AMD SC520 (Elan SC520) Élan SC520 Microcontroller Customer Development Platform User’s Manual

Élan™SC520 Microcontroller

Customer Development Platform

User’s Manual

Order #22450C

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

© Copyright 2001 Advan ced Micro Devices, Inc. All rights reserved.

The contents of this document are provided in connection with Advanced Micro Devices, Inc. ("AMD") products. AMD makes

no representations or warranties with respect to the accuracy or completeness of the contents of this publication and reserves

the right to make changes to specifications and product descriptions at any time without notice. No license, whether express,

implied, arising by estoppel or otherwise, to any intellectual property rights is granted by this publication. Except as set forth

in AMD's Standard Terms and Conditions of Sale, AMD assumes no liability whatsoever, and disclaims any express or implied

warranty, relating to its products including, but not limited to, the implied warranty of merchantability, fitness for a particular

purpose, or infringement of any inte l le ct ua l property right.

AMD's products are not designe d, intend ed, authorized or warranted for use as components in systems intended for surgical

implant into the body, or in other applicat ions intended to sup port or sustain life, or in an y other applicat ion in which the

failure of AMD's product could create a situation whe re personal injury, death, or severe property or en vi ronmental damage

may occur. AMD reserves the right to discontinue or make changes to its products at any tim e wit hout notice.

NO SUPPORT OBLIGA TION: AMD is not obligated to furnish, support, or make any further information, software, technical

information, know-how, or show-how available to you .

AMD, the AMD logo, combinations there of, Am186, AMDebug, AMD-K6, E 86, Élan, and PCnet are trademarks, Am486 is

a registered trademark , an d Fusi onE 86 is a service mark of Advanced Mic ro D e vic e s , Inc .

MMX is a trademark of Intel Corporation.

Windows and Windows NT are registered trademarks of Microsoft Corporation.

Netware is a registered trademark of Novell, Inc.

Other product names used in thi s public atio n are for i denti ficati on purpose s onl y and ma y be tradem arks of t heir re spec tive

companies.

IF YOU HAVE QUESTIONS, WE’RE HERE TO HELP YOU.

The AMD customer service network includes U.S. offices, international offices, and a customer

training center. Expert technical assistance is available from the AMD worldwide staff of field

application engineers and factory support staff to answer E86™ family hardware and software

development questions.

Frequently accessed numbers are listed below. Additional contact information is listed on the back

of this manual. AMD’s WWW site lists the latest phone numbers.

Technical Support

Answers to technical questions are available online, through e-mail, and by telephone.

Go to AMD’s home page at www.amd.com and follow the Support link for the latest AMD technical

support phone numbers, software, and Frequently Asked Questions.

For technical support questions on all embedded system products, send e-mail to

epd.support@amd.com (in the US and Canada) or euro.tech@amd.com (in Europe and the UK).

You can also call the AMD Corporate Applications Hotline at:

(800) 222-9323 Toll-free for U.S. and Canada

44-(0) 1276-803-299 U.K. and Europe hotline

WWW Support

For specific information on E86 products, acces s the AMD home page at www.amd.com and follow

the Embedded Processors link. These pages provide information on upcoming product releases,

overviews of existing products, information on product support and tools, and a list of technical

documentation. Support tools include online benchmarking tools and CodeKit software—tested

source code example applications. Many of the technical documents are available online in PDF form.

Questions, requests, and input concerning AMD’s WWW pages can be sent via e-mail to

web.feedback@amd.com.

Documentation and Literature Support

Data books, user’s manuals, data sheets, application notes, and product CDs are free with a simple

phone call. Internationally, contact your local AMD sales office for product literature.

To order literature, go to www.amd.com/support/literature.html or, in the U.S. and Canada, call

(800) 222-9323.

Third-Party Support

AMD FusionE86SM partners provide an array of prod ucts designed to meet critical time-to-market needs.

Products and solutions available include emulators, hardware and software debuggers, board-level products,

and software devel opment tools , amon g ot hers. The WWW site and the E86™ Family Products

Development Tools CD, order #21058, describe these solutions. In addition, mature development

tools and applications for the x86 platform are widely available in the general marketplace.

Contents

About the Élan™SC520 Microcontroller Customer

Development Platform

Features...............................................................................................................xii

Documentation ..................................................................................................xiii

About this Manual.........................................................................................xiii

Suggested Reference Material ...................................................................... xiv

Documentation Conventions ........................................................................xv

Chapter 1

Quick Start

Setting Up the Élan™SC520 Microcontroller CDP..........................................1-2

Set-Up Requirements.................................................................................... 1-3

Set-Up Procedure.......................................................................................... 1-5

Starting from a Floppy Disk........................................................................1-14

Starting from an IDE Hard Disk Drive....................................................... 1-15

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

v

Chapter 2

Features and Functions

Block Diagram and Component Locations........................................................2-2

Descriptions.......................................................................................................2-6

Élan™SC520 Microcontroller ......................................................................2-6

10/100BaseT Ethernet Controller..................................................................2-7

Super I/O .......................................................................................................2-8

PCI Card Slots.............................................................................................2-10

ISA Card Slots (General-Purpose Bus Slots)..............................................2-10

Test Interface Port (TIP) Connector............................................................2-10

Logic Analyzer Connector..........................................................................2-10

High-Speed UAR T............................................... .......................................2-11

Low-Speed UART.......................................................................................2-11

Hexadecimal LED Display..........................................................................2-11

Memory.......................................................................................................2-12

AMDebug™ Tool............................................................ ...... ...... ................2-17

In-Circuit Emulator (ICE) Connector..........................................................2-17

vi

Synchronous Serial Interface.......................................................................2-17

Integrated Drive Electronics (IDE).............................................................2-17

Optional Daughter Modules........................................................................2-18

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Appendix A

Jumper and DIP Switch Settings

Jumper Settings ................................................................................................A-1

Jumper JP2................................................................................................... A-2

Jumper JP3................................................................................................... A-3

Jumper JP4................................................................................................... A-4

Jumper JP5................................................................................................... A-5

ISA DMA Selection, Jumpers JP6–JP9 ....................................................... A-6

Jumpers JP10, JP11, JP12, JP13, and JP14.................................................A-11

Jumper JP18...............................................................................................A-12

Jumper JP20...............................................................................................A-13

DIP Switch Settings........................................................................................A-14

DIP Switch S3............................................................................................A-14

DIP Switch S4............................................................................................A-15

DIP Switch S5............................................................................................A-16

Appendix B

Resource Assignments

Chip Select Resource Assignments...................................................................B-2

GPIRQ Resource Assignments.......................... ............................................. ...B-3

GPDMA Resource Assignments......................................................... ...... ..... ...B-4

PIO Resource Assignments...............................................................................B-5

UART Resour ce Assignments............................................ ...............................B-7

Index

Index...........................................................................................................Index-1

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

vii

List of Figures

Figure 1-1. Jumper JP20.......................................................................................................1-8

Figure 1-2. Older Type of 34-Pin Floppy Disk Cable ........................................................1-10

Figure 1-3. Newer Type of 34-Pin Floppy Disk Cable......................................................1-11

Figure 1-4. Wiring Connection Changes on 34-Pin Ribbon Cable....................................1-13

Figure 2-1. Élan™SC520 Microcontroller CDP Block Diagram ........................................2-3

Figure 2-2. Élan™SC520 Microcontroller CDP Board Layout...........................................2-4

Figure 2-3. Connectors on the Élan™SC520 Microcontroller CDP....................................2-5

Figure 2-4. On-Board 10/100 Mbit/s Ethernet Controller Block Diagram..........................2-7

Figure 2-5. Super I/O Block Diagram..................................................................................2-9

Figure 2-6. SDRAM Configuration Diagram.....................................................................2-13

Figure 2-7. Flash Memory Configuration for Élan™SC520 Microcontroller CDP ..........2-15

Figure 2-8. Flash Memory Configuration Block Diagram.................................................2-16

Figure A-1. Jumper JP2 Default Setting ..............................................................................A-2

Figure A-2. Jumper JP3 Default Setting ..............................................................................A-3

Figure A-3. Jumper JP4 Default Setting ..............................................................................A-4

Figure A-4. Jumper JP5 Default Setting ..............................................................................A-5

Figure A-5. Jumper JP6, JP7, JP8, and JP9 Pin Numbering ................................................A-6

Figure A-6. Jumper JP6 Default Routing.............................................................................A-7

Figure A-7. Jumper JP7 Default Routing.............................................................................A-8

Figure A-8. Jumper JP8 Default Routing.............................................................................A-9

Figure A-9. Jumper JP9 Default Routing...........................................................................A-10

Figure A-10. Jumper JP18 Default Setting ..........................................................................A-12

Figure A-11. Jumper JP20....................................................................................................A-13

Figure A-12. DIP Switch S3 Default Setting.......................................................................A-14

