Page 1

AMD Geode™ LX Processor

DDR2 BIOS Porting Guide

1.0 Scope

The AMD Geode™ LX processor has an integrated DDR

memory controller. Due to the concerns over the availability

and increasing cost of DDR, AMD has developed a method

for operating DDR2 memory with the processor’s memory

controller. This application note details the software

changes necessary to enable this technology.

Note: The solution described in this document does not

conform to the JEDEC DDR2 Specification. This

solution may not work with all DDR2 memory.

Note: This is revision B of this document. The change

from revision A (also dated March 2009) is “AMD

Confidential” was removed.

2.0 Description

Initializing DDR2 SDRAM requires writing to additional

mode registers. In addition to the Mode Register (MR) and

Extended Mode Register (EMR), DDR2 defines two new

Extended Mode Registers, EMR(2) and EMR(3). The EMR

is renamed as EMR(1). Furthermore, the MR and EMR

definitions are not an exact match between DDR and

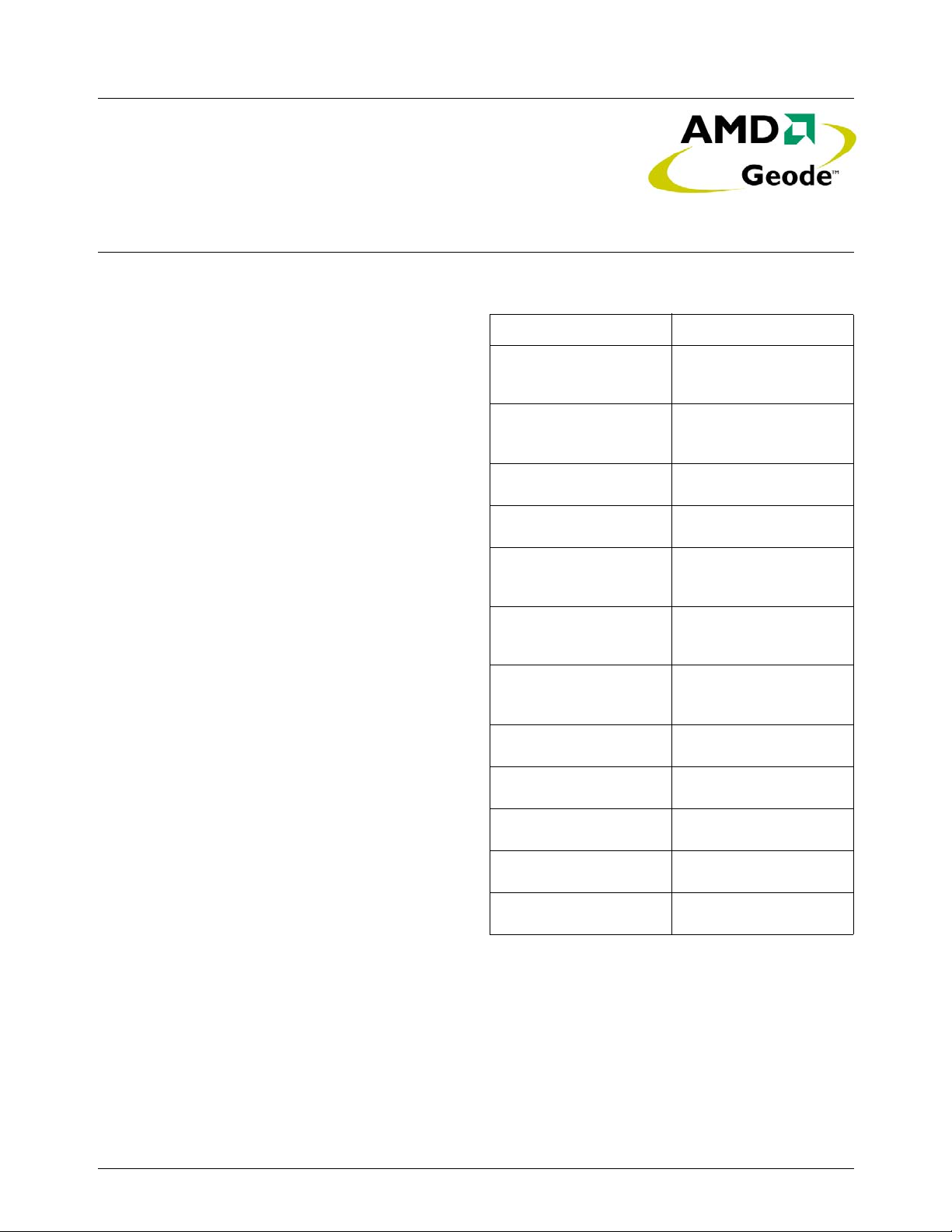

DDR2. Table 2-1 shows a comparison of the typical initialization steps for DDR vs. DDR2.

