Page 1

American® DR and A

model reference charts

model reference charts

PUSH BUTTON AUTOMATIC ELECTRICAL RATINGS

Surface

Model

DR10N 40 sec

DR35N 30 sec

Drying

Cycle

Surface

Model

DR10TN

DR35TN

DR20N 30 sec DR20TN

Auto 110-120

Auto

Drying

Cycle

Volts Amps Watts Hertz

15 601725

110-120Auto 20 602300

208 -240 10 50 /602300

AVAILABLE OPTIONS:

Stainless steel cover add (SS) after model no. Fixed nozzle add (F) after model no.

Hair dr ying with 80 second cycle add (H) after model no. Automatic models only.

Recess Mounted add (R) after model no. or order kit separately.

Series

SPECIFICATIONS

www.americandryer.com

Maintenance free

Quiet, dependable

operation

˚

360

revolving

nozzle

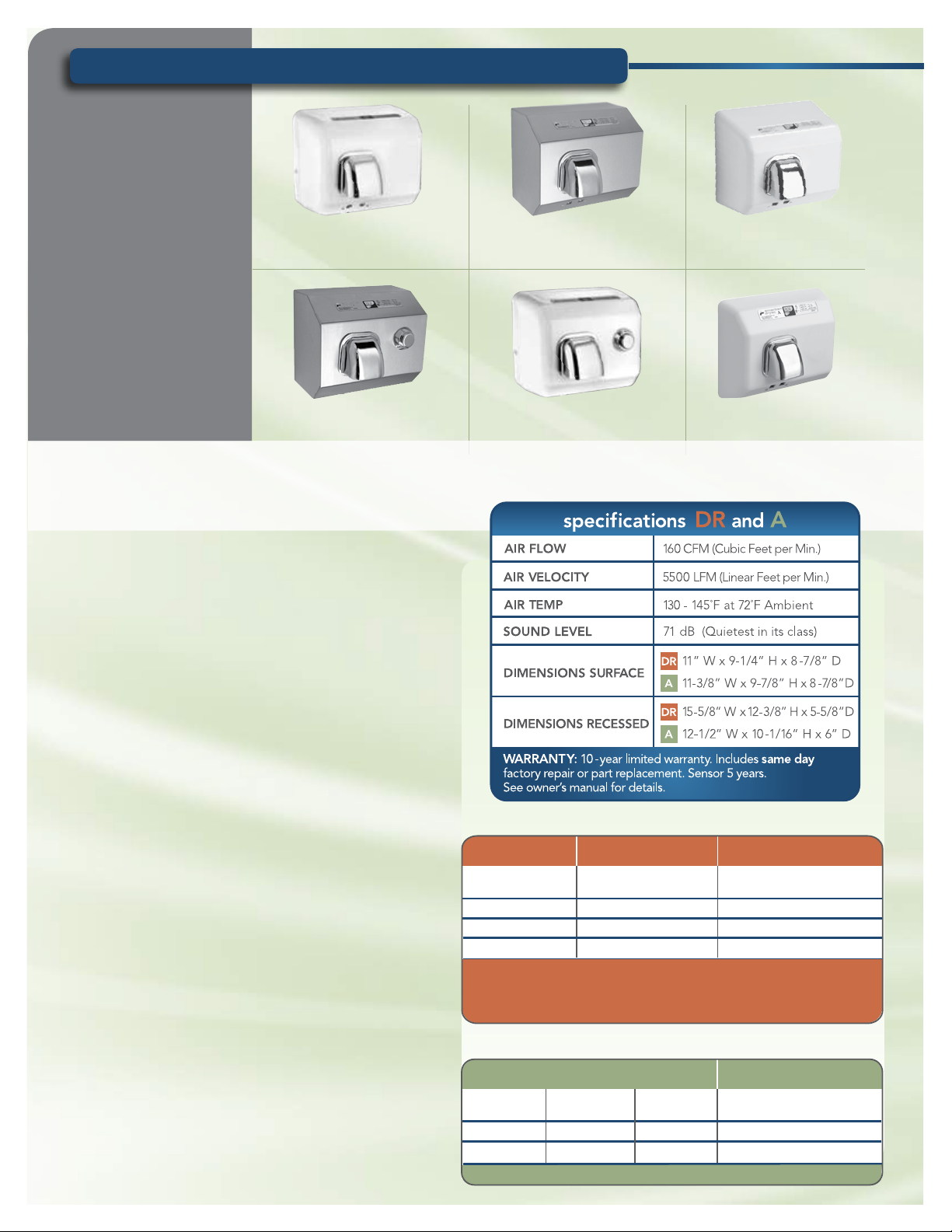

DR–TN Series White

Automatic

DR –TNSS Stainless Steel

Automatic

A –T Series White

Automatic / Surface Mount

Vandal resistant

Durable finish

looks new for years

10 year limited

warranty

DR–NSS Stainless Steel

Push Button

OVERVIEW:

THE DR AND A SERIES HAND DRYERS’ TIME-TESTED DESIGN FEATURES QUIET, DE PEN DAB LE O PER ATION IN A

HEAVY D UTY, VANDAL-RESIS TANT PACKAGE.

DR–N Series White

Push Button

A –TR Series White,

Automatic / Recessed Mount

construction features:

DR SERIES COVER & FINISH – One-piece, heavy duty,

16 gauge steel with white enamel finish or optional 18

gauge type 304 stainless steel with brushed finish (SS).

A SERIES COVER & FINISH – One-piece, heavy duty,

1/4” thick cast iron cover with white porcelain enamel

finish is the ultimate in vandal resistance.

