Page 1

PTAC

W

ALL

S

LEEVE

INSTALLATION INSTRUCTIONS

The wall sleeve must be installed before the air conditioner or heat pump chassis can be set in place.

Read the instructions thoroughly before proceeding.

AT TENTION INSTALLING PERSONNEL

As a professional installer you have an obligation to know the

product better than the customer. This includes all safety

precautions and related items.

Prior to actual installation, thoroughly familiarize yourself

with this Instruction Manual. Pay special attention to all

safety warnings. Often during installation or repair it is possible to place yourself in a position which is more hazardous

than when the unit is in operation.

Remember, it is your responsibility to install the product

safely and to know it well enough to be able to instruct a

customer in its safe use.

Safety is a matter of common sense...a matter of thinking

before acting. Most dealers have a list of specific good safety

practices...follow them.

The precautions listed in this Installation Manual are intended

as supplemental to existing practices. However, if there is a

direct conflict between existing practices and the content of

this manual, the precautions listed here take precedence.

RECOGNIZE THIS SYMBOL AS A SAFETY

PRECAUTIONDESCRIPTON

When 230/208 volt units are to be installed, the power supply

may be either cord connected or permanent wiring. Permanent wiring may be done through the hard wire junction box,

or the accessory subbase.

When 265 volt units are to be installed, the power supply

must be permanent wiring. Permanent wiring may be done

through the accessory hard wire junction box, or the accessory subbase. An exposed cord connection on 265 volt units

is not permitted.

The subbase accessory includes leveling legs. If added wall

sleeve support is required and the subbase is not to be used

an accessory leveling leg kit may be installed.

INDEX

A TTENTION INST ALLING PERSONNEL................................... 1

KIT ACCESSORIES................................................................. 1

DRAIN KIT ..................................................................... 1

SUBBASE, LEVELING LEGS, MAIN DUCT & HYDRONIC HEA T KITS ........ 1

PRE-INST ALLA TION CONSIDERA TIONS.................................. 3

OUTDOOR ENCLOSURE PANEL REMOVAL ................................... 3

WALL SLEEVE INST ALLA TION............................................... 4

KIT ACCESSORIES

DRAIN KIT

An indoor/outdoor drain kit is available as an accessory item.

When a drain kit is to be installed, do so before installing the

wall sleeve in the wall. See the drain kit for actual installation

instructions.