Figure A-13. DIP Switch S4 Default Setting.......................................................................A-15

Figure A-14. DIP Switch S5 Default Setting.......................................................................A-16

viii

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

List of Tables

Table 0-1. Notational Conventions ......................................................................................xv

Table 2-1. DMA Channels and IRQs Reserved for Super I/O ........................................... 2-8

Table 2-2. SDRAM Signals..............................................................................................2-12

Table 2-3. Chip Select (CS) Decoder Address Space....................................................... 2-16

Table A-1. DIP Switch S3 Settings .................................................................................. A-14

Table A-2. DIP Switch S4 Settings .................................................................................. A-15

Table A-3. DIP Switch S5 Settings .................................................................................. A-16

Table B-1. Chip Select Resource Assignments...................................................................B-2

Table B-2. GPIRQ Resource Assignments..........................................................................B-3

Table B-3. GPDMA Resource Assignments.......................................................................B-4

Table B-4. PIO Resource Assignments...............................................................................B-5

Table B-5. UART Resource Assignments...........................................................................B-7

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

ix

x

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

About the Élan™SC520 Microcontroller Customer Development Platform

The Élan™SC520 microcontroller customer development platform (CDP)

provides a robust evaluation and development platform for the ÉlanSC520

microcontroller. Using the ÉlanSC520 microcontroller, SDRAM, Am79C973

Ethernet controller, and PCI bus, the ÉlanSC520 microcontroller CDP serves as a

platform for embedded product development. Within the ÉlanSC520

microcontroller CDP, the embedded PCI bus c ontroller works we ll with other PCIready peripherals (audio, video, etc.).

The ÉlanSC520 microcontroller CDP uses an on-board 10/100 Mbit/s Ethernet

based on the Am79C973 PCnet™-FAST III device. In addition , the ÉlanSC520

microcontroller CDP uses an ALi Super I/O for additional interface functionality

including serial (two), parallel, IrDA, floppy, keyboard, and mouse devices. The

ÉlanSC520 microcontroller CDP contains 16-Mbytes of Flash memory that is

expandable to an additional 32 Mbytes through a daughter module (with a flexible

8- and 16-bit confi gur at ion on the GP-bus or 8-, 1 6-, or 32-bit on a SDRAM data

bus), system configuration jumpers, and PCI and ISA expansion connectors. The

ÉlanSC520 microcontroller CDP uses an ATX form factor.

The ÉlanSC520 microcontroller CDP enables you to:

• Develop firmware and application code for the ÉlanSC520-based embedded

microcontroller

• Benchmark embedded, network-ready applications on the high performance

ÉlanSC520 mi crocontroller

• Make power measurements

• Experiment with design trade-offs and assemble an ÉlanSC520 microcontroller

system using off-the-shelf components.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

xi

Features

The ÉlanSC520 microcontroller CDP contains the following features:

• 10/100BaseT Ethernet

• Super I/O peripheral chip containing:

- Floppy device

- Two serial devices (one IrDA shared with Serial Port 2)

- One parallel device

- Keyboard

-Mouse

• Three PCI card slots

• Tw o ISA card sl ots

• Test Interface Port (TIP) connector

• High-speed UART port

• Low-speed UART port

• Hex LED display

• Logic analyzer connector (AMP MICTOR type)

xii

• SDRAM (two 168-pin DIMM sockets)

• 16-Mbyte on-board Flash memory

• AMDebug™ (JT AG-compliant) test interface tool (co nnector POD1 or POD2)

• In-circuit emulator (ICE) connector (J10) support using a PROM ICE device

• Synchronous serial interface (SSI)

• Integrated drive electronics (IDE)

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Documentation

The Élan™SC520 Microcontroller Customer Development Platform User’s

Manual provides information about the system, features, functions, and interfaces.

Additional information can be found in “Suggested Reference Material” on

page xiv.

About this Manual

Chapter 1, “Quick Start”, describes how to quickly set up a nd begin using the

ÉlanSC520 m icrocontroller CDP.

Chapter 2, “Features and Functions”, describes the features and functions of the

ÉlanSC520 m icrocontroller CDP.

Appendix A, “Jumper and DIP Switch Settings”, describes the various jumpers,

switches, and settings.

Appendix B, “Resource Assignments”, des cribes the resource assignments for chip

select, GPIRQ, GPDMA, PIO, and UART.

A standard index is also included.

Élan™SC520 Microcontroller Customer Development Platform User’s M anual

xiii

Suggested Reference Material

The following AMD documentation may be of interest:

• Élan™SC520 Microcontroller Register Set Manual, order #22005

• Élan™SC520 Microcontroller User’s Manual, order #22004

• Élan™SC520 Microcontroller Data Sheet, order #22003

• Am486® Microprocessor Software User’s Manual, order #18497

• AMD Test Interface Port Board User’s Manual, order #22505A

• Am79C973/Am79C975 PCnet™-FAST III Single-Chip10/100 Mbps PCI

Ethernet Controller with OnNow Support, order #21510

• E86™ Family Products Development Tools CD, order #21058

For current application notes and technical bulletins, see ou r World W ide W eb page

at www.amd.com.

The following non-AMD documentation may also be of interest to you:

• PCI Local Bus Specification, Production Version, Revision 2.1, June 1, 1995,

PCI Special Interest G roup, 8 00-433 -5177 (US, 503-69 3-6232 (In ternati onal ),

www.pcisig.com.

• IEEE Std 1148\9.1-1990 Standard Test Access Port and Boundary-Scan

Architecture (order #SH16626-NYF), Institute of Electrical and Electronic

Engineers, Inc., 800-678-4333, www.ieee.org.

xiv

• PCI System Architecture, Mindshare, Inc., Third Edition. Reading, MA:

Addison-Wesley, 1995, ISBN 0-201-40993-3.

• ISA System Architecture, Mindshare, Inc., Third Edition. Reading, MA:

Addison-Wesley, 1995, ISBN 0-201-40996-8.

• The Indispensable PC Hardware Book, Hans-Peter Messmer, Third Edition.

Wokingham, England: Addison-Wesley, 1995, ISBN 0-201-40399-4.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Documentation Conventions

The Élan™SC520 Microcontroller Customer Development Platform User’s

Manual uses the notational conventions shown in Table 0-1 (unless otherwise

noted).

Table 0-1. Notational Conventions

Symbol Usage

Boldface Indicates that characters must be entered

exactly as shown, except that the alphabetic case is

only significant when indicated.

Italic Indicates a descriptive term to be replaced with a

user-specified term.

Typewriter face Indicates computer text input or output in an example

or listing.

EXE Indicates a DOS executable file.

HEX Indicates an Intel extended hex file.

<> Encloses a required parameter. To include the

information described within the angle brackets, type

only the parameters, not the angle brackets

themselves.

[] Encloses an optional parameter. To include the

information described within the brackets, type only

the parameter, not the brackets themselves.

| Separates alternate choices in a list. Only one of the

choices can be entered.

Élan™SC520 Microcontroller Customer Development Platform User’s M anual

xv

xvi

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Chapter 1

Quick Start

This chapter provides information to enable you to quickly set up and start using

the ÉlanSC520 microcontroller customer development platform (CDP). The

following sections describe how to connect, power up, and begin using the board.

The ÉlanSC520 Microcontroller is shipped with a BIOS that has been configured

specifically for the chipset used on this platform. The BIOS contains the code that

enables the ÉlanSC520 Microcontroller to function as a standard AT-compatible

PC, using A T -compatible displays, display adapters, mouse, and keyboards. Details

on the BIOS can be found in the online BIOS documentation shipped with your kit.

The ÉlanSC520 Microcontroller can run A T -compatible operating system software.

You can start the system with either a bootable floppy disk or an ATA (IDE) hard

disk drive that has the pre-installed operating system.

Embedded BIOS software typically supports the configuration of onboard Flash

memory as a resident Flash disk (RFD) that can also be set up as a boot device.

See the online BIOS manual included with your kit.

For information on how to:

• Set up the ÉlanSC520 microcontroller CDP, refer to “S et-Up Procedure” on

page 1-5.

• Boot the ÉlanSC520 microcontroller CDP from a floppy disk, refer to “Starting

from a Floppy Disk” on page 1-14.

• Boot the ÉlanSC520 microcontroller CDP from a hard disk drive, refer to

“Starting from an IDE Hard Disk Drive” on page 1-15.

• Modify the PromICE interface cable for booting the ÉlanSC520 microcontroller

CDP, refer to “Modifying the PromICE Interface Cable for Booting the

ÉlanSC520 Microcontroller CDP” on page 1-8. This procedure should be u sed

only with CDP board versions 1.0–1.2.

Additonal information and utilities are available as CodeKit software included with

your kit. CodeKit software can also be found at www.amd.com.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

1-1

Setting Up the Élan™SC520 Microcontroller

CDP

CAUTION: As with all computer equipment, the ÉlanSC520

microcontroller CDP may be damaged by electrostatic discharge

!