Addressing MR vs. EMR(1), EMR(2) or EMR(3) is determined by the states of BA[2:0] while the LOAD MODE command is presented on the control signals. The data written

to the registers is the pattern presented on A[15:0] when

the command is initiated. (Note, however, that A[15:13]=0,

and BA[2]=0 in all cases.)

Software on the LX processor issues LOAD MODE commands by writing the MC_CF07_DATA register. During the

operation, the memory controller (MC) uses various bits

and fields in the MC_CF07_DATA and MC_CF8F_DATA

registers. With the available settings, the LX processor is

not capable of generating the necessary signal patterns for

all the required LOAD MODE commands.

Table 2-1. Initialization Steps

DDR DDR2

Wait a minimum of 200µs

after clocks and power are

stable, then assert CKE.

Wait a minimum of 400ns,

then issue a PRECHARGE ALL command.

Issue a LOAD MODE

command to EMR to

enable the DLL.

Issue LOAD MODE command to MR with DLL

reset.

Wait at least 200 clock

cycles. Issue a PRECHARGE ALL command.

Issue two REFRESH

commands.

Issue LOAD MODE to MR

without DLL reset.

SDRAM initialization is

complete.

Wait a minimum of 200µs

after clocks and power are

stable, then assert CKE.

Wait a minimum of 400ns,

then issue a PRECHARGE ALL command.

Issue a LOAD MODE

command to EMR(2)

Issue a LOAD MODE

command to EMR(3).

Issue a LOAD MODE

command to EMR(1) to

enable the DLL.

Issue LOAD MODE command to MR with DLL

reset.

Wait at least 200 clock

cycles. Issue a PRECHARGE ALL command.

Issue two REFRESH

commands.

Issue LOAD MODE to MR

without DLL reset.

Issue LOAD MODE to

EMR(1) with OCD default.

Issue LOAD MODE to

EMR(1) with OCD exit.

SDRAM initialization is

complete.

