Page 1

AMD RS880 Databook

Device Specification for the RS880

Technical Reference Manual

Rev 1.40

P/N: 46112_rs880_ds_pub_1.40

© 2013 Advanced Micro Devices Inc

Page 2

Please note that in this databook, references to "DVI" and "HDMI" may refer to: (1) the function of the integrated DVI/HDMI interface described in details in section

2.3 and 3.8, as well as in other sections; or (2) the capability of the TMDS interface, multiplexed on the PCI-E external graphics interface, to enable DVI or HDMI

through passive enabling circuitries. Any statement in this databook on any DVI or HDMI-related functionality must be understood to apply to (1), (2), or both, according

to the immediate context of the reference.

USE OF THIS PRODUCT IN ANY MANNER THAT COMPLIES WITH THE MPEG-2 STANDARD IS EXPRESSLY PROHIBITED WITHOUT A LICENSE

UNDER APPLICABLE PATENTS IN THE MPEG-2 PATENT PORTFOLIO, WHICH LICENSE IS AVAILABLE FROM MPEG LA, L.L.C., 6312 S. FIDDLERS

GREEN CIRCLE, SUITE 400E, GREENWOOD VILLAGE, COLORADO 80111.

Trademarks

AMD, the AMD Arrow, ATI, the ATI logo, 3Dc+, AMD Athlon, AMD Phenom, AMD OverDrive, AMD PowerNow!, Avivo, Cool’n’Quiet, HyperMemory, PowerPlay,

PowerShift, AMD PowerXpress, AMD Radeon, SurroundView, Vari-Bright, CrossFire, and combinati ons thereof are trademarks of Advanced Micro Devices, Inc.

DisplayPort is a trademark of the Video Electronics Standards Assoctation.

HyperTransport is a trademark of the HyperTransport Technology Consortium.

Microsoft, Windows, Windows Vista, Windows 7, DirectDraw, and DirectX are registered trademarks of Microsoft Corporation.

OpenGL is a registered trademark of Silicon Graphics Internal.

PCI Express and PCIe are registered trademarks of PCI-SIG.

WinBench is a registered trademark of Ziff Davis, Inc.

Linux is a registered trademark of Linus Torvalds in the U.S. and other countries.

Other product names used in this publication are for identification purposes only and may be trademarks of their respective companies.

Disclaimer

The contents of this document are provided in connection with Advanced Micro Devices, Inc. ("AMD") products. AMD makes no representations or warranties with

respect to the accuracy or completeness of the contents of this publication and reserves the right to make changes to specifications and product descriptions at any time

without notice. No license, whether express, implied, arising by estoppel, or otherwise, to any intellectual property rights are granted by this publication. Except as set

forth in AMD's Standard Terms and Conditions of Sale, AMD assumes no liability whatsoever, and disclaims any express or implied warranty, relating to its products

including, but not limited to, the implied warranty of merchantability, fitness for a particular purpose, or infringement of any intellectual property right.

AMD's products are not designed, intended, authorized or warranted for use as components in systems intended for surgical implant into the body, or in other applications

intended to support or sustain life, or in any other application in which the failure of AMD's product could create a situation where personal injury, death, or severe

property or environmental damage may occur. AMD reserves the right to discontinue or make changes to its products at any time without notice.

© 2013 Advanced Micro Devices, Inc. All rights reserved.

Page 3

Table of Contents

Chapter 1: Overview

1.1 Introducing the RS880 ........................................................................................................................................................1-1

1.2 RS880 Features ...................................................................................................................................................................1-2

1.2.1 CPU HyperTransport™ Interface.........................................................................................................................1-2

1.2.2 Memory Interface.................................................................................................................................................1-2

1.2.3 AMD HyperMemory™........................................................................................................................................1-2

1.2.4 PCI Express® Interface........................................................................................................................................1-2

1.2.5 A-Link Express II Interface..................................................................................................................................1-3

1.2.6 2D Acceleration Features.....................................................................................................................................1-4

1.2.7 3D Acceleration Features.....................................................................................................................................1-4

1.2.8 Motion Video Acceleration Features....................................................................................................................1-5

1.2.9 Multiple Display Features ....................................................................................................................................1-5

1.2.10 DVI/HDMI™ .......................................................................................................................................................1-7

1.2.11 DisplayPort™ Interface .......................................................................................................................................1-7

1.2.12 Integrated HD Audio Controller and Codec.........................................................................................................1-8

1.2.13 System Clocks ......................................................................................................................................................1-8

1.2.14 Power Management Features ...............................................................................................................................1-8

1.2.15 PC Design Guide Compliance..............................................................................................................................1-8

1.2.16 Test Capability Features.......................................................................................................................................1-8

1.2.17 Packaging .............................................................................................................................................................1-9

1.3 Software Features................................................................................................................................................................1-9

1.4 Branding Diagrams .............................................................................................................................................................1-9

1.5 Graphics Device ID and Graphics Engine Clock Speed...................................................................................................1-10

1.6 Conventions and Notations ...............................................................................................................................................1-10

1.6.1 Pin Names...........................................................................................................................................................1-10

1.6.2 Pin Types............................................................................................................................................................1-10

1.6.3 Numeric Representation.....................................................................................................................................1-11

1.6.4 Register Field......................................................................................................................................................1-11

1.6.5 Hyperlinks ..........................................................................................................................................................1-11

1.6.6 Acronyms and Abbreviations.............................................................................................................................1-11

Chapter 2: Functional Descriptions

2.1 Host Interface......................................................................................................................................................................2-1

2.2 Side-Port Memory Interface................................................................................................................................................2-3

2.2.1 DDR2 Memory Interface......................................................................................................................................2-3

2.2.2 DDR3 Memory Interface......................................................................................................................................2-5

2.3 DVI/HDMI™......................................................................................................................................................................2-6

2.3.1 DVI/HDMI™ Data Transmission Order and Signal Mapping ............................................................................2-6

2.3.2 Support for HDMI™ Packet Types......................................................................................................................2-9

2.4 VGA DAC Characteristics................................................................................................................................................2-10

2.5 Clock Generation ..............................................................................................................................................................2-10

Chapter 3: Pin Descriptions and Strap Options

3.1 Pin Assignment Top View..................................................................................................................................................3-2

3.1.1 RS880 Pin Assignment Top View........................................................................................................................3-2

3.2 Interface Block Diagram.....................................................................................................................................................3-4

3.3 CPU HyperTransport™ Interface .......................................................................................................................................3-5

© 2013 Advanced Micro Devices, Inc. AMD RS880 Databook 1.40

Proprietary Table of Contents-1

Page 4

Table of Contents

3.4 Side-port Memory Interface............................................................................................................................................... 3-5

3.5 PCI Express® Interfaces .................................................................................................................................................... 3-6

3.5.1 1 x 16 Lane Interface for External Graphics ....................................................................................................... 3-6

3.5.2 A-Link Express II Interface for Southbridge....................................................................................................... 3-6

3.5.3 6 x 1 Lane Interface for General Purpose External Devices .............................................................................. 3-6

3.5.4 Miscellaneous PCI Express® Signals ................................................................................................................. 3-6

3.6 Clock Interface................................................................................................................................................................... 3-7

3.7 CRT Interface..................................................................................................................................................................... 3-7

3.8 Integrated DVI/HDMI™ Interface..................................................................................................................................... 3-7

3.9 TMDS Interface Multiplexed on the PCI Express® Graphics Lanes................................................................................ 3-8

3.10 DisplayPort™ Interface.................................................................................................................................................. 3-10

3.11 Power Management Pins................................................................................................................................................3-11

3.12 Miscellaneous Pins..........................................................................................................................................................3-11

3.13 Power Pins...................................................................................................................................................................... 3-12

3.14 Ground Pins.................................................................................................................................................................... 3-13

3.15 Strapping Options ........................................................................................................................................................... 3-14

Chapter 4: Timing Specifications

4.1 HyperTransport™ Bus Timing .......................................................................................................................................... 4-1

4.2 HyperTransport™ Reference Clock Timing Parameters ................................................................................................... 4-1

4.3 PCI Express® Differential Clock AC Specifications......................................................................................................... 4-2

4.4 Timing Requirements for REFCLK_P Used as OSCIN (14.3181818MHz)..................................................................... 4-2

4.5 Side-port Memory Timing for DDR2 Mode...................................................................................................................... 4-2

4.5.1 Read Cycle DQ/DQS Delay ................................................................................................................................4-2

4.5.2 Write Cycle DQ/DQS Delay ............................................................................................................................... 4-3

4.6 Power Rail Power-up Sequence......................................................................................................................................... 4-3

Chapter 5: Electrical Characteristics and Physical Data

5.1 Electrical Characteristics.................................................................................................................................................... 5-1

5.1.1 Maximum and Minimum Ratings........................................................................................................................ 5-1

5.1.2 DC Characteristics............................................................................................................................................... 5-2

5.2 RS880 Thermal Characteristics.......................................................................................................................................... 5-6

5.2.1 RS880 Thermal Limits ........................................................................................................................................ 5-6

5.2.2 Thermal Diode Characteristics............................................................................................................................ 5-7

5.3 Package Information .......................................................................................................................................................... 5-8

5.3.1 Physical Dimensions............................................................................................................................................ 5-8

5.3.2 Pressure Specification.......................................................................................................................................... 5-9

5.3.3 Board Solder Reflow Process Recommendations ............................................................................................. 5-10

Chapter 6: Power Management and ACPI

6.1 ACPI Power Management Implementation ....................................................................................................................... 6-1

6.2 Power Management for the Graphics Controller ............................................................................................................... 6-2

6.2.1 PCI Function Power States.................................................................................................................................. 6-2

6.2.2 PCI Power Management Interface....................................................................................................................... 6-2

6.2.3 Capabilities List Data Structure in PCI Configuration Space ............................................................................. 6-2

6.2.4 Register Block Definition.................................................................................................................................... 6-3

6.2.5 Capability Identifier: CAP_ID (Offset = 0)......................................................................................................... 6-4

6.2.6 Next Item Pointer (Offset = 1)............................................................................................................................. 6-5

6.2.7 PMC - Power Management Capabilities (Offset = 2) ......................................................................................... 6-6

AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

Table of Contents-2 Proprietary

Page 5

Table of Contents

Chapter 7: Testability

7.1 Test Capability Features......................................................................................................................................................7-1

7.2 Test Interface.......................................................................................................................................................................7-1

7.3 XOR Test ............................................................................................................................................................................7-1

7.3.1 Description of a Generic XOR Tree.....................................................................................................................7-1

7.3.2 Description of the RS880 XOR Tree....................................................................................................................7-2

7.3.3 XOR Tree Activation ...........................................................................................................................................7-2

7.3.4 XOR Tree for the RS880......................................................................................................................................7-2

7.4 VOH/VOL Test...................................................................................................................................................................7-4

7.4.1 Description of a Generic VOH/VOL Tree ...........................................................................................................7-4

7.4.2 VOH/VOL Tree Activation..................................................................................................................................7-5

7.4.3 VOH/VOL Pin List...............................................................................................................................................7-6

Appendix A: Pin Listings

A.1 RS880 Pin List Sorted by Ball Reference..........................................................................................................................1-2

A.2 RS880 Pin List Sorted by Pin Name..................................................................................................................................1-7

Appendix B: Revision History

© 2013 Advanced Micro Devices, Inc. AMD RS880 Databook 1.40

Proprietary Table of Contents-3

Page 6

Table of Contents

AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

Table of Contents-4 Proprietary

Page 7

List of Figures

Figure 1-1: Possible Configurations for the x16 PCIe® Graphics Interface ................................................................................. 1-3