WARNING: Read the following before using the

Élan™SC520 microcontroller CDP.

Before applying power , the following precautions should be taken to avoid damage

or misuse of the board:

• Make sure the power connector JP1 (ATX Power) is plugged into the ÉlanSC520

microcontroller CDP correctly.

- Refer to Figure 2-2 on page 2-4 for the JP1 (ATX Power) connector location.

• Check the materials that were shipped with your kit for README o r errata

documentation. Read all the information carefully before continuing.

For current application notes and technical bulletins, refer to the AMD W orld Wide

Web page at www.amd.com and follow the link to Embedded Systems.

(ESD). Please take proper ESD precautions when handling any

board.

1-2

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Set-Up Requirements

The following items are provided with the ÉlanSC520 microcontroller CDP.

•ÉlanSC520 microcontroller (pre-install ed)

• CR2032 Lithium battery (pre-installed)

• 64-Mbyte SDRAM DIMM module

• General Software BIOS (pre-installed)

• 34-pin ribbon cable with header (for floppy disk drive)

• 40-pin ribbon cable with header (for IDE drive)

• PCI video card

You must provide the following items:

• PS/2 keyboard

• PS/2 mouse

• Floppy disk drive

• IDE hard disk drive

• ATX power supply (any wattage)

• Color VGA monitor (any size)

To boot from a floppy disk, you must provide at least the following:

• A PC/AT-compatible 3.5-inch or 5.25-inch floppy disk drive

• A bootable DOS floppy disk

To boot from a hard disk drive, you must provide at least the following:

• An IDE hard disk drive

• PC/A T -compatible operating system (pre-installed on the hard disk drive) (DOS,

Microsoft Window s)

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

1-3

For correct configuration, the jumper and DIP switch settings must be set to the

default settings. Verify these settings before operating the ÉlanSC520

microcontroller CDP; refer to Appendix A, “Jumper and DIP Switch Setti ngs”.

If you install both a floppy disk drive and a hard disk drive, you can boot from

either device. Only one boot di sk image (floppy di sk or hard disk) is required. For

example, you can boot from the floppy disk drive, and then install the operating

system on a blank hard disk drive.

CAUTION: Use the configuration described here when you first

start the ÉlanSC520 microcontroller CDP. Be fore using other

!

features, read the appropriat e sections in Chapter 2, “Features

and Functions.”

1-4

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Set-Up Procedure

NOTE: For block diagram inf ormation, refer to Figure 2-1 on page 2-3. For layout

and connector locations, refer to Figure 2-2 on page 2-4.

!

Perform the following steps to set up the ÉlanSC520 microcontroller CDP:

1. Remove the ÉlanSC520 microcontroller CDP from the shipping carton, and

inspect the it to verify that it was not damaged during shipping. The ÉlanSC520

microcontroller CDP contains several jumpers. The following steps assume all

jumpers are set to the factory default configuration (settings are listed in

“Jumper and DIP Switch Settings” on page A-1).

2. If you are installing a floppy disk drive, perform the following steps:

a. Inspect the 34-wire, floppy disk drive cable. The red wire along one edge

of the ribbon cable indicates wire 1. Most cables have a connector for the

board at one end and two or more connectors along the length. Ther e may

be two different drive connectors at each location to accommodate

different drive types.

CAUTION: Ensure that all connections and settings are correct

before powering up the ÉlanSC520 microcontroller CDP.

Incorrect connections or settings can damage the ÉlanSC520

microcontroller CDP.

b. Connect one end of the floppy disk drive cable to the 34-pin connector

(connector P13) on the ÉlanSC520 microcontroller CDP (with wire 1

oriented towards the LED displays). If there is a twist in one span of the

cable, connect the opposite end to the board. Note the pin-1 position.

c. Connect the other connector on the floppy disk drive cable to the floppy

disk drive, just as you would for a standard PC installation. If there is a

twist in the cable, the position you use determines whether the drive

responds as A or B (typically drive A connects to the end of the cable,

beyond the twist). The connector’s orientation shou ld be indicated in the

drive documentation, or marked near the connector on the drive. Usually

wire 1 is oriented towards the drive’s power cable connector.

d. Find one of the 4-wire power connectors from the PC power supply and

attach it to the 4-pin connector on the f loppy d isk driv e just as y ou would

for a standard PC installation.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

1-5

3. If you are installing a hard disk drive, perform the following steps:

a. Connect the 40-pin hard disk drive cable into the IDE box header (P3).

Note the pin-1 position. The red wire along one edge of the ribbon cable

indicates wire 1.

b. Connect one end of the 40-wire IDE cable to the hard disk drive just as

you would for a standard PC installation. The connector’s orientation

should be indicated in the drive documentation, or marked near the

connector on the drive. Usually wire 1 is oriented towards the drive’s power

cable connector .

c. Connect the other end of the 40-wire IDE cable to the first 40-pin connector

(connector P3) on the ÉlanSC520 microcontroller CDP (with wir e 1

oriented towards the LED displays).

d. Find one of the 4-wire power connectors from the PC power supply and

attach it to the 4-pin connector on the hard disk drive just as you would for

a standard PC installation.

4. Connect the monitor cable from the monitor to the D-connector on the video

card just as you would for a standard PC.

5. Connect the ISA VGA or PCI video card into one of the ISA or PCI slots.

6. Connect the SDRAM DIMM module into either J2 or J3.

7. The ÉlanSC520 microcontroller is pre-installed in the ÉlanSC520

microcontroller CDP. If the microcontroller is mounted in a ZIF socket and

you need to re-seat or replace the microcontroller, per form the following steps:

1-6

a. Lift the lever-bar of the socket to the vertical position.

b. Place the ÉlanSC520 microcontroller over the ZIF socket, and then align

the golden arrow on the ÉlanSC520 microcontroller with the upper-left

corner (pin-A1) of the socket.

c. Place the ÉlanSC520 microcontroller flat on the ZIF socket, an d then lock

the lever-bar by pushing it down to the horizontal position.

8. Connect the PS/2 keyboard cable into the J1 lower-socket.

NOTE: The keyboard and mouse socket positions have changed in board

revision 1.4. They were reversed in previous board versions.

9. Connect the PS/2 mouse cable into the J1 upper-socket.

10. Connect the ATX power connector into the JP1 connector.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Configuring the System Setup (BIOS) Setting

Perform the following steps to configure the system setup (BIOS) setting:

1. In the drive assignment order:

a. Set Drive A: to Floppy Drive 0.

b. Set Drive C: to IDE 0 (M aster 1).

2. In the boot order block:

a. Set Boot 1st to Drive A:.

b. Set Boot 2nd to Drive C:.

3. In the IDE drive geometr y block, set device IDE0 to “Auto Config, Physical”

(typically for drives smaller than 1 Gbyte) or “Auto Config, LBA” (typically

for drives 1 Gbyte and larger). If only one IDE device exists, set the other IDE

devices to “not installed.”

4. In the floppy disk drive type bl ock, set Floppy 0: to 1.44 Mbyte, 3. 5.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

1-7

Modifying the PromICE Interface Cable for Booting the

Élan™SC520 Microcontroller CDP

NOTE: For CDP board versions 1.3 or 1.4, use either of the following jumper

settings on jumper JP20, according to your PromICE setup. If your CDP board

version is 1.3 or 1.4, skip “Modifying the PromICE Interface Cable Procedure” on

page 1-9.

Setting Jumper JP20 According to Your PromICE Setup

Use either of the following jumper settings on jumper JP20 according to your

PromICE setup. For the location of jumper JP20, refer to “Élan™SC520

Microcontroller CDP Board Layout” on page 2-4.

• When using Flash memory or a modified PromICE cable, jumper pins 1 and 3

and jumper pins 2 and 4.

• When using PromICE with the original cable (requiring no cable modi fications),

jumper pins 3 and 5 and jumper pins 4 and 6.

1-8

1

3

5

Figure 1-1. Jumper JP20

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

2

4

6

Modifying the PromICE Interface Cable Procedure

NOTE: This procedure applies only to CDP board versions 1.0–1.2.

The ÉlanSC520 microcontroller CDP enables you to boot either from a ROM/Flash

device in a 32-pin DIP socket U17, or from a PromICE (or compatible ROM

emulator) that is connected to the 34-pin connector labeled PROM ICE (located

adjacent to the diskette 34-pin connector). The boot device is selected by

positionin g JP18 to pins 1 an d 2 for the DIP socket, and to pins 2 and 3 for the

PromICE. The PromICE interface for the rev 1. 2 ÉlanSC520 microcontroller CDP

is designed in strict accordance with pinouts giv en in the PromICE User’s Manual,

version 3.4. However, this reference refers to UV-EPROM instead of the more

popularly used EEPROM and Flash memory devices, making the ÉlanSC520

microcontroller CDP incompatible.