46959A - March 2009 1

Page 2

3.0 Solution

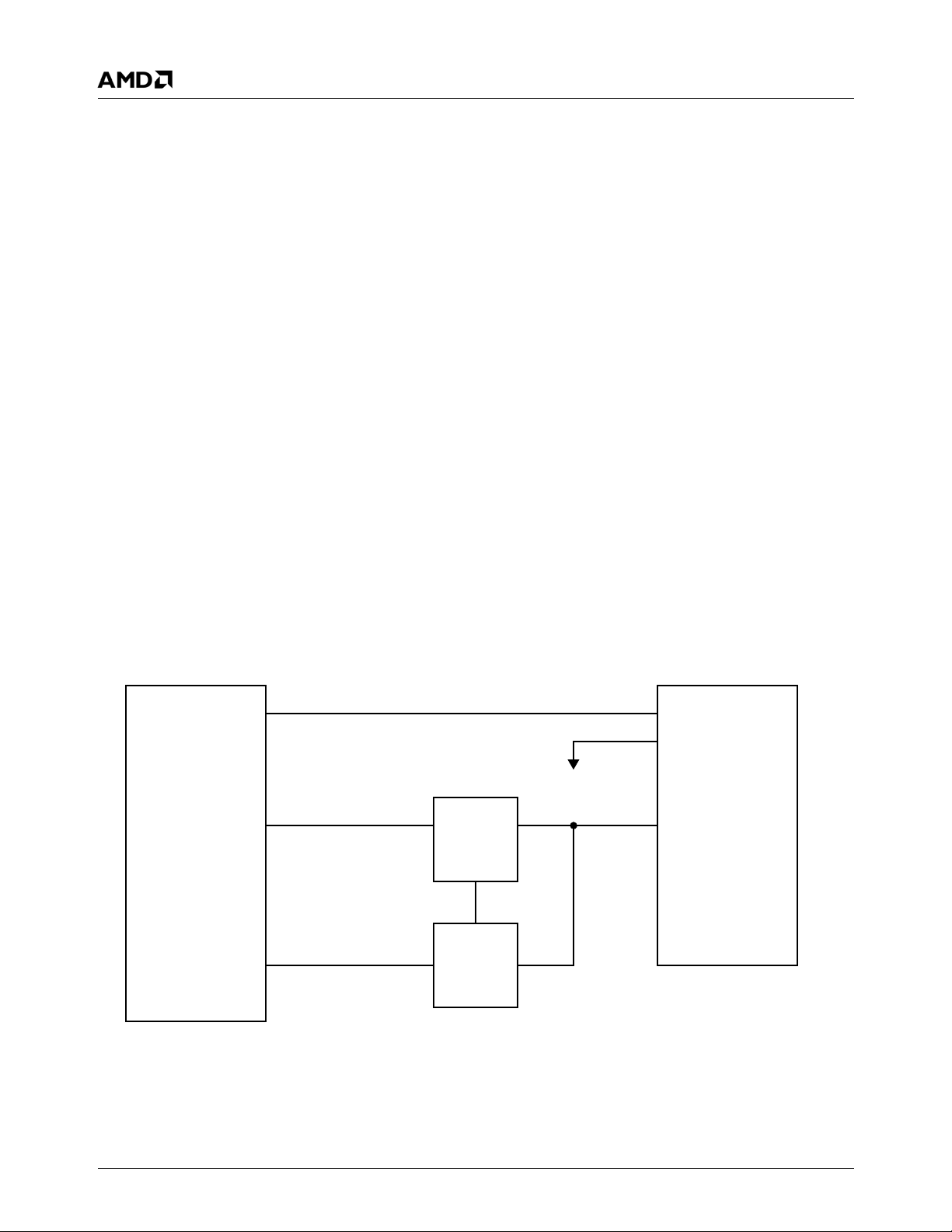

The method for initializing DDR2 memory on the processor

is to insert a CPLD and quick switches in the address and

BA signals. Figure 3-1 shows a block diagram of this

design. During initialization, the Enable signal opens

(default) the switches. BIOS tells the CPLD what pattern to

assert on the BA[n] and A[n] signals. Upon completion,

BIOS tells the CPLD to close the switches, giving control

over BA[n] and A[n] to the processor. Additional physical

and electrical details of the design are beyond the scope of

this document.

3.1 Hardware

This section explains the details of the initialization. First it’s

important to delineate two unique versions of this hardware

technology.

3.1.1 On-DIMM Design

This hardware form-factor has a DDR pin assignment (only

SO-DIMM as of this writing), but contains DDR2 SDRAM

modules, and the CPLD. This type of design will be attractive for customers wanting to upgrade existing systems.

The only board change required is a lower memory voltage.

Application Note

46959A - March 2009

Because the CPLD is contained on the DIMM assembly,

the only bus available for communication is I2C. The

CPLD’s I2C address is A0/A1 (i.e., the same as DIMM0).

The CPLD also contains the SPD information.

Also note that the CPLD uses CKE as its RESET# signal.

As a result, the list of BIOS changes may require moving

the assertion of CKE (e.g., if the SPD is accessed prior to

CKE).

3.1.2 On-board Design

This type of system will have the CPLD soldered onto the

motherboard, and will be able to use certain off-the-shelf

(OTS) DDR2 DIMMs. In this case, the CPLD does not contain SPD information.

Because the communication is not limited to I2C, using I/O

to send data to the CPLD simplifies the CPLD design and

speeds up initialization.

The I/O addresses selected for the AMD Geode™ LX Pro-

cessor Refresh Reference Design Kit (RDK) board are

AC10h and AC11h. This requires a modification to the Virtual PCI portion of the BIOS to identify the I/O range to an

operating system. As of this writing, the CPLD claims a

range of 8 bytes (i.e., AC10h-AC17h).

AMD Geode™

LX Processor

/

CS5536

A[13]

A[15:14],

BA[2]

A[12:0], BA[1:0]

Quick

Switches

A[12:0],

Enable

I2C

CPLD

BA[1:0]

Figure 3-1. AMD Geode™ LX Processor DDR2 Block Diagram

DDR2

SDRAM

2 AMD Geode™ LX Processor DDR2 BIOS Porting Guide

Page 3

Application Note

46959A - March 2009

3.2 CPLD Registers

The CPLD contains two registers that indicate how it

should assert the BA[1:0], A[12:0] signals and switch

enable signals.

• If accessing the registers via I2C, the register addresses

are 80h and 81h.

• If accessing with I/O, the addresses are AC10h and

AC11h.

The two registers are defined in Table 3-1 and 3-2. Instructing the CPLD to set or clear a signal causes the behavior to

occur immediately on its outputs.