Figure 1-2: RS880 Multiple Display Options ................................................................................................................................1-6

Figure 1-3: RS880 ASIC A11 Production Branding ....................................................................................................................1-10

Figure 2-1: RS880 Internal Block Diagram ................................................................................................................................... 2-1

Figure 2-2: Host Interface Block Diagram ..................................................................................................................................... 2-2

Figure 2-3: RS880 Host Bus Interface Signals ..............................................................................................................................2-3

Figure 2-4: RS880 Side-Port Memory Interface ............................................................................................................................ 2-4

Figure 2-5: Data Transmission Ordering for the Integrated DVI/HDMI™ and TMDS Interfaces ............................................... 2-6

Figure 3-1: RS880 Pin Assignment Top View (Left) .................................................................................................................... 3-2

Figure 3-2: RS880 Pin Assignment Top View (Right) .................................................................................................................. 3-3

Figure 3-3: RS880 Interface Block Diagram .................................................................................................................................3-4

Figure 4-1: RS880 Power Rail Power-up Sequence ......................................................................................................................4-3

Figure 5-1: DC Characteristics of the Integrated DVI/HDMI™ and the TMDS Interfaces .......................................................... 5-5

Figure 5-2: RS880 528-Pin FCBGA Package Outline ................................................................................................................... 5-8

Figure 5-3: RS880 Ball Arrangement (Bottom View) ................................................................................................................... 5-9

Figure 5-4: Recommended Stencil Opening Sizes for Solder Paste Pads on PCB ...................................................................... 5-10

Figure 5-5: RoHS/Lead-Free Solder (SAC305/405 Tin-Silver-Copper) Reflow Profile ............................................................ 5 -11

Figure 6-1: Linked List for Capabilities ......................................................................................................................................... 6-5

Figure 7-1: Example of a Generic XOR Tree ................................................................................................................................7-2

Figure 7-2: Sample of a Generic VOH/VOL Tree ......................................................................................................................... 7-5

© 2013 Advanced Micro Devices, Inc. AMD RS880 Databook 1.40

Proprietary List of Figures-1

Page 8

List of Figures

AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

List of Figures-2 Proprietary

Page 9

List of Tables

Table 1-1: Possible Configurations for the PCIe® General Purpose Links ....................................................................................1-3

Table 1-2: Graphics Device ID and Graphics Engine Clock Speed .............................................................................................1-10

Table 1-3: Pin Type Codes ............................................................................................................................................................1-10

Table 1-4: Acronyms and Abbreviations ......................................................................................................................................1-11

Table 2-1: Supported DDR2 Components ......................................................................................................................................2-4

Table 2-2: DDR2 Memory Row and Column Addressing ..............................................................................................................2-4

Table 2-3: Supported DDR3 Components ......................................................................................................................................2-5

Table 2-4: DDR3 Memory Row and Column Addressing ..............................................................................................................2-5

Table 2-5: Single Link Signal Mapping for DVI/HDMI™ ...........................................................................................................2-7

Table 2-6: Dual-Link Signal Mapping for DVI ..............................................................................................................................2-8

Table 2-7: Support for HDMI™ Packet Type .................................................................................................................................2-9

Table 2-8: VGA DAC Characteristics ..........................................................................................................................................2-10

Table 3-1: CPU HyperTransport™ Interface ..................................................................................................................................3-5

Table 3-2: Side-Port Memory Interface ..........................................................................................................................................3-5

Table 3-3: 1 x 16 Lane PCI Express® Interface for External Graphics ..........................................................................................3-6

Table 3-4: 1 x 4 Lane A-Link Express II Interface for Southbridge ...............................................................................................3-6

Table 3-5: 6 x 1 Lane PCI Express® Interface for General Purpose External Devices ..................................................................3-6

Table 3-6: PCI Express® Interface for Miscellaneous PCI Express® Signals ...............................................................................3-6

Table 3-7: Clock Interface ...............................................................................................................................................................3-7

Table 3-8: CRT Interface ................................................................................................................................................................3-7

Table 3-9: Integrated DVI/HDMI™ Interface ................................................................................................................................3-7

Table 3-10: TMDS Interface Multiplexed on the PCI Express® Graphics Interface (Dual-Link DVI) .........................................3-8

Table 3-11: TMDS Interface Multiplexed on the PCI Express® Graphics Interface (HDMI™ on Lane 0-3) ..............................3-9

Table 3-12: TMDS Interface Multiplexed on the PCI Express® Graphics Interface (HDMI™ on Lane 4-7) ..............................3-9

Table 3-13: Miscellaneous TMDS Interface Signals ......................................................................................................................3-9

Table 3-14: DisplayPort™ Interface Multiplexed on the PCI Express® Graphics Interface .......................................................3 -10

Table 3-15: Miscellaneous DisplayPort™ Signals .......................................................................................................................3-10

Table 3-16: Power Management Pins ...........................................................................................................................................3-11

Table 3-17: Miscellaneous Pins ....................................................................................................................................................3-11

Table 3-18: Power Pins .................................................................................................................................................................3-12

Table 3-19: Ground Pins ...............................................................................................................................................................3-13

Table 3-20: Strap Definitions for the RS880 ................................................................................................................................3-14

Table 4-1: Timing Requirements for HyperTransport™ Reference Clock (100MHz) Output by the Clock Generator ................4-1

Table 4-2: PCI Express® Differential Clock (GFX_REFCLK, GPPSB_REFCLK, 100MHz) AC Characteristics ......................4-2

Table 4-3: Timing Requirements for REF_CLKP Used as OSCIN (14.3181818MHz) .................................................................4-2

Table 4-4: RS880 Power Rail Power-up Sequence .........................................................................................................................4-3

Table 5-1: Maximum and Minimum Ratings .................................................................................................................................. 5-1

Table 5-2: DC Characteristics for 3.3V TTL Signals .....................................................................................................................5-2

Table 5-3: DC Characteristics for DDC Signals (DDC Mode) .......................................................................................................5-2

Table 5-4: DC Characteristics for AUX Signals (AUX Mode) ......................................................................................................5-2

Table 5-5: DC Characteristics for POWERGOOD .........................................................................................................................5-2

Table 5-6: DC Characteristics for HyperTransport™ and PCI-E Differential Clock (HT_REFCLK, GFX_REFCLK,

GPPSB_REFCLK, 100MHz) ..........................................................................................................................................................5-3

Table 5-7: DC Characteristics for REFCLK_P as OSCIN Input (14.3181818MHz) .....................................................................5-3

Table 5-8: DC Characteristics for the Memory Interface when Supporting DDR2 ........................................................................5-3

Table 5-9: DC Characteristics for the Memory Interface when Supporting DDR3 ........................................................................5-3

Table 5-10: DC Characteristics for the Integrated DVI/HDMI™ ..................................................................................................5-4

Table 5-11: DC Characteristics for the TMDS Interface Multiplexed on the PCI Express® Gfx Lanes ......................................5-4

Table 5-12: Electrical Specifications for the DisplayPort Interface ..............................................................................................5-5

Table 5-13: RS880 Thermal Limits ................................................................................................................................................5-6

Table 5-14: RS880 528-Pin FCBGA Package Physical Dimensions .............................................................................................5-8

Table 5-15: Recommended Board Solder Reflow Profile - RoHS/Lead-Free Solder .................................................................. 5 -11

© 2013 Advanced Micro Devices, Inc. AMD RS880 Databook 1.40

Proprietary List of Tables-1

Page 10

List of Tables

Table 6-1: ACPI States Supported by the RS880 ............................................................................................................................6-1

Table 6-2: ACPI Signal Definitions ................................................................................................................................................6-1

Table 6-3: Standard PCI Configuration Space Header Type 0 .......................................................................................................6-2

Table 6-4: PCI Status Register ........................................................................................................................................................6-3

Table 6-5: Capabilities Pointer (CAP_PTR) ...................................................................................................................................6-3

Table 6-6: Power Management Register Block ..............................................................................................................................6-3

Table 6-7: Power Management Control/Status Register (PMCSR) ................................................................................................6-4

Table 6-8: Capability Identifier (CAP_ID) .....................................................................................................................................6-4

Table 6-9: Next Item Pointer (NEXT_ITEM_PTR) .......................................................................................................................6-5

Table 6-10: Power Management Capabilities – PMC .....................................................................................................................6-6

Table 7-1: Pins on the Test Interface ..............................................................................................................................................7-1

Table 7-2: Example of an XOR Tree ..............................................................................................................................................7-2

Table 7-3: RS880 XOR Tree ...........................................................................................................................................................7-3

Table 7-4: Truth Table for the VOH/VOL Tree Outputs ................................................................................................................7-5

Table 7-5: RS880 VOH/VOL Tree .................................................................................................................................................7-7

AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

List of Tables-2 Proprietary

Page 11

1.1 Introducing the RS880

The RS880 is a ninth-generation Integrated Graphics Processor (IGP) that integrates a DirectX® 10.1 compliant Shader

Model 4.1 graphics core and a system controller in a single chip. It supports AMD’s AM3-socket CPUs, including the

AMD Phenom™ II and later desktop processors. The RS880 integrates an ATI RV620-based graphics engine, dual

display, an integrated DVI/HDMI™ interface, a TMDS interface, DisplayPort capability, and Northbridge functionality in

a single BGA package. This high level of integration and scalability enables manufacturers to offer enthusiast level

capabilities and performance while helping to minimize board space and system cost.

The RS880 is pin-compatible with AMD's mainstream 700 and 800-series products including the RS780, RS780M,

RX780, RX781, RS880M, and RX881, allowing a single design to target multiple market seg ment s .

Robust and Flexible Core Logic Features

The RS880 combines graphics and system logic functions in a single chip using a 21mm body BGA package, reducing

overall solution area. For optimal system and graphics performance, the RS880 supports a high speed HyperTransport™

interface to the AMD processor, running at a data rate of up to 4.4 GT/s and supporting both HT 1.0 and HT 3.0 protocols.

The RS880 is ideally suited for 64-bit operating systems, and supports platform configurations with greater than 4GB of

system memory. The rich PCI Express

external graphics and up to six other PCI Express peripherals, all supporting the PCI Express 2.0 standard with data rates

of up to 5.0GT/s. These capabilities are complemented by the advanced I/O features of AMD’s SB700-series

Southbridges.

Designed for Windows Vista

Chapter 1

Overview

®

(PCIe®) expansion capabilities of RS880 include support for PCI Express

®

The RS880 delivers a compelling Windows Vista experience. It harnesses the increased bandwidth of HyperTransport 3.0

to a DirectX 10.1 graphics core, which provides the 3D rendering power needed to generate the Windows Vista desktop

even under the most demanding circumstances. The AMD RV620-based graphics core employs a unified shader

architecture to deliver excellent 3D performance across the whole spectrum of 3D applications. It meets all current

Windows Vista Premium Logo requirements.

Leading Multimedia Capabilities

The RS880 incorporates AMD’s Unified Video Decoder (UVD) 2.0 technology, which provides dedicated hardware

decode of the H.264, VC-1, and MPEG-2 video formats used for HD contents and Blu-ray disks. The RS880 also

incorporates the innovative AMD Avivo™ HD display architecture, providing users with amazing visual quality.

Advanced scaling and color correction capabilities, along with increased precision through the entire display pipeline,

ensure an exceptional image on CRT monitors, LCD panels, and any other display device. Dual DisplayPort output

capability provides the ability to interface to the next generation of digital display devices. That is complemented by a

fully integrated DVI/HDMI and HDCP support, allowing compatibility with even the most modern high definition

televisions without the additional cost of external components.