TAMPER RESISTANT – Tamper resistant screws

secure cover to base. Air intake vents are shielded for

additional safety.

MOTOR – Permanently lubricated, maintenance free,

brushless induction motor with automatic resetting

thermal protector. 1/10 HP, 3200 RPM.

NOZZLE & PUSH BUTTON – Chrome plated zinc die

castings. 360˚ revolving nozzle is standard. A fixed

nozzle (F) is optional on all models.

DR SERIES TIMER – Push button models use a heavy

duty timer for extended life. Turns on with a light

touch. Turns off automatically.

AUTOMATIC SENSOR –

design. Microprocessor controlled infrared sensor

turns dryer on when hands are under the outlet for up

to 80 seconds.

HEATING ELEMENT – Constructed of NiChrome

resistance wire with automatic resetting thermostat.

Side mounted heating element operates in the black

range for maximum life.

RoHS compliant lead-free

DR model reference chart

PUSH BUTTON AUTOMATIC ELECTRICAL RATINGS

Surface

Model

DR10N 40 sec

DR20N 30 sec DR20TN

DR35N 30 sec

AVAILABLE OPTIONS:

Stainless steel cover add (SS) after model no. Fixed nozzle add (F) after model no.

Hair dr ying with 80 second cycle add (H) after model no. Automatic models only.

Recess Mounted add (R) after model no. or order kit separately.

Drying

Cycle

Surface

Model

DR10TN

DR35TN

Drying

Cycle

Auto 110-120

Auto

Volts Amps Watts Hertz

110-120Auto 20 602300

208 -240 10 50 /602300

15 601725

A model reference chart

AUTOMATIC ELECTRICAL RATINGS

Surface

Model

A70T

A80T A80TR

AVAILABLE OPTIONS: Fixed nozzle add (F) after model no.

Recessed

Model

A70TR

Drying

Cycle

Auto 110-120

Volts Amps Watts Hertz

208-240Auto 10 50/602300

20 602300

Page 2

DR Series Mounting Diagrams

®

A Series Mounting Diagrams

10 13/16

2 3/4 (70mm)

5/8 (17mm)

(274mm)

9 1/2

(241mm)

5/8

(17mm)

1 5/16 (33mm)

7/8 (22mm)

IN WALL

CONDUIT

ENTRANCE

7/8 (22mm)

SURFACE

CONDUIT

7 7/16

(189mm)

9 1/16

(230mm)

ENTRANCE

9 1/8 (232mm)

Figure 1 - DR Series Surface Mount

WALL

FRAME INSIDE

ROUGH OPENING

5 5/8

(143mm)

14 1/4

(362mm)

4 1/2

(114mm)

1 (25mm)

ROUGH

WALL

CONDUIT

ENTRANCE

10 7/8

(276mm)

1 5/8

(33mm)

OPENING

10 13/16

3 1/2 (89mm)

BOX DEPTH

15 5/8 W X 12 3/8 H

(397mm W X 314mm H)

TRIM PIECE

(275mm)

New RevisioN - CoNsult FaCtoRy FoR old dimeNsioNs

Figure 2 - DR-R Series Recessed Mount

3/4

(19mm)

▲

▲

7-1/16

(179mm)

▲

3/4

(19mm)

FRAME INSIDE

ROUGH OPENING

WALL

(8) WALL

BOX

MTG HOLES

3 1/4 (89mm)

BOX DEPTH

▲

▲

▲

2-3/4

(70mm)

10-3/4 (273mm)

9-1/4 (235mm)

▲

▲

7/8 (22mm) IN-WALL

CONDUIT ENTRANCE

7/8 (22mm) SURFACE

CONDUIT ENTRANCE

5/16 (8mm)

▲

DIA. MTG HOLES

▲

▲

8

▲

(203mm)

Figure 3 - A-T Series Surface Mount

2 1/4

(57mm)

7/8 (22mm)

CONDUIT

ENTRANCES

ROUGH WALL OPENING

11 (279mm)

3 1/2 (89mm) MIN WALL DEPTH REQ’D

Figure 4 - A-TR Series Recessed Mount

▲

▲

1

(25mm)

6 3/4

(171mm)

▲

▲

▲

1 (25mm)

▲

(217mm)

1-1/16

(27mm

)

▲

▲

1 1/2 (38mm)

▲

8-9/16

▲

9 -1/16

(230mm)

Represented by:

American Dryer, Inc.

12932 Farmington Road I Livonia I MI I 48150 I U.S.A.

Toll Free 800.485.7003 U.S. I Ph: 734.421.2400 I Fax 734.421.5580

Web: www.americandr yer.com

Email: sales@americandryer.com

© American Dryer, Inc. All Rights Reserved

GENERAL INFORMATION

DRYER PL ACEMENT :

Dryers should be placed at least 2 feet apart and at least 12” from

washbasin. Do not install dryer over washbasin. Automatic dryers should

be at least 18” above any projection which may interfere with the operation of the automatic sensor.

DRYER INSTALLATION:

Hand dryers require a dedicated circuit (max. 20 amp) and must be

properly grounded. One side of dryer should be mounted to stud. All

surface mount dryers are provided with conduit entrances for both

between wall and surface wiring.

QUANTITY ESTIMATE, HAND DRYER:

Average traffic washroom..............1 dryer per 2 washbasins

Heavy traffic washroom..................1 dryer per washbasin

54” wash fountain...........................4 dryers per sink

SHIIPPING WEIGHT: DR Series 16 lbs, A Series 28 lbs

Printed on Recycled Paper

USC

MADE IN U.S.A.

Loading...

Loading...