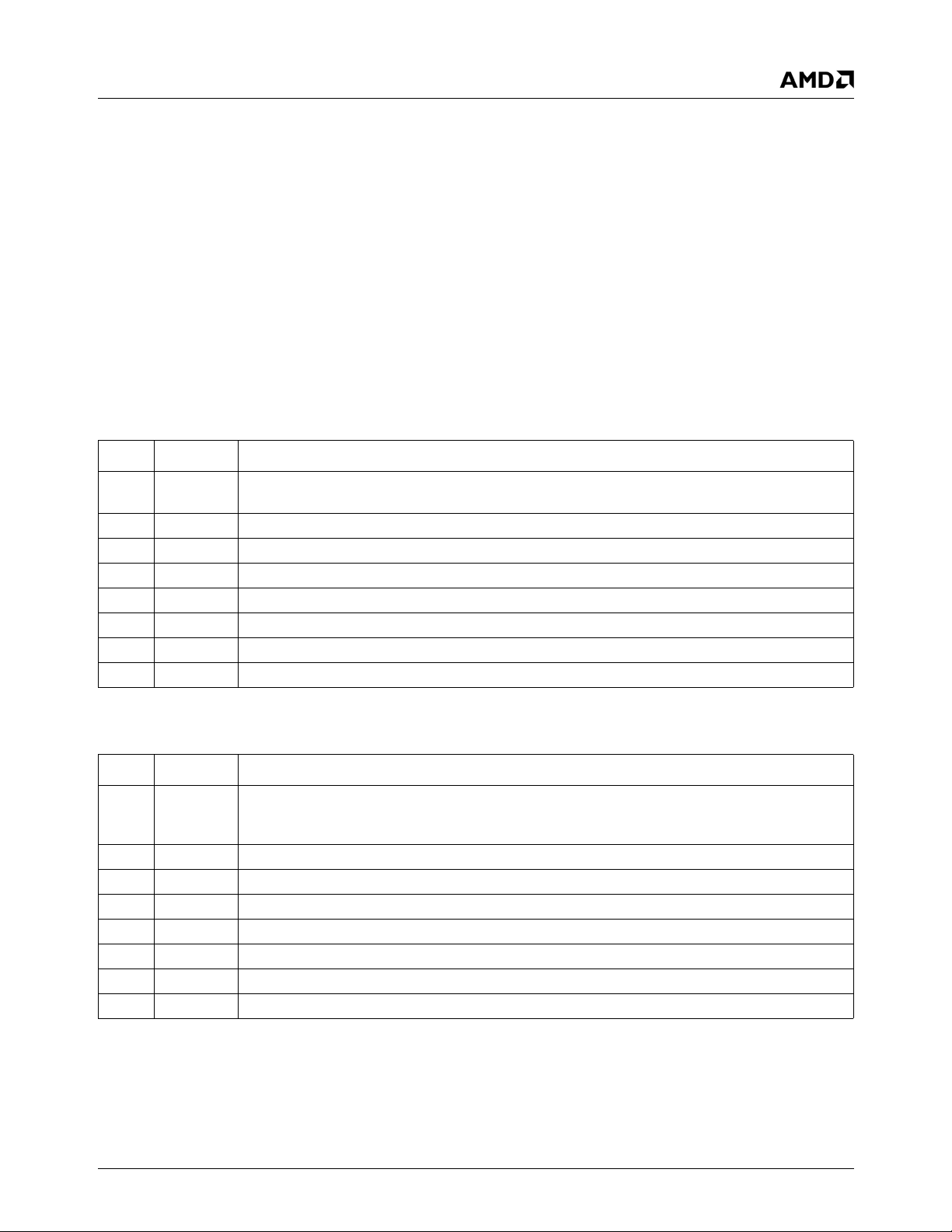

Table 3-1. REG_A Definition

Bit Name Description

7 A[7] Address signal 7. If SW_EN# is high, setting this bit causes the CPLD to assert the A[7] signal.

This behavior is consistent for all the A[n] and BA[n] fields.

6 A[6] Address signal 6

5 A[5] Address signal 5

4 A[4] Address signal 4

3 A[3] Address signal 3

2 A[2] Address signal 2

1 A[1] Address signal 1

0 A[0] Address signal 0

Prior to executing a LOAD MODE command, the BIOS sets

the CPLD registers to the desired pattern. The DRAM registers are programmed with the A[n] signals. The register

being initialized is determined by the pattern on BA[1:0]

(MR=00b, EMR(1)=01b, EMR(2)=10b and EMR(3)=11b).