*Note: AMD Avivo HD is a technology platform that includes a broad set of capabilities offered by certain AMD

Radeon™ products. Support for any AMD Avivo HD capability is subject to qualification of the RS880 ASIC. Full

enablement of some AMD Avivo HD capabilities may require complementary products.

Low Power Consumption and Industry Leading Power Manage ment

The RS880 is manufactured using the power efficient 55 nm technology, and it supports a whole range of industry

standards and new proprietary power management features. System power can be further reduced through the dedicated

local frame buffer interface supported by the RS880. The integrated UVD dramatically reduces CPU loading and hence

overall power consumption during Blu-ray video and HD contents playback.

© 2013 Advanced Micro Devices, Inc. 46112 AMD RS880 Databook 1.40

Proprietary 1-1

Page 12

Software Compatibility

The graphics driver for the RS880 is fully compatible with all other AMD Radeon™ class graphics controllers from

AMD. A single driver can support multiple graphics configurations across AMD’s product lines, including the AMD

Radeon family and the AMD chipset family. In addition, this driver compatibilit y allows the RS880 to benefit

immediately from AMD's software optimization and from the advanced Windows

Windows 7

®

support available in the Radeon family drivers.

1.2 RS880 Features

1.2.1 CPU HyperTransport™ Interface

•

Supports 16-bit up/down HyperTransport (HT) 3.0 interface up to 4.4 GT/s.

• Supports 200, 400, 600, 800, and 1000 MHz HT1 frequencies.

• Supports 1.6, 1.8, 2.0, and 2.2 GHz HT3 frequencies.

• Supports AMD’s AM3-socket CPUs, including the AMD Phenom II and later desktop processors.

• Supports LDTSTOP interface and CPU link stutter mode.

1.2.2 Memory Interface

Supports an optional dedicated local frame buffer (side-port) of up to 128MB through a 16-bit interface. Note,

•

however, that the memory interface is optimized for a 64MB local frame buffer. As such, the system BIOS will

downsize the side-port size if a 128MB memory device is populated.

• New highly flexible memory architecture allows asymmetric side-port and shared system memory frame buffer sizes.

Supported configurations include UMA only and UMA+side-port (interleave mode).

• New dynamic memory allocation scheme improves performance and reduces power simultaneously.

• Support for DDR2 system memories up to DDR2-800, with a maximum memory clock speed of 400MHz. Memory

clock is independent of any other clock source and can therefore be set to any frequency equal to or less than

400MHz (DDR2-800), allowing the use of lower speed side-port memories.

• Support for DDR3 system memories up to DDR3-1200, with a maximum memory clock speed of 600MHz. Memory

clock is independent of any other clock source and can therefore be set to any frequency equal to or less than

600MHz (DDR3-1200), allowing the use of lower speed side-port memories.

• Support one memory device of x16 width (see section 2.2.1.1, “Supported DDR2 Components,” on page 2-4.and

section 2.2.2.1, “Supported DDR3 Components,” on page 2-5, for details).

• Asynchronous HyperTransport and memory controller interface speeds.

• Supports DDR SDRAM self refresh mechanism.

• Supports dynamic CKE and ODT for power conservation.

RS880 Features

®

XP, Windows Vista®, and

1.2.3 AMD HyperMemory™

• Supports AMD HyperMemory™*.

* Note: Includes dedicated and shared memory. The amount of HyperMemory available is determined by various factors.

For details, please consult your AMD CSS representative.

1.2.4 PCI Express® Interface

•

Supports PCIe Gen2 (version 2.0).

• Optimized peer-to-peer and general purpose link performance.

• Highly flexible PCI Express implementation to suit a variety of platform needs.

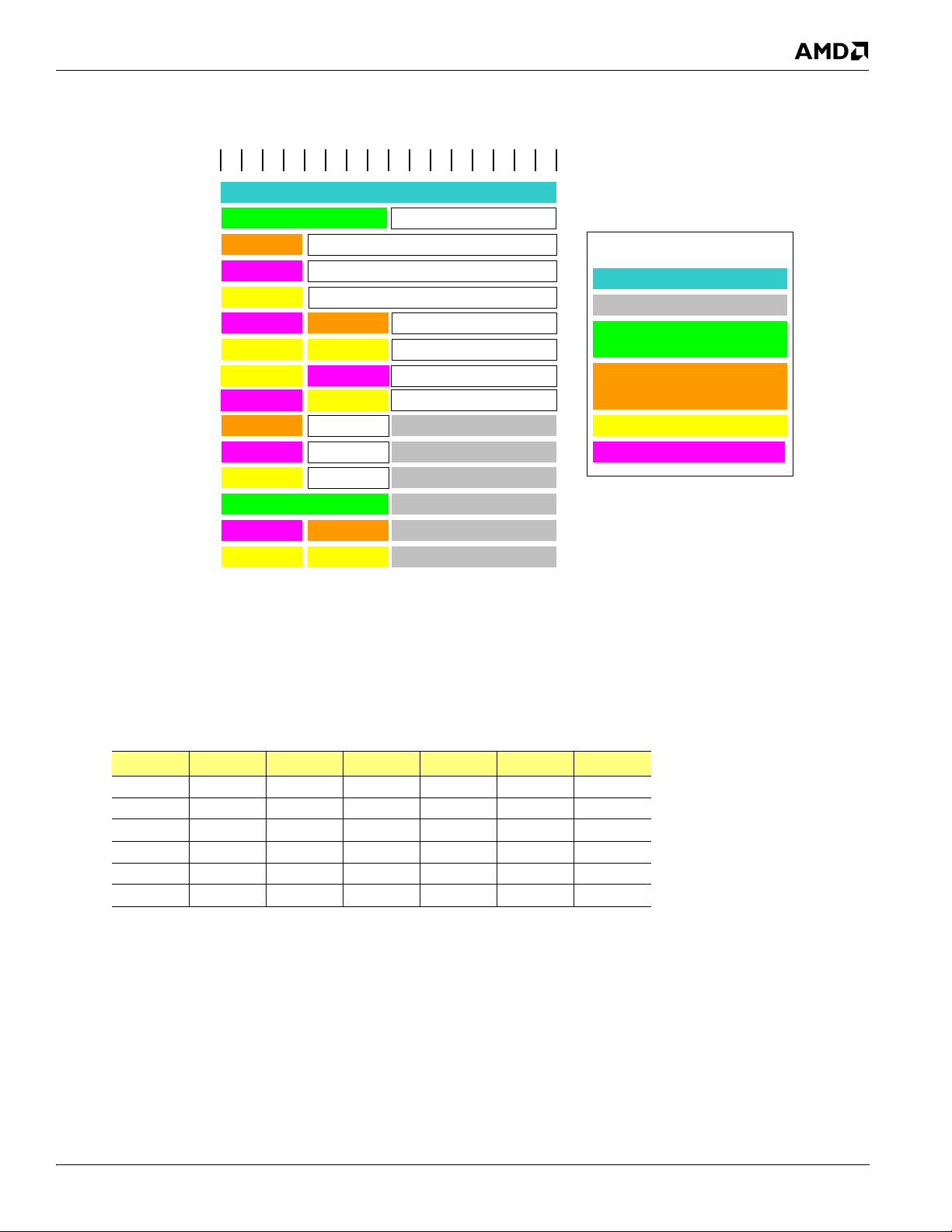

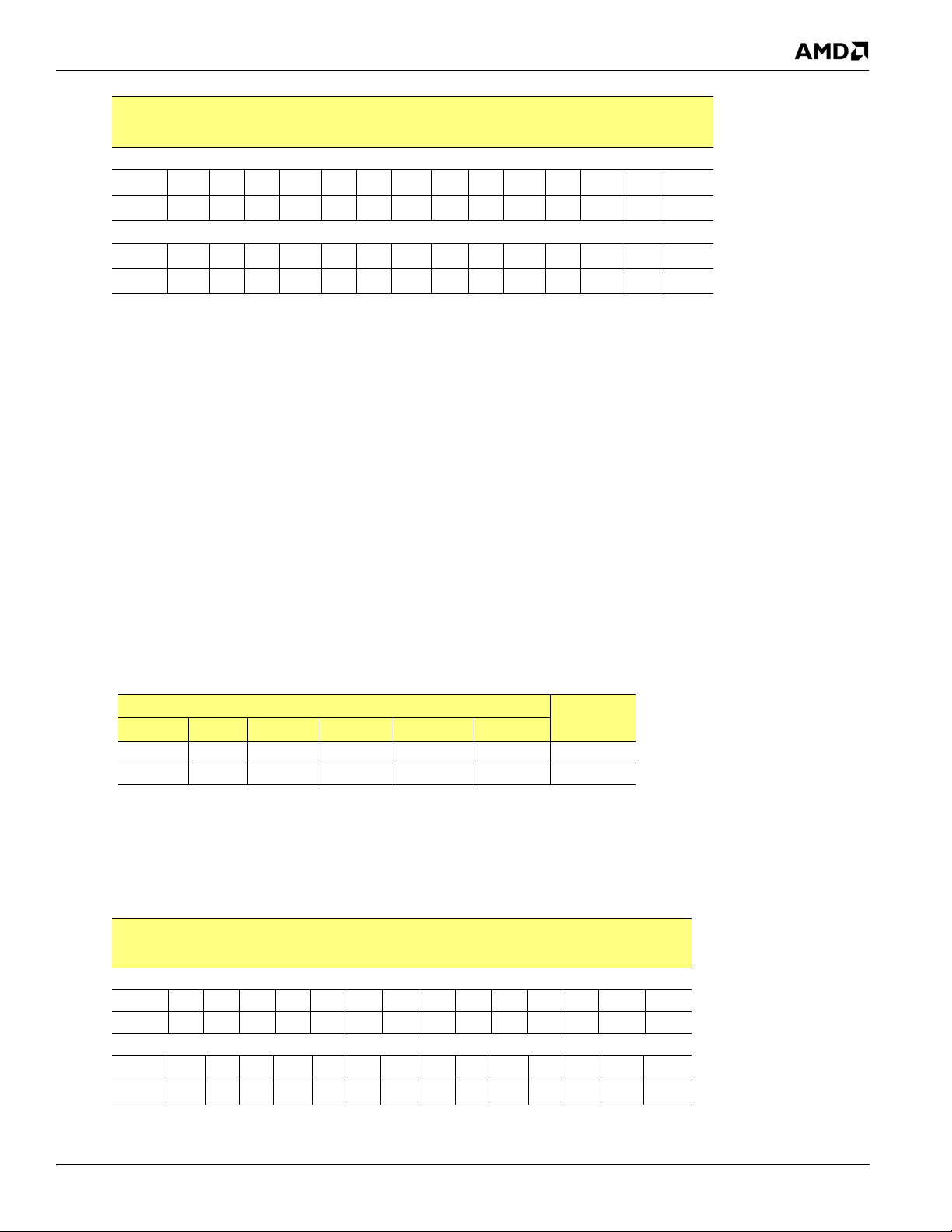

• A dual-port, x16 graphics interface, configurable to any one of the modes illustrated in Figure 1-1 for the RS880:

46112 AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

1-2 Proprietary

Page 13

RS880 Features

01 32 456789101112131415

PCI- E x16

PCI- E x 8 External Graphics

DL-DVI

PCI- E x 16 External Graphics

TMDS enabling Dual- Link

DVI(DL-DVI)

LEGEND

Not Used

TMDS enabling Single- Link

DVI(SL-DVI)

DisplayPort (DP)

TMDS enabling HDMI

PCI-E x 16 Interface

HDMI

SL-DVI

Not Used

DP

DP

Not Used

SL-DVI Not Used

HDMI Not Used

DP Not Used

DL-DVI

PCI- E x 8

SL-DVIHDMI

PCI- E x 8

PCI- E x 8

DPDP

HDMI Not Used

DP Not Used

SL-DVI Not Used

PCI- E x 8

PCI- E x 8

PCI- E x 8

DP Not Used

DP Not Used

HDMI

HDMI

Figure 1-1 Possible Configurations for the x16 PCIe

®

Graphics Interface

• Supports programmable lane reversal for the graphics link to ease motherboard layout when the end device does not

support lane reversal.