SUBBASE, LEVELING LEGS, MAIN DUCT, AND HYDRONIC HEAT

KITS

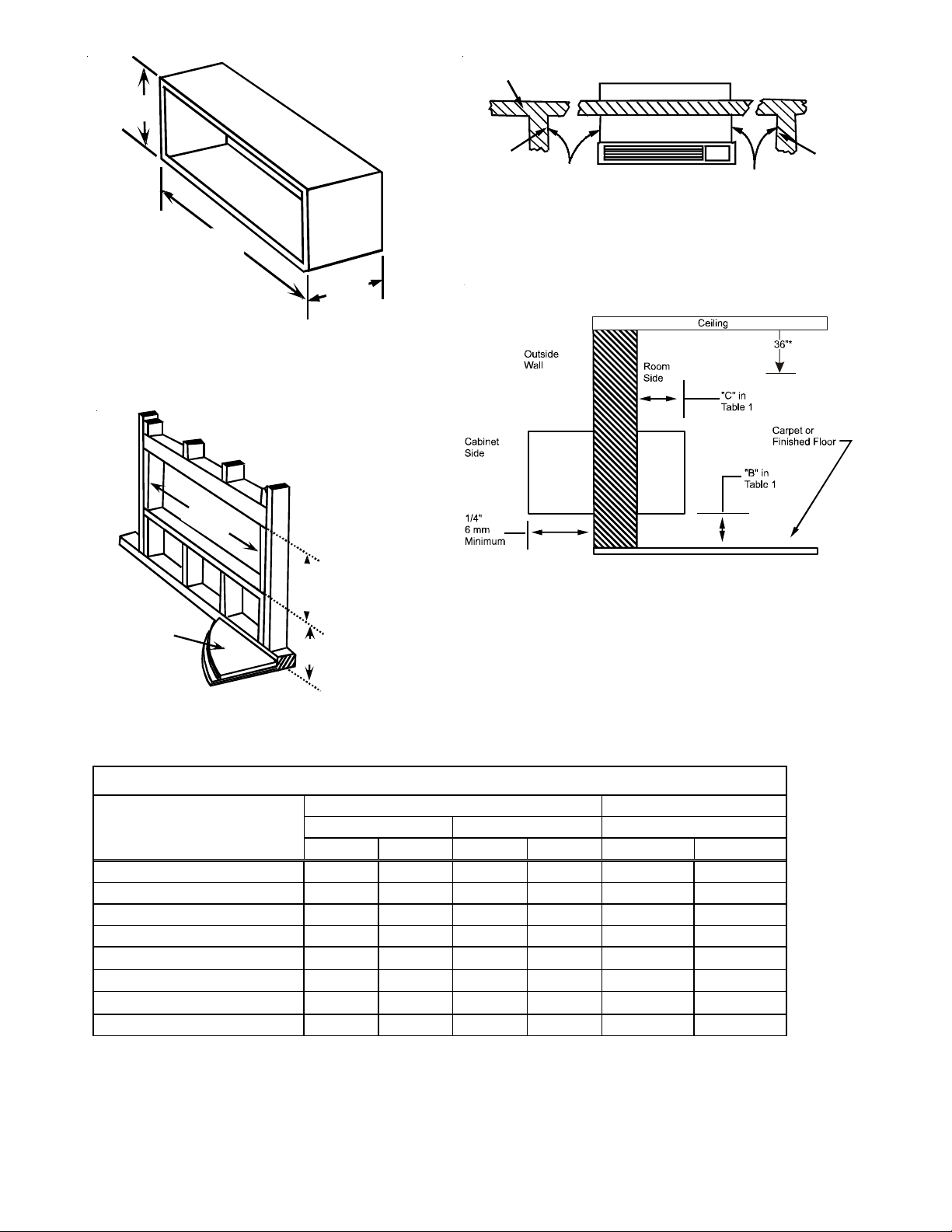

Installation of these kits requires drilling of mounting holes on

both sides of the wall sleeve. The minimum required clearance

distance between the wall sleeve and wall is shown in Table 1.

If the distance between wall sleeve and wall will be at or near

the minimum clearance distance, mount these kits on the

sleeve before installing the sleeve in the wall. The kit installation instructions are included with the accessory kits.

A3495105r4

01 / 2017

is a registered trademark of Maytag Corporation or its related companies and is used under license to

Goodman Company, L.P., Houston, TX, USA. All rights reserved.

5151 San Felipe, Suite 500 • Houston, TX 77056 • www.amana-ptac.com

© 1996, 2000, 2004-2005, 2017 Goodman Company, L.P.

Page 2

Outside

Wall

6

1

1

/

1

6

"

4

1

0

m

m

Internal

Adjacent

Wall

"A"

Minimum

Top of Wall Sleeve

"A"

Minimum

Internal

Adjacent

Wall

4

2

"

1

0

6

5

m

m

Wall Receptacle Within 58" From

Bottom Right Side Corner on

208/230 VAC Units Only

Figure 1 - Wall Sleeve Dimensions

4

2

1

1

0

/

4

7

"

M

5

i

m

n

m

i

m

u

m

Finished Floor

4

1

1

/

8

"

3

5

9

m

m

m

"

m

4

u

/

m

1

m

i

5

6

n

1

i

1

4

M

Dimension "B"

in Table 1

Allow Front Clearance (See Table 1)

Figure 3 - Minimum Unit Clearances

* To ensure proper airflow and filter removal, it is recommended

the wall sleeve be installed a mini mum of 36” from the ceiling.

Figure 4 - Minimum Interior and Exterior

NOTE: To ensure proper airflow and filter removal, it is recommended installation of the wall sleeve be a minimum of 36” from

the ceiling.

Figure 2 - Minimum Wall Opening Dimensions

MINIMUM CLEARANC ES AND PROJEC TIONS

MINIMUM CLEARANCES MINIMUM PROJECTION

OPTION

C (Figure 4)B (Figure 3)A (Figure 2)

Inches mm Inches mm Inches mm

Wal l Sl eeve Onl y 3 75 0 0 0 0

Subbase Kit 3 75 3 1 /4 85 2 3/4 70

Leveling Legs Kit 3 75 3 75 2 50

Duct Kit 3 75 0 0 2 3/8 35

Hydronic Heat Kit "A Series" 9 230 0 to 3 1/4

3

0 to 85

3

2

3

75

2

Hydronic Heat Kit "J Series" 6 150 0 0 2 1/2 65

Drain Kit 3 75 '0

1

'0

1

00

Hardwire Kit 3 75 1 1/4 30 0 0

1

If inside mounted then B = 1 1/2 inches (40 mm)

2

To achieve a flush fit between the hydronic front and the finished wall, Dimension “C” must be between 3” and 3 1/8”. If this dimension is more than

3 1/8” there will be a gap between the front and the wall. This gap could permit occupant access to hydronic lines or other dangerous parts. For flush

mounts, internal drain kits or flashing are required to prevent leaking from external drains into space. See drain kit installation for details on sleeve

positioning for internal drain kits.

3

This dimension can be from 0” to 3-1/4”, but cannot exceed 3-1/4”. If this dimension exceeds 3-1/4”, the skirt around the front will not reach the floor.

Table 1

2

Page 3

PRE-INSTALLATION CONSIDERATIONS

Before proceeding with the sleeve installation, ensure the

following guidelines for locating the wall opening and sleeve

are met:

• The wall opening must be the correct size. See Figure 1

for wall sleeve dimensions and Figure 2 for minimum

wall opening size.