Then the BIOS generates the LOAD MODE command by

setting, and then clearing, the PROG_DRAM bit in the

MC_CF07_DATA register. AMD also recommends setting

the MSR_BA field (same register) to the desired BA[1:0]

levels (same procedure as initializing DDR).

Table 3-2. REG_B Definition

Bit Name Description

7 SW_EN# Switch enable. When high, the CPLD asserts all of its A[n] and BA[n] signals, according to the

current settings in the internal registers. When low, the CPLD closes the switches and tri-states

its A[n] and BA[n] signals.

6 BA[1] Bank Address 1

5 BA[0] Bank Address 0

4 A[12] Address signal 12

3 A[11] Address signal 11

2 A[10] Address signal 10

1 A[9] Address signal 9

0 A[8] Address signal 8

AMD Geode™ LX Processor DDR2 BIOS Porting Guide 3

Page 4

3.3 Initialization Steps

Some of the following steps may be optional, depending on

the specific implementation. The reader is encouraged to

have a copy of the JEDEC standard for DDR2 SDRAM,

including the SPD byte definitions. The AMD Geode™ LX

Processors Data Book, order# 33234, is also recommended. The chapters for the memory controller and

GeodeLink™ Control Processor (GLCP) register definitions

will be useful.

3.3.1 Memory Controller Initialization

1) Enable the CKE signal earlier, if necessary. With the

On-DIMM solution, this allows the CPLD to come out

of reset. The CPLD cannot respond to any SPD reads

while in the reset state.

2) Identify whether the installed DIMM(s) are DDR2. The

information in SPD[2] (i.e., SPD byte number 2) indicates the fundamental memory type. If this value

equals 8, then the memory type is DDR2. A mixture of

memory types is not supported and the BIOS should

not allow this configuration.

3) Program the memory speed by setting the appropriate

dividers in the GLCP_SYS_RSTPLL register. This

may be decided by retrieving data from NVRAM, from

jumpers, or by calculating the best speed dynamically.

If dynamic, the BIOS should set the memory speed

slow enough to support the installed memory. The

memory’s minimum cycle time is indicated in SPD[9],

which has additional bits defined beyond the DDR

specification. If more than one DIMM is installed, the

slower of the two memories should be used in calculating the memory frequency.

Note that if setting the speed dynamically, certain configurations should be avoided. These are unrelated to

the memory technology installed. As is the case with

DDR, the core frequency must never be lower than the

GLIU frequency. The BIOS should try to avoid setting

an unsupported GLIU frequency.

4) Determine the physical configuration of the installed

DIMM(s). This procedure populates the fields in

b[63:32] of the MSR_CF07_DATA register.

SPD[5] indicates the number of ranks on the DIMM

assembly. Note that DDR2 defines this SPD byte differently than the DDR spec. The LX processor’s memory controller only supports DIMMs with 1 or 2 ranks

(indicated by 0 or 1). This setting determines the value

in the Dn_MB fields (i.e., D0_MB and D1_MB fields).

SPD[17] indicates the number of component banks.

The LX processor’s memory controller only supports 2

or 4 banks, but DDR2 devices may support 4 or 8. The

Dn_CB fields should be programmed with a 1 to indicate 4 banks. The BIOS should not allow configurations indicating 8 banks.

Application Note

46959A - March 2009

Calculate the size of each DIMM. SPD[31] indicates

the density of each rank and it is defined differently

than in the DDR specification. Multiply this by the number of ranks from SPD[5] to find the DIMM size. This

value is used to program the Dn_SZ fields.

Calculate the page size (i.e. the size of each row) for

each DIMM. The page size is defined as:

DIMM width * 2

(# of columns)

SPD[4] indicates the number of column addresses.

The width should always be 8 bytes, but may also be

read from SPD[6]. The LX processor’s memory controller only supports memory configurations that are

64 bits wide. The size is used to program the Dn_PSZ

fields.

5) Calculate the CAS# Latency (CL) and Write Latency

(WL). The WL is set with the WR2DAT field of the

MC_CF1017_DATA register. This is a change from

DDR to DDR2. With DDR technology WL=1, but for

DDR2 the WL=CL-1.

As of this writing, the memory controller may only

operate at WL=1 (i.e., WR2DAT may only be programmed to equal 1). This condition forces all implementations to use a CAS# Latency of 2.