• Supports six general purpose lanes, for up to six devices on specific ports. Possible configurations are listed in

Table 1-1.

Table 1-1 Possible Configurations for the PCIe® General Purpose Links

Config. B Config. C Config. C2 Config. E Config. K Config. L

GPP1 x4 x4 x2 x2 x2 x1

1.2.5 A-Link Express II Interface

© 2013 Advanced Micro Devices, Inc. 46112 AMD RS880 Databook 1.40

Proprietary 1-3

GPP2-----x1

GPP3 - - x2 x1 x2 x1

GPP4---x1-x1

GPP5 x2 x1 x2 x1 x1 x1

GPP6 - x1 - x1 x1 x1

• Supports x1, x2, x4, x8, x12 and x16 polarity inversion.

One x4 A-Link Express II interface for connection to an AMD Southbridge. The A-Link Express II is a proprietary

•

interface developed by AMD basing on the PCI Express technology, with additional Northbridge-Southbridge

messaging functionalities.

• Supports programmable lane reversal to ease motherboard layout.

Page 14

1.2.6 2D Acceleration Features

Highly-optimized 128-bit engine, capable of processing multiple pixe ls per clock.

•

• Hardware acceleration of Bitblt, line drawing, polygon and rectangle fills, bit masking, monochrome expansion,

panning and scrolling, scissoring, and full ROP support (including ROP3).

• Optimized handling of fonts and text using AMD proprietary techniques.

• Game acceleration including support for Microsoft's DirectDraw

Blit, and Masked Blit.

• Acceleration in 1/8/15/16/32-bpp modes:

• Pseudocolor mode for 8bpp

• ARGB1555 and RGB565 modes for 16bpp

• ARGB8888 mode for 32bpp

• Significant increase in the High-End Graphics WinBench

• Setup of 2D polygons and lines.

• Support for GDI extensions:

• In Windows XP and Windows Vista: Alpha BLT, Transparent BLT, and Gradient Fill.

• In Windows 7: Alpha BLT, Transparent BLT, Color Fill BLT, Stretch BLT, and Clear Type BLT.

RS880 Features

®

: Double Buffering, Virtual Sprites, Transparent

®

score due to capability for C18 color expansion.

• Hardware cursor (up to 64x64x32bpp), with alpha channel for direct support of Windows XP, Windows Vista and

Windows 7 alpha cursor.

1.2.7 3D Acceleration Features

DirectX 10.1 compliant, including full speed 32-bit floating point per component operations

•

• Shader Model 4.1 geometry and pixel support in a unified shader architecture:

• Full speed 32-bit floating point processing per component.

• High dynamic range rendering with floating point blending, text ure filtering and anti-aliasing support.

• High performance dynamic branching and flow control.

• Nearly unlimited shader instruction store, using an advance caching system.

• Advanced shader design, with ultra-threading sequencer for high efficiency operations.

• Advanced, high performance branching support, including static and dynamic branching.

• 32-bit floating point components for high dynamic range computations.

• Full anti-aliasing on render surfaces up to and including 128-bit floating point formats.

• Support for OpenGL

®

2.0

• Anti-Aliasing Filtering:

• 2x/4x/8x modes.

• Sparse multi-sample algorithm with gamma correction, programmable sample patterns, and centroid sampling.

• Temporal anti-aliasing.

• Adaptive anti-aliasing mode.

• Lossless color compression (up to 8:1) at all resolutions, up to and including widescreen HDTV.

• Anisotropic Filtering:

• 2x/4x/8x/16x modes

• Up to 128-tap texture filtering.

• Adaptive algorithm with performance (bi-linear) and quality (tri-linear) options.

• Improved quality mode due to improved subpixel precision, higher precision LOD computations, and

rotationally invariant LOD computations.

• Advanced Texture Compression (3Dc+™ ):

• High quality 4:1 compression for normal maps and luminance maps.

• Works with any single-channel or two-channel data format.

46112 AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

1-4 Proprietary

Page 15

RS880 Features

• HW support to overcome "Small batch" issues in CPU limited applications.

• 3D resources virtualized to a 32-bit addressing space, for support of large numbers of render targets and textures.

• New vertex cache and vertex fetch design, to increase vertex throughput from previous generations.

• Full support of 64-bit and 128-bit textures and surfaces, which can be 4x to 8x faster than previous generation of HW.

• Up to 8K x 8K textures, including 128 bpp texture are supported.

• New multi-level texture cache to give optimal performance, greater than 8x the previous designs.

• High efficiency ring bus memory controller:

• Programmable arbitration logic maximizes memory efficiency, software upgradeable.

• Fully associative texture, color, and Z cache design.

• New hierarchical Z and stencil buffers with early Z Test.

• New lossless Z-buffer compression for both Z and stencil.

• Fast Z-Buffer Clear.

• Z cache optimized for real-time shadow rendering.

• Z and color compression resources virtualized to a 32-bit addressing space, for support of multiple render targets

and textures simultaneously.

1.2.8 Motion Video Acceleration Features

•

Video scaling and fully programmable YCrCb to RGB color space conversion for full-speed video playback and fully

adjustable color controls.

• Adaptive de-interlacing eliminates video artifacts caused by displaying interlaced video on non-interlaced displays,

and by analyzing image and using optimal de-interlacing function on a per-pixel basis.

• Motion video acceleration for HD contents and Blu-ray technology.

• Dedicated UVD (Unified Video Decoder) 2.0 hardware for H.264,VC-1, and MPEG-2 decode:

• H.264 implementation is based on the ISO/IEC 14496-10 spec.

• VC-1 implementation is based on the SMPTE 421M spec.

1.2.9 Multiple Display Features

General

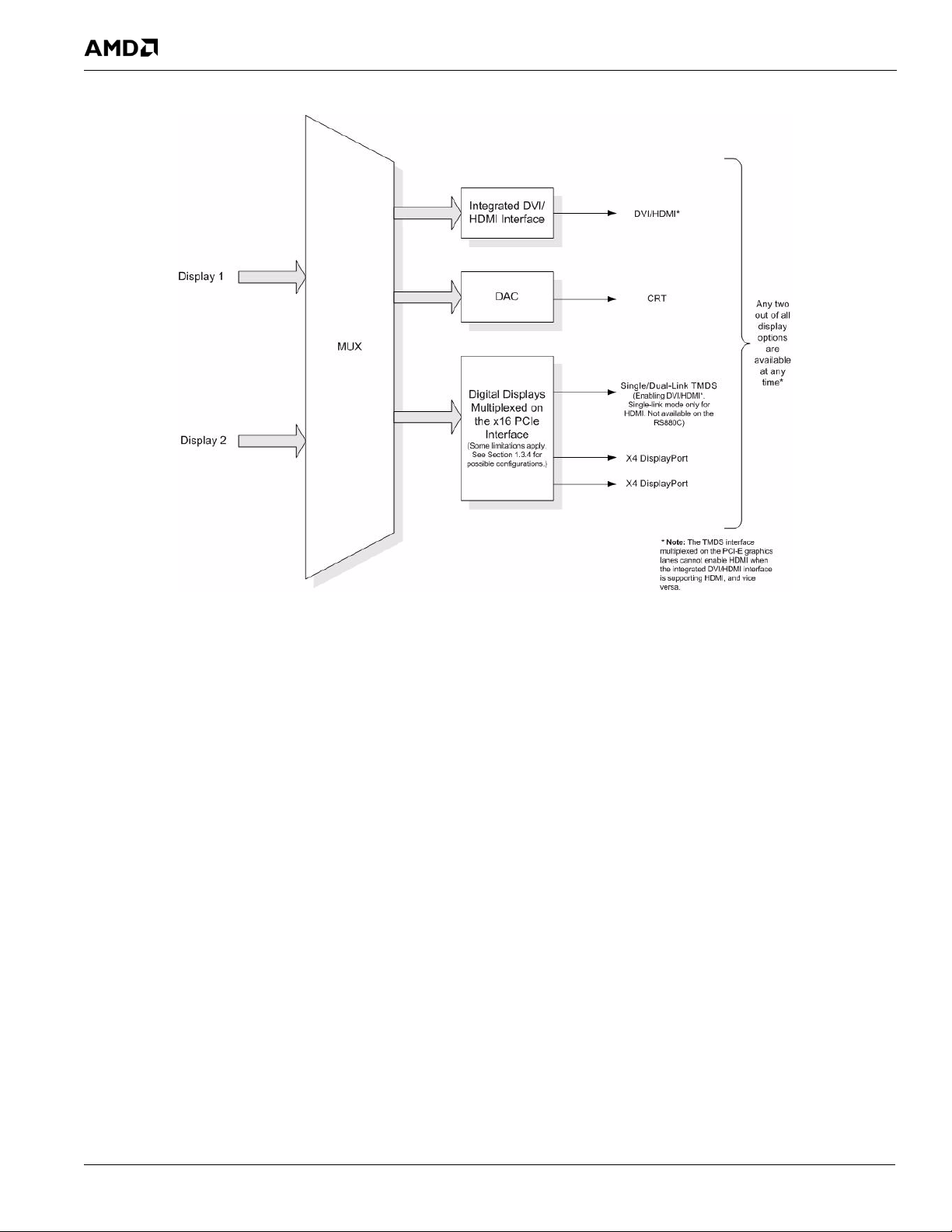

• Dual independent displays. Possible configurations are illustrated in Figure 1-2.

© 2013 Advanced Micro Devices, Inc. 46112 AMD RS880 Databook 1.40

Proprietary 1-5

Page 16

RS880 Features

Figure 1-2 RS880 Multiple Display Options

• Resolution, refresh rates, and display data can be completely independent for the two display paths.

• Each display controller supports true 30 bits per pixel throughout the display pipe.

• Each display path supports VGA and accelerated modes, video overlay, hardware cursor, hardware icon , and palette

gamma correction.

• Supports both interlaced and non-interlaced displays.

• Full ratiometric expansion ability is supported for source desktop modes up to 1920 pixels/line.

• Maximum DAC frequency of 400 MHz.

• Supports 8, 16, 32, and 64-bpp depths for the main graphics layer:

• For 32-bpp depth, supports xRGB 8:8:8:8, xRGB 2:10:10:10, sCrYCb 8:8:8:8, and xCrYCb 2:10:10:10 data

formats.

• For 64-bpp depth, supports xRGB 16:16:16:16 data format.

• Independent gamma, color conversion and correction controls for main graphics layer.

• Support for DDC1 and DDC2B+ for plug and play monitors.

• 8-bit alpha blending of graphics and video overlay .

• Hardware cursor up to 64x64 pixels in 2 bpp, full color AND/XOR mix, and full color 8-bit alpha blend.

• Hardware icon up to 128x128 pixels in 2 bpp, with two colors, transparent, and inverse transparent. AND/XOR

mixing. Supports 2x2 icon magnification.

• Virtual desktop support.

• Support for flat panel displays via VGA, DVI, or HDMI.

