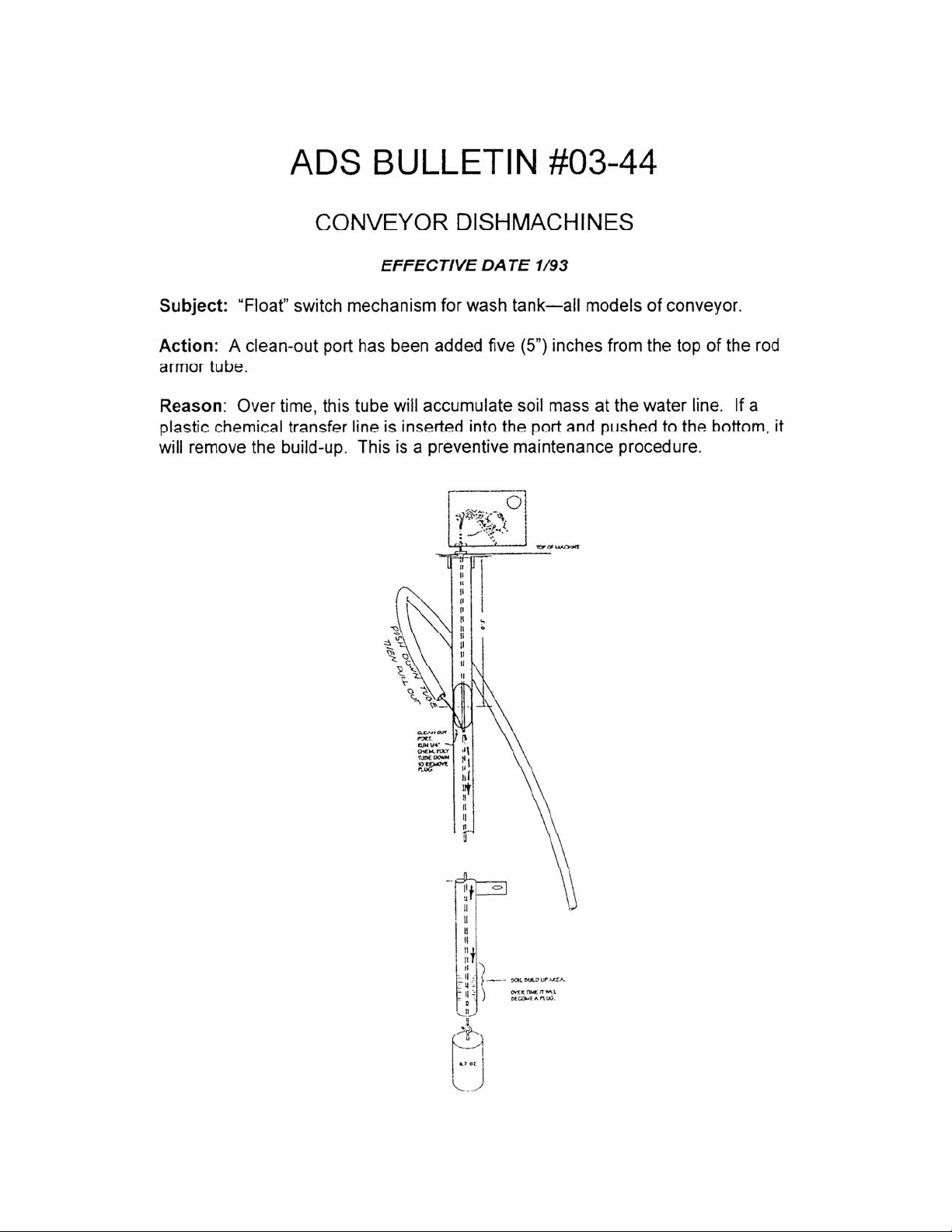

WATER CONTROL MECHANISM

1) Check for free movement of suspended rod and weight

2) Suspended weight is free moving and clear

3) Lever is free moving and has 1/16” clearance from box or attaching locknut. Operate the

lever 10 or 20 times with the tanks full, it should not stick on

“fi ll.” If it does stick, the problem will be interference with the rod, weight, or the switch button

spring may be too weak.