A typical CAS# Latency algorithm should use the data

in SPD[18], which is a bitmap of supported CL settings

(in units of memory clocks). The bitmap will have up to

3 bits set, representing (from most significant to least)

CL=X, CL=X-1 and CL=X-2, which is different than the

DDR definition. Additionally, SPD[9], SPD[23] and

SPD[25] will have the minimum cycle times at the

highest CAS# Latency setting, the next lower setting,

and second lower setting. Note that all cycle times

have additional bits defined in the DDR2 specification.

Normally, if two DIMMs are present, the algorithm

should set the lowest number that is supported by both

DIMMs at the current operating frequency. The process would be identical to DDR, however, it is simplified for DDR2 memory because of the requirement to

operate at CL=2.

In the event that SPD[18] does not indicate a supported CAS# Latency of 2, the BIOS may still take

some steps to determine if CL=2 is supportable. The

fundamental CAS# access time may be calculated

using the supported CAS# Latencies and their associated cycle times. Multiplying the number of clocks by

the cycle time equals the access time. Use the lowest

result from all the supported CL values. Then divide

this number by 2 to get the lowest cycle time supportable at CL=2. If the cycle time of the memory clock is

greater than or equal to this value, then CL=2 is typi-

4 AMD Geode™ LX Processor DDR2 BIOS Porting Guide

Page 5

Application Note

46959A - March 2009

cally supportable. As an example, consider the following DIMM characteristics:

CAS#

Latency

Min Cycle

Time (ns)

Max Cycle

Time (ns)

CL=5 3.0 8.0

CL=4 3.75 8.0

CL=3 5.0 8.0

This is has a fundamental access time of 15ns, and

therefore at CL=2, the minimum cycle time should be

7.5ns. This DIMM should be function normally at

133MHz, with a CL setting of 2.

6) Program the CAS_LAT field of the MC_CF8F_DATA

register with the CAS# Latency value (i.e., 2). Additional settings are programmed in the same register:

THZ_DLY: This adds 1 clock to the Read-Write turnaround time

TRUNC_DIS: This forces bursts of 4, preventing bursts

of 2 (unsupported in DDR2)

7) Program the memory controller with the appropriate

latencies for the memory. For DDR2, this step is nearly

identical to DDR technology. As a result, this document will not go into many details. The memory controller settings affected are fields in the

MC_CF8F_DATA register, and are determined by SPD

data:

Timing

Field

Parameter SPD Byte

ACT2PRE tRAS 30

PRE2ACT tRP 27

ACT2CMD tRCD 29

ACT2ACT tRRD 28

ACT2ACTREF tRC 41/40**

REF2ACT* tRFC 42/40**

* REF2ACT is in the MC_CF1017_DATA register.

**Contains an extension value, new for DDR2.

8) Program other timing control parameters. In the

MC_CF1017_DATA register:

WR_TO_RD (tWTR) should be set for 2 clocks.

RD_TMG_CTL should be set for 4 half-GLIU clocks

9) Set the drive strength control (EMR_DRV in

MC_CF07_DATA) to Reduced if the DIMM(s) support

it. This feature is indicated in SPD[22], bit 0.

The memory controller is now set up correctly, and is prepared for turning on the memory. Now follow the DDR2

memory initialization steps (as outlined Table 2-1 on page

1).

3.3.2 SDRAM Initialization

1) CKE may have already been asserted, due to the

requirement of the On-DIMM CPLD. If not, assert CKE

by clearing the MASK_CKEn bit(s) in the

MC_CFCLK_DBUG register. CKE needs to be

asserted for at least 400ns before executing step 2.

Also, set REF_STAG in MC_CF07_DATA to 4 clocks.

2) Issue a PRECHARGE ALL command. The memory

controller does not allow software to issue a single

PRECHARGE ALL command. Instead, the command

is inserted before a REFRESH or a LOAD MODE

command. Set the FORCE_PRE bit in the

MC_CFCLK_DBUG register to insert the PRECHARGE ALL.

Additionally, the PRECHARGE ALL command

requires that A[10] be set high. This presents a minor

architectural problem. The BIOS will not have the

opportunity to modify A[10] between the PRECHARGE ALL command and the subsequent LOAD

MODE command. So the CPLD must be prepared for

the LOAD MODE command to EMR(2) (i.e., the A[n]

and BA[n] bits set in its registers) and A[10] also set to

high.

3) Issue a LOAD MODE command to EMR(2). First set

the CPLD’s registers. Typical settings are REG_A=00h

and REG_B=C4h. The setting in REG_B is

SW_EN#=1, BA[1:0]=10b, and A[10]=1. Next, in

MC_CF07_DATA register, set MSR_BA to 10b and

PROG_DRAM to 1. Then clear PROG_DRAM and

FORCE_PRE.