• Integrated HD audio controller for HDMI audio data.

46112 AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

1-6 Proprietary

Page 17

RS880 Features

VGA Output

• Maximum resolutions supported by the VGA output for different refresh rates are:

• 2048x1536 @85Hz (pixel clock at 388.5MHz) for 4:3 format

• 2560x1440 @75Hz (pixel clock at 397.25MHz) for 16:9 format

• 2456x1536 @60Hz (pixel clock at 320MHz) for 16:10 format

• Support for stereoscopic monitors.

SurroundView™

• RS880’s SurroundView™ feature allows support for up to four independent monitors for systems equipped with an

additional ATI discrete graphics card (requires special BIOS and display driver support).

1.2.10 DVI/HDMI™

• Integrated DVI or HDMI* interface (passing HDMI CTS v1.3b): single-link support only for HDMI‡, 30-bit

dual-link support for DVI.

• Also supports a TMDS interface, enabling DVI or HDMI (passing HDMI CTS v1.3b), which is multiplexed on the

PCIe external graphics interface.‡

• 1620 Mbps/channel with 162 MHz pixel clock rate per link.

• Supports industry standard EIA-861B video modes including 480p, 720p, 1080i, and 1080p (for a full list of currently

supported modes, contact you AMD CSS representative). Maximum resolutions supported by various modes are:

• Single-link DVI: 1600x1200 @60Hz with standard timings, and 1920x1200 @60Hz with reduced blanking

timings.

• Dual-link DVI: 2560x1600 @60Hz.

• HDMI: 1080p.

• Supports YCbCr 4:4:4 and 4:2:2 modes with HDMI.

• HDMI basic audio support at 32, 44.1 or 48 kHz. Supports two-channel uncompressed audio data, and, for Windows

Vista platforms only, 5.1-channel audio data and DTS. HD audio device compatible with the Microsoft HD audio

driver.

• HDCP support for two independent display streams with on-chip key storage. Also available when the integrated

DVI/HDMI interface or the TMDS interface runs in dual-link mode.**

Notes: * CEC is not supported.

** HDCP content protection support is only available to HDCP licensees and can only be enabled when connected

to an HDCP-capable receiver.

‡ The TMDS interface multiplexed on the PCIe graphics lanes cannot enable HDMI when the integrated

DVI/HDMI interface is supporting HDMI, and vice versa.

1.2.11 DisplayPort™ Interface

•

Supports all mandatory features of the VESA DisplayPort Standard, Version 1.1, plus the following optional features:

• 10-bit support.

• YCbCr 4:4:4 and 4:2:2 support.

• HDCP support

• Optional test pattern support.

• Supports two independent displays over the PCIe interface for external graphics (see Figure 1-1,“Possible

Configurations for the x16 PCIe® Graphics Interface,” on page 1-3 for details).

• Supports 4, 2, or 1-lane transmission.

• Supports both the 2.7 Gbps and 1.62 Gbps link symbol rates.

© 2013 Advanced Micro Devices, Inc. 46112 AMD RS880 Databook 1.40

Proprietary 1-7

Page 18

• Supports the Auxiliary Channel (AUX CH).

• Supports a maximum resolution of 2560x1600 @60Hz with 4 lanes.

1.2.12 Integrated HD Audio Controller and Codec

•

Integrated HD Audio codec supports linear PCM and AC3 (5.1) audio formats for HDMI output.

• Separate logical chip function.

• Can encrypt data onto one associated HDMI output.

• Uses Microsoft UAA driver.

• Internally connected to the integrated HDMI, or HDMI-enabled interface, hence no external cable required.

• Support for basic audio (32, 44.1 or 48 KHz stereo) and AC3 or DTS at the same sample rates.

1.2.13 System Clocks

Support for an external clock chip to generate side-port memory, PCIe, and A-Link Express II clocks.

•

1.2.14 Power Management Features

•

Single chip solution in 55nm, 1.1V CMOS technology.

• Full ACPI 2.0 and IAPC (Instantly Available PC) power management support.

• Static and dynamic power management support (APM as well as ACPI) with full VESA DPM and Energy Star

compliance.

• The Chip Power Management Support logic supports four device power states defined for the OnNow Architecture—

On, Standby, Suspend, and Off. Each power state can be achieved by software control bits.

• Hardware controlled intelligent clock gating enables clocks only to active fun ctional blocks, and is completely

transparent to software.

• Dynamic self-refresh for the side-port memory.

• Support for Cool'n'Quiet™ via FID/VID change.

• Support for AMD PowerNow!™.

• Clocks to every major functional block are controlled by a unique dynamic clock switching technique that is

completely transparent to the software. By turning off the clock to the block that is idle or not used at that point, the

power consumption can be significantly reduced during normal operation.

• Supports AMD Vari-Bright™ technology.

• Supports dynamic lane reduction for the PCIe graphics interface when coupled with an AMD-based graphics device,

adjusting lane width according to required bandwidth.

RS880 Features

1.2.15 PC Design Guide Compliance

The RS880 complies with all relevant Windows Logo Program (WLP) requirements from Microsoft for WHQL

certification.

1.2.16 Test Capability Features

The RS880 has a variety of test modes and capabilities that provide a very high fault coverage and low DPM (Defect Per

Million) ratio:

• Full scan implementation on the digital core logic through ATPG (Automatic Test Pattern Generation Vecto rs).

• Dedicated test logic for the on-chip custom memory macros to provide complete coverage on these modules.

• A JTAG test mode to allow board level testing of neighboring devices.

• An EXOR tree test mode on all the digital I/O's to allow for proper soldering verification at the board level.

• A VOH/VOL test mode on all digital I/O’s to allow for proper verification of output high and output low values at the

board level.

• Access to the analog modules to allow full evaluation and characterization.

46112 AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

1-8 Proprietary

Page 19

Software Features

• IDDQ mode support to allow chip evaluation through current leakage measurements.

These test modes can be accessed through the settings on the instruction register of the JTAG circuitry.

1.2.17 Packaging

•

Single chip solution in 55nm, 1.1V low power CMOS technology.

• 528-FCBGA package, 21mmx21mm.

1.3 Software Features

• Supports Microsoft Windows XP, Windows Vista, and Windows 7.

• BIOS ability to read EDID 1.1, 1.2, and 1.3.

• Ability to selectively enable and disable several devices including CRT, LCD, and DFP.

• Register-compatible with VGA standards, BIOS-compatible with VESA VBE2.0.

• Supports corporate manageability requirements such as DMI.

• ACPI support.

• Full Write Combining support for maximum performance of the CPU.

• Full-featured, yet simple Windows utilities:

• Calibration utility for WYSIWYG color

• Independent brightness control of desktop and overlay

• End user diagnostics

• Drivers meet Microsoft's rigorous WHQL criteria and are suitable for systems with the "Designed for Windows"

logos.

• Comprehensive OS and API support.

• Hot-key support (Windows ACPI 2.0 or AMD Event Handler Utility where appropriate).

• Extensive power management support.

• Rotation mode support in software.

• Dual CRTC, simultaneous view, extended desktop support (Windows XP, Windows Vista, and Windows 7)

• DirectX 10.1 support.

• Switchable overlay support.

• H.264 playback support.

• Supports AMD OverDrive™ utility.

***Warning*** AMD and ATI processors are intendedto be operated only within their associated specifications and factory settings. Operating the AMD or ATI processor outside of specification or in

excess of factory settings, including but not limited to overclocking, may damage the processor and/or lead to other problems, including but not limited to, damage to the system components (including the

motherboard and components thereon (e.g. memory)), system instabilities (e.g. data loss and corrupted images), shortened processor, system component and/or system life and in extreme cases, total

system failure. AMD does not provide support or service for issues or damages related to use of an AMD or ATI processor outside of processor specifications or in excess of factory settings.

• Supports Hybrid CrossFire™.

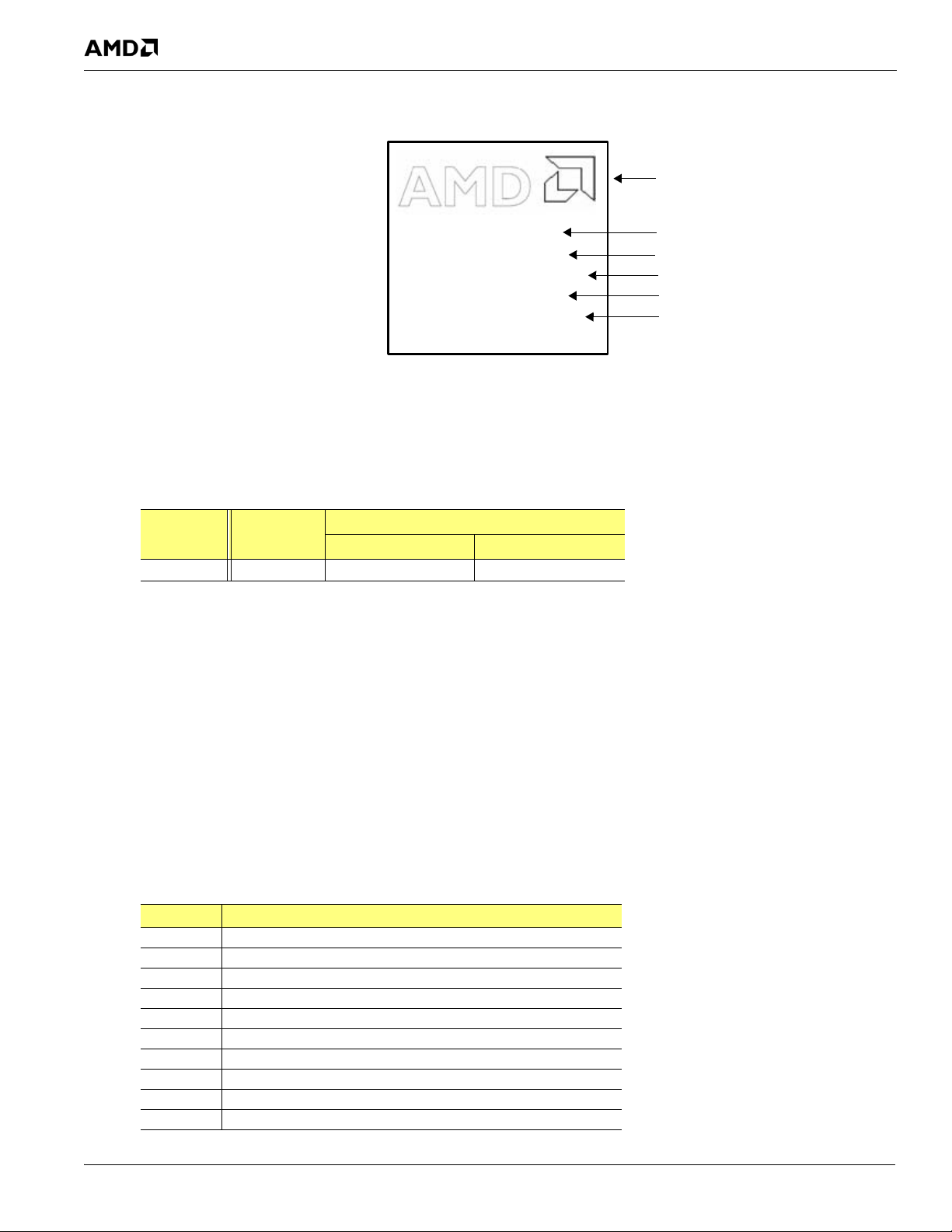

1.4 Branding Diagrams

Note: The branding can be in laser, ink, or mixed laser-and-ink marking.