CONVEYOR SYSTEM

1) Cam bearing is well-lubricated and rotates freely (marine grade grease)

2) No worn or sloppy parts, rocker arm free play is only 1/8”, greater than this

means the rubbing blocks are worn

3) All dogs are free moving

4) No chlorine chemical leaks on or near conveyor motor

Bolt table to the machine to avoid leaks under table lip

NORMAL CHECKS

1) Check for bent or damaged parts

2) Screens and trays are all in good order

3) Drains are clear

4) Dispenser is functional and adjusted w/no leaks

5) Curtains are in place and clean

6) Correct leaks to avoid damaged motors

7) Spray patterns are consistent and typical

8) Check racks (broken ladders or swaybacks cause high costs)

9) Lime build-up on any conveyor is a problem

ELECTRICAL CHECKS (by qualifi ed electrical technician)

1) Machine’s total amp draw: 52 amps at 3Ø, with everything working

2) Wash heater: 30 amps

3) Wash Motor: 8 amps

4) Rinse Heater: 6 amps

5) Rinse Motor or Conveyor Motor: 0.5-1.0 amps

6) Control Circuit: 0.65 amps

13

Conveyor Minimum Basic Requirements

1) Table with less then two racks “out” is not recommended.

2) A 90 degree curved table on the exit side is not recommended unless it is over fi ve racks distance

(100”) from the machine.

3) The minimum distance a sink or drain device can be to the entrance side (soil) of the conveyor is

20”. And no such device should be on the clean side.

4) Less then fi ve racks out should have a limit switch installed on the exit table.

5) Incoming rinse water shall be rated 120F at 120 GPH. Or 180F at 120 GPH.

6) Electrical wire supply shall be 6 gauge, 3 ph, 208v at 60 amp clean circuit.

Single phase 208v, one 60 amp/6AWG service and one 50 amp/8AWG service with a Neutral

(10 AWG) and suitable ground. ADC-66 is 3 gauge, 3 ph,

208v at 90 amps.

7) Tables to be bolted to the machine on clean and soil sides as noted in installation sheet and

manual.

8) Do not install chemical dispenser on top of control box or run chemical tubing over critical areas of

the machine top: plumbing, electrical boxes.

9) Do not install with 180-degree turn in the drain pipe. Make short runs and eliminate tight 90-degree

elbows when possible.

10) Adjust the tables to meet the machine. Do not adjust the tray track to meet an ill-formed table, fi x

the table. Tables must be slanted toward the machine; 0.5” drop over 70” of travel as a min.

14

AMERICAN DISH SERVICE

Limited Warranty

Parts and Labor

American Dish Service warrants to the original purchaser that its products are free of defects in material and workmanship and

agrees to repair or replace, at its option, any parts that prove to be defective within ninety (90) days from date of purchase.

American Dish Service may require reasonable proof of your date of purchase. Therefore, you should retain your copy of the

invoice or shipping document.

In addition, American Dish Service will exchange any part covered under this limited warranty which is found defective, as

determined by American Dish Service, under normal use and service up to two hundred and seventy (270) days following the fi rst

ninety (90) day limited warranty period as described above, excluding feed line, fl exible hose, and squeeze tubes.

The warranty does not cover equipment subject to accidents, freight damage, improper power and/or plumbing hookups, or lack

of routine required maintenance as determined by American Dish Service. This warranty is void if the defect is due to improper

installation, high chemical concentrations, misuse, modifi cation of the machine, repair or servicing other than by an authorized

American Dish Service dealer, or authorized agent, or operated in a manner contrary to applicable factory instructions herein or

failure to perform all required maintenance.

The timer cams for water and chemicals are adjustable. Proper adjustment is the responsibility of the installer of the equipment.