To fix this condition, perform one of the following task s:

• Modify a 34-pin floppy disk cable.

To modify a 34-pin floppy disk cable, perform step 1 on the following pages.

Step 1 describes how to remove the extra connectors prior to making the wiri ng

connection changes in step 2. Step 1 is optional, but is recommended.

• Make a standard 34-pin cable by using a cable press to attach a ber g connector

to both ends of a ribbon cable.

After making the standard 34-pin ribbon cable, perform step 2 to change the

wiring connections.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

1-9

1. To modify a 34-pin floppy d i sk cable, perfo rm the following steps:

The floppy disk cable contains extra connectors that are not required for this

application. After cutting off the extra connectors, the modified cable contains

the correct connectors that are properly keyed for the PromICE application.

NOTE: If you are using a newer type of floppy disk cable (not containing any cardedge interface connectors), perform step 1.b. instead of step 1.a.

a. If you are using an older type of floppy di s k cable (con tain i ng card- edge

interface connectors), use a razor knife or scissors to cu t the cable as shown

in Figure 1-2, and then proceed to step 2 to make the required wiring

connection changes.

After cutting the cable, make sure none of the exposed wires at the edge

of the cut cable are touching.

Cable Twist

Berg Connector

Figure 1-2. Older Type of 34-Pin Floppy Disk Cable

Cut The Cable Here

Berg Connector

34-Pin Cable After Modificatio n

Berg Connector (This

Connector Plugs Into

the Board)

1-10

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

b. If you are using a newer type of floppy disk cable (not containing any card-

edge interface connectors), use a razor knife or scissors to cut the cable

as shown in Figure 1-3, and then proceed to step 2 to make the required

wiring connection changes.

After cutting the cable, make sure none of the exposed wires at the edge

of the cut cable are touching.

Cable Twist

Berg Connector

NOTE: The information provided in Step 2 and Figure 1-4 assumes that you are

supporting the emulation of a 256K Flash device, because address lines A18 and

A19 are tied high.

2. To change the wiring connections on the 34-pin cable, perform the following

Cut The Cable Here

Berg Connector

Figure 1-3. Newer Type of 34-Pin Floppy Disk Cable

steps:

34-Pin Cable After Modification

Berg Connector

(This Conne ctor Plugs

Into the Board)

a. Being careful not to cut into the insulation of the wires, use a razor knife

to separate wires 2, 3, 4 and 5 from each other and from the other cable

wires, as shown in Fig ure 1-4.

b. Cut wires 2, 3, 4, and 5, as shown in Figur e 1-4.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

1-11

c. Remove about a half-inch of insulation from the ends of the following

wires:

Wires 2, 3, 4, and 5 on the side of the cable that connects to the PromICE

Wire 4, on the side of the cable that connects to the ÉlanSC520

microcontroller CDP.

NOTE: Do not remove the insulation from wires 2, 3, and 5 located on the side of

the cable that connects to the ÉlanSC520 microcontroller CDP.

d. Connect exposed wires 2, 3, and 4 by twisting the wire-ends together.

e. This connection provides a pull-up f or A18 and A19 to VCC becaus e they

are not used in addresses 256K–1 and below.

f. Connect exposed wire 4 to exposed wire 5 by twisting the wire-ends

together.

g. This connection fixes the compatibility issue originating in the PromICE

user’s manual.

h. To ensure that the exposed connected wires do not touch other wires, use

electrical tape to cover the exposed wires.

1-12

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

ÉlanSC520

Microcontroller CDP

Connector

Wire 1 (Red)

4

Exposed Wires 4 and 5

Twisted Together

5

Exposed Wires 2, 3, and 4

Twisted Together

234

PromICE Connector

Figure 1-4. Wiring Connection Changes on 34-Pin Ribbon Cable

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

1-13

Starting from a Floppy Disk

Use the following steps to start the ÉlanSC520 microcontroller CDP from a

bootable floppy disk:

1. Make sure you have installed the ÉlanSC520 microcontroller CDP correctly as

described in “Set-Up Procedure” on page 1-5.

CAUTION: Failure to verify the power supply connections can

result in total destruction of the ÉlanSC520 microcontroller

!

2. Plug the VGA monitor into an electrical outlet and turn it on.

3. Insert a bootable DOS floppy disk (not included) in the floppy disk drive.

4. Apply power to the ÉlanSC520 microcontroller CDP by connecting the PC

power supply to an electrical outlet. If the power supply is equipped with a

switch, turn it on. Then turn on the power switch on the CDP.

The power supply fan should start running, and the port 80h and 680h LEDs

should start to display power-on self-test (POST) status codes. Then the speaker

should beep and the monitor should start displaying startup information.

5. The first time you start the system, the BIOS might display a message reporting

a CMOS error or some other BIOS configuration problem. Follow the

instructions shown on the screen to enter the Setup utility . Once you are in the

Setup utility, you can set the system’s date, time, startup drive, and other

options.

CDP.

1-14

For more information on the included B IOS, including power -on status codes,

see the online BIOS manual included with your kit.

6. Save and exit the setup utility.

7. The system should now boot from the DOS floppy disk just like a standard PC.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Starting from an IDE Hard Disk Drive

Use the following steps to start up the ÉlanSC520 microcontroller CDP from an

IDE hard disk drive on which you have pre-installed an operating system (while it

was connected to another PC):

1. Make sure you have installed the ÉlanSC520 microcontroller CDP correctly as

described in “Set-Up Procedure” on page 1-5.

CAUTION: Failure to verify the power supply connections can

result in total destruction of the ÉlanSC520 microcontroller

!

2. Plug the VGA monitor into an electrical outlet and turn it on.

3. If a floppy disk drive is installed, make sure it is empty.

4. Apply power to the ÉlanSC520 microcontroller CDP by connecting the PC

power supply to an electrical outlet. If the power supply is equipped with a

switch, turn it on. Then turn on the power switch on the CDP.

The power supply fan and hard di sk should start running, and the port 80 h and

port 680h LEDs should start to display power-on self -test (POST) status codes.

Then the speaker should beep and the monitor should start displaying startup

information.

CDP.

5. The first time you start the system, the BIOS might display a message reporting

a CMOS error or some other BIOS configuration problem. Follow the

instructions shown on the screen to enter the Setup utility . Once you are in the

Setup utility, you can set the system’s date, time, startup drive, and other

options.

For more information on the included B IOS, including power -on status codes,

see the online BIOS manual included with your kit.

6. Save and exit the setup utility.

7. The system should now boot using the operatin g system on the hard disk drive.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

1-15

1-16

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Chapter 2

Features and Functions

The ÉlanSC520 microcontroller customer development platform (CDP) is

designed for validating features and functionality , qualifying specifications on the

ÉlanSC520 m icrocontroller, and for developing custo mer applicati ons.

For more information about the components of the ÉlanSC520 microcontroller

CDP, refer to the following sections:

•ÉlanSC520 microcontroller, page 2-6

• 10/100Ba seT Ethernet, page 2-7

• Super I/O and serial ports, page 2-8

- Floppy device

- Two serial devices

- One parallel device

- Keyboard

-Mouse

• PCI card slots, page 2-10

• ISA card slots, page 2-10

• Tes t interface port (TIP) connector, page 2-10

• Logic analyzer connector, page 2-10

• High-speed UART, page 2-11

• Low-speed UART, page 2-11

• Hexadecimal LED display, page 2-11

• SDRAM, page 2-12

• 16-Mbyte onboard Flash memory, page 2-14

• AMDebug™ (JTAG-compliant) test interface, page 2-17

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

2-1

• In-circuit emulator (ICE) connector support using PROM ICE, page 2-17

• Synchronous serial interface (SSI), page 2-17

• Integrated Drive Electronics (IDE), page 2-17

• Daughter modules: 32-Mbyte Fl ash memory module and TIP module, page 2-18

Block Diagram and Component Locations

The following figures show the features and layout of the ÉlanSC520

microcontroller customer development platform:

• Figure 2-1 on page 2-3 shows a block diagram and a summary of the functions

of the features.

• Figure 2-2 on page 2-4 shows the board layout and the locations of the

components.

• Figure 2-3 on page 2-5 shows the connectors on the ÉlanSC520 micr ocontroller

CDP.