© 2013 Advanced Micro Devices, Inc. 46112 AMD RS880 Databook 1.40

Proprietary 1-9

Page 20

Graphics Device ID and Graphics Engine Clock Speed

RADEON IGP

YYWW

MADE IN TAIWAN

WXXXXX

215-0752001

Part Number

Date Code (“YY” - Year, ”ZZ” - Week)

AMD Product Type

AMD Logo

Wafer Lot Number (“ZZ” may not be shown)

Country of Origin (China or Taiwan)

Note: Branding can be in laser, ink, or

mixed laser-and-ink marking.

WWWXXX.ZZ

MADE IN COO

Figure 1-3 RS880 ASIC A11 Production Branding

1.5 Graphics Device ID and Graphics Engine Clock Speed

Table 1-2 Graphics Device ID and Graphics Engine Clock Speed

1.6 Conventions and Notations

The following conventions are used throughout this manual.

1.6.1 Pin Names

Pins are identified by their pin names or ball references. Multiplexed pins sometimes assume alternate “functional names”

when they perform their alternate functions, and these “functional names” are given in Chapter 3, “Pin Descriptions and

Strap Options.”

All active-low signals are identified by the suffix ‘#’ in their names (e.g., MEM_RAS#).

1.6.2 Pin Types

The pins are assigned different codes according to their operational characteristics. These codes are listed in Table 1-3.

Table 1-3 Pin Type Codes

I Digital Input

O Digital Output

OD Open Drain

I/O Bi-Directional Digital Input or Output

I/OD Digital Input or Open Drain

M Multifunctional

Pwr Power

Gnd Ground

A-O Analog Output

A-I Analog Input

46112 AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

1-10 Proprietary

Variant

RS880 0x9710 300 500

Code Pin Type

Graphics

Device ID

Graphics Engine Clock Speed ( MHz)

Min. Max.

Page 21

Conventions and Notations

Table 1-3 Pin Type Codes (Continued)

Code Pin Type

A-I/O Analog Bi-Directional Input/Output

A-Pwr Analog Power

A-Gnd Analog Ground

Other Pin types not included in any of the categories above

1.6.3 Numeric Representation

Hexadecimal numbers are appended with “h” (Intel assembly-style notation) whenever there is a risk of ambiguity. Other

numbers are in decimal.

Pins of identical functions but different running integers (e.g., “GFX_TX7P, GFX_TX6P,... GFX_TX0P”) are referred to

collectively by specifying their integers in square brackets and with colons (i.e., “GFX_TX[7:0]P”). A similar short-hand

notation is used to indicate bit occupation in a register. For example, NB_COMMAND[15:10] refers to the bit positions

10 through 15 of the NB_COMMAND register.

1.6.4 Register Field

A field of a register is referred to by the format of [Register Name].[Register.Field]. For example,

“NB_MC_CNTL.DISABLE_BYPASS” is the “DISABLE_BYPASS” field of the register “NB_MC_CNTL.”

1.6.5 Hyperlinks

Phrases or sentences in blue italic font are hyperlinks to other parts of the manual. Users of the PDF version of this manual

can click on the links to go directly to the referenced sections, tables, or figures.

1.6.6 Acronyms and Abbreviations

The following is a list of the acronyms and abbreviations used in this manual.

Table 1-4 Acronyms and Abbreviations

Acronym Full Expression

ACPI Advanced Configuration and Power Interface

A-Link-E A-Link Express interface between the IGP and the Southbridge.

BGA Ball Grid Array

BIOS

BIST Built In Self Test.

BLT Blit

bpp bits per pixel

CEC Consumer Electronic Control

CPIS Common Panel Interface Specification

CRT Cathode Ray Tube

CSP Chip Scale Package

DAC Digital to Analog Converter

DBI Dynamic Bus Inversion

DDC

DDR Double Data Rate

DFP Digital Flat Panel. Monitor connection standard from VESA.

DP DisplayPort

DPM Defects per Million

DTV Digital TV

Basic Input Output System. Initialization code stored in a ROM or Flash RAM used to start up a

system or expansion card.

Display Data Channel. A VESA standard for communicating between a computer system and

attached display devices.

© 2013 Advanced Micro Devices, Inc. 46112 AMD RS880 Databook 1.40

Proprietary 1-11

Page 22

Table 1-4 Acronyms and Abbreviations (Continued)

Acronym Full Expression

DVD Digital Video Disc

DVI

DVS Digital Video Stream

EPROM Erasable Programmable Read Only Memory

FIFO First In, First Out

FPDI Flat Panel Display Interface

GDI Graphics Device Interface

GND Ground

GPIO General Purpose Input/Output

HDCP High-Bandwidth Digital Content Protection

HDMI High Definition Multimedia Interface

HDTV High Definition TV. The 1920x1080 and the 1280x720 modes defined by ATSC.

HPD Hot Plug Detect

iDCT inverse Discrete Cosine Transform

IDDQ Direct Drain Quiescent Current

IGP

JTAG Joint Test Access Group. An IEEE standard.

MB Mega Byte

MPEG

NTSC

PAL Phase Alternate Line. The standard definition TV system used in Europe and other areas.

PCI Peripheral Component Interface

PCIe PCI Express

PLL Phase Locked Loop

POST Power On Self Test

PD Pull-down Resistor

PU Pull-up Resistor

RAID Redundant Array of Inexpensive Disks

ROP Raster Operation

SDRAM Synchronous Dynamic RAM

TMDS Transition Minimized Differential Signaling

UMA Unified Memory Architecture

UV Chrominance (also CrCb). Corresponds to the color of a pixel.

UVD Unified Video Decoder

UXGA Ultra Extended Graphics Array

VBI Vertical Blank Interval

VESA Video Electronics Standards Association

VGA Video Graphics Adapter

VRM Voltage Regulation Module

Digital Video Interface. Monitor connection standard from the DDWG (Digital Display Work

Group).

Integrated Graphics Processor. A single device that integrates a graphics processor and a

system controller.

Motion Pictures Experts Group. Refers to compressed video image streams in either MPEG-1

or MPEG-2 formats.

National Television Standards Committee. The standard definition TV system used in North

America and other areas.

Conventions and Notations

46112 AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

1-12 Proprietary

Page 23

Conventions and Notations

This page is left blank intentionally.

© 2013 Advanced Micro Devices, Inc. 46112 AMD RS880 Databook 1.40

Proprietary 1-13

Page 24

Conventions and Notations

46112 AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

1-14 Proprietary

Page 25

Chapter 2

CPU

Interface

Register Interface

UVD

Setup

Engine2DEngine

3D

Engine

Overlay

Root

MUX

Display 1& 2

Integrated DVI/HDMI

TMDS, enabling DVI/HDMI

CRT

Memory Controller

CPU

BIF

SB

External

Graphics

Complex

A-Link-E II

Gfx Interface

PCIe

®

Interface

(1 x 16 Lanes)

GPP Interface

PCIe

®®

(6 x 1 Lanes)

Expansion

Slots or

On-board

Devices

(1 x 4 Lanes)

(Multiplexed on PCIe® Gfx Lanes)

DisplayPorts

(Multiplexed on PCIe

®

Gfx Lanes)

Optional 16-bit

DDR2/DDR3

Memory Channel

HyperTransport™

Unit

Functional Descriptions

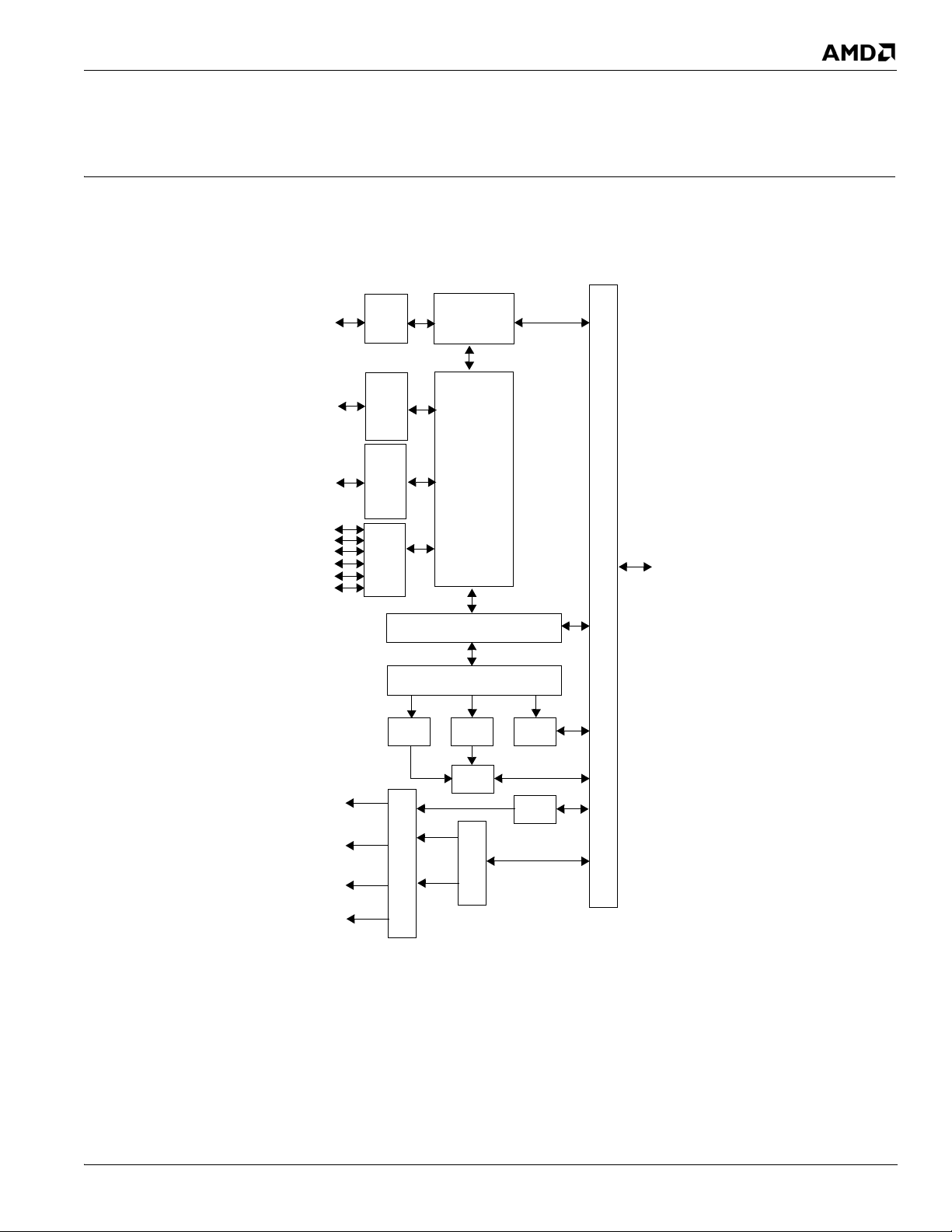

This chapter describes the functional operation of the major interfaces of the RS880 system logic. Figure 2-1, “RS880

Internal Block Diagram,” illustrates the RS880 internal blocks and interfaces.