Note that DDR2 defines A[10] of EMR(2) should be

programmed to 0. Setting A[10]=1 for the PRECHARGE ALL step causes a violation of the spec during the LOAD MODE command. However, AMD has

not observed any side effects of programming EMR(2)

with A[10]=1.

4) Issue a LOAD MODE command to EMR(3). Similar to

the previous step, set the CPLD’s registers. Typical

settings are REG_A=00h and REG_B=E0h. The setting in REG_B is SW_EN#=1, BA[1:0]=11b. Next, in

MC_CF07_DATA register, set MSR_BA=11b and

PROG_DRAM=1. Then clear PROG_DRAM.

5) Issue a LOAD MODE command to EMR(1) to enable

the DLL. Program the CPLD with the appropriate information for the EMR(1) definition. Note that in certain

cases, it might be appropriate to leave the DLL disabled to allow the DRAM to run at lower frequencies.

AMD does not recommend omitting this step, however.

DLL Enable is defined in b[0] of the EMR(1) register.

The desired setting goes into REG_A[0]. Also, the setting for the drive strength control goes into REG_A[1].

If previously set up, these two bits may be retrieved

from the MC_CF07_DATA register. All other A[n] bits in

AMD Geode™ LX Processor DDR2 BIOS Porting Guide 5

Page 6

Application Note

46959A - March 2009

the CPLD are typically 0. Set SW_EN# high and

BA[1:0] to 01b.

Next, in MC_CF07_DATA register, set MSR_BA=01b

and PROG_DRAM=1. Then clear PROG_DRAM.

6) Issue a LOAD MODE command to MR to reset the

DLL. Regardless of whether the DLL is running, AMD

does not recommend omitting this step.

Some memory devices require A[8]=1 and all other

A[n]=0 during this step. The JEDEC spec does not

indicate zeroing all other address pins. Therefore, it is

up to the BIOS to decide how to proceed during this

step. The other fields in the MR may be constructed

from existing settings in the MC.

Similar to the other LOAD MODE commands, set

SW_EN#=1 and BA[1:0]=00b. In the memory controller, set MSR_BA=00b and PROG_DRAM=1. Then

clear PROG_DRAM.

7) Wait 200 clock cycles, then issue a PRECHARGE ALL

command. As before, set the CPLD registers so that

A[10] will be high and all other A[n] signals are inconsequential. Keep SW_EN# high. Set the FORCE_PRE

bit in the MC_CFCLK_DBUG register to insert the

command before the subsequent step.

8) Generate two REFRESH commands by twice setting

then clearing the REF_TST bit in the CM_CF07_DATA

register. Clear the FORCE_PRE bit between the two

REFRESH commands to avoid an extra PRECHARGE

ALL command.

9) Issue a LOAD MODE command to MR to bring the

DLL out of reset. In the CPLD, set A[8]=0. Other A[n]

settings may need to be calculated.

– The burst length is in the MC_CF8F_DATA register

as TRUNC_DIS. Of course, 4 is the only common

setting, so this part may be abbreviated.

– The CAS# Latency may also be retrieved from the

MC_CF8F_DATA register. Due to the memory

controller restriction, this may be otherwise hardcoded to 2.

11) Issue a LOAD MODE command to EMR(1) to exit

OCD programming. A[1:0] (driver strength and DLL

enable) are retrieved from MC_CF07_DATA. Set

A[9:7]=000b for OCD default. Set SW_EN#=1 and

BA[1:0]=01b. In MC_CF07_DATA set MSR_BA=01b

and PROG_DRAM=1. Then clear PROG_DRAM.

12) Now the BIOS is finished with the CPLD and should

give control of the A[12:0] and BA[1:0] signals to the

memory controller. Write any value to REG_B with

SW_EN#=0.

13) Program the refresh rate in the REF_INT field of

MC_CF07_DATA. This process is identical to that used

with DDR technology. Each DIMM indicates its supported rate in SPD[12]. The BIOS determines an interval that is sufficiently short for both DIMMs.

Note, however, that the location for this step has

moved for DDR2. The reason is that I2C accesses to

an On-DIMM CPLD are very slow. If REF_INT is programmed earlier, the memory controller generates

REFRESH commands during the initialization

sequence. This disrupts initialization and prevents the

DRAM from operating properly.

There are some additional settings recommended by AMD.