2-2

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

SDRAM DIMM

Slot 1

SDRAM DIMM

Slot 2

UART 1

Transceiver

UART 2

Transceiver

Parallel

IDE

Floppy

Mouse

Keyboard

ISA Slot 1

ISA Slot 2

Data/

Address

HS UART

Transceiver

LS UART

Transceiver

System Clock

Reset

Decoupling

ATX Power

CFG Straps

SSI

Devices

MW/SPI

JTAG

AMDebug

SDRAM Bus

HS/LS UARTs

SSI

ÉlanSC520

Microcontroller

JTAG/AMDebug

Data

GP Address

GP Data

PCI Local Bus

Expansion

Flash Card

Connector

GP Buffer

GP Bus Data/Address

Super I/O

GP Bus

Data/Address

GP Bus Data/Address

GP Bus Data/Address

GP Bus Data/Address

TIP

Connector

GP Bus Data/Address

Hex LED

Display

PCI Slot 1

PCI Slot 2

PCI Slot 3

PCI Local Bus

PCnet™-

FAST III

DIP

Flash

HP Headers - GP Bus

NI Header - GP Bus

Figure 2-1. Élan™SC520 Microcontroller CDP Block Diagram

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

2-3

RJ-45

JP6

JP7

JP9

JP8

ISA 0 Connector

ISA 1 Connector

PCI Connector (SLT3)

PCI Connector (SLT4)

PCI Connector (SLT5)

JP14

JP10

JP13

JP11

JP12

Serial/Parallel Ports

MS/KB

M512x

IDE

CPU Interfac e

CPU Interface

Transformer

POD1 (JTAG)

POD2

(JTAG)

S3

S5

LED Driver

PCI Interface

Am79C973

PCI Interface

PCI Bus Header

Line Interface

PCI Interface

PCI Bus Header

SP503

Te st Hea der

Test Header

P11

P8

TIP

P12

P3

JP19

LS1

J12

J13

P13

IDE

LEDs

Floppy

J10

P4

DAQ Header

PROM ICE

LEDs

JP17

(SSI)

JP3

DIP

JP18

S4

JP20

JP4

JP5

Test Header

Flash Daughter Card (32 Mbyte)

P1

Addr

Flash EXP

ÉlanSC520

Microcontroller

388-BGA

GP Bus

VccPWR

Bank 1

Bank 0

JP1

J2

J3

ATX Power

HSUART (Top, J5)

JP2

Super I/O Parallel Port (Top, J7)

Super I/O Serial Ports (Bottom,

Reset

Mouse

Keyboard

LSUART (Bottom, J6)

J8, J9)

P10

DIMM Socket

DIMM Socket

P2

Data

Flash TSOP-II

Flash EXP

Battery

Power

Switch

SDRAM Header

P7

SDRAM Header

2-4

Figure 2-2. Élan™SC520 Microcontroller CDP Board Layout

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Keyboard

Super I/O Parallel Port J7

Mouse

ÉlanSC520 Microcontroller Serial Port 0,

High-Speed UART (COM 1, J5, RS-422A)

Board

Super I/O Serial Port 1

(COM 3, J8)

Super I/O Serial Port 2

(COM 4, J9)

NOTE: The mouse and keyboard connector positions are reversed (keyboard connector

on top) in CDP board versions 1.3 and earlier.

ÉlanSC520 Microcontroller Serial Port 1

Low-Speed UART (COM 2, J6, RS-232)

Figure 2-3. Connectors on the Élan™SC520 Microcontroller CDP

ATX-style headers are provided near the IDE connector for the following chassis

connections: reset switch JP19, speaker LS1, power status LED J12, and HD (IDE)

status LED J13.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

2-5

Descriptions

This chapter describes the features and functions of the ÉlanS C520 microcontroller

CDP . For additional information about the ÉlanSC520 microcontroller CDP , refer

to the following sections:

• Appendix A, “Jumper and DIP Switch Settings” for information about jumper

and switch settings.

• Appendix B, “Resource Assignments” for information about chip select,

GPIRQ, GPDMA, PIO on CDP, and UART assignments.

For component layout and locations, refer to Figure 2-2 on page 2-4.

Élan™SC520 Microcontroller

The Élan™SC520 microcontroller is a full-featured microcontroller developed for

the general embedded market. Designed for medium- to high-performance

applications in the telecommunications, data communications, and information

appliance markets, the ÉlanSC520 microcontroller is particularly well suited for

applications requiring high throughput combined with low latency and low cost.

The ÉlanSC520 microcontroller utilizes a high-performance, industry-standard,

33-MHz, 32-bit PCI bus for h igh-bandwid th I/O peripher als. The micro controll er

also contains a simple 8- and 16-bit general-purpose (GP) bus for a glueless

connection to low-bandwidth peripherals. The GP bus supports most legacy ISA

peripherals.

2-6

The ÉlanSC520 microcontroller utilizes the industry-standard x86 architecture

instruction set that enables compatibility across a variety of performance levels

from the low-end 16-bit Am186 process or s to the high -end AMD-K6E™ family

processors. Software written for the x86 architecture family is compatible with the

ÉlanSC520 mi crocontrolle r.

With the AMDebug technology, the ÉlanSC520 microcontroller provides a fullfeatured, high-performance in-circuit emulation capability that enables you to test

and debug your software earlier in the design cycle.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

In addition to these features, the ÉlanSC520 microco ntrol le r pro vides a highperformance SDRAM controller, ROM/Flash contr oller, flexible address-mapping

hardware, general-purpose bus interface, clock generation, integrated peripherals,

JTAG boundary scan test interface, and various system test and debug features.

For more information about the ÉlanSC520 microcontroll er, re fer to the

Élan™SC520 Microcontroller Data Sheet, Élan™SC520 Micr ocontr oller User’s

Manual, and the Élan™SC520 Microcontroller Register Set Manual, which are

included in your kit.

10/100BaseT Ethernet Controller

The ÉlanSC520 microcontroller CDP contains the Am79C973 PCnet™-FAST III

Ethernet controller chip. The high-performance 10/100Bas eT Ethernet port enables

the ÉlanSC520 microcontroller CDP to connect to a high-bandwidth LAN.

External magnetics for a built-in transceiver (PHY) are utilized for a full-duplex

implementation with an RJ45 10/100BaseT connector.

The Am79C973 device logically resides on the PCI bus and is wired for full busmastering capability. The PCI address bit 27 is used for the IDSEL

Am79C973 device. The Am79C973 registers can be configu red by either the PCI

configuration space mechanism, or by downl oading the configuration information

from a dedicated serial EEPROM (part U30). A 4K serial EEPROM is used so that

other board-level configuration information can be stored with the Am79C973

device configuration parameters. CodeKit software is provided to read and write

the serial EEPROM so it can be used for a wide variety of applications.

Figure 2-4 shows a block diagram of the 10/100BaseT Ethernet.

pin of the

PCI Bus

PCnet™-FAST III

Am79C973

Figure 2-4. On-Board 10/100 Mbi t/s Eth ernet Controller Block Diagram

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Magnetics

PE-H1081

RJ45

2-7

Super I/O

The ALi Super I/O Chip (Acer Laboratories, Inc., P/N M512x ) provides two 16550

compatible UARTs (serial ports) that operate at baud rates up to 1.15 Mbit/s, one

parallel port, a floppy disk interface, IrDA interface (shared with COM4), and a

keyboard/mouse controll er.

NOTE: The two serial ports (COM3 and COM4) of the Super I/O are not the same

as the two serial ports (COM1 and COM2) of the ÉlanSC520 microcontroller.

The two serial ports facilitate software development and other communications.

External transceivers are needed for the serial ports and IrDA interface. LEDs

indicate TX and RX activity on both serial ports. Both serial ports are routed to

industry-standard DB9 an d RS-232 connecto rs on the ÉlanSC520 microcontroller

CDP and are named as COM3 and COM4.

NOTE: The BIOS included with CDP version 1.4 maps the Super I/O UARTs to

COM3 and COM4. Earlier BIOS versions, used on boards with microcontroller

revisions A0 and A1, disa bled the microcontroller’s UART s and mapped the Super

I/O UARTs to COM1 and COM2 instead.

The EPP-supported parallel port is routed to an industry-standard DB25 connector .

The keyboard and mouse use PS/2 connectors . Table 2- 1 shows the DMA channels

and the IRQs for the Super I/O devices. Figure 2-5 on page 2-9 shows the b lock

diagram of the Super I/O configuration.

2-8

Table 2-1. DMA Channels and IRQs Reserved for Super I/O

Devices DMA Channels Reserved

for Super I/O

FDD DRQ0/DACK0

EPP (Paral l e l Po r t ) DRQ0/DACK

SIO1 — IRQ4

SIO2 — IRQ3

KB (Keyboard) — IRQ1

Mouse — IRQ12

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

0 IRQ7

IRQs Reserved for Super I/O

IRQ6

M512x

Super I/O Chip

IDE Connector

Floppy Disk Connector

Serial Port 1 Connector

Serial Port 2 Connector

Parallel Port Connector

IrDA Transceiver

AT Keyboard Connector

PS/2 Mouse Connector

Xcvr

Figure 2-5. Super I/O Block Diagram

GP bus

Xcvr

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

2-9

PCI Card Slots

Three industry-standard PCI card slots are prov ided to enable you to plug in mo st

PCI-V2.2-compliant peripheral cards to speed up their design process and to reduce

development time for your product. The ÉlanSC520 microc ontroller CDP supports

up to five PCI masters. The PCI card slots are 5V-capable (only).