2.1 Host Interface

The RS880 is optimized to interface with AMD processors through the HyperTransport

an overview of the HyperTransport

© 2013 Advanced Micro Devices, Inc. 46112 AMD RS880 Databook 1.40

Proprietary 2-1

Figure 2-1 RS880 Internal Block Diagram

TM

interface. For a detailed description of the interface, please refer to the

interface. This section presents

Page 26

Host Interface

HT Interface to CPU (PHY)

Configuration

Registers

Root Complex

Memory Controller

LTA

LRA

SCH

Data Link Layer

Protocol/Transacti o n La ye r

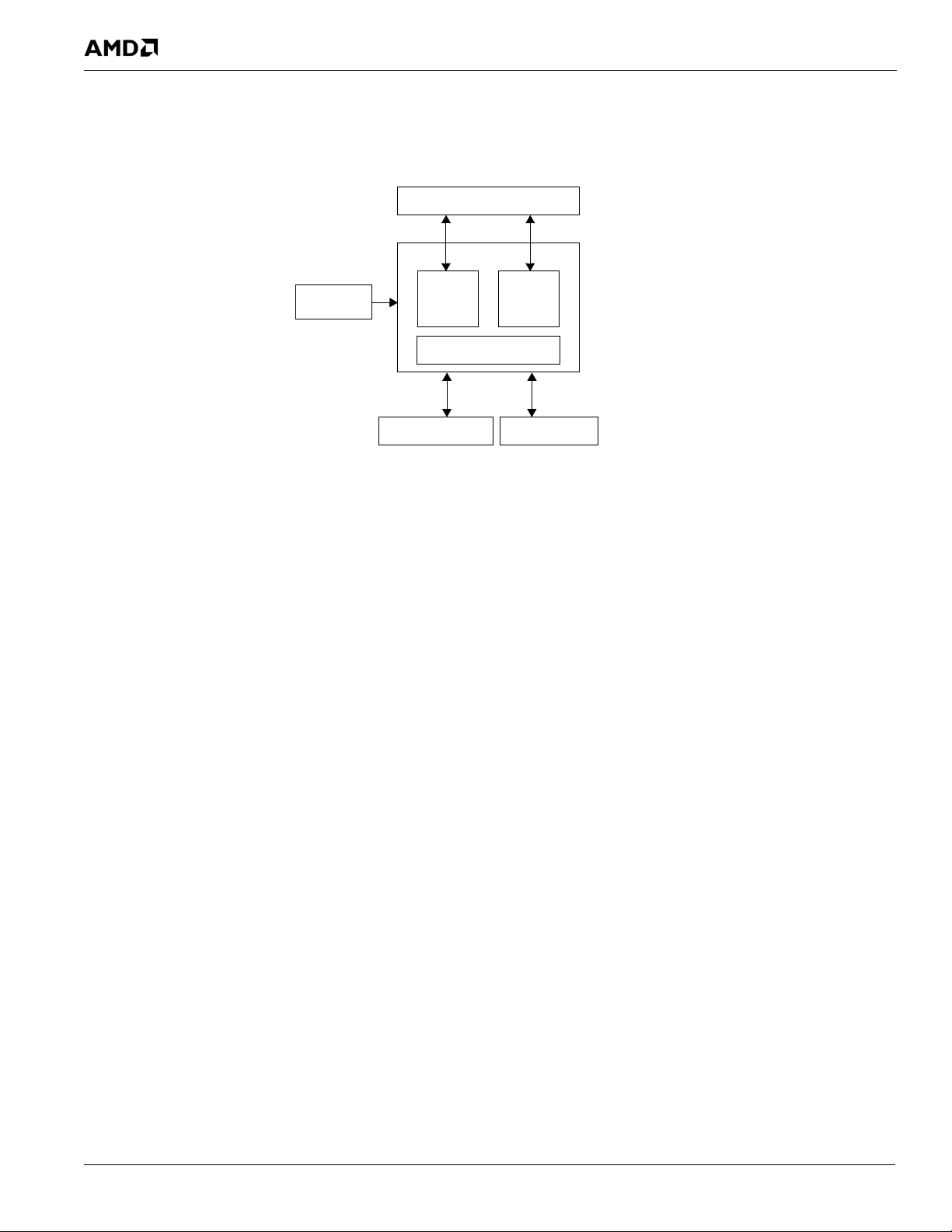

HyperTransport I/O Link Specification from the HyperTransport Consortium. Figure 2-2, “Host Interface Block

Diagram,” illustrates the basic blocks of the host bus interface of the RS880.

Figure 2-2 Host Interface Block Diagram

The HyperTransport (HT) Interface, formerly known as the LDT (Lightning Data Transport) interface, is a high speed,

packet-based link implemented on two unidirectional buses. It is a point-to-point interface where data can flow both

upstream and downstream at the same time. The commands, addresses, and data travel in packets on the HyperTransport

link. Lengths of packets are in multiples of four bytes. The HT link consists of three parts: the physical layer (PHY), the

data link layer, and the protocol/transaction layer. The PHY is the physical interface between the RS880 and the CPU.

The data link layer includes the initialization and configuration sequences, periodic redundancy checks,

connect/disconnect sequences, and information packet flow controls. The protocol layer is responsible for maintaining

strict ordering rules defined by the HT protocol.

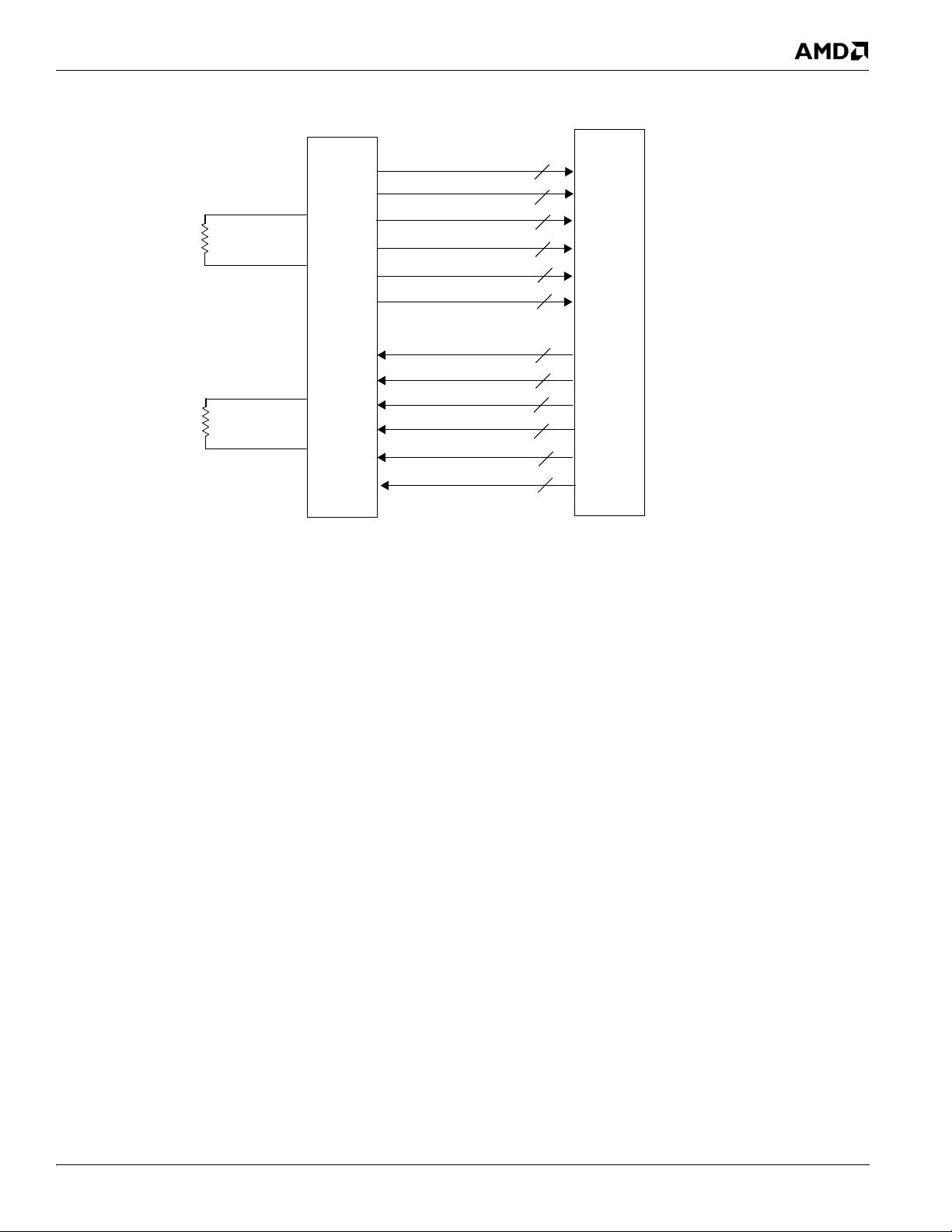

The RS880 HyperTransport bus interface consists of eighteen unidirectional differential data/control pairs and two

differential clock pairs in each of the upstream and downstream direction. On power up, the HT link is 8-bit wide and runs

at a default speed of 400MT/s. After negotiation, carried out by the HW and SW together, the link width can be brought

up to 16-bit and the interface can run up to 4.4GT/s. The interface is illustrated in Figure 2-3, “RS880 Host Bus Interface

Signals.” The signal name and direction for each signal is shown with respect to the processor. Note that the signal names

may be different from those used in the pin listing of the RS880. Detailed descriptions of the signals are given in section

3.3, “CPU HyperTransport™ Interface‚’ on page 3-5.

46112 AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

2-2 Proprietary

Page 27

Side-Port Memory Interface

HT_RXCADN

2

2

RS880

CPU

HT_RXCADP

HT_RXCTLN

HT_RXCTLP

HT_RXCLKN

HT_RXCLKP

16

16

HT_TXCADN

2

2

HT_TXCADP

HT_TXCTLN

HT_TXCTLP

HT_TXCLKN

HT_TXCLKP

16

16

2

2

2

2

HT_TXCALP

HT_RXCALN

HT_RXCALP

HT_TXCALN

2.2 Side-Port Memory Interface

In order to significantly decrease system power and increase graphics performance, the RS880 provides an optional

side-port memory interface for dedicated frame buffer memory, to be used exclusively for the integrated graphics core.

The side-port memory interface can significantly reduce system power by allowing the CPU to stay in its lowest power

state during periods of inactivity. Screen refreshes are fetched from the side-port memory, and there is no need to "wake

up" the CPU to fetch screen refresh data.

The RS880 memory controller is unique and highly optimized. It operates in 16-bit mode at very high speed (up to

DDR2-800 and DDR3-1200), and has a programmable interleaved mode that significantly increases the memory

bandwidth and reduces data latency to the integrated graphics core. The additional bandwidth provided to the internal

graphics core will also aid the RS880 in reaching and exceeding Microsoft's Windows Vista

requirements.