This warranty does not extend to machine malfunction resulting from improper cam adjustment.

All warranty work for machines will be performed, within the ninety (90) day period, during normal working hours, by an authorized

agent receiving prior authorization by American Dish Service. Overtime charges and expediting charges such as “overnight” and

“air freight” will be the responsibility of those requesting service outside normal American Dish Service procedures. Expenses due

to disconnections, delivering, returning, and reinstalling the machine are borne by the purchaser and are not the responsibility of

American Dish Service. Travel charges for time and mileage outside normal service area (75miles) shall be the responsibility of

those requesting service.

Defective parts become the property of American Dish Service. Parts replaced within the warranty period carry warranty only

until the end of the original limited warranty. Replacement parts not supplied by American Dish Service will relieve American Dish

Service of all future liability and responsibility. American Dish Service will provide the names of the nearest authorized dealers

upon request.

ADS is not responsible nor liable for any conditions of erosion or corrosion caused by corrosive detergents, acids, lye or other

chemicals used in the washing or cleaning process.

This warranty is void outside of the United States of America.

AMERICAN DISH SERVICE HAS MADE NO WARRANTIES THAT THE GOODS SOLD OR SERVICES PROVIDED ARE

MERCHANTABLE OR FIT FOR ANY PARTICULAR PURPOSE AND THERE ARE NO WARRANTIES, EXPRESS OR

IMPLIED WHICH EXTEND BEYOND THE EXPRESS LIMITED WARRANTY CONTAINED IN THIS AGREEMENT. UNDER NO

CIRCUMSTANCES SHALL AMERICAN DISH SERVICE BE LIABLE FOR ANY LOST SALES, LOST PROFITS OR ANY OTHER

INTANGIBLE LOSS OR ANY OTHER SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OR ANY

INABILITY TO USE THE PRODUCTS SOLD BY AMERICAN DISH SERVICE.

American Dish Service’s liability under this agreement shall in no event exceed the amount paid for the equipment purchased from

American Dish Service. This warranty will be void if the Warranty Registration Card is not returned to American Dish Service within

30 days of the equipments installation.

This warranty is void if the equipment is installed for residentuial use.

Any action under the terms of this Warranty must be commenced within one year from the date of purchase of the equipment.

15

COMMON SERVICE PROBLEMS

ADS BULLETIN #02-44

Effective Date 8/94

Rack travel and counting with a timer in CONVEYORS

Rack-style conveyors move dishracks across the sprays by the reciprocation of articulating dogs. These

dogs push in one direction and fold down in the return direction. They push against the “ladder” on the underside of the dishracks. The “speed” of NSF listed conveyor dishmachines is determined by the length of

time required for a Metro G-88 glassrack to travel across from the soil table to the clean table. The starting

and ending point is the table lip. The indicating point is the trailing edge of the rack. If it takes 36 seconds

to cross this distance the rated speed will be 6 feet per minute.

The speed is determined by two items: the action of the conveyor dogs and the placement of bars on the

rack ladder. If either of these are missing or damaged the speed will drop. If too many ladder bars are

missing the rack will not travel through the machine. In actuality, the rack is responsible for 50% of the

conveyor’s speed mechanism. Racks other than the Metro G-88 glass rack will cause some variations in

the speed. The ADC-44 uses ten dogs to reduce this variation and give more consistent output.

If a clock timer is installed to act as a rack counter it can only record the amount of time the machine is

operational. It can not sense an actual rack. It can, however, accurately record the amount of time the

machine uses chemicals and energy. By estimating the number of potential racks the conveyor is capable

of processing you can arrive at an approximation. Fortunately, the ADC design operates only when a rack

is present and shuts down mechanically when the rack exits. This will give closer rack fi gures then other

styles of conveyor control devices. If there is an inaccuracy in the overall count, it will be less actual racks

washed then the multiplied fi gure. Note: while the actual rack count may be less, the amount of chemicals,

water and energy (over time) will be correct.

16

171819

20

21

Loading...

Loading...