ISA Card Slots (General-Purpose Bus Slots)

Two industry-standard ISA card slots enable you to plug in a variety of off-theshelf, low-cost ISA peripheral cards to achieve design simplicity and reduced

development time.

Test Interface Port (TIP) Connector

The 60-pin, test interface port (TIP) connector enables you to use the optional

module to develop software and debug hardware. The TIP board contains a rich

set of peripherals used for debugging, diagnostics, evaluation, and reference

design. The TIP board is available through your AMD sales contact.

Logic Analyzer Connector

The logic analyzer connector enables you to use a logic analyzer to debug the

application design. All signals from the ÉlanSC520 microcontroller are connected

to the logic analyzer connectors, except for crystals, CLKPCIOUT (PCI clocks),

and CLKMEMOUT (SDRAM clocks).

AMD supports the Hewlett Packard (HP) and Tektronix logic analyzer connector

without shrouds and the HP connector with shrouds. Both types of connectors

attach to a specific Mictor connector on the ÉlanSC520 microcontroller CDP,

depending on what feature is being tested.

2-10

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

High-Speed UART

The High-Speed UART (port 0, COM1) is embedded in the ÉlanSC520

microcontroller. The High-Speed UART port enables you to communicate at a

speed of up to 1.152 Mbit/s through balanced RS-422A-compliant serial ports with

other serial communication equipment, for a longer distance and faster speed. You

can make the High-Speed UART port pin-compatible with the RS-232 by setting

the external pin strap. For co nnecto r location, refer to Figure 2- 2 on page 2 -4 and

Figure 2-3 on page 2-5.

NOTE: The BIOS included with CDP version 1.4 maps the microcontroller’s

UARTs to COM1 and COM2. Earlier BIOS versions, used on boards with

microcontroller revisions A0 and A1, disabled the microcontroller’s UARTs and

mapped the Super I/O UARTs to COM1 and COM2 instead.

Low-Speed UART

The low-speed UART (port 1, COM2) is embedded in the ÉlanSC520

microcontroller. The low-speed UART port enables you to communicate at a lower

speed of up to 460 Kbit/s through a single-ended RS-232-compliant serial port.

The low-speed UART is capable of high-speed, like the High-Speed UART port,

but is restricted through a low-speed transceiver th at limits this High-Speed UART

channel to a lower speed for the purpose of communicating with specific serial

communication equipment.

NOTE: The BIOS included with CDP version 1.4 maps the microcontroller’s

UARTs to COM1 and COM2. Earlier BIOS ve rsions, used with microcontr o ller

revisions A0 and A1, disa bled the microcontroller’s UART s and mapped the Super

I/O UARTs to COM1 and COM2 instead.

Hexadecimal LED Display

The hexadecimal LED display is a single-byte (two digits) hexadecimal LED

address at 80h and 680h. The hexadecimal LED display (error code display)

provides indications for CPU status as well as debugging status , which imp roves

the debugging process.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

2-11

Memory

The memory on the ÉlanSC520 microcontroller CDP consists of SDRAM and

Flash memory.

SDRAM

The ÉlanSC520 microcontroller CDP can have a maximum of four rows on two

DIMMs that connect into two industry-standard, 168-pin DIMM sockets. The

DIMMs are 64-bit wide main memory, using 16/64-Mbit x 8 SDRAM chips. Note

that the SDRAM DIMMs used are 64-bits wide only because they are configured

as two rows each. Error Correction Code (ECC) is not supported on the full

SDRAM DIMMs; the ECC supports only half of the DIMM capacity. Figure 2-6

on page 2-13 shows the SDRAM configuration diagram.

The two DIMM sockets are wired to enable you to install a co mbination of singleor double-sided DIMMs. This configuration yields a total of four rows of SDRAM

memory , using th e two DIMM so ckets. You can adjust the timing of the SDRAM

interface by using the registers in the ÉlanSC520 microcontroller.

Table 2-2 shows the SDRAM signals and the descriptions.

Table 2-2. SDRAM Signals

SDRAM Signal Description

2-12

CS0–CS3 Chip select signal for each row on DIMM

MA0–MA12 Memory address signals

MD0–MD31 Memory data signals

BA0–BA1 Memory bank select signal for each memory chip

DQM0–DQM3 Data byte masks

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

CS0

CS2

2Mx8x4 2Mx8x4 2Mx8x4

2Mx8x4

2Mx8x4 2Mx8x4 2Mx8x4

2Mx8x4

Socket 1

(J2)

CS1

CS3

MA12–MA0

MD31–MD0

BA1–RA0

DQM3–DQM0

2Mx8x4

2Mx8x4

Figure 2-6. SDRAM Configuration Diagram

2Mx8x4 2Mx8x4 2Mx8x4

2Mx8x4 2Mx8x4 2Mx8x4

Socket 2

(J3)

SDRAM Sockets

DRAM Bus

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

2-13

Flash Memory

The on-board Flash memory uses the AMD Am29LV017B and consists of

following configuration:

• Tw o 8-Mbyte banks in a 32-bit data width consisting of eight 2-Mbit x 8 devices

• The Flash memory is used for the BIOS and/or Ex ecute-I n-Place mem ory that

interfaces to the ÉlanSC520 microcontroller only through the SDRAM data bus

MD31–MD0 or the residential Flash disk (RFD).

• An additional two banks of Flash/ROM is optionally available on a 32-Mbyte

daughter module that can be configured to interface to eith er the 32-bit SDRAM

MD bus (with 8/16/32-bit data width (x32 is only available when data bus is

selected on SDRAM MD31–MD0 and selected by BOOTCS

ROMCS2

)) or with the 16-bit GP bus (with 8- or 16-bit selectable).

, ROMCS1, or

BOOTCS

assigned to the 16-Mbytes on-board Flash bank and/or the 32-Mbyte Flash

daughter card. Flash ROMs are config ured as 32-bit wide on both the on-board and

daughter m odules. If the Fla sh memory is set as 8-bit or 16-bit data width, the

higher bytes are not accessible on the ÉlanSC520 microcontroller CDP. The

ÉlanSC520 microcontroller CDP demonstrates the ability of only sizing the data

width for ROM access. The user can configure it in any bus size to access the entire

ROM space by rearranging the address b us for BOOTCS

The Flash ROM x8 DIP is connected on the GP bus and can be selected only by

BOOTCS

MD31–MD0, and it can be selected by BOOTCS

The Flash ROM daughter module contains configuration jumpers. Users can

configure the module as x8, x 16, x32 data width on the GP bus (GPD15–GPD0)

or the SDRAM Bus (MD31–MD0).

Figure 2-7 on page 2-15 shows the Flash memory configurat ion sup porte d by the

ÉlanSC520 mi crocontrolle r CDP.

Figure 2-8 on page 2-16 shows a Flash memory configuration block diagram.

Table 2-3 on page 2-16 shows the signals, inputs, and outputs for each type of

memory.

can be assigned to each Flash bank. ROMCS1 and ROMCS2 can be

, ROMCS1, and ROMCS2.

. The Flash ROM x32 onboard memory is connected only on SDRAM

, ROMCS1, and ROMCS2.

2-14

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

0x3FFFFFF

0x2000000

0x1FFFFFF

0x00000000x0000000

On-Board DIP

On-Board Flash - BOOTCS

0x3FFFFFF 0x3FFFFFF

0x1000000

0x0FFFFFF

0x0000200

0x00001FF

On-Board TSOP-II

(2Mx8 x 8)

0x0000000

Flash Daughter Board

(2Mx16 x 8)

(Max 64MB)

Expand Flash Module - ROMCS2On-Bo a rd Flash - R OMCS1

Figure 2-7. Flash Memory Configuration for Élan™SC520 Microcontroller CDP

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

2-15

512kx8 DIP/5V

GP bus

1Mx16 TSO P /3 V

1Mx16 TSO P /3 V

1Mx16 TSO P /3 V

1Mx16 TSO P /3 V

Buffer x32 Buffer x32

Figure 2-8. Flash Memory Configuration Block Diagram

Table 2-3. Chip Select (CS

SDRAM SCS3–SCS0 3–0 —

1Mx16 TSOP/3V

1Mx16 TSOP/3V

1Mx16 TSOP/3V

1Mx16 TSOP/3V

Signal

Name

) Decoder Address Space

Number of

Inputs Associated With

Outputs

Exp Flash

Connector

DRAM Bus

2-16

Flash/ROM BOOTCS

1GPA25–GPA0, BOOTCS,

CFG2–CFG0

ROMCS1

1GPA25–GPA0, ROMCS1,

CFG2–CFG0

ROMCS2

1GPA25–GPA0, ROMCS2,

CFG2–CFG0

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

AMDebug™ Tool

This in-system test feature is a standard JT AG-compliant test interface. The J T AG

utilizes two types of 2-mm connectors—one 20-pin full version (POD1) and one

12-pin simple version (POD2). Both connectors are used for the AMDebug tool.