2.2.1 DDR2 Memory Interface

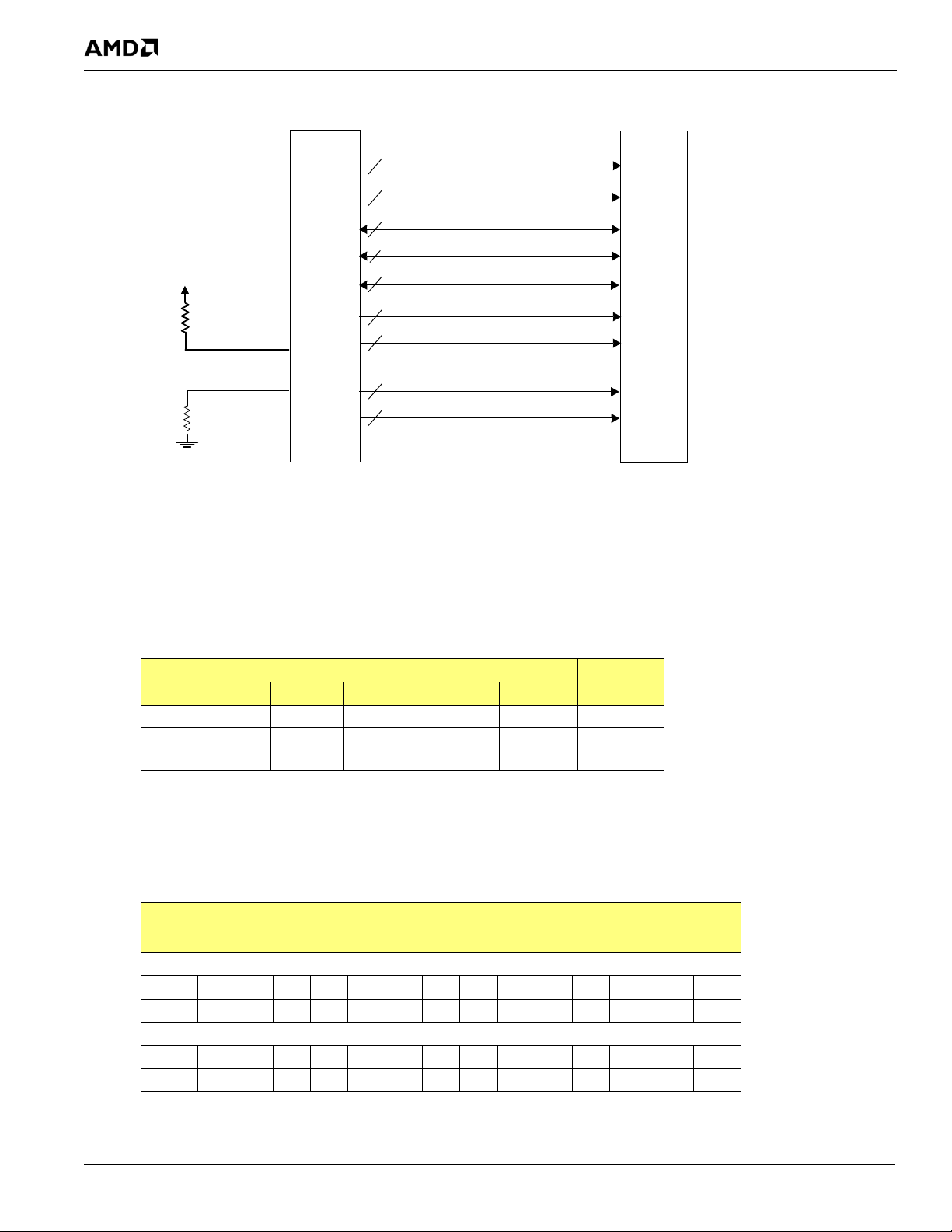

Figure 2-4, “RS880 Side-Port Memory Interface,” on page 2-4 illustrates the side-port memory interface of the RS880.

RS880 memory controller features and limitations:

• Supports a single memory device up to 128MB of physical size. However, as the memory interface is

optimized for a 64MB local frame buffer, the system BIOS will downsize the side-port memory if a 128MB

memory device is populated.

• Controls a single rank of DDR2 devices in 16-bit memory configuration.

• Supports device sizes of 256, 512, and 1024 Mbits, and a device width of x16.

• As the memory controller supplies only one chip select signal, only devices with one chip selec t are supp orte d.

• A wide range of DDR2 timing parameters, configurations, and loadings are programmable via the RS880

memory controller configuration registers.

Figure 2-3 RS880 Host Bus Interface Signals

®

Premium logo

© 2013 Advanced Micro Devices, Inc. 46112 AMD RS880 Databook 1.40

Proprietary 2-3

Page 28

Data Mask MEM_DM[1:0]

Data MEM_DQ[15:0]

2

4

16

RS880 Side-Port Memory

Interface

Data Strobes MEM_DQS[1:0]P/N

Un-buffered DDR2 SDRAM

MEM_CKE, MEM_RAS#,

Differential Clocks MEM_CKP/MEM_CKN

4

2

MEM_CAS#, MEM_WE#

14

Address MEM_A[13:0]

1

Chip Select MEM_CS#

1

On-Die Termination MEM_ODT

3

Bank Address MEM_BA[2:0]

MEM_CALN

MEM_CALP

VDD_MEM

Side-Port Memory Interface

Figure 2-4 RS880 Side-Port Memory Interface

2.2.1.1 Supported DDR2 Components

The memory controller supports DDR2 SDRAM chips in several configurations. These chips are organized in banks,

rows (or pages), and columns. The supported DDR2 components have four or eight banks. Table 2-1 lists the supported

memory components.

Table 2-1 Supported DDR2 Components

DDR2 SDRAM

Config Mbits CS Mode Bank Bits Row Bits Col Bits

16Mbx16 256 4 2 13 9 32

32Mbx16 512 10 2 13 10 64

64Mbx16 1024 11 3 13 10 128

Mbytes

2.2.1.2 Row and Column Addressing

Table 2-2 shows how the physical address P (after taking out the bank bit) is used to provide the row and column

addressing for each size of DDR2 memories.

Table 2-2 DDR2 Memory Row and Column Addressing

A13 A12 A11 A10 A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

Row P10 P14 P13 P12 P11 P22 P21 P20 P19 P18 P17 P16 P15

Column - - PC - P9P8P7P6P5P4P3 P2 P1

Row P23 P14 P13 P12 P11 P22 P21 P20 P19 P18 P17 P16 P15

Column - - PCP10P9P8P7P6P5P4P3 P2 P1

16Mbx16 devices

32Mbx16 devices

Address

46112 AMD RS880 Databook 1.40 © 2013 Advanced Micro Devices, Inc.

2-4 Proprietary

Page 29

Side-Port Memory Interface

A13 A12 A11 A10 A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

Row

Column

Row

Column

Note: PC = precharge flag

P23 P14 P13 P12 P11 P22 P21 P20 P19 P18 P17 P16 P15

- - PC P10 P9 P8 P7 P6 P5 P4 P3 P2 P1

P24 P23 P14 P13 P12 P11 P22 P21 P20 P19 P18 P17 P16 P15

- - PC P10 P9 P8 P7 P6 P5 P4 P3 P2 P1

2.2.2 DDR3 Memory Interface

RS880 memory controller features and limitations:

• Supports a single memory device up to 128MB of physical size. However, as the memory interface is

optimized for a 64MB local frame buffer, the system BIOS will downsize the side-port memory if a 128MB

memory device is populated.

• Supports a single rank of DDR3 device in 16-bit memory configuration.

• Supports device sizes of 512 and 1024 Mbits, and a device width of x16.

Address

64Mbx16 devices

128Mbx16 devices

• A wide range of DDR3 timing parameters, configurations, and loadings are programmable via the RS880 memory

controller configuration registers.

2.2.2.1 Supported DDR3 Components

The memory controller supports DDR3 SDRAM chips in several configurations. These chips are organized in banks,

rows (or pages), and columns. Table 2-3 lists the supported memory components.

Table 2-3 Supported DDR3 Components

DDR3 SDRAM

Config Mbits CS Mode Bank Bits Row Bits Col Bits

32Mbx16 512 9 3 12 10 64

64Mbx16 1024 11 3 13 10 128

2.2.2.2 Row and Column Addressing

Table 2-4 shows how the physical address P (after taking out the bank bit) is used to provide the row and column

addressing for each size of DDR3 memories.

Table 2-4 DDR3 Memory Row and Column Addressing

Address

A13 A12 A11 A10 A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

32Mbx16 devices

Row P23 P14 P13 P12 P11 P22 P21 P20 P19 P18 P17 P16 P15

Column - - PCP10P9P8P7P6P5P4P3 P2 P1

64Mbx16 devices

Row P23 P14 P13 P12 P1 1 P22 P21 P20 P19 P18 P17 P16 P15

Column - - PC P10 P9 P8 P7 P6 P5 P4 P3 P2 P1

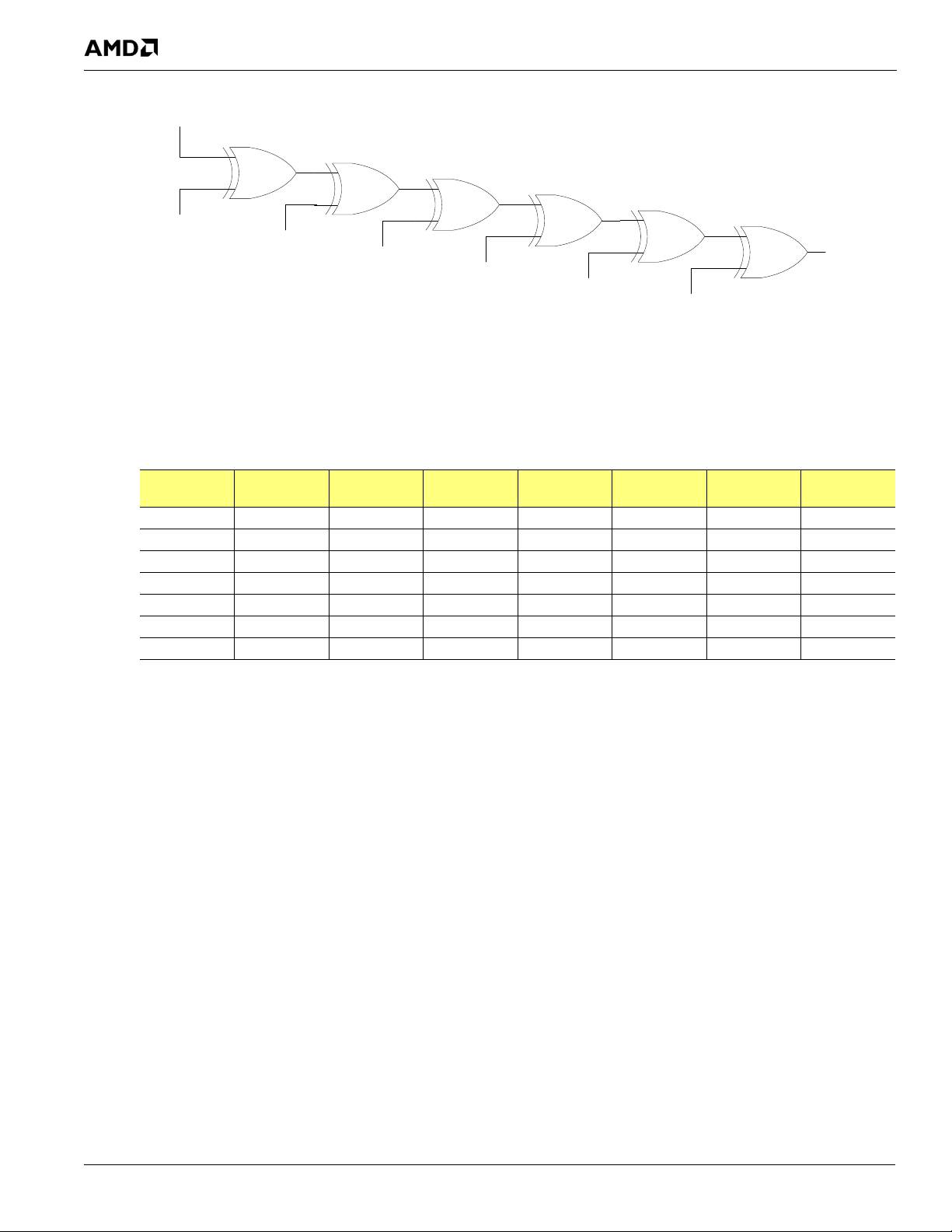

Mbytes