• Typically the GLCP_DELAY_CONTROLS register is set

up very early in POST, and usually with hardcoded

values. AMD recommends an initial setting of

F2F100FF_56960304 in this register.

• If there is no DIMM1, the SDCLK[5,3,1] should be

disabled in the GLCP_DELAY_CONTROLS register. Set

b[55] to do this.

• Program the PMode Sensitivity Counter values in the

MC_CF_PMCTR register. Typical values are PMode0

counter set to 0 for most aggressive, and PMode1

counter set to 200h.

• Program the PMode1 Up Delay field of

MC_CF1017_DATA to 209 clocks.

– The Write Recovery for Autoprecharge field is

calculated using information in SPD[36], which is

new for DDR2.

Set SW_EN#=1 and BA[1:0]=00b. In the memory controller, set MSR_BA=00b and PROG_DRAM=1. Then

clear PROG_DRAM.

10) Issue a LOAD MODE command to EMR(1) with OCD

set to Default. A[1:0] (driver strength and DLL enable)

are retrieved from MC_CF07_DATA. Set A[9:7]=111b

for OCD default. Set SW_EN#=1 and BA[1:0]=01b. In

MC_CF07_DATA set MSR_BA=01b and PROG_DRAM

=1. Then clear PROG_DRAM.

6 AMD Geode™ LX Processor DDR2 BIOS Porting Guide

Page 7

Application Note

46959A - March 2009

3.4 Other Information and Restrictions

The LX processor/DDR2 solution does not do DQS training. The LX processor’s memory controller does not have

the adjustability to make this worthwhile, and the speeds

are slow enough that this is not a problem.

The memory must be organized with 4 component banks.

This means that only 512Mbits, and lower, devices are supported. In addition, the memory controller only supports 1

or 2 ranks. Any other configurations should be avoided.

The DRAM must support a CAS# Latency of 2 clocks. A

DIMM’s SPD may not indicate that this is supported, due to

the higher typical operating frequencies of the memory.

The BIOS may determine that CL=2 is possible by considering the fundamental access time of the memory (i.e.,

cycle time multiplied by the normal CAS# Latency). The

reason for this restriction is that the LX processor’s memory controller must operate with a Write Latency of 1 clock.

DDR2 defines CAS# Latency equal to Write Latency + 1.

Supporting CL=2 at higher frequencies implies that the

memory must be of higher performance. To run the memory at 166MHz, this means that the memory should have

an access time of 12ns. 133MHz requires 15ns.

The typical LX processor/DDR2 implementation will run the

memory at lower frequencies than average. While 166MHz

is within the DDR2 specification, some memory vendors

may recommend operating with the DLL disabled. The customer should investigate this with their memory supplier.

Some DRAM modules may operate at higher frequencies

by raising their supply voltage. The customer should consult the memory manufacturer before taking this approach.

The BIOS may implement an algorithm that accounts for

the higher frequency. AMD has seen only limited success

with this technique.

AMD Geode™ LX Processor DDR2 BIOS Porting Guide 7

Page 8

© 2009 Advanced Micro Devices, Inc. All rights reserved.

The contents of this document are provided in connection with Advanced Micro

Devices, Inc. (“AMD”) products. AMD makes no representations or warranties with

respect to the accuracy or completeness of the contents of this publication and

reserves the right to make changes to specifications and product descriptions at

any time without notice. No license, whether express, implied, arising by estoppel

or otherwise, to any intellectual property rights is granted by this publication.

Except as set forth in AMD’s Standard Terms and Conditions of Sale, AMD

assumes no liability whatsoever, and disclaims any express or implied warranty,

relating to its products including, but not limited to, the implied warranty of merchantability, fitness for a particular purpose, or infringement of any intellectual

property right.

AMD’s products are not designed, intended, authorized or warranted for use as

components in systems intended for surgical implant into the body, or in other

applications intended to support or sustain life, or in any other application in which

the failure of AMD’s product could create a situation where personal injury, death,

or severe property or environmental damage may occur. AMD reserves the right to

discontinue or make changes to its products at any time without notice.

www.amd.com

TRADEMARKS

AMD, the AMD Arrow logo, AMD Geode, GeodeLink, and combinations thereof, are trademarks of Advanced Micro Devices, Inc.

Other product names used in this publication are for identification purposes only and may be trademarks of their respective companies.

One AMD Place • P.O. Box 3453 • Sunnyvale, CA 94088-3453 USA • Tel: 408-749-4000 or 800-538-8450 • TWX: 910-339-9280 • TELEX: 34-6306

Loading...

Loading...