In-Circuit Emulator (ICE) Connector

The in-circuit emulator (ICE) connector (J10) is used to speed up the design

development of application software. The ICE connector is a 34-pin, 1/10-inch

box header and is supported by PROM ICE.

Synchronous Serial Interface

The microcontroller’s synchronous serial interface (SSI) is populated with a 6-pin,

1/10-inch center SIP connector (JP17) that can communicate with an external

device.

In addition, two on-board EEPROM devices are populated on the SSI: one

synchronous peripheral interface (SPI), an d one MICROWIRE™ peripheral. These

EEPROM devices contain no relevant data when the CDP is shipped. They are

provided to demonstrate the use of the SSI port with these device types. They can

be freely written to or read using the SSI CodeKit software included with your kit,

or downloaded from www.amd.com.

Integrated Drive Electronics (IDE)

One IDE channel supports two IDE devices: one master and one slave. Usually,

the bootable device is set on the master and all other devices reside on the slave.

The IDE uses the GP-bus.

Header J13 is provided near the IDE connecto r to allow connection of an external

drive status LED.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

2-17

Optional Daughter Modules

The ÉlanSC520 microcontroller CDP can interface with two optional daughter

modules: the 32-Mbyte Flash memory module and the test interface port (TIP)

module. The 32-Mbyte Flash memory module provides additional memory for

developing and testing applications. The TIP provides an additional resource for

testing and debugging app lications, diagnostics , and hardware. The TIP modul e is

available through your AMD sales contact.

2-18

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Appendix A

Jumper and DIP Switch Settings

Each section in this appendix provides information about settings and operating

state descriptions for the respective components. For locations of the various

jumpers and DIP switches, refer to Figure 2-2 on page 2-4.

Jumper Settings

The following information provides the jumper settings and pin locations for the

various jumpers.

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

A-1

Jumper JP2

The following settings indicate the possible configurations for jumper JP 2.

Figure A-1 shows the jumper pins and the default setting for jumper JP2.

• To set to On or connect to chassis power supply, jumper pins 1 and 2.

• When using the on-board power supply, pins 1 and 2 are not jumpered.

NOTE: Jumper JP2 is not meant to be used as an external power switch connector .

If it is used to connect to an extern al switch, an on/of f toggle s witch must be used

(not the momentary-contact type typically used in an ATX chassis).

To PS-ON on JP1 (ATX Power)

1

2

To Switch S2

A-2

Figure A-1. Jumper JP2 Default Setting

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Jumper JP3

The following settings indicate the possible configurations for jumper JP3.

Figure A-2 shows the jumper pins and the default settin g fo r jum per JP3.

NOTE: When a row of j umper pins (ei ther pins 1 an d 2, pins 3 and 4, or pins 5

and 6) are jumpered on JP3, jumper pins on the same row of JP4 and JP5 cannot

be jumpered. For example, if pins 1 and 2 of JP3 are jump ered, th en pins 1 an d 2

of JP4 and JP5 cannot be jumpered. Only one pair (row) of jumper pins can be

jumpered on JP3.

• To boot from the on-board Flash bank 0, jumper pins 1 and 2.

• To boot from the on-board Flash bank 1, jumper pins 3 and 4.

• To boot from the expansion Flash board, jumper pins 5 and 6.

• To boot from the DIP Flash memory, jumper pins 7 and 8 (shown in Figure A-2).

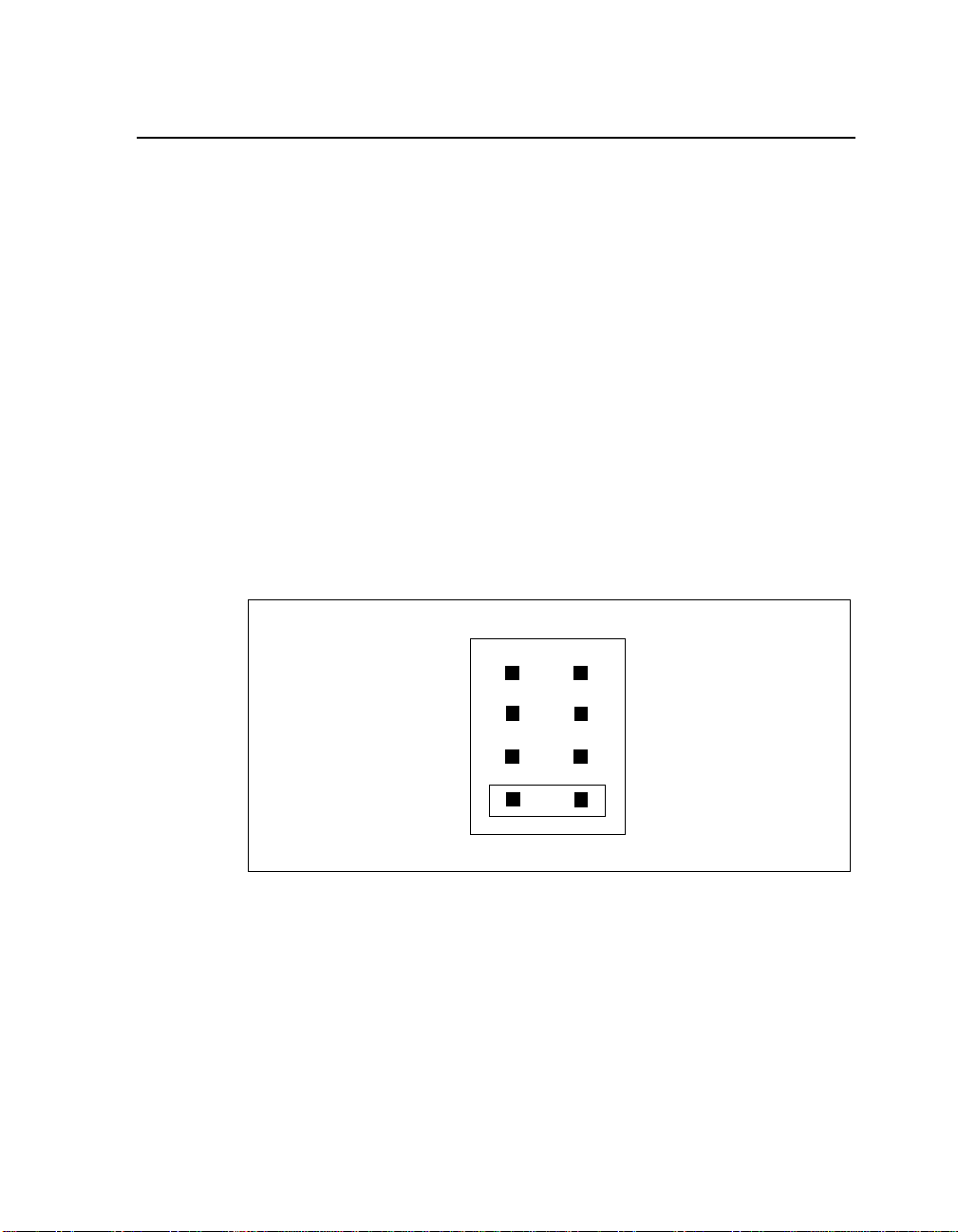

1

3

5

7

Figure A-2. Jumper JP3 Default Setting

Élan™SC520 Microcontroller Customer Development Platform User’s M a nual

2

4

6

8

A-3

Jumper JP4

The following settings indicate the possible configurations for jumper JP 4.

Figure A-3 shows the jumper pins and the default setting for jum per JP4.

NOTE: When a row of jumper pins (ei ther pins 1 and 2, pins 3 and 4, or pins 5

and 6) are jumpered on JP4, jumper pins on the same row of JP3 and JP5 cannot

be jumpered. For example, if pins 1 and 2 of JP4 are jump ered, th en pins 1 an d 2

of JP3 and JP5 cannot be jumpered.

• To s elect ROMCS1

2 (shown in Figure A-3).

• To select ROMCS1

• To select ROMCS1

Figure A-3. Jumper JP4 Default Setting

for accessing the on-board Flash ba nk 0, jumper pins 1 and

for accessing the on-board Flash bank 1, jumper pins 3 and 4.

for accessing the expansion Flash b oard, jumper pins 5 and 6.

1

3

5

2

4

6

A-4

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Jumper JP5

The following settings indicate the possible configurations for jumper JP5.

Figure A-4 shows the jumper pins and the default settin g fo r jum per JP5.