• The wall sleeve will need to be installed with minimum

clearances to the floor and adjacent walls. Minimum

projections of the sleeve into and out of the room will

also have to be met. See Figures 3 and 4 as well as Table

1 for details.

• If installed in a concrete or masonry wall, a lintel must

be provided in the wall opening for support. Do not use

the wall sleeve as a lintel. See Figure 5 for a typical

lintel construction.

• If used, a 208/230-volt wall receptacle must be located

within 58 inches of the lower right sleeve corner. Extension cords must not be used with the unit. See the note

on Figure 1.

• For installations in walls deeper than 13-7/8 inches,

special care is necessary to prevent problems with rain

water, condensate drainage and intake/discharge air.

Under these circumstances, careful job site analysis

and precautions are required. You must consult with

your Sales Representative and receive approval before

attempting such installations.

OUTDOOR ENCLOSURE PANEL REMOVAL

The sleeve stiffener must be taken out before the enclosure

panel can be removed from the sleeve.

1. Remove the zig-zag folded cardboard sleeve stiffener (Figure 7).

Lintel

Wood

Frame

Figure 5 - Framing with Lintel

• When installed in the opening, the wall sleeve must be

horizontally level from side to side and pitched (one

quarter bubble in the sight glass) to the outside. DO

NOT SLOPE THE WALL SLEEVE TOWARD THE ROOM.

(Figure 5)

• The installer must determine and supply the mounting

bolts and/or screws to attach the wall sleeve to the

sides of the wall opening. Make sure the wall opening is

adequate for strong support.

• The installer must provide adequate sealing and insulation around the sleeve after it is installed. See Figure 6

for one of many types of constructions.

13 1/2" (340 mm)

Concrete

Lintel

Maximum

(No Accessories)

1/4"

6 mm

Minimum

Projection

Sleeve

Stiffener

Figure 7- Sleeve Stiffener Removal

2. Remove the rear closure panel by folding the four flaps as

indicated in Figure 8.

Rear Closure

Panel

Flaps

Figure 8 - Rear Enclosure Panel

3. Grasping the top and bottom flanges of the rear closure

panel as shown in Figure 9, the entire panel is pulled out

diagonally from one side.

Caulk Top,

Bottom, and

Both Sides

Power Supply

Conduit

Finished

Floor

13 3/4"

350 mm

Steel

Lintel

Receptacle

Figure 6 - Block and Brick Veneer Installation

Figure 9 - Panel Removal

Install the wall sleeve condenser air grille by using the screws

and holes provided. (See the Installation Instructions provided for the grille kits.)

3

Page 4

WALL SLEEVE INST ALLATION

After the wall opening is checked and approved for location,

size, and clearances, complete the following to install the wall

sleeve.

1. Remove the outside enclosure panel from the wall sleeve.

2. Slide the wall sleeve into the wall opening. Do not distort

the cabinet shape to fit the wall opening; the unit chassis

must fit snugly and uniformly into the wall sleeve.

3. Locate the sleeve within the range of minimum projections, as shown in Figures 3 and 4, so both sides are at

least the minimum projection from the wall.

4. Check the level of the wall sleeve. For proper drainage,

the sleeve should be level from side to side and one-quarter bubble in the sight glass sloping to the outside.

See Figure 10 for proper location to check wall sleeve with

level. The level should show a 1/4 bubble slope to the

outside.

5. Two holes will need to be drilled in both sides of the wall

sleeve for mounting into the wall. Drill holes of proper size

and in the proper location so the screws will engage into

strong supporting members of the wall. DO NOT DRILL

THROUGH BOTTOM OF SLEEVE. Figure 12 shows possible

fastening methods.

Alternative

Fastening M e thod

(Field Supplied)

Wood Screw

Mounting

Holes

(Drilled by

Installer)

Plastic

Anchor

Toggle Bolt

Screws

Expansion

Anchor Bolt

Figure 12 - Wall Sleeve Attachment to Opening

6. Check the level of the wall sleeve and adjust if necessary.

7. Caulk or seal around the outside of the entire sleeve.

1/4 bubble

slope to

For proper placement, level should show 1/4 bubble slope to the outside

Place level on dimples in wall sleeves’ corners.

in both the left and right hand c orners.

the outside

Figure 10 - Checking Wall Sleeve for 1/4 Bubble Slope

NOTE: If using an internal drain kit, the sleeve must be level

from front to back.

See Figure 11 for proper location to check wall sleeve with

level. The sleeve should be level from side to side.

8. If the unit chassis will not be installed immediately, replace the enclosure panel on the outside opening of the

sleeve. This will prevent weather damage to the building

interior.

9. Recycle or dispose of packaging materials per local codes.

Place level on dimples or next to the dimples in wall sleeves’ corners.

For proper placement, sleeve should be level from front to back

in both the left and right hand corners.

Figure 11-Checking Wall Sleeve for Level

Level from

side to

to side

4

Loading...

Loading...