NOTE: When a row of j umper pins (ei ther pins 1 an d 2, pins 3 and 4, or pins 5

and 6) are jumpered on JP5, jumper pins on the same row of JP3 and JP4 cannot

be jumpered. For example, if pins 1 and 2 of JP5 are jump ered, th en pins 1 an d 2

of JP3 and JP4 cannot be jumpered.

• To select ROMCS2

• To select ROMCS2

4 (shown in Figure A-4).

• To select ROMCS2

Figure A-4. Jumper JP5 Default Setting

for accessing the on-board Flash bank 0, jumper pins 1 and 2.

for accessing the on-board Flash ba nk 1, jumper pins 3 and

for accessing the expansion Flash b oard, jumper pins 5 and 6.

1

3

5

2

4

6

Élan™SC520 Microcontroller Customer Development Platform User’s M a nual

A-5

ISA DMA Selection, Jumpers JP6–JP9

The ÉlanSC520 Microcontroller supports two DMA channels via its GPDRQ0,

GPDACK0

the ISA interface provides paths for seven DMA channels (0–3 and 5–7), which

are shared by attached devices. Jum pers JP6, JP7, JP8, and JP9 allow you to route

any one ISA-bus DMA channel to either of the microcontroller’s two DMA

channels. Figure A-5 shows the pin numbering for these jumpers.

, GPDRQ1, and GPDACK1 signals. The ISA-compatible signaling on

13 11 9 7 5 3 1

1412108642

Figure A-5. Jumper JP6, JP7, JP8, and JP9 Pin Numbering

A-6

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Jumper JP6

Jumper JP6 is used to route one ISA-compatible DRQn channel from the PC/

104-Plus connector to the microcontroller’s GPDRQ0 input. The following settings

indicate the possible configurations for jumper JP6.

• To route ISA DRQ0 to microcontroller GPDRQ0, jumper pins 1 and 2.

• To route ISA DRQ1 to microcontroller GPDRQ0, jumper pins 3 and 4.

• To route ISA DRQ2 to microcontroller GPDRQ0, jumper pins 5 and 6.

• To route ISA DRQ3 to microcontroller GPDRQ0, jumper pins 7 and 8.

• To route ISA DRQ5 to microcontroller GPDRQ0, jumper pins 9 and 10.

• To route ISA DRQ6 to microcontroller GPDRQ0, jumper pins 11 and 12.

• To route ISA DRQ7 to microcontroller GPDRQ0, jumper pins 13 and 14.

Jumper JP7 must be used to route the corresponding DACKx

selected channel number must match, for example DRQ0 and DACK0

signal (i.e., the

). Also, the

channel number selected must be different from the channel selected by JP8 and

JP9 (if any). Figure A-6 shows the default signal routing for jumper JP6, with ISA

DRQ5 routed to GPDRQ0.

ISADACK1

ISADACK0

JP9

JP7

DACK7

DACK6

DACK5

DACK3

DACK2

DACK1

DACK0

ISA Connectors

DRQ7

DRQ6

DRQ5

DRQ3

DRQ2

DRQ1

DRQ0

JP8

JP6

ISADRQ1

ISADRQ0

Élan™SC520

Microcontroller

GPDRQ0

GPDRQ1

GPDACK0

GPDACK1

Figure A-6. Jumper JP6 Default Routing

Élan™SC520 Microcontroller Customer Development Platform User’s M a nual

A-7

Jumper JP7

Jumper JP7 is used to route one ISA-compatible DACKn channel from the PC/

104-Plus connector to the microcontroller’s GPDACK0

settings indicate the possible configurations for jumper JP7.

• To route ISA DACK0 to microcontroller GPDACK0, jumper pins 1 and 2.

input. The following

• To route ISA DACK1

• To route ISA DACK2

• To route ISA DACK3

• To route ISA DACK5

• To route ISA DACK6

• To route ISA DACK7

to microcontroller GPDACK0, jumper pins 3 and 4.

to microcontroller GPDACK0, jumper pins 5 and 6.

to microcontroller GPDACK0, jumper pins 7 and 8.

to microcontroller GPDACK0, jumper pins 9 and 10.

to microcontroller GPDACK0, jumper pins 11 and 12.

to microcontroller GPDACK0, jumper pins 13 and 14.

Jumper JP6 must be used to ro ute the corresponding DRQx signal (i.e., the selected

channel number must match, for example DRQ0 and DACK0

). Also, the channel

number selected must be different from the channel selected by JP8 and JP9 (if

any). Figure A-7 shows the default signal routing for jumper JP7, with ISA DACK5

routed to GPDACK0

JP9

JP7

DACK7

DACK6

DACK5

DACK3

DACK2

DACK1

DACK0

.

DRQ7

DRQ6

DRQ5

DRQ3

DRQ2

DRQ1

DRQ0

JP8

JP6

ISADACK1

ISADACK0

ISADRQ1

ISADRQ0

A-8

GPDRQ0

GPDRQ1

GPDACK0

GPDACK1

ISA Connectors

Élan™SC520

Microcontroller

Figure A-7. Jumper JP7 Default Routing

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Jumper JP8

Jumper JP8 is used to route one ISA-compatible DRQn channel from the PC/

104-Plus connector to the microcontroller’s GPDRQ1 input. The following settings

indicate the possible configurations for jumper JP8.

• To route ISA DRQ0 to microcontroller GPDRQ1, jumper pins 1 and 2.

• To route ISA DRQ1 to microcontroller GPDRQ1, jumper pins 3 and 4.

• To route ISA DRQ2 to microcontroller GPDRQ1, jumper pins 5 and 6.

• To route ISA DRQ3 to microcontroller GPDRQ1, jumper pins 7 and 8.

• To route ISA DRQ5 to microcontroller GPDRQ1, jumper pins 9 and 10.

• To route ISA DRQ6 to microcontroller GPDRQ1, jumper pins 11 and 12.

• To route ISA DRQ7 to microcontroller GPDRQ1, jumper pins 13 and 14.

Jumper JP9 must be used to route the corresponding DACKx

selected channel number must match, for example DRQ0 and DACK0

signal (i.e., the

). Also, the

channel number selected must be different from the channel selected by JP6 and

JP7 (if any). Figure A-8 shows the default signal routing for jumper JP8, with ISA

DRQ6 routed to GPDRQ1.

ISADACK1

ISADACK0

JP9

JP7

DACK7

DACK6

DACK5

DACK3

ISA Connectors

DACK2

DACK1

DACK0

DRQ7

DRQ6

DRQ5

DRQ3

DRQ2

DRQ1

DRQ0

JP8

JP6

ISADRQ1

ISADRQ0

Élan™SC520

Microcontroller

GPDRQ0

GPDRQ1

GPDACK0

GPDACK1

Figure A-8. Jumper JP8 Default Routing

Élan™SC520 Microcontroller Customer Development Platform User’s M a nual

A-9

Jumper JP9

Jumper JP9 is used to route one ISA-compatible DACKn channel from the PC/

104-Plus connector to the microcontroller’s GPDACK1

settings indicate the possible configurations for jumper JP9.

• To route ISA DACK0 to microcontroller GPDACK1, jumper pins 1 and 2.

input. The following

• To route ISA DACK1

• To route ISA DACK2

• To route ISA DACK3

• To route ISA DACK5

• To route ISA DACK6

• To route ISA DACK7

to microcontroller GPDACK1, jumper pins 3 and 4.

to microcontroller GPDACK1, jumper pins 5 and 6.

to microcontroller GPDACK1, jumper pins 7 and 8.

to microcontroller GPDACK1, jumper pins 9 and 10.

to microcontroller GPDACK1, jumper pins 11 and 12.

to microcontroller GPDACK0, jumper pins 13 and 14.

Jumper JP8 must be used to ro ute the corresponding DRQx signal (i.e., the selected

channel number must match, for example DRQ0 and DACK0

). Also, the channel

number selected must be different from the channel selected by JP6 and JP7 (if

any). Figure A-9 shows the default signal routing for jumper JP9, with ISA DACK6

routed to GPDACK1

JP9

JP7

DACK7

DACK6

DACK5

DACK3

DACK2

DACK1

DACK0

.

DRQ7

DRQ6

DRQ5

DRQ3

DRQ2

DRQ1

DRQ0

JP8

JP6

ISADACK1

ISADACK0

ISADRQ1

ISADRQ0

A-10

GPDRQ0

GPDRQ1

GPDACK0

GPDACK1

ISA Connectors

Élan™SC520

Microcontroller

Figure A-9. Jumper JP9 Default Routing

Élan™SC520 Microcontroller Customer Development Platform User’s Manual

Jumpers JP10, JP11, JP12, JP13, and JP14

Jumpers JP10, JP1 1, JP 12, JP13, an d JP14 are used for REQn/GNTn tests and ar e

used for AMD internal use only.

Élan™SC520 Microcontroller Customer Development Platform User’s M a nual

A-11

Jumper JP18

Select the boot device either from DIP memory or from PROM ICE when JP3 is